SINGER 115 User Manual

SINGER

Sewing iVtacliine

115

THE SING

COMPANY

SINGER

A Trademark of THE SINQER COMPANY

sewing machine model 115

AS THE OWNER OF THE SINGER* 115 ...

you have a completely new smooth running machine

which offers you a new world of sewing enjoyment.

TO GET THE MOST ENJOYMENT FROM

YOUR SINGER...

take advantage of the free sewing lessons to which

you are entitled. Skilled, SINGER-trained teachers

will give you personal guidance and assistance in the

fundamentals of home sewing.

SINGER SERVICE

Wherever you go you will find expert, dependable

SINGER* Service close at hand. SINGER is interested

in helping you keep your SINGER Sewing Machine in top

running condition. That is why you should always call

your SINGER SEWING CENTRE if your machine ever

requires adjustment or repair. Only from your SINGER

SEWING CENTRE can you obtain the services of a

trained SINGER mechanic and warranted SINGER*

parts.

EVERYTHING FOR THE WOMAN WHO SEWS

The answer to your sewing needs is at your SINGER

SEWING CENTRE. There you will find a wide choice

of sewing aids, notions, sewing information and services.

Look for the famous red **S’’ and SINGER trademarks

on your SINGER SEWING CENTRE and the ever ready

SINGER Service Car. Look under SINGER SEWING

MACHINE COMPANY, in phone book, for address

nearest you.

