Page 1

\o

Page 2

Contents

Chapter 1: Getting to Know Your Machine

Principal Parts 2

Accessories 4

Choosing and Changing Accessories 6

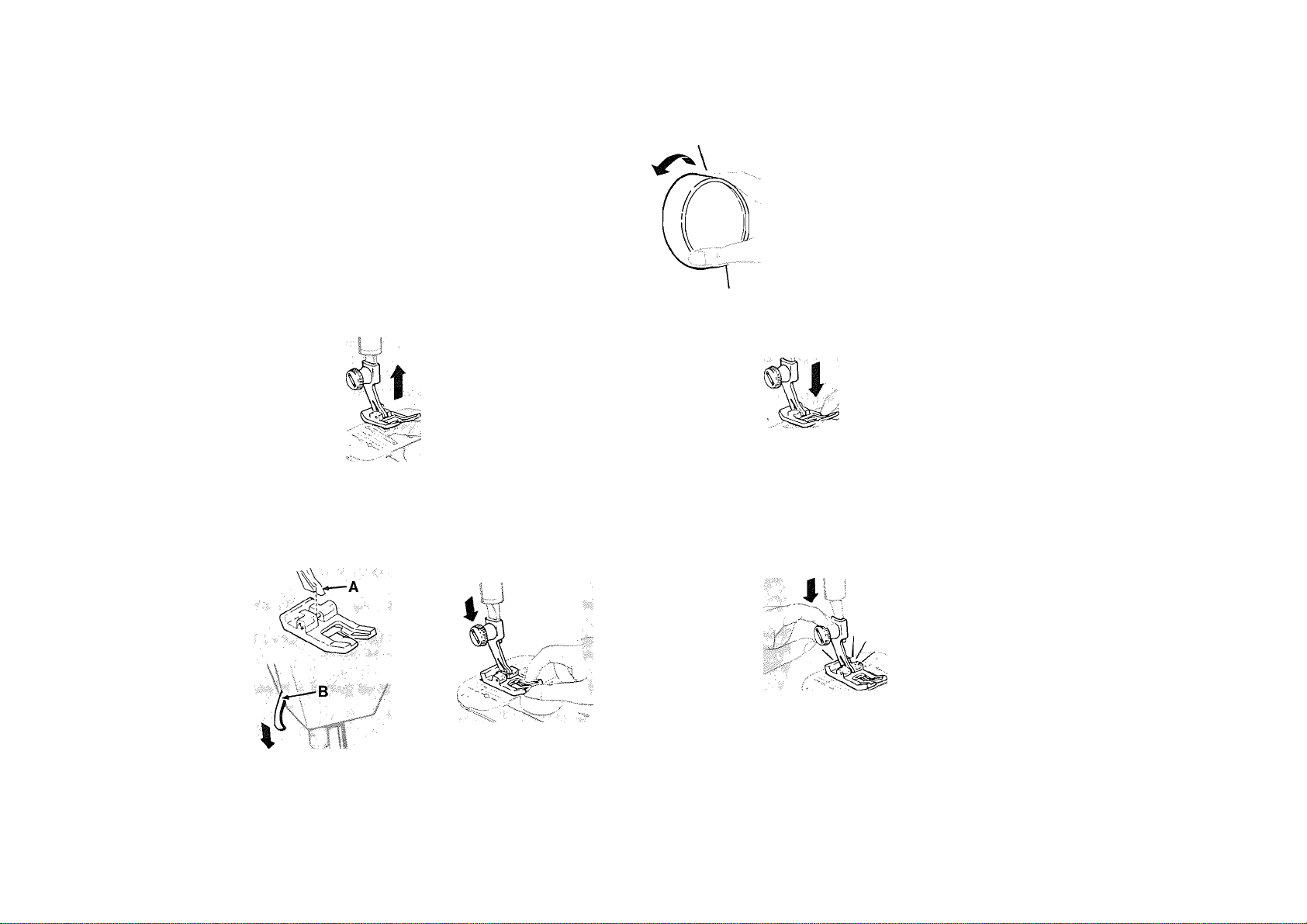

Changing Snap-on Presser Feet 6

Changing One-piece Presser Feet 7

Changing Needle Plates 7

Attaching Snap-on Feed Cover 7

Attaching Seam Guide 7

Choosing Needles 8

Needle-Fabric Combinations 9

Fabric Weight Table 10

Fabric, Thread and Needle Table 12

Operating Machine 14

Connecting Machine and Speed

Settings 14

Run Machine 15

Lifting the Presser Foot 15

Threading the Machine 16

The Bobbin 20

Winding • Changing ■ Removing ■

Replacing Bobbin

Raising the Lower Thread 23

Chapter 3: Electronic Sewing

Selecting a Stitch 24

______________

Chapter 4; Straight Stitching

Preparation • Sewing in Reverse 25

Adjusting Machinete Your Fabric

Adjusting Stitch Length 26

Regulating Presser Foot Pressure 26

Stitch Length Guidance Table 27

Upper Thread Tension 28

Tension Test 29

Lower Thread Tension 29

Sewing a Seam

Preparation 30

Placing Fabric Under Foot 30

Sewing with a Newly Wound Bobbin 30

Keeping Seams Straight 31

Turning Square Corners 31

Curved Seams 32

Reinforcing End of Seams 32

Applications

Darning 33

Darts 34

Quilting 35

Zipper Insertion 36

Chapter 5: Basic Zig-Zag Stitching

Adjusting Stitch Width and Length 38

Adjusting Upper Thread Tension 39

Adjusting Lower Thread Tension 39

Applications

Zig-Zag Seam Finishes 40

Lingerie Seams ■ Satin Stitching 41

Appliqué 42

Free-Motion Embroidery 43

_________

Chapter 6: Machine Stitch Patterns

How Stitches are Produced 44

Stitch Pattern Chart 44

Adjusting Stitches for Stretch Fabrics

Guiding and Supporting Fabric 45

Adjusting Pressure 45

Fabric Handling Table 46

Stitch Centring 48

Stitch Usage: Functional and Decorative

Arrowhead -

Arrowhead Stitch Finish 49

Featherstitch -

Fagoting 50

Patchwork Quilting 51

Overedge Stretch Stitch -

Overedged Seams 52

Seam Finishing 53

Blindstitch -

Hems 54

Ladder Seam 55

Honeycomb -

Replacing Lingerie Elastic 56

M-Stitch -

Stretch Garment Repair 57

Multi-Stitch Zig-Zag -

Mending a Tear 58

Finishes for Hems and Facings 58

Bar Tacks 59

Scallop Stitch -

Scalloping Seams and Edges 60

Straight Stretch Stitch -

Seams 61

Decorative Stitching

Border Designs 62

Smocking 63

Twin-Needle Stitching 64

Chapter 7: Buttonholes and Buttons

Buttonholes

Buttonhole Position

Buttonhole Length

Two-Step Buttonholing

Buttons

Attaching a Button

Forming a Thread Shank

Chapter 8: Free-Arm Sewing

Chapter 9: Caring for Your Machine

Cleaning the Machine 76

Removing and Replacing

the Bobbin Case 77

Replacing the Slide Plate 78

Changing the Light Bulb 78

Chapter 10: Performance Checklist 79

Your Personal Measurements 82

Personal Notes 83

Index 84

66

67

68

72

73

74

Copyright © 1978 THE SINGER COMPANY

All Rights Reserved Throughout the World

Page 3

©Bis^pier Getting to Know Yoyr Haehiiia

Congratulations...

You are about to sew on the

new advanced electronic

model 1050 sewing machine.

This Futura* sewing

machine features numerous

technological breakthroughs

as a result of years of SINGER

research.

We suggest you take time to

read through this operator’s

guide, as you sit at your new

machine. You will discover

how simiple it is to do the

sewing operation you desire

on the Futura* 1050.

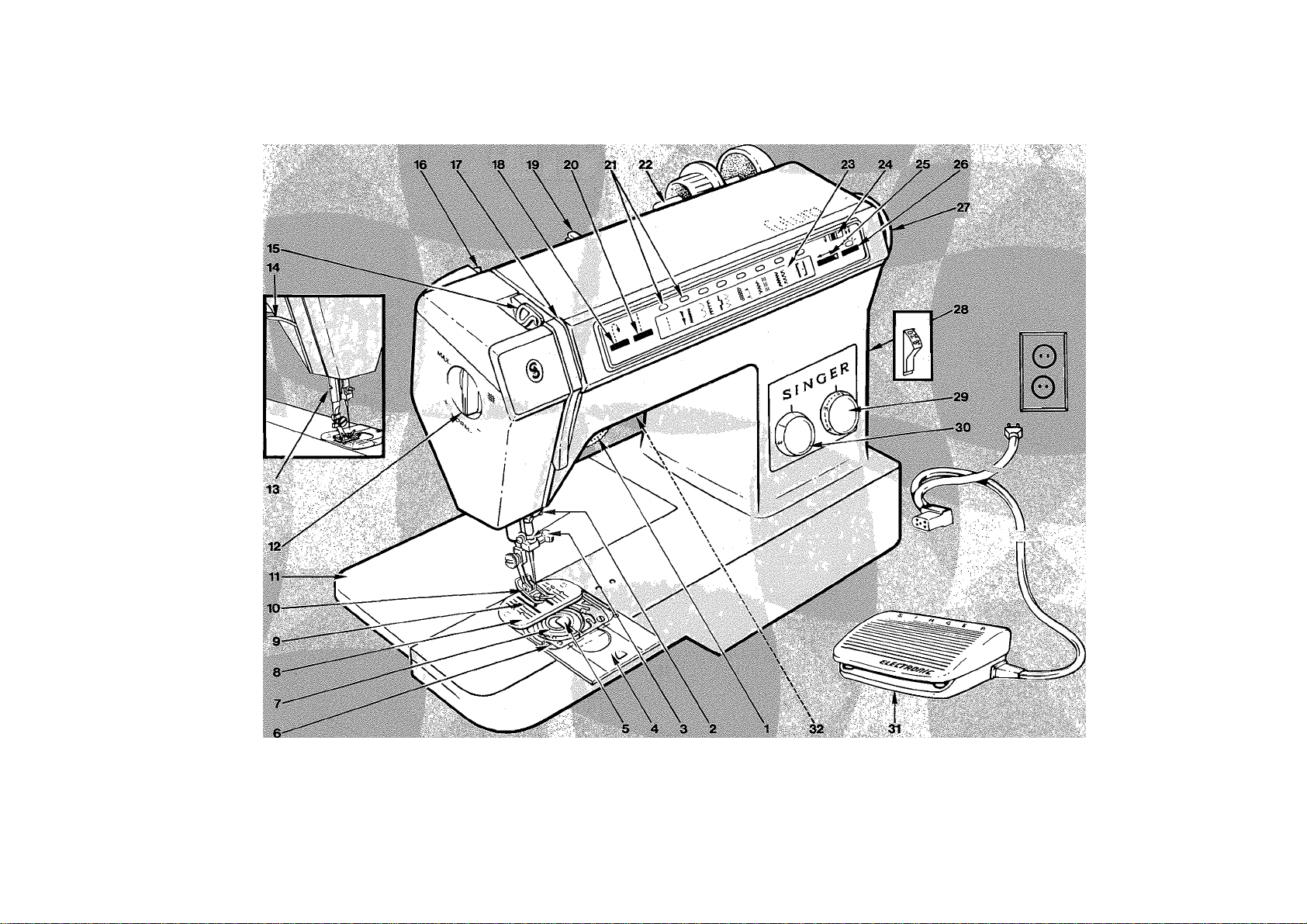

principal parts

1 Upper Thread Tension Dial

2 Thread Guides

3 Needle Clamp

4 See-through Slide Plate

5 Bobbin Latch

6 Bobbin Winding Push-button

7 Transparent Bobbin

8 General Purpose Needle Plate

9 Soft-touch Fabric Feed

10 General Purpose Presser Foot

11 Flip & Sew * Panel

12 Pressure Dial

13 Thread Cutter

14 Presser Foot Lifter

15 Take-up Lever

16 Rear Thread Guide

17 Tension Separator

18 Reverse Stitch Button

19 Snap-in Thread Guide

20 Straight Stitch Button

21 Stitch Selection Indicator Lights

22 Friction-free Spool Flolder

23 Stitch Panel

24 T\A/in Needle Safety S\«itch

25 Pattern Group Selector

26 Pattern Selector Button

27 Fland Wheel

28 Po\A/er and Light S\A/itch

29 Stitch Length Dial

30 Stitch Width Dial

31 Electronic Speed Controller

32 Se\A/ing Light

To ensure that you are always provided with the most modern

sewing capabilities THE SINGER COMPANY reserves the right

to change the appearance, design or accessories of this

sewing machine when considered necessary.

Page 4

Page 5

л ' '".А

o|}i

h:

У ^

8

|]

13

10

14

11

15

12

16

17

Page 6

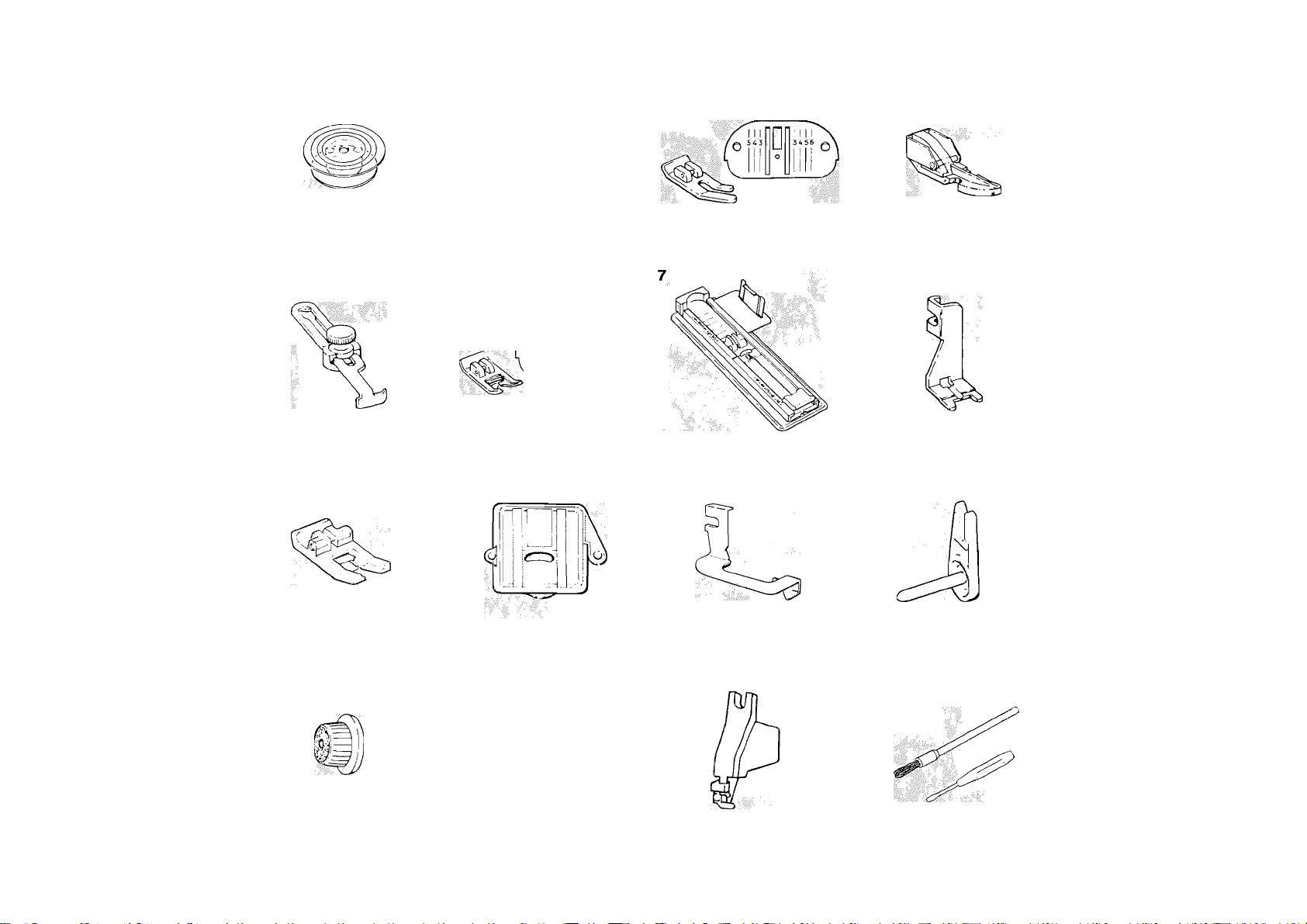

accessories

The accessories provided with your sewing machine are

designed to help you do many kinds of sewing easily.

1. Transparent Bobbins (No. 506417)

2. Needles

• Style 2020 for general sewing.

