Page 1

C

___

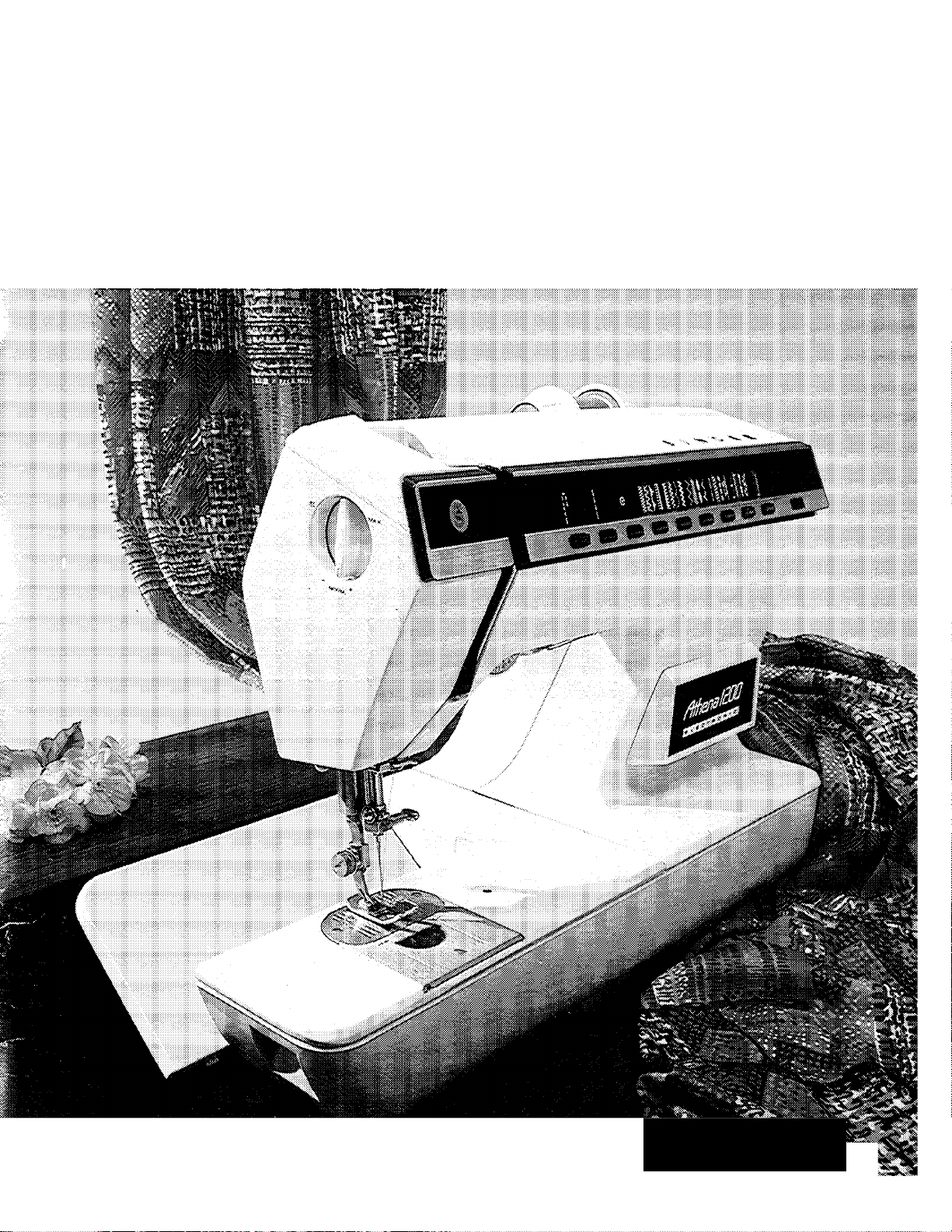

sewing machine • model 1200 • two way sewing surface

^ _

'

..........................

Page 2

■state

Congratulations ...

You are about to sew on the new. advanced electronic sewing machine .. .

Athens' 1200.

It makes sewing simple, foolproof and fun!

After years of Singer research, the Athens 1200 sewing machine features

these important technological breakthroughs;

«> Exclusive Solid-state Electronic Sewing System. Athens 1200 is the

sewing machine with the electronic “brain.” A wealth of stitch patterns. It

automatically programs your machine to sew any one of twenty-one

different practical and decorative stitches plus the two-step buttonhole.

® Exclusive Light Toych Fingertip Controls. They’re the buttons on the

front of the machine. You simply touch the one under the stitch you

want — the red indicator light comes on — and the Athens 1200 is ready

to sew. Any stitch Is instantly available at the touch of a button.

9 Exclusive individual Preference Panel Your own "control panel,” it

allows you to modify the programmed stitch dimensions to suit special

fabrics and satisfy personal preferences.

V..«

And that is only the beginning! There are many more new features. Such as

the Exclusive Pattern Repeat Sutton —that lets you sew one unit of a pattern,

for original decorative touches. And Exclusive Light Touch Fingertip Reverse

Button — for an instant reverse straight stitch. The Athens 1200 also has such

Singer advantages as the Exclusive flip & Sew* panel for both flat and In-theround sewing. Soft-Touch Fabric Feed that protects even the most delicate

fabrics. A variable speed Solid-state Controi System, that enables you to

maintain the same pressure on the speed controller as you sew through vary

ing fabric thicknesses.

In addition, the Athena 1200 has these Singer design features — a one-way

needle clamp that makes it impossible to put the needle in backwards, snapon presser feet that are quickly removed and easily replaced, and easy-tochange needle plates secured by magnets.

We suggest you take a few moments to read through this operator's guide, as

you sit at your new machine. You will quickly discover how simple It is to do

any sewing operation you desire on Athena 1200.

Cosyrisf!; ® 1977 5y THE SSNOES COUPAHy

Aii ae$0rveci Throughou; Sne WOficS

Page 3

Contents

Page

1. Getting to Know Your Machine ..................................................................................................................................... 2

Principal Parts............................................................................................................................................................ 2

Accessories ................................................................................................................................................................... 3

2. Getting Ready to Sew.................................................................................................................................................... 6

Choosing Needles ......................................................................................................................................................... 6

Choosing and Changing Accessories ........................................................................................................................... 7

Operating the Machine................................................................................................................................................... 9

Fabric Weight Table .................................................................................................................................................... 1C

Fabric. Thread, and Needle Table.............................................................................................................................. 12

Threading the Machine............................................................................................................................................... 14

The Bobbin................................................................................................................................................................... 16

Winding the Bobbin • Changing the Bobbin

3. Electronic Sewing..................................................................................................................................................... 20

Seiecting a Stitch.......................................................................................................................................................... 20

Patter.n Repeat Button © individual Preferences

Stitch Adjustments........................................................................................................................................................ 22

Stitch Width « Stitch Length « Stitch Length Guidance Table » Reverse Stitch-Balance «

Twin-Needle Switch

4. Straight Stitching ............................................................................................................................................................. 25

Preparation................................................................................................................................................................... 25

Fabric Handling.......................................................................................................................................................... 27

Pin Basting ® Speed Basting

Sewing a Seam ........................................................................................................................................................... 2S

Placing Fabric under Foot ® Sewing with a Newly Wound Bobbin « Keeping Sea.ms Straight ®

Turning Square Corners ® Curved Seams ® Reinforcing End of Seam

Applications................................................................................................................................................................ 32

Darning « Quilting * Chainstitchlng

5. Basic Zig-Zag Stitching ................................................................................................................................................. 40

Zig-Zag Stitching .......................................................................................................................................................... 40

Creative Applications .................................................................................................................................................. 41

6. Machine Stitch Patterns................................................................................................................................................... 46

Adjusting Stitches for Stretch Fabrics .......................................................................................................................... 46

Handling Special Fabrics.............................................................................................................................................. 47

Stitch Centering ........................................................................................................................................................... 48

Stitch Usage: Functional and Decorative..................................................................................................................... 49

Decorative Stitching ................................................................................................................................................... 64

Border Designs • Monograms • Topstitching « Smocking »Twin-Needle Stitching

7. Buttons and Buttonholes ................................................................................................................................................. 69

Buttons ........................................................................................................................................................................ 69

Buttonholes .................................................................................................................................................................. 70

Buttonhole Position » Buttonhole Length • Buttonhole Interfacing »Two-Step Buttonholing «

Balancing the Buttonhole » Stitching a Series of Button.holes » Cutts.ng Button Opening »

Corded Buttonholes

8. Free-Arm Sewing ............................................................................................................................................................ 75

9. Performance Checklist................................................................................................................................................... 79

10. Caring for Your Machine................................................................................................................................................. 82

11. Sewing Aids ................................................................................................................................................................... 84

Index........................................................................................................................................................................................ 87

Page 4

1. GETTING TO KNOW YOUR MACHINE

1

li

s

1

____________

o o o O

1

SSB88888 ISBSSSf

¡1

«« t

\ i IK i V;i'i

€> f

3SB6SS

asfflflgBEs

o

1-1

o

i i . s

1

o o

H < ^ s 1

o

r I y 1

jk j

B B

N||

' 1

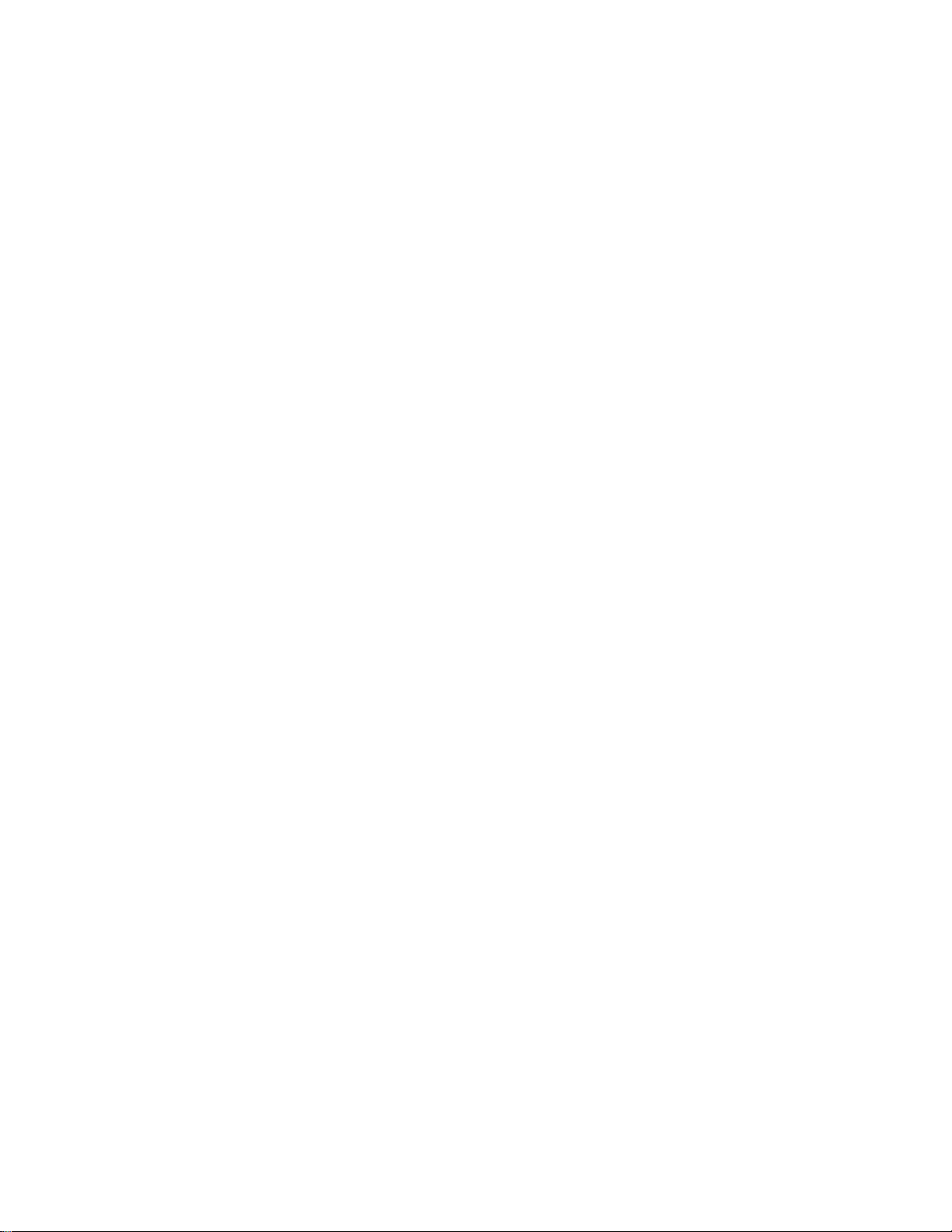

t. Tension Discs

2. Take-up Lever

3. Pressure Dial

4. Presser-fooi Lifter

5. Thread Guides

6. Thread Cutter

7. Hinged Plate

8. Presser Foot

9. General Purpose

Needle Plate

Vi. Sobiwn Latch

12. Transparent Bobbin

13. Slide Plate

14. Needle Clamp

15. Tension Dial

16. Suilt-sn Sewing Light

17. Circuit Breaker

18. Hiectricai Conrjectionsi

and Speed Controller

19. I.ndividual Preference

2C. Reverse Stitch-balance Contra:

21. Stitch-length Cont-ol

22. Twin-needie Swlt«^

23. Stitch-width Control

24. Power and Light Switch

25. Hand Wheel

26. Stitch Selection Pa.nel

27. Friction-free Spoof Holder

28. Snap-in Thread Guidepost

29. Hear Tinread Guide

Page 5

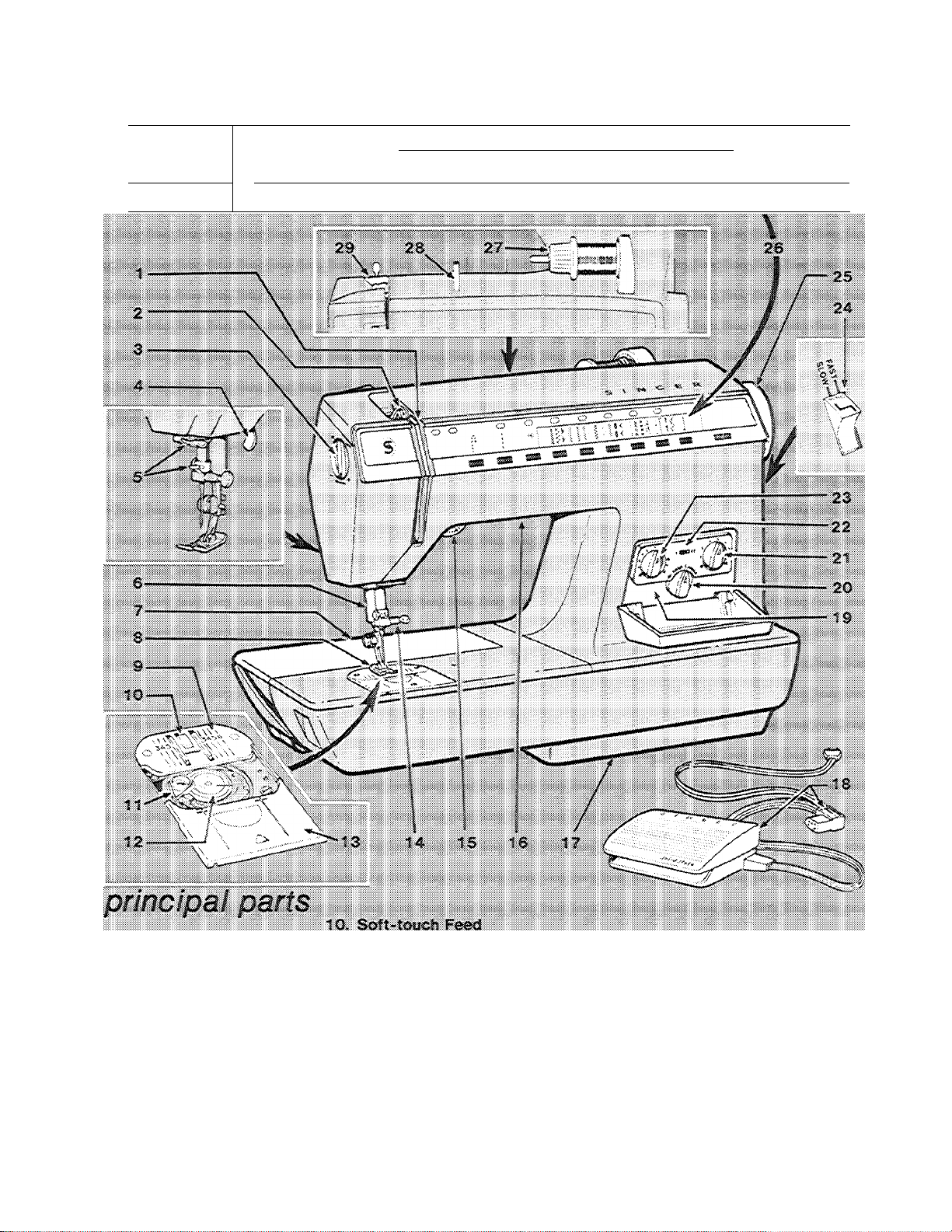

accessories

The accessories provided with your Model

1200 sewing machine are designed to help

you do many kinds of sewing easily and per

fectly. To increase the versatility of your

machine, additional accessories can be

purchased at your Singer store.