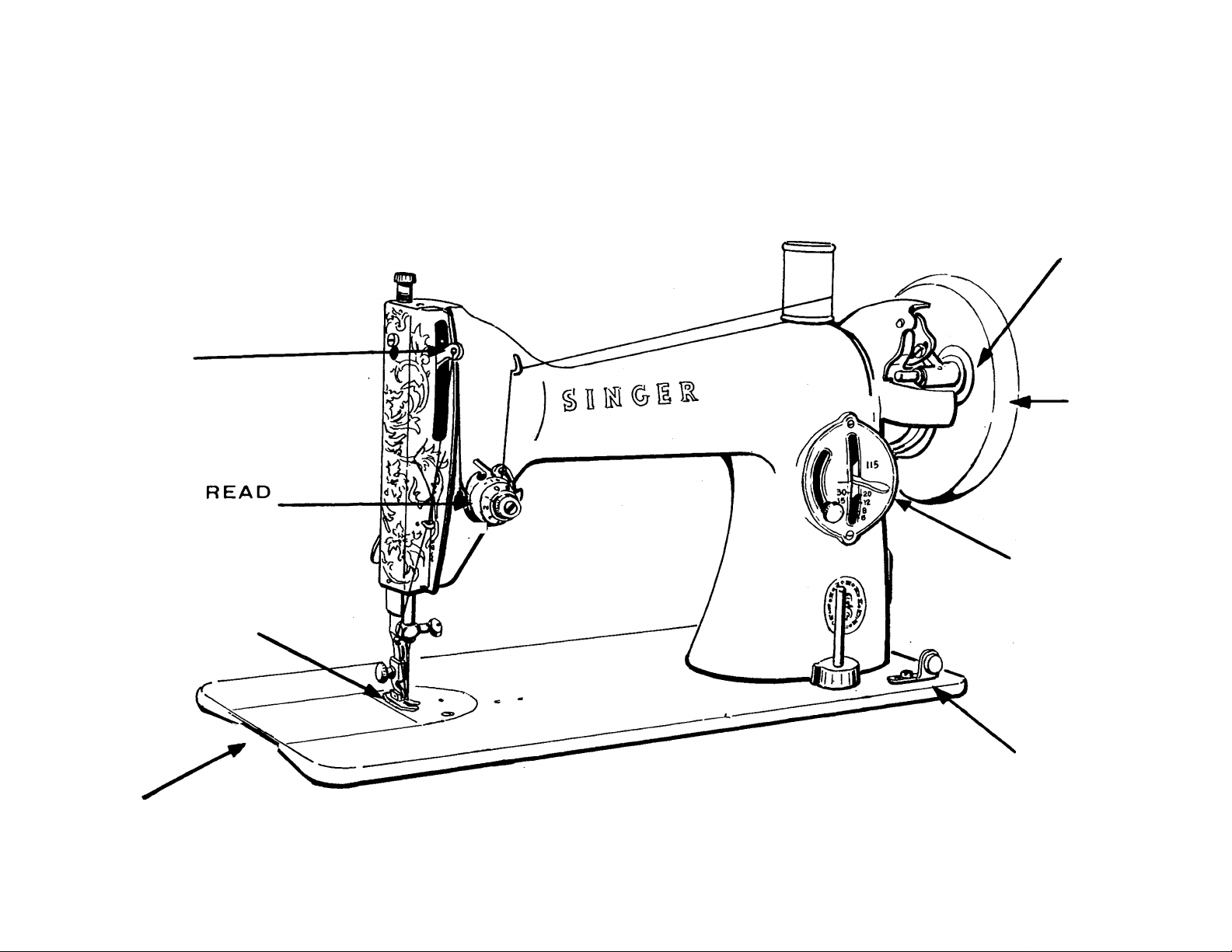

TAKE-UP

LEVER

NEEDLE TH

TENSION

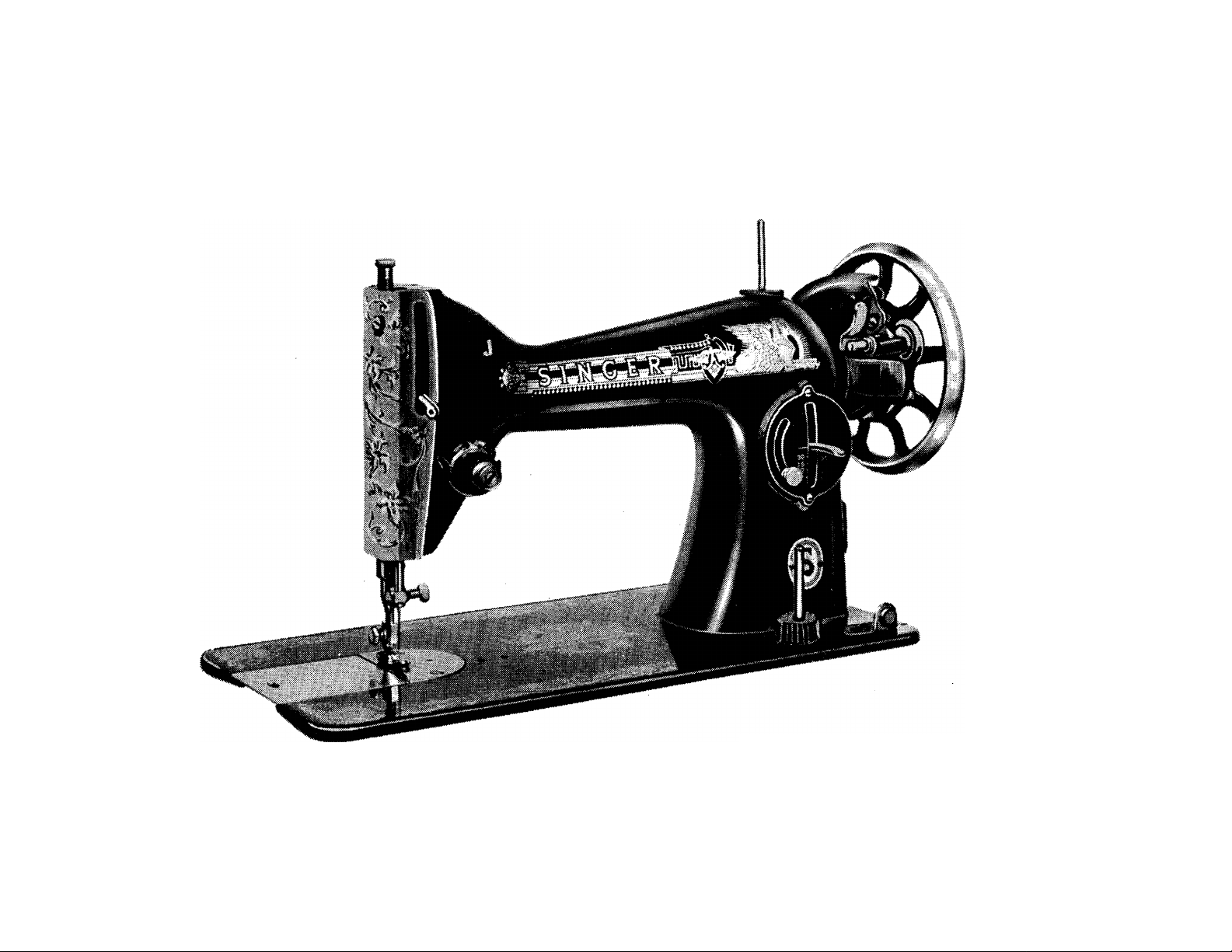

PRINCIPAL PARTS OF MACHINE 115

BOBBIN

WINDER

HAND

WHEEL

STITCH

LENGTH

REGULATOR

THROAT PLATE

SLIDE PLATE

BOBBIN WINDER

THREAD GUIDE

NEEDLE AND THREAD SELECTION

The selection of thread should be based on the fabric to be stitched. The thread should

blend with the fabric in colour, fibre and size.

Silk and wool fabrics should be stitched with silk thread; cotton fabrics should be stitched

with cotton or cotton mercerised thread, etc. The thread must be of a size that will imbed

itself into the texture of the fabric. Thread that is too heavy for the fabric will remain on

the surface and become weakened by friction and abrasion when worn.

The selection of the needle should be based on both the fabric and^hread being used. The

eye of the needle must be large enough for the thread to pass freely through it. The blade

of the needle must be fine enough not to mar the fabric with too large a puncture, yet heavy

enough to pierce the fabric without binding or deflecting.

You will obtain best stitching results from your Sewing Machine if it is fitted with a

SINGER* Needle.

NEEDLES AND THREAD

This machine uses needle, Catalogue

2020 (15 x 1). Sizes 11, 14, 16, 18,

19 and 21.

For perfect stitching, select correct needle

and thread to correspond with fabric. Be

sure to use like threads for both needle and

bobbin.

NEEDLE INSERTION

6

I I

f ?

Raise needle bar to highest point by turn

ing hand wheel toward you.

Loosen needle clamp screw.

Insert needle upward into clamp as far as

it will go, with flat side of needle to right

and long groove to left.

Tighten needle clamp screw.

