Page 1

СО

L

ÄPWee*^*ff

г^

1^

РШШРЩЩвЩЯР

ШШШДй

ш

о

Z.

ш

шт^шштЁ^тштшттт^^^шшт^^

шшшт^^тштшйш^^^^^^

.. .

......

......................................^ -.,^:.^-.1-.::....1.:. ■■....

....

,.х /...— :

...

............... ..--«ь

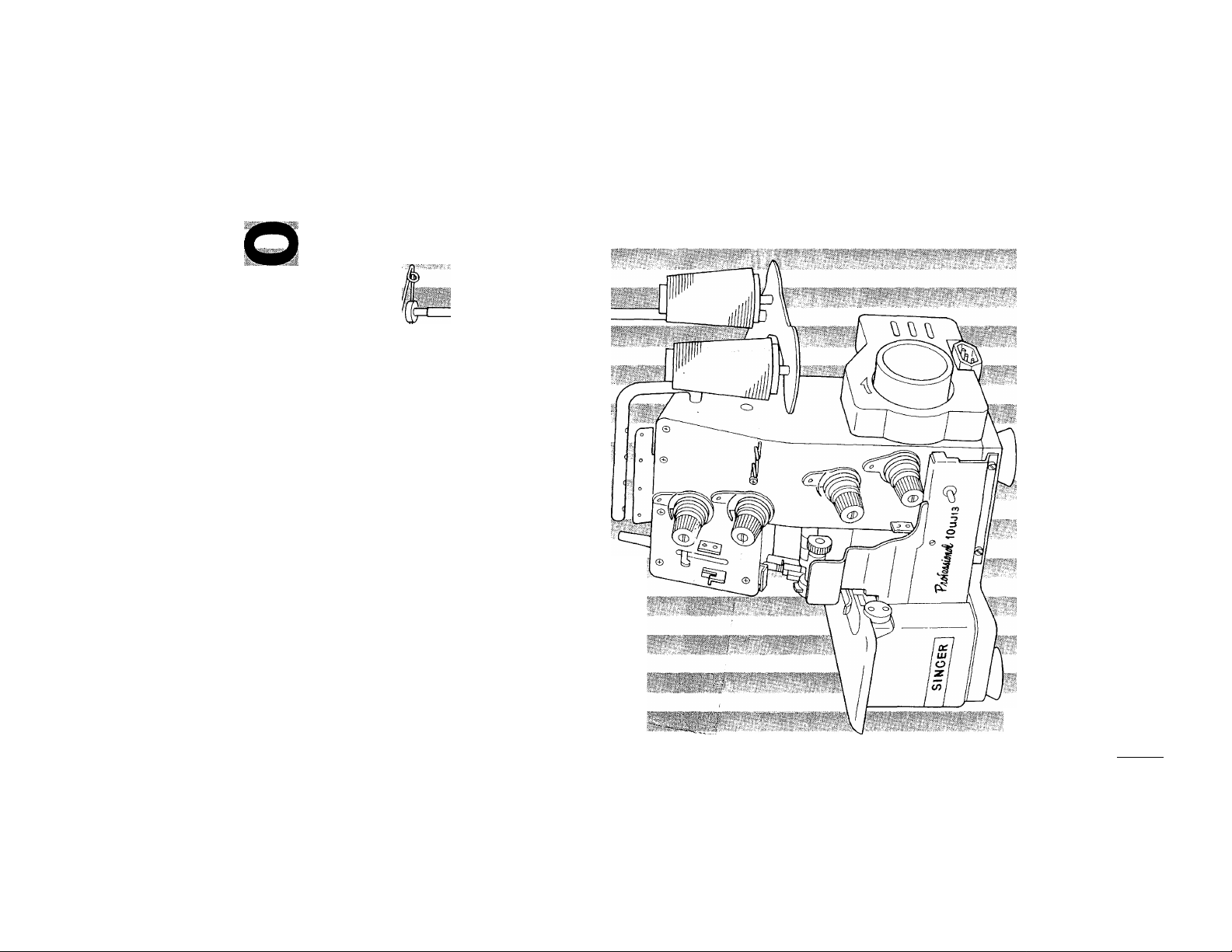

Page 2

Page 3

PREFACE

Thank you for your purchase of this machine.

Please refer to this booklet for proper use and optimum service of this

machine.

CONTENTS

1. Setting up the machine ...................................................................... 1

1-1 Correct installation of the motor

1- 2 Connecting the controller to the motor

2. Overedging .......................................................................................... 3

2- 1 How to thread correctly .............................................................. 3

2-2 Preparation and checking prior to sewing .................................. 5

2- 3 Sewing ........................................................................................ 5

3. Double chain stitching (straight seaming)

3- 1 Changing from overedging to double chain stitching

3-2 How to thread correctly .............................................................. 7

3- 3 Sewing

4. Interlocking (Safety stitching)

4- 1 Changing from double chain stitching to interlocking

4-2 How to thread correctly ............................................................ 10

4- 3 Sewing ...................................................................................... 10

5. Thread tension adjustment ............................................................... 11

5- 1 How to adjust the overedging seams ...................................... 11

5-2 How to adjust the double chain stitching seams

6. Presser foot adjustment .................................................................... 13

7. Adjusting stitch length ........................................................................ I3

8. Sewing speed ................................................................................... 14

9. How to install the needle.................................................................... 14

10. Replacing the cutting knives ......................................................... 15

11. Lubrication ......................................................................................... 18

12. Checking and adjustment

13. Applicational notes ............................................................................ 17

13-1 How to set the presser foot for sewing knitted material

(used only for double chain stitching)

13-2 Double-hinged presser foot ..................................................... 17

13-3 Removing stitches of double chain stitching seams

14. Supplement ....................................................................................... 19

15. Changing the carbon brushes of the motor ....................................... 20

16. Specifications ................................................................................... 21

17. Table showing relationship between thread and cloth

.......................................................................................

............................................................

..................................................................

................................................

......................................

.........................................

................

................

.....................

.....................................

...............

.....................

