sinercom LION100K, LION120K User Manual

LION SERIES

DSP Controlled UPS

100-120 kVA

3 Phase In - 3 Phase Out

Sinercom srl

Headquarter: Via G. Cappalonga 9/A- 00043 Ciampino (Rm) (Italy)

tel. +39.06.79800323 fax +39.06.79814644

Factory: Via Cascina Secchi 247/4b - 24040 Isso (BG)

tel. +39.0363.938231 fax +39.0363.998235

USER MANUAL

CONTENTS

I. GENERAL DESCRIPTION ...................................................................................... 3

1.1 Introduction ....................................................................................................... 3

1.2 Design Concept ................................................................................................ 5

1.2.1 Description of Blocks ............................................................................... 6

1.2.2 Operating Conditions of UPS………………………………………………...6

1.3 Front view of UPS Conditions of ups ................................................................. 7

1.4 Technical Specifications .................................................................................... 8

II. UPS INSTALLATION .............................................................................................. 9

2.1. Introduction ....................................................................................................... 9

2.2. Unpacking ......................................................................................................... 9

2.3. Equipment Positioning ...................................................................................... 9

2.4. Connecting the UPS Power Cables ................................................................... 10

2.5. Safety Earth ...................................................................................................... 10

2.6. Cable Connection Procedure ............................................................................ 10

2.6.1. Description of Connection Terminals of the UPS ....................................... 11

2.7. Battery Installation ............................................................................................ 12

III. FRONT PANEL ....................................................................................................... 14

3.1. Introduction ....................................................................................................... 14

3.2. Front Panel Menu Descriptions ......................................................................... 14

3.2.1 MEASUREMENTS menu ........................................................................... 17

3.2.2 ALARM LOGS menu .................................................................................. 20

3.2.3 INFORMATION menu ................................................................................ 20

3.2.4 OPTIONS menu ......................................................................................... 21

3.2.5 COMMAND menu ...................................................................................... 24

3.2.6 TIME menu................................................................................................. 24

3.2.7 SERVICE menu ......................................................................................... 25

3.2.8 ADJUST menu ........................................................................................... 25

3.2.9 User Pasword ............................................................................................. 26

3.3. Alarms and warning messages ......................................................................... 26

3.4. Alarm messages and quick troubleshooting ...................................................... 29

1

IV. OPERATING INSTRUCTIONS ................................................................................ 34

4.1 Introduction .......................................................................................................... 34

4.2 Operating ups in online mode .............................................................................. 34

4.2.1 Starting ups from a completely shut down position ..................................... 34

4.2.2 Shutting down the ups ................................................................................ 34

4.2.3 Switching the UPS from a normal

operation to maintenance bypass condition .............................................. 35

4.2.4 Switching the UPS from a maintenance

bypass condition to normal operation ....................................................... 35

4.3 UPS Behavior During mains outage .................................................................. 35

V. MAINTENANCE ....................................................................................................... 36

5.1 Scheduled maintenance .................................................................................... 36

5.2 Daily checks ..................................................................................................... 36

5.3 Weekly checks .................................................................................................. 36

5.4 Annual Maintenance .......................................................................................... 37

5.5 Storage conditions and transportation of ups ..................................................... 37

VI. FAULTS AND TROUBLESHOOTING .................................................................... 38

6.1. General Procedure for fault checking and troubleshooting ................................ 38

6.2. Before calling service ........................................................................................ 38

VII. UPS REMOTE MANITORING AND CONTROL .................................................... 39

7.1. Using Serial Port ............................................................................................... 39

7.2. Serial Communication port connection cable ..................................................... 39

7.3. Modem connection ............................................................................................ 40

7.3.1 Hardware configuration ............................................................................... 40

7.3.2 Functioning Principle .................................................................................. 40

7.3.3 Modem Programming Procedure ................................................................ 40

7.3.3.1 Smart modem (SM) programming ................................................... 40

7.3.4 Modem – UPS Connection Cable ............................................................... 41

7.4. Dry contact (ınterface) connections ................................................................... 41

7.5. Remote monitoring panel connection of UPS .................................................... 41

VIII. EFFICIENT USAGE OF UPS IN TERMS OF ENERGY CONSUMPTION ............. 42

2

SAFETY

IMPORTANT NOTICES

1. Read instructions carefully before installing and starting the UPS.

2. All warnings in the manual should be adhered to.

3. All operating instructions should be followed.

4. The unit should be supplied by a grounded outlet. Do not operate the unit without a ground source.

5. Power cables of the UPS should be routed carefully so that they are not to be walked on.

6. Please save this manual.

7. Please save or recycle the packaging materials.

WARNING!

Do not insert any object into ventilation holes or other openings.

To reduce the risk of fire or electric shock, install in temperature and humidity controlled

indoor area free of conductive contaminants.

To reduce the risk of fire, replace fuses with the same type and rating when necessary.

CAUTION!

Only qualified personnel should install or service UPS/batteries.

Risk of electric shock, do not remove cover. No user serviceable parts inside, refer

servicing to qualified service personnel.

The output may be energized even when the unit is not connected to a mains supply.

Risk of electric shock! Hazardous live parts inside. This unit is energized from the

battery supply even when the input AC power is disconnected.

