Page 1

3000 PSI

2.4 GPM

PREMIUM PRESSURE WASHER

INSTRUCTION

MANUAL

MANUEL

D’UTILISATION

MANUAL DE

INSTRUCCIONES

MODEL

MODÈLE

MODELO

MS60809-S

If your pressure washer is not working properly or if there are parts missing or broken,

please DO NOT RETURN IT TO THE PLACE OF PURCHASE. Contact our Customer

Service Department at 1-877-362-4271 or www.simpsoncleaning.com

Si votre rondelle de pression ne travaille pas convenablement ou s'il y a des

parties manquant ou cassé, s'il vous plaît le PAS LE RETOURNE AU LIEU

D'ACHAT. Contacter notre département de service clients à

www.simpsoncleaning.com

Si su lavadora a presión no trabaja correctamente ó encuentra partes rotas

ófaltantes, por favor NO LA REGRECE AL LUGAR DONDE LA COMPRO.

Contáctese con nuestro Departamento de Servicio al Cliente llamando al

1-877-362-4271 ou www.simpsoncleaning.com

IMPORTANT: Please make certain that the person who is to use this equipment carefully

reads and understands these instructions before operating.

IMPORTANT: Assurez-vous que toute personne qui utilisera cet équipement lise

attentivement ces instructions avant de l’utiliser.

IMPORTANTE: Aségurese por favor de que la persona que vaya a utilizar este equipo lea

con cuidado y comprenda estas instrucciones antes de operar.

VEA EL ESPAÑOL EN LA CONTRAPORTADA. INSTRUCTIVO DE OPERACIÓN,

CENTROS DE SERVICIO Y PÓLIZA DE GARANTÍA. ADVERTENCIA:

LÉASE ESTE INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

1-877-362-4271 o

SAVE THIS MANUAL FOR FUTURE REFERENCE

LISEZ ET CONSERVEZ CES INSTRUCTIONS

CONSERVE ESTAS INSTRUCCIONES PARA FUTURAS CONSULTAS

Part No. 7108644 Rev. 0 JUN 2016

Page 2

SAFETY GUIDELINES - DEFINITIONS

This manual contains information that is important for you to know and understand.

This information relates to protecting YOUR SAFETY and PREVENTING

EQUIPMENT PROBLEMS. To help you recognize this information, we use the

symbols below. Please read the manual and pay attention to these symbols.

DANGER: Indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

NOTICE: Indicates a practice not related to personal injury which, if not avoided,

may result in property damage.

IMPORTANT SAFETY INSTRUCTIONS

DANGER: Carbon Monoxide. Using an engine indoors can kill you in

minutes. Engine exhaust contains high levels of carbon monoxide (CO), a

poisonous gas you cannot see or smell. You may be breathing CO even if you

do not smell engine exhaust.

• NEVER use an engine inside homes, garages, crawlspaces or other partly

enclosed areas. Deadly levels of carbon monoxide can build up in these areas.

Using a fan or opening windows and doors does NOT supply enough fresh air.

• ONLY use outdoors and far away from open windows, doors and vents. These

openings can pull in engine exhaust.

• Even when the engine is used correctly, CO may leak into your home. ALWAYS use

a battery-powered or battery backup CO alarm in your house. Read and follow all

directions for CO alarm before using. If you feel sick, dizzy or weak at anytime,

move to fresh air immediately. See a doctor. You could have carbon monoxide

poisoning.

WARNING: Do not operate this unit until you read this instruction manual and

the engine instruction manual for safety, operation and maintenance instructions. If

you have any questions regarding the product, please contact our customer

service department at www.simpsoncleaning.com.

DANGER: Risk of injection or severe injury. Keep clear of nozzle. Do not

direct discharge stream at persons or live animals. This product is to be used

only by trained operators.

WARNING: This product and its exhaust contain chemicals known to the State

of California to cause cancer, birth defects or other reproductive harm. In addition,

some cleaning products and dust contain chemicals known to the State of

California to cause cancer, birth defects or other reproductive harm. Wash hands

after handling.

2- ENG

Page 3

WARNING: This product may not be equipped with a spark-arresting muffler.

If the product is not equipped and will be used around flam ma ble ma teri als or

on land covered with materials such as agricultural crops, forest, brush, grass or

other similar items, then an ap proved spark arrester must be installed and is legally

required in the state of California. It is a violation of California statutes section

130050 and/or sec tions 4442 and 4443 of the California Public Re sourc es Code,

unless the engine is equipped with a spark arrester, as defined in section 4442, and

maintained in ef fec tive work ing order. Spark arresters are also required on some

U.S. For est Service land and may also be legally required under other statutes and

or di nanc es.

SAVE THESE INSTRUCTIONS

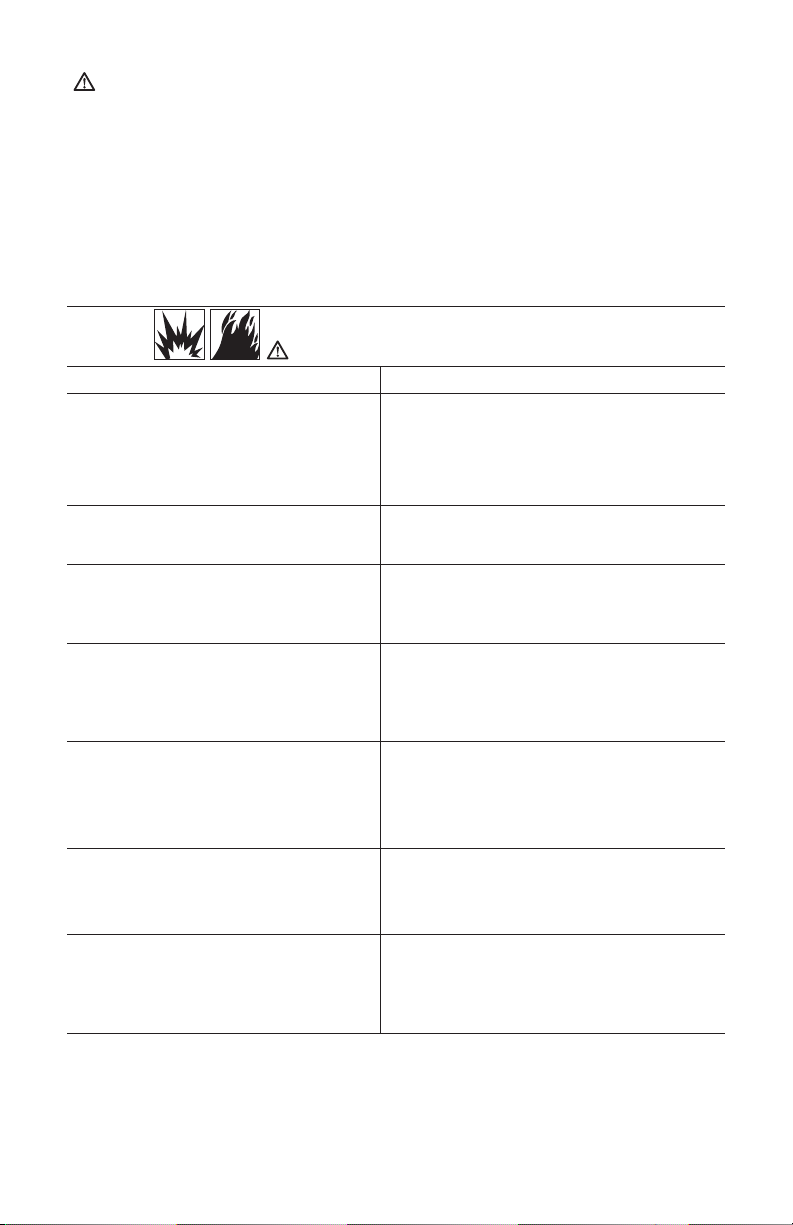

DANGER: RISK OF EXPLOSION OR FIRE

WHAT CAN HAPPEN HOW TO PREVENT IT

• Spilled gas o line and it’s vapors can

be come ignited from cigarette sparks,

electrical arcing, exhaust gas es and

hot engine components such as the

muffler.

• Heat will ex pand fuel in the tank which

could result in spillage and pos si ble

fire explosion.

• Operating the pressure washer in an

ex plo sive en viron ment could re sult in

a fire.

• Materials placed against or near the

pressure washer can in ter fere with

its proper ventilation fea tures caus ing

overheating and possible ig ni tion of

the materials.

• Muffler exhaust heat can damage

paint ed sur fac es, melt any material

sen si tive to heat (such as siding,

plastic, rub ber, vinyl or the pressure

hose, itself), and dam age live plants.

• Improperly stored fuel could lead to

acciden tal ignition. Fuel im prop er ly

secured could get into the hands of

children or oth er un qual i fied persons.

• Use of acids, toxic or cor ro sive

chemicals, poisons, in sec ti cides, or

any kind of flam ma ble solvent with

this product could re sult in se ri ous

injury or death.

• Shut off en gine and allow it to cool before

adding fuel to the tank.

• Use care in fill ing tank to avoid spill ing fuel.

Move pressure wash er away from fueling

area before start ing en gine.

• Keep maximum fuel level 1/2" (12.7mm)

be low bottom of filler neck to allow for

expansion.

• Operate and fuel equipment in wellventilat ed areas free from ob structions.

Equip areas with fire extinguisher suit able

for gas o line fires.

• Never op er ate pressure wash er in an area

containing dry brush or weeds.

• Always keep pressure washer a minimum

of 4' (1.2m) away from surfac es (such as

houses, au to mo biles or live plants) that

could be damaged from muffler exhaust

heat.

• Store fuel in an OSHA approved container, in a se cure location away from work

area.

• Do not spray flammable liquids.

3 - ENG

Page 4

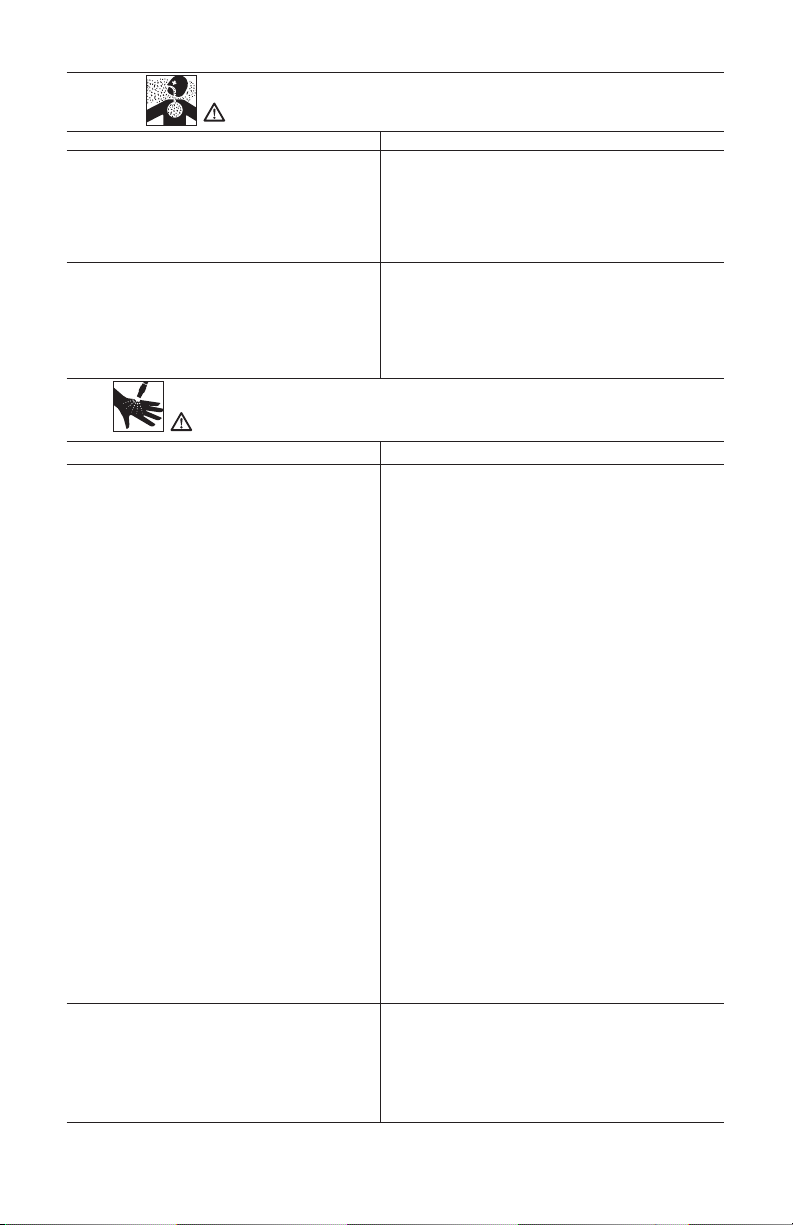

DANGER: RISK TO BREATHING (ASPHYXIATION)

WHAT CAN HAPPEN HOW TO PREVENT IT

• Breathing ex haust fumes will cause

• Operate pressure washer in a well-

se ri ous injury or death! En gine

exhaust contains carbon mon ox ide,

an odorless and deadly gas.

• Some clean ing fluids con tain

• Never op er ate unit in or near a lo ca tion

• Use only clean ing fluids spe cif i cally rec-

substanc es which could cause injury

to skin, eyes or lungs.

DANGER: RISK OF FLUID INJECTION AND LACERATION

WHAT CAN HAPPEN HOW TO PREVENT IT

• Your pressure washer operates at fluid

• Inspect the high pressure hose regularly.

pressures and velocities high enough

to penetrate human and animal flesh

which could result in amputation or

other serious injury. Leaks caused

by loose fittings or worn or damaged

hoses can result in injection injuries.

