Page 1

OPERATOR’S

MANUAL

42” Snow Plow/Dozer Blade

(42” Blade), Mfg. NO. 1691520

(Hitch Assembly), Mfg.

i

NO.

1692240

Page 2

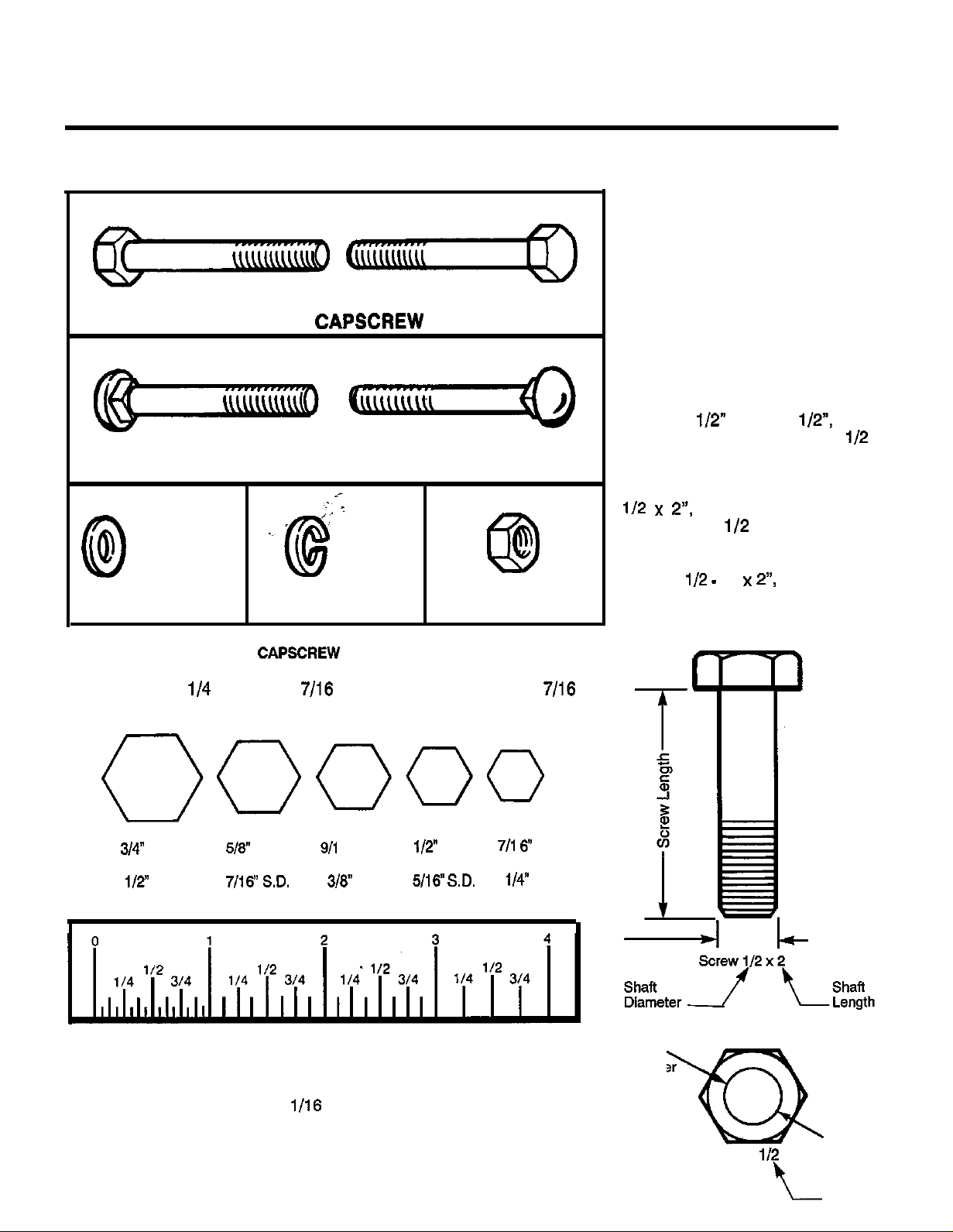

STANDARD

FASTENER

IDENTIFICATION

CHART

HEX CAPSCREW

CARRIAGE BOLT

Q

PLAIN WASHER

Shown below are actual size heads for standard screw sizes.

Example: a

wrench. To measure length, use the scale below.

l/4

screw has 7/16 head and thus requires a 7/16

.~,@--:

LOCKWASHER

HEX CAPSCREW IDENTIFICATION

@

NUT

Hardware sizes given in the

illustrations throughout this

manual.

