Page 1

Installation manual

TECHNOLOGY FOR SUSTAINABLE FISHERIES

www.simrad.com

Simrad ES120-7CD

120 kHz split-beam deep water transducer

Page 2

Page 3

SimradES120-7CD

Installationmanual

Thisdocumentprovidesageneraldescriptionofhowto

installtheSimradES120-7CDSplit-beamtransducer.The

informationmustberegardedasgeneralguidelinesand

recommendationsonly.Theinstallationshipyardmust

designandmanufactureinstallationhardwaretotthe

ES120-7CDtransduceroneachindividualtowedbody.

2October2009

339149/A

Page 4

Documenthistory

Kong sb e r gM a r itim eA S

St r a n dp rom e n a de n5 0

P.O. Box1 1 1

N- 31 9 1H orte n ,N or way

S im ra d

Tele ph on e :+ 473 30 34 00 0

Tele fa x:+ 473 30 42 98 7

con t a ct@s im ra d. c o m

w w w .s im r a d .co m

Simraddocumentnumber:339149/ISBN:978-82-8066-110-4/Currentrevision:A

Rev.A02.10.2009

Firstversion.

Copyright

©2009KongsbergMaritimeAS

TheinformationcontainedinthisdocumentremainsthesolepropertyofKongsbergMaritimeAS.Nopart

ofthisdocumentmaybecopiedorreproducedinanyformorbyanymeans,andtheinformationcontained

withinitisnottobecommunicatedtoathirdparty ,withoutthepriorwrittenconsentofKongsberg

MaritimeAS.Thedocument,oranypartofit,maynotbetranslatedtoanyotherlanguagewithoutthe

writtenapprovalfromKongsbergMaritimeAS.

Disclaimer

KongsbergMaritimeASendeavourstoensurethatallinformationinthisdocumentiscorrectandfairly

stated,butdoesnotacceptliabilityforanyerrorsoromissions.

Warning

Theequipmenttowhichthismanualappliesmustonlybeusedforthepurposeforwhichitwas

designed.Improperuseormaintenancemaycausedamagetotheequipmentand/orinjuryto

personnel.Theusermustbefamiliarwiththecontentsoftheappropriatemanualsbeforeattempting

toinstall,operateorworkontheequipment.

KongsbergMaritimeASdisclaimsanyresponsibilityfordamageorinjurycausedbyimproper

installation,useormaintenanceoftheequipment.

Support

Ifyourequiremaintenanceorrepair,contactyourlocaldealer.Y oucanalsocontactususingthefollowing

address:-.Ifyouneedinformationaboutourotherproducts,visitourwebsite.Onthewebsiteyou

willalsondalistofourdealersanddistributors.

Page 5

Installationmanual

Tableofcontents

ABOUTTHISMANUAL.......................................................5

SIMRADES120-7CD..........................................................6

TOWEDBODYDESIGN......................................................7

HOWTOINSTALLTHETRANSDUCER................................9

Examples..................................................................................................................9

Example1:Smalltransducer.......................................................................10

Example2:Mediumandlargetransducers...................................................11

Example3:Dualtransducerarrangement.....................................................12

TRANSDUCERHANDLINGANDMAINTENANCE................13

Rulesfortransducerhandling.................................................................................13

Approvedanti-foulingpaints..................................................................................14

Usingself-lockingtaps...........................................................................................14

IntroductiontoEmugeself-lockingthreads...................................................15

Drawingstandard........................................................................................16

Tapsandgauges..........................................................................................16

Self-locktapsprovidedbySimrad...............................................................17

Supplierandmanufacturer...........................................................................17

DRAWINGFILE...............................................................18

Echosounderconnections......................................................................................18

Splicingthetransducercable.......................................................................18

GeneralPurposeTransceiver(GPT)wiring...................................................19

GeneralPurposeTransceiver(GPT)transducerplugassembly.......................20

Outlinedimensionsandinstallationdrawings........................................................21

Outlinedimensions[324407].......................................................................22

Mountingring[204675]..............................................................................23

Clampingring[204677]..............................................................................25

339149/A

3

Page 6

SimradES120-7CD

4

339149/A

Page 7

ABOUTTHISMANUAL

Aboutthismanual

Purpose

Thepurposeofthisinstallationmanualistoprovidegeneric

descriptionsandillustrationsallowingthereadertounderstand

thebasicprinciplesforechosoundertransducerinstallation.

