SINGER 1030 User Manual

I”'

ilshion iTlaGhinelOSO

SUPER DELUXE FREE-ARM, STRETCH STITCH SEWING MACHINE

I.'--

iipiPP:ISiiiiK

_

___

,p^

■ #

X ^

Sew like a pro with your

lace stitch pattern on trscot

CONTENTS

Page

1. Getting to Know Your Machine ............................................................................................................................ 1

Principal Parts and What They Do.................................................................................................................... 1

Accessories............................................................................................................................................................ 2

2. Getting Ready to Sew............................................................................................................................................... 6

Needles .................................................................................................................................................................. 6

Operating Machine ............................................................................................................................................... 7

Choosing Needle and Thread............................................................................................................................... 8

Threading the Machine......................................................................................................................................... 9

Threading the Needle • Winding the Bobbin

Changing the Bobbin.......................................................................................................................................... 12

3. Tips on Straight Stitching ..................................................................................................................................... 14

Adjusting Machine to Your Fabric .................................................................................................................... 14

Setting Controls • Regulating Pressure • Regulating Needle-thread Tension • Setting

Stitch Length

Sewing a Seam.................................................................................................................................................... 16

4. All About Zig-Zag Stitching................................................................................................................................... 20

How Stitches Are Produced .............................................................................................................................. 20

Setting Pattern Selector • Adjusting Stitch Placement • Adjusting Stitch Width • Adjusting

Needle-thread Tension • Adjusting Stitch Length

Finding the Beginning of a Pattern Unit .......................................................................................................... 23

Adjusting Stitch Balance When Using Flexi-Stitch Patterns

Interchangeable Fash/on and F/ex/-Sf/fc/7 Discs .......................................................................................... 24

...........................................................................

23

5. Twin-Needle Stitching............................................................................................................................................ 26

6. Temporary Stitching............................................................................................................................................... 28

7. Buttons and Buttonholes ..................................................................................................................................... 34

Buttons ................................................................................................................................................................ 34

Buttonholes .................................................................................................................................................... 35

8. Sewing the Professional Way............................................................................................................................... 41

Construction Details ......................................................................................................................................... 41

Zippers • Corded Seams • Blindstitch Hems • Darts

Sewing Knit and Stretch Fabric......................................................................................................................... 44

Stretch Stitch Chart • Starting to Sew Using a Flexi-Stitch Pattern • Guiding and Supporting

Fabric • Adjusting Pressure • Plain Stretch Seams • Maxi-Topstitching • Overedged

Seams • Mock Overedging • Finishes for Hems and Facings

Handling Special Fabrics................................................................................................................................... 50

Fabric-Handling Table • The Even Feed foot

Decorative Touches

Satin Stitching • Applique • Free-Motion Embroidery • Hesitation Embroidery •

Topstitching

Keeping Up Appearances ................................................................................................................................. 58

Darning • Mending • Replacing Lingerie Elastic • Stitch Centering

9. Free-Arm Sewing .................................................................................................................................................. 61

Your Personal Measurements .......................................................................................................................... 65

10. Caring for Your Sewing Machine.......................................................................................................................... 66

11. Sewing Aids ........................................................................................................................................................... 69

..............

............................................................................................................................ 54

Index................................................................................................................................................................................ 70

principal parts and what they do

1. Console Cover protects against dust, Is

hinged for easy access to controls.

2. Stitch-balance Dial adjusts balance of

Flexi-Stitch patterns and buttonholes.

3. Disc Hoider holds any one of the in

terchangeable stitch-pattern discs.

4. Interchangeable Stitch-pattern Discs enlarge the scope of decorative as well as practical applications.

5. Pattern-selector Release Lever unlocks

the pattern selector.

6. Pattern Selector controls pointer on

stitch panel.

7. Stitch-width Dial controls zig-zag stitch

width.

8. Needle-position Ring places needle in

either J* (left), (center),

or J, (right) stitching position.

9. Stitch Pattern Panel pictures stitches

and allows for quick selection.

10. Take-up Lever controls flow of needle

thread.

11. Pressure Dial regulates presser-foot

pressure on fabric.

12. Rear Thread Guide holds needle thread

firmly in place while sewing.

13. Snap-in Thread Guidepost eliminates

possible tangling of thread.

14. Presser-foot Lifter, at back of machine,

allows you to raise and lower the presser

foot.

15. Thread Cutter is built into presser bar for

safety and convenience.

16. Buttonhole Lever sets the machine for

buttonholing.

17. Thread Guides

18. Zig-zag Foot holds fabric against feed.

19. F//p & Sew* Panel converts machine for

free-arm sewing.

20. Zig-zag Piate secured by magnets.

Guidelines on right and left sides help

you keep seams straight.

21. Soft-touch Feed moves fabric under

presser foot. Soft surface does not injure

fabric, even the most delicate.

22. Bobbin Latch allows you to switch from

sewing to bobbin winding without remov

ing bobbin.

23. Transparent Bobbin shows thread supply.

24. Slide Plate has a window to show bobbin

thread supply at a glance.

25. Needle Clamp holds single and twin nee

dles. It is designed to eliminate the

possibility of Inserting needle back

wards.

26. Tension Dial lets you select just the right

tension for your stitch, thread and fabric.

27. Built-in Sewing Light illuminates sewing

area.

28. Stitch-length Dial allows for a variety of

stitch lengths. To reverse stitching,

press dial all the way down and hold in

place.

29. Electrical Connections and Speed Con

troller

30. Power and Light Switch turns on the

machine and the sewing light

simultaneously.

31. Hand Wheel controls movement of take-

up lever and needle.

32. Friction-free Spool Holder, with horizon

tal pin holds spools of various sizes.

0

•5

1

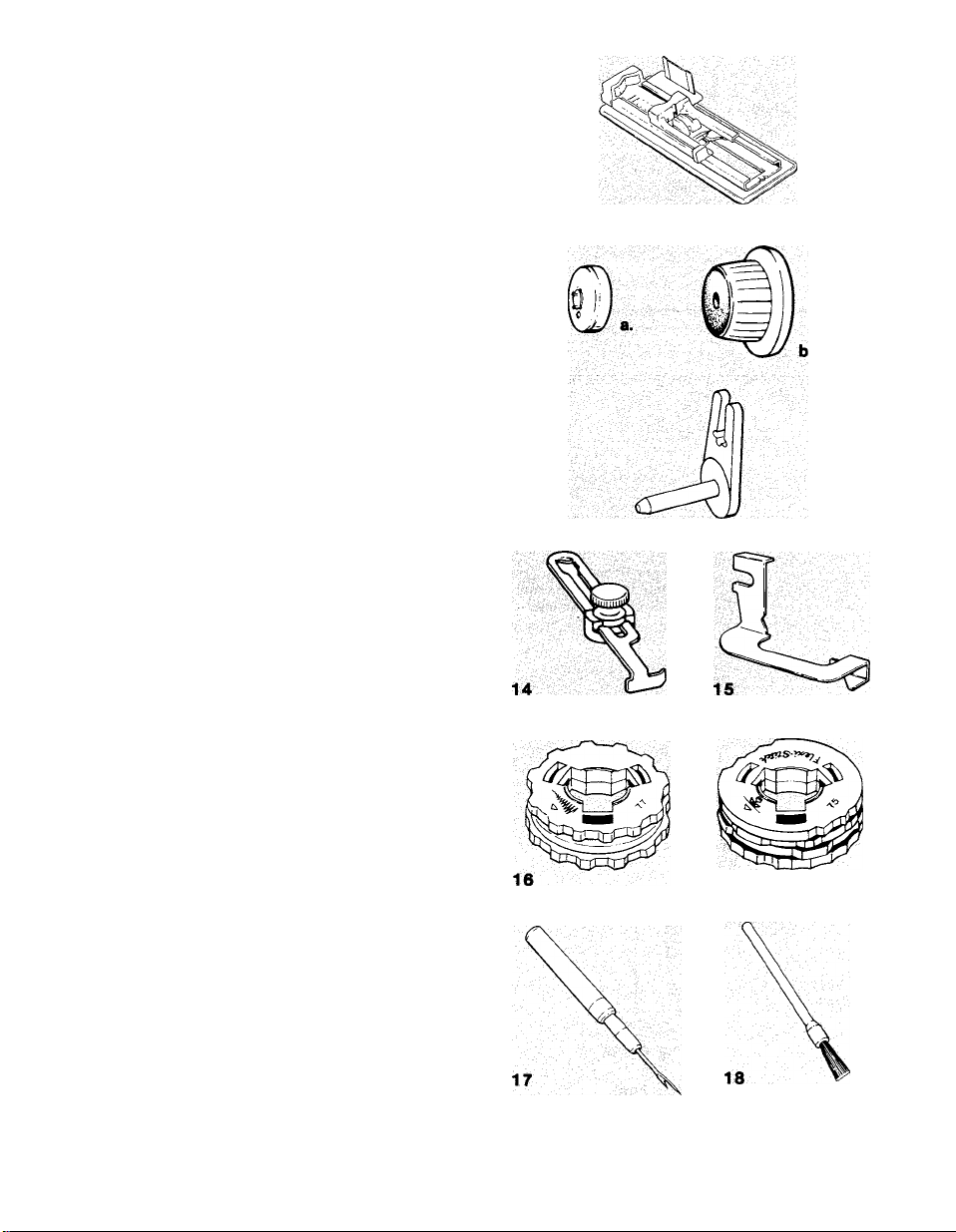

accessories

The accessories that come with your sewing

machine are designed to heip you do many

kinds of sewing easiiy and perfectiy.

1. Transparent Bobbins (No. 181551)

2. Needles ...

• Style 2020 for all-purpose sewing.

• Style 2045 for sewing knits, stretch

fabrics and elastic.

• Style 2025t for twin-needle decorative

stitching.

3. Zig-Zag Foot and Zig-Zag Plate, on your

machine when delivered. Use them for

alternating between straight and zig-zag

stitching as well as utility zig-zag sewing.

They can also be used for straight-stitch

ing firm fabrics. Numbers on plate indi

cate distance from needle in eighths of

an inch from center needle position.

