Page 1

Easily Programmed from the Front Panel

User-Friendly Software Functions Include:

Password

Display Scaling and Offset

Decimal Point Selection

Set Point Programming

Peak-Valley Values

Time Delay & Hysteresis

Screw Terminal Connector for Easy Installation

1/8 DIN, Shallow Depth Case,

3.24" (82mm) for Restricted Space Behind Panel

Three DC Process Ranges: 4-20mA, 1-5VDC, 0-10VDC

Optional 5-Amp Relay Outputs,

Excitation Outputs, and Analog Outputs

Hawk™ II H235 Series

Advanced Digital Panel Meter

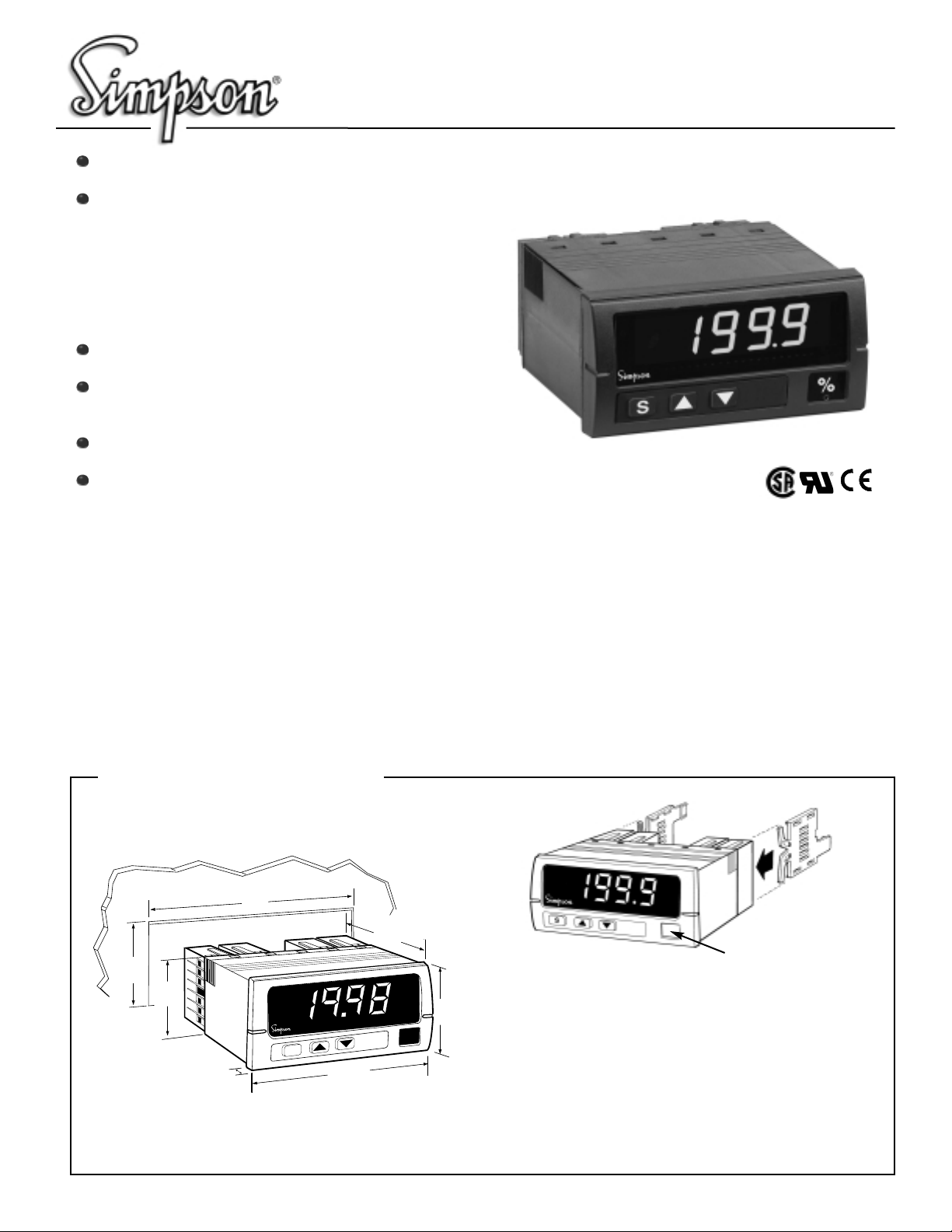

Installation and Panel Cutout

Mounting Requirements

The Hawk II series 1/8 DIN advanced digital panel meters require a

panel cutout of 1.77" (45mm) high by 3.62" (92mm) wide. To install

the Hawk II into a panel cutout, remove the clips from the sides of the

meter. Slide the meter through your panel cutout, then slide the

mounting clips back on the meter. Press evenly to ensure a proper

fit.

Engineering Label Placement

If replacement of the engineering unit label is required, place the tip

of a ball-point pen into the small hole at the base of the engineering

label in the bezel. Slide the label up until it pops out. Grasp and

remove. Slide the new label half the distance in, then use the ballpoint pen to slide it down into place.

Simpson’s Hawk II microprocessor-based advanced digital

panel meters are ideal for measuring and controlling a wide

variety of process variables. The display can be easily

scaled from the front panel to virtually any engineering units.

Excitation outputs are available for external transmitters and

transducers.

Two optional 5-amp relays include programming features for

hysteresis, time delay and relay operation. Optional analog

outputs are also available. Other programmable software

features include programmable decimal point and a pass-

word lockout feature. Depending on the password value

chosen the customer may lock out all changes, or merely

those relating to setup, leaving the set point values accessible to the operator.

The Hawk II series advanced digital panel meters are compactly designed for applications requiring minimal rear panel

depth and feature a standard 1/8 DIN case with a depth

behind the panel of only 3.24" (82mm). Screw terminals are

standard for easy installation.

DC Process

%

1.88"

48mm

0.52"

13mm

1.8"

45mm

3.24"

82mm

3.6"

92mm

1.74"

44mm

3.75"

95mm

S

Engineering Label

Loading...

Loading...