DO NOT TREAT FLUID INJECTION

• Never touch, grasp or attempt to cover a

AS A SIMPLE CUT! See a physician

immediately!

• Never place hands in front of noz zle.

• Direct spray away from self and others.

• Make sure hose and fit tings are tightened

• Do not allow hose to contact muf fler.

• Never attach or remove wand or hose

• When using replacement lances or guns

• Injuries can result if system pressure

• To relieve sys tem pres sure, shut off

is not reduced before attempting

maintenance or disassembly.

• Use only accessories rated equal to or

ventilated area. Avoid en closed areas

such as ga rages, base ments, etc.

occupied by humans or animals.

om mend ed for high pressure washers.

Fol low manufacturers recommendations.

Do not use chlorine bleach or any other

corrosive compound.

Replace the hose immediately if it is

damaged, worn, has melted from

contacting the engine, or shows any signs

of cracks, bubbles, pinholes, or other

leakage. Never grasp a high pressure

hose that is leaking or damaged.

pinhole or similar water leak on the high

pressure hose. The stream of water IS

under high pressure and WILL penetrate

skin.

and in good condition. Never hold onto

the hose or fittings during op er a tion.

fittings while sys tem is pres sur ized.

with this pressure washer, DO NOT use

a lance and/or lance/gun combination

that is shorter in length than what was

provided with this pressure washer as

measured from the nozzle end of the

lance to the gun trigger.

engine, turn off water sup ply and pull gun

trigger until water stops flowing.

higher than the rating of the pressure

washer.

4- ENG

Page 5

DANGER: RISK OF INJURY FROM SPRAY

WHAT CAN HAPPEN HOW TO PREVENT IT

• High-velocity fluid spray can cause

objects to break, projecting particles

at high speed.

• Light or unsecured objects can

become hazardous projectiles.

DANGER: RISK OF UNSAFE OPERATION

WHAT CAN HAPPEN HOW TO PREVENT IT

• Unsafe op er a tion of your pressure

wash er could lead to se ri ous in ju ry or

death to you or others.

• If proper starting procedure is not

followed, engine can kickback causing

serious hand and arm injury.

• The spray gun/wand is a powerful

clean ing tool that could look like a toy

to a child.

• Reactive force of spray will cause gun/

wand to kickback, and could cause

the op er a tor to slip or fall or misdirect

the spray. Im prop er control of gun/

wand can re sult in in ju ries to self and

others.

• Always wear ANSI-approved Z87.1

safety glasses. Wear protective clothing

to protect against accidental spraying.

• Never point wand at or spray people or

animals.

• Always secure trigger lock when wand

is not in service to prevent accidental

operation.

• Never permanently secure trigger in pullback (open) position.

• Do not use chlorine bleach or any other

corrosive compound.

• Be come fa mil iar with the op er a tion and

con trols of the pressure washer.

• Keep operating area clear of all persons,

pets and obstacles.

• Do not operate the product when fatigued

or under the influence of alcohol or drugs.

Stay alert at all times.

• Never compromise the safety fea tures of

this prod uct.

• Do not op er ate machine with missing,

broken or un au tho rized parts.

• Never leave wand unattended while unit is

running.

• If engine does not start after two pulls,

squeeze trigger of gun to relieve pump

pressure. Pull starter cord slowly until

resistance is felt. Then pull cord rapidly to

avoid kickback and prevent hand or arm

injury.

• Keep chil dren away from the pressure

washer at all times.

• Do not over reach or stand on an unstable

support.

• Do not use pressure washer while

standing on a ladder.

• Grip gun/wand firmly with both hands.

Expect the gun to kickback when

triggered.

5 - ENG

Page 6

DANGER: RISK OF INJURY OR PROP ER TY DAMAGE WHEN

TRANSPORTING OR STORING

WHAT CAN HAPPEN HOW TO PREVENT IT

• Fuel or oil can leak or spill and could

result in fire or breathing hazard.

Se rious in ju ry or death can re sult.

Fuel or oil leaks will dam age carpet,

paint or oth er surfaces in ve hi cles or

trailers.

• Oil could fill the cylinder and damage

the engine if the unit is not stored or

transported in an upright position.

• If pressure washer is equipped with a fuel

shut-off valve, turn the valve to the OFF

position before transporting to avoid fuel

leaks. If pres sure wash er is not equipped

with a fuel shut-off valve, drain the fuel

from tank before trans port ing. Only transport fuel in an OSHA-approved container.

Al ways place pressure washer on a

protective mat when transporting to

protect against dam age to vehicle from

leaks.

Always transport and store unit in an

upright position. Re move pres sure

washer from vehicle immediately upon

arrival at your destination.

DANGER: RISK OF ELEC TRI CAL SHOCK

WHAT CAN HAPPEN HOW TO PREVENT IT

• Spray di rect ed at elec tri cal outlets or

switch es, or ob jects con nect ed to an

elec tri cal circuit, could re sult in a fatal

electrical shock.

• Unplug any elec tri cal ly op er at ed product

before attempting to clean it. Direct spray

away from electric out lets and switches.

DANGER: RISK OF CHEMICAL BURN

WHAT CAN HAPPEN HOW TO PREVENT IT

• Use of acids, toxic or corrosive

chemicals, poisons, in sec ti cides, or

any kind of flam ma ble solvent with this

product could re sult in se ri ous injury or

death.

• Do not spray ac ids, gasoline, ker o sene,

or any other flammable materials with this

product. Use only household de ter gents,

cleaners and degreasers recommended

for use with pres sure washers.

• Wear pro tec tive clothing to protect

eyes and skin from con tact with sprayed

materials.

6- ENG

Page 7

WHAT CAN HAPPEN HOW TO PREVENT IT

WARNING: RISK OF BURSTING

• Over inflation of tires could result in

serious injury and property damage.

• High-velocity fluid spray directed at

pneumatic tire sidewalls (such as

found on automobiles, trailers and

the like) could damage the sidewall

resulting in serious injury.

WARNING: RISK OF HOT SURFACES

WHAT CAN HAPPEN HOW TO PREVENT IT

• Con tact with hot sur fac es, such as

engine exhaust com po nents, could

result in se ri ous burn.

• Use a tire pressure gauge to check the

tires pressure before each use and while

inflating tires; see the tire sidewall for the

correct tire pressure.

NOTE:

Air tanks, compressors and similar

equipment used to inflate tires can fill small

tires similar to these very rapidly. Adjust

pressure regulator on air supply to no more

than the rating of the tire pressure. Add air

in small increments and frequently use the

tire gauge to prevent over inflation.

• On pressure washers rated above

1600 psi (11032 kPa) use the widest

fan spray (40º nozzle) and keep the

spray a minimum of 8" (20 cm) from the

pneumatic tire sidewall. Do not aim spray

directly at the joint between the tire and

rim.

• During op er a tion, touch only the control

surfaces of the pres sure washer. Keep

children away from the pres sure washer

at all times. They may not be able to

recognize the haz ards of this product.

WARNING: RISK OF INJURY FROM LIFTING

WHAT CAN HAPPEN HOW TO PREVENT IT

• Serious injury can result from

attempting to lift too heavy an object.

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

7 - ENG

• The pressure washer is too heavy to be

lifted by one person. Obtain assistance

from others before lifting.

Page 8

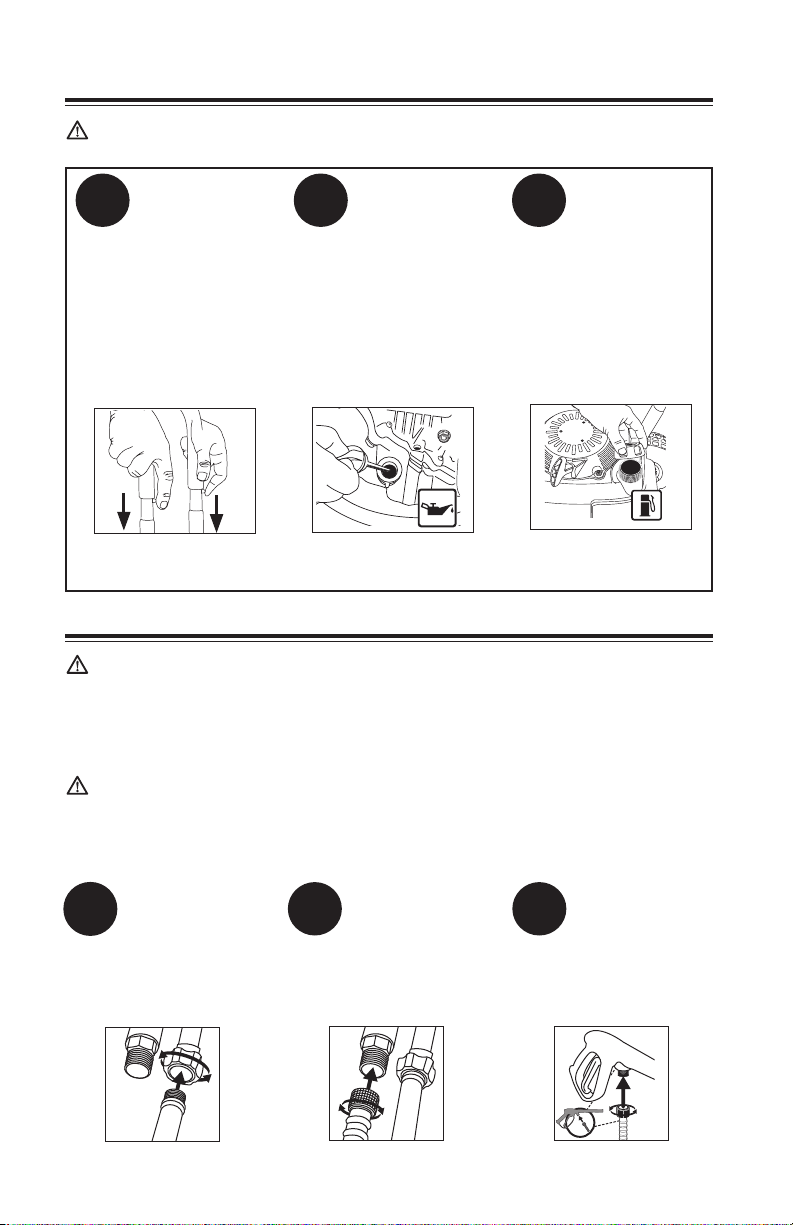

QUICK SETUP GUIDE

WARNING: To reduce the risk of injury, read the pressure washer instruction

manual and the engine instruction manual before operating pressure washer.

Install the

Handle

A

onto frame, depress the

Place handle

snap buttons, and slide

the handle assembly

onto the frame until snap

buttons snap into place.

IMPORTANT: Ethanol ShieldTM (sold separately) is a fuel stabilizer that helps eliminate

and prevent ethanol related problems in power equipment. Follow the instructions on

the container and add to the gasoline.

oil. Before starting engine,

add the oil. Check oil level

prior to each use. Refer to

Engine Owner’s Manual

for complete procedure.

Add/Check Oil

The engine is

B

shipped without

Add Gasoline

In a well

C

area add fresh, high

quality, unleaded gasoline

with a pump octane rating

of 86 or higher. Do not

overfill. Wipe up spilled

fuel before starting the

engine. Refer to Engine

Owner’s Manual for

complete procedure.

ventilated outdoor

QUICK START GUIDE

DANGER:

• Never run engine indoors or in enclosed, poorly ventilated areas. Engine exhaust

contains carbon monoxide, an odorless and deadly gas.

• Risk of fluid injection and laceration. When using the high pressure setting, DO

NOT allow the high pressure spray to come in contact with unprotected skin, eyes

or with any pets or animals. Serious injury will occur.

WARNING: Do not allow the unit to run for more than two minutes without the

gun trigger being pulled. This could cause overheating and damage to the pump.

When the temperature inside the pump rises too high, the thermal relief valve will

open and release a spray of water from the pump to lower the internal temperature. The valve will then close.

