Simplicity Broadmotor Series, AGCO Allis 1600 Series, Massey Ferguson 2600 Series Service & Repair Manual

Not for Reproduction

Service & Repair Manual Broadmoor Series

MANUFACTURING, INC.

500 N Spring Street / PO Box 997

Port Washington, WI 53074-0997 USA

© Copyright 2001 Simplicity Manufacturing, Inc.

All Rights Reserved. Printed in USA.

Rev 4/2001

TP 500-2493-00-BM-SMA

Repair Manual Contents

This manual is divided into the sections listed below.

Please click hyperlink to access the specific contents of that section.

1 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 — 1-14

2 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 — 2-4

3 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 — 3-12

4 Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 — 4-8

5 Belt Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 — 5-6

6 Common Service Procedures . . . . . . . . . . . . . . . . . . . 6-1 — 6-10

7 Electrical System Service. . . . . . . . . . . . . . . . . . . . . . . 7-1 — 7-34

8 Steering & Front Wheel Repair. . . . . . . . . . . . . . . . . . 8-1 — 8-14

9 Drive Controls Service. . . . . . . . . . . . . . . . . . . . . . . . . . 9-1 — 9-8

10 Hand Controls Service. . . . . . . . . . . . . . . . . . . . . . . . . . 10-1 — 10-6

11 Transmission Removal & Installation. . . . . . . . . . . . 11-1 — 11-8

12 Transmission Tear Down . . . . . . . . . . . . . . . . . . . . . . . 12-1 — 12-16

14 Seat Deck & Fuel Tank Service. . . . . . . . . . . . . . . . . . 14-1 — 14-8

15 PTO Clutch Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-1 — 15-6

16 Mower Deck Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-1 — 16-22

13 Hood & Dashboard Service . . . . . . . . . . . . . . . . . . . . . 13-1 — 13-8

Not for Reproduction

1 - 1

1 General Information

Table of Contents

SECTION CONTENTS

Models Covered

Models & Identification................................................................. 1-2

Introduction

Introduction .................................................................................. 1-3

Manual Content ........................................................................... 1-3

Safety Rules

Safety Rules - General Operation................................................ 1-4

Safety Rules - Service And Maintenance .................................... 1-6

General Repair Information

Bearings & Bushings ................................................................... 1-9

Belts & Pulleys............................................................................. 1-9

Electrical Parts............................................................................. 1-9

Fasteners & Hardware............................................................... 1-10

Genuine Replacement Parts...................................................... 1-10

Hydraulic Parts .......................................................................... 1-10

Paint........................................................................................... 1-10

Required Tools & Equipment..................................................... 1-10

Systems Checks ........................................................................ 1-10

Torque Specifications ................................................................ 1-11

Specifications..............................................................................1-12

SECTION 1. GENERAL INFORMATION

Not for Reproduction

1 General Information

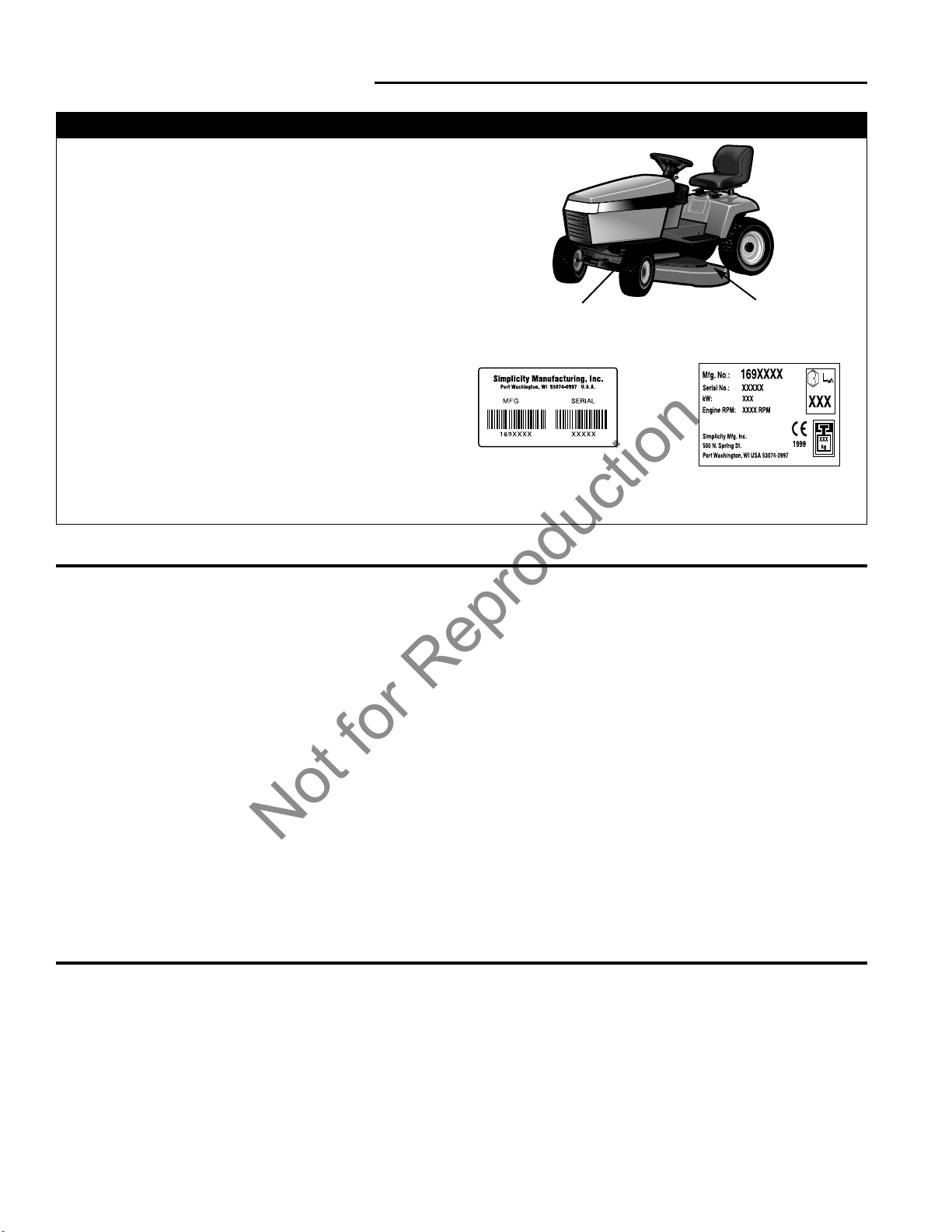

Models Covered In This Manual

1 - 2

1693052 Broadmoor, 14HP Hydro

1693054 Broadmoor, 16HP Hydro

1693056 Broadmoor, 16HP V Hydro

1693058 1614H, 14HP Hydro

1693060 1616H, 16HP Hydro

1693062 1616VH, 16HP V-Twin Hydro

1693064 2616H, 16HP Hydro

1693066 2616VH, 16HP V-Twin Hydro

1693068 Broadmoor, 14HP Hydro (Export)

1693070 Broadmoor, 16HP Hydro (Export)

1693072 Broadmoor, 16HP V Hydro (Export)

1693275 Broadmoor, 18HP V Hydro

1693277 1618H, 18HP V-Twin Hydro

1693279 2618H, 18HP V-Twin Hydro

1693281 Broadmoor, 18HP V Hydro (Export)

1693351 Broadmoor, 14HP Hydro

1693353 Broadmoor, 16HP Hydro

1693355 Broadmoor, 16HP V Hydro

1693358 Broadmoor, 14HP Hydro (Export)

1693360 Broadmoor, 16HP Hydro (Export)

1693362 Broadmoor, 16HP V Hydro (Export)

1693365 1614H, 14HP Hydro

1693367 1616H, 16HP Hydro

1693369 1616VH, 16HP V-Twin Hydro

1693372 2615H, 16HP Hydro

1693374 2616VH, 16HP V-Twin Hydro

1693580 Broadmoor, 16HP Hydro

1693592 Broadmoor, 16HP V Hydro

1693594 Broadmoor, 16HP V Hydro (Export)

1693596 1615H, 16HP Hydro

1693598 2616H, 16HP Hydro

1693600 Broadmoor, 18HP V Hydro

1693602 1618H, 18HP V-Twin Hydro

1693604 2618H, 18HP V-Twin Hydro

1693613 Broadmoor, 18HP V Hydro (Export)

1693617 1616VH, 16HP V-Twin Hydro

1693622 2616VH, 16HP V-Twin Hydro

1693662 Broadmoor, 16HP Hydro (Export)

1693817 Broadmoor, 16HP V Hydro

1693819 Broadmoor, 16HP V Hydro (Export)

1693821 1616VH, 16HP V-Twin Hydro

1693823 2616VH, 16HP V-Twin Hydro

Tractors

Mower Decks

1692682 38” Mower Deck

1692682 38” Mower Deck

1692683 38” Mower Deck

1692683 38” Mower Deck

1692683 38” Mower Deck

1692683 38” Mower Deck

1692684 44” Mower Deck

1692684 44” Mower Deck

1692685 44” Mower Deck

1692685 44” Mower Deck

1692685 44” Mower Deck

1692685 44” Mower Deck

1693170 38” Mower Deck (Export)

1693170 38” Mower Deck (Export)

1693171 44” Mower Deck (Export)

1693171 44” Mower Deck (Export)

1693267 50” Mower Deck

1693267 50” Mower Deck

1693283 50” Mower Deck (Export)

1693283 50” Mower Deck (Export)

1693284 50” Mower Deck

1693284 50” Mower Deck

1693284 50” Mower Deck

1693284 50” Mower Deck

Mower Deck

Identification Tag

Tractor

Identification Tag

IDENTIFICATION TAG LOCATIONS

AMERICAN MODELS

CE MODELS

SSAAMMPPLLEE

SSAAMMPPLLEE

MODELS COVERED &

IDENTIFICATION NUMBERS

This manual contains service information for the

models listed below. Consult the Identification

Tag located on the tractor frame for the manufacturer’s identification number and serial number.

Always use the manufacturer’s identification number and serial number when ordering parts or documentation. Attachments are not covered in this

manual. Refer to the attachment operator’s manual or authorized dealer for service information.

Transmissions are identified by identification number tags located on the transmission casing.

Not for Reproduction

1 - 3

1 General Information

Introduction

INTRODUCTION

This manual is divided into sixteen major sections of service information required for the models specified.

