Page 1

INSTALLATION INSTRUCTIONS

Thank you for buying this Washing Machine. It has been made for self installation by the customer.

Your dealer, Authorised Service centres or service technician can install it if you wish,

BUT YOU WILL HAVE TO PAY A FEE.

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN DAMAGE

TO THE WASHING MACHINE WHICH MAY NOT BE COVERED BY WARRANTY.

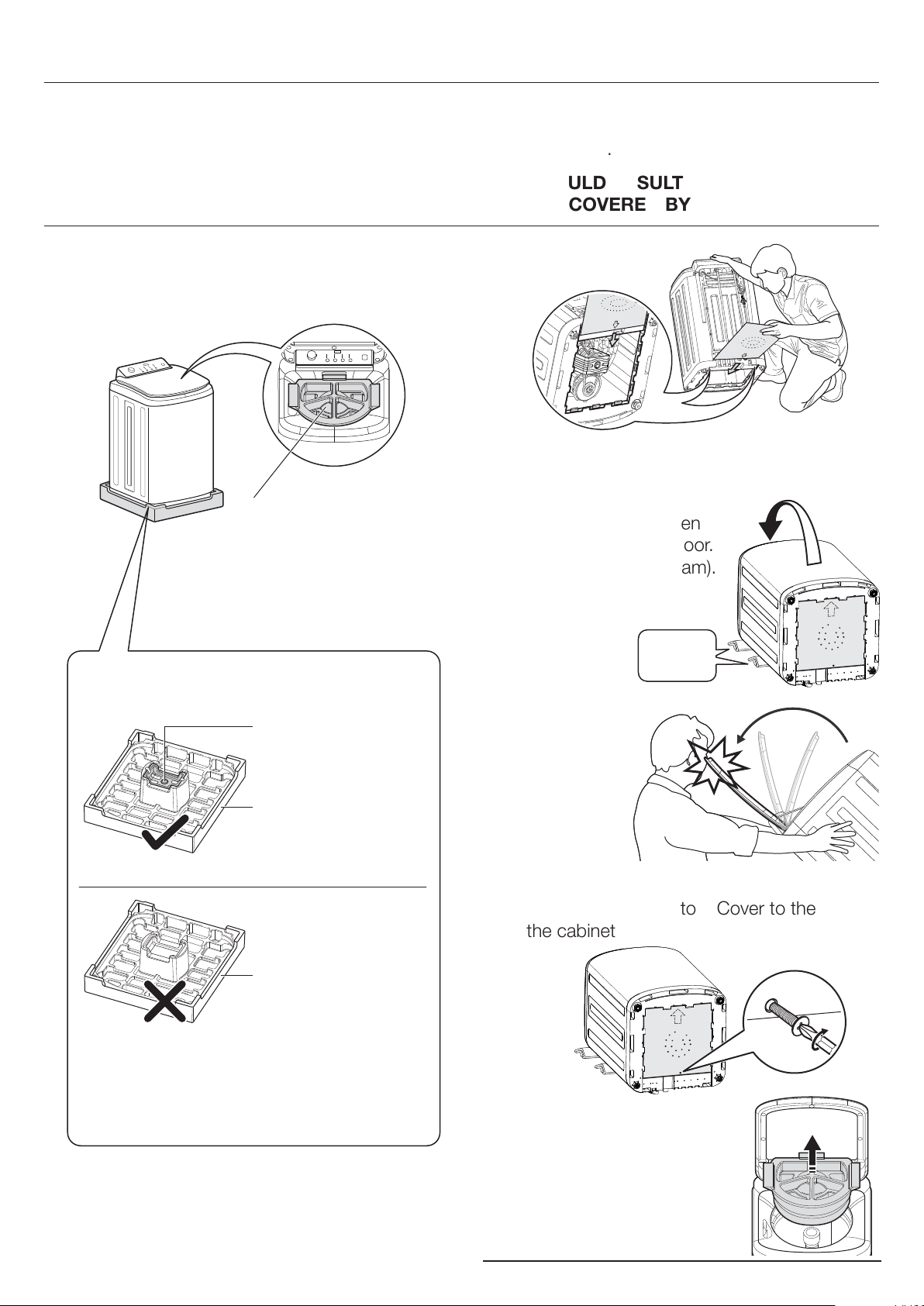

UNPACKING INSTRUCTIONS & BOTTOM

COVER INSTALLATION

Lift the machine out of the packaging base.1.

Lie down the washing machine on its back,

3.

taking care not to damage cabinet by placing

IMPORTANT:

The top polystyrene must

be removed LAST, for

protecting the drum from

hiting the cabinet when

the machine is tilted.

NOTE: After lifting the machine out, please

check packaging base as below:

two of the corner

packing pieces between

the machine and the floor.

(as shown in the diagram).

corner

packing

Plastic Motor Base

Polystyrene Base

All the packaging base should be removed.

Polystyrene Base

In case of packaging plastic motor base

remaining inside the product, please tilt the

machine to check and remove plastic

motor base from the washing machine

motor base.

Tilt the washing machine a little from back side

2.

and insert the Bottom Cover into the slot at

the bottom of the machine (as shown in the

diagram).

