Page 1

INSTRUCTION MANUAL AND ACCESSORIES

Full zig-zag sewing machine

free-arm

Model 1022

or

Flat-bed

Model 1021

SINGER

Page 2

Page 3

The machine is intended for household use

IMPORTANT SAFETY

INSTRUCTIONS

When using an electrical appliance, basic safety precautions

should always be followed, including the following:

Read all instructions before using the sewing machine.

DANGER

To reduce the risk of electric shock:

1. An applicance should never be left unattended when plugged

in. Always unplug this appliance from the electric outlet im

mediately after using and before cleaning.

2. Always unplug before relamping. Replace bulb with same type

rated max. 15 Watts.

WARNING

To reduce the risk of burns, fire, electric shock, or injury to

persons:

1. Do not allow to be used as a toy. Close attention is necessary

when this appliance is used by or near children.

2. Use this appliance only for its intended use as described in

this manual. Use only attachments recommended by the

manufacturer as contained in this manual.

3. Never operate this appliance if it has a damaged cord or plug,

if it is not working properly, if it has been dropped or dama

ged, or dropped into water. Return the appliance to the nea

rest authorized dealer or service center for examination, re

pair, electrical or mechanical adjustment.

4. Never operate the appliance with any air openings blocked.

Keep ventilation openings of the sewing machine and foot

controller free from the accumulation of lint, dust, and loose

cloth.

5. Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being

used or where oxygen is being administered.

Page 4

8. To disconnect, turn all controls to the off (”0”) position, then

remove plug from outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug,

not the cord.

10. Keep fingers away from all moving parts. Special care Is

required around the sewing machine needle.

11. Always use the proper needle plate. The wrong plate can

cause the needle to break.

12. Do not use bent needles.

13. Do not pull or push fabric while stitching. It may deflect the

needle causing it to break.

14. Switch the sewing machine off (”0”) when making any

adjustments in the needle area, such as threading needle,

changing needle, threading bobbin, or changing presser

foot, and the like.

15. Always unplug sewing machine from the electrical outlet

when removing covers, lubricating, or when making any

other user servicing adjustments mentioned in the instruc

tion manual.

16. Machine has be stored in dry and clean rooms to protect

against rust.

SAVE THIS INSTRUCTION

Page 5

CONTENTS

Getting to Know Your Sewing Machine

Principal Parts — And What They Do

Accessories — And When To Use Them

..................

2

................... 2

-----

p

'age

6

Getting Ready to Sew

Preliminary Steps

......................

.......................

Choosing Needle and Thread ...

Threading Your Sewing Machine

Straight Stiching

........

Adjusting Selectors

Sewing a Seam ...

Zick-Zack Stitching

Satin Stitching ...

Twin-Needle Stitching ..

Preparation

...............

Threading the Needle

Buttons and Buttonholes

Buttons ......................

Buttonholes

...............

Sewing the Professional Way

Lingerie, Seam finishes ..............

Hints on Sewing Special Fabrics

Construction Details

...................

Aplique, Attaching elastic

Free Arm Sewing

.......... ............

Keeping Up Appearances

........

...........

..........

.

9

¡0

16

17

19

22

24

25

25

26

27

27

28

31

31

32

34

37

41

Caring for Your Machine

Cleaning the Machine

.................................

..................

.

Removing Bobbin Case, Face Plate and Bulb

Performance Checklist

................................

44

44

46

Page 6

19 Needle Thread 18 Needle Thread 17 Snap-in Thread 16 Spool Holder

1 Bobbin-Winder

Tension Disc

2 Pressure

Dial

3 Take-up

Lever

4 Presser-

Foot Lifter

principal parts

Tension Discs

15 Bobbin-Winder

14 Hand

Wheel

5 Thread

Cutter

8 Needle

Plate

10 Slide Plate

13 Sewing

Ughi

12 Extension Table

Release Push Button

11 Extension

Table

Page 7

and what they do

1. Bobbin-Winder Tension Disc regulates thread tension for bobbin

winding.

2. Pressure Dial regulates presser-foot pressure on fabric^ It has an all

purpose setting plus settings for extra-light and extra-heavy pressure,

and for darning.

3. Take-up Lever controls flow of needle thread.

4. Presser-Foot Lifter, at back of machine, allows you to raise and

lower presser foot. High-lift position allows easy placement of bulky

fabrics.

5. Thread Cutter is built into presser bar for safety and convenience.

6. Needle Clamp holds single and twin needles and is designed to

eliminate the possibility of inserting needle backwards.

7. Presser Foot holds fabric against feed. The foot snaps off for quick

removal.

8. Needle Plate lifts out for easy removal. Guidelines on right and left

sides extend to slide plate to help you keep seams straight.

9. Feed moves fabric under the presser foot.

10. Slide Plate opens for easy removal and replacement of the bobin, and

raises and lowers the pin that holds the needle plate in position.

11. Extension Table lets you convert the machine for either flat or tubular

bed sewing.

12. Extension Table Release Push Button unlocks the extension table.

13. Sewing Light illuminates the sewing area.

14. Hand Wheel positions take-up lever and needle. Always turn it

toward you.

15. Bobbin-Winder lets you fill the bobbin with thread quickly and easily.

16. Spool Holder with Horizontal Pin holds thread spools of various

sizes.

17. Snap-in Thread Guide Post provides smooth flow of thread from

spool holderto tension discs.

18. Needle-Thread Tension Dial lets you select the appropriate tension for

your stitch, thread, and fabric. The numbers eliminate guesswork in

duplicating settings.

19. Needle-Thread Tension Discs, controlled by the tension dial,

regulate thre amount of tension on your needle thread.

Page 8

PRINaPAL PARTS (Contmued)

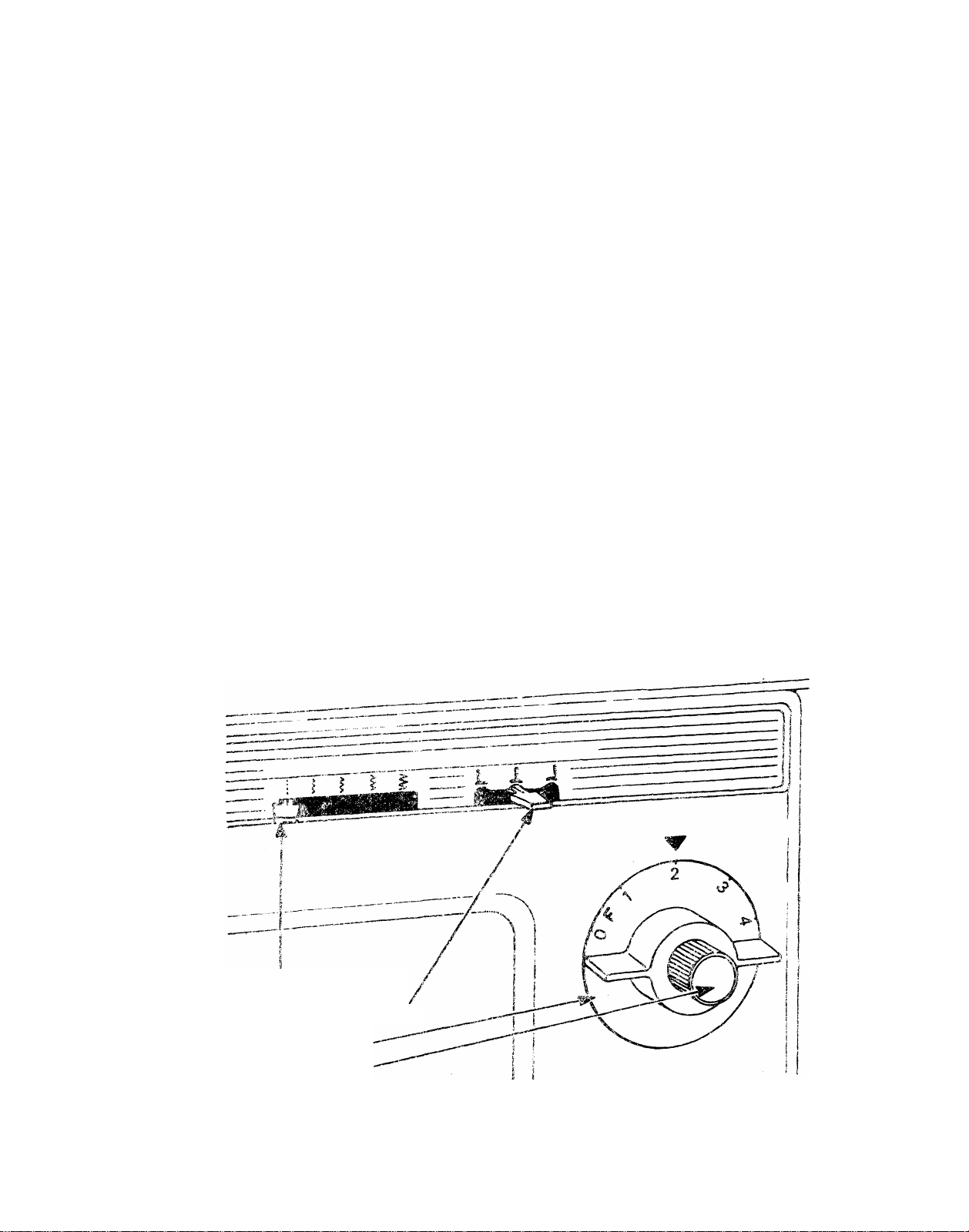

20. Siiteli Width Selector controls the width of zig-zag stitching and

pcsilions needle for straight stitching. Use ! setting for straight

si^tch^ng.

21V PJeecMe-Fositiion Selector places needle In either left center or

rtchl stitching position. Use center position for straight stitching.

22. Stitch Coritroi Dial allows for a variety of stitch lengths, including 0-

1 for zig zag satin stitching.

