SIMTEK STK16C68-W45I, STK16C68-W35I, STK16C68-W45, STK16C68-W35, STK16C68-W25I Datasheet

...

STK16C68

8K x 8 AutoStorePlus™ nvSRAM

QuantumTrap™ CMOS

Nonvolatile Static RAM

FEATURES

• Transparent Data Save on Power Down

• Internal Capacitor Guarantees AutoStore™

Regardless of Power-Down Slew Rate

• Nonvolatile Storage without Battery Problems

• Directly Replaces 8K x 8 Static RAM, Battery-

Backed RAM or EEPROM

• 20ns, 25ns, 35ns and 45ns Access Times

• STORE to EEPROM Initiated by Software or

AutoStorePlus™ on Power Down

• RECALL to SRAM Initiated by Software or

Power Restore

• 10mA T ypical I

• Unlimited READ, WRITE and RECALL Cycles

• 1,000,000 STORE Cycles to EEPROM

• 100-Year Data Retention over Full Industrial

Temperature Range

• No Data Loss from Undershoot

• Commercial and Industrial Temperatures

• 28-Pin 600 mil PDIP and 350 mil SOIC Packages

at 200ns Cycle Time

CC

DESCRIPTION

The STK16C68 is a fast SRAM with a nonvolatile

EEPROM element incorporated in each static memory

cell. The

number of times, while independent nonvolatile data

resides in

the

automatically on power down. An internal capacitor

guarantees the

down slew rate. Transfers from the

SRAM (the RECALL operation) take place automatically

on restoration of power. Initiation of

RECALL cycles can also be controlled by entering con-

trol sequences on the

pin-compatible with 8k x 8

SRAMs, allowing direct substitution while enhancing

performance. The STK12C68, which uses an external

capacitor, and the STK15C68, which uses charge

stored in system capacitance, are alternatives for systems needing AutoStore™ operation.