These sections are:

1. General Information

2. Troubleshooting

3. Maintenance

4. Adjustments

5. Belt Replacement

6. Common Service Procedures

7. Electrical System Service

8. Steering & Front Wheel Repair

9. Drive Controls Service

10. Hand Controls Service

11. Transmission Removal & Installation

12. Transmission Tear Down

13. Hood and Dashboard Service

14. Seat Deck & Fuel Tank Service

15. PTO Clutch Service

16. Mower Deck Repair

Since part numbers are subject to change and may vary

by model year and manufacturing number, all parts in

this manual are referred to by general description.

Specific part number information may be found in the

respective Parts Manual for the unit being serviced.

Always use the manufacturing number that appears on

the Identification Tag of the unit you are servicing to

identify component part numbers.

MANUAL CONTENT

This manual is intended primarily for use by dealer service personnel as a technical reference manual or as a

compliment to normal service training.

While the information in this manual has been developed

to permit mechanics and service technicians to perform

most service procedures quickly and effectively, it is

assumed that those using this manual will have some

outdoor power equipment service experience or other

basic power equipment service training with similar types

of products.

In addition, it is assumed that all those performing service on these units are familiar with the general principles of operation of these units, and understand all operating controls, safety instructions, and normal handling

precautions for servicing large, high horsepower riding

tractors and mowers.

Engine information is available from the appropriate

engine manufacturer in a separate service manual.

General engine information and basic engine troubleshooting information is provided, but is intended for

general guidance only. The engine manufacturer’s manual should be always be consulted first before making

any major adjustments, part changes, or other major

repairs.

This manual includes all relevant service information for

model years 1990 through 1995, and whenever necessary, includes inset illustrations or other references to

help identify previous part designs and alternative service procedures.

The service techniques in this manual also assume that

the person providing service has access to a standard

assortment of mechanic’s hand tools, and approaches

most disassembly and repair procedures with availability

of these basic tools in mind. Whenever specialized or

custom tools are available to save time, reduce effort, or

improve overall service efficiency, the most effective safe

repair method available should be utilized.

Not for Reproduction

1 General Information

Safety Rules

1 - 4

GENERAL OPERATION

• Read, understand, and follow all instructions in the manual and on

the unit before starting.

• Only allow responsible adults, who are familiar with the instructions, to operate the unit (local regulations can restrict operator

age).

• Clear the area of objects such as rocks, toys, wire, etc., which

could be picked up and thrown by the blade(s).

• Be sure the area is clear of other people before mowing. Stop unit

if anyone enters the area.

• Never carry passengers.

• Do not mow in reverse unless absolutely necessary. Always look

down and behind before and while travelling in reverse.

• Be aware of the mower discharge direction and do not point it at

anyone. Do not operate the mower without either the entire grass

catcher or the deflector in place.

• Slow down before turning.

• Never leave a running unit unattended. Always disengage the

PTO, set parking brake, stop engine, and remove keys before dismounting.

• Turn off the PTO switch to disengage the blades when not mowing.

• Stop engine before removing grass catcher or unclogging chute.

• Mow only in daylight or good artificial light.

• Do not operate the unit while under the influence of alcohol or

drugs.

• Watch for traffic when operating near or crossing roadways.

• Use extra care when loading or unloading the unit into a trailer or

truck.

• Data indicates that operators, age 60 years and above, are

involved in a large percentage of riding mower-related injuries.

These operators should evaluate their ability to operate the riding

mower safely enough to protect themselves and others from injury.

• Keep in mind the operator is responsible for accidents occurring to

other people or property.

• All drivers should seek and obtain professional and practical

instruction.

• Always wear substantial footwear and trousers. Never operate

when barefoot or wearing sandals.

• Before using, always visually check that the blades and blade hardware are present, in-tact, and secure. Replace worn or damaged

parts.

• Never operate the machine with defective guards, or without safety

protective devises in place.

• Disengage attachments before: refuelling, removing an attachment,

making adjustments (unless the adjustment can be made from the

operator’s position).

• When the machine is parked, stored, or left unattended, lower the

cutting means unless a positive mechanical lock is used.

• Follow the manufacturer’s recommendation for wheel weights or

counterweights.

SLOPE OPERATION

Slopes are a major factor related to loss-of-control and tip-over accidents,

which can result in severe injury or death. All slopes require extra caution.

If you cannot back up the slope or if you feel uneasy on it, do not operate

on it.

Control of a ride-on machine sliding on a slope will not be regained by the

application of the brake. The main reasons for loss of control are: insufficient tire grip on the ground, speed too fast, inadequate braking, the type

of machine is unsuitable for it’s task, lack of awareness of the ground conditions, incorrect hitching and load distribution.

Read these safety rules and follow them closely. Failure to obey these rules could result in loss of control

of unit, severe personal injury or death to you, or bystanders, or damage to property or equipment.

This mowing deck is capable of amputating hands and feet and throwing objects.

The triangle in text signifies important cautions or warnings which must be followed.

WARNING

Never operate on slopes greater than 17.6 percent

(10°) which is a rise of 3-1/2 feet (106 cm) vertically in

20 feet (607 cm) horizontally.

When operating on slopes use additional wheel

weights or counterweights. See your dealer to

determine which weights are available and

appropriate for your unit.

Select slow ground speed before driving onto slope.

In addition to front and rear weights, use extra caution

when operating on slopes with rear-mounted grass

catcher.

Mow UP and DOWN the slope, never across the

face, use caution when changing directions and DO

NOT START OR STOP ON SLOPE.

Do

• See your authorized dealer for recommendations of wheel weights

or counterweights to improve stability.

• Mow up and down slopes, not across.

• Remove obstacles such as rocks, tree limbs, etc.

• Watch for holes, ruts, or bumps. Uneven terrain could overturn the

unit. Tall grass can hide obstacles.

• Use slow speed. Tires may lose traction on slopes even through

the brakes are functioning properly. Choose a low gear so that you

will not have to stop or change speeds while on the slope.

• Use extra care with grass catchers or other attachments. These

can change the stability of the unit.

• Keep all movement on the slopes slow and gradual. Do not make

sudden changes in speed or direction.

• Always keep unit in gear especially when traveling downhill. When

clutching, release clutch slowly.

Do Not

• Do not start or stop on a slope. If tires lose traction, disengage the

blade(s) and proceed slowly straight down the slope.

• Do not turn on slopes unless necessary, and then, turn slowly and

gradually downhill, if possible.

• Do not mow near drop-offs, ditches, or embankments. The mower

could suddenly turn over if a wheel is over the edge of a cliff or

ditch, or if an edge caves in.

• Do not mow on wet grass. Reduced traction could cause sliding.

• Do not try to stabilize the unit by putting your foot on the ground.

• Do not use grass catchers on steep slopes.

• Do not mow slopes you cannot back up.

• Do not shift to neutral and coast down hill.

TP 600-2459-00-XX-SMA

Not for Reproduction

1 - 5

1 General Information

Safety Rules

Slope Operation Continued

Children

Tragic accidents can occur if the operator is not alert to the presence of

children. Children are often attracted to the unit and the mowing activity.

Never assume that children will remain where you last saw them.

• Keep children out of the mowing area and under the watchful care

of another responsible adult.

• Be alert and turn unit off if children enter the area.

• Before and during reverse operation, look behind and down for

small children.

• Never carry children. They may fall off and be seriously injured or

interfere with safe unit operation.

• Never allow children to operate the unit.

• Use extra care when approaching blind corners, shrubs, trees, or

other objects that may obscure vision.

TOWING

• Never allow children or others in or on towed equipment.

• Tow only with a machine that has a hitch designed for towing. Do

not attach towed equipment except at the hitch point.

• Follow the manufacturer’s recommendations for weight limit for

towed equipment and towing on slopes.

• On slopes, the weight of the towed equipment may cause loss of

traction and loss of control.

• Travel slowly and allow extra distance to stop.

• Do not shift to neutral and coast down hill.

TRANSPORTING AND STORAGE

• Always observe safe refueling and fuel handling practices when

refueling the tractor after transportation or storage.

• Always follow the engine manual instructions for storage preparations before storing the tractor for both short and long term periods.

• Always follow the engine manual instructions for proper start-up

procedures when returning the unit to service.

• Never store the unit or fuel container inside where there is an open

flame or pilot light, such as in a water heater. Allow unit to cool

before storing.

EMISSIONS

• Engine exhaust from this product contains chemicals known, in

certain quantities, to cause cancer, birth defects, or other reproductive harm.

• Look for the relevant Emissions Durability Period and Air Index

information on the engine emissions label.

WARNING

When transporting this tractor on an open trailer,

make sure unit is facing forward, toward the direction

of travel. If tractor is facing backward, wind lift could

cause damage to the hood.

SERVICE AND MAINTENANCE

• Use extra care in handling gasoline and other fuels. They are flammable and vapors are explosive.

a) Use only an approved container.

b) Never remove gas cap or add fuel with the

engine running. Allow engine to cool before refueling. Do not

smoke.

c) Never refuel the unit indoors.

• If fuel is spilled, do not attempt to start the engine but move the

machine away from the area of spillage and avoid creating any

source of ignition until fuel vapors have dissipated.

• Replace all fuel tank caps and fuel container caps securely.

• Never fill containers inside a vehicle or on a truck bed with a plastic

bed liner. Always place containers on the ground away from your

vehicle before filling.

• Remove gas-powered equipment from the truck or trailer and refuel

it on the ground. If this is not possible, then refuel such equipment

on a trailer with a portable container, rather than from a gasoline

dispenser nozzle.

• Keep nozzle in contact with the rim of the fuel tank or container

opening at all times until fueling is complete. Do not use a nozzle

lock-open device.

• If fuel is spilled on clothing, change clothing immediately.

• Maintain or replace safety and instruction labels as necessary.

• Never run a unit in an enclosed area.

• Keep nuts and bolts, especially blade attachment bolts, tight and

keep equipment in good condition.

• Never tamper with safety devices. Check their proper operation

regularly and make necessary repairs if they are not functioning

properly.

• Keep unit free of grass, leaves, or other debris build-up. Clean up

oil or fuel spillage.

• Stop and inspect the equipment if you strike an object. Repair, if

necessary, before restarting.

• Never make adjustments or repairs with the engine running unless

specified otherwise in the engine manufacturer’s manual.

• Grass catcher components are subject to wear, damage, and deterioration, which could expose moving parts or allow objects to be

thrown. Frequently check components and replace with manufacturer’s recommended parts, when necessary.

• Mower blades are sharp and can cut. Wrap the blade(s) or wear

gloves, and use extra caution when servicing them.