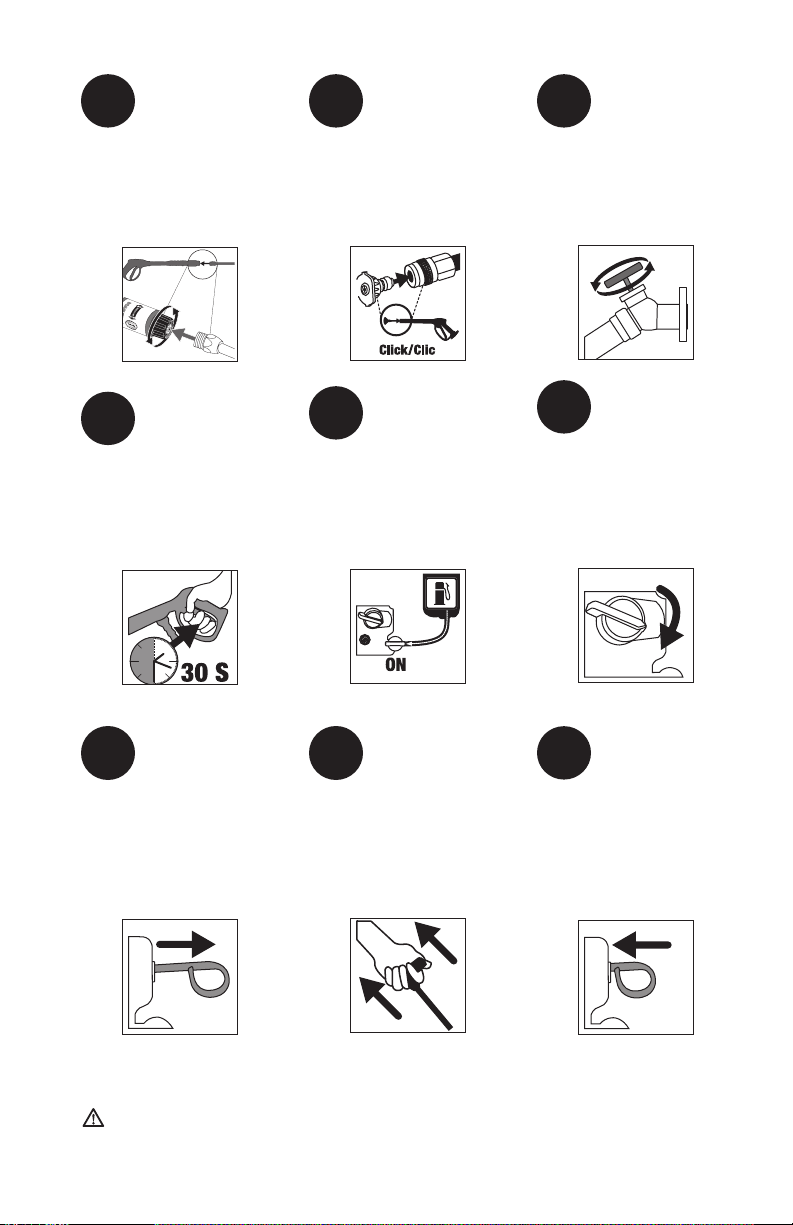

Connect Garden

Hose to Pump

1

the garden hose to

the pump inlet.

See Label #1 on the

back of the unit.

Thread

Connect High

Pressure Hose

2

to Pump

Thread the high pressure

hose to the pump outlet.

See Label #2 on the

back of the unit.

Thread the other end

of the high pressure

hose to the spray gun.

Connect High

Pressure Hose

3

to Spray Gun

8- ENG

Page 9

Connect Spray

Wand to Spray

4

Gun

Thread the spray

wand into the end

of the spray gun.

Connect QC

Nozzles to Spray

5

Wand

Pull quick connect coupler back and insert

nozzle. Release quick

connect coupler and

twist nozzle to make sure

it is secure in coupler.

Turn Water

Faucet

6

Completely On

Do not run the unit

without water supply

connected and turned on.

Use Cold Water Only.

Release Air from

System

7

air from pump and

high pressure hose by

depressing trigger until a

steady stream of water is

present. Approximately

30 seconds.

The Choke Pin has been

preset by the factory to be

in the CLOSED Position.

See Label #10 on the

side of the engine.

Release all

Verify the Choke

Pin is Pulled Out

10

to the CLOSED

Position

Verify the Fuel

Valve is turned

8

to the OPEN

Position

The Fuel Valve has been

preset by the factory to

be in the OPEN position.

See Label #8 on the

side of the engine.

OFF

ON

Pull the Recoil

Starter Grip

11

recoil starter grip to

start the engine.

See Label #11 on the

side of the engine.

Pull the

Verify the Engine

Switch is turned

9

to the ON

Position

See Label #9 on the

side of the engine.

OFF

ON

Push the Choke

Pin to the OPEN

12

Position

Gradually move the

Choke Pin to the

OPEN Position after

engine starts.

See Label #12 on the

side of the engine.

WARNING: This Guide is not a substitute for reading the operator's manual. User

must read and understand operator's manual before using this product.

9 - ENG

Page 10

GET TO KNOW THE PRESSURE WASHER

NOTE: Photographs and line drawings used in this manual are for reference

only and do not represent a specific model.

Compare the illustrations with your unit to familiarize yourself with the location of

various controls and adjustments. Save this manual for future reference.

1

C

B

K

G

D

L

H

E

F

A

I

J

BASIC ELEMENTS OF A PRESSURE WASHER (FIG. 1)

A. High Pressure Pump: Increases the pressure of the water supply.

B. Engine: Drives the high pressure pump. Refer to the Engine Owner’s Manual

for location and operation of engine controls.

C. High Pressure Hose: Carries the pressurized water from the pump to the gun

and spray wand.

D. Spray Gun: Connects with spray wand to control water flow rate, direction,

and pressure.

E. Quick-Connect Spray Wand: Allows the user to quickly change out high

pressure nozzles. See How To Use Spray Wand instructions in Operation

section.

F. Detergent Siphon Hose: Feeds cleaning agents into the pump to mix with

the water. See

Operation

How To Apply Chemicals/Cleaning Solvents

section.

10- ENG

instructions in

Page 11

G. Handle

H. Frame

I. Pump Outlet

J. Pump Inlet

K. Quick Connect Nozzles

L. Dial-N-Wash

®

Adjustable Pressure Regulator: Use the Dial-N-Wash to

increase and decrease the pressure. Refer to the Dial-N-Wash Adjustment

paragraph.

BASIC ELEMENTS OF AN ENGINE

Refer to the Engine Owner’s Manual for location and operation of engine controls.

Choke Control: Opens and closes carburetor choke valve.

Starter Grip: Pulling starter grip operates recoil starter to crank engine.

Engine Switch: Enables and disables ignition system.

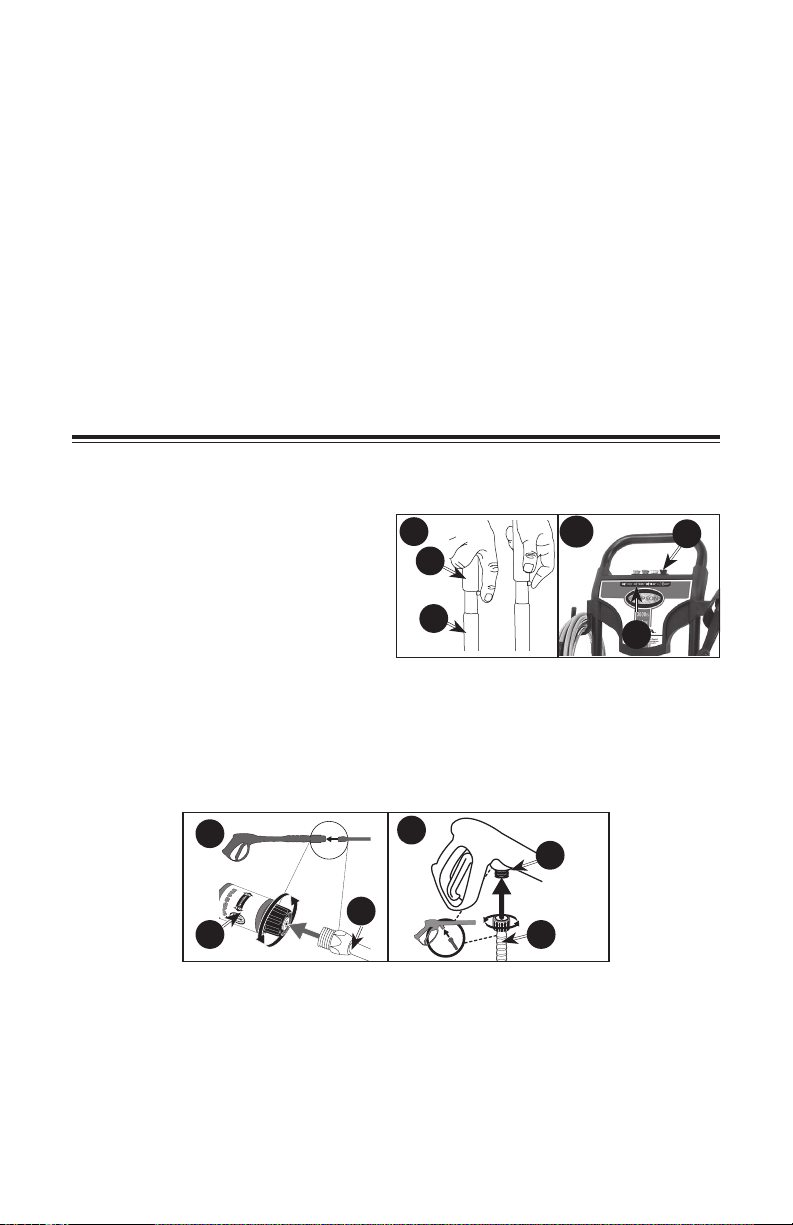

ASSEMBLY INSTRUCTIONS (FIG. 2 – 4)

1. Locate and remove all loose parts from the carton.

2. Cut four corners of the carton from top to bottom and lay the panels flat.

3.

Place handle (G) onto frame (H),

depress the snap buttons, and slide

the handle assembly onto the frame

until snap buttons snap into place.

NOTICE: Risk of personal injury. Avoid

placing hands between handle and

frame when assembling to prevent

pinching.

4. Remove the colored quick-connect nozzles (K) from the plastic bag and insert

them into correct grommet on the nozzle holder. Nozzles are color coded to

match colored nozzles on label (Q).

5. Connect wand (E) to gun (D). Tighten securely.

6. Attach high pressure hose (C) to gun (D). Tighten se cure ly.

2

G

H

2A

K

Q

3

D

4

D

E

C

NOTE: The pump on this unit is maintenance free and requires no oil. If

there is a problem with the pump, contact our Customer Service Group on

www.simpsoncleaning.com as soon as possible.

NOTICE: The engine is shipped without oil. Before starting engine, add the oil

provided. Damage to the engine will occur if the engine is run without oil, this

damage will not be covered under warranty.

11 - ENG

Page 12

OPERATION

PRESSURE WASHER TERMINOLOGY

PSI: Pounds per Square Inch. The unit of measure for water pressure. Also used

for air pressure, hydraulic pressure, etc.

GPM: Gallons per Minute. The unit of measure for the flow rate of water.

CU: Cleaning Units. GPM multiplied by PSI equals CU.

Bypass Mode: Allows water to re-circulate within the pump when the gun trigger is

not pulled. This feature allows the operator to release the trigger gun and reposition

themselves without having to turn the engine off in between cleaning actions.

WARNING: Do not allow the unit to run for more than two minutes without

the gun trigger being pulled. This could cause overheating and damage to

the pump. When the temperature inside the pump rises too high, the thermal

relief valve will open and release a spray of water from the pump to lower the

internal temperature. The valve will then close.

