SINGER 101-12 User Manual

Form 18416

Rev. (1151)

SINGER*

ELEaRlC SEWING MACfflNES

101-4 and 101-12

WITH ATTACHMENTS 120606

HORIZONTAL ROTARY HOOK, FOR FAMILY USE

*A Trademark of THE SINGER MANUFACTURING COMPANY

THE SIN GER MA NUF ACT URI NG CO MPA NY

PRINTED IN U. S. A.

Copyright (g) 1936 The Singer Manufacturing Company

18416

SINGER

ELECTRIC SEWING MACHINES

101-4 and 101-12

WITH ATTACHMENTS 120606

HORIZONTAL ROTARY HOOK, FOR FAMILY USE

'E8037

Cabinet 40

THE SIN GER MA NUF ACT URI NG CO MPA NY

TO ALL WHOM IT MAY CONCERN i

The improper placing or renewal of the TradeMark “SINGER” or any other of the Trade-Marks

of The Singer Manufacturing Company (all of

which are duly Registered Trade-Marks) on any

machine that has been repaired, rebuilt, recon

ditioned, or altered in any way whatsoever

outside a SINGER factory or an ¿Authorized

SINGER agency is forbidden.

DESCRIPTION

Machine 101-4, for family use, has a rotary sew

ing hook on a vertical axis and makes the lock stitch.

It is especially designed for operation by elec

tricity, having an efficient electric motor built in

the back of its arm, the speed of the machine being

controlled by means of a knee lever.

It is also equipped with the electric SINGERLIGHT.

Cabinets 40 and 306, shown on pages 1 and 10,

respectively, are intended for use with Machine

101-4. When closed, either of these cabinets resembles

an attractive desk or hbrary table, the sewing

machine and motor being entirely concealed.

Machine 101-12 is the same as Machine 101-4

except that the heavy parts are made of aluminum

which reduces the weight of the machine to the

minimum so that it is easy to carry.

Portable Case 204, shown on pages 11 and 12,

is regularly sent out with this machine.

Motor Can be Operated on Either Alternating

Current or Direct Current

The electric motor, which is built in Machines

101-4 and 101-12, can be operated on either direct

current or 25 to 75 cycle alternating current without

change of adjustment. The standard windings of

the motor are for 110-120 volts, but motors can also

be furnished for any voltage between 50 and 250.

Special motors for 32 volts direct current and

above 75 cycle alternating current have also been

developed and are available.

Points to Determine Before Connecting

Motor to Electric Service Line

Obtain the following information from the Electric

Light Company which supplies the electric current

for the circuit to which the motor is to be connected:

1. Whether alternating current or direct current

is used.

2. What is the voltage? The voltage must be

within the range stamped on the motor name plate

(B, Fig. 2, page 5).

3. If the electric service line is alternating current,

what is the number of cycles? The number of cycles

must be within the range stamped on the motor

name plate.

4. The current and voltage of the electric service

line and, if alternating current, the number of cycles,

can be verified by looking at the name plate on

electric meter installed by the local Electric Light

Company.

