Singer 121D200A Service Manual

1

SERVICE

SINGER

Sewing

121D200A

MANUAL

Machine

Form

21624

(876)

Copyright®1976

Aii

Rights

*A

Trademark

Reserved

of

THE

The

Singer

Throughout

SiNGER

Company

the

World

COMPANY

PrintedInU.S.A.

LUBRICATION

Moving

oil

are:

parts

Impregnated

have

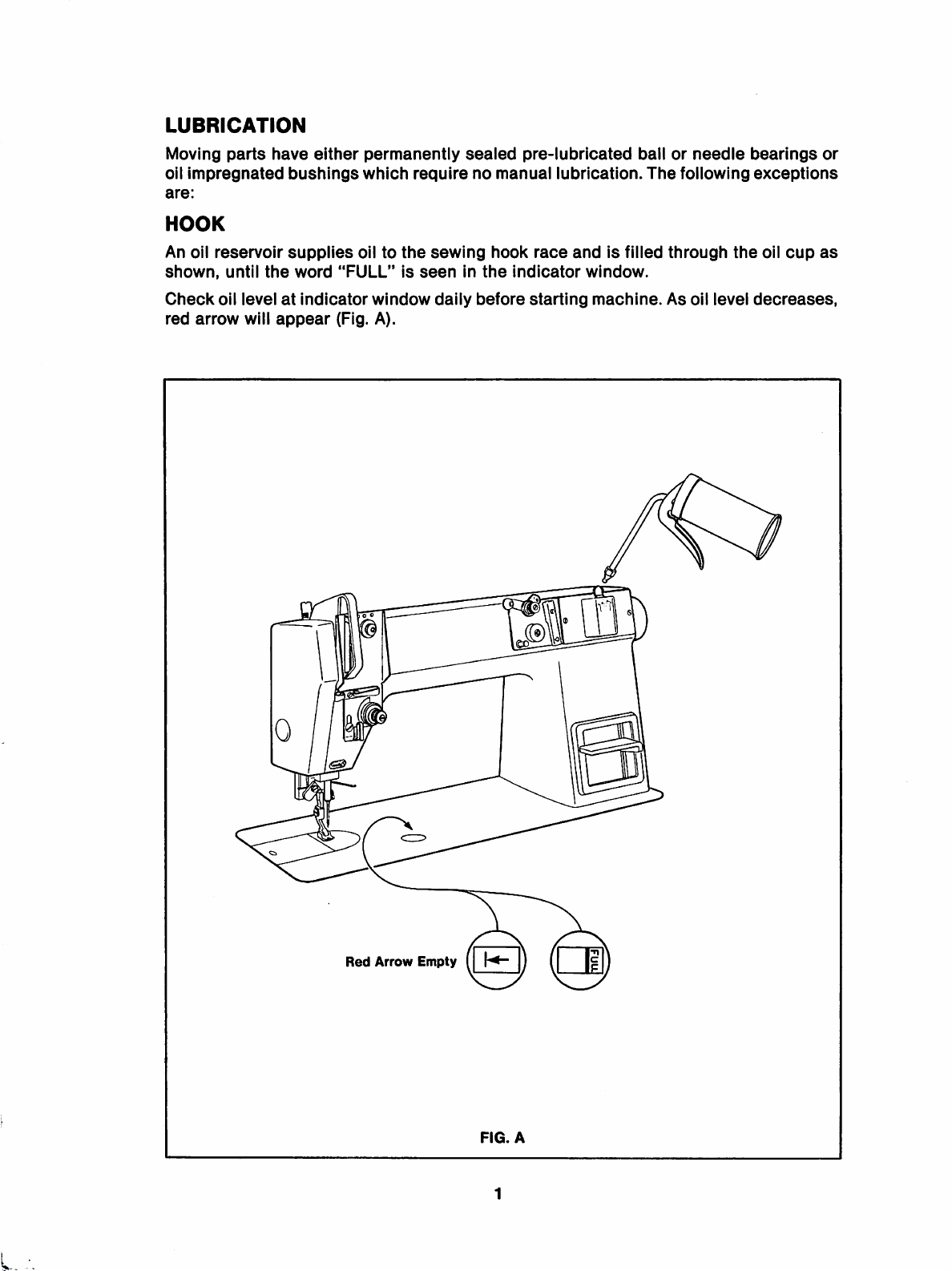

HOOK

An oil

shown,

Check

red

reservoir

until

the

oil levelatIndicator

arrow

will

bushings

supplies

word

appear

either

permanently

which

oiltothe

"FULL"Isseen

window

(Fig. A).