4. Straight-stitch Foot and Straight-stitch

Plate. Use these when your fabric or

sewing procedure requires close control.

Numbers on plate indicate distance from

needle in eighths of an inch.

The straight-stitch plate is also used for

chainstitching.

5. Button Foot holds most flat buttons

securely for fastening.

6. Feed Cover Plate for button sewing and

free-motion work.

7. Zipper Foot for inserting zippers and

stitching corded seams.

8. Overedge Foot used with overedge

stretch stitch for seams in stretch fabrics

at stitch width 5 only.

9. Special-purpose Foot. Use this for all

kinds of decorative stitching.

10. Even Feed Foot for sewing hard-to-feed

pile, stretch, and bonded fabrics. Also

excellent for matching plaids and stripes

and for topstitching.

tCAUTION: Use this needle with the zig-zag needle plate and zig-zag or special purpose foot only.

Do not use any other accessories with this needle as needle breakage will occur.

11. One-step Buttonhole Foot allows you to

stitch complete buttonhole up to 1-1/2

inches in a single step. It determines the

correct buttonhole length, either by plac

ing button in foot or by using gauge on

foot.

12. Spool Holders a. Small Spool Holder for use with small

diameter tubes of thread.

b. Large Spool Holder on your machine

when delivered. For use with medium

and large spools of thread.

13. Detachable Spool Pin for decorative

twin-needle stitching and two-thread

topstitching.

14. Seam Guide helps you keep seam

allowances even.

15. Blindstitch Hem Guide. Use this with the

zig-zag foot to position and guide the

hem.

11

12

13

16. Stitch-pattern Discs

• One reversible Flexi-Stitch disc on

holder in machine when delivered.

• Five discs in accessory box: three

reversible Flexi-Stitch* discs and two

reversible Fash/on* Stitch discs.

• Each reversible disc produces two pat

terns.

17. Seam Ripper to pick and cut threads

quickly and neatly.

18. Lint Brush for cleaning your sewing

machine.

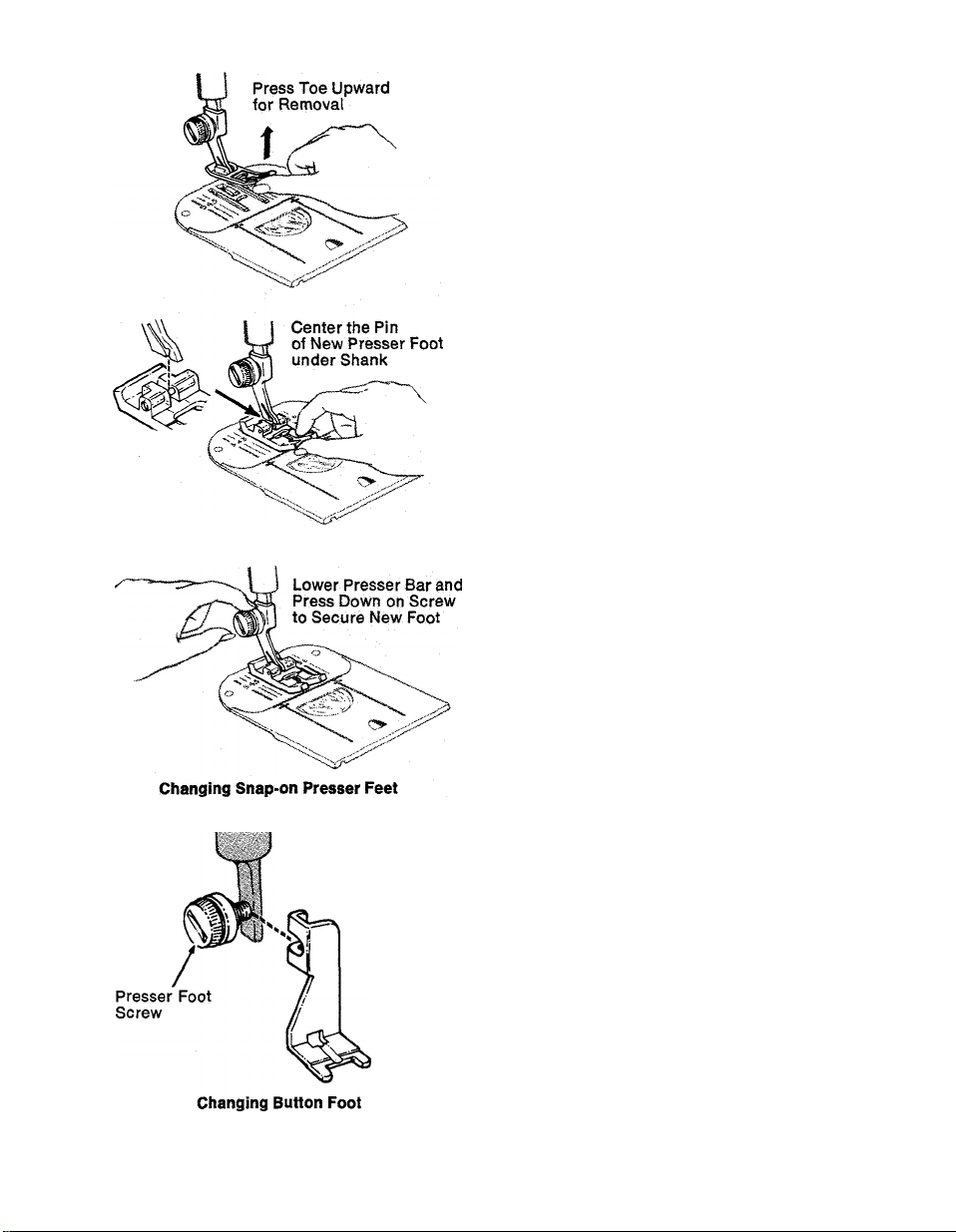

CHANGING PRESSER FEET

Snap-on Presser Feet

Most of the presser feet furnished with your

machine snap on and off a common shank.

1. Raise take-up lever to its highest position

by turning the hand wheel toward you.

2. Raise presser foot.

3. Press toe of presser foot upward (as far as

it will go) and then snap down to remove.

4. Center the new presser foot under the

shank and lower the presser-foot lifter so

that the shank fits over the presser-foot pin.

5. Press presser-foot screw down until foot

snaps into place.

To remove and replace the shank of snap-on

presser feet, follow instructions below for onepiece presser feet.

One-piece Presser Feet

1. Raise take-up lever to its highest position

by turning the hand wheel toward you.

2. Raise presser foot.

3. Loosen presser foot screw and remove the

foot guiding it to the right.

The Button Foot

• Hook button foot around the presser bar and

tighten presser-foot screw.

The Even Feed Foot

• Guide Even Feed foot into position from back

of machine, making sure the movabie arm

straddies the needie ciamp. Tighten

presser-foot screw secureiy with a coin. To

remove, ioosen screw and guide foot to the

right and away from you.

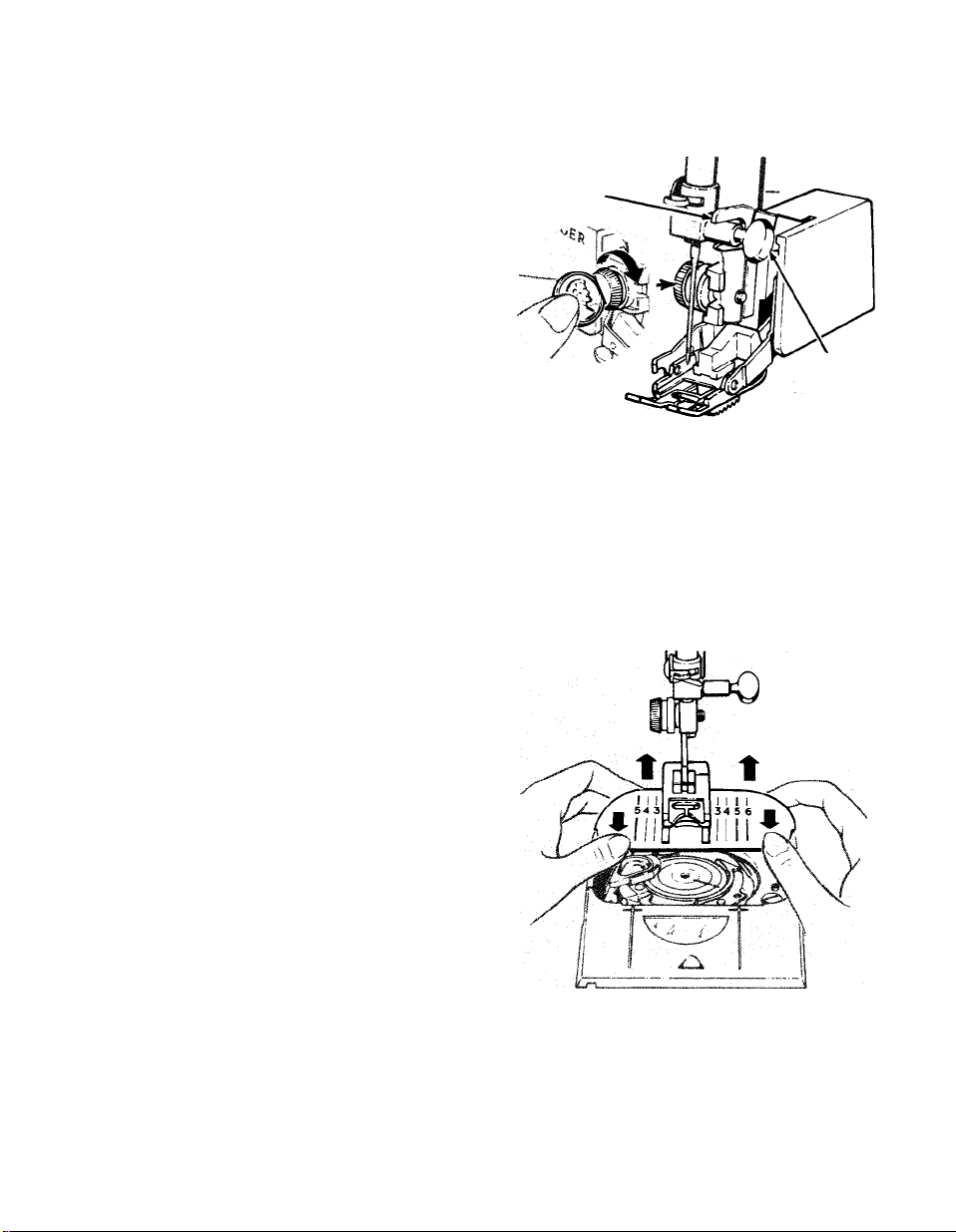

CHANGING PLATES

(Note; Remove bobbin if it contains thread in

order to prevent thread being caught when

piate is repiaced.)