• Style 2045 for sewing knits, stretch fabrics and elastic.

• Style 2025 for twin-needle decorative stitching on

woven and knit fabrics.

3. Straight Stitch Foot and Straight Stitch Needle Plate.

Use these when your fabric or sewing procedure requires

close control.

These accessories, recommended for all straight stitch

sewing, are especially helpful for edge stitching and collar

pointing, or for stitching delicate or spongy fabrics.

4. Zipper Foot for inserting zippers and stitching corded

seams.

5. Seam Guide helps you keep seam allowances even.

6. General Purpose Foot and General Purpose Needle Plate

are on your machine when delivered. Use them for alter

nating between straight and zig-zag stitching as well as

utility zig-zag sewing. They can also be used for straight

stitching on firm fabrics.

7. Two-step Buttonhole Measuring Foot allows you to stitch

buttonholes for flat buttons up to 3.5 cm (1% inches) in

diameter. It also allows you to determine correct button

hole length by using gauge lines on foot.

8. Button Foot holds most buttons securely for stitching.

9. Special Purpose Foot Use this for all kinds of decorative

stitching.

10. Snap-on Feed Cover for button sewing, free-motion work

and darning.

11. Blindstitch Hem Guide. Use this with the general purpose

foot to position the hem for blindstitch hemming.

12. Detachable Spool Pinfor decorativetwin-needlestitching.

13. Large Spool Holder on your machine when delivered. For

use with medium and large spools of thread.

14. Small Spool Holder for use with small diameter tubes of

thread.

15. Needle Threader

16. Lint Brush for cleaning your sewing machine.

17. Screwdriver for regulating lower thread tension.

To increase the versatility of your machine, additional acces

sories can be purchased at your Singer store.

Page 7

■gfei?p'lcï' i,’ôüfiïp gî ■

choosing and changing accessories

Changing Presser Feet

Snap-on Presser Feet

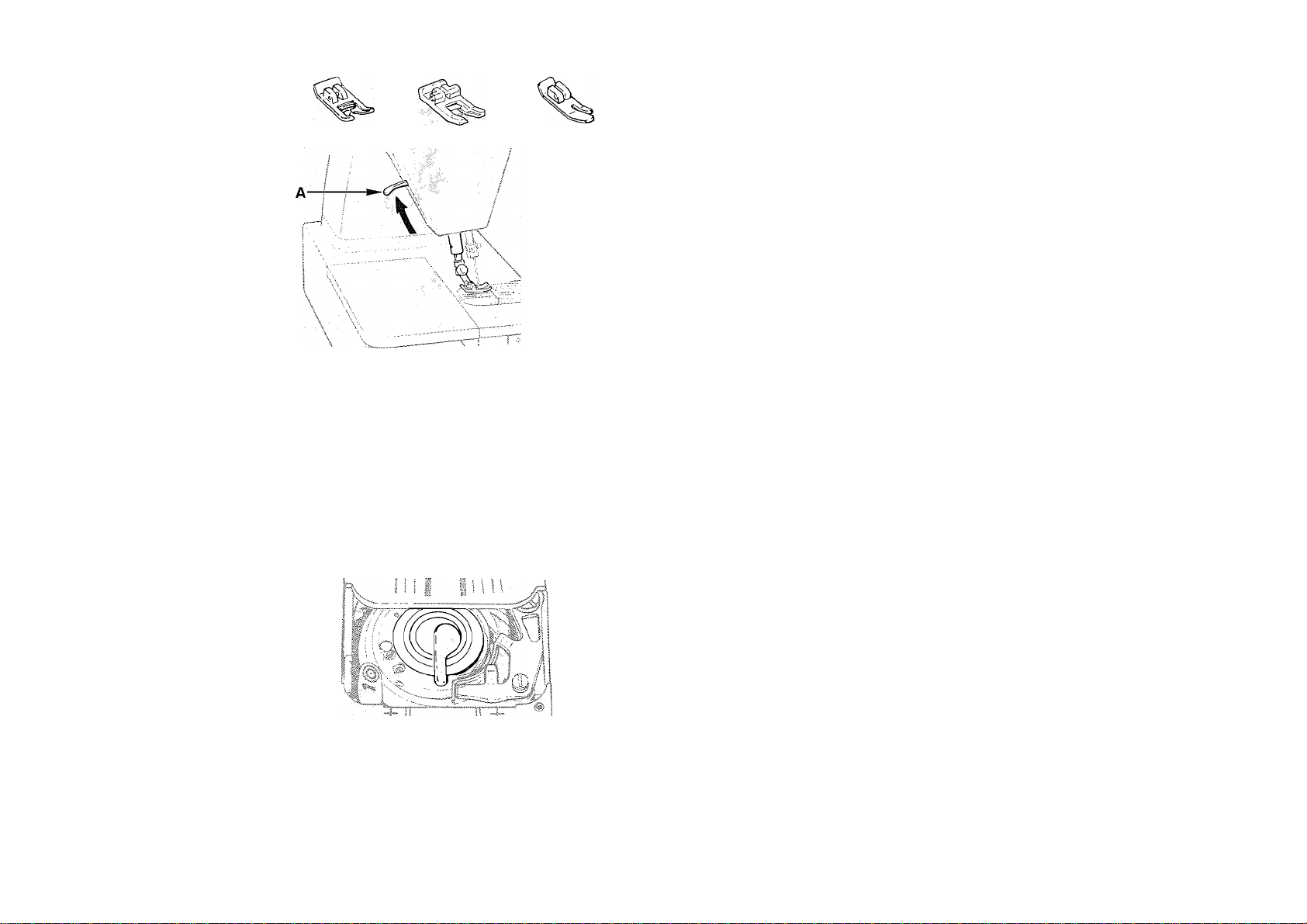

Most of the presser feet furnished with your machine snap on

and off a common shank.

• Raise needle and take-up lever to highest position by

turning the hand wheel toward you.

Caution: Disconnect the power

line plug from the socket outlet

when changing needles, feet or

needle plates or when leaving the

machine unattended. This elimi

nates the possibility of starting

themachinebyaccidentallypressing the speed controller.

• Raise presser foot.

To Remove Foot

■ ■ ■

1a. Press toe of presser foot upward as far as it will go. 1b. Then snap down to remove.

2. Centrethe new presser foot under the shank A. 3. Press presser foot screw down firm/y until foot snaps into

/.ower ihe presser foot//ffer B so that the shank fits over place.

the presser foot pin. To remove and replace the shank of snap-on presser feet,

follow instructions on next page for one-piece presser feet.

Page 8

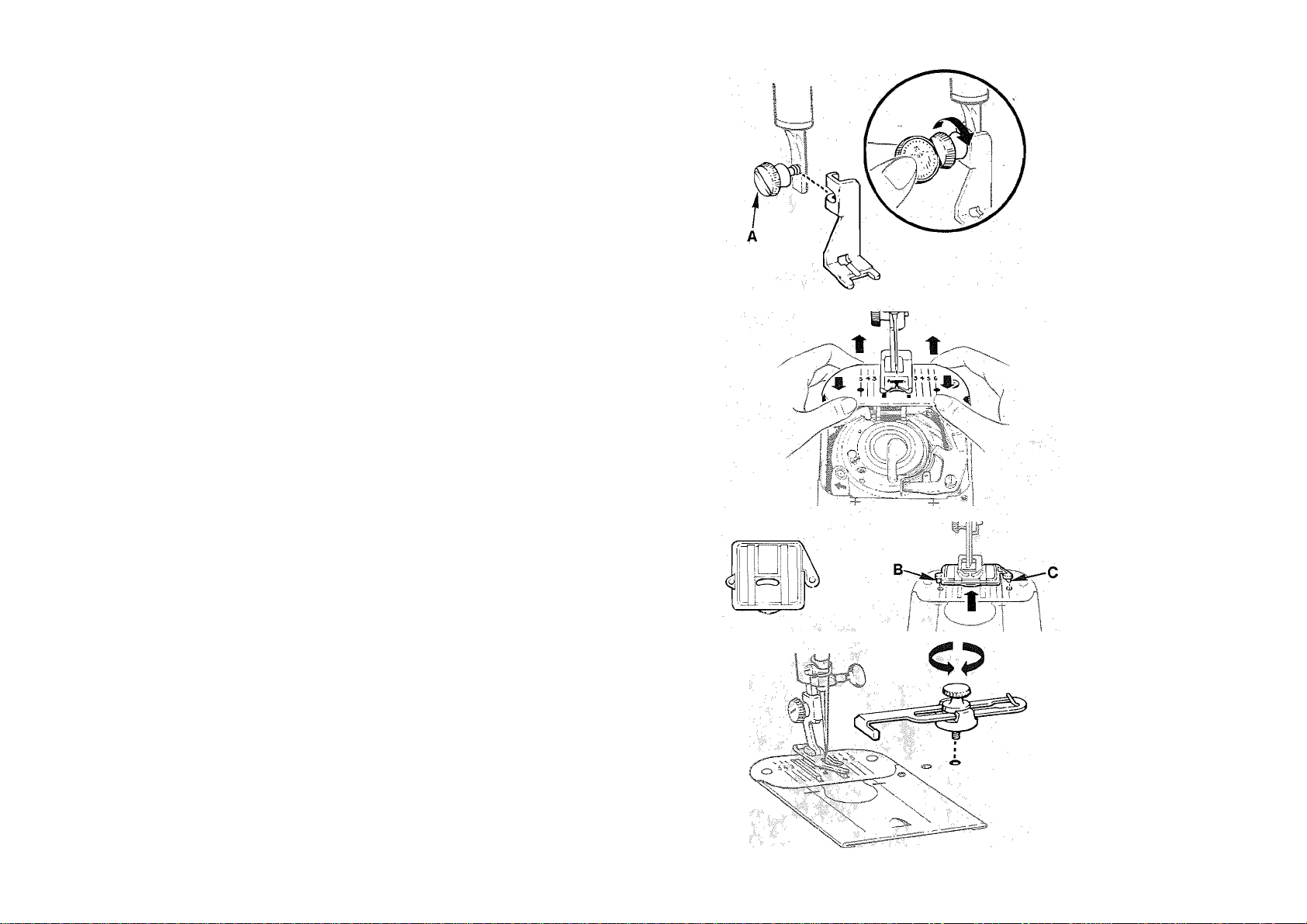

One-piece Presser Feet (Button Foot)

• Raise needle and take-up lever to highest position by

turning the hand wheel toward you.

• Raise presser foot.

• Loosen presser foot screw A and remove the foot, guiding

it to the right.

To Replace One-piece Feet

• Hook one-piece foot around the presser bar and tighten

presser-foot screw.

Note: Insert the edge of a coin in the slot of the presser-foot

screw to loosen it and to tighten it securely.

Changing Needle Plates

Note: Remove bobbin if it contains thread in order to prevent

thread being caught when plate is replaced.

• Raise needle and take-up lever to highest position by

turning the hand wheel toward you.

m Raise presser foot.

• Open slide plate. Press down on front edge of needle plate

and lift up and out.

• Position new plate over pins and release. Plate is drawn

into position by magnets.

® Close slide plate.

Caution: The straight stitch foot and zipper foot must oniy be

used with the straight stitch needie píate. Needie breakage

can occur if the straight stitch foot or zipper foot is used with

any other needie piate.

Attaching Snap-on Feed Cover

• Raise needle and take-up lever to highest position by

turning hand wheel toward you.

• Raise presser foot.

• Slide snap-on feed cover away from you, as illustrated over

needle plate until points B and C are positioned directly

over holes in needle plate. Then snap down.

To remove, open slide plate then simply lift up front edge of

feed cover.

Attaching the Seam Guide

Place screw in the right hand hole to the right of the slide

plate; line up straight edge of guide with the needle plate

guideline for desired seam width, and tighten screw.

Page 9

\l

2020

J

V V

2025

2045

2032

choosing needles

Important: Your SINGER sewing machine has been designed

to obtain best results with SINGER* needles. You should follow

the recommendations in this instruction book and on the

needle package for correct style and size of needle for dif

ferent types and weights of fabric.

The needles you use should be straight to ensure perfect

stitch formation. The needle should also be fine enough to

prevent the fabric from being marred with large punctures,

yet heavy enough to pierce the fabric without being bent or

deflected.

Remember too, that the eye of the needle must be large

enough for the thread to pass through freely; too fine a needle

will cause the thread to fray. See Fabric, Thread and Needle

Table, page 12.

For general purpose sewing in a wide range of fabrics, the

Style 2020 needle, in sizes 9 through 18, will give you excellent

results.

For best results when sewing on knits, woven stretch fabrics,

bonded vinyls, and elastic use Style 2045 ball point Yellow

Band* needle, available in sizes 11,14, and 16.

For decorative stitching on light and mediumweight woven

and knit fabrics, use the twin-needle. Style 2025.

For sewing leathers, real and simulated, the Style 2032 needle,

available for purchase at your Singer Sewing Centre, Is re

commended.

Changing the Needle

Caution: Disconnect the power line plug from the socket

outlet before changing needles.

• Raise needle to its highest point by turning the hand wheel

toward you. Loosen needle-clamp screw A and remove the

needle.

• Insert new needle up into clamp B as far as it will go, with

the flat side of the needle to the back.

@ Tighten needle-clamp screw.

Page 10

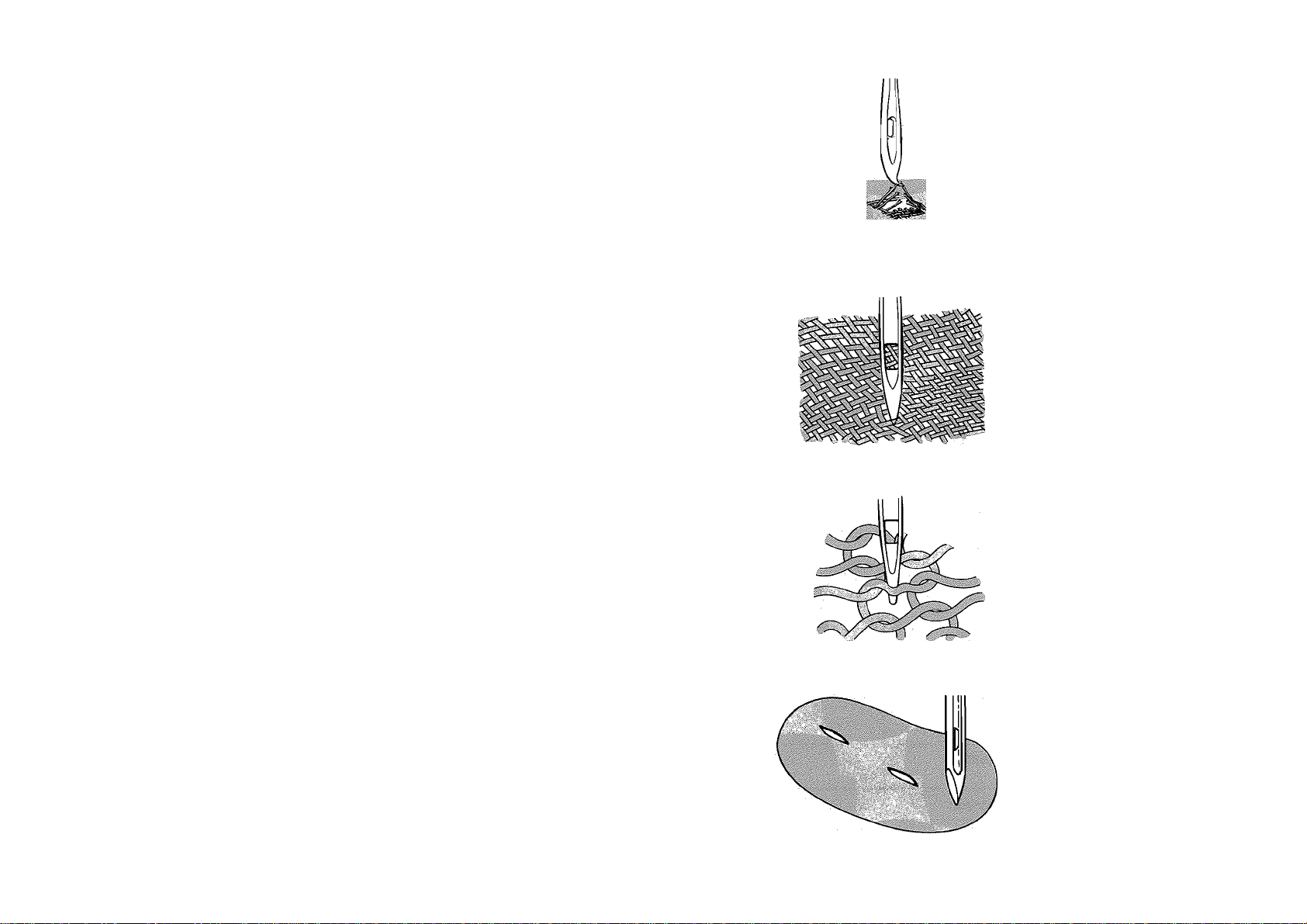

Needle-Fabric Combinations

Be sure to check the Fabric, Thread and Needle Table on

page 12 before you begin to sew. The importance of selecting

the correct size, as well as the correct type needle for the

fabric and thread you are using, cannot be emphasized too

greatly.