sealed

pre-lubricated

requirenomanual

sewing

dally

In

before

hook

the

race

Indicator

starting

lubrication.

and

Is filled

window.

machine.

ballorneedle

The

following

through

As oil level

bearings

exceptions

the

oil

decreases,

cup

or

as

0

Red

Arrow

Empty(H-

FIG.

A

L.

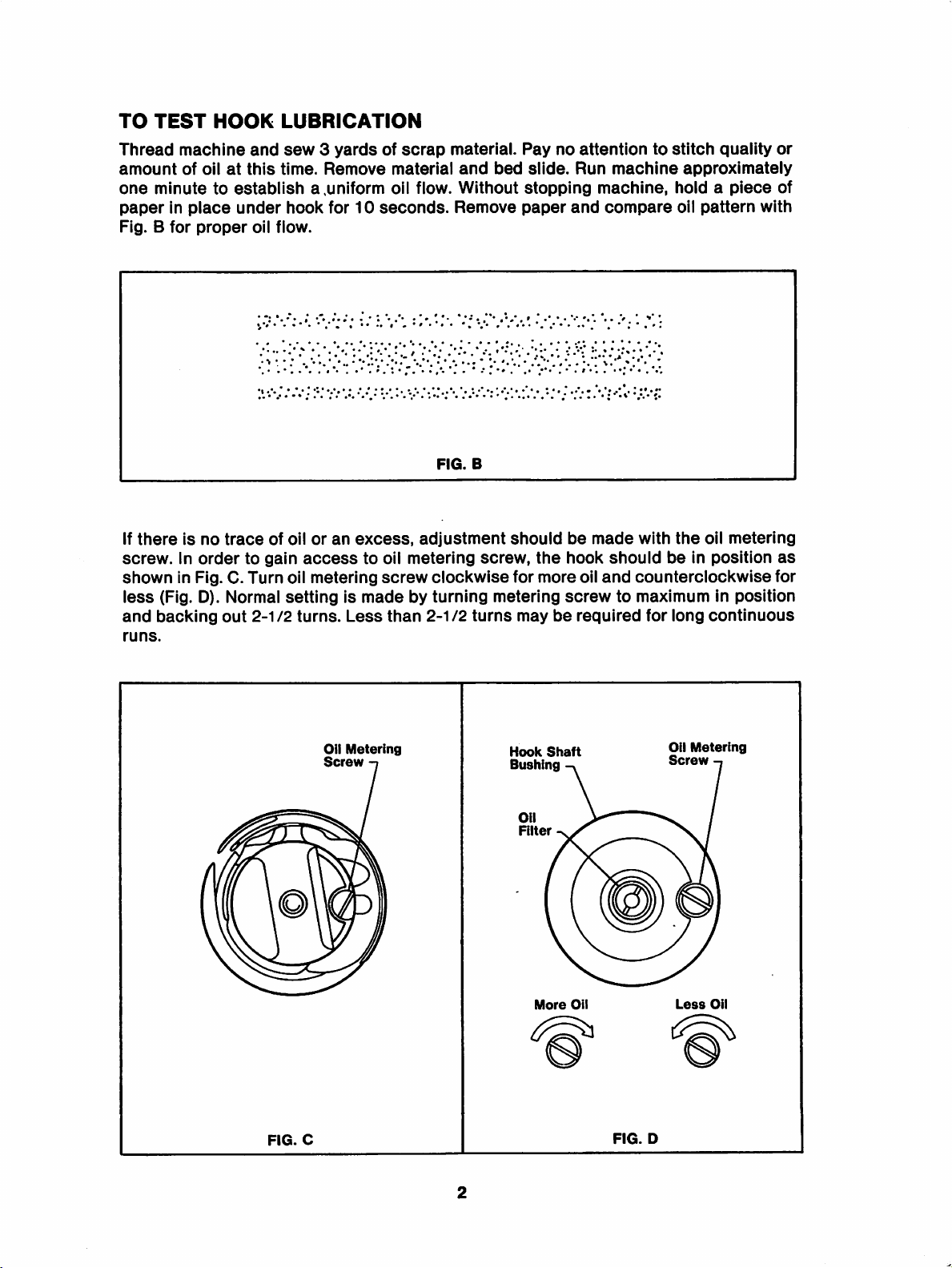

TO

TEST

Thread

amount

one

minutetoestablish

paperinplace

Fig. B

If

thereisno

HOOK

machine

of oilatthis

for

proper

trace

and

under

oil flow.

of oiloran

screw,inordertogain

shown

less

and

runs.

in Fig. C. Turn oil metering

(Fig. D). Normal

backing

out

2-1/2

LUBRICATION

sew3yardsofscrap

time.

Remove

a,uniform

hook

for10seconds.

material

oil flow.

excess,

access

to

oil

screw

material.

and

Without

Remove

FIG.

adjustment

metering

clockwise

settingismadebyturning

turns.

Less

than

2-112

Paynoattentiontostitch

bed

slide.

stopping

paper

B

should

screw,

the

for

metering

turns

mayberequired

•••

, " • # •♦•

more

Run

and

be

made

hook

oil

screw

quality

machine

machine,

compare

should

and

counterclockwise

approximately

hold a