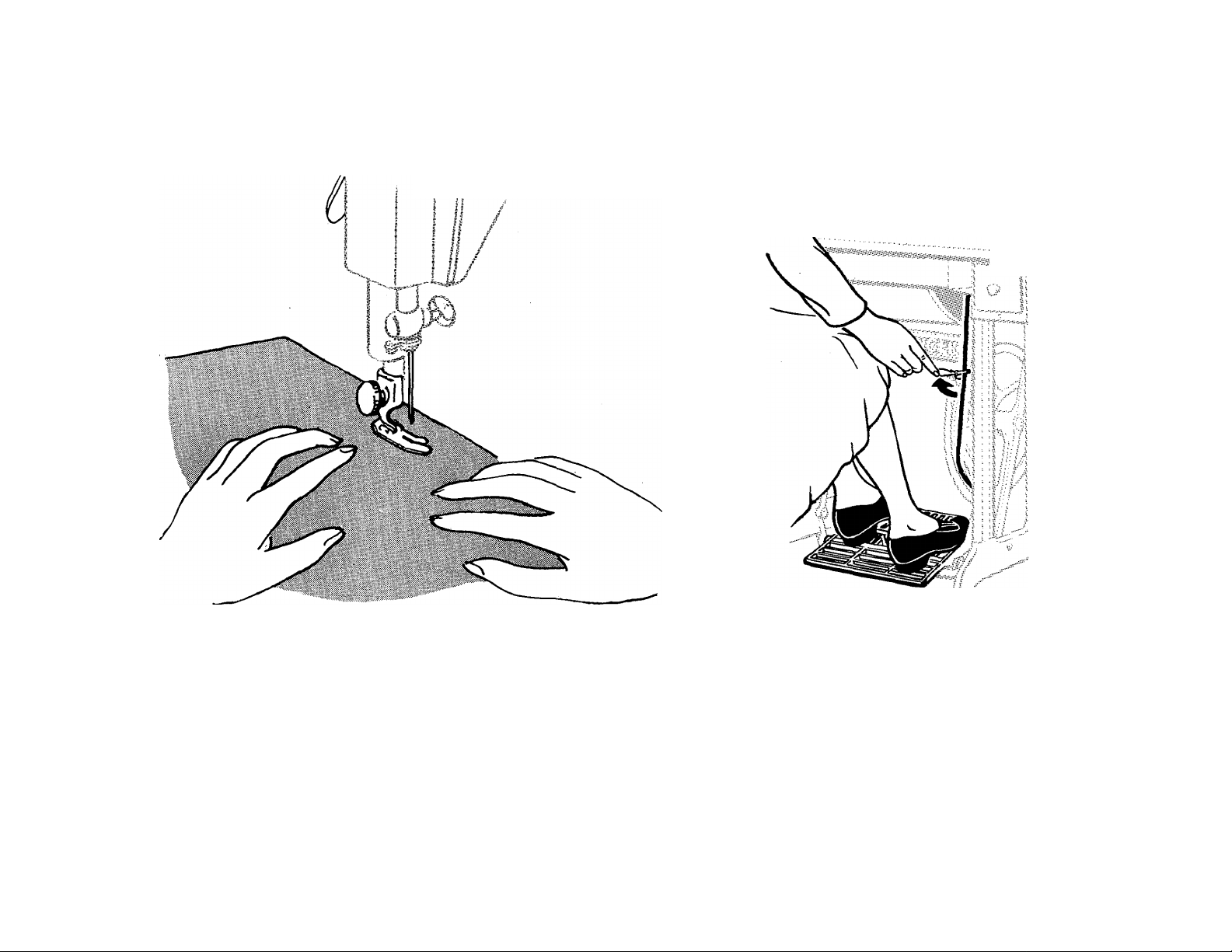

TO OPERATE THE MACHINE

Treadle Drive

Raise presser foot.