Abouttheinformationprovidedinthisdocument

Theinformationinthisdocumentmustberegardedasgeneral

guidelinesandrecommendationsonly.Theinstallationshipyard

mustdesignandmanufactureinstallationhardwaretoteach

individualtransducerandvessel.

Approvalbymaritimeauthorities

Wheneverrequired,theinstallationshipyardmustalsohavethe

installationapprovedbytheapplicablemaritimeauthorities.

Additionalinformation

Foradditionaldetailedinformationaboutthetransducerto

beinstalled,refertothedocumentationprovidedwiththe

transducer.Drawingsanddescriptionscanalsobeobtainedfrom

t t p : / / w w w . s i m r a d . c o m .

h

339149/A

5

Page 8

SimradES120-7CD

SIMRADES120-7CD

Thepurposeofthismanualistheprovidethebasicinformation

requiredtoinstalltheSimradES120-7CDSplit-beamtransducer.

Transduceranddocuments

•SimradES120–7CD:324410

•Productspecication:339095

•Drawings:

–Outlinedimensions:324407

–Mountingring:871–204675

–Clampingring:871–204677

Note

Althoughdrawingsareprovidedtoexplaintheinstallation

principles,theinstallationshipyardmustprovidethenal

drawingsrequiredtotthetransducertoeachindividual

vessel.Also,whenapplicable,theinstallationshipyard

musthavethedrawingsandinstallationapprovedbythe

propermaritimeauthorities.Thedrawingsspecicforthe

ES120-7CDtransducerarelocatedintheDrawingleon

page18.

Technicalspecications

RefertotheES120-7CDproductspecication.

Additionalpartsprovidedforinstallation

ThefollowingitemscanbesuppliedbySimradtofacilitate

installation:

•Mountingring:ES1–204719

•Clampingring:ES1–203672

•Transducercable(forextension):642–078215

Note

ThiscableisNOTsuitableasatowcable!

•Thefollowingpartsmust(ifrequired)beprovidedbythe

installationshipyard:

–Malebulkheadconnector:8–pinBurton5500Series

w w . b u r t o n e e . c o m )