Correct needle selection is closely related to stitch quality

and appearance. Damaged fabric is almost always caused bya

needle that is bent, burred, or that is an inappropriate style

for the fabric and thread you are using.

The three types of needles most commonly used by sewers are

the regular, ball point, and wedge. To obtain good results, the

correct size and type of needle for the fabric and thread you

are using, must be chosen.

The regular needle, Style 2020, which is called a set-point

type needle, is for stitching woven fabrics such as denim,

gabardine, and drapery coating.

2020

2045

Ball point needles, Style 2045, are appropriate for stitching

most knits, lingerie, lace, mesh, stretch fabrics, and elastic

materials. The special rounded tip of the ball point needle

ensures gentle separation of the fabric yarns.

The wedge needle. Style 2032, is the best for stitching leather,

vinyl, and dense materials. It is designed to cut through with a

minimum of friction and also shape the punctures to ensure a

desired appearance.

2032

Page 11

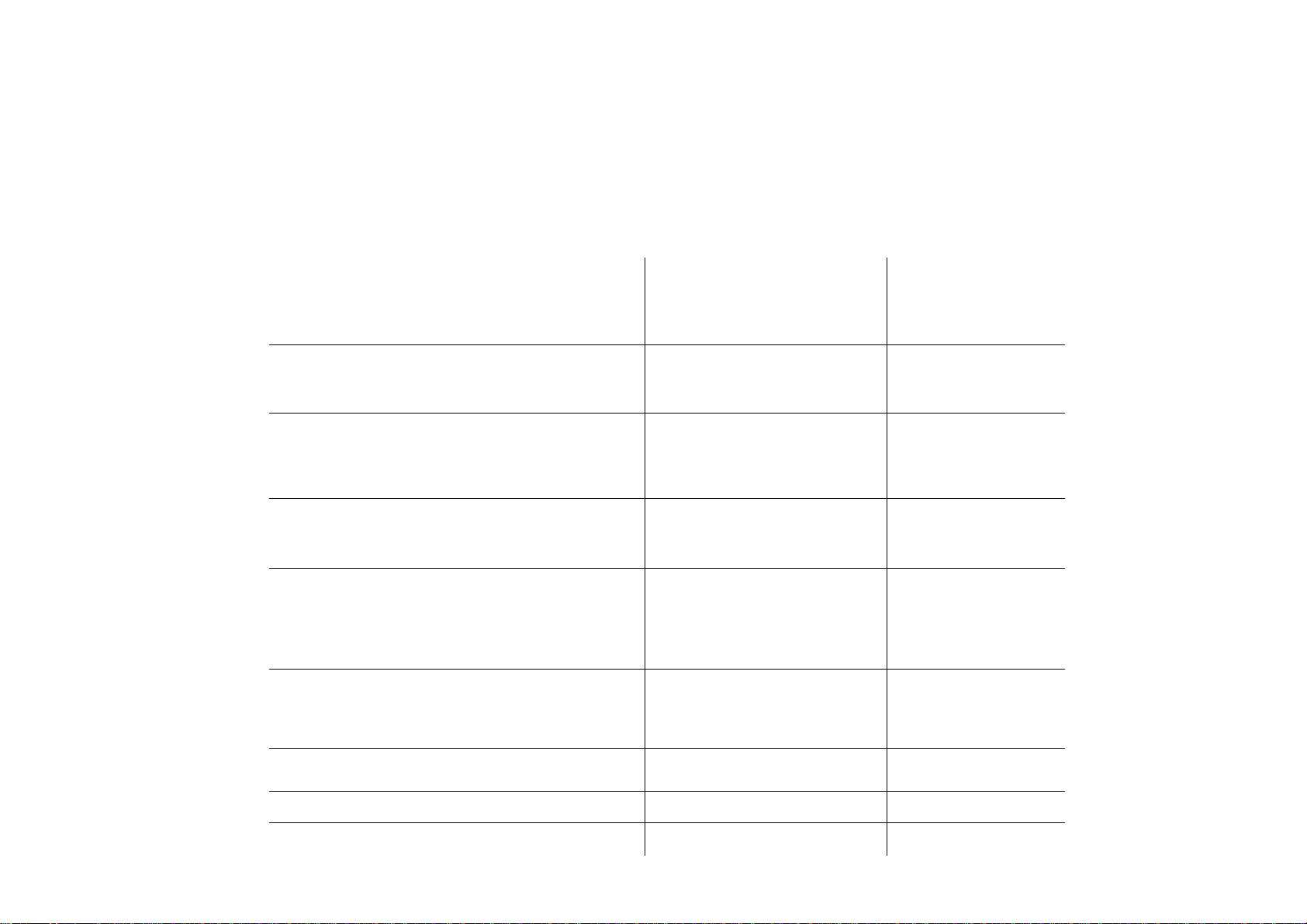

Fabric Weight Table There are thousands of fabrics around the world, each manu

factured with a specific fibre and weight. The fabrics below

have been classified according to weight to give a small sample

of what is available for purchase.

Referto this tabletodeterminethe weight and type of fabric you

Fibre

and

Construction

Filmy Sheer

Silk

(Woven)

Chiffon,

Organza,

Tulle

Net, Lace, Ninon

(Knit)

Rayon

Tulle

Net, Lace

(Woven)

(Knit)

Cotton

(Woven)

Voile,

Tulle

Net, Lace Challis, Organdy, Muslin, Batiste, Dimity,

(Knit)

Wool

(Woven)

(Knit) Jersey

Synthetic

(Woven)

Chiffon,

Organza,

Tulle

Net, Lace, Ninon,

Crepe de Chine

(Knit)

Synthetic

Blends

Voile Broadcloth, Batiste, Eyelet, Gingham,

(Woven)

(Knit)

Velvet, Crepe de Chine, Shantung, Faille

Jersey

Velvet, Taffeta, Satin

Ciré

Lawn, Percale, Eyelet, Gingham, Piqué, Poplin

Jersey

Cashmere, Rannel, Mohair, Felt, Crepe

Crepe, Velvet, Taffeta, Satin

Raschel, Single Knit, Sweater Knit,

Bonded Knit, Tricot, Ciré

Poplin

Single Knit

10

Leather

Plastic

Vinyls

Kidskin, Patent, Chamois, ImitationLeathers & Suedes, Leather, Suede

Plastic Film Plastic Film

Page 12

will be using in order to select the correct needle and thread

combination.

For correct needle and thread combination for your fabric, refer

to the Fabric,Thread and Needle Table on the following page.

Medium

Velvet, Crepe de Chine, Shantung,

Suiting, Brocade

Velvet, Taffeta, Satin, Crepe

Velveteen, Corduroy, Velvet, Reece,

Velour, Terry, Chintz

Stretch Velours ■, Stretch Terry ■

“ Usually contain some synthetic fibers also.

Suiting, Rannel, Gabardine, Felt, Serge, Mohair

Jersey

Velvet, Crepe, Taffeta, Satin, Gabardine

Jacquard, Double Knit, Sweater Knit, Bonded Knit, Tricot,

Spandex, Stretch Terry, Stretch Velour, Deep Pile, Fake Furs

Very

Heavy

Brocade, Taffeta, Satin, Crepe

Corduroy, Denim, Ticking, Canvas,

Linen, Drapery Fabric, Burlap

Suiting, Tweed, Duffel Coating, Blanketing

Double Knit, Flelenca, Fake Furs

Denim, Duck, Canvas,

Sailcloth, Upholstery

Fabric

Linen Type, Poplin, Corduroy, Gabardine

Terry Knit

Patent, Imitation-Leathers & Suedes,

Leather, Suede, Reptile

Bonded Vinyl (Knit Back), Patent, Embossed, Printed

Denim, Gabardine, Drapery Fabric

Double Knit

Buckskin, Calfskin, Suede, Reptile Upholstery Leather

Upholstery Vinyl Upholstery Vinyl

11

Page 13

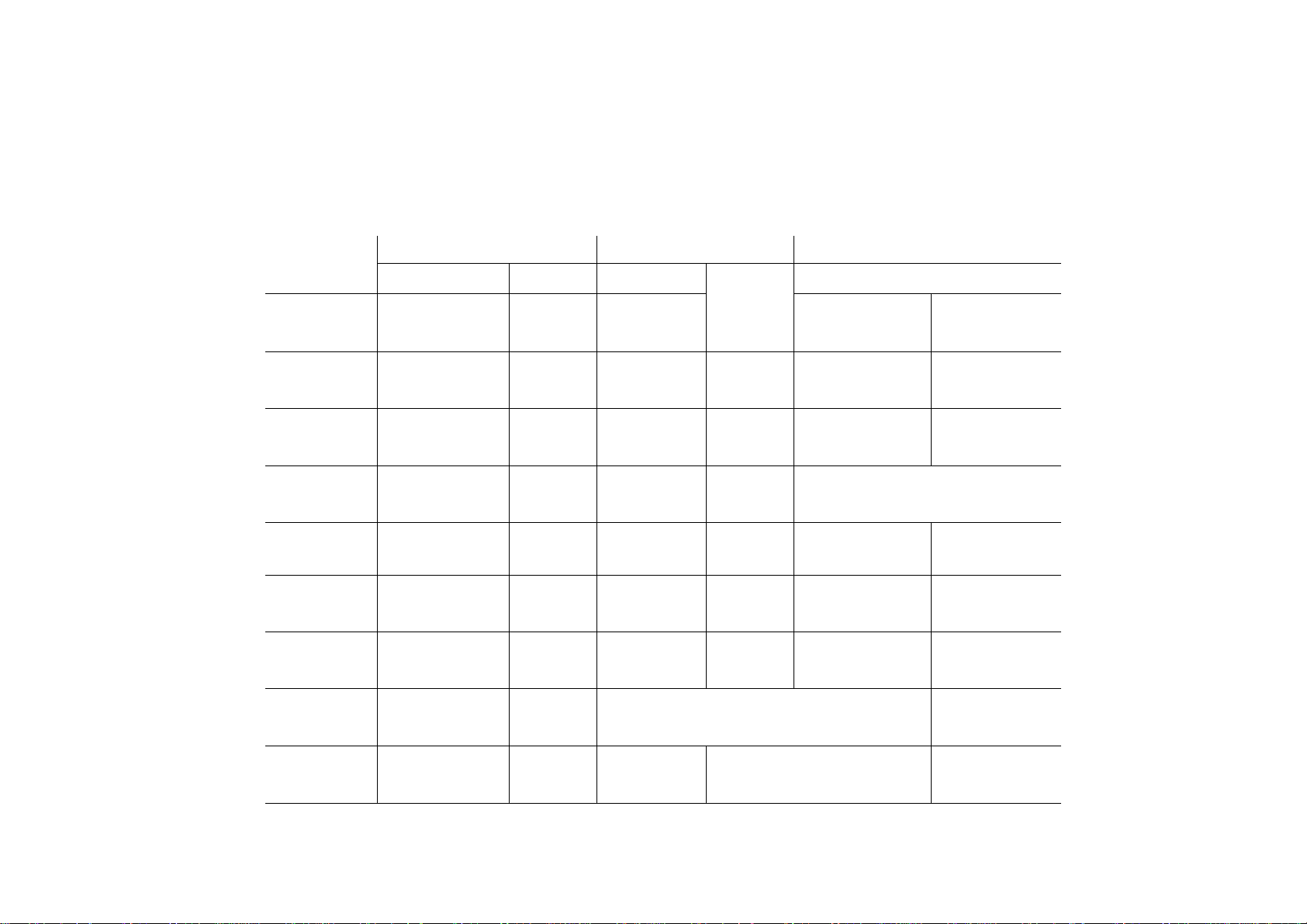

Fabric, Thread and Needle Table

Choosing the correct needle and thread for your fabric is of

utmost importance. Correct choice wiil make the difference

in the wear and appearance of your new garment. The Fabric

Weight Tabie on the previous page; and the Fabric, Thread

and Needle Table below are practical guides to needle and

thread selection. Refer to them before starting a sewing pro

ject. Be sure to use the same size and type of thread in both

needle and bobbin.

Type

of

Fabric

Silk

Rayon

Cotton

Wool

Synthetic

Synthetic

Blends

Leather

Filmy Sheer

Light

Threads Needles Threads Needles Threads Needles

Fine Silk

Rne Mercerized

Rne Silk

Rne Mercerized

Rne Cotton

Rne Mercerized 2020-9 ■

Rne Synthetic 2020-9 ■ Rne Synthetic

Rne Synthetic 2020-9 ■

2020-9 "

2020-9"

Rne Silk

Rne Mercerized 2020-9 ■

Rne Silk

Rne Mercerized

Fine Cotton

Rne Mercerized 2020-9 ■

Rne Silk

Rne Mercerized

Rne Synthetic 2020-9"

2020-9 ■

2020-11

2020-9" Rne Synthetic 2045-11

Rne Silk

Fine Mercerized 2020-11

Fine Silk

Fine Mercerized

Medium Cotton

Medium Mercerized 2020-11

Rne Silk

Fine Mercerized

Fine Synthetic

Medium Mercerized

Medium Synthetic 2032-11

2020-11

2020-11

2045-11

12

Plastic

Vinyls

' Size 9 needle is recommended for sewing only. For bobbin winding, use larger size needle.

I I

Fine Synthetic

I

Rne Mercerized

1 Rne Mercerized

Rne Synthetic

2020-11

2020-11

Page 14

To select the correct needle and thread for your fabric, first

refer to the Fabric Weight Table to determine the weight and

type of the material you are using.

Next refer to the Fabric, Thread and Needle Table.

Find the fabric you are using in Type of Fabric column at left.

(Silk, rayon, etc.) Then locate the fabric weight column (filmy,

sheer, etc.) for your fabric at top of table. Read across from

Type of Fabric column to correct weight of fabric column.

There, the correct thread and needle choice for your fabric

will be found.

Example: If you are sewing a medium weight wool, find wool

in Type of Fabric column. Read across to Medium (weight)

column and you will see that a medium silk or mercerized

thread and a size 2020-14 needle are to be used.

Medium

Threads

Medium Silk

Medium Mercerized 2020-11

Medium Synthetic

Medium Mercerized 2020-11

Medium Cotton

Medium Mercerized 2020-14

Medium Silk

Medium Mercerized

Medium Synthetic

M,edium Synthetic 2045-14 Heavy Synthetic 2045-16 Heavy Synthetic

Medium Mercerized

Medium Synthetic

Needles

V'/' ■ ■ . ..