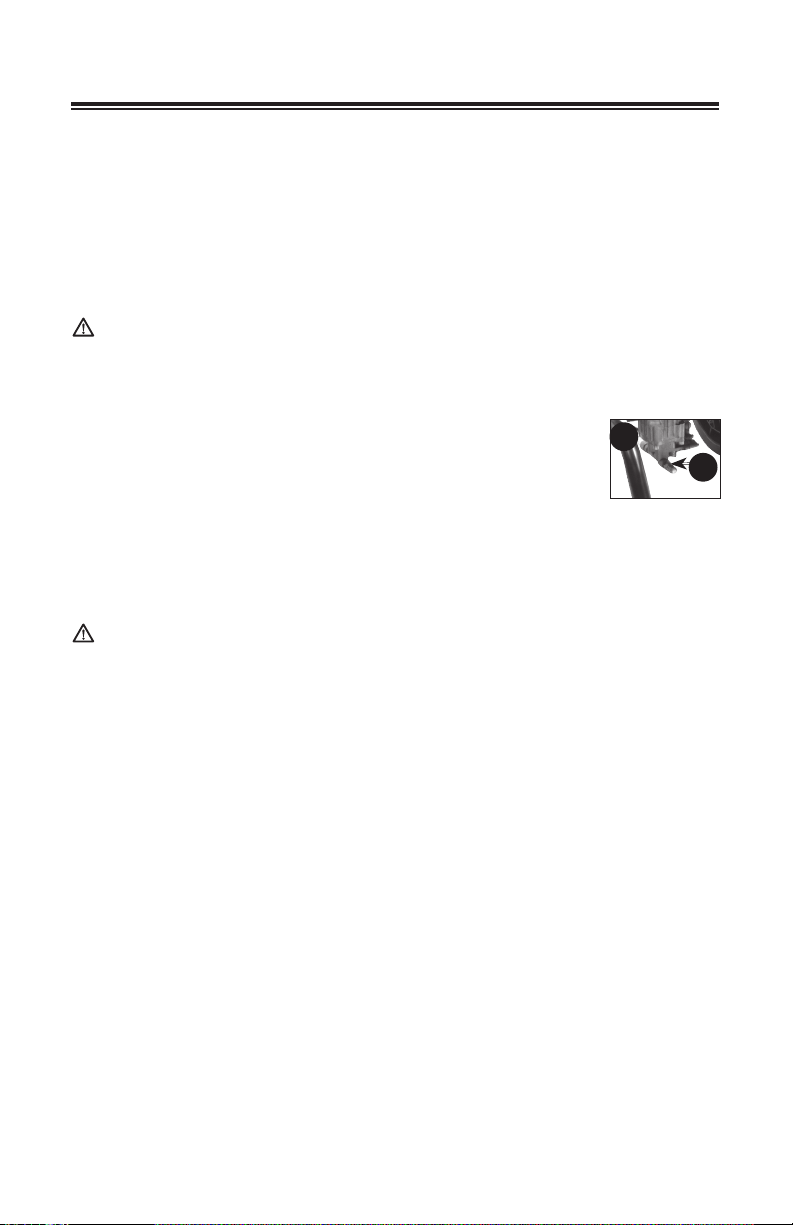

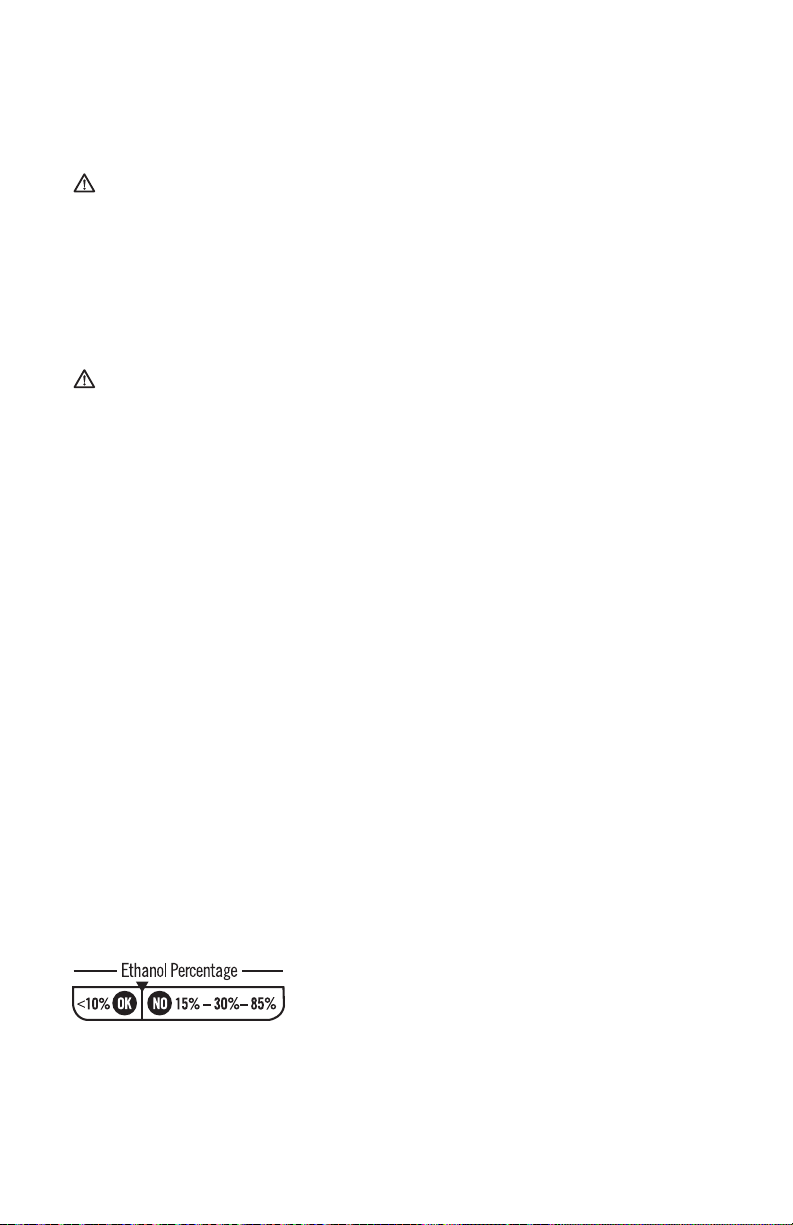

Thermal Relief Valve (P, Fig. 5): When the temperature inside the

pump rises too high, this valve will open and release a gush of water

in an effort to lower the temperature inside the pump. The valve will

then close.

Detergent Injection System: Mixes cleaners or cleaning solvents with the water

to improve cleaning effectiveness.

Water Supply: All pressure washers must have a source of water. The minimum

requirements for a water supply are 20 psi and 5 Gallons Per Minute. If your water

source is a well, the garden hose length can only be 30 ft. (9m) max.

WARNING: To reduce the possibility of contamination always protect

against backflow when connected to a potable water system.

PRESSURE WASHER OPERATING FEATURES

PRESSURE ADJUSTMENTS

The pressure setting is preset at the factory to achieve op ti mum pres sure and

cleaning. If you need to lower the pres sure, it can be accomplished by these methods.

1. Back away from the sur face to be cleaned. The further away you are, the

less the pressure will be on the surface to be cleaned.

2. Use the Dial-N-Wash to increase and decrease the pressure. Refer to the

Dial-N-Wash Adjustment paragraph.

NOTICE: DO NOT attempt to increase pump pressure. A higher pressure setting

than the factory set pressure may damage pump.

DIAL-N-WASH ADJUSTMENT (FIG. 6, 7)

1. Choose the correct high pressure nozzle (0˚, 15˚ or 40˚) for the job to be

performed. Refer to How To Use Spray Wand.

2. The Dial-N-Wash is shipped in the MAX pressure setting, the MAX pressure

bar is aligned with the arrow (R) on the collar as shown in Figure 6.

Rotating the Dial-N-Wash (L) counterclockwise until it stops places it in the

MIN pressure setting, the arrow (R) will align with the MIN pressure bar as

shown in Figure 7.

5

P

12- ENG

Page 13

6

7

R

R

L

Adjust the pressure by rotating the

Dial-N-Wash (L) clockwise for

higher pressure or

counterclockwise for lower

pressure, aligning the arrow with

the desired pressure bar on the

Dial-N-Wash.

NOTE: To apply chemicals the black low pressure nozzle must be installed and

the Dial-N-Wash must be in the MAX pressure setting.

HOW TO USE SPRAY WAND

The nozzles for the spray wand are stored in the nozzle holder on the panel assembly.

Colors on the panel identify nozzle location and spray pattern. Refer to the following

chart to choose the correct nozzle for the job to be performed.

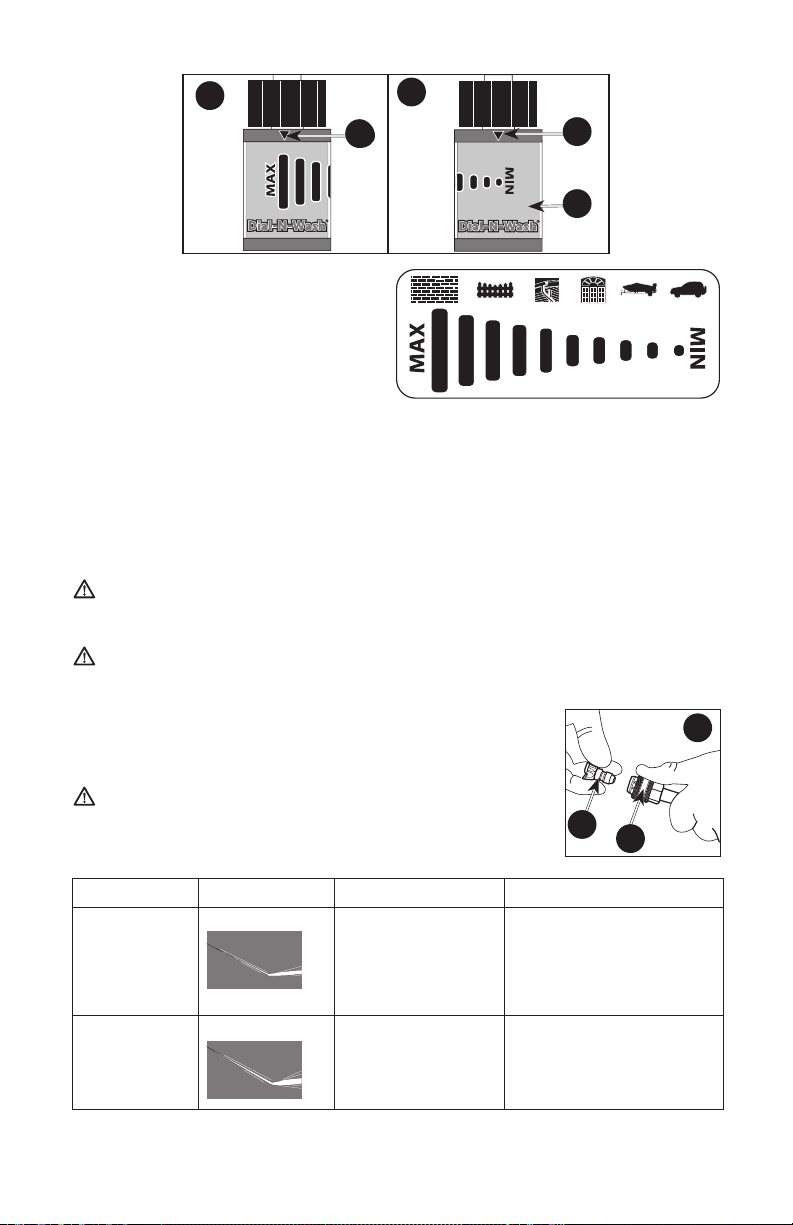

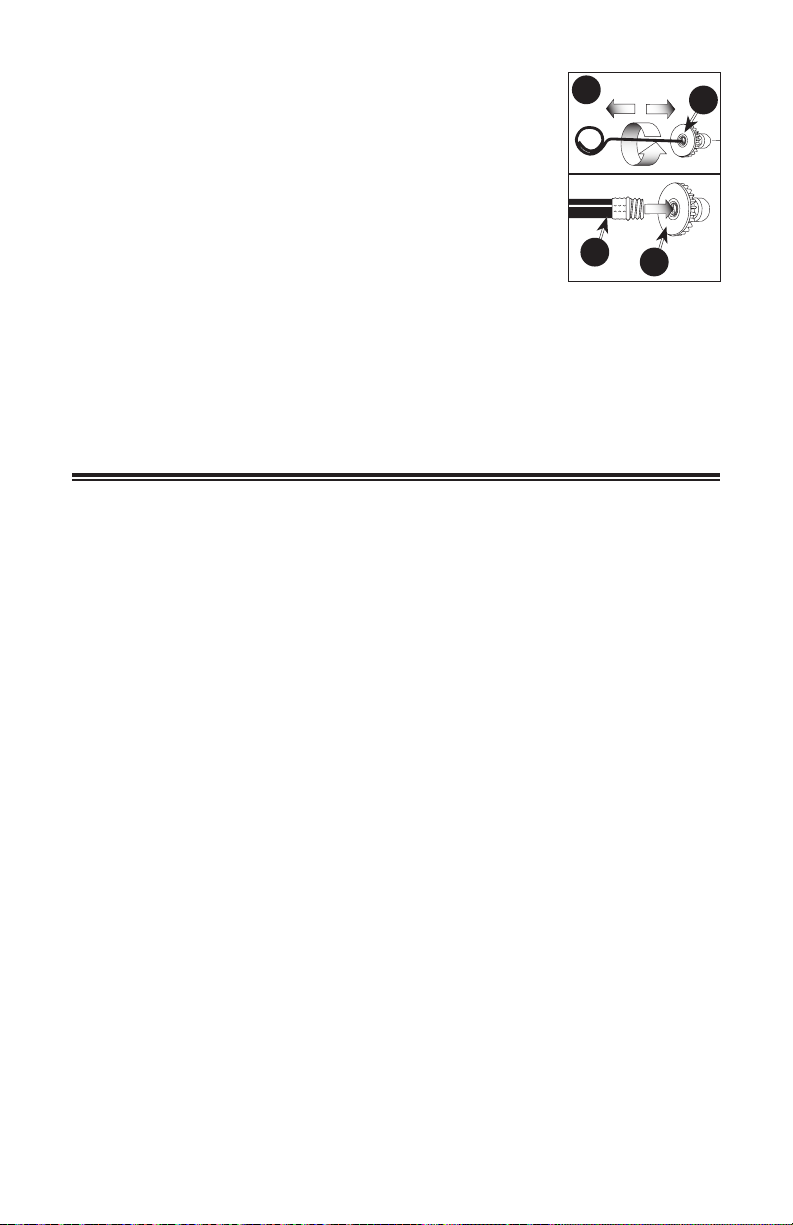

CHANGING NOZZLES ON SPRAY WAND (FIG. 8)

DANGER: Risk of fluid injection. Do not direct discharge stream toward

persons, unprotected skin, eyes or any pets or animals. Serious injury will

occur.

WARNING: Flying objects could cause risk of serious injury. Do not

attempt to change nozzles while pressure washer is running. Turn engine off

before changing nozzles.

1. Pull quick-connect coupler (E) back and insert nozzle (K).

8

2. Release quick-connect coupler and twist nozzle to make

sure it is secure in coupler.

WARNING: Flying object could cause risk of serious

injury. Ensure nozzle is completely inserted in quickconnect socket and quick-connect collar is fully engaged

K

E

(forward) before squeezing gun trigger.

