User's Manual

PWS1-NA Series Bi-directional Grid-support

Utility-interactive

Energy Storage Inverter

1

Sinexcel

PWS1-NA Series Bi-directional Grid-support Utility-interactive

Energy Storage Inverter

User's Manual

Data version: V1.1

Filed in: March 15, 2017

BOM code: A81150292

Applicable to: PWS1-50K/100K/150K/250K-NA

Shenzhen Sinexcel Electric Co., Ltd. (“Sinexcel”) provides its customers with all-around technical support. Users can contact

Sinexcel local office or customer service center or directly contact Sinexcel Headquarters.

Shenzhen Sinexcel Electric Co., Ltd.

All rights reserved. In case of any content change, it shall be without prior notice.

Shenzhen Sinexcel Electric Co., Ltd.

Website: www.sinexcel.com

Add: Building 6, Area 2, Baiwangxin High-tech Industrial Park, No. 1002, Songbai Road, Nanshan District, Shenzhen

Postcode: 518055

Hotline: 0755-8651-1588

Fax: 0755-8651-3100

E-mail: service@sinexcel.com

Contents

Chapter I Overview ......................................................................................... 1

1.1 Model definition .................................................................................................................................................................... 1

1.2 Symbolic interpretation ...................................................................................................................................................... 1

1.3 System application ................................................................................................................................................................ 2

1.4 Important Safety instructions ........................................................................................................................................... 3

1.5 Precautions .............................................................................................................................................................................. 4

1.5.1 Personnel requirements .............................................................................................................................................. 4

1.5.2 Equipment use scope ................................................................................................................................................... 5

1.5.3 Rack label ......................................................................................................................................................................... 5

1.5.4 Description ....................................................................................................................................................................... 5

Chapter II Introduction to Modules.......................................................................... 6

2.1 Overall dimension of PCS-AC module ........................................................................................................................... 6

Chapter III Introduction to System.......................................................................... 8

3.1 System composition ............................................................................................................................................................. 8

3.2 Technical parameters ........................................................................................................................................................... 8

3.3 Overall dimension .............................................................................................................................................................. 11

3.4 Appearance description ................................................................................................................................................... 12

Chapter IV Device Installation ............................................................................ 15

4.1 Transport and storage ...................................................................................................................................................... 15

4.2 Removal ................................................................................................................................................................................. 15

4.3 Open-case inspection ....................................................................................................................................................... 16

4.3.1 Overview ........................................................................................................................................................................ 16

4.3.2 Packing list .................................................................................................................................................................... 16

4.4 Installation requirements ................................................................................................................................................ 16

4.4.1 Environment requirements ..................................................................................................................................... 16

4.4.2 Ground requirements ................................................................................................................................................ 16

4.4.3 Ventilation ..................................................................................................................................................................... 17

4.4.4 Operation space .......................................................................................................................................................... 17

4.4.5 Other requirements ................................................................................................................................................... 18

4.5 Rack installation .................................................................................................................................................................. 18

4.6 Electrical connection ......................................................................................................................................................... 19

4.6.1 Input requirement ...................................................................................................................................................... 19

4.6.2 Output reqirement ..................................................................................................................................................... 20

4.6.3 Wiring mode ................................................................................................................................................................ 20

4.6.4 System grounding ...................................................................................................................................................... 21

4.6.5 DC port wiring ............................................................................................................................................................. 22

4.6.6 AC port wiring ............................................................................................................................................................. 22

4.6.7 Wiring of terminal strips .......................................................................................................................................... 23

4.7 Check after installation .................................................................................................................................................... 24

Chapter V Commissioning and Operation ...................................................................... 25

5.1 Status ...................................................................................................................................................................................... 25

5.1.1 Automatic startup ...................................................................................................................................................... 26

5.2 Startup and shutdown ...................................................................................................................................................... 26

5.2.1 Check before startup ................................................................................................................................................. 26

5.2.2 Startup steps ................................................................................................................................................................ 26

5.2.3 Shutdown steps ........................................................................................................................................................... 27

5.2.4 Emergency shutdown................................................................................................................................................ 27

Chapter VI Operation Control Display Panel ................................................................. 28

6.1 Operation instructions ..................................................................................................................................................... 28

6.1.1 Main monitoring startup ...................................................................................................................................... 28

6.2 Home ...................................................................................................................................................................................... 28

6.3 Information ........................................................................................................................................................................... 29

6.4 Logs ......................................................................................................................................................................................... 29

6.5 Settings .................................................................................................................................................................................. 30

6.5.1 Local ................................................................................................................................................................................ 30

6.5.2 Model .............................................................................................................................................................................. 30

6.5.3 System ............................................................................................................................................................................ 30

6.5.4 AC settings .................................................................................................................................................................... 31

6.5.5 DC settings .................................................................................................................................................................... 34

6.5.6 AC Debug ...................................................................................................................................................................... 35

6.6 On/Off .................................................................................................................................................................................... 35

6.7 Control mode ...................................................................................................................................................................... 37

6.8 Tactics ..................................................................................................................................................................................... 37

6.8.1 Local strategy ................................................................................................................................. 错误!未定义书签。

6.9 Log in/out ............................................................................................................................................................................. 38

Chapter VII Communication Mode ............................................................................ 39

7.1 Communication interface ................................................................................................................................................ 39

7.1.1 RS-485 port .................................................................................................................................................................. 39

7.1.2 Ethernet port ................................................................................................................................................................ 40

7.1.3 Communication with BMS ....................................................................................................................................... 40

7.2 Monitoring system structure .......................................................................................................................................... 41

Chapter VIII Maintenane and Preservation ................................................................... 43

8.1 Operation environment requirements ........................................................................................................................ 43

8.2 Electrical and fixed connection inspection ................................................................................................................ 43

8.3 Clearing and cleaning ....................................................................................................................................................... 43

Appendixes ................................................................................................ 44

Appendix 1: Fault information of storage inverter ...................................................................................................................... 44

Appendix 2: Quality assurance and after-sales service ............................................................................................................. 45

Installation Records ...................................................................................... 46

1

Chapter I Overview

1.1 Model definition

This section introduces product model definition in this user’s manual.

Fig. 1-1 Product model definition

For example:

PWS1-100K-NA: 100kW bi-directional grid-support utility-interactive storage inverter (for North America)

1.2 Symbolic interpretation

Danger

This instruction indicates that there is a safety risk during operation. If this kind of warning information is not followed, it will

directly result in a serious human casualty accident.

Warning

This instruction indicates that there is a potential risk during operation. If this kind of warning information is not follow ed, it

might result in a serious human casualty accident.

Attention

This instruction indicates that there is a potential risk during operation. If this kind of warning information is not follow ed, it

might result in device damage.

50K

NA

PWS1

Bi-directional ES Inverter

Rated Power: 50 to 250K

For North America

2

Symbol

Explanation

Risk of burns

Operation after 10 minutes

Read the manual

ETL mark.

The Storage Inverter complies with the requirements of the applicable UL 9540

guidelines.