• Check brake operation frequently. Adjust and service as required.

• Use only factory authorized replacement parts when making

repairs.

• Always comply with factory specifications on all settings and

adjustments.

• Only authorized service locations should be utilized for major service and repair requirements.

• Never attempt to make major repairs on this unit unless you have

been properly trained. Improper service procedures can result in

hazardous operation, equipment damage and voiding of manufacturer’s warranty.

• On multiple blade mowers, take care as rotating one blade can

cause other blades to rotate.

• Do not change engine governor settings or over-speed the engine.

Operating the engine at excessive speed can increase the hazard

of personal injury.

• Disengage drive attachments, stop the engine, remove the key,

and disconnect the spark plug wire(s) before: clearing attachment

blockages and chutes, performing service work, striking an object,

or if the unit vibrates abnormally. After striking an object, inspect

the machine for damage and make repairs before restarting and

operating the equipment.

• Never place hands near the hydro pump cooling fan when the tractor is running. Cooling fan is located on top of the transaxle

Not for Reproduction

1 General Information

Safety Rules

1 - 6

SERVICE AND MAINTENANCE

The service information provided in this manual is intended to provide you with the knowledge required to perform

a wide range of service procedures on the listed equipment.

While appropriate safety reminders and safety warnings

have been included here and elsewhere in this manual to

help promote the use of safe service techniques, you

must also observe all appropriate shop safety rules

whenever performing these procedures.

No single manual, including this one, can include every

possible warning or safety instruction necessary to guarantee complete safety - you must apply your common

sense and knowledge of shop and power equipment

safety whenever performing service, whenever working

around others who are operating, servicing, or handling

equipment, and whenever you are present in a work

environment where hand or power tools, shop equipment, or outdoor power equipment may be present.

This includes taking the necessary safety precautions to

help ensure a safe workplace, exercising reasonable

care to avoid unsafe acts, and being alert for potential

hazards as you move about the workplace or engage in

various service activities.

If you encounter a service situation involving the use of

an unfamiliar tool, procedure, or part, and rereading the

appropriate section of this manual does not provide the

information you want, contact your Simplicity dealer

before proceeding. Never attempt a repair that you’re

not sure about, since help is usually never more than just

a phone call away.

Practicing safe service procedures not only helps protect

you and those you work around, it also contributes to

providing safe, reliable equipment .

Personal Protective Equipment

• Wear protective safety glasses whenever using hand

or power tools, shop equipment, and whenever working under power equipment to protect your eyes from

falling debris and small parts.

• Wear safety goggles or full face protection when handling battery electrolyte fluid, or when performing

grinding or sharpening operations that produce

sparks or flying debris. Extensive grinding may

require the use of protective sleeves and an apron.

• Wear work gloves when handling sharp surfaces

such as mower blades, or when working around

sharp edges. Never wear gloves that are loose fitting

or that have tie straps, as these could cause your

hands to get caught by rotating parts, resulting in

serious injury. Chemical-resistant Rubber gloves are

recommended when handling or pouring battery electrolyte.

• Steel-toe safety shoes are highly recommended to

protect feet from falling tools, heavy parts, and other

shop equipment.

Fuel Handling Safety

• Always use extra care when handling gasoline gasoline is highly flammable, and gasoline vapors

are explosive as well as toxic if inhaled.

• Never store fuel indoors, or refuel a unit indoors.

Gasoline vapors can easily travel unseen to distant

sources of ignition such as pilot lights or open flames

on water heaters, furnaces, stoves, or other gas

operated appliances, sparks from electric motors or

other electrically-operated tools and equipment, welding equipment, grinders, or burning smoking materials. Contact with these or any other sources of ignition will cause an explosion and/or fire, serious personal injury, and damage to property and equipment.

• Never transfer gasoline from one container to another

unless the containers are connected by an approved

grounding strap. Hand or power operated transfer

pumps can generate a static charge of electricity,

causing dangerous sparking and ignition of fuel or

fuel vapors. Always follow the pump manufacturer’s

safety and operating instructions.

• Use only approved containers for fuel, and always

handle the container with extreme care to avoid

spillage or leaking of explosive vapors.

• Never smoke or allow others in the area to smoke

while refilling the fuel tank, or when handling gasoline cans. Make sure any smoking materials that had

been in use in the area are fully extinguished before

opening a fuel can or starting refueling .

Not for Reproduction

1 - 7

1 General Information

Safety Rules

Exhaust Gas Safety

• Internal combustion engines produce and exhaust

Carbon Monoxide (CO), an odorless, colorless, gas

that causes dizziness, nausea, flu-like symptoms,

unconsciousness, or even brain damage or death, if

breathed for prolonged periods.

• If exposed to Carbon Monoxide gas, get to a fresh air

source immediately and seek medical attention. CO

can build up in your blood, and can cause lingering

symptoms or permanent damage if left untreated.

• Operate the unit outdoors or in a well ventilated area,

or pipe exhaust gases out of the work area to an outside location where the exhaust can be dissipated

safely away from doors, windows, air conditioners, or

other potential sources of outside-air intake that could

permit reentry of hazardous fumes.

• Never enter an enclosed area where an engine has

been running and exhaust gases have been allowed

to collect. Open adjacent windows or doors first to

permit outside air to ventilate the area, and allow sufficient time for a complete air exchange to occur.

Battery/Electrolyte Safety

• Lead-Acid batteries use an electrolyte containing sulphuric acid, a highly corrosive liquid that can cause

severe chemical burns if allowed to come into contact

with skin, or blindness if allowed to contact your eyes.

Always wear approved eye goggles or a full face

shield and protective gloves when handling electrolyte or filling the battery.

• Lead-acid batteries also produce hydrogen, a colorless, highly explosive gas that can be easily ignited

by a single spark. Charging the battery incorrectly or

hooking up jumper cables improperly can cause

sparking, and must be avoided. Always follow recommended battery charging and jumper cable procedures.

• When removing or installing battery cables, disconnect the negative cable FIRST, and reconnect it

LAST. If not done in this order, the positive terminal

could be accidentally shorted to the frame by a tool,

creating a dangerous spark that can ignite nearby

fuel vapors or escaping hydrogen gas from the battery.

• Keep battery securely fastened in position with vent

tube directed down and out of battery compartment.

Replace battery if electrolyte leakage occurs. Make

sure the battery vent tube is properly installed, and is

not plugged with clippings or other debris. Replace

the vent tube if cracked, damaged, or missing from

unit.

• Old batteries should be disposed of by recycling.

Electrical System Safety

• Loose connectors, worn wires, damaged wire insulation, and loose termination hardware can cause

sparks, short-circuits, and erratic equipment operation. Always check wiring for damage, and make

appropriate repairs before placing unit back into operation.

• Use care when working around exposed terminals to

prevent short-circuiting the electrical system.

Sparking, electric shocks, and damage to the system

may result from accidental contact between terminals

and metal hand tools.

Elevating Unit Safely

• Always support unit on approved jack stands when

working on an elevated unit, and keep unit from

rolling by engaging parking brake and placing wheel

chocks behind wheels still on floor or work table.

• Secure unit to work-surface of scissor-lift worktables

or other powered lift tables in accordance with the

manufacturer’s instructions. Unsecured units may

roll unexpectedly while work is being done, causing

injuries.

• Never work under an elevated unit unless it is properly supported by jack stands, locked from rolling with

wheel chocks or equivalent, and you can quickly

escape from under the unit in an emergency using a

rolling device such as a mechanic’s creeper.

• Always protect your eyes from falling debris or small

parts by wearing approved safety glasses or goggles.

• Remove the ignition key and disconnect the spark

plug wires before working under a unit. Accidental or

inadvertent starting could result in serious injuries.

Proper Tool Use

• Use power and hand tools only for the use that they

were designed. Never alter or modify tools, or improvise using tools that are not suitable for the job at

hand.

• Keep all hand and power tools in good repair, and put

them away when done to avoid cluttering the work

area. Use extra care when using corded tools

around moving or rotating parts such as belts and

pulleys, since the cord could get caught and suddenly

pull the tool, or you, into the area of moving parts.

• Always check the unit to ensure that all hand and

power tools and tool attachments have been

removed from the unit after use. Small tools and tool

attachments left on the equipment can fall into the

cutting path when the unit is placed into service, and

become a hazard to bystanders if struck by mower

blades.

Not for Reproduction

1 General Information

Safety Rules

1 - 8

Work Area Safety

• Always keep the work area clear of clutter from discarded parts, and debris from parts boxes or packaging materials. Small parts, hardware items, and other

debris or refuse left lying around can become slip,

trip, and fall hazards if not removed and discarded of

properly.

• Always observe general shop safety rules for housekeeping, and tend to oil spills and other spilled fluids

promptly to prevent slip and fall injuries.

• Allow sufficient work area around the equipment you

are working on to permit comfortable working positions. Never put yourself in a position that would prevent you from escaping quickly in the event of emergencies such as sudden shifts in equipment position,

fire, or other situations requiring an immediate reaction on your part.

Compressed Air Safety

• Always use care when using compressed air to blow

dirt and debris off equipment - always direct the air

blast away from yourself and others in the area, and

protect your eyes with safety glasses to prevent injury

from particles that may blow back toward your face.

• Never use high pressure air directly against your skin

to clean dirt and debris - the air pressure could actually force foreign material or fluids into your skin,

causing serious injuries.

• Use care when filling tires - lawn and garden tractors

utilize low pressure tires, and over-pressurization is

hazardous to you and anyone who operates the

equipment with improper tire pressures. Always consult the air pressure recommendations for the unit

involved before adding additional air to the tires.

Grease & Lubricant Safety

• Normal service and maintenance involves the use of

oils and greases that could present a fire hazard if

not handled properly. Always dispose of oily rags

properly to prevent fires caused by spontaneous

combustion.

• Spilled lubricants pose dangerous slip hazards and

must be taken care of immediately. Wipe up spills

carefully, or use absorbent materials to soak up

spilled fluids. Always dispose of rags, paper towels,

and other saturated absorbents properly.

• Store oils and greases away from flame or other ignition sources. Petroleum-based fluids can be ignited

by smoking materials and sparks - always treat oils

and greases as potentially flammable materials.

Always cap oil and grease containers when done

using, and store or dispose of properly.

General Servicing Safety

• Always check safety devices and switches for proper

operation - never alter these devices or make temporary or makeshift repairs. Use only factory-authorized parts and procedures, and check newlyinstalled parts for proper operation.

