Page 1

6/2006 1

TP 300-5196-00-IS-SN

Dealer Setup

& Adjustment Instructions

Intermediate Frame Snowthrowers

ATTENTION SETUP PERSONNEL:

Sections and items denoted by the Setup symbol

provide the information necessary to fully assemble,

test, and prepare the units described above for

delivery to your customers.

Additional information concerning functional tests,

general adjustment procedures, and the location of

normal lubrication points are included in these

instructions.

The safety warnings provided in this guide and in

the operator's manual included with the unit contain

important information that must be obeyed when

assembling, setting-up, operating, servicing, transporting, or storing the unit.

These warnings are highlighted by the safety alert triangle symbol shown above, which signifies that an important safety message is being provided.

You must read, understand, and follow these warnings and

instructions, and use safe shop and work practices at all

times while working on or around this unit and all other

outdoor power equipment.

Mfg. No. Description

7800084 I75246E, 7.5HP OHV, Snowthrower

7800085 I7524E, 7.5HP OHV, Snowthrower

7800086 EI75246E, 7.5HP OHV, Snowthrower (CE)

7800087 I7524EX, 7.5HP OHV, Snowthrower (CE)

7800138 EI75246, 7.5HP OHV Snowthrower (CE)

Refer to the Dealer Setup & Adjustment binder Index for a

complete listing of products covered by this document.

Form No. 7100731

Revision 00

TABLE OF CONTENTS:

SAFETY RULES........................................................2

SETUP PROCEDURES

Quick Setup List.......................................................3

Uncrating .................................................................4

Reduce and Check Tire Pressures .........................4

Assembly ..................................................................5

Un-Folding Handles ................................................5

Install Drift Cutters ..................................................5

Spout Rotator..........................................................6

Control Levers.........................................................6

Clean-Out Tool........................................................6

Check Fluid Levels & Fill.........................................7

Lubricate the Snowthrower.....................................7

Lubricate the Auger Shaft & Assembly..................8

Perform Safety Checks............................................9

ADJUSTMENT PROCEDURES

Auger Drive Linkage Adjustments .......................10

Traction Drive Linkage Adjustment......................10

Speed Selector Adjustment ..................................11

Discharge Control Adjustment .............................11

Chute Direction Control Rod Gear Adjustment...12

Scraper Bar & Skid Shoe Adjustment ..................12

Drive Belt Replacement .........................................13

Traction Drive Belt Replacement ..........................13

Auger Belt Replacement.......................................14

Page 2

Intermediate Frame Snowthrowers

TP 300-5196-00-IS-SN

6/20062

SAFETY RULES

GENERAL OPERATION

• Read, understand, and follow all instructions in the

manual and on the unit before starting.

• Only allow responsible adults, who are familiar with

the instructions, to operate the unit (local regulations

can restrict operator age).

• Clear the area of objects such as rocks, toys, wire,

etc., which could be picked up and thrown.

• Be sure the area is clear of other people. Stop unit if

anyone enters the area.

• Always look down and behind before and while travelling in reverse.

• Be aware of the discharge direction and do not point

it at anyone. Do not point the discharge at glass

enclosures, automobiles, or windows.

• Disengage all clutches (release drive and auger control levers) before starting the engine.

• Never leave a running unit unattended. Always disengage the auger and traction controls, stop engine,

and remove keys.

• Stop engine before unclogging chute.

• Operate only in daylight or good artificial light.

• Do not operate the unit while under the influence of

alcohol or drugs.

• Watch for traffic when operating near or crossing

roadways.

• Use extra care when loading or unloading the unit

into a trailer or truck.

• Keep in mind the operator is responsible for accidents occurring to other people or property.

• Data indicates that operators, age 60 years and

above, are involved in a large percentage of power

equipment-related injuries. These operators should

evaluate their ability to operate the unit safely enough

Read these safety rules and follow them closely. Failure to obey these rules could result in loss of control

of unit, severe personal injury or death to you, or bystanders, or damage to property or equipment.

The triangle in text signifies important cautions or warnings which must be followed.

Do

• See your authorized dealer for recommendations

counterweights to improve stability.

• Travel up and down slopes, not across.

• Remove obstacles such as rocks, tree limbs, etc.

• Watch for holes, ruts, or bumps. Uneven terrain could

overturn the unit. Snow can hide obstacles.

