Sinexcel PWS2-30M-EX User Manual

Energy Storage Inverter

PWS2-30M-EX

User's Manual

Shenzhen Sinexcel Electr i c Co. , Lt d.

User’s Manual

Sinexcel PWS2-30M-EX Energy Storage Inverter

Data version: A05

Filed in: Feb 21, 2019

Applicable to: PWS2-30M-EX

Shenzhen Sinexcel Electric Co., Ltd. (“Sinexcel”) provides its customers with all-around

technical support. Users can contact local Sinexcel office or customer service center or

directly contact Sinexcel Headquarters.

Shenzhen Sinexcel Electr i c Co. , Lt d.

All rights reserved. In cas e of any content change, it shoul d be w it hout prior notice.

Shenzhen Sinexcel Electr i c Co. , Lt d.

Website: www .sinexcel.com

Add: Building 6, Area 2, Baiwangxin High-tech Industrial Park, No. 1002, Songbai Road,

Nanshan District, Shenz hen, China

Postcode: 518055

Hotline: 0755-8651-1588

Fax: 0755-8651-3100

E-mail: service@sinexcel.com

CONTENT

CHAPTER 1 OVERVIEW __________________________________________ - 1 -

1.1 MODEL DEFINITION __________________________________________________ - 1 -

1.2 ICON INTERPRETATION _______________________________________________ - 1 -

1.2.1 Icons in the manual ____________________________________________ - 1 -

1.2.2 Inverter prompt icons ___________________________________________ - 2 -

1.3 SAFETY INSTRUCTIONS ______________________________________________ - 2 -

1.3.1 Safety instructions for mechanical installation ________________________ - 3 -

1.3.2 Safety instructions for electrical connection _________________________ - 3 -

1.3.3 Safety instructions for inverter operation ____________________________ - 4 -

1.3.4 Safety instructions for maintenance and replacement _________________ - 4 -

1.3.5 Others ______________________________________________________ - 5 -

1.4 PRECAUTIONS _____________________________________________________ - 6 -

1.4.1 Personnel requirements _________________________________________ - 6 -

1.4.2 Purposes of usage _____________________________________________ - 6 -

1.4.3 Label on enclosure ____________________________________________ - 6 -

1.4.4 Notes _______________________________________________________ - 6 -

CHAPTER 2 INTRODUCTION TO ENERGY STORAGE SYSTEM __________ - 7 -

2.1 SYSTEM APPLICATION ________________________________________________ - 7 -

2.1.1 System structure diagram _______________________________________ - 7 -

2.2 OVERALL DIMENSION ________________________________________________ - 8 -

2.3 APPEARANCE _____________________________________________________ - 8 -

2.4 TECHNICAL PARAMETERS _____________________________________________ - 9 -

2.5 TECHNICAL SPECIFICATION ___________________________________________ - 10 -

2.5.1 Principle description ___________________________________________ - 10 -

2.5.2 Function description ___________________________________________ - 11 -

2.5.3 De-rating ___________________________________________________ - 12 -

CHAPTER 3 EQUIPMENT TRANSPORT , STORAGE A ND INSTALLATION __ - 15 -

3.1 TRANSPORT AND STORAGE ___________________________________________ - 15 -

3.2 INSTALLATION FLOW ________________________________________________ - 16 -

3.3 OPEN-CASE INSPECTION ____________________________________________ - 17 -

3.4 MODEL CHECK AND PREPARATION ______________________________________ - 17 -

3.5 INSTALLATION REQUIREMENTS ________________________________________ - 18 -

3.6 ELECTRICAL CONNECTION ___________________________________________ - 18 -

3.7 CHECK AFTER INST ALL A TION __________________________________________ - 25 -

3.7.1 Cable connection check ________________________________________ - 25 -

3.7.2 Electric and communication check _______________________________ - 25 -

CHAPTER 4 DEBUG A ND OPERATION _____________________________ - 28 -

4.1 STARTUP AND SHUTDOWN ___________________________________________ - 28 -

4.1.1 Check before startup __________________________________________ - 28 -

4.1.2 Startup steps ________________________________________________ - 28 -

4.1.3 Shutdown steps ______________________________________________ - 28 -

4.2 MONITORING INTERFACE INFORMATION _____________________________________ - 29 -

4.3 CONTROL METHOD ___________________________________________________ - 31 -

CHAPTER 5 COMMUNICATION MODE ______________________________ - 33 -

5.1 COMMUNICATION INTERFACE _________________________________________ - 33 -

5.1.1 RS-485 interface _____________________________________________ - 33 -

5.1.2 Ethernet interface ____________________________________________ - 33 -

5.2 BMS COMMUNICATION ______________________________________________ - 34 -

5.3 MONITORING SYSTEM STRUCTURE _____________________________________ - 34 -

CHAPTER 6 MAI NTE NA N CE ______________________________________ - 36 -

6.1 OPERATION ENVIRONMENT REQUIREMENTS _______________________________ - 36 -

6.2 ELECTRICAL AND FIXED CONNECTION INSPECTION __________________________ - 36 -

6.3 CLEARING AND CLEANING ____________________________________________ - 36 -

APPENDIXES __________________________________________________ - 37 -

PWS2 - 30M - EX

For Europe and Australia

Rated power:30kW

M: For modular design

Wide battery voltage-supported

energy storage inverter

The WARNING icon indicates that there is a potential risk during

The CAUTION icon indicates that there is a potential risk during

Chapter 1 Overview

1.1 Model definition

The model definition of PWS2-30M-EX energy storage invert er is show n i n Fig. 1-1:

Fig. 1-1 Model definition

1.2 Icon interpretation

This user’s manual is about install ation and use of Sinexcel PWS2-30M-EX energy storage

inverter.

To ensure personal and property safety or use this product efficiently, please read this

user’s manual carefully before installation and use.