1

2

q

6

8

9

9

12

18

17

18

22

Page 4

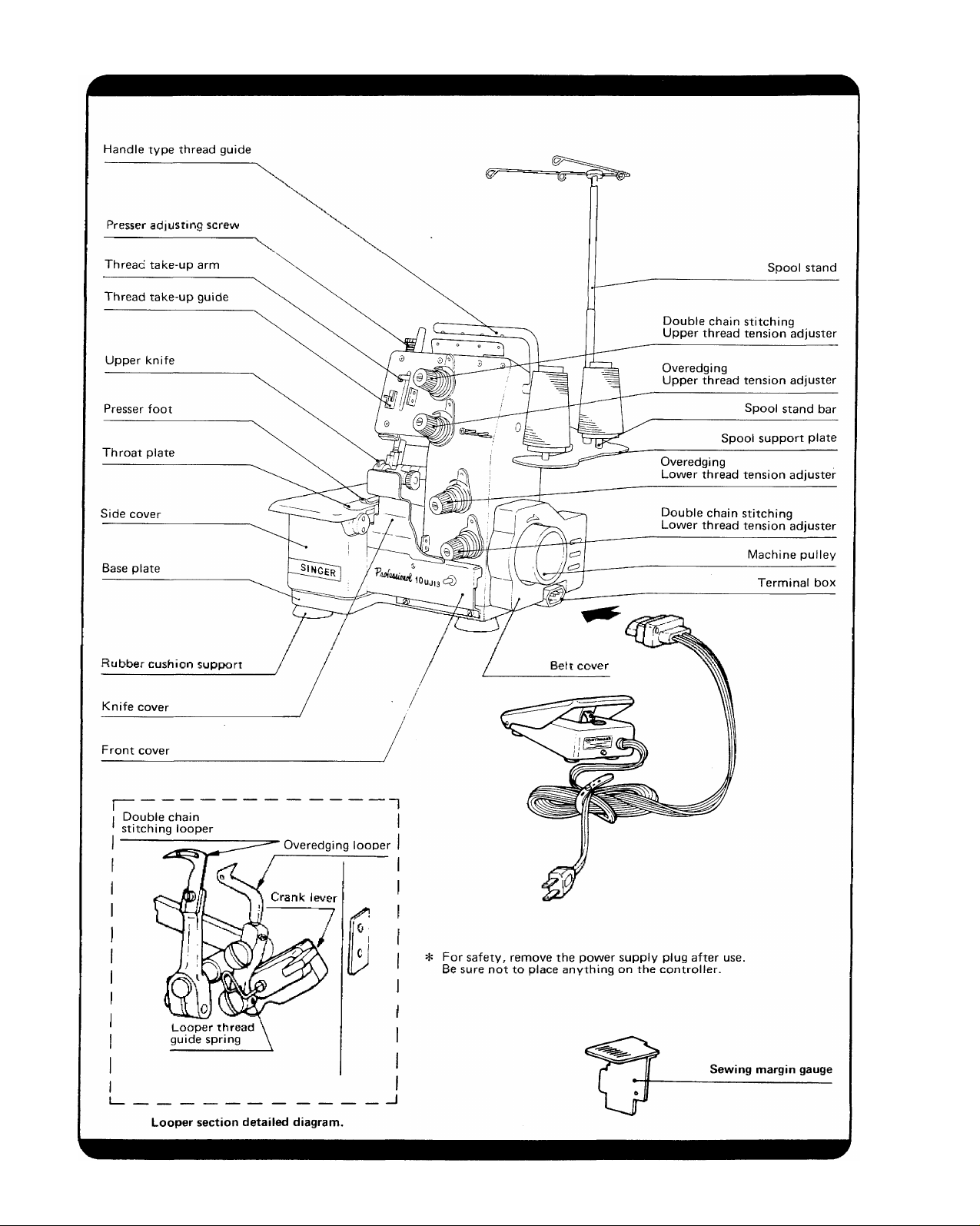

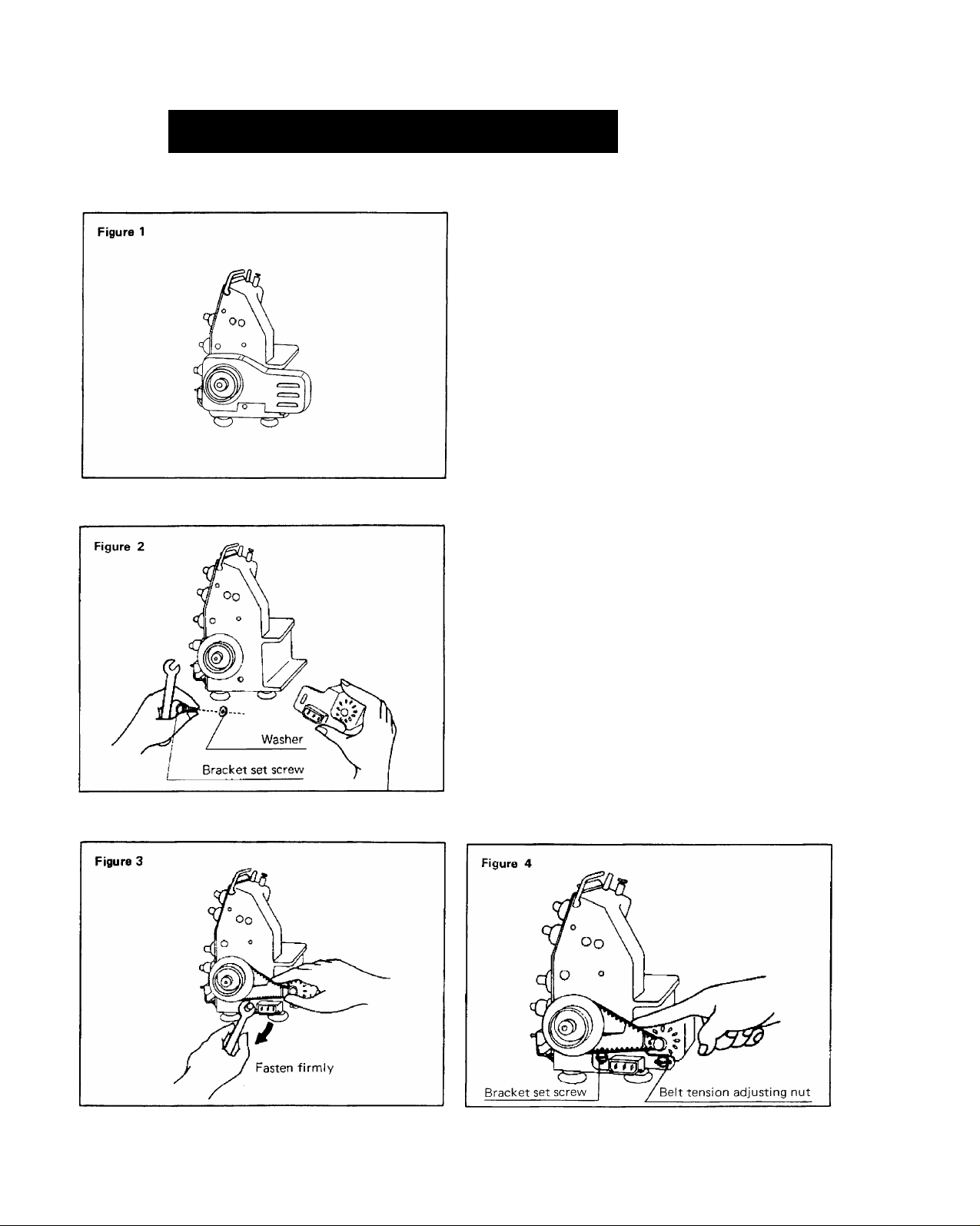

SETTING UP THE MACHINE

It is important that this sewing machine be set up

in the correct manner before use,

1-1 Correct installation of the motor

• Loosen the two belt cover screws and detach

the belt cover.

• The bracket set screw {Figure 2), bracket set

washer (Figure 2) and the belt are packed in

this set and attached to the machine body

by fastening the set screw while setting the

belt as shown in Figure 3.

Belt tension is considered adequate, if it

bends slightly when pressed by finger as

shown in Figure 4, When the belt tension is

not adequate, further adjust the tension by

moving the belt tension adjusting nut

(Figure 4) to the right or left.

• Replace the belt cover.