1. Transparent Bobbins (No.181551)

2. Meedies

e Style 2020 for all-purpose sewing.

e Style 2045 for sewing knits, stretch

fabrics and elastic.

e Style 2025 for twin-needle decorative

stitching.

тРОПТАНТ: Your SINGER sewing

machine has been designed to obtain

best results with SINGER* needles. You

should follow the recommendations in

this instruction book and on the needle

package for correct style and size of nee

dle for different types and weights of

fabric.

Л

3. General Purpose Foot and General Pur

pose Needle Platet are on your machine

when delivered. Use them for alternating

between straight and zig-zag stitching as

well as utility zig-zag sewing. They can

also be

fabrics.

4. Straight-stitch Foot and Straight-stitch

Needle Platet. Use these when your

fabric or sewing procedure requires

close control.

These accessories, recommended for all

straight-stitch sew'ing, are especially

helpful for edge stitching and collar

pointing, or for stitching delicate or

spongy fabrics.

5. Seam Guide helps you keep seam

allowances perfectly even.

6. Special-purpose Foot. Use this for all

kinds of decorative zig-zag stitching.

used for straight-stitching firm

tNytnbers on plate indicate distance from needle in eighths of an inch.

Page 6

!N!C«£

8/'i ■; p ;i

r

h

ps

\

p"

r*" V

1 ~~csi 2 & ; I

1 ,■’2 —ccd, — 28

' —eg: i=3—

S2NGER

1 3

___

: 1 “

'N"****

..

.w

......

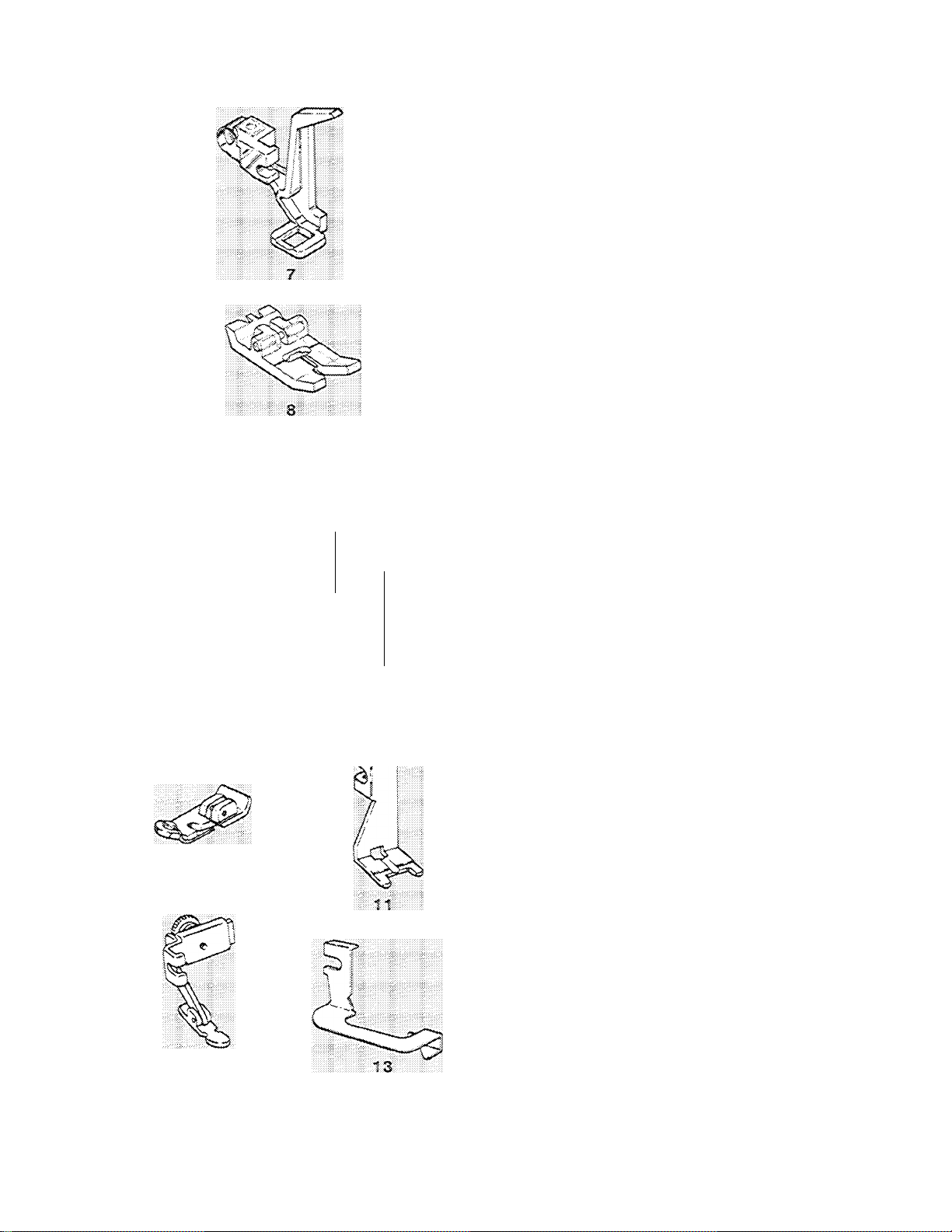

7. Darning and Embroidery Foot is recom

mended for all types of free-motson work.

It is ideal for embroidery, monogramming

and decorative designs because the

transparent toe fully reveals the line of

the design to be followed.

8. Two-step Byttorshole Foot lets you stitch

buttonholes of any length In two easy

steps.

9. Buttonhole Gauge has slots for marking

buttonhole guidelines.

10. Overedge Fool used with overedge

.

stretch stitch for seams In stretch

fabrics.

10

11. Button Foot holds most buttons securely

for stitching.

12. Zipper Foot for inserting zippers and

stitching corded seams.

13. Blindstitch Hem Guide. Use this with the

general purpose foot to position the hem

for blindstitch hemming.

Page 7

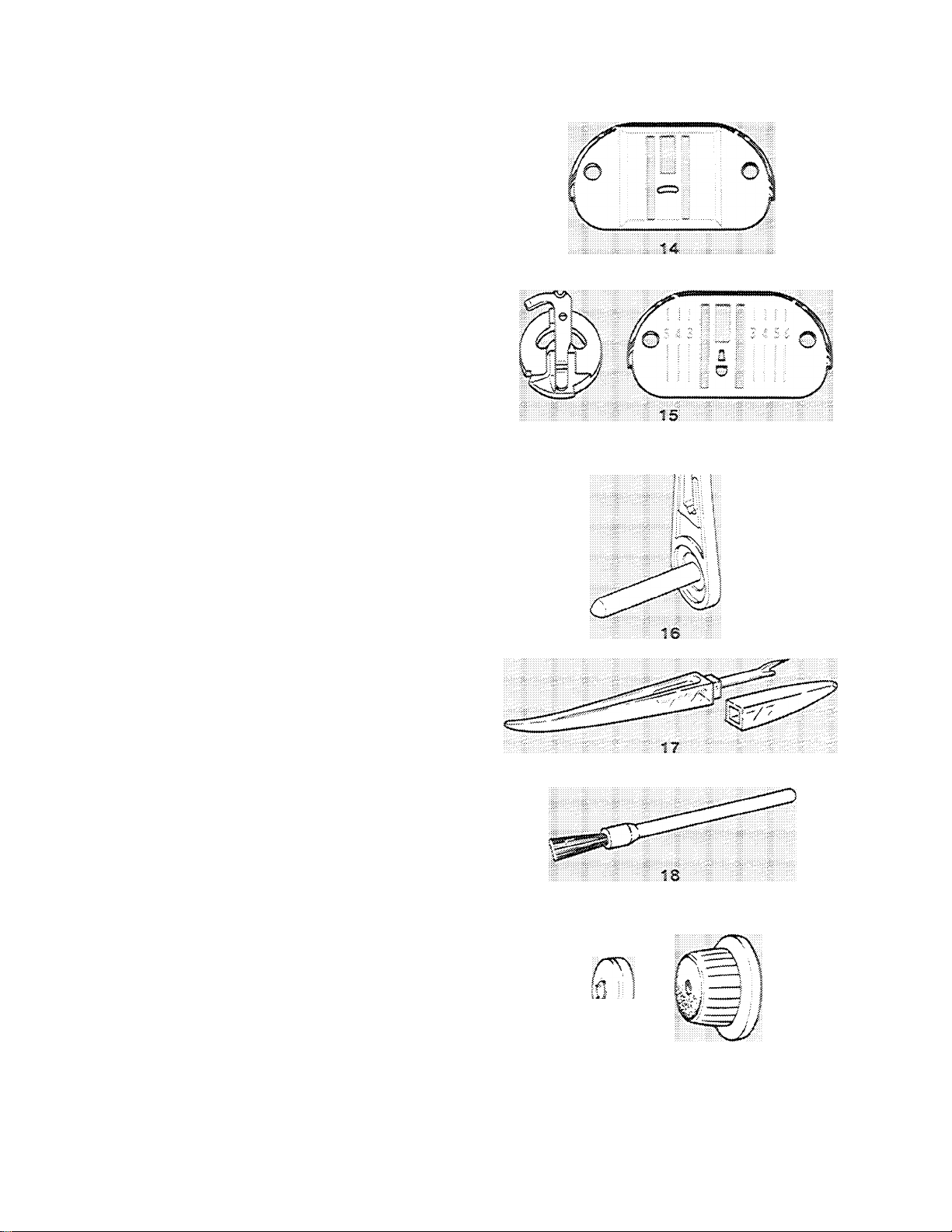

14. Feed Cover Plate for button sewLng and

free-motion work.

15. Chainstitch Fittings

a. Bobbin-case insert

b. Chainstitch Piaiet

16. Detachable Spool Fin for decorative

twln-needie stitching and two-thread

topstitching.

17. Seam Ripper to pick and cut threads

quickly and neatly without damage to the

fabric.

Lint Brysh for cleaning your sewing

machine.

9. Small Spool Holder

a For use with small diameter tubes of

thread.

20. Large Spool Holder on your machine

when delivered. For use with medium! and

large spools of thread. ig

tNumbers on plate incicate Ussiance from nestiia in eighths of an inch.

¡20':

Page 8

ETTING READY TO S

The needles you use should be straight to en

sure perfect stitch formation. The needle

should also be fine enough to prevent the

fabric from being marred' with large

punctures, yet heavy enough to pierce the

fabric without being bent or deflecied.

Remember too, that the eye of the needle

Regular Meedle

jl I

Vn’i

H A

Sail Point

Ye::ow 33r,d* Kee€\t

P

must be large enough for the thread to pass

through freely: too fine a needle will cause the

thread to fray. See Fabric, Thread and Needle

Table, page 12.

For general-purpose sewing in a wide range

of fabrics, the Style 2020 needle, in sizes 9

18, will give you excellent results.

¡i'

*■ V ”1....

Style 2025

ITwin-Needle

.......

For best results when sewing on knits, woven

stretch fabrics, bonded vinyls, and elastic use

Style 2045 ball point Yellow Band* needle,

available in sizes 11, 14, and 16.

:

For decorative stitching on light and medium-

weight woven fabrics, use the twin needle.

Style 2025.

For sewing leathers, real and simulated, the

Style 2032 needle, available for purchase at

your Singer Sewing Center, is recommended.