23. Reverse-Stitch Push Bottoni lets ycu reverse stitching direction.

20 Stiich Widin Selector

2 Hceóìe- Pesiti on Selector

22 SrHcrf Centro'D'ol

23 Reverse-Stitch^"

Push Bovion

Page 9

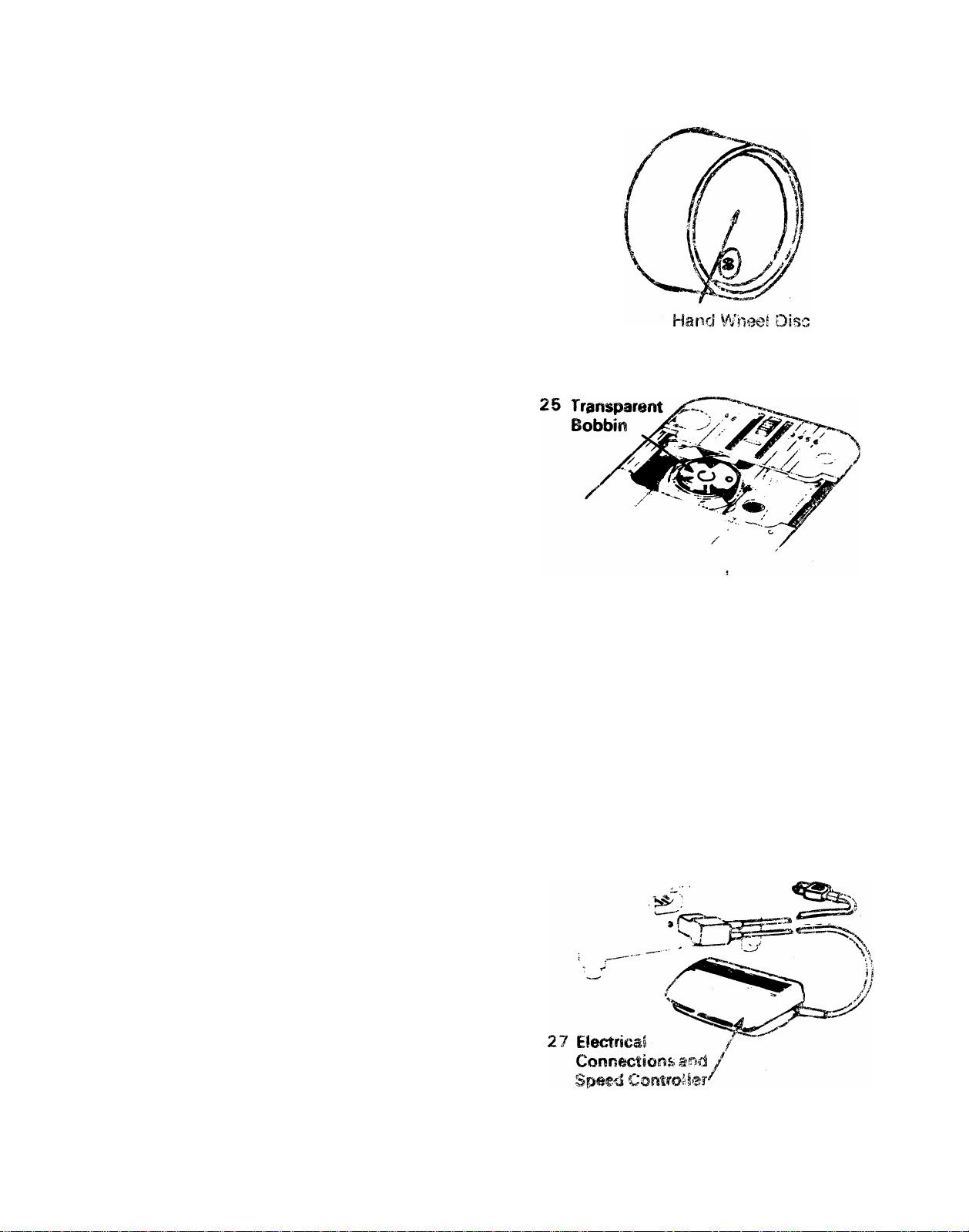

24. Hand Wheel Disc automatically disen

gages clutch for easy bobbin winding.

25. Transparent Bobbin shows thread

supply... is easily removed for bobbin

winding.

26. Power and Light Switch turns on

the power and the sewing ligh?

simultaneously.

27. Electrical Connections and Speed

Controller are designed for con

venience and safety.

See instructions for connecting and ope

rating machine and controller on page 9.

' ^ i / and

/

/

j

\ 26 Power

' " / Light Switch

m

L, !L

S

Page 10

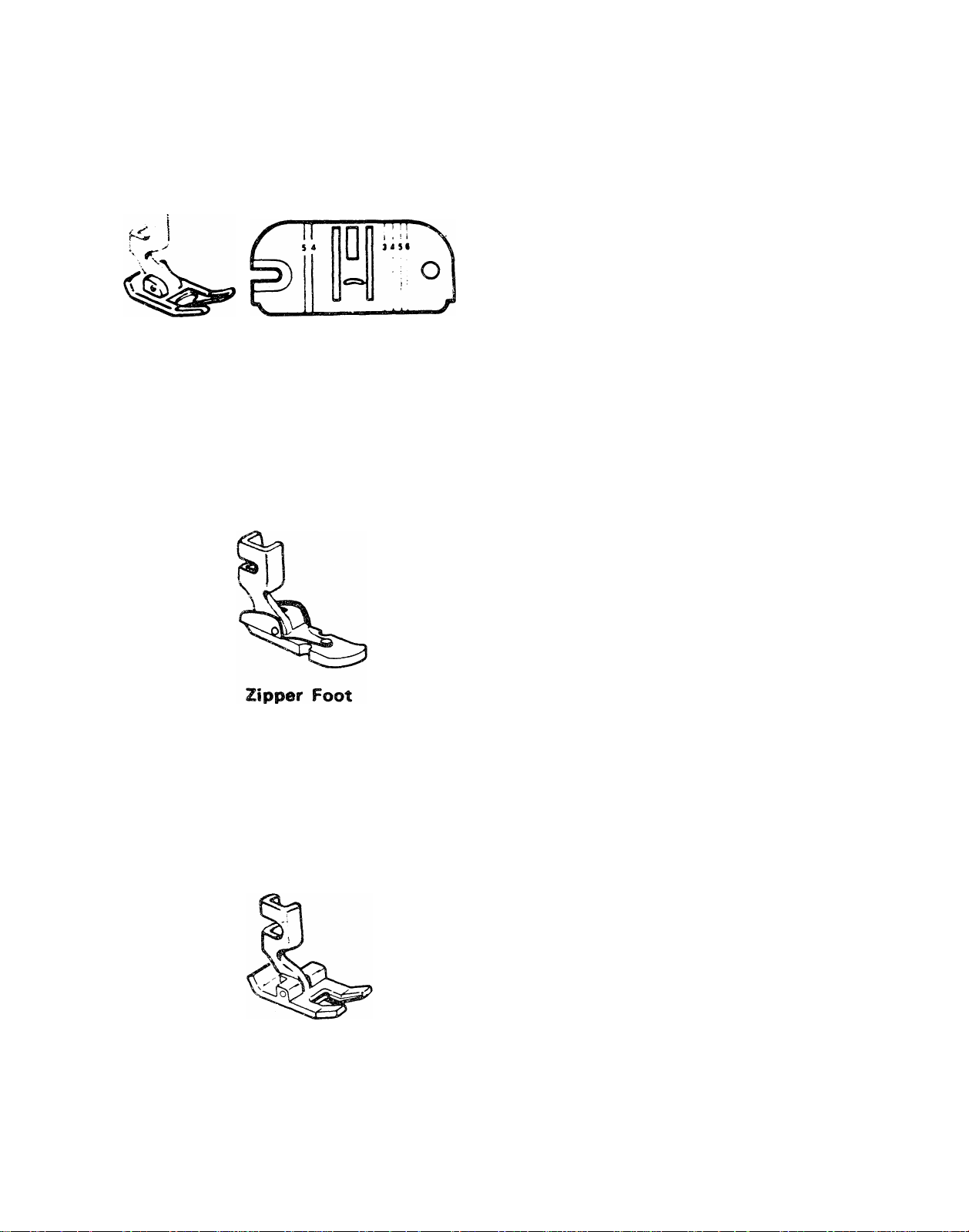

accessories... and when to use them

General Purpose

Foot

General Purpose

Needle Plate

GENERAL PURPOSE FOOT

AND NEEDLE PLATE

The general purpose foot and the general

purpose needle plate are in place on the

machine. Use them for all utility sewing,

with either straight or zig-zag stitching.

ZIPPER FOOT

The zipper foot is used to place stitching

dose to a raised edge. It can be fitted to

the presser-foot shank for use on either

right or left side of the needle.

Special Purpose Foot

SPECIAL PURPOSE FOOT

The special purpose foot is used for a!!

kinds of decorative zig-zag stitching. Use

this foot for:

» Zig-zag satin stitching

® Appliqué

® Buttonholes

® Twin-needle stitching

Page 11

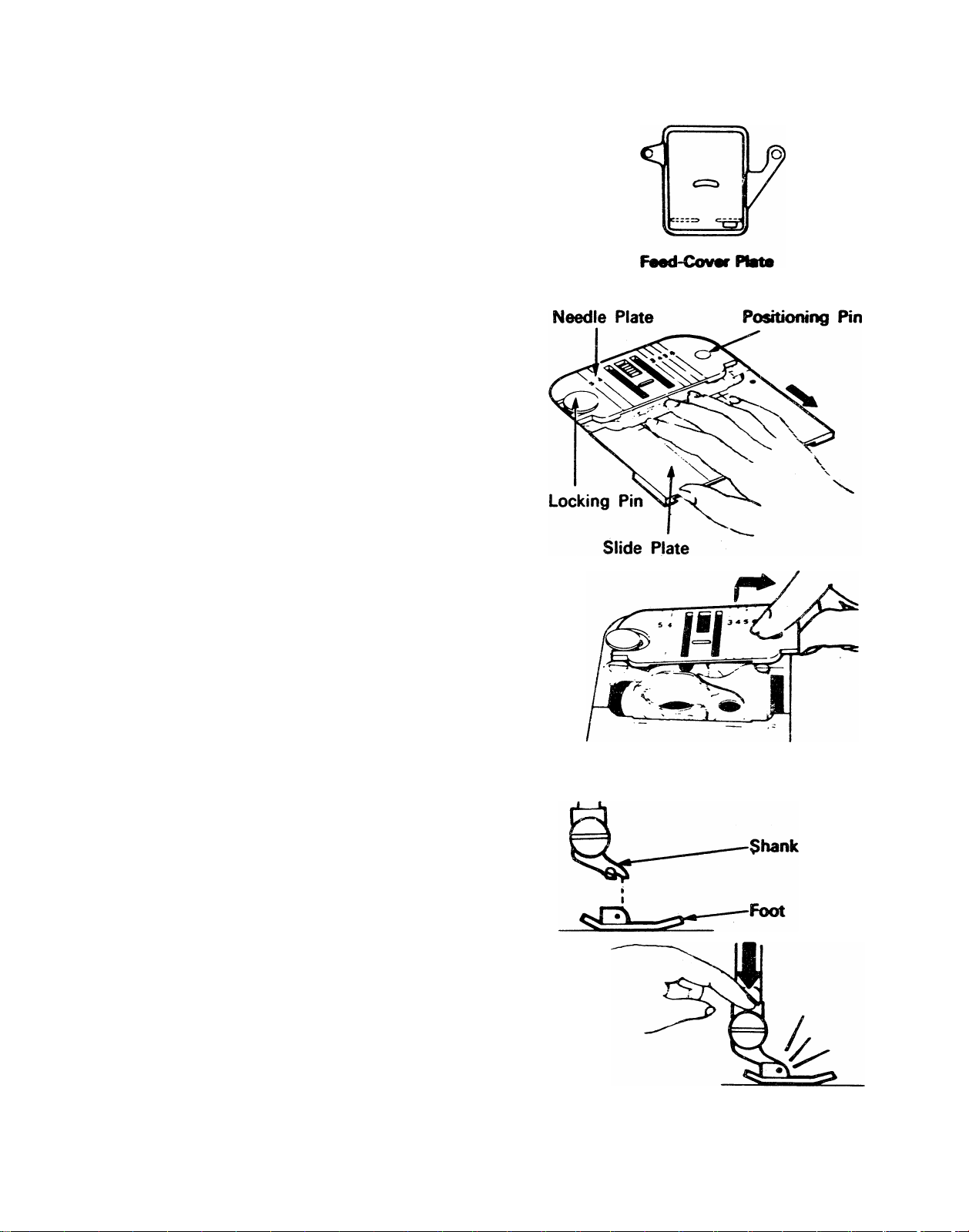

FEED-COVER PLATE

The feed-cover plate which allows free

fabric movement is used for darning

(page 43), embroidery and button sew

ing (page 27). By covering the feed

with the feed-cover plate the fabric is

not moveable.

CHANGING NEEDLE PLATE

• Raise presser foot. (You do not need

to remove the foot.)

• Turn hand wheel toward you until

needle is in its highest position.

• Open slide plate with downward finger

pressure.

• Place thumb under needle plate and

draw plate to the right to remove.

