Page 1

HIGH POWER MULTI SYSTEM

SERVICE MANUAL

EN

MS-E48AIN, MS-E56AIN

Outdoor unit

Page 2

“Originalinstructions”

IMPO

RTANT N

OTE:

Read this manual ca

r

efully befo

r

e installing

or operating your new air conditioning

unit. Make sure to save this manual for

futu

re r

efe

r

ence.

Page 3

Contents

PRODUCT ................................................................................................................... 1

1MODELS LIST ...................................................................................................................... 1

1.1Outdoor Unit .......................................................................................................................... 1

1.2 DB Module ............................................................................................................................. 1

2

PRODUCT DATA ..................................................................................................................

2

2.1

Product Data of Outdoor Unit ................................................................................................ 2

2.2 Product Data of DB Module .................................................................................................. 4

3

Working T emperature Range ................................................................................................. 4

4

PIPING DIAGRAM ............................................................................................................... 5

CONTROL ...................................................................................................................

. 6

1

OPERATION FLOWCHART ................................................................................................. 6

1.1

Cooling/Dry Operation ...........................................................................................................

7

1.2

Heating Operation ................................................................................................................

... 8

2

MAIN LOGIC ....................................................................................................................

.. ...9

2.1

Control Function of Outdoor Unit .......................................................................................... 9

2.2 Protection Function ............................................................................................................... 10

2.3

Other function ................................................................................................................

....... 11

2.4

Control Function of Indoor Unit ........................................................................................... 12

3

REMOTE CONTROLLER .................................................................................................. 15

3.1

Wired Remote Controller ..................................................................................................... 15

3.2

Wireless Remote Controller ................................................................................................. 2 0

4

Central Controller SCC-16 .................................................................................................... 2 3

4.1

General Introduction ...........................................................................................................

.. 23

4.2

Communication Network ...................................................................................................... 2 4

4.3

LCD ...........................................................................................................................

............ 25

4.4Buttons .................................................................................................................................. 25

INSTALLATI

ON ....................................................................................................... 27

1

PRECAUTIONS FOR INSTALLATION ............................................................................ 27

1.1Precautions for Installation ..................................................................................................

27

1.2

Key Points of Installation ....................................................................................................

. 29

Installation of the Outdoor Unit ........................................................................................... 3 5

3.9

Installation and Servicing Space .......................................................................................... 3 4

3.8

Outline Dimension of the Outdoor Unit .............................................................................. 3 4

3.7

Selection of Installation Location ........................................................................................ 3 3

3.6

Parts and Components of Unit ............................................................................................. 3 3

3.5

. 32Names of Main Parts ...........................................................................................................3.4

Precaution for Operation Test .............................................................................................. 3 2

3.3

. 32Precaution for Installation ...................................................................................................3.2

32

Precautions for R410A .........................................................................................................3.1

OUTDOOR UNIT INSTALLATION .................................................................................. 3 2

3

FLOW CHART OF INSTALLATION ................................................................................. 3 1

2

Page 4

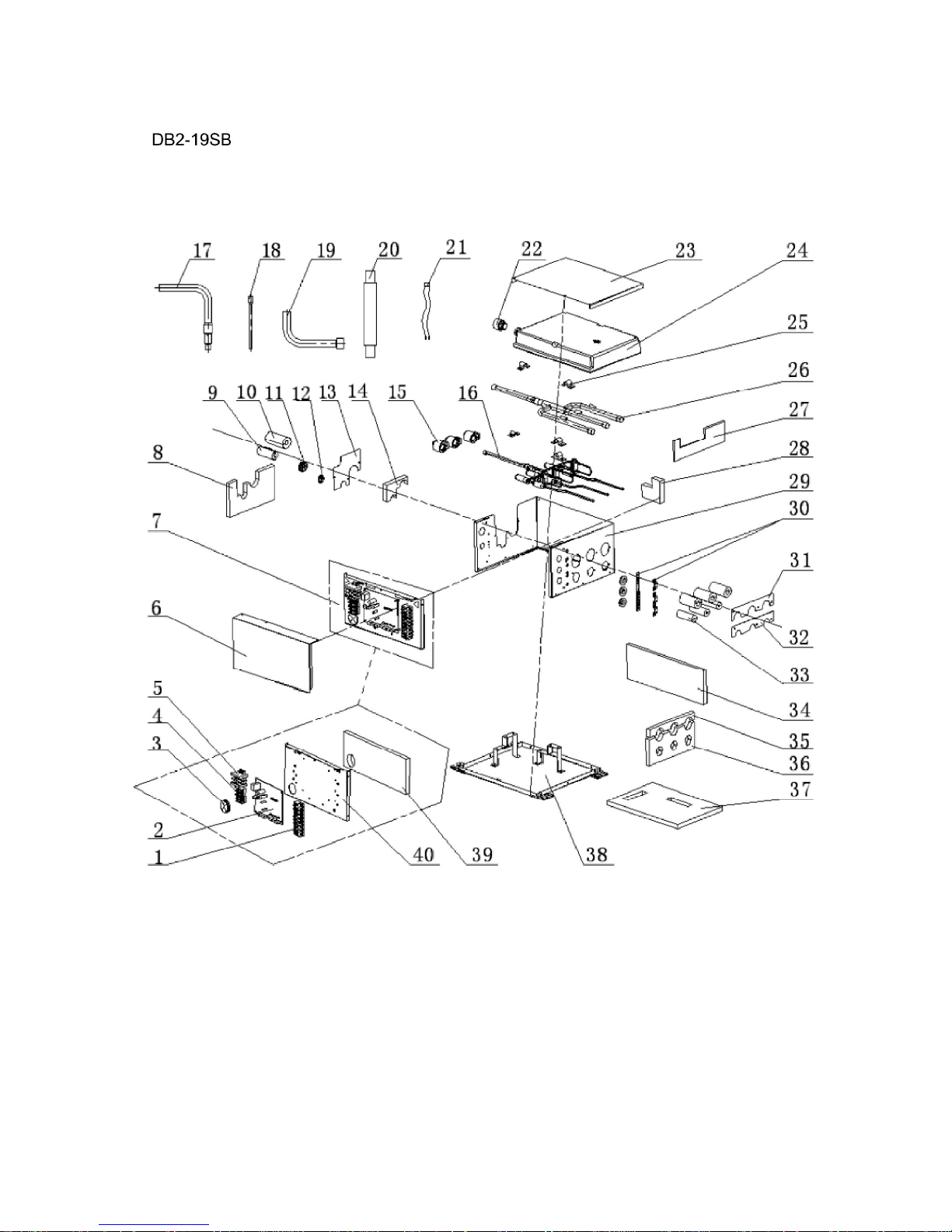

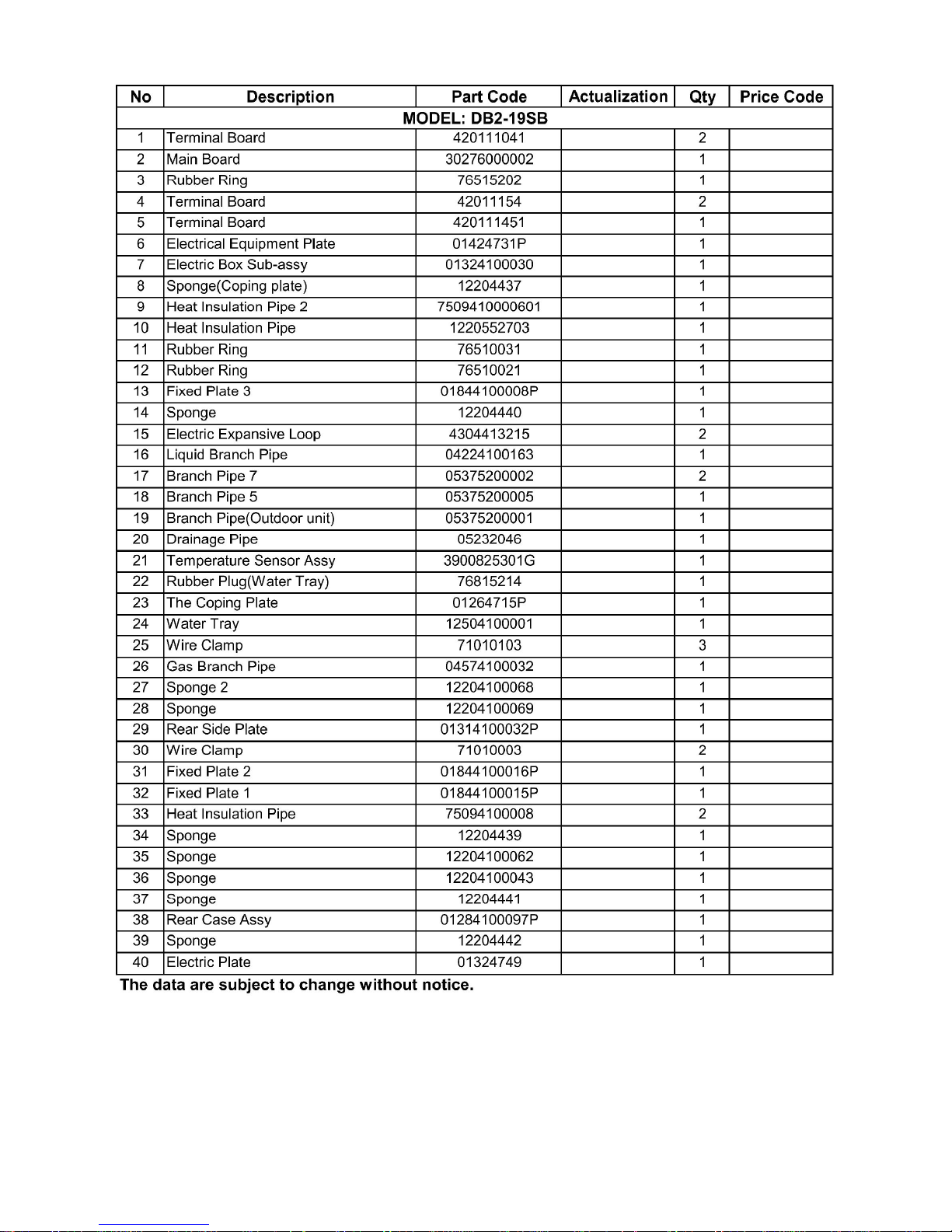

4 DB MODULE INSTALLATION ......................................................................................... 3 6

4.1Precaution for Installation .................................................................................................... 36

4.2Names of Main Parts ............................................................................................................ 36

4.3

Selection of Installation Location ........................................................................................ 3 6

4.4

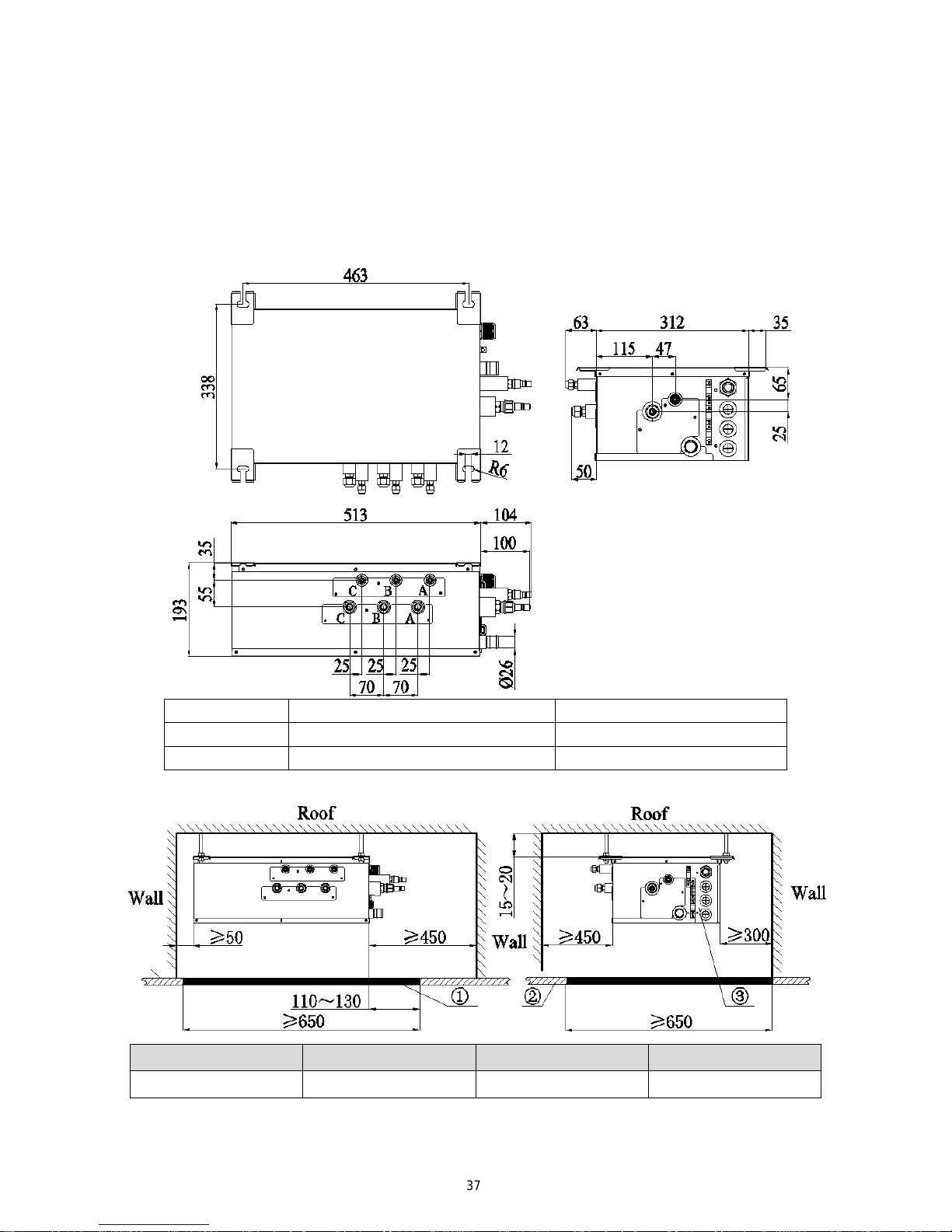

Outline Dimension and Servicing Space of DB3-16AF ...................................................... 3 7

4.5

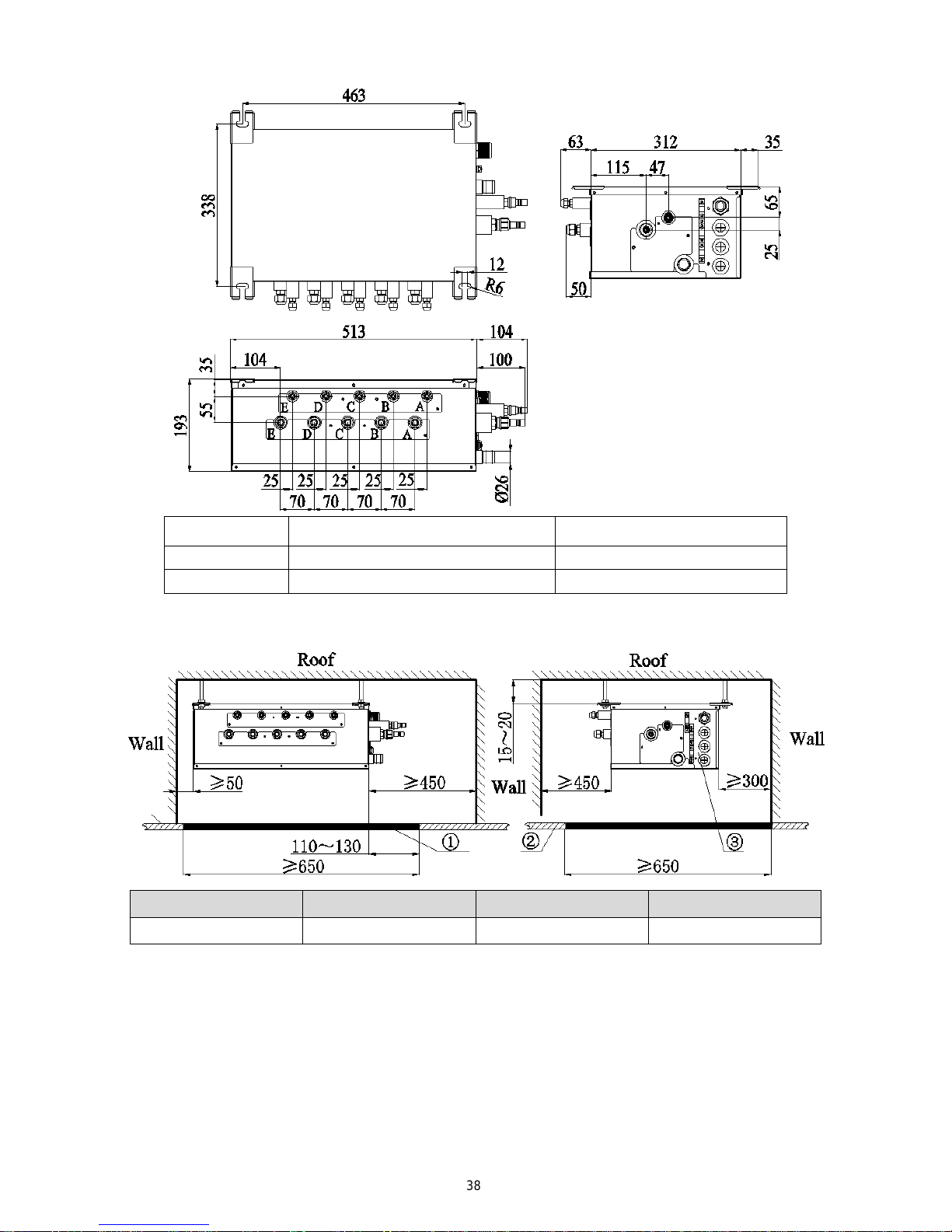

Outline Dimension and Servicing Space of DB5-16AF ...................................................... 3 7