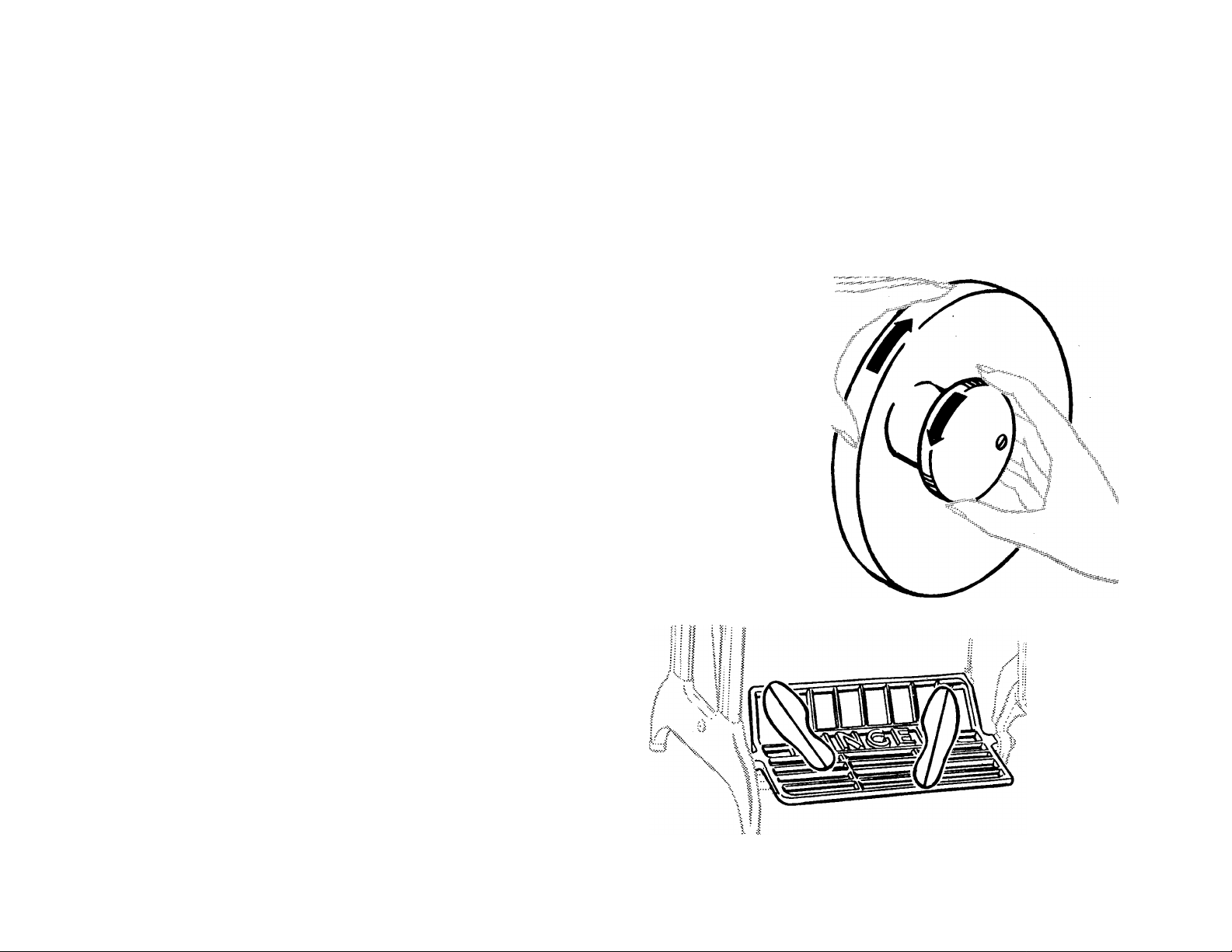

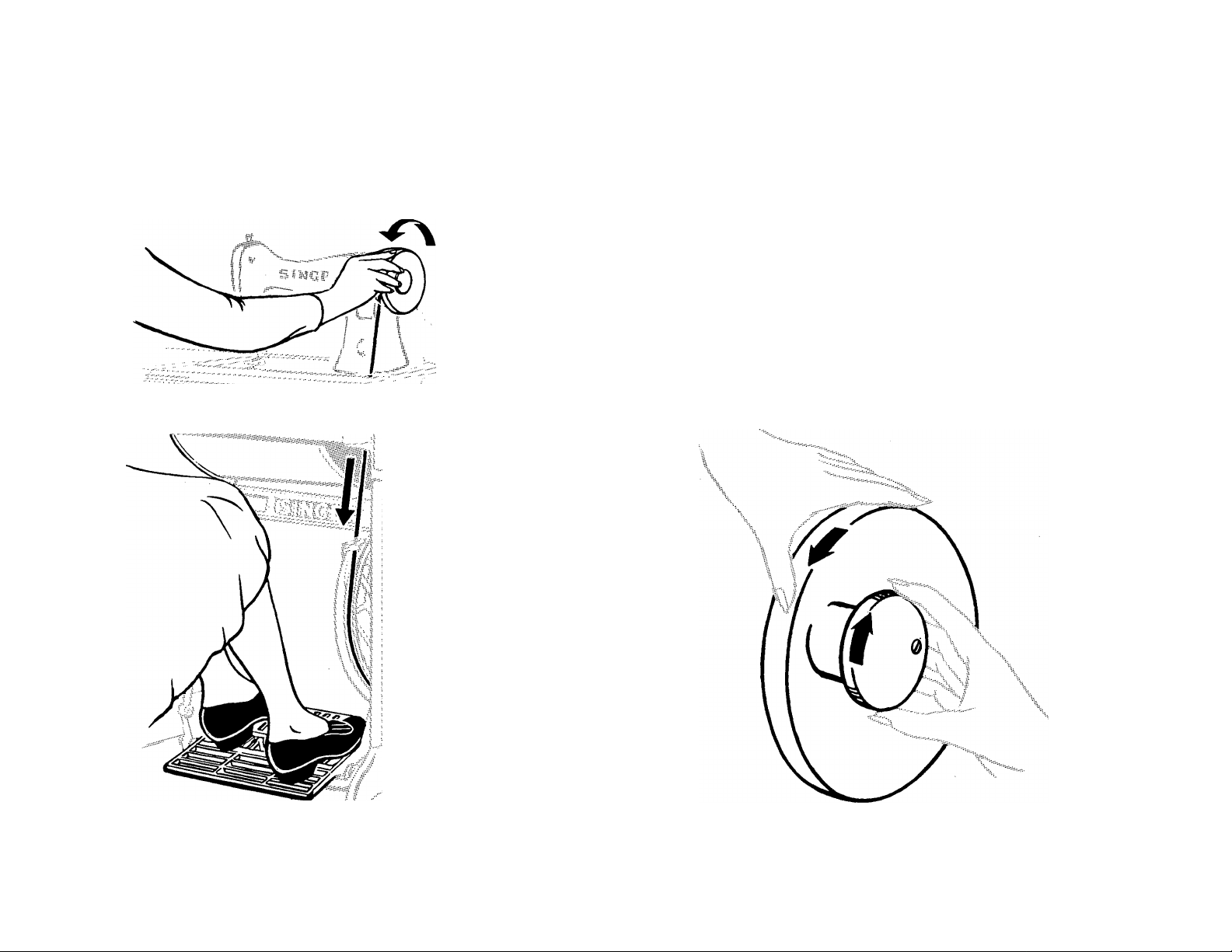

Loosen hand wheel by turning stop motion

screw over toward you.

Place both feet on treadle.

\\

'V

Treadle Drive (Cont’d)

8

TO OPERATE THE MACHINE (Cont’d)

Turn hand wheel over toward you and allow

feet to move freely and lightly with motion

of treadle.

Practise this motion until you are able to

restart machine with hand wheel turning

over toward you.

Tighten stop motion screw.

9

TO OPERATE THE MACHINE (Cont’d)

Belt Shifter

Place material under presser foot and

lower the presser bar.

Operate machine (without thread) until

you become accustomed to guiding the

To disengage belt, operate treadle and

move belt shifter as shown.

To engage belt, work treadle slowly with

hand wheel turning over toward you.

material.

NOTE; Belt tension should be only heavy enough to keep belt from slipping.

Hand Attachment

10

TO OPERATE THE MACHINE (Cont’d)

• Fasten attachment with thumb nut.

SPRING

STUD

LOCATING

BRACKET

THUMB

NUT

Pull spring stud and position hand lever in

• Place material under presser foot and lower

foot.

• Operate machine (without thread) by turning

handle over from you until you become

accustomed to guiding material with left hand.

socket.

Assemble hand attachment to machine arm

locating bracket on bracket seat, and at

same time positioning hinged finger in one

of slots in hand wheel as shown above.