Page 5

Figure 5

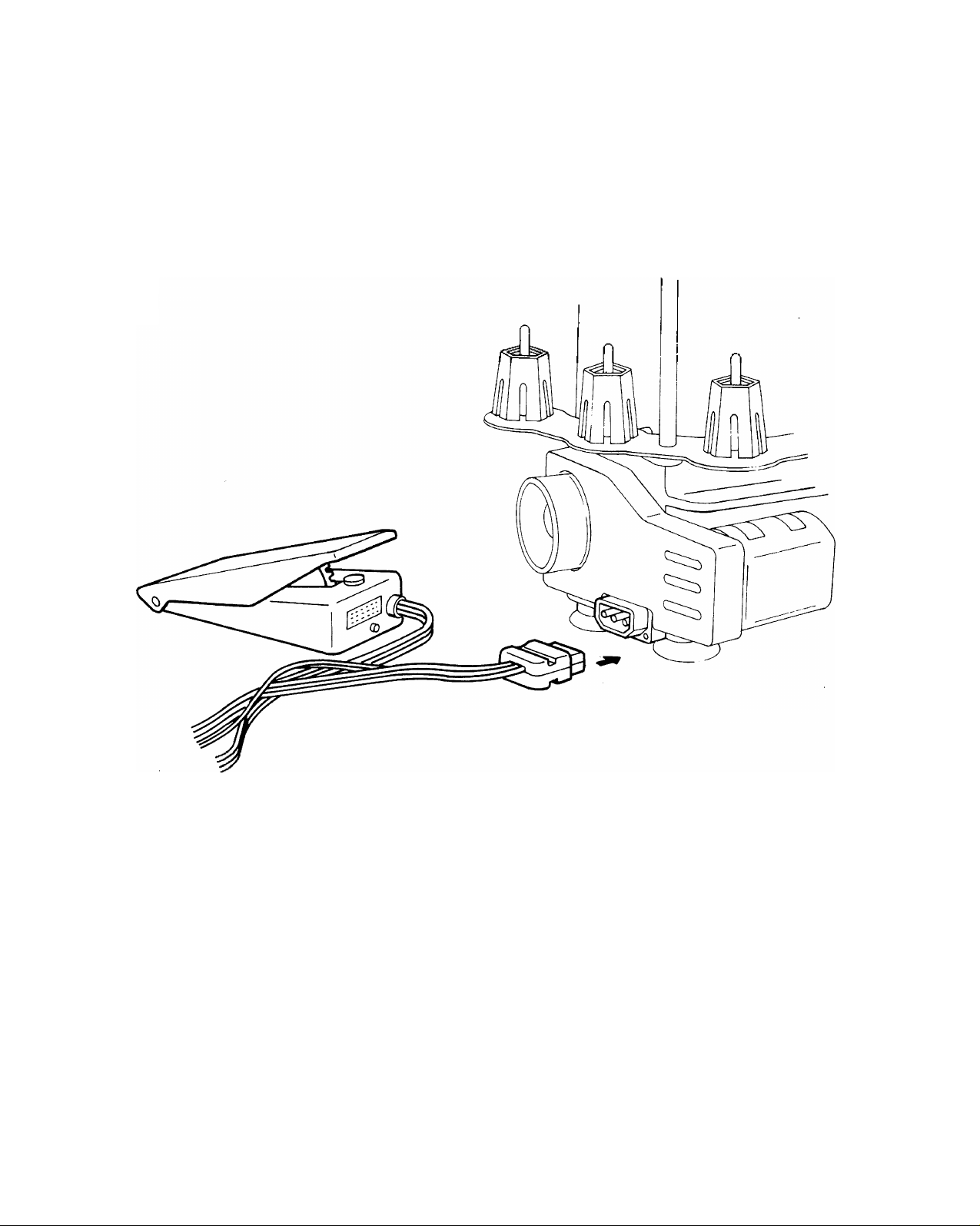

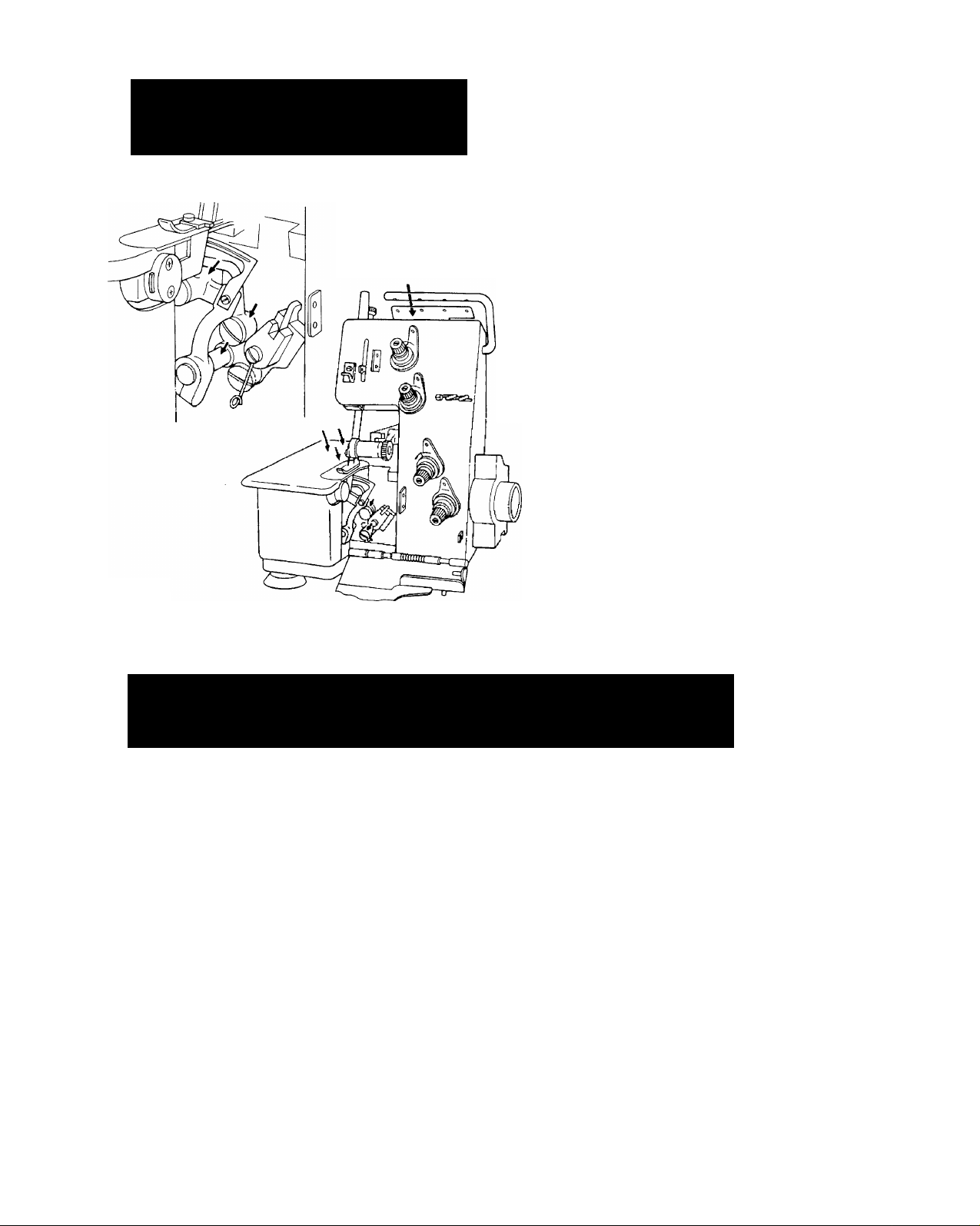

1-2 Connecting the controller to the motor

Connect the controller socket as shown in

Figure 5.

Next, insert the plug into the power source.

This machine runs faster when the controller

pedal is depressed with strong force, and the

speed decreases when the controller pedal is

lightly depressed.

*For safety, remove the power supply

plug after use.

Be sure not to place anything on the

controller.

Page 6

OVEREDGING

2

2-1 How to thread correctly

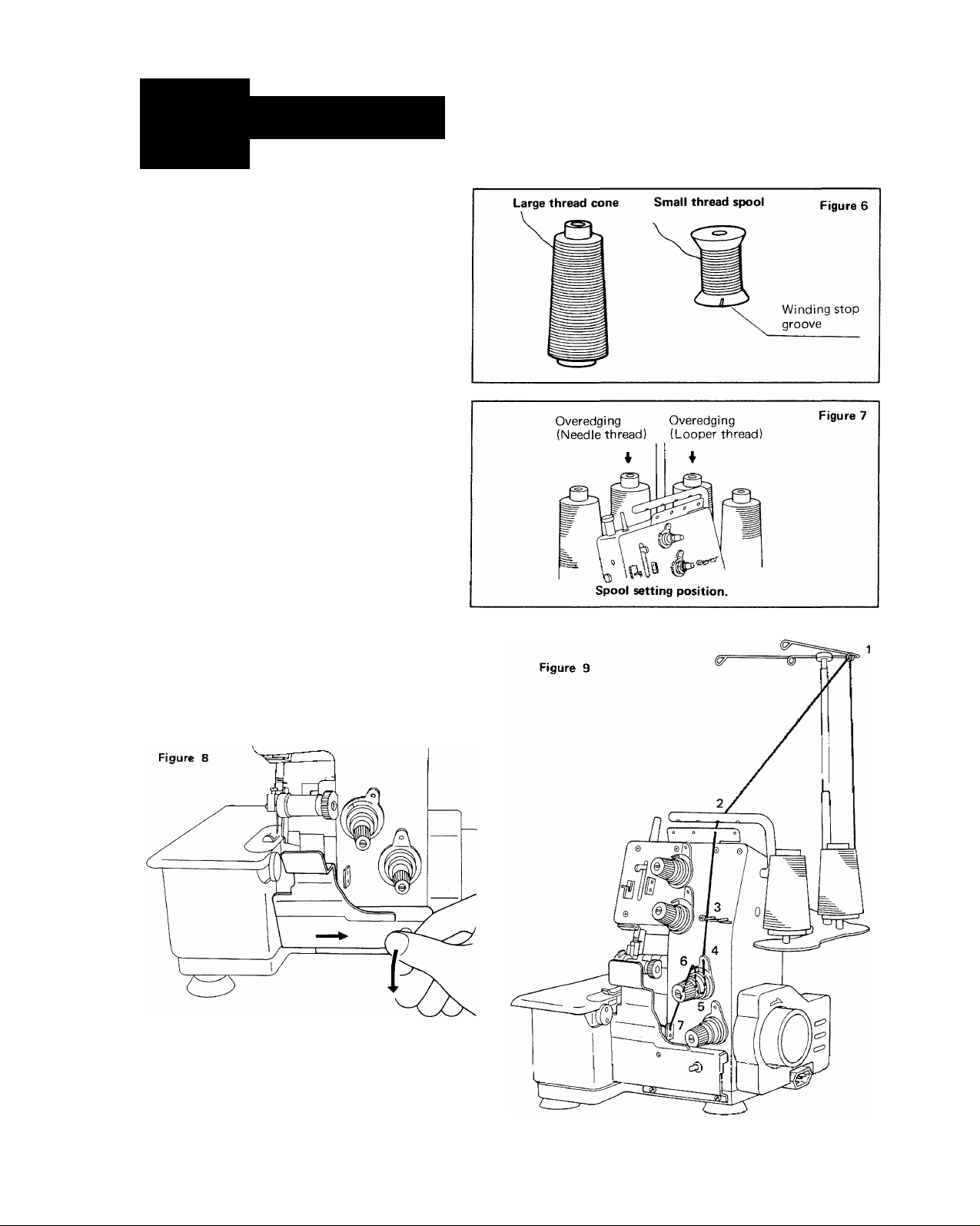

(1) Spool setting

Large thread cones (Figure 6) are

generally used for this machine, how

ever, it is possible to use small thread

spools (Figure 6) as well. In this case,

it is required that the thread spool be

set in such a way that the winding

stop groove in on the bottom.