4.6Installation Instruction ......................................................................................................... 38

5

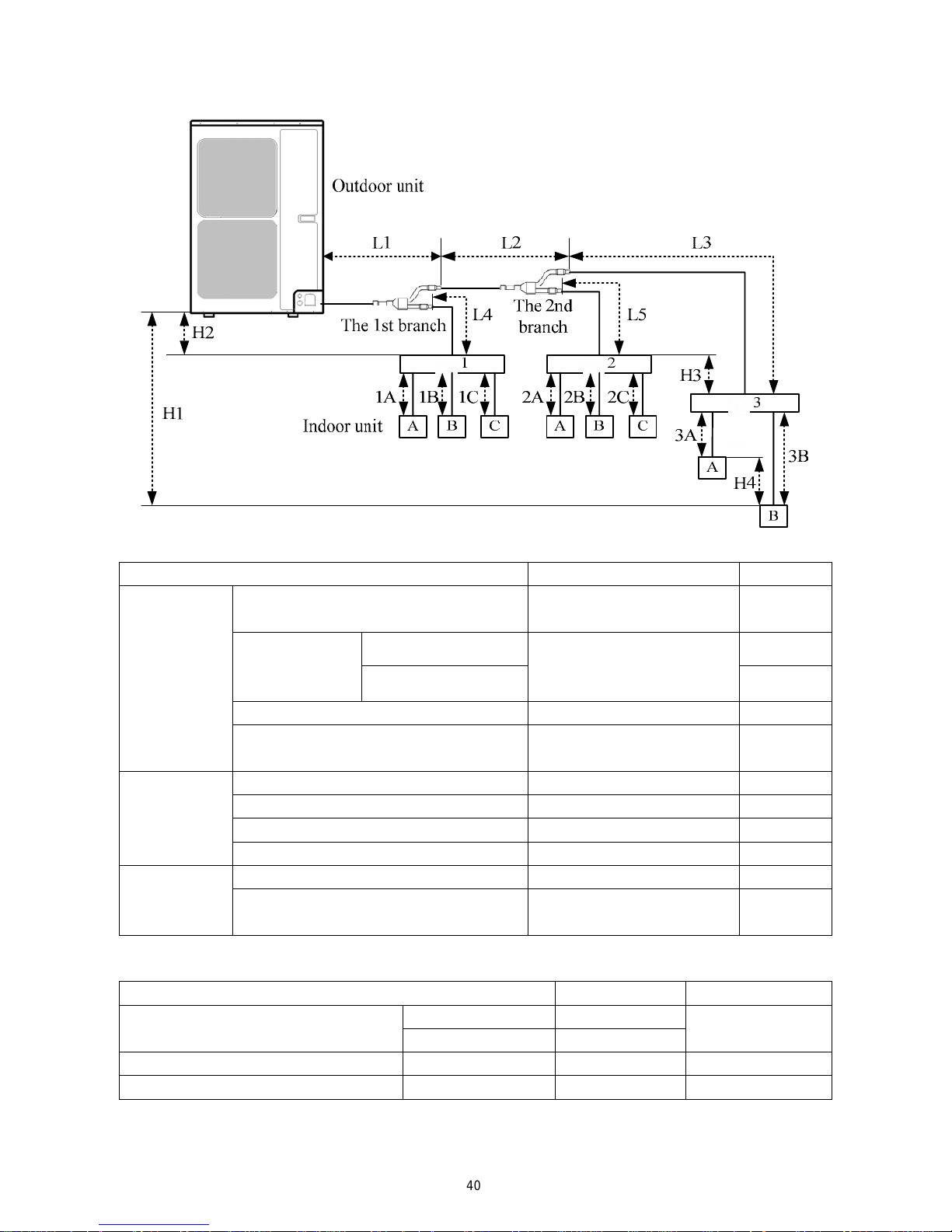

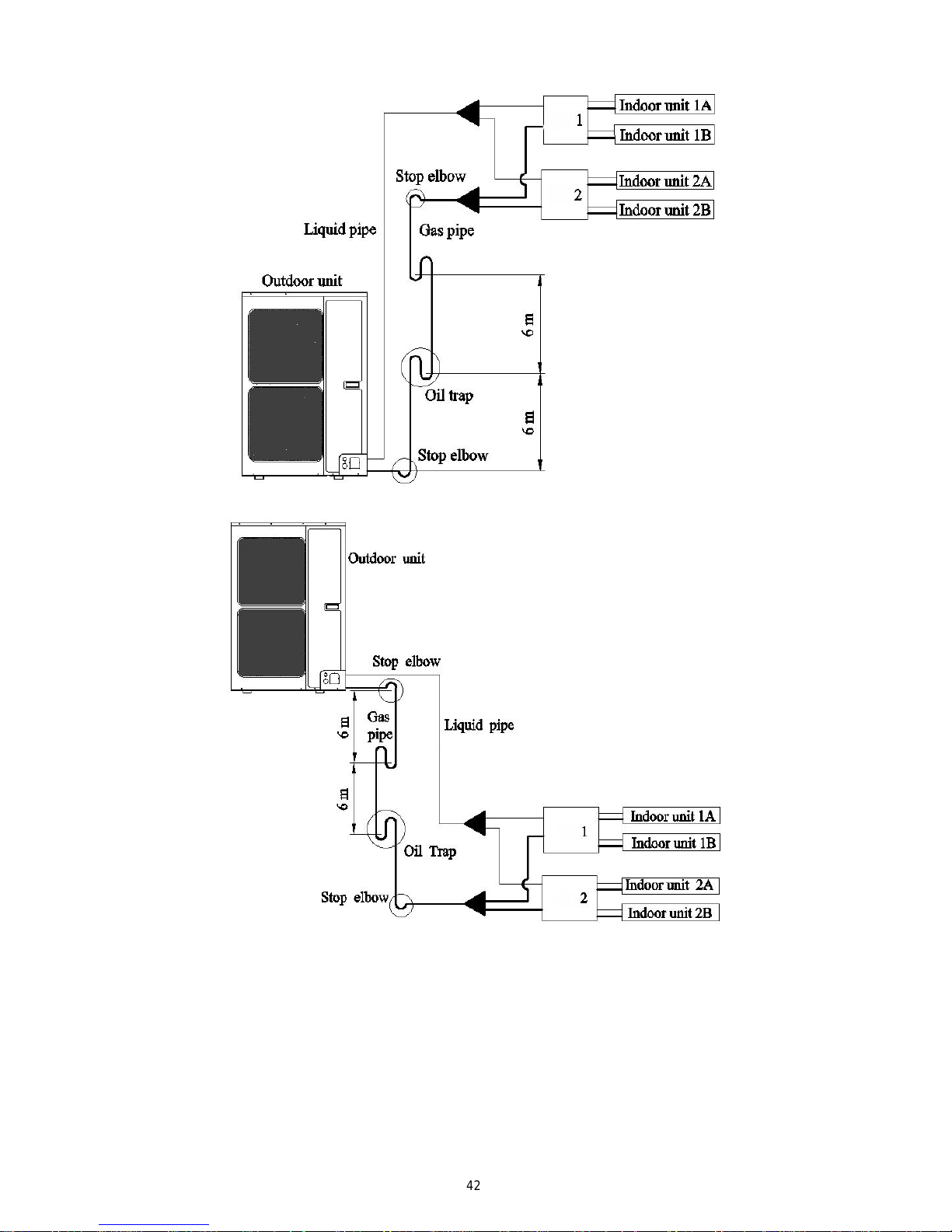

REFRIGERATION PIPING WORK ................................................................................... 4 0

5.1

Allowable Length and Drop Height of Connecting Pipe ..................................................... 4 0

5.2

Dimension of Connecting Pipe ............................................................................................ 4 0

5.3

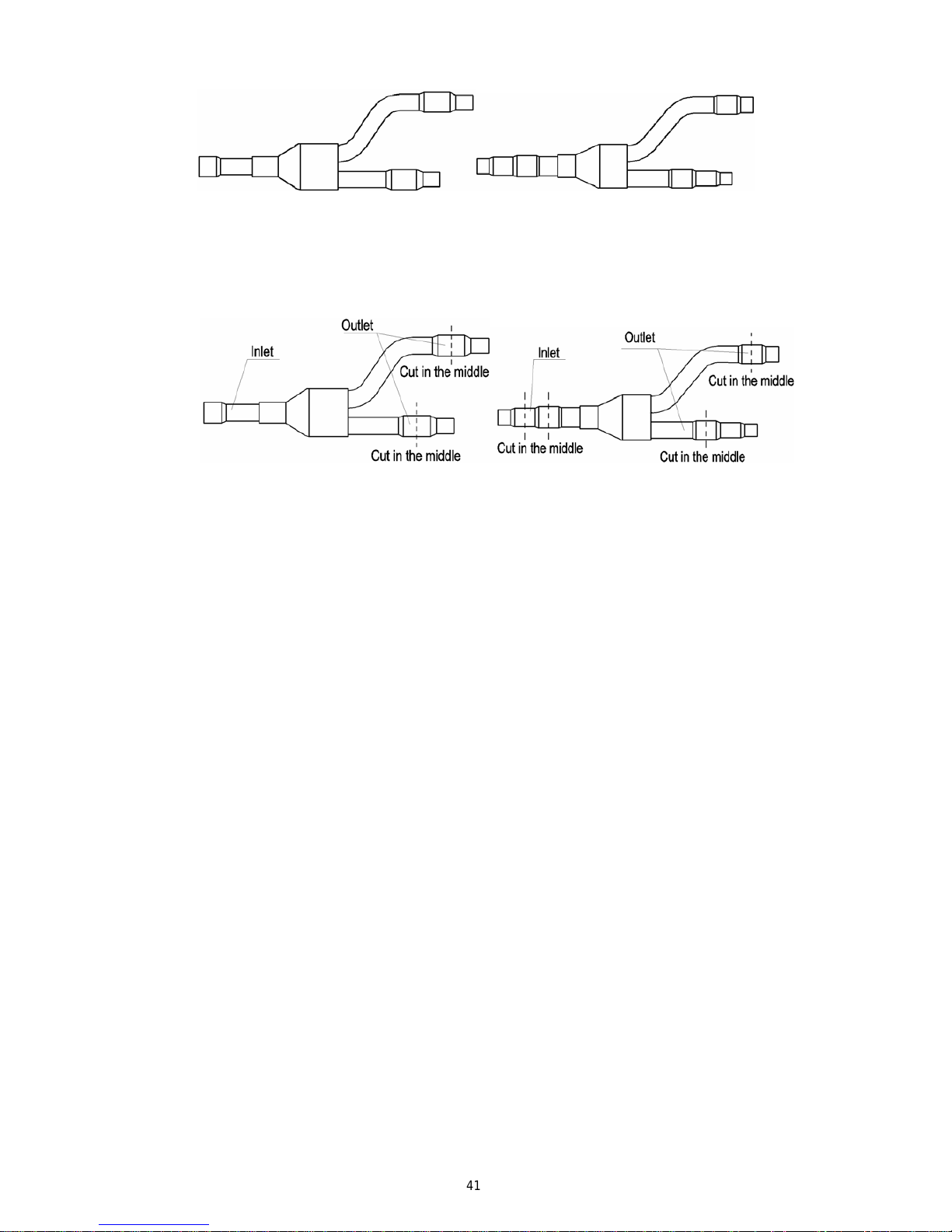

Connection of Branch Pipe .................................................................................................. 4 0

5.4

Design Requirements for Oil Trap ....................................................................................... 41

5.5

Connection of Outdoor Unit Refrigerant Pipe ..................................................................... 4 3

5.6

Installation of Piping Adapter .............................................................................................. 4 3

5.7

Precaution for Connection ................................................................................................... 4 4

5.8Leak T est ............................................................................................................................... 46

5.9

Vacuum Operation ................................................................................................................

46

5.10

Refrigerant Charging ..................................................................................................... 4 7

6

Electrical Wiring Work......................................................................................................... 5 0

6.1

Wiring Connection ...............................................................................................................

50

6.2

Requirements of Power Circuit and Cable ........................................................................... 51

6.3

Ground Requirements .......................................................................................................... 51

6.4

Precautions of Electrical Wiring Work ................................................................................ 51

6.5

Precaution of Laying Wires .................................................................................................. 52

6.6

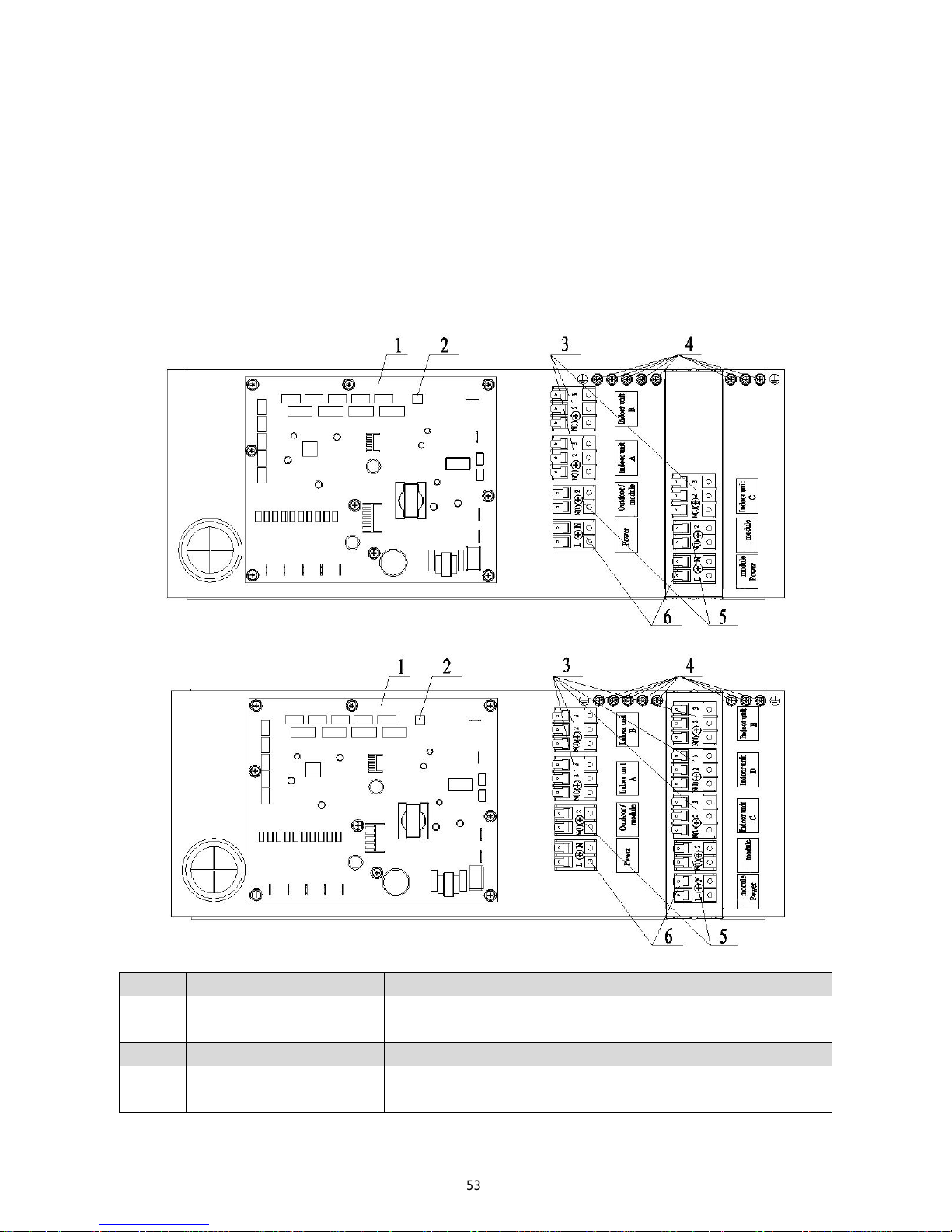

Electrical Wiring Work for Outdoor Unit ............................................................................ 52

6.7

Electrical Wiring Work for BU Module ............................................................................... 5 3

6.8

Instructions for DIP Switch .................................................................................................. 55

6.9

Electrical Wiring Work for Indoor Unit ............................................................................... 55

7

INSTALLATION OF DRAINAGE PIPELINE ................................................................... 56

Pressure Protection .................................................................... 6 6

Malfunction display: Low

2.2

Pressure Protection ................................................................... 6 5