SRAM can be read and written an unlimited

EEPROM. Data transfers from the SRAM to

EEPROM (the STORE operation) can take place

STORE operation regardless of power-

EEPROM to the

STORE and

SRAM inputs. The STK16C68 is

SRAMs and battery-backed

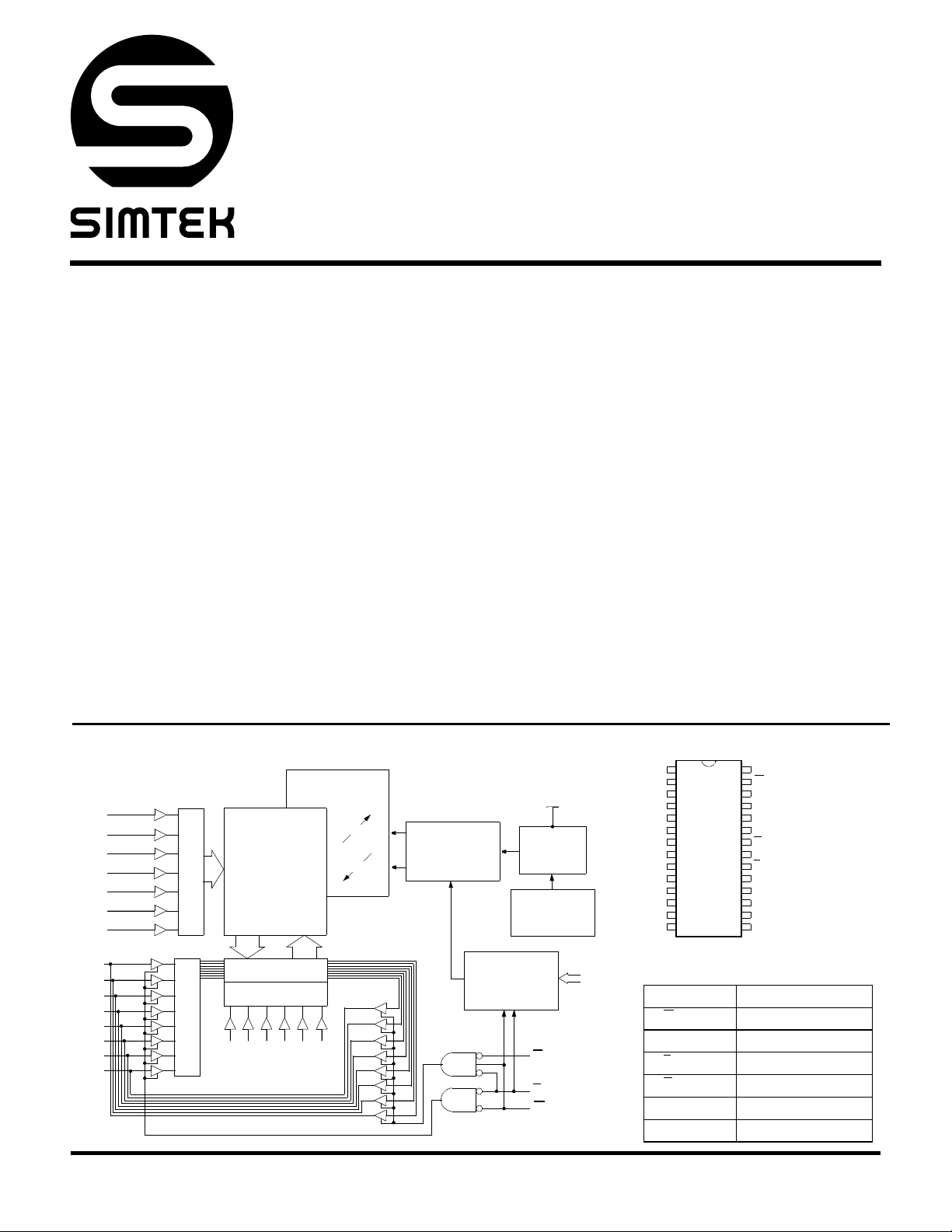

BLOCK DIAGRAM

EEPROM ARRAY

128 x 512

A

DQ

DQ

DQ

DQ

DQ

DQ

DQ

DQ

5

A

6

A

7

A

8

A

9

A

11

A

12

0

1

2

3

4

5

6

7

INPUT BUFFERS

ROW DECODER

STATIC RAM

ARRAY

128 x 512

COLUMN I/O

COLUMN DEC

A0A

2

1

A3A

STORE

RECALL

A

A

10

4

STORE/

RECALL

CONTROL

SOFTWARE

July 1999 4-73

CAPACITOR

DETECT

V

CC

POWER

CONTROL

INTERNAL

G

E

W

A0 - A

PIN CONFIGURATIONS

NC

1

A

2

12

3

A

7

A

4

6

A

5

5

A

6

4

A

7

3

8

A

2

9

A

1

10

A

0

11

DQ

0

12

DQ

1

DQ

13

2

V

14

SS

PIN NAMES

12

A0 - A

W Write Enable

DQ0 - DQ

E Chip Enable

G Output Enable

V

CC

V

SS

28

V

CC

27

W

26

NC

25

A

8

A

24

9

A

23

11

22

G

21

A

10

20

E

19

DQ

7

18

DQ

6

17

DQ

5

16

15

28 - 600 PDIP

DQ

4

28 - 350 SOIC*

DQ

3

*see order info

7

Address Inputs

Data In/Out

Power (+ 5V)

Ground

12

STK16C68

ABSOLUTE MAXIMUM RATINGS

Volt age on Input Rel ative to VSS. . . . . . . . . . –0.6V to (VCC + 0.5V)

Volt age on DQ

Temperature under Bias . . . . . . . . . . . . . . . . . . . . . –55°C to 125°C

Storage Temperature . . . . . . . . . . . . . . . . . . . . . . . –65°C to 150°C

Power Dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1W

DC Output Current (1 output at a time, 1s duration). . . . . . . . 15mA

. . . . . . . . . . . . . . . . . . . . . . –0.5V to (VCC + 0.5V)

0-7

a

Note a: Stresses greater than those listed under “Absolute Maximum

Ratings” may cause permanent damage to the device. This is a

stress rating only, and functional operation of the device at conditions above those indicated in the operational sections of this

specification is not implied. Exposure to absolute maximum rating conditions for extended periods may affect reliability.