1. Raise take-up iever to its highest position

by turning the hand wheel toward you.

2. Raise presser foot.

3. Open slide plate. Press down on front edge

of plate and lift up and out.

4. Position new plate over pins and release.

Plate is drawn into position by magnets.

See special instructions on page 30 for

attaching straight-stitch plate for

chainstitching.

5. Close slide piate.

Movable

Arm

Needle

Clamp

Changing Even Feed Foot

Removing Needle Piate

A

f

(TV

r

1^

nl

f

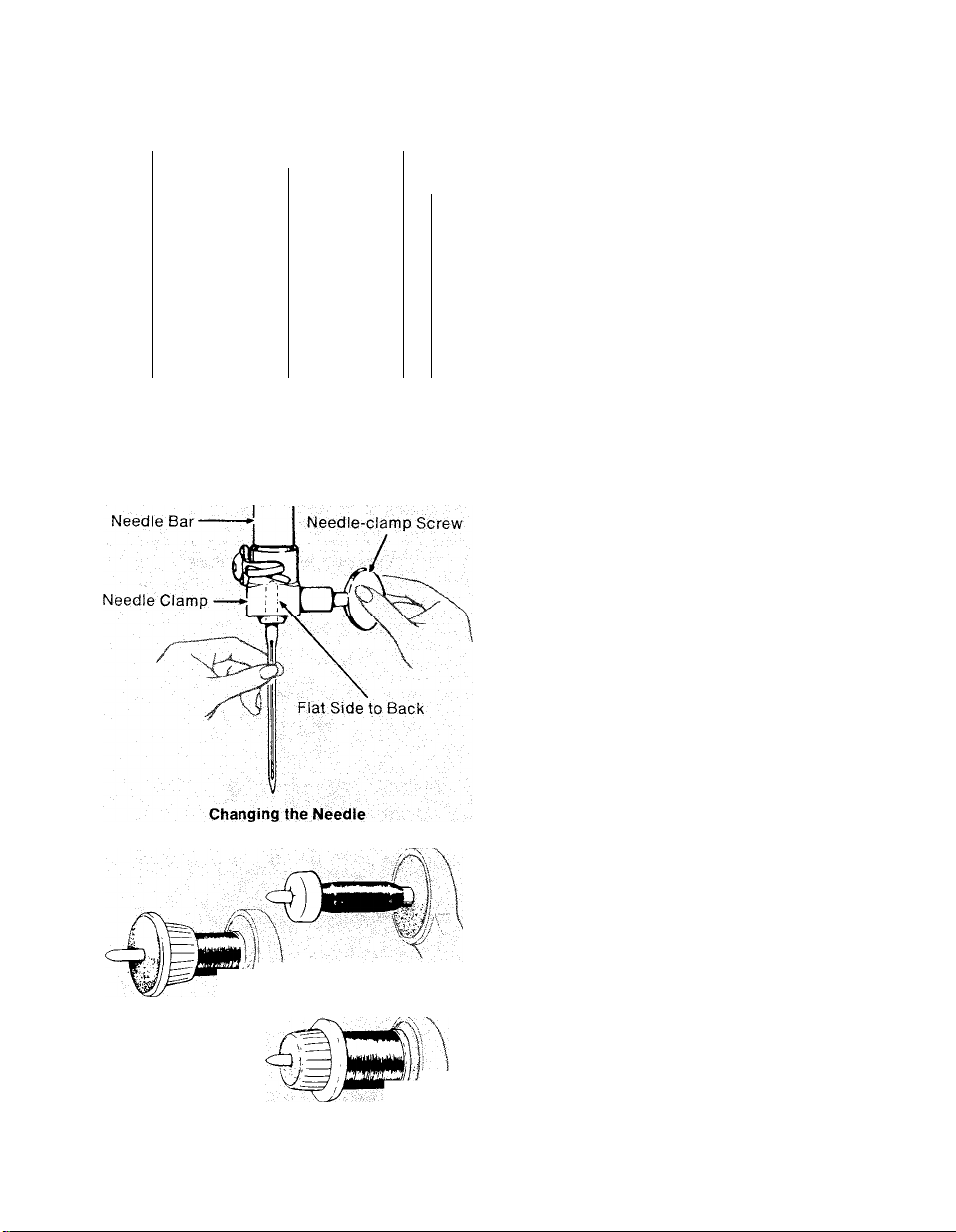

style 2020 Style 2025

Regular Needle 5ty|g 2045 Twin-Needle

Ball Point

Yellow Band Needie

\ To Hold Small Tubes

To Hold Small Spools

To Hold Large Spools

needles

The needle you use should be straight and not

bent to ensure perfect stitch formation and

needle penetration through the fabric. The

needle should also be fine enough to prevent

the fabric from being marred with large

punctures, yet heavy enough to pierce the

fabric without being bent or deflected.

Remember, too, that the eye of the needle

must be large enough for the thread to pass

through freely; too fine a needle will cause the

thread to fray.

IMPORTANT: Your SINGER sewing machine

has been designed to obtain best results with

SINGER* needles. You should follow the

recommendations in this instruction book and

on the needle package for correct style and

size of needle for different types and weights

of fabric.

• Style 2020 (15x1) needles, for all-purpose

sewing.

• Style 2045 bail-point Yellow Band* need\es,

for sewing synthetic knits and stretch

fabrics.

• Style 2025 needle, for twin-needle decora

tive stitching.

CHANGING THE NEEDLE

1. Raise needle to its highest point by turning

the hand wheel toward you. Loosen needleclamp screw, and remove the needle.

2. Insert new needle in clamp, with the flat

side of the needle to the back; push it up as

far as it will go.

3. Tighten needle-clamp screw.

SPOOL HOLDER

Place spool or tube of thread on horizontal

spool pin. If spool has a retaining slit, the slit

should be placed against the spool cushion to

the right. Select correct spool holder accord

ing to the type and diameter of spool being

used. The diameter of the end of the spool

holder should always be larger than that of the

spool itself. Press holder firmly against spool

to prevent it from turning.

operating machine

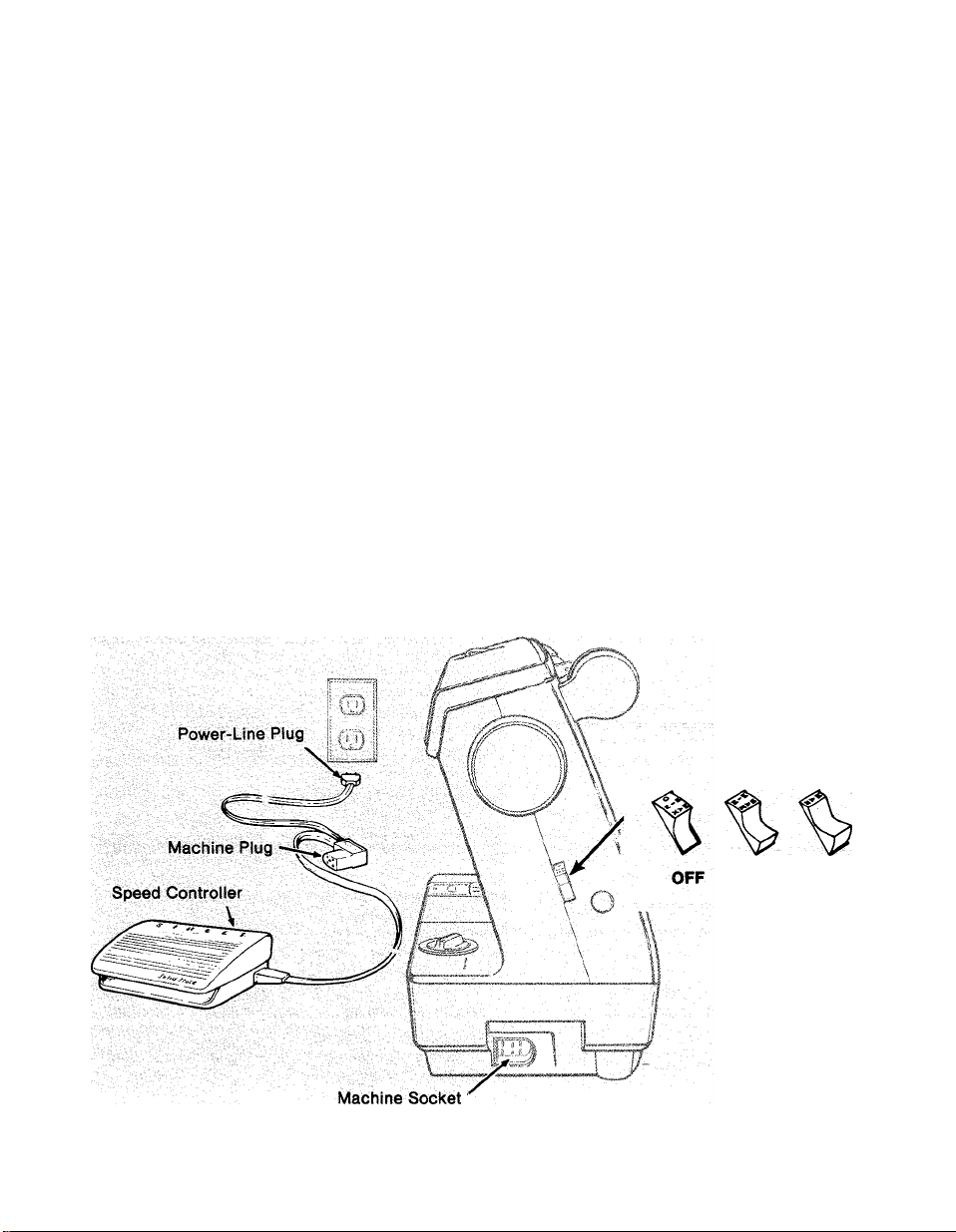

CONNECTING MACHINE

Before plugging in your machine, be sure that

the voitage and number of amperes indicated

at the right end of the machine, conform to

your electricai power suppiy.