• Use slow speed. Tires may lose traction on slopes.

Choose a low gear so that you will not have to stop or

shift while on the slope.

• Keep all movement on the slopes slow and gradual.

Do not make sudden changes in speed or direction.

• Always keep unit in gear especially when traveling

downhill.

Do Not

• Do not start or stop on a slope. If tires lose traction,

disengage the auger and proceed slowly straight

down the slope.

• Do not turn on slopes unless necessary, and then,

turn slowly and gradually downhill, if possible.

• Do not operate near drop-offs, ditches, or embankments. The unit could suddenly turn over if a wheel is

over the edge of a cliff or ditch, or if an edge caves in.

• Do not operate on wet surfaces. Reduced traction

could cause sliding.

• Do not shift to neutral and coast down hills.

EMISSIONS

• Engine exhaust from this product contains chemicals

known, in certain quantities, to cause cancer, birth defects,

or other reproductive harm.

• Look for the relevant Emissions Durability Period and Air

Index information on the engine emissions label.

to protect themselves and others from injury.

• All operators should seek and obtain professional

and practical instruction.

• Always wear substantial footwear and appropriate

winter clothing. Wear foot-ware that improves traction on slippery slopes. DO NOT wear long scarves

or loose clothing that could become entangled in

moving parts.

• Before using, always visually check that all hardware

is present, in-tact, and secure. Replace worn or

damaged parts.

• Never operate the machine with defective guards, or

without safety protective devises in place.

• Stop engine before: refuelling, removing an attachment, making adjustments (unless the adjustment

can be made from the operator’s position).

• Follow the manufacturer’s recommendation for wheel

weights or counterweights.

• Adjust skid shoe height to clear gravel or crushed

rock surfaces.

• Do not touch snowthrower parts which may be hot

from operation. Allow such parts to cool before

attempting to service the unit.

CLEARING A CLOGGED DISCHARGE CHUTE

Hand contact with the rotating impeller inside the discharge chute is the most common cause of injury associated with snowthrowers. Always use a clean-out tool,

not your hands. to clean out the discharge chute.

To clear the chute:

1. SHUT OFF THE ENGINE.

2. Wait 10 seconds to be sure the impeller blades have

stopped rotating.

3. Always use a clean out tool, not your hands.

WARNING

Gasoline is highly flammable and must be

handled with care. Never fill the tank when the

engine is still hot from recent operation. Do not

allow open flame, smoking or matches in the

area. Avoid over-filling and wipe up any spills.

Page 3

Intermediate Frame Snowthrowers

6/2006 3

TP 300-5196-00-IS-SN

Quick Setup List -

Page Setup Procedure Steps to Perform

4 Uncrating

4 Reduce Tire Pressures ❏ Reduce Tire Pressure to 20 psi (137 kPa) & Check

4 Assembly ❏ Install Drift Cutters

5 Assembly ❏ Un-Folding Handles

❏ Connecting Shift Rods

6 Assembly ❏ Spout Rotator

❏ Control Levers

❏ Clean-Out Tool

7 Check Fluid Levels & Fill ❏ Auger Gearcase

❏ Engine Crankcase

❏ Fuel Tank

7 Lubricate Snowthrower ❏ Lubricate all grease & oil points

8 Lubricate Snowthrower ❏ Lubricate the auger Shaft & Assembly

9 Perform Safety Checks

Functional Checks

❏ Check that all Safety Guards are in place.

❏ Check Scraper Bars & Skid Shoe Height

❏ Check Drive Control & Auger Control

❏ Check Chute Direction Control

❏ Check Chute Deflector Control

❏ Check Speed Selector Control

Operational Checks

❏ Start Engine & Test ALL Controls

❏ Test Auger Stopping Time

(Auger MUST stop within

5 seconds after the control is released.)

❏ Test Drive Controls

❏ Check For Fluid Leaks

Page 4

Intermediate Frame Snowthrowers

TP 300-5196-00-IS-SN

6/20064

Uncrating

1. Using a reciprocating saw, cut crate sides from bottom skid. Lift crate from bottom skid.

2. Remove screws securing skid shoes to bottom skid.

Roll snowthrower from bottom skid backwards.

3. Make sure klik-pin is inserted through hole in wheel

and axle shaft and secured.