Malfunction display: High

2.1

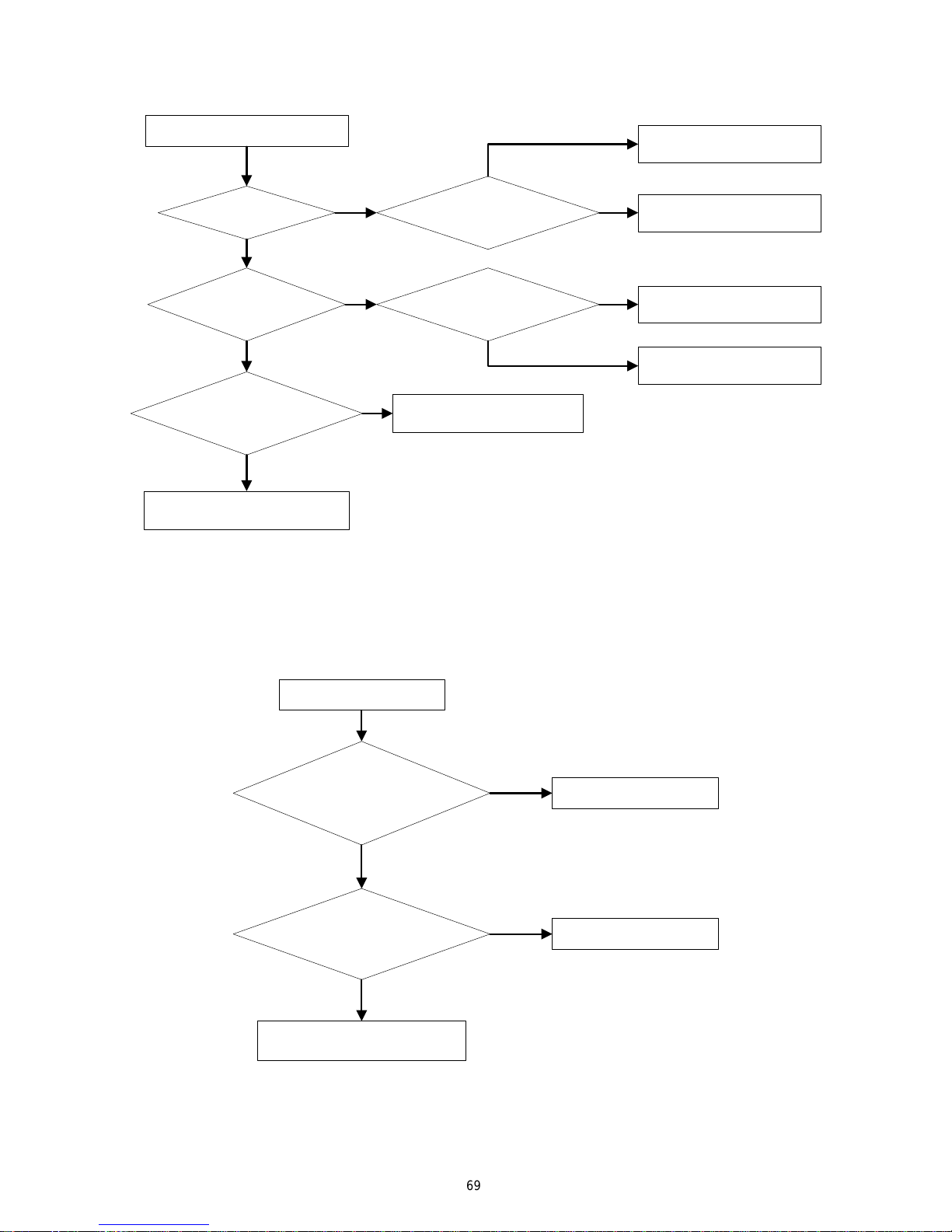

FLOW CHART OF TROUBLESHOOTING ...................................................................... 6 4

2

..... 62

Error description .............................................................................................................

1.3

62

Problem Handling ................................................................................................................

1.2

Check before Contacting Maintenance Serviceman ............................................................ 6 1

1.1

.... 61

Troubleshooting ...............................................................................................................

1

...................................................................................................... 61

NCE MAINTENA

Installation of Protective Layer on Connection Pipe ........................................................... 60

8

Key Points for Condensate Pipe Installation ........................................................................ 56

7.2

Material Quality Requirements for Condensate Pipe .......................................................... 5 6

7.1

ature sensor error ................................................................... 6 9

Malfunction display: Temper

2.7

Malfunction display: Indoor unit water full protection ........................................................ 6 9

2.6

Malfunction display: Communication error ......................................................................... 6 8

2.5

Malfunction display: Current protection .............................................................................. 6 7

2.4

e temperature protection ...................................................... 6 7

Malfunction display: Discharg

2.3

Page 5

2.8

Malfunction display: High/Low

pressure sensor error ........................................................ 7 0

3

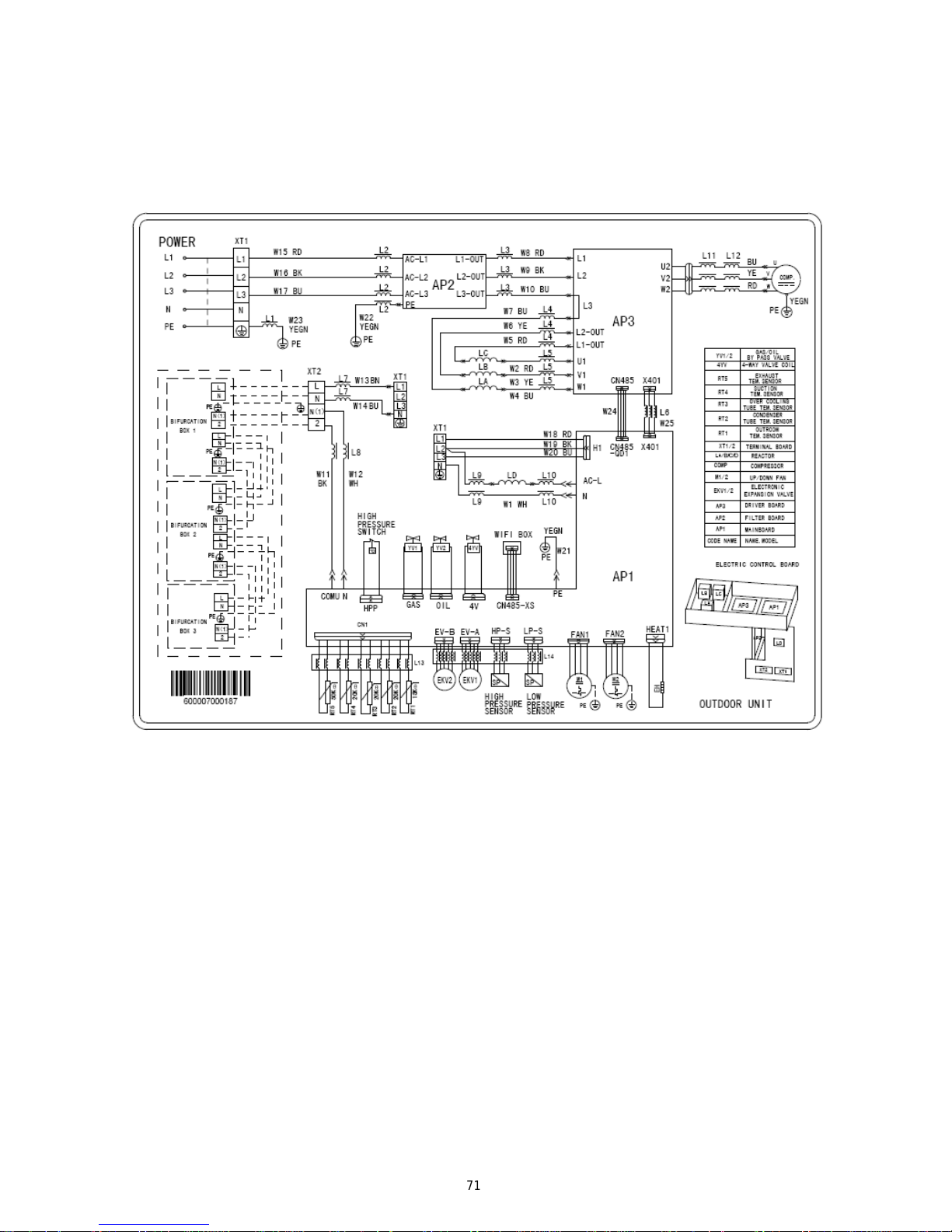

POWER DISTRIBUTION ................................................................................................... 7 0

3.1

Diagram of Power Distribution ............................................................................................ 7 0

3.2

Wiring diagram ................................................................................................................

.... 71

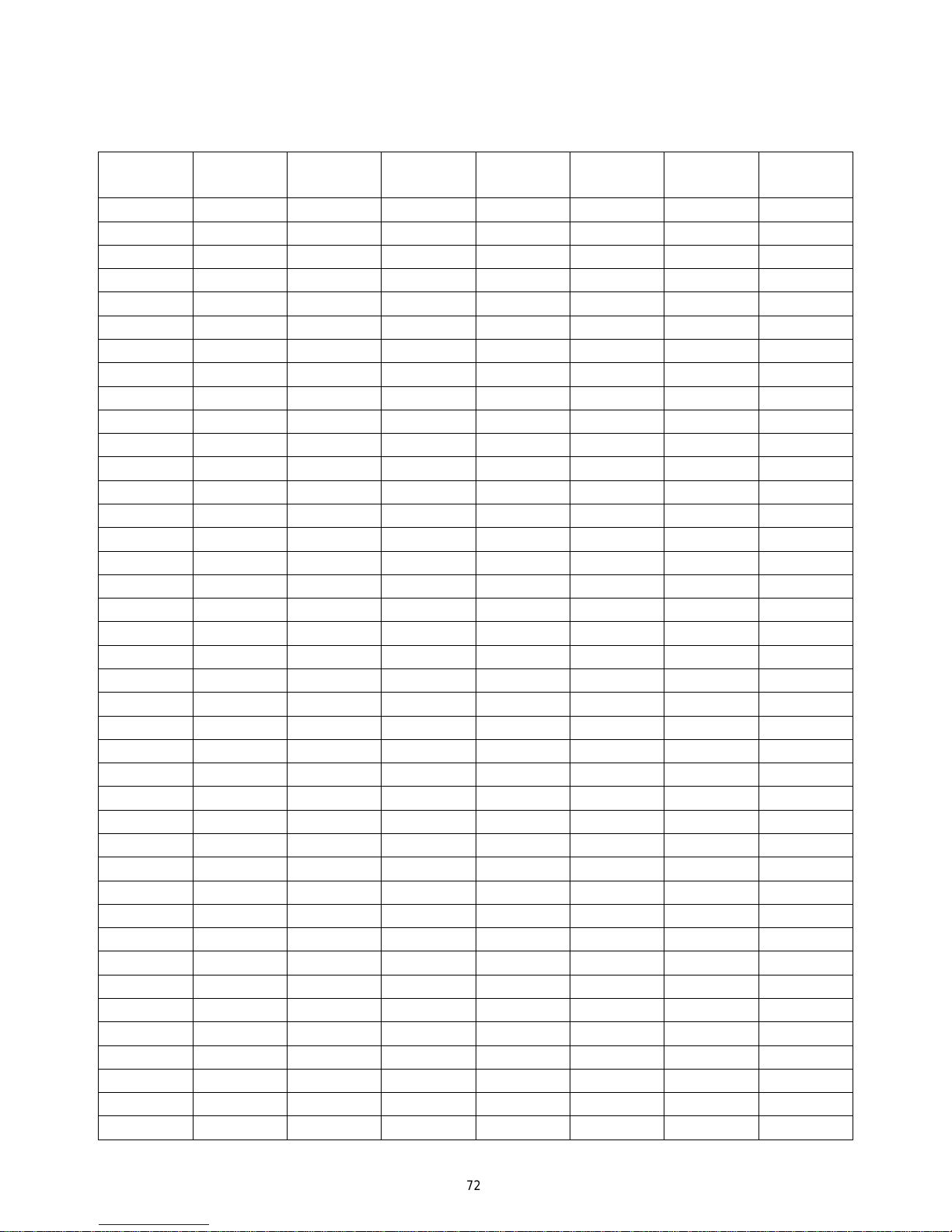

4

THE RESISTANCES OF COMMON

TEMPERATURE SENSORS ................................. 7 2

4.1

15 K

Ω

................................................................................................................................... 72

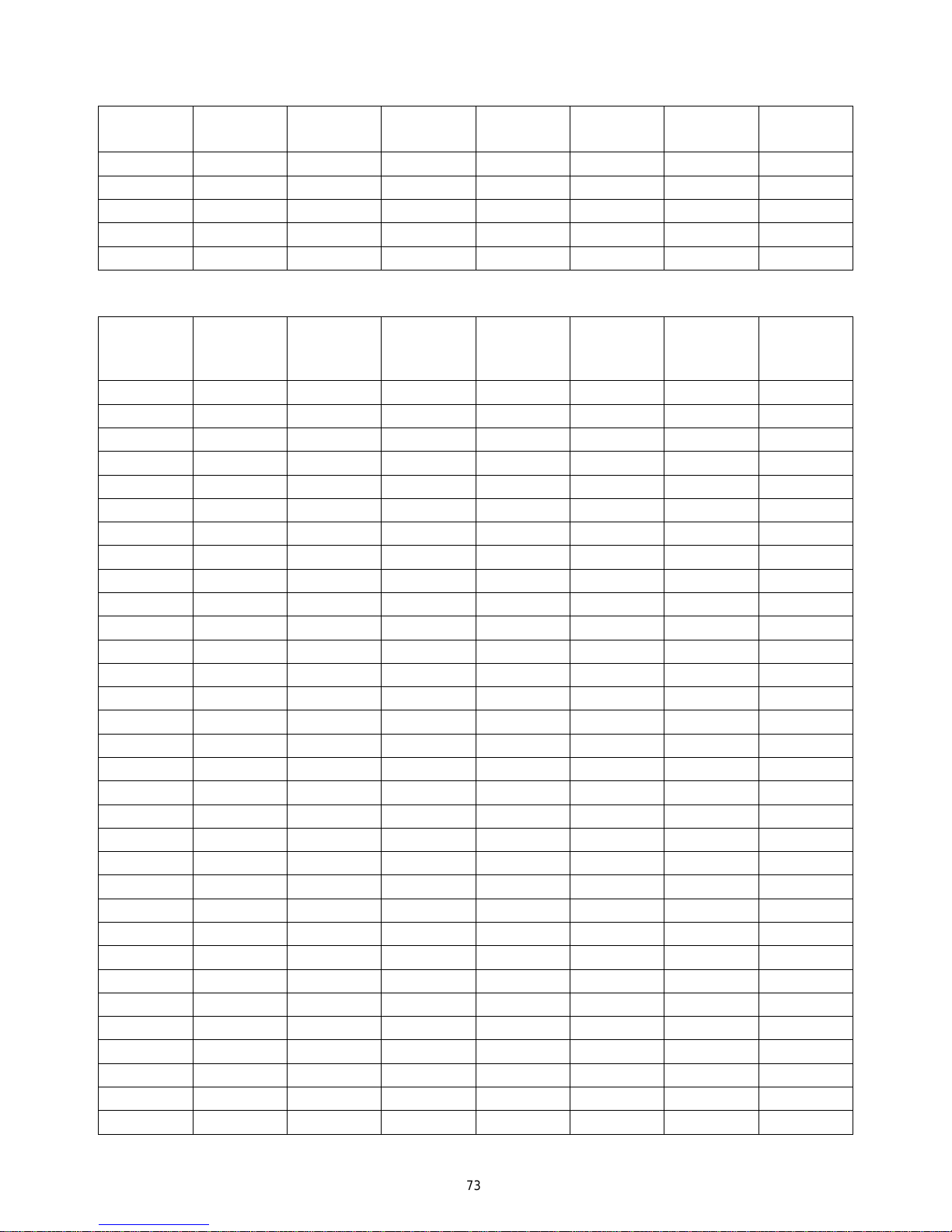

4.2

20 K

Ω

................................................................................................................................... 73

4.3

50 K

Ω

................................................................................................................................... 74

5

DISASSEMBLY AND ASSEMBLY PROCEDURE OF MAIN PARTS ............................ 7 7

5.1

Outdoor Unit ..................................................................................................................