To reduce the risk of electric shock, disconnect the UPS from the mains supply before installing

a computer interface signal cable. Reconnect the power cables only after signaling interconnections have

been made.

CAUTION !

Units are designed to operate on the concrete floor.

ABOUT THE BATTERIES

CAUTION: RISK OF ELECTRIC SHOCK!

The battery circuit is not isolated from the mains voltage. Hazardous voltages may

occur between the battery terminals and the ground!

A battery can present a risk of electric shock or burn from high short circuit currents. The

following precautions should be taken when working on batteries :

* Remove watches, rings or other metal objects.

* Use tools with insulated handles.

The batteries in this UPS are recyclable. Batteries must be disposed of according to local

environmental laws. The batteries contain lead and pose a hazard to the environment and human health

if not disposed of properly.

Do not dispose of batteries in a fire. The batteries may explode. Do not open or mutilate the

batteries. They contain an electrolyte which is toxic and harmful to the skin and eyes. If electrolyte

comes into contact with the skin the affected area should be washed immediately.

The internal energy source (the battery) cannot be de-energized by the user.

When changing batteries, install the same number and same type of batteries.

3

I. GENERAL DESCRIPTION

1.1 Introduction

SINERCOM LION Series Uninterruptible Power Supplies are double-conversion; on-line

UPS’s manufactured with the latest IGBT and PWM technology, to produce an uninterruptible,

fully DSP (Digital Signal Processor) controlled pure sine wave output to critical loads.

SINERCOM LION Series units are 3-phase in/3-phase out devices, and they are installed

between a three phase critical load, and a 3-phase+N mains supply

The advantages of using LION UPS:

Power blackout protection:

If the mains power fails, the UPS continues to supply the critical load using the energy

stored in its batteries, keeping the load immune from power disturbances.

Increased power quality:

The UPS has its own internal voltage and frequency regulating software, which

ensures that, its output to the critical load is maintained within close tolerances, independent of

voltage and frequency variations on the mains power lines.

Fully digital control by three DSP controller for each UPS:

The UPS is controlled by 3 independent DSP chips which are communicating each

other continuously. Rectifier, Inverter and User Interface modules have separate DSP’s to

achieve the highest performance. Each DSP module has many parameters to control and

monitor the system to have the best electrical power output and to help diagnostic.

Increased noise rejection:

By rectifying the input AC power to DC power and then converting it back to AC

(Double-Conversion) any electrical noise present on the input mains supply line is effectively

isolated from the UPS output. Therefore the critical load is supplied with only clean and

uninterrupted AC power.

4

Basic Features:

PWM and IGBT technology

Pure sinusoidal output wave form and true on-line topology

High input power factor (IGBT rectifier), Input current limiting

Low input current THD (IGBT rectifier)

Low output voltage THD

High AC/AC and DC/AC efficiency (up to 94%)

3 separate DSP (Digital Signal Processor) control

Cold-start feature

Static By-Pass feature: Provides uninterruptable transfer to bypass source in case of overload

Bypass leakage current sense system

Maintenance bypass switch and warning system, by-pass short circuit protection

Separate bypass input facility (split bypass), generator operation sense input

LCD alphanumeric display panel providing battery, load, voltage, power and status information

Improved diagnostics and correct fault infor mation

Up to 192 event memory record system (7000 alarms or warnings total)

Real time clock and calendar system

Overload operation 10 minutes at 100% - 125% load, 1 minute at 125% - 150% load

Output overload, over-current and short circuit protection, output current limiting

Reliable operation at even 100% unbalanced load condition

Non-linear load supply feature (CF 3:1)

Double polarity battery (with common terminal)

Automatic and manual battery test and battery temperature compensation features

3 separate maintenance clock counters

Battery charge with current limiting

Automatic and manual boost charge feature

Battery deep discharge protection

Temperature protection with 3 separate sensors

Interactive communication

Diagnostic and settings with PC ability

2 separate RS232 communication ports (standard)

Multi UPS monitoring on same communication line by RS485 (optional)

4 dry contact alarm relay outputs as standard (8 optional relay outputs)

Improved remote monitoring panel system (optional)

RS232 port multiplexer (optional)

Direct network connection with optional SNMP support

MODBUS Adapter (optional)

AT command set definitions for dump modems

Communication via Windows based T-MON software and remote monitoring and control of UPS

Optional softwares compatible for most computer platforms

Ability for labeling of UPSs by users

Emergency power-off support

Conformity to international and local standards

AC input and output filters

Optional graphic front panel

CE compliance

Input, bypass and load phase order protection

Optional leakage current alarm system

Input and output isolation transformers (optional)

Enhanced accessory options

100.000 hours MTBF

2 years system warranty

10 years spare parts warranty

or UPS fault.

in detail to user

via modem

5

(F10

-

F11-F12)