oil

pattern

with

the

beinposition

piece

oil

metering

to maximum in position

for long

continuous

or

of

with

as

for

FIG.

Oil

Oil

Metering

Screw

C

Hook

Bushing

Oil

Filter

More

Shaft

Oil

FIG.

Metering

Screw

Less

Oil

D

Ifoilflow is not satisfactory, remove hook assembly and oil filter. Check filter. Oil wick

shouldbereplaced

sometimes

screw

clogged.

Oil

is not

Filter

indicates

securely

wheneverithas

that

the

filter

tightened.

Inspect

become

wick

has

all oil

clogged

become

with lint or dirt. An

detached

passagestosee

excess

from

the

screw

they have not

of oil

or

the

become

(S)

Hook

Assembly

MACHINE

1.

Move

2.

Lead

3.

Through3eyeletsofthread

4.

Units

5.

Down

6.

Into

7.

Over

8.

Uptoand

9.

Down

10.

Through

11.

Through

THREADING

needletohighest

thread

with

through

and

check

through

from

U.T.T.,

around

spring

through

needle

needle

thread

tension

thread

bar

eye

thread

through

retainer

and

thread

retainers

thread

from

point

stand

guard

pretensioner

assembly

under

slack

retainer

guide

lefttoright

through

thread

and

(2)

