Page 1

/yVWv\

/vAvvA

w^/W

АЛЛА

AA/v;

sœ

/V^y\

ЛДЛЛ

/VWW

Page 2

Instruction Book for the

Singer' Sewing Machine

For Treadie Macitine Owners

To adjust your machirte for treadie sewing,

loosen hand wheel knob A by turning it toward

you with the right hand while holding hand wheel

with the left hand.

Place both feet on the treadle as illustrated. Turn

hand wheel over toward you, allowing your feet to

move freely with the motion of the treadle. Prac

tice this motion until you are able to start and

keep the machine in operation with the hand

wheel turning toward you. Remember that the

faster you operate the treadle, the faster the

machine will sew.

When you have

become accustomed

to the treadle motion,

tighten the hand wheel

knob by turning it away

from you. Place a

piece of material under

the presser foot and

lower the presser foot

lifter. Now operate the

machine (without

thread) until you

become accustomed

to guiding the material.

Enjoy Sewing!

Copyright (c) 1982 TH£ SiNGER COWB^NY

Ail Rights Reserve<i Throughout the World

"A Trademark ot The Singer Company

Page 3

For Eyropean Territories—

This product is suppressed for radio and television

interference in accordance with the Internationai

Eiectrotechnical Commission of the CISPR.

IMPORTANT: Machines for Great Britain and some

other countries having similar wiring standards are

shipped from the factory without a plug for connection

to the mains. The wire in this m^ains lead are coloured

in accordance with the following code:

Blue: neutral (N) Brown; live (L)

As the colours of the wires in the mains lead of this

appliance may not correspond with the coloured mark

ings identifying the terminals in your plug, proceed

as follows;

The wire which is coloured blue must be connected

to the terminal which is marked with the letter N or

coloured black. The wire which is coloured brown

must be connected to the terminal which is m^arked

with the letter L or coloured red. If a 13 Amp. (8S1363)

plug is used, a 3 Amp. fuse must be fitted, or if any

other type of plug is used, a 5 Amp. fuse mrust be fitted

either in the plug or adaptor or at the distribution

board.

Dear Customer:

We recommend that for future reference you record

the sériai number of your Sewing Machine in the

space provided.

Serial No

Refer to illustration

at right for location

of serial number on

your machine.

Serial No.

Page 4

Contents

1, Getting to Know Your ШасЫт . .

Principal Parts

Accessories

2. Getting Ready to Sew

Choosing and Changing Accessories

Operating Machine

The Bobbin Thread .................................

Threading the Machine

3. straight Stitching

Setting Selectors

Sewing a Seam ...

Applications ...

4 Basic 25g-Zag Stitching

Setting Seiectors

Satin Stitching

Stitch Usage

.............

............................................

.........................

.......................................

...

..................................

..................

.................

..................................

................................

................

.........

..............

................

................

................

................

...... 20

.........

................

................

................

................

.

................

..... 40

. ,

............

4

4

6

.........

10

10

18

.... 24

28

28

32

34

38

38

42

5. Pattern Stitching

Selecting a Stitch.....................................

Stitch Pattern Groups

Adjusting Stitches for Stretch Fabrics .... 50

Decorative Stitching.......................

6. Buttonholes and Buttons . .

Garment Preparation

.............................

..................

Four-Step Buttonholing..........................

Buttons

7. Caring for Your IVIachine ........................

a Twin Needle Stitching

9. Home Service Hints . .

Index

....................................................

...............................

...............

...........

................

.........

... 48

................

................

.........

................

................

................

. . . . . 84

.........

■ 86

................

46

46

62

66

66

70

74

76

88

Page 5

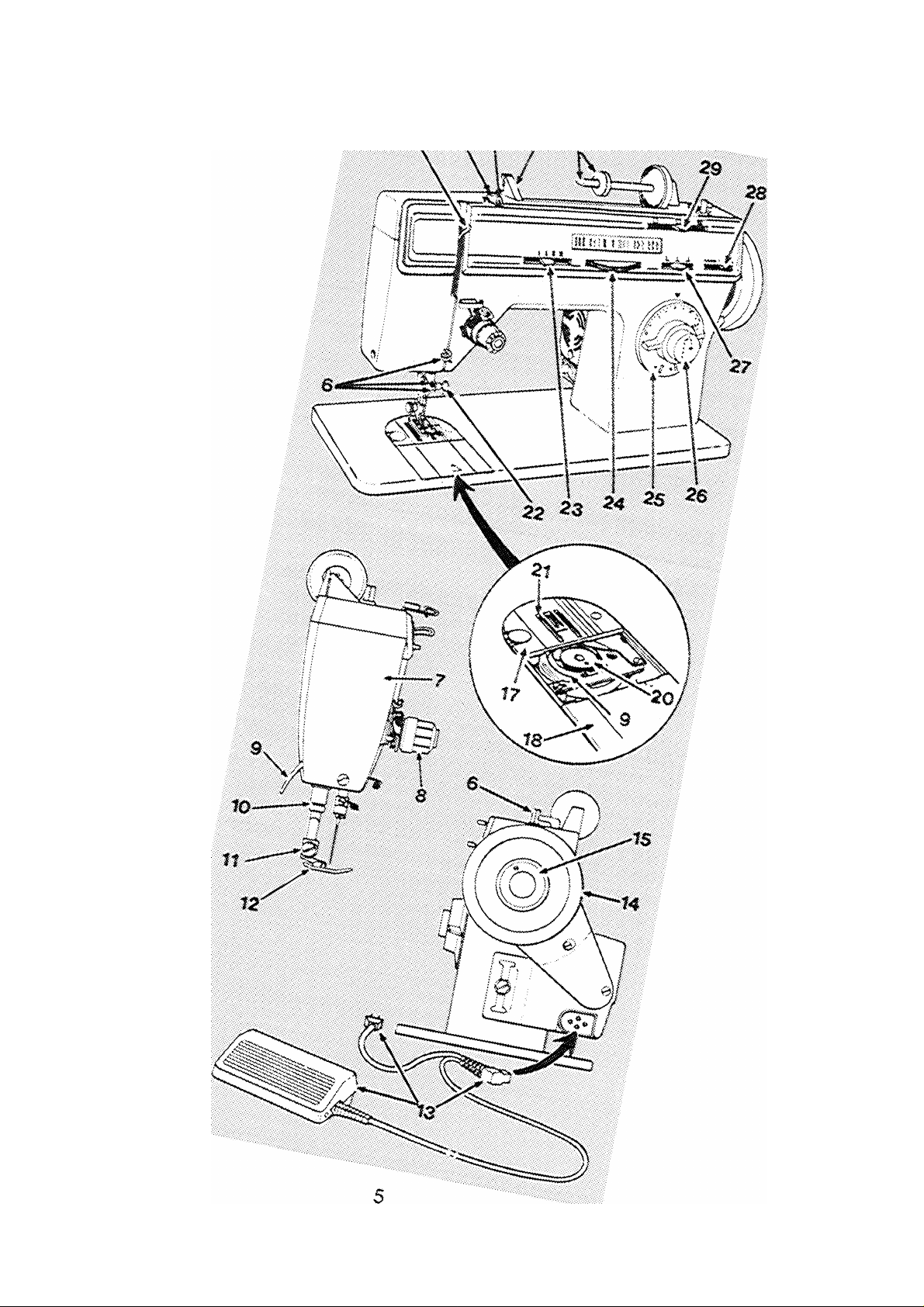

Your IVIachfne

1. Spool Pin and Spool Holder

2. Thread Guide Post

3. Thread Gul6es

4 Bobbin Winder Tension Disc

5. Take-Up Lever

6. Thread Guides

7. Face Plate

8. Needle-Thread Tension Dial

9. Presser Foot Lifter

10. Thread Cutter

11. Presser Foot Screw

12. General Purpose Presser Foot

13. Electrical Connections and Speed Controller

14. Hand Wheel

15. Hand Wheel Knob

16. Bobbin Winder Spindle

17. General Purpose Needle Plate

18. Slide Plate

19. Bobbin Case

20. Bobbin

21. Feed

22. Needle Clamp

23. Stitch Width Selector

24. Stitch Pattern Group Selector

25. Stitch Length Selector

26. Reverse Stitch Push Button and

Buttonhole Balance Knob

27. Needle Position Selector

28. Stitch Balance Control

29. Stitch Pattern Selector

4

Page 6

s 4 3 г 1

Page 7

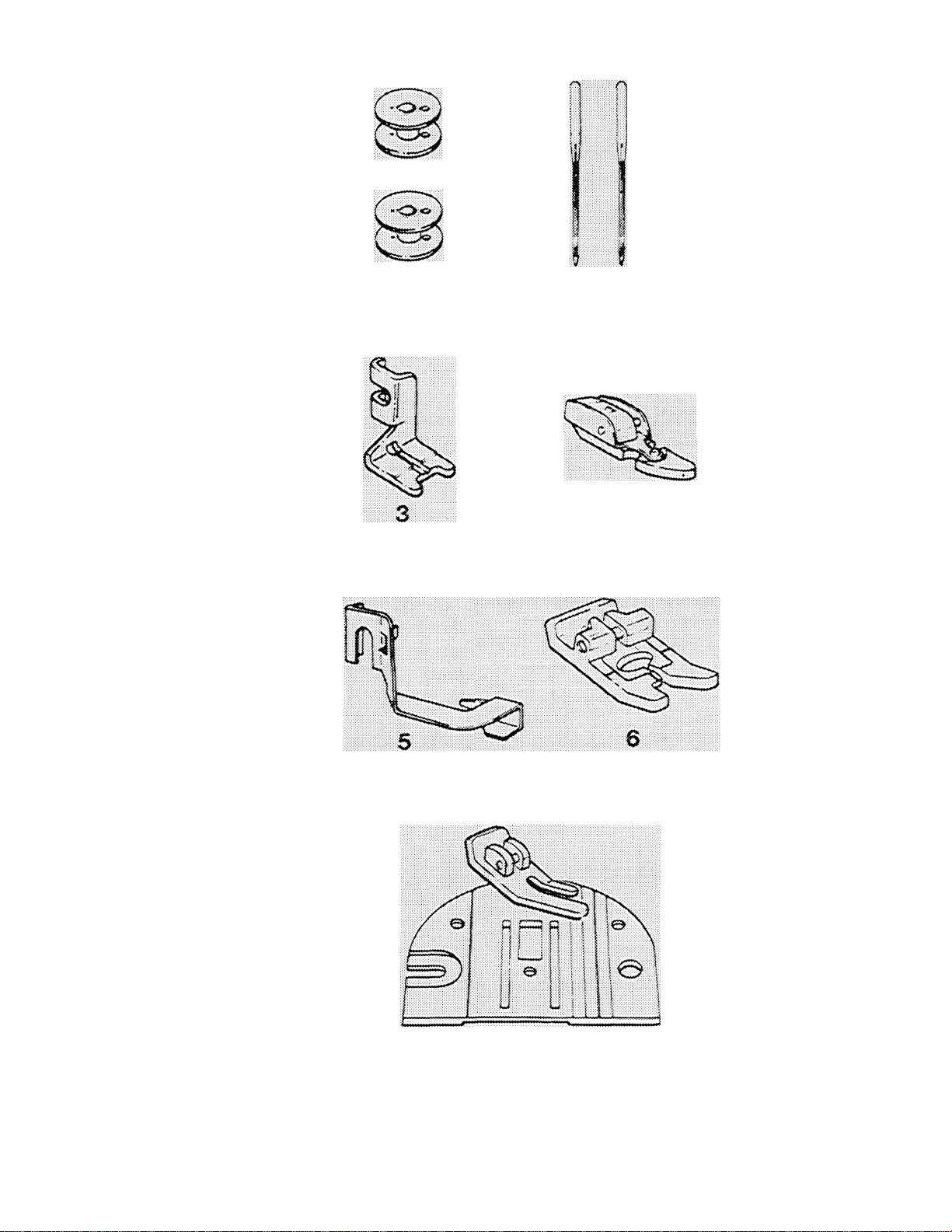

Accessories

The accessories provided wsth your sewing ciachioe

are designed to neip you do many kinds ot sewing

easiiy,

1, Transparent Bobbins (No-172336)

2. Singer* Needles

♦ Style 2020 for general sewing,

♦ Style 2045 for sewing knits, stretch fabrics and

elastic.