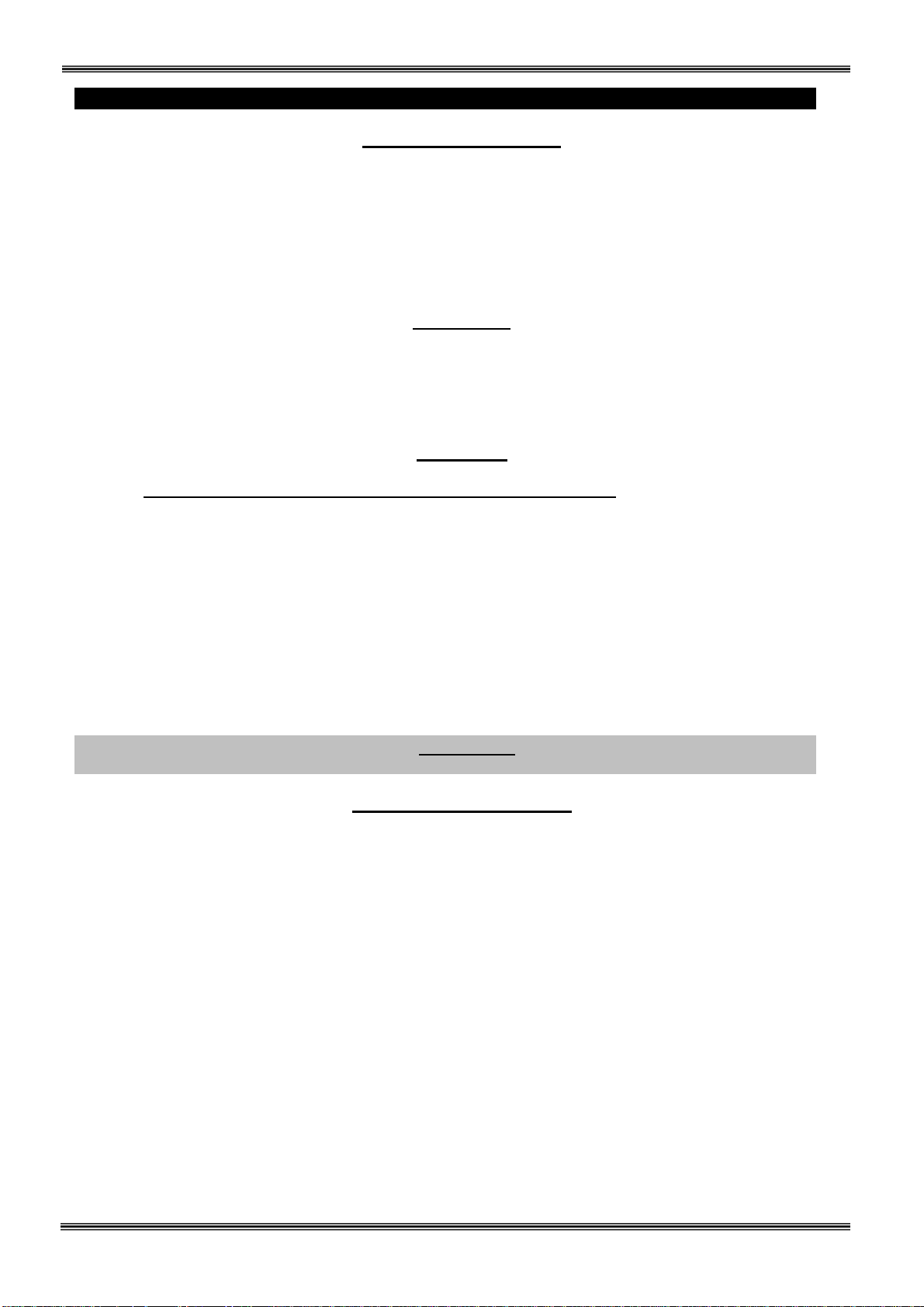

1.2 Design Concept

3 PHASE

MAINS I/P

S1 (F1-F2-F3) : Rectifier Input Switch / Fuse

S2 (F4-F5-F6) : Bypass Input Switch / Fuse

S3 : Maintenance Bypass Switch

S4 (F7-F8-F9) : Output Switch / Fuse

S5 (F10-F11-F12) : Battery Switch / Fuse

K1 : Rectifier Input Contactor

K2 : Inverter Output Contactor

S3

Maintenance

Bypass Switch

S2

(F4-F5-F6)

S1

(F1-F2-F3)

K1

-

Rectifier /

Charger

Battery

(Dual Polarity)

SB

Static

Bypass

-

Inverter

S5

K2

S4

(F7-F8-F9)

3 PHASE

AC Output

6

1.2.1 DESCRIPTION OF BLOCKS

RECTIFIER: In LION Series UPSs, a DSP controlled IGBT rectifier with PWM technique is used to increase

input power factor (PFC) and to decrease input current harmonics (THDI).

The IGBT rectifier accepts 3-phase AC input and produces a dual polarity DC voltage for both supplying the

inverter and charging the batteries.

BATTERIES: Batteries are used as reserve DC power supply for the Inverter in case of mains failure. In LION

Series, batteries are connected in series with a center-tap output to obtain a dual polarity DC supply.

Batteries are discharged by the inverter during mains failure. The discharged batteries are re-charged by the

IGBT Rectifier on a constant voltage / current limiting basis, if AC mains power is available.