Assembly

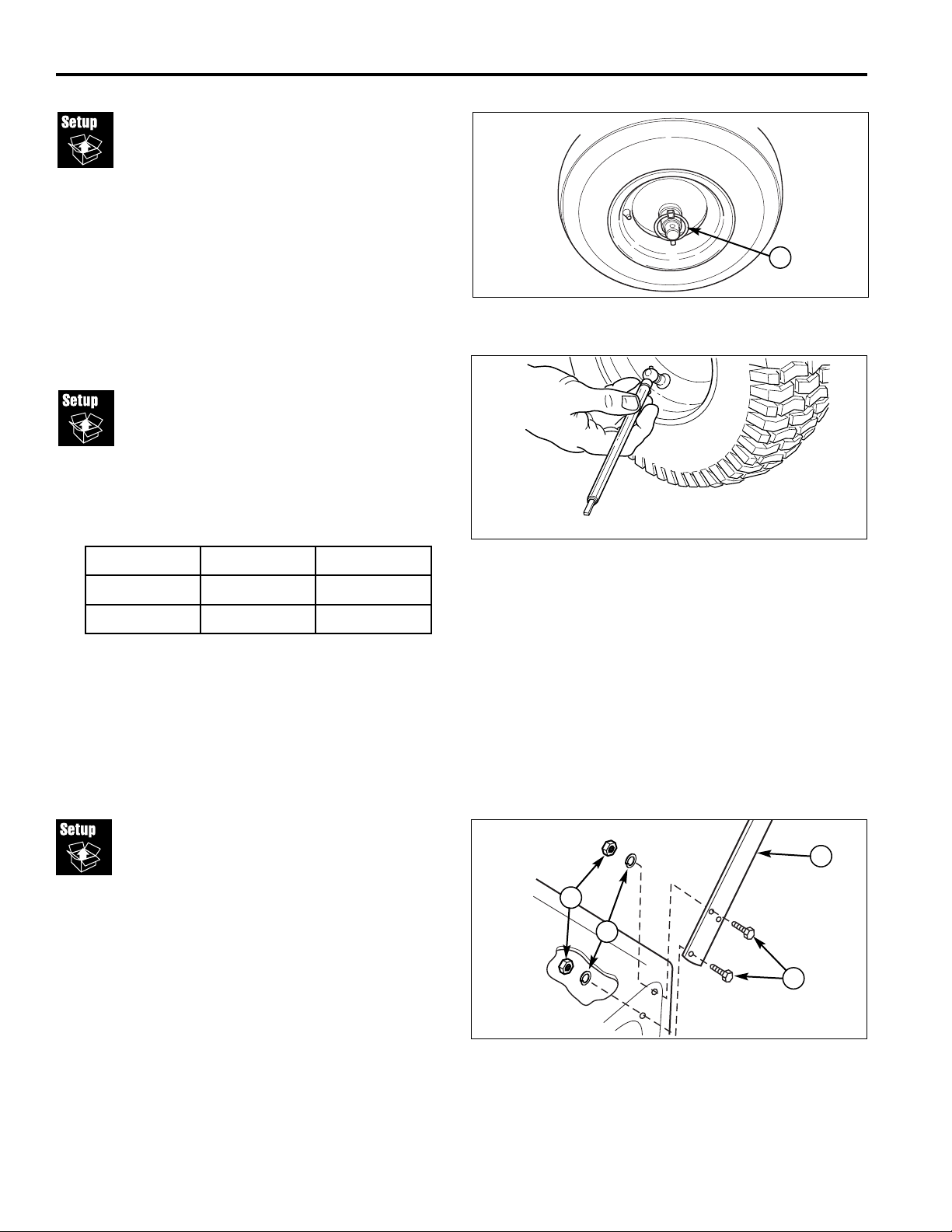

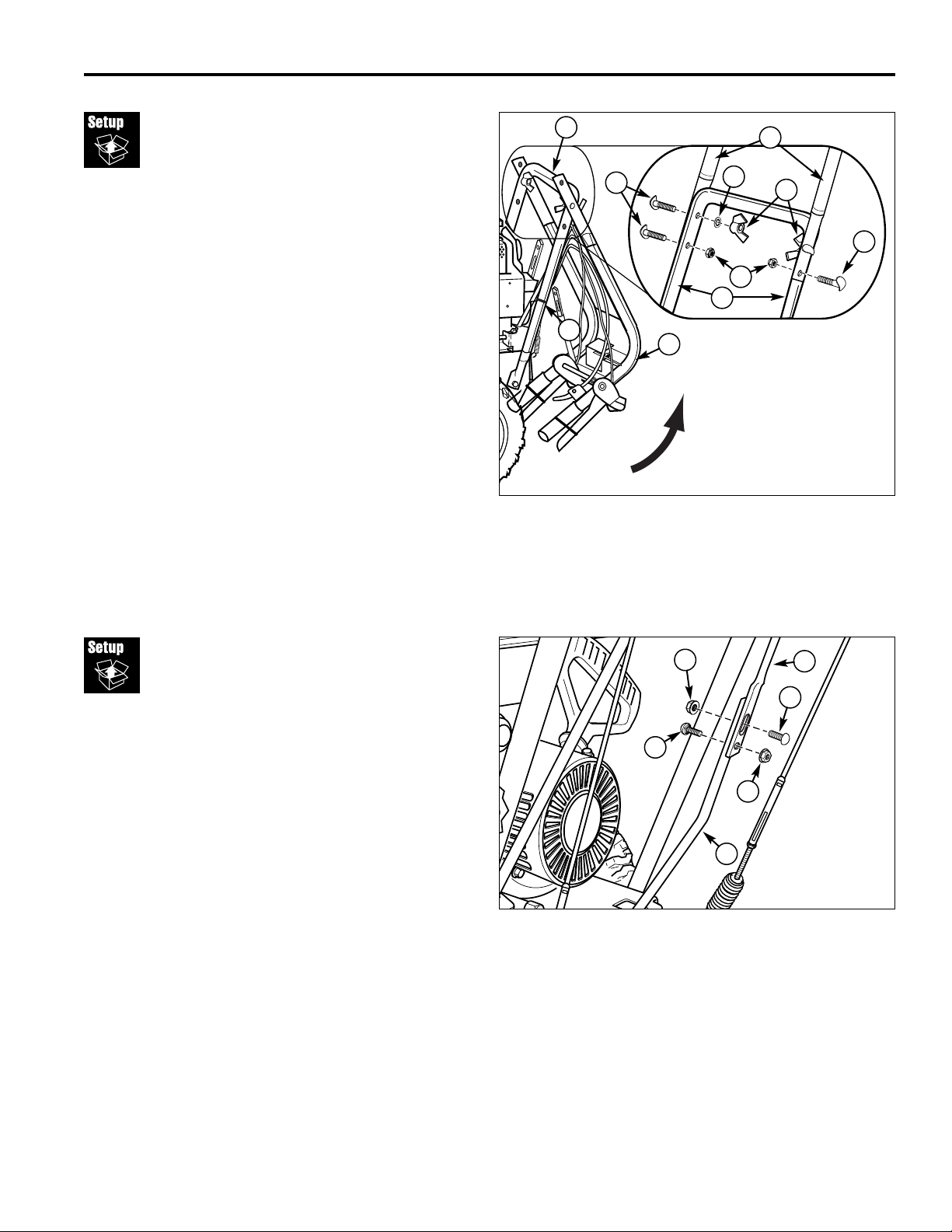

Install Drift Cutters

Drift cutters (if equipped) are mounted to snowthrower

auger housing backwards or shipped loose. Refer to

Figure 3. Remove hardware and install drift cutters with

hardware as shown.

Figure 1. Klik-pin-locked

A. Klik-Pin

Figure 3. Assemble Drift Cutters

A. Taptite Screw, E Round Hole

5/16-18 x 3/4 F. Nut, 5/16-18

B. Drift Cutter G. Lockwasher, 5/16-18

C. Tab H. Capscrew,

D. Square Hole 5/16-18 x 3/4

A

The tires are over inflated for shipping purposes. It is very

important to reduce the tire pressure to the following

pressure:

Reduce and

Check Tire Pressure

Figure 2. Checking Tire Pressure

B

F

H

G

Size PSI bar

15 x 5.0-6 20 1,38

4.80-8 20 1,38

Page 5

Intermediate Frame Snowthrowers

6/2006 5

TP 300-5196-00-IS-SN

D

E

G

A

A

Figure 4. Un Folding Handle Bars (Some Models)