(2) Lower thread (looper thread) insertion

First, open the front cover as shown in

Figure 8.

Then, the thread should be inserted in

the order as shown in Figure 9. After

inserting the thread, close the front

cover.

* Threading for overedging is diagramed

in red inside the side cover.

First pull the knob to the right and

then push downward.

Page 7

Figure 12

8 Correct threading at looper section.

Figure 11

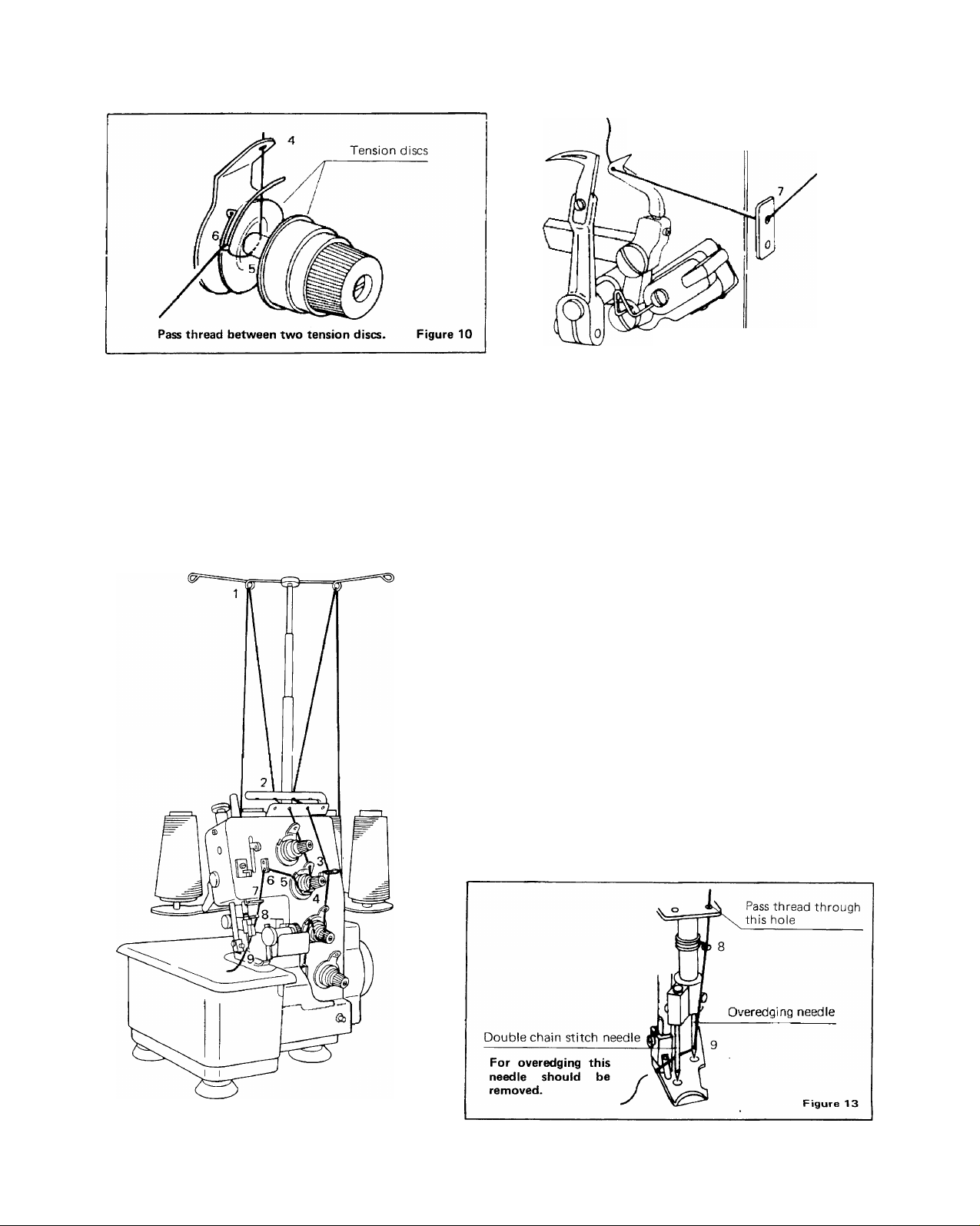

(3) How to thread the upper thread correct

ly (needle thread)

The thread should be inserted in the

order shown in Figure 1 2.

After inserting the thread from the

front to rear through the needle eye

while facing the machine, the end of the

thread should be pulled out about 10

cm.

* Tweezers are helpful for threading

needle eyes.

Note: For overedging, the left-hand

needle should be removed (see

page 14)

Page 8

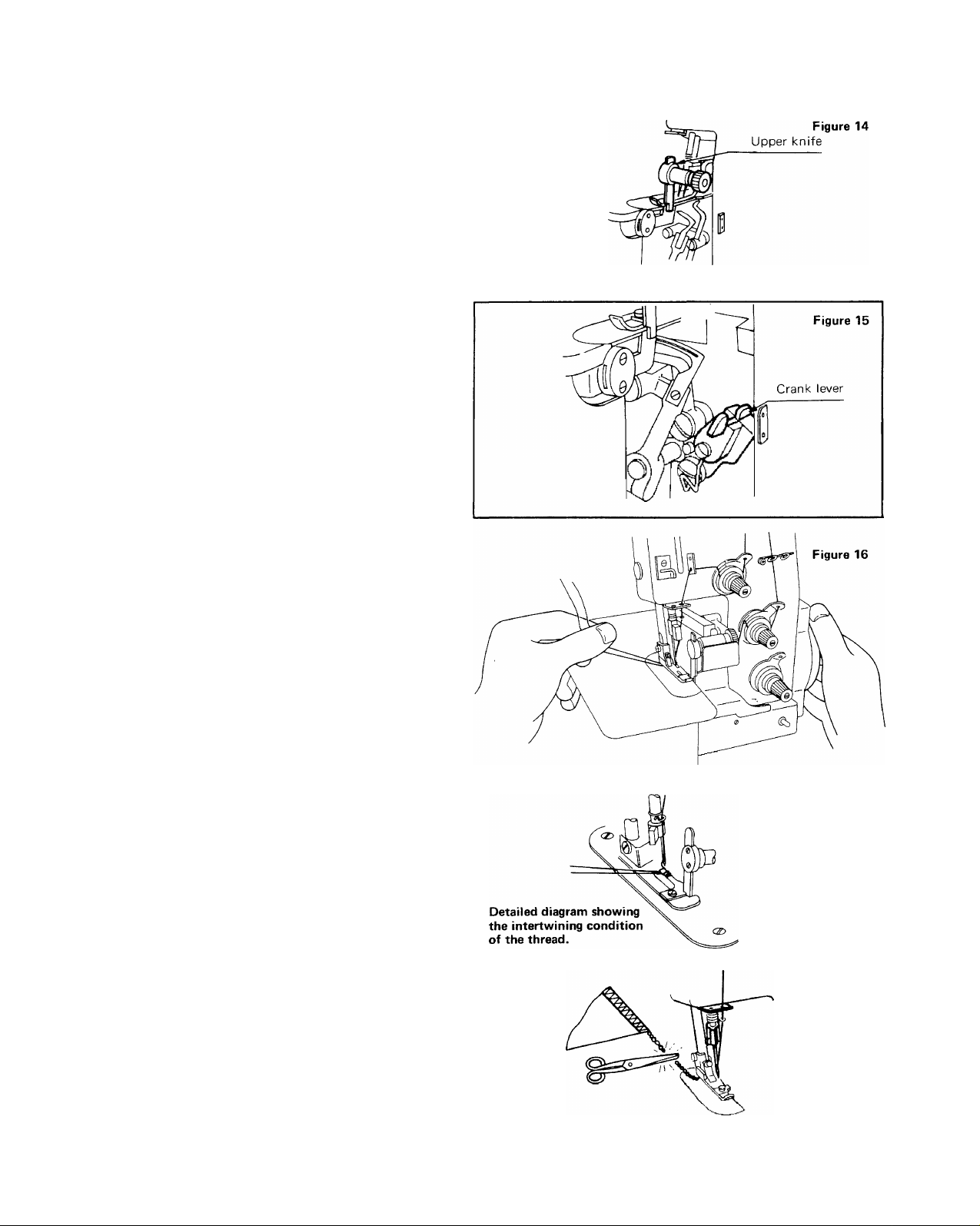

2-2 Preparation and checking prior to sewing

At the time of shipment, this machine is set

for interlocking. However, please recheck

the machine again in the order given below.