(w

6

339149/A

Page 9

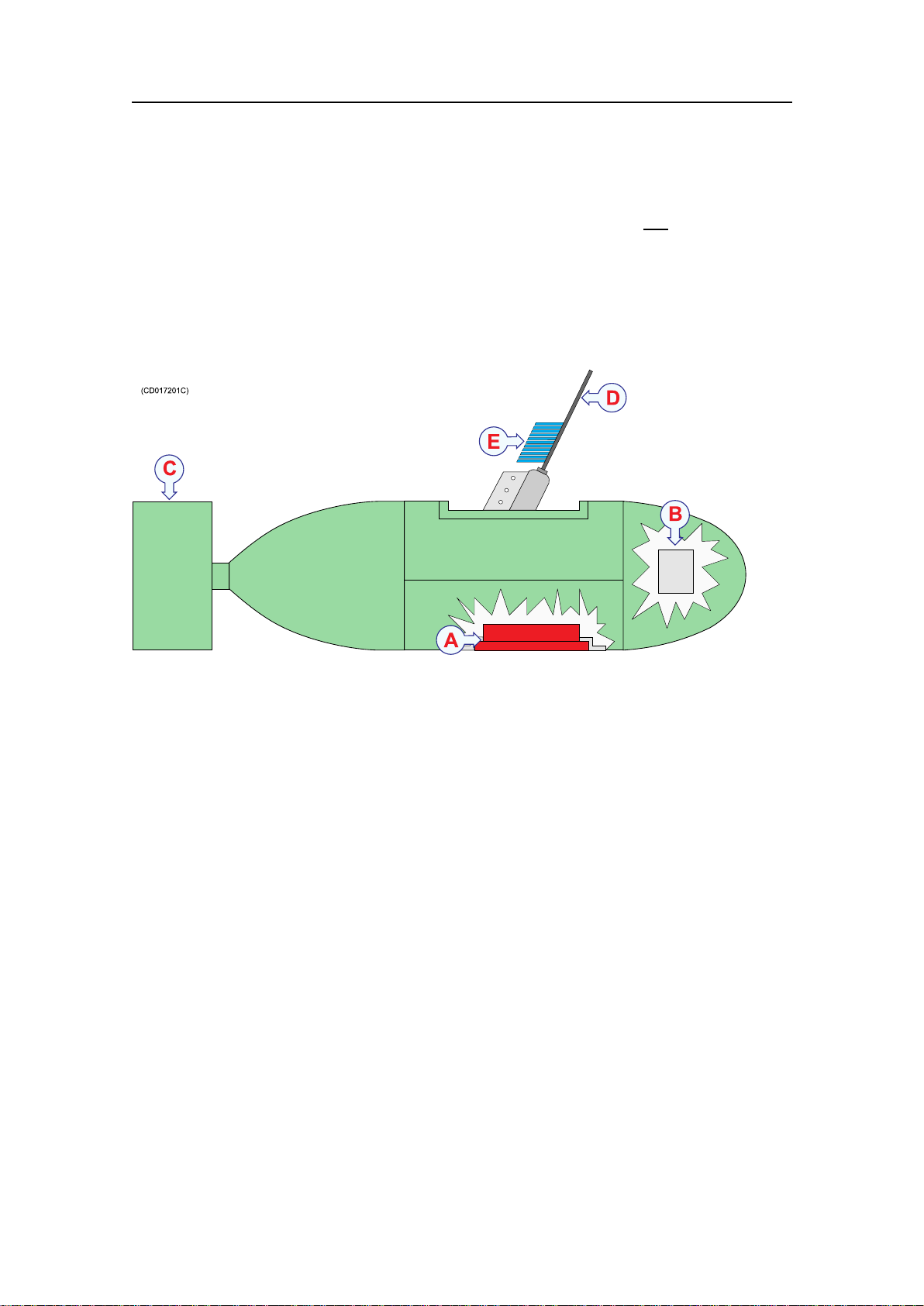

TOWEDBODYDESIGN

A

B

C

D

E

(CD017201C)

Towedbodydesign

Figure1Example,towedbody

Atowedbodyusedtoholdthetransducerisn

o t providedby

Simrad.Thedesignandmanufacturingofsuchabodymustbe

madebyyourownorganisation,orbyathirdpartyyouwish

toengagetodothis.Duringthedesignphase,thefollowing

considerationsmustbemade.

ATransducermountedthroughthebodyplatingbymeansof

amountingring

BWatertightcompartmentwithtransceiverelectronics

CTailn

DTowlinewithbuilt-incablesforpowersupply,controland

datatransfer(ethernet)

EFairings

Locationoftransceiverelectronics

Ifyourtowedbodydesigncomprisesawatertightcompartment,

youmaychoosetoinstallthetransceivercircuitryinsidethe

towedbody.Inordertodoso,youmustinstallwatertightsockets

onthebulkheadinordertoconnectthetransducercable(s),

controlanddatatransfer(Ethernet)andoperatingpower.By

usingathisarrangement,youavoidthesignallossyoumay

experienceusingalongtransducercable.

Depth

Theupperwaterlayersoftheseacontainamyriadofsmall

airbubblescreatedbythebreakingwaves.Inheavyseasthe

uppermost5to10metresmaybeair-lled,withthehighest

concentrationsnearthesurface.Airbubblesabsorbandreect

339149/A

7

Page 10

SimradES120-7CD

thesoundenergy,andmayinworstcasesblockthesound

transmissiontotally.Therefore,designthetowedbodysothatit

canoperateindeepwater.

Caution

Observethemaximumoperationaldepthofthe

transducer.Donotexceedthislimitation.

Donotallowthetowedbodytohittheseabed.This

mayinictpermanentdamagetothetransducer(s).

Noisefromprotrudingobjectsonthebody

Objectsprotrudingfromthetowedbody,suchaszincanodes,

sonartransducersorevenarudderorakeel,maygenerate

turbulenceandownoise.Holesandpipeoutletsarealso

possiblenoisesources,asthesemayactasresonantcavities

amplifyingtheownoiseatcertainfrequencies.Donotplace

anechosoundertransducerinthevicinityofsuchobjects,and

especiallynotclosebehindthem.Forthesamereason,itis

veryimportantthatthebodyareaadjacenttothetransducer

faceisassmoothandlevelaspossible.Eventracesofsealing

compound,sharpedges,protrudingboltsorboltholeswithout

llingcompoundwillcreatenoise.