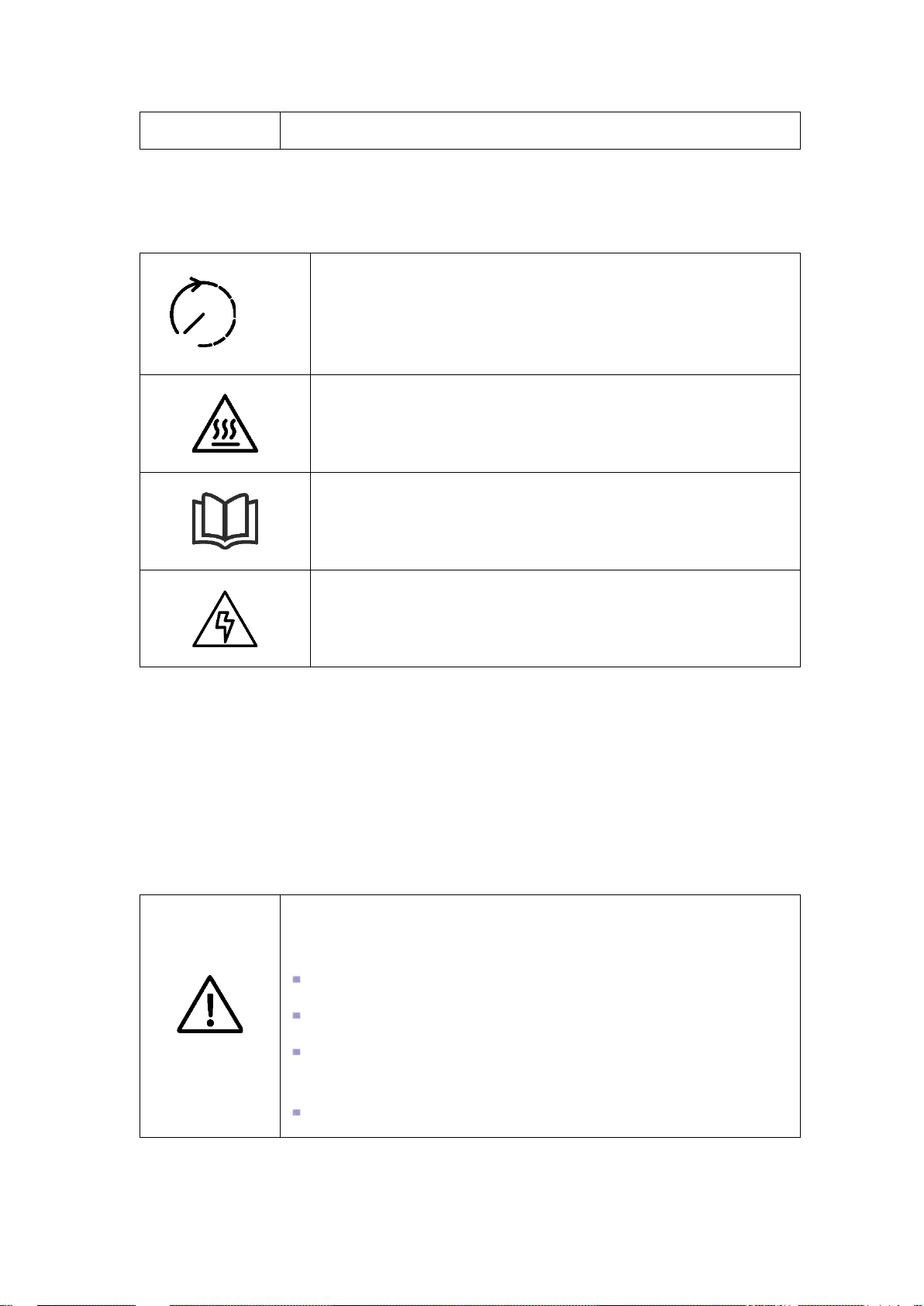

1.2.1 Icons in the manual

The following are the ex amples for icons in t his user’s manua l. Please read and und erstand

the definition of each icon.

The DANGER icon indicates that there is a safety risk during operation.

If this kind of warning information is not fol lowed, it will direct ly result in

DANGER

WARNING

a serious human casualty accident.

operation. If this kind of warning information is not followed, it might

result in a serious human c asualty accident.

operation. If this kind of warning information is not followed, it might

CAUTION

result in device damage.

The NOTE icon indicates the additional information in the manual and

a highlight and supple men t for the c ontent . It prov ides s kills an d tip s o f

product usage and can help you efficiently solve some problems in

- 1 -

by waiting for 10 minutes after inverter and power grid are

application.

1.2.2 Inverter prompt icons

The following are the examples for icons on the inverter. Please read and understand the

definition of each icon.

This icon indicates that internal co nductive device can be touched

10min

disconnected from storag e battery.

This icon ind icates that t he inverter surface is hot dur ing operatio n.

Keep cautious. Don’t touch the inv erter surface.

This icon indicates that be fore any operat ion of the in verter, please

read this product manual carefully.

The ELECTRICAL DANGER icon indicates that only professional

and qualified personnel can carry out equipment installation and

electric operation.

1.3 Safety instructions

PWS2-30M-EX energy storage inverter is designed and tested in strict accordance with

relevant international safety standards. Its installation, trial operation, operation and

maintenance should comply with safe operation specifications of electrical and electronic

equipment. Incorrect use or wrong operation might endanger operator or a t hird par t y and

destroy the inverter or other properties. To prevent the above circumstances from

happening, the following precautions should be strictly abided by in the process of

operation and maintenance. The detailed descr iption will be provided in relevant chapter .