11

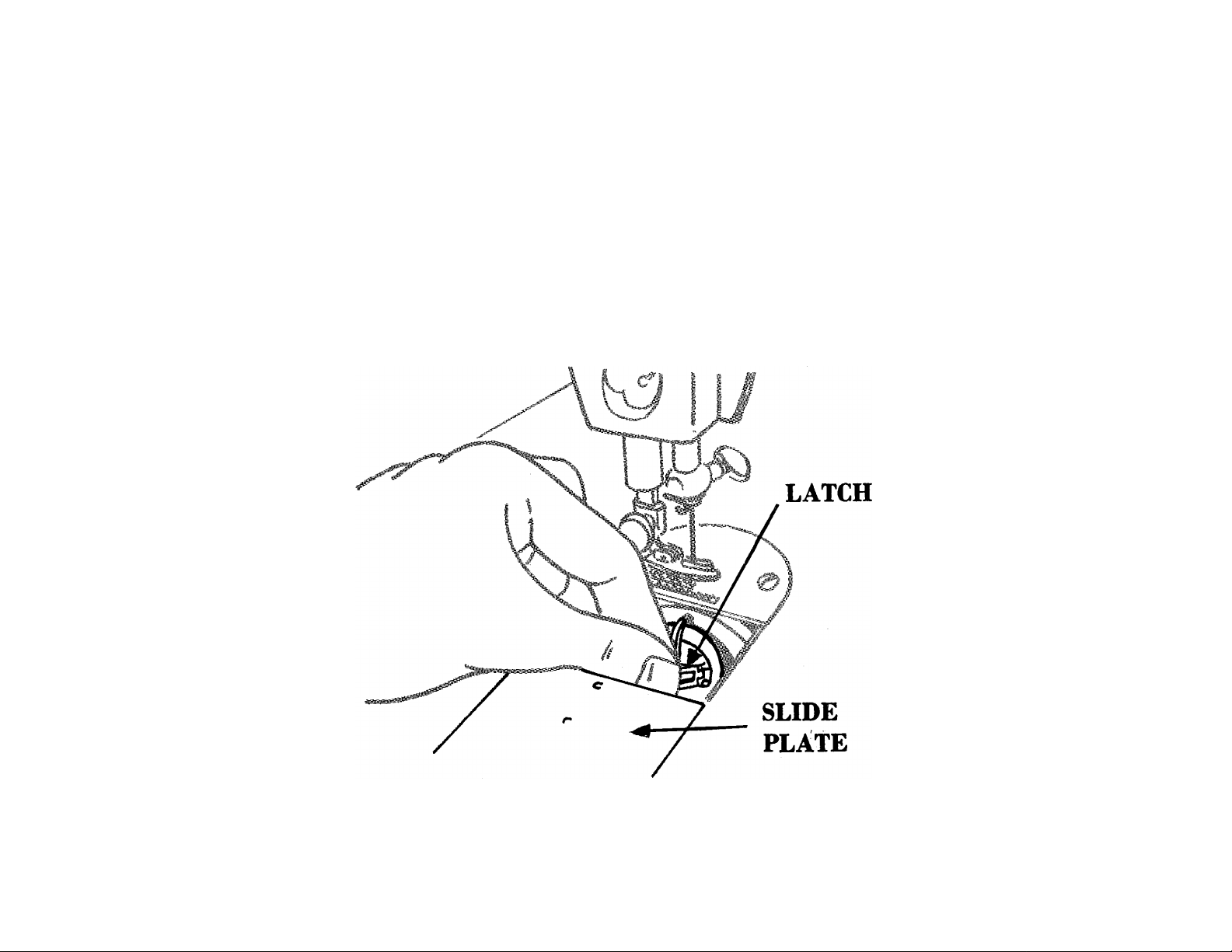

REMOVING BOBBIN CASE AND BOBBIN

Raise thread take-up lever to its highest position.

Open slide plate.

Grasp bobbin case latch and withdraw bobbin case.

Release latch and bobbin will drop out.

^_^-■■-V’