• Make sure all hardware items are properly tightened,

especially blade attachment bolts. Replace any hardware that appears damaged.

• Check brake operation, and adjust or repair as

required. Always comply with factory specifications

on settings and adjustments.

• Check grass catcher components for wear, damage,

or deterioration, and replace with factory authorized

parts if necessary.

• Always make repairs using factory authorized

replacement parts only. Using parts that don’t meet

factory specifications can result in sudden or premature failures, poor or erratic equipment performance,

and potential safety hazards to operators and

bystanders.

• Always comply with factory specifications on settings

and adjustments when installing new parts, making

repairs, or performing routine service procedures.

• Always test repairs before releasing units to customers, paying special attention to any items that are

safety-related. Correct any problems noted, and recheck to ensure that the problems have been fully

remedied.

• Make sure all safety and operating instruction decals

are legible, properly located, and securely attached.

Replace any decals that can’t be read or are in danger of falling off.

• Always advise equipment owners of any potential

operating or safety problems that may be arising due

to anticipated wear, and request that the owner

address the problem before a hazard develops.

• Never allow a unit to be placed back into service if a

serious safety or operating problem is evident.

Advise the owner of the problem and the possible

hazards associated with the problem, and request

permission to correct the deficiencies.

• Use extreme care when working on older models that

do not have all of the latest safety devices and

switches. Disengage the PTO and transmission

before starting the unit, or commencing repairs.

• Always use care when removing or installing parts to

prevent damage from dropping or rough handling.

Support heavy parts properly to prevent damage or

personal injury to yourself and others.

Not for Reproduction

1 - 9

1 General Information

Repair Information

GENERAL REPAIR INFORMATION

In addition to providing specific repair procedures for the

equipment listed at the beginning of this section, this

manual provides the following additional general instructions for dealing with repairs to various types of components.

This information is designed to help you deal more effectively with these components by providing basic service

knowledge and other useful tips.

Bearings & Bushings

Roller bearings, ball bearings, and bushings are used to

provide support to rotating shafts and other parts such as

gears, pulleys, and sprockets that are used to transmit

rotary motion. Over time, bearings and bushings may

require additional lubrication to transmit this rotary

motion with minimal friction, or may need replacement

due to normal operation and wear. Normal service for

bearings and bushings includes removal, cleaning,

inspection, lubrication, and replacement.

REMOVAL

Most bearings and bushings used on the listed equipment can be easily removed by following the appropriate

detailed procedures found throughout this manual. Care

should always be exercised to avoid scratching or damaging the bearing or bushing, the mounting shaft, and

surrounding components. Bearing or bushing removal is

usually necessary when excessive play or wobble is

noticed on the part it supports, when unusual noise or

vibration is apparent, or when a burning smell is present

at the bearing location.

CLEANING

Sealed bearings and bushings can be cleaned by careful

wiping with a cloth. Bearings with one-sided or removable shields and plain bushings can be cleaned by

immersion in safety solvent, and brushing with a part

cleaning brush. Oil-impregnated bushings, and bushings

made of nylon or other synthetic materials, can be

cleaned with safety solvents, or wiped clean, but should

not be immersed in solvent for periods longer than that

necessary to remove heavy or caked-on build-ups of

grease. All petroleum-based solvents are flammable, so

appropriate precautions regarding flames, sparks, and

other ignition sources should always be observed.

Gasoline should never be used because of its volatility

and its highly toxic nature.

INSPECTION

Once cleaned, bearings can be properly inspected for

wear, scratches, visible damage such as corrosion,

cracked seals or scorching, and rough, or noisy, operation. Bushings can be visually checked for scratches,

uneven wear, or other visual damage.

LUBRICATION

After passing inspection, bearings and bushings should

be lubricated in accordance with factory specifications,

and reinstalled according to the appropriate installation

instructions. New bearings and bushings must also be

properly lubricated before use. For optimal performance,

and as a practical preventive maintenance measure,

bearings and bushings used in pairs or multiple sets

should all be replaced at the same time.

Belts & Pulleys

Belts and pulleys transmit rotary motion from power

sources to work components, providing the force needed

to drive transmissions, operate mower decks, and power

various attachments. This continual use eventually

causes belts to wear out, and over time may also require

the replacement of pulleys and pulley bearings.

Belt wear and various types of damage are easily

checked by visual examination, which is covered in

greater detail elsewhere in this manual. Pulleys may

also be checked visually for wear or apparent damage,

but pulley bearings usually require removal, cleaning,

and inspection to determine if replacement is required.

Belt and pulley life can be optimized by making sure that

proper belt tension and alignment are observed when

belts are installed. Proper belt tension and alignment

should also be maintained by performing periodic checks

and adjustments. In addition, only factory authorized

replacement belts will minimize problems caused by

size, thermal instability, and variations in quality.

Electrical Parts

The electrical parts used on these units has been specifically engineered for outdoor power equipment, and is

designed to provide years of reliable operation. As with

all electrical components and systems, electrical contacts must be kept clean and dry, and all terminations

must be securely fastened or connected. Also, all electrical components, wiring, and connectors should be periodically inspected for corrosion, signs of excessive heat

build-up, or other damage that signals that it is time to

repair or replace the item.

Specific procedures for electrical troubleshooting and

most common repairs is covered in separate sections of

this manual.

Not for Reproduction

1 General Information

Repair Information

1 - 10

Fasteners & Hardware

All hardware and fasteners used in this equipment must

meet factory specifications for SAE grade, size, and

torque, and must be kept securely tightened. Locking

hardware that degrades with use should be replaced

when service is performed in affected areas. Always

observe factory specifications for torque, or consult the

torque chart for torque information.

Genuine Replacement Parts

Only factory authorized replacement parts should be

used when making repairs or performing routine maintenance. The use of parts that do not meet stringent factory specifications can cause poor performance, premature

failures, and lead to potential safety hazards. In addition,

the use of non-factory authorized replacement parts will

void your warranty.

Hydraulic Parts

Hydraulic parts are adversely affected by dirt and contamination, and care must be exercised when performing

service on these parts to prevent foreign material from

entering. Specific service information appears elsewhere in this manual, and all precautions and procedures must be followed when repairing or servicing these

parts.

Paint

The paint on outdoor power equipment provides for an

attractive appearance, as well as a barrier to corrosion

caused by exposure to moisture in the environment.

Scratches, abrasions, and other damage to painted surfaces should be repaired promptly to prevent the formation of rust and premature part failure. Factory supplied

paints are available that provide both an accurate color

match and superior corrosion resistance.

Required Tools & Equipment

All repairs in this manual can be accomplished with standard mechanic’s hand tools. The use of appropriate

power tools such as impact wrenches and power drivers

may aid in part removal and replacement, but care must

be exercised to avoid causing damage to components

from excessive tightening. Transmission service, steering service, tire and wheel service, and service to components located under the frame also requires the use of

a jack with suitable capacity, and jack stands to support

the unit being worked on.

Systems Checks

In addition to performing individual component service,

components affected by related parts changes should

also receive attention at the time service is performed.

Examples of this include part replacements that are part

of a safety device, electrical components, transmission

components, and pulleys that are part of the same power

delivery system. Giving attention to related parts will

help ensure that the parts most likely to be affected by

the wear of similar or nearby parts, or parts subjected to

the same amount of stress or wear, are given appropriate attention before a failure can occur.

Not for Reproduction

1 General Information

Torque Specifications

1 - 11

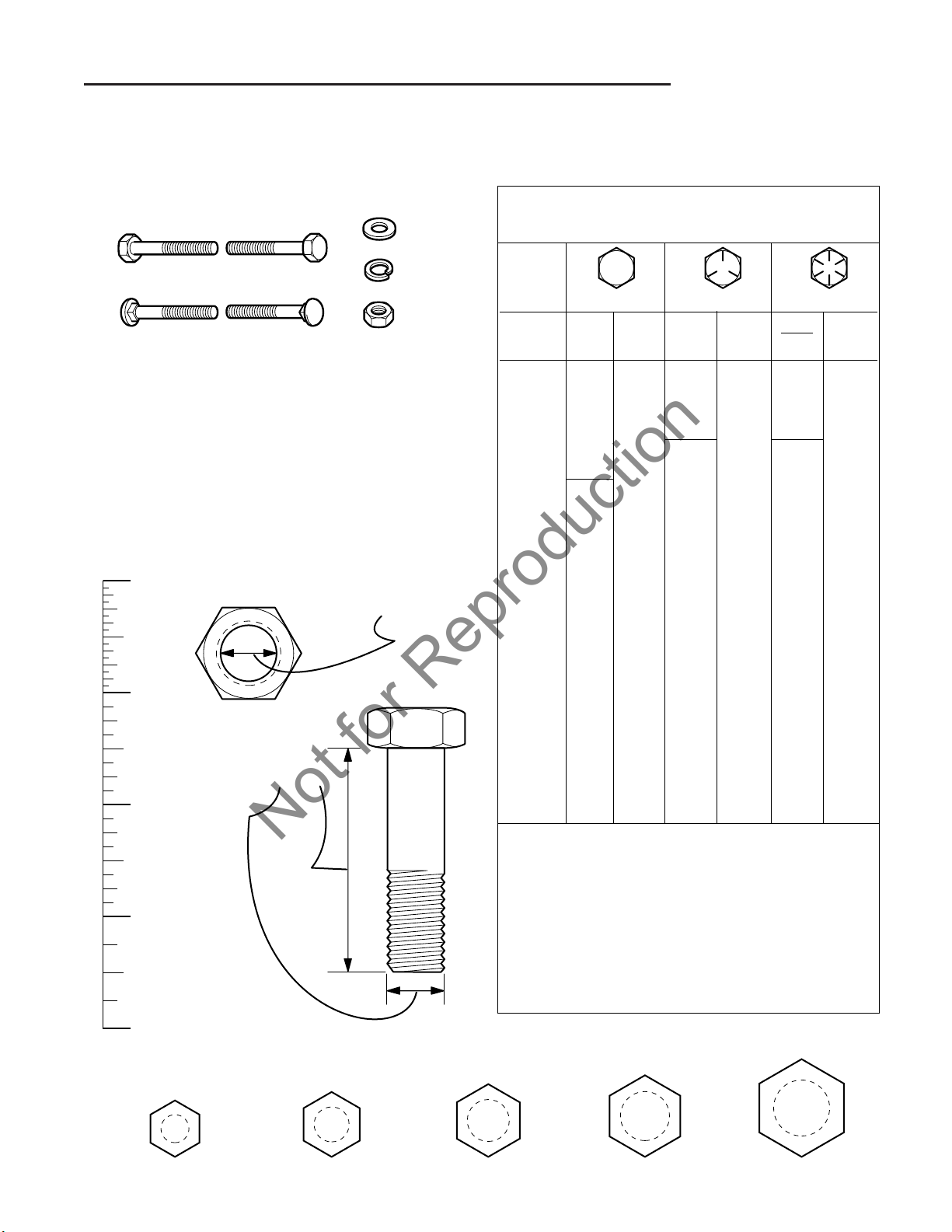

Torque Specification Chart

FOR STANDARD MACHINE HARDWARE (Tolerance ± 20%)

Hardware

Grade

SAE Grade 2 SAE Grade 5 SAE Grade 8

Size Of in/lbs in/lbs in/lbs

Hardware ft/lbs Nm. ft/lbs Nm. ft/lbs Nm.