• Insert new needle plate under locking

pin and over positioning pin.

• Close slide plate.

CHANGING PRESSER FEET

The presser feet that are supplied with

your machine snap on and off a common

shank. To change the foot:

9 Raise presser-foot lifter and turn hand

wheel toward you to raise needle to Its

highest position.

» Press toe of presser foot upward (as

far as it will go) and then snap down

to remove the foot.

• Center the new presser foot under the

shank and lower the presser-foot lifter

so that shank fits over the presser-foot

pin.

• Press down on presser-foot screw until

foot snaps into place.

Changing Needle Plate

Changing Presser Foot

Page 12

ACCESSORIES (Continued)

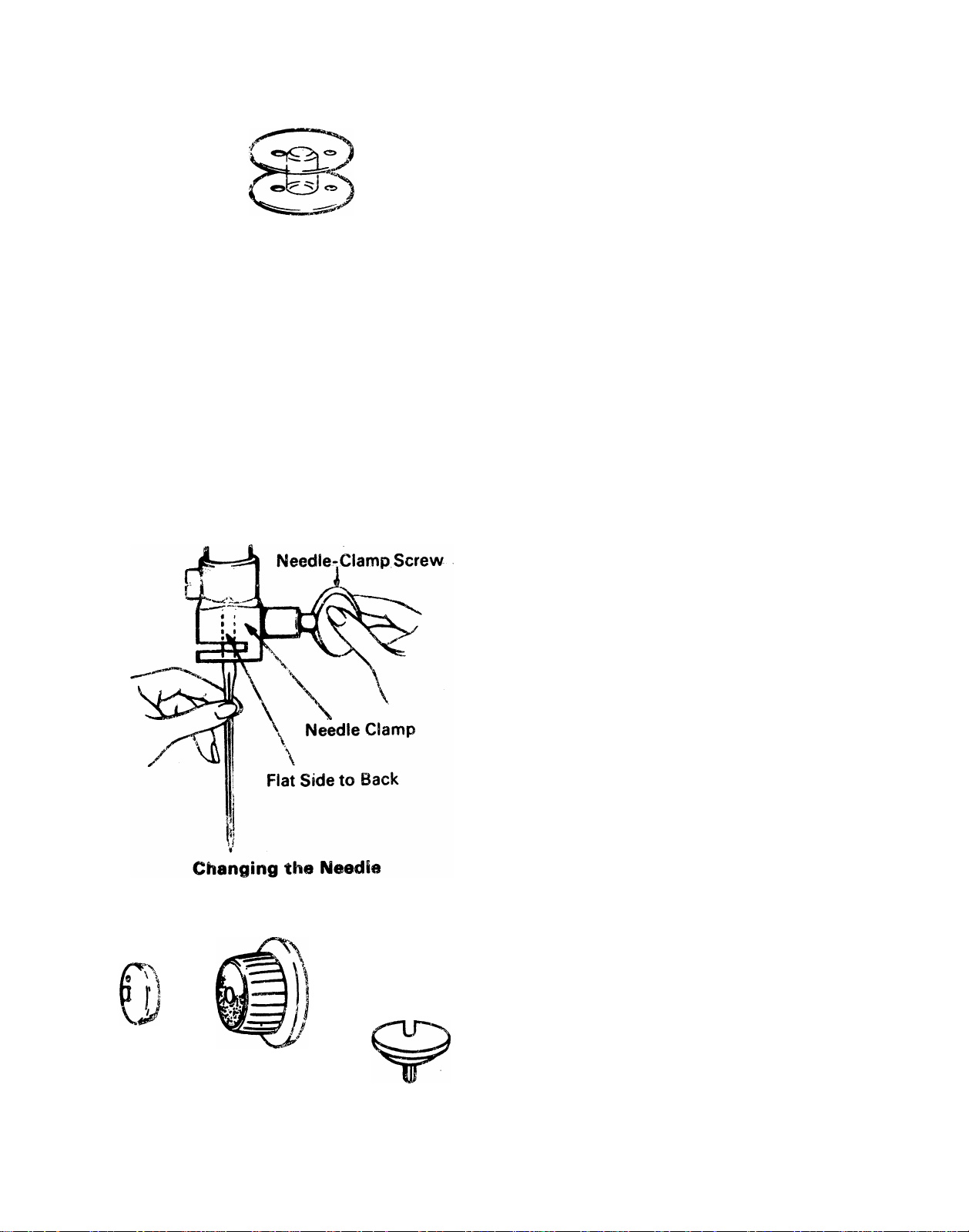

BOBBINS

Transparent

Bobbin

Regular Needle

(Yellow Band) Needle

Ball-point

Twin Needle

Transparent, drop-in bobbin,

thread supply at a glance.

shows

NEEDLES

• Type 705 H needles for all-purpose

sewing

^ Type 705 HS ball-point (yellow

band) needles, for sewing knits and

stretch fabrics.

Type 705 H twin needle for decora-

•tive twin-needle stitching.

ATTACHING FEED-COVER PLATE

1. Raise presser foot. (You do not need

to remove the foot).

2. Turn hand wheel toward you until Is

at Its habest position.

3. Slide feed-cover plate under the

presser foot, until securing pins are

located directly over holes in needle

plate. Then snap down.

Small and Large

Spool Holders

A

Detaohable

Spool Fin

CHANGING THE NEEDLE

The needle clamp is designed so that the

needle can only be inserted with the flat

side of the needle to the back. To change

the needle:

1. Raise needle bar to its highest position,

loosen needle-clamp screw, and re

move needle.

2. Insert new needle in clamp, with thé

flat side of the needle to the back; push

it up as far as it will go.

3. Tighten needle-clamp screw.

SPOOL HOLDERS

The spool holders hold spools of various

sizes in position on the horizontal spool

pin. Because spool does not turn, thread

unwinds smoothly.

DETACHABLE SPOOL PIN

The secondary detachable spool pin is

used for twin-needle sewing.

Page 13

preliminary steps

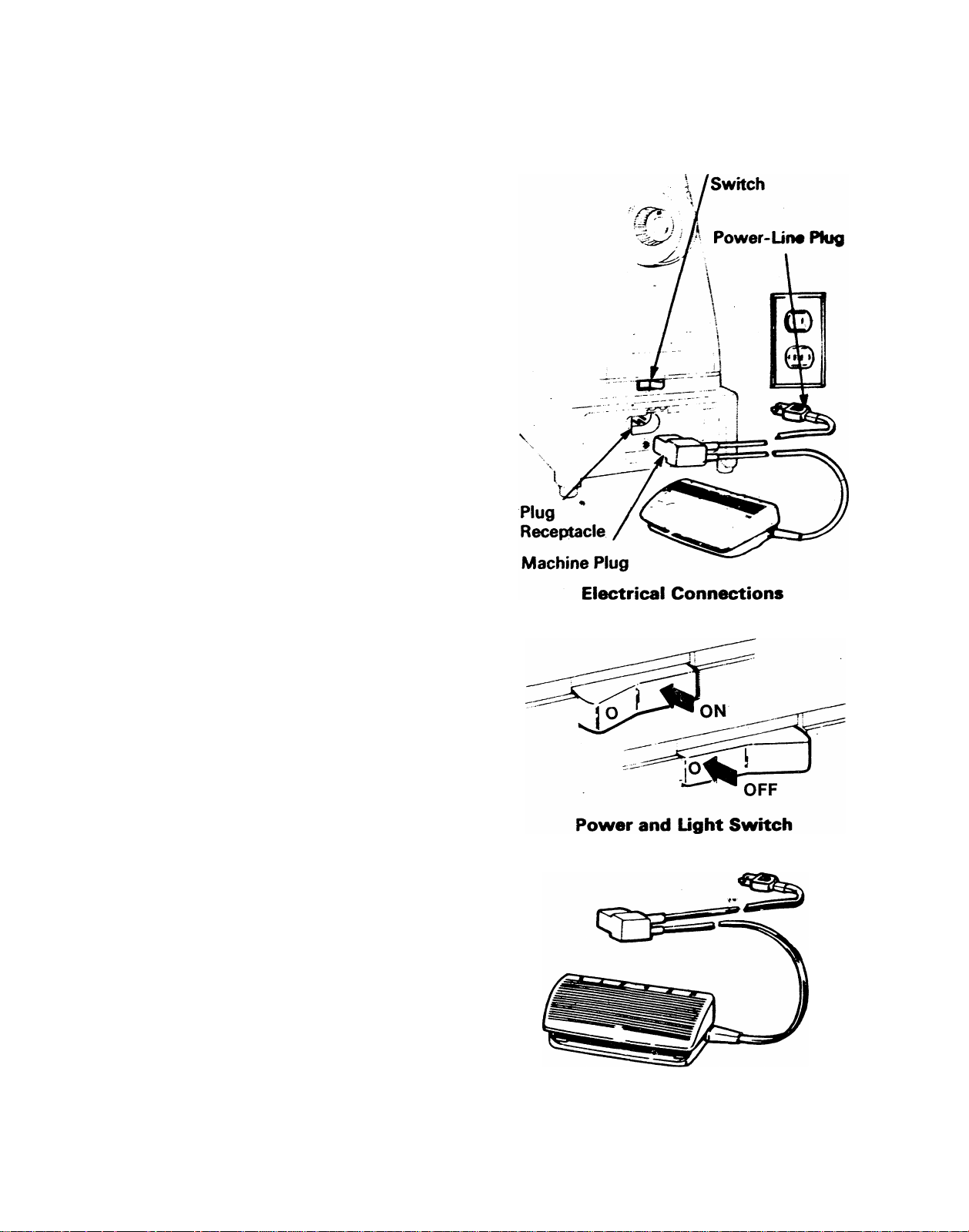

CONNECTING THE MACHINE

Before plugging in your machine, be sure

that the voltage and number of cycles

indicated on the plate under the hand

wheel conform to your electrical power

supply.

Push the machine plug into the receptacle

at the right end of the machine bed. Then

connect the power-line plug to your

efectrical outlet.

OPERATING MACHINE AND CONTROLLER

To turn on both machine and sewing

light, press power and light swith to ON

position. To turn off machine and light,

press switch at „0” to OFF position.

Power and Light

\A^ARNINGl Turn off the po

wer and light switch before changing

needles, presser feet, and needle plates

and when leaving the machine unatten

ded. This eliminates the possibility of

starting the machine by accidentally pus

hing the speed controller.

To start the machine, press the speed

controller. The harder you press, the fas

ter the machine will sew.

To stop the machine from sewing,

remove pressure from speed controller.

Speed Controller

Page 14

choosing needle and thread

The needle and thread you choose will depend upon the fabric being

stitched. The table below is a practical guide to needle and thread selection.

Refer to it before startirjg a sewing project. Be sure to use the same size and

type of thread in both needle and bobbin.