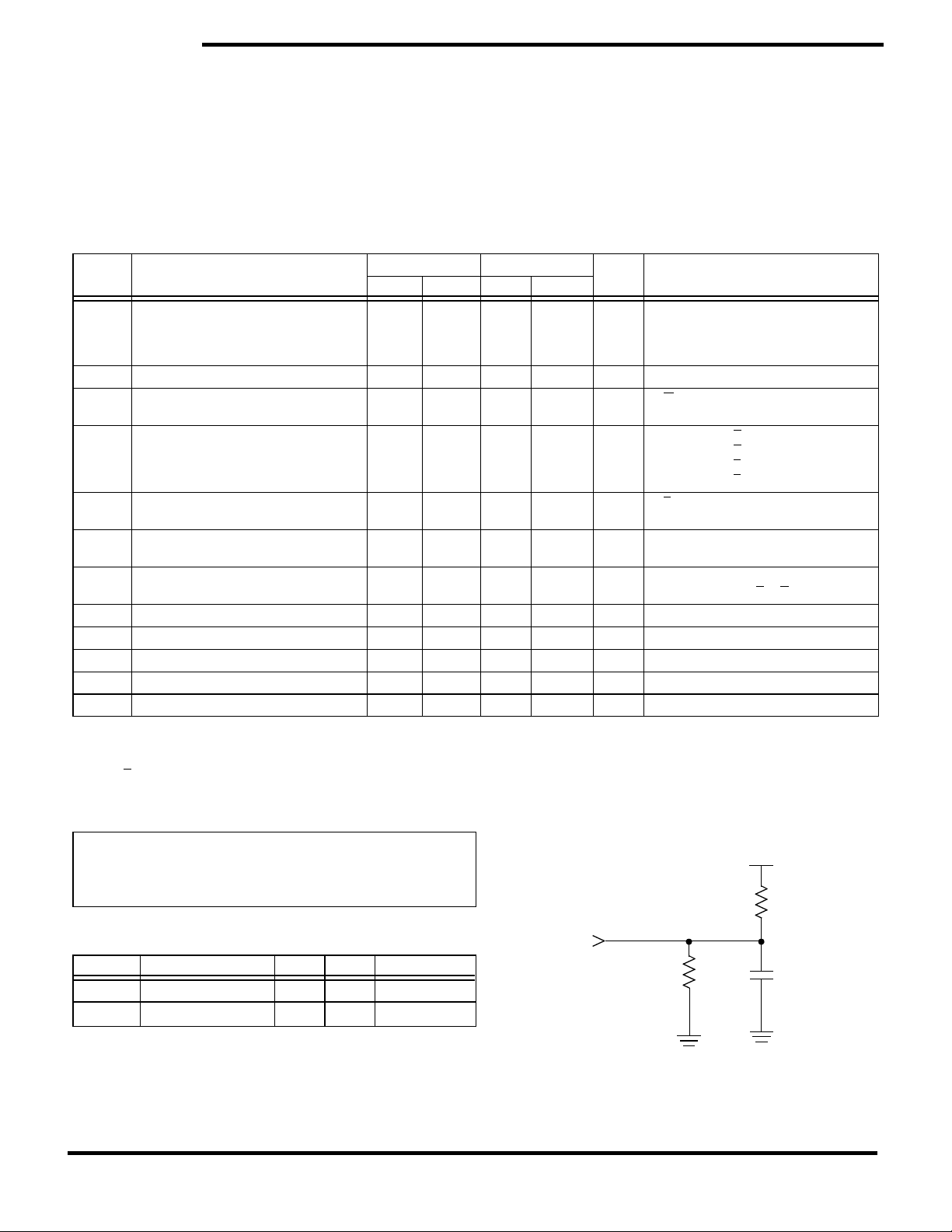

DC CHARACTERISTICS (VCC = 5.0V ± 10%)

SYMBOL PARAMETER

c

I

CC

I

CC

I

CC

I

SB

I

SB

I

ILK

I

OLK

V

V

V

V

T

IH

IL

OH

OL

A

Average VCC Current 100

1

d

Average VCC Current during STORE 3 3 mA All Inputs Don’t Care, VCC = max

2

c

Average VCC Current at t

3

5V, 25°C, Typical

e

Average VCC Current

1

(Standby, Cycling TTL Input Levels)

e

VCC Standby Current

2

(Standby, Stable CMOS Input Levels )

Input Leakage Current

Off-State Output Leakage Current

Input Logic “1” Volta ge 2.2 V

Input Logic “0” Volta ge VSS – .5 0.8 VSS – .5 0. 8 V All Inputs

Output Logic “1” Voltage 2.4 2.4 V I

Output Logic “0” Voltage 0.4 0.4 V I

Operating Temperature 0 70 –40 85 °C

AVAV

= 200ns

Note b: The STK16C68-20 requires VCC = 5.0V ± 5% supply to operate at specified speed.