o

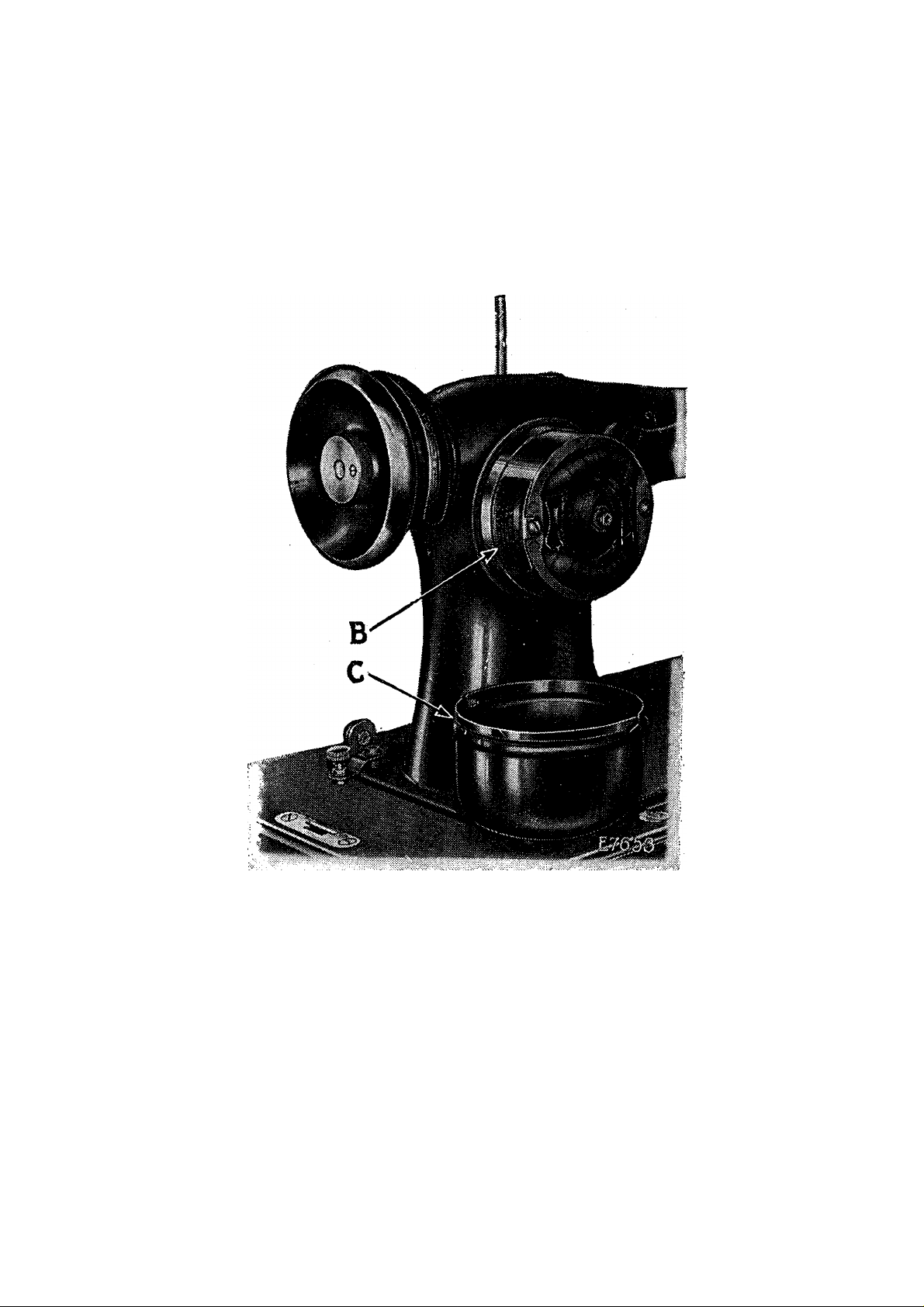

To Remove the Motor Cover

Turn the motor cover (C, Fig. 2) over toward the

balance wheel and pull it outwardly to remove it,

thus exposing the motor name plate (B, Fig. 2).

Fig. 2. Motor Cover Removed Showing

Motor Name Plate

When replacing the motor cover (C), have the

two notches in the cover engage the pins at the top

and bottom of the motor frame.

6

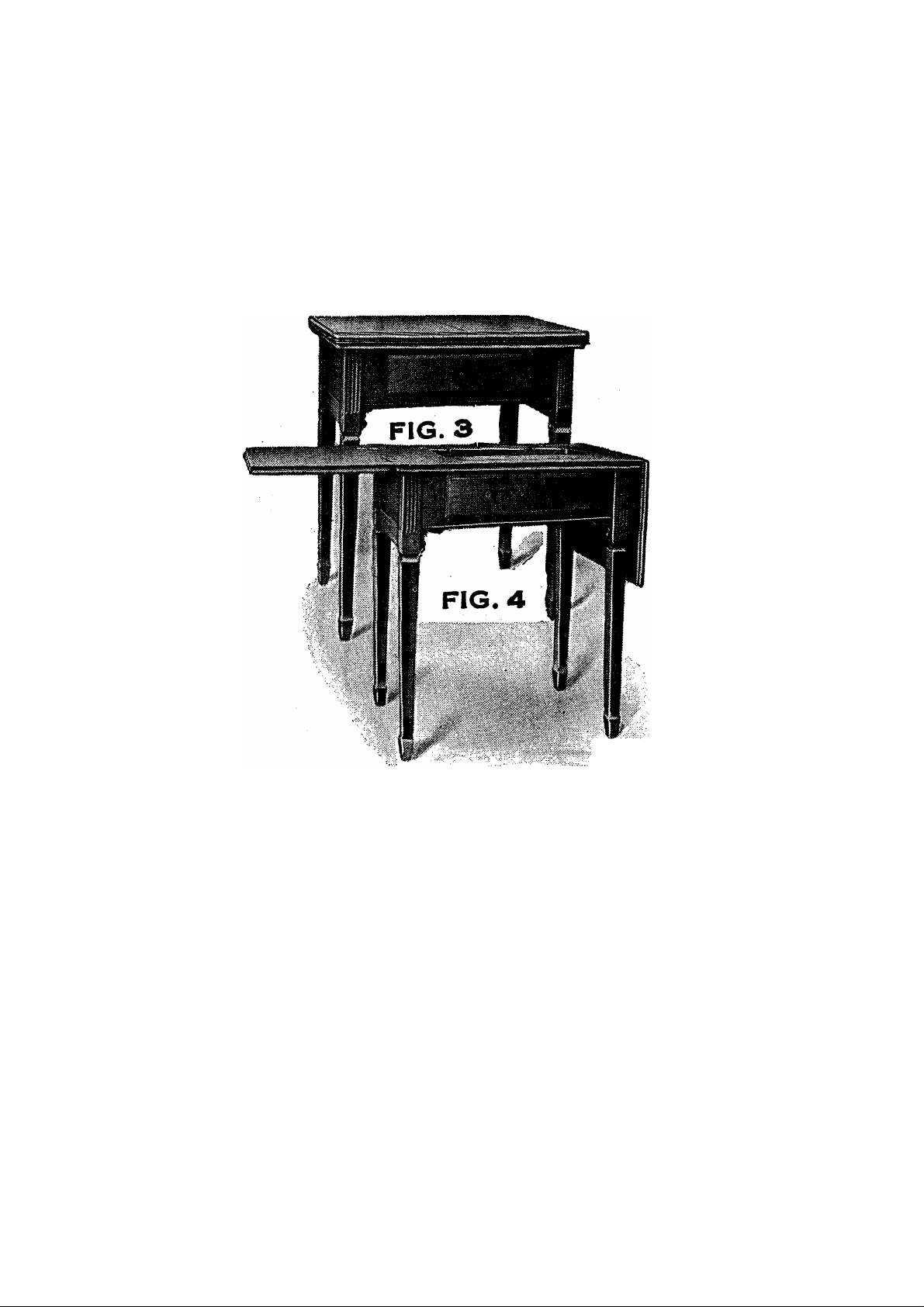

To Open Cabinet 40

(See Figs. 3, 4, 5 and 6)

Raise the two leaves at the top of the table and

the supporting rod will automatically spring out at

Figs. 3 and 4. To Open Cabinet 40

the left of the table. Allow the left leaf to rest on

the supporting rod and the right leaf to hang

loosely at the right of the table, as shown in Fig. 4.