INVERTER: It is manufactured by using the latest IGBT and DSP (Digital Signal Processing) technologies,

and Pulse Width Modulation (PWM) technique. The Inverter converts the DC BUS voltage supplied by the

IGBT Rectifier and / or the batteries into a well regulated, fully digital controlled 3-phase AC voltage with fixed

voltage and frequency.

The output of the inverter is used to supply the critical loads connected to the UPS output.

STATIC TRANSFER SWITCH (STATIC BYPASS): This is an electronically controlled transfer switch, which

enables the critical load to be connected either to inverter output or to by-pass power source. During normal

operation, the load is supplied by the inverter output, but in case of an overload or a UPS failure it is

automatically transferred to the bypass source without any interruption.

MAINTENANCE BYPASS SWITCH (MBS): This is a manually controlled mechanical switch, which is used to

supply the critical load, using the bypass source, when the UPS is shut down for maintenance or

troubleshooting purposes.

The load is unprotected against mains supply disturbances and black-outs when it is connected to either static

or maintenance bypass supply.

1.2.2. OPERATING CONDITIONS OF UPS

UPS may be in one of the following operating conditions:

A. Normal Operation (If Mains supply is available):

All fuses and power switches are closed (except the Maintenance Bypass Switch), and the load is supplied by

the Inverter Output. During normal operation, the Rectifier supplies DC power to the Inverter and charges the

Batteries at the same time.

B. Battery Operation :

The Batteries are connected to the Rectifier output. In case of a mains failure (mains power outage or AC

input voltage out of tolerance), the Rectifier stops operating and the DC voltage necessary for the inverter

operation is supplied by the batteries. Therefore the AC voltage output supplying the critical load is not

interrupted, until the batteries are fully discharged. At the end of the discharging time the inverter is turned off

and it start again automatically, together with the rectifier, when the mains power is restored, and the UPS

returns o normal operation. For UPS with a split bypass source, at the end of discharging time, static transfer

switch transfers the load to the split bypass source without interruption if the split bypass source is available

and in acceptable tolerances about voltage and frequency, as still the rectifier input is not available.

The Rectifier is also turned off and inverter operates on batteries during automatic or manual battery test

procedure.

C. By-Pass Operation :

If the Inverter output is overloaded or in case of a problem in the UPS, the static switch transfers the load to

the bypass supply without any interruption, provided that the bypass supply is available and within the

tolerated limits regarding voltage and frequency. At the end of the overloading period, if the fault condition is

restored, static switch transfers the critical load again to the inverter output. Note that, during operation from

the bypass supply, the critical load may be effected by any possible disturbances or power failure in the

bypass supply.