A. Upper Handle Assembly E. Locknut, 5/16-18

B. Wing Nuts F. Cable Ties

C. Lower Handle Assembly G. Lockwasher

D. Special Bolts, 5/16-18 x 2

C

C

C

B

A

D

D

C

Figure 5. Connecting Shift Rods (Some Models)

A. Lower Shift Rod C. Carriage Bolts

B. Upper Shift Rod D. Locknuts

Assembly

Un-Folding Handles

Folding handles (if equipped) are shipped in the down

position and need to be rotated up and secured. Cut

cable ties (F, Figure 4) that secure control cables to lower

handle assembly (C). Be careful not to cut or damage

the control cables. Loosen wing nuts (B) and remove

any packing materials. Rotate upper handle assembly (A)

up. Slide 5/16-18 special bolts (D) through upper handle

assembly (A) and lower handle assembly (C). Tighten

5/16-18 locknuts (E) and 5/16-18 special bolts (D).

Tighten wingnuts (B), lockwashers (G) and 5/16-18 special bolts (D).

F

Assembly

Connecting Shift Rods

On models with folding handles the shift rods need to be

connected. Connect upper shift rod (B, Figure5) and

lower shift rod (A) rods as shown. Secure with carriage

bolts (C) and locknuts (D).

D

B

Page 6

Intermediate Frame Snowthrowers

TP 300-5196-00-IS-SN

6/20066

Assembly

Control Levers

On models with control lever cables need to be checked.

Remove wire ties or cardboard tubes (A, Figure 6) that

secure the control levers (B) to the handles (D). Make

sure that the “Z” bend ends (C) of the control cables (E)

are secured in the holes on the control levers (B) as

shown. Check that the cables (E) are not kinked and

have freedom of movement.

D

B

A

Figure 6. Control Levers (Tube Handle Models)

A. Wire Ties D. Handles

B. Control Levers E. Control Cables

C. “Z” Bend Ends

C

A

B

C

D

E

E

Assembly

Spout Rotator

On models with folding handles the spout rotator is two

pieces and needs to be connected. Remove crank handle (A, Figure 7) from its packaging. Slide crank handle

(A) through dash (B) and slide into crank tube (C) line up

holes and secure with hair pin (D).

D

B

A

C

A

C

Figure 7. Control Levers (Folding Handle Models)

A. Crank Handles C. Crank Tube

B. Dash D. Hair Pin

Figure 8. Clean-Out Tool (all Models)

A. Clean-Out Tool C. Upper Clip

B. Lower Clip

Assembly

Clean-Out Tool

A clean-out tool is included with all models. Check to be

sure the clean-out tool is secured as shown in figure 8.

A

B

C

Page 7

Intermediate Frame Snowthrowers

6/2006

7

TP 300-5196-00-IS-SN

Figure 9. Auger Gear Case Lubrication

A. Pipe Plug

Figure 10. Lubricate Deflector Cap hinges

Check Fluid

Levels & Fill

1. Check auger gear case lubrication. Place the

snowthrower on a level surface. Remove the pipe

plug (A, Figure 9). The lubricant should be level with

the hole. If not, add Simplicity Winter Weight Worm

Gear Oil

2. Fill the engine crankcase with oil as described in the

engine Owner's Manual.

3. Fill the fuel tank with gasoline. Be sure to check your

engine Owner's Manual for gasoline recommendations. Do not overfill; allow space for gasoline expansion.

Lubricate the

Snowthrower

With an oil can, apply medium weight (10W) oil to points

shown in Figures 10 thru 15. There are two grease fittings in the auger shaft (Figure 15). Wipe fittings clean

and apply two or three shots of grease. Also, use grease

on points shown in Figure 12.

Generally, all moving metal parts should be oiled where

contact is made with other parts. Keep oil and grease off

belts and pulleys

NOTE: Make sure auger shaft grease fittings have been

lubricated to prevent shaft rusting. Apply grease until it

comes out both sides of shaft (gear box side and housing

bearing side). Grease may be squeezed out at shear pin

locations.

WARNING

Gasoline is highly flammable and must be

handled with care. Do not allow open flame,

smoking or matches in the area. Avoid overfilling.

CAUTION

It is very important that grease fittings on the

auger shaft are lubricated regularly. If the auger

rusts to shaft, damage to worm gear may occur if

shear pins do not break.

