Page 1

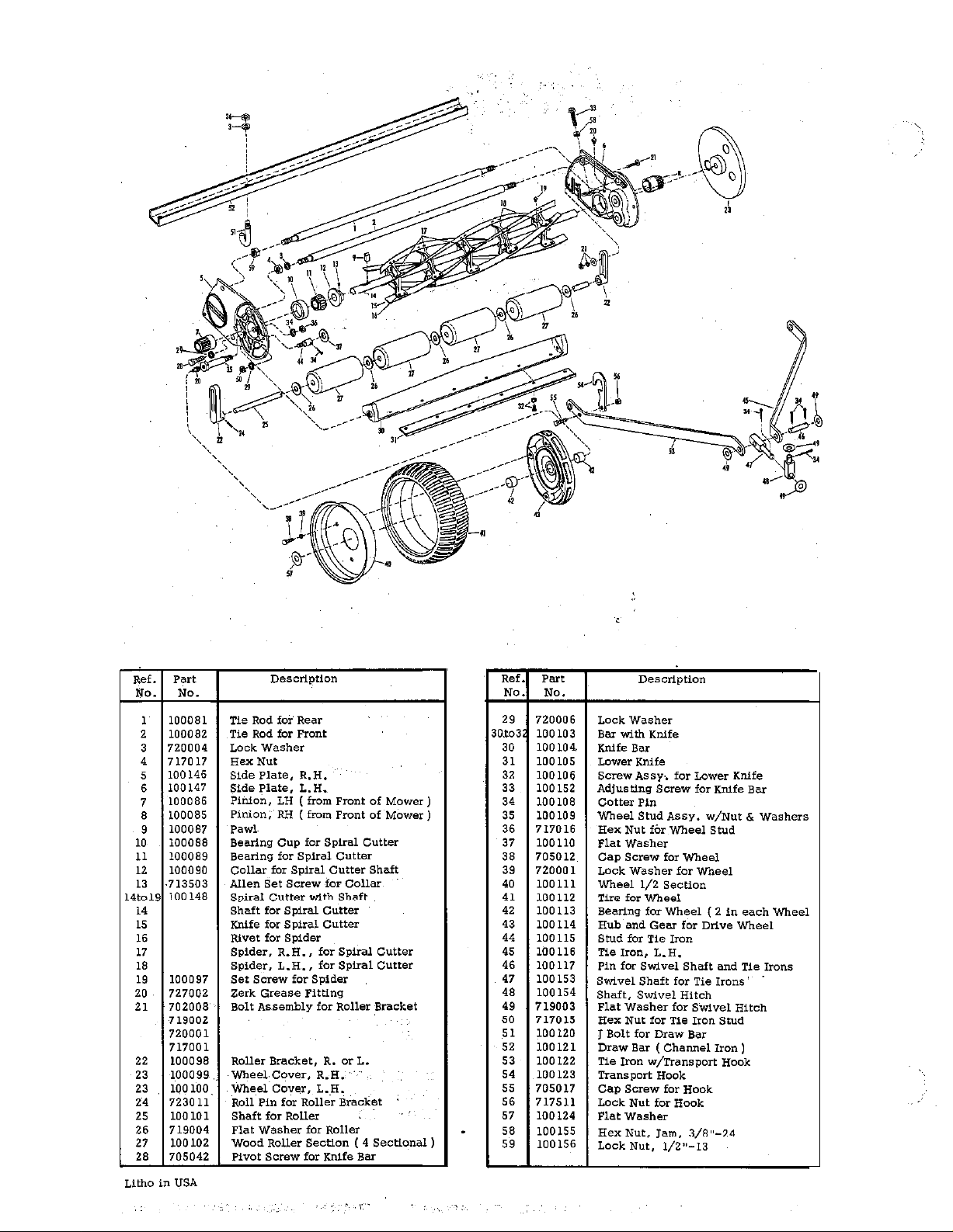

3 GANG MOWER

ARTICLE 273

INSTRUCTIONS ‘AND PARTS LIST

TO ASSEMBLE HITCH

1. Atiach Tie Irons (Ref. Nos. 45 and 53) to the Stud

on Side Plate of each Cutting Unit, using Flat Washers

and

Cater Pins provided. The Tie

Transport

each Cutting Unit as you stand behind them.

