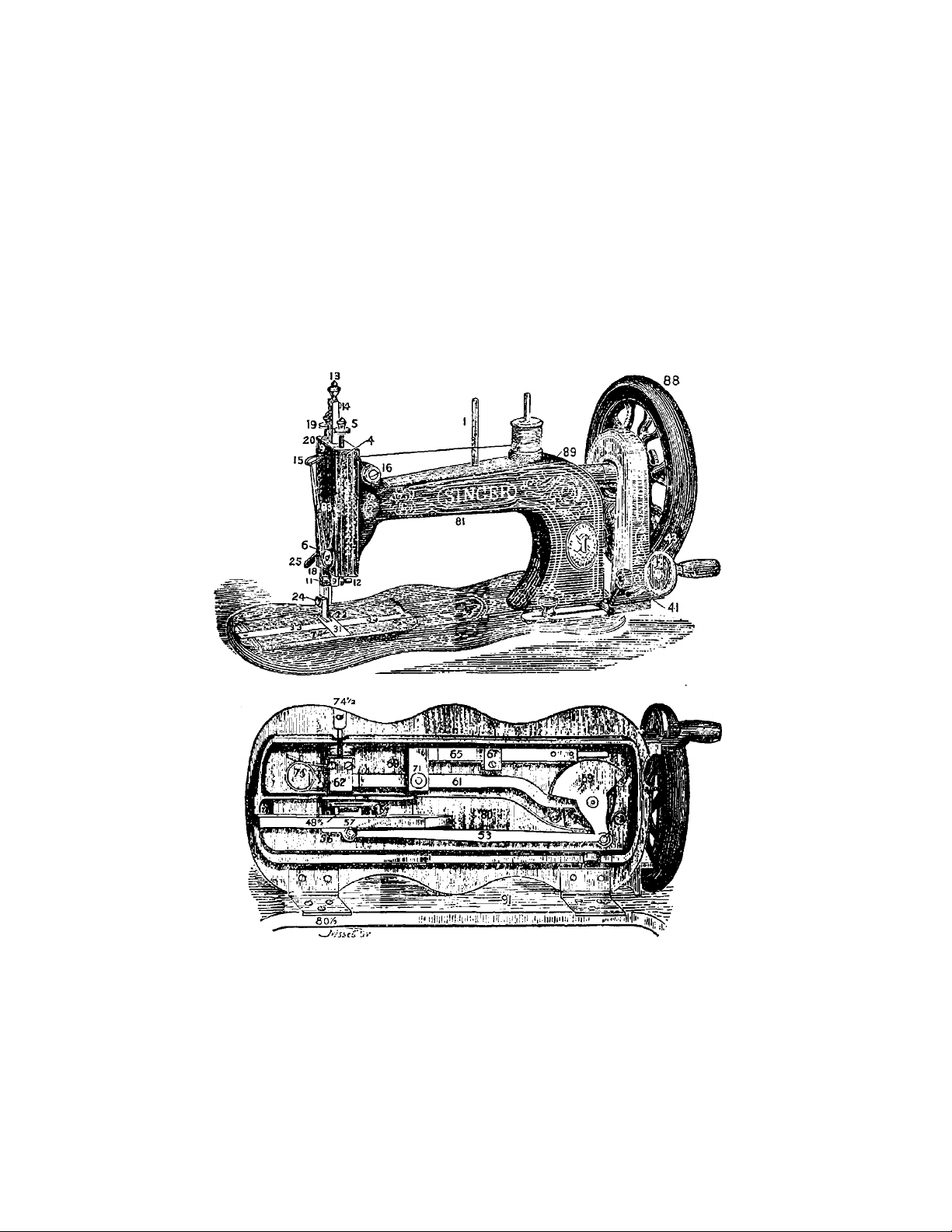

SINGER 12K User Manual

Form K2

INSTRUCTIONS FOR USING

SINGER 12K

“FAMILY”

SEWING MACHINE

■JIL

Under View of Machine

The figures shown in the above illustrations are the numbers of

the i)arts. When ordering parts for this machine the numbers

must be followed by “ 12K,”

THE SINGER MANUFACTURING CO.

e.g.,

48J/12K.

BALANCE WHEEL STOP MOTION.

This device allows the balance wheel to run free, so that bobbins

may be wound and the correct method of treadling acquired,

without operating the stitching mechanism. To loosen the wheel,

hold it with the left hand, and with the right hand pull out the disc

sufficiently to allow of its being turned either to the right or left,

thus liberating the projection on the inner side of the disc from its

recess.

To lock the balance wheel, hold it with the left hand and, with

the right, turn the disc until the projection springs back into its

recess.