CAUTION:

Pay attention

to the

machine lid,

may hit your

body.

4.

Use the screw provided in the user manual

bag to secure the Bottom Cover to the bottom

of the cabinet

Lift the machine up to

5.

upright position and open

the washing machine lid.

Remove the top

polystyrene.

Page 2

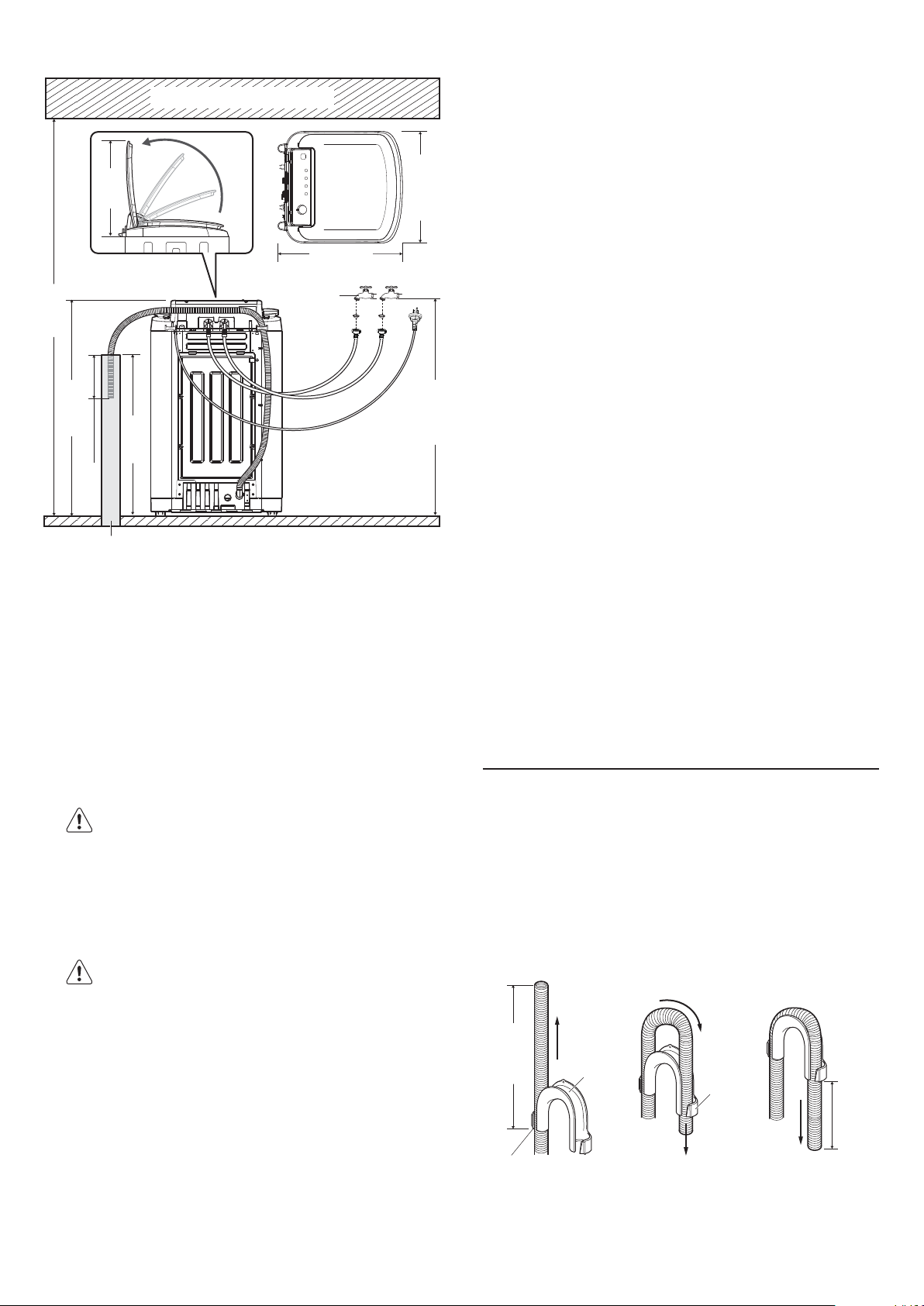

INSTALLATION REQUIREMENTS

Overhead Cupboards

554mm

D: 642mm

3/4” BSP

Thread

1500 Min.

H: 948mm

900 Min.

100mm Max.

32mm diameter extended

floor drain or 70 litres trough

Electrical: A properly earthed three pin power

1.

HotCold

1

3

3

0

0

0

0

m

m

m

m

point not more than 1500 mm from the

washing machine. It is not recommended that

an extension cord be used. If you need to use

an extension cord or portable outlet, make

sure that it is not subject to splashing or

ingress of moisture.

This machine is designed to operate on a

220-240 V, single-phase, 50 Hz supply.

“An incorrect power supply may void

your warranty.”

Check that your domestic electrical installation

can take the maximum load required (500 W),

also taking into account any other appliances

in use.

The manufacturer declines any

responsibility for damage or injury through

failure to comply with the above safety

precaution.