If a washer or nut is identified as

“washer, l/2” or “nut, i/2”, this

means the inside diameter is

inch

If a screw is identified as “screw,

i/2 x 2”,

diameter is

shaft of the screw is 2 inches

long. If a screw is identified as

“screw,

“16” means that the screw has

16 threads per inch.

SAMPLE: SCREW IDENTIFICATION

this means the shaft

l/2

inch and the

l/2 -

16 x

2”,

the number

l/2

00000

314”

Head

screw with screw with

l/9” S.D.

Place the washer or nut on the above scale to

determine the inside diameter. The actual inside

diameter can vary

comparison.

5/r?”

Head

7116’S.D.

WASHER AND NUT IDENTIFICATION

9/l 6” Head

screw with

318”

S.D.

1116

inch. Use the scale for

I/2” Head

screw with

5116”

SD.

7/l 6” Head

screw with

t/4” S.D.

SAMPLE: NUT IDENTIFICATION

Inside

Diameter

32

Nut.

l/2

Shaft

Diameter

Inside

Diameter

Page 3

Table of Contents

Inside

Front

STANDARD FASTENER IDENTIFICATION CHART

SAFETY RULES

General

Preparation

Operation

PARTS ILLUSTRATION ..............................................................................................................................

ASSEMBLY. .................................................................................................................................................

INSTALLATION.. ..........................................................................................................................................

REMOVAL

OPERATION AND NORMAL CARE

Transporting

Operation On Slopes

Dozing and Snow Plowing ........................................................................................................................

Normal Care

ADJUSTMENTS

.....................................................................................................................................................

...............................................................................................................................................

..................................................................................................................................................

....................................................................................................................................................

..............................................................................................................................................

................................................................................................................................

..............................................................................................................................................

......................................................

Cover

2

2

2

3

4

5

8

8

8

8

9

Skid Shoes

Blade Angle ,.._.__,,,._....,_........................................................................................................................... 10

Spring Tension

TORQUE SPECIFICATIONS

..___..._.._..,,............................................................................................................................

__...._...,,_.___.._.................................................................................................................... 10

CH+F _..............................................................................

.~ ‘:

.

Inside Rear Cover

Accessories

For best performance, it is recommended to use tire chains and two (2) rear wheel weights. A

mounted weight box can also be added for addiiional traction. The maximum weight added to the tractor

should not exceed 35 Ibs./wheel plus 100 additional pounds in the rear weight box.

A Snow Cab is available to protect operator from winter weather.

rear-

10

1

Page 4

safety Rules

Read these safety rules and follow them closely. Failure to obey these rules could result in loss of con-

trol of vehicle, severe personal injury to yourself or bystanders, or damage to property or equipment. The

in the text signifies important cautions or warnings which must be followed.

ALL WARNING, CAUTION, and instructional

messages on this attachment and on your

tractor should be carefully read and obeyed. Per-

sonal bodily injury can result when these

GENERAL

*Read the operators manual carefully. Be thor-

oughly familiar with the controls and proper use of

the equipment. Know how to stop the unit and disengage the controls quickly.

*Never allow children to operate the machine. Do

not allow adults to operate it without proper

instruction.

*Keep the area of operation clear of all persons,

particularly small children and pets.

*Do

not carry passengers.

*Make sure:

a. tractor and attachments are in good operating

condition.

b. all safety devices and shields are in place

c. and in good working condition, and

d. all adjustments (skid shoe height, etc.) have

been made.

instruc-

*Do

not run the engine indoors. Exhaust fumes are

dangerous.

*Shift into neutral before attempting to start the

engine.

*Wear

proper footwear. Do not operate tractor

when barefoot or when wearing open sandals or

canvas shoes.

OPERATION

l

Do not allow anyone to use the snow plow/dozer

blade unless they have been instructed on how to

operate it safely.

l

Never attempt to adjust, repair or service the snow

plow/dozer blade while the tractor engine is

running.

*Do

not allow others near the snow/dozer blade

while it is being used.

*Use the snow plow/dozer blade only in daylight, or

good artificial light.

PREPARATION

*Handle gasoline with care-it is highly flamma-

ble.

a. Use approved gasoline container.

b. Never remove the cap of the fuel tank or add

gasoline to a running or hot engine, or fill the

fuel tank indoors. Wipe up spilled gasoline.