Note c: I

Note d: I

Note e: E

and I

CC

1

and I

CC

2

≥ VIH will not produce standby current levels until any nonvolatile cycle in progress has timed out.

are dependent on output loading and cycle rate. The specified values are obtained with outputs unloaded.

CC

3

are the average currents required for the duration of the respective STORE cycles (t

CC

4

COMMERCIAL INDUSTRIAL

MIN MAX MIN MAX

N/A

90

75

65

10 10 mA

32

27

23

20

1.5 1.5 mA

±1 ±1 µA

±5 ±5 µA

+ .5 2.2 VCC + .5 V All Inputs

CC

90

75

65

N/A

28

24

21

UNITS NOTES

mA

mA

mA

mA

mA

mA

mA

mA

t

= 20ns

AVAV

t

= 25ns

AVAV

t

= 35ns

AVAV

t

= 45ns

AVAV

W

≥ (V

– 0.2V)

CC

All Others Cycling, CMOS Levels

t

= 20ns, E ≥ V

AVAV

t

AVAV

t

AVAV

t

AVAV

E

≥ (VCC – 0.2V)

All Others V

V

CC

V

= VSS to V

IN

V

CC

V

= V

IN

OUT

OUT

).

STORE

= 25ns, E ≥ V

= 35ns, E ≥ V

= 45ns, E ≥ V

= max

= max

SS

= –4mA

= 8mA

IH

IH

IH

IH

≤ 0.2V or ≥ (VCC – 0.2V)

IN

CC

to VCC, E or G ≥ VIH

b

AC TEST CONDITIONS

Input Pulse Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0V to 3V

Input Rise and Fall Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ≤ 5ns

Input and Output Timing Reference Levels. . . . . . . . . . . . . . . 1.5V

Output Load. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .See Figure 1

CAPACITANCE

SYMBOL PARAMETER MAX UNITS CONDITIONS

C

C

IN

OUT

Input Capacitance

Output Capacitance

f

(TA = 25°C, f = 1.0MHz)

8pF

7pF

∆V = 0 to 3V

∆V = 0 to 3V

Note f: These parameters are guaranteed but not tested.