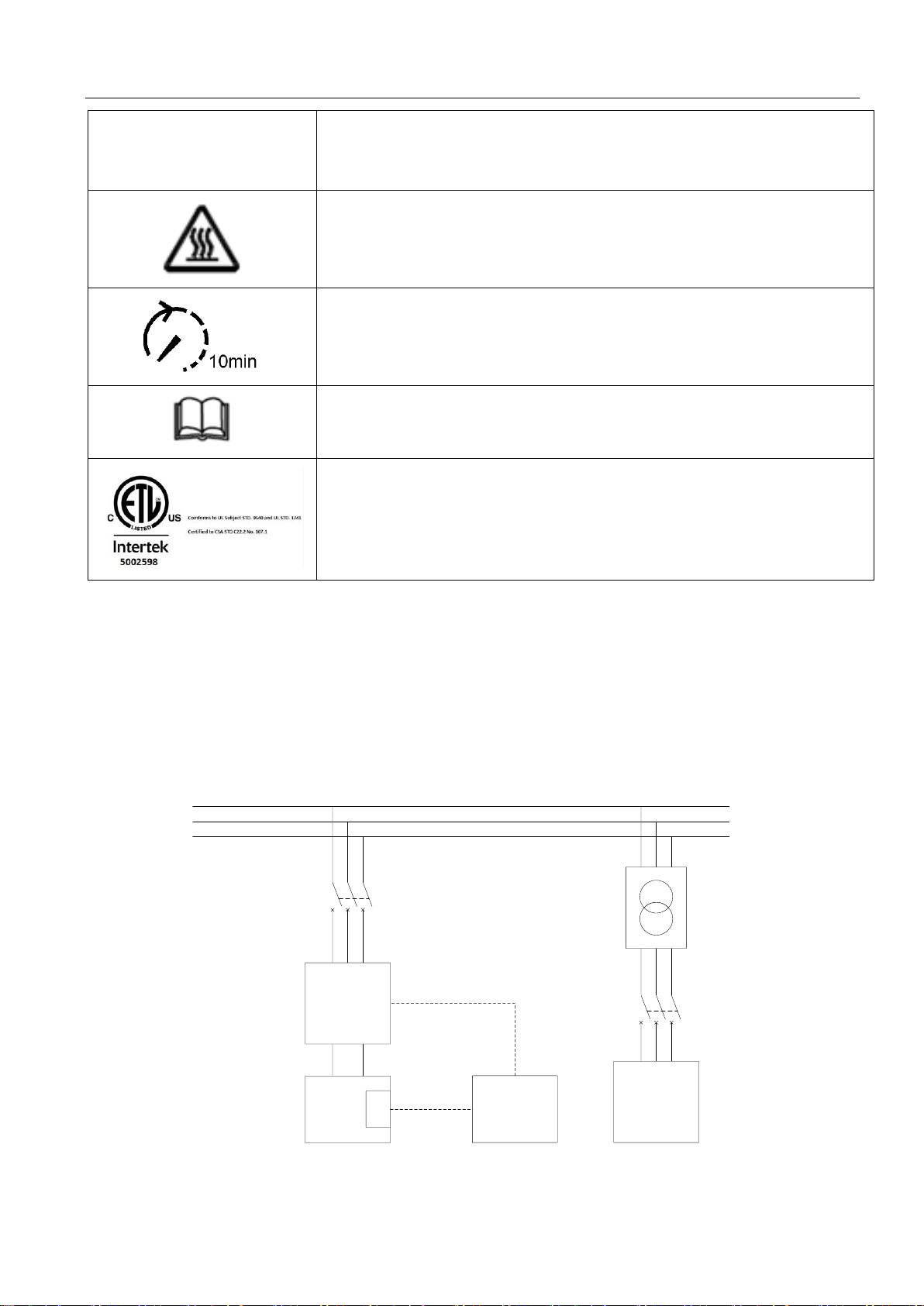

1.3 System application

energy storage system is composed of battery, storage inverter and AC distribution unit. Batteries are input to the storage

inverter after series-parallel connection of batteries. The storage inverter outputs it to AC distribution unit. It operates in different

modes according to the need.

PWS1-

50/100/150/25

0K-NA

L1

L2

L3

Battery

Array

AC 480V bus

(Optional)

AC MCCB 690V

200A 3P

BMS

RS-485 or

Ethernet

RS-485 or

Ethernet or

CAN

AC MCCB

Industrial/

Commercial

Load

Remote

Controller

(Field-

depend)

480V:208V

+

-

Fig. 1-2 Energy storage system diagram

3

The storage inverter plays a core role in the whole system and is characterized with high conversion efficiency, wide range

input voltage, rapid grid-tie/off-grid switching and convenient maintenance. It has a complete protection function (such as

islanding protection, DC overvoltage protection, AC overvoltage-under-voltage protection, over/under-frequency protection,

inverted sequence protection and output overload protection) and can meet grid-tie/off-grid operation requirements.

Attention

The storage inverter has a built-in isolation transformer.

1.4 Important Safety instructions

This user’s manual is about installation and use of Sinexcel PWS1 series 50~250kW energy storage inverter.

Before installation, please read this user’s manual carefully.

The storage inverter must be commissioned and maintained by the engineers designated by the manufacturer or the

authorized service partner. Otherwise, it might endanger personal safety and result in device fault. Any damage against the

device caused thereby shall not be within the warranty scope.

The storage inverter is only used for commercial/industrial purposes, and it cannot be used as an energy saving device related

to life support device.

This manual contains important instruction for Models PWS1-50K/100K/150K/250K-NA that shall be followed during

installation and maintenance of the Bi-directional Storage Inverter.

Danger

Any contact with copper bar, contactor and terminal inside the device or connected with the loop of utility grid might result

in burning or fatal electric shock.

Don’t touch any terminal and conductor connected with the loop of utility grid.

Pay attention to any instruction and safety documents about power on-grid.

Warning

There might be an electric shock risk inside the device!

Any operation related to this device will be conducted by professionals.

Pay attention to the safety precautions listed in safety instruction and installation documents.

Pay attention to the safety precautions listed in user’s manual and other documents.

4

Warning—large leakage current

Before connecting input power supply, please ensure that the grounding is reliable.

The device must be grounded complying with the local electric codes.

Warning

When storage battery is connected to storage inverter, there is DC voltage at input port. Please pay attention to it during

operation.

Warning

Don’t touch electric parts within 15 minutes after power outage!

There is dangerous energy in capacitance storage. Don’t touch device terminal, contactor and cooper bar and other

electric parts within 15 minutes after disconnecting all device power supplies.

Attention

All maintenance and preservation inside the device require using tools and shall be conducted by trained personnel.

The components behind the protective cover plate which are opened by tools cannot be maintained by users.

Please read this user’s manual before operation.

1.5 Precautions

1.5.1 Personnel requirements

The storage inverter is only commissioned and maintained by the engineers designated by the manufacturer or the authorized

service partner. Otherwise, it might endanger personal safety and result in device fault. Any damage against the device caused

5

thereby shall not be within the warranty scope.

1.5.2 Equipment use scope

The storage inverter is only used for commercial/industrial purposes, and it cannot be used as an energy saving device related

to life support device.

1.5.3 Rack label

Rack label contains important information for safe operation of rack. Don’t tear it up or damage it. S

Ensure that the rack label is clear and readable. If it is damaged or obscure, please replace it immediately.

1.5.4 Description

To facilitate users to use this manual more conveniently, a lot of pictures have been provided in the manual. The pictures can

be only used for explanative and schematic purposes. As for product details, the real product shall prevail.