...... 77

PARTS GUIDE.............................................................................................................................. 82

Page 6

PRODUCT

1 MODELS LIST

1.1 Outdoor Unit

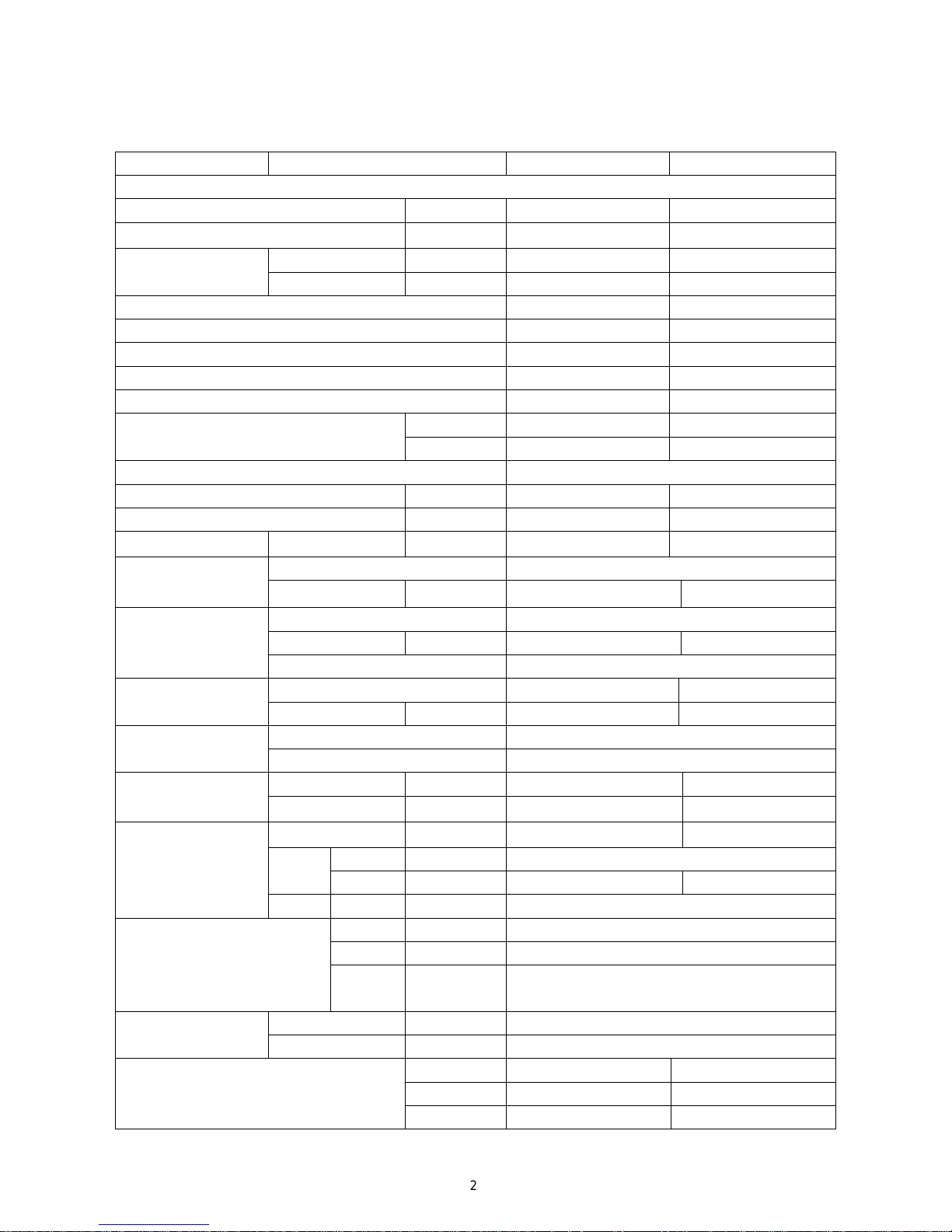

Model Product code

Capacity Capacity

Refriger

ant

Power supply

Appearance

Cooling

(kW)

Heating

(kW)

Ph, V, Hz

MS-E48AIN

CN860W0250 14.0 16.0

R410A 3,380~415,50

MS-E56AIN

CN860W0260 16.0 18.0

1.2 DB Module

Model Product code

Number of connectable

indoor units

Refrigerant

Power supply

Appearance

Min Max Ph, V, Hz

DB3-16AF EN0130050 1 3

R410A 1,220~240,50

DB5-16AF LN01300220 1 5

1

Page 7

2 PRODUCT DATA

2.1 Product Data of Outdoor Unit

Model Heat

pump MS-E48AIN

MS-E56AIN

Cooling capacity KW 14.0 16.0

Heating capacity KW 16.0 18.0

Nominal input

Cooling KW 4.60 5.2

Heating KW 4.25 4.7

EER/COP 2.7/3.2 2.65/3.5

Minimum NO. of connectable indoor units

2

2

Maximum NO. of connectable indoor units

8

9

Minimum No. of DB modules to be connected

1 1

Maximum No. of DB modules to be connected

3 3

T ot al capacity index of to be connected

indoor units

Min 50 50

Max 135 135

Power supply 3Ph,380~415V, 50Hz

Dimensions (H×W×D) mm 1345×900×340 1345×900×340

Net weight/Gross weight kg 116/125 116/125

Sound pressure level cooling/heating dB(A) 58 58

Fan

Refrigerant

Refrigerant oil

Compressor

Piping connections

Piping length

Height

Type Axial-flow

Air Flow Volume m3/h 7000 7000

Name R410A

Charge kg 4.95 4.95

Control

Electronic expansion valve

Type FV50S FV50S

Charge L 1.35 1.35

Type Inverter Rotary

Quantity 1

Gas mm

Φ15.9

Φ19.05

Liquid mm

Φ9.52

Φ9.52

System total m 135 145

OU-DB m 55 total

DB-IN m 80

90 1

room DB-IN m

15

OU-DB m

30

OU-IN m

30

m 15

Operation range

℃ 18~48

DB-DB/

IN-IN

Cooling DB

Heating

℃DB -10~24

Loading quantity

20' GP 25 25

40' GP 50 50

40' HQ 50 50

2

Page 8

Notes:

a. The rated cooling capacity data is measured under the following work condition: Indoor Temperature is 27℃

DB, 19℃WB. Outdoor Temperature is 35℃DB. The rated heating capacity data is measured under the following

work condition: Indoor Temperature is 20℃DB. Outdoor Temperature is 7℃DB, 6℃WB.

b. The data will change with the change of products. Refer to those parameters listed on nameplate.

c. Noise was tested in semi-silenced room, so the actual noise value will be a little higher for change of ambient.

3

Page 9

2.2 Product Data of DB Module

Model

DB3-16AF

DB5-16AF

Maximum numbers of connectable indoor units 3 5

Power Supply V-Ph-Hz 220~240-1-50

Connection port to

outdoor unit

Gas pipe(inner diameter) mm Φ15.9 Φ15.9

Liquid pipe(inner diameter) mm Φ9.52 Φ9.52

Connection Method Flare Flare

Connection port to

indoor unit

Gas pipe(inner diameter) mm Φ9.52 Φ9.52

Liquid pipe(inner diameter) mm Φ6.35 Φ6.35

Connection Method Flare Flare

Drainage pipe

External dia. mm Φ31 Φ31

Thickness mm 3 3

Net weight/Gross weight kg 8/10 9/11

Notes:

a. The rated cooling capacity data is measured under the following work condition: Indoor Temperature is 27℃

DB, 19℃WB. Outdoor Temperature is 35℃DB. The rated heating capacity data is measured under the following

work condition: Indoor Temperature is 20℃DB. Outdoor Temperature is 7℃DB, 6℃WB.

b. The data will change with the change of products. Refer to those parameters listed on nameplate.

c. Noise was tested in semi-silenced room, so the actual noise value will be a little higher for change of ambient.

3 W ork ing Temperature Range

Sorts

Indoor side state Outdoor side state

Dry bulb temp. ℃ Wet bulb temp. ℃ Dry bulb temp. ℃ Wet bulb temp. ℃

Rated Cooling 27 19 35 24

Max. cooling 32 23 48 26

Min. cooling 21 15 18 —

Rated Heating 20 15 7 6

Max. heating 27 — 24 18

Min. heating 20 15

-10

—

4

Page 10

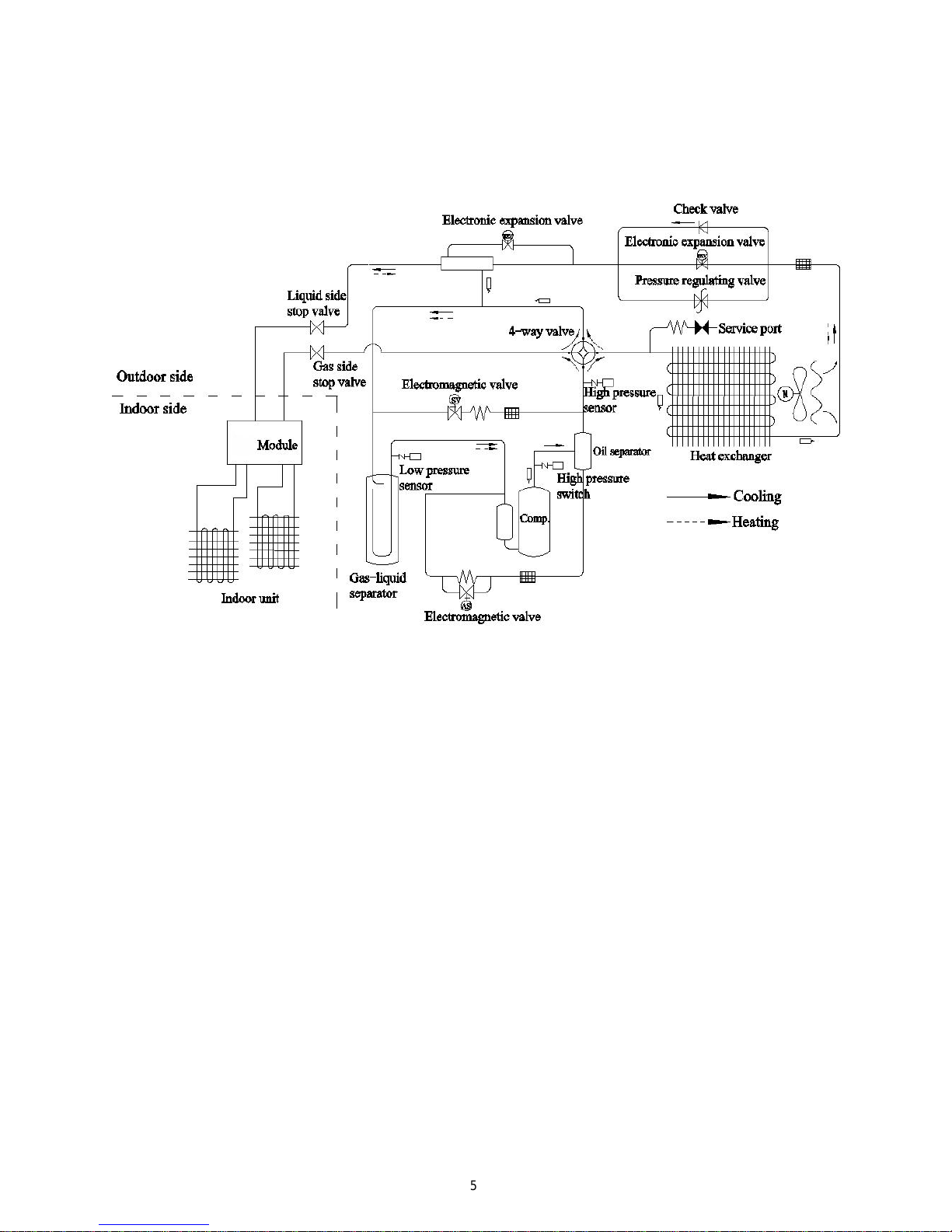

4 PIPING DIAGRAM

Schematic Diagram of High Power Multi System

The units start to work once the power is switched on.

During the cooling operation, the low temperature, low pressure refrigerant gas from the heat exchanger of

each indoor unit gets together and then is taken into the compressor to be compressed into high temperature, high

pressure gas, which will soon go to the heat exchanger of the outdoor unit to exchange heat with the outdoo r air

and then is turned into refrigerant liquid. After passing through the DB module, the temperature and pressure of

the refrigerant liquid will further decrease and then go the main valve. After that, it will be divided and go to the

heat exchanger of each indoor unit to exchange heat with the air which needs to be conditioned. Consequently, the

refrigerant liquid become low temperature, low pressure refrigerant gas again. Such a refrigeration cycle goes

round and round to achieve the desired refrigeration purpose.

During the heating operation, the four-way valve is involved to make the refrigeration cycle run reversely.

The refrigerant radiates heat in the heat exchanger of the indoor unit (so do the electric heating devices) and

absorb heat in the heat exchanger of the outdoor unit for a heat pump heating cycle so as to achieve the desired

heating purpose.

DB

5

Page 11

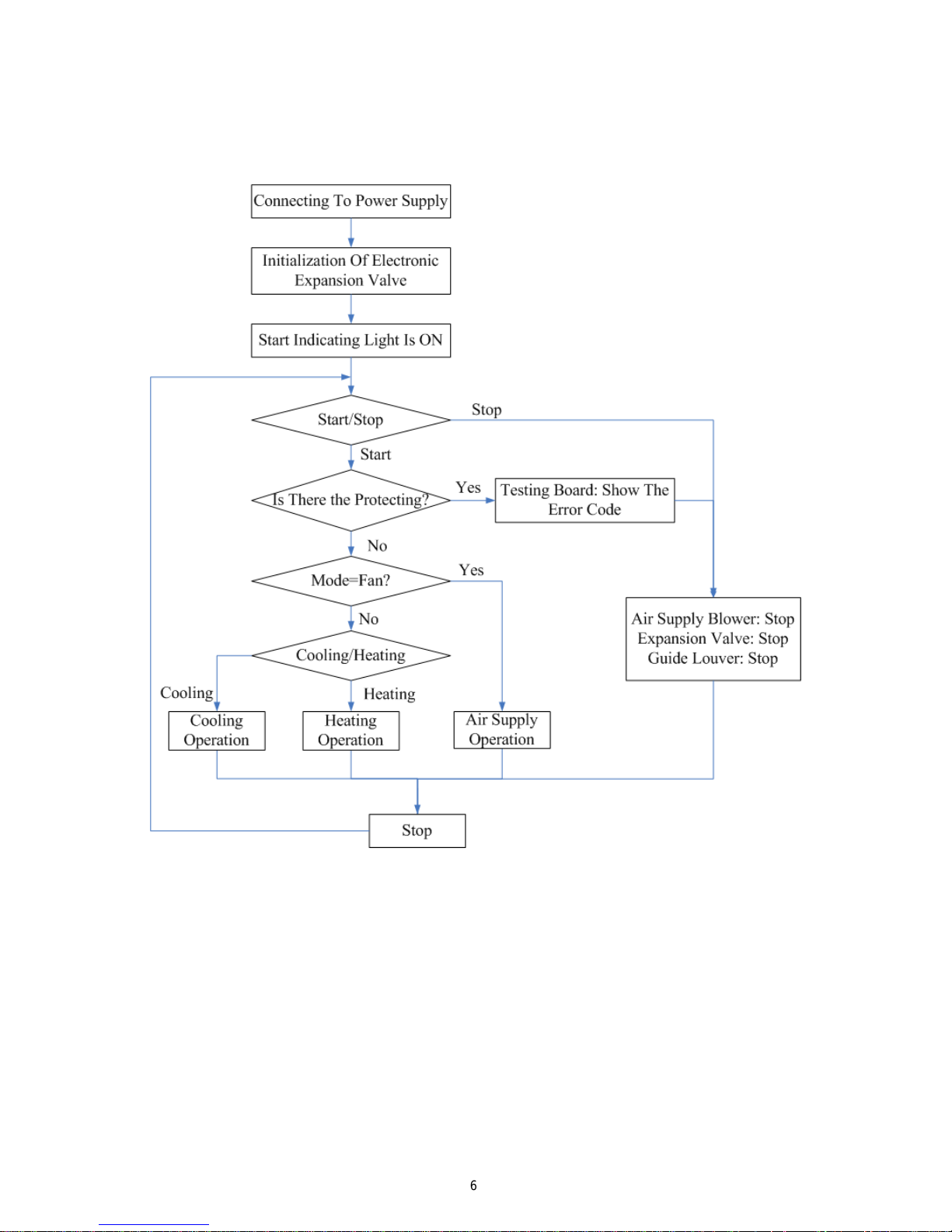

CONTROL

1 OPERATION FLOWCHART

6

Page 12

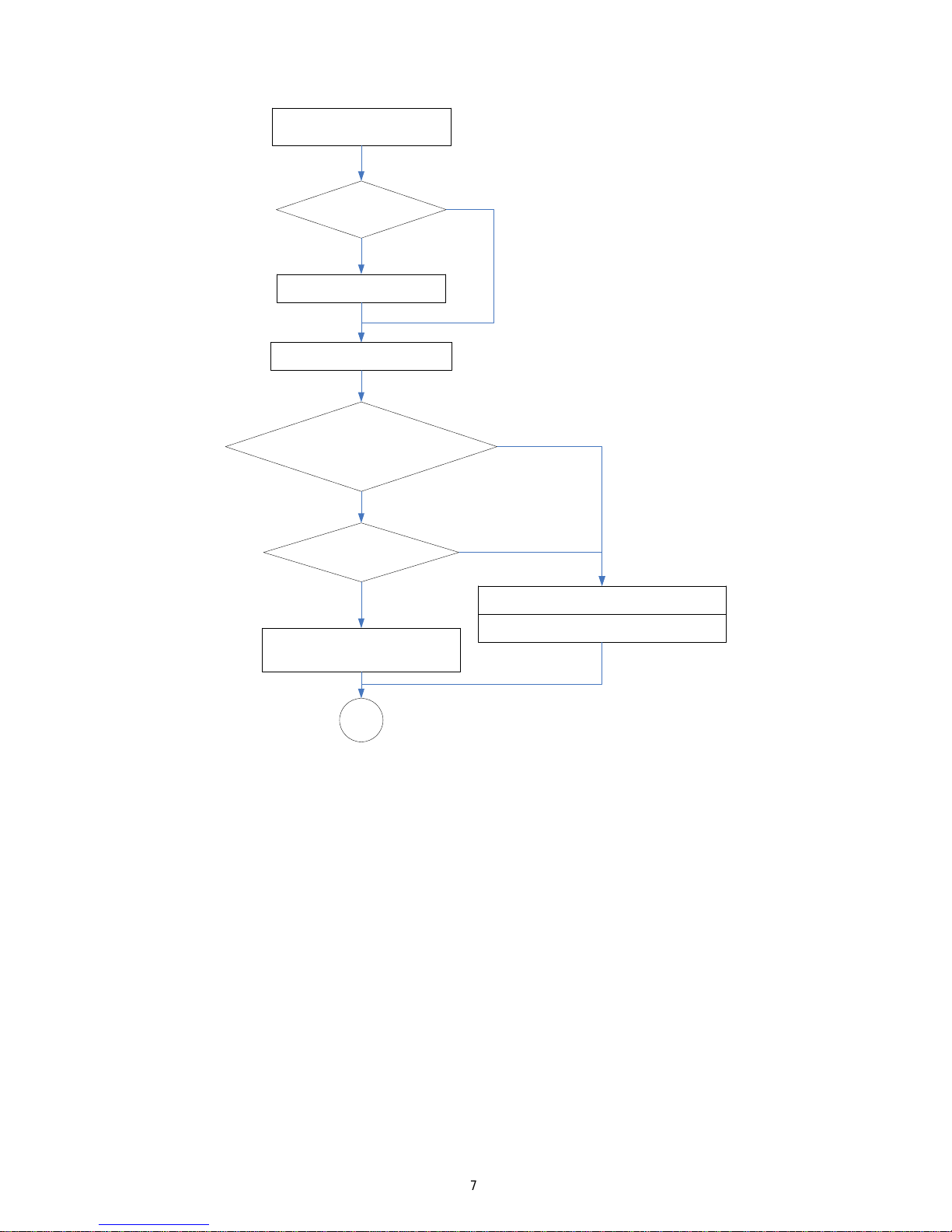

1.1 Cooling/Dry Operation

Guide Louvers Swing

Is there Guide

Louver?