*Always lower the snow plow/dozer blade com-

pletely to the ground when leaving it unattended to

prevent it from being accidentally lowered and

causing injury. Make sure blade is locked in

“DOWN” position due to spring-assist.

*Always operate the tractor at reasonable speeds

to prevent the blade from catching an object and

stopping the tractor abruptly.

2

Page 5

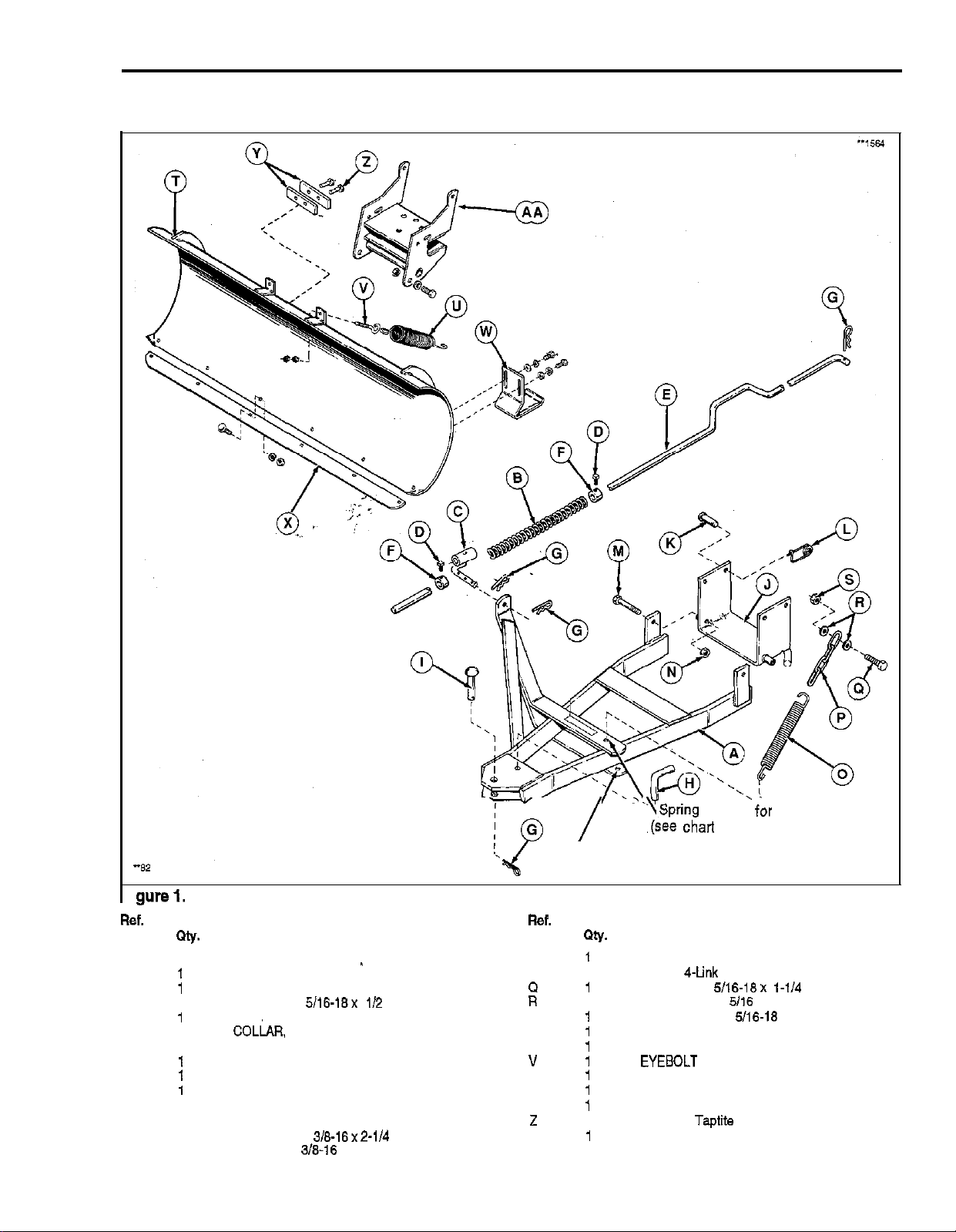

PARTS ILLUSTRATION

42” Snow Plow/Dozer Blade

gurei.

Rd.

NO.

A

B

C

D 2

E

F

G 4

H

I 1

J

K

L

M

N 2 LOCKNUT, 318-16

Qtv.