6

Chapter II Introduction to Modules

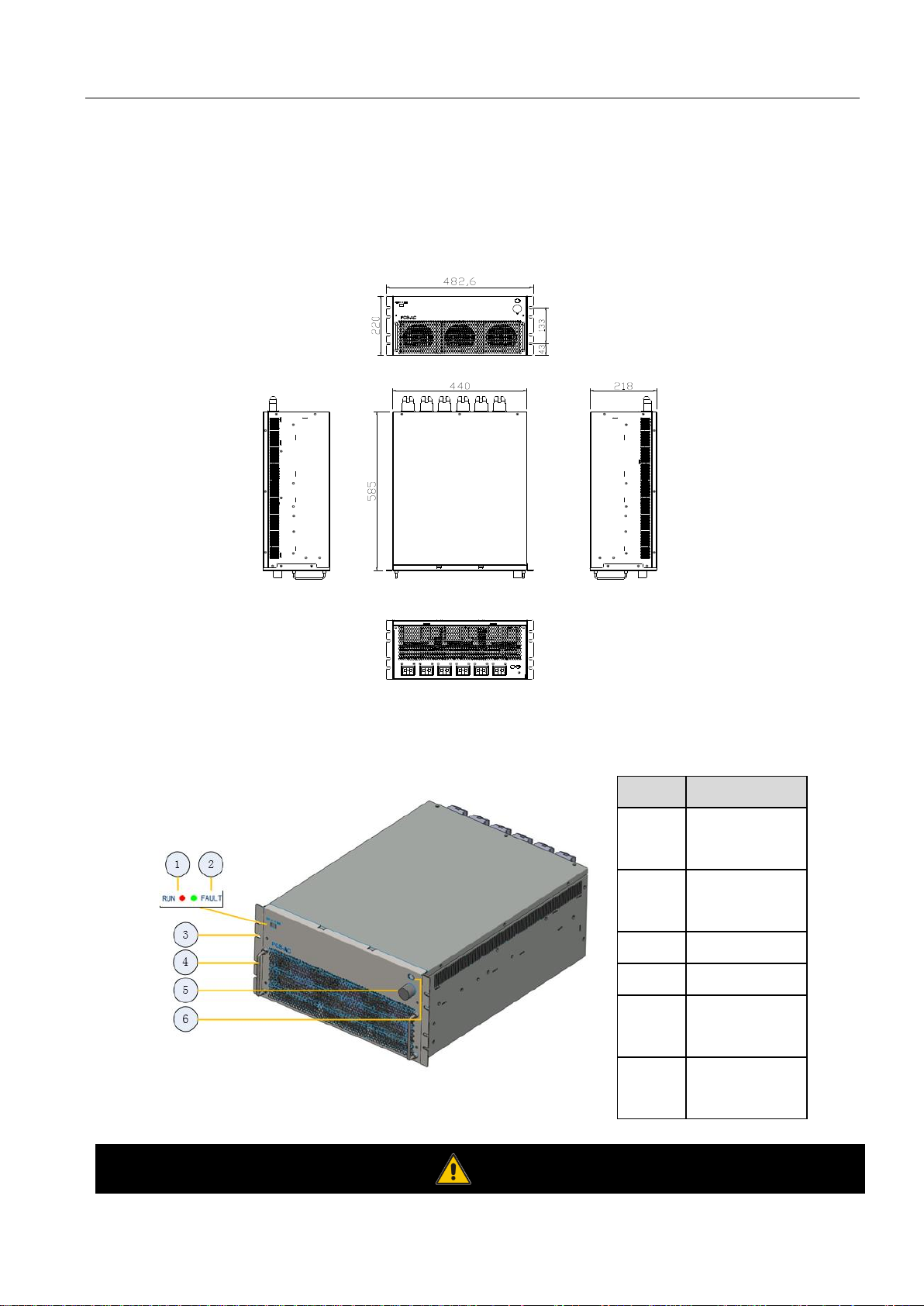

2.1 Overall dimension of PCS-AC module

Fig.2-1 is a diagram for overall dimension of PCS-AC module case and installation hole.

Fig. 2-1 Overall dimension and installation diagram for PCS-AC module

Fig. 2-2 Front view for PCS-AC module

Position

Description

1

Normal indicator

light

2

Fault indicator

light

3

Hanger

4

Handle

5

Communication

cable

6

Power supply

cable

Warning

7

The handle on the front panel of the module cannot bear the weight.

The front panel of PCS-AC module has two LED lights, namely one green (Normal) light and one red (Alarm) light. When the

device is in standby state, the green light (Normal) flickers once every 1s. When the device is in sleep state, green and red

lights are off. When the device is in normal operation, the green light (Normal) is always on. When the device has a fault

warning, the red light (Alarm) will be always on or flicker.

8

Chapter III Introduction to System

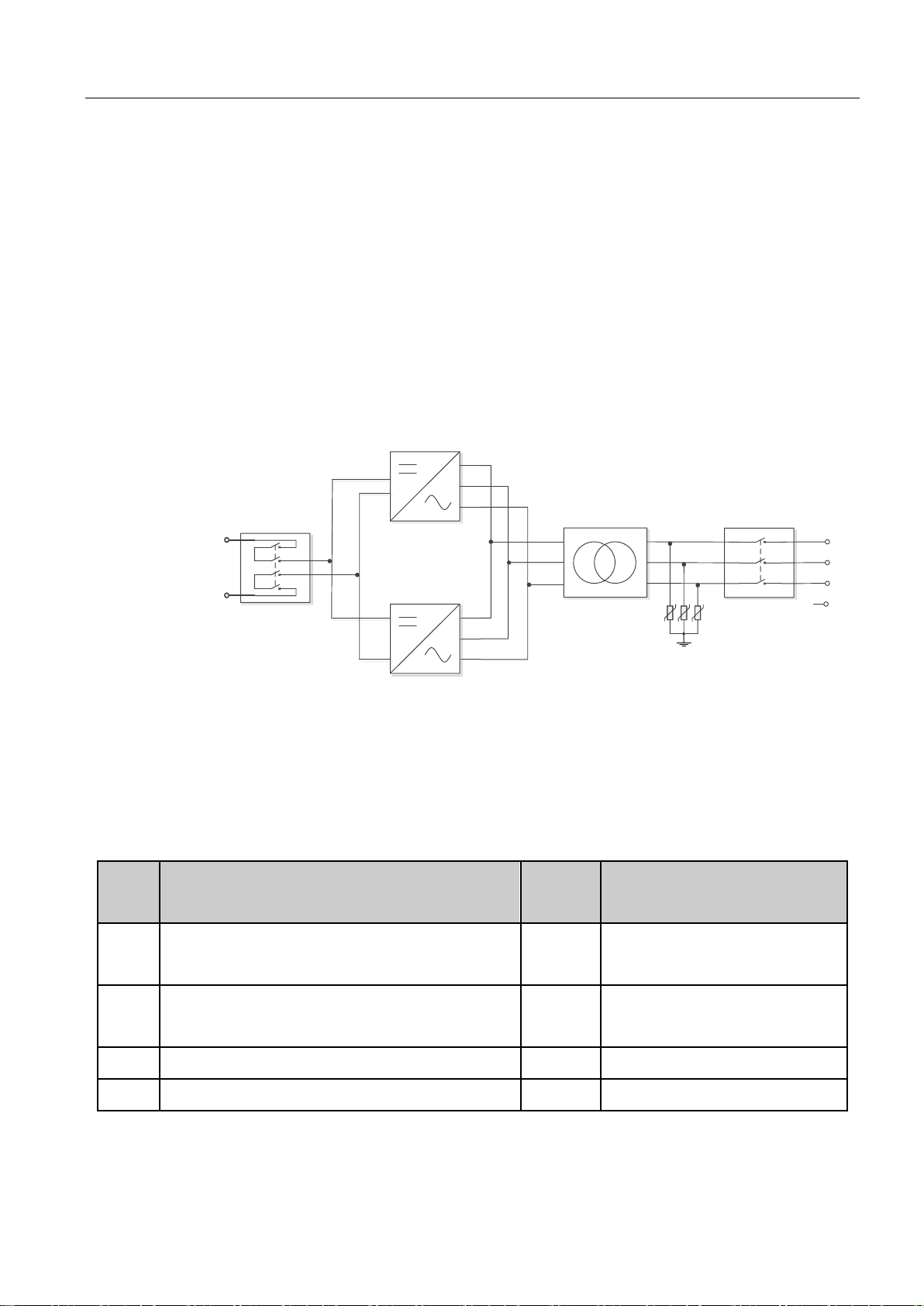

3.1 System composition

PWS1-50K/100/150K/250K storage inverter is composed of 1 or multiple set(s) of PCS-AC modules. The modules identify

master-slave systems through the dial-up codes on the panel. #1 is a master system, while other modules track the master

system. The storage inverter rack is equipped with lightning protector, AC/DC breaker and distribution units. If grid-tie/off-grid

switching is to be achieved, extra power distribution unit needs to be added. Fig.3 -1 is a topological graph for its composition

and structure.