12

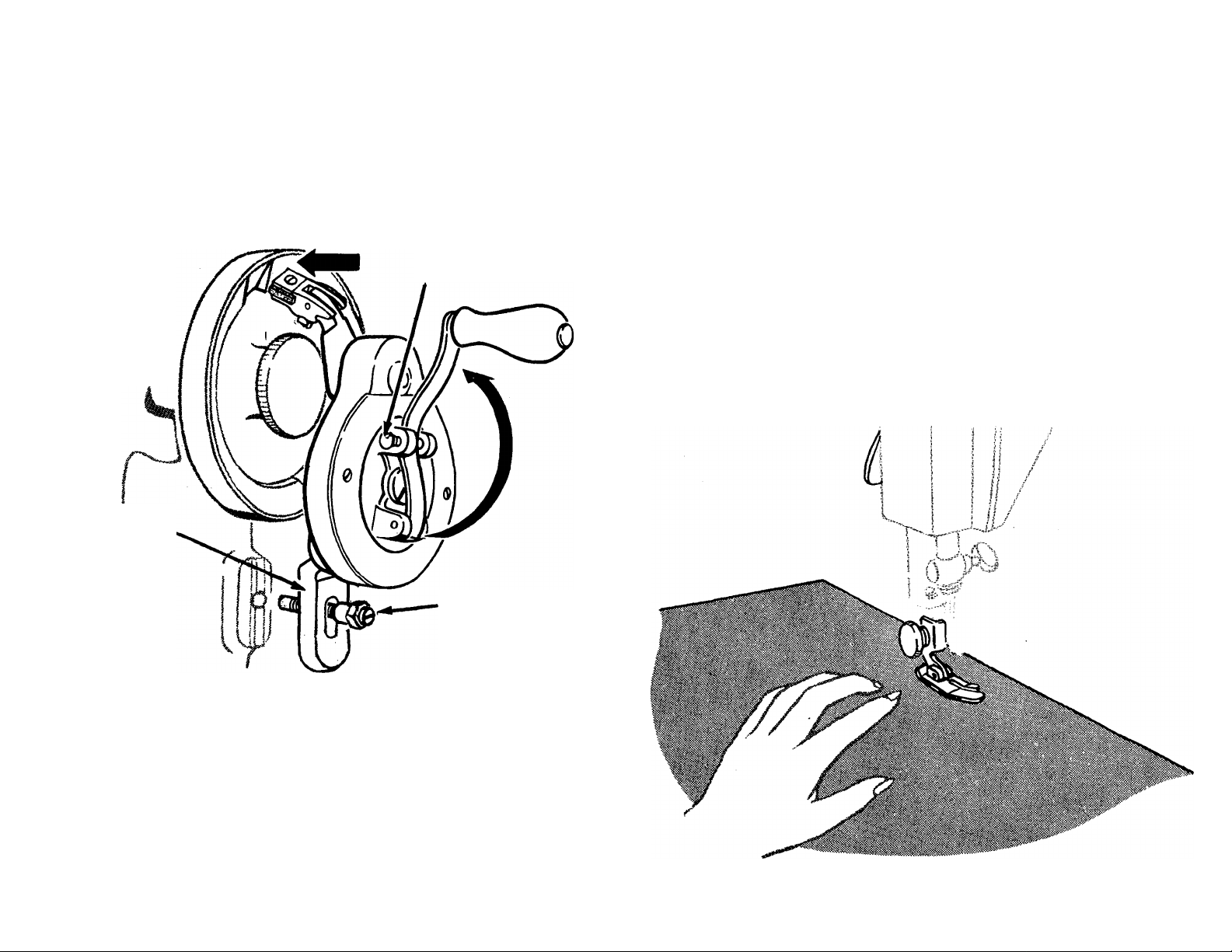

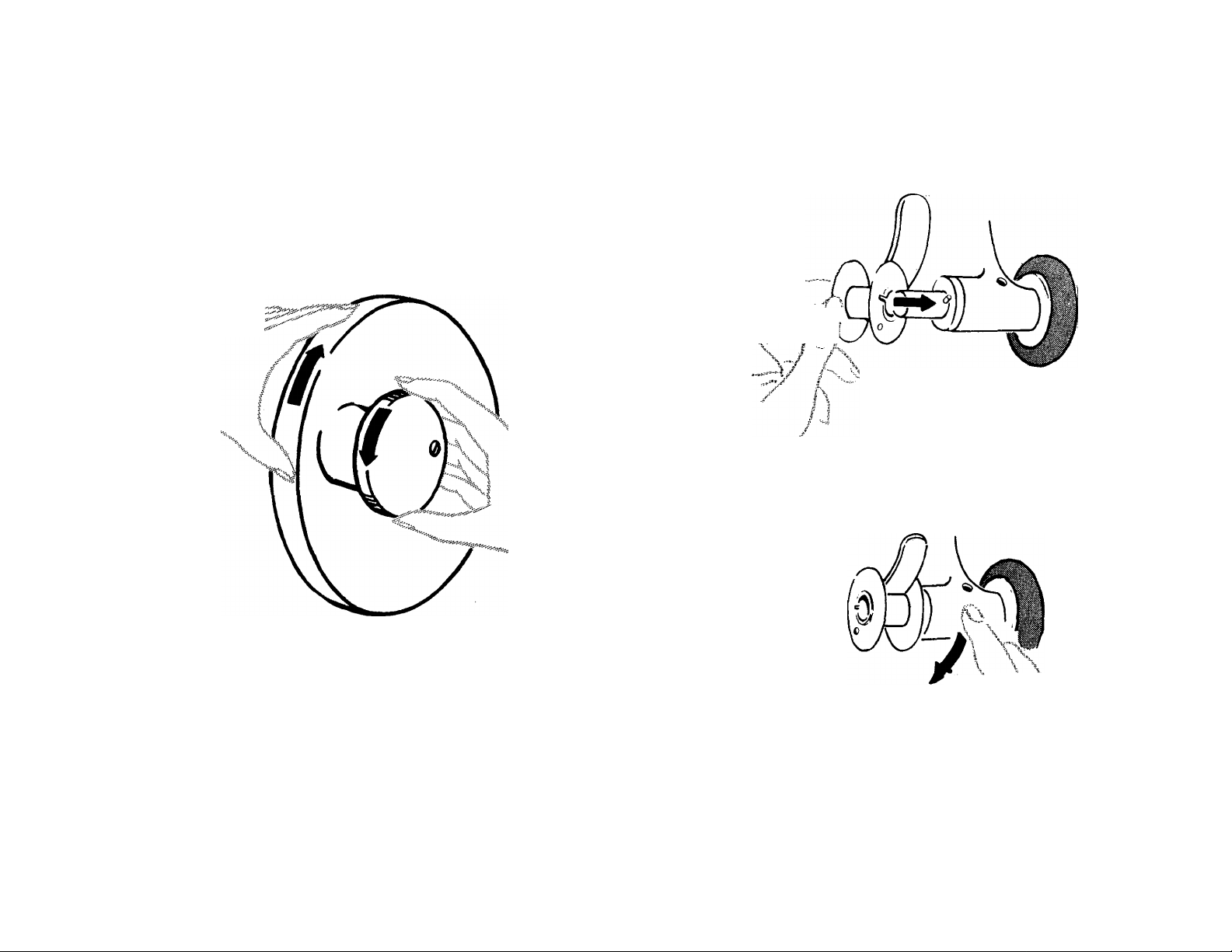

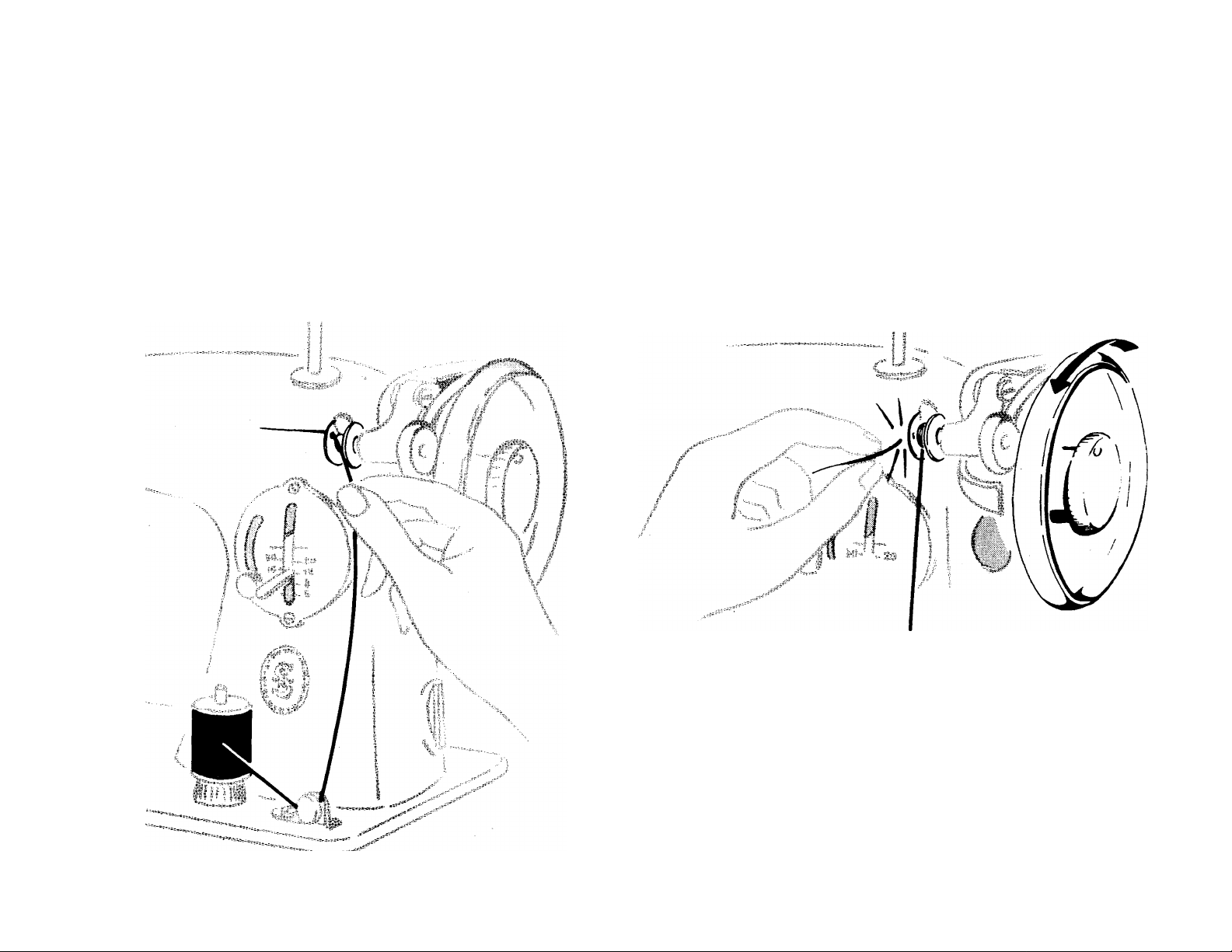

WINDING THE BOBBIN

Loosen stop motion screw with right hand.

Place empty bobbin on spindle.

\Y'\ /\ \

‘i \-'\ \ Irx

\ U

Press bobbin winder down against hand

wheel.

13

WINDING THE BOBBIN (ContM)

i

Place spool of thread on spool pin.

Thread between tension discs and through

bobbin as shown.

Hold end of thread and start machine. (End

of thread will break off after a few coils have

been wound on bobbin.)