July 1999 4-74

OUTPUT

5.0V

480 Ohms

30 pF

255 Ohms

INCLUDING

SCOPE AND

FIXTURE

Figure 1: AC Output Loading

STK16C68

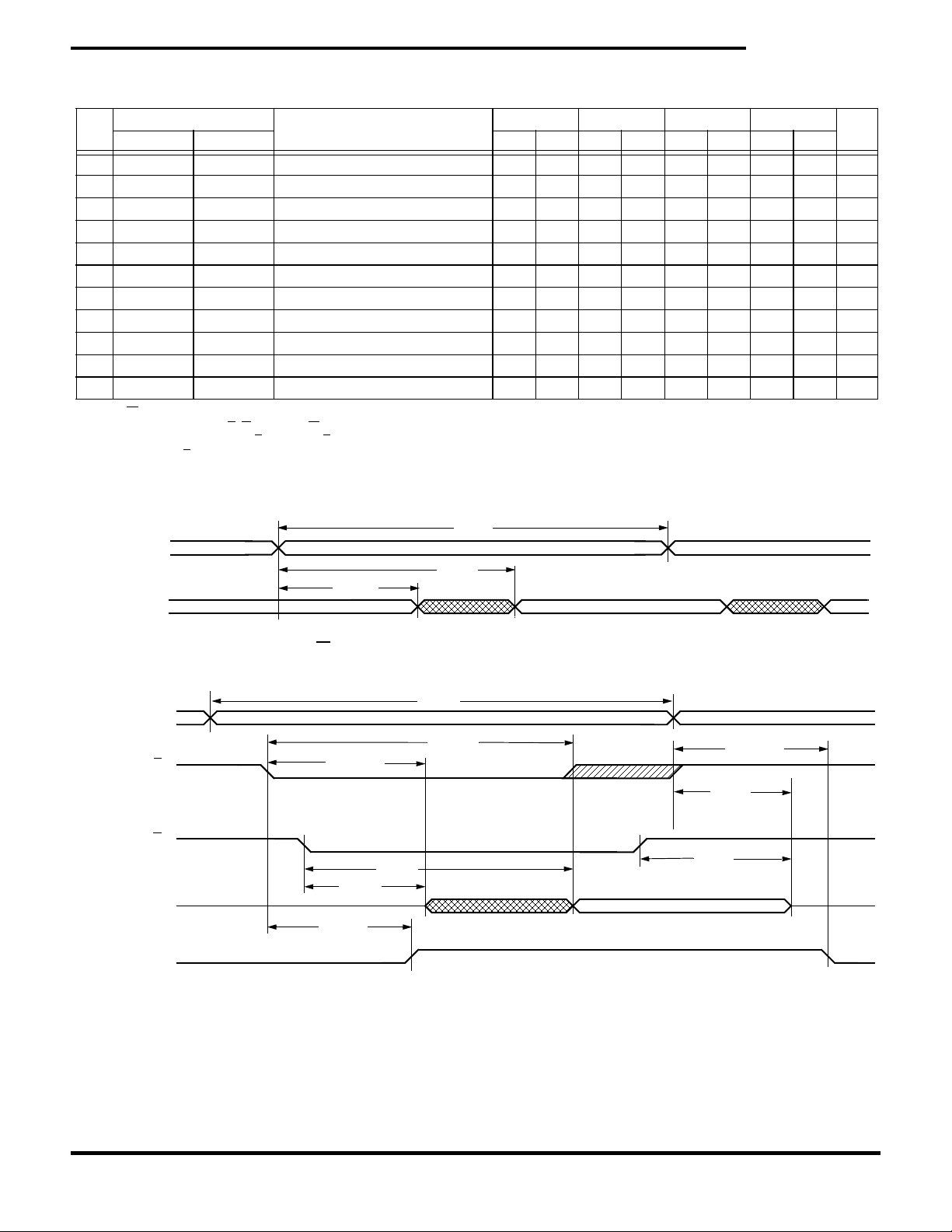

SRAM READ CYCLES #1 & #2 (V

NO.

10 t

11 t

#1, #2 Alt. MIN MAX MIN MAX MIN MAX MIN MAX

1t

ELQV

2t

AVAV

3t

AVQV

4t

GLQV

5t

AXQX

6t

ELQX

7t

EHQZ

8t

GLQX

9t

GHQZ

ELICCH

EHICCL

SYMBOLS

g

h

h

i

i

f

e, f

t

ACS

t

RC

t

AA

t

OE

t

OH

t

LZ

t

HZ

t

OLZ

t

OHZ

t

PA

t

PS

Chip Enable Access Time 20 25 35 45 ns

Read Cycle Time 20 25 35 45 ns

Address Access Time 22 25 35 45 ns

Output Enable to Data Valid 8 10 15 20 ns

Output Hol d after Address Change 5 5 5 5 ns

Chip Enable to Output Active 5 5 5 5 ns

Chip Disable to Output Inactive 7 10 13 15 ns

Output Enable to Output Active 0 0 0 0 ns

Output Disa ble to Outpu t Inactive 7 10 13 15 ns

Chip Enable to Power Active 0 0 0 0 ns

Chip Disable to Power Standby 25 25 35 45 ns

PARAMETER

Note g: W must be high during SRAM READ cycles and low during SRAM WRITE cycles.

Note h: I/O state assumes E

Note i: Measured +

, G < VIL and W > VIH; device is continuously selected.

200mV from steady state output voltage.

SRAM READ CYCLE #1: Address Controlled

ADDRESS

t

AVQV

DQ (DATA OUT)

t

AXQX

5

STK16C68-20 STK16C68-25 STK16C68-35 STK16C68-45

g, h

2

t

AVAV

3

DATA VALID

= 5.0V ± 10%)

CC

b

UNITS

SRAM READ CYCLE #2: E Controlled

ADDRESS

t

ELQX

t

ELICCH

6

t

GLQX

10

4

t

GLQV

8

DQ (DATA OUT)

I

CC

E

G

STANDBY

g

t

AVAV

2

t

ELQV

ACTIVE

1

t

GHQZ

DATA VALID

t

9

7

EHQZ

t

EHICCL

11

July 1999 4-75

STK16C68

SRAM WRITE CYCLES #1 & #2 (V

NO.