2020-14

2045-14 Heavy Synthetic 2045-16 Heavy Synthetic

2032-14

Threads Needles Threads Needles

Heavy Silk

Heavy Mercerized 2020-14 Heavy Silk 2020-14

Heavy Synthetic

Heavy Mercerized

Heavy Cotton

Heavy Mercerized 2020-16

Heavy Mercerized 2020-16 Heavy Mercerized 2020-16

Heavy Mercerized

Heavy Synthetic 2032-16

Heavy

2020-14

Heavy Synthetic

Heavy Mercerized

Heavy Cotton

Heavy Meroerized

Heavy Mercerized

Heavy Synthetic 2032-18

Very Heavy

2020-14

2020-18

2045-16

or

2020-18

2045-16

or

2020-18

Medium Mercerized

Medium Synthetic

Medium Mercerized

Medium Synthetic

2020-11

2020-11

Medium Mercerized

Medium Synthetic

Medium Mercerized

Medium Synthetic

2020-14

2020-14

Heavy Mercerized

Heavy Synthetic 2020-16

Heavy Mercerized

Heavy Synthetic

2020-16

13

Page 15

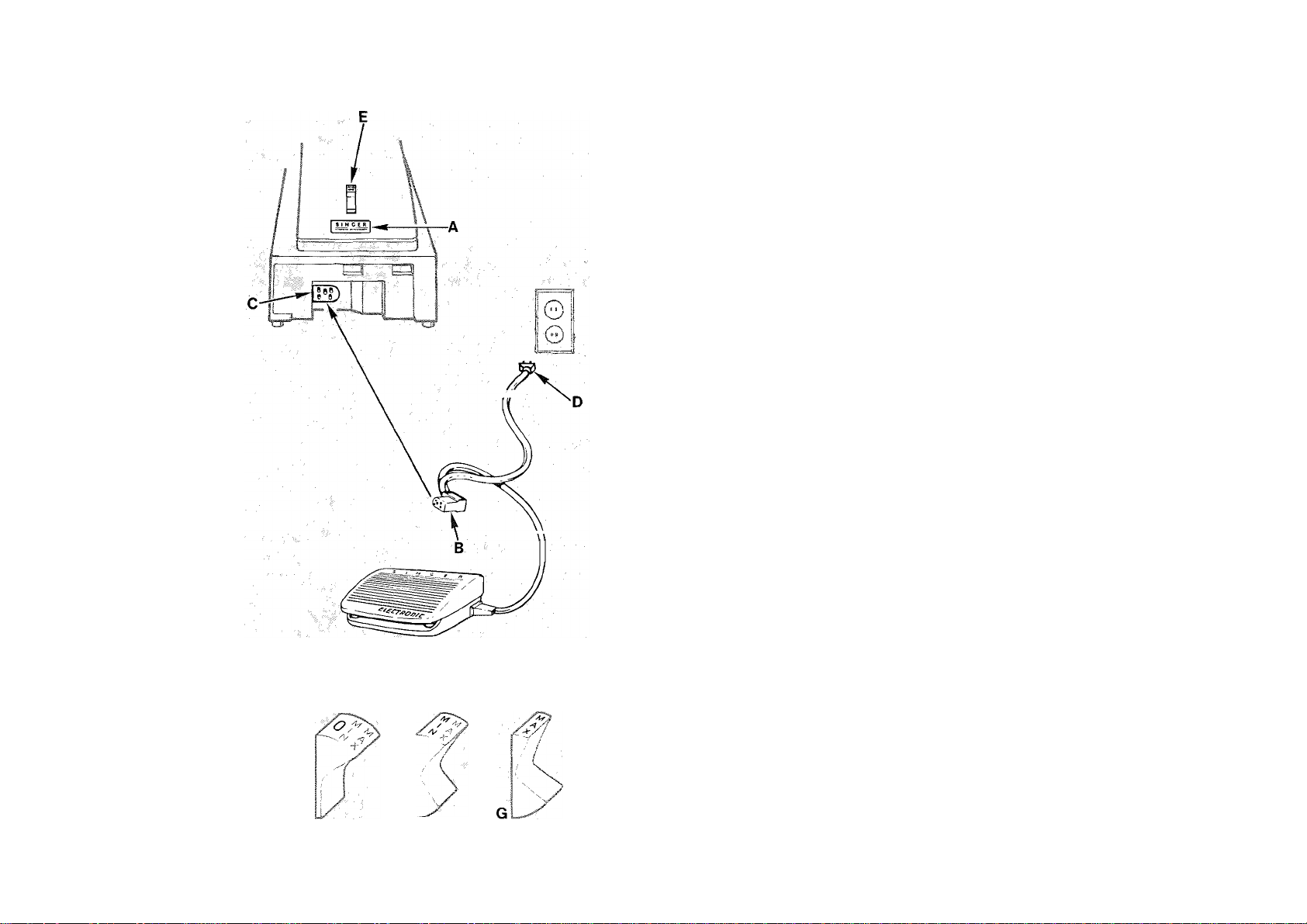

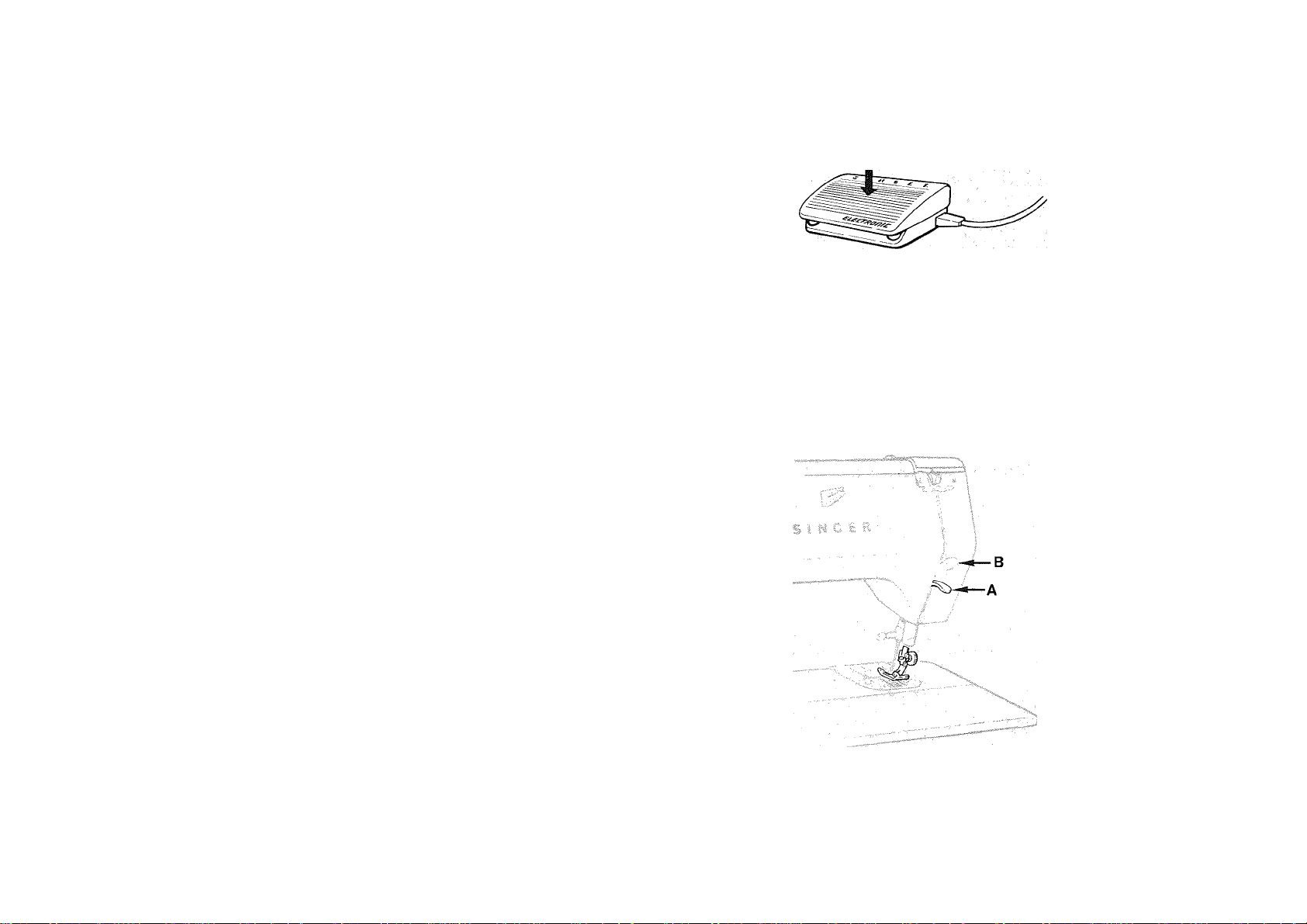

operating machine

Connecting Machine

Before plugging in your machine, be sure that the voltage

and number of cycles indicated at the electrical nameplate

A on the right end of the machine, conform to your electrical

po\wer supply.

e Push the machine plug B into the machine socket C.

e Connect the po\wer-line plug D to your electrical outlet.

Important: Machines for Great Britain and some other countries

having simiiar \«iring standards are shipped from the factory

\«ithout a piug for connection to the mains. The \«ires in this

mains lead are coloured in accordance \«ith the follow/ing code:

Biue - Neutral (N) Bro\«n - Live (L)

Note: As the colours of the \«ires in the mains iead of this

appliance may not correspond \«ith the coloured markings

identifying the terminals in your plug, proceed as follow/s:

Connect bro\«n \«ire to terminal marked L or coloured red.

Connect blue \«ire to terminal marked N or coloured black.

When using a BS 1363 (British Standard) fused plug a 3Amp.

fuse must be fitted. If the terminals of the plug are unmarked

consult a qualified electrician before use.

14

To turn on the machine and set speed range, push the po\wer

and light s\witch E to desired speed. This \will also turn on the

sev/ing light.

® The MIN setting F (s\witch pressed in halfway) allows for

maximum control. Use this setting for special jobs where

intricate construction details require close control.

9 The MAX setting G (switch pressed in all the way) allows

for full speed capacity of the machine. It Is best for long,

straight seams, easy-to-handle fabrics, and general sewing

where a variety of speeds are needed.

Caution: Disconnect the power line plug from the socket

outlet when changing needles, feet or needle plates or when

leaving the machine unattended. This eliminates the possi

bility of starting the machine by accidentally pressing the

speed controller.

Page 16

To run the machine, press the foot operated speed controller.

The speed controller has an electronic circuit which provides

constant speed when sewing on fabrics of varying density in

either speed range. You may also set your own speed for

sewing on delicate, light or heavy fabric. The harder you press,

the faster the machine will sew within the selected speed

range. The lighter you press, the slower the machine will sew

within the selected speed range.

Note: Your machine has a built-in fuse which protects its

electronic brain. If the machine does not operate (stitch selector

lights do not light up) after making electrical connections and

turning on switch, the fuse may need to be replaced. Contact

your local Singer Sewing Centre for additional information.

Lifting the Presser Foot

The presser-foot lifter A allows you to raise and lower the

presser foot. Extra-high lift position B permits easy placement

of bulky fabrics. Make sure the lifter is all the way down

before starting to sew.

15

Page 17

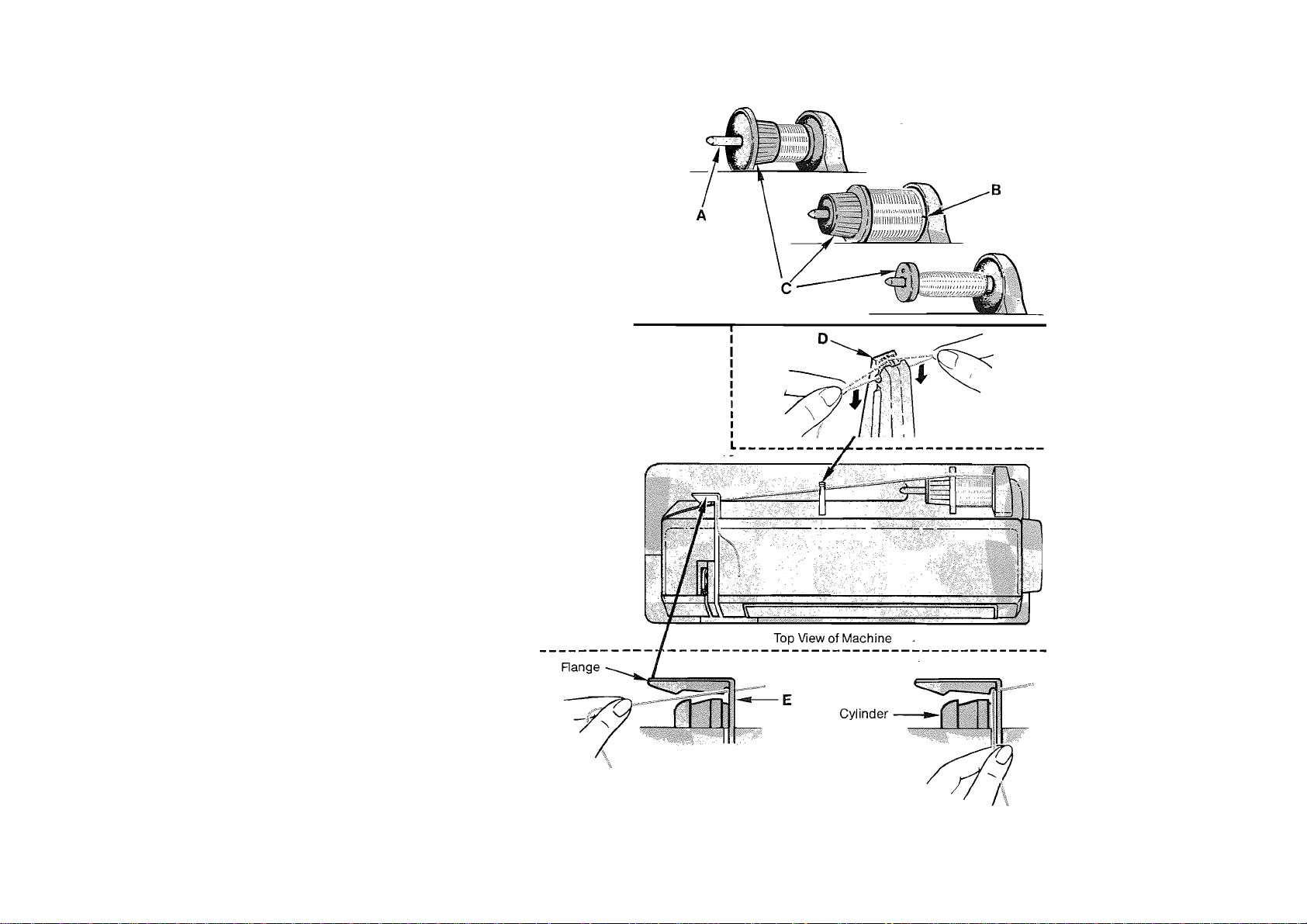

threading the machine

Preparation

• Place spool of thread on horizontal spool pin A. If spool

being used has a thread retaining slit B, it should be placed

against the spool cushion to the right.

• Select correct spool holder according to type and diameter

of spool being used. The diameter of the end of the spool

holder should always be larger than that of the spool itself.

• Press spool holder C firmly against spool.

• Raise the needle and take-up leverto highest position

by turning the hand wheel toward you.

• Raise the presser foot, to release thread tension.

Step1

• Snap thread into thread guide post D.

Step 2

• Thread the rear thread guide E Pass thread under

flange, then over to the far right end of cylinder.

16

Page 18

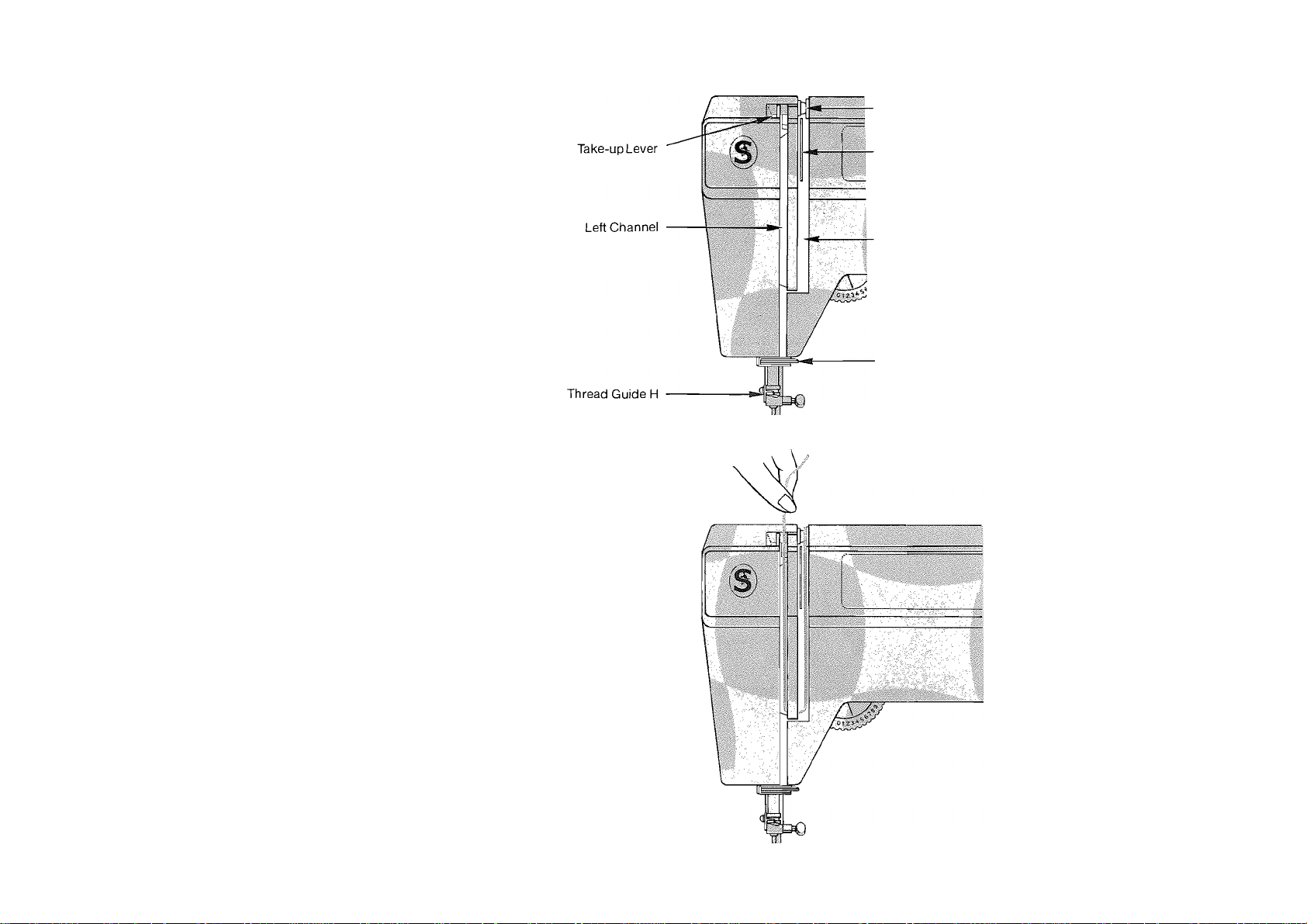

Principal Threading Parts

Step 3

® Draw thread firmly into tension disc on right of

tension separator.