1

1

1

1

2

1

1

4

4

2

Description

BAR ASSY., Push

SPRING

GUIDE ASSY., Rod

SETSCREW,

ROD. Lift

5/1&18x 112

COLLR. Set

SPRING, Clip

PIN, Pivot

PIN, King W

BRACKET ASSY. X

PIN

CLIP, Pin

CAPSCREW. 3/8-16x

I

2-114

_

.ySpring location

,(see

/

chart on page 6).

fir

garden tractors

Spring location for lawn tractors

(see chart on page 6).

Ref.

NO.

0

P

Q

R

S

T

U

v

Y

z

AA

QW.

1

1

1

2 WASHER, Flat,

1

1

1

1

1

1

1

1

1

Description

SPRING

CHAIN,

4-Link

CAPSCREW, 5/16-18x l-114

LOCKNUT. Hex.

5116

5116-18

BLADE

TRIP ASSY., Spring

EYEBOLT

SHOES, Skid (Assembled)

PLATE, Wear (Assembled)

STOP, Bar

SCREW, Taptite

FRAME, Pivot

3

Page 6

42” Snow Plow/Dozer Blade

ASSEMBLY

1.

Place the blade on a flat surface.

2. install two bar stops (A, figure 2) using the two

5/l 6-l 8 x 1” taptite’screws (B).

Figure 2. Bar Stop

A. Bar Stop

B. Taptite Screw,

5/l

6-l 8 x 1

3:

Insert

4. Hook the spring (C) into the pivot frame (D).

5. Repeat steps 3 and 4 for the other spring

6.Tighten the nut (B) on both eyebolts down to

?.Add the other nut (E) to each

eyebolt

screw on 5/16 nut (B) only far enough so that it is

flush with the end of the

Stretch the spring with a pliers to hook springs on

eyebok (A).

expose about

first nut (B) secure with a wrench and tighten the

second nut (E) securely on each

(A, figure 3)

eyebolt.

3/4”

(19 mm) of thread.

thru.iug

eyebolt.

on blade and

Hold the

eyebok.

Figure 3. Tension Springs

A.

Eyebolt

0. Nut,

C. Spring

5116

D. Pivot Frame

E. Nut,

5/16

Page 7

8. Assemble the chain (A, figure 4) to the tractor as

follows:

a. On left-hand side, remove the upper self-tapping

screw that holds bumper to frame. This is the hole

used for installing chain in the following steps,

using one 5/16-18x

washers (D), and one

b. Place one 5/16 washer onto the screw. Then place

the chain on the capscrew, and then the other

5/16 washer.

c.

Insert the capscrew (B, figure 4) as shown. From

inside frame, install

Tighten snug only at this time. The spring (C) will

be installed in “Installation” section (step 6), and

hardware will be tightened.

l-114 capscrew (B), two 5/16

5/16 locknut.

5/16

locknut onto capscrew.

42” Snow Plow/Dozer Blade

I

Figure 4. Chain

A. Chain

B.

Capscrew

C. Spring

D. Flat Washer

INSTALLATION

1. Drive the tractor over the push bar until rear of

push bar is under front hitch.

P.Stop engine, remove key and set parking brake.

3.Attach the bracket (J, figure 5) to the two rear

holes in the tractor

safety clips (G) provided. Insert the pins from the

outside. Make sure the push bar mounting holes

(in the bracket) are toward the front.

4.Attach the push bar to the bracket, using the two

3/8-16x 2-l/4

provided.

hitch

with the four pins

capscrew (H) and 3/8 locknuts

(F)

and

(I)

gure 5. Hitch and Lift Rod

Lift Rod

Front Set Collar

Spring Clip

Spring

Rear Set Collar

Pin

G. Safety Clip

H. Capscrew.

I. Locknut,

J. Bracket

K. Push Bar

3/8-16x

2-;I4

3/S-16

Page 8

42” Snow Plow/Dozer Blade

5. Raise the push bar and hook up the spring (A, figure 6) in location

B

or C as follows:

Location

B

C

I

6. Lower the push bar and tighten the capscrew and

nut which hold chain to tractor frame.

I

Tractor (Series)

4000,5000,500,600,

12LT. 12RT.

6000,800,

16GTH,

Resent

17GTH

I

gure 6. Lift-Assist Spring

Spring

Spring Location-Lawn Tractors (See Chart)

Spring Location - Garden Tractors (See Chart)

Page 9

7. Insert front of push bar (A, figure 7) into pivot

frame on rear of blade. Then install king pin (C)

down thru holes in

hitch

and pivot frame. Secure

king pin (C) with spring clip (D).