7

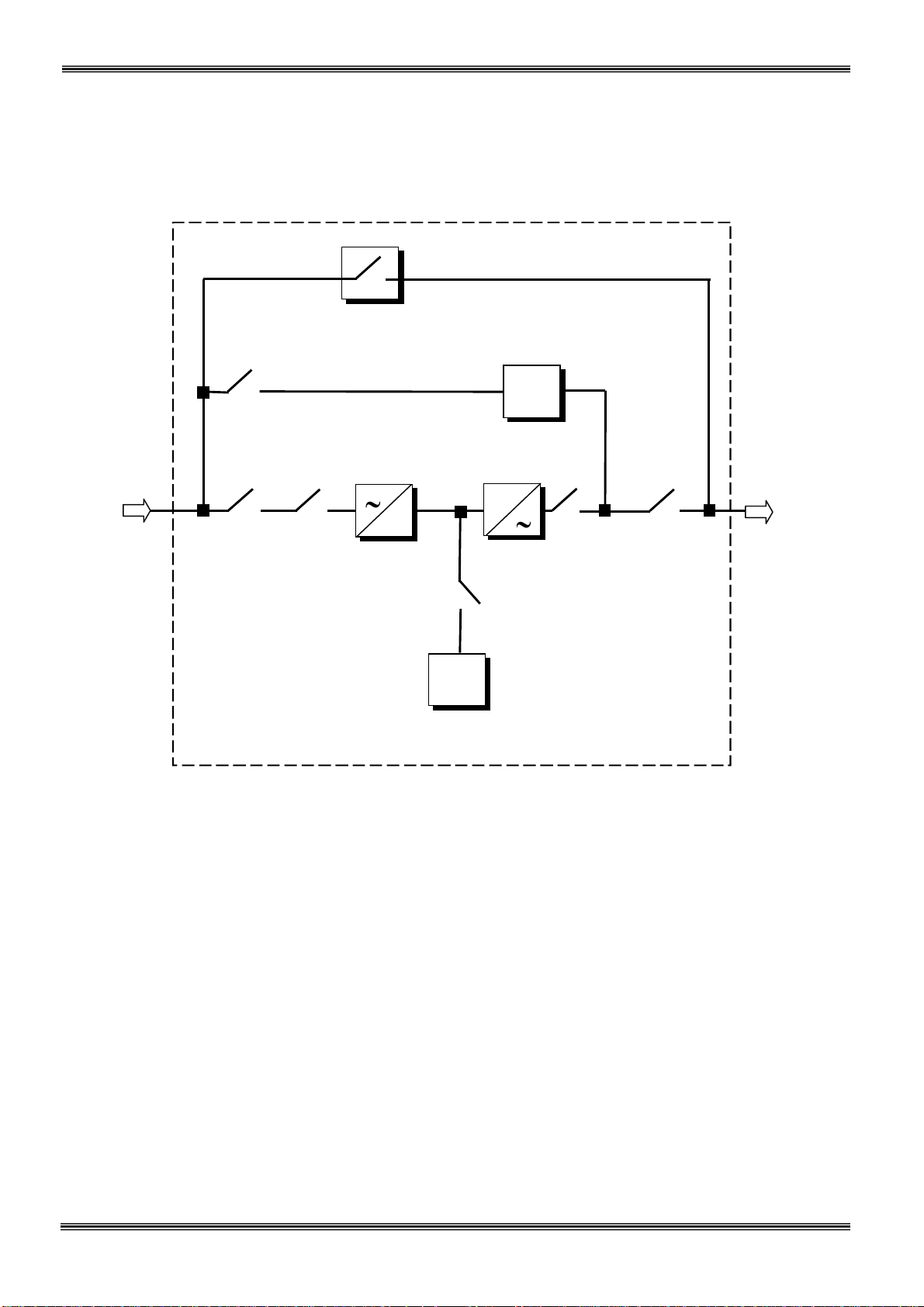

S7

S1

S3

S2

S4

1.3 Front view of UPS Connection Panel

Batt. circuit

breaker

output

and input

(AC output, F7-F8-F9)

(AC input, F1-F2-F3)

(maintenance by-pass’ı)

(By-Pass, F4-F5-F6)

Generator

On/off

switch

Figure 1.3 a 100-120 kVA Switches, Fuses and Interface Connections

input

Emergency

Temperature

sensor

stop

Relay Output contacts

Relay

2

Relay

3

Relay

4

COM1 - RS232

Communation Socket

(DB9 female)

COM2 - RS232

Communation Socket

(DB9 female)

SNMP

(Optional)

8

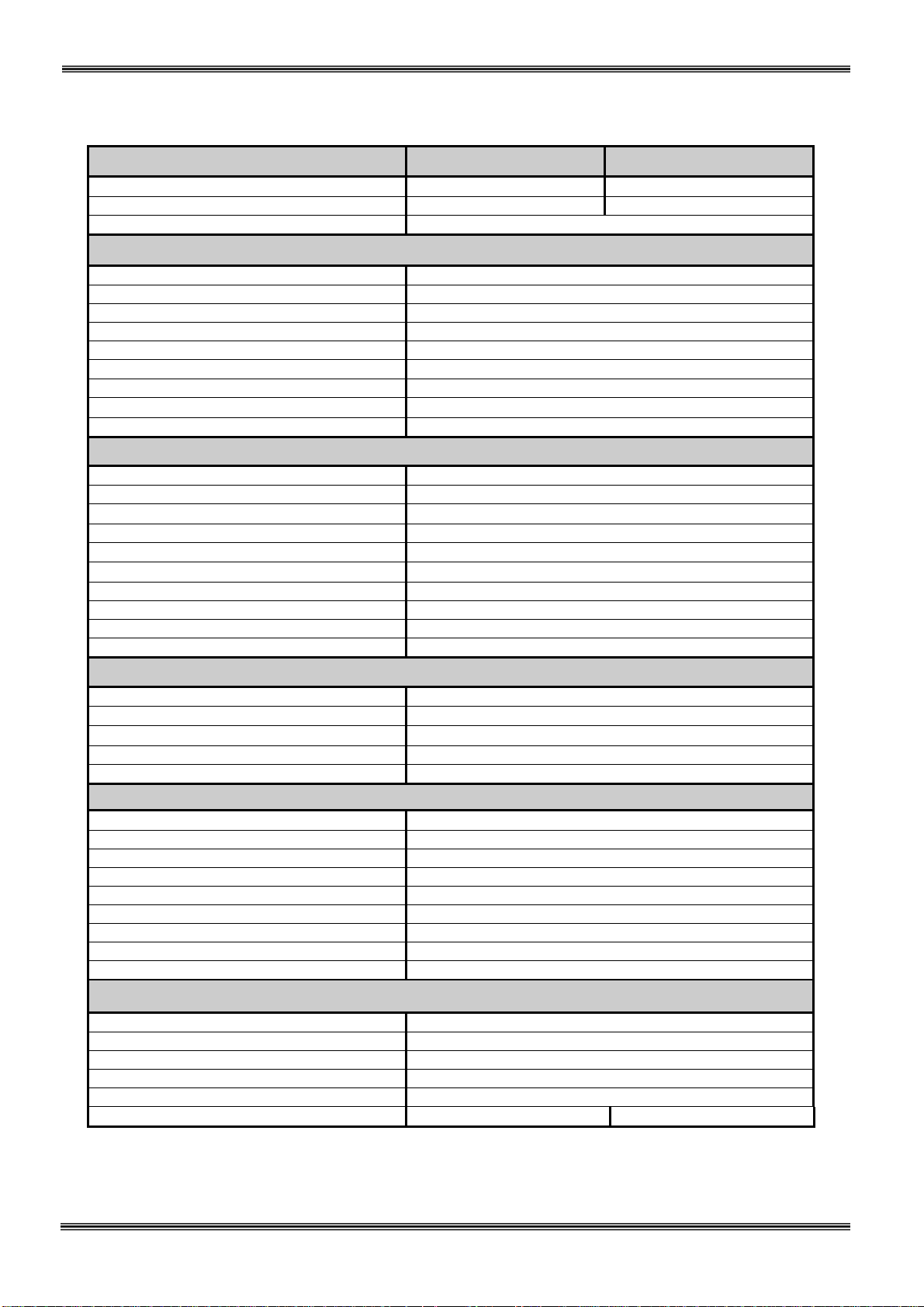

1.4 Technical Specifications

2.