• Draw thread down right channel and up left channel

toward the take-up lever.

RearThread Guide

Tension Separator

Right Channel

Thread Guide G

Continued Next Page

17

Page 19

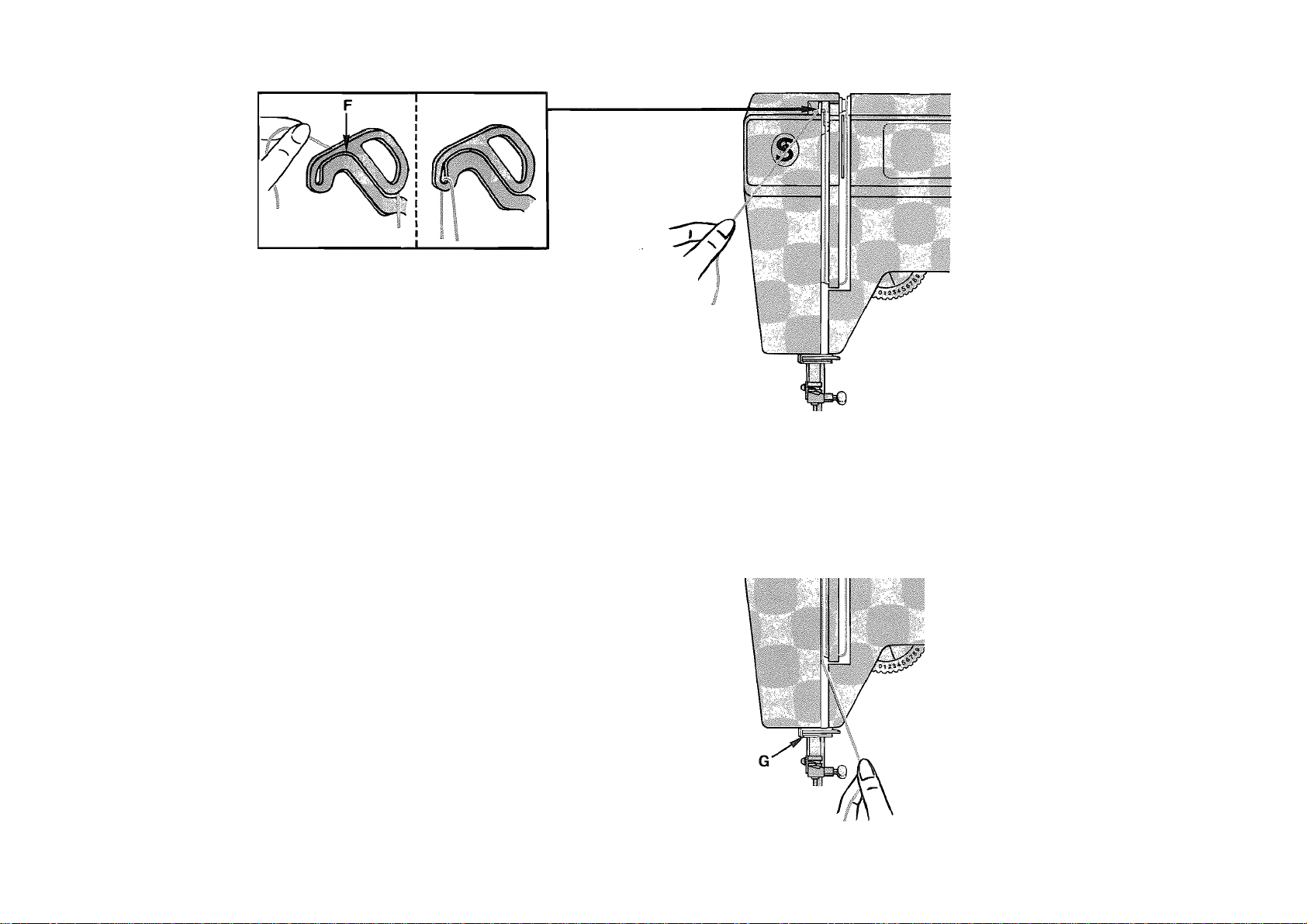

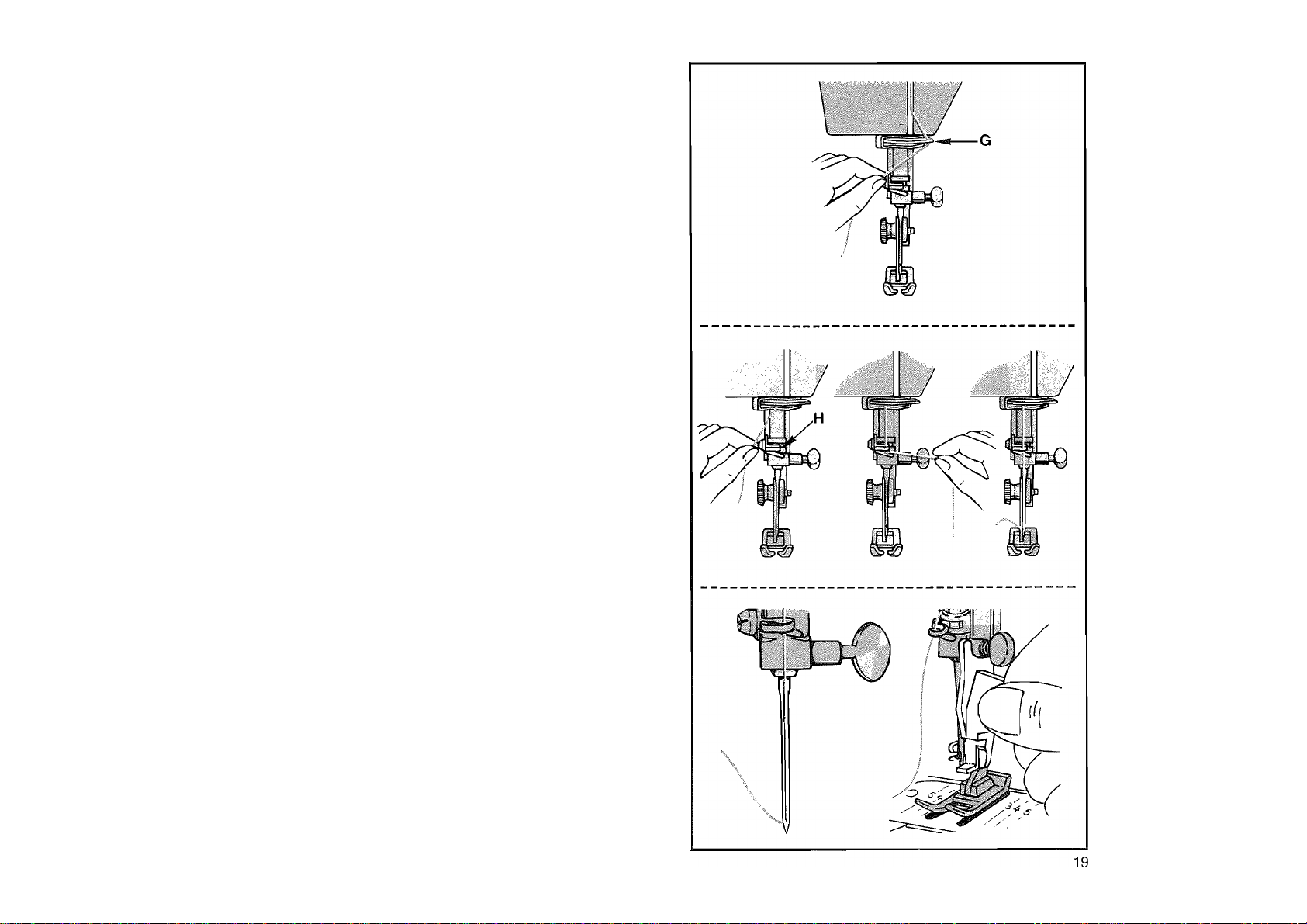

step 4

e Thread take-up lever by guiding thread to back of

lever and around to your left. Bring thread through

slit F by pulling it tow/ard you and into eyelet.

Step 5

• Follow/ thread back dow/n through left channel and

then tow/ard thread guide G.

FIT

Continued Next Page

18

Page 20

step 6

Lead thread into thread guide G by drawing thread lightly to

the left until it completely slips into the left channel.

Step?

• Then draw thread through guide H from the rear of guide

to the right.

steps

Drawing 10 cm (4 inches) of thread down toward needle, lower

presser foot and thread needle front to back.

Using the Needle Threader

Lower the presser foot.

Position the needle threader as illustrated, with the top of

the needle threader resting against the needle clamp which

correctly aligns the needle threader hook to the needle eye.

Pass the hook through the needle eye, guide thread into the

hook and draw the hook and thread through the needle eye.

Page 21

the bobbin

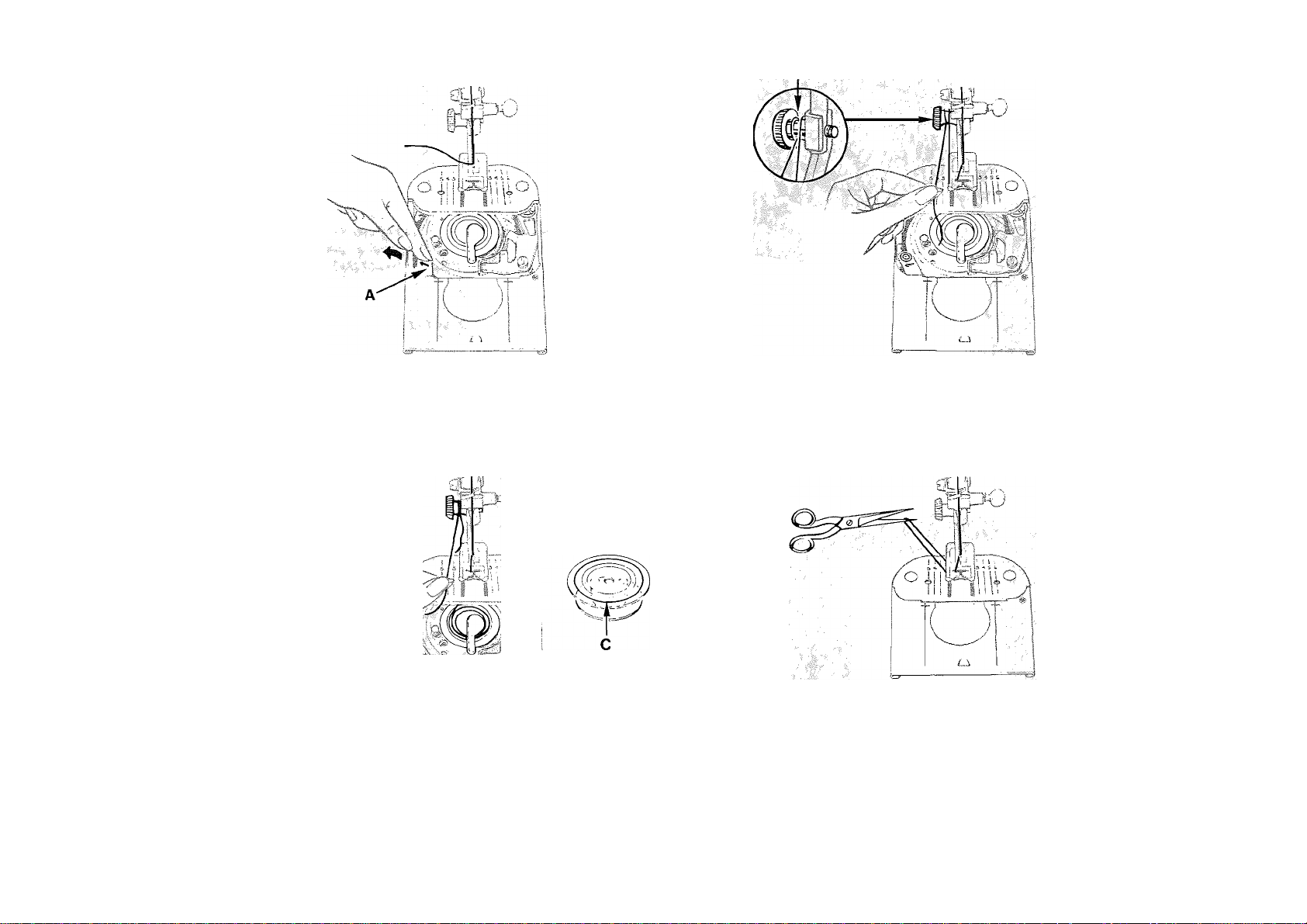

Winding the bobbin

The push-button bobbin will make your sewing go faster than

ever before - whether you are using a lot of one kind of thread

or small quantities of different threads.

You will find a bobbin in place under the slide plate of your

machine. To open slide plate, simply pull it gently toward you.

If the bobbin runs out of thread while you are sewing, you can

rewind it without removing it from the machine. The window

in the slide plate lets you see lower thread supply at a glance,

to help avoid running out of thread in the middle of a seam.

..I*-,

li ■'3

Preparation Steps

№

1. Use general purpose,

presser foot.

special purpose, or straight stitch

j

2. Raise presserfoot by raising presserfoot lifter A to release

tension on thread, and raise the needle and take-up lever

to highest position by turning hand wheel toward you.

(Make sure your needle is larger than a size 9.)

3. Open slide plate and make sure bobbin is empty. For

removal of bobbin and thread, see pages 22 and 23.

B

4. Set machine for straight stitching by pressing button B

under stitch symbol on stitch panel. For additional infor

mation on pattern selection, see page 24.

20

Page 22

Winding Steps

B

We recommend the use of a moderate speed when winding

a bobbin.

1. Move bobbin winding button Ato extreme left.

.r'x

4. Close slide plate to release bobbin winding button tosewing

3. Pull thread end away after a few coils have been wound,

e Watch the bobbin as it fills. Do not allow thread to wind

beyond the outside FULL ring C.

2, Draw upper thread away from you between toes of presser

foot under left side of presser foot, then up from the front

and around presser foot screw B. Hold end of thread firmly.

Start machine, run at moderate speed.

position.

To start sewing, pull thread back under presser foot and cut.

Place threads diagonally under foot to left side, position

needle in fabric where desired, lower presser foot, and

start machine.

21

Page 23

Removing and Changing the Bobbin

f there isafull bobbin in the machine and you wish to change it:

1. Raise needle and take-up lever to highest position by

turning hand wheel toward you. Open slide plate. Raise

bobbin latch by inserting tinger under end ot latch at centre

ot bobbin.

2. Insert tinger under rim ot bobbin immediately to right ot latch

and remove bobbin.

3. Check empty bobbin tirst to ensure that both halves are

tightened securely as described on page 23, Removing

Thread trom Bobbin. With latch raised, slide bobbin with

circle side up into bobbin case.

4. Snap latch down to secure bobbin,

e Wind the bobbin. See page 21.

Using Previously Wound Bobbin

A tull bobbin is inserted in the same manner as an empty one.

5. Place bobbin into case with at least 10cm (4 inches) otthread

leading ottto right side ot latch. Allow the thread to lay in the

slot in the slide plate when closed.