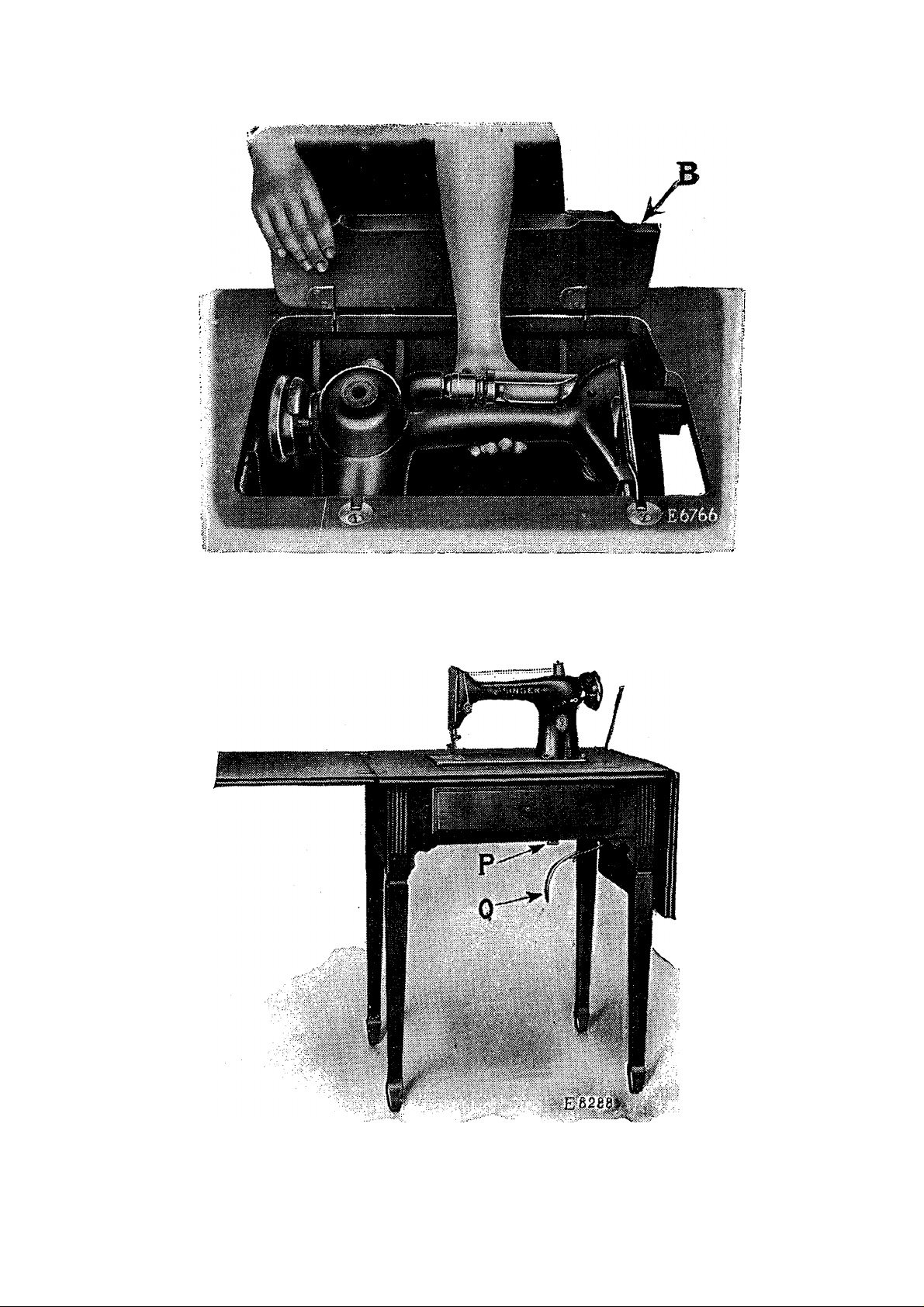

With the right hand raise the front hinged portion

(B, Fig. 5) of the table, and at the same tijne, place

the left hand under the front side of the arm of the

machine, as shown in Fig. 5, being very careful

not to touch the electric lamp or shade» and

raise the sewing machine head, then replace the

hinged portion of the table and lower the machine

so that it rests on the table, as shown in Fig. 6.