MODEL LION100K LION120K

Output (KVA) 100 kVA 120 kVA

Output (KW) 90 kW 108 kW

Output Power Factor 0,9

INPUT

Number of Phases 3 Phase + Neutral

Input Voltage 220/380, 230/400 or 240/415 Vac

Input Voltage Tolerance +20% , -25% (+15% at 240/415Vac)

Input Power Factor (PF) 0,98 - 0,99 (at full load)

Input THDI <= 5% (at full load)

Input Frequency

By-pass Voltage 220/380, 230/400 or 240/415 Vac 3 Phase + Neutral

By-pass Frequency

RFI Level EN62040-2

OUTPUT

Number of Phases 3 Phase + Neutral

Output Voltage 220/380, 230/400 or 240/415 Vac

Output Voltage Tolerance

Output Frequency 50 Hz.

Output Frequency Tolerance (Synchronous)

Output Frequency Tolerance (Battery)

Efficiency (100% Load) up to 94%

Load Crest Factor 3:1

Output Voltage THD (linear load) <3%

Overload 125% Load 10min. , 150% Load 1min.

BATTERY

Total Number 60 blocks 12V (2x30 serial 60 batteries, external)

Float Charge Voltage (250C)

End of Discharge Voltage

Battery Test Automatic and Manual

Boost Charge Available

COMMUNICATION INTERFACES

RS232 Com Port 2 each standard (COM1 and COM2)

External Temperature Measurement Input Available (standard)

RS485 Comm. Port Optional

Remote Monitoring Panel Optional

SNMP Adapter Optional

Modbus Adapter Optional

Alarm Relay Contacts 4 each dry contacts (function programmable) 8 optional

Digital Inputs 2 each optional

Emergency Power-Off Input Available (standard)

50 Hz. 5%

50 Hz. 2%

1%

2%

0,2%

405V DC

300V DC

ENVIRONMENT

Operating Temperature 0 – 400C

Operating Humidity <= %90 (non-condensing)

Acoustic Noise < 68 dB

Dimensions (WxDxH) (mm) 515 x 855 x 1450

Device Type and Protection Class Class 1 – IP20

Weight (app. kgs) 216 230

3.

9

II. UPS INSTALLATION

2.1 Introduction

WARNING!!!

Do not apply electrical power to the UPS equipment before the arrival of authorized service personnel.

The UPS equipment should be installed only by qualified service personnel.

The connection of the batteries and the maintenance should be done by qualified service personnel.

Do not make any short- circuit to the battery poles. Because of high voltage and high short-circuit current,

there is risk of electrical shock or burn.

Eye protection should be worn to prevent injury from accidental electrical arcs. Remove rings, watches and

all metal objects. Only use tools with insulated handles. Wear rubber gloves.

This chapter contains location installation information of the UPS and the batteries. All the establishments

have their own specialties and needs. So in this part, the installation procedure is not being explained step by

step. Instead, general procedure and the applications are explained for the technical personnel.

2.2 Unpacking

The UPS is packed and enclosed in a structural cardboard carton to protect it from damage.

1) Inspect for damage that may have occurred during the shipment If any damage is noted, call the shipper

immediately and retain the shipping carton and the UPS.

2) Carefully open the carton and take the UPS out.

3) Retain the carton and packing material for future use.

Unit package contents:

1) A user manual and Guarantee certificate.

2) Battery cabinet and/or shelf (Optional)

3) Battery connection cables.

2.3 Equipment Positioning

ATTENTION: Units are designed to operate on the concrete floor.

1. The equipment’s installation place must be an easy serving place.

2. Install the UPS in a protected area with adequate air flow and free of excessive dust.

3. You must therefore allow for a minimum gap of 250 mm behind the unit to allow adequate air flow

4. Select a suitable place (temperature between 0C and 40C) and the relative humidity (%90 max)

5. It is recommended to place the equipment in an air-conditioned the room (24C)

6. Temperature is a major factor in determining the battery life and capacity. Keep batteries away from main

heat sources or main air inlets etc.

7. In case of an operating the UPS in a dusty place, clean the air with a suitable air filtration system.

8. Keep out of your equipment from explosive and flammable items.

9. Avoid direct sunlight, rain, and high humidity.

WARNING!!! Check the capacity of the forklift if it is available for lifting.

DO NOT LEAN OR LIFT THE UPS CABINET AFTER THE BATTERIES HAVE BEEN

INSTALLED.

10

2.4 Connecting the UPS Power Cables

WARNING!!! A separate power line should be used to supply the UPS AC input. Never use the same line to

supply another electrical device. Do not use any additional cable to increase the length of the

UPS’s input cable. It is advised to use an MCCB suitable for the input current on the UPS’s

input line.