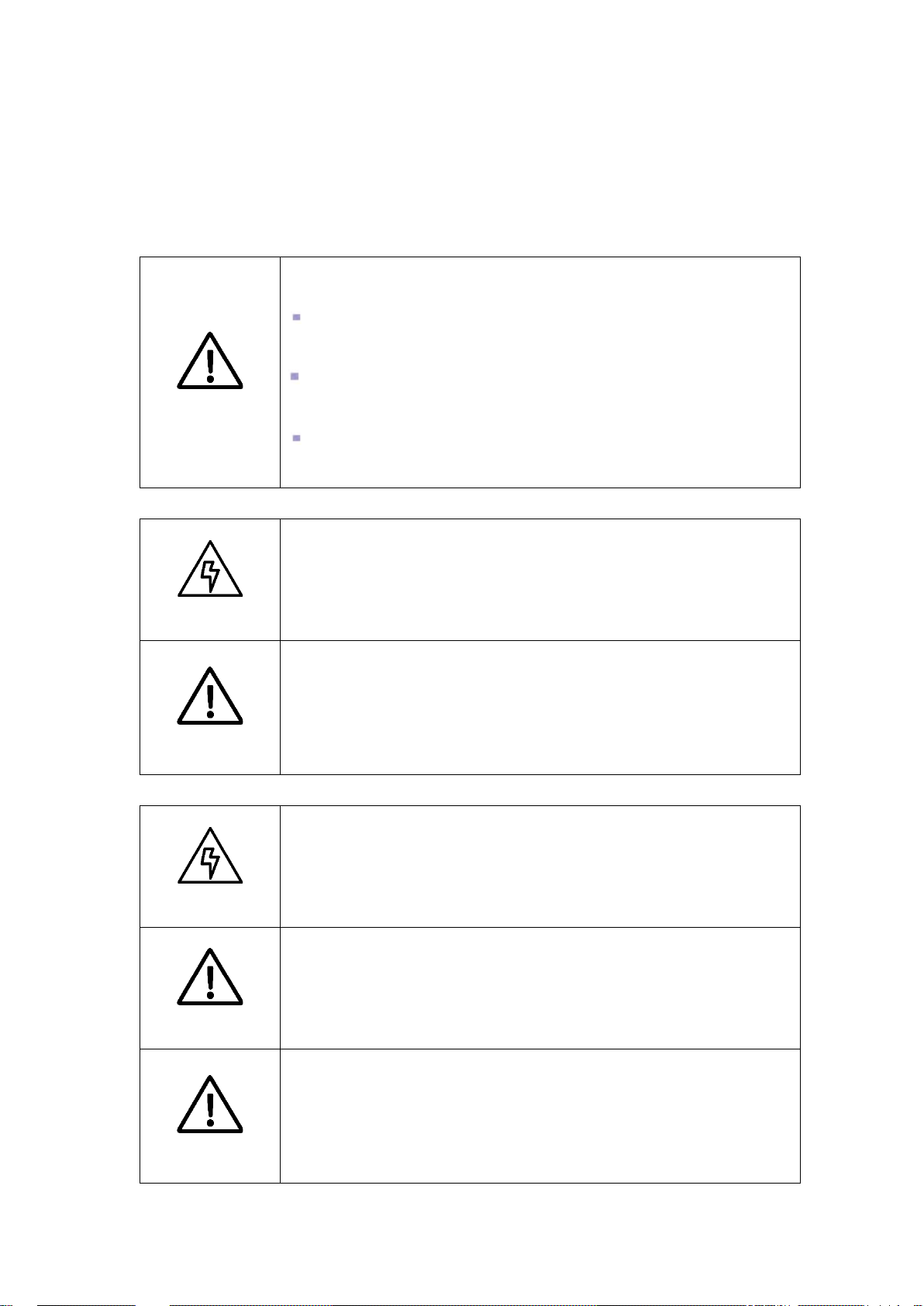

All installation, debugging and maintenance should be completed by

professionals. Profess ionals should:

be approved engineer by t he fact or y or its agent;

be professionally traine d;

WARNING

fully read this manual and learn about safe operation matters for

electrical and electronic equipment;

be familiar with relevant safety specification of ele ctric system.

Professionals who meet the above conditions can:

- 2 -

Removal and placement of the inverter should abide by the

Any system (equipment) damage caused by modification and

During equipment operation, the ventilation should be good. The

All electrical installations should meet national/regional electrical

(1) Install the inverter;

(2) Setup energy storage system as per customer’s requir ement;

(3) Conduct trial operation of energy storage system;

(4) Operate, debug and m aint ain energy storage system.

Equipment wrong operation might cause injury !

description in this manua l.

Improper equipment operation might cause electric shock, burn or

CAUTION

contusion.

disassembly without permission does not fa ll int o the warranty scope.

1.3.1 Safety instructions f or mec h ani cal installation

Before inverter installation, ensure that the inverter does not have any

electric connection.

DANGER

Poor ventilation for install at ion w i ll weaken the system performance!

equipment should be upr ight, and there s hould b e no strong air curr ent

CAUTION

to prevent airflow so as to ensur e t hat t he device is cooled well.

1.3.2 Safety instructions f or el ec tr i cal connection

Be careful in electric connection. There is dangerous voltage between

the two poles of storage battery. Don’t touch the metal terminal when

DANGER

CAUTION

there is no sufficient pr ot ection.

The cables used in energy storage system must be connected firmly

and with good insulation and pr oper specification.

standards;

CAUTION

Grid-tied operation can be conduct ed after per mission is obtained from

local national/regiona l ele ct r ic pow er department.

- 3 -

of the

to this device will be conducted by

injury or equipment damage. Before any operation, users should

Before power-on, please ensure that it is reliably grounded and the

grounding meets local electrical standards.

1.3.3 Safety instructions for inverter operation

Any contact with copper bar, uncovered contact spot or terminal inside

the device that is connected to the loop of power grid might result in

burning or fatal electric sh ock.

Don’t touch any terminal and conductor connected with the power

DANGER

grid.

Pay attention to any instruction and safety documents about grid

connection.

There might be an electric shock risk inside the device! When the

inverter operates or is electrified, don’t open the enclosure

inverter.