8-32 19 2.1 30 3.4 41 4.6

8-36 20 2.3 31 3.5 43 4.9

10-24 27 3.1 43 4.9 60 6.8

10-32 31 3.5 49 5.5 68 7.7

1/4-20 66 7.6 8 10.9 12 16.3

1/4-28 76 8.6 10 13.6 14 19.0

5/16-18 11 15.0 17 23.1 25 34.0

5/16-24 12 16.3 19 25.8 27 34.0

3/8-16 20 27.2 30 40.8 45 61.2

3/8-24 23 31.3 35 47.6 50 68.0

7/16-14 30 40.8 50 68.0 70 95.2

7/16-20 35 47.6 55 74.8 80 108.8

1/2-13 50 68.0 75 102.0 110 149.6

1/2-20 55 74.8 90 122.4 120 163.2

9/16-12 65 88.4 110 149.6 150 204.0

9/16-18 75 102.0 120 163.2 170 231.2

5/8-11 90 122.4 150 204.0 220 299.2

5/8-18 100 136 180 244.8 240 326.4

3/4-10 160 217.6 260 353.6 386 525.0

3/4-16 180 244.8 300 408.0 420 571.2

7/8-9 140 190.4 400 544.0 600 816.0

7/8-14 155 210.8 440 598.4 660 897.6

1-8 220 299.2 580 788.8 900 1,244.0

1-12 240 326.4 640 870.4 1,000 1,360.0

NOTES

1. These torque values are to be used for all hardware

excluding: locknuts, self-tapping screws, thread forming

screws, sheet metal screws and socket head setscrews.

2. Recommended seating torque values for locknuts:

a. for prevailing torque locknuts - use 65% of grade 5

torques.

b. for flange whizlock nuts and screws - use 135% of

grade 5 torques.

3. Unless otherwise noted on assembly drawings, all torque

values must meet this specification.

Hardware Identification & Torque Specifications

Common Hardware Types

3/8

5/16

1/4

1/2

DIA.

7/16

DIA.

Wrench & Fastener Size Guide

Standard Hardware Sizing

When a washer or nut is identified as 1/2”, this is the

Nominal size, meaning the inside diameter is 1/2 inch; if a

second number is present it represent the threads per inch

When bolt or capscrew is identified as 1/2 - 16 x 2”, this

means the Nominal size, or body diameter is 1/2 inch; the

second number represents the threads per inch (16 in this

example, and the final number is the body length of the

bolt or screw (in this example 2 inches long).

The guides and ruler furnished below are designed to

help you select the appropriate hardware and tools.

Not for Reproduction

Hex Head Capscrew

Washer

Carriage Bolt

1/4 3/4

1/4 3/4

0

Nut, 1/2”

1/2

1

1/2

Screw, 1/2 x 2

2

1/4 3/4

1/2

3

1/4 3/4

1/2

4

Body

Diameter

Body

Length

Lockwasher

Hex Nut

Inside

Diameter

No

Marks

1 General Information

Specifications

1 - 12

NOTE: Specifications are correct at time of printing and are subject to change without notice.

ENGINE

14 HP & 16 HP Briggs & Stratton Vanguard

Make Briggs & Stratton

Model Vanguard™ V-Twin

Horsepower 16 HP @ 3600 rpm

Cylinder 2

Bore 2.68 in (68 mm)

Stroke 2.60 in (66 mm)

Displacement 29.3 Cu. in (480 cc)

Construction Overhead Valve, Cast-Iron Sleeves,

Aluminum Crankcase

Electrical System 12 Volt, 16 amp Alternator Regulated Battery

Capacity 340 Cold Cranking amps, 41 Min. Reserve

Industrial Rated Starter Motor

Ignition Magnetron Electronic Ignition

Air Cleaner Ducted Paper Cartridge and Foam

Pre-cleaner

Lubrication Full Pressure Lube w/ Oil Filter

Oil Capacity 56 Oz. w/Filter (1.7 L)

Muffler Quiet Compact, Low Back Pressure

16 HP Briggs & Stratton V-Twin

Make Briggs & Stratton

Model Intek™ V-Twin

Horsepower 16 HP @ 3600 rpm

Cylinder 2

Bore 2.97 in (76 mm)

Stroke 2.89 in (73 mm)

Displacement 40.0 Cu. in (656 cc)

Construction Overhead Valve, Cast-Iron Sleeves,

Aluminum Crankcase

Electrical System 12 Volt, 9 amp Alternator Regulated Battery

Capacity 340 Cold Cranking amps, 41 Min. Reserve

Ignition High Energy Electronic Ignition

Air Cleaner Ducted Paper Cartridge and Foam

Pre-cleaner

Lubrication Full Pressure Lube w/ Oil Filter

Oil Capacity 4 Pints w/Filter (1.9 L)

Muffler Quiet Compact, Low Back Pressure

18 HP Briggs & Stratton Vanguard

Make Briggs & Stratton

Model Vanguard™ V-Twin

Horsepower 18 HP @ 3600 rpm

Cylinder 2

Bore 3.03 in (77 mm)

Stroke 2.64 in (67 mm)

Displacement 38 Cu. in (624 cc)

Construction Overhead Valve, Cast-Iron Sleeves,

Aluminum Crankcase

Electrical System 12 Volt, 16 amp Alternator Regulated Battery

Capacity 340 Cold Cranking amps, 41 Min. Reserve

Industrial Rated Starter Motor

Ignition Magnetron Electronic Ignition

Air Cleaner Ducted Paper Cartridge and Foam

Pre-cleaner

Lubrication Full Pressure Lube w/ Oil Filter

Oil Capacity 2 Quarts w/Filter (1.9 L)

Muffler Quiet Compact, Low Back Pressure

16 HP Kohler

Make Kohler

Model Command™ CV16S

Horsepower 16 HP @ 3600 rpm

Cylinder 1

Bore 3.55 in (90 mm)

Stroke 2.64 in (67 mm)

Displacement 26.0 Cu. in (426 cc)

Construction Overhead Valve, Cast-Iron Sleeve,

Aluminum Crankcase

Electrical System 12 Volt, 15 amp Alternator Regulated Battery

12 Volt, 340 Cold Cranking amps,

41 Min. Reserve Capacity

Ignition High Energy Electronic Ignition

Air Cleaner Ducted Paper Cartridge and Foam

Pre-cleaner

Lubrication Full Pressure Lube w/ Oil Filter

Oil Capacity 2 Quarts w/Filter (1.9 L)

Muffler Quiet Compact, Low Back Pressure

TRANSMISSION:

Type Tuff Torq K61

Hydrostatic

Pump Variable Displacement Axial Piston

Motor Fixed Displacement Reversible Axial Piston

Control Single Lever Foot Pedal, Free-Wheeling

Lever for Manual Tractor Movement

Hydraulic Fluid 10w 30 Premium Engine Oil

External Oil Reservoir

Speeds Forward: 0 - 5.6 MPH (0 - 9.0 km/h)

@ 3400 rpm Reverse: 0 - 3.2 MPH (0 - 4.8 km/h)

Differential Bevel Gear with Controlled Traction

Axle Shaft 1 in

Continuous Torque 188 ft. lbs.

Output

Drawbar Rating 251 lbs.

Maximum Weight 629 lbs.

on Axle

CHASSIS:

Frame Heavy Steel Channel - 10-12 Gauge

Power Take-Off Point: Front

Engine Mounting: Above Front Axle

Pivot Point Location: Front Axle

Rear Wheels Tire Size: 20 x 10.00-8 Turf Type

Pneumatic Inflation Pressure: 6-8 psi

(41-55 kPa)

Front Axle 1-3/4 in x 3 in 12 Ga. Fabricated Tube

Front Wheels Tire Size: 15 x 6.00-6

Pneumatic Inflation Pressure: 12-15 psi

(82-103 kPa)

Accessibility Hood Tips Forward

Seat Type: Bucket, High Back w/Quick Adjust,

Spring Suspension

Adjustable to Suit Different Size Operators

Turning Radius Inside Rear Tire: 16 in (40.6 cm)

Fuel Tank Material: Non-Corrosive Polyethylene

Fuel Tank Gauge Built Into Filler Cap

Capacity: 4 Gallons (15.1 L)