FABRIC, THREAD AND NEEDLE TABLE

FABRIC

DELICATE—tulle, chiffon,

fine lace, organza

LIG HTWEIG HT—batiste,

organdy, jersey, voile, taffeta,

crepe, chiffon, velvet, plastic film

MEDIUM WEIGHT—gingham,

percale, piqué, linen, chintz,

faille, satin, fine corduroy, velvet,

suitings, deep-pile fabrics, vinyl

MEDIUM HEAVY—gabardine,

tweed, sailcloth, denim, coatings,

drapery fabrics, vinyl, deep-pile

fabrics

H EAVY—overcoatings,

denim, upholstery fabrics,

canvas

THREAD

Fine polyester, nylon,

and cotton thread

50 mercerized cotton

"A" silk

Polyester thread

Cotton-wrapped polyester

50 mercerized cotton

60 cotton

"A" silk

Polyester thread

Cotton-wrapped polyester

Heavy-duty

mercerized cotton

40 to 60 cotton

Polyester thread

Heavy-duty

mercerized cotton

24 to 40 cotton

Polyester thread

NEEDLES

Type Size

705 H 70

705 H

705 H

705 H

705 H

80

90

100

110

ALL WEIGHTS—decorative

straight stitch topstitching

in woven fabrics

KNIT, WOVEN, STRETCH

and ELASTIC FABRICS—

polyester doubleknit, spandex,

nylon, tricot, ciré tricot, jersey,

pan né velvet

LEATHER—suede, kidskin,

capeskin, lambskin, lined

leathers

LIGHT and MEDIUM

WEIGHTS—decorative

twin-needle stitching

in woven fabrics

10

"D"silkt

(Buttonhole twist)

"A" nylon

50 mercerized cotton

"A" silk

Cotton-wrapped

polyester

50 mercerized cotton

Polyester thread

"A" silk

Cotton-wrapped

polyester

50 mercerized cotton

t Use with 50 mercerized cotton or "A" silk in bobbin.

705 H

705 HS

Ball-Point

(Yellow Band)

705 H

705 H

(twin)

100

or

110

90

80

90

100

90

Page 15

threading your sewing machine

Like all sewing machines that produce

what is called a "lockstitch", your se

wing machine sews with two threads.

The upper thread comes from the spool

and is threaded through the eye of the

needle. The lower thread comes from

bobbin, the small transparent spool

that you wind using the machine. It is

best to wind the bobbin before the

needle.

THE SPOOL HOLDER

• Remove spool holder from spindle by

sliding it to the left.

• Place spool of thread on horizontal

spool pin. If spool being used has a

retaining slit, this should be placed

against the spool cushion on the right.

• Select correct spool holder according to

type and diameter of the end of the

spool being used. The diameter of the

end of the spool holder should always

be larger than that of the spool itself.

• Press spool holder firmly against spool.

Spool Holders

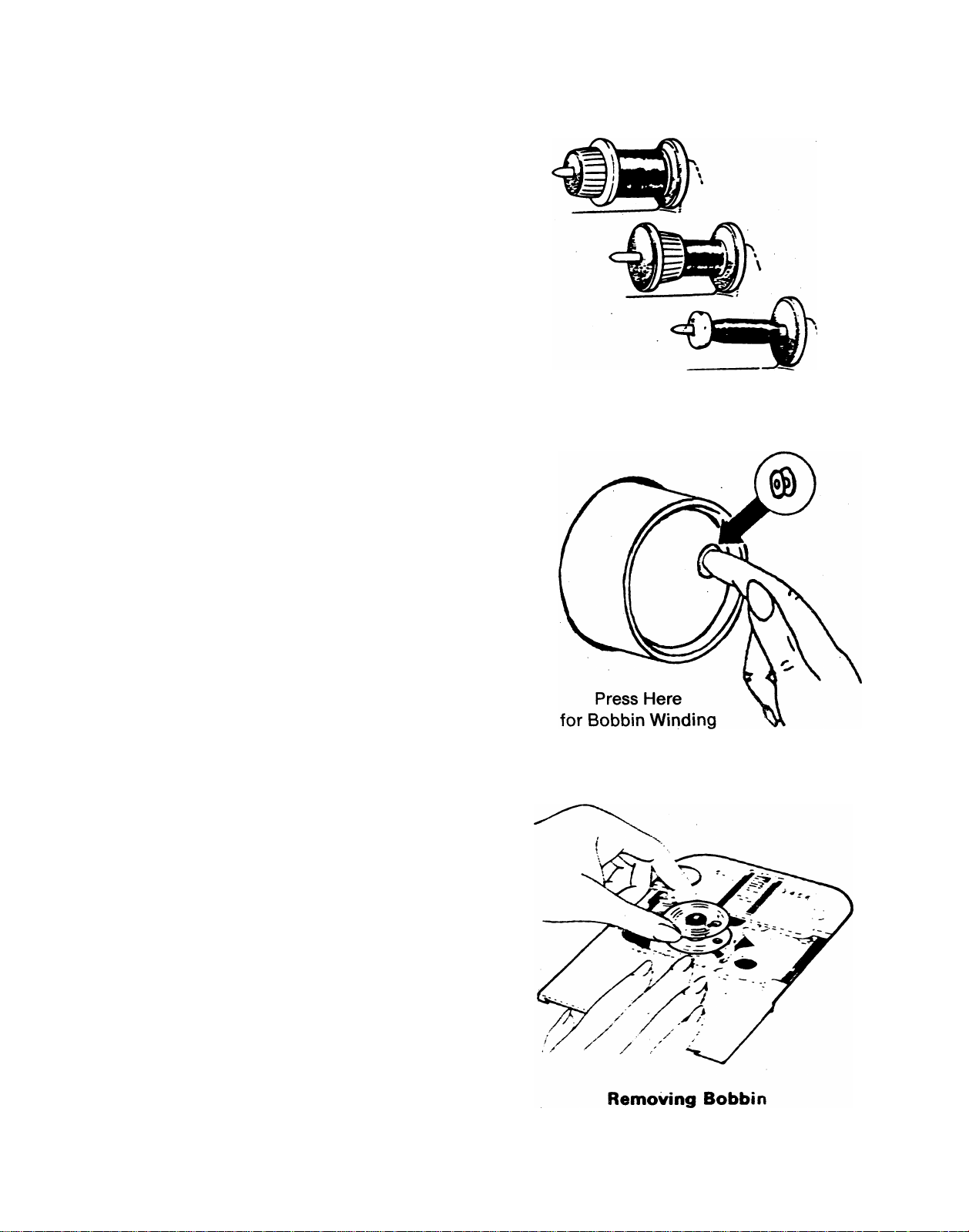

THE BOBBIN THREAD

Winding the Bobbin

• Raise the presser foot and turn the hand

wheel toward you until needle is at its

highest position.

• To disengage clutch, place your thumb

directly on bobbin symbol located In

side hand wheel disc and press down.

• Open slide plate to make bobbin

accessible.

• Lift out bobbin and close slide plate to

make sure needle plate is secure while

winding.

11

Page 16

THE BOBBIN THREAD (Continued)

Press Here

for Sewing

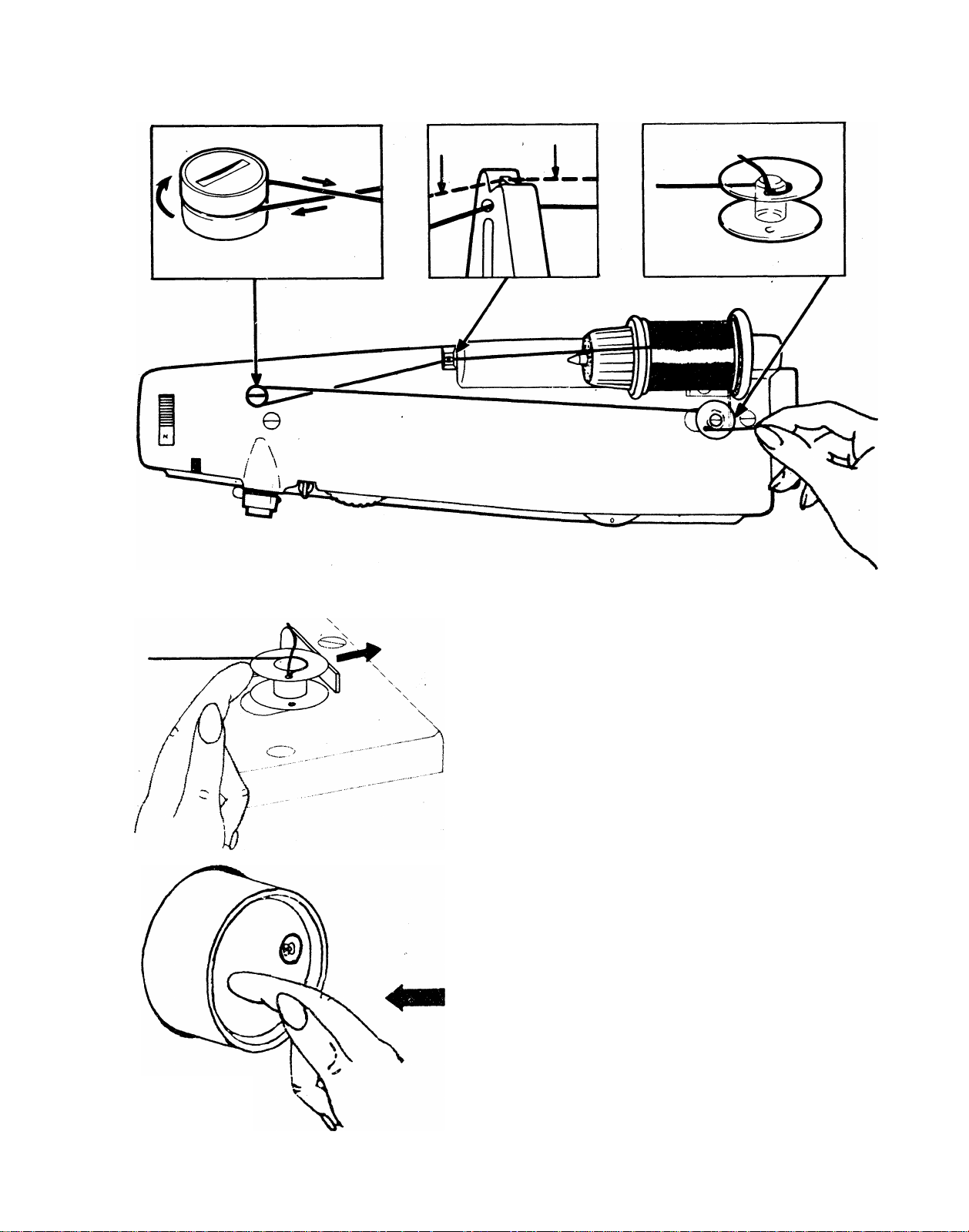

• Place spool of thread on spool pin.

Snap thread in the thread guide post

then lead thread around bobbin winder

tension disc, as illustrated above.

• Pass thread, from the inside, through

hole in bobbin and place bobbin on

spindle.

• push bobbin and spindle to the right

to engage the bobbin winder. Hold

thread end as shown and start the

machine, winding at moderate speed.

• Cut off thread end after a few coils

have been wound on the bobbin.

• When required amount of thread has

been wound (winding will stop when

bobbin is full), stop machine. Cut con

necting thread

• Push bobbin and spindle toward the

left to disengage bobbin winder. Re

move bobbin.

• Release hand wheel disc for sewing.