Only intact and closed cabinet can protect operator’s personal and

property safety.

Any operation related

professionals.

WARNING

Pay attention to the safety precaut ions listed in this manual and other

documents.

When AC of the inverter is loaded, DC disconnection is not allowed. If

disconnection is required, shutdown operation should be conducted

first. After the AC load isolation switch of the inverter is disconnected

and it is confirmed that there is no voltage at the AC terminal of the

inverter, DC connection can be turned off.

During inverter operation, t he ventilation duct must not be blocked.

CAUTION

1.3.4 Safety instructions for maintenance and replacement

Improper equipment m aintenanc e and operat ion m ight caus e persona l

strictly abide by the follow i ng s t eps:

DANGER

Disconnect the AC isolation switch between the power grid and the

- 4 -

contact spot, copper bar and other electric parts with body or

CAUTION

During electrical connection and maintenance, temporary warning

pasted and barriers should be set up to prevent

irrelevant personnel entering electrical connection or maintenance

Components might be caused by any contact with PCBs or other

inverter, and then turn off D C br eaker of the battery box.

Wait for at least 10 minutes until internal energy storage elements

are discharged off. During this period, don’t touch equipment termina l,

conductor.

Use detecting device to chec k and ensur e t hat ther e are no v oltage

and current on the device.

Stop irrelevant personnel from entering the maintenance site!

signs should be

area.

The inverter can be restarted only after its malfunction affecting safet y

performance is removed.

CAUTION

CAUTION

CAUTION

Power can be supplied again a fter t he inv ert er is fully disconn ected for

1 minute.

There are no serviceable parts in the inverter. If any maintenance is

required, please contact o ur aft er -sales personnel.

Don’t replace the internal elements at will. O therwise, our company will

not undertake any quality guarantee and joint liability for any losses

caused thereby.

electrostatic sensitiv e components or improper oper at ion.

Don’t touch the circuit boar ds.

Abide by electrostatic protection specifications and wear anti-static

wrist strap.

1.3.5 Others

Safety signs, warning lab el and nameplate on the inv er t er :

Must be clearly visible;

WARNING

Should not be removed or covered.

- 5 -

1.4 Precautions

1.4.1 Personnel requirements

Energy storage inverter must be debugged and maintained by the engineers designated

by the manufacturer or its agent. Otherwise, it might endanger personal safety and result

in device fault. Any damage aga inst the device ca used thereby will not fall into the warranty

scope.

1.4.2 Purposes of usage

Energy storage inverter is only used for commercial/industrial purposes, and it cannot be

used as an energy saving dev ice rel at ed to life support device.

1.4.3 Label on enclosure

The label on enclosure contains important information for safe operation to the inverter.

Don’t tear or damage it.

The label on enclosure should be clear and readable. If it is damaged or becomes vague,

please replace it.

1.4.4 Notes

To help users read this manual more conveniently, a lot of pictures are provided in this

manual. Such pictures are only used for de scription and indic ation. For detailed in formation,

please refer to the product itself.

- 6 -

Chapter 2 Introduction to energy storage system

Energy Management

System

Intelligent Power

Distribution Unit

or manual sw itch

Grid

Ethernet/RS-485

Energy Storage Inverter

Battery and

Industrial Load

Battery Managem ent

System

RS-485

Communication

2.1 System application

As shown in Fig. 2-1, the energy storag e sy ste m set up by PWS2-30M-EX is composed of

battery (pack), energy stor age invert er, intelligent (or manual) power distribution unit, EMS

and BMS. Battery pack is conn ected t o ener gy storage inv ert er. Energy storage inverter is

connected with the load and power grid through intelligent (or manual) power distribution

unit. Energy storage inverter communicates with EMS through Ethernet interface (or RS485 interface) to indirectly control charging and discharging of battery pack. EMS

communicates with energy storage inverter, BMS and/or intelligent electric meter through

RS-485 interface to d isp atch the energy of an energy storage system.

2.1.1 System structure diagram

The structure diagram of energy storage system is shown below. PWS2-30M-EX energy

storage inverter pushes t he dat a to EMS or other host syst ems in re al time.

The Intelligent power distribution unite is a remote controllable disconnector. A manual

switch can also work. This component is used to isolate the grid when the system needs

to run in off-grid mode.