L

1

L

2

L

3

N

Transformer AC Breaker Q3

+

IN1

-

PCS AC 1

PCS AC n (n=0/ 1/ 2)

DC Breaker Q1

AC SPD

Fig. 3-1 Topological graph for storage inverter

Main composition of PWS1-50K/100/150K/250K storage inverter rack is shown in Table.3-1.

Table 3-1 Main composition of the storage inverter rack

Serial

No.

Item

Quantity

Remark

1

Rack

1

The rack is equipped with distribution

components.

2

PCS-AC module

1~5

50kW 1 set; 100kW 2 sets; 150kW 3 sets;

250kW 5 sets

4

Isolation transformer

1 5

Power Management Unit

1

Built-in on the rack door.

3.2 Technical parameters

Table 3-2 is detailed parameters for storage inverter.

9

Table 3-2 Technical parameters

PWS1-50K-NA

PWS1-100K-NA

PWS1-150K-NA

PWS1-250K-NA

AC parameters

Rated output

power

50kW

100kW

150kW

250kW

Wiring mode

3-phase and 4-wire system (including transformer)

Output overload

capacity

55kW

110kW

165kW

275kW

On/off-grid switch

time

≤ 80ms (For shorter time, it can be customized.)

Utility-Interactive

AC voltage

Rated voltage: 480V; voltage range: 423V~528V

Voltage accuracy

<1%

Ramp rate

accuracy

<10%

Frequency

60Hz, frequency range: 59.5Hz~60.5Hz

Frequency

accuracy

<0.1Hz

AC rated current

60A

120A

180A

300A

Maximum AC

input short circuit

current

(charge mode)

1200A

2500A

3500A

6000A

Maximum output

overcurrent

protection

Yes

Yes

Yes

Yes

AC output fault

current and

duration

300A 200ms

600A 200ms

900A300ms

1500A 300ms

Trip limit and trip

time accuracy

80ms (±30ms)

80ms (±30ms)

80ms (±30ms)

80ms (±30ms)

Total harmonic

distortion of

current

<3%

Power factor

0.8 leading~0.8 lagging adjustable

PF accuracy

±2%

10

Active power

accuracy

5%

Inactive power

accuracy

8%

Stand-alone

Rated output

voltage

480Vac

Rated output

frequency (Hz)

60Hz

DC parameter

DC voltage range

650V (500V-850V)

DC input/output

current

100A

200A

300A

500A

Rated DC power

50kW

100kW

150kW

250kW

Charging mode of

on-grid

It can charge and discharge with constant current and power and supports three-section

charging (pre-chargeequalized chargefloating charge).

System

Dimension

800mm*2160mm*800mm (W*H*D)

1200mm*2160mm*800mm

(W*H*D)

Weight

465kg

680kg

910kg

1280kg

Noise

≤70dB

Enclosure

NEMA1(IP20)

Allowable

environment

temperature

-20℃~50℃(auto de-rate at 45℃ or above)

Cooling mode

Forced air cooling

Humidity

0~95% (no condensation)

Allowable

maximum

elevation

3000m

Display

Touch screen

Standard

communication

interface

RS 485, CAN and Ethernet

11

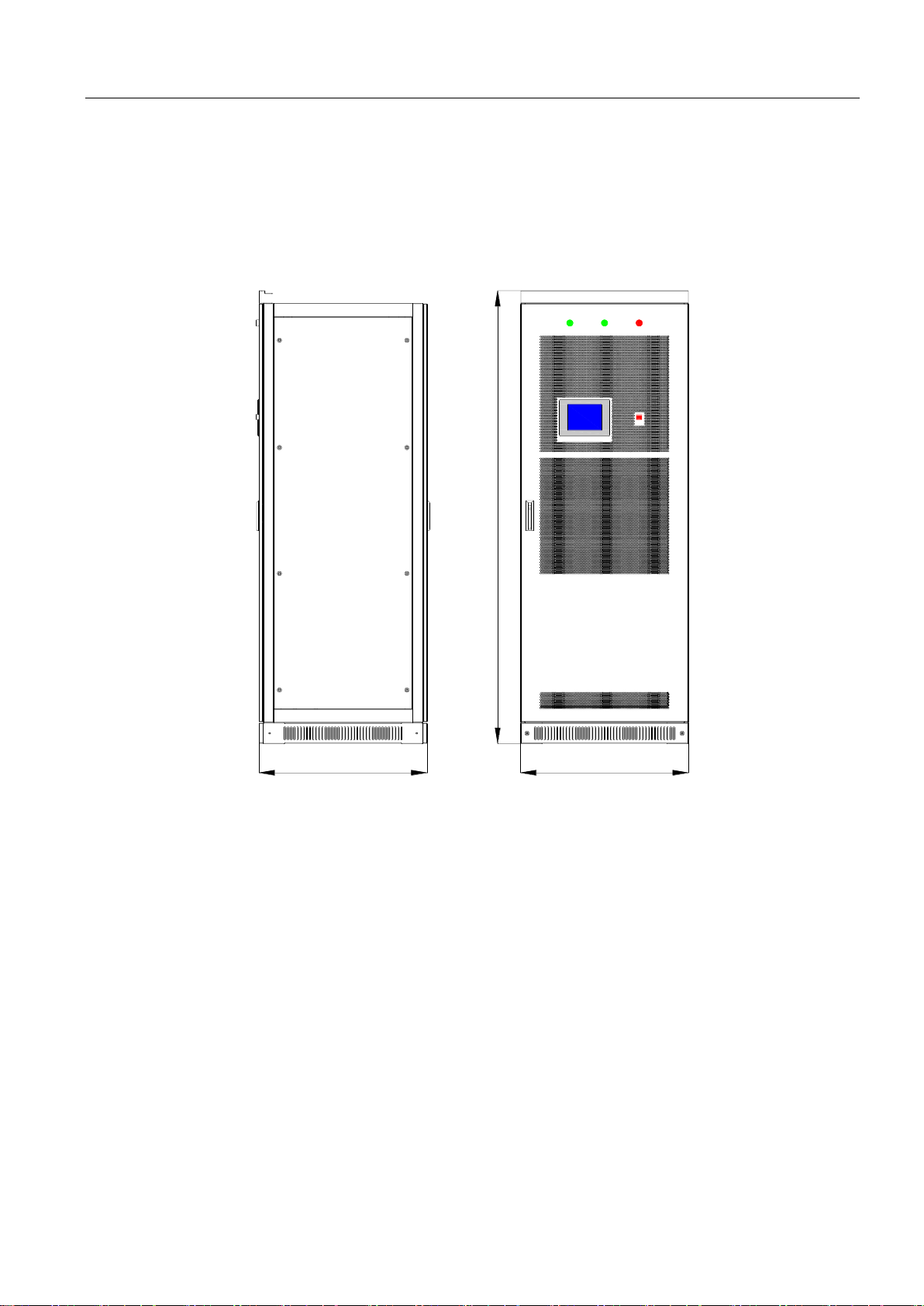

3.3 Overall dimension

The overall dimension of the storage inverter is shown in Fig.3-2.

The PWS1-50K/100K/150K Rack, width: 800mm, height: 2,160mm (without lifting rings); depth: 800mm.

The PWS1-250K Rack, width: 1200mm, height: 2,160mm (without lifting rings); depth: 800mm.

故障/FAULT

电源/POWER 运行/RUN

EPO

2160

800800

12

Fig. 3-2 Overall dimensions of storage inverter

3.4 Appearance description

The appearance of the storage inverter is shown in Fig.3-3. Screen body is mainly composed of touch screen, normal indicator

light, alarm indicator light and emergency shutdown button etc.