Cooling Operation

Is the process of

preventing restart operation?

(3 minutes)

Fan Motor:Operation

Temperature

Adjustment

Electronic Expansion

Valve:Capacity Conctrol

Fan Motor: Stop

Electronic Expansion Valve: Stop

Stop

Yes

No

No

Yes

Yes

No

(Go to the previous page)

7

Page 13

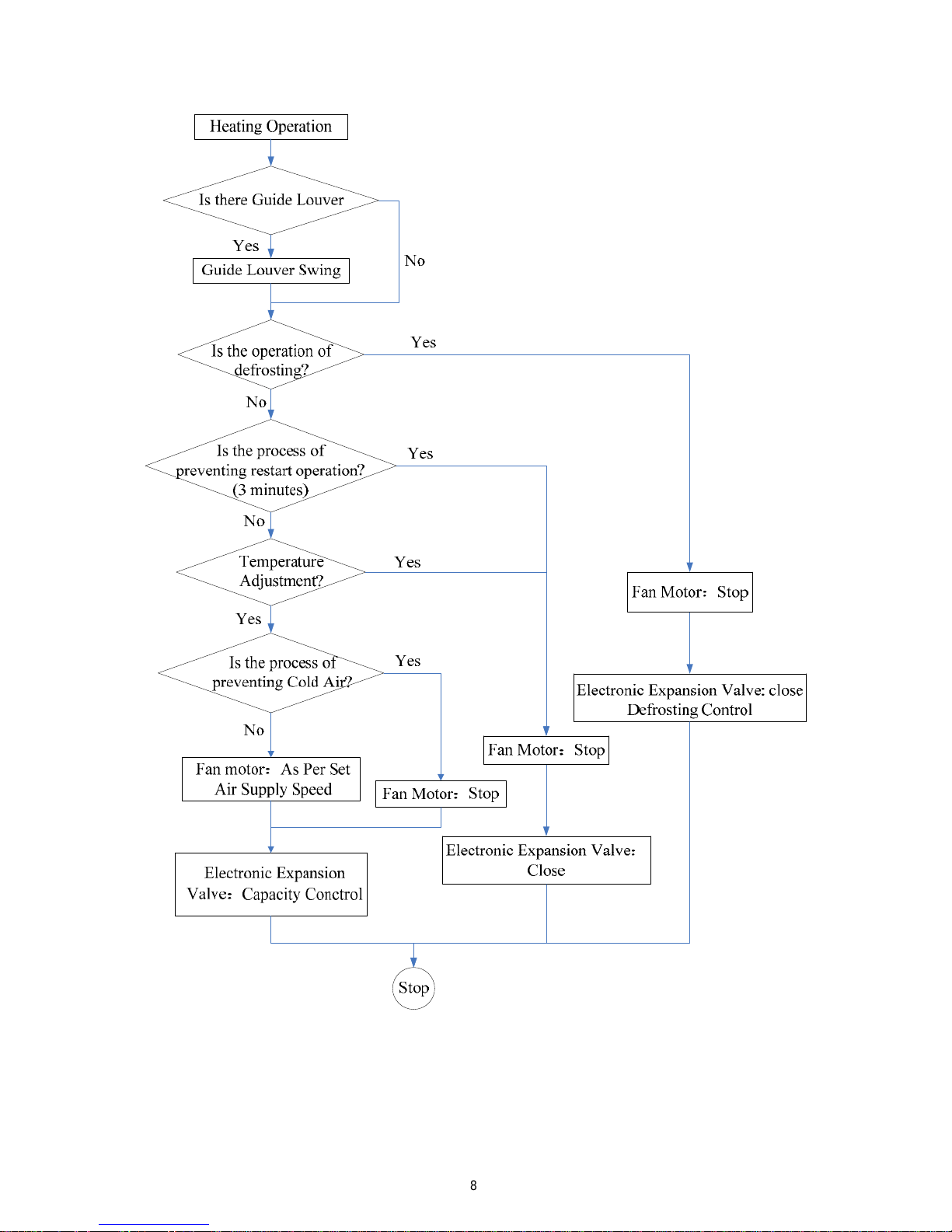

1.2 Heating Operation

8

Page 14

2 MAIN LOGIC

2.1 Control Function of Outdoor Unit

2.1.1 Cooling Mode

1) Cooling conditions and process:

If the compressor is in stop status and start the unit for cooling operation, when one of the indoor units

reaches the cooling operation condition, the unit starts cooling operation; in this case, the electronic expansion

valve, the outdoor fan and the compressor start operation.

2) Stop in cooling operation

a) Compressor stops

The compressor stops gradually, the outdoor fan stops after 1 min.

b) Some of the indoor units reach the stop condition (the compressor does not stop)

The compressor operates according to the required frequency. For the indoor unit with no requirement, the

corresponding electronic expansion valve is closed to 0P.

3) Cooling mode transfers to heating mode

When the unit transfers to heating mode, the 4-way valve is energized after the compressor runs for 40s. The

other disposals are the same as stopping in cooling mode.

4) 4-way valve:

In this mode, the 4-way valve is closed.

5) Outdoor fan control in cooling mode

The outdoor fan starts before 5s of the starting of compressor. The outdoor fan will run in high speed for 40s

after starting and then it will run in set speed.

The fan shall run at every speed for at least 80s. (When the quantity of indoor unit changes, the control part

will adjust the outdoor fan according to the quantity of indoor unit and outdoor temperature.); when the

compressor stops, the outdoor fan runs at present speed and stops after 1 min.

2.1.2 Dry Mode

1) The dry conditions and process are the same as those in cooling mode;

2) The status of 4-way valve: closed;

3) The temperature setting range: 16 ~ 30℃;

4) Protection function: the same as those in cooling mode;

5) In dry mode, the maximum value A of the capacity requirement percentage of single unit is 90% of that

in cooling mode. The open condition of the electronic expansion valve, outdoor fan and compressor is

the same as those in cooling mode.

2.1.3 Heating Mode

1) Heating conditions and process: When one of the indoor units reaches the heating operation condition,

the unit starts heating operation.

2) Stop in heating operation:

a) When all the indoor units reach the stop condition, the compressor stops and the outdoor fan stops after 1

min;

b) Some of the indoor units reach the stop condition. The compressor reduces the frequency immediately and

operates according to the required frequency;

c) Heating mode transfers to cooling mode (dry mode), fan mode:

The compressor stops;

The outdoor fan stops after 1min;

9

Page 15

The status of 4-way valve: energized;

3) Outdoor fan control in heating mode

The outdoor fan starts before 5s of the starting of compressor and then it will run in high speed for 40s; The

fan shall run at every speed for at least 80s; When the compressor stops, the outdoor fan stops after 1min.

4) Defrosting function

When the defrosting condition is met, the frequency of the compressor starts to decrease and wait for

defrosting; the electronic expansion valve of all indoor units open in big angle; the outdoor fan stops after the stop

of the 4-way valve, meanwhile, the 4-way valve reverses the direction; after the 4-way valve reverses the direction,

the frequency of the compressor starts to rise; then begin to calculate the time of defrosting, the frequency of the

compressor rises to reach the defrosting frequency.

5)

Oil-returned control in heating mode

a) Oil-returned condition

The whole unit is operating in low frequency for a long time

b) Oil-returned process in heating mode

The indoor unit displays “H1”.

c) Oil-returned finished condition in heating mode

The duration reaches 5min

2.1.4 Fan Mode

The compressor, the outdoor fan and the 4-way valve are closed; temperature setting range is 16~30℃.

2.2 Protection Function

2.2.1 Mode Conflict Protection of indoor unit

When the setting mode is different of different indoor unit, the unit runs in below status:

1) The mode of the first operating indoor unit is the basic mode, when compare the mode of the other

indoor units to see if there is a conflict. Cooling mode (dry mode) is in conflict with heating mode.

2) Fan mode is in conflict with heating mode and the heating mode is the basic mode. No matter which

indoor unit operates first, the unit will run in heating mode.

2.2.2 Overload Protection Function

When the tube temperature is a little low, the compressor raises the operation frequency; when the tube

temperature is a little high, the compressor frequency is restricted or lows down the operation frequency; when the

tube temperature is too high, the compressor protection stops running. If the discharge temperature protection

continuously appears for 6 times, the compressor can’t resume running. The compressor can resume running after

cutting off the power and then putting through the power. (If the running time of the compressor is longer than

7min, the protection times record will be cleared).

2.2.3 Discharge Protection Function

When the discharge temperature is a little low, the compressor raises the operation frequency; when the

discharge temperature is a little high, the compressor frequency is restricted or lows down the operation frequency;

when the discharge temperature is too high, the compressor protection stops running. If the discharge temperature

protection continuously appears for 6 times, the compressor can’t resume running. The compressor can resume

running after cutting off the power and then putting through the power. (If the running time of the compressor is

longer than 7min, the protection times record will be cleared).

10

Page 16

2.2.4 Communication malfunction

Detection of the quantity of installed indoor units and DB modules: After 3min of energizing, if the outdoor

unit does not receive the communication data of certain indoor unit, the outdoor unit will judge that indoor unit is

not installed and will treat it as it is not installed. If the outdoor unit receives the communication data of that

indoor unit later, the outdoor unit will treat that unit as it is installed.

2.2.5 Compressor high-pressure protection

1) When the high-pressure switch is detected cut off for 3s continuously, the compressor will enter

high-pressure protection as it stops when reaching set temperature. Meanwhile, the outdoor unit will

send the signal of “high-pressure protection” to the indoor units;

2) After the appearance of high-pressure protection, the compressor can resume running only after cutting

off the power and then putting through the power.

2.2.6 Compressor low-pressure protection

1) Low Pressure Protection for Shutdown

a). After the compressor stops for five minutes, if it is detected that the low pressure protection is work, then

a low pressure protection signal will be send out.

b). If it is detected continuously for three seconds that the low pressure protection is work after the

compressor stops for less than five minutes, then a low pressure protection signal will be send out. However, if the

low pressure protection occurs twice in one hour, then it becomes unrecoverable and has to be recovered by

powering the outdoor unit again.

2) Low Pressure Protection during the Operation

a) When it is detected continuously for three seconds that the low pressure protection is work, then the whole

unit should be shut off and a low pressure protection signal should be sent to the indoor unit.

b) On condition that a low pressure protection error occurs and the whole unit has stopped for more than

three minutes and it is detected continuously for six seconds that the low pressure protection switch is closed, then

this error can be eliminated. However, if the low pressure protection occurs twice in one hour, then it has to

eliminate the error by powering the outdoor unit again.

2.2.7 Compressor overload protection

If the compressor overload switch is detected having movement, the indoor unit will display the

corresponding malfunction as it stops when the indoor temperature reaching set temperature. When the

compressor stops for more than 3min and the compressor overload switch is reset, the unit will resume operation

status automatically. If the protection appears for more than 6 times (if the running time of the compressor is

longer than 30min, the protection times record will be cleared), the unit can not resume operation status

automatically, but can resume running only after cutting off the power and then putting through the power.

2.3 Other function

2.3.1 Refrigerant Recovery

The refrigerant can be recovered from the outdoor unit. When the unit is powered on and runs under the

COOL mode, it is available within five minute to go the refrigerant recovery mode by operate the testing board of

the outdoor unit with “Fo” displayed.

2.3.2 How to quit the refrigerant recovery:

When the refrigerant recovery has started, it will quit by operate the testing board of the outdoor unit or the

power is cut off.

11

Page 17

2.4 Control Function of Indoor Unit

2.4.1 Running Mode

1. COOL 2.DRY 3.HEAT 4.AUTO 5 FAN

2.4.2 Basic Functions of the System

1) COOL Mode

Under this mode, the fan and swing function goes as the set conditions, and the set temperature range is 16℃

~30℃.

2) DRY Mode

Under this mode, the fan will run at the low speed and the swing function is performed under the set

conditions. The set temperature range is 16~30℃.

3) FAN Mode

Under this mode, only the fan of the indoor unit runs. And if the auto speed is set, the fan will run under the

same condition as the COOL mode.

4) HEAT Mode

a) Under this mode, the set temperature range is 16℃~30℃.

b) The defrosting symbol “H1” will be displayed when the defrosting signal is received from the outdoor

unit.

5) AUTO Mode

a) When the ambient temperature is higher than 25℃, the unit will run as the COOL mode.

b) For the cooling and heating unit, if the ambient temperature is or lower than 22℃, the unit will run as the

HEAT mode.

c) When the indoor ambient temperature is higher than 22℃ but lower than 26℃, the unit which starts to

work under the AUTO or DRY mode will shift to the FAN mode, while the unit which starts to work under other

mode will keep the current running mode.

2.4.3 Other Control

1) Beeper Control

When the controller is powered on or it receives a valid either press button signal or remote control signal,

the beeper will utter a warning tone.

2) Auto Speed Control

a). Under the HEAT mode:

◆ If the ambient temperature is equal or higher than the set temperature, the fan will run at the low speed;

◆ If the ambient temperature minus 3℃ is equal or lower than the set temperature, the fan will run at the

medium speed;

◆ If the ambient temperature minus 3℃ is lower than the set temperature minus 3℃, the fan will run at

the high speed.

b). Under the COOL mode:

◆ If the ambient temperature is equal to or lower than the set temperature, the fan will run at the low

speed;

◆ If the ambient temperature is between the set temperature and the set temperature minus 3℃, the fan

will run at the medium speed;

◆ If the ambient temperature is higher than the set temperature plus 3℃, the fan will run at the high speed.

c). Under the FAN mode:

◆ The fan will run at the medium speed constantly.

◆ Once the fan starts, its speed cannot be changed unit it has run for at least 30 seconds at the currently set

12

Page 18

speed.

d) Under the HEAT Mode: (Ambient temperature herein is the temperature without temperature

compensation)

◆ When the ambient temperature is or lower than the set temperature, the indoor unit runs at the high

speed.

◆ When the ambient temperature is higher than the set temperature but lower than the set temperature plus

2℃, the indoor unit fan runs at the medium speed.

◆ When the ambient temperature is or lower than the set temperature plus 2℃, the fan runs at the low

speed.

e) Under the COOL and FAN Modes

◆ When the ambient temperature is or higher than the set temperature plus 3℃, the indoor unit runs at

high speed.

◆ When the ambient temperature is higher than the set temperature plus 1℃, but lower than the set

temperature plus 3℃, the indoor unit fan runs at the medium speed.

◆ When the ambient temperature is or lower than the set temperature plus 1℃, the fan runs at the low

speed.

f) Once the fan starts at a certain speed, it will keep running at this speed for no less than 30 seconds prior to

any changeover stated above.

3) AUTO Press Button

The whole unit will run under the AUTO mode by pressing this button when the unit is off. In this condition,

the fan of the indoor unit will run at the auto speed with the swing function activated. When the unit is on, it will

be turned off by pressing this button. This button is unavailable to the floor/ceiling unit.

4) Sleep

Under this mode, the proper sleep curve will be adopted in accordance with different set temperatures.

Under the COOL mode or the DRY mode, the temperature will go up by 1℃ after one hour and by another

1℃ after another hour, after that, the temperature will be kept on.

Under the HEAT mode, the temperature will go down by 1℃ after one hour and by another 1℃ after

another hour, after that, the temperature will be kept on.

5) Timer

a) Timer On

When the unit is powered on but in the idle condition, it is available to set when to start the unit. Then, when

the unit starts, it will run as the previously set mod. The set range of the timer is 0.5~24 hours with a interval of

0.5 hour.

b) Timer Off

When the unit is on, it is available to set when to stop the unit. The set range of timer is 0.5~24 hours with a

interval of 0.5 hour.

6) Memory

a) Memorizing Objects: modes (AUTO, COOL, DRY, FAN, HEAT), swing, set temperature, set fan speed,

etc.

b) When the indoor unit works without the wired controller, it will resume the working condition as the

power failure occurs after it is powered on again. When the indoor unit is with the wired controller, it is available

to set the memory function by pressing the corresponding buttons of the wired controller.