Fig. 2-1 Structure of energy storage system

- 7 -

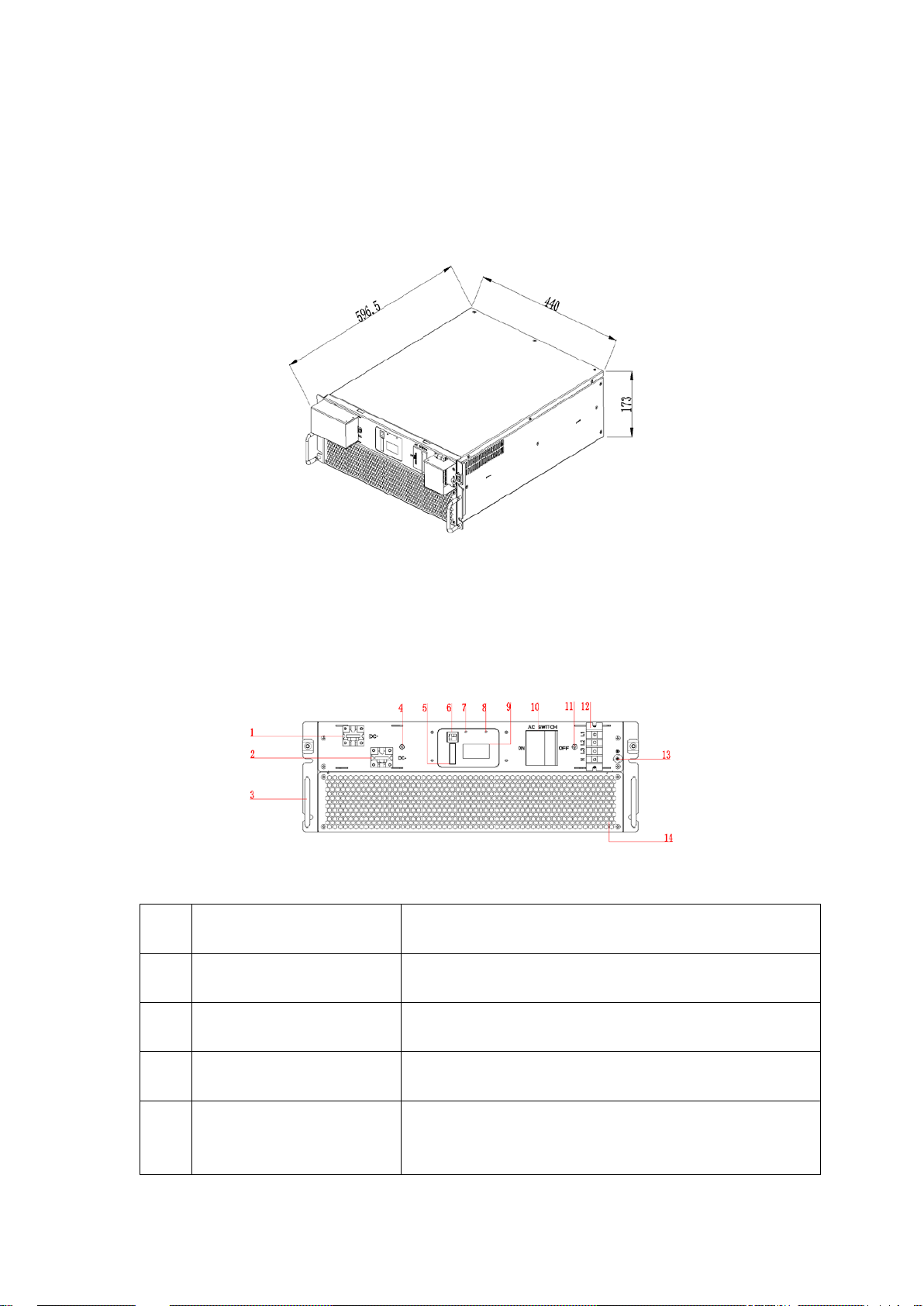

2.2 Overall dimension

Overall dimension of PWS2-30M-EX is shown in Fig.2-2.