♦ Style 20251 for twtnmeedie 6eco^auve stitching

3* Button Foot holds most flat buttons securely for

fastening,

4. Zipper Foot tor inserting Zippers and stitching

corded seams,

5. Bfindstitch Hem Guide. Use this with the gen

eral purpose foot to position and guide the hem.

6. Buttonhole Foot ;s used to make bar tack but-

tonhoies m four steps.

7. Straight Stitch Foot and Straight Stitch Needle

Plate are used when your fabric or sewing pro

cedure reouires close control These accessories

are recommendec for all straight stitch sew:ng

iCAUTION: Use this needle with me general pur

pose needle plate and general purpose or special pur^

pose foot only Do not use any other accessories with

this needle as needle Preakage will occur.

To ensure that you are always provided with the most

r^odern sewing capabilties. THE MANUFACTURED?

reserves the right to change the appearance, design

or accessories of this sewing machine when con

sidered necessaw

6

Page 8

4

Page 9

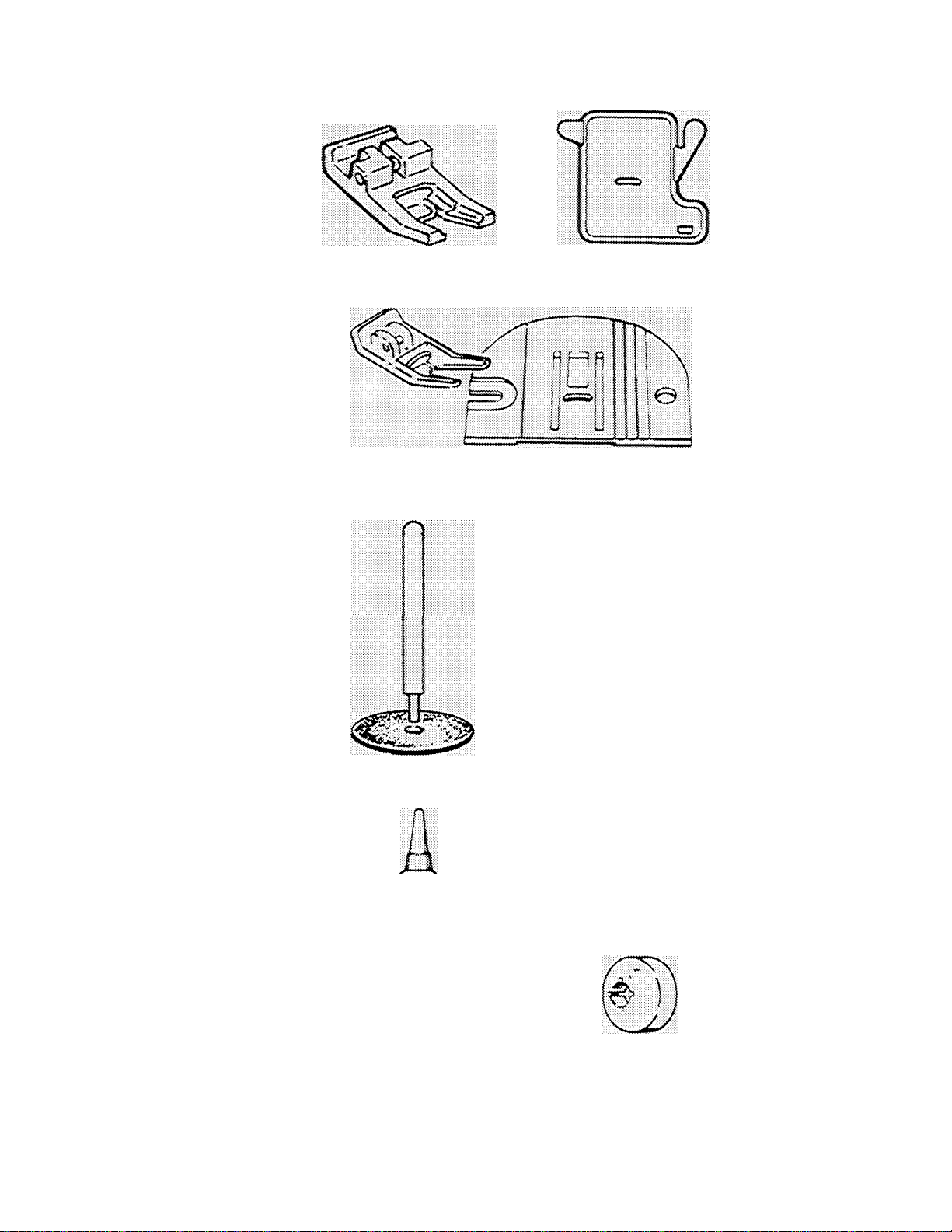

8. Special Purpose Foot, Use this for ali kinds of

decorative stitching«

9. Snap-in Feed Cover for button sewing, free-

motion work and darning.

10. General Purpose Foot and General Purpose

Needle Plate are on your machine when deliv

ered. Use them for aiternating between straight

and zig-zag stitching.

11. Spool Pin and Felt Washer is used for twinneedle sewing.

12. Lint Brush for cleaning your sewing machine.

13. Tube of Oil for oiling the machine.

14. Small Spool Holder for use with small diameter

SDOOis of thread.

8

Page 10

8

9

11

2

ЯЗОИ

Jiâ

13

14

Page 11

2. Getting Ready to Sew

Choosing and Changing

Accessories

CAUTION: Disconnect the power line plug from the

socket outlet when changing needles, feet, or needle

plates, or when leaving the machine unattended. This

eliminates the possipility of starting the machine by

accidentally pressing the speed controller.