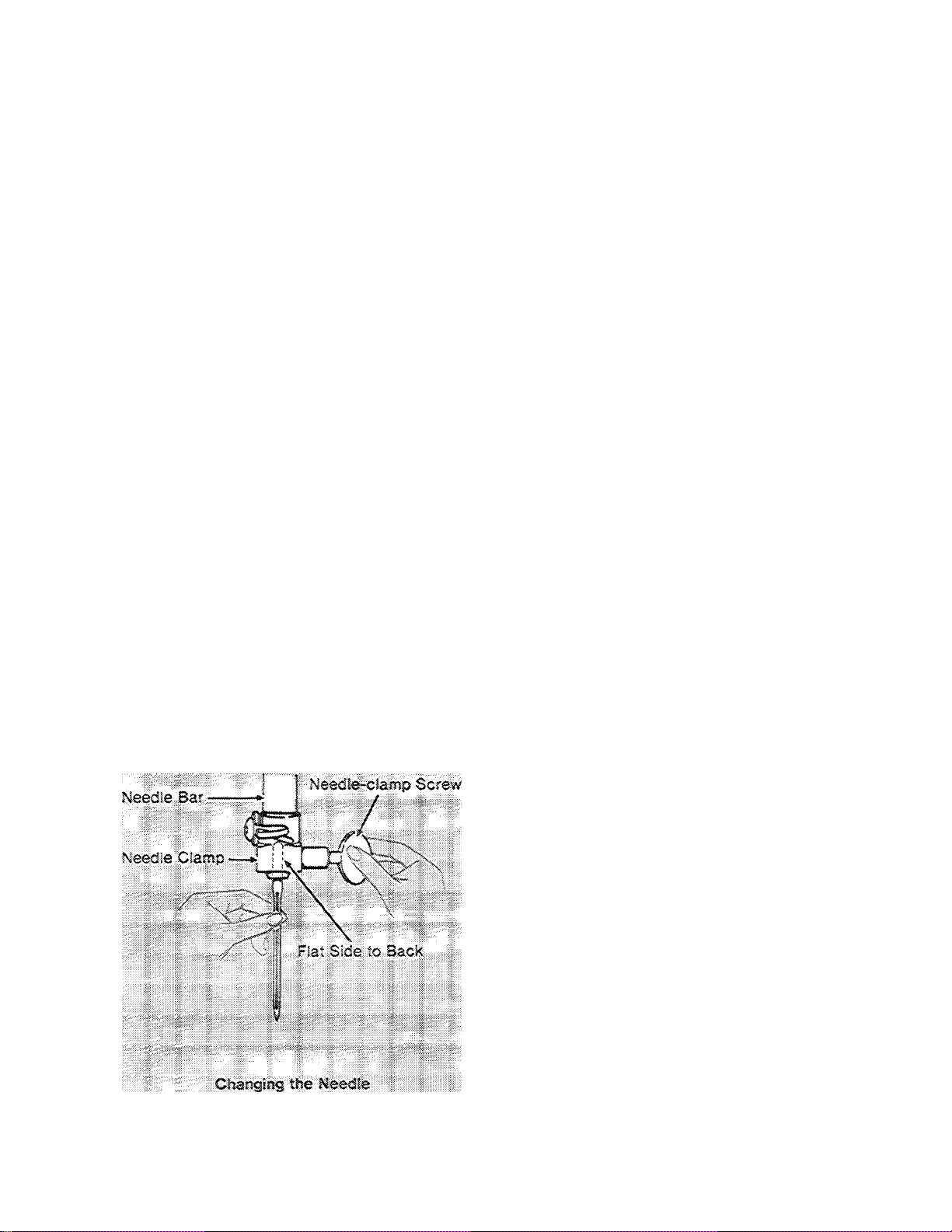

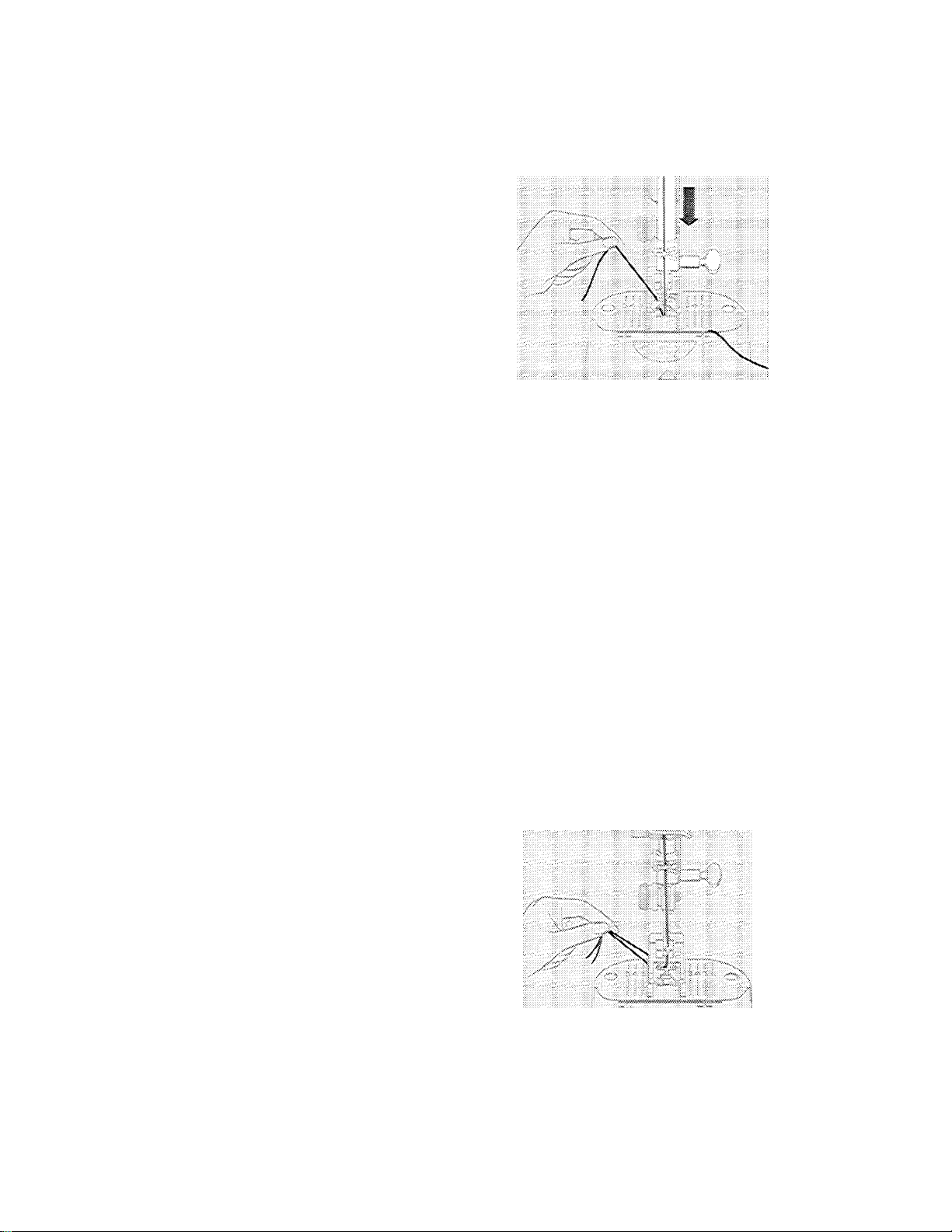

Changing the Needle

® Raise needle to its highest point by turning

the hand wheel toward you. Loosen needleclamp screw, and remove the needle.

® Insert new needle up into clamp as far as it

will go. with the flat side of the needle to the

back.

« Tighten needle-damp screv/.

Page 9

choosing and changing

accessories

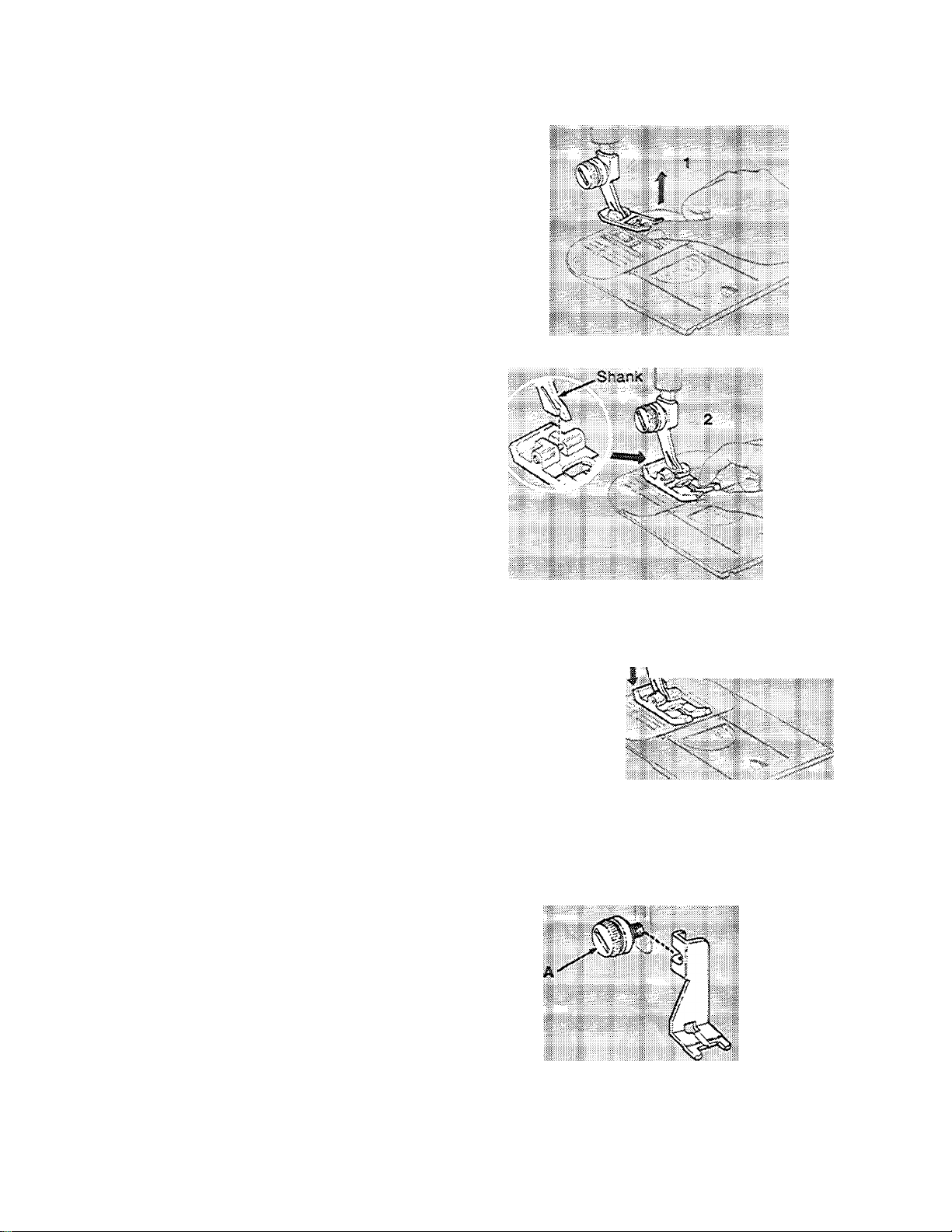

CHANGIMG PRESSEH FEET

Snap-on Presser Feet

Most of the presser feet furnished with your

machine snap on and off a common shank,

e Raise needle and take-up lever to highest

position by turning the hand wheel toward

you.

» Raise presser foot.

1. Press toe of presser foot upward (as far as

it will go) and then snap down to remove.

2. Center the new presser foot under the

shank and lower the presser-foot lifter so

that the shank fits over the presser-foot

pin.

3. Press presser-foot screw down firmly until

foot snaps into place.

To remove and replace the shank of snap-on

presser feet, follow instructions below for

one-piece presser feet.

One-piece Presser Feet

CButton Foot and Zipper Foot)

• Raise needle and take-up lever to highest

position by turning the hand wheel toward

you.

« Raise presser foot.

e Loosen presser foot screv»^ (A) and remove

the foot, guiding it to the right.

Note: When changing one-piece presser

feet, you should insert the edge of a coin in

the slot of the presser foot screw to tighten

presser foot securely.

To Replace One-piece Feet

® Hook one-piece foot around the presser bar

and tighten presser-foot screw.

Changing Snap-on Presser Feet

Changing One-piece Presser Foot

Page 10

Aítachins Darning and Embroidery Foot

Darning and Embroidery Foot

1. Raise needle and take-up lever to highest

position by turning hand vsrheel toward you.

2. Raise foot.

3. Loosen presser foot screw and remove

presser foot shank.

4. Guide darfiing and embroidery foot into

position from back of machine. Make sure

lifting finger (B) is above needle clamp.

5. Tighten presser foot screw with coin.

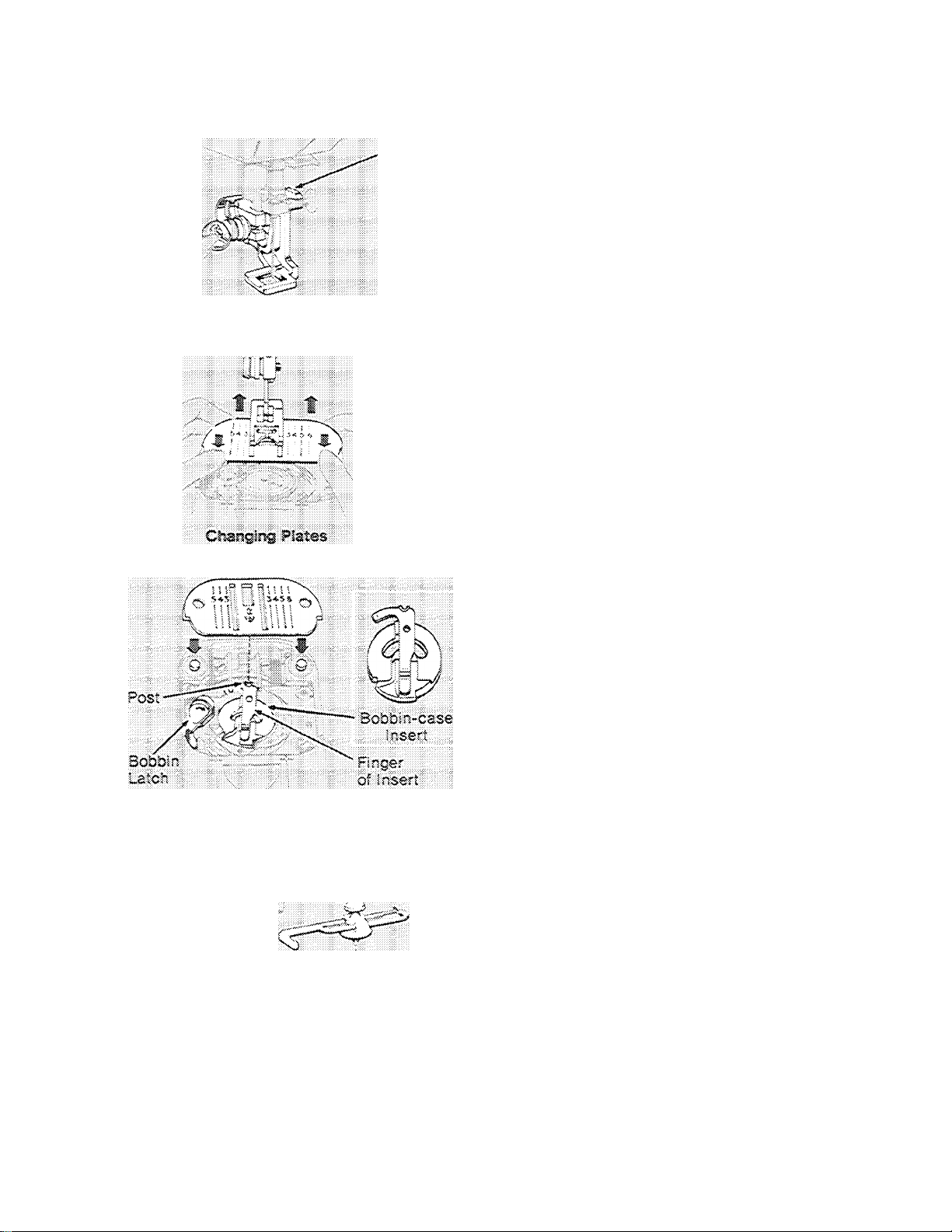

CMAmmuB i^eeole plates

Mote: Remove bobbin if it contains thread in

order to prevent thread being caught when

piate is replaced.

1. Raise needle and take-up lever to highest

position by turning the hand wheel toward

you.

2. Raise presser foot.

3. Open slide plate. Press down on front edge

of plate and lift up and out.

Attaching Cbalnstitch Fittings

4. Position new plate over pins and release.

Plate is drawn into position by magnets.

See special Instructions below for attach

ing chainstitch plate.

5. Close slide plate.

Chainstitch Plate and Insert

1. Raise needle and take-up lever to highest

position and raise presser foot.

2. Open slide plate.

3. Move bobbin latch to left and remove bob

bin and needle plate from machine.

4. Place bobbin-case Insert in bobbin case as

shown, with finger of insert positioned

under the feed.

5. Position chainstitch plate over holding

pins, making certain that the post of the

bobbin-case insert finger enters the hole in

the plate.