Inclinationofthetransducerface

Ideally,thetransducerfaceshouldbemountedinparallelwith

theseasurfacewhenthetowedbodyisinnormaltrim,asthis

willprovidethemostaccurateechoinformation.However,itis

alsoveryimportantthatthew

a t e r o w overthetransducerface

islaminar.Inordertoensurelaminarow,thetransducerface

maybetiltedslightlyupwardsinrelationtothewaterow.This

allowstheowingwatertomeetthefacedirectly,andassures

laminarow .Theinclinationanglemusthoweverbedetermined

carefully.Theanglemustbesmallontransducerswithnarrow

beamangles.Asaruleofthumb,mounttransducerswithbeam

anglessmallerthansevendegreeswithminimuminclination

angle.Thesmallerbeamangleyourtransducerhas,thesmaller

theinclinationanglecanbe.Makesurethatyoudonotmount

thetransducerwithanegativeinclinationangle.Thismaycause

turbulenceunderthetransducerface,andreducedechosounder

performance.

8

339149/A

Page 11

HOWTOINSTALLTHETRANSDUCER

Howtoinstallthetransducer

Installationonatowedbody

Transducersdesignedtowithstandlargewaterpressureare

providedforuseintowedbodies.Therecommendedinstallation

methodisthroughthehullplatinghullusingmountingand

clampingrings.Theinstallationarrangementonthetowedbody

mustbedesignedbythemanufacturerofthetowedbodytot

itsshapeandcharacteristics.

Usemountingandclampingringswhenever

provided

Circulartransducersmaybeprovidedwithmountingand

clampingrings,orwithdrawingstoallowforlocalproductionof

these.Themountingringisweldedtotheholeinthetowedarray,

whiletheclampingringtsaroundtheedgeofthetransducer

body.Boltsthroughtheclampingringintothemountingringwill

thensecurethetransducerbetweenthem.Notethatallsplit-beam

transducersusedirectionguidestoallowcorrectmounting.

Smoothsurfaceisimportant

Mountingscrewsorboltsmustnotbeextrudingfromthevehicle.

Ensurethatthesurfaceofthetransducerface,thevehicle,the

vehicleplatingandputtyaroundthetransducerisasevenand

smoothaspossible.Obstructionsonthesesurfaceswillcreate

problemswiththewaterow.

Examples

Observethefollowingexamplesoftransducerinstallation.

339149/A

9

Page 12

SimradES120-7CD

A

B

D

E

(CD017010H)

C

Example1:Smalltransducer

Theillustrationbelowshowstheinstallationprincipleofasmall

circulartransducerusingclampingandmountingrings.

Figure2Installationprinciple,smalltransducer

AMountingring

BHullplatingontowedbody

CTransducer

DClampingring

EBolt

10

339149/A

Page 13

Example2:Mediumandlargetransducers

A

B

C

D

E

(CD017010G)

Theillustrationbelowshowstheinstallationprincipleofa

mediumorlargetransducers.Notethataclampingringisnot

required,asthetransducerbodyisshapedtofacilitatethis

function.

Figure3Installationprinciple,mediumandlargetransducers

AMountingring

BHullplatingontowedbody

Howtoinstallthetransducer

CTransducer

D“Clampingring”

functionalityfacilitated

bytransducerbody

EBolt

339149/A

11

Page 14

SimradES120-7CD

A

B

C

(CD017201B)

Figure4Dualtransducerarrangement

Example3:Dualtransducerarrangement

Theillustrationbelowshowsatypicalthroughthehullinstallation

ofsmallandlargecirculartransducersonatowedbody.

ASmalltransducer

BMediumorlargertransducer

CElectronicequipmentinwatertightcompartment

12

339149/A

Page 15

TRANSDUCERHANDLINGAND MAINTENANCE

YouMUSTobservethefollowingrulesforhandling,

maintenanceandpainting.

Rulesfortransducerhandling

Note

Donotliftthetransducerbythecable.

Donotexposethetransducertodirectsunlight.

Donotexposethetransducertoexcessiveheat.

Transportprotection

Transducerhandlingandmaintenance

Sometransducersaredeliveredwithacoverplateontheface

forprotectionduringtransport.Letthisplatestayonaslongas

possible,butdonotforgettoremoveitbeforethevesselgoes

intothesea.