Not for Reproduction

1 - 13

1 General Information

Specifications

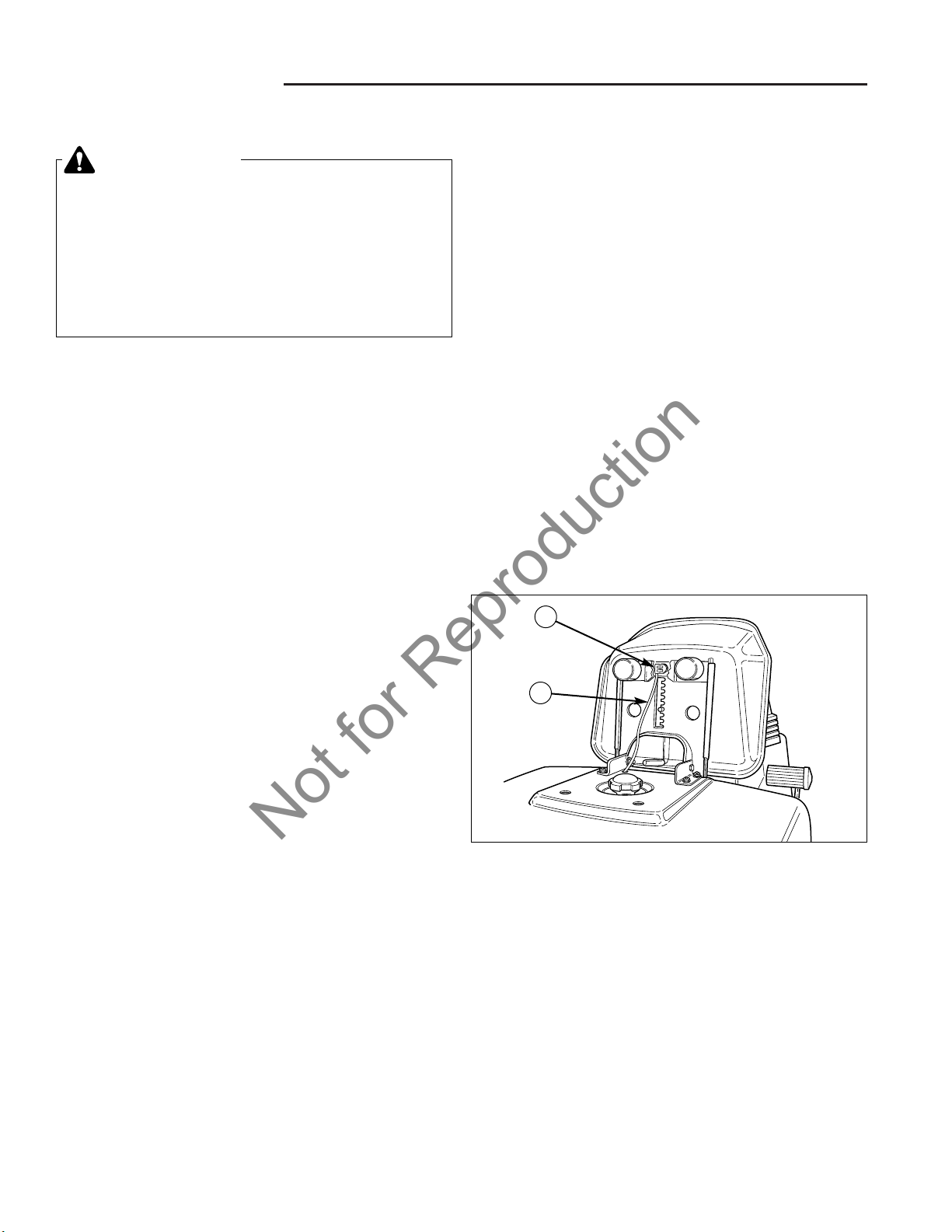

CONTROLS:

Steering 15" (38 cm) Steering Wheel

System: Gear and Sector, 1.25 turns Lock to

Lock

Clutch/ Location: Right Front

Brake Pedal Combination Clutch/Brake/Parking Brake

Pedal

Location Mower Lift Lever: Right Side

PTO Clutch: Electric, Dash Mounted

Hydrostatic Control-Single Lever Foot Pedal

Ignition Key Switch: On Lower Dash Panel

Throttle Lever On Dash Panel and Choke

Knob On Lower Dash Panel

Light Switch: On Dash Panel

Separate Indicator Lights for Safety

Interlock Switch: Operator Present,

PTO Disengaged,

Low Oil Pressure Warning Light, Hourmeter

DIMENSIONS:

Overall Length 70.25 in (178 cm)

Overall Width 35 in (88.9 cm)

Height To Top of Steering Wheel: 40 in (101.6 cm)

To Top of Engine Cover: 34 in (86.7 cm)

Wheel Base 50.75 in (129 cm)

Weight (apx..) Net: 424 lbs. (192 kg) w/o mower

536 lbs. (243 kg) w/mower

Shipping: 575 lbs. (261 kg) w/o mower

687 lbs. (312 kg) w/mower

Tractor Height

w/Snowcab 71.5 in (181 cm)

Tractor Length

w/Snowthrower est. 98 in (249 cm)

Tractor Length

w/Dozer Blade est. 94 in (239 cm)

50” MOWER: 12 GA.

Effective Cutting

Width 50 in Mower - 50 in (127 cm)

Overall Width

with Deflector 50 in Mower - 62 in (157.5 cm)

Weight 50 in Mower - 135 lbs. (61.4 kg)

Variable Cutting Ht. 1.0 - 3.6 in (3.2 to 8.0 cm)

Blade Arrangement Three Staggered Blades

Mower Drive V-Belt From Tractor Engine PTO Electric

Clutch

Spindle Bearings Lubricated and Sealed Ball Bearings

Lube Fitting Provided

44” MOWER: 12 GA.

Effective Cutting

Width 44 in Mower - 44 in (111.8 cm)

Overall Width

with Deflector 44 in Mower - 56 in (142.2 cm)

with Turbo 58" (147 cm)

Weight 44 in Mower - 112 lbs. (51 kg)

Variable Cutting Ht. 1.0 - 3.6 in (3.2 to 8.0 cm)

Blade Arrangement Three Staggered Blades

Mower Drive V-Belt From Tractor Engine PTO Electric

Clutch

Spindle Bearings Lubricated and Sealed Ball Bearings

Lube Fitting Provided

38” MOWER: 12 GA.

Effective Cutting

Width 38 in Mower - 38 in (96.5 cm)

Overall Width

with Deflector 38 in Mower - 49.5 in (125.7 cm)

with Turbo 38 in Mower - 51.5 in (131 cm)

Weight 38 in Mower - 100 lbs. (45 kg)

Variable Cutting Ht. 1.0 - 3.6 in (2.5 to 9.1 cm)

Blade Arrangement Two Blades

Mower Drive V-Belt From Tractor Engine PTO Electric

Clutch

Spindle Bearings Lubricated and Sealed Ball Bearings

Lube Fitting Provided

Not for Reproduction

1 General Information

Notes

1 - 14

Not for Reproduction

2 - 1

2 Troubleshooting

Table of Contents

SECTION CONTENTS

Troubleshooting

Troubleshooting the Tractor ......................................................... 2-2

Troubleshooting the Mower.......................................................... 2-3

SECTION 2. TROUBLESHOOTING

Not for Reproduction

2 Troubleshooting

Tractor Troubleshooting

2- 2

TROUBLESHOOTING

While normal care and regular maintenance will extend

the life of your equipment, prolonged or constant use

may eventually require that service be performed to

allow it to continue operating properly.

The troubleshooting guide below lists the most common

problems, their causes and remedies.

Troubleshooting the Tractor

PROBLEM CAUSE REMEDY

Engine will not turnover or start. 1. Brake pedal not depressed. Fully depress brake pedal.

2. PTO (electric clutch) switch Place in OFF position.

in ON position.

3. Out of fuel. If engine is hot, allow it to cool, then refill

the fuel tank.

4. Engine flooded. Push choke knob in (twin cylinder models)

or move throttle control out of CHOKE

position (single cylinder models).

5. Circuit breaker tripped. Wait one minute for automatic reset.

Replace if defective.

6. Battery terminals require See Battery Maintenance Section.

cleaning.

7. Battery discharged or dead. Recharge or replace.

8. Wiring loose or broken. Visually check wiring & replace broken or

frayed wires. Tighten loose connections.

9. Solenoid or starter motor faulty. See Electrical Troubleshooting Section.

10. Safety interlock switch or See Electrical Troubleshooting Section.

module faulty.

11. Spark plug(s) faulty, fouled Clean and gap or replace.

or incorrectly gapped. See engine manual.

12. Water in fuel. Drain fuel & refill with fresh fuel.

13. Gas is old or stale. Drain fuel & replace with fresh fuel.

Engine starts hard or runs poorly. 1. Fuel mixture too rich. Clean air filter. Check choke adjustment

(engine speed control).

2. Spark plug(s) faulty, fouled, or Clean and gap or replace.

incorrectly gapped. See engine manual.

Engine knocks. 1. Low oil level. Check/add oil as required.

2. Using wrong grade oil. See engine manual.

Excessive oil consumption. 1. Engine running too hot. Clean engine fins, blower screen and

air cleaner.

2. Using wrong weight oil. See engine manual.

3. Too much oil in crankcase. Drain excess oil.

Engine exhaust is black. 1. Dirty air filter. Replace air filter. See engine manual.

2. Choke closed. Open choke.

Engine runs, but tractor will 1. Ground speed control pedals Depress pedals.

not drive. not depressed.

2. Transmission release lever Move into drive position.

in “push” position.

3. Drive belt is broken. See Drive Belt Replacement.

4. Drive belt slips. See cause and remedy below.

5. Brake is not fully released. See Brake Adjustment.

WARNING

To avoid serious injury, perform maintenance on

the tractor or mower only when the engine is

stopped and the parking brake engaged.

Always remove the ignition key, disconnect the

spark plug wire and fasten it away from the plug

before beginning the maintenance, to prevent

accidental starting of the engine.

Not for Reproduction

2 - 3

2 Troubleshooting

Mower Troubleshooting

Tractor Troubleshooting Cont.

Tractor drive belt slips. 1. Brake is out of adjustment. See Adjustments Section.

2. Pulleys or belt greasy or oily. Clean as required.

3. Belt stretched or worn. Replace with new belt.

4. Idler pulley pivot bracket Remove idler pulley bracket, clean and lubricate.

“frozen” in declutched position.

Brake will not hold. 1. Brake is incorrectly adjusted. See Brake Adjustment.

2. Internal brake worn. See Transmission Teardown.

Tractor steers hard or 1. Steering linkage is loose. Check and tighten any loose connections.

handles poorly. See Steering Gear Adjustment.

2. Improper tire inflation. Check and correct.

3. Front wheel spindle Grease spindles. See Lubricating the

bearings dry. Tractor.

Drive belt does not stop when 1. Belt stops or belt tension See Adjustments Section.

clutch/brake pedal depressed. out of adjustment.

Troubleshooting the Mower

PROBLEM CAUSE REMEDY

Mower will not raise. 1. Lift link not properly attached Attach or repair.

or damaged.

Mower cut is uneven. 1. Mower not leveled properly. See Mower Adjustment.

2. Tractor tires not inflated See Maintenance Section.

equally or properly.

Mower cut is rough looking. 1. Engine speed too slow. Set to full throttle.

2. Ground speed too fast. Slow down.

3. Blades are dull. Sharpen or replace blades.

See Mower Blade Service.

4. Mower drive belt slipping Clean or replace belt as necessary.

because it is oily or worn.

5. Check PTO (Electric Clutch) See Adjustments Section.

Adjustment.

6. Blades not properly fastened See Servicing the Mower Blades.

to arbors.