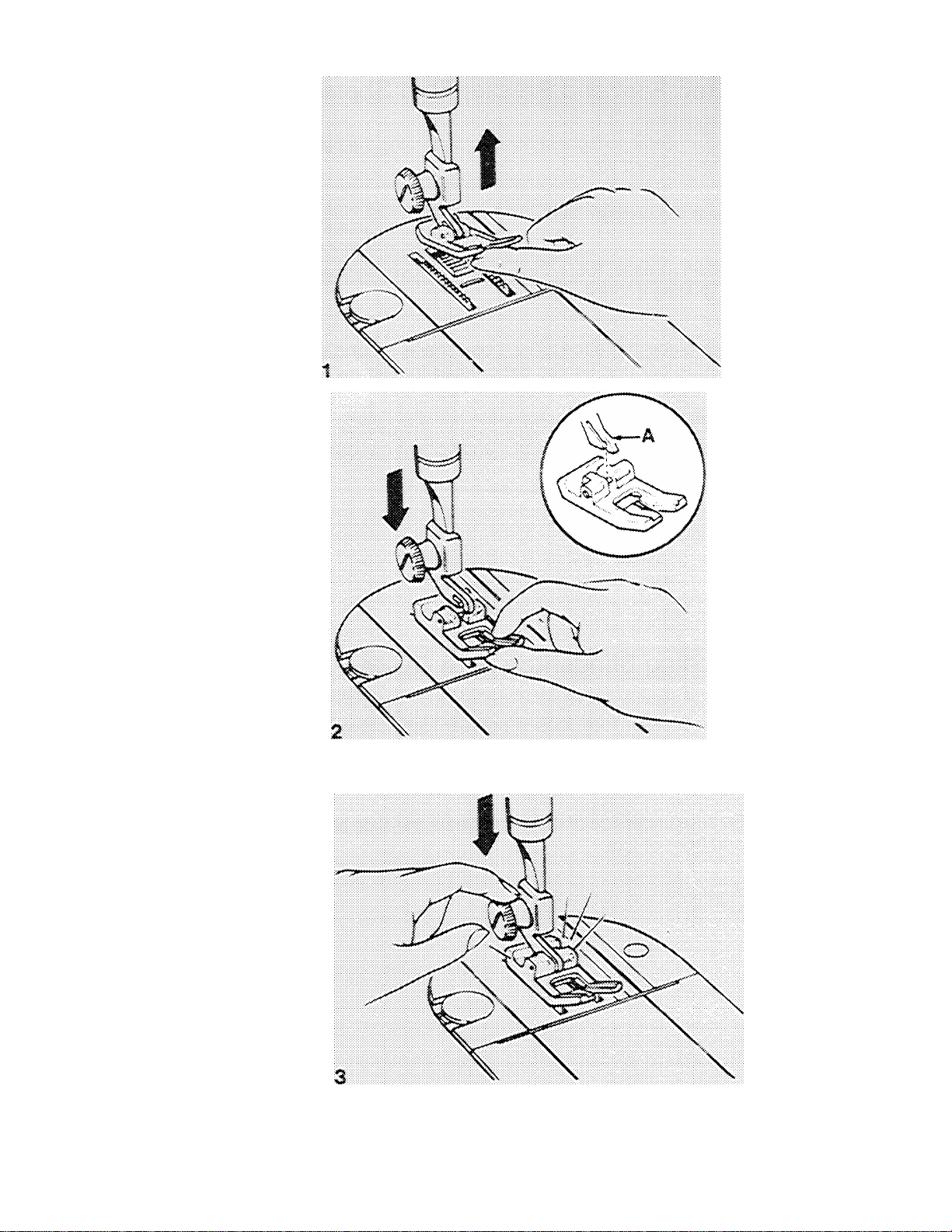

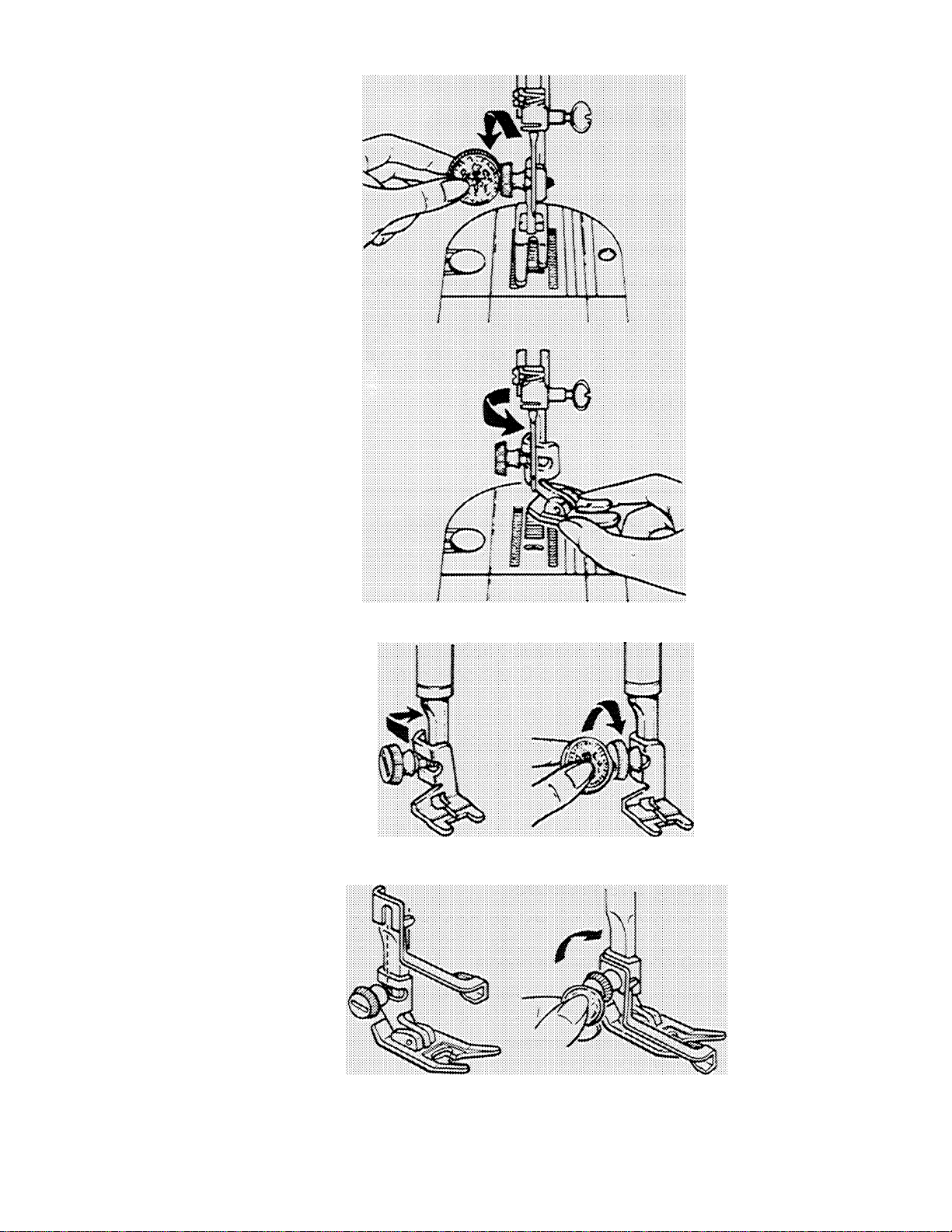

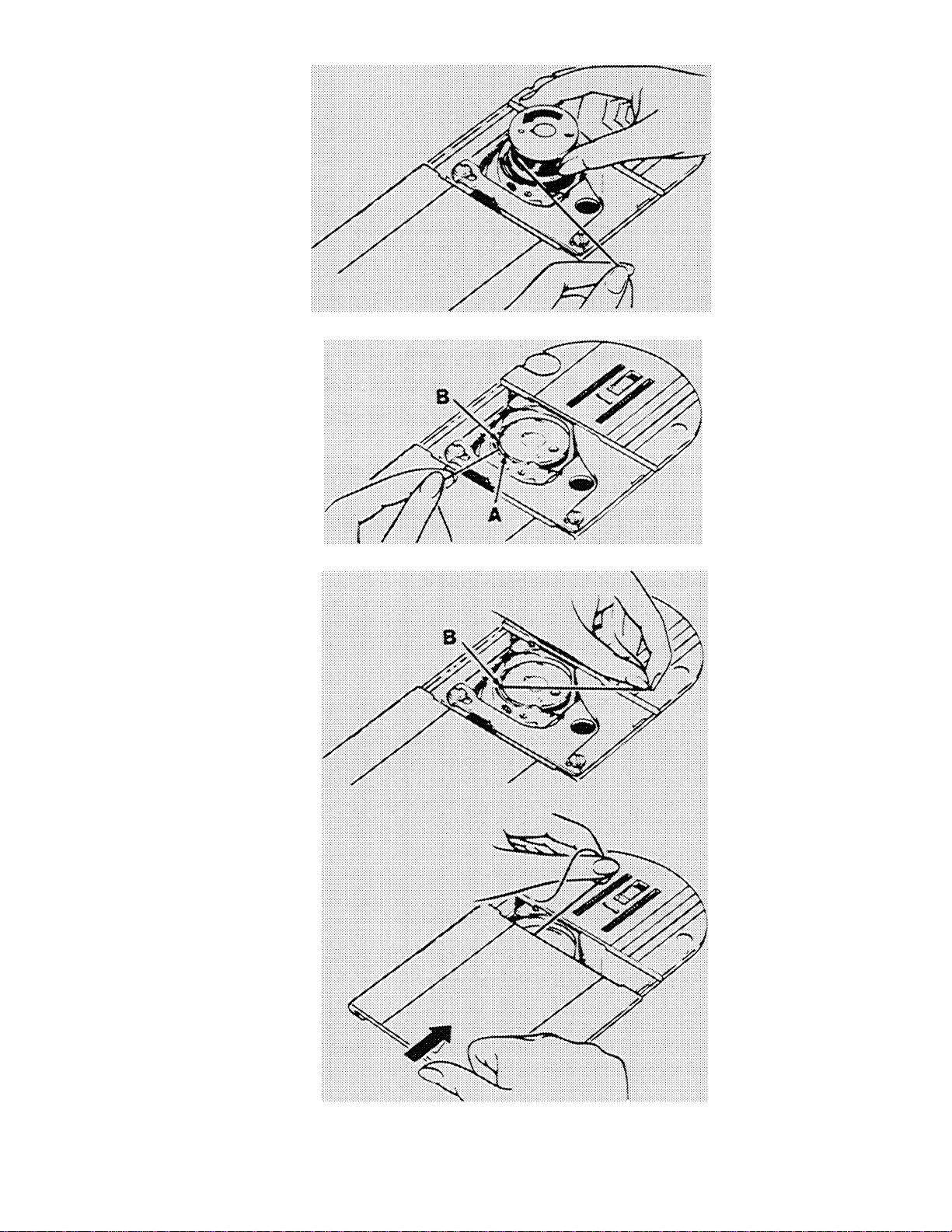

Changing Presser Feet

♦ Raise needle to highest position by turning the hand

wheel toward you.

* Raise presser foot.

1 Press toe of presser foot upward as far as it will go

until it snaps free.

Z Centre the new presser foot under the shank A.

Lo'wer the presser foot lifter so that the shank fits

over the presser foot pin.

3, Press presser foot screw down firmly until foot

snaps into place.

Page 12

Page 13

Removing and Replacing the Button f=bot and Presser Foot Shank

• Raise needle to highest poshion oy turning the hand

wheel toward you.

* Raise the presser foot

• Loosen presser foot screw A and rennove the shank

B. guiding it to the nght.

♦ To replace the accessory, hook shank around the

presser bar and tighten the presser foot screw.

NOTE: Insert the edge of a com m the seat of the

presser foot screw to loosen it and tighten it securely.

Attaching Blindstitch Hem Guide

♦ Raise presser foot, loosen presser foot screw and

slip blindstitch hem guide between screw and shank

of the general purpose foot,

• 8e sure underside of the guide clears the slide plate

and front of foot.

• Tighten screw with a coin.

•

12

Page 14

ÍO

Page 15

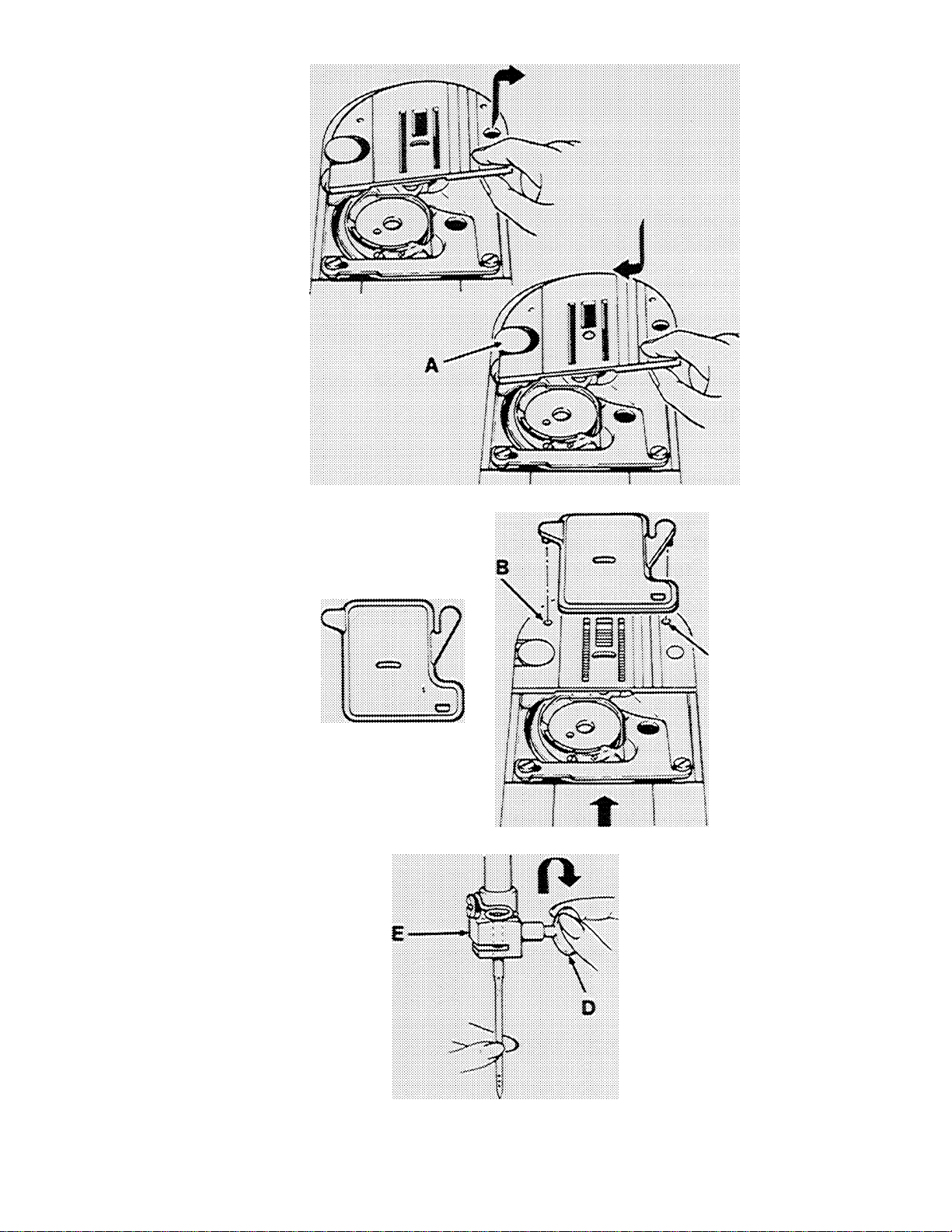

Changing Needle Plates

NOTE: Remove bobbin if it contains thread in order

to prevent thread being caught when plate is replaced.

• Raise needle to highest position by turning the hand

wheel to'ward you.

• Raise presser foot,

• Open slide plate. Place thumb under right side of

needle plate, lift it up and withdraw it to right.

• Replace needle plate under clarriping pin A, push it

firmly to the left and press down until it snaps into

place.

• Close slide plate.

Attaching Snap-in Feed Cover

♦ Raise needle40 highest position by turning hand

wheel tov^ard you.

♦ Raise presser foot, open slide plate and insert gen

eral purpose needle plate,

♦ Slide snap-in feed cover away from you over needle

plate until points B and C are positioned directly

over holes in needle plate as illustrated. Snap in

point 8. Then push point C in toward point 8 until it

snaps into place. Close slide plate.

♦ To remove, open slide plate, then simply lift up front

edge of feed cover and remove. Close slide plate.