2. Attach Swivel Hitch Joint (Ref. No. 47 and 48)

the front of each set of Tie Irons, using Pins (Ref.

No. 46). The Flat Washers go to the outside of Tie

Irons. Secure with Cotter Pins.

3. Attach Draw Bar (Ref. No. 52) with flat side down

over

NOTE: The two center holes in Draw Bar are offset

to

one side. The Draw Bar must be placed with the

offset holes toward front of the Mower. Attach Draw

Bar to Tie Rod with

“J” Bolt should be on front side of Tie Bar. Attach

with Lock Washer and Hex Nut.

4. Attach the Swivel Hitch (Ref. No. 47 and 48) of each

rear Mower to Draw Bar (Ref. No. 52) of front Mower

by inserting Hitch from the underneath side of Draw

Bar, attach with Flat Washer and Cotter Pin.

&ok

attached go on the right side of

the Rear Tie Rod (Ref. No. 1) of one Mower.

two

“J” Bolts (Ref. No. 51). The

Irons

LUBRICATION

Each Mower is equipped with four

(one fitting on each Side Plate and one fining on each

wheel stud). Use regular Alemite grease or equal for

these fittings and

Roller and all moving parts of Hitch. Your Mowers should

be kept thoroughly lubricated. The Drive Pinions are lubri-

cated through the Reel Bearing fittings and it is

sary to

remove Drive Wheels +a lubricate these Pinions.

use

a good grade of oil on Wood

Alemite Zerk finings

ADJUSTMENT OF CUTTING UNIT

The revolving knives should touch the bottom knife lightly

from end to end. The bottom knife can be brought

closer

to

the revolving knives by the

bar adjusting screws located at each end of cutter bar.

Firs+ loosen very slightly the front jam

screw at each end, then loosen jam nut an rear screws

and tighten the rear screws until the wtter bar touches

the reel. Be sure that all four screws and jam

tight after adjustment is made.

use

nut

of

and

two

with the

not neces-

cutter

adlusting

nuts

are

DO NOT ADJUST MOWER TOO TIGHTLY . . .

If the bottom knife and reel knives are rubbing

tightly together the reel knives will wear irregularly

cause excessive wear. If reel is

rear

screws

and

tighten

adiustment

to

nicked and requires s inding, send the mower to a

Competent

is obtained. If the reel has become badly

repair man for proper attention.

the

two

too

fight, loosen the

front

screwy

until proper

too

and

two

CUTTING HEIGHTS

With wheels in “Low” position, the cutting heights are

from 1” to

the cutting heights are from

of roller gives many heighti in either position.

To change cutting heights,.

Turn mower qn side, remove hex nut and lock washer

on

wheel ?ud. Pull wheel stud

(do

not reihove)

position and push wheel stud through sideplate hole.

Replace lock washer and hex

If the pinion and

sure they are replaced properly. When the pinion and

paw1

are in proper position the wheel will roll back-

wards freely and turn the spiral cutter when moved for-

ward. Keep nut on wheel stud tight,

Z-l/S”.

When wheels are in “High” position,

l-7/8” to

move

wheels to other position.

and slide cover and wheel to other

paw1

are removed from the shaft, be

nut

3”. Adjustment

iust out

of

and tighten securely.

sideplate

TO TRANSPORT

Each Mower is equipped with a Transport Hook (on right

hand Tie Iron). For Transport tilt each Mower forward

(one at a time) and place Hook

lifts the rear of each Mower from mowing position.

over

front Tie Rod. This

TO ORDER REPAIR PARTS SUPPLY THE FOLLOWING:

1. Quantity wanted.

2. The part number and name of part. (Not reference

numb,er).

3. Model Number. (See Model Number at top of this

page).

4. Your name and address. (Please Print).

Parts ordered will be

of cost, send list of

sent,

C.O.D. If

parts

and we will send quotation.

you

wish estimate

DO NOT RETURN GANG MOWERS TO THE. FACTORY

UNLESS YOU HAVE A LETTER AUTHORIZING YOU

TO DO SO.

SIMPLICITY MANUFACTURING COMPANY

/

PORT WASHINGTON, WIS.

Page 2

Loading...

Loading...