A

Figure 11. Lubricate Control Levers & Lube Axles

Page 8

Intermediate Frame Snowthrowers

TP 300-5196-00-IS-SN

6/20068

Figure 16. Lubricating the Auger Shaft Assembly

A. Grease Fittings C. Cotter Pins

B. Shear Pins D. Auger Assembly

A

B

D

C

A

B

D

C

LUBRICATING THE AUGER SHAFT &

ASSEMBLY

1. Remove cotter pin (C, Figure 16) and shear pin (B).

2. Use a grease gun and squirt several shots of grease

into grease fitting (A).

3. Rotate auger assembly (D) several times to distribute

the grease evenly. Repeat step 2.

4. Reinstall shear pin (B) and cotter pin (C).

5. Repeat procedure for other side.

Figure 12. Lubricate Points Where chute Contacts

Flange (Oil); Lubricate Ring Gear and Pinion Gear

While Rotating Spout (Grease)

Figure 13. Lubricate Points Where Control Rods

Pass Thru Bracket

Figure 14. Lubricate Free Hand Control

Figure 15. Drive Lubrication

A. Hex Shaft

A

Page 9

Intermediate Frame Snowthrowers

6/2006 9

TP 300-5196-00-IS-SN

Check Snowthrower Controls

1. Check the skid shoes to make sure they are set at the

desired height. Adjust if necessary.

2. Check the traction drive control (A, Figure 18).

Snowthrower motion should stop when the control is

released.

3. Check the auger control (C). Auger movement should

stop when the control is released.

4. Check the chute direction control (D) for proper

operation. The discharge chute should rotate freely in

both directions.

6. Check the speed selector (B) for smooth operation.

The control must move freely into each speed position gate and remain in position when released.

If controls do not function properly, perform the

appropriate adjustment as shown in the

Adjustment Section.

6. The auger is secured to the shaft by shear pins,

which will break if the auger strikes an object. Extra

shear pins are provided. Keep these pins with the

Operators Manual. Lubricate the auger shaft.

Figure 18. Snowthrower Controls

A. Traction Control

B. Speed Selector

C. Auger Control

D. Chute Direction Control

B

C

A

Operational Checks

1. Engage the auger control and release. Do this ten

(10) times. Auger should come to a complete stop

within five seconds each time. If not, perform

Auger Adjustments.

3. Engage traction control and release. Do this ten

times. Unit should come to a complete stop each

time. If it does not, perform the Traction Drive

Adjustments.

4. Remove the engine key. The engine must stop.

Perform

Safety Checks

Check Engine Controls

1. Make sure all safety guards are in place and all nuts,

bolts, clips, cotter pins and wires are secure.

2. Check to make sure spark plug wire is attached.

3. Check all controls for proper operation:

a. The engine should stop when the key is removed.

b. The fuel shut-off valve should stop the flow of fuel

to the engine

c. The recoil starter or electric starter (if equipped)

should crank the engine when activated.

4. Check the engine area for oil or gasoline leaks.

Correct any problems in accordance with the engine

manufacturers instructions.

5. Check to make sure that the on/off switch is set to the

ON position.

Figure 17. Check Engine Controls

A. Primer D. Choke

B. Fuel Shut-Off Valve E. Key

C. Recoil Starter F. On/Off Switch

A

B

C

D

E

D

F

Page 10

Intermediate Frame Snowthrowers

TP 300-5196-00-IS-SN

6/200610

Auger Drive Linkage

Adjustment

Adjustments

Figure 19. Auger Drive Adjustment

A. Adjusting Flats D. Nut

B. Spring Hook E. Adjustment Screw

C. Lever

A

C

D

E

B

1. With the drive lever released, the hook (B, Figure 19)

should barely touch the lever (C) without raising it. There

can be a maximum 1/32” clearance as shown.

2. To adjust, loosen nut (D, Figure 19) by holding the

adjusting flats (A)and turning nut (D). Turn adjustment

flats and hold screw. The adjustment screw is a phillips

screw and the head can be held or turned by inserting a

screwdriver through the spring.

3. Hold adjusting flats (A) and tighten nut (D).

4. Start unit and check auger. Auger must not be

engaged unless auger control is depressed.

5. With engine running, fully depress auger control, the

auger should engage and run normally.