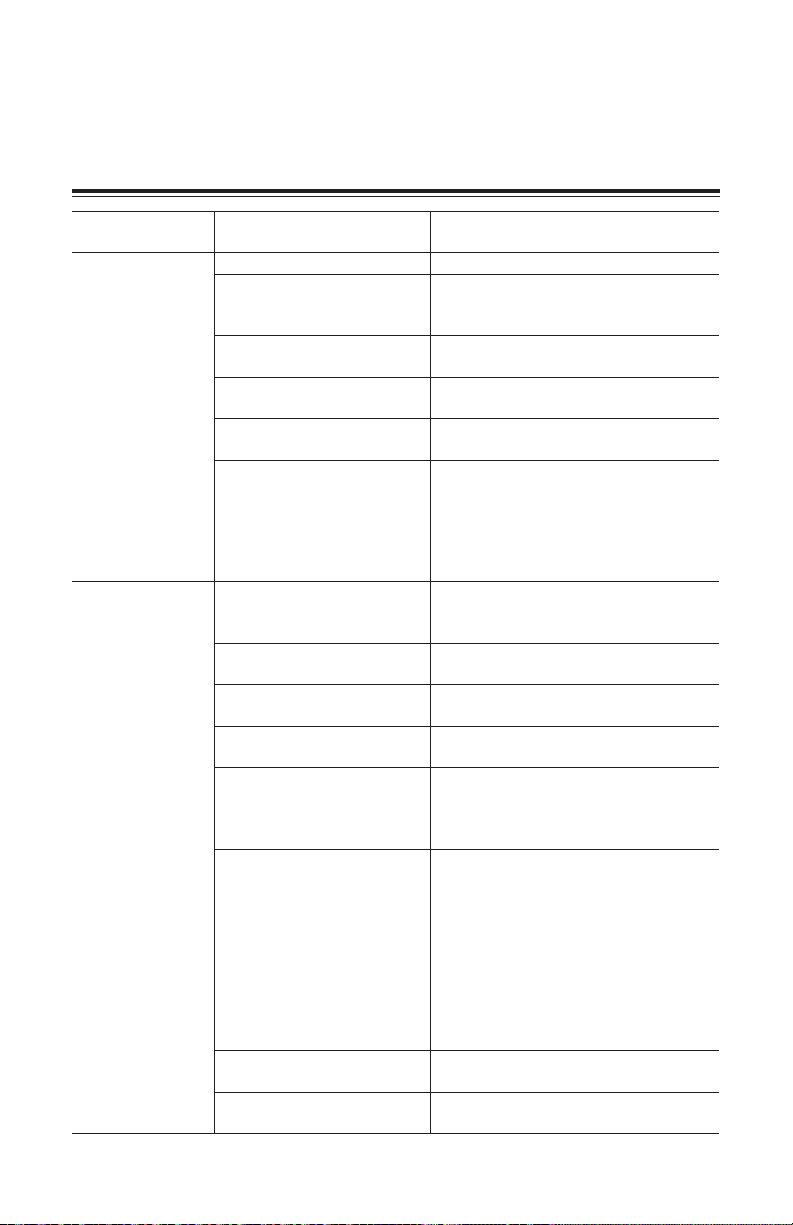

NOZZLE COLOR SPRAY PATTERN USES SURFACES*

Red

0˚

powerful pinpoint

for spot cleaning

of hard, unpainted

surfaces or for

unpainted metal

or concrete;

DO NOT use on wood

high reach areas

15˚

Yellow

intense cleaning

of unpainted

hard surfaces

13 - ENG

grills, driveways, concrete

or brick walkways,

unpainted brick or stucco

Page 14

NOZZLE COLOR SPRAY PATTERN USES SURFACES*

White

40˚

cleaning of

painted or delicate

surfaces

auto/RV, marine, wood,

painted brick and stucco,

vinyl, painted siding

Black

low pressure

applies cleaning

solutions

Low pressure

spray is safe on all

surfaces. Always verify

compatibility of cleaning

solution prior to use.

*NOTICE: The high pressure spray from your pressure washer is capable of

causing damage to surfaces such as wood, glass, automobile paint, auto striping

and trim, and delicate objects such as flowers and shrubs. Before spraying, check

the item to be cleaned to assure yourself that it is strong enough to resist damage

from the force of the spray.

HOW TO APPLY CHEMICALS/CLEANING SOLVENTS (FIG. 9)

Applying chemicals or cleaning solvents is a low pressure operation. NOTE: Use

only soaps and chemicals designed for pressure washer use. Do not use bleach.

To Apply Chemicals:

1. Ensure detergent siphon hose (F, Figure 9) is

attached to barbed fitting location near high

9

pressure hose connection of pump as shown.

2. Place other end of detergent siphon hose with

filter on it into container holding chemical/cleaning

solution. NOTE: For every 7 gallons of water

pumped 1 gallon of chemical/cleaning solution will

F

be used.

3. Install the black low pressure nozzle into the quick connect fitting of the spray

wand and rotate the Dial-N-Wash (L) to the MAX pressure setting as shown in

Figure 6. See How To Use Spray Wand paragraph in this section.

NOTE: To apply chemicals the black low pressure nozzle must be installed and

the Dial-N-Wash must be in the MAX pressure setting as shown in Figure 6.

4. After use of chemicals, place detergent siphon hose into container of clean

water and draw clean water through chemical injection system to rinse system thoroughly. If chemicals remain in the pump it could be damaged. Pumps

damaged due to chemical residue will not be covered under warranty.

NOTE: Chemicals and soaps will not siphon if the black soap nozzle is not installed

on the spray wand.

STARTING (FIG. 10–13)

WARNING: To reduce the risk of injury, read the pressure washer instruction

manual and the engine instruction manual before starting pressure washer.

DANGER: Risk of fluid injection and laceration. When using the high

pressure setting, DO NOT allow the high pressure spray to come in contact

with unprotected skin, eyes, or with any pets or animals. Serious injury will

occur.

14- ENG

Page 15

• Your washer operates at fluid pressures and velocities high enough to penetrate

human and animal flesh, which could result in amputation or other serious injury.

Leaks caused by loose fittings or worn or damaged hoses can result in injection

injuries. DO NOT TREAT FLUID INJECTION AS A SIMPLE CUT! See a physician

immediately!

DANGER: Carbon Monoxide. Using an engine indoors can kill you in

minutes. Engine exhaust contains high levels of carbon monoxide (CO), a

poisonous gas you cannot see or smell. You may be breathing CO even if you

do not smell engine exhaust.

• Breathing ex haust fumes will cause se ri ous injury or death! En gine exhaust

contains carbon mon ox ide, an odorless and deadly gas.

• Operate pressure washer in a well-ventilated area. Avoid en closed areas

such as ga rages, base ments, etc.

• Never op er ate unit in or near a lo ca tion occupied by humans or animals.

WARNING: Risk of Fire, Asphyxiation and Burn. Never fill fuel tank when

engine is running or hot. Do not smoke when filling fuel tank.

• Never fill fuel tank completely. Fill tank to 1/2" (12.7mm) below bottom of filler

neck to provide space for fuel expansion. Wipe any fuel spillage from engine and

equipment before starting engine.

• DO NOT let hoses come in contact with very hot engine muffler during or

immediately after use of your pressure washer. Damage to hoses from contact with

hot engine surfaces will NOT be covered by warranty.

NOTICE: Risk of property damage. Never pull water supply hose to move pres sure

washer. This could damage hose and/or pump inlet.

• DO NOT use hot water, use cold water only.

• Never turn water supply off while pressure washer engine is running or damage to

pump will result.

• DO NOT stop spraying water for more than two minutes at a time. Pump operates

in bypass mode when spray gun trigger is not pressed. If pump is left in bypass

mode for more than two minutes internal components of the pump can be

damaged.

If you do not understand these precautions, please contact our customer service

department at www.simpsoncleaning.com

Prior to starting, refer to your engine manual for proper starting procedure.

1. In a well ventilated outdoor area add fresh, high quality, unleaded gasoline

with a pump octane rating of 86 or higher. Do not overfill. Wipe up spilled

fuel before starting the engine. Refer to Engine Owner’s Manual for correct

procedure.

IMPORTANT: Ethanol Shield

TM

(sold separately) is a fuel stabilizer that helps

eliminate and prevent ethanol related problems in power equipment. Follow the

instructions on the container and add to the gasoline.

NOTICE: Use of fuels with greater than 10% ethanol are

not approved for use in this product per EPA regulations

and will damage the unit and void the warranty.

2. Check engine oil level. See Engine Owner’s Manual for correct procedure.

3. Connect the water hose to the water source. Turn the water source on to

remove all air from the hose. When a steady stream of water is present, turn

the water source off.

15 - ENG

Page 16

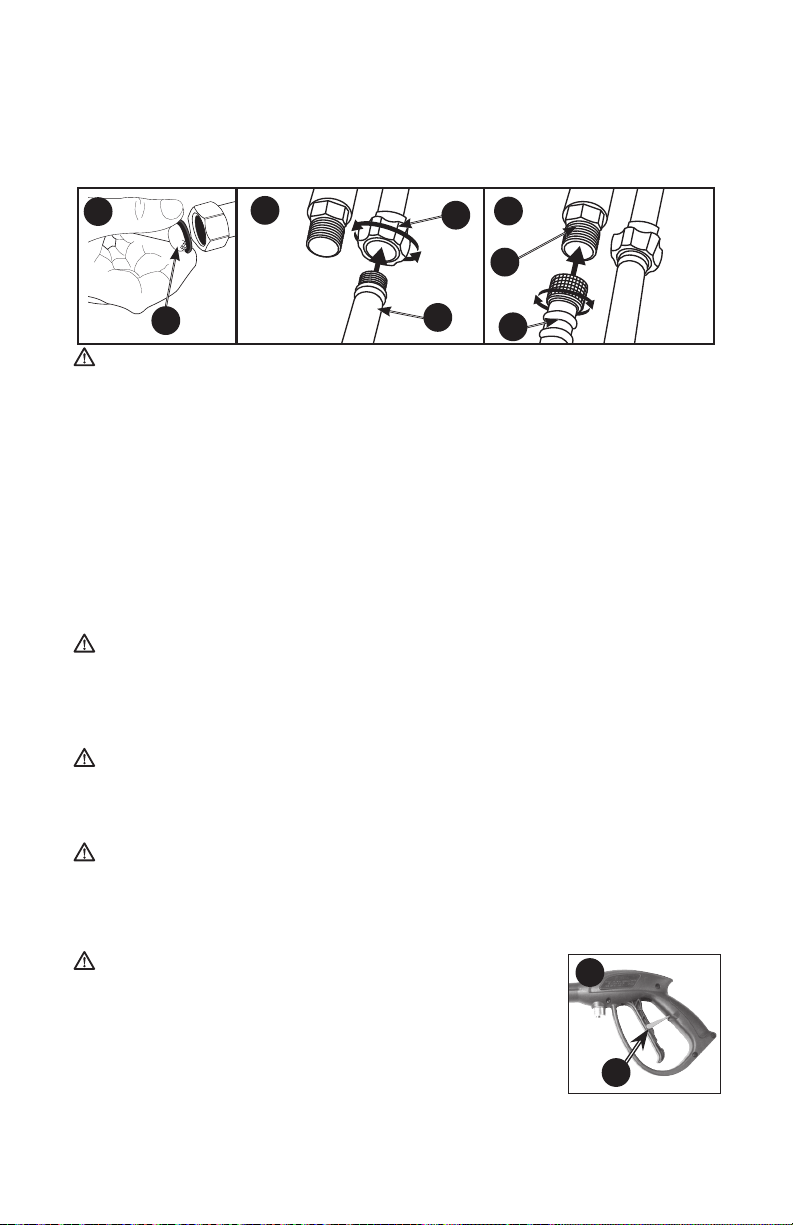

4. Verify the filter screen (M) is in water inlet of pump. NOTE: Convex side faces

out.

5. Connect water source (N) to pump inlet (J). NOTE: Water source must provide

a minimum of 5 gallons per minute at 20 psi.

6. Connect

high pressure hose (C) to pump outlet (I).

10

11

M

N

12

J

I

C

WARNING: To reduce the possibility of contamination always protect

against backflow when connected to a potable water system.

7. Choose the correct nozzle for the job to be performed. See How To Use spray

Wand instructions in this section. NOTE: If applying a chemical or cleaning

solution, see How To Apply Chemicals/Cleaning Solvents instructions in this

section.

8. Turn water source on.

NOTICE: Risk of property damage. Failure to do so could cause damage to the

pump.

9. Remove all air from the pump and high pressure hose by depressing trigger

until a steady stream of water is present.

10. Start engine. See Engine Owner’s Manual for correct procedure.

WARNING: Risk of unsafe operation. If engine does not start after two

pulls, squeeze trigger of gun to relieve pump pressure. Pull starter cord slowly

until resistance is felt. Then pull cord rapidly to avoid kickback and prevent

hand or arm injury.

11. Depress trigger on gun to start water flow.

WARNING: Risk of unsafe operation. Stand on a stable surface and

grip gun/spray wand firmly with both hands. Expect the gun to kick when

triggered.

12. Release trigger to stop water flow.

WARNING: Do not allow the unit to run for more than two minutes without

the gun trigger being pulled. This could cause overheating and damage to

the pump. When the temperature inside the pump rises too high, the thermal

relief valve will open and release a spray of water from the pump to lower the

internal temperature. The valve will then close.