Engine stalls easily with 1. Engine speed too slow. Set to full throttle.

mower engaged. 2. Ground speed too fast. Slow down.

3. Carburetor improperly adjusted. See Engine Manual.

4. Cutting height set too low. Cut tall grass at maximum cutting

height during first pass.

5. Discharge chute jamming Cut grass with discharge pointing toward

with cut grass. previously cut area.

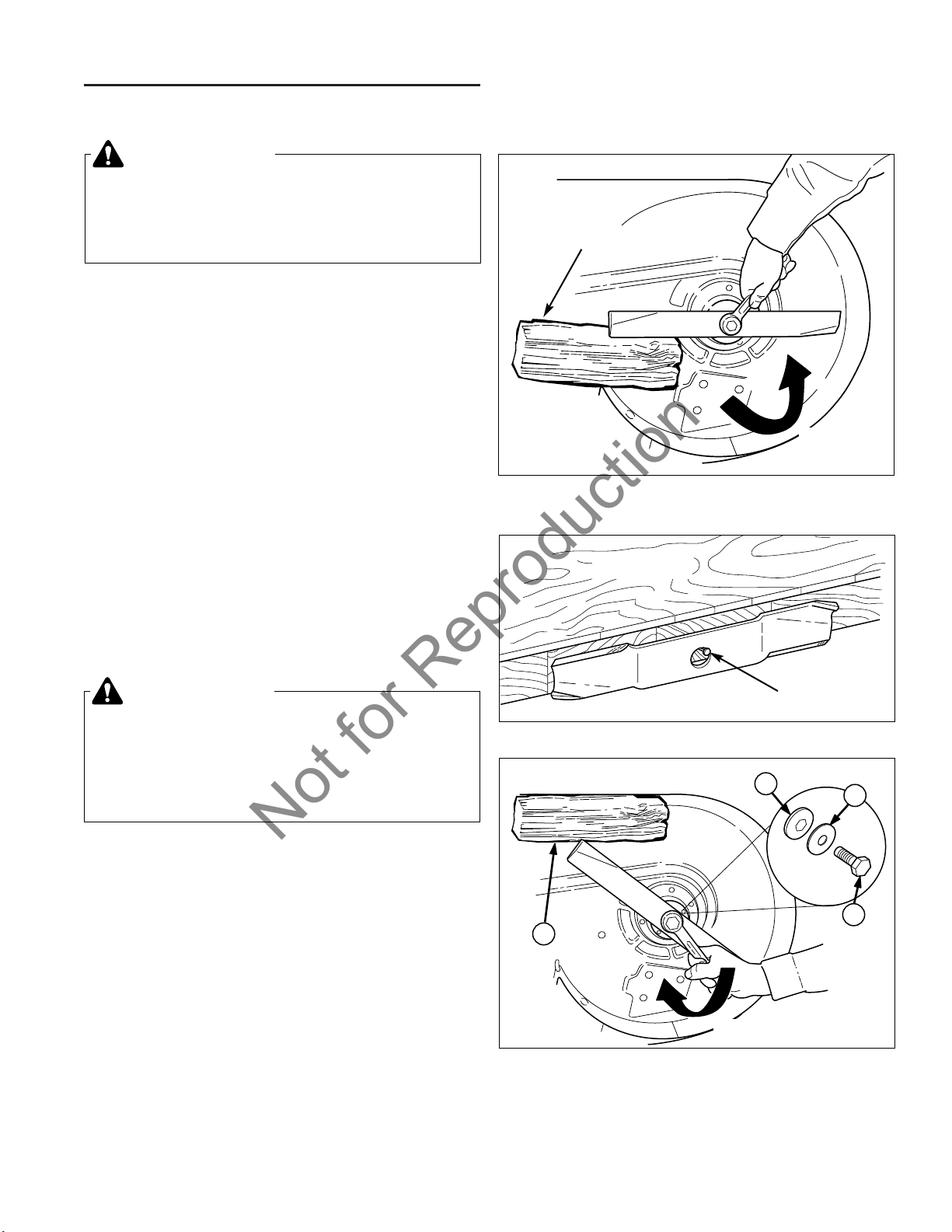

Excessive mower vibration. 1. Blade mounting screws Tighten to 45-55 ft.lbs. (61-75 N.m.).

are loose.

2. Mower blades, arbors, Check and replace as necessary.

or pulleys are bent.

3. Mower blades are out Remove, sharpen, and balance blades.

of balance. See Servicing the Mower Blades.

4. Belt installed incorrectly. Reinstall Correctly.

Excessive belt wear or breakage. 1. Belt tension too tight. Adjust belt tension.

2. Bent or rough pulleys. Repair or replace.

3. Using incorrect belt. Replace with correct belt.

Mower drive belt slips 1. Idler pulley spring broken or not Repair or replace as needed.

or fails to drive. properly attached.

2. Belt stops out of adjustment. Check belt stops.

3. Mower drive belt broken. Replace drive belt.

Not for Reproduction

2 Troubleshooting

Notes

2- 4

Not for Reproduction

3 - 1

3 Maintenance

Table of Contents

SECTION CONTENTS

Storage

Temporary.....................................................................................3-2

Long Term.....................................................................................3-2

Starting After Long Term Storage .................................................3-2

Maintenance Schedule..........................................3-3

Checking Tire Pressures.......................................3-3

Check / Change Transmission Oil........................3-4

Accessing the Engine ...........................................3-5

Fuel Filter Replacement ........................................3-5

Oil & Filter Change ................................................3-5

Check / Change Air FIlter......................................3-5

Inspect & Replace Spark Plugs............................3-5

Lubrication .............................................................3-6

Lubricate Rear Axles.............................................3-7

Battery Maintenance

Check Battery Fluid.......................................................................3-8

Clean Battery and Cables .............................................................3-8

Servicing the Mower Blades.................................3-9

Perform Safety Checks

Functional Tests..........................................................................3-10

Dash Safety Lights Test ..............................................................3-10

Mower Blade Stopping Check.....................................................3-10

Seat Switch Connection ..............................................................3-10

Safety Interlock System Check ...................................................3-11

Blade Brake Check .....................................................................3-11

SECTION 3. MAINTENANCE

Not for Reproduction

3 Maintenance

Storage

3 - 2

WARNING

Never store the unit, with gasoline in engine or

fuel tank, in a heated shelter or in enclosed,

poorly ventilated enclosures. Gasoline fumes may

reach an open flame, spark or pilot light (such as

a furnace, water heater, clothes dryer, etc.) and

cause an explosion.

Handle gasoline carefully. It is highly flammable

and careless use could result in serious fire

damage to your person or property.

Drain fuel into an approved container outdoors

away from open flame or sparks.

STORAGE

Temporary Storage (30 Days Or Less)

Remember, the fuel tank will still contain some gasoline, so

never store the unit indoors or in any other area where fuel

vapor could travel to any ignition source. Fuel vapor is also

toxic if inhaled, so never store the unit in any structure used

for human or animal habitation.

Here is a checklist of things to do when storing your unit

temporarily or in between uses:

• Keep the unit in an area away from where children may

come into contact with it. If there’s any chance of unauthorized use, disconnect the spark plug wires.

• If the unit can’t be stored on a reasonably level surface,

chock the wheels.

• Clean all grass and dirt from the mower.

NOTE: If storing your tractor between winter snow removal

jobs in a cold area, we suggest that you fill the fuel tank at

the completion of each job to prevent water condensation in

the fuel tank. Wait for engine to cool before filling tank.

Long Term Storage (Longer Than 30 Days)

Before you store your unit for the off-season, read the

Maintenance and Storage instructions in the Safety Rules

section, then perform the following steps:

1. Drain crankcase oil and refill with a grade of oil that will

be required when unit is used again.

2. Prepare the mower deck for storage as follows:

a. Remove mower deck from the unit.

b. Clean underside of mower deck.

c. Coat all bare metal surfaces with paint or light coat

of oil to prevent rusting.

3. Clean external surfaces and engine.

4. Prepare engine for storage. See engine owner’s

manual.

5. Clean any dirt or grass from cylinder head cooling fins,

engine housing and air cleaner element.

6. Cover air cleaner and exhaust outlet tightly with plastic

or other waterproof material to keep out moisture, dirt

and insects.

7. Completely grease and oil unit as outlined in the Normal

Care section.

8. Clean up unit and apply paint or rust preventative to any

areas where paint is chipped or damaged.

9. Be sure the battery is filled to the proper level with water

and is fully charged. Battery life will be increased if it is

removed, put in a cool, dry place and fully charged

about once a month. If battery is left in unit, disconnect

the negative cable.

10. Drain fuel system completely or add a gasoline stabilizer

to the fuel system. If you have chosen to use a fuel stabilizer and have not drained the fuel system, follow all

safety instructions and storage precautions in this manual to prevent the possibility of fire from the ignition of

gasoline fumes. Remember, gasoline fumes can travel

to distant sources of ignition and ignite, causing risk of

explosion and fire.

NOTE: Gasoline, if permitted to stand unused for extended

periods (30 days or more), may develop gummy deposits

which can adversely affect the engine carburetor and cause

engine malfunction. To avoid this condition, add a gasoline

stabilizer to the fuel tank and run the engine a few minutes,

or drain all fuel from the unit before placing it in storage.

STARTING AFTER

LONG TERM STORAGE

Before starting the unit after it has been stored for a long

period of time, perform the following steps.

1. Remove any blocks from under the unit.

2. Install the battery if it was removed.

3. Unplug the exhaust outlet and air cleaner.

4. Fill the fuel tank with fresh gasoline. See engine

manual for recommendations.

5. See engine owner’s manual and follow all instructions

for preparing engine after storage.

6. Check crankcase oil level and add proper oil if

necessary. If any condensation has developed during

storage, drain crankcase oil and refill.

7. Inflate tires to proper pressure. Check fluid levels.

8. Start the engine and let it run slowly. DO NOT run at

high speed immediately after starting. Be sure to run

engine only outdoors or in well ventilated area.