The connection of the electrical panel should be supplied by a grounded outlet. Otherwise, the UPS and

the load connected to the output will be left ungrounded. The grounding system must be

checked, and must be strengthen if required. Potential difference between ground and neutral

must be less than 3V AC.

Descriptions of the UPS input output cable connection terminals are shown in figure 2.1

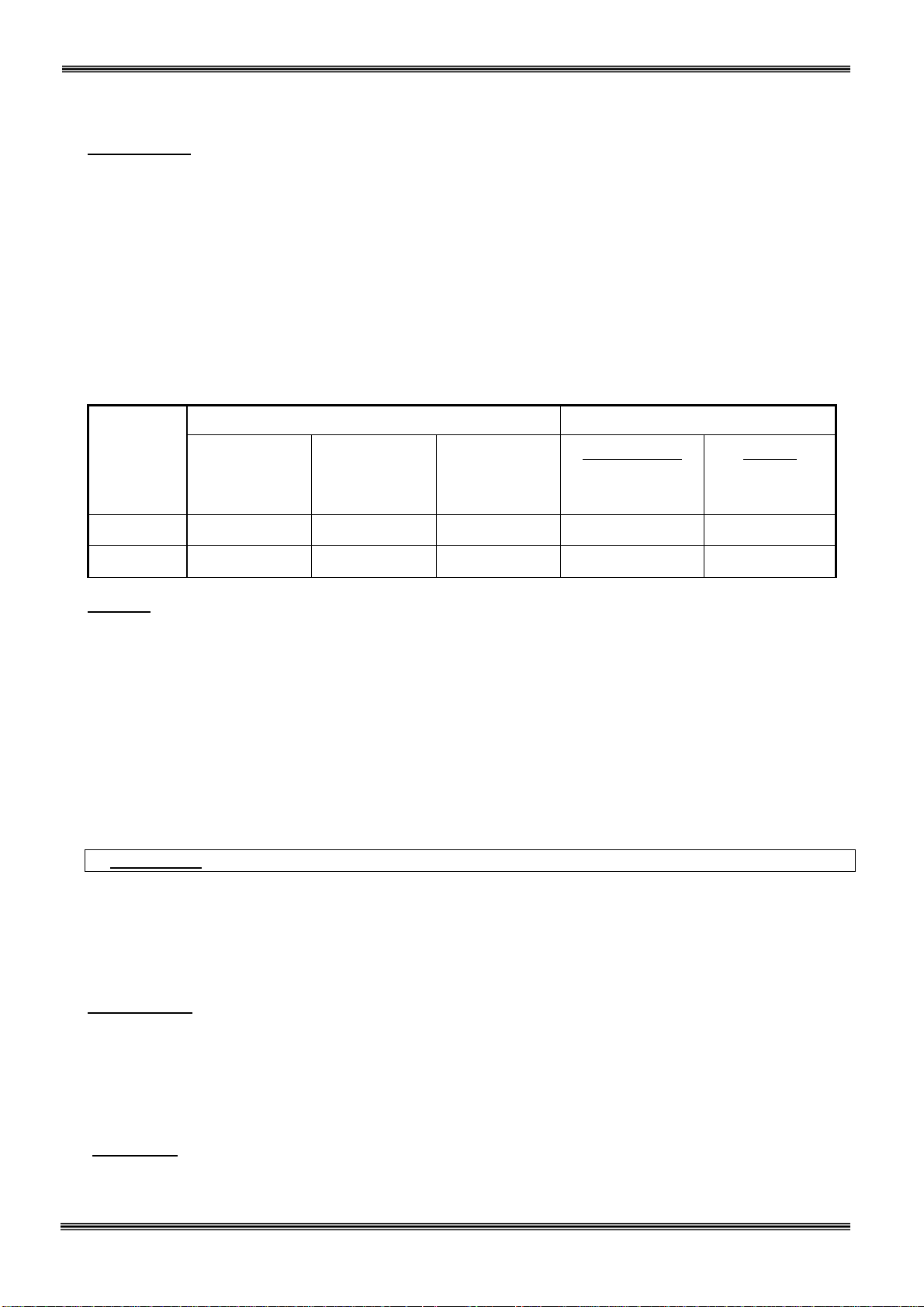

Recommended input line cable and fuse ratings are given in the table below.

UPS power

(kVA)

100 50 35 35

Recommended cable size (mm2)

Line input

Bypass input /

UPS output

External Battery

Input / output

Cable connections

U-V-W-N

M8 bolt M8 bolt

Battery

connections

+ & -

120 50 50 50

M8 bolt M8 bolt

NOTES: The neutral conductor should be sized for 1,5 times the output/bypass phase current. These

recommendations are for guideline purposes only and are superceded by local regulations and

codes of practice.

2.5 Safety Earth

The safety earth cable must be connected to the earth BUS BAR and bonded to each cabinet in the system and

also the earthing and neutral bonding arrangements must be in accordance with the local laws.

ATTENTION!!! Failure to follow adequate earthing procedures can result in electric shock hazard to

personnel, or the risk of fire.