• The MAX, setting B (switch pressed in all

the way) allows for full speed capacity of the

machine. It is best for long, straight seams,

and easy-to-handle fabrics.

• Push the machine plug into the machine

socket.

• Connect the power-line plug to your electri

cal outlet.

To turn on the machine and set speed range,

push the power and light switch to desired

speed. This will also turn on the sewing light.

• The MIN. setting A (switch pressed in half

way) allows for maximum control. Use this

setting for special jobs where intricate con

struction details require close control. The

speed range this setting provides is ap

propriate for almost all of your sewing

needs.

Connecting and Operating Machine

To run the machine, press the foot or knee

speed controller, The harder you press, the

faster the machine will sew within the

selected speed range. The lighter you press,

the slower the machine will sew within the

selected speed range.

CAUTION: Switch off the power and light

switch when changing needles, feet or needle

plates or when leaving the machine unattended.

This eliminates the possibility of starting the

machine by accidentally pressing the speed

controller.

Power and Light Switch

choosing needle and thread

The needle and thread you choose will depend

upon the fabric being stitched. The table be

low is a practical guide to needle and thread

FABRIC, THREAD AND NEEDLE TABLE t

selection. Refer to It before starting a sewing

project. Be sure to use the same size and type

of thread in both needle and bobbin.

THREAD ’

DELICATE— tulle, .chiffon, :,finé lace, or

ganza, chiffon yèjvèt

LIGHTWEIGHT — batiste, organdy, voile,

taffeta, crepe, chiffon velvet, ptastic film,

satin, surah, peau de soie, shantung,

brocade

MEDIUM WEIGHT — gingham, seersucker,

madras, percatei pigUei linen, ehiniz. f^

fine cordurby:, velveteen, suitings, vinyl,,

terry cloth, challis. twill

MEDIUM HEAVY — gabardine, tweed, sail-

cloth, duck, denim, coatings, drapery

fabrics, vinyl, deep-pile fabrics, corduroy,'

bonded fabric

HEAVY — overcoatings, upholstery fabrics,

canvas

KNITS, WOVEN STRETCH , AND ELASTIC -

double knits, bonded, knits, spandéx, ny

lon tricot, ciré: tricot, jersey, panne velvet,

stretch terry

LEATHER — sUede, kidskih, calf, capeskih,

buckskin, cabretta, patent, cobra, lined

leathers, simulated leathers

VINYLS , (KNIT BACK)- suede, Imitatibn

reptile, crinkle patent, patent, embossed

and printed vinyls

WOVEN FABRICS (ALL WEIGHTS) - dec

orative straight-stitch topstitching

LIGHT AND MEDIUM WEIGHTS (WOVEN) -,

decorative twin-needle stitching

tDoes not apply to chainstitching.

ttSize 9 needle recommended for sewing only. For bobbin winding, use iarger size needle.

tttUse with mercerized cotton, “A” silk, or polyester thread in bobbin.

Fine polyester, nylon,

or cotton thread

Cotton-wrapped

polyester (FINE)

, 100% polyester

50 mercerized cotton ,

‘‘ÀY,ny:lpn:,; i,;,,'

“A.” silk

Cotton-wrapped polyester

100% polyester

50 mercerized cotton

' ' 60 cotton

"A" silk

Cotton-wrapped polyester

100% polyester

Heavy-duty

mercerized cotton

40 to 60 cotton

Cotton-wrapped polyester

Heavy-duty

mercerized cotton

40 cotton

Cotton-wrapped polyester

100% polyester

"A" nylon

50 mercerized cotton

, “A" silk

Cotton-wrapped polyester

100% polyester

50 mercerized cotton

■‘A" nylon

"A” silk

Cotton-wrapped polyester

100% polyester

50 mercerized cotton

“A” nylon

‘ A" silk

"D-silk’M ' L

(Buttonhole twist)

Cotton-wrapped polyester

100% polyester

50 mercerized cotton

Style 2020

(15x1)

Style 2020

(15x1)

Style 2020

(15x1)

Style 2020

(15x1),:

style 2020

(15x1)

Stylo 2045

Ball Point

Yellow Band

Style 2032

style 2045

Ball Point

Yellow Band

Style 2020

(15x1)

Style 2025

(twin)

11:

14

16

18

.14

11

14

16

14

16

18

14

9tt

8

threading the machine

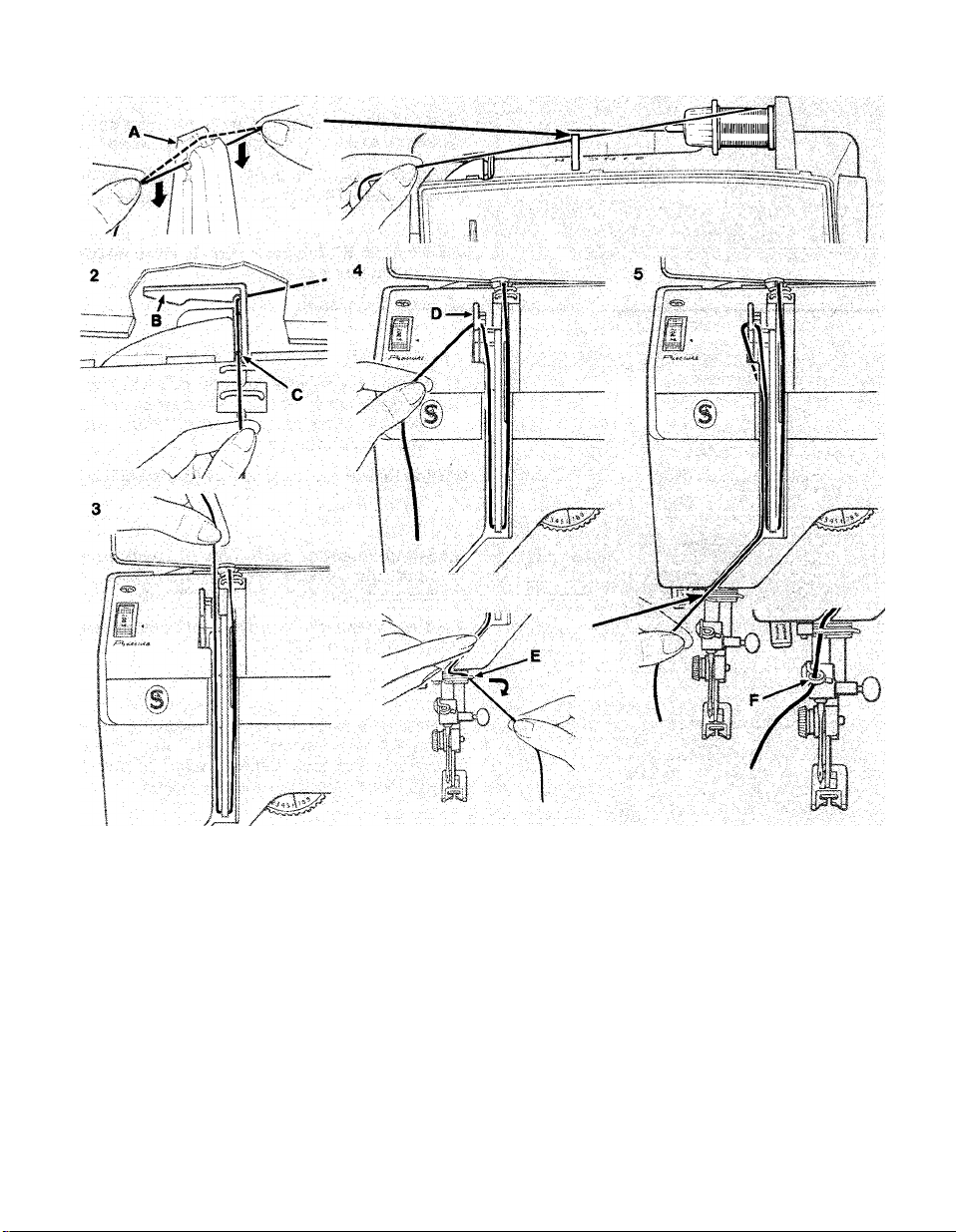

THREADING

• Raise take-up lever to its highest position by

turning hand wheel toward you. Raise

presser foot to release the tension discs.

1. Lead thread from spool holder and snap it

down into thread guidepost A.

2. Raise console cover and thread the rear thread

guide by holding thread in left hand and guiding

it over wing B and into channel C.

3. Draw thread firmiy between tension discs,

down right-hand channel, and up left-hand

channel.

4. Thread take-up lever D by guiding thread

down over top of lever and then up Into

eyelet.

5. Lead thread from take-up lever down into

ieft channel and then Into lower thread

guides E and F.

• Thread the needie using the needle

threader. Refer to page 10 for instruc

tions on using the needle threader.