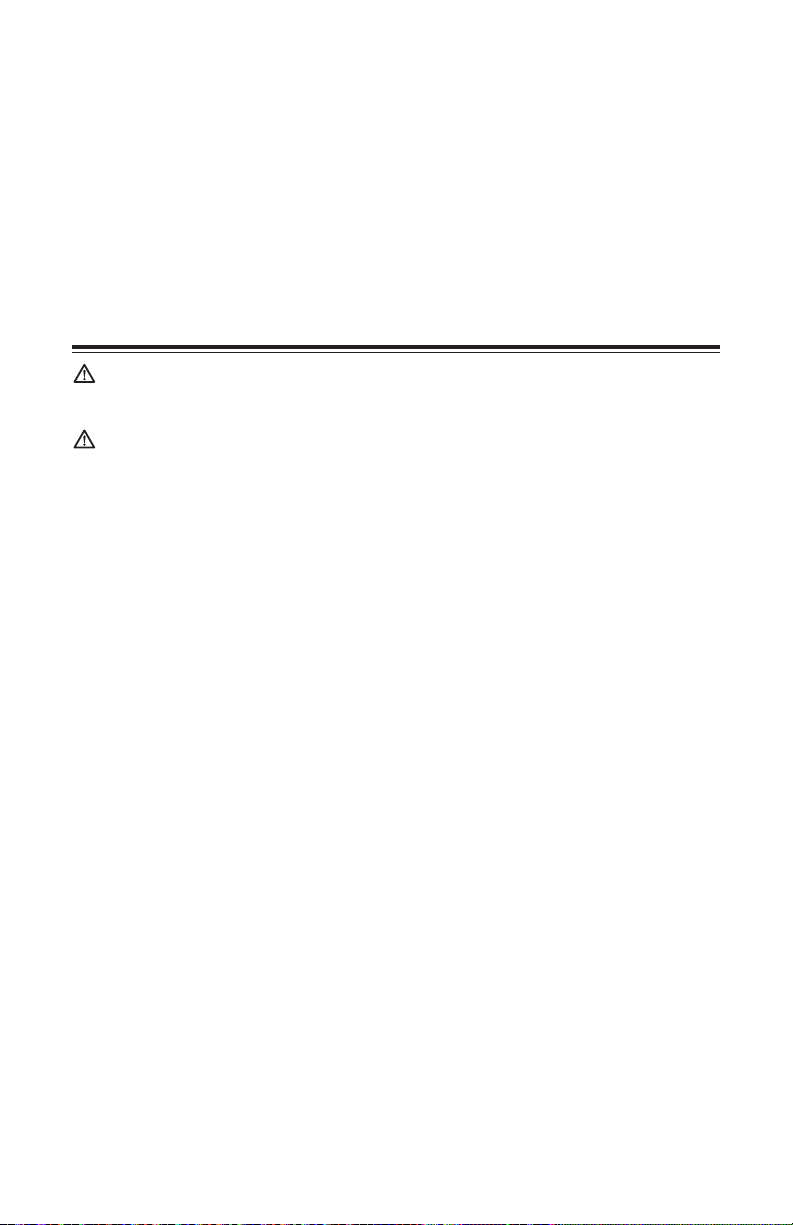

WARNING: Risk of injury from spray. Always engage the

trigger lock (O) when gun is not in use. Failure to do so

13

could cause accidental spraying.

SHUTTING DOWN

1. After each use, if you have applied chemicals, place

detergent siphon hose into container of clean water and

draw clean water through chemical injection system to

rinse system thoroughly.

O

16- ENG

Page 17

NOTICE: Risk of property damage. Failure to do so could cause damage to the

pump.

2. Turn engine off. See Engine Owner’s Manual.

NOTICE: Risk of property damage. NEVER turn the water off with the engine

running.

3. Turn water source off.

4. Pull trigger on spray gun to relieve any water pressure in hose or spray gun.

NOTE: Failure to release system pressure will prevent removal of high pressure

hose from spray gun or pump connection.

5. See Storage section in this manual for proper storage procedures.

MAINTENANCE

WARNING: Risk of burn hazard. When performing maintenance, you may

be exposed to hot surfaces, water pressure or moving parts that can cause

serious injury or death.

WARNING: Risk of fire hazard. Always disconnect, spark plug wire,

let the engine cool and release all water pressure before performing any

maintenance or repair. The engine contains flammable fuel. Do not smoke or

work near open flames while performing maintenance.

To ensure efficient operation and longer life of your pressure washer, a routine

maintenance schedule should be prepared and followed. If the pressure washer is

used in unusual conditions, such as high-temperatures or dusty conditions, more

fre quent maintenance checks will be required.

ENGINE

Consult the Engine Owner’s Manual for the man u fac tur er's recommendations for

any and all maintenance. NOTE: The engine drain plug is located at the rear of the

unit.

PUMP

The pump was filled with oil at the factory. The pump on this unit is maintenance

free and requires no oil to be added or changed. If there is a problem with the pump

contact us at www.simpsoncleaning.com

CONNECTIONS

Connections on pressure washer hoses, gun and spray wand should be cleaned

regularly and lubricated with light oil or lithium grease to prevent leakage and

damage to the o-rings.

NOZZLE CLEANING (FIG. 14)

If the nozzle becomes clogged with foreign materials, such as dirt, excessive

pressure may develop. If the nozzle becomes partially clogged or restricted, the

pump pressure will pulsate. Clean the nozzle immediately using the nozzle kit

supplied and the following instructions:

1. Shut off the pressure washer and turn off the water supply.

2. Pull trigger on gun handle to relieve any water pressure.

3. Disconnect the spray wand from the gun.

17 - ENG

Page 18

4. Remove the high pressure nozzle (K) from the spray wand.

Remove any obstructions with the nozzle cleaning tool

14

K

provided and backflush with clean water.

5. Direct water supply (N) into nozzle to backflush loosened

particles for 30 seconds.

6. Reassemble the nozzle to the wand.

7. Reconnect spray wand to gun and turn on water supply.

8. Start pressure washer and place spray wand into high

pressure setting to test.

N

K

CLEAN THE WATER INLET FILTER (FIG. 10)

This screen filter should be checked periodically and cleaned if necessary.

1. Remove filter by grasping end and removing it from water inlet of pump.

2. Clean filter by flushing it with water on both sides.

3. Re-insert filter into water inlet of pump. NOTE: Cone side faces out.

NOTE: Do not operate the pressure washer without filter properly installed.

STORAGE

ENGINE

Consult the Engine Owner’s Manual for manufacturer’s recommendations for

storage.

TO PREVENT FUEL-RELATED PROBLEMS

1. Add Ethanol Shield

When adding a gasoline stabilizer, fill the fuel tank with fresh gasoline. If only

partially filled, air in the tank will promote fuel deterioration during storage.

If you keep a container of gasoline for refueling, be sure that it contains only

fresh gasoline.

2. After adding a gasoline stabilizer, run the engine outdoors for 10 minutes

to be sure that treated gasoline has replaced the untreated gasoline in the

carburetor.

3. Turn the fuel valve to the OFF position.

4. Continue to run the engine until it stops from the lack of fuel in the carburetor

fuel bowl. Running time should be less than 3 minutes.

PUMP

The manufacturer recommends using SIMPSON® / POWERWASHER® Pump

Guard or equivalent when storing the unit for more than 30 days and/or when

freezing temperatures are expected. SIMPSON

is environmentally friendly.

NOTE: Using pump guard helps provide proper lubrication to the internal seals of

the pump regardless of temperature or environment.

NOTICE: Risk of property damage. Use only SIMPSON

Pump Guard or equivalent. Other products could be corrosive and/or contain alcohol which may cause pump damage.

1. Turn off pressure washer and disconnect hoses from pump.

2. Unscrew bottle valve from Pump Guard bottle and remove seal.

3. Screw bottle valve back onto bottle.

4. Attach bottle to water inlet of pump.

TM

fuel stabilizer following the manufacturer’s instructions.

®

/ POWERWASHER® Pump Guard

®

/ POWERWASHER®

18- ENG

Page 19

5. Squeeze bottle to inject contents into pump.

6. With ignition switch off, simultaneously pull starter rope and squeeze bottle.

Repeat until protector fluid exits pump outlet. NOTE: This step may require

two people.

PRESSURE WASHER

1. Drain all water from high pressure hose and wrap it onto hose wrap.

2. Drain all water from the spray gun and wand by holding spray gun in a vertical

position with nozzle end pointing down and squeezing trigger. Store in gun

holder.

3. Wrap up and secure detergent siphon hose so it is protected from damage.

ACCESSORIES

DANGER: Risk of fluid injection. When using replacement spray wands or

guns with this pressure washer, DO NOT use a spray wand and/or spray gun/

wand combination that is shorter in length than what was provided with this

pressure washer as measured from the nozzle end of the wand to the gun

trigger.

NOTICE: The use of any other accessory not recommended for use with this tool

could be hazardous. Use only accessories rated equal to or greater than the rating

of the pressure washer.

SPECIFICATIONS

MODEL MS60809-S

PSI Max* 3000 psi

GPM Max* 2.4 gpm

High Pressure Hose 25 ft. (7.6 m)

Presure of Inlet Water 20–100 psi

Inlet Water cold tap

Soap Consumption Rate 10% max

* Rated Pressure and Rated Water Flow is within manufacturing tolerance of

(+/- 10%).

In a continued commitment to improve quality, the manufacturer reserves the right

to make component changes, design changes, or specification changes when

necessary and without notice.

SERVICE INFORMATION

Do not return this product to your retailer. Please contact our customer service

department at www.simpsoncleaning.com

LIMITED WARRANTY

90 DAY LIMITED WARRANTY ON PRODUCT COMPONENTS EXCLUDING PUMP

SIMPSON® warrants to the original purchaser that the wheels, gun, hose, wand, spray

nozzle(s) and other components of the

warranty are free from defects in material and workmanship for 90 days from the date

of purchase.

SIMPSON

19 - ENG

®

pressure washer covered under this

Page 20

ONE YEAR LIMITED WARRANTY ON PUMP AND FRAME

SIMPSON

®

warrants to the original purchaser that the pump of the SIMPSON

®

pressure washer covered under this warranty is free from manufacturer’s defects in

material and workmanship for one year from the date of purchase. The one year limited

warranty applies to the pump only.

SIMPSON

®

will repair or replace, at SIMPSON®'s option, products or components

which have failed within the above warranty periods. Service will be scheduled

according to the normal work flow and business hours at the service center location,

and the availability of replacement parts. All decisions of

SIMPSON

®

with regard to this

limited warranty shall be final.

This warranty gives you specific legal rights, and you may also have other rights which

vary from state to state.

ENGINE WARRANTY

The engine, emission control system and related components are covered under the

terms and conditions outlined by the engine manufacturer’s warranty and are the sole

responsibility of the engine manufacturer. A copy of the engine manufacturer’s warranty

has been provided to you with your

SIMPSON

®

pressure washer. Please consult the

engine manufacturer’s warranty to process a claim or obtain service to the engine,

emission control system or related components.

RESPONSIBILITY OF ORIGINAL PURCHASER (INITIAL USER):

• To process a warranty claim on your

SIMPSON

®

pressure washer, report the

concern to 1-877-362-4271 or cservice@fna-group.com for authorization and

direction to the nearest authorized service centre in your area.

• Retain original cash register sales receipt as proof of purchase for warranty work.

• Use reasonable care in the operation and maintenance of the product as described

in the Owners Manual(s).

THIS WARRANTY DOES NOT COVER:

• Merchandise sold as reconditioned, used as rental equipment, or floor or display

models.

• Merchandise that has become damaged or inoperative because of ordinary wear,

misuse, cold, heat, rain, excessive humidity, water quality, freeze damage, use

of improper chemicals, negligence, accident, failure to operate the product in

accordance with the instructions provided in the Owners Manual(s) supplied with

the product, improper maintenance, the use of accessories or attachments not

recommended by

SIMPSON

®

, or unauthorized repair or alterations.

• Repair and transportation costs of merchandise determined not to be defective.

• Damage due to chemical deterioration, scale build up, rust, corrosion or thermal

expansion

• Costs associated with assembly, required oil, adjustments or other installation and

start-up costs.

• Expendable parts or accessories supplied with the product which are expected to

become inoperative or unusable after a reasonable period of use, including but not

limited to springs, nozzles, o-rings, washers, and similar accessories.

• Merchandise sold by

SIMPSON

®

which has been manufactured by and identified

as the product of another company, such as gasoline engines. The product

manufacturer’s warranty, if any, will apply.

• ANY INCIDENTAL, INDIRECT OR CONSEQUENTIAL LOSS, DAMAGE,

OR EXPENSE THAT MAY RESULT FROM ANY DEFECT, FAILURE OR

MALFUNCTION OF THE PRODUCT IS NOT COVERED BY THIS WARRANTY.

Some states do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you.

20- ENG

Page 21

• IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM

THE DATE OF ORIGINAL PURCHASE. Some states do not allow limitations on

how long an implied warranty lasts, so the above limitations may not apply to you.

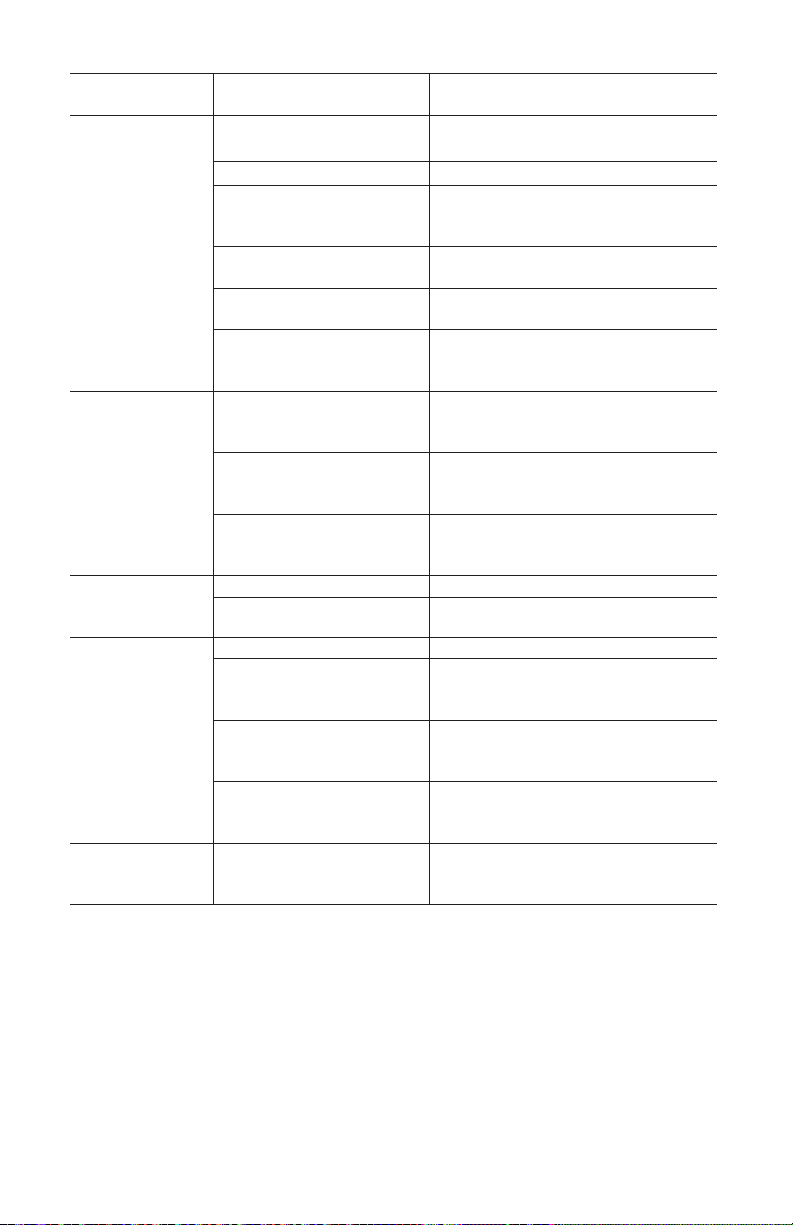

TROUBLE SHOOTING GUIDE

OPERATIONAL

ISSUE

Engine will

not start (see

Engine Owner’s

Manuall for

further engine

troubleshooting)

No or low

pressure

(initial use)

POSSIBLE CAUSE SOLUTION

No fuel. Add fresh fuel.