6. Close slide plate.

ATTACHIMC THE SEAÜ GUIDE

SieamLGMsde,,

Place screw in hole to the right of the slide

piate; line up straight edge of guide with the

needle plate guideline for desired seam width,

and tighten screw.

Page 11

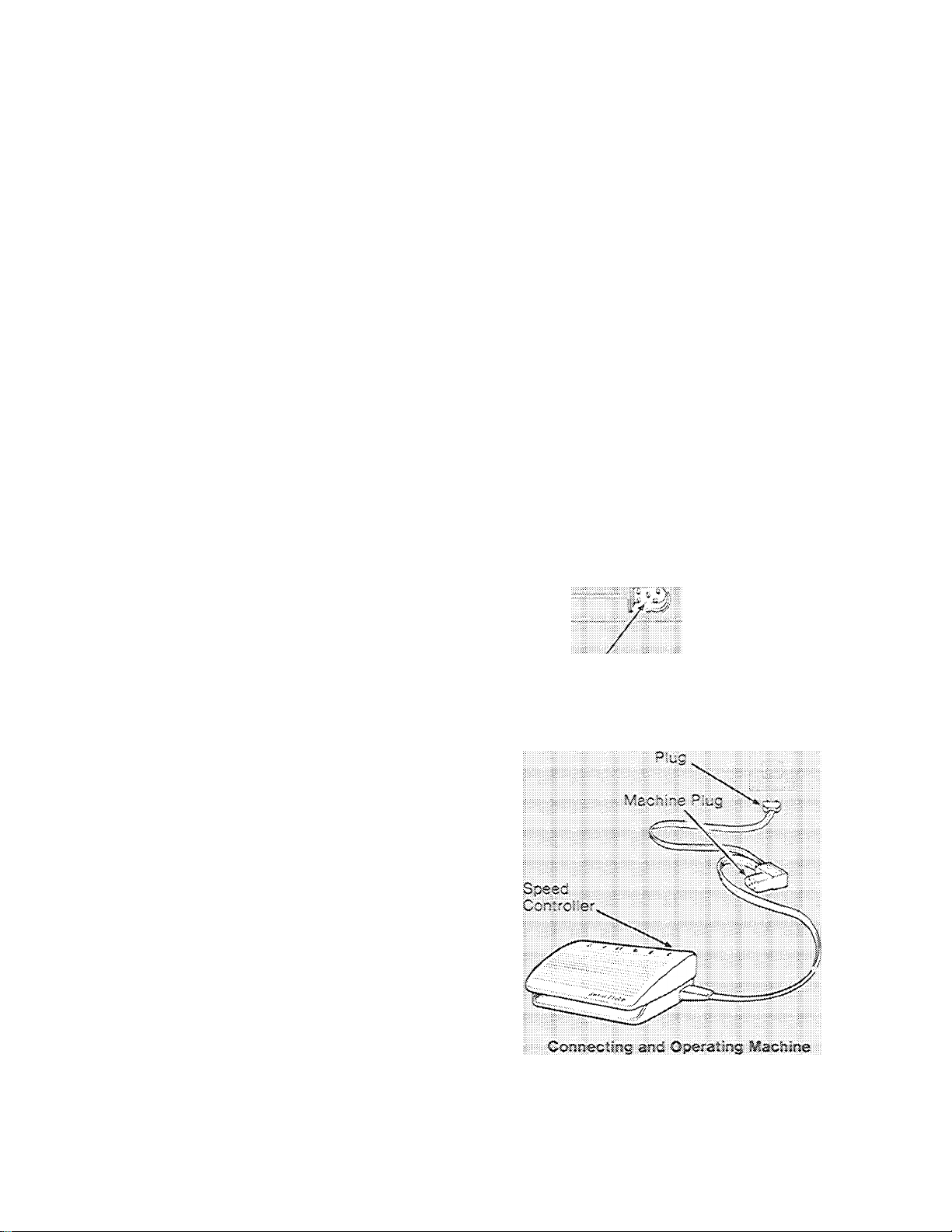

operating machine

CONNECTING mCHINE

® Push the machine piug into the machine

socket.

« Connect the power-Hne piug to your eiectn-

cai outiet

To turn on the machine and set speed range,

push the power and light switch to desired

speed. This will also turn on the sewing light.

• The SLOW setting A (switch pressed in

halfway) allows for maximum control. Use

this setting for special jobs such as button

sewing and buttonhole making, decorative

patterns, bobbin winding, and where Intri

cate details require close control,

• The FAST setting B (switch pressed In all

the way) allows for full speed capacity of the

machine. It is best for long, straight seams,

easy-to-handle fabrics, and general sewing

where a variety of speeds are needed.

s0ower and Li^ht Switch

..

...............

CAUTION: We recommend that you turn off

the power and light switch before changing

neadies, presser feet or plates ana when leav

ing the machine unattended. This eliminates the

possibility of starting the machine by acciden-

tafiy pressing the speed controller.

To run the ríiachine, press the foot or knee

speed controller. The harder you press, the

faster the machine wili sew within the

selected speed range. The lighter you press,

the slower the machine will sew within the

selected speed range.

Vach'ne Soco:

Power-

Line

Page 12

There are thousands of fabrics around the world; each manufactured with a specific fiber and

weight. The fabrics below have been classified according to weight to give a small sample of

what is available for purchase.

TYPE à

.

Ill.li

.......

|#o|énÌ"

...

.

..

..

.

rìLKY W4*M ^ yCSHT

I®

phi ten 1"'

ITuii 1

iteti"

Lace

Ninon

Crepe deChine

tesn|ung| 1

fTilllilil

Jersey

,.:sTite|ai

.

PtenT

i;'Qire''r|r|:'li||'-|'^

.

Polli

..

..........

If;

"ipibiilt:

pati

Ciallls

.

...

VERY

y.EDTJsi

HEA\-Y

HEAVY

iteilet 1'"

.

iCribedechinei?i!i

¡Shintuig 1

|tel|ei 1'

.

;.||Taielas|::

.

pirolteiltt ;|r::

iijlTafflsia

........

........................

?l|Crepe?fi||f:i

itesfeteih 1

Cbriuroy

■"titenipi.........t||ii

Denim

l"|d|bii^

...........

L|wnp''

:;:0erealei;v::||s.:::~:3Ì

Eyelet

Gingham

Ribuli

Pishmereiff'1'-^

ifiannil....ii

“yohair''' I"''

.

..............

dfepi'"'

t Usyaiiy contain some synthetic fiisers also.

10

■■ICahyasfii:i'i|^

|; Spie l dp " I

Upholstery:,

ITerly ¡t

Drapery Fabric

i ■ ;Fab|d^ |

■::s:::i8:Urlap::i:::||i<y

ptri tchlteldur b ft

stretch Terry t

SUitiig

y|pia|neli|.yyiysls,.

Ipaterdine | ■ ■

.

-IReliiSy-sh'i?^^

..lW®:id

.

1'■

iPoplhi'i"'1

Slanketlng

iSepe 1

"i|yo|alrt|"'r~”i||t

tperfey'l|iJ''1|iJ'J

Page 13

FABRIC WEIGHT TABLE (coni.

FIBER

iSYNTHETIC

'|Vliveh| ■ ^

SYNTHETIC

SLENDS

..

FILMY SHEER

CHsffoo

'Èssili,,: !Il:

Olgahza

Talle

Mmon ,„

Crepé deChiae

Voile

UGHI

iCrééeY:i:..i: :i :..

1.BiHilliiiii

iiVelyet ..:

::vei®i::i

„.Tafteta i::::::: j::

fiSatin

jglallela,,;

I'isain :::

.

.

...............

ilJacdoard |

Single Knil

jiswiater Khi|:i:::i,

Í::

.Bonded Knit

;Trlodtti|'"'t?

:;Cir4

^iTridbt 3

.

iCíréíchiTerry

|Slreich:;yeloor

iFaKeFuirs

ILinln 7§pq W}

Batiste

Eyelet

„.poplin ,l„

iCordurdy ibraperylFabhic

Gingham

Poplin *

Crepé

Gadardlsne i:

Double Knii

Bonded Knit

Spandey

Deep Pile

..

Gabardine

HEAVY

Double Knit

::iHi¡enoá:

:||aK|:Fu|s Í5

..

:::i|Denim i

.

pabprdipe

HEAVY

...

CKnl)

%EmmB

PLASTIC

vinyls:

Plasió rim

Single kiit " 1 Terry Knit

iKidskin

Patent

iPaiInt I

Jmltatioh-

Chamois Leathers &

Irnitaiioii-

iSuedes

.......

Leathers & ■Leather

Suedes

teatiar :|

Suede

iBeptile '

Suedei:i|i-!t;i

Plastic Film S

Bonded Vinyl

|Knit Back! :|

^IliBateht 1,

Embdssdd:,

Printed 3

..

DoubleKnIt

Buckskin

palfskin::,

Suede

Beptile .......

Upholstery i

Vinyl

....

lipHolstes^y

.

Leal he rs;

Upholstery

,;i,. vilyl.,,..:::,,,.

Page 14

FABRIC, THREAD AMD UEEDIM TABLE

Choosing the correct needie and thread for your fabric is of utmost importance. Correct choice

wiii make the difference in the wear and appearance of your new garment. The Fabric Weight Ta

ble on the previous page: and the Fabric. Thread and Needle Table below are practical guides to

needie and thread selection. Refer to them before starting a sewing project. Se sure to use the

same size and type of thread in both needie and bobbin.

To select the correct needle and thread for your fabric, first refer to the Fabric Weight Table to

determine the weight and type of the material you are using.

Next refer to the Fabric, Thread and Needie Table.

TYFE

OF

FABRIC

t|iiiiiiiii|ii

.........

t|i::l|^:C|ys

.....

SYNTHETIC

SYNTHETIC

SiEiidsf

........

1 Fine Silk

f||

iiiPihpiiM|tde|zedii I..||dS|3f9i|iit

i:|;lih^;Siiiikss..

Fine Mercerized

.

Fine Mercepzeá

tp||5|pd|piii

.

|iii■

..

j;pi" IpF! riiCiSintih i

...iiilitill''

NEEDLES

..................

|2d:2|nS|

...

SHEER

LIOHT

THREAD NEEDLES THREAD

fiheiSilki

iipeiipdr|erli|ediil;

.

IPeÉílkl

....

.

Fine Mercsr;zed ;

Til.2|2b|TlT|

r.."|02ü|Í'^f

Finé Silk ii

:^::Fi||ejS|k..

Fi|é Mérc|rizid

.....

TlhiiCbtpi:''”it

ij,:.,.

......

lIsÉglll

Fine Sii.k

F ne Mercerized i

iigiiniSiSynlhetlc i:...,:2|:20|3;::|| I í|i||éiiS|n:thetlc:|Híií>^^

.

li;l|2Í20:||iid^ti|

..

..

Mecij-^ Mercerized

Fi|eS|k I;

1 :Pi;|e‘pifcirizdpi'l^

tiFt|é'%ihthiptld||tlt'”

\EED_ES

Í02Í-íl|r

::::f|Q:2|Ui5s|:

ti!|p||U|i|p

LEATHER

PLASTIC:

Size 9 needie is recommended for severing oniy. For bobbin winding, use iarger size needie

Yeciurr, Synmetic 2C32-'

Fine Mercerized

Fine Syntheuc

Pipe Mercerized

Filpii|hthitlclTi

2C2C

Page 15

Find the fabric you are using in Type of Fabric column at left. (Silk, rayon, etc.) Then locate the

fabric weight column (filmy, sheer, etc.) for your fabric at top of table. Read across from Type of

Fabric column to correct weight of fabric column. There, the correct thread and needle choice

for your fabric will be found.

Example: If you are sewing a medium weight wool, find wool in Type of Fabric column. Read

across to Medium (weight) column arid you will see that a medium silk or mercerized thread artd

a size 2020-14 needle are to be used.

VERY HEAVY

rmmAU NEEDLES

Medium Silk |

Mec&m: lierderizidI

Med ium By

iedlum :§ercehz|d j

Med^l|rn=ldl!dh'‘'Medium Mercehzec

Mediumj^iik™

.

Medru-m Mercerized

i§ddi|m::Syhlplfdi.ih'i

fl edid m iy hifetidl t'

Medium Mercerized

Medfcm Svnthetidiiiii..

.

.

.....

k 2020-11 1

202Z-U

2045-t4

2045-14

d:2m2-|4 1

THREAD

|lepy§|k ,,,,

Heavy Mercerized

,ipeaiyiS|nthitid;ii

Heavy Mercerized

...gea|yl|:|ftdif''

...

Heavy Mercerized

Heavy Mercerized

r'ttiiieaiyiSfhthi*id;ti

Sinihet id' 1

Heavy Mercerized

Heavy Synthetic

NEEDLES

1 2020-14

..

1 2020l4"l

1 2|20-i::6;i|i

2020-16

.

|i ,2i45ii6i(|':

.

.

..................

,, 2D32J.6 1,..

THREAD

Heavy Silk

!|:;pieai|ysSynthetic

H |H ealy Mercirlzel

ttipeayy''0ctldi'‘i’^^

p|pe#yi5||drcerize|;»....

Heavy Mercerized 2020-16

|iped|yiSyh|h|l

..

;(.2|20y|eid|

If liibppo

Heavy Mercerized

..

Mdayy Synthetic,;;

.

MEEDIES

2020-14

2020-14

|2D|S-:1|«S

..

iilSIg-lS !

...

M

..............

Medium Mercerized

.

................................ if

Meclum Mercerized

Medlim ¿yhlietldi ''

2D20-t 1

'''2$blni"l|

Medium Mercerized :

: iOpediimiSf bi|d|id

Medium Me-'cenzed i

Medium Sy.ntnetic "

...2|20|it4ii||

...

............

................

”■ ;peiyy'li:erc|f 1^^ if

...

.

iilipielfiSynlpidil^

Heavy MercIriZidli..

'’1

" ilN

If""'

.....

O’^ ■* ib

............