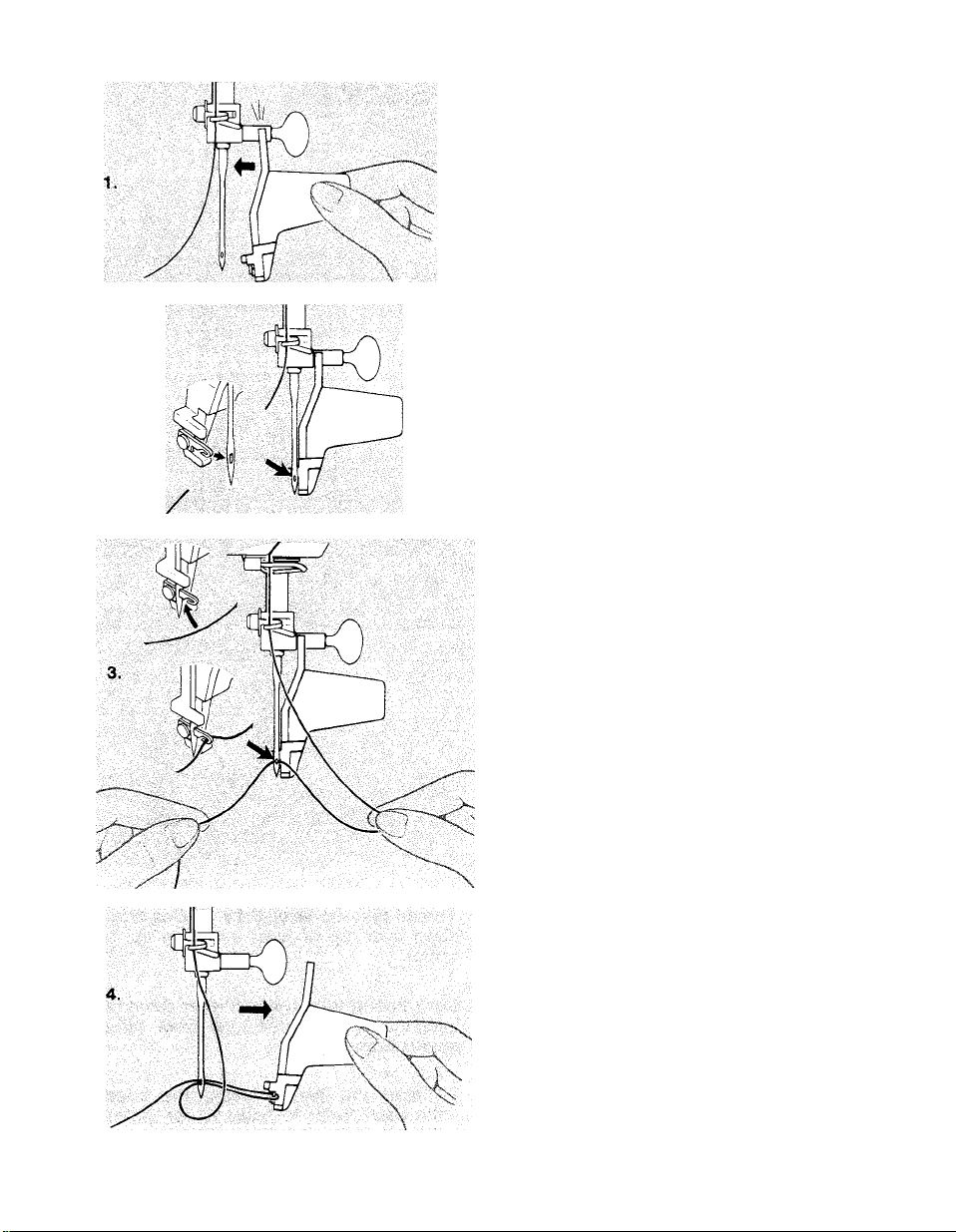

USING THE NEEDLE THREADER

The needle threader may be purchased sepa

rately at your local Singer Sewing Center.

Thread the machine in the usual way up to the

needle, then follow the instructions below.

Turn hand wheel toward you to raise needle

to its highest position.

Lower the presser foot.

. Holding the needle threader by its tab with

the right hand, position U-shaped part of

threader under bar of needle clamp. Snap

threader up onto bar.

Slide threader over to left, as far as it will go.

I. Swing threader back just far enough to

clear the needle. Align metal hook of

threader with the eye of the needle.

Swing threader forward so that hook passes

through eye of needle.

10

3. Holding approximately 3 inches (7.6cm) of

thread between your hands, loop thread

under metal hook. Leave slack in thread on

each side of hook. Release thread.

4. Holding threader by its tab with right hand,

draw metal hook and thread back through

eye of needle.

•

• Slide threader to the right off bar of needle

clamp. Carefully unhook thread from needle

threader.

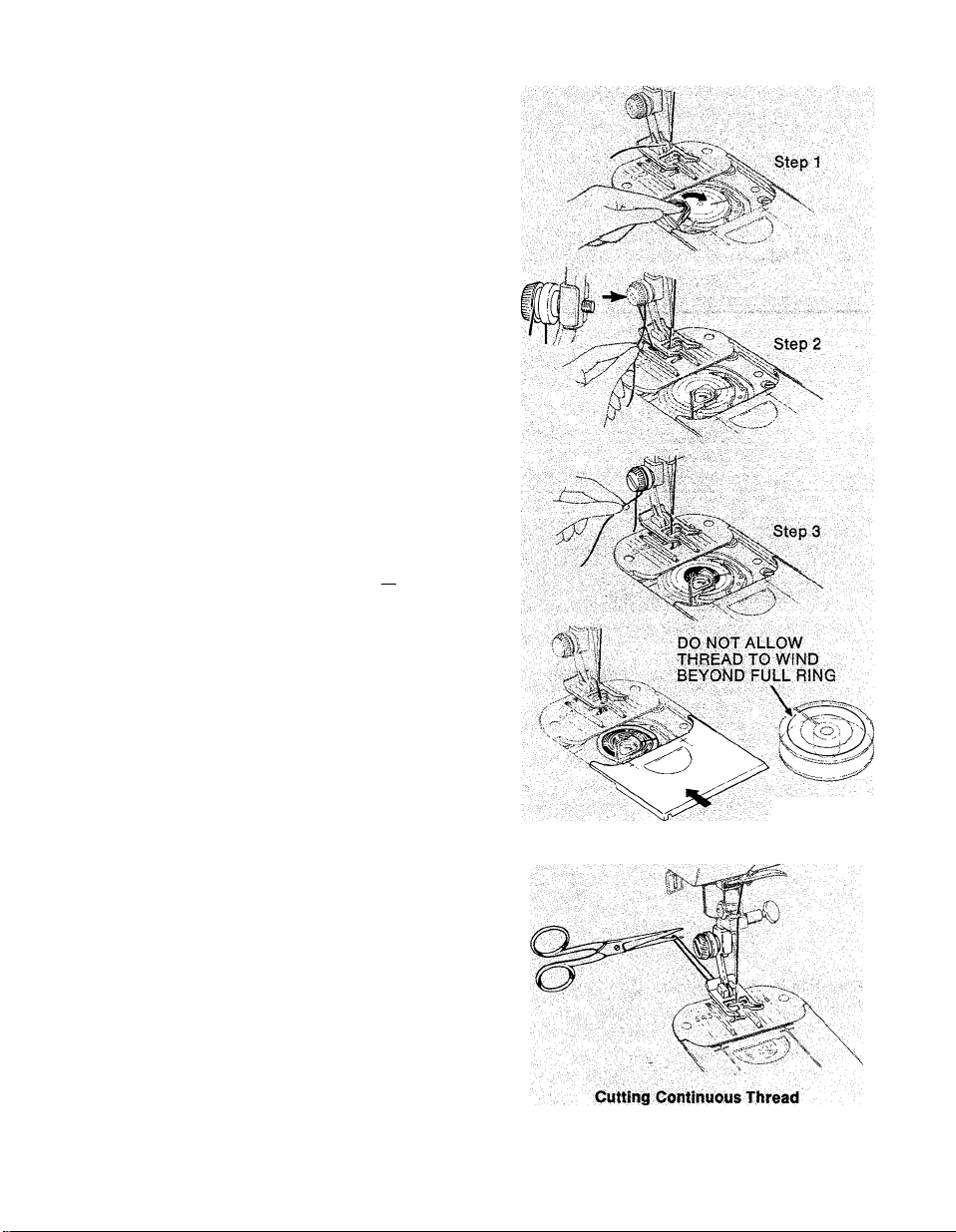

WINDING THE BOBBIN

You will find a bobbin in place under the slide

plate of your machine. (To open slide plate,

simply draw it gently toward you.) If the bobbin

runs out of thread during sewing, you can re

wind it without removing it from the machine.

The window in the slide plate lets you see

bobbin-thread supply at a glance, to help

avoid running out of thread in the middle of

a seam.

Preparation Steps

1. Raise the take-up lever to its highest posi

tion by pressing lightly on the speed con

troller or by turning the hand wheel toward

you.

2. Raise the presser foot to release tension

discs.

3. Open slide plate and make sure bobbin is

empty. For removal of bobbin and thread,

see page 12.

4. Set pattern-selector release lever by turn

ing it clockwise, see page 14, and set stitch

control dials for straight stitching; stitch

pattern I , needle position/^(center)

and stitch width.

If pattern-selector release lever fails to lock

into place, turn the hand wheel slightly toward

you and then reset lever.

Winding Steps

Winding Steps

1. Move bobbin latch to right (wind position).

2. Draw needle thread back between toes of

presser foot, under left side of presser foot,

then up, into and around thread retainer, as

shown. Do not hold thread end. Start the

machine, running it at a moderate speed.

3. Pull thread end away after it has separated

from bobbin.

• Keep your eye on the bobbin as it fills.

Do not allow thread to wind beyond the

outside FULL ring.

4. Close slide plate to release bobbin latch to

sewing position.

To start sewing, pull thread back under

presser foot and cut. Place threads diagonally

under foot to right or left side, position needle

in fabric where desired, lower presser foot,

and start machine.