22

Page 24

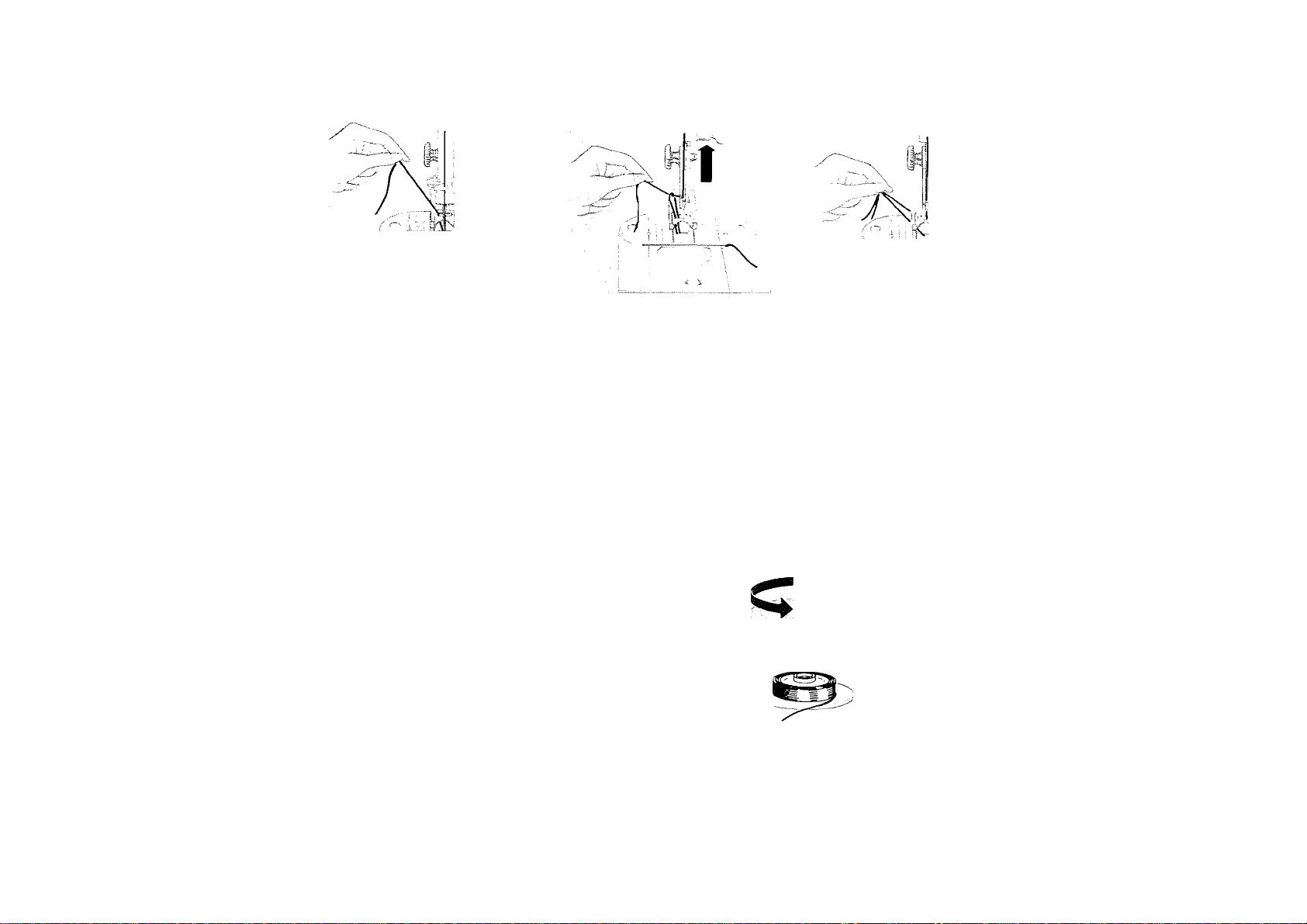

1

Raising the Lower Thread

1. Hold upper thread lightly

with left hand and turn hand

wheel slowly toward you so

the needle enters plate.

2., Continue turning hand

wheel and holding upper

thread until needle rises.

Tighten your hold on the

upper thread and bring up

lower thread in a loop.

Removing Thread from Bobbin

1. If there is not much thread left on the bobbin in the

machine, simply pull the thread end through the

needle plate until bobbin is empty.

3. Open the loop with your

fingers, draw approximately

10 cm (4 inches) of both

upper and lower threads

under the presser foot and

place them diagonally to

left.

If there is a lot of thread on the bobbin, remove bobbin,

unscrew the two halves of the bobbin and remove all

the thread. Then tighten bobbin halves securely.

23

Page 25

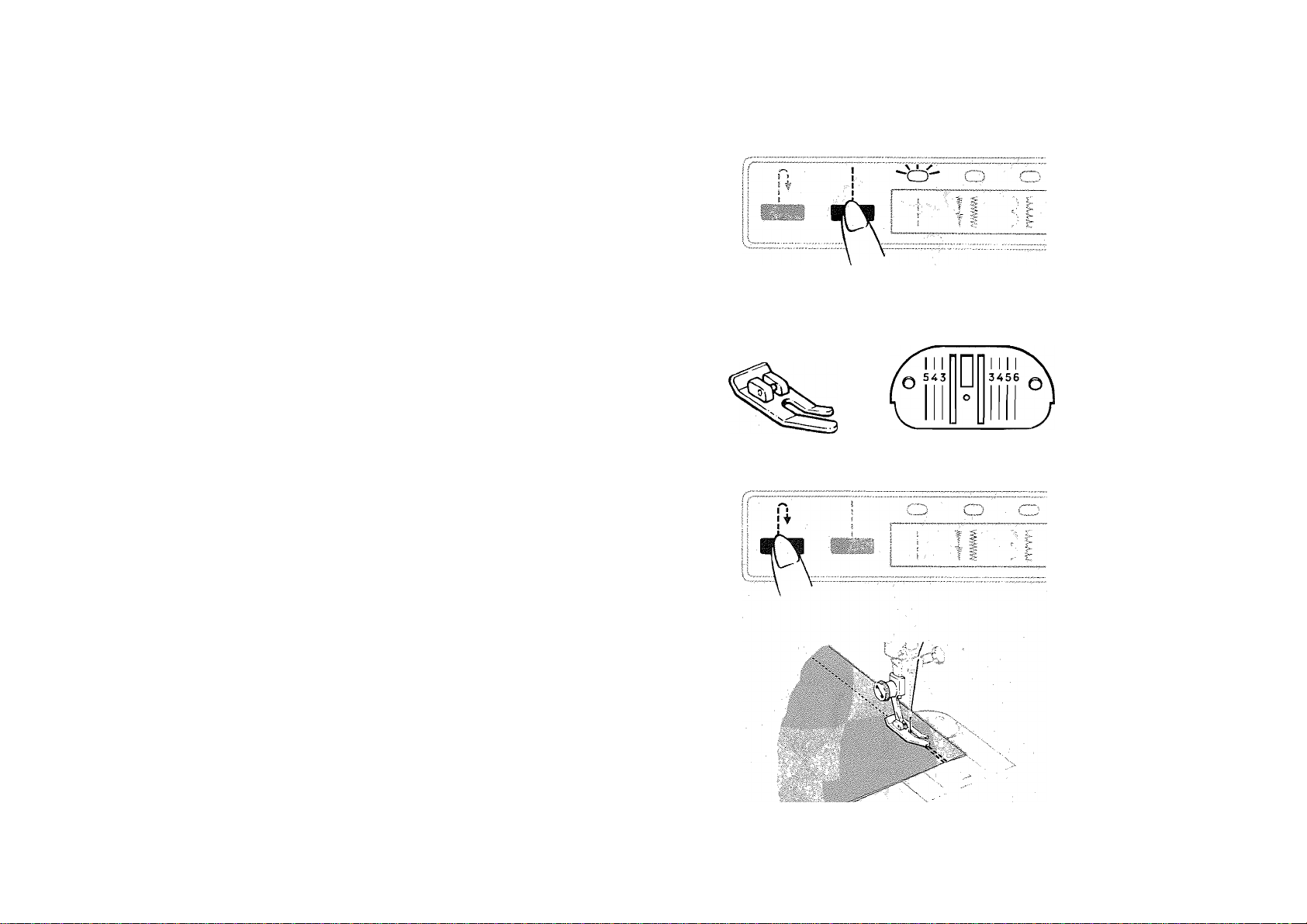

ei SeLJImg

selecting a stitch

• Turn machine on.

(Note movement of needle each time power switch is

turned on.)

• When machine is turned on, it will automatically be pro

grammed to produce a straight stitch as indicated by the

red light which will appear above the straight-stitch

symbol i .

• To select a particular stitch pattern, press pattern selector

button A until the red light B appears above the pair

of stitches in which desired stitch is contained.

Each press of the button advances the indicator light one

pair of patterns to the right.

B

!♦

o o

'i it

4^

If necessary, slide pattern group selector C to position

desired stitch under light. Machine is ready to sew desired

pattern when red light appears above it.

The two red patterns at the end of the panel represent the

buttonhole. For additional information on buttonhole, see

page 66.

Press straight-stitch selector button D if you want to return

to straight stitching after pattern stitching.

For reverse stitching, press and hold in reverse stitch

selector button E while sewing.

Note; The machine will only reverse in straight stitch.

o o o ^

11

-i il!

■J

24

4' 5‘ 6‘ 7

Group 1

1 Arrowhead

2 Scallop

3 Domino Stitch

4 Honeycomb

5 Feather

6 Ric-Rac

7 left Side of Buttonhole

Flexi-Stitch • Patterns

5" 6*

Group 2

1 Plain Zig-Zag

2 Elastic Stretch

3 Multi-Stitch Zig-Zag

4 Blindstitch

5 Straight-Stretch Stitch

6 Overedge Stretch

7 Right Side of Buttonhole

Straight-Stretch Stitch

Page 26

(SI‘2a®aSii Siragg].# Stlfreihimg

preparation

Select straight stitch.

A red light wiil be seen above the stitch symbol to indicate

that the machine is ready to produce a straight stitch.

Straight stitch needie plate and foot are best for all straight

stitching. The straight stitch foot ailows you to controi the

fabric easily when stitching around a curve or close to the

fabric edge. The design of the foot helps prevent skipped

stitches.

The straight stitch foot is to be used oniy with the straight

stitch needle plate. When you use the straight stitch needle

plate your machine will only sew a straight stitch even if you

touch another pattern symboi by mistake.

Always change back to the appropriate needle plate and

presserfoot when doing sewing other than straight stitching.

Use of Reverse Stitch

If you wish to reinforce the beginning or end of a seam, keep

finger on the reverse stitch button.

Machine will only sew a straight stitch in reverse for as long

as you keep your finger on the button.

25

Page 27

adjusting machine to your fabric

' \i

Vi,

№ 'll

Adjusting Stitch Length ”

Before starting to sew, adjust the stitch length of your pattern

on a scrap of fabric.

Turning the stitch length control toward 4 increases the length

of your stitch, and turning the control toward 0 decreases the

length. Turn the control until desired length is obtained.

Note: When sewing FlexiStitch patterns, adjust stitch length

control within yellow FlexiStitch area--. FlexiStitch patterns

are illustrated on page 24.

For information concerning appropriate stitch iength see chart on

opposite page.

26

MAX.

(

Regulating Presser Foot Pressure

Correct pressure is important to feed fabrics smoothly and

evenly. The NORM, (normal) setting is an all-purpose setting

that can be used for sewing a wide variety of fabrics of different

weight and texture. Alternative settings + and — above and

below NORM, (normal) are also provided.

Lower presser foot before setting pressure.

1. To increase pressure, turn dial from NORM, toward MAX.

2. To decrease pressure, turn dial from NORM, toward

3. For darning, set dial on ^.

I

NORM.

1

Page 28

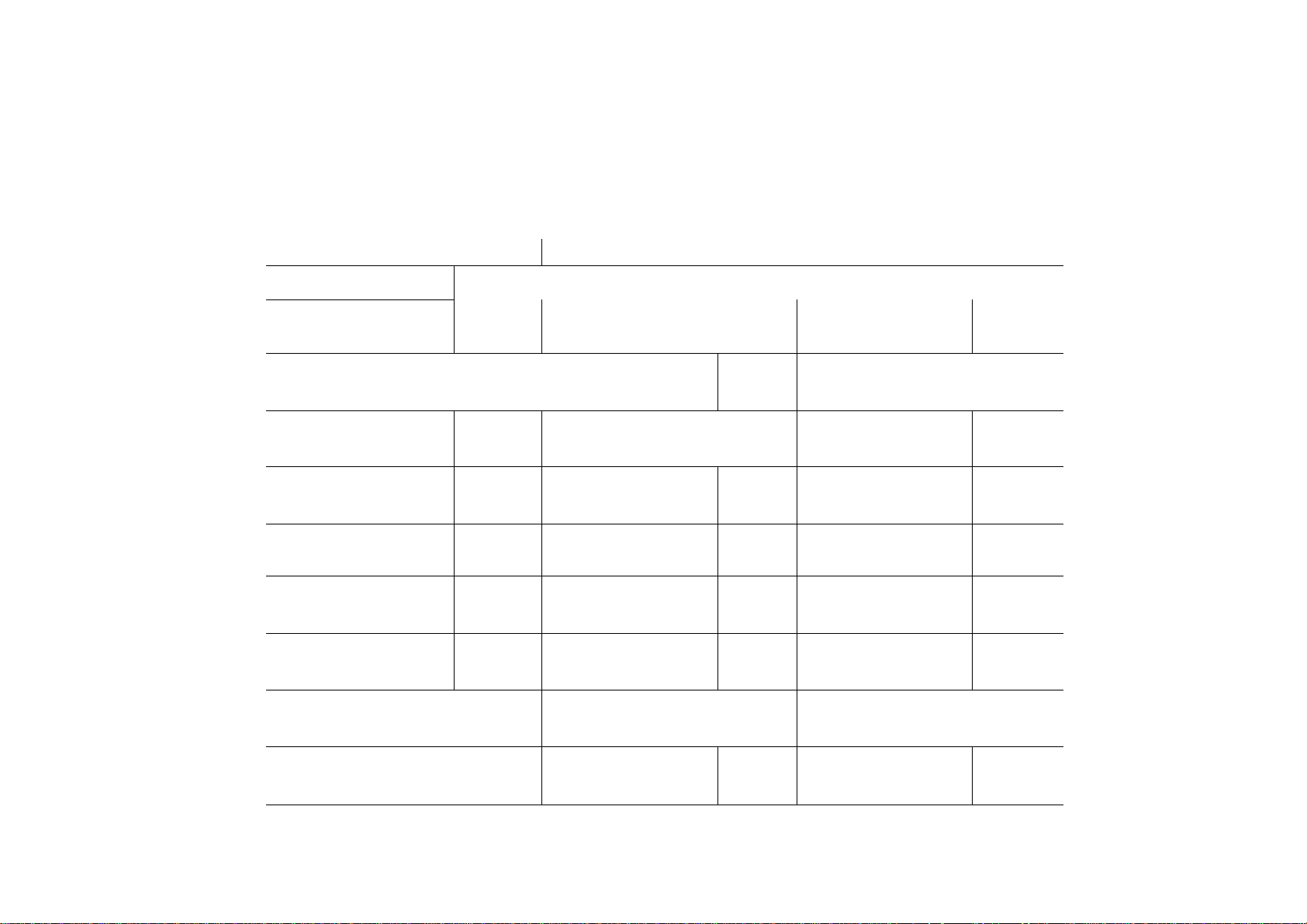

Choosing the correct stitch length is of utmost importance. guide to stitch length selection. Refer to it before starting a

The correct choice will make the difference in the wear and sewing project. Remember to make a test sample on a scrap

appearance of your new garment. The table below is a practical piece of the fabric you will be using.

Stitch Length Guidance Table

Part of

Weight of Fabrics

Article or

Garment

Straight Main Seams 1.5-2 1.5-2 2-2.5

Curved Main Seams 1.5-2 1.5-2 1.5-2

Neckline* &Armholes 1.5-2

Stay Stitching * 1.5-2 1.5-2 1.5-2 1.5-2

Gathering 3-4 3-4 3-4 4 4

Zippers * 1.5-2

Top Stitching * 3 3

Stress Areas or Seams

Rimy Sheer

1.5-2 1.5-2

1.5-2 2-2.5 2-2.5

1.5-2

1.5-2 1.5-2 1.5-2 1.5-2

Light Medium Heavy Very Heavy

2-2.5 2.5

2-2.5 2-2.5 2.5

2-2.5 2-2.5 2 - 2.5

2-2.5 2-2.5

2.5

3-4 3-4 4 4

2.5-3

4

2.5

1.5-2

Slow to moderate speed.

Stress Areas in Knit or Stretch Fabrics

Contrary to common belief it is not always necessary to use

a s-t-r-e-t-c-h stitch on ail seams in garments made from

these fabrics. Always consider the ’’stress” areas, for example;

armholes, crotch seams, also how much the garment will be

required to ’’give” and where. Use a stretch stitch where

needed. Moreover, always ascertain that the fit of the garment

is correct before sewing any seam with a s-t-r-e-t-c-h stitch.

Ripping out a s-t-r-e-t-c-h stitch is difficult and may damage

fabric. For sewing on stretch fabrics, see pages 45 and 61.

27

Page 29

Upper Thread Tension

Having selected the correct needle and thread combination

for the fabric being used, it may be necessary to adjust the

tension of the sewing machine to ensure a well balanced stitch.

A well balanced stitch is produced when the upper and lower

threads appear the same on the fabric, illustration A.

Yourmachine has an adjustable uppertension control system.

This control exerts tension on the upper and lower thread

as they pass through the machine to form a stitch.

• Too much tension will produce a tight stitch which will

cause puckered seams, illustration B.

To decrease tension, turn dial to a lower number.

28

• Too little tension will produce a loose stitch, illustration C.