故障/FAULT

电源/POWER

运行/RUN

EPO

4

1

2

3

5

Fig. 3-3 Front look of PWS1 50~250K-NA storage inverter

Position

Description

1

Power indicator light

2

Fault indicator light

3

Normal indicator light

4

Emergency

shutdown button

5

Touch screen

Taking PWS1-150K-NA as an example: After opening the front door, the internal layout is shown in Fig.3-4. Main components

include module, AC/DC breaker and surge protection device.

The internal layout of PWS1-250K-NA is shown in Fig.3-5.

2100

1200800

故障/FAULT电源/POWER 运行/RUN

EPO

13

Fig. 3-4 Internal layout diagram for PWS1-50~150K-NA

storage inverter

Position

Description

1

PCS-AC module

(1~3 module(s))

2

Battery switch

3

AC breaker (load)

1

2

4

14

1

2

3

Fig. 3-5 Internal layout diagram for PWS1-250K-NA

storage inverter

Position

Description

1

PCS-AC module

(1~5 module(s))

2

Battery switch

3

AC breaker (load)

15

Chapter IV Device Installation

4.1 Transport and storage

Rack and module of the storage inverter are packed separately in the packing cases. That is, multiple modules and a rack

packed separately in the packing cases. During device transport and storage, pay attention to the logo on the packing case.

The storage inverter is modularly designed so as to facilitate device positioning and transport. The selection of storing position

should ensure that:

There is no corrosive gas around it.

There are over-wetting and high-temperature sources.

It is not a dusty environment.

It complies with the firefighting requirements.

Attention

During rack transport and storage, stacking is not allowed. The device top cannot be placed with other articles.

The rack should be placed vertically at forward direction. Don’t keep it upright place it horizontally.

4.2 Removal

When removing the module of the storage inverter which is not unpacked from packing case, a forklift can be used to remove

the whole case.

Users can lift the device bottom with a forklift or through the lifting hole on its top with a crane.

Fig. 4-1 Moving storage inverter

Warning

16

Before the rack is moved, please ensure that the module is fixed stably.

4.3 Open-case inspection

4.3.1 Overview

Before installation of storage inverter, open-case inspection needs to be conducted. The inspection includes the following:

Check whether the items in the packing are consistent with real items.

Check whether the data of product nameplate is consistent with the contract, including product model, rated capacity

and voltage grade.

Check whether the ex-factory documents and accessories are complete.

Check whether the module of the storage inverter is deformed.

Check whether the inverter rack is deformed, paint peeling or loose.

4.3.2 Packing list

Refer Table 4-1 for packing list of rack of storage inverter:

Table 4-1 Packing list

Item

Quantity

Remark

User’s manual

1 copy

Overall dimension and foundation

installation diagram

1 copy

Schematic diagram

1 copy

External terminal diagram

1 copy

Certificate of quality

1 copy

4.4 Installation requirements

4.4.1 Environment requirements

It is installed indoor. Direct sunshine, rain and ponding should be avoided.

The installation environment is clean. The air should not contain lots of dust.

The installation position should not be shaky.

Environment temperature should be -20~55℃. (The software conducts de-rating for 45℃ above.)

The installation position is convenient for observing touch screen.

4.4.2 Ground requirements

The rack of the storage inverter needs to be installed on the flat ground. The weight-bearing of the ground for installation

should be greater than 1,000kg/ m

2

.

17

4.4.3 Ventilation

The storage inverter is forced air-cooling. Every module has an independent ventilation route. The module heat dissipation

mode is air inlet in the front and air outlet in the rear. The cold air is inhaled from the mesh openings of front door of the rack.

After heat absorption, the hot air is discharged from the mesh openings of rear door of the rack.

To ensure the quality of air inlet, please carry out installation according to the operation space requirement in 4.4.4, and a

proper space should be reserved for air inlet and outlet. A blower is required to be installed in the machine room so as to

ensure that the heat emitted from the storage inverter can be discharged outside the room.

Attention

At the rear of the rack, heat dissipation and ventilation equipment needs to be installed so as to ensure that the heat emitted

from the storage inverter can be discharged outside the machine room.

4.4.4 Operation space

The installation space of the storage inverter should have a proper distance from its peripheral walls so as to ensure that the

machine door can be opened and closed conveniently and there will be sufficient space for module insertion and extraction,

normal heat dissipation and user’s operation.

B

A

Fig. 4-2 Installation space of storage inverter

Position

Description

A front

≥1,000mm, ensure that the

front door of the rack can be

fully opened. There is

sufficient space for cold air

to enter. Users can

conveniently insert and

extract the module and

operate the breaker.

B rear

≥1,000mm, ensure that the

rear door of the rack can be

fully opened. Ventilation and

heat dissipation should be

ensured. Users can have

sufficient space for

maintenance.

18

4.4.5 Other requirements

1) Waterproofing

The protection grade of the rack of the storage inverter is IP20. It is only installed and used in a dry and clean room. Water

leakage in room should be avoided so as to prevent the storage inverter from being damaged.

2) Rat-proofing

After wiring, fireproofing mud should be used to seal inlet and outlet holes so as to meet the rat-proofing requirement.

Fireproofing mud is not provided by Sinexcel.

4.5 Rack installation

After the rack is removed to the installation position of energy storing deice with a forklift or a tool. Fine adjust the rack and

remove it to the designed position, open the internal door of rack, use M13 screw to fix the rack.

Fig. 4-3. Diagram for rack base (Upper: 50k~150k; Below: 250k)

57,3

22,8

640

685,5

38,3

22,8

544

579,5

22,8 22,8

579,5

22,8

12-24

12-14

Front of rack

Front of rack

19

When the rack needs to be fixed on the steel channel, Φ14 holes can be made in the steel channel. Fix the rack to the steel

channel with screws.

Fig. 4-4 Fix the rack to the steel channel

Fig. 4-5 Fix the rack to the concrete floor

When the rack is fixed to the concrete floor, make holes on the floor and fix the rack to the concrete floor with expansion

screws.

4.6 Electrical connection

4.6.1 Input requirement

DC voltage of the storage inverter should be within the input scope, or the storage inverter will be unable to operate. When

configuring serial quantity of batteries, the maximum charging voltage and minimum discharging voltage should be fully

considered. For details, please consult our technical personnel.

The battery pack working with the PCS should be certified by CSA E61233 or UL1973. And the charging/discharging voltage

should be between 520Vdc and 850Vdc. It should also be equipped with DC air switch and the BMS certified by CSA No. 0.8

or UL991+UL1998. While installation of external battery pack, please make sure switches in fig4-6/fig4-7 in 4.6.3 are

disconnected.

Attention

Every DC input circuit branch in Bi-directional Hybrid Storage Inverter should be able to operate independently. It does not

support common battery pack. The batteries need to be connected to each branch port.

Cable

groove

Fixed screw

Channel

steel

cable

groove

Ground

Foot screw

20

4.6.2 Output reqirement

The output of the storage inverter is 3-phase and 4-wire. When designing energy storage system, the storage inverter has

been equipped with an isolation transformer, the voltage of its output side can directly be connected to the low-voltage utility

grid.

4.6.3 Wiring mode

The storage inverter adopts the wiring mode of lower inlet and outlet. The cables fall into the cable trough via the wire holes

at the base. Open the front door and dismantle the internal door to display wiring the cooper bars. As for wiring requirements,

single cables or multiple cables with proper wire diameter should be selected (image update). It is suggested that the current

in 1mm

2

wire should be ≤3A.

The installation instructions shall indicate that the wiring methods in accordance with the National Electrical Code, ANSI/NFPA

70 are to be used.