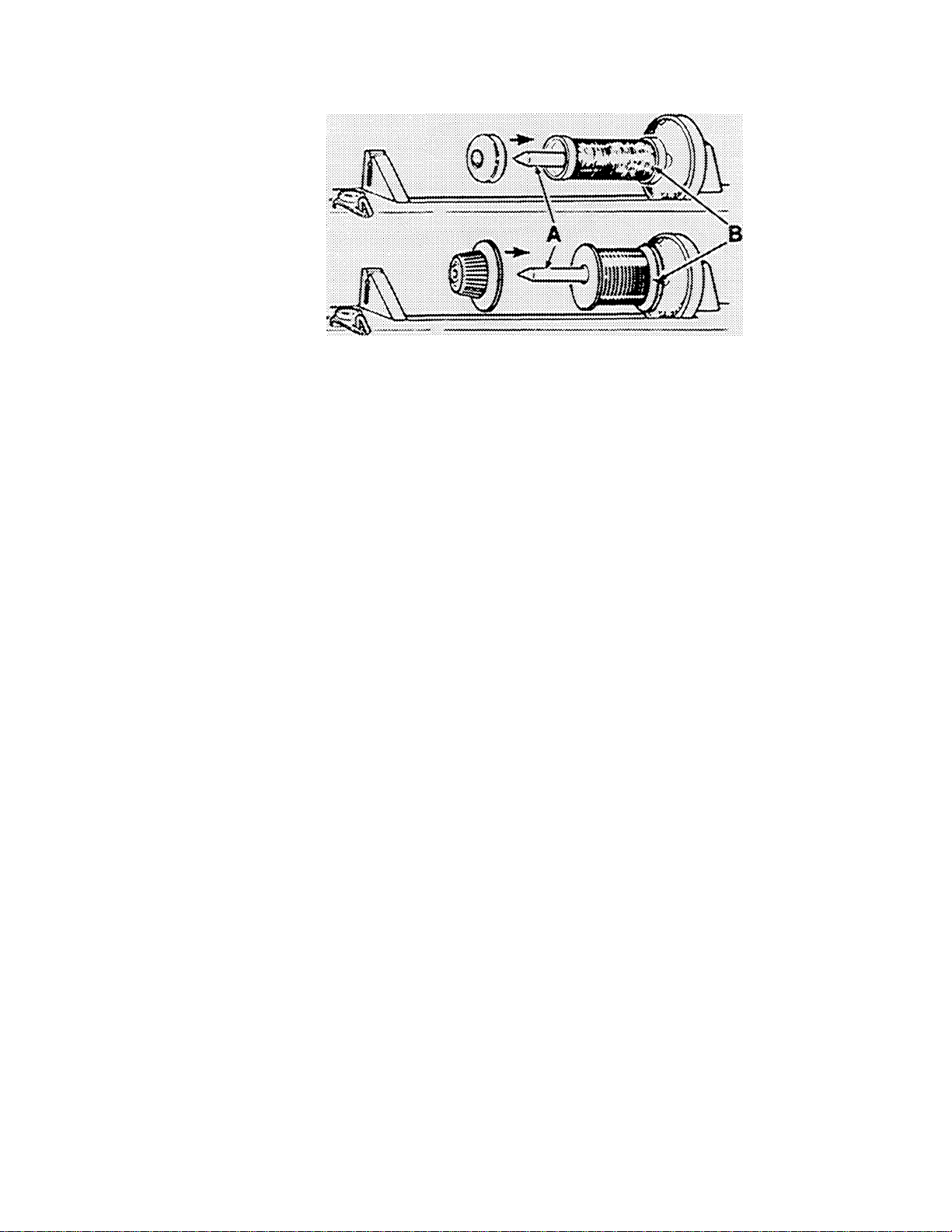

Changing the Needle

♦ Raise needle to its highest position by turning the

hand wheel reward you. Loosen the needle-damp

screw D and remove the needle.

♦ Insert new needle with the flat side of the needle to

the back, up into clamp E as far as it will go.

♦ Tighten needle-clamp screw.

14

Page 16

с

15

Page 17

Fabric, Thread

The needie and thread you choose wiB depend upon

the fabric to be stitched. The needle should be tine

enough to prevent the fabric from being marred with

large punctures, yet heavy enough to pierce the fabric

without being bent or deflected.

FABRIC

FILIVIY—Chiffon, Organza, TuHe, Voile

SHEER--Net. Lace. Ninon. Crepe de Chine, Voile

JUG NT-—Velvet. Crepe de Chine. Shantung, Fatile,

Organdy, Muslin. Batiste. Dimity, Lawn,

Percale, Piqué, Poplin Cashmere. Flannel,

Mohair, Felt. Taffeta, Satin, Ghaliis, Eyelet,

Gingham. Crepe, Broadcloth

MEDIUM—Velvet, Crepe de Chine, Shantung,

Suiting. Satin. Crepe. Velveteen, Corduroy,

Fleece, Flannel, Gabardine. Felt, Serge. Mohair

HEAVY—Brocade, Taffeta, Satin, Crepe, Corduroy,

Linen. Drapery Fabric. Burlap, Suiting,

Gabardine, Poplin Denim. Ticking, Canvas

I VERY H€AVY—Denim. Duck, Canvas, Sailcloth,

I Coaling, Blanketing. Upholstery Fabric

KNITS, STRETCH AND ELASTICS-Jersey. Ore,

Sweater Knit, Bonded Knit, Tricot, Stretch Terry,

Double Knit. Spandex. Deep Pile. Fake Furs

LEATHER, PLASTIC, VINYLS-Kidskin. Patent

Leathers and Suedes, Plastic Film, Lmitation

Upholstery Vinyl and Leather

16

Page 18

and Needle Table

The eye of the needie must be large enough for me

thread to pass through it freely: too tme a needle will

cause the thread to tray.

The table below :s a guide to needle and thread seiec'

tion Refer to И before starting a sewing project Be

sure to use me same size and type of thread ¡n pom

needle and dodPin.

THREAD

Fine silk, cotton,

mere, or Synth.

Fine Silk, cotton,

mere, or Synth.

Fine silk, cotton,

mere, or Synth.

Medium cotton,

mere, or synth.

Medium silk, cotton,

mere, or synth.

Heavy silk, cotton,

mere, or synth. ?

. NEEDLE i

2020 9.11

2020

2020

2020

2020

11И

I ti i

liillliillillllli

iiiiiiiiiiiiiiiiiiiií

Heavy silk, cotton, j

mercerised or |

synthetic I

Fine, medium, or j

heavy synthetic |

Fine nnerc. synth. i

Med mere. synth. j

Hvy. mere. ^ synth. |

17

2020

or

2026

2045

2020

or

2032

16 i

18

iiliiiiilllilliiii

iiiiiiiiiíiiiliiiiiiiil

iiliiiiilllilliiii

i 1t.14,16

11,14.16.18 I

Page 19

Operating Machine

Connecting Machine

Before plugging in your machine, be sure that the volt*

age and number of cycles indicated on the electrical

nameplate A, conform to your electrical power supply.

If your speed controller cord has a motor dIscon*

nect plug, push plug B into the receptacle at the right

end of machine. Then connect plug C to your socket

outlet.

If the speed controller cord is wired directly to the

motor, simply connect plug C to your socket outlet.

CAUTION: Disconnect the power line plug from the

socket outlet when changing needles, feel or needle

plates or when leaving the machine unattended. This

eliminates the possiPility of starting the machine by

accidentally pressing the speed controller

If your machine has a sewing light switch, press or

turn switch on the machine, as required.

If machine has a three-position switch:

• The OFF setting {switch moved to 0 symbol).

• The MIN, setting {switch moved to I symibol) al

lows the maximum control for special jobs.

• The MAX, setting (switch moved to 11 symbol) ah

lows for full speed capacity of the machine.

To run the machine and control speed, press the

speed controller 0 with your foot. The harder you

press, the faster the machme wi sew. To stop ma

chine. remove foot from controller.

CAUTION: Because of the up and down movement

of the needle, you must work carefully and watch the

sewing area when operating the machine.

18

Page 20

19

Page 21

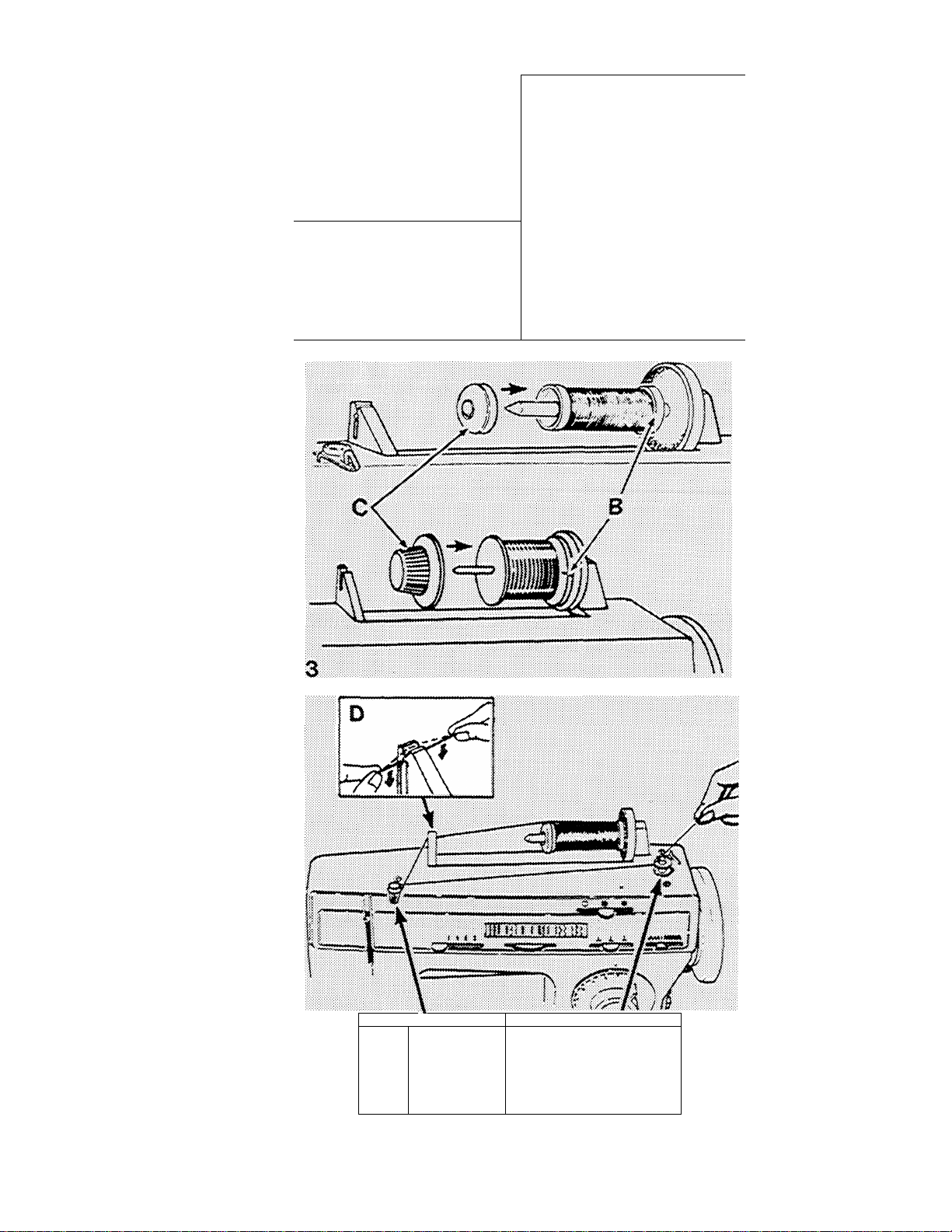

The Bobbin Thread

Winding the Bobbin

Preparation Steps

1. Raise the presser foot and turn hand wheei toward

you until needle is in highest position.

Z* Loosen hand wheel knob A by turning it toward you

with the right hand while holding hand wheel with

the left hand.

3. Place thread spool on spool pin with thread retain

ing silt B to the right. (Break paper at the end of

spool if necessary,)

• Place spool holder C on spool pin and press firmly

against the thread spooi.

Winding Steps

• Snap thread into thread guide post D and open top

cover.

• Lead thread around bobbin v^inder tension disc E,

as illustrated, and through small hole in bobbin from

inside out.

• Place bobbin on spindle and move bobbin wmder

F to right.

• Hold thread end and start the machine. Cut off

thread end after a few coils have been wound.