Fig. 5. Raising Machine Out of Cabinet 40

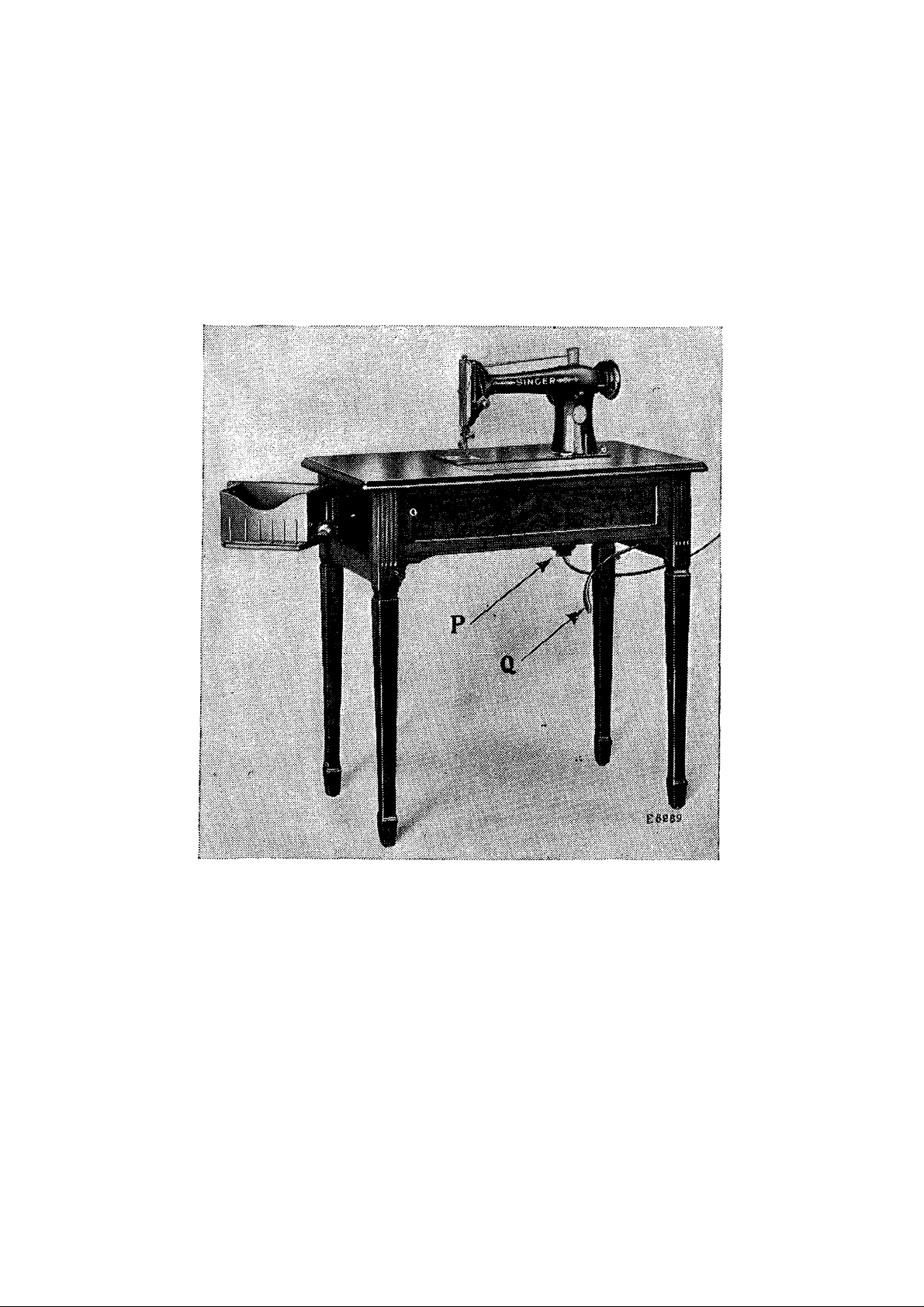

Pull down the knee lever (Q) to the vertical posi

tion as shown in Fig. 6.

Fig. 6. Knee Lever Lowered to Operating Position

ON Cabinet 40

Also Electrical Connection

8

To Connect Machine 101-4 on Cabinet 40 to

Electric Service Line

Push the terminal plug at one end of the electric

cord as far as it will go on the three-pin terminal

block under the cabinet, as shown at (P) in Fig. 6.

Attach the plug at the other end of the cord to

the nearest electric socket and the machine is

ready for operation.