(1) Is the tip of the blade on the upper

knife facing in a downward direction?

(The knife should be in the position to

cut the cloth.) (Figure 14)

(2) Is the crank lever in the slot? (Figure 15)

(3) If the crank lever is not in the slot,

rotate the machine pulley by hand

placing the needle in the lowest posi

tion, At this point, the crank lever may

be set into the slot by pushing down

ward, thus allowing the looper for

overedging to operate.

2-3 Sewing

(1) After the completion of threading, hold

the ends of both the upper and lower

threads with the fingers of the left hand

creating a minor tension as shown in

Figure 16 and turn the machine pulley

with the right hand in the clockwise

direction.

Confirm that both threads are inter

twining. Then, set the cloth, and begin

to sew. (Figure 17)

(2) If the tension balance of the upper and

lower threads is not satisfactory, it is

possible that puckering will appear on

the cloth or that the seams will become

irregular.

Refer to the section "Thread tension

adjustment". (Page 11)

(3) After the seam is completed, continue

sewing about 3—5 cm at the end of the

cloth and cut the threads as shown in

Figure 18.

Figure 17

Figure 18

Page 9

DOUBLE CHAIN STITCHING

3

Figure 19

(STRAIGHT SEAMING)

3-1 Changing from overedging to double chain

stitching

It is required that all parts which are set for

overedging be changed for double chain

stitching in the order given below,

[Changing steps]

(1) Open the front cover and remove the

knife cover and set the sewing margin

gauge. Align the two round marks in

the same direction (Figure 19).

(2) As shown in Figure 20, press the knife

holder with a finger of the left hand and

rotate the upper knife holder knob

slightly upward with the right hand.

Then release the finger and rotate the

knob with the right hand until the

rotation comes to a stop with a click.

(3) Rotate the machine pulley by hand and

when the needle reaches its lowest

point, remove the crank lever from the

slot.

Then, the overedging looper will not

operate, (Figure 21)

(4) Remove needle from right side of needle

clamp and insert needle in left hand

needle hole in the clamp, (See Page 14)

Page 10

3-2 How to thread correctly

(1) Method for inserting upper thread

It is required that the thread be inserted

in the order shown in Figure 22.

After inserting the thread from the

front to the rear through the needle

eye while facing the machine, the end

of the thread should be pulled out for

about 10 cm from the needle.

^Tweezers are helpful for threading

needle eyes.

Tension discs

Pass thread between two tension discs. Figure 23

Figure 22

Page 11

(2) Method for inserting lower thread

Open the front cover, then insert the

thread in the order as shown in Figures

25 and 26. The end of the lower

thread also should be pulled out about

10 cm. After inserting the thread, close

the front cover.

In this case, the thread that has been

pulled out may be left as it is. There

is no need to pull it out to the surface

of the throat plate.

* Threading for double chain stitching is diagramed in

blue also inside the side cover.

3-3 Sewing

(1) Set the cloth as shown in Figure 27.

When beginning to sew, the first few

stitches should be made slowly.

(2) If the tension balance between the

upper and lower threads is not satis

factory, puckering may result in the

cloth or the seams will become irregular.

Please refer to the section "Thread

tension adjustment". (Page 11)

(3) After completing the seam, sew 3—5 cm

of additional stitching from the end of

the cloth as shown in Figure 28 before

cutting. With regard to disposal of the

thread chain, either tie the threads at

the edge of the cloth or, if the cloth is

of knitted material, fold back and fix

with a crochet needle.

In case the seam needs to be strength

ened, the same position should be sewn

twice in a parallel line.

Page 12

4 INTERLOCKING ( SAFETY STITCHING )

4-1 Changing from double chain stitching to

interlocking

All parts which are set for double chain

stitching must be changed to interlocking in

the order given below.

[ Changing steps ]

(1) Open the front cover and remove the

sewing margin gauge and insert the knife

cover. Align the two round red marks

in the same direction (Figure 29 & 30).

Figure 29

Figure 30

(2) As shown in Figure 31, pressing the

knife holder with a finger of the left

hand, rotate the upper knife holder

knob slightly forward with the right

hand. Then release the finger of the left

hand, rotate the knob until it comes to

a stop with a click. The tip of the blade

on the knife is then facing downward

and is in the operating position. It will

then be in a position to cut the cloth.

(3) Rotate the machine pulley by hand and

when the needle is at its lowest point,

pull down and set the crank lever.

Thus, the looper for overedging be

comes operational. (Figure 32)

(4) Insert overedging needle in right side of

needle clamp. (See Page 14}

Page 13

4-2 How to thread correctly

Overedging and double chain stitching can

be done simultaneously by using all four

threads as shown in Figure 33.

*Concerning threading, refer to the section

"How to thread correctly" for both

overedging and double chain stitching.

(Page 3 & 7).

4-3 Sewing

The sewing of interlocking is the same as

overedging and double chain stitching. Refer

to the section "Sewing" of both overedging

and double chain stitching. (Page 5 & 8)

^Concerning thread tension, refer to the

section "Thread tension adjustment".

(Page 11).

Figure 33

10

Page 14

THREAD TENSION ADJUSTMENT

5

5-1 How to adjust the overedging seams

Thread tension adjustment will differ ac

cording to the type of cloth, thickness, and

thread being used.

Adjust the tension using the upper and lower

thread tension adjusters while watching the

seams. (Figure 34)

Thread tension may be increased by turning

in a clockwise direction.

(1) When the tension of the lower thread is

too heavy (Figure 35), loosen the lower

overedging thread tension adjuster.

(2) When the tension of the upper thread is

too heavy (Figure 36), loosen the upper

overedging thread tension adjuster.

When the stitching seams appear as

shown in Figure 37, the tensions are

satisfactory.

(A) When the tension of the lower thread is too heavy.

Upper thread

(B) When the tension of upper thread is too heavy.

(C) Ideal stitching seam.

Figure 35

Figure 36

Figure 37

1 T

Page 15

Figure 38

Double chain stitch

Upper thread tension adjuster

Double chain stitch

Lower thread tension adjuster

5-2 How to adjust the double chain stitching

seams

Thread tension adjustment will differ ac

cording to the type of cloth, thickness, and

thread being used.

Adjust the tension using the upper and lower

thread tension adjusters while watching the

seams. (Figure 38)

Thread tension may be increased by turning

in a clockwise direction.

(A) When the tension of the upper thread is too light.

Front

(B) Ideal stitching seam.

Front

■ Figure 39

When sewing light-weight or knitted materi

als, the seams can be neatly finished if

the material is slightly pulled with the left

hand. (Figure 41)

Figure 40

1 2

Page 16

6

PRESSER FOOT ADJUSTMENT

The presser foot pressure of this machine

is adjusted for standard (medium) thickness.

Adjust only in the case when very thin or

very thick cloth is being sewn.

Sew thin cloth with less pressure, and,

thick cloth with more pressure.

*Turn presser adjusting screw clockwise

for more pressure and counterclockwise

for less pressure.

7 ADJUSTING STITCH LENGTH

Presser adjusting screw

Very thick cloth

f

Very Thin cloth

Medium thick cloth

How to adjust the pressure.

Less -A

More

Figure 42

(1) Holding the machine pulley with the

right hand, grasp the heart-shaped driver

(included in the accessories box) with

the left hand and loosen the feed

regulator fixing screw. The feed regula

tor fixing screw can be loosened by

turning the machine pulley in a counter

clockwise direction while pressing the

fixing screw with the heart-shaped

driver.

(2) Set the graduation on the feed regulator

knob to the indicator. The larger the

number on the feed regulator knob, the

larger the stitches will be.

(3) After completing adjustments, firmly

tighten the feed regulator fixing screw.

13

Page 17

3 SEWING SPEED

The machine has a maximum speed of 1,500

SPM. The speed can be controlled by pedal

depression on the controller.

"^The electric motor used for this machine is

a special motor designed for use only with

this machine and should not be used for other

purposes.

9

HOW TO INSTALL THE NEEDLE

With regard to the needles for this sewing

machine, SINGER needle Cat. No. 2053

90/14 can be used for both double chain

stitching and overedging.

(1) For needle installation, first turn the

machine pulley so as to raise the needle

bar up as far as it will go.

(2) Next, loosen the needle clamp screw

(Figure 45), insert the tip of the needle

into the needle hole (Figure 45) on the

presser foot, and insert the needle into

the needle hole of the needle clamp

as far as it will go.

(3) Firmly tighten the needle clamp screw.

*For the direction of inserting the

needle, it is requested that the needle

be set so that the thread guide groove

is facing the front when facing the

machine as shown in Figure 46.