• When reouired amount of thread has been wound

(winding will stop when bobbin is full) stop machine

and cut connecting thread.

• Move bobbin winder to the left and remove bobbin,

• Hold hand wheel and tighten hand wheel knob.

Page 22

::||||||||||ÌÌI

"Ni ÌtBì

. V:ì

f

%u Ú. '/

^ Л Э

w ^

r*^ 1

^ i

Щ11(щ1 ^ \

\ '

XtN

1

2

T

5sÄJ2L

ъТ^

У E :

1 ^

|f '""^

21

Page 23

Threading the Bobbin Case

1 Hold bobbin $0 tha* thread unwinds in direction

shown, and insert bobbin m bobbin case.

2. Puli thread mto notch A \n bobbin case, draw h

toward left and into slot 8.

3. Draw approximately I0cm (4 inches) of thread diag

onally across the bobbin.

4 Close slide plate, allowing thread to extend through

the slot between the slide plate and the needle plate.

22

Page 24

23

Page 25

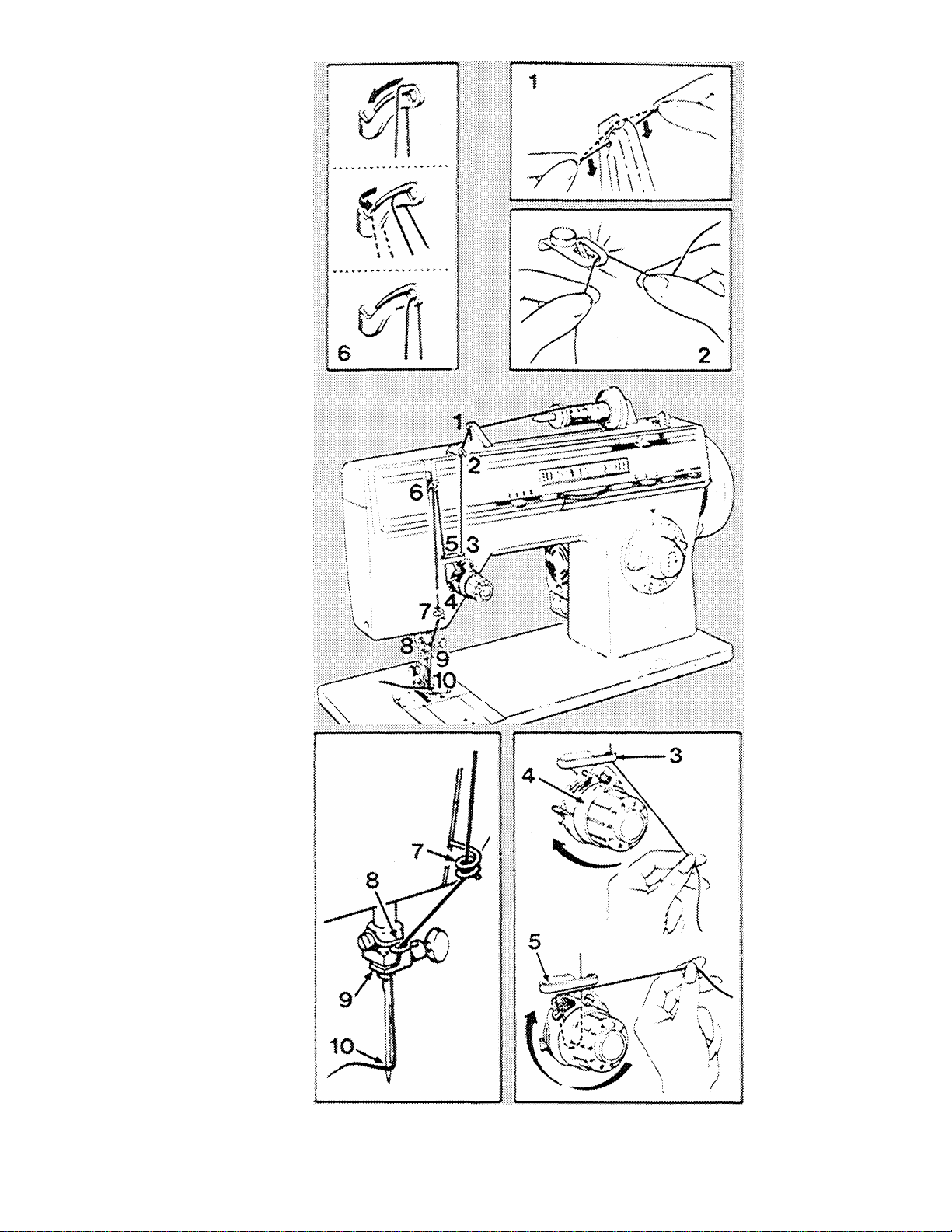

Threading the Machine

♦ Place spool of thread on horizontal spool pin A. If

spool being used has a thread retaining slit B, it

should be placed against the spool cushion to the

right.

♦ Raise the presser foot, to release thread tension.

♦ Raise the take-up lever to highest position by turning

hand wheel toward you.

♦ Snap thread into thread guide post 1*

♦ Holding thread ends in each hand, snap thread into

upper thread guide 2.

♦ Pass thread through thread guide 3.

♦ With right hand on thread spool, thread the needle

thread tension 4. Slide thread over metal plate be

tween tension discs with left hand. Lead thread

under tension and tension wire. Thread tension wire

by firmly pulling thread up and over to the right,

♦ Guide thread through point 5,

♦ Thread take-up lever 6, as illustrated,

♦ Draw thread through points 7 and S, guiding thread

from rear of each guide to the right,

♦ Pass thread through guide 9. Thread the needle 10

from', front to back, drawing I0cm (4 inches) of

thread through the needle eye.

24

Page 26

25

Page 27

Raising the Bobbin Thread

Hold needie thread iightiy with left hand and turn hand

wheel slowly toward you until the needle enters plate

Continue

thread until

needle thread and bnng up bobbin thread in a loop.

Open the loop with your fingers. Draw approximately

10 cm (4 inches) of both threads under the presser foot

and place them diagonally to left. Close slide plate.

'n^ng hand wheel and holding needle

needle rises. Tighten your hold on the

26

Page 28

a?

Page 29

3. straight Stitching

Setting Selectors

Before you move the selectors to set your machine for

straight stitching, turn the hand wheel toward you until

the needle is above the needle plate,

1o begin setting your machine for straight stitching,

depress and hold reverse-stitch button in, then slide

the stitch pattern selector until it is aligned with the

blue colour ban

♦ Needle Position:!, UL] J,

• stitch Width, 011 I i i

Stitch Length: 1,5-4 to suit fabric

Straight stitching can be performed with pattern group

selector set on any pattern group and stitch width

lever at t only,

Adjusting Stitch Length

The stitch length dial controls the length of stitches.

The numbers around the edge of the dial express

stitch length in mm; the lower the number the shorter

the stitch. Generally, shorter stitches are best for light

weight fabric, The area from 0 to 1 is used for the

adjustment of zig-zag satin stitching {see page 40).

Setting the Dial

♦ Turn dial so that stitch length desired is positioned

under symbol.

♦ To shorten stitch length, turn dial toward a lower

number.

♦ To lengthen stitch length, turn dial toward a higher

number.

For reverse stitching, depress push button located in

centre of dial, hold in until reverse stitching is com

pleted, then release push button.

28

Page 30

m

m

WiV

Ф

Page 31

Needle Thread Tension

Having selected the correct needle and thread com

bination for the fabric being used, it nsay be necessary

to adjust the tension of the sewing machine to insure

a well-balanced stitch.

A weii-balanced stitch is produced when the top and

under thread appear the same on the fabric.

Your machine has an adjustable top tension control

system. This control exerts tension on the threads as

they pass through the machine to form a stitch.

♦ Too much tension will produce a tight stitch which'

will cause puckered seams.

• Too little tension will produce a loose stitch.

When an even amount of tension is exerted on both

ihteaós. a smooth even stitch known as a balanced

stitch, is produced.

Tension Test

To help understand the effect of tension on fabric and

thread, try this sample test:

* Take two pieces of a medium weight woven fabric

in a solid light colour about 15cm (6 inches) long,

* Place a 2020 size 14 needle in the machine.

♦ Thread the top of your machine with a polyester or

cotton dark colour thread and use a lighter colour

thread of the sam.e fibre and size in the bobbin.

• Select straight stitch.

♦ Seam the two pieces of fabric together starting with

the top tension control at t Then as you sew, slowly

turn the tension control from 1 through 9.

♦ Sew another row turning the dial back to 1 Ydu

should have a balanced stitch on each row between

the start and finish In each case.

• The different coloured threads will help you to see

the effect that the tension has on the top and bottom

threads.

Now that you have observed the effects of tension,

we suggest that you perform a similar test on a scrap

of fabric you plan to use, being sure to duplicate the

number of thicknesses of your garment.

30

Page 32

Page 33

Sewing a Seam

1 Select straight stitch and set the stitch length dial

on desired setting. Raise presser foot. Puii thread

back under presser foot leaving at least 10cm

(4 inches) of thread.

Z Position needle approximately 1.3cm. (i/2 inch)from

fabric edge. Then lower presser foot and backstitch

airrjost to the edge of the fabric for reinforcement

by stitching in reverse direction. For additional informatson on reverse stitching refer to page 28,

Stitch forward to end of seam and stop machine

before the end of stitching line. {Do not sew beyond

edge of fabric.)

CAUTION: Do nor pul! the fabric while you are

stitching as this may deflect the fieedle causing a

to break.

3. Raise needle by turn mg hand wheel toward you.

Press reverse stitch push button, and back stitch

1.3cm (1/2 inch) to reinforce end of stitching.

4 Raise needle by turning hand wheel toward you.

Raise foot and remove fabric by drawing it,to the

back and to the left. Cut threads on thread cutter at

rear of presser bar

32

Page 34

33

Page 35

Applications

Darning with an Embroidery Hoop

♦ Needle Position: i*

* Stitch Width: jT| I I 1 1

♦ Stitch Length; 0

• No Presser Foot

• Snap-in Feed Cover

* Embroidery Hoop Designed for Machine Use

• Position work under needle and lower presser bar,

• Hold needle thread loosely with left hand, turn hand

wheel toward you. and draw bobbin thread up

through fabric. Hold both thread ends and lower

needle into fabric.

• Stitch across opening, msoving hoop under needle

at a slight angle from lower left to upper right. Keep

lines of stitching closely spaced and even in length.

When opening is filled, cover area with crosswise

lines of stitching.

Quilting

Quilting is the art of stitching two or more thicknesses

of fabric together in a planned design. A padding is

stitched to the underside of the fabric to produce a

soft, puffed effect that is becoming to some wearing

apparel and to many fabric furnishings.

Preparing the Fabric

Baste a light padding of cotton flannel, synthetic quilt

batting, sheet wadding, or a iightweight wool interlin

ing to the underside of the fabric. When using sheet

wadding, first back it with voile, batiste, or net to pre

serve the sheet wadding through wear. Baste the lay

ers of fabric and padding together on the lengthwise

and crosswise grains.

Basic Procedure

• Draw both threads under the foot and diagonally

across feed to left.

• Position the needle, lower the foot and start stitching.

34

Page 36

35

Page 37

zipper Insertion

How the zspper is inserted wíü depend on the type ot

garment and the location of the zipper. With the adjust

able zspper toot, you w:i; find it easy to sew an even

hne of sthchsng cióse to the zspper For instructions on

inserting Zipper foot on machine, see page TO,

♦ Needle Position: L \M A

♦ Stitch Width: m i I i i

♦ Stitch Length: To suit fabric

♦ General Purpose Needle Plate

♦ Zipper Foot

♦ Speed; MIN.