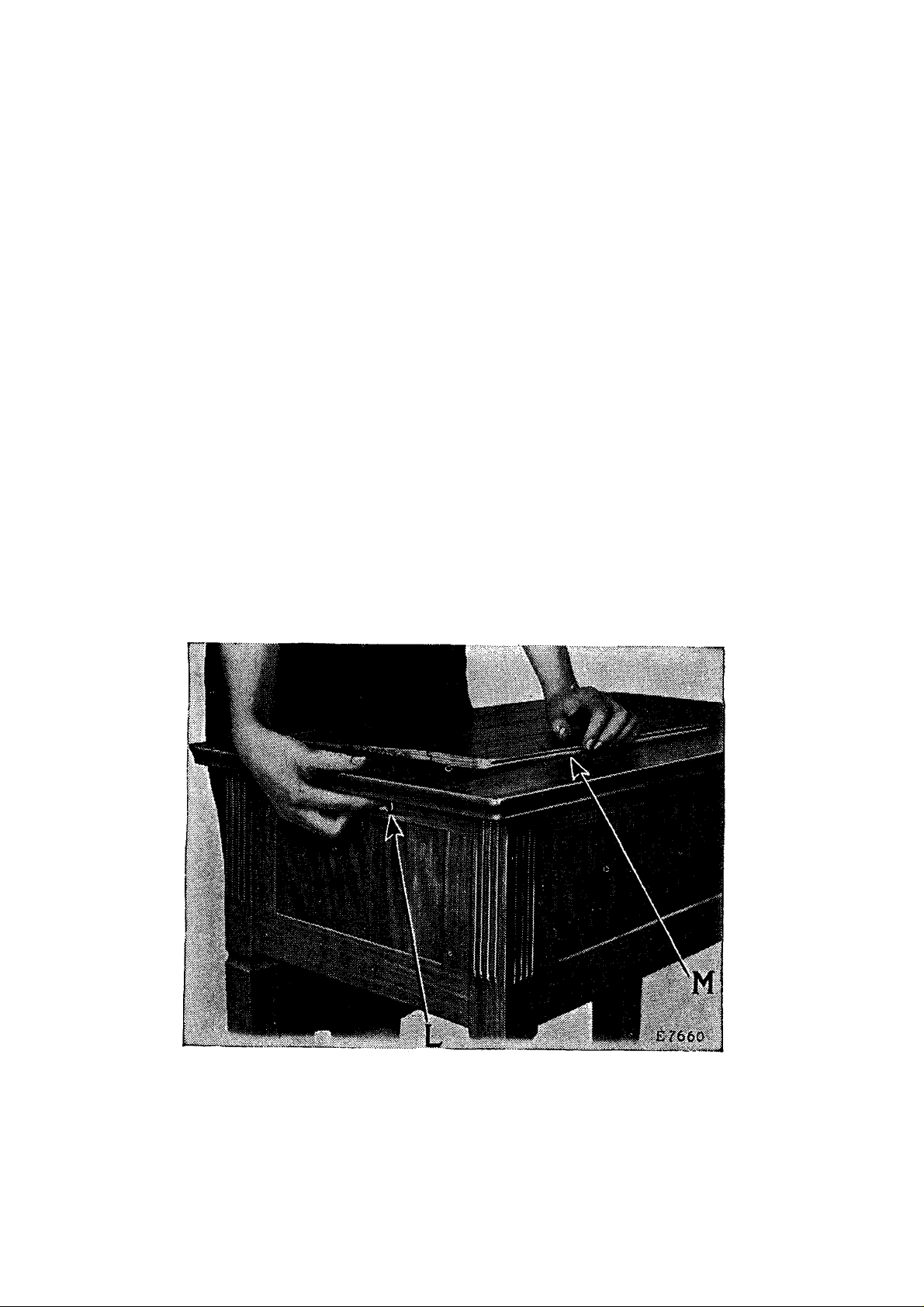

To Open Cabinet 306

With the right hand push in the lever (L, Fig. 7)

at the right of the table and at the same time with

the left hand raise the hinged flaps of the table top

as shown at M in Fig. 7.