14

Page 18

1 O REPLACING THE CUTTING KNIVES

The knife should be changed only after removing

the plug from the electric power source.

(1) The upper knife may be changed after

loosening the upper knife set screw and the

lower knife may be changed after loosening

the lower knife holder set screw and the

lower knife set screw as shown in Figure 47.

The position of the lower knife must be

(2)

arranged in such a way that it can be set in

the indentation for the knife in the throat

plate as shown in Figure 48.

(3)

The normal position for setting the upper

knife can be determined when the upper

knife reaches its lowest point during opera

tion. The front tip of the cutting edge of the

upper knife should be about 0.5—1.0 mm

below the surface of the tip of the cutting

15

Page 19

1 1 LUBRICATION

Five/ten drops of oil for

one oiling are necessary

only in this portion.

As special materials (oil impregnated metal) are

used for parts of this machine actual additional

lubrication is negligible. However, since oil wick

is provided for the inner sections, oil should be

provided no more than once or twice per month

to those parts (6 Positions) marked in red which

can be seen from the outside of the machine, in

addition to those parts (5 Positions) shown in

Figure 49. 1-2 drops of oil is sufficient for one

oiling.

Figure 49

*1 2 CHECKING AND ADJUSTMENT

This machine is so designed that there is abso

lutely no need for complex professional adjust

ments.

The following five examples are the only possible

instances where difficulties are likely to occur

through lack of fundamental adjustments.

These points should be carefully considered

when operating this machine.

A) When the machine does not operate —

Is the electric cord properly inserted into the

plug receptacle?

Is there any slipping in the set position of

the motor?

I s the belt loose?

B) When the thread breaks —

Have the threads been inserted correctly?

Is the thread tension too strong?

Is the needle bent?

Is the presser pressure adequate?

C) When the needle breaks —

D) When the seams are irregular—

E) When the seams are not satisfactory —

Are there any problems with regard to the

type of thread being used?

Has the needle been inserted correctly?

Is the needle touching against the throat

plate or presser foot?

Has the needle been inserted correctly?

Is the needle bent or the point worn?

Has the needle been inserted correctly?

Have the threads been inserted correctly?

Is the presser pressure sufficient?

Is the tension adjustment of the upper and

lower threads satisfactory?

Have the threads been correctly inserted?

16

Page 20

1 3 APPLICATIONAL notes

13-1 How to set the presser foot for sewing

knitted materials

(used only for double chain stitching)

This presser foot is very convenient for sewing

cloth parts with many curves.

(1) First, raise the presser bar lifter, then remove

the presser set screw (Figure 51).

(2) After changing the presser foot firmly tight

en the set screw after confirming that the

needle holes are in the proper position.

13-2 Double-hinged presser foot

Double-hinged presser foot, part number SUJ-

8101-00A, illustrated in Figure 50(A), is rec

ommended for overedging and safety stitching

when sewing over cross seams and for better

formation of the stitching at the start and finish

of the seams of heavier cloth materials.

This presser foot is optional and must be ordered

separately.

Presser foot for sewing knitted material.

Figure 50

Figure 51

1 7

Page 21

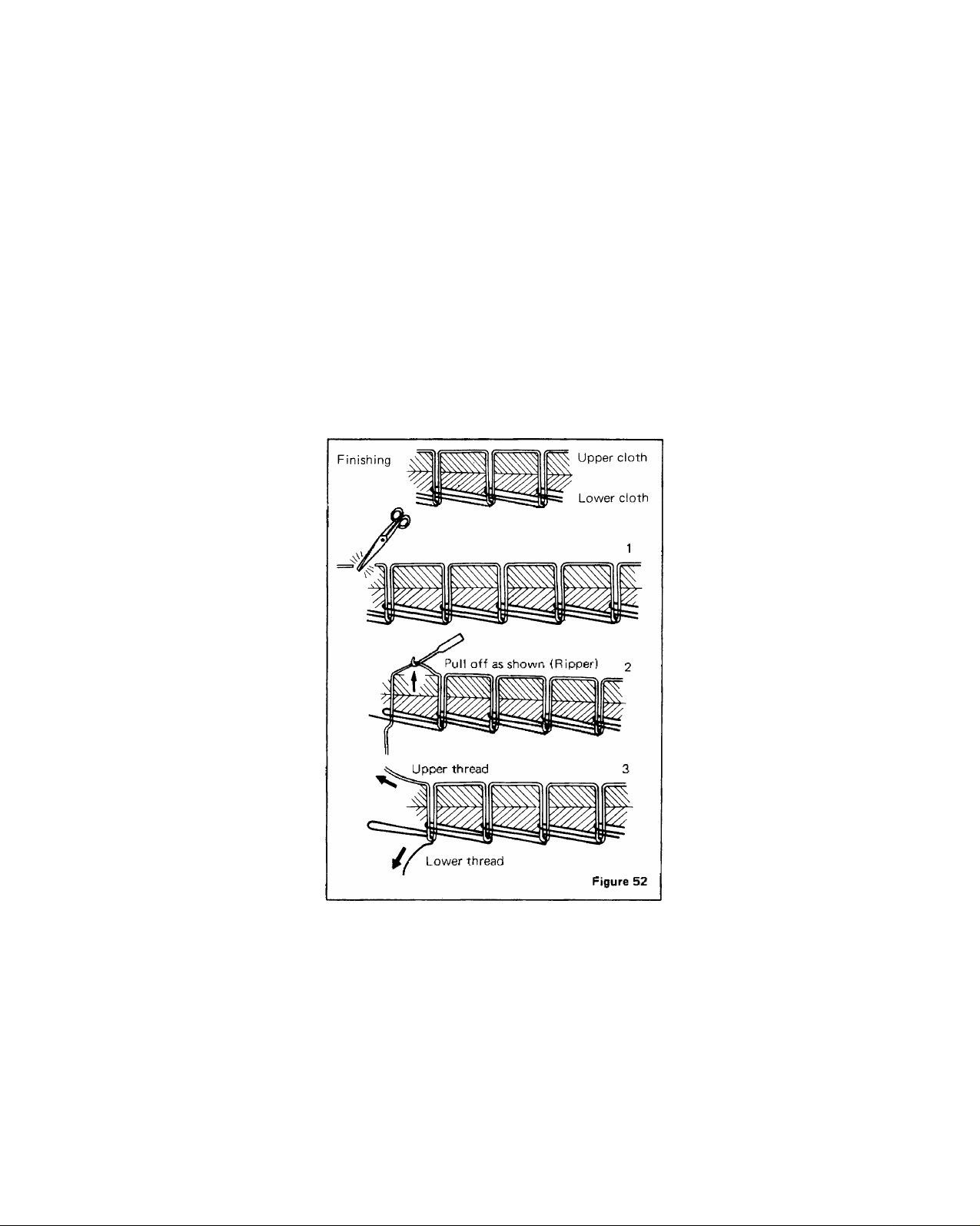

13-3 Removing stitches of double chain stitch

ing seams

When loosening seams, remove the threads in the

reverse direction of sewing as shown in Figure

52.

18

Page 22

1 4 SUPPLEMENT

Detailed list of contents

1) Machine

2) Motor

3) Controller set

4) Vinyl cover

5) Instruction booklet

6) Accessory box

(Contents)

Screw driver

Spanner (for motor bracket)

Needles

Upper knife

Tweezers

Cleaning brush

Oil

Heart-shaped driver (for adjusting stitch length)