The Zipper toot can oe used either to the left or right

of the needle, depending on where the teeth of the

zipper are placed

Adjusting the Zipper Foot

When the zipper is to the right of the needie;

A, Attach right side of zipper foot to shank (needle wiii

enter right notch in foot).

When the zipper is to the ¡eft of the needle:

8. Attach the left side of zipper foot to shank (needle

wH enter left notch m foot).

36

Page 38

в

37

Page 39

4. Basic Zig-Zag Stitching

VvVvW/vVv^

Setting Selectors

Set the stitch pattern seiector on the colour bar that

matches the cotour of the zig-zag stitch framed by the

pattern group selector. See page 46.

Before turning selector, make sure needle is out of

the fabric.

Needle Position Selector

Most of your zig-zag stitching weH be done in centre

X, needle position.

Left X» and right A settings are used for special

stitch placement.

stitch Width Selector

To produce a piam zig-zag or a decorative stitch, the

stitch width selector es moved from its straight stitch

■positEon : to any of hs other four positions. The fur

ther you rnove the selector toward the right, the wider

your stitch will be.

Adjusting Stitch Length

Any stEtch length setting from 1 to 4 w:il give you an

open zig-zag stitch.

The higher the number, the more open, or farther

apart your stitches will be.

The area between 0 and 1 on the dial :s used for the

adjustment of zig-zag satin ststching. a series of closely

spaced plain zig-zag stitches that form a smooth,

satin-like surface, (Refer to page 4Q for mformaten

on satin stitching.)

Bobbin Thread Tension

SoPPEn thread tension s$ controlled Py screw A located

on the boPPEn case. The tension ;s set at the factory for

regular sewing and should not be aciusted unless the

corners of a zig-zag stitch cannot be locked by adjust

ing the needle thread tension.

On those rare occasions when it becomes necessary

to adjust the bobbin thread tension, use a very small

screwdrEver. A very slight turn of screw A will change

the appearance of your stitchEng.

♦ To mcrease tension, turn screw to the fEght.

♦ To decrease tension, turn screw to the left

Page 40

ì wm

- тш

ллм

c*>

ю

- mm

« ммл

^ ллм

//М

ш

т

мм

Page 41

Satin Stitching

Wnen you w!$h to p'ocuce a sat;n stitch, nnake a test

sample first so you can adjust stitch length and thread

tension Dropeny. Sott fabric nnay require a backing to

insure a firm stitch. CriSp o'gandy. iawn'or a fusible

intertacinc are suitabie tor th;s ouroose

: thi<

Accessory and Selector Settings

♦ Pattern Group: i[|]| (Blue)

• Needle Position: L \Xl À

* Stitch Width: : f

♦ Stitch Ler^gth' 0 to 1

♦ Generai Purpose Needie Piate

♦ Generai Purpose Foot

J

Adjusting Stitch Length

• Turn stnch ienqth seiector dial to 1

• Run !ne rYiacn;ne at a slow speed and siowiy turn

stitch length dial toward the right until stitches are

cioseiy spaced and form a smooth surface

Adjusting Needle Thread Tension

Zig-zag stitching usually requires less needle thread

tension than straight stitching. Thread machine cor^

rectiy and make a test sample with the same fabric,

thread, needle and stitch pattern combination you

plan to use. Stitches should lie flat without causing

fabnc to pucker,

if puckenng occurs, lower the tension oy turning d;ai

to a lower number. An underlay or tissue baper back

ing may be needed

Satin stitching requires less tension than straight

stitching or open zig-zag stitching. Furthermore, the

Wider the stitch, the lighter the tension on the thread

must be Notice the stitching on your sample. If the

'abnc IS puckered, lower the needle-threao tension

by turning the tension dial to a lower number.

Page 42

4%

Page 43

Stitch Usage

The stitch most commonly used in apo^^dué is a pia^n

zig-zag. Cioseiy spaced to form a satin stitch. The

Width of this stitch can be varied to accommodate

fabrics of different weaves and textures. Other stitch

patterns can also be used.

Preparation

Make a test sample to decide which of the fonowing

methods i$ the most appropriate tor your fapric and

design. Mark design on piece of fabnc to be appHquec.

Cut out design leaving about 2 cm (3/4 inch) margin

aH around. Position the design. Baste it to the fabnc.

Method 1

♦ Select oanern and adjust stitch width dial for desired

appiiQue stitch. Adjust stitch length to fine setting,

between 1 and 0.

* Foriow the outer edge of the design with a decora^

tive stitch.

• Tnm away the excess fabric on the outer edges of

the stitching.

Method 2

♦ Select straight stitch.

♦ Outline the entire design with a short stitch.

♦ Trim raw edges to the stitching and remove basting.

* Select stitch pattern and stitch width desired, and

set stitch length on a satin stitch setting for a doseiy

spaced stitch, between 1 and 0.

* Stitch, following the straight stitch outline. This

method will produce a smooth overedged finish.

With no raw edges to be tnmmed after stitching.

Method 3

• Purchasec rriotsfs can be appiíduéd quickly and easily by using either a straight or decorative stnch.

42

Page 44

43

Page 45

Zig-Zag Seam Finishes

Seam edges support the garment and should be given

a durable finish if the fabric is likely to ravel There are

two methods of finishing seams in such fabrics: trim

ming seam edge or overedging. Make a test sample to

determine which method best suits your fabric.

• Pattern Group: «flii

• Needie Position;

• Stitcin Width: i i

♦ Stitch Length: 1 to 3 to suit fabric

♦ General Purpose Needle Plate

♦ General Purpose Foot

(Biue)

l! 1

Method 1 —Trimmed Seam Finish

♦ Adjust strtch width and length to give you the most

open ststch that will secure the fabric edge, avoid

harsh overstitching.

♦ Stitch near the edge of seam allowance and trim

seam edges evenly after stitching.

Method 2—Overedge Seam Finish

♦ Adjust needle thread tension, stitch width and stnch

length to suit fabric.

♦ Trim seam edges evenly.

♦ Place trimmed seam under the foot and overecge

the seam allowance as illustrated

Ungerie Seams

To make a lingerie seam durable and flexible use the

plain zig-zag stitch at a narrow width setting. This

seam treatment is particularly suitaPle for bias seams.

When seammg nylon tncot insert a 2045 needle in the

machine before you begin to sew.

• Straight stitch the seam line on wrong side of fab; ic.

• Press both seam allowances in the samte direction.

• From the right side, topstitch with narrow zig-zag

stitching, letting the needle alternately enter the

seam ime and seam thickness. (Stitch width narrow;

stitch length 1 to 15,)

44

Page 46

45

Page 47

5. Pattern Stitching

Selecting a Stitch

Setting Stitch Pattern Group Selector

1. Rotate the pattern group seiector until the orange

frame is behind the group containing the stitch you

desire.

Now set the stitch pattern selector for the selected

oattern colour.

Setting Stitch Pattern Selector

1. Depress and hold the reverse stitch push button.

Z Slide pattern selector until it is aligned with the

colour bar that corresponds with the colour of the

stitch you have chosen.

Release the reverse stitch push button. Vbur sewing

machine is now ready to sew your desired stitch

oattern.

46

Page 48

«ЛЛЛ/

nWí

fxnru

mra

AMW

xi^tíi.tx¡.í

f'fY'rfTvfT

SS S»»

'''VeM4ww '

a

OI

Page 49

stitch Pattern Groups

There are two kinds of stitch patterns built into your

machine: Fashion Stitch patterns A and FlexhStitch

patterns B. The Fashion Stitch patterns, colour-coded

blue on your machine, are produced by the side to side

movement of the needle. The FlexhStitch patterns,

color-coded green and yellow {identified by t in the

illustration at right) are produced by both the side to

side movement of the needle and the back and forth

movement of the feed to produce multi-purpose and

decorative stitch patterns.

The six groups of three stitches each that are built into

your machine are illustrated at right.

Adjusting Stitch Length for FlexhStitchmg

for all green or yellow FlexhStitch patterns, stitch

length is controlled with a single setting of the stitch

length selector. Simple rotate it until the (green-yellow)

mark is under the triangle above the selector.

Adjusting Stitch Balance

When you are using a FlexhStitch palterri you may

need to balance your stitching in order to achieve the

correct pattern (See illustration C.)

Before you move the stitch balance control lever from

its neutral oosltlon (lever at center mark i ), make a

test sample, if adjustment is required, stitch slowly

and move the stitch balance control lever as you sew.

♦ Slide the lever toward the left to separate the for

ward and reverse stitches of the pattern.

♦ Slide the lever toward the right to brlr\g the forward

and reverse stitches of the pattern together.

46

Page 50

алАллЛ

MW

\

v>w^-

Л Л

Л

/ Ч Л / i

W V ^

аЛЛлЛЛ

ллЛллЛ ^

TTTT

^ÄWA

AWW

кХШШАД/

Wrmmnr :

L

AW\

АЛА/

ШШ

/vV\

>y +«y

4

VSÄMWW

>д

rrrr*7WJ\-

/www*^!

: : : : wwwl: 'Mb ibíí k

-"mBeS-x-ì*^-:-:

i

UyMft

ättW ЯпИп Л

wvm/-

Twy^^

r\f\JV

1

__ _ __ _ _ _ __ _ _ _

__ _ _ _ __ _ _ _ _ _ _ _

s<^

о

0

)

Page 51

Adjusting Stitches

for Stretch Fabrics

Guiding and Supporting Fabric

Most fabrics of stretch or knit construction need only

to be guided in front of the presser foot when you use

one of the stretch stitches. Some fabrics—nylon tricot

and eiasticized fabrics, for example—do require sup

port while being stitched,

1. For nylon tricot and similar synthetic knits, apply

gentle tension by holding the seam in front and back

of the presser foot as you sew.

2. For eiasticized fabric, stretch lace, and knits with an

unusual amount of elasticity, apply firm tension in

front and back of the presser foot to stretch the

seam as the stitches are being placed.

CAUTION: Do riot pail the fQPric while you are stitching as

this may deflect the rieedie. causing it to oreak.

50

Page 52

51

Page 53

Biindstitch Hems

BHndstitcning provides a durable hem fsnisn that i$

almost mvssibie, While :t is best suited to straight or

slightly curved hems, taped, bound, or turned hem

edges can also be biindstitched with ease.

♦ Pattern Group: (Blue)

♦ Needle Posstion; i<* [ij -i

♦ Stitch Width. : Ijl f

♦ Stitch Length: Tp $u:t faorsc

♦ General Purpose Needle Plate

♦ General Purpose Foot

♦ BNndstitch Hem Guide

1. Raise presser foot, loosen screw, and slip blindstitch hem guide between screw and shank of foot

Make sure underside of the guide clears the slide

plate and front of foot Tighten screw with com.

2. Prepare hem in the usual way. it is advisable to

baste the hem Place the basting at least T3 cm

(W inch) below the edge of hem allowance to avoid

catching the flange of guide as you stitch,

3. With the wrong Side of work uppermost, turn the

hem. under, creating a soft fold from the top edge

of hem,

4 Position hem under the foot w;th the soft told resting

against the wall of guide. Make sure the flange of

the guide iS between sott fold and top of hem, as

Shown

5. Lower presser foot. Stitch so that the straight

stitches fail on the hem allowance and zig-zag

' stitches pierce the soft fold of work. Adjust stitch

Width if necessary While stitching, guide hem edge

in a straight ime and feed soft fold evenly against

wall of the guide

52

Page 54

53

Page 55

Ladder Seam

The biindsthcn iadder searri ;s partcu^ahy apDropnate

for КПП and stretch tabrscs И ss юеа1 for stretcnaoie

construction seanns. and edge finishes for necKiines,

pockets and collars in sportswear and swimsuits

• Pattern Group: 5У]^ (Blue)

• Needle Position L [XJ À

• Stitch Width: : I I I i

♦ Stitch Length: 15 to 2.5

♦ General Purpose Needle Plate

♦ General Purpose Foot

* 'Make a test sample to aciust stitch width and length

and needle thread tension to su:t the fabric Needle

thread tension snouid oe lighter than normal.