2.6 Cable connection procedure

WARNING!!! All connections of the UPS must be done by qualified service personnel

After positioning the UPS, the cables must be connected as described below:

1. Verify all switches and fuses in front of the UPS are at “0” position. (OFF)

2. Connect the 3 phase AC input coming from the mains distribution panel to the AC input terminals as shown

on the label. (Figure 2.1)

ATTENTION!!!: ENSURE CORRECT PHASE SEQUENCE.

If there is a phase sequence error, UPS doesn’t transfer the load to INVERTER output. If you

can’t see SYNC:OK in the INFORMATION MENU on LCD, then change the input phase sequence.

3. Connect the output of the UPS to the load distribution panel.

4. Connect the battery groups. Refer to battery installation section.

WARNING :

- CHECK BOTH OF THE BATTERY GROUPS FOR CORRECT POLARITY AND VOLTAGE

- DO NOT TURN ON THE BATTERY SWITCH (F5) BEFORE STARTING THE UPS

11

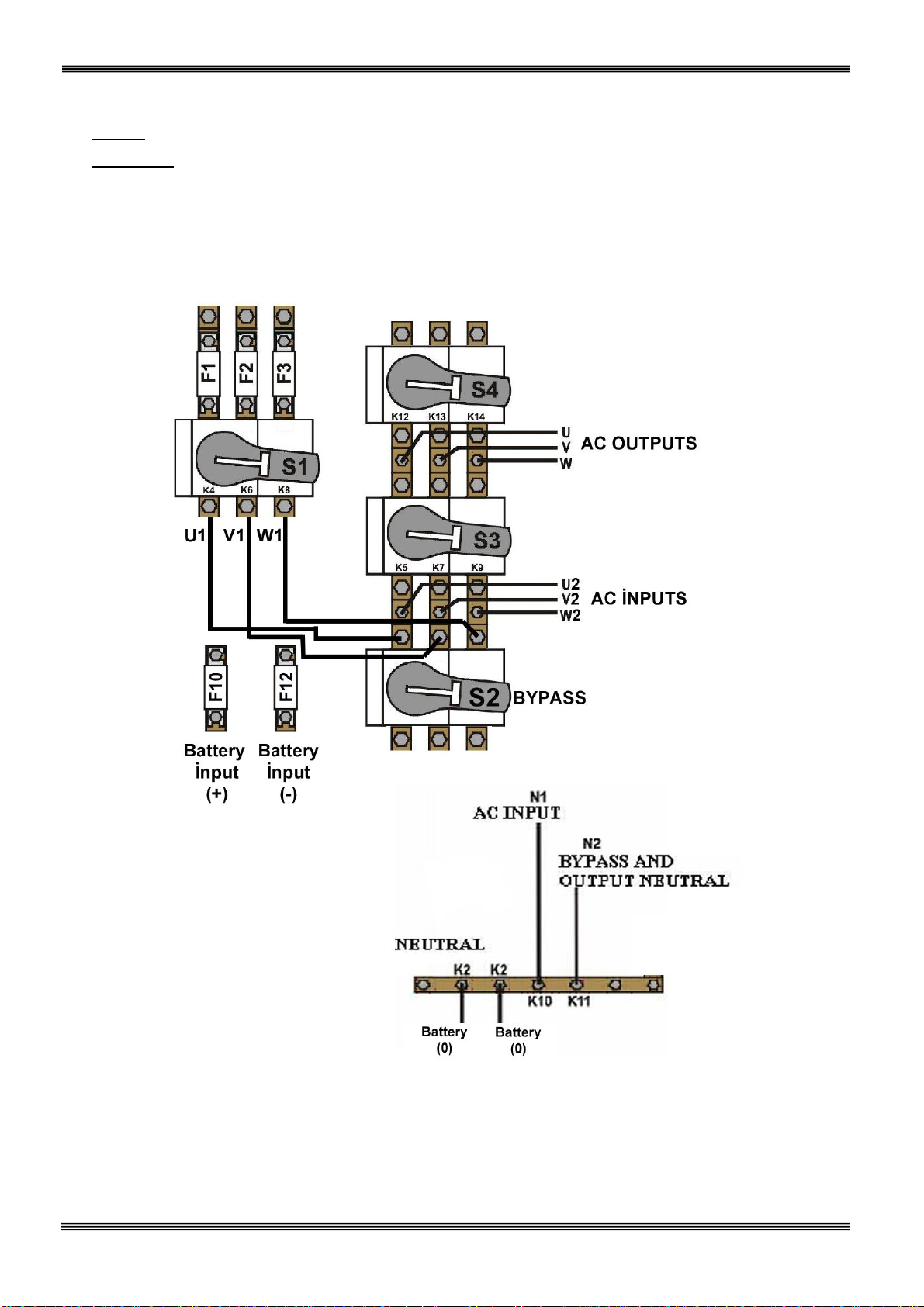

Figure 2

.

2

100-120 kVA

POWER

Cable Connection

5. Connect the copper earth bus, to the safety earth of the mains distribution panel.

NOTE : The earth and the neutral connections must be in accordance with the local rules.

WARNING: Note that the Input Neutral (N1) MUST also be connected to K10 terminal

2.6.1 Description of connection terminals of the UPS :

Loading...

Loading...