1

2

3

4

6

5

7

Position

Description

1

DC+

2

DC-

3

PE

4

A/L1

5

B/L2

6

C/L3

7

N

Fig. 4-9 PWS1-50K-NA rack wiring copper bars

1

2

3

4

6

5

7

Position

Description

1

DC+

2

DC-

3

PE 4 A/L1

5

B/L2

6

C/L3

7

N

Fig. 4-10 PWS1-100K-NA rack wiring copper bars

21

1

2

3

4

6

5

7

Position

Description

1

DC+

2

DC-

3

PE 4 A/L1

5

B/L2

6

C/L3

7

N

Fig. 4-11 PWS1-150K-NA rack wiring copper bars

1

2

3

4

5

6

7

Position

Description

1

DC+

2

DC- 3 PE

4

A/L1

5

B/L2

6

C/L3

7

N

Fig. 4-12 PWS1-250K-NA rack wiring copper bars

4.6.4 System grounding

The modules in the storage inverter realize grounding connection with the rack through hangers.

As for rack grounding, the rack bottom is installed with grounded cooper bars. During wiring, refer to the following table for

cable diameter. The grounding resistance should be less than 4Ω.

22

Notice that the ac output neutral is not bonded to ground.

Warning

Rack and modules need to be grounded reliably!

4.6.5 DC port wiring

1) Use a multi-meter to measure the voltage of storage battery port, and ensure that the voltage is within input voltage range

of storage inverter.

2) Disconnect DC switch at previous level. Wiring operation can be conducted after using a multi-meter to measure and confirm

that there is no voltage between positive and negative poles of DC input.

3) Connect the positive pole of storage battery to “DC+” of DC input of Q1 switch.

4) Connect the negative pole of storage battery to “DC-” of DC input of Q1 switch.

5) Confirm wiring firmness.

Danger

Disconnect DC distribution switch and ensure that there is no dangerous voltage in the system during wiring.

Attention

The positive and negative poles of batteries cannot be connected inversely. Before wiring, a multi-meter needs to be used

for measurement.

4.6.6 AC port wiring

1) Use a phase-sequence meter for measurement, and ensure that the phase consequence of wires should be a positive

Rated power

Copper PE line section recommendation

(mm²)

50kW

≥16

100kW

≥25

150kW

≥35

250kW

≥45

23

consequence.

2) Disconnect AC output distribution switch Q2 at back level in storage inverter.

3) Use a multi-meter to measure and ensure that the cables connected to the terminals are electrically neutral.

4) During on-grid, A(L1)/B(L2)/C(L3) phases of AC output distribution switch Q2 of utility grid and PE are respectively

connected to A(L1)/B(L2)/C(L3) phases of utility grid and PE.

If grid-tie/off-grid switching is to be achieved, extra power distribution unit and wires need to be added.

5) Confirm wiring firmness.

Warning

Ensure that there is no dangerous voltage at connection points during wiring.

Attention

All wires are connected to the wiring terminals externally from the wiring holes at the bottom of storage inverter. After wiring,

fireproofing mud should be used to seal the wiring holes.

4.6.7 Wiring of terminal strips

Except power cable connection in the whole storage inverter, there are also auxiliary power connection, input and output of

some node signals. All of them are led to the terminal strips with cluster cables in the rack. The port definition of external wiring

for terminal strips is shown in Fig.4-13.

BMS Fault Signal

On/Off grid Switch Node 1

On/Off grid Switch Node 2

From external BMS

To external RS485

From external AUX Power

Fig. 4-6 Definition of terminal strip ports

24

4.7 Check after installation

After installation of storage inverter, inspection is conducted after the installation:

1) The device should be placed and installed reasonably, meeting safe distance requirements.

2) Wiring should be correct at one time. Lower leading wire and ground screen are in good connection. The constructor is

required to inspect the grounding resistance.

3) Compare ex-factory main wiring diagram and site wiring. Check whether there is any difference and judge whether such

difference will affect the safe operation of energy storage system.

25

Chapter V Commissioning and Operation

5.1 Status

After external wiring of the storage inverter is completed, and wiring is fully checked, close the breaker in AC port. The storage

inverter can be switched in different modes under the conditions in Fig.5-1.

Ongrid

Alarm

Power

-off

Offgrid

Stand

-by

Power

-on

Sending power-on

command

V

EOD<Vbat<Vchg

V

bat

<

V

EOD

Failure

Failure cleanup

Sending power-on command

Setting on-grid

charging/discharging

Sending power-off

command

Sending power

-

off

command

Sending power

-

off

command

Failure

Failure cleanup

Off

-

grid to on-grid

On

-

grid to on

-

grid

Fig. 5-1 Status diagram for storage inverter

Refer to the following table for status of storage inverter.

Table 5-1 Status of storage inverter

Status

Conditions

State indication

Standby

DC switch is closed, AC switch is closed, and the

device has no fault.

RUN green light flickers quickly, and the

module green light flickers quickly.

On-grid

The device does not alarm, on-grid mode is set, and

the device receives startup command.

RUN green light is always on, and the module

green light is always on.

Off-grid

The device does not alarm, off-grid mode is set, and

the device receives startup command.

RUN green light is always on, and the module

green light is always on.

Alarm

Any fault information

Red light is always on, the module red light is

always on or flickers, and the buzzer makes an

alarm.

Shutdown

The device receives shutdown command.

RUN green light flickers slowly, and the

module green light flickers slowly.

26

5.1.1 Automatic startup

In automatic startup, the storage inverter system will automatically inspect and judge startup conditions. If the system function

is normal and it meets the system setting conditions, it will start automatically. If the voltage of utility grid is too low or high, the

frequency is abnormal, DC voltage is too low or high, the storage inverter will make an alarm, shut down automatically and

stop providing power outside.

After meeting the following conditions, the storage inverter will restart automatically, and the output is recovered.

DC voltage is normal.

The voltage of utility grid is normal in on-grid mode, or there is no voltage of utility grid in off-grid mode.

Operation mode setting is correct.

There is no other alarm fault.

If automatic startup is not set in storage inverter, users can start the device by hands through touch panel.

5.2 Startup and shutdown

The storage inverter must be installed completely and commissioned by engineers. External power switches have been closed,

and then startup steps can be conducted.

5.2.1 Check before startup

Before startup, check the device according to the following steps:

1) Inspect and ensure that no damage sign is in external part of the module, and DC breaker Q1 and AC breaker Q2 are at

“OFF” position.

2) Complete installation according to Chapter IV, and check whether DC input wiring and AC output wiring in the storage

inverter are normal, and the grounding is good.

3) Check whether battery voltage is normal.

4) Check whether phase voltage and wire voltage in utility grid side are in the normal range, and record the voltage.

5.2.2 Startup steps

These startup steps are applicable to the circumstance that the storage inverter system is in outage state and can be started.

Operation steps are as follows:

1) Close output switch of battery rack and connect power supply to DC port of the device.

2) Close DC breaker Q1. Green indicator light flickers in green. After about 10s, the red indicator light is always on in red. At

this moment, THE HMI will indicate the warning information such as “under-voltage of grid” and “abnormal grid frequency”. If

step 2 and step 3 are conducted before the red light is always on, the flickering in red will not appear.

3) Set monitoring parameter to control operation mode. See setting information in 6.2.

4) After step 3 is conducted, return to “main wiring diagram” on THE HMI and start DC/AC modules.

5) According to the current operation mode setting and DC input, the host will automatically operate and display.

27

5.2.3 Shutdown steps

During normal operation of storage inverter, the following steps can be conducted if shutdown is required.

1) On THE HMI, return to “main wiring diagram”, and click AC/DC module to “shut down”.

2) Normally, main monitoring indicator light flickers in green for about 30s.

3) Disconnect DC breaker Q1.

4) Disconnect AC breaker Q2.

As for above operation process, it has been shut down after step 2 is conducted. The power components stop operating in

system, and BUS bar and auxiliary power supply in system still exist for a long time. Therefore, relevant control system is still

in standby state. In this state, device setting and maintenance are not allowed. After step 4 is conducted, the storage inverter

is in a shutdown state, and the internal connector bars are electrically neutral in system. After the internal capacitance in

modules fully discharges, relevant maintenance and setting can be conducted.