Fig. 7. To Open Cabinet 306

9

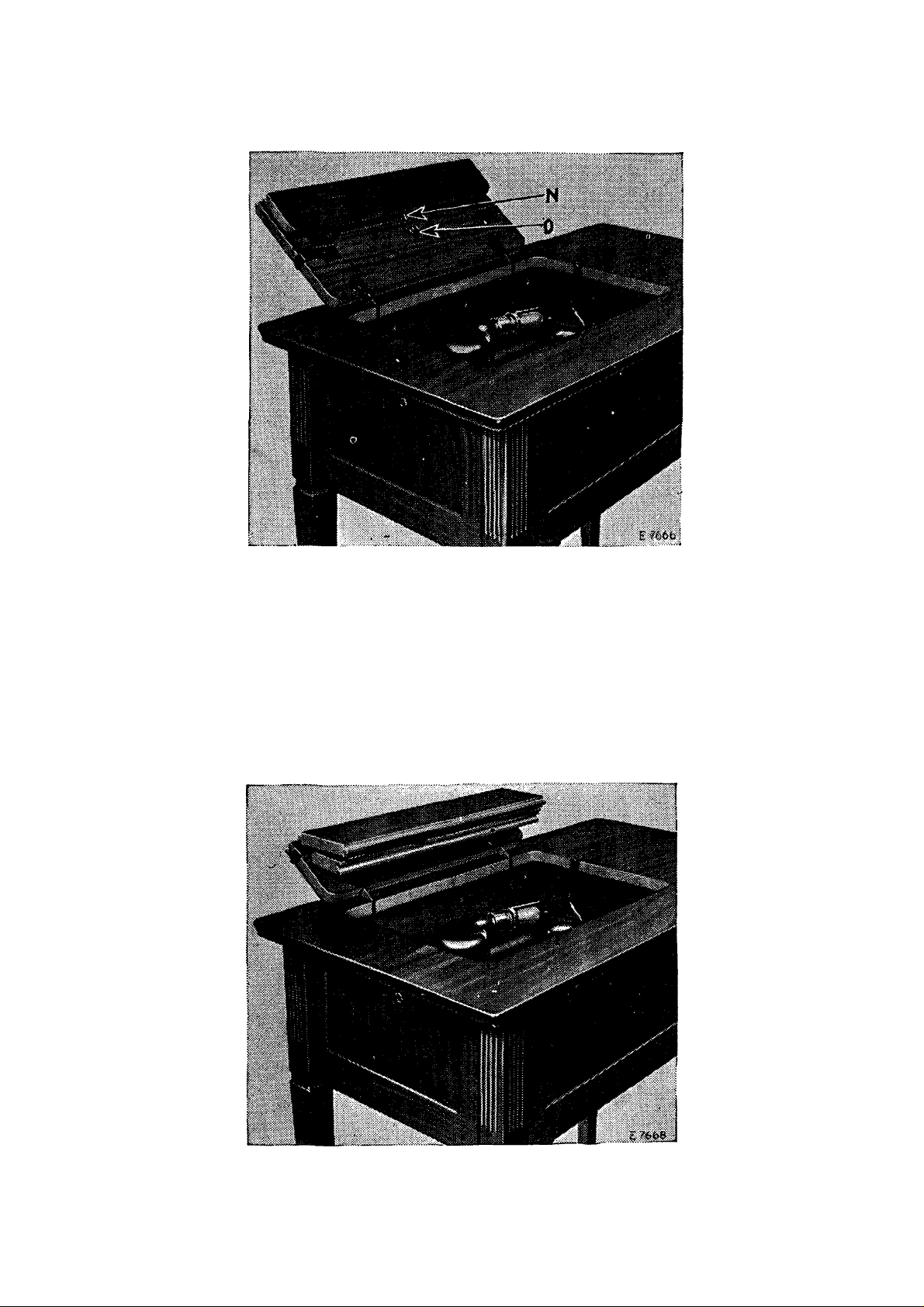

Fig. 8. To Open Cabinet 306

Fold back the hinged flaps as shown in Figs. 8 and

9, having the catch (N, Fig. 8) enter the spring clip

(O, Fig. 8).

Fig. 9. To Open Cabinet 306

10

Raise the sewing machine head out of the cabinet

as shown in Fig. 5, being very careful not to

touch the electric lamp or shade, then turn down

the hinged flaps of the table top and lower the ma

chine so that it rests on the table as shown in Fig. 10.

Fig. 10. Knee Lever Lowered to Operating Position

ON Cabinet 306 .

Also Electrical Connection

Pull down the knee lever (Q) to the vertical posi

tion as shown in Fig. 10.

Fig. 10 shows the swing-out drawer at the left of

the table. This drawer is provided >yith holders for

spools, bobbins arid oil can and has a compartment

for the box of attachments.

11

To Connect Machine 101-4 on Cabinet 306 to

Electric Service Line

Push the terminal plug at one end of the electric

cord as far as it will go on the three-pin terminal

block under the cabinet as shown at P in Fig. 10.

Attach the plug at the other end of the cord to the

nearest electric socket and the machine is ready

for operation.

To Open Portable Set 204

After removing the cover, remove the knee lever

(S, Fig. 11) from the two cleats (R, Fig. 11).