12 t

13 t

14 t

15 t

16 t

17 t

18 t

19 t

20 t

21 t

WLWH

ELWH

DVWH

WHDX

AVWH

AVWL

WHAX

WLQZ

WHQX

SYMBOLS

#1 #2 Alt. MIN MAX MIN MAX MIN MAX MIN MAX

AVAV

t

AVAV

t

WLEH

t

ELEH

t

DVEH

t

EHDX

t

AVEH

t

AVEL

t

EHAX

i, j

t

Write Cycle Time 20 25 35 45 ns

WC

t

Write Pulse Width 15 20 25 30 ns

WP

t

Chip Enable to End of Write 15 20 25 30 ns

CW

t

Data Set-up to End of Write 8 10 12 15 ns

DW

t

Data Hold after End of Write 0 0 0 0 ns

DH

t

Address Set-up to End of Wri te 15 20 25 30 ns

AW

t

Address Set-up to Start of Write 0 0 0 0 ns

AS

t

Address Hold after En d of Write 0 0 0 0 ns

WR

t

Write Enable to Output Disable 7 10 13 15 ns

WZ

t

Output Active afte r En d of Write 5 5 5 5 ns

OW

PARAMETER

Note j: If W is low when E goes low, the outputs remain in the high-impedance state.

Note k: E

or W must be ≥ VIH during address transitions.

SRAM WRITE CYCLE #1: W Controlled

ADDRESS

t

ELWH

E

STK16C68-20 STK16C68-25 STK16C68-35 STK16C68-45

k

12

t

AVAV

14

19

t

WHAX

= 5.0V ± 10%)

CC

b

UNITS

17

t

20

t

WLQZ

AVWH

13

t

WLWH

W

DATA IN

DA TA OUT

18

t

AVWL

PREVIOUS DATA

SRAM WRITE CYCLE #2: E Controlled

ADDRESS

18

t

AVEL

E

1 7

t

AVEH

W

DATA IN

15

t

DVWH

DATA VALID

HIGH IMPEDANCE

16

t

WHDX

21

t

WHQX

k

12

t

AVAV

t

ELEH

14

13

t

WLEH

15

t

DVEH

DATA VALID

t

EHAX

t

EHDX

19

16

DA TA OUT

HIGH IMPEDANCE

July 1999 4-76

STK16C68

AutoStorePlus™/POWER-UP RECALL (V

NO.

22 t

23 t

24 V

25 V

Note l: t

SYMBOLS

Standard MIN MAX

RESTORE

FB

SWITCH

RESET

starts from the time VCC rises above V

RESTORE

Power-up RECALL Duration 550 µsl

Maximum VCC Slew Time to Ground 500 ns f , h

Low Voltage Trigger Level 4.0 4.5 V

Low Voltage Reset Level 3.9 V f

SWITCH

PARAMETER

.

AutoStorePlus™/POWER-UP RECALL

V

CC

5V

24

V

SWITCH

25

V

RESET

23

t

FB

AutoStore™

= 5.0V ± 10%)

CC

STK16C68

UNITS NOTES

b

OWER-UP RECALL

W

DQ (DATA OUT)

22

t

RESTORE

POWER-UP

RECALL

BROWN OUT

NO STORE DUE TO

NO SRAM WRITES

NO RECALL

(V

DID NOT GO

CC

BELOW V

RESET

)

BROWN OUT

AutoStorePlus™

NO RECALL

(V

DID NOT GO

CC

BELOW V

RESET

BROWN OUT

AutoStorePlus™

RECALL WHEN

V

RETURNS

CC

)

ABOVE V

SWITCH

July 1999 4-77

STK16C68

SOFTW ARE ST ORE/RECALL MODE SELECTION

E W G A12 - A0 (hex) MODE I/O with G Low I/O with G High NOTES

Output High Z

Output High Z

Output High Z

Output High Z

Output High Z

Output High Z

Output High Z

Output High Z

Output High Z

Output High Z

Output High Z

Output High Z

LHX

LHX

0000

1555

0AAA

1FFF

10F0

0F0F

0000

1555

0AAA

1FFF

10F0

0F0E

Read SRAM

Read SRAM

Read SRAM

Read SRAM

Read SRAM

Nonvolatile

Read SRAM

Read SRAM

Read SRAM

Read SRAM

Read SRAM

Nonvolatile

STORE

RECALL

Output Data

Output Data

Output Data

Output Data

Output Data

Output High Z

Output Data

Output Data

Output Data

Output Data

Output Data

Output High Z

Note m: The six consecutive addresses must be in the order listed. W must be high during all six consecutive cycles to enable a nonvolatile cycle.

m

m

SOFTW ARE ST ORE/RECALL CYCLE

NO. SYMBOLS P ARAMETER

26 t

27 t

28 t

29 t

30 t

31 t

AVAV

n

AVEL

ELEH

h, n

ELAX

RECALL

STORE

n

STORE/RECALL Initiation Cycle Time 20 25 35 45 ns

Address Set-up Time 0 0 0 0 ns

Clock Pulse Width 15202530 ns

Address Hold Time 15 20 20 20 ns

RECALL Cycle Duration 20 20 20 20 µs

STORE Cycle Duration 10 10 10 10 ms

n, o

STK16C68-20 STK16C68-25 STK16C68-35 STK16C68-45

MIN MAX MIN MAX MIN MAX MIN MAX

(VCC = 5.0V ± 10%)

UNITS

Note n: The software sequence is clocked with E controlled READs.