Step 4

11

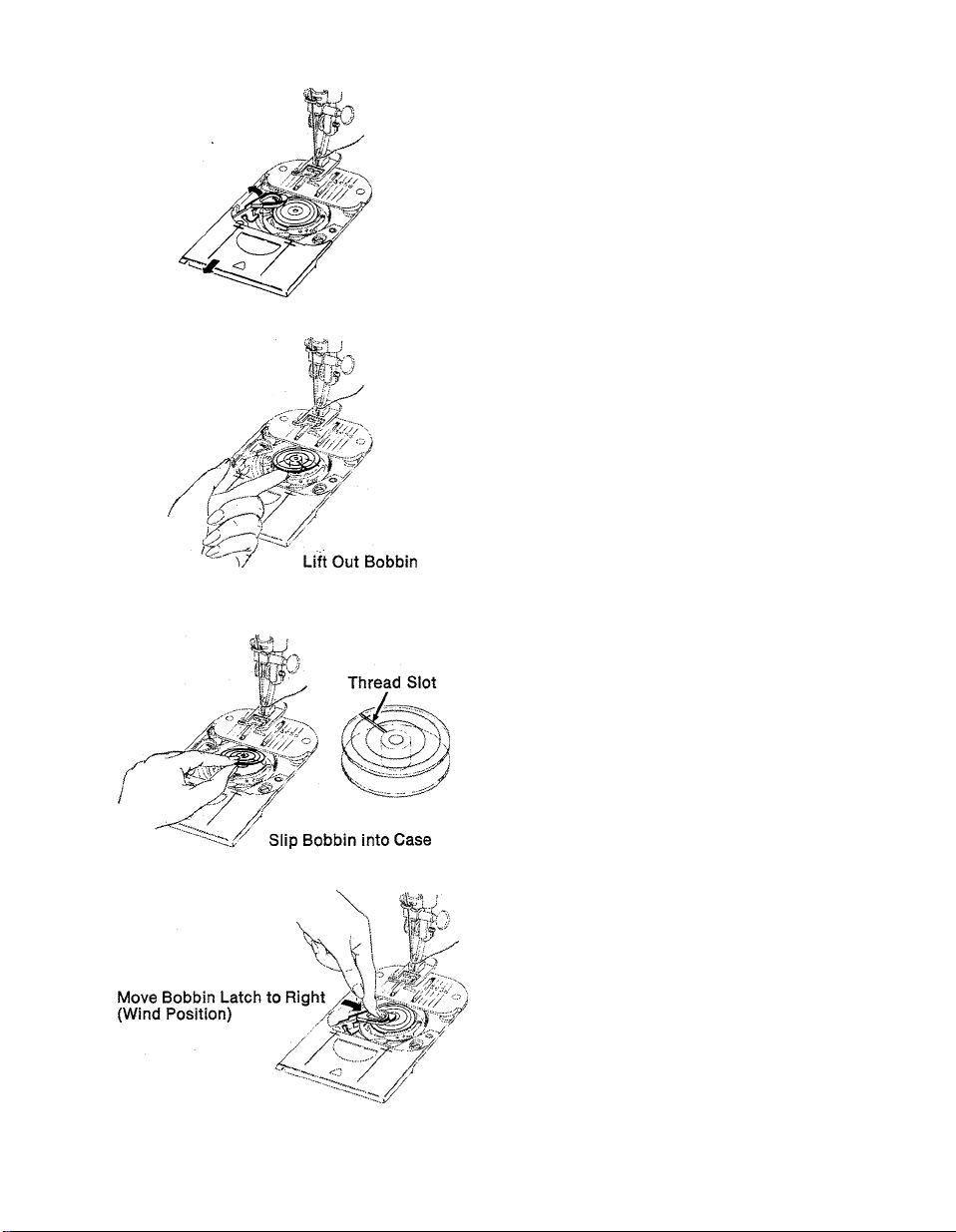

Removing Bobbin

Open Slide Plate and Move Bobbin Latch to Left

Replacing Empty Bobbin

changing the bobbin

REMOVING THE BOBBIN

Raise take-up lever to its highest position.

1. Open slide plate; move bobbin latch to left.

2. Remove bobbin by inserting fingernail un

der rim of bobbin.

12

REPLACING AN EMPTY BOBBIN

1. Slip bobbin (slot on top) into bobbin case.

2. Move bobbin latch to right (wind position).

3. Leave slide plate open until you have fin

ished winding the bobbin.

REMOVING THREAD FROM BOBBIN

You can leave the bobbin in place while re

moving thread. With slide plate closed, pull

thread end through the plate with a steady

motion. Do not pull the thread across the feed

as this may damage it.

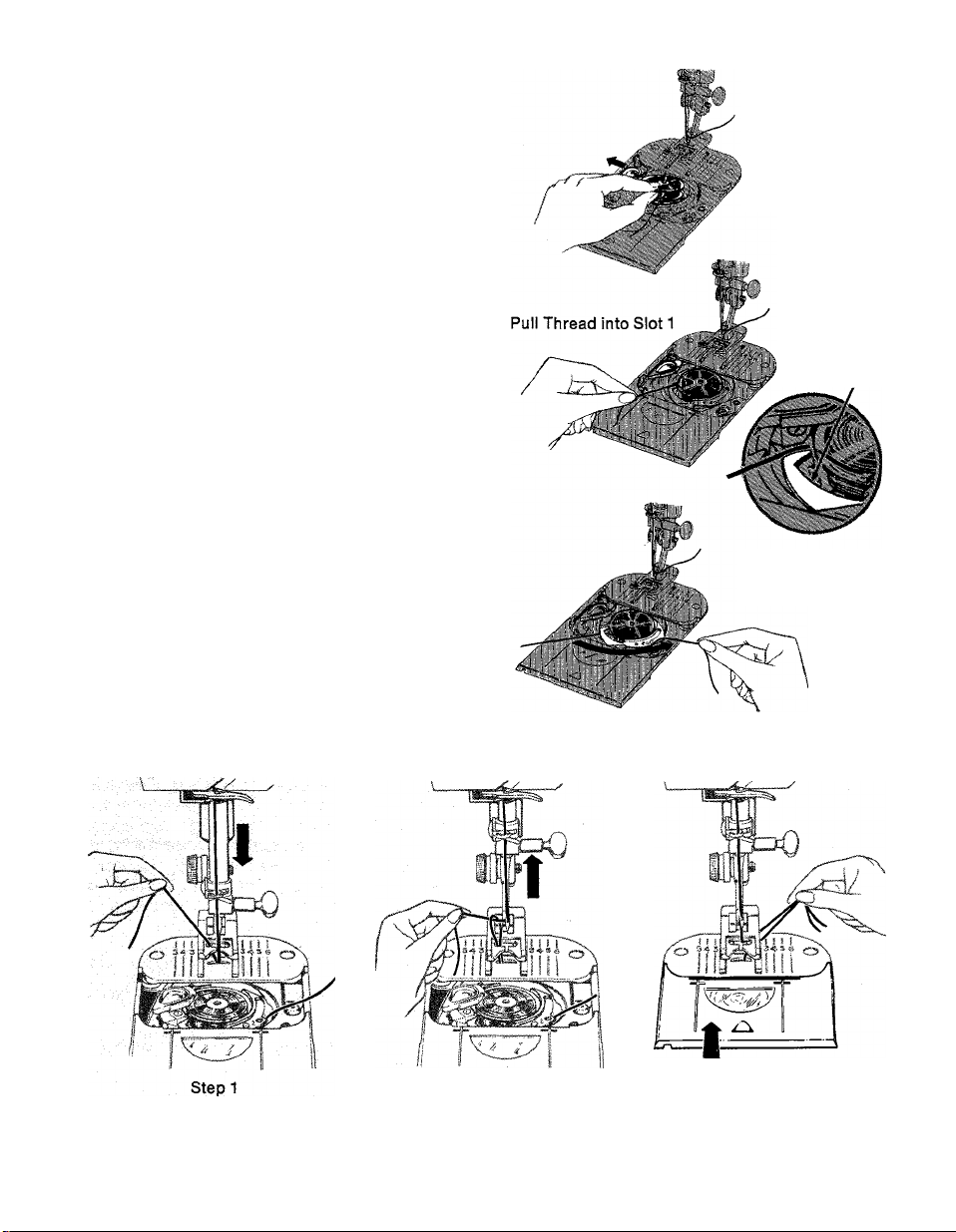

REPLACING A WOUND BOBBIN

Raise take-up lever to its highest position.

1. Open slide plate; move bobbin latch all the

way to the left.

2. Draw about an inch of thread from bobbin

and place bobbin in case.

3. Pull thread into bobbin-case slot (point 1),

draw it under flat spring and around to (or

slightly past) point 2, leaving two or three

inches of free thread. (Leave slide plate

open.)

RAISING THE BOBBIN THREAD

Set stitch width dial at .

1. Move bobbin latch to right (sewing posi

tion). Hold needle thread lightly with left

hand and turn hand wheel slowly toward

you so the needle enters plate.

2. Continue turning hand wheel and holding

needle thread until needle rises. Tighten

your hold on the needle thread and bring

up bobbin thread in a loop.

3. Open the loop with your fingers, draw nee

dle and bobbin threads under the presser

foot and place them diagonally to right or

left. Then close the slide plate.