14

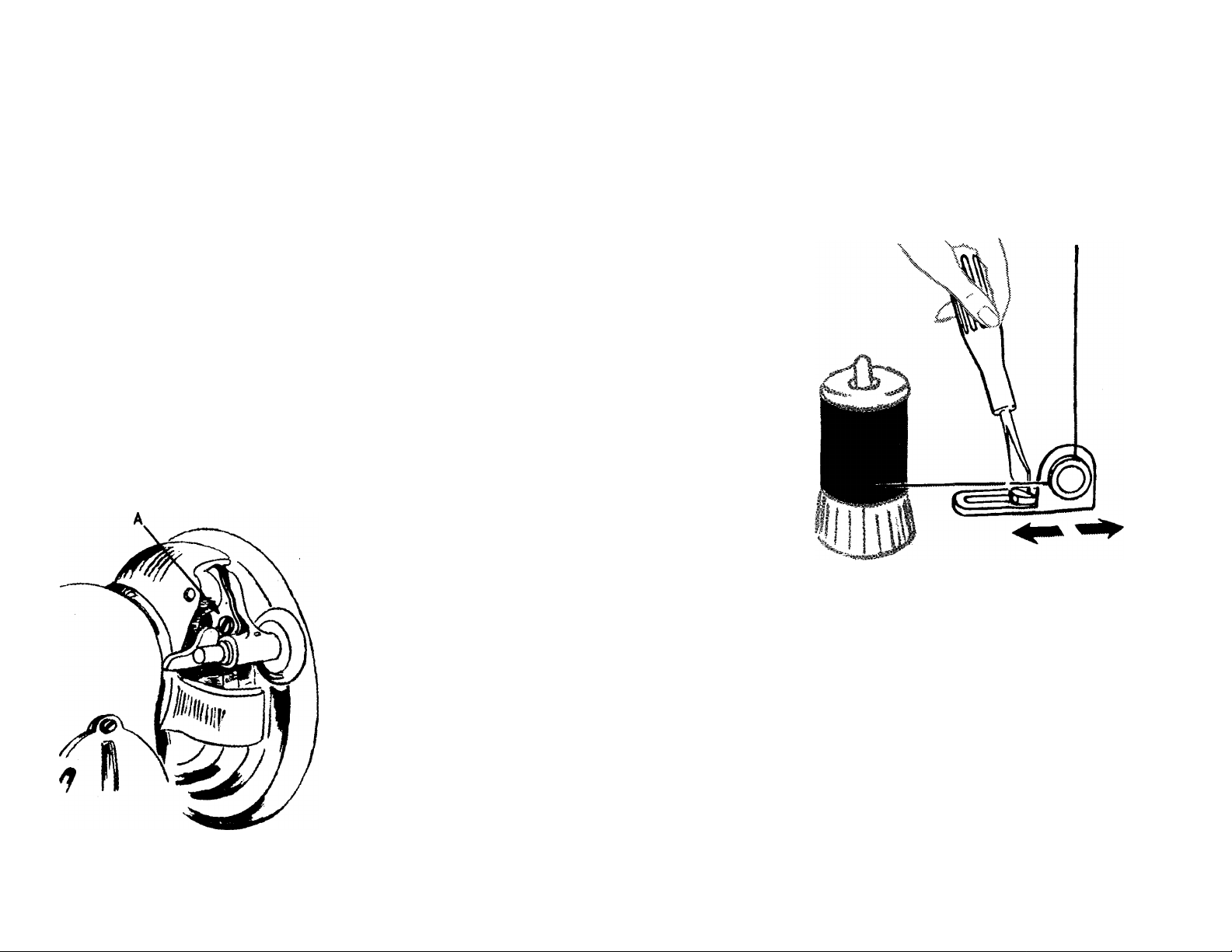

WINDING THE BOBBIN (Cont’d)

When bobbin is full

I Stop machine.

I When bobbin is full the bobbin winder

will lift away automatically.

I Remove bobbin and tighten stop motion

screw.

TO CONTROL AMOUNT OF THREAD ON BOBBIN

i Loosen screw which holds

stop latch to bobbin winder

frame (A).

1 Press bobbin winder frame on

handwheel for more thread

on bobbin

1 Lift bobbin winder frame for

If thread doesn’t wind evenly

Loosen screw which holds

bobbin winder tension

bracket to machine bed.

Move bracket to left if

bobbin winds high on

right; move to right if

bobbin winds high on left.

less thread on bobbin.

1 Tighten stop latch screw.

Tighten tension bracket

screw.

15

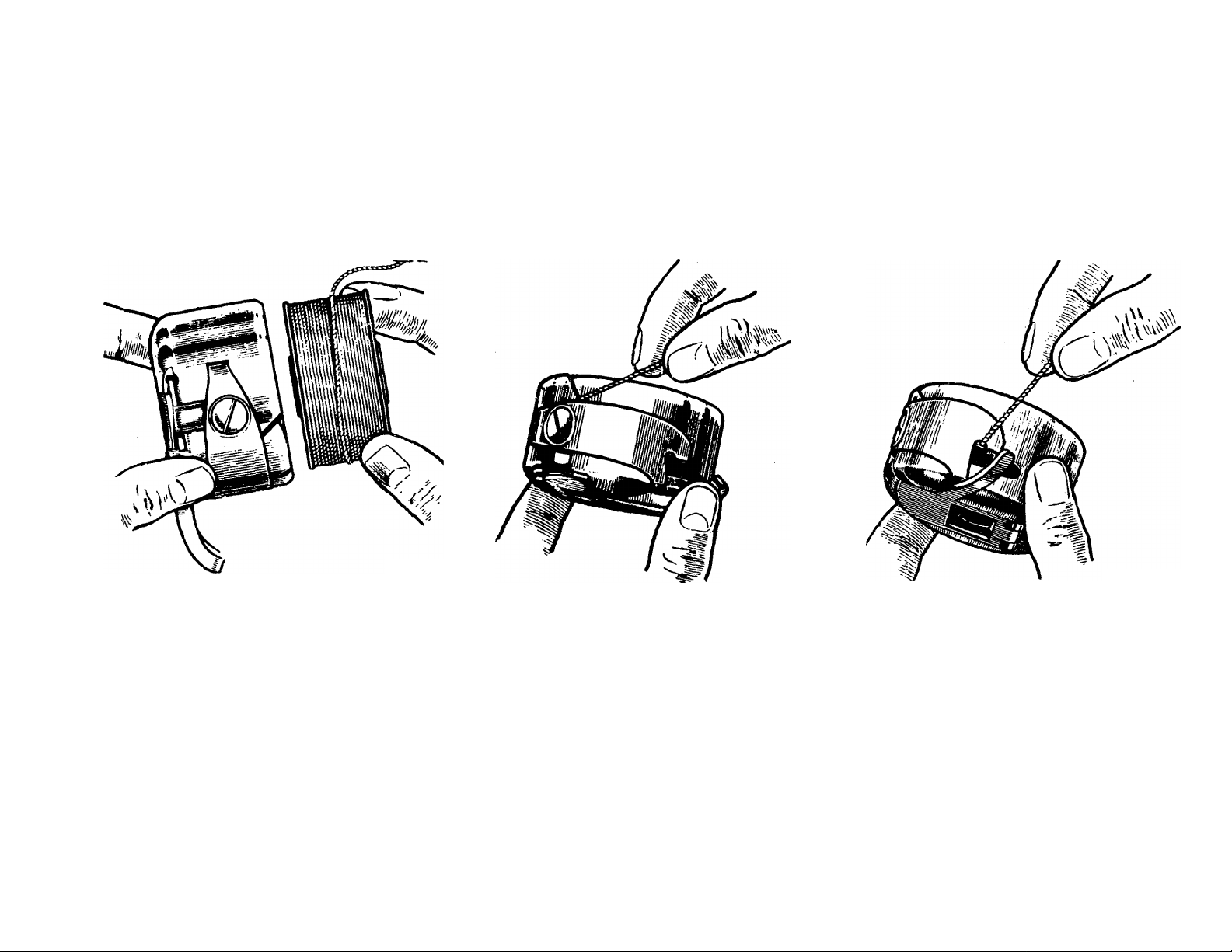

THREADING THE BOBBIN CASE

K2692

Hold bobbin case and bob

bin so that thread leads off

in direction shown above.

K2693

Place bobbin into bobbin

case. Pull thread into

slot.

K2694

Pull thread under tension

spring and into slot at

end of spring, as shown.

Loading...

Loading...