Pressure builds up after

two pulls on the recoil

Squeeze gun trigger to relieve

pres sure

starter or after initial use

Choke lever in the "No

Choke" position

Spark plug wire

Move choke to the "Choke"

po si tion

Attach spark plug wire.

not attached.

Engine switch in OFF

Place engine switch in ON position

po si tion

Choke lever in the

"Choke" position on a

Move choke to the "No Choke"

po si tion

"hot" engine or an engine

that has been exposed

to thermal heat for a

long period of time

Spray wand not in

high pressure

See How to Use Spray

Wand instructions in the

Operation Section

Low water supply Water supply must be at

least 5 gpm @ 20 psi

Leak at high pressure

hose fitting

Repair leak. Apply sealant tape

if necessary

Nozzle obstructed See Nozzle Cleaning instructions

in the Maintenance section

Water filter screen

clogged

Remove and clean filter. See

Cleaning Water Inlet Filter

paragraph in the Maintenance

section for the correct procedure

Air in hose Turn off the engine, then the water

source. Disconnect the water

source from the pump inlet and

turn the water source on to remove

all air from the hose. When there is

a steady stream of water present,

turn water source off. Re- con nect

water source to pump inlet and

turn on wa ter source. Squeeze

trigger to re move re main ing air

Choke in the

“Choke” position

High pressure hose

is too long

Move choke to the “No Choke”

po si tion

Use high pressure hose under

100 feet (30m)

21 - ENG

Page 22

OPERATIONAL

POSSIBLE CAUSE SOLUTION

ISSUE

Will not draw

chemicals

Spray wand not in

low pressure

See How to Use Spray Wand

paragraph in the Operation Section

Chemical filter clogged Clean filter

Chemical screen not

in cleaning solution

Make sure end of detergent

siphon hose is fully submerged

into cleaning solution

Chemical too thick Dilute chemical. Chemical should

be the same consistency as water

Pressure hose is too long Lengthen water supply hose

instead of high pressure hose

Chemical build up in

chemical injector

Please contact our customer

service department at

www.simpsoncleaning.com

No or low

pressure

(after period of

normal use)

Worn seal or packing Please contact our customer

service department at

www.simpsoncleaning.com

Worn or obstructed valves Please contact our customer

service department at

www.simpsoncleaning.com

Worn unloader piston Please contact our customer

service department at

www.simpsoncleaning.com

Water leaking at

gun/spray wand

Worn or broken o-ring Check and replace

Loose hose connection Tighten

connection

Water leaking

at pump

Loose connections Tighten

Piston packings worn Please contact our customer

service department at

www.simpsoncleaning.com

Worn or broken o-rings Please contact our customer

service department at

www.simpsoncleaning.com

Pump head or tubes

damaged from freezing

Please contact our customer

service department at

www.simpsoncleaning.com

Pump pulsates Nozzle obstructed See Nozzle Cleaning paragraph

in the Maintenance section

for the correct procedure

22- ENG

Page 23

MESURES DE SÉCURITÉ - DÉFINITIONS

Ce guide contient des renseignements importants que vous deviez bien saisir.

Cette information porte sur VOTRE SÉCURITÉ et sur LA PRÉVENTION DE

PROBLÈMES D'ÉQUIPEMENT. Afin de vous aider à identifier cette information,

nous avons utilisé les symboles ci-dessous. Veuillez lire attentivement ce guide en

portant une attention particulière à ces symboles.

DANGER : indique une situation dangereuse imminente qui, si elle n’est pas

évitée, causera la mort ou des blessures graves.

AVERTISSEMENT : indique une situation potentiellement dangereuse qui, si

elle n’est pas évitée, pourrait causer la mort ou des blessures graves.

ATTENTION: indique une situation potentiellement dangereuse qui, si elle n’est

pas évitée, peut causer des blessures mineures ou modérées.

AVIS : indique une pratique ne posant aucun risque de dommages corporels

mais qui par contre, si rien n’est fait pour l’éviter, pourrait poser des risques de

dommages matériels.

DIRECTIVES DE SÉCURITÉ IMPORTANTES

DANGER: monoxyde de carbone. Le fonctionnement d’un moteur à

l’intérieur provoque la mort en quelques minutes. L’échappement du moteur

contient des niveaux élevés de monoxyde de carbone (CO), un gaz toxique,

indoors et invisible. Il est possible que vous inhaliez du CO meme EN

L’ABSENCE de l’odeur de l’échappement du moteur.

• NE JAMAIS utiliser un moteur à l’intérieur d’une habitation, de garages, d’un

vide sanitare ou d’autres espaces partiellement clos. Ces endroits peuvent

accumuler des niveaux mortels de monoxyde de carbone, L’utilisation d’un

ventilateur ou l’ouverture des fenêtres et portes NE fournit PAS assez d’air

frais.

• Utiliser UNIQUEMENT à l’extériur et loin de fenêtres, portes et évents. En

effet, ces ouvertures peuvent asprier l’énchappement du moteur à l’intérieur

d’un espace.

• Même lors de l’utilisation correcte du moteur, le monoxyde de carbone

pourrait pénétrer dans l’habitation. TOUJOURS utiliser un advertisseur de

CO alimenté à pile ou un avertisseur do CO de secours à pile dans la maison.

Lire et repecter toutes les directives de l’avertisseur de CO avant son

utilisation. En cas de malaise, étourdissement ou faiblesse, à tout moment,

déplacer la personne à l’air frais immédiatement. Consulter un médecin. Ce

sont des signes d’intoxication oxycarbonée.

AVERTISSEMENT : ne pas utiliser l’appareil avant d’avoir lu le mode d’emploi, et

celui du moteur, et l’intégralité des directives de sécurité, d’utilisation et d’entretien.

Si vous avez n'importe quelles questions quant au produit, s'il vous plaît

contacter notre département de service clients à www.simpsoncleaning.com

DANGER : risque d’injection ou de blessure grave. S’éloigner de la buse.

Ne pas diriger le jet en direction de personnes. Ce produit ne doit être utilisé

que par des opérateurs formés.

23 - FR

Page 24

AVERTISSEMENT : ce produit et ses émanations contiennent des produits

chimiques reconnus par l’État de la Californie comme étant cancérigènes et pouvant

entraîner des anomalies congénitales ou d’autres problèmes liés aux fonctions

reproductrices. De plus, certains produits nettoyants et poussières contiennent des

produits chimiques reconnus par l’État de la Californie comme étant cancérigènes

et pouvant entraîner des anomalies congénitales ou d’autres problèmes liés aux

fonctions reproductrices. Se laver les mains après la manipulation de l’appareil.

AVERTISSEMENT : il est possible que le produit ne soit pas doté d’un silencieux

avec pare-étincelles. Si le produit n’en est pas équipé et qu’il est destiné à être

utilisé près de matières inflammables ou sur un terrain cultivé ou couvert d’arbres,

arbustes, herbes ou autres matières similaires, alors l’installation d’un pareétincelles homologué est obligatoire et exigée par la loi dans l’État de Californie.

Le produit sans cet équipement viole la législation californienne, section 130050

et/ou sections 4442 et 4443 du California Public Resources Code, à moins que le

moteur ne soit muni d’un pare-étincelles comme stipulé à la section 4442 et tenu

en bon état de fonctionnement. Les pare-étincelles sont exigés sur certaines terres

du Service des forêts américain et peuvent être également exigés par d’autres

législations ou ordonnances.

CONSERVER CES DIRECTIVES

DANGER : RISQUE D’EXPLOSION OU D’INCENDIE

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Les cigarettes, étincelles, arc

électrique, gaz d’échappement et

des parties chaudes du moteur telles

qu’un silencieux peuvent enflammer

l’essence déversée et ses vapeurs.

• Le combustible du réservoir se dilate

sous l’effet de la chaleur et pourrait

se solder par un déversement et un

incendie ou une explosion.

• Le fonctionnement de la laveuse

haute pression dans un milieu explosif

pourrait se solder par un incendie.

• Du matériel déposé contre ou près de la

laveuse haute pression peut interférer

avec les fonctionnalités d’aération

de l’équipement et provoquer une

surchauffe et l’allumage du matériel

(risque d’incendie).

• Éteindre le moteur et le laisser refroidir

avant de remplir le réservoir d’essence

• Être attentif et éviter de déverser de

l’essence lors du remplissage du

réservoir. Éloigner la laveuse haute

pression de la zone de ravitaillement

avant de démarrer le moteur.

• Laisser environ 12,7 mm (1/2 po) de

dégagement sous le bord du goulot de

remplissage pour permettre l’expansion

de l’essence.

• Utiliser et faire le plein d’essence de

l’équipement dans des zones bien

dégagées de tout obstacle. Installer un

extincteur adéquat dans les zones de

travail pour combattre les incendies à

base d’essence.

• Ne jamais utiliser la laveuse haute

pression dans une zone avec arbustes

ou broussailles secs.

24- FR

Page 25

• La chaleur de l’échappement du

silencieux peut endommager des

surfaces peintes, faire fondre tout

type de matériel sensible à la chaleur

(comme du revêtement extérieur,

plastique, caoutchouc, vinyle ou

• Toujours éloigner la laveuse haute

pression d’au moins 1,2 m (4 pi) de

toutes surfaces (telles que desmaisons,

voitures, ou des plantes vivantes) qui

pourraient être endommagées par la

chaleur s’échappant du silencieux.

même le tuyau haute pression) et

nuire aux plantes vivantes.

• De l’essence mal entreposée pourrait

provoquer un allumage (incendie)

accidentel. Ranger l’essence de

façon sécuritaire pour en empêcher

l’accès aux enfants et à toutes autres

• Entreposer l’essence dans un

contenant homologué par la Loi sur la

santé et la sécurité du travail dans un

emplacement sécuritaire loin de la zone

de travail.

personnes non qualifiées.

• L'utilisation d'acides, de produits

chimiques toxiques ou corrosifs, de

• Ne pas vaporiser des liquides

inflammables.

poisons, d'insecticides ou de toute

sorte de solvant inflammable dans

ce produit pourrait provoquer des

blessures graves ou la mort.

DANGER : RISQUE D’ASPHYXIE

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Respirer les vapeurs d’échappement

provoquera de graves blessures voire,

un décès ! Les gaz d’échappement

des moteurs contiennent du

monoxyde de carbone, un gaz

inodore et mortel.

• Utiliser la laveuse haute pression dans

une zone bien aérée. Éviter les endroits

clos comme les garages, les sous-sols,

etc.

• Ne jamais utiliser l’appareil dans un

endroit habité par des hommes ou des

an maux.

• Certains liquides nettoyants

contiennent des substances pouvant

provoquer des blessures à la peau,

aux yeux ou au système respiratoire.

• Utiliser uniquement des liquides

nettoyants spécialement recommandés

pour les laveuses haute pression. Suivre

les recommandations des fabricants.

Ne pas utiliser de produit à blanchir au

chlore ou tout autre composé corrosif.

25 - FR

Page 26

DANGER : RISQUE D’INJECTION ET DE LACÉRATION

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Votre laveuse haute pression

fonctionne à des pressions de liquides

et des vitesses suffisamment élevées

pour pénétrer la peau de l’homme

et animale, ce qui pourrait se solder

par une amputation ou autre blessure

grave. Des fuites provoquées par

des raccords lâches ou des tuyaux

usés ou endommagés peuvent se

solder par des blessures par injection.

NE PAS TRAITER UN INJECTION

DE LIQUIDE COMM UNE SIMPLE

COUPURE ! Consulter un médecin

immédiatement !

• Inspecter périodiquement le tuyau haute

pression. Remplacer immédiatement le

tuyau s’il est endommagé, usé, s’il a

fondu en contact avec le moteur ou

s’il démontre un signe de fissure, des

bulles, des trous d’épingle ou tout autre

fuite. Ne jamais saisir untuyau haute

pression quifuit ou est endommagé.

• Ne jamais toucher, saisir ou essayer

de couvrir un trou minuscule ou tout

autre fuite similaire sur le tuyau haute

pression. Le jet d’eau EST sous haute

pression et PÉNÈTRERA la peau.

• Ne jamais mettre les mains

devantl’embouchure.

• Éloigner le jet, ne pas le diriger vers soimême ou autrui.