To increase tension, turn dial to a higher number.

When an even amount of tension is exerted on both threads,

a smooth even stitch known as a balanced stitch, is produced.

Page 30

Tension Test

To help understand the effect of tension on fabric and thread,

try this simple test:

• Take two pieces of a medium weight woven fabric in a solid

light colour about 15 cm (six inches) long.

• Place a 2020 size 14 needle in the machine.

• Thread the top of your machine with a polyester or mer

cerized dark colour thread and use a lighter colour thread

of the same fibre and size in the bobbin.

• Select straight stitch.

• Seam the two pieces of fabric together starting with the

upper tension control at 0. Then as you sew, slowly turn the

tension control from 0 through 9.

• Sew another row turning the dial back to 0. You should

have a balanced stitch on each row mid-way between the

start and finish in each case.

• The different coloured threads will help you to see the

effect that the tension has on the upper and lower threads.

Now that you have observed the effects of tension, we suggest

that you perform a similar test on a scrap of the fabric you

plan to use, being sure to duplicate the number of thicknesses

of your garment.

Lower Thread Tension

The lower thread tension has been set at the factory for most

types of stitching. However, for fine fabrics, we recommend

reducing lower thread tension by turning screw A counter

clockwise as far as possible, using the small screwdriver from

accessories.

When stitching is completed, be sure to turn screw A clock

wise back to its position for regular sewing.

29

Page 31

sewing a seam

Preparation

• stitch: straight stitch |

• Stitch length: to suit application or fabric

• Straight stitch needle plate

• Straight stitch foot

Thread machine in the usual way.

Placing Fabric Under Foot

Most fabrics can be placed under the foot by raising the

presser foot lifter A to its normal up position 1, where it locks.

When using bulky fabric, multiple fabric layers, or an embroi

dery hoop, raise the presser foot lifter to the high rise position

2, thus increasing the space between foot and needle plate.

Hold presser foot lifter in position while placing fabric under

the presser foot.

• Lower presser foot lifter all the way down and start to sew.

30

>

When starting to stitch at the fabric edge:

• Position needle in very edge of fabric, by turning the hand

wheel toward you.

• Lower the presser foot and stitch. Thread will lock over

fabric edge.

OR

When starting to stitch away from fabric edge:

• Leave presser foot in its upper position.

• Pull thread back under presser foot and cut.

• Position needle in from fabric edge, then lower the presser

foot and stitch.

Backstitch to lock stitching by pressing the reverse button

while sewing. Only a few stitches are needed to lock stitching

line in place. Do not go over edge of fabric.

Sewing with a Newly Wound Bobbin

Page 32

Keeping Seams Straight

To keep the seam straight, use one of the numbered guide

lines A on the needle plate. Line 5, the most commonly used,

is extended on the slide plate for you convenience.

The crosslines B serve as guides when stitching a square

corner.

For extra help in keeping the seam straight, you may wish

to use the seam guide. Because it allows you to guide stitches

evenly between 3 mm (Vs inch) and 32 mm (1 'A inches) from

the fabric edge, it is particularly useful for very narrow or very

wide seams.

To attach seam guide to machine, refer to page 7.

Turning Square Comers

To turn a square corner 1.6 cm (Vs inch) from the fabric edge,

you need not measure or mark the seam. Simply use the

crosslines A on the slide plate.

• Line up your fabric with right or left guideline 5 on the plate.

Stitch seam, slowing speed as you approach corner.

e Stop stitching, with the needle down, when the bottom

edge of the fabric reaches the cornering crosslines on the

slide plate.

e Raise presserfoot slightly and turn fabric on needle, bringing

bottom edge of fabric in line with guideline 5.

• Lower the presserfoot and stitch in new direction.

31

Page 33

Curved Seams

• Use a short stitch for elasticity and strength. For example,

if the stitch length control on your machine is set on 2

for straight seams, adjust the control between 1.5 to 2 to

stitch curved seams in the same fabric.

• If you use the seam guide, attach it at an angle so that the

edge that is closer to the needle acts as a guide.

Reinforcing End of Seam

• stitch to the edge of the fabric. (Do not sew beyond edge

of fabric)

• Press reverse stitch button and hold in place. Backstitch

approximately 1.5 cm (’/2 inch) to reinforce end of seam.

Release reverse stitch button.

• Raise needle and take-up lever to highest position by

turning hand wheel toward you and raise presser foot.

Remove the fabric by drawing it to the back and left.

• Cut threads on thread cutter at rear of presser bar.

o

! +

II

o

& :i'

^ III

32

Page 34

applications

Darning

With Embroidery Hoop

• Stitch: straight stitch j

• Stitch length: 0

• Snap-on feed cover (To attach feed cover see page 7)

• No presser foot or shank

• Embroidery hoop

For best results. Flip & Sew panel should be up when darning with

embroidery hoop.

Without Embroidery Hoop

• stitch: straight stitch |

• Stitch length: between 1 and 1.5

• General purpose needle plate

• Special purpose foot or general purpose foot

• Pressure setting: ^

* •

• Trim ragged edges from area to be darned and centre worn

• Select straight stitch.

• Position work in hoop and place hoop under presser bar,

• Hold upper thread loosely with left hand, turn hand wheel

• Select straight stitch.

• If area to be darned is open, baste an underlay in place.

• Place area to be darned under presser foot; lower presser

foot and start stitching, aiternately drawing fabric toward

you and pulling it gently away from you.

• Outline area to be darned with running stitches for rein

• Stitch across opening, moving hoop back and forth under

• Continue this forward and backward motion as you fill the

area with parallel lines of stitching. For additional strength,

cover area with crosswise lines of stitching.

• When opening is filled, cover area with crosswise lines of

section in embroidery hoop.

then lower the presser bar to engage tension.

toward you, and draw lower thread up through fabric. Hold

both thread ends and lower needle into fabric.

Snip off thread ends after a few stitches.

forcement as illustrated.

foot. Keep lines of stitching closely spaced and even in

length.

stitching.

33

Page 35

Darts

Darts can be made in the usual way on your machine. That is,

you begin stitching at the wide end of the dart, stitch to the

point, and then fasten the two thread ends.

However, you can avoid the problem of fastening the thread

ends by making a "continuous-thread” dart and stitching in

the opposite direction. This method is particularly useful for

darts in sheer fabrics, where transparency requires a neat,

clean finish. It is also useful for darts made on the right side

of a garment as a style detail.

Regular Darts (Illustration A)

® Stitch: straight stitch |

B

e Stitch length: to suit fabric

® Straight stitch needle plate

m Straight stitch foot

•

Stitch from the seam edge, tapering gradually to the point.

Stitch beyond the fabric to form a thread chain 1.5 cm

('/2 inch) to 2 cm (3/4 inch) long.

Clip thread ends about 5 cm (2 inches) from dart point

and tie the ends into a single knot close to the stitching.

34

Continuous-thread Darts (Illustration B)

• Set the machine as for regular darts.

e To wind an empty bobbin with enough thread for a single

thread dart up to 20 cm (8 inches) long, turn hand wheel

over once by hand and cut off thread end. Make four

additional turns of the hand wheel.

• Close slide plate, and position the needle in the very edge

of the fold, at the point of basted or pinned dart. Lower

presserfoot.

• Stitch carefully, making the first three or four stitches in

the fold of the fabric, then sew towards the wide end of

the dart.

• Reinforce wide end of dart with reverse stitching and as

work is removed from machine, bobbin will be completely

emptied, ready for rewinding for next dart.

Page 36

Quilting

Quilting is the art of stitching two or more thicknesses of fabric

together in a planned design. A padding is stitched to the

underside of the fabric to produce a soft, puffed effect that is

becoming to some wearing apparel and to many fabric

furnishings.

e Stitch; straight stitch |

e Stitch iength: to suit appiication or fabric

« Straight stitch needie piate

e Straight stitch foot

sheet wadding, or a lightweight wool interlining to the under

side of the fabric. When using sheet wadding, first back it with

voile, batiste, or net to preserve the sheet wadding through

wear. Baste the layers of fabric and padding together on the

lengthwise and crosswise grains.

Basic Procedure

9 Select straight stitch.

9 Draw both threads under the foot and diagonally across

feed to left.

• Position the needle, lower the foot and start stitching.

Note: For best results use the quilting foot availablefor separate

purchase at your local Singer store.

Note: If you are quilting a very large piece, work from the

centre of the fabric to the edges. Guide the fabric with both

hands.

Preparing the Fabric

Baste a light padding of cotton flannel, synthetic quilt batting,

If the fabric has a floral or scroll design, the pattern in the fabric

can be your quilting design. Stitch it from the top side.

■

:■ ,

i

Mf\

t .»

I / V

35

Page 37

Zipper Insertion

How the zipper is inserted will depend on the type of the

garment and the location of the zipper. With the adjustable

zipper foot, you will find it easy to sew an even line of stitching

close to the zipper. For inserting zipper foot on machine, see

page 6.

• Stitch; straight stitch |

• Stitch length: to suit fabric

• Straight stitch needle plate only

• Zipper foot

The zipper foot can be used either to the left or right of the

needle - depending on where the bulk of the garment is

placed.

Attaching the Zipper Foot

When the zipper is to the left of the needle:

• Attach left side of zipper foot to shank (needle will enter

left notch in foot) - see illustration A.

When the zipper is to the right of the needle:

• Attach right side of ^pper foot to shank (needle will enter

right notch in foot) - see illustration B.

* •

36

Zipper inserted under left Lapped Seam

• Baste the seam line the exact length of the garment opening

and press the seam open.

• Attach thezipperfoot to the right of the needle (illustration A),

e Open the zipper.

• Ratten out the back seam allowance and place the zipper

face down on it, as illustrated, with the edge of the zipper

teeth following the seam line.

• Stitch the zipper tape onto the seam allowance.

Continued on next page.

Page 38

• Adjust the foot to the left of the needle (illustration B on

page 36).

• Close the zipper and turn it face up.

• Smooth back the seam allowance at the edge of the zipper.

• Top stitch to the tape close to the folded edge.

• Spread garment flat and turn zipper face down over front

seam allowance.

• Hand baste zipper to garment from wrong side, through

zipper tape, seam allowance, and front of garment.

Turn garment right sidecut.

Adjust zipper foot to right side of needle and stitch across

the lower end of the zipper and up to the waistline, using

the basting stitches as a guide.

Remove bastings. Press.

37

Page 39

-v' >J3 ij

la&ic

Wi

Stiff

Zig-Zag Stitching

• stitch: zig-zag ^

• Stitch width; to suit application or fabric

• Stitch length: to suit application or fabric

• General purpose needle plate

• General purpose foot

Adjusting Stitch Width

Before starting to sew, adjust the stitch width of your pattern

on a scrap of fabric.

Turning the stitch width control toward the largest zig-zag

symbol increases the width of your stitch, and turning the

control toward the straight stitch symbol decreases the width.

Turn the control until the desired width is obtained.

Note: When sewing Flexi-Stitch patterns, set stitch width con

trol on yellow Flexi-Stitch dot ».

38

* •

Adjusting Stitch Length

Before starting to sew, adjust the stitch length of your pattern

on a scrap of fabric.

Turning the stitch length control toward 4 increases the length

of your stitch, and turning the control toward 0 decreases the

length. Turn the control until desired length is obtained.

Note: When sewing Flexi-Stitch patterns, adjust stitch length

control within yellow Flexi-Stitch area

D

--

.

Page 40

Adjusting Upper Thread Tension

Zig-Zag stitching usuaily requires iess upper thread tension

than straight stitching. Be sure your machine is threaded

correctly and make a test sample with the fabric and thread

you plan to use so that you can adjust tension to suit the stitch

pattern you have chosen. The stitches should lie flat against

the fabric without causing the fabric to pucker, illustration A.

If the stitches are not flat and the fabric is puckered, illustration

B, lower the upper thread tension by turning the dial to a

lower number.

Lower Thread Tension

Lower thread tension has been set at the factory for most

types of stitching.

Adjusting Lower Thread Tension for Balanced Open Zig-Zag Stitching

A balanced open zig-zag stitch where both lower and upper

threads lock at the corner of each stitch in the fabric as shown,

can be achieved by turning screw A to the left (counterclock

wise) as far as it will go, using the small screwdriver in your

accessory box.

® Set upperthread tension dial on 1.

• Using two layers of scrap fabric, sew slowly stitch by stitch,

gradually rotating tension dial to higher number until the

upper and lower threads lock at the corner of each stitch

and the stitch formation is the same on both sides of the

fabric.

When stitching is completed, return screw A to position for

regular sewing by turning to right (clockwise) as far as it will go.

\

39

Page 41

applications

Zig-Zag Seam Rnishes

Seam edges support the garment and should be given a

durable finish if the fabric is likely to ravel. There are two

methods of finishing seams in such fabrics: method 1 .trimming

iAAMAAAVVVVVVWVVXVVVVVVVVVVVVVVVV

hAMANW\/W^W)/^

after stitching seam edge, or method 2, overedging. Makea test

sample first to determine which method best suits your fabric.

Method 1 - Trimmed Seam Finish

• Stitch: zig-zag ^ or multi-stitch zig-zag

• Stitch width: to suit application or fabric

• Stitch length: to suit application or fabric

• General purpose needle plate

• General purpose foot

• Select appropriate stitch pattern.

• Adjust stitch width and length if necessary.

• Place stitching near the edge of the seam allowance.

• Trim seam edges evenly, as illustrated, after stitching is

completed.

40

Method 2 - Overedged Seam Rnish

• Stitch: zig-zag ^ or multi-stitch zig-zag <;

• Stitch width: to suit application or fabric

• Stitch length; to suit application or fabric

• General purpose needle plate

• General purpose foot

•

• Trim seam edges evenly.

• Adjust stitch length and width if necessary.

• Place stitching over the trimmed edge of the seam allowance as iilustrated.

Page 42

Lingerìe Seams

To make a lingerie seam durable and flexible, use the plain

zig-zag stitch at a narrow width setting. This seam treatment

is particularly suitable for bias seams. When seaming nylon

tricot, insert a Yellow Band needle in the machine before you

begin to sew.

• Straight stitch the seam on wrong side of fabric.

• Press both seam allowances in the same direction.

• From the right side, topstitch with narrow zig-zag stitching,

letting the needle alternately enter the seam line and the

seam thickness.

Satin Stitching

Satin stitching, a series of closely spaced zig-zag stitches

that form a smooth, satin-like surface, illustration A, is useful

for both practical and decorative work. Stitch patterns can be

sewn at satin-stitch length.

Set your machine for desired stitch. Adjust stitch length for

satin stitching (see below); stitch width in narrow to medium

range. Use general purpose plate and special purpose foot.

Adjusting Stitch Length

• Set machine for a medium length stitch.

• Run machine at slow speed.

• Gradually adjust stitch length from 1 toward 0 until stitches

are closely spaced and form a smooth surface.

/M/WV\AAAAAA/\AAMM

Adjusting Upper Thread Tension

Satin stitching usually requires less tension than straight

stitching and open zig-zag stitching. Furthermore, the wider

the satin stitch, the lighter the tension on your thread must be.

Notice the stitching on your sample. If the fabric is puckered,

illustration B, or the lower thread is pulled to the fabric sur

face, lower the upper thread tension by turning the dial to a

lower number.

41

Page 43

Appliqué

The stitch most commonly used in appliqué is a plain zig-zag,

closely spaced to form a satin stitch. The width of this stitch

can be varied to accommodate fabrics of different weaves and

textures. Other stitch patterns can also be used.

Preparation

Make a test sample to decide which of the following methods

is the most appropriate for your fabric and design. Mark design

on piece of fabric to be appliqued. Cut out design leaving

about 2 cm pA inch) margin all around.

Position the design.

Baste it to the fabric.

Method 1

® Set pattern selector and stitch width dial for desired

applique stitch. Adjust stitch length to fine setting, between

1 and 0.

• Follow the outer edge of the design with a decorative stitch.

• Trim away the excess fabric on the outer edges of the

stitching.

Method 2

® Select straight stitch.

• Outline the entire design with a short stitch.

• Trim raw edges to the stitching and remove basting.

• Selecht stitch pattern and stitch width desired, and set stitch

length on a satin stitch setting for a closely spaced stitch,

between 1 and 0.

® Stitch, following the straight stitch outline. This method will

produce a smooth overedged finish, with no raw edges to

be trimmed after stitching.

42

Method 3

® Purchased motifs can be appliqued quickly and easily by

using either a straight or decorative stitch.

Page 44

Free-Motion Embroidery

In free-motion embroidery, you sew without a presser foot and

9 Stitch, outlining or filling in design with zig-zag stitches.

control fabric movement by means of an embroidery hoop.

Either a straight ora plain zig-zag stitch can be used. Because

you can move the hoop in any direction - forward or back

ward, from side to side, or even diagonally - free-motion

stitching is extremely useful forembroidery designs. The hoop

should be one designed for machine use.