Fig. 11. Knee Lever in Position in Cover

12

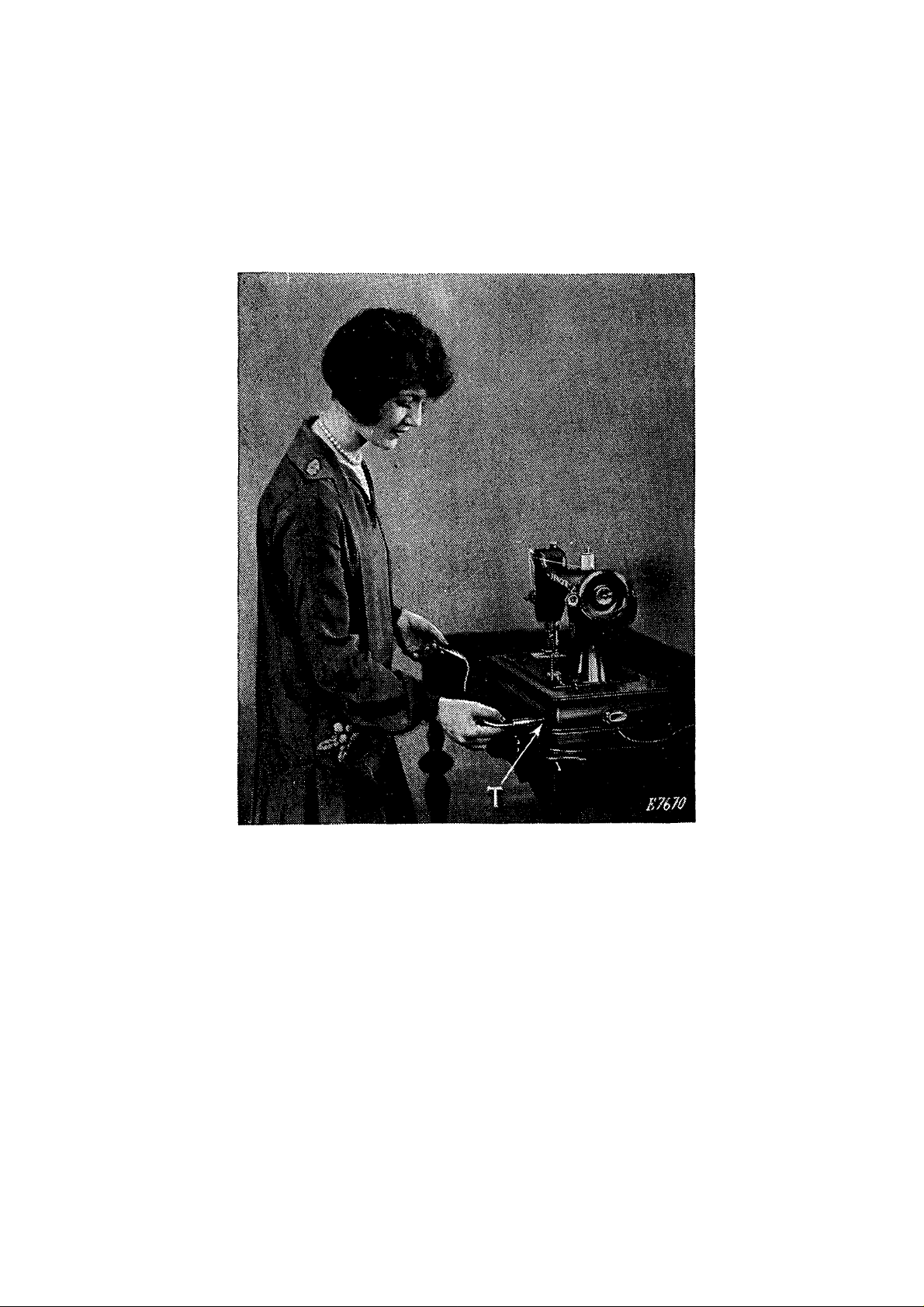

Fia. 12. Placing Knee Lever in Position

ON Portable Set 204

Hold the knee lever in a horizontal position with

the handle toward the left as shown in Fig. 12, and

push the end of the lever into the socket (T, Fig. 12).

13

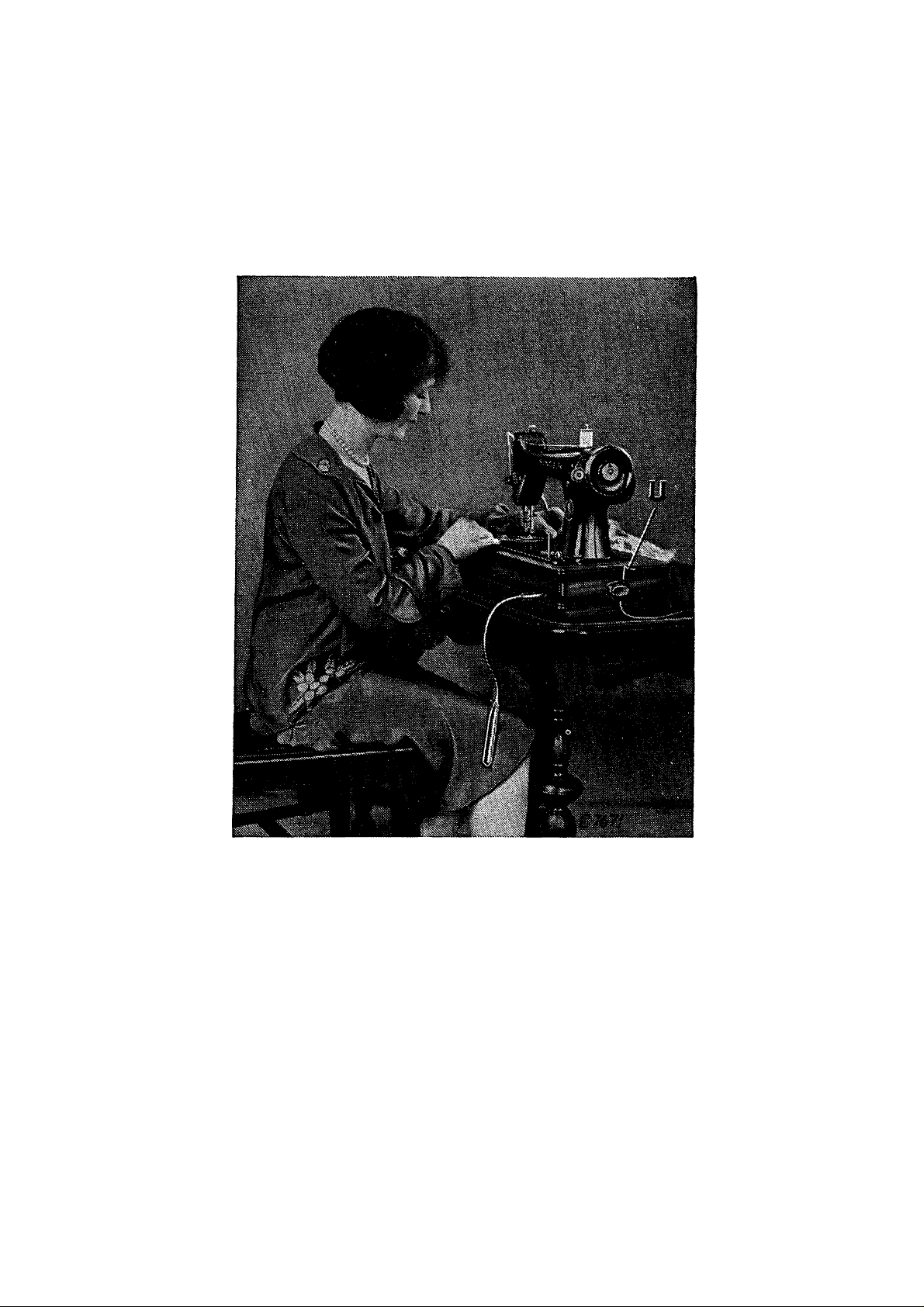

Fia. 13. Knee Lever in Position Ready for Operation on

Portable Set 204

Also Electrical Connection

.Mow the knee lever to drop to the vertical

position as shown in Fig. 13 and the end of the

lever will engage the stop in the knee lever socket.

14

To Connect Machine 101-12 on Portable Set 204

to Electric Service Line

Push the terminal plug at one end of the eldctric

cord as far as it will go on the three-pin terminal

block at the right of the cabinet as shown at U in

Fig. 13. Attach the plug at the other end of the cord

to the nearest electric socket and the machine is

ready for operation.

To Ensure Perfect Action of the Machine

The balance wheel must always turn over toward

the operator.