12

Page 17

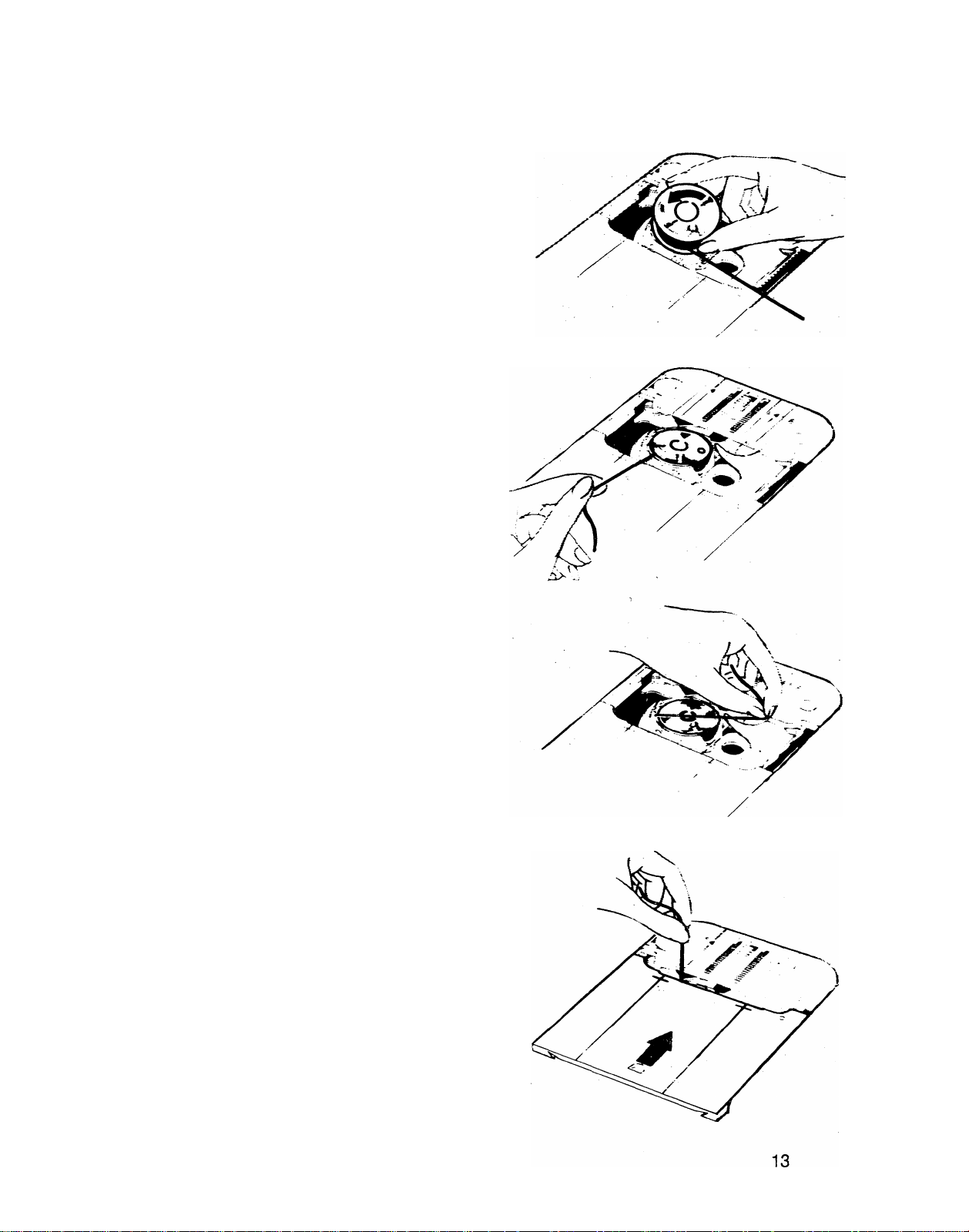

THREADING THE BOBBIN CASE

1. Open slide plate. Hold bobbin so that

thread unwinds in direction shown, and

put bobbin in bobbin case.

2. Pull thread into notch, draw it under

tension spring and back into slot.

3. Draw about three inches of thread

diagonally across the bobbin.

4. Ciose slide plate allowing thread to

enter slot between the needle plate and

the slide plate.

Page 18

THE NEEDLE THREAD

Lead thread

under ughx

Allow spring to return to its

normal up position and con

tinue threading the machine

Threading the Needle

1. Turn hand wheel to raise take-up lever

to its highest position, and raise presser

foot to release the tension discs.

2. Place spool of thread on spool holder

and lead thread through all points as

shown, making sure to:

• Hold thread as illustrated while guiding

thread into tension discs.

• Thread tension discs as illustrated.

® Thread takerup lever from back to front,

guiding thread down over top of lever

and then up into eyelet.

14

• Thread needle from front to back,

drawing about 10 cm of thread

through eye of needle.

Page 19

RAISING THE BOBBIN THREAD

Now that you have wound the bobbin and

threaded the needle, you will need to raise

the bobbin thread through the needle hole

in the needle plate.

1. Hold needle thread lightly with left

hand and turn hand wheel slowly

toward you so that needle enters hole

in needle plate.

2. Continue turning hand wheel and

holding needle thread until needle

rises. Tighten your hold on the needle

thread and bring up bobbin thread in a

loop.

3. Open the loop with your fingers.

4. Place both needle and bobbin threads

under presser foot and draw to back

of machine.

You are now ready to sew

15

Page 20

1 i J

Needle Position

Before you move the selectors to set your

sewing machine for straight stitching,

turn the hand wheel toward you until the

needle is above the needle plate.

SETTING THE MACHINE

• Move needle position selector to X

(center).

I

• Set stitch width selector on •

STARTING TO SEW

« Place needle and bobbin threads under

presser foot and draw to back of

machine.

Stitch Width

• Position the needle in the fabric where

desired for stitching start.

• Lower the presser foot and start the

machine.

To sew perfectly on a wide variety of

fabrics, adjust stitch length, pressure and

thread tension as instructed on the

following pages.

16

Page 21

adjusting selectors for your fabric

ADJUSTING STITCH LENGTH

The stitch length dial regulates the length

of stitches. The numbers on the dial ex

press stitch length in mm; the higher the

number the longer the stitch. Generally,

shorter stitches are best for lightweight

fabric; longer ones for heavy fabric. The

0—1 area is used for the adjustment of

zigzag satin stitching.

Setting the Selector

• Turn dial so that the stitch length

desired is positioned under the ▼

symbol on the control panel.

• To shorten the stitch length, turn the

dial clockwise to a lower number.

• To lengthen the stitch, turn the dial

counterclockwise to a higher number.

For reverse stitching, press the reversestitch push button (located in the center

of the dial) In as far as It will go and hold

in place (the button can be pushed in

while the machine is sewing). Release

pressure on the push button to return to

iforward stitching.

ReverseStitch

Push

Button

(For detailed instructions on adjusting

the stitch length for zig-zag satin stitching,

see page 24 )

Reverse Stitching

17

Page 22

STRAIGHT STITCHING (Continued)

Pressure Dial

Adjusting Pn

Dial

ure

ADJUSTING PRESSURE

Numbered settings on pressure dial will

assist you in obtaining correct pressure

for fabric you are using. NORM (norma!)

setting is an all purpose setting for sewing

a wide variety of fabrics of different

weights and textures. Settings above and

below NORM setting are also provided.

When you need extra control, regulate the

setting to heavier or lighter pressure to

suit fabric being sewn.

When darning without an embroidery

hoop, set dial at lowest setting, ^ . See

page 42for instructions.

L o wer presser foot before setting pressure.

® To increase pressure, turn dial from

NORM (normal) toward MAX (maxi

mum).

® To decrease pressure, turn dial from

NORM (normal) toward W .

® For darning, set dial on ft .

Increase Decrease

Adjusting Thraad Tansion

REGULATING THREAD TENSION

Correct tension is important because too

much or too little will weaken your seams

or cause your fabric to pucker, Make a

test sample with fabric and thread you

plan to use and examine it. A perfect stitch

will have needle and bobbin threads

locked between two layers of fabric with

no loops on top or bottom and no puckers.

The tension dial regulates the degree of

tension on your needle thread. Set it

according to the type of thread and fabric

you use. The numbers on the dial eliminate

guesswork in duplicating settings.

If the stitches in your test sample look

loose, increase needle-thread tension. If

the fabric puckers, decrease tension.

® To increase tension, turn dial to higher

number.

® To decrease tension, turn dial to lower

number.

18

Page 23

sewing a seam

PIN BASTING

Pin basting is a time-saver and can be

used when you sew easy-to-handle

fabric. Use fine pins and place them:

• On top of the fabric (never on the

underside in contact with the feed).

• At right angles to the stitching line.

• Just nipping into the fabric at the

stitching line (never extending under

both sides of the presser foot).

STARTING A SEAM

1. Set stitch length dial for desired length.

2. With presser foot up, align fabric

with appropriate seam guideline on

needle plate (as described on the fol

lowing page). Position needle in fa

bric about 1.2 cm from the back ed

ge.

3. Lower presser foot. Backstitch to the

edge of the fabric for reinforcement by

pusfling in the reverse-stitch push

button located in the center of the

stitch length dial. Hold the button

until the stitches reach the edge of the

fabric and then release for forward

stitching.

Page 24

STRAIGHT STITCHING (Continued)

Using Guidelines

KEEPING THE SEAM STRAIGHT

As you stitch, use one of the numbered

lines on the needle plate as a guide for

keeping the seams straight. Numbers in

dicate distances in eights of a cm from

the needle. If you want a 1.5 cm seam, for

example, keep the righthand edge of your

fabric on the number 5 guideline.

Fabric after Turning

Pivoting at Corner

20

TURNING SQUARE CORNERS

To turn a square corner 1.5 cm from

the fabric edge, you need not measure

or mark thé seam. Simply use the

crosslines on the slide plate.

• Line up your fabric with right or left

guideline 5 on the needle plate. Stitch

seam, slowing speed as you approach

corner.

• Stop stitching, with the needle down,

when the bottom edge of the fabric

reaches the cornering crosslines on the

slide plate.

• Raise presser foot ^and turn fabric on

needle, bringing bottom edge of fabric

in line with guideline 5.

• Lower the presser foot and stitch in new

direction.

Page 25

GUIDING AND SUPPORTING

THE FABRIC

Most fabrics need only to be guided in

front of the presser foot. Some fabrics,

however, require support while being

stitched. Filmy sheers, panne velvet, and

tricots, for example, need to be held taut

in front and back of the presser foot while

being sewn.

\N/K F^N IN G!! Do not pull the

fabric while you are stitching as this may

deflect the needle causing it to break.

REINFORCING END OF SEAM

1. Stitch to the fabric edge.

2. Push in reverse-stitch push button

and backstitch 1.5 cm to reinforce

the end of the seam.

Guiding Fabric

3. Raise presser foot and remove fabric

by drawing it to the back and left.

4. Cut threads on thread cutter at rear of

presser bar.

Supporting Fabric

21

Page 26

ì i

/1 \ ^

Adjusting Stitch Width

L X J

Before moving stitch width and needle

position selectors make sure needle is

above fabric.

ADJUSTING WIDTH OF DESIGN

To produce a zig-zag stitch pattern, move

the stitch width selector from straight

stitch setting i to any zig-zag setting to

the right. Stitch width is increased as the

selector is moved to the right.

Buttonhole Sewing

Butto 1 Sewing

Most used Widths

Setting for

Single Needle

Work

Adjusting Stitch Placement

Too Tight

Decorative

Stitching

at Narrow

ADJUSTING STITCH

PLACEMENT

Most of your basic zig-zag stitching will

be done in center ( ) needle position.

Left ( ) and right ( J ) settings are

used for special stitch placement, as in

buttonhole sewing and button sewing.

ADJUSTING NEEDLE-THREAD

TENSION

Zig-zag stitching requires less needle-

thread tension than straight stitching.

Make a test sample with the fabric and

thread you plan to use so that you can

adjust the tension properly. The stitches

should lie flat against the fabric without

causing the fabric to pucker.

Correct

Adjusting Needle-Thread Tension

22

If the stitches are not flat and the fabric is

puckered, reduce needle-thread tension

by turning the dial to a lower number.