You can vary the length of stitches simply by moving the hoop

faster or slower under the needle. The faster you move the

hoop, the longer the stitches will be. You can also vary the

A series of bar-tacks can be used to form spray-like leaves or

flowers. This technique adds variety and lightness to many

designs. Leaves and petals formed in this way may carry the

thread from one bar tack to the next. This carrying thread

eliminates tying of the thread ends.

width of zig-zag stitches from wide to narrow by controlling

the angle at which the hoop is placed and moved under the

needle.

Flower Embroidery

• stitch: zig-zag ^

@ Stitch width: to suit application or fabric

9 Snap-on feed cover (To attach feed cover see page 7)

9 No presser foot or shank

Preparation

Trace design on right side of fabric. Prepare the area to be

embroidered using an underlay if the fabric is soft. Place the

work in an embroidery hoop approximately 18 cm (7 inches)

in diameter. If the design to be embroidered covers a large

area, it will be necessary to reposition the work in the hoop as

each section is completed.

For a smooth, satiny surface, place parallel stitches close

together, moving hoop slowly and steadily. For an irregular

texture, move the hoop more rapidly, allowing some stitches

to overlap.

•¡t

*>(-

Procedure

® Position work under needle and lower presser bar to engage

tension.

9 Hold upper thread loosely and turn handwheel toward you

to bring lower thread up through fabric. Hold both thread

ends and lower needle into fabric.

43

Page 45

Chapter 6: Machine Stitch Patterns

how stitches are produced

In addition to the straight stitch, your machine can produce

a variety of stitch patterns. Fashion* Stitch patterns (white on

panel) are produced by the side-to-side movement of the

Stitch Pattern Chart

Pattern group selector moved to right

Arrowhead Stitch - Combines beauty and utility.

Individual pattern units reinforce points of strain.

Use them on pocket corners in place of bartacks.

Scallop Stitch - Makes perfectly formed, evenly

spaced scallops for edgings and tucks.

Domino Stitch - An interesting pattern for

decorative stitching.

Honeycomb Stitch - Ideal for smocking and

useful for mending, overcasting and attaching

elastic and stretch lace.

needle. Fiexi-Stitch* patterns (yeiiowon panel) are produced

by both the side-to-side movement of the needle and the

back-and-forth movement of the feed.

Pattern group selector moved to left

Plain Zig-Zag Stitch - Used for general-purpose

stretch sewing, bar tacks, finishing seams,

embroidery and appliqué.

Elastic Stretch (or ”M”) Stitch - Ideal for plain

and overedged seams in knit and stretch fabrics,

stretch garment repair and for attaching elastic.

Multi-stitch Zig-Zag - Lets you mend, join and

reinforce without bulk. Ideal for bar tacking.

Blindstitch - For finishing hems and making

ladder seams.

44

Featherstitch - Extremely versatile. Use it for

fagoting, embroidering, quilting and lattice

seams.

Ric-Rac Stitch - For heavy-duty general-purpose

stretch sewing. Also reversible topstitching.

Straight Stretch Stitch - Ideal for plain seams

that stretch and for repairing and reinforcing

seams.

Overedge Stretch Stitch - Used for joining and

overedging seams in woven, knit and stretch

fabrics in one operation.

Page 46

adjusting stitches for stretch fabrics

Guiding and Supporting Fabric

Most fabrics of stretch or knit construction need only to be

guided in front of the presser foot when you use one of the

stretch stitches. Some fabrics - nylon tricot and eiasticized

fabrics, for example - do require support while being stitched.

1. For nyion tricot and similar synthetic knits, apply gentle

tension by holding the seam in front and back of the presser

foot as you sew.

2. For eiasticized fabric, stretch lace, and knits with an unusual

amount of elasticity, apply firm tension in front and back of

the presser foot to stretch the seam as the stitches are

being placed.

Caution: Do not pull the fabric while you are stitching as this

may deflect the needle, causing it to break.

Adjusting Pressure

when Sewing Knit and Stretch Fabric

Some knit and stretch fabrics, because of their structure, re

quire either more or less than normal (NORM.) presser bar

pressure to feed smoothly and evenly.

• For thick, soft or very stretchy knits, decrease pressure by

turning dial from NORM, (normal) toward ^ (darn).

• For nylon tricot, ciré and similar hard surface synthetic knits,

increase pressure by turning dial from NORM, (normal)

toward MAX (maximum).

X

45

Page 47

handling special fabrics

Fabric Handling Table

Many fabrics, because of their construction or finish, demand

special attention in sewing. Techniques used in stitching and

handling, and choice of machine accessories, will vary with

the fabric. Let the table below guide your selection.

Fabric

Vinyl-

leather-look, patent, suede, reptile

Pile-

velvet, velveteen, oorduroy

Deep Pile -

fake fur

Permanent Press-

peroale, broadoloth, shirting

Rne Knits -

trioot, jersey

Blanket Binding-

satin faoe

Special Handling

Use transparent tape as a substitute for pins or basting - Topstitch to hold seams and

edges flat - Avoid worked (maohine) buttonholes. Use bound buttonholes.

Stitch in direction of nap - Use plain seams - Zig-Zag or bind seam edges to prevent

fraying - Press over a self-fabric cloth.

Pin rather than baste seams - Stitch in direction of nap - Use plain seams for short-hair furs;

narrow overedged seams for shaggy, bulky furs - Shear pile from seam allowances to reduce

bulk

Control seam tension manually by holding fabric taut as it passes under the presser

foot. Sew at moderate speed. -

Use namow overedged, double stitched, or French seams - Hold thread ends securely for

a few stitches at start of seam - Support seams while stitching. See page 45 to increase

presser-foot pressure.

Hand-baste binding to blanket (pin marks show) - Miter corners.

46

Soft Sheer-

chiffon, voile, China silk

Napped Fabric -

cashmere, mohair, camel hair

Use French seams, double stitched - Hold ends of upper and lower thread when you

begin to stitch - Support fabric while stitching.

Cut with nap running down - Sew in direction of nap - Topstitch to hold seams and

edges flat.

Page 48

Stitch Length-Type Needle Style-Size Machine Accessories

Long straight stitch

Medium Straight Stitch for seams

Medium Zig-Zag or Honeycomb Stitch

for overcasting

Long Straight Stitch for plain seams

Medium to Short Zig-Zag Stitch

for overedged seams

Medium Straight Stitch Style 2020 Size 11 or 14

Medium Straight Stitch

Medium to Short Namow Zig-Zag or

Narrow Overedge

Long Straight Stitch

Medium to Long Zig-Zag Stitch or

Decorative Stitch

Style 2020 Size 14 or 16 for woven backing.

St^e2045 Size 14 or16 for knit backing

Style 2020 Size 14.

Style2045

Size 14 or 16 for panne velvet

Style 2020 Size 16

Style 2045 Size 11 or 14

Style 2020 Size 11 or 14

General Purpose Foot ■

General Purpose Needle Plate

General Purpose Foot “

(General Purpose Foot onlyior overcasting)

General Purpose Needle Plate

General Purpose Foot ■

General Purpose Needle Plate

Straight Stitch Foot

and Needle Plate

Straight Stitch Foot

and Needle Plate (for straight stitching).

General Purpose Foot

and Needle Plate (for zig-zag stitching).

General Purpose Foot “

General Purpose Needle Plate

Medium to Short Straight Stitch

Medium to Long Straight Stitch

■ For best results when sewing this fabric, we recommend use of the Even Feed Foot, available at your Singer Sewing Centre.

Style 2020 Size 9 or 11

Style 2020 Size 11 or 14

Straight Stitch Foot and Needle Plate

General Purpose Foot ■

General Purpose Needle Plate

47

Page 49

stitch centring

• stitch: stitch desired

• Stitch width: to suit application or fabric

• Stitch length: to suit application or fabric

• General purpose needle plate

• Special purpose foot

• Speed range: MIN.

* •

• Draw a vertical line on a sheet of paper or use graph paper,

if available.

• Place paper under presser foot with drawn line centred

under black vertical guideline of special purpose foot.

• Lower needle by turning hand wheel toward you, and posi

tion it on drawn line of paper.

• Lower presser foot.

• Carefully sew along the drawn line on the paper, using

When sewing, it is important to correctly guide the stitches

on your fabric to achieve centred stitching. A line of stitching

is centred when it lies evenly on an imaginary line on the fabric.

To clearly see what stitch centring is, and to practice even

black vertical guideline of foot to guide stitching. Do not

watch needle.

• After you have sewn along the drawn line, carefully remove

paper from under presser foot.

stitch guidance and machine control, try the test below.

Use a light colour upper and lower thread for this test. This

will demonstrate to you how a correctly centred line of stitch

ing lies on a given line.

• Attach special purpose foot.

Notice that foot is clear plastic for better visibility and has

vertical black line in the centre to guide stitch placement

on fabric.

• Select straight stitch.

If you have correctly guided the paper while sewing, the

stitched line will be centred. Notice that the stitching lies

evenly on the drawn line.

Try a paper sampler using a variety of stitches to practice

stitch centring.

To assure centred stitching on the fabrics you sew, use a

guideline marked with tailor’s chalk.

Centred Stitching

on Sampler

48

Page 50

stitch usage: functional and decorative

Many stitches on your new machine have both functional and

decorative applications. The foiiowing pages inciude exampies

to illustrate the versatility of these stitches. Though many

stitches can perform in a given application, to avoid repetition

-Hm

only one stitch has been used in each example. We, there

fore, hope that the examples provided will help you to use

your own creative talents.

Arrowhead Stitch

The arrowhead stitch provides a decorative and secure finish on fashion seams or darts that end on the outside

of a garment, at the top of pleats, and at the ends of pockets in tailored clothes. Individual pattern units reinforce

points of strain. Use the arrowhead stitch on pocket corners in place of bar tacks or in a border design for an

effective decorative touch.

Arrowhead Stitch Finish

Stitch: arrowhead stitch y

Stitch with:

Stitch length: 0-1 to suit application or fabric

General purpose needle plate

Special purpose foot

• Set machine according to the code above.

•

To Find Beginning Of Pattern Unit

• On a scrap of fabric, stitch until you come to the end of a

complete pattern unit. Now you are ready to start stitching

at the beginning of the next unit.

• Raise presser foot and remove scrap.

• Position motif or design under needle, lower presser foot,

and stitch.

To create effective border designs, as illustrated, stitch arrow

heads from the middle of each side and work out in both

directions toward the corners.

^ ^ ^ /

\\\/// /

Viv'

V

T r

“St

i

T r

1 »

49

Page 51

y Featherstitch ^

^ The featherstitch is an extremely versatile stitch. Use it for fagoting, embroidering and quilting. There are numerous

^ applications for the featherstitch. Two of them have been provided below. ^

A^>V999>V>V>^>V999>V>V>^9>V999>V>V>^>V999>^999>V9>^>^'>V9'>^y‘>V'>V>^'>V99>^>V'>V>^'>^>^

Fagoting

• Stitch: featherstitch ^

X.

iitf

• Stitch width: ij ^ ^

• Stitch length: 2-2.5

• General purpose needle plate

• General purpose foot or special purpose foot

The art of joining two pieces of fabric with an open, lacy

decorative stitch is called fagoting. You can create this attrac

tive trimming with the featherstitch. Use it for decorative

stretch seams in bathing suits or for joining together narrow

strips of fabric to make an entire garment section.

• Turn under (and hem by hand slipstitching) the raw edges

of the fabric strips or seams to be joined. Press flat or you

may zig-zag raw edges.

• Baste two fabric edges to be joined on to tissue paper

leaving approximately 3 mm (Ve inch) gap between the two

edges. Stitch, guiding two fabric edges under the centre

of presser foot. Allow the needle to alternately make a stitch

in each fabric strip and two stitches in the centre of the

opening. The tissue paper should be gently pulled off when

fagoting is completed.

50

Page 52

Patchwork Quilting

• Stitch: featherstitch ^

• Stitch width: ! ^ ^ i ^ ^

• Stitch iength: 2 - 2.5

• Generai purpose needle plate

• General purpose foot or special purpose foot

* •

Patchwork for quilts and wearing apparel, formerly put together

with hand stitching, can be quickly pieced and decorated at

the same time by using the featherstitch. Joinings are both

flexible and durable when this method is used.

Procedure:

• Cut a fabric underlay to size. Baste a light layer of padding

to underlay if a quilted effect is desired.

• Prepare patches, turning under 6 mm ('A inch) seam allow

ance. On non-woven fabric this step is not necessary.

• Baste patches to underlay in arrangement desired, butting

all edges.

0 Stitch in lengthwise and crosswise rows, allowing stitches

to straddle patches.

51

Page 53

Overedge Stretch Stitch

Although the overedge stretch stitch may be used creatively, it is primarily applied in finishing seams, hems, and

facing edges. Use it to overedge seams that require stretch such as crotch seams. It is particularly helpful in ski suit,

snow/suit and swimsuit construction. Examples of how to use the overedge stretch stitch follow.

I ■

A

Overedged Seams

® Stitch: overedge stretch stitch ^

• Stitch width: i ^ i % § ^

• Stitch length: 2 - 2.5

o General purpose needle plate

® General purpose foot

Method 1

Make a test sample to determine the suitability of an overedge

seam finish for your garment. Duplicate the grain or direction

of knit of your garment seam. Adjust thread tension to suit

fabric. Use an appropriate Yellow Band needle in the machine

for a synthetic knit. (See Fabric, Thread and Needle Table on

page 12.)

m Baste the garment together on the seam line allowing for

1.5 cm (% inch) seam allowance and fit in the usual way.

@ After making any necessary adjustments, trim seam edge

evenly to a scant 5 mm ('A inch) from seam line basting.

• Place trimmed seam under the foot so that the straight

stitches fall on the basted seam line and zig-zag stitches fall

over the seam edge.

52

Page 54

Mock Overedge

This finish is appropriate for buiky knits, fine tricots and fabrics

thatcuri or fray.

Method 2

» Makeatestsampie.

• Baste the garment together on the seam iine and fit in the

usuai way.

• After making any necessary adjustments, suggested in

Method 1, piace seam under presser foot. Stitch so that

the stitches on the ieft side of the pattern penetrate the

basted seam iine.

9 Press after stitching and trim away excess fabric to produce

a narrow seam edge. When the seam supports the garment,

omit the trimming step and press seam open in the usuai

way.

.1

Overedged Seam Finish

® Stitch: overedge stretch stitch ^

e Stitch width: i ^ i 5 ?

• Stitch length: 2 - 2.5

• General purpose needle plate

• General purpose foot

* •

o Trim seam edges evenly.

• Place stitching over the trimmed edge of the seam allowance as illustrated.

A.

53

Page 55

-y- -y

--------y---------y-.........

y-

-y-

-y y-

-y- -y y y--------------------------y- -y-

-y-

-y-

Blindstitch

The blindstitch has many practical and functional uses. Its most common use provides a durable hem finish. The

ladder seam, as described on the next page, is one creative application of the blindstitch. However, the creative

ways one might apply this stitch are unending.

-A.

A. -A

____A____A____A-------A____A____A____A____A____A____A____A____A____A___

Blindstitch Hems

Blindstitching provides a durable hem finish that is almost

invisible. It is best suited to straight or slightly curved hems.

Taped, bound, or turned hem edges can also be blindstitched

with equal ease.

• Stitch: blindstitch

■

2

, - M

3 ^

• Stitch width: to suit application orfabric

• Stitch length: 1-2

• General purpose needle plate

• General purpose foot

• Blindstitch hem guide

1. Raise presser foot, loosen screw, and slip blindstitch hem

guide from the front between screw and shank of foot.

Make sure underside of the guide clears the slide plate

and front of foot. Tighten screw with coin.

2. Prepare hem in the usual way. It is advisable to baste the

hem. Place the basting at least 1.3 cm (V2 inch) below the

edge of hem allowance to avoid catching the flange of

guide as you stitch.

j

54

3. With the wrong side of work uppermost, turn the hem

under, creating a soft fold from thetop edge of hem.

4. Position hem under the foot with the soft fold resting

against the wall of guide. Make sure the flange of the guide

is between soft fold and top of hem, as shown.

5. Lower presser foot. Stitch so that the straight stitches fall

on the hem allowance and zig-zag stitches pierce the soft

fold of work. Adjust stitch width if necessary. While stitch

ing, guide hem-edge in a straight line and feed soft fold

evenly against wall of the guide.

Page 56

Ladder Seam

The blindstitch ladder seam is particularly appropriate for knit

and stretch fabrics. It is ideal for stretchable construction

seams, and edge finishes for necklines, pockets and collars

in sportswear and swimsuits.

Stitch; blindstitch ^

Stitch width; i J ^ ^ S

Stitch length: 1.5-2.5

General purpose needle plate

General purpose foot or special purpose foot