(

Page 16

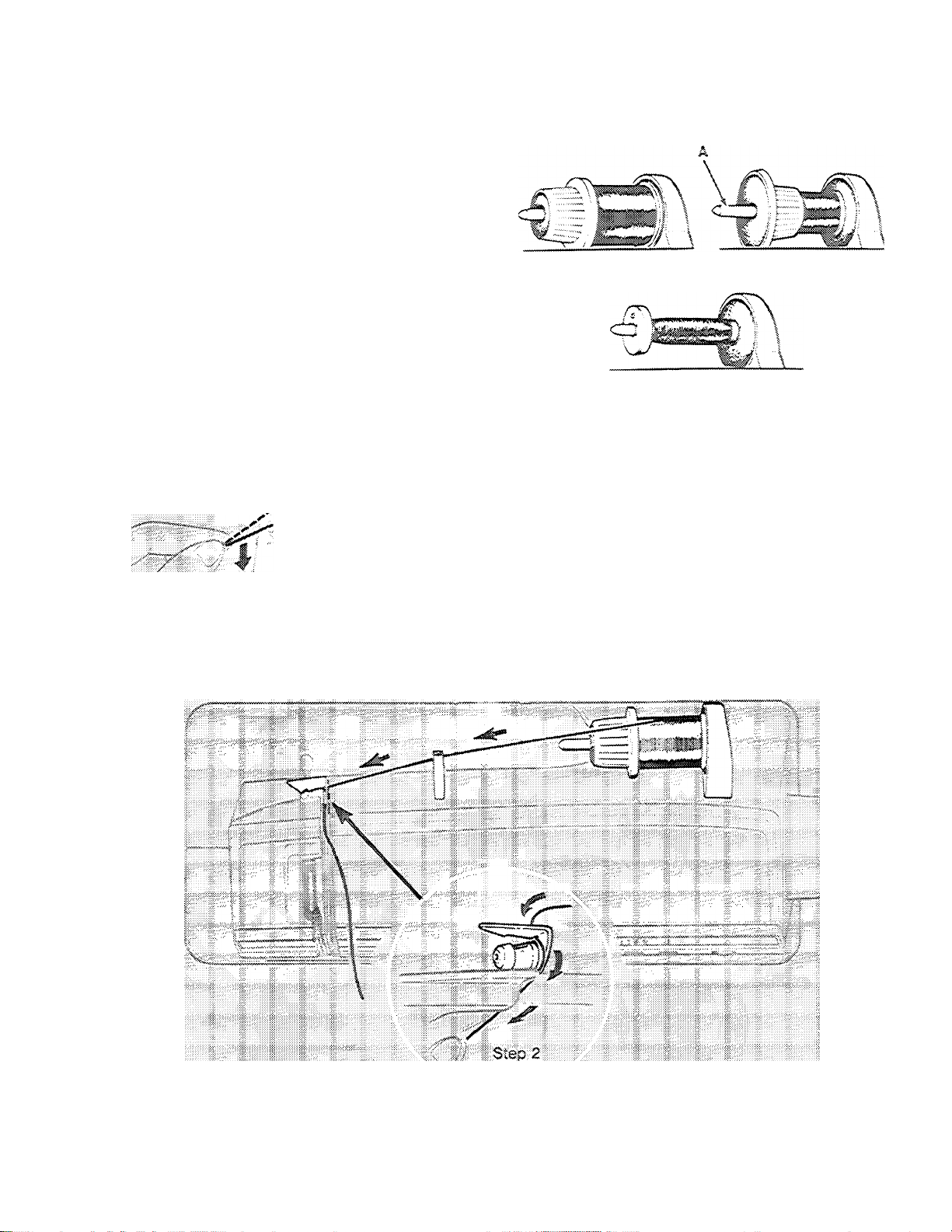

• Place spool of thread on horizontal spool pin

{A). If spool being used has a thread retain

ing silt, this should be placed against the

spool cushion to the right,

» Select correct spool holder according to

type and diameter of spool being used. The

diameter of the end of the spool holder

should always be larger than that of the

spool itself.

® Press spool holder firmly against spool.

i‘R|isi[fhih^

'

''' ■ ^<0.:

Step I

........

...... .

.....

.

you.

* Raise the presser foot.

1. Snap thread into thread guide post.

"\1

2. Thread the rear thread guide. Pas|i

threac under flange then over to the far

llll'righiiphliPi^

.

Page 17

Step 3

v\i

\ ■

, I, Stip; ^ 5| J

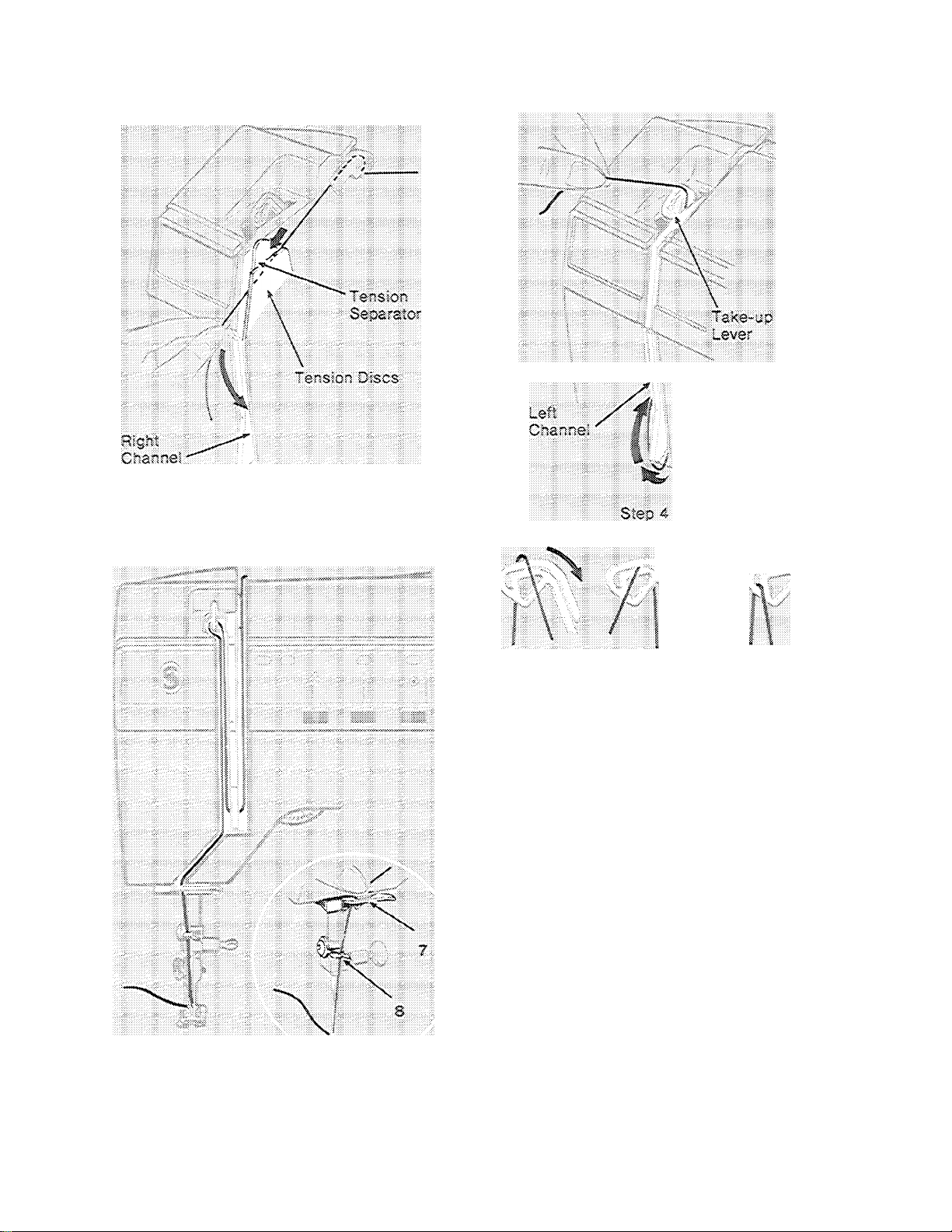

3. Draw thread firmly into tension disc on

I ri|Nt |f tsnsibri ie|Jirat|r;^ I

4. Draw thread down right ohannei and up

"W....................................................

,:i|:,,,td|::bai:i^sd Ie|b:h iidlliCbilPdl:^

......

^1:,:: :>

Bring thread through slit by pulling it

:|:|ridpaibtyi|!a:^

.

6. Follow thread back down through left

channel and then diagonally toward

lr|

....

Iipi|

..........

W.

g|iiii;1|fPi|d-B|^

...

..................

ili|

diagonal thread channel, guide thread to

I t|d tip n td| tb pad|g uf18ti| |

Step 6:;

;ir :7iei|driw f IreiSit

Drawing 4 inches (10cm) of thread down

ri|is|pwpi|let|eeileiiopers^

I thread needle front to back.

15

Page 18

Step

Step 1

Step 3

lMÉ¡M

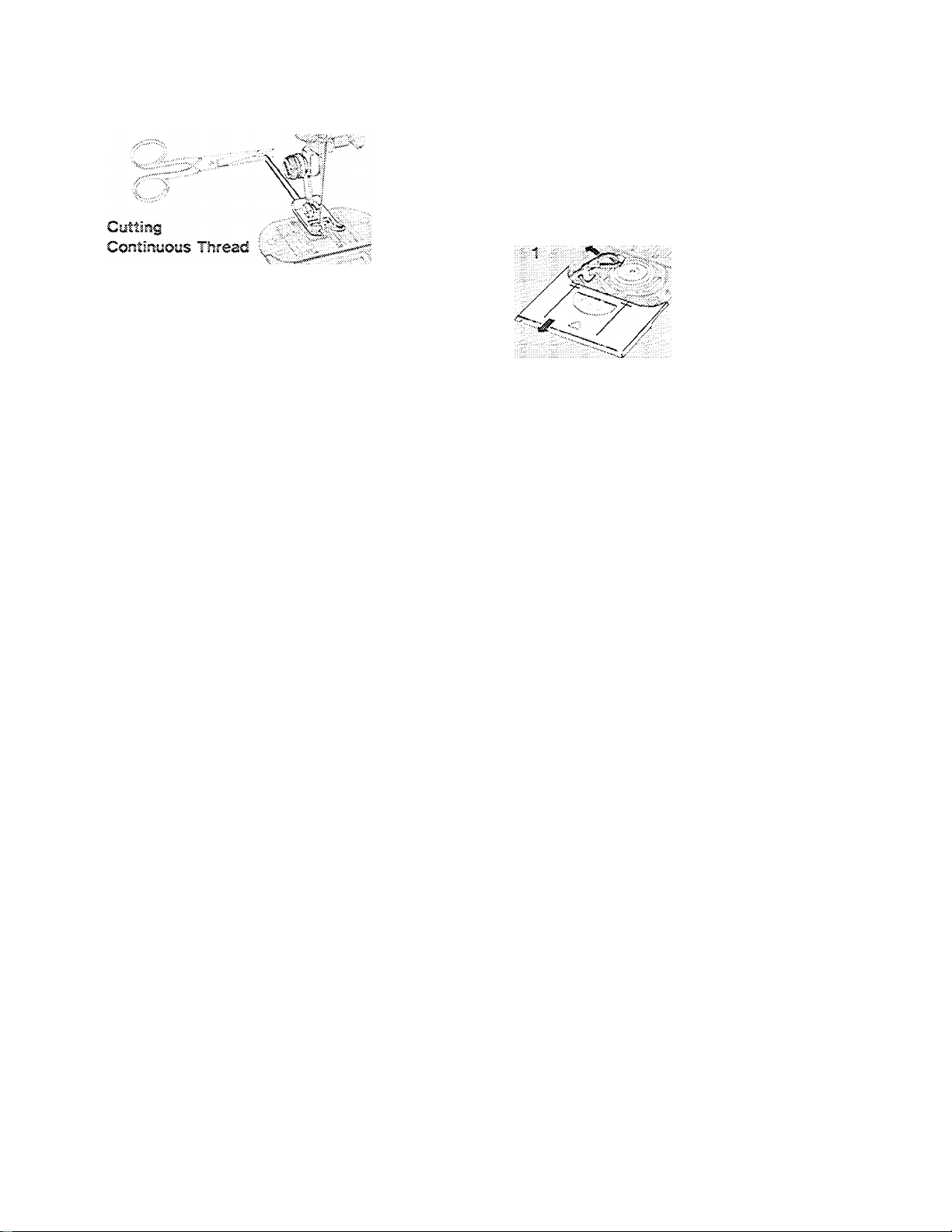

wmmuQ THE bobbiu

You wiH find a bobbin in place under the slide

piate of your machine. (To open shoe piafe,

simpiy draw it gerttiy toward you.) if the bob

bin runs out of thread during sewing, you can

rewind it without removing it from the

machine. The window in the slide piate iels

you see bobbin-thread supply at a glance, to

help avoid running out of thread in the middie

of a seam.

Preparation Steps

® Raise the needie and iake-uo lever to high

est position by turning the hand wheel

toward you.

® Raise the presssr foot to release tension

discs.

® Open slide piate and make sure bobbin is

empty. For removal of bobbin and thread,

see page 17.

1. Rotate group selector dial to right until

blindstitch symbol ^ appears in the yellow

field above pattern selector button,

2. Activate blindstitch ^ by pressing button

under the graphic on stitch panel.

3. Then press pattern repeat symbol 0 to

stop needie from its up and down motion.

This Will ensure a smooth flow of thread

from the thread spool to the bobbin.

Detailed information on seiecting stitches is

found on page 20.

;í:,íS

Winding Steps

1. ypve bobbin latch A to extreme right (wind

position).

2. Draw needie thread back between toes of

presser foot, under left side of prssser foot

then up, into and around thread retainer.

Start machine, running it at a moderate

speed.

3. Puli thread end away alter it has separated

from bobbin.

« Watch the bobbin as it fliis. Do not allow

thread to wind beyond the outside FULL

ring B.

4. Close slide piate to release bobbin latch to

sewing position.

Page 19

To start sewmg, puli thread back under

presser foot and cut. Place threads diagonally

under foot to left side, position needle In

fabric where desired, lower presser foot and

start machine.

CHAIIGIMQ THE BOBBIH

Remo¥ing tlie BoiJbin

Raise media and take-up lever to its highest

position by turning the hand wheel toward you.

1. Open slide plate; move bobbin iatcn to left.

J^erngving;: Sobbin;:

2. Remove bobbin by Inserting finger

mder

rim of bobbin.

Replacing an Emptf Bobbin

1. Slip bobbin (thread slot on top) Into bobbin

case.

2. Move bobbin latch to extreme right (wind

position).

® Leave slide plate open until you have

finished winding the bobbin.

Removing Tbread from Bobbin

You can leave the bobbin in plaoe while

removing thread. With slide plate closed, pull

thread end through the plate with a steady

motion. Do not pull the thread across the feed

as this may damage It.

Thread Slot

Bepisacing EmptytSdfebifs

17

Page 20

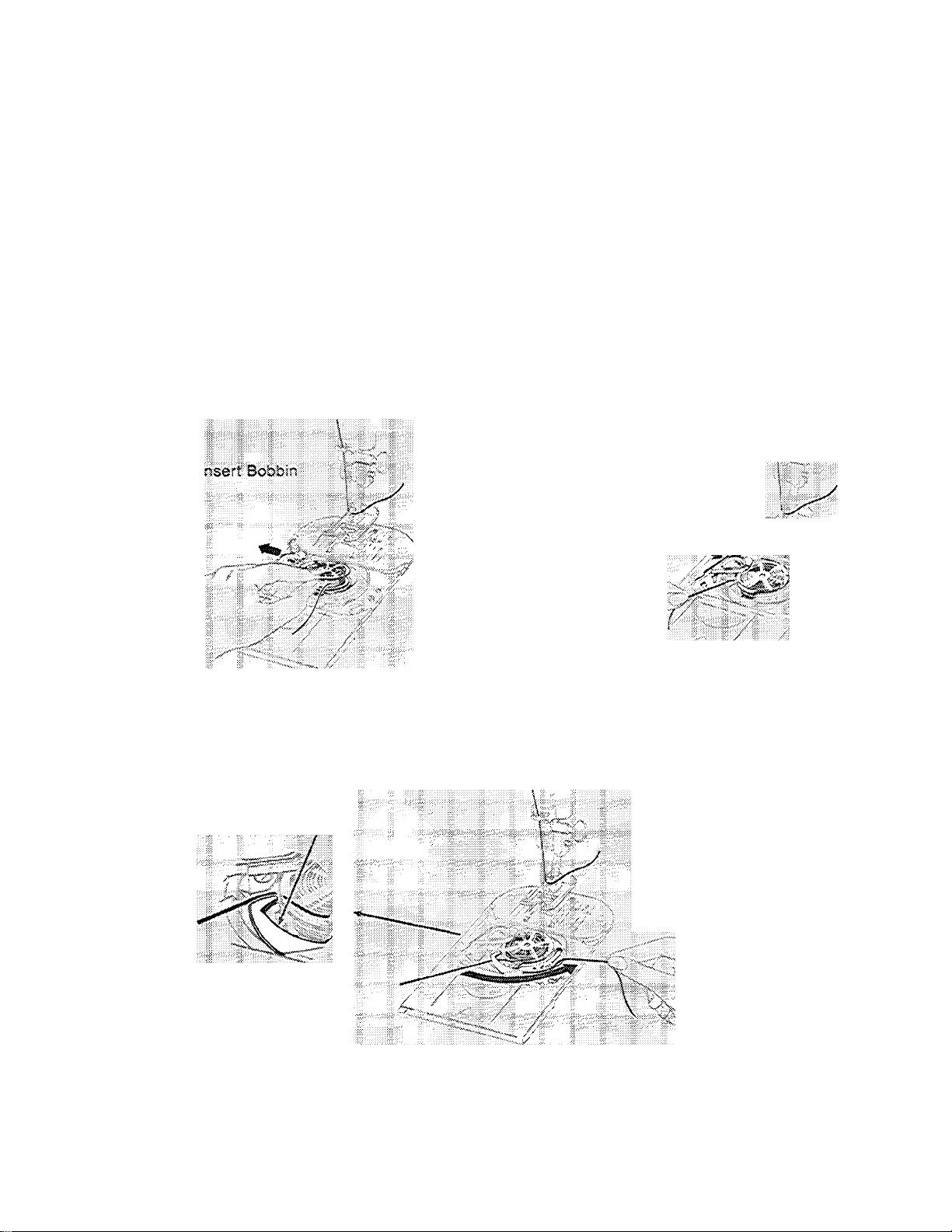

Hepiacing a Wound Bobbin

Raise needie and take-up iever to its highest

position by turning hand wheel toward you.