Paintingthetransducerface

Ananti-foulingpaintmaybeappliedtothetransducerface.

Becausesomepainttypesmaybeaggressivetothepolyurethane

inthetransducerface,pleaseconsultSimrad’slistofapproved

paints.SeeApprovedanti-foulingpaintsonpage14.

Cleaningthetransducerface

Wheneveropportunityarise,forexamplewhenthevesselisdry

docked,thetransducerfacemaybecleanedforshellsandother

marinefouling.B

f a c e . Useapieceofsoftwoodoraverynegradeemerypaper.

Specialrulesforacousticwindows

Arctictankshaveacousticwindowsmadeofpolycarbonate.

T

h e s e m u s t n e i t h e r b e p a i n t e d n o r c l e a n e d w i t h c h e m i c a l s .

Acousticwindowsmustnotbeexposedtodirectsunlight.

e c a r e f u l n o t t o m a k e c u t s i n t h e t r a n s d u c e r

339149/A

13

Page 16

SimradES120-7CD

Approvedanti-foulingpaints

ThisisSimrad’slistofapprovedantifoulingpaintson

polyurethanetransducerhousing.

Jotun

Headofceaddress:P .O.Box2021,N-3248Sandefjord,Norway

Website:w

w w . j o t u n . c o m .

1Racing

2Non-stop

3SafeguardUniversalprimer(125micron)withAntifouling

SeaQuantumUltra(125micron)

4AntifoulingSeaguardian

InternationalMarineCoatings

Address:World-wideofces

Website:w

w w . i n t e r n a t i o n a l - m a r i n e . c o m .

1Intersleektiecoat+425FCS

•BXA386/BXA390/BXA391Grey

•HKA563/HKA570/HKA571Y ellow

•MixBXA386,BXA390andBXA391rst,thenapply.

Whendry ,mixHKA563,HKA570andHKA571,apply.

2Intersmooth360EcoloexSPC

3MicronExtra

HempelIFACoatings

Usingself-lockingtaps

14

Headofceaddress:HempelA/S,Lundtoftevej150,Kgs.

Lyngby ,DK-2800Copenhagen,Denmark

Website:w

w w . h e m p e l . c o m .

1HempelA/FClassic76550

Note

Refertothemanufacturer’sdocumentationanddatasheetsfor

acompleteprocedure.

Screwconnectionsaregenerallymadesothattheycanbe

loosenedagain.However,accidentalloosening,especiallyunder

dynamicstress,mustbeavoided.Forthisreasonitisoften

necessarytouseadditionallockingdevices.Theseareoften

expensive,theycanbeusedonceonly,orreactcriticallyto

temperaturechanges.

339149/A

Page 17

IntroductiontoEmugeself-lockingthreads

A B C

2

1

(CD017020B)

Emugeself-lockisatapdesignwithanintegratedlockingfeature.

Standardmetricboltsareused.Theinternalthreadprovidesa

self-lockingconnection,whichcanbeusedrepeatedly.Itisnot

necessarytoinvolveasecondarylockingdevice(e.g.chemical,

nylonormechanical).TheEmugeself-lockboltswithstand

vibrationsbetterthanstandard(metric)threads,becausethe

threadcontactstopsthesidewaysmovement.Thespecial

designoftheinternalthreadprolealsoprovidesamoreeven

distributionofthetighteningstressoverthewholethreadlength.

Theassemblyisjustaseasyaswithanormal(metric)thread.

Thereisnogeneralapplicablestandard(e.g.DINstandard)for

theEmugeself-lockthread.

Figure5Example,internalandexternalthreads

Transducerhandlingandmaintenance

AEmuge’ ssaw-toothproleuptopitchP≤0.7mm

BEmuge’ssaw-toothproleuptopitchP≥0.7mm

CStandardthread

1Externalthread

2Internalthread

Advantages

•Thethreadlockingfeatureisintegratedintheinternalthread

•Modiedprolewithrampsurfaceinthedirectionofstress

•30degreerampsurfaceprovidesself-lockingeffect

•Easyassembly

•Noassemblyerrors(forgettingthelockingdevice)possible

•Useofstandardexternalthreads(screws)withtoleranceclass

“medium”

•Evendistributionofstressoverthewholethreadlength

•Nostrippingofthreads

339149/A

15

Page 18

SimradES120-7CD

M8SL*

M10SL*

(CD017020A)