Do not run the machine with the presser foot

resting on the feed without cloth under the presser

foot.

Do not run the machine when both bobbin case

and needle are threaded, unless there is material

under the presser foot.

Do not try to help the machine by pulling the

fabric, lest you bend the needle. The machine feeds

the work without assistance.

The slide over the bobbin case should be kept

closed when the machine is in operation.

To Turn SINGERLIGHT “On»» or “Off»»

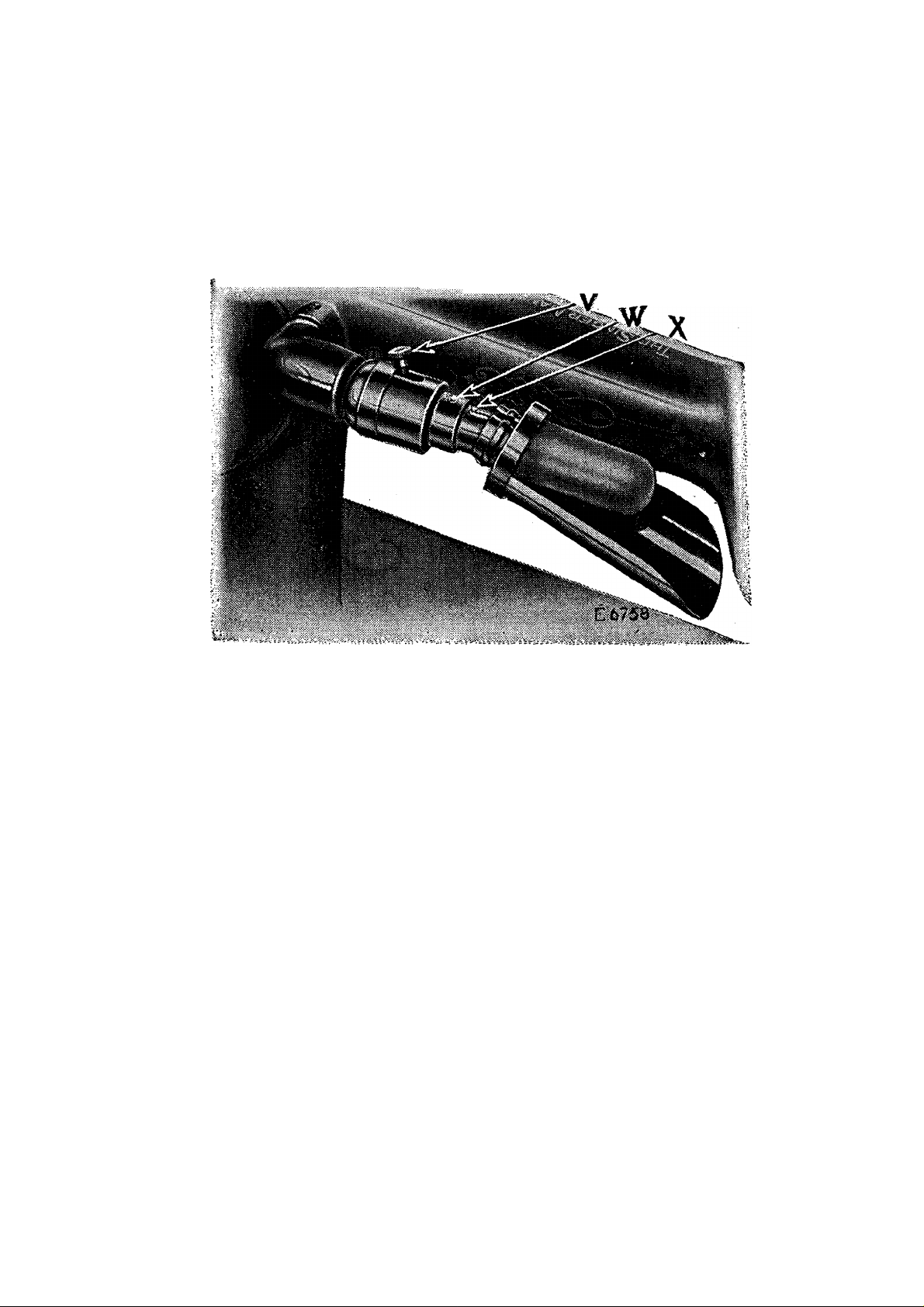

Reach over the top of the machine and move the

switch lever (V, Fig. 14) to the right or left as

desired.

To Remove and Replace the Bulb

To remove the bulb, hold the SINGERLIGHT

socket tightly with one hand and with the other hand

turn the shade halfway around until the pin (W,

15

Fig. 14) for the shade is in the slot of the shade, then

gently slip the shade off and allow it to hang free as

shown in Fig. 14.

...... .

Fiq. 14

Do not attempt to unscrew the bulb. It is of

the bayonet and socket type and does not unscrew.

Press the bulb into the socket and at the same

time turn it until the bulb pin (X, Fig. 14) is out

of the notch in the socket, then withdraw the

bulb and shade.

To insert a new bulb, pass the bulb through the

collar of the shade with the slot of the shade up

ward. Hold the socket tightly with one hand and

at the same time with the other hand press the

bulb into the socket with the bulb pin (X, Fig. 14)

in the slot and turn it until this pin is in the notch.

Then slip the shade over the socket, the pin (W,

Fig. 14) for the shade entering the slot of the shade.

See that the pin (W) is in the groove of the shade

and turn the shade halfway around, or until it is

at the top.

Loading...

Loading...