13

Page 19

c) When the indoor unit works without the wired controller, if the timer is not set for the last remote control

instruction, the system will memorize this last instruction and works following it; if the timer is set, it will be

canceled as the power failure occurs and will have to be reset.

d) When the indoor unit works with the wired controller, it will work as the message sent by the wired

controller after it is powered on again.

7) Selection of the Indoor Temperature Sensor

a) For the duct type indoor unit: Under the COOL, HEAT, DRY, or FAN mode, the return air

temperature sensor is adopted; while under the HEAT mode, it is the receiver temperature sensor.

For the cassette type, floor ceiling type indoor unit: Under all modes, the return air temperature sensor is

adopted.

b) When the duct type, cassette type, or the floor ceiling type indoor unit works with the wired controller, the

ambient temperature sensor can be set in the following four ways:

01: The indoor temperature sensor is set for the return air.

02: The indoor temperature sensor is set for the wired controller.

03: The indoor temperature sensor is set for the wired controller under the HEAT mode, and for the return air

under any other mode.

04: The indoor temperature sensor is set for the return air under the HEAT mode, and for the wired controller

under any other mode.

c) Setting of the Ambient Temperature Sensor of the Wired Controller XK19.

◆ When the unit is off, it is available to go to the debugging status by pressing the “Function” and “Timer”

buttons for five seconds, and the corresponding code will be displayed on the temperature area of the

wired controller. There are four kinds of codes which can be adjusted through the “▼”/“▲” button.

◆ The 03 is the default code. The setting of the ambient temperature sensor of the wired controller should

be memorized.

◆ The “Enter/Cancel” button shall be pressed to confirm and leave the setting. If there is no response to

the last button press within 20 seconds, then the system will quit the setting and go to the normal “Off”

status but with the setting still saved.

8) Switchover of the Defrosting Mode

On condition that the unit is off, if “H1” is not displayed on the wireless controller, then the unit will go to

the setting status of the “Defrosting Mode 1”as it is turned on through the wired controller. Then, once the indoor

unit receives this signal, it will soon send it to the outdoor unit. In contract, if “H1”is displayed, the unit will go

the setting status of the “Defrosting Mode 2”, and the indoor unit also will send this signal to the outdoor unit as

soon as it receives it.

On condition that the unit is off, it is available to switch over the “Defrosting Mode 1” and “Defrosting Mode

2” by pressing the “MODE” and “BLOW” buttons simultaneously.

9) Turbo

As soon as the controller receives the “Turbo” instruction, the fan of the indoor unit will run at the high

speed.

10) Blow

Blow Function: It is a function to automatically blow off the moist inside the exchanger of the indoor unit to

prevent mould growing after the unit is shut off.

a) On condition that this function is activated, when the “On/Off” press button is operated, the fan of the

indoor unit will still run for ten minutes (with the symbol “BLOW” displayed). At this time, the fan will stop as

this function is deactivated.

b) This function is unavailable under the AUTO, FAN, and HEAT modes.

14

Page 20

3 REMOTE CONTROLLER

3.1 Wired Remote Controller

3.1.1 Wired Controller XK19

It is designed for the cassette type, duct type and floor ceiling type indoor units.

◆ Outside View of the Wired Controller

◆ LCD of the Wired Controller

No. Symbols Description

1

Swing function.

2

Sleep function

3

Running modes of the indoor unit (Cooling, Dry, Fan, Heating and Auto).

4

Defrosting function for the outdoor unit.

5

Gate-control function.(this function is yet unavailable for this unit)

6

Lock function.

7

High, middle, low or auto fan speed of the indoor unit.

8

Shield functions (buttons, temperature, On/Off, Mode or Save is shielded or Save is

shielded by the remote monitor)

9

Turbo function.

10

Memory function (The indoor unit resumes the original set ting state after power failure and

then power recovery).

15

Page 21

11

Master wired controller (this function is yet unavailable for this unit).

12

It blinks under on state of the unit without operation of any button.

13

Energy-saving function.(this function is yet unavailable for this unit)

14

Ambient/preset temperature value.

15

Electric auxiliary heating function.(this function is yet unavailable for this unit)

16

Blow function.

17

Timing value.

18

Quiet function (two types: quiet and auto quiet).(this function is yet unavailable for this

unit)

19 SET It will be displayed under the debugging mode.

3.1.2 Buttons

Buttons on the Wired Controller

No. Name Function

1 Enter/cancel

① Function selection and cancellation.

② Press it for 5s to examine the outdoor ambient temperature.

2 ▲

① Running temperature setting of the indoor unit, range:16~30℃.

② Timer setting, range:0.5-24 hr.

6 ▼

3 Fan Setting of the high/middle/low/auto fan speed.

4 Mode Setting of the Cooling/Heating/Fan/Dry mode of the indoor unit.

5 Function Switchover among the functions of Swing/Sleep/Turbo/Save/E-heater/Blow /Quiet etc.

7 Timer Timer setting.

8 On/Off Turn on/off the indoor unit.

4+2 ▲+Mode

Press them for 5s under off state of the unit to enter/cancel the Memory function (If

memory is set, indoor unit after power failure and then power recovery will resume the

original setting state. If not, the indoor unit is defaulted to be off after power recovery.

Memory off is default before delivery.).

3 +6 Fan+▼

By pressing them at the same time under off state of the unit,

will be displayed on

the wired remote controller for the cooling only unit, while

will be displayed on the

wired remote controller for the cooling and heating unit.

16

Page 22

2 +6 ▲+▼

Upon startup of the unit without malfunction or under off state of the unit, press them at

the same time for 5s to enter the lock state, in which case, any other buttons won’t

respond the press. Repress them for 5s to quit this state.

3.1.3 Operation Instructions

1) On/Off

Press On/Off to turn on the unit and turn it off by another press.

2) Mode Setting

Under the “On” state of the unit, press Mode to switch the operation modes as the following sequence:

Cooling-Dry-Fan-Heating.

3) Temperature Setting

Press ▲ or ▼ to increase/decrease the preset temperature. If press either of them continuously, the

temperature will be increased or decreased by 1℃ every 0.5s.

In the Cooling, Dry or Heating mode, the temperature setting range is 16℃~30℃.

In the Fan mode, the setting temperature is fixed at 26℃.

In the Auto mode, the setting temperature is unadjustable.

4) Fan Setting

Under the “On”/“Off” state of the unit, press Fan and then fan speed of the indoor unit will change circularly.

5) Timer Setting

Under the “On”/“Off” state of the unit, press Timer to set timer off/on.

Timer on setting: press Timer, and then LCD will display “xx.x hour”, with “hour” blinking. In this case,

press ▲ or ▼ to adjust the timing value. Then press Enter/cancel to confirm the setting.

Timer off setting: press Timer, if LCD won’t display xx.x hour, and then it means the timer setting is

canceled.

Timer range: 0.5-24hr. Every press of ▲ or ▼ will make the set time increased or decreased by 0.5hr. If

either of them is pressed continuously, the set time will increase/ decrease by 0.5hr every 0.5s.

6) Swing Setting

Swing On: Press Function under on state of the unit to activate the swing function. In this case, it will blink.

After that, press Enter/cancel to make a confirmation.

Swing Off: When the Swing function is on, press Function to enter the Swing setting interface, with blinking.

After that, press Enter/cancel to cancel this function.

Notes:

a. Sleep, Save, Turbo, Blow or Quiet setting is the same as the Swing setting.

b. After the setting has been done, it has to press the key “Enter/cancel” to back to the setting status or quit

automatically five seconds later.

7) Sleep Setting

Sleep on: Press Function under on state of the unit till the unit enters the Sleep setting interface. After that,

press Enter/cancel to confirm the setting.

Sleep off: When the Sleep function is activated, press Function to enter the Sleep setting interface. After that,

press Enter/cancel to can this function.

Sleep off is default after power failure and then power recovery, and the sleep functions is unavailable under

the fan mode.

Sleep mode

In the Cooling or Dry mode, the temperature will increase by 1℃ after the unit runs under Sleep 1 for 1 hr

and 1℃ after another 1hr.After that, the unit will run at this temperature.

In the Heating mode, the temperature will decrease by 1℃ after the unit runs under Sleep 1 for 1hr and 1℃

after another 1hr. After that, the unit will run at this temperature.

17

Page 23

Notes:

a. During the above setting, if Function is pressed down or there is not any operatio n w ithi n 5s, slee p curve

setting will be canceled.

b. 26℃ is the default Sleep curve temperature before delivery. The wired controller will automatically

memorize the Sleep curve after the setting.

8) Turbo Setting

Turbo function: The unit at the high fan speed can realize quick cooling or heating so that the room

temperature can quickly approach the setting value.

In the Cooling or Heating mode, press Function till the unit enters the Turbo setting interface and then press

Enter/Cancel to confirm the setting.

When the Turbo function is acti va ted, press Function to enter the Turbo setting interface and then press

Enter/Cancel to cancel this function.

Notes:

a. When the Turbo function is activated, if the difference between the room temperature and set temperature

is at or below 2℃ (detected in successive 1 min.), the Turbo function will be automatically deactivated.

b. Turbo function is unavailable in the Dry and Fan mode. And the Turbo function is off after power failure

and then power recovery. If Quiet function is on, Turbo function will be canceled subsequently.

9) E-heater Setting

E-heater (auxiliary electric heating function): In the Heating mode, E-heater is allowed to be turned on for

improvement of efficiency.

Once the wired controller or the remote controller enters the Heating mode, this function will be turned on

automatically.

Press Function in the Heating mode to enter the E-heater setting interface and then press Enter/cancel to

cancel this function.

Press Function to enter the E-heater setting interface, if the E-heater function is not activated, and the n pr ess

Enter/Cancel to turn it on.

10) Blow Setting

Blow function: After the unit is turned off, the water in evaporator of indoor unit will be automatically

evaporated to avoid mildew.

In the Cooling or Dry mode, press Function till the unit enters the Blow setting interface and then press

Enter/Cancel to active this function.

When the Blow function is activated, press Function to the Blow setting interface and then press

Enter/Cancel to cancel this function.

Notes:

a. When the Blow function is activated, if turning off the unit by pressing On/Off or by the remote controller,

the indoor fan will run at the low fan speed for 10 min, with “BLOW” displayed on the LCD. While, if the Blow

function is deactivated, the indoor fan will be turned off directly.

b. Blow function is unavailable in the Fan or Heating mode.

11) Other Functions

Lock

Upon startup of the unit without malfunction or under the “Off” state of the unit, press ▲ and ▼ at the

same time for 5s till the wired controller enters the Lock function. In this case, LCD displays. After that, repress

these two buttons at the same time for 5s to quit this function.

Under the Lock state, any other button press won’t get any response.

Memory

Memory switchover: Under the “Off” state of the unit, press Mode and ▲ at the same time for 5s to switch

18

Page 24

memory states between memory on and memory off. When this function is activated, Memory will be displayed.

If this function is not set, the unit will be under the “Off” state after power failure and then power recovery.

Memory recovery: If this function has been set for the wired controller, the wired controller after power

failure will resume its original running state upon power recovery. Memory contents: On/Off, Mode, set

temperature, set fan speed, Save function and Lock function.

Enquiry of the Outdoor Ambient Temperature

Under the “On” or “Off” state of the unit, press Enter/Cancel for 5s, and the outdoor ambient temperature

will be displayed after a sound of click. This enquiry state will quit by pressing Function or On/Off or during the

temperature adjustment. If there is not any operation for 10s, it will also quit automatically.

3.1.4 Errors

If there is an error occurring during the operation of the system, the error code will be displayed on the LCD.

If multi errors occur at the same time, their codes will be displayed circularly.

Note: In event of any error, please turn off the unit and contact the professionally skilled personnel.

Error Error Code

High pressure protection E1

Low pressure protection E3

Discharge protection E4

Over-current protection P5

Communication error E6

Indoor water overflow protection E9

Mode conflict E7

Anti-freezing protection E2

Defrosting or oil returning for heating H1

Indoor ambient temperature sensor open/short circuit F1

Evaporator temperature sensor open/short circuit F2

Indoor unit (liquid valve) refrigerant pipe inlet temperature sensor error b5

Indoor unit (gas valve) refrigerant pipe outlet temperature sensor error b7

Condenser coil inlet temperature sensor open/short circuit A5

Condenser coil midway temperature sensor error F4

Condenser coil outlet temperature senor open/short circuit A7

Discharge air temperature sensor error F5

Outdoor ambient temperature sensor error F3

Module temperature sensor error oE

Outdoor unit overall error oE

19

Page 25

1) ON/OFF

Press this button to turn on the unit. Press this button again to turn off the unit.

2) -

Press this button to decrease set temperature. Holding it down above 2 seconds rapidly decreases set

temperature. In AUTO mode, set temperature is not adjustable.

3) +

Press this button to increase set temperature. Holding it down above 2 seconds rapidly increases set

temperature. In AUTO mode, set temperature is not adjustable.

4) MODE

Each time you press this button, a mode is selected COOL, DRY, FAN, and HEAT *, as the following:

*Note: Only for models with heating function.

After energization, AUTO mode is defaulted. In AUTO mode, the set temperature will not be displayed on

the LED of the indoor, and the unit will automatically select the suitable operation mode in accordance with the

room temperature to make indoor room comfortable.

5) FAN

This button is used for setting Fan Speed in the sequence that goes from AUTO,

, , ,

, , then back to Auto.

Low speed Low-Medium speed Medium speed

Medium-High speed High speed

6) SWING

20

2

Page 26

Press this button to set up &down swing angle, which circularly changes as below:

This remote controller is universal. If any command

, or is sent out, the unit will carry out the

command as

indicates the guide louver swings as:

7) I FEEL:

Press this button to turn on I FEEL function. The units automatically adjust temperature according to the

sensed temperature. Press this button again to cancel I FEEL function.

8)

Press this button to achieve the on and off of healthy and scavenging functions in operation status. Press this

button for the first time to start scavenging function; LCD displays“

”. Press the button for the second time to

start healthy and scavenging functions simultaneously; LCD displays“

” and “ ”. Press this button for the

third time to quit healthy and scavenging functions simultaneously. Press the button for the fourth time to start

healthy function; LCD display “

”. Press this button again to repeat the operation above.

9) SLEEP:

◆ Press this button, can select Sleep 1 (

), Sleep 2 ( ), Sleep 3 ( ) and cancel the Sleep, circulate

between these, after electrified, Sleep Cancel is defaulted.

◆ Sleep 1 is Sleep mode 1, in Cool or dry mode: sleep status after run for one hour, the main unit setting

temperature will increase 1℃, after 2 hours the setting temperature will increase 2℃, but the maximal setting

temperature is 30℃, then the unit will run at this setting temperature all along; In Heat mode: sleep status

after run for one hour, the setting temperature will decrease 1℃, after 2 hours the setting temperature will

decrease 2℃, but the minimal setting temperature is 16℃, then the unit will run at this setting temperature.

◆ Sleep 2 is sleep mode 2, that is air conditioner will run according to the presetting a group of sleep

temperature curve.

◆ Sleep 3- the sleep curve setting under Sleep mode by DIY:

① Under Sleep 3 mode, press "Turbo" button for a long time, remote control enters into user individuation

sleep setting status, at this time, the time of remote control will display "1hour ", the setting temperature

"88" will display the corresponding temperature of last setting sleep curve and blink (The first entering

will display according to the initial curve setting value of original factory);

② Adjust "+" and "-" button, could change the corresponding setting temperature, after adjusted, press

"Turbo" button for confirmation;

③ At this time, 1 hour will be automatically increased at the timer position on the remote control, (that are

"2 hours " or "3 hours " or "8 hours "), the place of setting temperature "88"will display the

corresponding temperature of last setting sleep curve and blink;

④ Repeat the above step (2) ~ (3) operation, until 8 hours temperature setting finished, sleep, curve

setting finished, at this time, the remote control will resume the original timer display; temperature

21

Page 27

display will resume to original setting temperature.

Sleep3- the sleep curve setting under SLEEP mode by DIY could be inquired:

◆ The user could accord to sleep curve setting method to inquire the presetting sleep curve, enter into user

individuation sleep setting status, but do not change the temperature, press "Turbo" button directly for

confirmation.

Note: In the above presetting or enquiry procedure, if continuously within 10s, there is no button pressed, the

sleep curve setting within 10s, there is no button pressed, the sleep curve setting status will be automatically quit

and resume to display the original displaying. In the presetting or enquiry procedure, press "ON/OFF" button,

"Mode" button, "Timer" button or "Sleep" button, the sleep curve setting or enquiry status will quit similarly.

10) TEMP:

Press this button, could select displaying the indoor setting temperature or indoor ambient temperature. When

the indoor unit firstly power on it will display the setting temperature, if the temperature's displaying status is

changed from other status to"

",displays the ambient temperature, 5s later or within 5s, it receives other

remote control signal that will return to display the setting temperature. If the users haven't set up the temperature

displaying status, that will display the setting temperature.

11) QUIET:

Press this button, the Quiet status is under the Auto Quiet mode (display "

"signal ) and Quiet mode

(display "

" signal) and Quiet OFF (there is no signal of ""displayed),after powered on, the Quiet OFF is

defaulted.

Note: the Quiet function cannot be set up in Fan and Dry mode; Under the Quiet mode

(Display "

" Under the Quiet mode (Display "" signal), the fan speed is not available.

12) CLOCK :

Press CLOCK button, blinking

. Within 5 seconds, pressing + or - button adjusts the present time.