Your local Plumber can advise you on this.

Water pressures between 50-800kPa are

acceptable.

Floor Drain: The Washing Machine should be

3.

installed where a floor drain or hole (depending

on plumbing laws) is located. A floor drain is

W: 575mm

required to drain away any water which may

overflow from the washing machine due to a

hose leak or malfunction.

Area: For the washing machine a floor area of

4.

700 mm wide by 730 mm deep is required.

1

1

5

0

0

m

m

The floor should be firm and have a slope of

less than 20 mm in 600 mm. If you have

cupboards above the washing machine then

refer to the diagrams for clearance dimensions.

A 30 mm gap is required underneath the

1200mm Min.

washing machine when installed on a carpeted

floor.

Drain: A drain, either in the trough or as an

5.

extended floor drain at least 900 mm high and

32 mm diameter which can take a flow of 30

litres per minute of water and is less than 900

mm from the side of the machine.

Longer drain hoses can be purchased from

your dealer, Authorised Service Centres or

Spare Parts Centres if the drain or trough is

further away.

A storage trough that will hold 104 litres is

required if you are going to save all the wash

water.

INSTALLING DRAIN HOSE

Fitting hose former.

1.

Obtain hose former from inside the washbowl

and fit it to the drain hose. If your drain hose is

factory fitted you will need to pull the drain

hose from the hose transport retainer before

fitting the hose former.

bend hose

2.

Water: Cold and hot water taps with 3/4” BSP

threads less than 800 mm from the back of

the washing machine and at least 1200 mm

from the floor. Longer inlet hoses can be

purchased from Electrolux Home Products Pty.

Ltd. Spare Parts Centres or Authorised Service

Centres if the taps are further away.

If the HOT water temperature exceeds

70°C then a tempering valve must be fitted.

450 approx.

Pull apart to

insert hose.

Positioning of drain hose.

2.

Hose

Former

Pull apart

to insert

hose.

pull hose

Adjust the free length of hose to suit your

installation.

Adjust

length to

suit

trough.

Page 3

NOTE: It is important that the top of the drain

hose is above the joint between the washing

machine cabinet and the top panel (see picture).

INSTALLING INLET WATER HOSES

When installing this washing machine, use the

1.

hoses supplied. DO NOT USE OLD HOSES.

Adjust this

length to suit

your trough.

Trough

Top of drain hose must be above

the join (arrowed) between the

top panel and the cabinet.

DRAIN HOSE INSTALLATION OPTIONS

Trough

Ensure trough

is unplugged

to prevent

overflow or

siphon-back

of waste

water into

washing

machine bowl.

Trough

Bypass

The inlet hoses have the sealing washer fitted.

Take the inlet hose with the RED coloured end

2.

and connect to the hot water tap. Similarly

connect the hose with the BLUE end to the

cold water tap.

Make sure the connections are tight.

Water Tap

Filter and rubber washer

inside nut.

Twist

Inlet hose

3.

Turn the taps on and check that there are no

leaks from the connections.

If you only have a cold water tap, you must

4.

remove the inlet hose with the RED ends from

the washing machine and fit a blank cap with

a sealing washer to the HOT water inlet valve,

otherwise water will leak out of the valve.

NOTE: With cold water tap only, you must

only select cold water temperatures.

Extended Floor

Drain

32mm

diameter

extended floor

drain or 70

litres trough.

900mm Min.

100mm Max.

Part Number:

0065-200-012

A blank cap is available from Electrolux Home

Products Pty. Ltd. Spare Parts Centres or

Authorised Service Centres.

Turn off the water taps and move the washing

5.

machine into its final position.

Make sure that the inlet and drain hoses

do not kink.

Page 4

LEVELLING OF MACHINE

It is important that your washing machine

stands firm and level on the floor to ensure

correct operation.

Use a spirit level on the front and side panels

1.

of the washing machine to check the levels.

The spirit level should be used close to the

corners of the washing machine for accuracy.

By hand, or using a spanner if necessary, the

front legs are adjustable and the rear legs are

factory fitted in a fixed position (Unadjustable

legs have a round base).

Use a spirit level on the

front and side panels to

check the levels.

When the washing machine is levelled, try to

3.

rock it from corner to corner. If it does rock,

adjust the legs again until it is levelled and

does not rock.

Can rock

corner to

corner, please

adjust the legs

again.

Stable, does

not rock.

Tilt the washer a little to adjust the front legs.

If you do not have a spirit level, as a guide use

2.

the edge of a door frame, cupboard or bench

to check that the washing machine is levelled.

Never place cardboard, wood or similar

materials under the machine to compensate

for any unevenness in the floor.

OPERATION

Turn on the water taps and check for any

1.

leaks at the connections.

Connect the plug to a power-point and switch

2.

on power.

Your automatic machine is now ready for

3.

operation. Please refer to your Owner’s Manual

to understand the many features of your new

washing machine and for the operating

instructions.

Install the machine on a flat hard floor. Make

sure that air circulation around the machine is

not impeded by carpets, rugs etc.

Check that the machine does not touch the

wall or cupboard units.

A00275001-001-232014

Loading...

Loading...