8. Using king pin as the pivot, swivel push bar to

align holes for pivot pin (E). Then install pivot pin

downward thru holes in blade and push bar. The

pivot pin can be installed in any of three holes,

depending on desired blade angle.

3

:.,

j.. :

42” Snow Plow/Dozer Blade

I

Figure 7. Dozer Blade Assembled and Installed

A. Push Bar

B. Pivot Frame E. Pivot Pin

C. King Pin

D. Spring Clip

9,Assemble lift rod as shown in figure 8. (The

exploded view illustration is shown in figure 1.)

Insert tip of rod guide (A, figure 8) thru hole in lift

arm (B) of push bar. Trap the rod guide on each

side of

10. Connect rear of lift rod to

lift

arm with spring clips (C and D).

lift

lever mounted on

tractor using the spring clip.

il.

Perform adjustments, see page 9.

Figure 8.

A. Rod Guide

B.

Lift

Arm (Push Bar)

C. Outer Spring Clip

D. Inner Spring Clip

7

Page 10

42” Snow Plow/Dozer Blade

REMOVAL

1.

Lower the blade,

2. Remove blade and lii rod from push bar.

3. Raise push bar and unhook the spring (A, figure 6)

from the chain.

4. Disconnect the lift rod from the lift lever on tractor

by removing the spring clip.

5. Remove the bracket

hitch by removing four pins and safety clips.

6. Reinstall all pins (king pin, pivot pin, clevis pins)

and secure with spring or safety clip for storage.

OPERATION AND NORMAL CARE

Transporting

For maximum ground clearance, transport the blade

to and from work areas fully raised and

straight ahead.

Be particularly careful and operate at low trac-

tor speeds in any area where the blade can

hook on solid objects. Such objects can

cause the tractor to be jarred or come to an

abrupt stop.

Operation On Slopes

Never operate on slopes greater than 30 percent

(16.7”) which is a rise of 3’ (91 cm) in

forward. Use two rear wheel weights (one per wheel)

when operating on slopes greater than 20 percent

(11.3”).

A

(J,

figure 5) from the tractor

angled

WARNING

lo’ (305 cm)

Dozing and Snow Plowing

When dozing, push the dirt to the desired location,

then drag the blade backwards for final leveling. Pack

down the dirt or gravel by driving the tractor over the

leveled area.

Use any grade to your advantage. Plow downhill and

set the blade angle

ly snow) is moving downhill as it leaves the blade. For

large

drifts

of snow,

plowing a full blade width.

Always use full engine throttle and use the ground

speed control lever to control ground speed and

obtain the needed power to move the material.

Operate at a safe speed, depending on conditions, so

that you have complete control of the tractor. Rear

wheel weights and chains are recommended for slip-

pery surfaces.

so

that plowed material (especial-

bite

off small amounts instead of

Always operate up and down the face of slopes, and

never across the face. Use a slow ground speed on

slopes.

8

Page 11

Normal Care

After dozing jobs, hose down the blade to remove

excess dirt. Coat bare metal surfaces to prevent rusting. Lightly oil all pivot points.

If the wear plate (A, figure 9) on the bottom of the 42”

blade is worn excessively, replace it

by removing the six carriage bolts (B), lo&washers

(C) and nuts (D).

wrth

a new one

42” Snow Plow/Dozer Blade

igure 9.

,.

Wear Plate

. Carriage Bolt,

Lockwasher

Nut

3/9-16 x

1

ADJUSTMENTS

Lift Rod

For initial setting, place front set collar (A, figure 10)

1”

from rod guide with blade fully lowered. Place rear

set collar (B) against spring (C). Tighten the

setscrews in the two set collars. To adjust, perform

the following:

1. Fully raise the blade by raising on the tractor lift

lever. Measure distance between scraper bar and

ground. If it measures approximately

erly adjusted. If not, proceed to step 2.

2. Lower the blade. Loosen the setscrew in the front

set collar. Move the set collar back to increase

clearance or forward to decrease clearance.

Tighten the setscrew. Recheck the measurement.

MOTE:

ent adjustments. Lower the blade to adjust rear set

collar. Moving the rear set collar toward rear will allow

the blade to follow a rolling contour. The farther back

the rear set collar is positioned, the more the blade

will float. Moving the rear set collar toward the front

will increase blade down pressure.

D%rent

ground contours may require differ-

6”,

it is prop

Figure 10.