A. Open slide plate; move bobbin latch to left.

B. Draw about an inch (2.5cm) of thread from

bobbin and insert bobbin in case. Move

bobbin latch slightly to the right (sewing

position).

■Replacing aiWoéml Bobbin

C. Puli thread into bobbin-case slot (1), draw

it under flat spring and around to and past

point (2) leaving three inches (7cm) of free

thread.

D. Close slide plate. Closing slide plate

makes raising bobbin thread easier

because this step prevents the thread from

coming out of the threading points.

Flat Spring:

Draw Thread ■

i^roind fas t|Po I |t (iil

Page 21

hand and turn hand wheel slowly

toward you so the needle enters plate.

4

2. Continue turning hand wheel and hold*

'r||fih|rhdid:ii'''"

■ ¡rani bing'p

3. open the loop with your fingers, draw

■' rt|nd|iie|ini''idibi|XP

proximately 4 inches |lOcm), under

■ ¡the: piesier |fodl 'aihd |pldde |tlie:m

■■■rifidiii®

.

I

'#SSS6;is!!;i

Page 22

select

i urn macnme on.

(You win note a slight movement of needle

each time power switch is activated)

Rotate group selector dial to the right or left,

to choose one of four different pattern groups

whloh will contain the particular paitern you

wish to sew.

After rotating group selector dial, press button

under the desired pattern. A red light will ap

pear above seleoted pattern.

I О

О

0

I

0 О О О

- > ■ > 'Ч -tN А. у J 0^ if; 1 Si U? ^

^^^----------------------------------------------^|5

1

■Srcc?

sr ,,,

.

.

■>

• ^-Tl -••'si • ••••-•

•4-.

2

4

.

N

Ч

3

1

A

■Щ

'mZ

5

Stitch width and length are automatically pro

grammed, but can be changed for individual

preferences or fabric requirements, as de

scribed on page 22.

Follow same procedure for stitch selection to

automatically switch to another pattern.

Mote; We recommend use of the SLOW

speed setting when sewing buttonholes, bast

ing stitch, decorative patterns, or maxi

stretch stitch.

____________________

-------

-

.

0|шр)2

Flair; Zig-Zag

31

p uli-Stiic'h Zlg-iag |

4

.

..

iplptsidtllliiiii

m

Blind Stitch

tSastir.g Stitch

ffRexi-Stitch Patterns

tttVtaxi-Sirstch Stitch

;

Group 1

Group 3

.

.

ttf

..

IItOybred^e itreph' l| ■ ■

stllhiEdithliih

11 Hdheypdmb"

Greek Key

i. 1. Lelt aid R|^ht|iidgL,|,,,

iff'

, tt

J QfbupiS I ;

Ifidfer'i'

Scallop

1 ■ ■ ;iead|r :

ill: ArrovlKead ^" 1

Group 4

.

II Grduplp :il

lir..Zic-Zid'Fpnt:'

|||||li|)|l!iil|i|j|^

II ilOdaf Jillll 1

ft

Page 23

РАттЕшы шРЕт вттоп

Single Unit Sewing

The pattern repeat button 0 on your machine

lets you sew one unit of a pattern. For exam

ple; one arrowhead, one dog.

Procedure

Select desired pattern (such as arrowhead

shown here).

Press pattern repeat button 0.

Red light will appear above symbol.

Press down on controHer,

Machine will stitch one unit of the pattern

each time you follow this procedure.

You can also use pattern repeat button to

stitch a series of identical buttonholes, as de

scribed on page 73; and to aid in bobbin wind

ing as described on page 16.

INDIVlOyAL PREFEBEHCES

Your sewing machine will produce most of

your stitching requirements at a preprogram

med stitch width and stitch length.

Stitch Width Light

Stitch Length Light

О

S

Pattern Repeat Button

\ I / ‘Sect Ligh

+ ®

V ^

To accom.m,odaie different fabric charac

teristics or satisfy a personai preference, you

can change the settings by opening the cover

of the individual preference panel and then

manually adjust the controls located on the

panel as described on page 22.

liiiili'

Arrowhead

Stitch-width Control

Individual Preference Controls

ё i V i did a 3 P relerehde Ria ne i

Bi Cover

Page 24

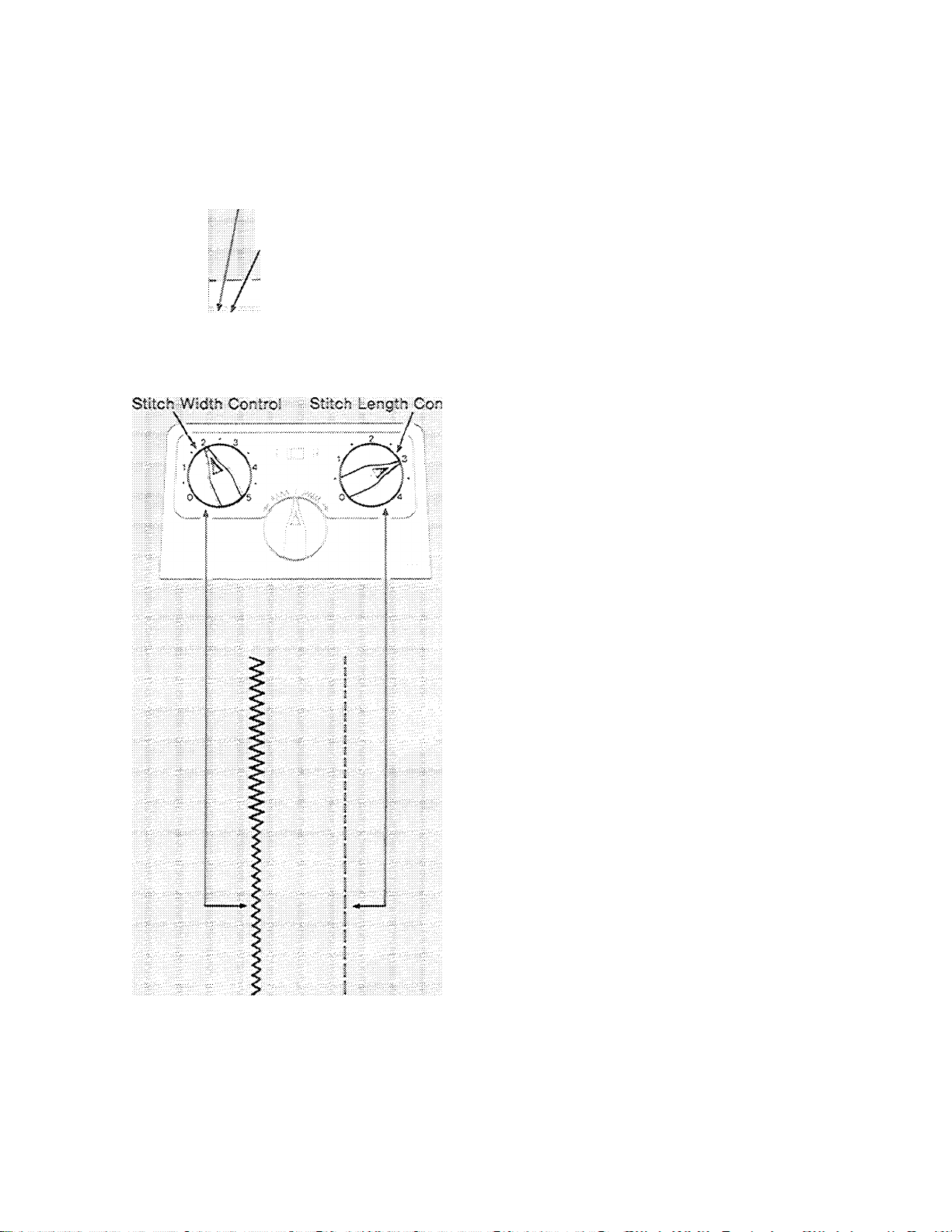

STITCH WIDTH

Stitch Width Ughi

Stitch Length Light

® Select desired pattern.

« Open cover of individual preference panel.

Lightly touch stitch width pointer to activate

stitch width control, indicated by a red light

on sts

r* H

panel.

« Turn pointer siowiy and sew until desired

width is obtained.

Machine will now stitch at preferred width.

STITCH LEMGTH

® Select desired pattern.

«- Lightly touch the stitch length pointer with

your finger to activate the stitch length con

trol, Indicated by a red light on stitch panel.

o Turn pointer slowly and sew until desired

length is obtained.

Machine will now stitch at the preferred

length.

Mote: Both stitch width and stitch length con

trols may be used simultaneously.

® To cancel, press any button except those for

reverse or pattern repeat sewing.

22

Page 25

Choosing the correct stitch length is of utmost importance, i he correct choice will make the

differer^ce in the wear and appearance of your new garment. The table below is a practical guide

to stitch length selection. Refer to it before starting a sewing project. Remember to make a test

sample on a scrap piece of the fabric you will be using.

STITCH LENGTH GUIDANCE TABLE

PART OF

ARTICLE OR

GARMENT

i'sSiBAlOlli

......

II

CURVED

MAIMSEAMSf"

.

FILMY

2|| ‘

.

SHEER

ifGty

Eif

WEIGHT OF FABRICS

LIGHT

MEDIUM

E''f.:s;;|2|||

f0m§2

..

Ifsp

.

.

.

...

ill

...

... ...

4 " ;

i||2-;;2tB;|:E:. 2.5

..

,

HEAVY

VERY HEAVY

2.5

j2;i2tSii;l

..

|?2!|2t5:li'i

S|2^i|;|.S|i

||:2t4i2t5||||:

lii

4 ■:

.

........

::i

..

4

TOPSTITCHIMG'^

STRESS AREAS

.

..........................J:.:,

:#tsi2l|lt

z

|pSit2i|ii

1.5-2"

4

1.5-2?^

4

.

El

■f Slow to iooderats speed.

Stress Areas In Knit or Stretch Fabrics

Contrary to common belief it is not always necessary to use a S-t-r-e-t-c-h stitch on all seams in

garments made from these fabrics. Always consider the “Stress” areas, for example; arm,holes,

crotch seams, also now much the garment 'will be required to “give” and where. Use a stretch

stitch where needed. Moreover, always ascertain that the fit of the garment is correct before

sewing any seam v/ith a S-t-r-e-t-c-h stitch. Ripping out a S-t-r-e-t-c-h stitch is difficult and may

damage fabric. See page 46 for sewing on stretch fabrics.

23

Page 26

B«ve?se StItCih- Balat?ce Centres!

■A

/

ttSSipif'

n

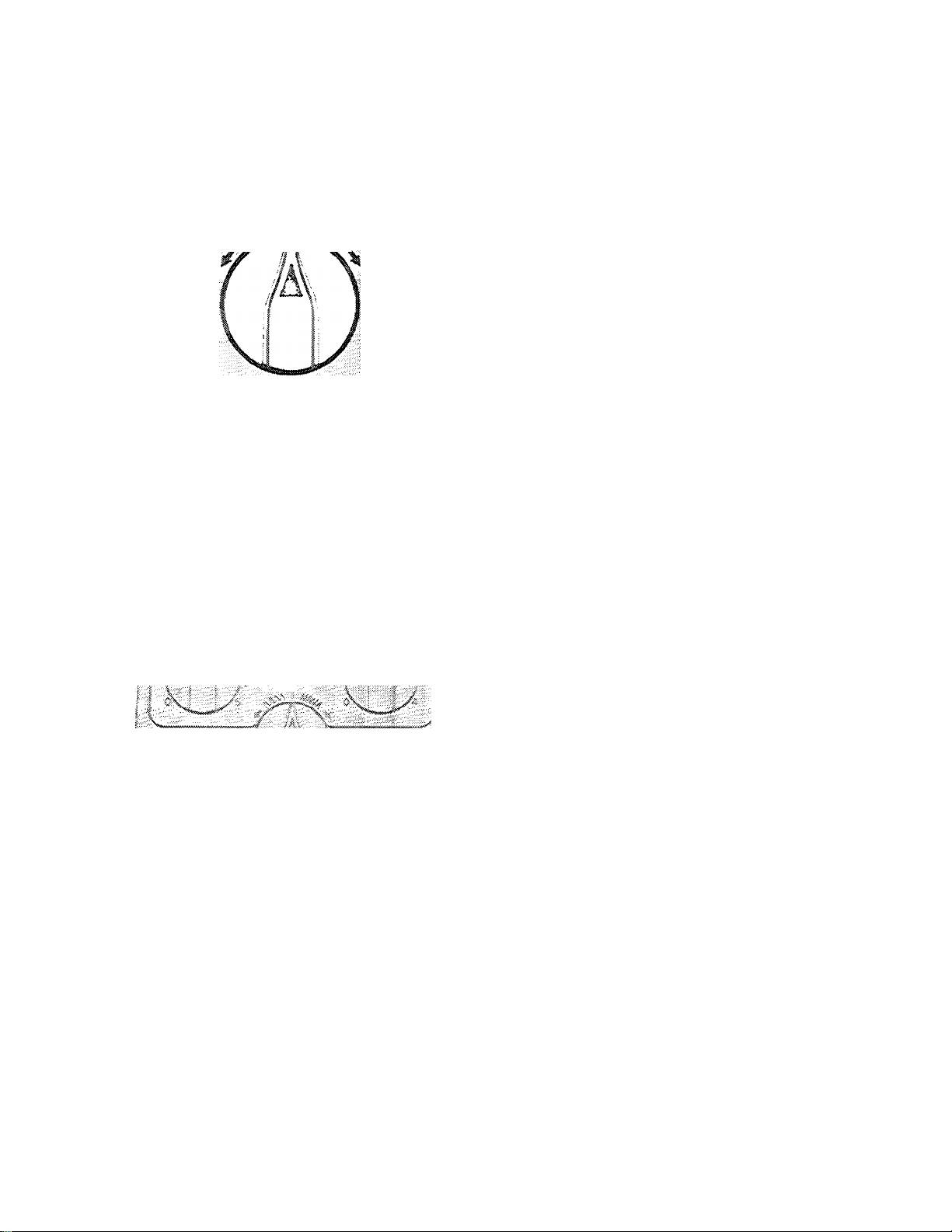

REVERSE STfTCH-BALAI^CE

To change the appearance of a Rexi-Stitch

pattern or buttonholes, adjust the reverse

stitch-balance control.