Note o: The six consecutive addresses must be in the order listed in the Software STORE/RECALL Mode Selection Table: (0000, 1555, 0AAA, 1FFF,

10F0, 0F0F) for a STORE cycle or (0000, 1555, 0AAA, 1FFF, 10F0, 0F0E) for a RECALL cycle. W

must be high during all six consecutive

cycles.

SOFTW ARE ST ORE/RECALL CYCLE: E Controlled

26

t

AVAV

ADDRESS

27

t

AVEL

E

t

ELEH

28

o

26

t

AVAV

ADDRESS #6ADDRESS #1

b

29

t

ELAX

Q (DATA OUT)

DATA VALID

July 1999 4-78

DATA VALID

31 30

t

/ t

STORE

HIGH IMPEDANCE

RECALL

DEVICE OPERATION

STK16C68

The AutoStorePlus™ STK16C68 is a fast 8K x 8

SRAM that does not lose its data on power-down.

The data is preserved in integral QuantumTrap™

EEPROM while power is unavailable. The nonvolatil-

ity of the STK16C68 does not require any system

intervention or support: AutoStorePlus™ on powerdown and automatic RECALL on power-up guarantee data integrity without the use of batteries.

NOISE CONSIDERATIONS

Note that the STK16C68 is a high-speed memory

and so must have a high-frequency bypass capacitor of approximately 0.1µF connected between V

CC

and VSS, using leads and traces that are as short as

possible. As with all high-speed

CMOS ICs, normal

careful routing of power, ground and signals will

help prevent noise problems.

SRAM READ

The STK16C68 performs a READ cycle whenever E

and G are low and W is high. The address specified

on pins A

bytes will be accessed. When the

determines which of the 8,192 data

0-12

READ is initiated

by an address transition, the outputs will be valid

after a delay of t

initiated by E

at t

, whichever is later (READ cycle #2). T h e d a ta

GLQV

or G, the outputs will be valid at t

(READ cycle #1). If the READ is

AVQV

ELQV

or

outputs will repeatedly respond to address changes

within the t

access time without the need for tran-

AVQV

sitions on any control input pins, and will remain valid

until another address change or until E

brought high or W

is brought low.

or G is

SRAM WRITE

A WRITE cycle is performed whenever E and W are

low. The address inputs must be stable prior to

entering the

until either E

The data on the common I/O pins DQ

ten into the memory if it is valid t

of a W

E

controlled WRITE or t

controlled WRITE.

It is recommended that G

entire

WRITE cycle to avoid data bus contention on

the common I/ O li nes. If G

will turn off the output buffers t

WRITE cycle and must remain stable

or W goes high at the end of the cycle.

will be writ-

0-7

before the end

DVWH

before the end of an

DVEH

be kept high during the

is left low, internal circuitry

after W goes low.

WLQZ

AutoStorePlus™ OPERATION

The STK16C68’s automatic STORE on power-down

is completely transparent to the system. The

AutoStore™ initiation takes less than 500ns when

power is lost (V

depends only on its internal capacitor for

CC

< V

) at which point the part

SWITCH

STORE

completion. This safe transfer of data from SRAM to

EEPROM takes place regardless of power supply

slew rate.

In order to prevent unneeded

automatic

WRITE operation has taken place since the most

recent

STORE cycles are performed regardless of whether

or not a

STORE will be ignored unless at least one

STORE or RECALL cycle. Software-initiated

WRITE operation has taken place.

STORE operations, the

POWER-UP RECALL

During power up, or after any low-power condition

(V

< V

CC

latched. When V

voltage of V

be initiated and will take t

If the STK16C68 is in a

power-up

), an internal RECALL request will be

RESET

once again exceeds the sense

CC

, a RECALL cycle will automatically

SWITCH

to complete.

RESTORE

WRITE state at the end of

RECALL, the SRAM data will be corrupted.