Fig. 2-2 Overall dimension of PWS2-30M-EX (unit: mm)

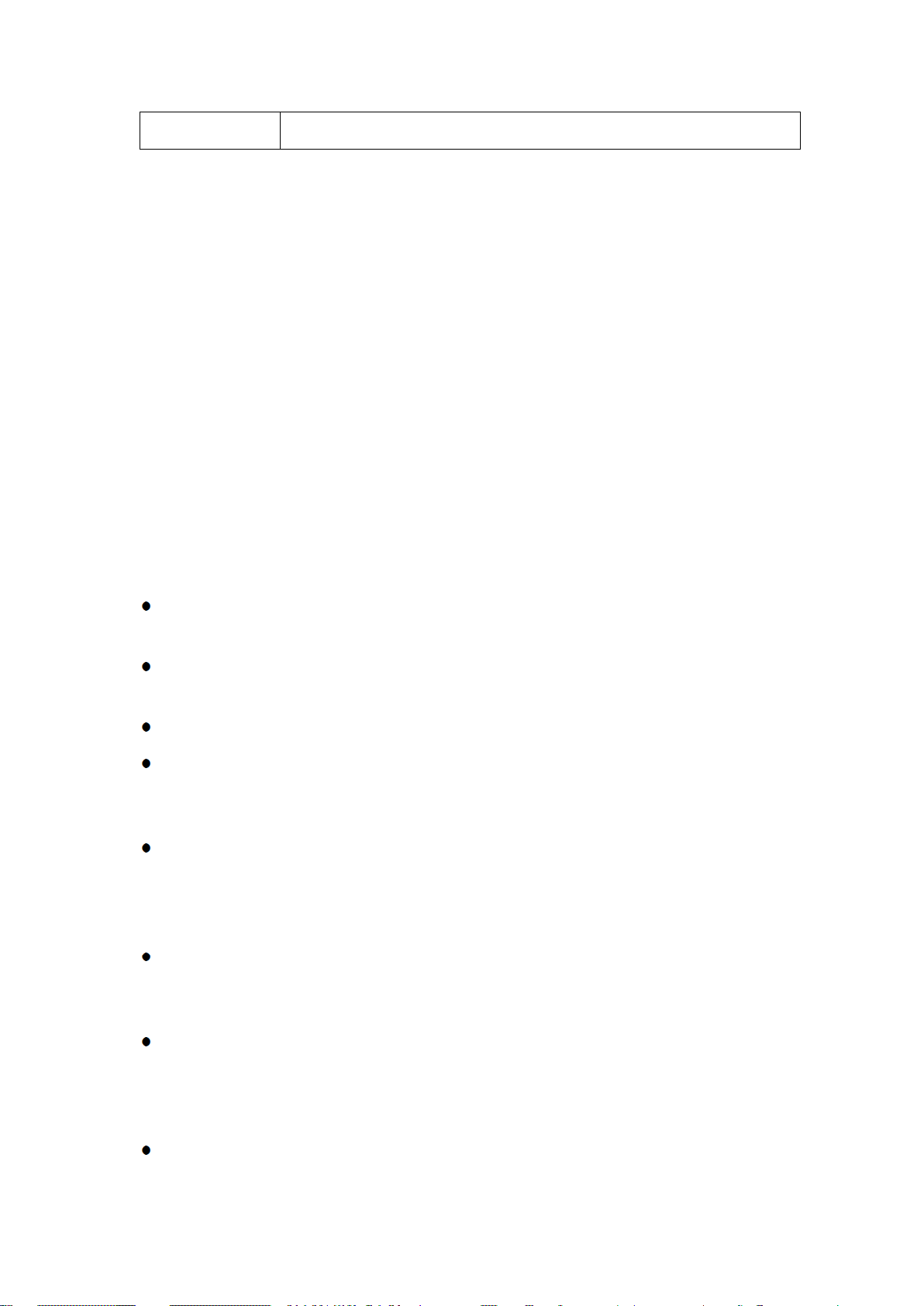

2.3 Appearance

The appearance of PWS2-30M-EX is shown in Fig.2-3.

Fig. 2-3 Appearance of front side of PWS2-30M-EX

SN Name Description

1 Positive DC port To connect positive power cables to the battery cabinet

2 Negative DC port To connect negative power cables to the bat t er y cabinet

3 Knob Pulling module can’t be used for bearing

DC protection shell fixing

4

point

For DC terminal protection case fixing

- 8 -

5 Communication interfaces Including RS-485, EPO

6 Internet port Ethernet

7 Running lights Lights on during normal o per at ion

8 Fault indicator Lights on during abnormal running

9 Monitor screen Display monitoring content

10 AC breaker

11

AC protection shell fixi ng

point

Safety device to connect or disconnect the current in

AC port.

