Page 1

DISPLAY

Type: 7-segment, red LED

Height: 0.56” (14.2mm)

Decimal Point: 3-position software program-

mable from front panel

Overrange: Display reads “EE”

Underrange: Display reads “-EE”

Alarm Indicators: Two LED indicators for

alarm conditions on front panel

POWER REQUIREMENTS

AC Voltages: 24, 48, 120, 220VAC, ±10%

DC Voltages: 12-48VDC, ±15%

Power Consumption: 6VA

ACCURACY:

0.2% of reading ± 2 counts

APPROVALS:

UL recognized; CSA and; CE certified

ENVIRONMENTAL

Operating Temperature: 0°C to +50°C

Storage Temperature: -10°C to +60°C

Relative Humidity: <90% non-condensing

Ambient Temperature: 23°C

Temperature Coefficient (per °C):

±100PPM/ °C

±0.05dgt/ °C

Warmup Time: 10 minutes

NOISE REJECTION

NMRR: 50db, GR = 50

CMRR: 100db, GR = 1

ANALOG TO DIGITAL CONVERSION

Technique: Special dual slope

Rate: Approximately 2 display updates per

second, nominal

MECHANICAL

Depth: 3.24” (82mm)

Bezel: 3.8” x 1.9” x 0.32”

(96mm x 48mm x 8.1mm)

Panel Cutout: 3.6” x 1.8”

(92mm x 45mm) 1/8 DIN

Case Material: ABS/polycarbonate blend

Weight: Approximately 10.5oz (297.7g)

Specifications

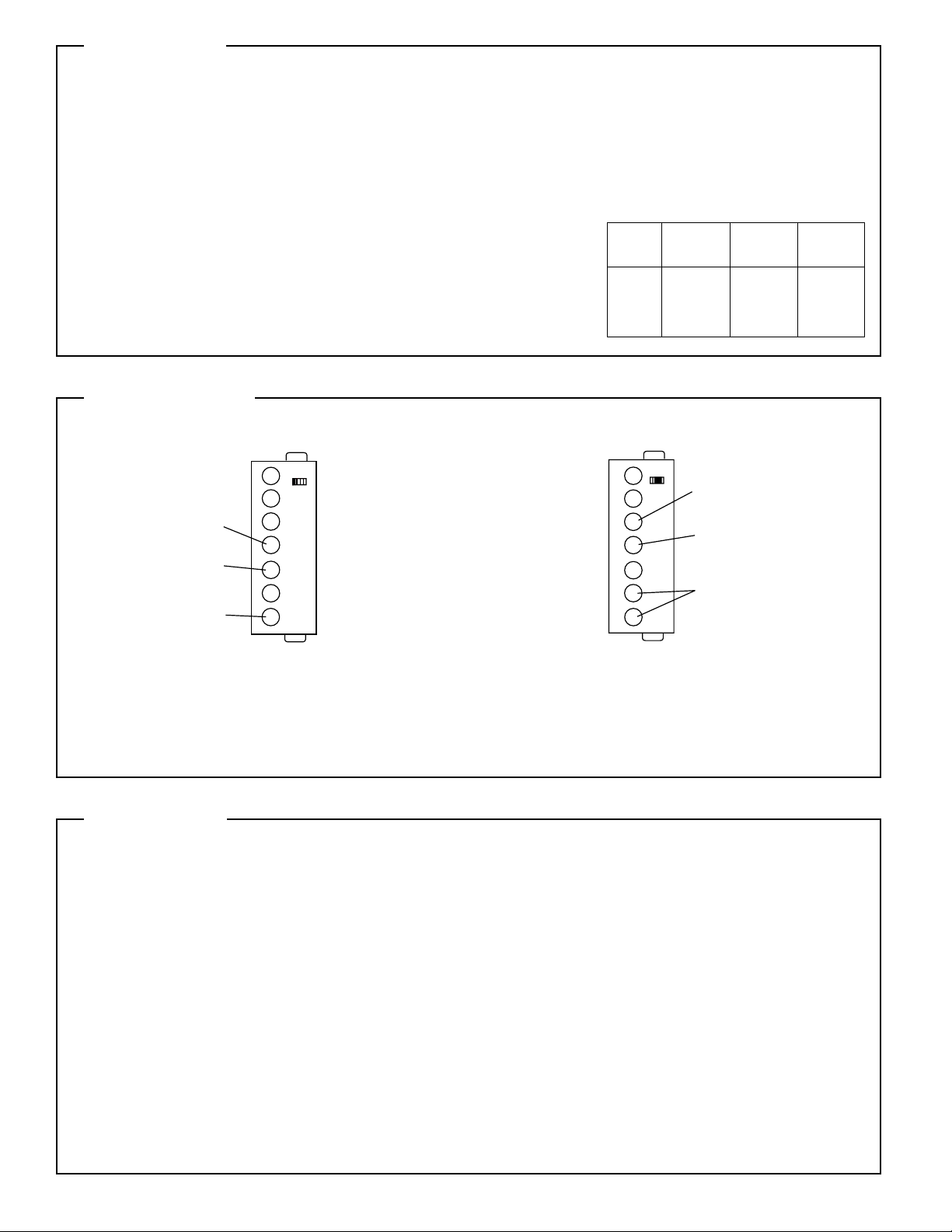

Wiring Diagram

Input Signal: Connect the signal to be monitored to the IN HI and the IN

LO terminals. Note that the IN HI signal has two terminals that can be

used, depending on the process being monitored. The upper IN HI terminal accepts 4-20 mA inputs. The lower IN HI terminal accepts 1-5VDC

and 0-10VDC inputs.

Supply Power: Connect the power to the supply power terminals.

Display Hold: Short the terminals marked HOLD to activate. The com-

parison of the input variable with the alarm set point remains active. To

reactivate this display, disconnect the short circuit.

Programming

INPUTS: DC Process

Input Power (-)

Input Power (+)

Display Hold

The Programming mode allows the user to define the instrument parameters:

- Password for access to programming

- Decimal point position

- Minimum and maximum values of the electrical range

- Display scaling

The normal measurement and control functions are not active during programming mode. The output relays are de-energized. Analog outputs

are low.

Termination of programming mode and return to the measurement and

control mode is automatic at the end of all the programming steps or

after three minutes with no key activation. Display will briefly show “End,“

then “Run.“

Access to programming

Press and hold the S key and then press ▲. The display should show

“PAS.” During this phase the instrument asks for the password, which is

a number from 0 to 199. The instrument is delivered with a password of

0. Use the ▲ and ▼ keys to change the displayed value. Press S to

enter the password and move to the next parameter.

If a number from 0 to 99 is used as the password, the operator cannot

change any of the parameters without knowing the password. This is

helpful in locking out the front panel from accidental programming. In situations where the operator needs the flexibility to change the set points

only, use a password from 100 to 199. This allows the operator to

access the set point programming mode, but jumps past the other programming functions. If the correct password is entered, the programming functions are accessed as normal.

IN LO

Signal Input

IN HI 4-20mA

Signal Input

IN HI 1-5V, 0-10V

Signal Input

Maximum

Input Display Voltage Overload

Range Resolution Drop (10 Sec.)

4-20mA 10A 0.2V 200mA

(Input

Impedance) (1 Min.)

1-5V 10mV 1M 690V

0-10V 10mV 1M 690V

Loading...

Loading...