thread

regulator

take-up

post

eyelet

atop

machine

arm

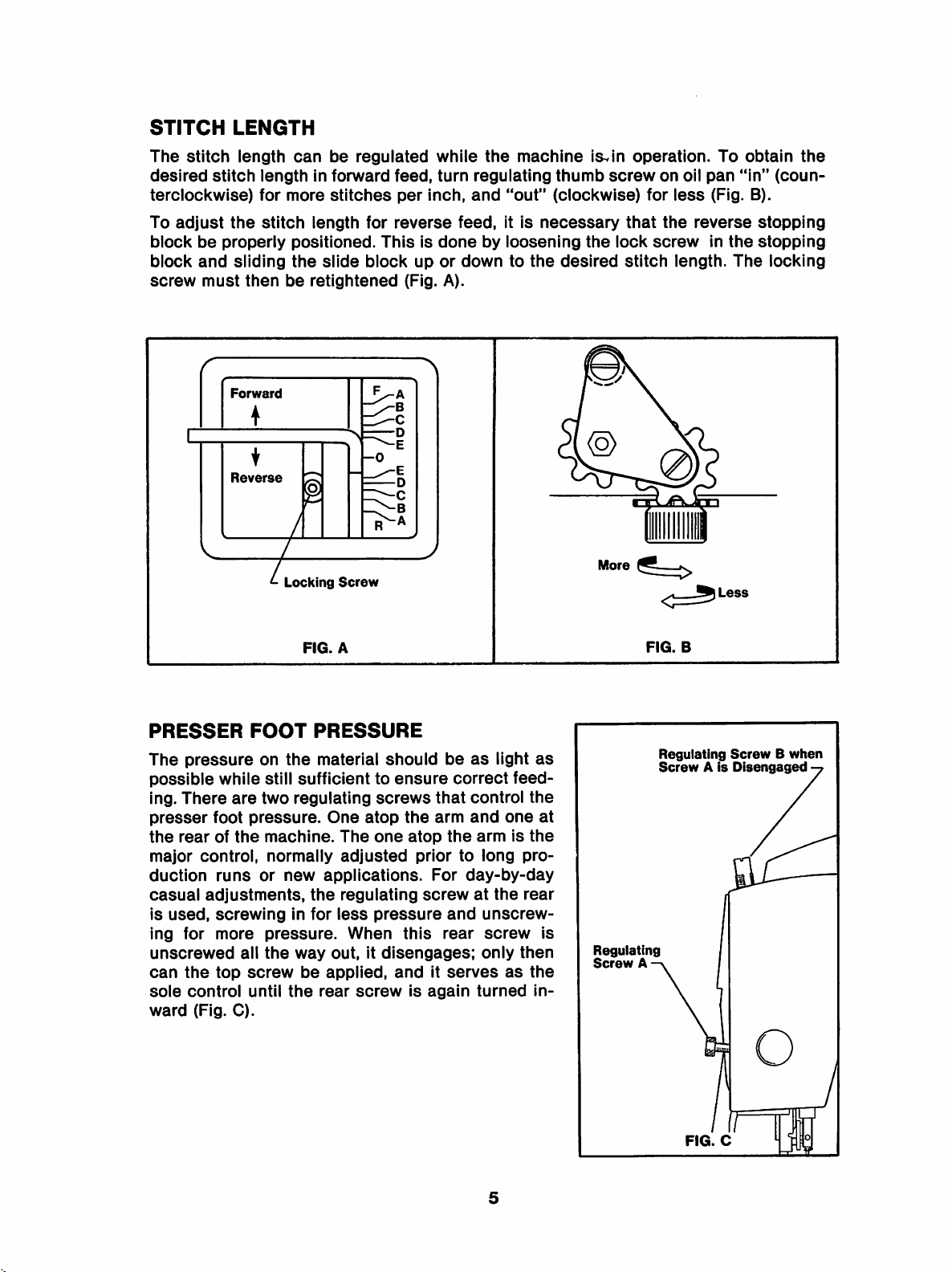

STITCH

The

desired

LENGTH

stitch

stitch

terclockwise)

To

adjust

block

block

screw

be

and

must

the

properly

Forward

Reverse

length

can

lengthInforward

for

more

stitch

length

positioned.

sliding

then

the

be

retlghtened

I

be

stitches

slide

regulated

feed,

per

for

reverse

ThisIsdone

block

(Fig. A).

-0

while

Inch,

turn

feed.

the

machine

regulating

and

"out"

It Is

by

loosening

upordowntothe

\s^'m

thumb

(clockwise)

necessary

the

desired

operation.

screw

that

lock

stitch

on

for

the

screw

oil

pan

less

(Fig. B).

reverse

In

length.

To

obtain

"In"

the

The

the

(coun

stopping

stopping

locking

PRESSER

The

pressure

possible

ing.

There

presser

the

rearofthe

major

control,

duction

casual

Is

ing

unscrewed

can

sole

ward

adjustments,

used,

for

the

control

(Fig.

Locking

FIG.

FOOT

on

the

while

still

sufficienttoensure

are

two

regulating

foot

pressure.

machine.

normally

runs

or

new

the

screwingInfor

more

top

all

screw

until

C).

pressure.

the

way

be

the

Screw

A

PRESSURE

material

should

screws

One

atop

the

The

one

atop

adjusted

applications.

regulating

less

pressure

When

out.Itdisengages;

applied,

rear

andItserves

screw

this

Is

be

as

light

correct

that

control

arm

and

the

armIsthe

priortolong

For

day-by-day

screwatthe

and

unscrew

rear

screw

only

again

turned

feed

one

as

as

the

pro

rear

then

the

In

at

Less

FIG.