For AC termin al protection case fixing

12 AC port To connect AC power cables

13 Ground port To connect ground protection point.

14 Air outlet Ventilation duct exit for heat dissipation

2.4 Technical parameters

Technical parameters of PWS2-30M-EX energy st or age inverter:

Table 2-1 Technical parameters

Product Model PWS2-30M-EX

DC PORT - BATTERY

Battery Voltage Range 200~750V

DC.Max Current 90A

DC.Max Pow er 33kW

AC GRID-TIE PARAMETER

Rated Output Power 30kW

Rated Voltage 400V

Voltage Range -20%~+15%

Rated Frequency 50Hz

Frequency Range -2.5~+1.5Hz

AC.Rated Current 43.3A

Output THDi

Power Factor 0 leading~0 lagging

AC OFF-GRID PARAMETER

≤3%

- 9 -

Voltage 380/400V

Voltage Adjustable Range ±5%

Frequency 50Hz

Output THDu

Output THDu

SYSTEM PARAMETER

Peak Efficiency 97.1%

Wiring Mode 3P3W+PE, 3P4W+PE

Isolation Mode No-isolation

Cooling

Noise 60dB

Working Temp.

IP Degree IP20

Max Elevation 4000M(de-rating in case of exceeding 2,000m)

Humidity Range 0~95%

Size (W*D*H) 440*550*173mm

Weight 30kg

Type of battery Lithium battery, lead-acid battery

COMMUNICATION

Display LCD Screen

Communication Protocol Modbus TCP/IP, MESA

Communication Socket

-20℃~60℃(de-rating in case of exceeding 45°C)

≤1%(Linear load)

≤5%(Nonlinear load)

Forced air cooling with

replaceable fan module

Ethernet、RS485

2.5 Technical specification

2.5.1 Principle description

There are three operation modes: grid-tied discharging, char ging and off-grid discharging.

When the battery volt age connected to PWS2-30M-EX is within the preset normal voltage

range, the inverter can operate under grid-tied discharging, charging and off-grid

discharging. If the inverter is in discharging state, the DC power supply of the battery can

be inverted into 3-phase AC power supply. If the inverter is in charging state, the 3-phase

AC power energy of the pow er gr id ca n be stored into battery (pac k).

The protection circuit of the inverter is used to ensure safe operation of the inverter and

operators’ safety.

Energy storage inverter without built-in isolation tran sform er.

If the capacity of the ener gy storage device does not meet t he demand,

CAUTION

multiple parallel connections can be made. Each inverter is equipped

with a suitable battery capacity on the DC side and the AC side is

- 10 -

connected to the grid in parallel.

2.5.2 Function description

The functions of PWS2-30M-EX are as follows:

Grid-tied discharging: The inverter is in inver ting state, conv erts DC into AC that meets the

requirement of power grid department in installation region, and feeds the energy back to

the power grid.

Grid-tied charging: The inverter is i n rectification state and tr ansmits 3-phase AC to charge

the battery (pack) by the set char ging mode.

Off-grid discharging: The inverter is in inverting state, converts DC into AC that meets the

requirement of power gr id depart ment in in stal lation r egi on, an d prov id es pow er supp ly for

3-phase load in the micro-grid.

Data storage and display: Storage and operation informatio n, oper at io n r ec ord and failure

record are displayed on the LC D scr een.

Communication function:

Standard RS-485 interface can be connected with monitoring device such as EMS,

BMS.

Standard Ethernet interface is used to communicate with upper computer to realize

such functions as remote cont r ol a nd r emote software upgradin g.

Reactive power configuration: Regulate the reactive power of the storage system.

FVRT: frequency/voltage ride-through, this function can be enabled or disabled, for

more information, please refer to UL1741 Supplement A or other similar rules about

Utility-Inter active Distribute Generators.

Soft-Start/Reconnection ramp rate: This function will apply when system suspend

happens caused by utility voltage abnor mal, and reconnect after utility r estore normal.

The default value is 2, twice of rated power per second, which means within 0.5

seconds the system restores to full output.

Anti-Islanding: enable or disable anti-island ing function. For more informati on, please

refer to UL1741 Supple ment A or other similar ru les about Uti lity -Interact ive D ist ribut e

Generators.

Volt/Watt: Available when activated and operating in discharge mode. When the

actual voltage is above the point, the active power will be regu lated with the ramp rat e.

The ramp rate is defined as multiple of set active power per 1% of rated voltage that

above the Volt/Wat t point.

Volt/VAR: Available when activated and operating in discharge mode. In this mode,

Reactive power as a function of grid voltage. In Volt/Var mode, the Q configuration is

- 11 -

Loading...

Loading...