Sewing margin gauge

Presser foot for knitted material

Net

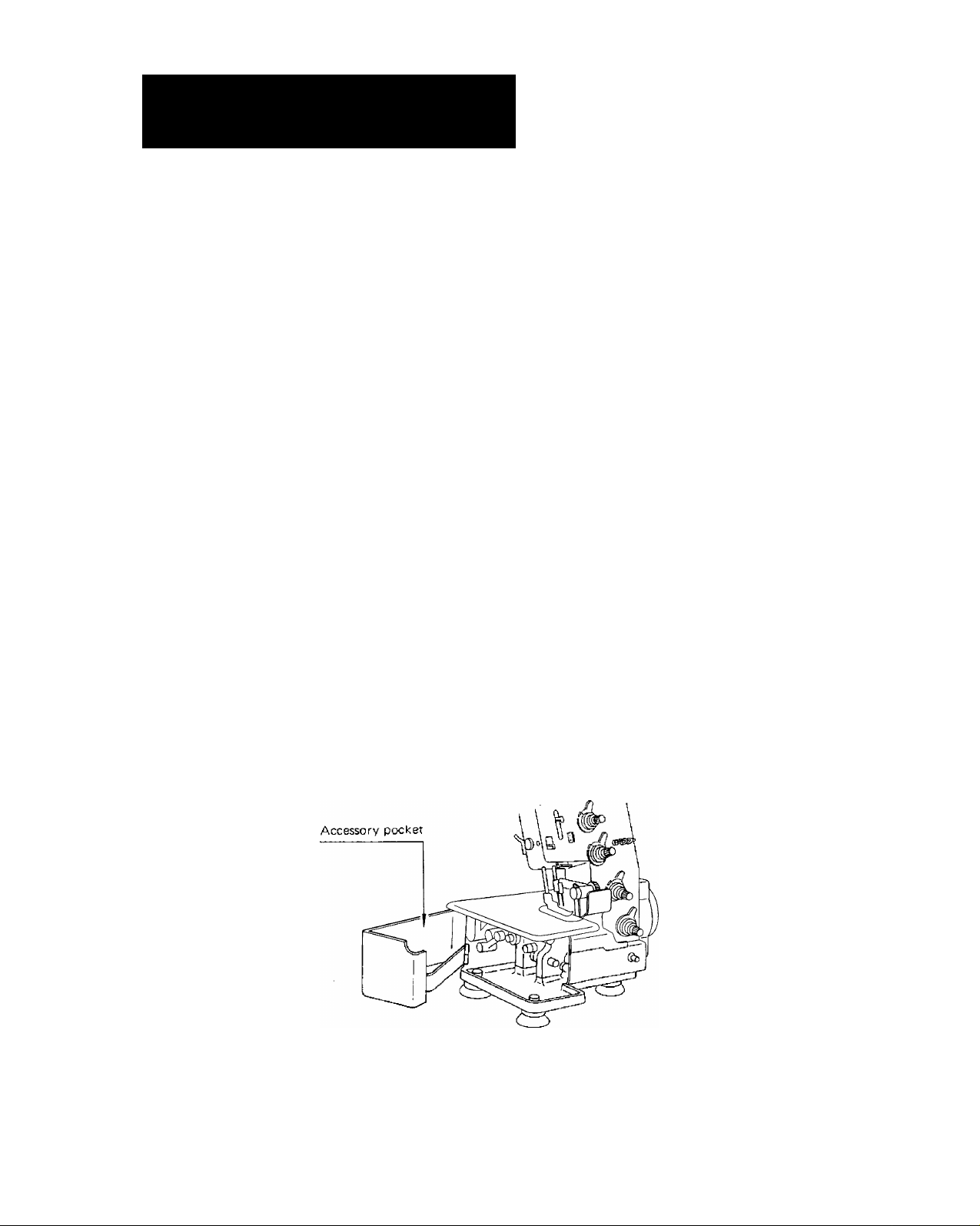

It is recommended that the pocket on the side

cover be used for storing the accessories at the

time of using the machine as shown in Figure 53.

Figure 53

1 9

Page 23

CHANGING THE CARBON BRUSHES

15

OF THE MOTOR

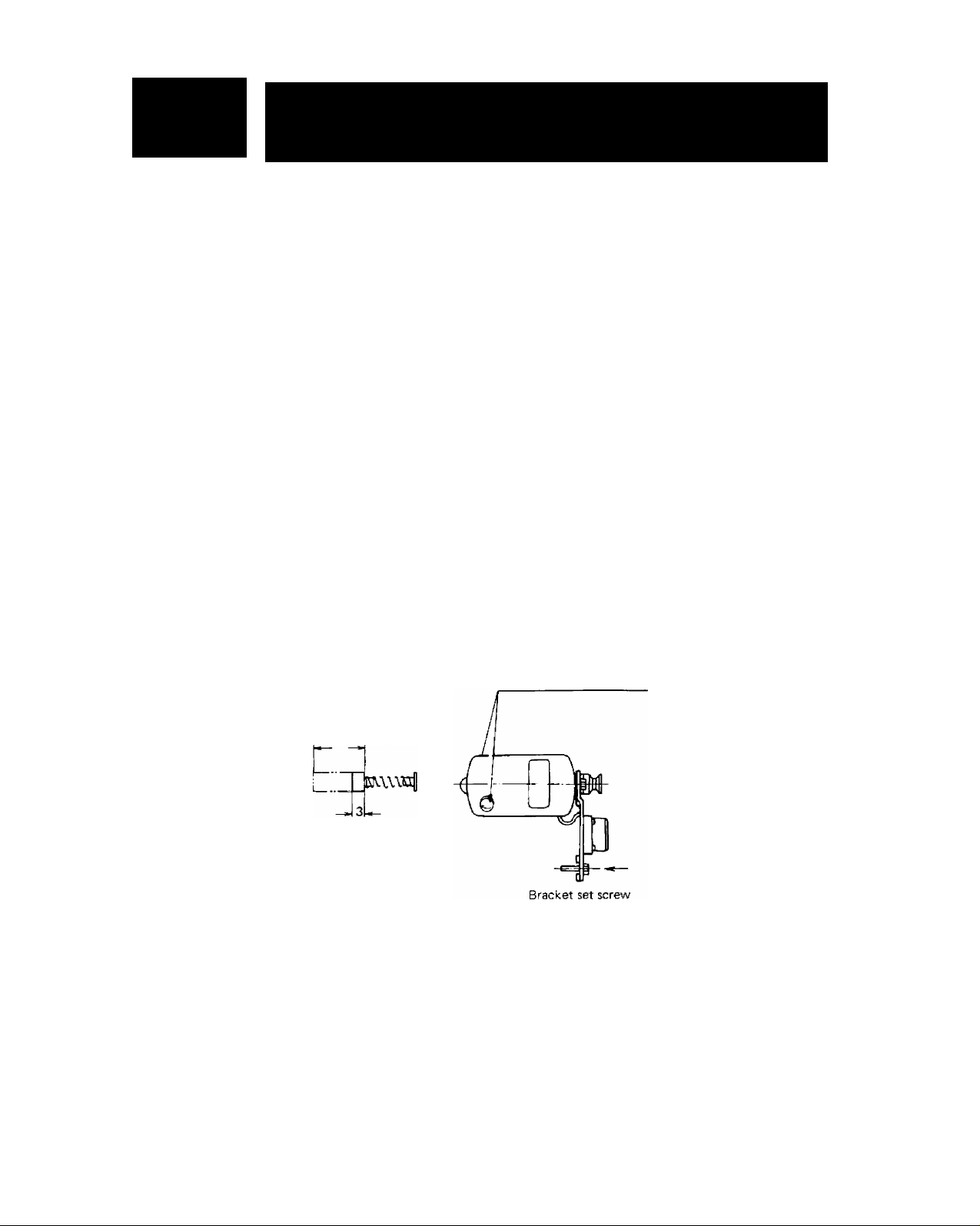

Two carbon brushes (in two positions) are

used for the motor on this sewing machine.

The carbon brushes should be changed according

to the following method, as they will wear

after long hours of use.

A) Period for changing carbon brushes

The carbon brushes should be changed when

they have worn too short for contact (see

carbon brush figure),

B) First remove the motor. Remove the brush

caps (see figure of motor), and replace the

brushes.

Figure of carbon brush

Brush cap (two)

10mm

The carbon brushes should be changed when

the brush section has worn down to approxi

mately 3 mm as shown in the figure.

Carbon brushes may be purchased from any

sewing machine shop or electrical appliance

shop.

Note: Special care should be taken with

regard to the aforementioned points as

failure to change the brushes may result in

sparks emitting from the motor which will

cause damage to the motor.

