Page 1

SERVICE MANUAL

CASSETTE, FLOOR&CEILING, DUCT UNITS

DC INVERTER

SERIES

OUTDOOR UNITS

OUTDOOR AND INDOOR UNITS

Page 2

8. Refrigeration System Principles

Refrigeration Cycle: The low-temperature and low-pressure refrigerant vapour in the evaporator is

compressed into high-temperature and high-pressure gas by the compressor, and then the gas enters

into condenser.The gas becomes high-temperature and high-pressure liquid through heat exchange with

outdoor air, and then the liquid passes through the capillary for cooling and decompression by throttling

and enters into evaporator.After that, the gas-liquid refrigerant in the envopator is completely evaporated

to cool the indoor air.The vapour out of the evaporator is re-compressed by the compressor. So is the

above procedure recycled that the cooled air in the duct is contiuously sent to air-conditioning area with

the help of fan motor.

Heating Cycle: It is

reverse to cooling cycleDŽIn this case, 4-way valve will reverse and flow direction of

refrigerant changes, i.e the vapour out of the compressor enters into heat exchanger for condensation.

The refrigerant after condensation passes through the capillary for throttling.After that it evaporates in

the outdoor heat exchanger, at last it will be sucked and compressed by compressor. So is the above

procedure recycled that the hot air in the duct is contiuously sent to air-conditioning area with the help of

fan motor.