• S’assurer que le tuyau et les raccords

sont serrés et en bon état. Ne jamais

s’agripper au tuyau ou aux raccords en

cours de fonctionnement.

• Ne pas mettre le tuyau en contact avec

le silencieux.

• Ne jamais attacher ou retirer le tube ou

les raccords du tuyau avec le système

sous pression.

• Si une lance ou un pistolet de rechange

est utilisé avec cette laveuse à pression,

NE PAS utiliser une lance et/ou une

combinaison lance et pistolet dont la

longueur est inférieure à celle des lance

et pistolet fournis avec cette laveuse à

pression; la mesure se fait de l’extrémité

de la buse à la détente du pistolet.

• Il y a risque de blessures si la pression

n’est pas réduite avant d’essayer

de procéder à un entretien ou un

démontage.

• Pour décompresser le système, éteindre

le moteur, fermer l’approvisionnement

en eau et enclencher la détente du

pistolet jusqu’à l’arrêt complet de

l’écoulement d’eau.

• Utiliser uniquement des accessoires de

classement égal ou supérieur à celui de

la laveuse haute pression.

26- FR

Page 27

DANGER : RISQUE DE BLESSURE PAR JET

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Un jet de liquide à haute vitesse peut

briser des objets et projeter les éclats

à haute vitesse.

• Toujours porter des lunettes de sécurité

conformes à la norme ANSI Z87.1

Porter des vêtements protecteurs pour

se protéger de jets accidentels.

• Ne jamais diriger la lance ou le jet vers

une personne ou des animaux.

• Des objets légers ou mal fixés

peuvent se transformer en projectiles

dangereux.

• Toujours fixer solidement le verrou de

la détentelorsque le tube pulvérisateur

est inutilisé pour empêcher tout

fonctionnement accidentel.

• Ne jamais fixer, de façon permanente, la

détente en position arrière (ouverte).

DANGER : RISQUE D’UTILISATION DANGEREUSE

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Une utilisation dangereuse de

la laveuse haute pression pourrait

provoquer de graves blessures, voire

son propre décès ou celle d’autres

personnes.

• Ne pas utiliser de produit à blanchir au

chloreou tout autre composé corrosif.

• Se familiariser ave le fonctionnement

et les commandes de la laveuse haute

pression.

• Tenir la zone de travail exempte de

toutes personnes, animaux et obstacles.

• Ne pas utiliser le produit en cas de

fatigue ou sous l’emprise d’alcool ou de

drogues. Rester vigilant en tout temps.

• Ne jamais rendre inopérant les

caractéristiques de sécurité du produit.

• Ne pas utiliser l’appareil avec des

pièces manquantes, brisées ou non

autorisées.

• Ne jamais laisser le tube pulvérisateur

sans surveillance lors du fonctionnement

de l’appareil.

• Suivre la procédure de démarrage

correcte pour éviter l’effet de rebond

moteur qui provoquerait ainsi une

blessure grave à la main ou au bras.

• Si le moteur ne démarre pas après

deux tentatives, appuyer sur la détente

du pistolet pour décompresser la

pompe. Tirer délicatement la corde

du démarreur jusqu’à obtention d’une

résistance. Puis tirer rapidement sur

celui-ci pour éviter l’effet de rebond

moteur et empêcher toute blessure à la

main ou au bras.

27 - FR

Page 28

• Le pistolet et le tube de pulvérisation

sont des outils de nettoyage puissants

• Garder la laveuse haute pression hors

de portée des enfants en tout temps.

qui ressemblent à un jouet pour un

enfant.

• Le pistolet et le tube de pulvérisation

réagissent à la pression du jet et

provoqueront un effet de rebond

qui pourrait faire glisser, ou tomber,

l’opérateur ou rediriger le jet. Une

maîtrise imparfaite du pistolet et de la

lance peut provoquer des blessures à

soi même et à autrui.

• Ne pas trop tendre les bras ou se tenir

debout sur une surface instable.

• Ne pas utiliser une laveuse haute

pression debout sur une échelle.

• Saisir solidement à deux mains

le pistolet/tube de pulvérisation.

S’attendre à un effet de rebond lors de

l’enclenchement de la détente.

DANGER : RISQUE DE BLESSURE OU DE DOMMAGE À LA

PROPRIÉTÉ LORS DU TRANSPORT OU DU RANGEMENT

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Il y a risque de fuite ou de

déversement d’essence ou d’huile

qui pourrait se solder par un incendie

ou des problèmes respiratoires,

des blessures graves, voire la mort.

Des fuites d’essence ou d’huile

endommageront les tapis, peinture ou

toutes autres surfaces de véhicules

ou de remorques.

• Il est possible que de l’huile remplisse

le cylindre et endommage le moteur

si l’appareil n’est pas rangé ou

transporté à la verticale.

• Si la laveuse haute pression est dotée

d’une soupape d’arrêt, FERMER la

soupape d’arrêt avant le transport

pour éviter toute fuite d’essence. S’il

n’y a pas de soupape d’arrêt, purger

l’essence du réservoir avant le transport.

Transporter l’essence uniquement dans

un contenant homologué par la Loi sur

la santé et la sécurité du travail.

Toujours installer la laveuse haute

pression sur un revêtement protecteur

lors du transport pour protéger le

véhicule de tout dommage de fuites.

Toujours transporter et ranger

l’appareil à la verticale. Retirer

immédiatement la laveuse haute

pression du véhicule dès l’arrivée à

destination.

DANGER : RISQUE DECHOC ÉLECTRIQUE

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Un jet en direction de prises

électriques ou d’interrupteurs ou tout

objet branché à un circuit électrique

pourrait se solder par un choc

• Débrancher tout produit fonctionnant

à l’électricité avant d’essayer de le

nettoyer. Éloigner le jet des prises

électriques et interrupteurs.

électrique..

28- FR

Page 29

DANGER : RISQUE DE BRÛLURE CHIMIQUE

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• L’utilisation d’acides, de produits

chimiques toxiques ou corrosifs, de

poisons, d’insecticides, ou de tout type

de solvant inflammable avec le produit

risque de se solder par des blessures

graves, voire la mort.

Ne pas pulvériser d’acides, d’essence,

•

de kérosène ou toute autre matière

inflammable avec ce produit.

Utiliser uniquement des détergents

domestiques, des nettoyants et des

dégraissants recommandés avec la

laveuse haute pression.

• Porter des vêtements protecteurs pour

protéger les yeux et la peau contre le

contact avec les matériaux sous pression.

AVERTISSEMENT : RISQUE D’ÉCLATEMENT

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

•

Des pneus surgonflés pourraient

provoquer des blessures graves et

des dommages à la propriété.

• Utiliser un manomètre pour vérifier

la pression des pneus avant chaque

utilisation et lors du gonflage; consulter

le flanc de pneu pour obtenir la pression

correcte.

REMARQUE :

des réservoirs d’air,

des compresseurs et d’autres appareils

similaires utilisés pour gonfler les pneus

peuvent remplir de petits pneus à ces

pressions très rapidement. Régler

le régulateur de pression d’air à une

pression moindre que celle indiquée sur

le pneu. Ajouter l’air par petite quantité et

utiliser fréquemment le manomètre pour

empêcher un surgonflage.

• Tout liquide pulvérisé à haute vitesse

directement sur les flancs des pneus

(comme ceux que l’on retrouve sur les

voitures, remorques et autres véhicules

semblables) risque d’endommager

les flancs et d’entraîner des blessures

graves.

• Avec les laveuses haute pression cotées

au-dessus de 11032 kPa (1 600 psi),

utiliser le jet en éventail le plus large (buse

de 40º) et maintenir le jet à au moins 200

mm (8 po) des flancs des pneus. Ne

pas diriger le jet directement sur le joint

séparant le pneu et la jante.

AVERTISSEMENT : ATTENTION SURFACES CHAUDES

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Le contact de surfaces chaudes

comme les composants

d’échappement moteur, pourrait

provoquer des brûlures graves

• En cours de fonctionnement, ne toucher

que les surfaces de commande de la

laveuse haute pression. Tenir en tout

temps les enfants à l’écart de la laveuse

haute pression. Ils n’ont pas assez de

jugement pour reconnaître les dangers

inhérents au produit.

29 - FR

Page 30

AVERTISSEMENT : RISQUE DE BLESSURE EN SOULEVANT LE

PRODUIT

CE QUI PEUT SE PRODUIRE COMMENT L’ÉVITER

• Essayer de soulever un objet trop

lourd peut se solder par de graves

blessures.

• La laveuse haute pression est trop

lourde pour être soulevée par une seule

personne. Demander de l’aide avant de

la soulever.

CONSERVER CES DIRECTIVES

POUR UN USAGE ULTÉRIEUR

GUIDE D’INSTALLATION RAPIDE

AVERTISSEMENT: Pour réduire le risque de blessure, veuillez lire le manuel

d’instructions de la laveuse à pression et du moteur avant d’utiliser l’appareil.

Installation de

la poignée

A

l'ensemble de poignée

sur le cadre, enfoncez

les boutons-poussoirs

et glissez l'ensemble

de poignée dans

le cadre jusqu'à ce

que les boutonspoussoirs s'enclenchent

dans les trous.

Placez

livré sans huile. Avant

de démarrer le moteur,

ajouter l’huile fournie.

Vérifier le niveau d’huile

avant chaque utilisation.

Consultez le guide du

moteur pour connaître

la procédure appropriée.

IMPORTANT: Ethanol ShieldTM (vendu séparément) est un stabilisateur de

carburant qui aide à éliminer et à prévenir les problèmes liés à l'éthanol dans les

équipements de puissance. Suivez les instructions sur le contenant et ajouter

àl'essence.

Ajouter / Voir

pétrole

B

Le moteur est

extérieur bien aéré,

ajoutez de l'essence

pure, sans plomb, de

haute qualité et ayant

un indice d'octane de

86 ou plus. Ne pas

trop remplir. Essuyez

l’essence déversée

avant de démarrer

le moteur. Consultez

le guide du moteur

pour connaître la

procédure appropriée.

Ajouter

l’essence

C

Dans un endroit

30- FR

Page 31

GUIDE DE DÉMARRAGE RAPIDE

DANGER :

• Ne faites jamais tourner le moteur à l’intérieur ou dans un endroit clos, mal

aéré. Les émanations d’échappement contiennent du monoxyde de carbone,

un gaz inodore et mortel.

• Risque d’injection de liquide et de lacération. Lorsque vous utilisez le réglage

à haute pression, NE LAISSEZ PAS le jet à haute pression entrer en contact

avec la peau non protégée ou des animaux de compagnie ou autres. Des

blessures sérieuses surviendront.

AVERTISSEMENT: ne laissez pas l'unité fonctionner pendant plus de deux

minutes sans la gâchette du pistolet tiré. Cela pourrait provoquer une surchauffe et d'endommager la pompe. Lorsque la température à l'intérieur de

la pompe est trop élevée, la soupape de décharge thermique ouvrira et libérer

de l'eau à partir de la pompe pour abaisser la température interne. Alors la

vanne se ferme.

Branchez le

tuyau

1

d’arrosage à la

pompe

Filetez le tuyau

d’arrosage à l’entrée

de la pompe.

Voir l'étiquette #1

sur de l'appareil.

Filetez le tuyau à

haute pression à la

sortie de la pompe.

Voir l'étiquette #2

sur de l'appareil.

Branchez le

tuyau

2

d’arrosage à la

pompe

Branchez la

lance

3

d’arrosage au

pulvérisation

Filetez la lance

d’arrosage dans

l’extrémité du pistolet

de pulvérisation.

pistolet de

Branchez la

lance

4

d’arrosage au

pulvérisation

Filetez la lance

d’arrosage dans

l’extrémité du pistolet

de pulvérisation.

pistolet de

Branchez les

buses à

5

raccord rapide

à la lance

d’arrosage

Tirez sur le coupleur

et insérez la buse.

Relâchez le coupleur

à raccord rapide et

tournez la buse afin de

vous assurer qu’elle y

soit bien sécurisée.

31 - FR

Ouvrez le

robinet d’eau

6

au complet

Ne faites pas

fonctionner l’appareil si

l’alimentation d’eau n’est

pas branchée et ouverte.

Utilisez uniquement

de l’eau froide.

Page 32

Relâchez l’air

du système

7

Relâchez

tout l’air de la pompe

et du tuyau à haute

pression en appuyant

sur la gâchette jusqu’à

ce qu’un écoulement

constant d’eau soit

présent. Environ

30 secondes.

Assurez-vous

que le robinet

8

de carburant

soit à la

position

OUVERT (open)

Le robinet de carburant

a été préréglé en usine

de façon à être à la

position OUVERT (open).

Voir l'étiquette #8

sur de l'appareil.

Assurez-vous

que

9

l’interrupteur

du moteur soit

à la position

MARCHE (on)

Voir l'étiquette #9

sur de l'appareil.

OFF

ON

Assurez-vous

que la tige du

10

volet de départ

soit tirée à la

position FERMÉ

(closed)

La tige du volet de

départ à été préréglée

en usine pour être à la

position FERMÉ (closed).

Voir l'étiquette #10

sur de l'appareil.

OFF

ON

Tirez la poignée

du lanceur

11

Tirez la poignée

du lanceur pour faire

démarrer le moteur.

Voir l'étiquette #11

sur de l'appareil.

Poussez la tige

du volet de

12

départ à la

position

OUVERT (open)

Déplacez, de façon

graduelle, la tige du volet

de départ à la position

OUVERT (open) lorsque

le moteur démarre.

Voir l’étiquette #12 sur

le côté du moteur.

AVERTISSEMENT: Ce guide n’est pas un substitut pour la lecture du manuel