TO ENSURE PERFECT ACTION OF THE MACHINE.

The balance wheel must always turn from the top towards

you.

The presser foot must be raised, except when sewing.

Do not work the machine with the shuttle and the needle

threaded, except when sewing.

The slides (33) over the shuttle must be closed before starting

to work the machine.

TO OPERATE THE TREADLE MACHINE.

Loosen the balance wheel as described above, place both feet

upon the treadle and turn the balance wheel over towards you.

at the same time allowing the feet to move freely and lightly with

the motion of the treadle. Continue to do this until a regular and

easy movement is acquired and you are able to work the treadle so

that you can re-start the machine without the balance wheel

turning in the wrong direction.

When familiar with the working movement, lock the balance

wheel, and place a piece of material under the presser foot (23).

Lower the latter by means of the lifter (25) and again work the

machine, without its being threaded, until you are accustomed to

guiding the material.

TO SET THE NEEDLE.

Raise the needle bar (9) to its highest point and loosen the

needle clamj) nut (12). Hold the needle with the left hand and,

with its long groove towards you, place its point down through the

hole in the throat plate (31). Turn the wheel (88) slowly towards

you, while you guide the needle under the needle clamp (11), then

tighten the clamp nut (12). With the left hand insert the point

of a fine needle into the eye, resting it on the throat plate (31).

Loosen the clamp nut or screw (12), and pressing the fine needle

into the eye in a direct line from you, turn the wheel (88) slowly

until the line engraved on the needle bar (9) is level with the toj) of

the arm. Then tighten the clamp nut or screw (12).

TO THREAD THE NEEDLE.

Place a reel of thread on the spool pin nearest the balance wheel

and lead the end of thread through the guide (4), then down from

front to back under and between the tension discs (6), up and from

front to back through the hole in the check lever (15), down and

through the hole in the needle clamp (11), then from front to back

through the eye of the needle, leaving an end of thread three inches

long, which should be i)laced under and to the back of the presser

foot.

TO WIND THE BOBBIN.

Withdraw the left slide and turn the balance wheel until the

shuttle is in full view, then lift it from the machine and remove the

bobbin. Put a reel of thread on the spool pin, place the

bobbin in the spooler (41) and secure the end of the thread by

placing it between the end of the bobbin and the cup of the

spooler. Operate the machine and guide the thread upon the

bobbin slowly from one end to the other, always having the

thread a trifle higher at the ends than in the centre.

TO THREAD THE SHUTTLE.

Having removed the bobbin from the spool winder, take it

between the thumb and finger of the right hand, being careful that

the thread is over the bobbin towards the hand. At the same time

take the shuttle in the fingers of the left with its point towards the

hand, place one end of the bobbin in the spring centre in the end of

shuttle cavity next to the point, and gently press the other end

into its place. Pass the thread through the bottom long slot, in at

the upper slot, and thence over to the tension holes, passing it

through the one nearest the blunt end first, then through as many

holes as may be necessary to obtain the tension required, always

finishing, however, by passing it through the hole nearest the point,

either from the inside outward, or from the outside inward (in the

latter case pass it out through the slot below) and finally, in every

case, under the spring.

TO COMMENCE SEWING.

Open the left hand shuttle slide (33), place the shuttle in its

carrier (57), leaving out about two inches of thread. Close the slide

to within an eighth of an inch, draw about two inches of thread

down from the check lever (15) and through the eye of the needle.

Hold the end of thread with the left hand, allowing it to be slack

from the hand to the needle, and turn the wheel (88) towards you

until the needle moves down and up again to its highest point.

Pull the thread you are holding, and the under thread will be

brought up with it through the hole in the throat plate. Close the

slide, place both ends of thread and the material to be sewn, under

the presser foot, lower the presser bar lifter (25) and commence to

sew by turning the balance wheel from the top tow'ards you. After

making a few stitches, stop and examine them. Should there be

loops projecting or a straight thread upon the lower surface, turn

the tension screw (5) on the top of the machine to the right, so as to

tighten the tension on the needle thread. If the thread lies straight

upon the upj)er surface, turn the tension screw to the left to loosen

the tension of the needle thread. The secret of perfect sewing lies

in adjusting the tension on the needle thread and that on the shuttle

thread so that they are equal.

TO REMOVE THE WORK.

Raise the needle bar (9) to its highest point, draw about three

inches of thread downwards from the check lever (15), and raise the

lifter (25). Move the material back and to the left about three inches

and cut the threads close to the work so as to leave the ends long

enough to recommence sewing. Before removing the work from

the machine, however, seams should be secured by taking a few

stitches in the opposite direction, as in hand sewing.

Loading...

Loading...