Before moving the pointer from its neutral

position, make a test sample.

If adjustment is required, stitch slowly and

move the reverse stitch-balance pointer in

either direction as you sew, until desired pat

tern appearance is obtained.

For information on balancing a buttonhole see

page 73.

Return pointer to neutral position {A) after

sewing Flexi-Stitch patterns and buttonholes.

Fiexi-Stitches illustrated on page 20.

4 i

J !

■3 !

i !

i S

.5 i

3 I

i s

s s

5 i

5 S

i i

3 s

4 I

:s s

i i

s i

i s

;,iS

sr r

.. $

5

Mi

1 s

i s

ML ^

TWm-HEEQLE SWITCH

Always move twin-needle switch, located on

individual preference panel, to the right (|| )

symbol before doing twin-needle sewing.

Caution: Unless switch has been activated,

needle breakage can result.

When you have completed twin-needle sew

ing, be sure to return switch to the left ( f )

position.

See page 68 lor twin-needle sewing.

Remember: If, when adjusting a control, you

accidentally touch another control: re-select

desired pattern, then readjust desired control.

Close individual preference panel cover when

you have attained desired stitch appearance.

24

Page 27

.li

For straight stitching, ^ press button under

straight stitch symbol {i) on stitch panel.

A red light will appear above symbol to indi

cate that machine is ready to produce a basic

straight stitch.

Straight-stitch needle plate and foot are best

for all straight stitching. Use these accesso

ries when fabric requires close control. They

are especiaily

telpful for stitching delicate

fabrics.

If you use the straight-stlich foot with a nee

dle plate other than the straight-stitch needle

plate, be sure to set the rmchine for straight

stitching to prevent possible needle breakage.

Note however, that when you use the straight-

stitch needle plate, you get this exclusive

feature: If you press another buiton by

mistake, your machine will still sew a straight

stitch.

Always change back to the appropriate nee

dle plate and presser foot when sewing other

than straight stitching.

SEWIMQ 11^ HEVEBSE

If you wish to reinforce the beginning or end of

a seam, press and hold the reverse stitch

button.

Machine will only sew a straight stitch in

reverse for as long as you hold the button,

regardless of the stitch pattern you have been

sewing.

1 O O

Reverse Stitch '

StraightiStitih bight ;

o o

® I I S I § I^ - j I^ I

1 g|N 1^. I sil< 1 J i

■!Ì|ÌÌi|||:StÌC|#

o

25

Page 28

M«e<Sie-Thread Tension

I^EEOLE-THliEAO TEMSIOf^

Havmg selected the correct needle and

thread combination for the fabric being used,

it may be necessary to adjust the tension of

the sewing maohine to ensure a well balanoed

stitch.

A well balanced stitch is when the top and

under thread appear the same on the fabric.

Your new machine has an adlustable tension

control system. This control exerts tension on

the top and under thread as they pass through

the machine to form a stitch.

« Too much tension will produce a tight stitch

which will cause puckered seams.

o Too little tension will produce a loose stitch.

When an even amount of tension is exerted on

both threads, a smooth even stitch known as a

balanced stitch, is produced.

To help understand the effect of tension on

fabric and thread, try this simple test:

® Take two pieces of a medium weight woven

fabric in a solid light color about six inches

long.

o Place a 2020 size 14 needle in the machine.

« Thread the top of your machine with a

polyester or mercerized dark color thread

and use a lighter color thread of the same

fiber and size in the bobbin.

o Select a medium stitch length.

Seam the two pieces of fabric together start

ing with the top tension control at “0”. Then

as you sew, slowly turn the tension control

from “0” through to its highest setting.

6 Sew another row turning the dial back to

“0”, You should have a balanced stitch on

each row mid-way between the start and

finish in each case.

«The different colored threads will help you

to see the effect that the tension has on the

top and bottom threads.

Now that you have observed the effects of

tension, we suggest that you perform a similar

test on a scrap of the fabric you plan to use.

being sure to duplicate the number of

thicknesses of your garment.

26

Page 29

' O'

/г

Pin basting is a time saver and can be used

when you sew easy-to-handle fabrics. Use

fine pins and place them so that:

• They are at right angles to the presser foot

and just nip into the fabric at the stitching

line.

• They do not extend under both sides of the

presser foot. Never place pins on the under

side of the fabric in contact with the feed.

SPEED BASTIUO

The basting stitch produces temporary long

stitches in a variety of lengths. This allows

you to choose the correct length for your sew

ing job, considering the weight of your fabric

and how securely the pieces need to be held

together. A few of the many sewing jobs for

which you will find speed basting particularly

useful are;

at the Stitching Line

Pin Placement

e Joining seams for trial fittings

• Marking construction guidelines

c Basting pleats, hems and seams

® Stitch: speed basting j

e. Length: to suit fabric

® General purpose plate

e General purpose foot

Mote: The even feed foot cannot be used for

speed basting.

Select needle and thread according to your

fabric. A fine needle and a soft pliable thread

are recommended when basting stitches are

not to be removed before pressing, as in the

case of pleats or hems. Choose a thread color

to contrast with your fabric so that it can be

seen easily.

Stitch

■<v.c:h

stitch

Length

27

Page 30

Pfocedyre

Thread the machine in the usual way.

1. Set machine for basting at a short stitch

length, and take a few stitches to position

and secure basting start.

2. Adjust to the length of basting stitch

desired — stitches approximately 1 inch

(2.5cm) long are recommended for seam

basting — and proceed. Stitch slowly, sup

porting the fabric in front and back of the

presser foot if stitches are more than 112-

inch (1.3cm) long.

Caution: Do not puli the fabric while you are

stiiChmg as this may deflect the needle, caus

ing It to break.

3. Take a few short stitches to secure end of

basting.

Stitch Length

The stitch length control dial on the personal

preference panel (see page 22) regulates the

length of basting stitches. Because the Inter

val at which the needle enters the fabric is

changed when you machine baste, the length

of the stitch is no longer the same as for regu

lar stitching.

Ecstir.g a Saarr:

Very short stitches are recommended to

fasten stitching starts and endings.

For Longer

Basting Stitches

bread Tension

Speed basting requires a light needle-thread

tension. When tension is correctly adjusted,

stitches up to 1 inch (2.5cm) long should lie.

flat In firm fabrics. If stitches are longer than 1

inch, place tension on the fabric by holding it

lightly in front and back of the presser foot as

you sew. to prevent pucker.

See page 26 for further information on nee

dle-thread tension.

28

Page 31

pmpmmon

«> Stitch: straight t

• Length: to Suit fabric

« Straight stitch needie piateor

genera: purpose piate

■9 Straight stitch foot or generai purpose foot

Thread nnachine in the usual way.

PLACE FABRIC UMPEB FOOT

Most fabrics can be piacec under the foot by

raising the presser foot lifter (A) to its normal

up position (1), where It locks. When using

bulky fabric, multiple fabric layers, or an

embroidery hoop, raise the presser foot lifter

to the high rise position (2), thus increasing

the space between foot and needle plate.

Hold presser foot lifter In position while plac

ing fabric under the presser foot.

• Lower presser foot lifter all the way down

and start to sew.

J,

.....

.......

SEWmO WITH A MEWLY WOUUB

BOBBIU

When starting to stitch at the fabric edge:

• Position needle in very edge of fabric, by

turning the hand wheel toward you.

® Lower the presser foot and stitch. Thread

will lock over fabric edge.

OR

When starting to stitch away from fabric edge;

® Leave presserfoot in its upper position.

« Pull thread back under presser foot and cut.

« Position needie in from fabric edge, then

lower the presser foot and stitch.

Page 32

„it|C5|si|g yfo§ ■

|!:i«iswi

........

^ ^uislelifses

«0§m

------

. . —5/c" ;■: .6c~.

—u—(1,9cm)

^Crossisne

m

i|i||;i;i;i|: ,: i.^ i:;:;;;

lltt

Pivoting at Comer

3/S" C9:nm)

lEPiMCS SEmS STRAICsH"

To keep the seam straight, use one of the

numbered guideNnes on the plate. The num

bers indicate distance, in eighths of an inch,

from the needle, if you want a 5/S-lnch

(1,6cm) seam, for example, line up your fabric

with the number 5 guideline. Note that both

number 5 guidelines (the most commonly

used) are extended on the slide plate for your

oonvenience; the crosslines serve as guides

when stitching a square corner.

For extra help In keeping the seam straight,

you may wish to use the seam guide. Because

it allows you to guide stitches evenly between

1/8-inch (Smm) and 1-1/4 inches (3cm) from

the fabric edge, it is particularly useful for

very narrow or very ’wide seams.

To insert seam guide on machine see page 8.

TyRriiMG SQUARE CORNERS

To turn a square corner 5/8~lnch (1.6cm)

from the fabric edge, you need not measure or

mark the seam. Simply use the crosslines on

the slide plate.

♦ Line up your fabric with right or left

guideline 5 on the plate. Stitch seam, slow

ing speed as you approach corner.

Fabric after Turning

♦ Stop stitching, with the needle down, when

the bottom edge of the fabric reaches the

cornering crosslines on the slide plate.

♦ Raise presser foot slightly end turn fabric on

needle, bringing bottom edge of fabric in

line with guideline 5.

® Lower the presser foot and stitch in new

direction.

30

Page 33

1. For example. If the stitch length control on

your machine is set on 2 the machine will

sew approximately 12 stitches to the inch

for straight seams. Adjust the control bet

ween 1 .S to 2 or 15 to 20 stitches per inch

to stitch curved seams in the same fabric.

2. if you use the seam guide, attach it at an

angle so that the edge that is closer to the

needle acts as a guide.

IMF

EMU

1. Stitch to the edge of the fabric. (Do not sew

beyond edge of fabric)

2. Press reverse stitch button and hold in

place. Backstitch approximately 1/2-inch

(1 -3cm) to reinforce end of seam. Release

reverse stitch button.

3. Raise needle to its highest position by

turning hand wheel toward you and raise

presser foot. Remove the fabric by drawing

it to the back and left.

4. Cut threads on thread cutter at rear of

presser bar.

iiig

r V

l^everse Stitching

Stitching a Curved Seam

.

..

Page 34

applications

DARNING

Worn or torn spots on children’s clothes,

knits, and household linens can be darned

effortlessly and quickly with little practice.

You may choose to darn either with or without

acoessories. When greater control is needed,

use the accessories.

With Accessoriest

6 Stitch; straight stitch i

• Stitch length: 0

6 Cover plate

® Darning and embroidery foot

1. Trim ragged edges from area to be darned

and center worn section in embroidery

hoop.

2. Select straight stitch.

3. Position work in hoop and place hoop

under foot, then lower the presser bar to

engage tension.

4. Hold needle thread loosely with left hand,

turn hand wheel to'ward you, and draw bob

bin thread up through fabric. Hold both

thread ends and lower needle into fabric.

Snip off after a few stitches.

5. Outline area to be darned with running

stitches for reinforcement as illustrated.

6. Stitch across opening, moving hoop back

and forth underfoot. Keep lines of stitching

closely spaced and even in length.

7. When opening is filled, cover area with

crosswise lines of stitching.

32

Darning with Embroidery Hoop

tFor best resuiis, hinged piste shcuic be up v.'hen darning with embroidery hoop.

Page 35

BAUmUQ

Wiilloyt Accessories

9 Stitch: straight stitch i

® Stitch iength: between 1 and 1.5

« Generai purpose needle plats

» Special purpose foot

« Pressure setting; (darn)^

1. Select straight stitch.

2. if area to be darned is open, baste an un

derlay in place.

3. Place area to be darned under presser

foot; lower presser foot and start stitching,

alternately drawing fabric toward you and

pulling It gently away from you.

A. Continue this forward and backward mo

tion as you fill the area with parallel lines of

stitching. For additional strength, cover

area with crosswise lines of stitching.

Dammg Without Accessories

HESITATION EMBROiOERY

Hesitation embroidery is free-motlon

embroidery using speed basting. The time

lapse that occurs between needle penetra

tions permits unhurried hoop movement (ap

preciated by the beginner), it also permits

unusually long stitches, as well as short ones

for unique decorative effects.

e Stitch; basting stitch |

o Stitch iength: 0

« Cover plate

« Darning and embroidery foot

« Speed range: SLOW

1. Trace or transfer design outline to fabric

and center in embroidery hoop. Designs

and motifs with shaggy outlines and tex

tured surfaces are usually best.

2. Select speed basting.

3. Position hoop under needle, lower presser

bar, and raise bobbin thread.

4. Move hoop back and forth, filling design

with long and short stitches as in regular

free-moilon embroidery, as described on

page 45.

33

Page 36

Quilting is the art of stitching two or more

thicknesses of fabric together in a planned

design. A padding is stitched to the underside

of the fabric to produce a soft, puffed effect

that is becoming to some wearing apparel and

to many fabric furnishings.

V'

R'

«Stitch: straight stitch ]

o Stitch length: to suit fabric, design,

and effect desired

» General purpose needle plate

® Straight-stitch foot

>te: For best results use the quilting foot

available for separate purchase at your local

Singer store.

Preparing the Fabric

Baste a light padding of cotton fiannsl, syn

thetic quilt batting (split), sheet wadding, ora

lightweight wool interlining to the underside of

the fabric. When using sheet wadding, first

back it with voile, batiste, or net to preserve

the sheet wadding through ’wear. Baste the

layers of fabric together on the lengthwise

and crosswise grains.

Basic Procedyre

1. Select straight stitch.

2. Draw both threads under the foot and

diagonally across feed to left.

3. Position the needle, lovj&r the foot and

start stitching.

Mote: If you are quilting a very large piece,

work from the center of the fabric to the

edges. Guide the fabric with both hands.

34

If the fabric has a floral or scroll design, the

pattern in the fabric can be your quilting

design. Stitch it from the top side.

Page 37

cmmsTiTcmuQ

Single-thread chainstitching looks like regu

lar straight stitching on top but is a series of

interlocking loops on the underside of the

fabric. The stitches are produced by the nee

dle thread alone so you do not need a bobbin

thread or a bobbin. Because the stitches are

formed by a single thread, the interlocked

loops ravel easily, allowing the entire line of

stitching to be removed with just a pul! on the

thread end.

Here are a few of the many sewing jobs for

which you will find chainstitching useful.

Prefsafsng Machine

* Threedins Take-up Eyelet

lii

:iil

5kr-5i 3: S;::: !; if 5^54 '

^ ^' Ul Y ilu n ^

Hi 'a? yp.i i 11

iU ii ili

® Sewing temporary hems and tucks to extend

the life of children’s clothes, and curtains

and linings that might shrink.