6. Release auger control. Auger must stop within 5

seconds.

Traction Drive Linkage

Adjustment

1. With the drive lever released there should be no

slack in the cable when moved slightly from side to

side, but bellcrank arm (C, Figure 20) remains in fully

down position.

2. To adjust tension on the cable loosen adjustment hex

nut (D) by holding the adjusting flats (A). Turn the

adjustment screw. The adjustment screw is a phillips

screw and the head can be held or turned by inserting a screwdriver through the traction drive clutch

cable spring

3. Engage the drive lever to check the adjustment.

When correct, tighten hex nut securely. The unit

should able to be pushed forward and back freely.

Run-In Adjustment

1. After 5 hours of use, check for proper adjustment.

Readjust clutch cable if necessary by increasing tension on cable. A small amount of bellcrank arm

movement is permissible if unit passes operating

checks described in the Caution at right.

Figure 20. Traction Drive Adjustment

A. Adjusting Flats D. Nut

B. Spring Hook E. Adjustment Screw

C. Bellcrank Arm

D

E

B

C

WARNING

Do not over-tighten, as this may cause traction

drive to engage without depressing the traction

drive control (bellcrank arm must remain in down

position).

Verify that the cables are not over-tightened: With

speed selector in position 1 and traction drive

control fully released, push snowthrower forward.

The unit should move forward freely.

If unit does not move forward freely, the cable has

been over-tightened. To remedy, loosen tension

on clutch cable slightly, and recheck.

Page 11

Intermediate Frame Snowthrowers

6/2006 11

TP 300-5196-00-IS-SN

1. Loosen the two nuts (A, Figure 21).

2. Place the shift lever (B, Figure 18) in 5th gear. The

lower speed selector rod (B, Figure 21) will properly

locate itself due to an integral spring.

3. Grasp upper speed selector rod (C, Figure 21), and

pull up, then tighten the two nuts (A) while maintaining the position of the upper rod. Make sure the

shoulders of the carriage bolts are in the slots.

4. Always check traction drive tension and auger drive

tension after adjusting speed selector.

Figure 21. Drive Linkage

A. Nut C. Upper Speed

B. Lower Speed Selector Rod

Selector Rod

A

A

B

C

Speed Selector

Adjustment

If the discharge control is difficult to operate, first

lubricate the pinion gear (A, Figure 22) and ring gear (E).

The pinion gear can be adjusted by loosening the bolts

(C) which hold the pinion gear bracket. If the pinion gear

is too tight against the ring gear, move it away slightly

and then retighten the bolts. Check operation again. If

discharge control is still difficult to operate, see Chute

Direction Control Rod Gear Adjustment.

Figure 22. Discharge Control

A. Pinion Gear

B. Control Rod

C. Bolt (2)

D. Bracket

E. Ring Gear

A

E

D

C

B

Discharge

Control Adjustment

Page 12

Intermediate Frame Snowthrowers

TP 300-5196-00-IS-SN

6/200612

If the discharge chute becomes difficult to rotate or

begins to operate erratically, the chute direction control

rod gears may require adjustment:

1. Loosen the gear bracket mounting nuts (Figure 23).

2. Slide the gear bracket into the position that provides

the best engagement between the gears.

3. Tighten the bracket mounting nuts, and check for

smooth operation.

4. Readjust if necessary.

5. Lubricate the Chute Direction Control rod gears with

lithium grease.

Chute Direction Control

Rod Gear Adjustment

Figure 23. Chute Direction Gear Adjustments

Mounting Nuts

Figure 24. Skid Shoe Adjustment

A. Scraper Bar

B. Skid Shoe

C. Nuts

A

B

C

On smooth surfaces such as concrete or asphalt, the

scraper bar should scrape the surface. On surfaces such

as gravel, the scraper bar should be high enough so that

it will not pick up gravel or debris.

The height of the scraper bar is controlled by raising or

lowering the Skid Shoes (See Figure 24).

1. To raise the scraper bar height, rest the scraper bar on

a strip of wood equal in thickness to the desired height.

2. Make sure the scraper bar is parallel to the ground

surface.

3. Loosen the skid shoe nuts and let the skid shoes drop

to the surface.

4. Tighten the nuts, making sure the Skid Shoes are

adjusted equally and are parallel to the surface.