B

Regulating

ScrewAis

ScrewBwhen

Disengaged

Is

Regulating

Screw

A

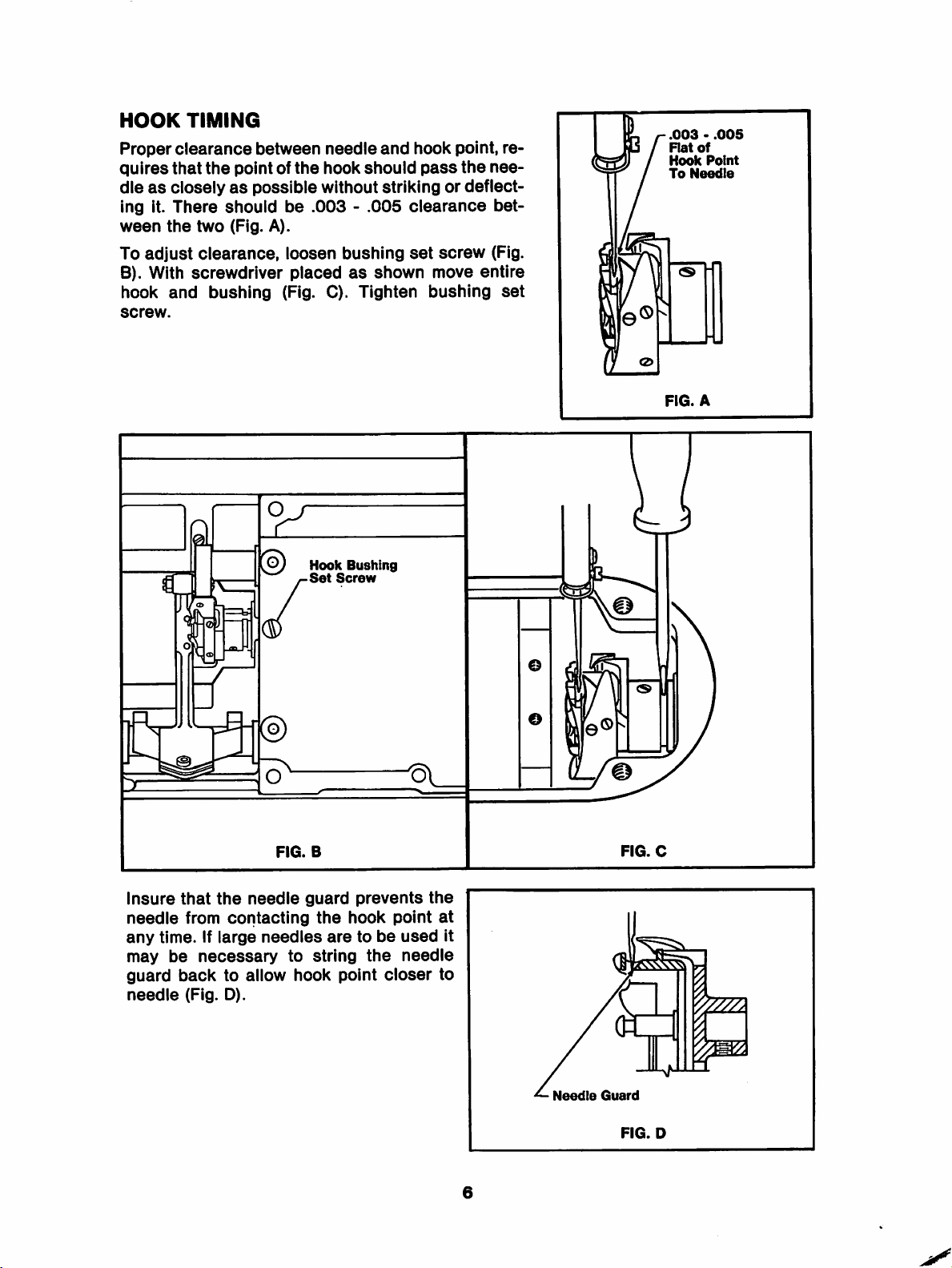

HOOK

Proper

quires

TIMING

clearance

that

the

between

pointofthe

dieascloselyaspossible

ing it.

ween

To

B). With

hook

screw.