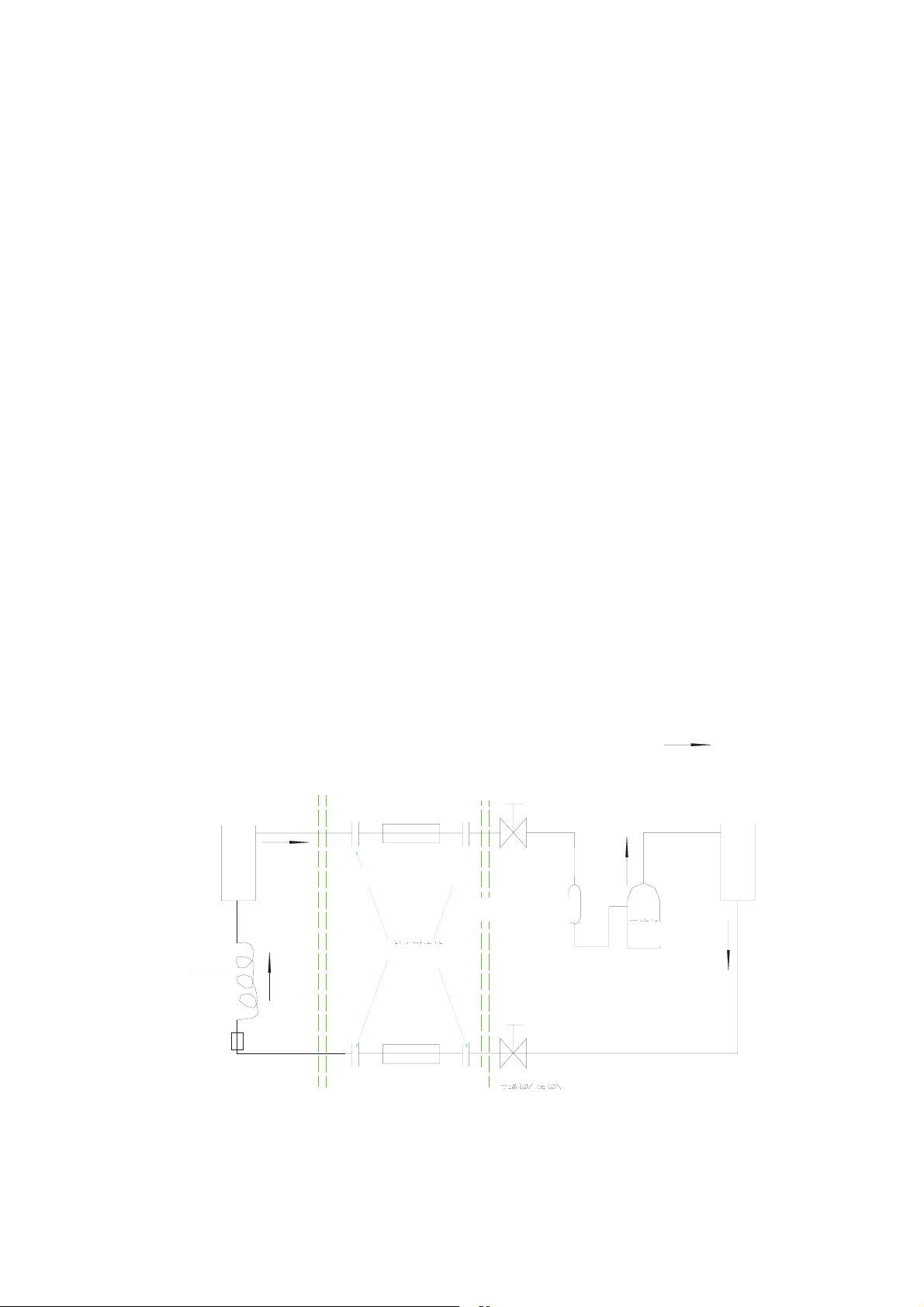

Working Principle of the Unit:

Flow direction during cooling

Flow direction during heating

3-way Valve (gas valve)

Outdoor Unit

Indoor Unit

Connection pipe

(with insulating tube)

Gas-liquid separator

Compressor

Flare joint

Main Capillary

Connection pipe

(with insulating tube)

3-way Valve (liquidvalve)

(a) Working principle of cooling only unit

27

Page 3

(b) Working principle of heat pump unit

Fig. 6-1

Flow direction during cooling

Flow direction during heating

3-way Valve (gas valve)

Indoor Unit 4-way Valve Outdoor Unit

Connection pipe

(with insulating tube)

Gas-liquid separator

Comp-

Flare joint

ressor

Main Capillary

A

uxiliary Capillary

Filter

Connection pipe

One-way Valve

3-way Valve (liquidvalve)

(with insulating tube)

28

Page 4

Chapter II Control Functions

1. Control Mode

The 4-in-1 DC Inverter Unit consists of outdoor mainboard, indoor mainboard and manual

controller, which are lined via communication wires. In this way, one outdoor unit can be used with

different indoor units of the equal capacity (duct type unit, floor ceiling unit, cassette type unit and

ceiling type unit), and the cooling and heating share one electronic expansion valve.

The outdoor compressor is DC inverter compressor, in which the advance

d sine wave control

mode is used, featuring in low vibration, low noise and high efficiency. The single-phase unit also

uses the PFC control, with PFC value up to 0.99 or higher, so the interference to the electric grid

is very low.

The outdoor unit also applies the advanced PI algorithm, able to

automatically and quickly adjust

the working frequency of the compressor according to the change of indoor loads. This can not

only meet the user’s requirements for comfort but also save unnecessary electric energies.

This unit can be controlled via LCD controller easily or controlled fr

om remote controller. It can

also be controlled from centralized controller, or put under remote monitor by PC computer.

Besides, it can also be configured with weekly timer wired controller which can automatically

switch on or off the unit at predefined time for each day in a week. This is suitable to family, office,

factory and man-free places.

2 Introduction Control Functions

2.1 Basic Control Functions

2.1.1 Cooling Mode

After setting to cooling mode, the indoor fan will

run at preset speed after 3 seconds and the

outdoor unit will start to calculate the system load demand. If the load is “0”, the other loads

except the indoor fan and indoor drainage pump will not be put into operation. If the load is over

“0”, the electronic expansion valve will be firstly opened and then the outdoor fan is started. After

30 seconds, the compressor is started.

Under cooling mode the range of temperature setting is 16~30

and the initial value is 26.

2.1.2 DRY Mode

The DRY mode is basically same as the cooling mode. The dif

ference is that: The speed of

indoor fan is fixed at low speed; and The maximum value of capacity output is 90%.

°C

°C °C

29

Page 5

Under DRY mode, the range of temperature setting is 16°C~30°C and the initial value is 24°C.