Page 27

ADJUSTING STITCH LENGTH

Any stitch length setting from 1 to 4 will

give you an open zig-zag stitch. The higher

the number, the more open, or farther

apart, your stitches will be. The stitch area,

between 0 and 1 bn the dial, is used for

adjusting zig-zag satin stitching (see next

page for specific instructions).

Stitch Length Dial

ADJUSTING PRESSURE AND CHOOSING ACCESSORIES

Turn to page 18 under "Straight Stitching" for instructions on

adjusting pressure.

For information on choosing accessories, refer to pages 6 and 7

and to detailed instructions for sewing with zig-zag stitch patterns

included in the section called "Sewing the Professional Way" that

starts on page 31.

General Purpose

Foot

General Purpose

Needle Plate

Zipper Foot

Special Purpose

Foot

23

Page 28

satin stitching

Satin stitching—a series of closely spaced

zig-zag stitches that form a smooth, satin

like surface—is useful for both practical

and decorative work.

When you wish to produce a satin stitch

for appliqué or bar tacks, for example,

make a test sample first so that you can

adjust the stitch length and thread tension

properly. Soft fabrics may require a back

ing to ensure firm satin stitching.

ACCESSORIES AND

SELECTOR SETTINGS

« Needle Position; ^

Adjusting Stitch Length

Ji 3 4 5l

r-ri'-rrn n Tr

Incorrect

Correct

Adjusting Thread Tension

• Stitch Width: ^ to ^

• Stitch Length: 0-1

• General Purpose Needle Plate

• Special Purpose Foot

• Pressure: NORM

Adjusting Stitch Length

1. Turn stitch length selector dial to 1

(the beginning of 0-1 area).

2. Run machine at a slow speed.

3. Gradually turn the stitch length dial

clockwise until stitches are closely

spaced and form a smooth surface.

Adjusting Thread Tension

Satin stitching requires less tension than

straight stitching or open zig-zag stitch

ing. Futrhermore, the wider the stitch, the

lighter the tension on the thread must be.

Notice the stitching oh your sample. If the

fabric is puckered, lower the needlethread tension by turning the tension dial

to a lower number.

24

Page 29

By using a twin needle, you can produce

two parallel, closely spaced, decorative

lines of stitching simultaneously. You

can use either one or two colors of thread

and you can choose either a straight-

stitch or zig-zag stitch.

SETTIIMG THE MACHINE Straight Stitching

• Needle Position;

Stitch Width:

• Stitch Length: Optional

• General Purpose Needle Plate

• General Purpose Foot

only

Zig-Zag Stitching

Needle Position: i only

Stitch Width: See illustrations at right

Stitch Length: Optional

General Purpose Needle Plate

General Purpose Foot (Open Stitching)

Special Purpose Foot (Satin Stitching)

Center Only

1 i J

Straight Stitchir>g

Maximum

Setting

Center ( X ) needle position setting must

be used. Stitch width must not exceed

settings illustrated at right.

Ceriter Only

1 i -i

Zig-Zag Stitching

25

Page 30

TWIN-NEEDLE STITCHING (Continued)

Use twin needle. Type 705 H (size 90).

INSERTING THE TWIN NEEDLE

Before inserting the twin needle, make

sure you are using the general-purpose

needle plate and that the needle position

dial is set at X ^ ^nd the stitch width

does not exceed the settings shown on

page 25.

To insert the twin needle, simply raise

needle to its highest point and loosen the

needle-clamp screw. Remove the single

needle and insert the twin needle in its

place. Tighten needle-clamp screw

securely.

threading for twin-needle stitching

For best results, use No. 50 mercerized or synthetic thread. Thread the

machine as for single-needle stitching, except pass thread between center

and back tension discs, and through right eye of needle. Attach secondary

spool pin in hole on top cover. Pass thread from second spool through guide

(by-passing the snap-in thread guide post) as illustrated, then between

center and front tension discs. Thread through remaining points, making

certain to omit the thread guide above the needle and pass thread through

left eye of needle.

26

Page 31

buttons

Needl-e Position:

• General Purpose Presser Foot

• Feed Cover Plate

(left)

Flat buttons can be sewn on quickly and

easily using the plain zig-zag stitch. The

space between the holes in the button

determines stitch width settings. For

buttons vyith standard hole spacing, use

settings I and | as shown. For buttons

with unusual hole spacing, use setting j

and increase or decrease the width ( |')

as necessary.

1. Attach feed-cover needle plate (see

page 7).

2. Set stitch width at i and needle

position at (left). Position button

under foot and lower needle into

center of left hole by turning hand

wheel toward you. Lower foot. Turn

hand wheel toward you until needle

rises out of button and is just above

the foot

3. Set stitch width at medium-wide zig

zag ( I ) setting. Check stitch width

by turning hand wheel slowly toward

you; the needle should enter the right

hole of the button. Take six or more

zig-zag stitches to attach button. End

on leftside.

4. To fasten stitching, return to stitch

width ! and take three or four stitches.

Remove feed-cover plate from the

general-purpose needle plate when

work is completed.

27

Page 32

Horizontal Placement

on Crosswise Grain

Vertical Placement on

Lengthwise Grain

Buttonhole

Length Guide

Markings

buttonholes

BUTTONHOLE POSITION

Accurate guidelines are essential to keep

buttonholes a uniform distance from the

faced edge of the garment evenly spaced,

and on the grain of the fabric. For center

closures, place guidelines as follows:

1. Mark the center line of the garment as

indicated on your pattern. This guide

line can be hand basted and should

follow a lengthwise fabric thread.

2. Mark a position guideline for each

buttonhole.

• Horizontal buttonholes are pla

ced to extend 3 mm beyond the

center-line basting of the gar

ment. Horizontal guidelines for the

buttonholes should follow a cross

wise thread of the fabric, and, if

basted, be longer than the finished

length of the buttonhole. Determine

the length of the buttonhole (as

described below) and mark ends of

each buttonhole vertically.

• Vertical buttonholes are placed so

that the center-line basting of the

garment is in the center of the

buttonholes. Determine buttonhole

length and mark ends of each button

hole horizontally across the center

line and use the center-line basting

as a buttonhole guide when stitch

ing.

Button

Opening

Length of

Button

Opening

28

Button

Opening

Buttonhole

Stitching

BUTTONHOLE LENGTH

First, decide how long the button ope

ning must be. Then, add 2 mm to the

measurement for each bar tack (the

closing stitches at each end of the but

tonhole). To find the length of the but

ton opening, cut a slit In a scrap of fa

bric the diameter of the button you in

tend to use. Increase length of opening

until button slips through easily.

Page 33

STITCH WIDTH

Two stitch width settings are required for making buttonholes: one for side

stitching and one for the bar tack. Two possible combinations are illustrated.

Selector Setting

for Bar Tack

Selector Setting

for Side Stitching

Procedure

Set stitch length in 0-1 area of stitch

length dial. Attach special purpose foot.

Set the pattern selector at | , needle

position selector at and stitch width

selector at the width desired for the side

stitching. Place work under needle, align

ing center marking of buttonhole with

center slot in the special purpose foot.

Side Stitching

Position needle In fabric at point A.

Lower foot and stitch to end of marking.

Leave needle in fabric at point B. Raise

foot and pivot work on needle. Lower

foot. Take one stitch without changing

width setting, bringing work to point C.

Bar Tack

Adjust stitch width selector for bar tacks

and take at least six stitches. Stop at point

D.

29

Page 34

BUTTONHOLES (Continued)

Side Stitching

Readjust stitch width selector for side

stitching. Complete work to point E.

Leave needle in fabric.

Final Bar Tack

Adjust stitch width selector for bar tacks,

and take at least six stitches ending at

point F.

30

i I

Fastening Stitch

To secure stitching, move selector to !

and take three stitches. Remove work,

draw threads to underside, fasten, and

trim. Cut opening for button with sharp

scissors.

Page 35

UNGERIE SEAMS

To make seams in lingerie durable and

flexible, use a combination of straight and

zig-zag stitching.

Method 1

For 1.5 cm bias seam in woven fabric:

• Straight-stitch the seam (with stitch

width at i ) on wrong side of fabric.

• Press both seam allowances in the

same direction. Then, from the right

side, top-stitch with narrow zig-zag

stitching, letting needle alternately

enter seam line and seam thickness.

Method 2

For narrow seams in nylon tricot:

• Cut fabric for 1.5 cm seam allowance.

For a 1.5 cm Seam

• Straight-stitch seam line on wrong side

of fabric. Then place a line of medium

wide, open zig-zag stitching close to

the straight stitching.

SEAM FINISHES

• Needle Position: JL

• Stitch Width: \ or % (maximum)

• Stitch Length: 1,2 to 3 mm depending on

choice of stitch and fabric

• General Purpose Needle Plate and Foot

Seam edges support the garment and

should be given a durable finish if the

fabric is likely to ravel. There are two

methods of finishing seams in such

fabfics: trimming seam edge or over

edging. Make a test sample first to deter

mine which method best suits your fabric.

Page 36

hints on sewing special fabrics

LEATHER-LOOK VINYL

• Use masking tape or zipper adhesive

tape instead of pins or basting to hold

seams, zippers and hems in place for

stitching.

• Stitch with a long stitch (1 to 3 mm).

A short stitch may cut the fabric.

• Sew with a steady, even pace and

stitch accurately. Seams cannot be

ripped out without leaving needle

marks in the fabric.

• The shiny side of some vinyls tends to

stick to metal surfaces. Use a strip of

tissue paper between the fabric and

metal machine surfaces to prevent this.

• Topstitching holds seams and garment

edges smooth and flat and adds a

decorative note.

• Reinforce button and buttonhole areas

with interfacing. Bound buttonholes

are the best choice for vinyls with knit

Diagonal Stitching

Across the Point

backing.

• For sharp points on collars and lapels,

take one or two stitches diagonally

across the point to allow enough space

to smoothly enclose the seam edge.

CIRÉ (Wet-Look Taffeta and Tricot)

• Use masking tape or zipper adhesive tape instead of pins or basting to

hold seams, zippers, and hems In place for stitching.

• Stitch accurately; seams cannot be ripped out because needle marks

femain in the fabric.

• Sew seams under light tension by holding fabric slightly taut at front and

back of needle.

• Stitch ciré taffeta with a fairly long stitch 2,5 to 3 mm and use an

enclosed edge finish for seams and hems.

• Stitch ciré knits with a medium length-stitch 2 mm and use a fine

ball-point needle.

• Machine-worked buttonholes (as well as bound buttonholes) can be

made in ciré fabric. Always use an interfacing and make sure the close

zig-zag stitches do not cut the fabric.

32

Page 37

DEEP-PILE FABRICS (Fake Fur)

• Pin, rather than baste, seams. Place

pins at close intervals at right angles

to the seam line. Pins with colored

heads are easy to see gnd remove.

• Sew in direction of nap.

• Stitch with a fairly long machine

stitch(2,5to3mm)and use polyester/cotton thread in a size 90 or 100

Type 705 H needle.

• As seam is stitched, smooth pile away

from seam allowance with a darning

needle or upholstery pin.

• After stitching seams with a 1.5 cm

seam allowance, use small hand

scissors to shear pile from entire se

am allowance to reduce bulk.

• Stitch 6 mm pre-shrunk tape into

neckline and shoulder seams for sta

bility and reinforcement or stitch

with the straight stretch stitch.

• Leather and leather-look fabrics com

plement fur fabrics; use them for bound

buttonholes and easy button loops.

• Coat hems are less bulky If they are

narrow and finished with a 8 cm fa

bric facing or grosgrain ribbon.