There

the

adjust

and

shouid

two

(Fig. A).

clearance,

screwdriver

bushing

be

loosen

placed

(Fig. C).

needle

hook

and

shouid

hook

pass

without striking or

.003-.005

bushing

as

clearance

set

shown

Tighten

Hook

Bushing

Set

Screw

point, re

the

deflect

screw

move

bushing

nee-

bet

(Fig.

entire

set

.003•.005

Rat

of

Hook

Point

To

Needle

FIG.

A

FIG.

FIG.

C

D

Insure

needle

any

time. If

may

guard

needle

that

from

be

necessary

back

(Fig. D).

the

needle

contacting

large

needles

to allow

FIG.

to

B

guard

the

string

hook

prevents

hook

aretobe

the

point

point

used

needle

closer

the

at

to

it

Needle

Guard

6

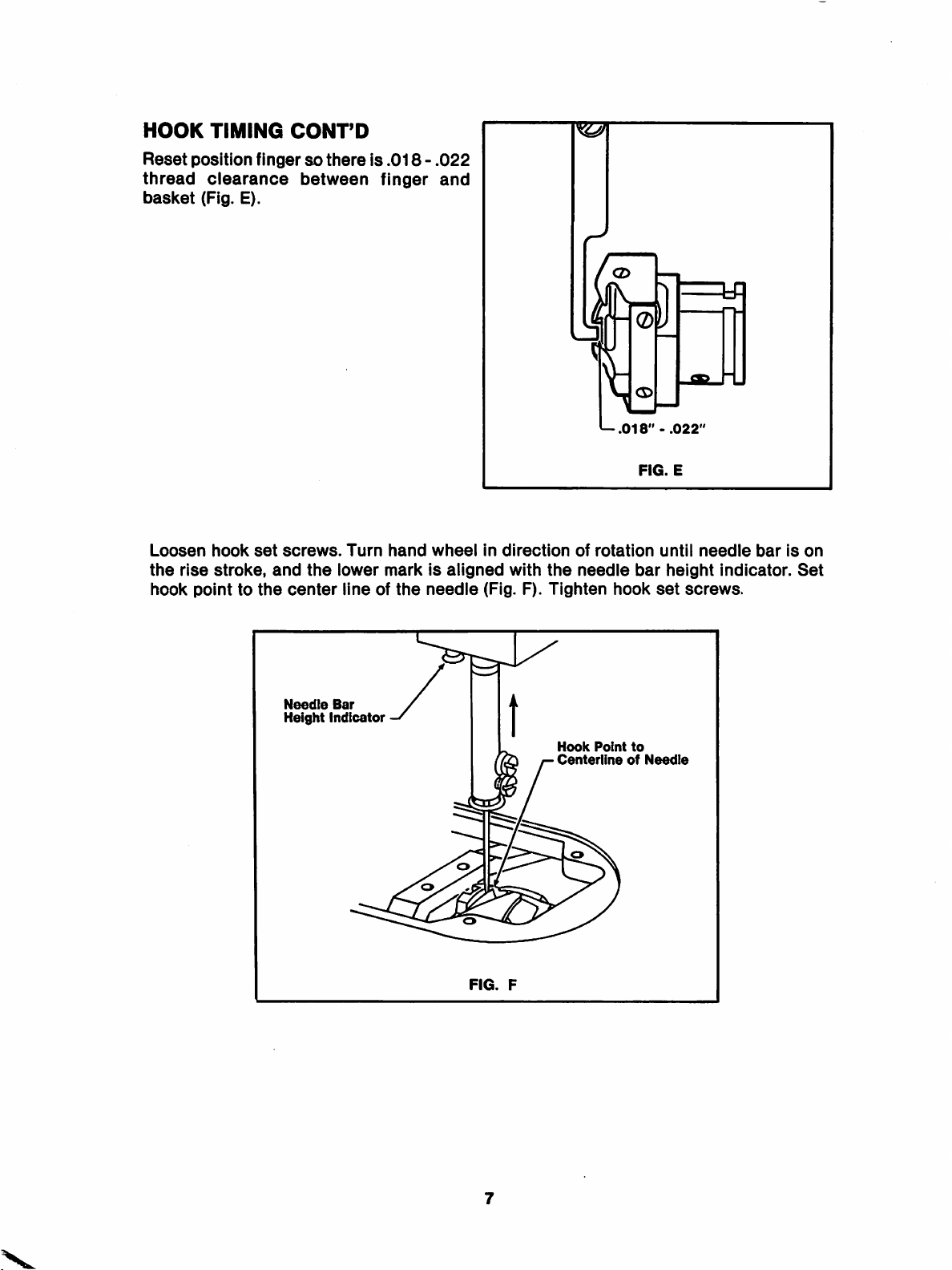

HOOK

Reset

thread

basket

TIMING

position

clearance

(Fig. E).

CONT'D

fingersothereis.018-.022

between

finger

and

Loosen

the

rise

hook

hook

set

stroke,

pointtothe

screws.

and

center

Needle

Height

the

indicator

Turn

lower

lineofthe

Bar

hand

wheel

in

markisaligned

needle

(Fig. F).

direction

with

of

the

needle

Tighten

Hook

Centeriine

^.018"

rotation

hook

Point

of

FIG.

bar

to

-

until

height

set

Needle

.022"

E

screws.

needle

indicator.

barison

Set

FIG.

F

TIMING

Manually

on

counterbalance

on

take-up

FEED

rotate

stud

LIFTING

arm

shaft

aligns

connecting

SHAFT

until

timing

with

timing

link (Fig. A).

TO

mark

mark

ARM

SHAFT

Timing

Marks

0

FIG.

A

Loosen

bed

shaft

(Fig. C).

pulley

Set

Screw

bed

until

Timing

set

shaft

screws.

®

(2)

timing

timing

marks

r

FIG.

belt

pulley

markatfeed