2.1.3 Heating Mode

After setting to heating mode, the outdoor unit will st

art to calculate the system load demand. If

the load is “0”, all the other loads will not be put into operation. If the load is over “0”, the electronic

expansion valve will be firstly opened and then the outdoor fan is started. After 30 seconds, the

compressor is started, the 4-way valve is energized and the indoor fan runs under anti cold air

mode.

Under DRY mode, the range of temperature setting is 16°C~30°C and the ini

tial value is 20°C.

2.1.4 Fan Mode

When the indoor unit is set to fan mode, all the loads of the out

door unit will be stopped and the

indoor fan will run at preset speed. Under this mode, the fault is detected but will not be treated.

The temperature is not adjustable, displayed at 26°

C.

2.1.5 Auto Mode

Under this mode, the run mode will vary with the ambient temper

ature according to the following

conditions:

When T

amb.

˚26°C, the unit will run under cooling mode and the preset temperature is 26°C;

When 20°CT

amb.

26°C, the unit will run under DRY mode and the preset temperature is 24°C;

When T

amb.

˘20°C, the unit will run under heating mode and the preset temperature is 20°C.

When T

amb.

24°C, the unit will exit the heating mode. For cooling-only unit, when T

amb.

˘20°C,

the unit will run under fan mode and the preset temperature is 20. When T

amb.

24°C, the unit will

exit the fan mode.

Once the mode is activated, the unit will run

30 seconds the shortest before it switch the run

status under auto mode according to the ambient temperature.

2.2 Special Control Functions

2.2.1 Energy-saving Func

tion

Set a upper and lower limit of temperature by using manual controlle

r, so that the temperature of

air conditioner is set to an energy-saving range, thus to save the power consumption of the air

conditioner. For example, the temperature under cooling mode is defaulted 1630°C, but the

user may customize it to 2630°C by using manual controller. In this range, the lowest setting is

26°C other 16°C.

2.2.2 Memory Function

Upon re-energization after power shutdown or failure, the air conditioner can

memorize the last

work mode, temperature setting, fan speed and other parameters, so that it is not necessary to

repeat setting of those parameters. The user may also inactivate this function by using manual

controller.

2.2.3 Timer Function

For easy control of the air conditioner, the user may set the air conditione

r to timer on or timer off

by using the manual controller. The timer is available with two modes for user’s option, i.e.

countdown and 7-day time section.

30

Page 6

2.2.4 Sleep Function

If the user requires air conditioner during sleep, this function may automatically increase or

decrease the preset temperature, so as to meet the users’ needs for comfort and also save the

energy. If used with timer function, the energy saving effect will be better.

2.2.5 Alarm Function

When the air conditioner is abnormal, it can automatically display the faul

t or protection type,

while triggering the sound and lighting alarm.

2.2.6 Week Timer Centralized Control Function

The user may select centralized controller to control 16 units simultaneously for their start/stop,

timer on/of

f each day and key shield. The function is powerful, particularly suitable to

long-distance air conditioner system with many units.

2.2.7 Remote Monitor Function

By selecting the remote monitor function, the user may mo

nitor the working parameters and

control the run mode of the air conditioner from a family PC. This is suitable to centralized control

of air conditioners in hotel, restaurants and factory. Up to 254 sets of units may be monitored

simultaneously.

2.2.8 Fresh Air Function (Duct

Type Unit)

This function is suitable to duct type unit and help

ful to introduce outdoor fresh air and enhance

the user’s comfort during use of the air conditioner. It is a truly air conditioning system.

2.2.9 Drainage Function (Duct Type Unit)

This function is suitable to duct type unit and help

ful to extend the applications of the air

conditioner. By this function, the installation of air conditioner will no longer be restricted.

2.2.10 Air Valve Control Function (Duct

Type Unit)

This function is suitable to duct type unit. By this

function, the unit may be connected to 8 air valve

controllers. The fan speed is controlled by controlling the number of air valves that will be opened

or closed, thus to meet the needs of each room for air flow.

31

Loading...

Loading...