• Cut and fit garment, allowing tor i,5 cm (5/S inch

seam allowance Baste seam Nne.

• Place fabric uncer presser toot so that the stm:oht

stitches fall on the seam line casting and the points

toward the centre of the ca-ment

♦ After stitching, open seam py pulling tabnc Pack on

opposite Sides of the seam to produce ladder effect

Press seam allowance after openmg.

* •

54

Page 56

55

Page 57

Construction Stitches Mufti-Stitch Zig-Zag

The muiti-stitch zig-zag is an extremeiy versatile stitch.

Use it to mend, join, or reinforce without bulk. With this

stitch you may attach elastic and stretch lace, con

struct lingerie and swimsuits, and finish seams. There

are many other useful applications for the multi-stitch

zig-zag.

Mending a Tear

• Pattern Group: Igjf (Slue)

• Needle Position; L ^ À

• Stitch Width: ■ t I l[|3

• Stitch Length; .5 to 1

• General purpose needle plate,

• General purpose toot or special purpose foot.

• Irim ragged edges,

• Place underlay on the wrong side of tear tor rein

forcement, Saste one side of unoerlay in place.

• Stitch on the right side, bringing the edges of the tear

together. Shorten stitch length at ends and corners

to give extra strength,

• Trim underlay.

Finishes for Hems and Facings

Hem and facing edges in knit and stretch fabrics will

be less apt to press through and mark when given a

flat edge finish. Edge finishing with the multi-stitch

zig-zag eliminates the bulk of turned-in edges and re

tains fabric flexibility.

• Make a test sample to check thread tension and

stitch length if you are using the multi-stitch zig-zag.

• Place stitching about 1.3 cm (1/2 inch) from hem or

facing edge. Avoid stretching edge while sewing.

• Press after stitching and trim away excess fabric

close to the stitching line.

56

Page 58

57

Page 59

iyiy!tl* *Stitcli Zig-Zag Bar Tacks

With the multi-stitch zig-zag you can make strong bar

tacks. Multi-stitch zig-zag bar tacks are effective for

tacking belt loops on heavy fabrics such as denim, 8e

sure to check the Fabric, Thread and Needle Table on

page 16 for correct thread and needle selection with

your choice of fabric.

Paitetn Group: (Blue)

♦ Needle Position: JL iXj ^

♦ Stitch Width:; II I fj]

♦ Stitch Length: 0 to 1

♦ Snap-in feed cover.

General pi^rpose foot or special purpose foot,

We recommend making a test sample first using

scraps of the material you will be sewing the bar tacks

on. duplicating all thicknesses.

1. Mark position for the finished end of belt loop on

the fabric.

♦ Place belt loop, wrong side up, straight stitch with

cut end 3 mm (1 /8 inch) fromi edge of garment: do

not stitch beyond edges of the belt loop. Trim the

end close to the stitching and press.

2 Fold belt loop back on the stitching line and press.

• Set your machine according to the code above,

* Stitch 3 mm (1/8 inch) from the fold using the

multi-stitch zig-zag.

3. Fold over loose end and bar tack.

58

Page 60

59

Page 61

Patchwork Quilting

!7ìì

* Pattern Group: (Blue)

• Needle Position: iM ^

• Stitch Width: ; I I l[i]

♦ Stitch Length: .5 to 1

♦ Genera: purpose needle plate.

* General purpose foot or special purpose foot.

Patchwork for quilts and wearing apparel, formerly put

together with hand stitching, can be quickly pieced

and decorated at the same time by using the domino

stitch. Joinings are both flexible and durable when

this method is used.

Procedure

• Cut a fabric underlay to size. Baste a light layer of

padding to underlay if a quilted effect is desired.

Prepare patches, turning under 6 mm {1/4 inch)

seam allowance. On non-woven fabric this step is

not necessary.

Baste patches to underlay in arrangement desired,

butting ail edges.

• Stitch in lengthwise and crosswise rows, allowing

stitches to straddle patches.

60

Page 62

ш

^ iff

tn¡:

^ ^ ^

^ ^ ^

тш^тшшшшщ:

.. ....

ШЁштШЁт

ЩЩ

iîî

'» it

■ iïf

it

❖

it

.

.................

it -Öf

it

it

it

i»

it §шт

it

it

ií: ^

^ -äCt 0 i"

^ ^ , ,

iiiiiiiiiiiii::; """""""""""""

у4 W

if

61

Page 63

Decorative Stitching

Your sewing machine has several stitches which are

purely decorative. These versatile stitches allow you

to add imagination and creativity to your sewing proj*

ects. With these decorative stitches, you can apply to

clothes and household items: interesting details,

youthful and feminine accents, and personalized ef

fects. Some of the many applications of the decorative

stitches include border designs, appliqué, twin-needle

stitching, finished hems, smocking, embroidering,

monograms and topstitching accent lines on clothes.

The following pages illustrate decorative stitches on

your machine and provide examples for their creative

use.

Border Designs

Border designs that add a decorative touch to wearing

apparel and household items can be created by com

bining different types of straight stitching and zig-zag

stitching. Simple or elaborate, delicate or bold, they

can be varied to suit the application. Use them as you

would a braid or to simulate horizontai, vertical or

bias strioes on plain fabric.

Procedure

Mark or crease fabric for the centre line of first row of

stitching. If spacing between rows is not greater than

1.3 cm (1/2 inch), gauge additional rows with the pres

ser foot. If spacing is wider, mark for each line of

stitching. Use a backing of crisp lawn, organdy or a fu

sible interfacing. Be sure to make a test sample on a

swatch of your fabric to check stitch settings and

thread tension, being sure to duplicate thickness and

interfacing or backing if appropriate.

62

Page 64

лЛЛлЛЛлЛЛлЛЛлЛЛ

1/1Шы1ЁНш1Ш1Ы1НкА

vvwwww

*шт

/ \

^ \

/ \ / У -

\ у Ч У\ / \

Ч / / N. / ^

чУ Ч / \ У ЧУ \

чУ Ч/ ЧУ ЧУ ч

ч / ч у "^ч У ^

' ^ \ \ / \. /

V

У Ч / ч У \ У \

/ ^Ч / \ ч у Ч /

у V у Ч .У^ ЧУ N /

у \/ \У \У Ч /

V

л.-

У

^у.

у \

--тс

у ч

у \ ^

V /

\y

>r

\

./

\

63

Page 65

Monograms

Many decorative stitch patterns can be used for rr-onograms and motifs—to add a persona! touch to a

biouse coilar, for exampie, or for initialing household

linens. Vbu can buy designs or create them yourself

to suit the stitch paltern you wish to use.

Very simple straighMine monograms can be made

with the plain zg*2ag stitch, or you can create a motif

by arranging individual pattern units to form a design.

Refer to page 46 for information on setting selectors

for zig-zag and decorative stitching,

When you use a decorative stitch pattern to form a

motif, you will want to start at the beginning of the

arrowhead, crescent or whatever pattern you have

selected.

Finding Beginning of Pattern Unit

1. On a scrap of material, stitch until you come to the

end of a complete pattern unit, as indicated A. Now

you are ready to start stitching at the beginning of

the next unit.

Z Rai$e,presser foot and remove scrap.

3. Position motif under needle, lower the presser foot

and stitch.

64

Page 66

A

65

Page 67

6. Buttonholes

and Buttons

Buttonholes can be made easily wch the manua: tour*

step method. Before sewjng on your garm^ent. always

make a test buttonhole duplicating the number of

thicknesses of fabric and interfacing if appropriate.

Garment Preparation

Suttonhofe Positioni

Accurate guideisnes are essential to keep buttonhOies

at a uniform distance from the edge of the garment,

evenly spaced, and on the grain of the fabric,

1. Mark the centre line on the garment. Th^s guideline

can be made by machine or hand basting or usmg

tailor's chalk.

Be sure that tne space from the centre line to the

finished edge of the garment iS at least equal to

three-quarters the diameter of the button. With this

spacing, the button will not extend beyond the edge

when the garment ss buttoned.

Make sure that the centre Hne marking foiiows a

lengthwise fabric thread.

A, Centre line

8. Buttonhole

C. Finished Edge of Garment

D* Diameter of Sutton

Z Mark a position guideline tor each buttonhole.

Horizontal buttonholes B are placed to extend 3mm

(1/8 inch) beyond the centre line Aof the garment, as

shown, so that the buttons wiii be in the centre of the

figure when the garment is fastened.

Horizontal buttonhole guidelines should follow a

crosswise faPnc thread

♦ Mark the norizontai buttonhole guideline for each

buttonhole It should be longer than the finished

length of the buttonhole

• Mark the starting point for each buttonhole 3mm

(1/8 inch) bevond the centre line (see illustration).

66

Page 68

о

D

r^

<D

OÍ

Page 69

Vertical buttonholes C are placed so that the centre

line A of the garment is in the centre of the buttonhole,

as shown,

♦ Mark the ends of each buttonhole horizontally

across the centre line basting and use the centre

line marking as the buttonhole guide when stitching.

Buttonhote Length

♦ The buttonhole length should be just long enough to

allow the button to slip through the opening without

stretching it.

♦ To make sure the measurement is correct, cut a sHt

sn a scrap of fabric equal to the diameter of the but

ton you intend to use,

♦ Increase length of opening until button slips through

easily.

This test is particularly advisable for buttons of un

usual shape or thickness.

68

Page 70

О)

(О

Page 71

Four-Step Buttonholing

The tour dsai setiinqs for dunonhonog are iocated on

the sthcn length selector. As you turnone dsai tor each

steo, you' rr^achu^e :s autoniaticaiiy set for the couect

needie oosition, stitch width, and stccn length, as weH

as tor stitching direction tor that step. You need riot

turn the fabhc Ouririg outtonhoiing.

* Pattern Group: ij||| (Blue)

• Generat Purpose Needle Plate

Buttonhole Poot

Preparation

♦ Prepare and marK your garnnent, as instructed on

page 66

♦ Position work under needle, aligning centre raarking

ot buttonnoie with centre ime on tne toot Align end

rTiarking ot duttonnoie with the hon/ontai nnes on

tru:i toot

♦ Set the buttonhole balance knob K tn neutral pose

tion, as alustrated. The buttonhole balance knob<

when turned slightly to the nght or left, enables you

to balance the stitch density of both sides of the

buttonhole. Refer to the next page for information on

balancing buttonhole stitch density.

Step 1: Side Stitching

Raise needle above the tabnc and turn tne buttonhole

dial to step 1. Position needle m fabnc at pomt A.

Lower the foot and stitch to end of buttonhole {point 8).

The er^d marking should be aligned with tne nonsontai

lines on the fool

Step 2: Bar Tack

Raise the needle out ot the fabrsc. Turn buttonnoie dial

tostep 2and take at least tour stitches. Stop at point C.

Step 3: Side Stitching

Raise the needle out ot the tabric Turn buttonnoie dial

to step 3. Complete worn, to point D, Raise needle.

Step 4: Bar Tack

Raise nie rieedie out ot the tabnc and turn buttonhole

umT to step 4v Take at least tour stitches ending at

point E* Toi a srnooth. satin appearance and greater'

oumoiinv. stitch around the buttonhole a second time

by mpeating tne tom mtep seouence

70

Page 72

A

В

71

Page 73

Balancing the Buttonhole

Stitch density on the ieft and right sides of the buttonhole may be balanced by adjusting the buttonhole bal

ance knob K. Use the buttonhoie balance knob to

obtain similar stitch appearance on left and right sides

of the buttonhole. A very slight turn will produce a

noticeable density change.

To change the density on either side of your test but

tonhole follow the procedure below. Before sewing on

your garment be sure to make a test buttonhoie on a

sample of your fabric to check that the stitch density

is simiiar on left and right sides of your buttonhoie.