alignment

y

in Fig. A

TO

]

n

Q) ®

B

set

screws

bar

endofshaft

and

(Fig. B).

Fig. C

Hold

aligns

must

pulley

with

occur

stationary

timing

simultaneously.

FIG.

mark

Timing

C

and

on

Tighten

Marks

rotate

casting

8

FEED

DOG

SETTING

Centrally locate feed dog in throat plate slots. Feed dog must not make contact with

throat

plate,asnoted. Align by loosening

Feed

Dog

feed

FIG.

dog

A

screws.

No

Then

Contact

retighten

screws

Fig. A.

LATERAL

SETTING: Loosen pinch screw infeed bar crank

(Fig.

B).Shift feed barasre

quired. Ensure that feed bar does not contact position finger. Tighten pinch screw and

check

axial play at pendant link. Adjust feed lifting shaft to minimize play.

Leveling

Eccentric

Feed

Pinch

Height

Locking

Bar

Crank

Screw

Eccentric

and

Nut

FIG.

Leveling

Set

B

Screws

Eccentric

9

LENGTHWISE

crank

plate.

HEIGHT

To

protrude

adjust,

height.

pinch

SETTING:

.040"-.043"

loosen

Tighten

SETTING:

screw.

locking

Adjust

Positionsothat

With

feed

above

eccentric

the

locking

nut.

stitch

feed

dogatIts

throat

nut

length

dog

does

highest

plate.

and

turn

to

longest

not

contact

point

eccentric

the

stitch

either

full

depthofthe

until

and

loosen

feed

endofslotsInthroat

teeth

should

feed

dogIsat

correct

bar

LEVELING

Is

levelatthe

NOTE: It

other.

SETTING:

topofIts

may

be

Loosen

feed

necessary

set

screwsInfeed

path.

Tighten

to

set

feed

dog

set

bar

screws.

height

crank.

and

Turn

level In

eccentric

conjunction

until

feed

with

dog

each

10

Loading...

Loading...