A. Front Set Collar

B. Rear Set Collar

C. Spring

9

Page 12

42” Snow Plow/Dozer Blade

Skid Shoes

Alternate holes are provided to permit adjustment of

the shoe assemblies for raising and lowering the

blade to various working heights (see figure 11).

When cleaning snow from gravel or earth drives or

walks the shoe assemblies should be lowered fully to

prevent blade contact with gravel or ground. When

cleaning smooth hard surfaces, like concrete, the

shoe assemblies are normally placed fully up to allow

the blade to scrape the surface.

To adjust the skid, raise the blade off the ground and

block with a piece of wood. Loosen the capscrews (A,

figure 11) and move the skid shoes

desired height. Tighten the capscrews securely.

(6) up or down to

Figure 11. Skid Shoes

A. Capscrews,

B. Skid Shoes

3/S-18 x 314

Blade Angle

To adjust the angle of the blade, proceed as follows:

1.

Lift the blade off the ground using the tractor lift

lever.

2. Remove the pivot pin (H, figure 1 and E, figure

move the blade to desired angle and reinstall the

pivot pin in a diierent hole.

i),

Spring Tension

This snow plow/dozer blade is spring loaded so that

when the blade strikes a solid object, the springs will

allow the blade to release as shown in figure 12 rather

than cause damage. The blade will go back to original

position after object is cleared.

To adjust spring tension, hold rear nut (A, figure 12)

and loosen front nut (B). Tighten rear nut (B) to

increase spring tension or loosen nut to decrease

spring tension. Tighten front nut

are drawn firmly together.

(8) so the two nuts

I

Figure 12. Spring Tension

A. Adjustment Nut (Rear)

B. Jam Nut (Front)

10

Page 13

NOTES

42” Snow Plow/Dozer Blade

11

Page 14

42” Snow Plow/Dozer Blade

NOTES

12

Page 15

TORQUE SPECIFICATIONS FOR

STANDARD MACHINE HARDWARE

TOLERANCE

4096

SEE

a-32

8-38

lo-24

lo-32

w-20

114-28

S/18-18

5118-24

318-18

318-24

7118-14

7118-20

l/2-13

l/2-20

9118-12

9118-18

5/a-ii

518-18

314-10

314-18

7/a-9

7/8-14

l-a

1-12

SAE GRADE

0

h/Lb.

FtJLbs.

Nm.

R

SAEGRADE#5

Q

In./Lbs.

FtJLbs.

Nm.

19 2.1 30 3.4

20 2.3

31

3.5

27 3.1 43 4.9

31 3.5 49 5.5

88 7.8

8

10.9

78 8.8 10 13.8

-7T

15. 17 23.1

12 18.3 19 25.8

20 27.2 30 40.8

2

31.3

40.8

35 47.8

50

35 47.8 55 74.8

50

as.

75 102.

55 74.8 90 122.4

85

88.4

110 149.8

75 102. 120 183.2

90 122.4 150 204.

loo 138. 180 244.8

180 217.8 280 353.8

180 244.8

140 190.4

155 210.8 440

220 299.2

300

400

580

408.

544.

598.4

788.8

240 328.4 840 870.4

68.

SAEGRADEII)

Q

InJLbs.

FtJLbs.

Nm.

41 4.8

43

80

aa

12

14

25

25

45

50

70

80

4.9

8.8

7.7

18.3

19.

34.

34.

81.2

68.

95.2

108.8

110 149.8

120

150

183.2

204.

170 231.2

220 299.2

240 328.4

388

525.

420 571.2

800

aa0

900

818.

897.8

1,224.

1,000 1,380.

NOTE:

1. These torque values are to be used for all hardware

excluding: locknuts, self-tapping screws, thread forming

screws, sheet metal screws and socket head setscrews.

2.

Recomended seating torque values for locknuts:

a. For prevailing torque locknuts. use 65% of grade

torques.

b. Forflange whizlock nuts (and screws) - use 135%

of grade 5 torques.

3.

Unless otherwise noted on assembly drawings all torque

values must meet this specification.

BOLT HEAD MARKING

S.A.E. GRADE:

5

Page 16

SIMPLICITY MANUFACTURING, INC.SIMPLICITY MANUFACTURING, INC.

500 N. Spring Street500 N. Spring Street PRINTED IN U.S.A.PRINTED IN U.S.A.

Port

Washington, Wi 53074

Port

Washington, Wi 53074

FORM 1709932FORM 1709932

3/94-IPS3/94-IPS

Loading...

Loading...