Smoothing Pile away

from Seam Allowance

Deep-Pile Fabrics

• Slash through the center fold of darts

and finger-press open, or stitch with a

narrow zig-zag stitch and trim away

excess fabric after stitching.

VELVET AND VELVETEENt

• Use a light-pressure dial setting to prevent crushing pile.

• Mark and baste with silk thread.

• Use a Type 705 H, size 80 needle, and a fine thread for seaming. "A"

silk or nylon thread is recommended for velvet.

• Always stitch In the direction of the nap.

• For unpuckered seams, pin or hand baste together and then stitch under

light tension (see page 18). Extra-long, straight seams may be machine

basted with a long, wide zig-zag stitch.

• To sew pann§ velvet, use a ball-point needle and a shorter-than-normal

stitch length (1.5 to 2 mm).

33

Page 38

At the notions counter i

Center, you will find

kinds of zippers, one of which

sew= The zipper package

easy-to-foiiow instructions

ting the zipper» And, with

foot, you wiii find it easy

even

CS-)

o Stitch Width: »

snser-

zipper

form an

zip-

P®giti©8^

o General Purpose Needle

o Zipper Foot

Plate

Attaching the Zipper

When the zipper is to

^edle!

IViove

allow shank to enter riqhi side

m

s to trie /err of the needle:

o IViove

St 1

t so

block on zipper foot to

needle will enter left notch

(The zipper foot is snapped

instructed on page 7.)

t of the

shank as

34

D SEAiViS

seam is a

ment for

blouses, and lingerie. To

seam, make the welting

ready-made at a notions

t into the seam,

zipper foot

fs. clothes,

e a

steps, use

stitching dose

Page 39

TOPSTITCHING

A practical, simple way to accent the

lines of a dress or coat is to place one or

more rows of stitching along collars,

lapels, facing edges, pockets, seams, etc.

For a tailored look, use lines of regular

straight stitching; sew them with button

hole twist for added emphasis. For decora

tive interest, use a zig-zag stitch.

Topstftching

with Zig-Zag Stitch

Steps in Making a Dart in Interfacing

DARTS IN INTERFACING

• Needle Position: JL

• Stitch Width: § (maximum)

• Stitch Length: 1 mm or to suit fabric

• General Purpose Needle Plate and Foot

With zig-zag stitching, interfacings can be

shaped without bulk.

1. Cut out the dart allowance on the

stitching line.

2. Bring raw edges together and pin or

baste in place over a muslin stay.

3. Stitch, backstitching at both ends of

dart for reinforcement.

Step 2

Step3

35

Page 40

APPLIQUÉ

Applique adds beauty and interest to clothing and household linens. You

can create your own design, trace a simple outline from a coloring book,

or use a motif cut from a printed fabric. Fabrics of like or different texture

combine equally well.

A closely spaced zig-zag stitch is most commonly used in appliqué work.

Athough you may vary stitch width to accomodate fabric weave or tex

ture, never allow the stitch to be too wide.

Preparation

• Baste appliqué design to fabric.

• Outline design with straight stitching

(use a short stitch).

• Remove basting and press.

• Attach special purpose foot.

Appliquéing

1. Set machine for desired stitch width.

Adjust stitch length in the 0-1 area of

the stitch length dial.

2. Outline the entire design with appliqué

stitching.

3. Cut away the fabric on the outer edges

of the stitching with embroidery

scissors.

ATTACHING ELASTIC

Elastic will remain stretchable when it is

attached with the plain zig-zag stitch.

The flexible joining produced by this

stitch allows elastic banding to be

stitched under, over, or between fabric

layers, making it particularly useful in the

construction of lingerie and swimsuits.

• Needle Position:

Attaching Elastic with

Plain Zig-Zag

36

• Stitch Width:

• Stitch Length: About 1.25 mm

• General Purpose Needle Plate and Foot

(maximum)

Page 41

free arm sewing

Free arm sewing simplifies fabric hand

ling when you sew circular and hard-to-

-reach garment areas. A few of the

sewing jobs for which you will find it

particularly useful are illustrated. To

prepare your machine for free arm se

wing, press the extension table release

push-button and remove the extension

table.

Page 42

FREE ARM SEWING (Continued)

38

HATS, BAGS AND DOLLS'

CLOTHES

Use the free arm of your machine

when you make hats, bags and dolls’

clothes. You will find it a real advan

tage for seaming small circular areas,

and in the placement of decorative top

stitching.

Page 43

GUFFS

Attaching a cuff to a gathered sleeve

or accenting it with decorative top sti

tching is greatly simplified when you

use the free arm. The fabric flows smo

othly around the bed giving you full

visibility and control of the seam line.

Page 44

FREE ARM SEWING (Continued)

BADGES, EMBLEMS AND INSIGNIA

Badges, emblems and insignia of all

sizes and shapes can be quickly atta

ched to shirts and uniforms when the

free arm is used. Slip the sleeve or

other hard-to-reach area over the free

arm and secure emblem with zig-zag

sewing.

Page 45

keeping up appearances

MENDING

The zig-zag stitch is just as useful for

mending as it for creative sewing. It forms

a flexible bond for repairing tears or se

wing stretch garments.

Mending a Tear

• Needle Position: JL

• Stitch Width: \ or % (maximum)

• Stitch Length: About 1 mm

• General Purpose Needle Plate and Foot

1. Trim ragged edges.

2. Place underlay on the wrong side of

tear for reinforcement. (It is best not

to baste or pin the underlay since you

will be bringing the edges of tear

together in the next step.)

3. Stitch on the right side, bringing the

edges of the tear together.

4. Shorten stitch length at ends and

corners to give extra strength.

5. Trim underlay.

Bar Tacks

Bar tacks, to reinforce points of strain, are

made with the zig-zag stitch at satin stitch

length. Use them at pocket comers, to at

tach garters, secure shoulder straps, belt

loops and zipper openings.

Tear Mended with

Zigzag Sdlch

Bar-Ta<d(ed Belt Loof»

41

Page 46

KEEPING UP APPEARANCES (Continued)

DARNING

Worn or torn spots on children's clothes,

knits, and household linens can be darned

effortlessly and quickly with little practice.

You may choose to darn either with or

without an embroidery hoop. When

greater control is needed, an embroidery

hoop is usually best.

Darning without Embroidery Hoop

® Needle Position: ^

s

® Stitch Width: •

® Stitch Length: 2mm

® General-Purpose Needle Plate and Foot

® Pressure: ^

Darning Without

Embroidery Hoop

1. If the area to be darned is open, baste an

underlay in place.

2. Place area to be darned under presser

foot; lower presser foot and start

stitching, alternately drawing fabric

toward you and pulling it gently away

from you.

3. Continue this forward and backward

motion as you til! the area with parallel

fines of stitching. For additional

strength, cover area with crosswise

lines of stitching.

Repairing Stretch Garments

© Needle Position: ^

® Stitch Width: | to $

® Stitch Length: 1 or to suit fabric

® General Purpose Needle Plate and Foot

Stretch Garment Repair

42

Seams and hems in stretch and elasticized

garments retain their elasticity when stit

ched with the zig-zag stitch. This stitch is

particulary effective when used in top-

stitch applications (as shown) or to over

edge, Make a test sample to check selec

tor settings.

Page 47

Darning with Embroidery Hoop^

• Needle Position; JL

• Stitch Width: !

• Stitch Length; In 0-1 Area

• Feed Cover Plate

® No Presser Foot

• Presser Bar: Lowered

Preparation

Remove presser toot with shank (by

removing the screw which fastens the

shank to the presser bar). Attach feedcover needle plate. Instruction for at

taching the feet-cover plate is given on

page 8.

1. Trim ragged edges from area to be

darned.

2. Center worn section in embroidery

hoop.

3. Position work under needle over feedcover plate and lower presser bar to

engage tension.

4. Hold needle thread loosely with left

hand, turn hand wheel over and draw

bobbin thread up through fabric. Hold

both thread ends and lower needle

into fabric.

5. Outline area to be darned with running

stitches for reinforcement.

6. Stitch across opening, moving hoop

under needle at a slight angle from

lower left to upper right. Keep lines of

stitching closely spaced and even in

length.

7. When opening is filled, cover area with

crosswise lines of stitching.

This method of controlling fabric move

ment with an embroidery hoop may be

used to do embroidering and mono-

gramming.

■’^Embroidery Hoop not included with machine

accessories.

Darning With Embroidery Hoop

43

Page 48

cleaning the machine

Your machine will serve you perfectly for many years if you take a few

moments of your time to keep it clean. How often you will need to clean the

machine will depend on how often you use it.

WARNING: Before cleaning your machine^ disconnect power-

-line plug from electrical supply.

Clean between

tension discs

Clean

y

Remove lint frdm exposed parts.

With a soft cloth, clean:

• Tension discs, take-up lever, and

thread guides.

• Presser bar and needle bar.

• Bobbin case. (If there is an excessive

amount of lint in the area, remove the

bobbin case for cleaning. See page 45

for instructions.)

• Machine surface. (If necessary, dahnpen

thecloth and use a mild soap.)

Remove face plate as instructed on page

45 and clean area behind it with a lint

brush.*

Remove needle plate as instructed on

page 7 and, using a brush, clean the

rotating hook area under the needle plate

and slide plate.

NOTE: Your machine requires oiling at

only one point under normal condi

tions.

* Brush not included with machine accessories.

Page 49

removing bobbin case, face plate and buib

DANGER: Before removing

bobbin case, face piate and iight buib

disconnect power-iine puig from eiectri-

cal supply.

REMOVING AND REPLACING

BOBBIN CASE

• Raise the presser foot.

• Turn hand wheel toward you until

needle is above the presser foot.

• Remove needle plate as instructed on

pa§dl.

® Remove bobbin.

To remove bobbin case, turn bobbin case

holder to back as far as it will go. Lift out

bobbin case.

To replace bobbin case, guide the forked

end under the feed and then draw the

bobbin case under the position plate as

illustrated. Turn holder all the way forward

to lock bobbin case in position. After

locking bobbin case in position, check

that bobbin case is not jammed, but has

slight rotational movement.

® Replace needle plate.

• Fully close slide plate.

REMOVING FACE PLATE

• Loosen and remove screw and remove

face plate by sliding it downward.

REPLACMG FACE PLATE

® Slide face plate up so that rim is en

gaged under edge cf top cover.

® Align screw hole at lower edge of plate

with screw hole in machine and replace

and tighten screw.

45

Page 50

CARING FOR YOUR MACHINE (Continued)

Locks

Unlocks

This machine

is designed to

use a 15 watt

maximum light

bulb

Th/s machine is designed to use a 15

watt maximum light bulb.

CHANGING THE LIGHT BULB

Disconnect power-line plug from elec

trical supply.

Removing the Bulb

With thumb and forefinger lower the light

bracket. Do not attempt to unscrew bulb.

Press it up into socket and at same time

turn bulb over in direction shown to

unlock bulb pin.

Raise Presser Foot

and Needle

Lift Retaining

Spring into Slide

Plate Grooves

Replacing the Bulb

Press new bulb into socket with bulb pin

entering slot of socket, and turn it over in

direction shown to lock bulb in position.

Release bracket, and entire assembly will

snap back Into recess.

REPLACING THE SLIDE PLATE

You will not have any occasion to remove

the slide plate. However, if it should

accidentally become disengaged from

the machine, it is easily replaced.

• Raise presser foot and needle.

• Place slide plate In slideway with the

front edge close to, but not covering,

the retaining spring (as shown in illu

stration).

• With a screwdriver, lift each end of the

spring into each of the side grooves on

the underside of the slide plate.

Replacing the Slide Plate

46

« Draw the plate gently toward you and

fully engage the spring.