Holding down either button above 2 seconds increases or decreases the time by 1 minute every 0.5 second and

then by 10 minutes every 0.5 second. During blinking after setting, press CLOCK button again to confirm the

setting, and then

will be constantly displayed.

13) T-ON/ T-OFF:

Press T-ON button to initiate the auto-ON timer. To cancel the auto-timer program, simply press this button

again.

After press of this button,

disappears and "ON "blinks. 00:00 is displayed for ON time setting. Within

5 seconds, press + or - button to adjust the time value. Every press of either button changes the time setting by 1

minute. Holding down either button rapidly changes the time setting by 1 minute and then 10 minutes. Within 5

Seconds after setting, press TIMER ON button to confirm.

Press T-OFF button to initiate the auto-off timer. To cancel the auto-timer program, simply press the button

again. TIMER OFF setting is the same as TIMER ON.

14) TURBO:

22

Page 28

Press this button to activate / deactivate the Turbo function which enables the unit to reach the preset

temperature in the shortest time. In COOL mode, the unit will blow strong cooling air at super high fan speed. In

HEAT mode, the unit will blow strong heating air at super high fan speed.

15) LIGHT:

Press LIGHT button to turn on the display's light and press this button again to turn off the display's light. If

the light is turned on,

is displayed. If the light is turned off, disappears.

16) X-FAN:

Pressing X-FAN button in COOL or DRY mode, the icon

is displayed and the indoor fan will continue

operation for 10 minutes in order to dry the indoor unit even though you have turned off the unit. After

energization, X-FAN OFF is defaulted. X-FAN is not available in AUTO, FAN or HEAT mode.

3.3.2 Guide for General Operation

1) Combination of "+"and "-" buttons: About lock

Press "+" and "-" buttons simultaneously to lock or unlock the keypad. If the remote controller is locked,

is displayed. In this case, pressing any button, blinks three times.

2) Combination of "MODE " and "-" buttons :

About switch between Fahrenheit and centigrade At unit OFF, press "MODE" and "-" buttons

simultaneously to switch between and .℃℉

3) Combination of " TEMP " and "CLOCK" buttons : About Energy-saving Function

Press “TEMP” and “CLOCK” simultaneously in COOL mode to start energy-saving function. Nixie tube on

the remote controller displays “SE”. Repeat the operation to quit the function.

4) Combination of "TEMP " and "CLOCK" buttons: About 8℃ Heating Function

Press “TEMP” and “CLOCK” simultaneously in HEAT mode to start 8℃ Heating Function Nixie tube on

the remote controller displays “

” and a selected temperature of “8℃”. (46℉ if Fahrenheit is adopted). Repeat

the operation to quit the function.

5) About Back-lighting Function

The unit lights for 4s when energizing for the first time, and 3s for later press.

a. Single control: it is intended to control the running parameters of a designated indoor unit individually.

conditioning system.

enient control to the air

ce shielding to realize convfurther, it also can set the weekly timer and long-distan

unit, including on/off, running mode, fan speed etc, and also perform the single control and centralized control,

Through this central controller, it is available to view and control those running parameters of the indoor

. 3 outdoor units and 16 indoor units

controlling up to

This central controller is a kind of regional controller, which is designed for free match units, capable of

4.1.1 Function Introduction

General Introduction

4.1

Central Controller SCC-16

4

23

Page 29

4.1.2 Scope of application

The central controller cannot be adapted to all kinds of indoor units and the wired remote controller must

be used in the indoor units. So the wall mounted and console types are beyond the scope of the central

controller.

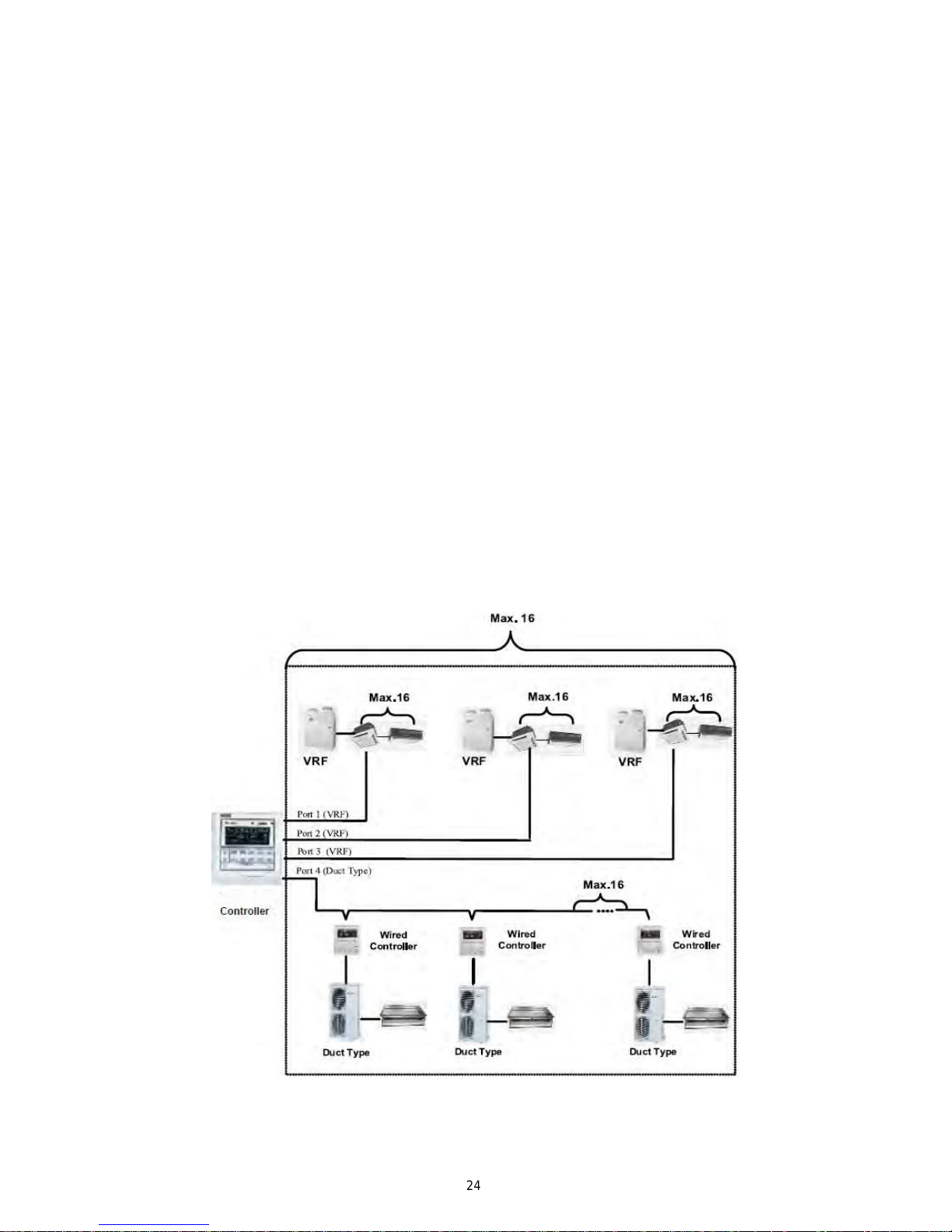

4.2 Communication Network

Note: The central controller can connect with maximum up to

16 indoor units

.

Central

the communication module, which can extremely ease and simplify the installation.

This smart zone controller can be connected to the unit through the communication line without the need of

When some error occurs, the error symbol and the error code will be displayed to warn a quick maintenance.

parameter setting of the current running mode, set temperature, fan speed, weekly timer, shielding function etc.

After the debugging to the controller is finished, it can check the on-line indoor units and display the

e. Clock: it is intended to set and display the weekday, hour and minute.

long-distance control.

d. Weekly timer under single or centralized control: it is intended to set when to start/stop the unit through

b. Centralized control: it is intended to control the running parameters of all indoor units at the same time.

c. Shielding under single or centralized control: it is intended to shield the running parameter of the indoor

unit.

24

Page 30

4.3 LCD

No. Name Description

1 Fan speed It displays the fan speed of the indoor unit, high, medium, low and auto.

2 Running mode It displays the running mode of the indoor unit, auto, cool, dry, fan and heat.

3 System clock

It displays the current time (hour and minute) in 24-hour time system and also

the week day.

4 Shield It displays the shielded status, “ALL”, “TEMP”, “MODE” and “ON/OFF”.

5 Weekly timer It displays the timing period (unit: 0.5 hour) which will circulate every week.

6

Set temperature/

Indoor unit code

It displays the set temperature, indoor unit code (01-16), and symbols of Celsius

and Fahrenheit scale.

7 Control mode

It displays “CENTER” under the centralized control m ode and no display un der

the single control mode.

8

Ambient temperature/

Serial port

It displays the ambient temperature, serial port as well as symbols of Celsius and

Fahrenheit scale.

9

Indoor unit code/

on/

off status

Numbers indicate the indoor unit codes which will be displayed when the

corresponding indoor unit is online; “□” indicates the on/off status of the indoor

unit, that is, when it is bright, it m eans the unit is “On”; when it is gone out, it m eans

the unit is “Off”.

10 Error , Child lock

It displays the error codes when some error(s) arises and also “CHILD LOCK”

when this function is activated.

4.4 Buttons

4.4.1 Outline of Buttons

25

Page 31

4.4.2 Introduction to the Function of Buttons

No. Name Function Description

1 Mode It is used for the switchover among different modes.

2 Fan It is used to set the fan speed, high, medium, low or auto.

3 On/Off It is used to set the on/off status of the indoor unit.

4

▲

1. Under the single/centralized control status: It is used to set the r unning t em perature of

the indoor unit with max.30 and min.16 ;

℃℃

2. Under the timing setting status: It is used to set the timing period with max.24 hours

and min.0 hour;

3. Under the clock setting status: it is used to set the hour (max.:23, min.: 0) and minute

(max.:59, min.: 0) of the clock.

5

▼

6 Mon 1/9

It is used for the switchover between unit 1 and unit 9 ; Under the timing or clock setting

status, it indicates Monday.

7 Tue 2/10

It is used for the switchover between unit 2 an d unit 10; Under the timing or cloc k setting

status, it indicates Tuesday.

8 Wed 3/11

It is used for the switchover between unit 3 and unit 1 1; Under t he timing or clock setting

status, it indicates Wednesday.

9 Thu 4/12

It is used for the switchover between unit 4 an d unit 12; Under the timing or cloc k setting

status, it indicates Thursday.

10

Fri 5/13 It is used for the switchover between unit 5 and unit 13; Under the timing or clock setting

status, it indicates Friday.

11

Sat 6/14 It is used for the switchover between unit 6 and unit 14; Under t he timing or cloc k setting

status, it indicates Saturday.

12

Sun 7/15 It is used for the sw itchover between un it 7 and unit 15; Under the timing or clock setting

status, it indicates Sunday.

13 8/16 It is used for the switchover between unit 8 and unit 16.

14 Ti mer/Ti me

It is used to set the timing or on/off time of the selec ted indoor unit as well as to set th e

clock of the system.

17 All on/All off It is used to start/stop all indoor units.

16 Shield It is used to deactivate some or all functions of a single or a group the indoor unit(s).

15 Central It is used for the switchover between single and centralized control modes.

26

Page 32

INSTALLATION

1 PRECAUTIONS FOR INSTALLATION

1.1 Precautions for Installation

Before installation, please ensure the installing site, power ratings, possible operating range (pipe distance,

height difference between indoor and outdoor unit, power voltage) and installing space are correct and suitable.

To ensure correct installation, please make sure to read the Safety Considerations thoroughly before

starting the installation works.

After completing the installation and test run and confirming that all are normal, please introduce to the

client on how to use and repair the machine according to the Operating Instructions. Besides, please

deliver the considerations herein to the clients together with the Operating Instructions, and ask them to

keep properly.

Warning!

:It indicates improper operation which will lead to human casualty or severe injury.

Caution!

: It indicates improper operation which will lead to injury or property damage.

Warning !

The installation and relocation should be left to the appointed service center and must be installed by professional or

qualified persons. Otherwise, it maybe cause water leakage, electric shocks or fire etc.

Please install the air conditioner according to the instructions given in the installation instructions. Improper

installation may cause fall down, water leakage, electric shock or fire etc.

To install a large air-conditioning system in a small room, please make sure to take measures to prevent that the

refrigerant will not exceed the limit concentration in case of leakage. For the measures to prevent the refrigerant from

exceeding the limit concentration, please consult your dealer. If no proper measures, it might cause human suffocation

in case of refrigerant leakage.

Please install the unit on a solid place where is strong enough to support the weight of the unit; Otherwise, the unit

would fall down and cause injury or death.

Please keep the room well-ventilated and it could avoid oxygen deficit.

Electrical work should be carried out in accordance with the installation manual and the local laws and regulations.

Insufficient capacity or incomplete electrical work may cause electrical shock or fire etc.

Please use suitable cables and connect them securely. Please fix the terminal joints securely. The terminal

connection shall not be affected due to any external force applied onto the cable. Improper connection and fixing may

cause heating and fire accidents.

The power supply must adopt the special circuit with air switch protection and assure it has enough capaci ty ; T he

unit will be turned on or off according to your requirement automatically, please do not turn on or off the unit

frequently. Otherwise, disadvantage effect may be caused to the unit.

Never cut off or damage power cables and control wires. If the power cable and signal control wire were damaged,

it must be replaced by the manufacturer, its service agent or similarly qualified persons in order to avoid a hazard.

The electrical work should use a cable length enough to cover the entire distance with no connection. If it is

unavoidable, please make sure the connection should be reliable and the external forces will not act on the wires.

Otherwise it will cause electrical shock or fire etc.

When erecting or relocating the air conditioner, do not let any air enter into cooling circulation system except the

specified refrigerant. If any air is mixed, abnormal high pressure will occur in the cooling circulation system, thus

causing crack or human injury accidents.

27

Page 33

Do not use or store flammable, explosive, poisonous or other dangerous substances beside the air conditioner.

The compressor will vibrate sharply if the voltage is too low and damage the refrigerating system. Electrical

component are easy to damage if the voltage is too high.

The voltage should be stable; there shouldn’t be big fluctuation

Please take notice of the installation foundation of the unit after long use, if it is damaged, it may lead to the fall of

the unit and cause the injury.

The refrigerant pipes and accessories must be designed exclusively for R410A.

Caution!

Before installation, please check that whether the power supply corresponds with the requirement specified on the

nameplate and also check its security.

Before using the unit, please check the piping and wiring, ensure they are correct to avoid water leakage,

refrigerant leakage, electric shock, or fire etc.

Ground connection: connect to the ground reliably! The ground wire should be connected to the appropriative

grounding device of the building. If the appropriative grounding device is not available, please ask a professional to

install. Never connect the ground wire to gas pipe, water pipe, lightning rod, telephone line or other unreliable places

considered by a professional.

The total capacity of the indoor units which runs at the same time cannot exceed the capacity of the outdoor units;

otherwise, the cooling (heating) effect of each indoor unit would be lower than the nominal capacity.

If the supply power fails when the unit is running, then the indoor unit will send the “start” signal to the outdoor

unit three minutes later after the power recovery.

It must install an earth leakage breaker. Otherwise, it maybe cause electric shocks or fire etc.

Install the air conditioner, the power wire and transmission line must be more than one meter away from televisions

or radios which can emit electromagnetic waves to prevent image interference or noise. Otherwise, the unit maybe

cannot work.

The drain pipe should be installed as instructed in the manual to guarantee the proper drainage; meanwhile it should

be insulated to prevent condensing; otherwise the improper installation would cause water leakage and then wet the

household wares in the room.

Be sure to shut off the power supply when you do not use the air conditioner for a long time. Otherwise, the dusts

may accumulate in it, which may cause overheating or fire hazards.

Never standing on the outdoor unit or place objects on it. Person or objects fal ling from the unit may cause injury.

The air conditioner is not support to install in the circumstances as the following that where there is full of mist of

oil, corrosive gas, flammable gases, the acidic or alkaline vapor and the ocean.

Before startup of the compressor, please turn on the main power switch of the unit for more than 8 hours and it

makes sure that the heater belt of the compressor has been energized for at least eight hours! Once the compressor is

started, it must be guaranteed that it works continuously for at least 30 minutes, otherwise it would be damaged!

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety. Children should be supervised to ensure that they do not

play with the appliance.

Never operate the unit with wet hands. Otherwise, it may cause electric shock.

Before cleaning and repairing, it is necessary to stop working and turn off the power supply. Otherwise, it may cause

electric shock or damage.

It is suggested to have a power-on test annually.

28

Page 34

1.2 Key Points of Installation

Installation Procedures Description and Acceptance Criteria

Material Selection and Equipment Inspection

◆ The materials specified on the engineering drawing shall be

purchased as specified (e.g. copper tube, thermal insulation

tube, PVC pipe, power cables, air switch, etc).

◆ The materials not specified on the engineering drawing shall

be purchased according to the actual quantity of works (e.g.

hanger frame, cable duct, etc).

◆ Check if the outdoor unit, indoor unit, DB modules,

communication wires and accessories are complete.

Installation of

indoor unit

Communica

tion wire

Connection

◆ The power cables shall be separated from communication

wires at a least distance of 2cm.

◆ To avoid breaking the communication wires, please do not use

strong force.

◆ For multiple units, please mark them properly.

◆ Switch on the unit, and ensure there is no display of

“Communication Wire Error E6”.

Address dial

code

◆ Each DB module and indoor unit under the same system has a

unique address dial code.