•Economicallyefcientlockingsystem,noadditional

componentsarenecessary

•Undiminishedholdingpowerevenunderdynamicstress

•Repeatedlooseningandre-tighteningwithoutlossoffunction

•InternalthreadscanbeproducedwithEmugetaps,cold

formingtapsorthreadmills

•Largerthreadholediameters,i.e.increasedtoollifefor

threadingtools

•Largertolerancesforthreadholediameters

Drawingstandard

Wheneverself-lockingthreadsarerequired,thisisshownon

thetechnicaldrawing.Inthecaseoftappingthroughholes,

thearrowattheendofthecenterlineillustratesthescrew-in

directionofthebolt.

Figure6Drawingexamples,self-lockingthread

Thedrawingisnormallyprovidedwiththefollowingtext(or

similar):

Note:Theself-lockthreadsmarkedwithSL*mustbemadein

accordancewithprocedure842–202125.Drilldiametersfor

threadsdifferfromstandard.Self-locktapscanbesuppliedby

Simrad.

Tapsandgauges

Thepretensionlockingthreadself–lock(taps)frommanufacturer

Emugemustbeused.

16

339149/A

Page 19

Figure7Exampleofuse

(CD017020C)

Transducerhandlingandmaintenance

Note

Inthecaseoftappingthroughholesitisimportantthatthe

proleoftheEmugeself-lockthreadsisinthecorrectdirection

comparedwiththeenteringdirectionofthebolt.

UseEmugeself-lockgauges.Notethatthegaugemustbeused

inthecorrectdirection.

Self-locktapsprovidedbySimrad

Thefollowingself-locktapsareonstockatSimrad,andcanbe

orderedfromus.

Threads

M6ø5.2700-078838

M8ø7.0700-078531

M10ø8.8700-078408

M12ø10.7700-078409

M16ø14.5700-078410

Drilldiameterfor

threads

Part.no

Supplierandmanufacturer

Norwegiansupplieris:

TingstadAS,P.O.Box83,Kalbakken,0902Oslo,Norway

h

t t p : / / w w w . t i n g s t a d . n o

Manufactureris:

EMUGE-WerkRichardGlimpel,NurnbergerStrasse96-100,

D-90607Lauf,Germany

h

t t p : / / w w w . e m u g e . d e

339149/A

17

Page 20

SimradES120-7CD

DRAWINGFILE

Thischaptercontainsrelevantdrawingsrelatedtotheelectrical

andphysicalinstallationoftheSimradES120-7CDSplit-beam

transducer.

Note

Themechanicaldrawingsareforinformationandguidanceonly.

Theyarenotinscale,andmaydifferslightlyfromtheoriginal

drawings.Alldimensionsareinmmunlessotherwiseisnoted.

TheoriginalinstallationdrawingsareavailableonPDFand/or

AutoCadformat.Visitw

Topics

•Echosounderconnectionsonpage18

w w . s i m r a d . c o m todownload.

Echosounderconnections

•Outlinedimensionsandinstallationdrawingsonpage21

Observethefollowinginformationrelatedtoelectrical

connectionoftheES120-7CDSplit-beamtransducer.

Splicingthetransducercable

Ifyouneedtosplicethetransducercable,itisveryimportantto

usethecorrectcable,andtoavoidgroundloops.Westrongly

recommendtheuseofajunctionbox.

18

339149/A

Page 21

GeneralPurposeTransceiver(GPT)wiring

M

E

F

J

H

D

C

K

L

A

B

N

Burton

connector

E

H

D

C

F

J

A

B

Connectionbox

withBurtonsocket

GPT Transducer

socket

Quadrant1

Quadrant2

Quadrant3

Quadrant4

Screentoplughousing

W802-11

Rev.A

Deepwatertransducer ,termination

Forward

Starboard

Port

Quadrantsseenfromtop

ofthetransducer

2 1

3

4

2

1

6

3

5

4

7

8

2

1

6

3

5

4

7

8

Aftstarboard

Forestarboard

Foreport

Aftport

Pin1

Q1

Q2

Q3

Q4

Pin7

Pin3

Pin2

+

+

+

+

-

-

-

-

Pin4

Pin8

Pin6

Pin5

3 2 1

6 5 4

8 7

ObservethedrawingbelowtoconnecttheSimradES120-7CD

Split-beamtransducertotheGeneralPurposeTransceiver(GPT).