• Close slide plate.

Page 51

performance checklist

Should sewing difficulty be encountered, review the sections of this

instruction book that explain the sewing operation you are performing, if

the problem still exists, the following hints will help you correct it.

If the machine does not sew; make sure . . .

• Machine is connected to electrical supply.

• Power and light switch Ison.

® Hand wheel disc is in sewing position. (See page 12.)

If needle bar moves but stitch is not formed, make sure » .

• Needle is straight and sharp.

e Needle size is correct for the thread you are using. (See page 10.)

« Machine is correctly threaded.

• Bobbin contains thread.

« Bobbin and bobbin case are correctly inserted in machine.

• Bobbin case area is free of lint and loose thread ends.

If fabric does not move, make sure ...

• Presser foot Is down and that pressure dial Is adjusted for the weight and

texture of your fabric.

« Stitch length selector is correctly set.

® Feed-cover plate has been removed from the general purpose needle

plate.

® All lint is removed from around the feed.

To avoid breaking of needles, make sure . . .

« Needle is not bent and that It is correct for machine, and

proper size for the thread you are using.

• Needle is fully inserted in needle clamp.

• Twin needle does not strike needle plate when doing twin-needle

stitching. (See page 25.)

• Presser-foot shank is securely fastened to presser bar.

• Needle plate is correctly seated and slide plate is fully closed.

• Fabric being guided of supported behind the needle is not being pulled

too hard or too fast.

47

Page 52

PERFORMANCE CHECKLIST (Continued)

If Stitching is irregular, or needle thread breaks, make sure ...

Machine is correctly threaded.

Thread is even and free from knots.

Needle is straight and sharp, and correct size for thread.

Needle-thread tension is not too tight.

Bobbin case is correctly threaded and properly inserted.

Threads are correctly placed under presser foot when you start to sew.

Bobbin case area is free of lint and loose thread ends.

Bobbin or bobbin case is not damaged.

Also remember to ...

Turn hand wheel toward you to position needle and take-up lever.

Raise needle above fabric before making adjustments to stitch width and

needle position.

Start and finish sewing with take-up lever in its highest position.

Adjust stitch length, pressure, and thread tension to suit your fabric

Test stitch on a fabric sample before starting a sewing job.

Lower presser foot before setting pressure dial.

Tighten hand wheel knob and disengage bobbin winder after winding a

bobbin.

Remove feed-cover needle plate after button sewing and after darning

with an embroidery hoop.

Clean your machine periodically.

CAUTION

Do not attempt to adjust the motor drive belt.

Refer to your nearest Service Centre

should any adjustment be required.

48

Page 53

The machine is intended for household use.

Voltage rating

Rated frequency

Lrght bulb power (1 amp) .................................................... max 12 Watts

Appliances class II — machine does not require earthing

............................................................................ 120 Volts

.............

....................

60 Hz (Hertz, cycle per second)

CAUTION

Read all Instructions before using the sewing machine.

DANGER

An appliance should never be left unatlended when plugged in.

Always unplug this appliance from the electric outlet immediately

after using and before cleaning.

WARNINGS

1. Never operate the appliance with the air openings blocked.

Keep the air openings free of lint, hair, loose clothes and the

like.

2. Keep fingers away from all moving parts. Special care is requi

red around the sewing machine needle.

3. Do not use bent needles.

4. Always use the proper needle plate. The wrong plate can cause

the needle to break.

5. Do not pull or push fabric while slitching. It may deflect the

needle causing it to break.

6. Switch the sewing machine off „0” when making any adjust

ments in the needle area, such as threading needle, changing

needle, threading bobbin, or changing presser foot, and the

like.

7. Always unplug sewing machine from the electrical outlet when

removing covers, lubricating, or when making any other user

servicing adjustments mentioned the instruction manual.

8. Operate sewing machine only when mounted in sewing machi

ne table, case, and the like.

9. Always unplug before relamping. Replace bulb with same type

rated max 15 Watts.

10. Sewing machine has a DOUBLE ELECTRICAL INSULATION.

Replacement parts for a double insulated product must be iden

tical to those parts in the product.

Page 54

Page 55

NEW SEWING MACHINE WARRANTIES

MECHANICAL MODELS

(applies to machines other than the Touch-Tronic* and Creative Touch* Fashion Machine Models)

LIMITED 10 YEAR WARRAKrY

SEWING MACHINE HEAD

If any manufacturing defect appears in the sewing machine head or any of its parts other thafi those

listed below within 10 years of purchase, we will repair it free of charge.

LIMITED 2 YEAR WARRANTY

MOTORS, LIGHT ASSEMBLY, WIRING, SWITCHES

AND SPEED CONTROLS

If any manufacturing defect appears in tliese parts within 2 years of purchase, we will repair it free of

charge.

LIMITED 90 DAY WARRANTY

ADJUSTMENTS, BELTS, RINGS, BULBS and ATTACHMENTS

Within 90 days of purchase we will provide, free of charge, required adjustments. During the same period

we will also replace, free of charge, defective belts, bobbin winder rubber rings, light bulbs, or

attachments, if any.

GENERAL

THESE WARRANTIES fvV\Y ONLY BE USED BY THE ORIGINAL CONSUMER OWNER OF THE

SEWING MACHINE; THEY ARE NOT TRANSFERABLE TO ANY SUBSEQUENT OWNERS. SERVICE

UNDER THESE WARRANTIES MAY ONLY BE OBTAINED WITHIN THE 48 CONTIGUOUS STATES,

ALASKA AND HAWAII.

Service under the above warranties may be obtained by returning the sewing machine v/ th t'ni5 warranty

document and proof of purchase to your place of purchase or authorized service center as listed on the

back of this sheet. Please consult your phone book for the location nearest you. If you have any

questions reguarding these warranties, you may write to:

SINGER SEWING COMPANY

200 METROPLEX DRIVE

EDISON, NJ 08817

This sewing machine is warranted only in normal household (non-commercial) use. These warranties do

not cover failures caused by abuse, lack of maintenance in accordance with SINGER care and cleaning

instructions, misuse, or events beyond our control. These warranties give you specific legal rigfits, and

you may also have other rights which vary from state to state.

ANY IMPLIED WARRANTY, INCLUDING WITHOUT LIMITATION THE WARRANTIES OF

MERCflANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. APPLICABLE TO THIS SEWING

MACHINE IS LIMITED IN DURATION TO THE DURATION OF THIS W.RITTEN WARRANTY. SINGER

SHALL NOT BE LIABLE FOR CONSEQUENTIAL ECONOMIC DAMAGES RESULTING FROM BREACH

OF THIS WARRANTY OR ANY IMPLIED WARRANTY. Some states do not allow limitations on how long

an implied warranty will last or the exclusion or limitation of incidental or consequential darriages, so the

above limitations or exclusions may not apply to you.

The Singer Company does not authorize any person to create for it any obligation or liability in connection

with the above machines and parts beyond those set fourth herein.

THE SINGER COMPANY DISCLAIMS LIABILITY UNDER THIS WARRANTY FOR ANY DAMAGE OR

DEFECT RESULTING FROM THE USE OF OTHER THAN SINGER PARTS AND APPROVED SERVICE

IN THE REPAIR OF YOUR MACHINE.

To keep your machine operating properly, we recommend that you take instructions on use provided lor

new machine owners, follow the operating instructions and periodically have your machine serviced and

tuned by a sewing machine.specialist knowledgeable about Singer* Sewing Machines.

*A Tradornark of THE SINGER COMPANY

Page 56

Mailing Address: P.C. Box 110, Englishtown, N.J. 07726

Service Centers. Inc.

Street Address: 200 Craig Road, Freehold, N. J. 07728

Tc!; 201-409-6007

Fax: 201-409-6954

ARIZONA

2340 West Grand Avenue

Phoenix, AZ 85009

(602) 252-1340

CAUFQ.RM1A mwA

14399 Paramount Blvd.

Paramount, CA 90723

(213) 531-6352

4737 Auburn Blvd.

Sacramento, CA 95841

(916) 334-0322

740 El Camino Real

San Carlos, CA 94070

(415) 592-8065

4354 Twain Avenue

San Diego. CA 92120

(619) 280-9387 (313) 528-1670

COIQ-BADQ

7865 W. 16th. Avenue 1031 E, Moore Lake Dr. N.E. (215) 788-9200

Lakewood, CO 80215

(303) 232-0283 (512) 571-7113

FLORIDA (412) 733-1114

3454 Beach Blvd. Ashari Plaza

Jacksonville', FL 32207 7177 N. Lindbergh Blvd.

(904) 396-1578

7875 Gateway Mall (401) 724-5347

St. Pettersburg, .FL 33702

(813) 577-6263

GEORGIA

3501 Memorial Drive

Decatur, GA 30032

(404) 289-3510

ILLINOIS

2316 East Rand Road

Arlington Heights, IL 60004

(708) 253-3325

INDIANA

Devington Plaza

6000 East 46th

Indianapolis, IN 46226

(317) 546-3400

419 Brady Street

Davenport, !A 52801

(319)322-8092

MARYLAND

8560 Laureldale Drive

Laurel, MD 20724

(301) 792-4530

.MlgJdlGAM

785 East Big Beaver

Troy. Mi 48084 (804) 855-3946

MiMM£S0TA

Fridley. MN 55432

Hazelwood, MO 63042

(314) 895-1119

5158 Ararat Dr. (304) 925-8288

Kansas City, MO 64129

(816) 861-6161

iMEW

1029 Chestnut St.

Roselle. NJ 07203

(201) 272-8555

ЙЕЖ-ЮНК

1216 Burnet Ave.

Syracuse. NY 13203-3212

(315) 474-0202

OHIO

Siiverton Center

6928 Montgomery Rd.

Siiverton, OH 45236

(513) 793-7977

1929 E. Aurora Rd.

Twinsburg, OH 44087-1920

(216) 425-2240 '

OKLAHOMA

9449 E. 31st. St.

Tulsa. OK 74145 Midvale, Utah 84047(918) 622-9277

QMEG.QH

2613 S.E. 122nd. Avenue

Portland,.OR 97235

(503)760-4780

PEMNSYlVANiA

329 Basin St.

Bristol, PA 19007

2063-A Route 285

Pittsburg. PA 15239

RUomjimAm

38 East Ave.

Pawtucket, Ri 02860

SOUTH CAROLINA

505 W. Palmetlvy oi.

Florence, SC 29501

(803) 662-0901

TENNESSEE

3664 Cherry Road

Memphis, TN 38118

(901)365-6514

TEXAS

Royal Hines Bus. Park

11171 Harry Hines Blvd.

Suite 115

Dallas, TX 75229

(214) 241-4222

6003-B Bellaire Blvd.

Houston. TX 77081

(713) 664-1478

М1АЙ

55 East Center St.

(801) 566-2031

Ш.Ш1А

1529 Azalea Garden Rd.

Nortolk, VA 23502

W.ASHmG-.I.QN

1519 130th Ave. N.E.

Bellevue, WA 98005

(206) 462-1274

E, 1503 Francis

Spokane, WA 99207

(509) 483-9435

WEST VIRGINIA

5006 MacCorkle Ave. S.E.

Charleston, WV 25304

Wl§ QONSm

8203 W. Silver Springs Dr.

Milwaukee, W1 53218

(414) 438-1889

TQNY MASRAILA

(213) 630-1358

Fax; (213) 630-1304

Par am o un t. CA 90723

GLENN DOLAN

(313) 528-1670

Fax

Troy, Ml 48084

Nationwide Network of Product Service Centers

Loading...

Loading...