5.2.4 Emergency shutdown

When the storage inverter system is abnormal, press the emergency shutdown button “EPO” on the rack door and then conduct

steps 3~5 in 5.2.3.

Warning

To prevent personal injury, please use a multi-meter to measure the voltage at input terminal if case maintenance or

opening is conducted. After ensuring that there is no mains supply, relevant operation can be conducted!

After about 15 minutes, the upper cover plate can be opened after DC BUS bar capacitance fully discharges (refer to

warning label on module case surface).

28

Chapter VI Operation Control Display Panel

6.1 Operation instructions

Operation control can be conducted via HMI (human-computer interface). This section introduces the HMI display content and

settable parameters.

6.1.1 Main monitoring startup

After auxiliary power of the storage inverter is connected, THE HMI is on. At this moment, an initializing interface will appear.

It shows that the system is booting. After system booting, the interface will disappear.

The system is booting,please wait……

Fig. 6-1 Initializing

6.2 Home

After initializing, the home page is shown. On the main wiring diagram, system AC/DC voltage and current, general system

status can be seen.

Fig. 6-2 main wiring diagram

29

6.3 Information

Fig. 6-3 System information

In the Info pages, administrators can obtain the overview of the entire system operation parameters.

6.4 Logs

Fig. 6-4 Logs

In logs page, users can review current alarm, past alarm, operation record, status record of the system, and operation curves.

30

6.5 Settings

6.5.1 Local

Fig. 6-5 Local settings

In this page, system time, communication baud rate and IP address, etc. can be set.

6.5.2 Model

This page is reserved for other models.

6.5.3 System

Fig. 6-6 System parameter interface

Boot mode: default set “manual”.

Energy Management mode: please set it as “AC”. If “DC” is set according to the actual demand, set “charging and discharging

current” and “charging and discharging power” in DC parameter

DC setting mode: reserved function for special models.

Word1/2: reserved function for diagnosis.

31

6.5.4 AC settings

32

Fig. 6-7 AC settings

33

AC operation mode: to set the operation mode, constant power or constant inactive power.

PF: set to regulate the PF of the entire storage system

Power configuration: Set to regulate the power of the storage system

Q configuration: Set to regulate the inactive power of the storage system

Grid reconnection delay: please keep the default configuration.

Normal ramp rate: please keep the default configuration. This function will apply when set power changes. The default value

is 2 rated power per second, which means within 0.5 seconds the system can runs to full output.

Soft-Start/Reconnection ramp rate: please keep the default configuration. This function will apply when system suspend

happens caused by utility voltage abnormal, and reconnect after utility restore normal. The default value is 2, twice of rated

power per second, which means within 0.5 seconds the system restores to full output.

Off-grid V range: to regulate the off-grid output voltage.

P Change mode: to set the power change pattern, step-to-top, or ramp-rise.

Ground-fault detection: enable or disable ground-fault detection.

Anti-Islanding: enable or disable anti-islanding function. For more information, please refer to UL1741 Supplement A or other

similar rules about Utility-Interactive Distribute Generators .

Off grid start mode: Can be set as step-to-top, or ramp-rise.

Active power regulation: enable or disable active power regulation.

6.5.4.1 FVRT

FVRT: frequency/voltage ride-through, this function can be enabled or disabled, for more information, please refer to UL1741

Supplement A or other similar rules about Utility-Interactive Distribute Generators .

O/UVR* protect voltage: to set the over/under voltage ride though protect voltages.

O/UVR* trip time: to set the over/under voltage ride though trip times.

O/UFR* protect frequency: to set the over/under frequency ride though protect frequencies.

O/UFR* trip time: to set the over/under frequency ride though trip times.

6.5.4.2 Volt/Var

Volt/Var regulation is only available when enabled. In Volt/Var mode, the Q configuration is disabled.

Volt/Var point: to set the Volt/Var switch point.

When the actual voltage between Volt/Var point 1 and 2, the capacitive inactive power will be increased.

When the actual voltage between Volt/Var point 3 and 4, the inductive inactive power will be increased.

For more information, please refer to UL1741 Supplement A or other similar rules about Utility-Interactive Distribute

Generators .

Max inductive reactive regulation: to set the maximum inductive reactive power regulation.

Max capacitive reactive regulation: to set the maximum capacitive reactive power regulation.

6.5.4.3 Volt/Watt

Volt/Watt regulation is only available when activated and operating in discharge mode. When the actual voltage is above the

point, the active power will be regulated with the ramp rate. The ramp rate is defined as multiple of set active power per 1% of

rated voltage that above the Volt/Watt point.

34

Volt/Watt point: to set the Volt/Watt trigger threshold.

Volt/Watt ramp rate: to set the ramp rate when Volt/Watt is triggered.

Volt/Watt delay: to set the output power restore time delay after the utility voltage restores normal.

6.5.4.4 Freq/Watt

Available when activated and operating in discharge mode. When the actual frequency is above the point, the active power

will be regulated with the ramp rate. The ramp rate is defined as multiple of set active power per hertz that above the above

the Freq/Watt point.

Freq/Watt point: to set the Freq/Watt trigger threshold.

Freq/Watt ramp rate: to set the ramp rate when Freq/Watt is triggered

6.5.5 DC settings

Fig. 6-8 DC settings

DC operation mode: please set it as “auto”.

CHG/ DCRG current: Set charging or discharging current within the rated power according to the actual demand. (Available

only after “energy dispatching mode” in “system parameter” is set as “DC dispatching”, and DC operation mode is set as

“constant I mode”.)

CHRG/ DCHRG power: Set charging and discharging power within the rated power page according to the actual demand. (It

is valid only after “energy dispatching mode” in “system parameter” is set as “DC dispatching”, and DC operation mode is set

as “constant P mode”.)

EOD V of Batt: Prioritize the setting according to the manufacturer’s recommendation. Conduct setting according to the

following data in case of manufacturer’s data cannot be obtained:

Set 2V lead battery according to 1.67~1.80V* number of batteries in series;

set 3.2V lithium batteries according to 2.70~2.75V* number of batteries in series.

Float CHRG V: Prioritize the setting according to the manufacturer’s recommendation. Conduct setting according to the

following data when manufacturer’s data cannot be obtained: Set 2V lead batteries according to 2.20~2.27V* number of

batteries in series; set 3.2V lithium batteries according to 3.60~3.70V* number of batteries in series. Keep consistent with the

equalizing voltage of battery.

35

Equal CHRG V: Prioritize the setting according to the manufacturer’s recommendation. Conduct setting according to the

following data when manufacturer’s data cannot be obtained: Set 2V lead battery according to 2.20~2.27V* number of batteries

in series; set 3.2V lithium batteries according to 3.60~3.70V* number of batteries in series.

E/C to F/C I: Prioritize the setting according to the manufacturer’s recommendation. Set 2V lead batteries according to

0.02C~0.05C in case of manufacturer’s data cannot be obtained. Other connection types can be set as 1A.

Max. CHRG I: Set 50K as 100A, set 100K as 200A and set 150K as 300A.

Max. DCHRG I: Set 50K as 100A, set 100K as 200A and set 150K as 300A.

Max. Precharge I: Set 50K as 100A, set 100K as 200A and set 150K as 300A.

DCHRG Inception Voltage: Conduct setting according to EOD voltage when there are no special requirements.

DCHRG End Voltage: Conduct setting according to EOD voltage when there are no special requirements.

Precharge V: Conduct setting according to EOD voltage when there are no special requirements.

Precharge to Quick Charge Voltage: Conduct setting according to EOD voltage when there are no special requirements.

Precharge Time: Conduct setting according to client’s requirement. When the client does not require pre-charge function, set

it as 1min.

Precharge Max. I: Conduct setting according to client’s requirement. When the client does not require pre-charge function,

set it as 10A.