1. Make a test buttonhole with the balance knob in

neutral position (indicator line or dot directly below

▼ symbol on control panel).

Z If the stitches on the left sice of the buttonhole are

too open, turn the balance knob from its neutral

position to the right to increase density of the side

stitching.

3. If the stitches on the right side of the buttonhole are

too open, turn the balance knob from its neutral

position to the left to increase density of the side

stitching.

After buttonhole stitching is completed, retu rn balance

knob to its neutral position (indicator line or dot directly

below ▼ symbol on control panel).

72

Page 74

к

73

Page 75

Buttons

Most fiat buttons can be sewn quickiy and easily using

the zig-zag stitch.

• Pattern Group:: Sj|j| (8iue)

• Needle Position: L ¡X! Jl

• Stitch Width: i | 1¡|

• Stitch Length: 0

• General Purpose Needle Plate

• Snap-in Feed Cover

• Sutton Foot

Sewing on a Bytton

♦ Set your machme up according to the code above.

♦ Mark position of buttor^^ on garment. Place garment

under foot. Align garment so that the button is

directly under the foot. Lower the presser foot to grip

button centrally.

1« Turn hand wheel very slowly toward you until nee

dle point aligns with hole of the button. Adjust zig

zag stitch width, if necessary to permit clean entry

of the needle.

2. Continue turning hand wheel one complete

revolution and observe that the needle point is pro

perly positioned to enter the other hole.

• Take six to twelve stitches.

Remove garment from machine. Pull threads to un-

derside of garment and trim

74

Page 76

1

fm

m

{

«essa

iftiMltiltnti till

/ÎT^TTr'n

/VWA/

VWW

JLL.U

АЛМ

m

a

□ Il

fìì

ж"

СП

m

||i

1^

m

N<W<4

m

t

h

и

::

1

s^m

АЛ/V

vwv

wvr

y-vyw

vv^vv^

Page 77

7. Cariog for Your Machine

Cleaning the Machine

CAUTION: Before cleaning your machine, discon

nect the power hne plug from the socket outlet.

Per:odica:?y. depending on machine use. c^ean

and Oii 4 your machine, usmg one drop ot Oii on

inustrated areas

Top and Bottom

Clean and oil the top and bottom areas marked on the

illustration. Use a large screwdriver to remove screws

A, B and C from top cover.

To replace the covers, simply line up the screwholes

and replace screws with a large screwdriver.

76

Page 78

Page 79

To clean y andoH ® the front intenor of machine,

remove screw from face piate. With a soft cioth or Hnt

brush, clean and oil points indicated by arrows. Re*

place face plate and screw.

To clean bobbin and feed areas, remove needle plate,

as instructed on page 14 . Remove 'Dobbin case as m*

structed on next page. Using soft cloth or brush, clean

area as illustrated. Replace needle plate and bobbin

case, as instructed on pages 14 and 80.

if necessary, a mild solution of soap and water may be

used on exterior areas to remove stubborn stains. No

other cleaning iiquic or powder should be used.

I: Do not attempt to adjust the motor pelt.

Contact your nearest Service Centre should any ad-

justment be reQuired.

78

Page 80

79

Page 81

Removing and Repiacing Bobbin Case

CAUTION; Before removing bobbin case, dis

connect the power-line plug from the socket out

let.

IMPORTANT: The bobbin case is manufac

tured from, a special phenolic compound specially

designed to provide smooth friction-free sewing.

With proper handling the bobbin case will give you

years of reliable, trouble-free sewing. The bobbin

case is the most important part of your sewing

m,achine. Please handle with care and do not

force when removing and replacing it.

• Turn hand wheei toward you to raise needie to its

highest position,.

1. Open slide plate, rennove needle plate and

remove bobbin.

2. insert scre\A/driver into bobbin case holder A and

turn it toward the rear as illustrated.

3. To remove bolsbin case:

• insert index finger into centre of bobbin case.

With index finger and thumb gently lift and

push bobbin case away from you until the case

is released from holder.

4. To replace bobbin case:

• Insert index finger into centre of case and grip

with thumb above the screws. Gently slide the

flat tab at the rear of the bobbin case under

neath the curved section of feed B while main

taining slight upward pressure, then slide bob

bin case all the way to the rear. Lower the bob

bin case and draw it toward you so that tab C is

positioned under plate D. Gently wiggle case to

insure proper seating in the rim of the rotating

hook. In this position bobbin case should be

free to float slightly from side to side.

• When you are sure bobbin case is properly

seated lock case into position by turning hoider

A back, as illustrated.

Replace bobbin, needle plate and dose slide

plate.

80

Page 82

81

Page 83

CAüTtON: Before changing íighí bulb wake sure

you have disconnected power fine plug from socket

outlet This machine is designed to use a 15-watt max

imum bayonet base bulb only.

The screw located on the machine face plate must

be removed before the face plate can be opened.

* Remove face plate.

♦ Do not attempt to unscrew the bulb.

1« Press it up into the socket and at the same time turn

bulb over in direction shown to unlock the bulb pin

and guide out o^ socket.

♦ Press new bulb into socket, with bulb pins enter

ing slot of socket,

Z Turn it over in direction shown to lock bulb in

posñbn.

♦ Replace face plate.

You will not have any occasion to remove the slide

plate. However, if it should accidentally become dis

engaged from the machine, it is easily replaced.

* Raise the presser foot and make sure needle is in its

highest position.

• Place slide plate in slide way with the front edge

close to, but not covering, the retaining spring (as

shown).

♦ With a small screwdriver, lift each end of the spring

into each of the side grooves on the underside of the

plate.

♦ Draw the plate gently toward you and fully engage

the spring.

• Close slide plate.

82

Page 84

83

Page 85

Twin-needie sewsng capabiHty has been built into this

sewing machine. With the purchase of a No, 2025

twin-needle, you may sew two rows of stitching at the

same time,

The twin-needie Simuitaneousiy produces two paraiiei,

closeiy spaced iines of pattern stitching, you can

stitch With either one or two colours of thread.

♦ Stitch: Pattern desired

♦ Needle Position; 1»

♦ Stitch Width: j[ | I

» Stitch Length: .5-4 to suit fabric

♦ General Purpose Needle Plate

♦ General Purpose Foot

* •

tCAUTION: Do not use a stitch width greater than

what is recommended, A wider stitoh will result in

needle breakage,

• Insert twinmeedle.

• Thread as for single-needle stitching, except pass

thread between centre and back tension discs A,

and through left eye of needle.

• Insert a second spool pin into hole on the top cover

of machine, as illustrated.

• Place second spool of thread on right spool pin

and felt.

• Thread machine in usual way, except pass thread

from second spool between centre and front ten

sion discs B, as shown.

• Thread through remaining points, making certain

to omit the thread guide above the needle and pass

thread through right eye of needle.

84

Page 86

co

co

Page 87

9. Home Service Hints

Whenever sewing difficulty is encountered, review the

sections of the instruction book that explain the opera

tion you are performing to make sure you are using the

machine correctly, if the problem still exists, the foh

lowing checklist may help you to correct it.

If you still have difficulties, call your nearest Sewing

Centre,

WhattoDolf...

Heedla Breaks

♦ Make sure needle is fully in

serted into needle clamp .

♦ Make sure needle is not being

pulled to one side as fabric is

removed fromi the machine

..........................

........................

see page 14,15

see page 32.33

* Make sure presser foot or

accessory is securely fas

tened to presser bar

♦ Make sure fabric is not being

pulled while sewing....................................see page 32,33

• Make sure ^itch width does

not exceed [111] 11 when a

twin-needle is used

....................................

....................................

see page 12,13

see page 84,85

Thread Breaks

♦ Make sure machine is prop-

erlythreaded ...................................... . see page 24,25

• Make sure needle-tnread ten

sion is not too tight .

• Make sure thread is unwind

ing freely from spool

• Make sure bobbin case area

is free of lint and loose

threads

................................ see page 78,79,80,81

........................

.......................

see page 30,31.40,41

see page 20,21,24,25

• Make sure the needle is

straightandsharp...........................: . .. . .seepage 16,17

86

Page 88

Fabric Does Not Feed Properly

® Make sure presser foot is cor-

rectlyattachedtomachine

• Make sure stitch length dial is

correctlyset

• Make sure lint has not accu

mulated around feed.

..................

................

. , see page 28.29,40,41

...

......................

, see page 12,13

see page 78J9

Skipped Stitobes

• Make sure needle is correct

style for machine and size for

thread

® Make sure machine is cor

rectly threaded .........................

• Make sure needle is securely

fastened to needle bar . . . . , see page 14,15

• Make sure the needle is nei

ther bent nor damaged. . .

...........................

. ......................see page 16,17

...........

...............

see page 24,25

, see page 16,17

Fabric Pyckers

• Make sure needle-thread ten

sion is not too tight

.....................

see page 30,31,40,41

Needle Ttiread Breaks While Winding Bobbin

® Make sure machine is cor

rectly threaded......................................see page 20,21

® Make sure thread is unwind

ing freely from spool

...............

87

.............

see page 20,21

Page 89

Accessories

Aí^iique...............

Soqqsn

W'irvdinq...........................

Boquín Case

Removing .

Threading

Bobdinlhread

Raising

..................

..................

........................

.......................

Bc;tor^s

Suttonhoies . .

Position

.............

Procedure

Caring for Your Machine

Cioaning the Machine

Connecting the Machine

Construction Stitches

Darning

Decorative Stitching

Fabric, Thread and Needle Tabie .

Feed Cover.

Attaching and Removing.

Finishes, Hems and Facing

Handwheei

..............

Light Buib

Monograms

Needle ....................

Changing

..........

Position .

Thread Tension .

Threading .

.............

.............

Needie Rates ............

Changing Rates

General Purpose

Straight Stitch

Operating the Machine

........

Citing the Machine

PresserPeet

CnangingPeet .

Presser Foot Litter

Pnncipat Parts .

Quitting . .

Reverse St itching

Satin Stitching

Seams.

$eam< Finishes

................

..........

...........

...............

........

Speed Contfoiter _

Stitch Batanee Control ... ,

Stitch Length

.................

Stitch Pattern Groups .....

Stitch Pattern Selectors . .

Stitch Pattern Group Selector ..

Stitch Width . ..

Straight Stitching

........

............

Stretch Fabrics, Adjusting Stitches

Take*up Lever .......

Threading the Machine . . ..

Twin-Needie Stitching . . .

2ig>2ag Stitching ...

^ ^ . 6,7.S,S

.......... 42,43

6,7.20,21

...........

20.21

22.23

. . ^ ^ . 80.St

. 22.23

20.21.22.23,26.27

26,27

.......... 74,75

........

66«73

66*69

70*73

.......... . . 76*33

. . 76*7$

. 18*1$

..........

56*67

. 34,35

62.63

*6-17

a,$.14.15

. .14,15

......................

56,57

. . . . 4.5

82.63

. 64,65

6,7,14-17.24,25,30,31,38.41

.......... ... 14.15

33.39

.. . 30,31,40.41.

. 24,25

..........6,7,8,9,14,15

........... 14,15

3.9

..........

...........

6,7

18,19

....................... 76,79

. . . ^ 6*13

.............

10,11.12.13

..........4,5

. , .4,5

. 34.35.60,61

. 2a,2$,32,33

... 40,41

. . ^ 32,33.54,55

............ , .. . 44.45

.......... ... 4,5.18.1$

.......... 48.49

4,5,28,29,38.39,40.41.48.49

43,49

........... .46.47

...... 46,47

, . . . .4,5,38,3$

. , 28.29

. ..... $0,51

...........

... 24.25

. , ^ .84,85

....... 38

PartNo. It9593-0C1N

Printed in Taiwan

88

Loading...

Loading...