◆ The wired controller and its corresponding indoor unit have

the same address dial code.

Remote Control

◆ Select the remote control mode.

◆ The centralized controller and communication module shall be

installed free from the source of interference.

Power cord

◆ The power cable must meet the specifications.

Drainage

Pipe

Installation

◆ The PVC pipes must meet the specifications.

◆ A specific gradient must be provided along the water flow

direction.

◆ Carry out water detection after installation.

◆ Carry out thermal insulation to the drainage pipe only after the

water detection is accepted.

Thermal

insulation

◆ The thermal insulation tube must meet the specifications.

◆ Seal between the thermal insulation pipes to avoid air entry.

Installation of

connection pipes

Welding

◆ The copper tube must meet the specifications.

◆ Ensure it is dry and clean inside the tube.

◆ Make sure to charge nitrogen as required for protection when

welding the tubes.

◆ Please keep to the welding process and ensure the system free

of leakage.

◆ Add a dual-way filter on liquid pipe side

◆ For multiple systems, please mark them properly.

◆ Carry out leakage detection under pressure after welding.

Purge and make leakage

detection under pressure

◆ Purge the system clean.

◆ Keep the pressure for 24 hours

◆ Except for the influence by temperature, it is deemed

29

Page 35

acceptable if pressure drop is within 0.02MPa. (With the

temperature change by 1 , the pressure will change by ℃

approx. 0.01MPa)

Thermal insulation

◆ The thermal insulation tube must meet the specifications.

◆ Seal between the thermal insulation pipes to avoid air entry.

Installation of outdoor unit

◆ Select the installing position correctly.

◆ Build the foundation according to the anchor bolt position and

the dimension of outdoor unit

◆ Build the damping device properly.

◆ Avoid sharp knock when handling the outdoor unit. The

inclination angle shall not be higher than 15°.

Connection of indoor unit and outdoor unit

◆ Tighten the nuts.

◆ Provide proper protection to the outdoor connection pipe,

communication wires and power supply.

Leakage detection under pressure

◆ Keep the pressure for 24 hours. Except for the influence by

temperature, it is deemed acceptable if pressure drop is within

0.02MPa. (With the temperature change by 1℃, the pressure

will change by approx. 0.01MPa).

Vacuuming

◆ Establish vacuum simultaneously in the gas pipe and liquid

pipe;

◆ The vacuuming time shall be long enough.

◆ Put still for 1 hour after vacuuming. It is deemed acceptable if

the pressure will not rise.

Add refrigerant

◆ Add refrigerant according to the volume as specified on the

engineering drawing.

Open the valve of outdoor unit

Commissioning of complete unit

Remarks:

a. Described above are general working procedures. The procedures might vary with the site conditions.

b. For detailed installation rules, please see the description in each chapter

30

Page 36

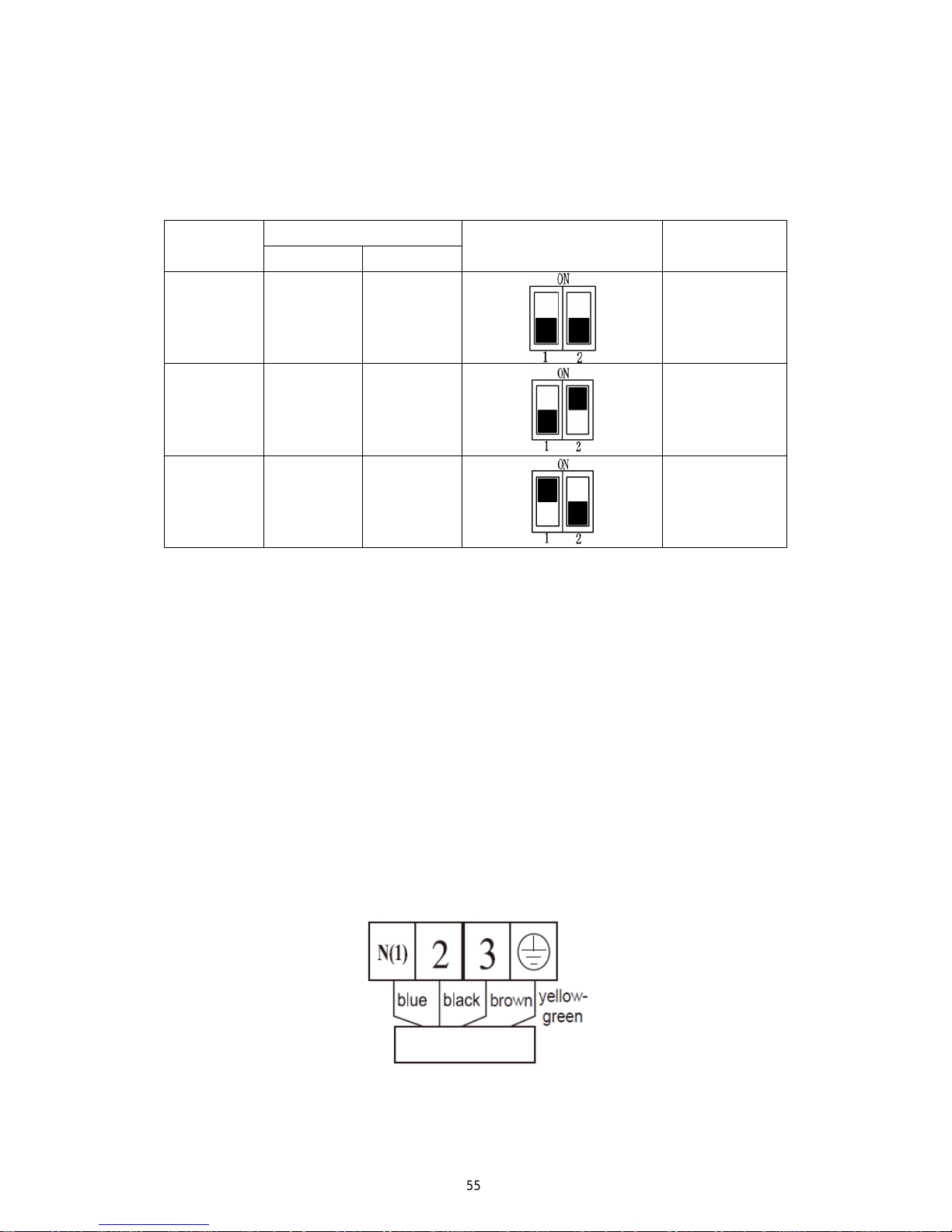

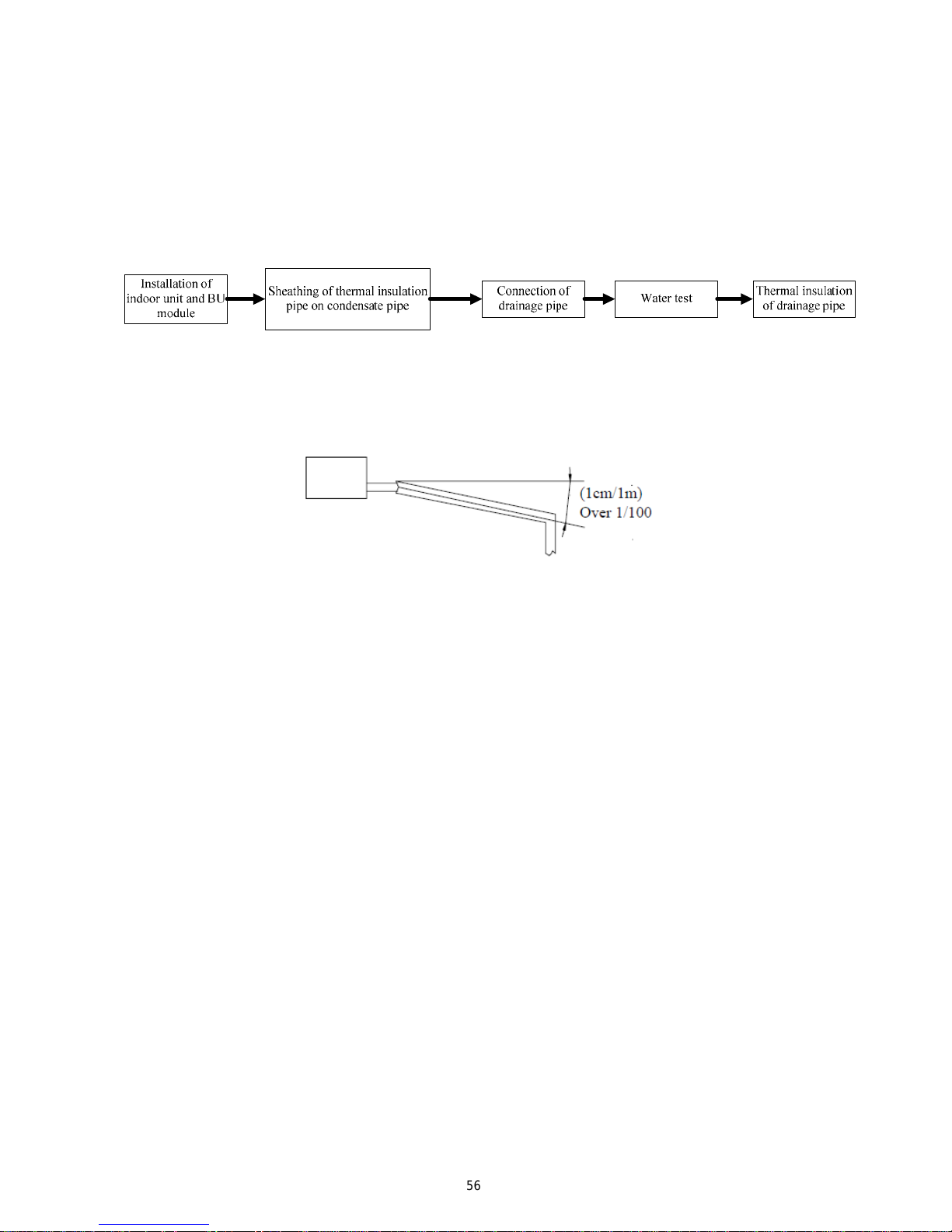

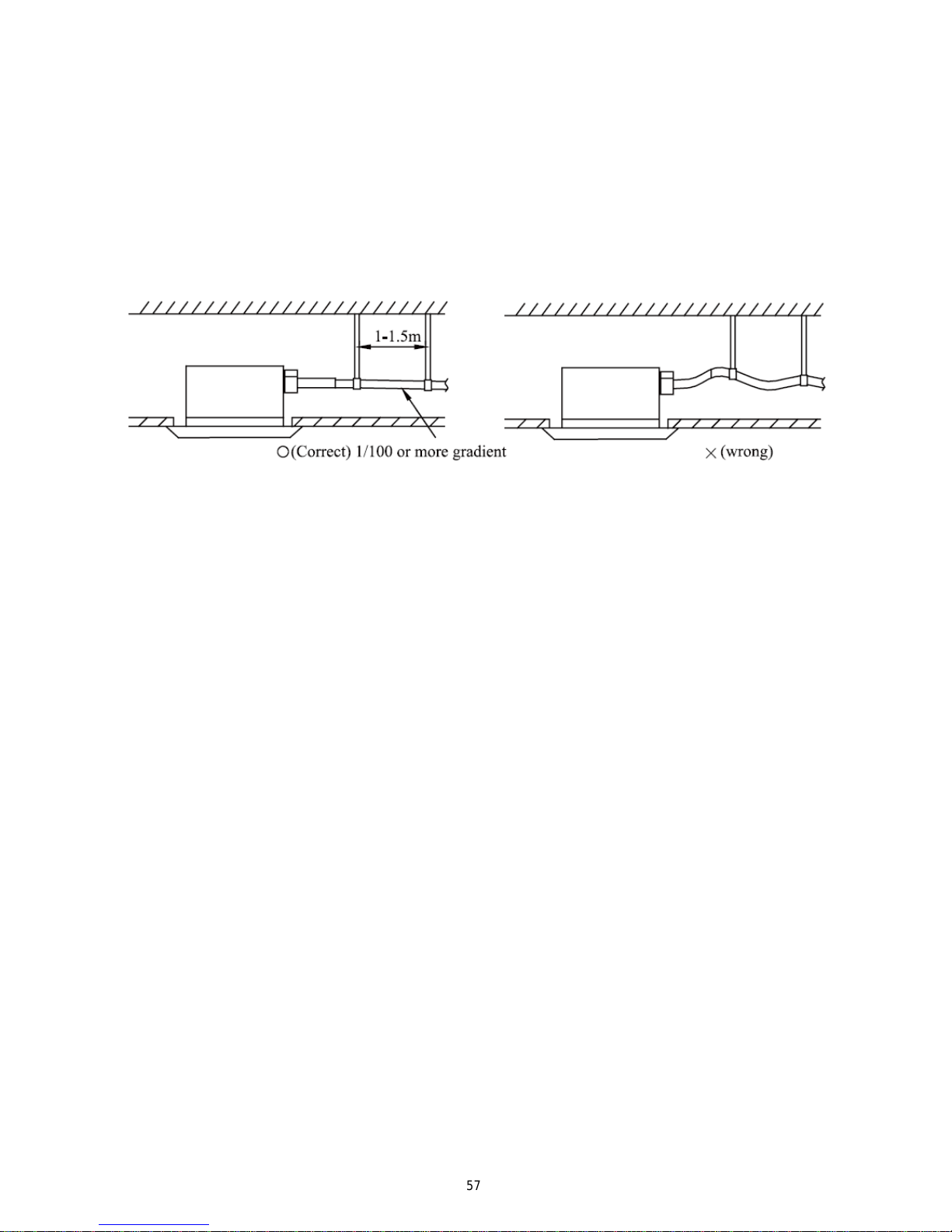

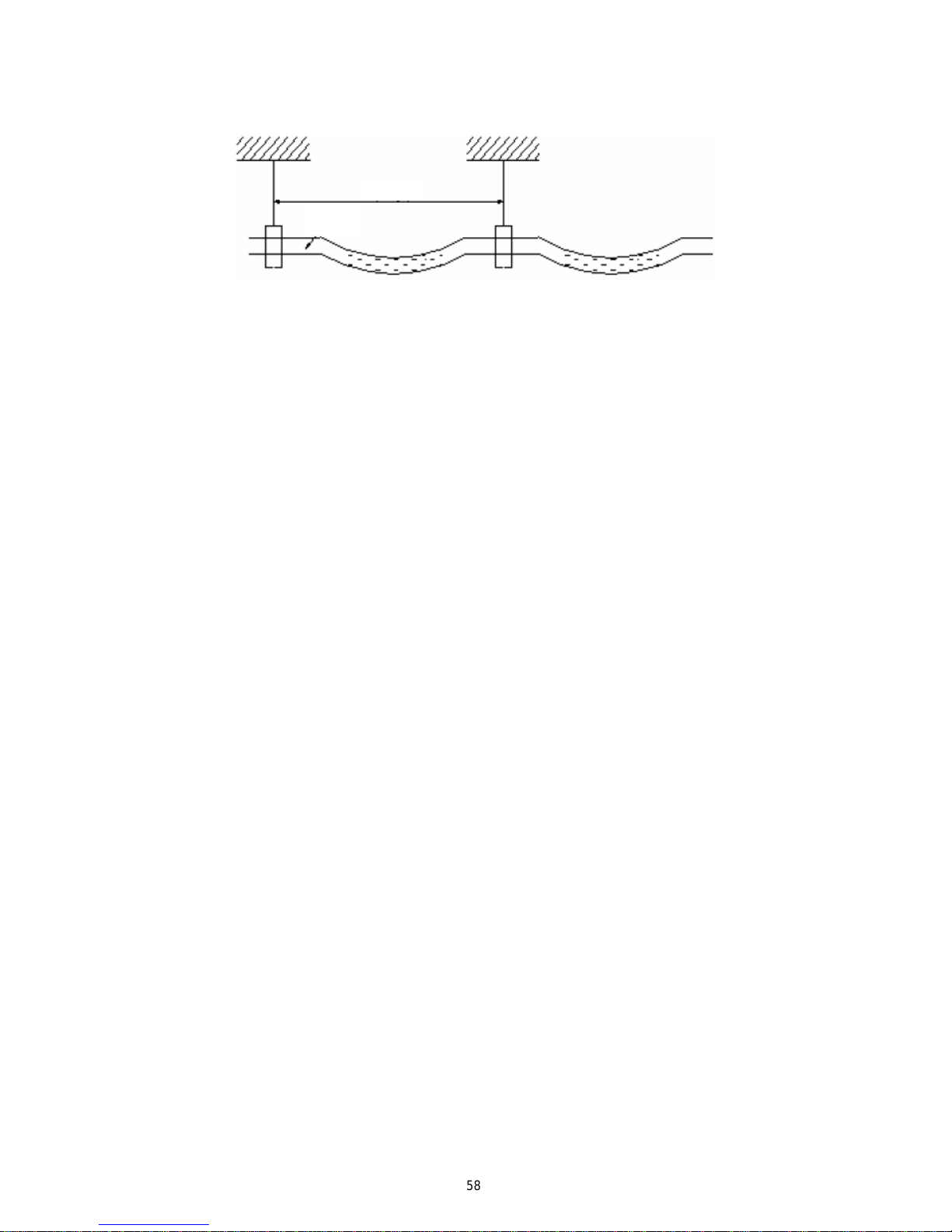

2 FLOW CHART OF INSTALLATION