Charge Cutoff Current: keep the default value.

6.5.6 AC Debug

Fig. 6-9 Parameter diagnosis interface

Reserved function for diagnosis.

6.6 On/Off

Enter “On/Off” interface to conduct manual startup and shutdown operation in this interface.

36

Fig. 6-10 On/Off

After parameters are set and startup condition is met, machine startup and shutdown can be operated via “Sys ON” and “Sys

OFF”.

37

6.7 Control mode

Enter “ctrl mode”. It includes “Local manual”, “Local auto”, “Remote control” and “Lock out” functions.

Fig. 6-11 Control mode

Local manual: Set parameters on the monitoring screen to control machine operation.

Local auto: It is used with “local auto”. Under this mode, monitor and maintain the current parameter setting (unchangeable),

and operate according to the period for “local auto”—power configuration.

Remote control: Under this mode, monitor and maintain the current parameter setting. The parameter setting can be changed

by remote control.

Lock out: Under this mode, monitor and maintain the current parameter setting. The parameter setting cannot be changed by

remote control.

In case of no special requirements, please set it as “local manual” mode.

6.8 Tactics

Fig. 6-12 Local strategy

The tactics page are reserved functions for specific users who need self-controls

38

6.9 Log in/out

Fig. 6-13 Login page

Click “login/out” to enter login page, enter login password 123456789 and obtain administrator authority.

39

Chapter VII Communication Mode

7.1 Communication interface

The storage inverter supports Modbus protocol, adopts RS485 and Ethernet communication interface and facilitates users to

conduct background monitoring for the storage inverter and realize remote signaling, remote metering and remote regulating

of storage inverter.

7.1.1 RS-485 port

The front door of the storage inverter is embedded with touch screen Management Unit. User interface can be seen at its back.

In particular , the position number of RS485 communication interface in the monitoring panel is J23. It is led to terminal strip

ports 9 and 10. Users can transfer serial port signal to the one which can be processed by PC via interface converter (such

as RS485 transferred to 232). The storage inverter is commissioned alone via background software. It can read operation and

warning information. Corresponding setting, startup and shutdown operations can be conducted.

Power

Management

Unit

LAN

USB

CAN L

CAN H

CAN GND

485_3B

485_3GND

485_3A

SD

J25

J23

To

external

RS485

RS485/232

Converter

Fig. 7-1PC conducts monitoring via RS485

40

7.1.2 Ethernet port

The monitoring panel integrates Ethernet port with position numbered as RJ25. It supports Modbus TCP/IP protocol and has

its own IP address like a PC. Ethernet connection requires a switch, and fixed IP needs to be set. Connecting cables are

twisted pair (namely network cable). The internet ports of multiple The storage inverter are connected to the switch, and the

switch is connected to remote control computer. The state of the storage inverter can be monitored and controlled in real time

by setting IP address and port number in the monitoring computer.

Fig. 7-2 Ethernet communication scheme for single storage inverter

Fig. 7-3 Ethernet communication scheme for multiple storage inverters

7.1.3 Communication with BMS

The inverter communicates with battery management unit (BMS) to monitor battery state information, give an alarm and

provide fault protection for battery according to the battery state and improve the safety of storage battery. It supports CAN

communication. In particular, the position number of CAN communication interface in the monitoring panel is J23. It is led to

terminal strip ports 7 and 8.

41

Power

Management

Unit

LAN

USB

CAN L

CAN H

CAN GND

485_3B

485_3GND

485_3A

SD

J25

J23

From

external

BMS

CAN

BMS

Fig. 7-4 Energy storage inverter and BMS communication

7.2 Monitoring system structure

Background monitoring system can operate and control the storage inverter via computer network. This has provided great

convenience for learning about the operation of energy storing station. The overall structure diagram for monitoring system is

shown in Fig.7-5.

IE access

LAN

RS485

LAN

RS485

Fig. 7-5 Structure diagram for background monitoring system

42

Chapter VIII Maintenance and Preservation 43

Chapter VIII Maintenane and Preservation

8.1 Operation environment requirements

Device operation environment must comply with the operation environment required for the device:

Allowable environment temperature: -20~55℃ (power de-rating for 45 ℃above)

Allowable relative humidity: 0~95% (non-condensing)

Allowable maximum elevation: 3,000m

Note: When exceeding the maximum elevation, the storage inverter will have de-rating output. Please consult customer service

center for specific de-rating coefficient.

8.2 Electrical and fixed connection inspection

After being put into operation, conduct regular inspection on device’s electrical and fixed part connection. Such inspection is

advisably conducted every three months. Record for each inspection should be made.

Rack grounding connection;

Module grounding connection;

Electrical connection for DC input;

Electrical connection for AC input;

Electrical connection for auxiliary power supply;

Electrical connection for communication cables.

AC/DC switch, SPD and fan.

Access monitored fault information.

8.3 Clearing and cleaning

Before the device is put into operation, the dust and sundries in its cooper bars, terminals and mesh openings should be

cleaned.

After the device is put into operation, the dust in machine room should be cleaned regularly. Check whether the ventilating

and air exhaust facilities in machine room are normal. They are advisably cleaned once every three months.

Appendixes

Appendix 1: Fault information of storage inverter

Table 9-1 presents the visible fault types of storage inverter. From this table, users can simply and quickly identify the system faults

from the fault types displayed on touch screen. In multiple module parallel system, the warning information interface will indicate

the number of fault slaves and fault type.

Table 9-1 Fault information

Fault type

Description

Overvoltage of utility grid

The voltage of utility grid is higher than the set upper limit. After faults are recovered,

restart the storage inverter.

Overvoltage of utility grid

The voltage of utility grid is lower than the set lower limit. After faults are recovered,

restart the storage inverter.

Inverted sequence of utility grid

The phase sequence of AC utility grid is inverse.

Abnormality of utility grid frequency

Utility grid frequency exceeds the set scope. After faults are recovered, restart the

storage inverter.

Islanding of storage inverter

There is islanding in storage inverter.

Overvoltage of DC input

Overvoltage of DC input is higher than the upper limit. After faults are recovered,

restart the storage inverter.

Low DC voltage

Overvoltage of DC input is lower than the lower limit. After faults are recovered, restart

the storage inverter.

Abnormality of BUS bar voltage

DC BUS bar voltage is too high or low, which results in system shutdown. After faults

are recovered, restart the storage inverter.

Abnormality of balanced circuit

BUS bar voltage is imbalanced (internal fault information)

Soft start fault

Soft start fault (internal fault information)

Emergency shutdown

EPO action, emergency shutdown

Over-temperature of inverter

The temperature of inverter radiator is too high.

Fan fault

At least one cooling fan has faults.

Monitoring parameter setting fault

Monitoring parameter setting is incorrect. Please modify the setting.

Appendix 2: Quality assurance and after-sales service

1) Quality assurance

If there are fault products during warranty period (refer to the warranty card), users should provide relevant certificates for purchased

products. Shenzhen Sinexcel Electric Co., Ltd. (“Sinexcel”) will provide free maintenance or replace it with a new product.

2) Disposal of claim products

The replaced nonconforming products will be disposed by Sinexcel. Users should properly store the claim products. As for the

products requiring repair, users should give reasonable and sufficient time. We apologize for any inconvenience caused to you.

3) In case of any of the following circumstances, Sinexcel will not offer any quality assurance:

Transport damage;

The device is operated under the environment conditions beyond this user’s manual or in severe condition.

The device is incorrectly installed, refitted or used.

Users dismantle or assemble the device or system parts at will.

It is beyond the warranty period.

Product damage is caused by emergencies or natural disasters.

If customers require maintenance for the product faults above, our company will offer paid maintenance services after being judged

by customer service department.

Installation Records

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

..............................................................................................................................................................................................................

............................................................................................................................................

Loading...

Loading...