To help avoid this situation, a 10kΩ resistor should

be connected either between W

between E

and system VCC.

and system VCC or

SOFTWARE NONVOLATILE STORE

The STK16C68 software STORE cycle is initiated by

executing sequential

address locations. During the

of the previous nonvolatile data is first performed,

followed by a program of the nonvolatile elements.

The program operation copies the

nonvolatile memory. Once a

ated, further input and output are disabled until the

cycle is completed.

Because a sequence of

addresses is used for

tant that no other

vene in the sequence or the sequence will be

aborted and no

To initiate the software

READ sequence must be performed:

READ cycles from six specific

STORE cycle an erase

SRAM data into

STORE cycle is initi-

READs from specific

STORE initiation, it is impor-

READ or WRITE accesses inter-

STORE or RECALL will take place.

STORE cycle, the following

July 1999 4-79

STK16C68

0

20

40

60

80

100

50 100 150 200

Cycle Time (ns)

TTL

CMOS

Average Active Current (mA)

1. Read address 0000 (hex) Valid READ

2. Read address 1555 (hex) Valid READ

3. Read address 0AAA (hex) Valid READ

4. Read address 1FFF (hex) Valid REA D

5. Read address 10F0 (hex) Valid READ

6. Read address 0F0F (hex) Initiate STORE cycle

The software sequence must be clocked with E

controlled READs.

Once the sixth address in the sequence has been

entered, the

chip will be disabled. It is important that

STORE cycle will commence and the

READ

cycles and not WRITE cycles be used in the

sequence, although it is not necessary that G

low for the sequence to be valid. After the t

be

STORE

cycle time has been fulfilled, the SRAM will again be

activated for

READ and WRITE operation.

SOFTWARE NONVO LATILE RECALL

A software RECALL cycle is initiated with a

sequence of

to the software

RECALL cycle, the following sequence of READ

operations must be performed:

1. Read address 0000 (hex) Valid READ

2. Read address 1555 (hex) Valid READ

3. Read address 0AAA (hex) Valid READ

4. Read address 1FFF (hex) Valid REA D

5. Read address 10F0 (hex) Valid READ

6. Read address 0F0E (hex) Initiate RECALL cycle

Internally, RECALL is a two-step procedure. First,

the

SRAM data is cleared, and second, the nonvola-

READ operations in a manner similar

STORE initiation. To initiate the

tile information is transferred into the

After the t

be ready for

RECALL operation in no way alters the data in the

EEPROM cells. The nonvolatile data can be recalled

cycle time the SRAM will once again

RECALL

READ and WRITE operations. The

SRAM cells.

an unlimited number of times.

HARDWARE PROTECT

The STK16C68 offers hardware protection against

inadvertent

during low-voltage conditions. When V

software

STORE operation and SRAM WRITEs

< V

CC

STORE operations and SRAM WRITEs are

SWITCH

inhibited.

LOW AVERAGE ACTIVE POW ER

The STK16C68 draws significantly less current

when it is cycled at times longer than 50ns. Figure 2

shows the relationship between I

time. Worst-case current consumption is shown for

both

CMOS and TTL input levels (commercial tem-

perature range, V

= 5.5V, 100% duty cycle on

CC

chip enable). Figure 3 shows the same relationship

for

WRITE cycles. If the chip enable duty cycle is

less than 100%, only standby current is drawn

when the chip is disabled. The overall average current drawn by the STK16C68 depends on the following items: 1)

CMOS vs. TTL input levels; 2) the

duty cycle of chip enable; 3) the overall cycle rate

for accesses; 4) the ratio of

the operating temperature; 6) the V

O loading.

and READ cycle

CC

READs to WRITEs; 5)

level; and 7) I/

CC

,

Figure 2: ICC (max) Reads

July 1999 4-80

100

Average Active Current (mA)

80

60

40

20

0

50 100 150 200

Cycle Time (ns)

Figure 3: ICC (max) Writes

TTL

CMOS

ORDERING INFOR M ATION

STK16C68

STK16C68

- W 25 I

Temperature Range

Blank = Commercial (0 to 70°C)

I = Industrial (–40 to 85°C

Access Time

20 = 20ns (Commercial only)

25 = 25ns

35 = 35ns

45 = 45ns

Package

W = Plastic 28-pin 600 mil DIP

*(call factory for availability of this package)

S = Plastic 28-pin 350 mil SOIC*

)

July 1999 4-81

Loading...

Loading...