6 Hemming curtains and draperies that may

need to be altered.

e Attaching woven and stretch hem tape.

e Making stay chains (French tacks) to

anchor linings.

« Basting for trial fittings.

Preparation

» Select needle and thread according to your

fabric. (See Fabric, Thread and Needle

Chart on page 12.) Thread the machine in

the usual way except for the take-up lever.

For chainstitching, pass the thread through

the triangular eyelet as shown.

1. Raise take-up lever to its highest position

and raise presser foot. Open slide plate.

2. Move bobbin latch to left and remove bob

bin and plate.

Post

Finger

0 I G

/r\.

of

Insert

rki

Adjusting Tension

To find the correct tension setting for

chainstitching, set the tension dial on 3 and

make a test sample in your fabric. If the loops

in the chain on the underside of the fabric are

loose and irregular in size, increase tension.

When the tension is correctly adjusted, the

chain will be flat and smooth and the fabric

unpuckered.

® To increase tension, turn dial to a higher

number.

* To decrease tension, turn dial to a lower

number.

3. Place bobbin-case insert in bobbin case as

shown, with finger of insert positioned under

the feed.

4. Position chainstitch plate over holding

pins, making certain that the post of the

bobbin-case insert finger enters the hole in

the plate. Close slide plate.

35

Page 38

Releaslsig liie Chain from Machine

SEWmQ A CHMUSTITCH SEAM

9 Stitch: straight stitch !

® Stitch length: 2.5-3

« Soboin case insert

o Chainstitch needle plate

® Straight stitch foot

Starting and Chaining Off

1. Turn hand wheei toward you to position

needle in very edge of fabric. Lower the

presser foot.

2. Start the machine, and stitch to end of

seam. Continue stitchi.ng beyond edge of

fabric, making a chain from one to two in

ches long (2.5 to 5cm). Do not attempt to

stitch in reverse. Chalnstitching can be

sewn in a forward direction only.

3. Cut chain between fabric and presser foot.

4. After chaining off. start a new line of stitch

ing by raising the presser foot slightly and

positioning the fabric in front of needle.

Lower presser foot and stitch to end of

seam.

' V

^ it

' ' V '

I

f , -A

Beleasiog the Chain from the Machine

When you finish chainstitching, the chain can

easily be removed from the machine.

1. Raise presser foot.

2. Hold end of chain with your left hand.

3. Turn hand wheel slowly toward you with

your right hand until needle is ail the way

down in the needle hole.

4. Then turn hand w'heel slowly away from

you. pulling gently on chain, which will

unravel as needle rises.

Mote: This is the only time you should ever

turn hand wheel away from you.

36

Page 39

Removing Stitching from fabric

Chainstitching can be removeci smoothly and

cleanly in seconds by freeing the last stitch

formed in the fabric.

1. Simply cut the last loop formed on the un

derside of the fabric.

2. Pick up the free thread end from the top of

the fabric.

3. Pull the free thread end, rem.oving entire

line of stitching.

Removing the Chainstitch Accessories

« Raise take-up lever to its highest position

and raise presser foot.

« Open slide plate and remove the cnainsiitch

plate.

» Move bobbin latch to left and lift out the bob

bin-case insert.

« Replace zig-zag or straight stitch plate and

bobbin (see pages 8 and 17). Close slide

plate.

Hemoving the Stitching

o Unthread chainstltch eyelet in take-up lever

and reihread for regular sewing.

I i r? t i I ;

o o\

t., U “

^ ''

r."... Xt

oX

II

}

...

Cl

wX

Removing Chainstltch Plate

37

Page 40

V ' Y f ****•, ^

г

»1

■

iiliiiiii

li■iЯi■iИi■i

11в1Ш1Ш1М1Ш®

Ш

i

CHAINSTITCH APPLICATIONS

Here are several ways in which you will fine

chainstitching quicker than either regular

straight stitching or hand basting.

Garment Fitting

Time and energy can be saved when

chainstitching is used to baste garment sec

tions or muslin shells for trial fittings. The

firm.ness of the stitch ensures accuracy in fit

ting. yet the stitching can be ripped out in sec

onds if adjustments are necessary.

Constryctioii Gyidelioes

in many instances, construction guidelines

for pockets, buttonholes, and other details

can be advantageously marked with

chainstitch Pasting. The stitching will give a

clearly defined line marking. Yet, unlike chalk

or pins, it will not rub off or become lost as the

fabric is handled. This method lends itself

particularly to use on wools and other fabrics

that do not retain the penetration ma.i-ks of the

needle.

38

stay Stitcliing

h

'"y-»

Chainstitching can be used to stay-stitch

neckhnes, shoulderlines, and waistlines

before gar.meni assembly. Flexible, yet firm,

this stitching will hold the original shape of

these areas and prevent stretching.

Page 41

Slipcover Welting — Tubylar Trimming

Chainstitching has an affinity for fabrics cut

on the bias. The loop formation of the

chainstitch is a natural lor corded welting and

tubular trimming where a certain amount of

elasticity is needed to prevent stitchses from

“cracking”.

Beit Carriers and Stay Cbalos

Stay chains (sometimes called French tacks)

and belt loops, normally time-consuming

hand-worked detail finishes, can now be

quickly made by machine. To produce a

chain, place the first stitch in the fabric. Stitch

off fabric and continue stitching until a suffi

cient length of chain is produced. Thread

chain through emibroidery or darning needle

and tack to garment or lining. A stitch length

setting of 12 is recommended.

Growlb and Shrinkage Tucks

Tucks are frequently put into curtains, linings,

and children’s clothes to allow for fabric

shrinkage and child’s growth. “Letting down”

is no longer a chore when tucks are

chalnstitched. Simply unlock the last loop of

the chain formed on the unde.»-side of the tuck

and puli out the stitching.

39

Page 42

.I?

о

1|И

Ш% И,

о

I ;-11;

о

Г?!

« Si:ten: zig-zag §

« Stitch width: to suit fabric

» Stitch length; to suit fabric

a General purpose needle plate

® General purpose foot

Too Tight

» Rotate the group selector dial (A) to the right

as far as it will go. The zig-zag symbol wil

now appear in the yellow field above patterrt

selector button |S).

® Press pattern selector button {8). A red light

will appear above the zig-zag syrrsboi to indi

cate that machine is ready to produce a

basic zig-zag stitch at maximum stitch width

and medium stitch lenath.

cnmmuQ sTi

To change stitch length or width see page

22 in Chapter 3. Electronic Sewing.

Zig-Zag stitching usually requires less needie-thread tension than straight stitching. Be

sure your machine is threaded correctly and

make a test sample v^ith the fabric and thread

you plan to use so that you can adjust tension

to suit the stitch pattern you have chosen. The

stitches should lie flat against the fabric with

out causing the fabric to pucker.

tne st:to.ne$ are not

puckered, lower the needle-thread tension

turning the dial to a lower number.

flat

an

the fabric is

Page 43

Zig-zag stitching has found a solid place in

home sewing. The zig-zag stitch can be used

creatively as well as practically. The following

examples are effective uses of the zig-zag

stitch. The results are left up to your imagina

tion and ingenuity.

ZIG-ZAG SEAI^ FINISHES

Seam edges support the garment and shou

be given a durable finish if the fabric is likely

to ravel. There are two methods of finishing

seams in such fabrics: method 1. trimming

after stitching seam edge, or method 2, over

edging. Make a test sample first to determine

which method best suits your fabric.

f^ethod No. 1 —Trimmed Seam Finish

«Stitch; zig-zag g or multi-stitch zig-zag T

• Stitch width: to suit fabric

« Stitch length: to suit fabric

« General purpose needle plate

» General purpose foot

1. Select appropriate stitch pattern.

2. Adjust stitch width and length if necessary.

3. Place stitching near the edge of the seam

allowance.

4. Trim seam edges evenly, as shown, after

stitching is comipleted.

THmmlng Edges

41

Page 44

Overedged Fmish

Method Mo. 2 — Overedged Seam Finish

Stitch: zig-zag $ or muiti-stitch zig-zag >

Stitch width: to suit fabric

Stitch length: to suit fabric

General purpose rseedie plate

Genera! purpose foot

1. Adjust stitch length and width if necessary.

2. Trim seam edges evenly.

3. Place stitching over the trimmed edge of

the seam allowance as illustrated.

LINGERIE SEAMS

• Stitch: zig-zag g

® Stitch width: narrowortosuitfabrlc

« Stitch iength: to suit fabric

« General purpose needle plate

e General purpose foot

To make a lingerie seam durable and flexible,

use the plain zig-zag stitch at a narrow width

setting. This seam treatment is particularly

suitable for bias seams. When seaming nylon

tricot, insert a Yellow Band needle in the

machine before you begin to sew.

Lingerie Seam

® St.>'alghi-stitch the seam on wrong side of

fabric.

• Press both seam allowances in the same

direction,

« From the right side, topstitch with narrow

zig-zag stitching, letting the needle alter

nately enter the seam line and the seam

thickness.

42

Page 45

SATIN STITCNING

* Stitch: zig-zag §

® Stitch width: to suit fabric

® Stitch length: 0 to 1

* General purpose r4eedle plate

« Special purpose foot

Note: Other decorative stitch patterns ex

cept stretch stitch patterns, may be sewn at

satin-stitch length.

Satin stitching, a series of closely spaced zig

zag stitches that form a smooth, satin-like

surface, is useful for both utility and decora

tive work. It is accomplished by sewing a zig

zag stitch with stitch length pointer In the area

between 0 and 1. For best results, the special

purpose foot must be used.

When you wish to produce a satin stitch,

make a test sample first so that you can adjust

the stitch length and thread tension properly.

Soft fabrics may require a backing to ensure

firm: satin stitching. Crisp organdy or lawn is

suitable for this purpose.

lUfclBl®!

5-^^ wi i!W> aw \

Adjusting Stitch Length for Satin Stitching

1. Open the personal preference panel, (A).

Set the stitch length pointer on 1.

2. Run the machine at a slow speed.

3. Gradually m,ove pointer from 1 toward 0 by

rotating the pointer downward until

stitches are closely spaced and form a

smooth surface.

Stitch width may be varied in a similar man

ner. Move stitch width pointer to any desired

setting: the higher the number, the wider the

stitch.

Adjusting Tension for Satin Stitching

Satin stitching generally requires even less

tension than open zig-zag stitching. Further

more, the wider the satin stitch, the lighter the

tension on the thread must be. Thus, a stitch

width setting of 5 requires the least tension;

narrower stitching requires somewhat .more.

Notice the stitching on your sample. If the

stitching looks too taut, or if the fabric is

puckering, lower the needle thread tension by

turning the tension dial to a lower number.

Incorrect

Correct

43

Page 46

lifc

/

APPLIQUE

Make a test sarr^ple to decide which of the

foHowing methods is the most appropriate for

your fabric and design. Mark design on piece

of fabric to be appHqued. Cut out design ieav-

ing about 3/4-inch {2cm) margin ali around.

Position the design.

Baste it to the fabric.

Method 1

® Set pattern seiector and stitch-width dial for

desired applique stitch. Adjust stitch length

to a fine setting, between 1 and 0.

• Follow the outer edge of the design with a

decorative stitch.

» Trim away the excess fabric on the outer

edges of the stitching.

Hettiod 2

sMoîhod 2

« Select straight stitching.

lit

« Outline the entire design with a short stitch.

e Trim raw edges to the stitching and remove

basting.

• Select stitch pattern and stitch width

desired, and set stitch iength on a satin

stitch setting lor a ciosely spaced stitch,

between 1 and 0.

® Stitch, foiiowing the straight stitch outiine.

This method wlli produce a smooth overedged finish, with no raw edges to be trim

med after stitching.

Method 3

® Purchased motifs can be appliqued quickly

and easily by using either a straight or

decorative stitch.

44

Method 3

Page 47

¥ПЕЕ-ШОТЮЫ STITCHiHG

In free-motion stitching, you sew without a

presser foot and control fabric movement by

means of an embroidery hoop. Either a

straight or a plain zig-zag stitch can be used.

Because you can move the hoop in any direc

tion — forward or backward, from side to side,

or even diagonally — free-motion stitching is

extremely useful for embroidery designs. On

the other hand, it is equally useful for darning.

if you are embroidering, you can vary the

length of stitches simply by moving the hoop

faster or slower under the needle. The faster

you move the hoop, the longer the stitches will

be. You can also vary the width of zig-zag

stitches from wide to narrow by controlling the

angle at which the hoop is placed and moved

under the needle.

For darning, the embroidery hoop used in

free-motion stitching enables you to hold the

fabric taut — a real advantage when your

fabric is lightweight or soft and thus likely to

pucker. See page 32 for directions.

2. Hold needle thread loosely and turn hand

wheel toward you to bring bobbin thread up

through fabric. Hold both thread ends and

lower needle Into fabric.

3. Stitch, outlining or filling in design with zig

zag stitches. For a smooth, satiny surface,

place parallel stitches close together, mov

ing hoop slowly and steadily. For an irregu

lar texture, move the hoop more rapidly,

allowing some stitches to overlap.

A series of bar-tacks can be used to form

spray-like leaves or flowers. This technique

adds variety and lightness to many designs.

Leaves and petals formed in this way may

carry the thread from one bar tack to the next.

This carrying thread eliminates tying of the

thread ends.

FLOWER EliBROIOERY

Pattern; zig-zag §

® Stitch width: to suit fabric

® Feed cover needle plate

a No presser foot

Preparation

Trace design on right side of fabric. .P.*'epare

the area to be embroidered using an underlay

if the fabric is soft. Place the work in an

embroidery hoop approximately 7 inches

(18cm) in diameter. If the design to be

embroidered covers a large area, it will be

necessary to reposition the work in the hoop

as each section is completed.

The darning and embroidery foot may be used

to assist fabric control.

Procedure

1. Position work under needle and lower

presser bar to engage tension.

Compfeted Flower Design

liiiiiii

45

Page 48

6. MACHINE STITCH PATTERNS

adjusting stitches

GUIDING AND SUPPORTING FABRIC

Most fabrics of stretch or knit construction

need only to be guided in front of the presser

foot when you use one of the stretch stitches.

Some fabrics —nylon tricot and elasticized

fabrics, for example — do require support

while being stitched.

o For nylon tricot and similar synthetic knits,

apply gentle tension by holding the seam in

front and back of the presser foot as you

sew.

« For elasticized fabric, stretch lace, and knits

with an unusual amount of elasticity, apply

firm tension in front and back of the presser

foot to stretch the seam as the stitches are

being placed.

Applying Firrri Tension

MAX

mnm.

CAUTION: Do not puli the fabric while you are

stitchi,ng as this may deflect the needle, caus

ing it to break.

ADJUSTING PRESSURE WHEN

SEWING KNIT AND STRETCH FABRIC

Some knit and stretch fabrics, because of

their structure, require either more or less

than normal (NORU) presser-bar pressure to

feed smoothly and evenly.

e For thick, soft or very stretchy knits,

decrease pressure by turning dial from

NORM (normal) toward DARN.

e For nylon tricot, ciré and similar hard sur

face synthetic knits, increase pressure by

turning dial from NORM (normal) toward

MAX (maximum).

46

Page 49

handling special fabrics

Many fabrics, because of their construction or finish, demand special attention in sewing. Tech

niques used in stitching and handling, and choice of machine accessories, will vary with the

fabric. Let the table below guide your selection.

FABmc-HAmLmQ table

FABHiC

leptiie

veive:,