Replacing a Wound Bobbin

Insert Bobbin

Draw Thread

Under Flat Spring

Around to Point 2

Flat Spring

Raising the Bobbin Thread

Step 2

Step 3

13

adjusting machine to your fabric

StitchWidth

Dial

Straight-Stitch Settings

1 ri

1 1

i

N

1

1 i

H i

1 1

1

J j

j i

Pressure Dial

j

-------

R

|_H_|

NeedlePosition

Ring

■ ■

1

■

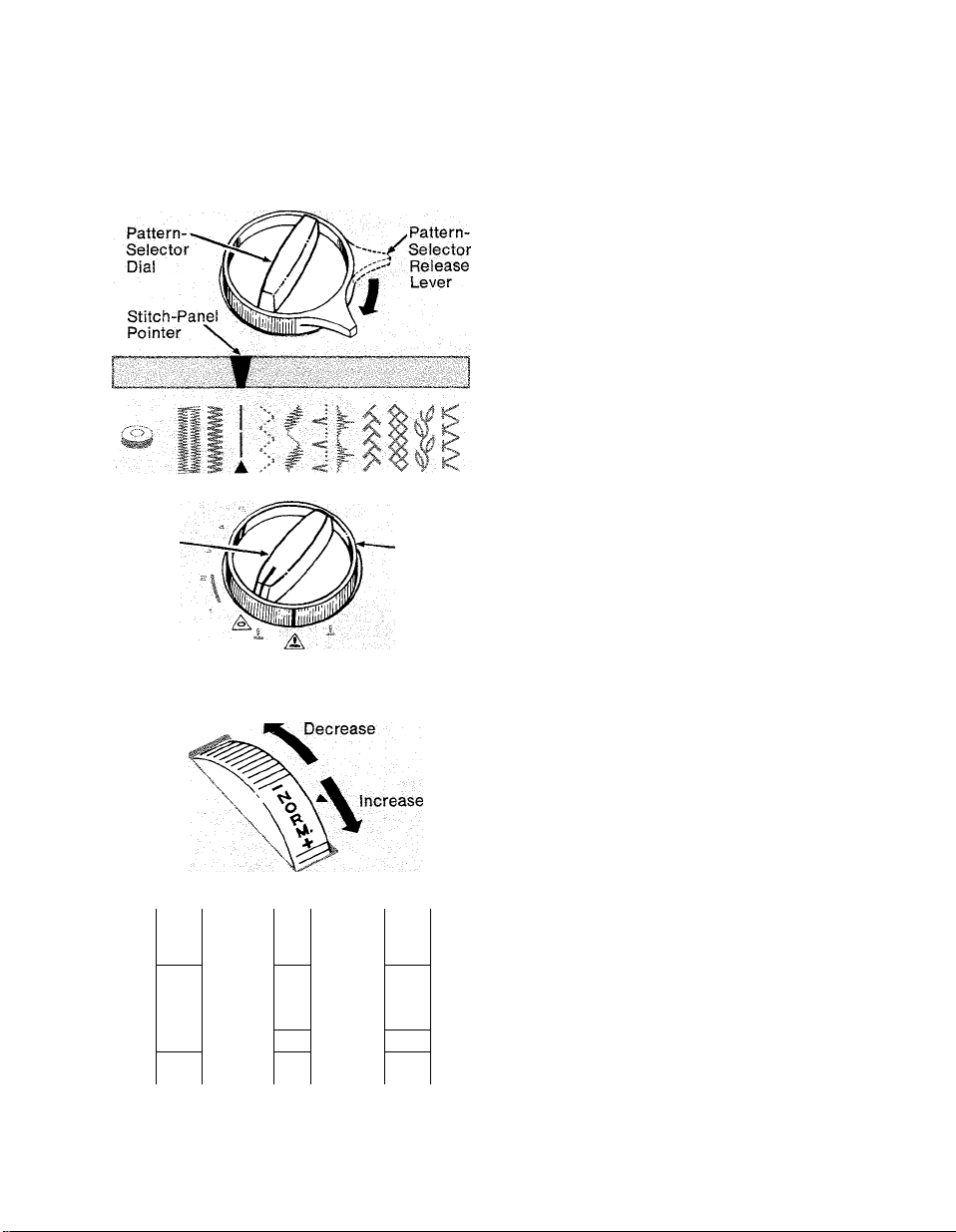

SETTING CONTROLS

1. Set pattern-selector release lever by turn

ing it clockwise until it locks in place. If

lever fails to lock, turn hand wheel slightly

and reset lever.

NOTE: Do not attempt to turn pattern-

seiector release lever after it is locked in

place. It repositions itself when you start

the machine or turn the hand wheel.

2. Turn pattern-selector dial until stitch-panel

pointer is above | setting.

3. Turn stitch width dial to and turn needle

position ring to (center).

4. Attach straight-stitch foot and straight-

stitch plate (see pages 4 and 5).

NOTE: When alternating between straight and

zig-zag stitching use the zig-zag foot and zig

zag plate, and set pattern selector on zig-zag

setting I .

REGULATING PRESSURE

The pressure dial regulates the pressure that

the presser foot exerts on the fabric. The NORM

(normal) setting can be used for sewing a wide

variety of fabrics of different weight and texture.

Intermediate settings, above and below NORM,

are also provided. Generally lighter than normal

pressure is best for thick, soft fabrics. See

page 45 for adjusting pressure when sewing

knits.

Lower the presser foot before setting pressure.

• To increase pressure, turn dial from NORM

toward MAX.

• To decrease pressure, turn dial from NORM

toward DARN.

• For darning, set dial on DARN.

•

14

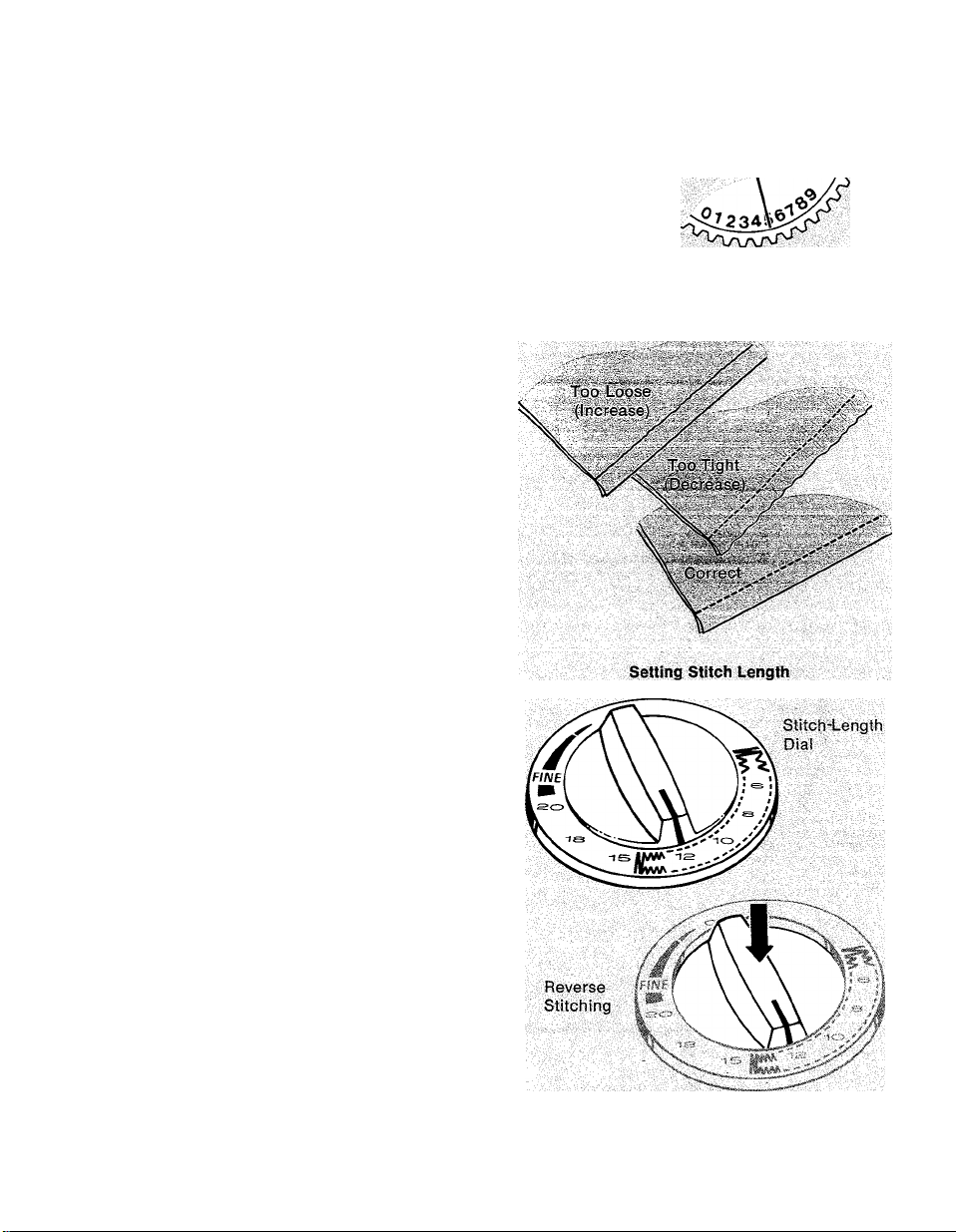

REGULATING NEEDLE-THREAD TENSION

The tension dial reguiates the degree of ten

sion on your needie thread and iets you select

just the right setting for your stitch, thread,

and fabric. The numbers on the dial eliminate

guesswork in duplicating settings.

Correct tension is important because too much

or too little will weaken your seams. To find

the correct tension setting, make a test on a

sample of your fabric. If the fabric puckers or

the bobbin thread is pulied to the fabric sur

face, decrease tension. If the surface or under

side stitches look loose, increase tension.

• To increase tension, turn dial to a higher

number.

• To decrease tension turn dial to a lower

number.

NOTEr The tension dial controls needle-thread

tension only. Bobbin-thread tension has been

correctly set at the factory, and you do not

need to adjust it.

Regulating Needle-thread Tension

SETTING STITCH LENGTH

The stitch-length dial regulates the length of

both straight and zig-zag stitches. The num

bers 6 to 20 represent the number of straight

stitches per inch: the higher the number, the

shorter the stitch. Generaily, shorter stitches

are best for lightweight fabric; longer ones for

heavy fabric. Curved seams, bias-cut seams,

and scallops require short straight stitches

(15 to 20) for elasticity and smooth contours.

Bound buttonhoies should be sewn with a

short stitch for durability and strength.

• To set stitch iength, turn dial to setting

desired.

•

• For reverse stitching, press diai ali the way

down and hoid in piace.