5. To lower the height of the scraper bar, raise the Skid

Shoes.

6. If the scraper bar becomes worn, it can be adjusted

by loosening the nuts and bolts attaching it to the

snowthrower, making the adjustment, and tightening

the hardware. It may also be replaced by removing

the mounting nuts and bolts attaching it to the

snowthrower.

The scraper bar is adjustable. (See Figure 25). If desired

scraper bar height adjustment cannot be achieved solely

by raising or lowering the skid shoes:

1. Loosen the nuts securing the scraper bar to the auger

housing, and raise or lower the scraper bar until

desired height is achieved.

2. Tighten the nuts, making sure the scraper bar is

parallel with the bottom edge of the auger housing.

Scraper Bar &

Skid Shoe Adjustment

Figure 25. Scraper Bar Adjustment

A. Scraper Bar

B. Nuts

A

B

Page 13

Intermediate Frame Snowthrowers

6/2006 13

TP 300-5196-00-IS-SN

Drive Belt

Replacement

Traction Drive Belt Replacement

1. Disconnect the spark plug wire and fasten it away

from the spark plug. Remove belt cover.

2. Pull the drive belt idler pulley arm away from the belt

to relieve tension, and slide the belt off engine pulley

(A, Figure 27).

3. Slip the belt off the traction pulley (See Figure 26) and

pull the belt out of the unit between the auger pulley

and the traction pulley (the lower cover need not be

removed for this step).

4. Reverse the procedure to install the new belt. Be sure

there are no twists in the belt, and that the belt is

properly seated in the pulley grooves.

5. Replace the belt cover.

6. Start the unit, and check the traction drive for proper

operation. See "Traction Clutch Rod Adjustment" for

adjustment procedures.

WARNING

Snowthrower must move only when the traction

drive control is depressed, and must stop when

the lever is released (disengaged).

Figure 26. Traction Drive Pulley

(Lower Cover Removed For Clarity)

Traction Drive Belt & Pulley

Figure 27. Auger Drive Belt Pattern

A. Engine Pulley D. Driven Pulley

B. Drive Belt E. Belt Stops

C. Idler Pulley

A

B

D

E

C

Page 14

Intermediate Frame Snowthrowers

TP 300-5196-00-IS-SN

6/200614

Auger Drive Belt Replacement

1. Drain the fuel tank and run engine out of gas.

2. Disconnect spark plug wire and fasten it away from

the spark plug.

3. Remove belt cover.

4. Loosen auger belt guide and slide belt off engine pulley and away from idler pulley. (See Figure 28).

5. Depress and secure both the auger and traction control levers to provide clearance for belt removal.

6. Tilt the snowthrower forward and rest it on the auger

housing.

7. Remove lower cover.

8. Loosen hex screws securing the belt stop (Figure 29),

and pivot the belt stop away from the pulley to permit

removal of belt.

9. Pull the belt out of the unit, and install the new belt on

the auger drive pulley.

10. Position belt stop to provide 1/8" clearance between

stop and belt when engaged, and tighten securely.

11. Replace lower cover.

12. Return unit to normal upright operating position.

13. Remove both control levers.

14. Install auger belt over engine pulley.

15. Adjust auger belt guide as described under ADJUSTING AUGER BELT GUIDE.

16. Install belt cover.

17. Connect spark plug wire and fill fuel tank.

18. Start Unit and check auger for proper operation. See

DRIVE BELT ADJUSTMENT PROCEDURES if additional adjustment is necessary.

WARNING

Auger must NOT rotate unless the Auger Control

lever has been depressed.

Proper Auger Drive

Belt adjustments stop the auger within 5 seconds

after the Auger Control is disengaged.

Figure 29. Auger Drive Pulley and Belt Stop

Auger Belt Stop

Auger Drive Pulley

Figure 28. Auger Belt Guide Adjustment

Belt Guide

& Gap

Belt Guide

Screws

Page 15

Intermediate Frame Snowthrowers

6/2006 15

TP 300-5196-00-IS-SN

NOTES

Page 16

Intermediate Frame Snowthrowers

16

© 2006 Simplicity Manufacturing, Inc. All Rights Reserved

MANUFACTURING, INC.

500 N Spring Street / PO Box 997

Port Washington, WI 53074-0997 USA

NOTES

Loading...

Loading...