20

Page 24

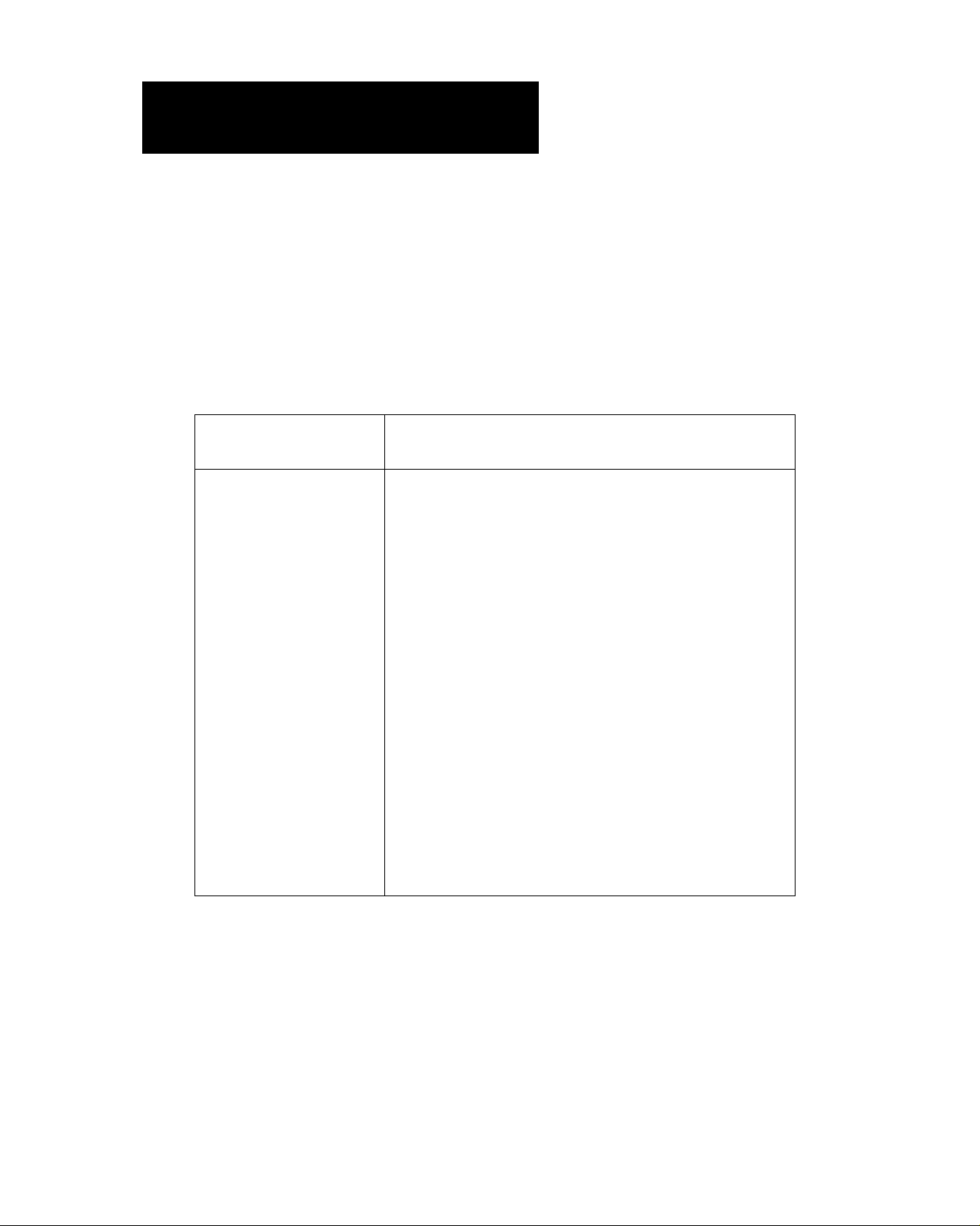

1 0 SPECIFICATIONS

ítem Specification

Overedging width

Distance between needles 3 m/m

Stitch length {feed)

Needle bar stroke 27 m/m

Knife movement 6 m/m

Presser foot lift

Feed dog height

Needles

Number of threads

Method of lubrication

Machine dimensions Length 250 m/m x Breadth 250 m/m x Height 310 m/m

Weight of machine |

4 m/m

1 6 m/m

3.5 m/m

0.7 m/m

SINGER needle Cat. No. 2053, 90/14

4

Semi-automatic oil wick lubrication

Approximately 10 kgs (with motor and controller)

21

Page 25

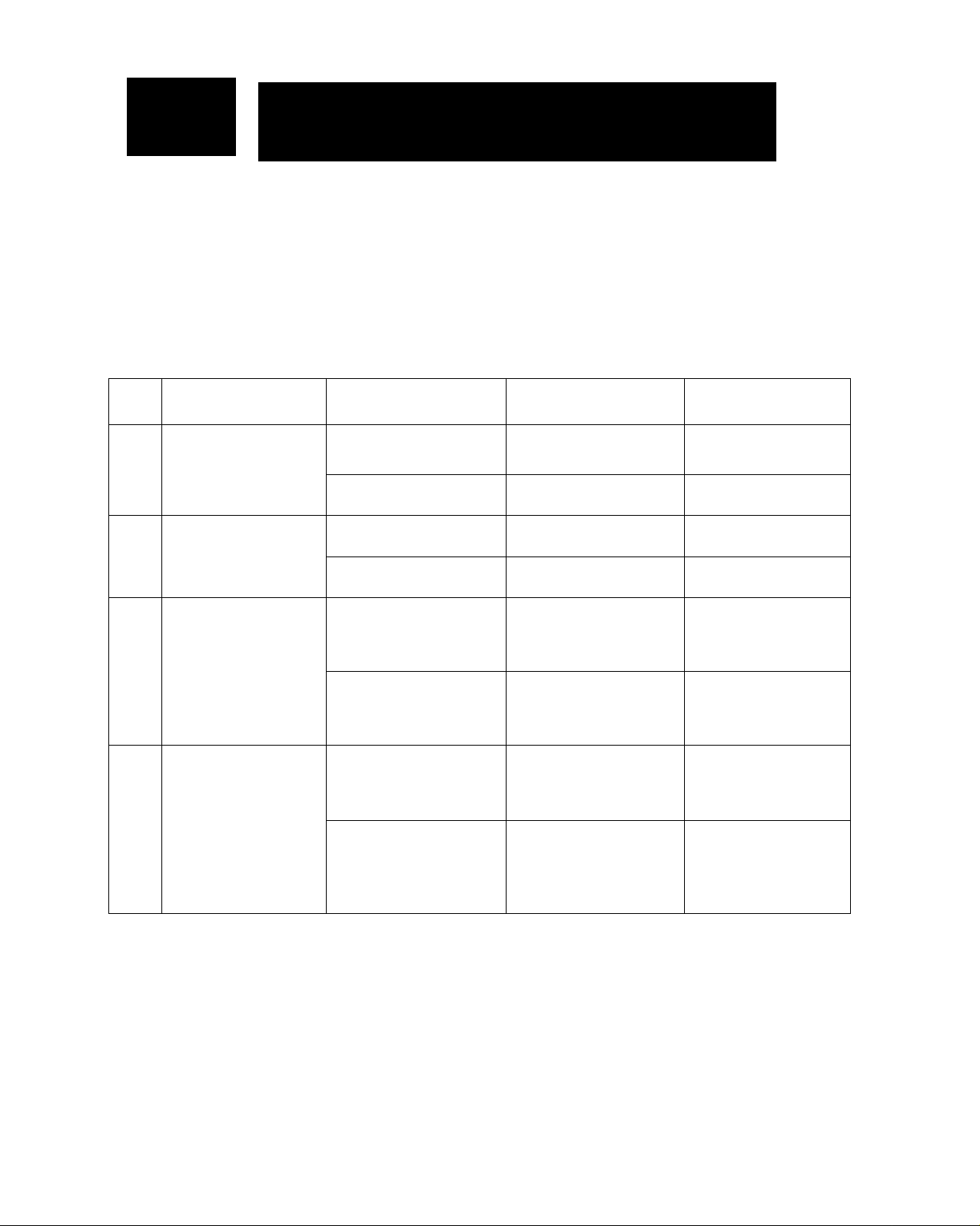

TABLE SHOWING RELATIONSHIP

17

No. Type of cloth Use Type of thread

Thin cloth (organdy,

thin tricot, taffeta,

1

silk, crepe, suit lining)

Ordinary cloth

2

(cotton, tricot, linen,

satin, cloth in general)

Thick cloth (tweed,

3

denim, suit cloth)

Knitted cloth

4

(knitted goods,

knitted cloth)

BETWEEN THREAO ANO CLOTH

Double chain stitching

(straight seaming)

Overedging

Double chain stitching

Overedging

Double chain stitching

Overedging

Double chain stitching

Overedging

Cotton #80 ~ #100

Silk #80-#100

Cotton #80 ~ #100

Silk #80-#100

Cotton #60- #100

Silk #50-#100

Cotton #60-#100

Silk #50- #100

Cotton #40 — #60

Silk #40-#60

Tetron and woolly nylon

threads

Cotton #40 — #60

Silk #40-#60

Tetron and woolly nylon

threads

Cotton #40 — #50

Silk #30- #40

Tetron, woolly nylon and

transparent nylon threads

Woolly nylon and tetron

threads

♦ Very thin woollen

thread may be used

as the lower thread.

Length of stitch

2.0 m/m — 3.0 m/m

3.0 m/m — 4.0 m/m

2.0 m/m — 3.0 m/m

3.0 m/m — 4.0 m/m

2.0 m/m — 4.0 m/m

3.0 m/m — 5.0 m/m

2.0 m/m — 4.0 m/m

3.0 m/m — 5,0 m/m

22

Page 26

' t

I

''3

ip

I

m

■-

I

a

■

1

m

m

i

pa

I

\

\i

i -5

'■1

‘ilp

'i

i

im

I

■

i.

I

J

vi

1«

1

i

' s

a

, -i

. '--.i

SINGER

Printed in jcpan

(?i

Loading...

Loading...