15

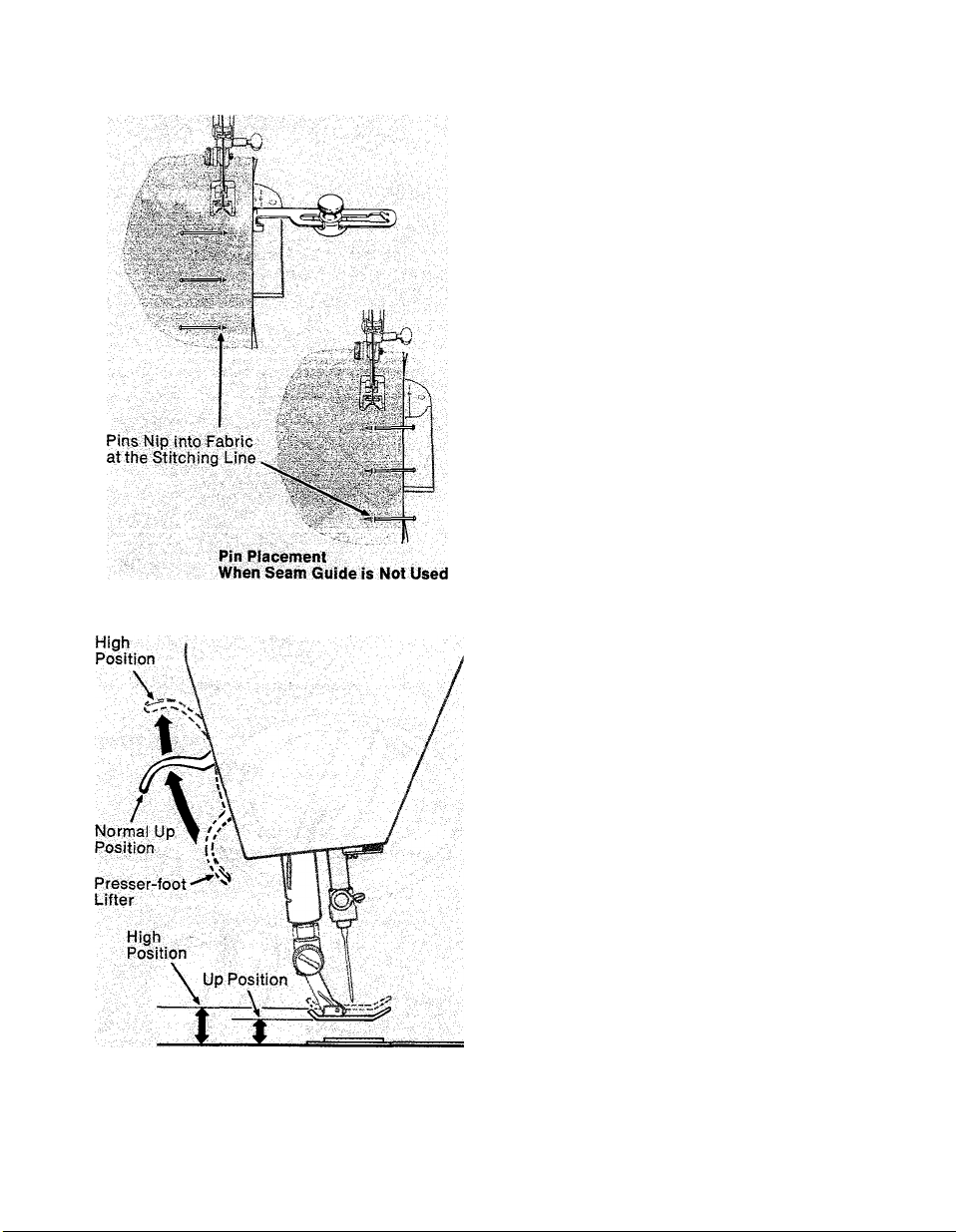

Pin Placement

When Seam Guide is Used

sewing a seam

PIN BASTING

Pin basting is a time saver and can be used

when you sew easy-to-handle fabric. Use fine

pins and place them so that;

• They are at right angles to the presser foot

and just nip into the fabric at the stitching

line.

• They do not extend under both sides of the

presser foot. Never place pins on the under

side of the fabric In contact with the feed.

• Sew, pulling pins out of fabric as you stitch.

We do not recommend sewing over pins.

For information on speed basting by maohlne,

turn to page 28.

16

PLACING FABRIC

Most fabric can be placed under the presser

foot by raising the presser-foot lifter to its up

position. When placing bulky fabrics, such as

coating, knit or terry cloth, or several fabric

layers, raise the presser-foot lifter to its high

position and make sure needle is at its highest

point. Hold lifter in position (since it does not

lock) while placing fabric under the presser

foot. Make sure the lifter is all the way down

before starting to sew.

Presser-foot Lifter Settings

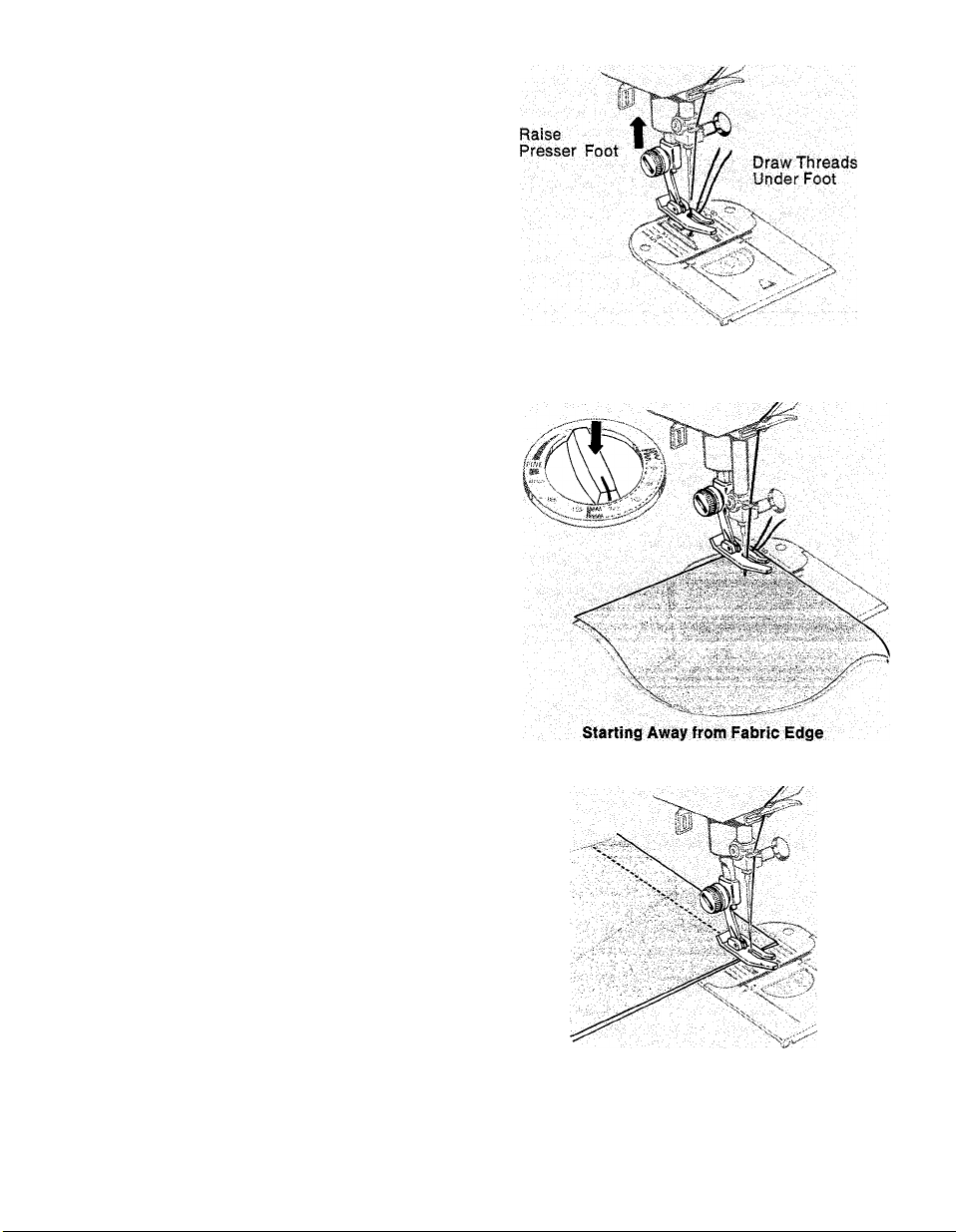

STARTING THE SEAM

Always test-stItch seams on fabric scraps

before stitching your garment. This will ena

ble you to get the feel of handling the fabric.

Also, it will indicate whether tension, pres

sure, stitch length, needle and thread are cor

rect.

To avoid tangied threads on the underside of

the fabric. It is important to start and end

seams carefully.

• Raise the take-up iever to its highest posi

tion by turning the hand wheel toward you or

pressing ilghtly on the speed controiler.

Raise presser foot.

• Draw needle and bobbin threads under foot

and place them diagonally to right.

• Hoid thread ends and with a light touch on

the speed controller or by turning the hand

wheei toward you, position needle in fabric

about V2 inch from fabric edge.

• Lower the presser foot.

• Press stitch-length dial all the way down

and hold in place.

• Start machine and backstitch to edge of

fabric. (Do not sew beyond edge of fabric.)

• Release the stitch-length dial and sew In

forward direction.

•

Stitching to End of Seam

17

Using Guidelines /

Stitching Line

Pivoting at Corner

Using Seam Guide for

I Extra-Wide Seam

KEEPING SEAMS STRAIGHT

To keep the seam straight, use one of the

numbered guidelines on the plate. The num

bers indicate distance, in eighths of an inch,

from the needle. If you want a ®/8-inch seam,

for example, line up your fabric with the num

ber 5 guideline. Note that both number 5

guidelines (the most commonly used) are ex

tended on the slide plate for your conve

nience; the crosslines serve as guides when

stitching a square corner.

For extra help in keeping the seam straight,

you may wish to use the seam guide. Because

it allows you to guide stitches evenly between

Vs inch and 1V4 inches from the fabric edge. It

is particularly useful for very narrow or very

wide seams.

Attaching Seam Guide

Place screw in hole to the right of the slide

plate: line up straight edge of guide with the

needle plate guideline for desired seam width

and tighten screw.

TURNING SQUARE CORNERS

To turn a square corner % inch from the

fabric edge, you need not measure or mark

the seam. Simply use the crosslines on the

slide plate.

• Line up your fabric with right or left

guideline 5 on the plate. Stitch seam, slow

ing speed as you approach corner.

• Stop stitching, with the needle down, when

the bottom edge of the fabric reaches the

cornering crosslines on the slide plate.

• Raise presser foot slightly and turn fabric on

needle, bringing bottom edge of fabric in

line with guideline 5.

• Lower the presser foot and stitch in new

direction.

18

Loading...

Loading...