Formoreinformationabouttheseconnections,refertothe

applicableechosounderinstallationmanual.

Drawingle

339149/A

19

Page 22

SimradES120-7CD

Rubbersleeve

Rubbersleeve

Retainingring

Contactbody

Plug

fasteningring

Upperplugcase

Bottomcap

andcableclamp

Washers

Heat-shrinkabletubing

Lowerplugcase

Outerscreentogetherwithinnerscreen.

Drainwire,foldbackoverjacket

andtemporaryfastenedwithtape.

Outerscreenandinnerscreenbraidwire

untapedandspreadoutunderwasher

CD010219APage1of1

824-201575Rev .C

Note:

Allmeasurementsareinmm.

Thedrawingisnotinscale.

GeneralPurposeTransceiver(GPT) transducerplugassembly

20

339149/A

Page 23

Outlinedimensionsandinstallationdrawings

Note

Observethe32Nmtorquewhenthetransducerismountedusing

themountingandclampingrings.

Observethe17Nmmaximumtorquewhenthetransduceris

mountedusingthethreadedinsertsonthetransducerbody.

Topics

•Outlinedimensions[324407]onpage22

•Mountingring[204675]onpage23

•Clampingring[204677]onpage25

Drawingle

339149/A

21

Page 24

SimradES120-7CD

R1

ø130

ø152

(76)

GuidecamFOR WARD

(Bottom)

Maximumtighteningtorque(M8):17Nm

Nonstatedradii:2mm

Cablelength:1,5m

Weightinair:4,5kg

Weightinwater:2,2kg

M8,depth12mm

R5

ø24

ø180

R1

80

70,2

85,2

Allmeasurementsareinmm

Thedrawingisnotinscale

324407Rev .B

CD017028-001 Page1of1

Outlinedimensions[324407]

22

339149/A

Page 25

Mountingring[204675]

Drawingle

339149/A

23

Page 26

SimradES120-7CD

24

339149/A

Page 27

Clampingring[204677]

Drawingle

339149/A

25

Page 28

SimradES120-7CD

26

339149/A

Page 29

Index

Index

A

About,5

informationinthis

manual,5

Additionalinformation,5

Airbubbles,7

Anti-fouling

paint,14

Approval

maritimeauthorities,5

C

Clampingring

blister,9

drawing,25

example,10

D

Depth,7

Dimensions

drawing,22

Drawing

Clampingring,25

GPTTransducerplug,20

Mountingring,23

outlinedimensions,22

Drawingle,18

E

Emuge,15

Example

Clampingring,10

Mountingring,10

G

GPTTransducerplug

drawing,20

H

Handling,13

Handlingrules,13

Heat,excessive

doNOTexpose,13

I

Inclination

angle,8

Installation

drawings,6,18

hardware,6

responsibility,6

Installationmethod

Towedbody,9

Introduction,6

L

Laminarow,8

Lifting,13

M

Maintenance,13

Maritimeauthorities

approval,5

Mountingring

blister,9

drawing,23

example,10

N

Noise

airbubbles,7

protrudingobjects,8

O

Ordernumber

transducer,6

Outlinedimensions

drawing,22

P

Paint

anti-fouling,14

Physicaldimensions

drawing,22

Protrudingobjects,8

Purpose

thismanual,5

S

Self-lockingtaps,15

Simradwebsite,5

Smoothsurface,9

Sunlight

doNOTexpose,13

Surface

blister,9

T

Taps,self-locking,15

Towedbody

installation,9

Transceivercircuitry

location,7

Transducer

depth,7

lifting,13

ordernumber,6

Transducerplug

drawing,20

W

Watertight,7

339149/A

27

Page 30

Page 31

Page 32

Simraddocumentnumber:339149

Kong sb e r gM a r itim eA S

St r a n dp rom e n a de n5 0

P.O. Box1 1 1

N- 31 9 1H o r te n,N orwa y

S im r a d

Tele ph on e :+ 473 30 34 00 0

Tele fa x:+ 473 30 42 98 7

con t a ct@s im ra d. c o m

w w w .s im r a d .co m

ISBN-13:978-82-8066-110-4

©

2009KongsbergMaritimeAS

Loading...

Loading...