Not for Reproduction

3 - 3

3 Maintenance

Schedule

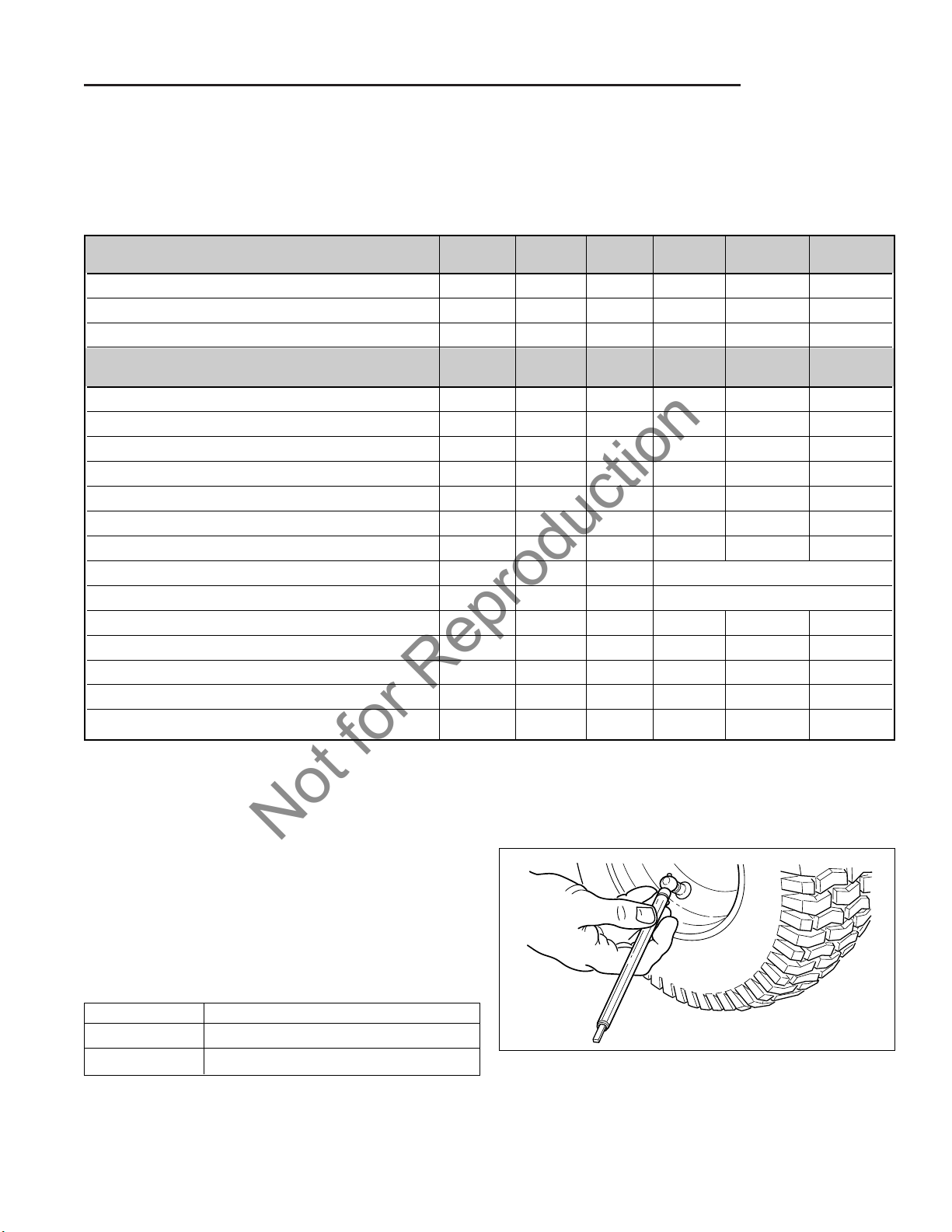

MAINTENANCE SCHEDULE & PROCEDURES

The following schedule should be followed for normal care of your tractor and mower. You will need to keep a record

of your operating time. Determining operating time is easily accomplished by multiplying the time it takes to do one

job by the number of times you’ve done the job, or you can install the optional hour meter.

* See the engine manufacturer's owner's manual.

** Change original engine oil after first 5 hours of operation.

*** More often in hot (over 85° F: 30° C) weather or dusty operating conditions.

**** Perform service after the first 50 hours of operation, then every 250 hours.

Tire Pressure

Front 12-15 psi (83-104 kPa)

Rear 6-8 psi (41-55 kPa)

Figure 1. Checking Tire Pressure

CHECK TIRE PRESSURES

Tire Pressure should be checked periodically, and maintained at the levels shown in the chart. Note that these

pressures may differ slightly from the “Max Inflation”

stamped on the side-wall of the tires. The pressures

shown provide proper traction, improve cut quality, and

extend tire life.

Before Before Every Every Every Spring

SAFETY ITEMS First Use Each Use 5 Hours 25 Hours 100 Hours & Fall

Check Safety Interlock System ●●

Check Tractor Brakes ●●

Check Mower Blade Stopping Time ●●

Before Before Every Every Every Spring

NORMAL CARE ITEMS First Use Each Use 5 Hours 25 Hours 100 Hours & Fall

Check Tractor/Mower for loose hardware ●●●

Check Engine Air Filter *, *** ●●

Check Engine Oil Level * ●● ●

Change Engine Oil & Filter *, **, *** ●●

Lubricate Tractor & Mower *** ●●

Check Tire Pressure ●● ●

Check Transmission Fluid ●●

Change Transmission Fluid **** Every 250 Hours

Check/Adjust PTO Clutch **** Every 250 Hours

Check Fuel Filter ●●

Clean Battery & Cables ●●

Clean & Sharpen Mower Blades ●●

Inspect Spark Plug(s) * ●●

Lubricate Rear Axle Shafts Yearly

Not for Reproduction

3 Maintenance

Check / Change Transmission Oil

3 - 4

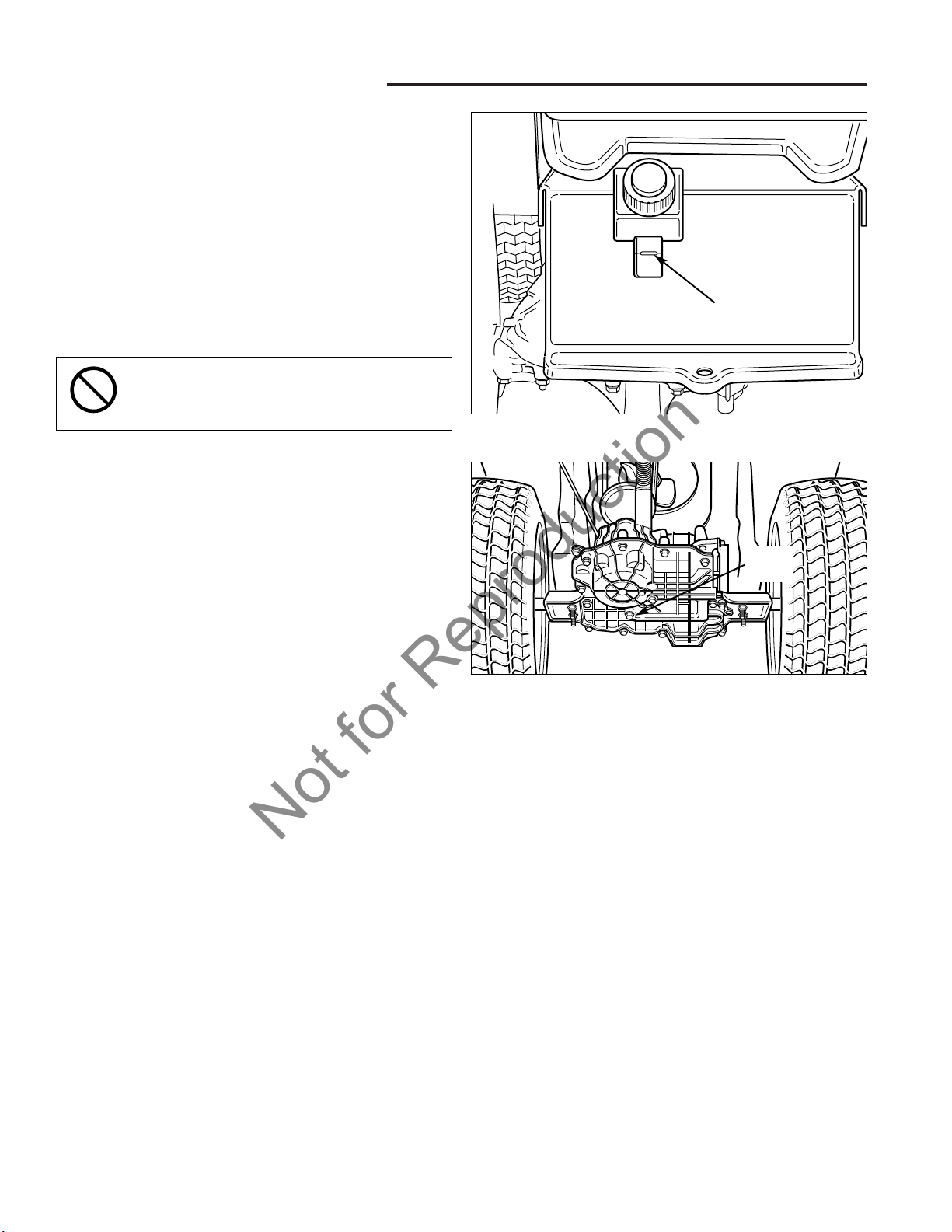

CHECK / CHANGE

TRANSMISSION OIL

The transmission oil should be checked before each use,

and changed at the intervals shown or if it has become

discolored from overheating or contamination.

Service Interval: After initial 50 Hrs, then every 250 Hrs.

Oil Capacity: Apx. 3.5 Quarts

Oil Type: SAE 10W-30 with a minimum API rating

of SG/CD.

Checking the Oil Level:

1. Locate the reservoir tank on the rear of the unit.

Observe the oil level. Oil should be up to the FULL

mark (see Figure 2). DO NOT OVERFILL. Empty

space is required for heat expansion.

2. If necessary, clean the area surrounding the reservoir

cap, remove the cap, and add oil.

Changing the Transmission Oil:

1. Drain hydrostatic system by removing drain plug (see

Figure 3). Drain oil into a suitable container.

2. Reinstall the drain plug.

3. Add oil a few ounces at a time until the reservoir is

filled to the FULL mark. DO NOT OVERFILL. Empty

space is required for heat expansion.

4. Run tractor for several minutes and recheck the

transmission oil level. If the transmission is excessively noisy or unresponsive, perform the purging

procedure found in the Service section.

FULL

Figure 2. Transmission Oil Reservoir

Full Mark

Figure 3. Transmission Drain Plugs

Do not allow dirt, water, or other debris to

enter the reservoir. Even a small amount of

dirt can irreparably damage the transmission

Drain

Plug

Not for Reproduction

3 - 5

3 Maintenance

Engine Service

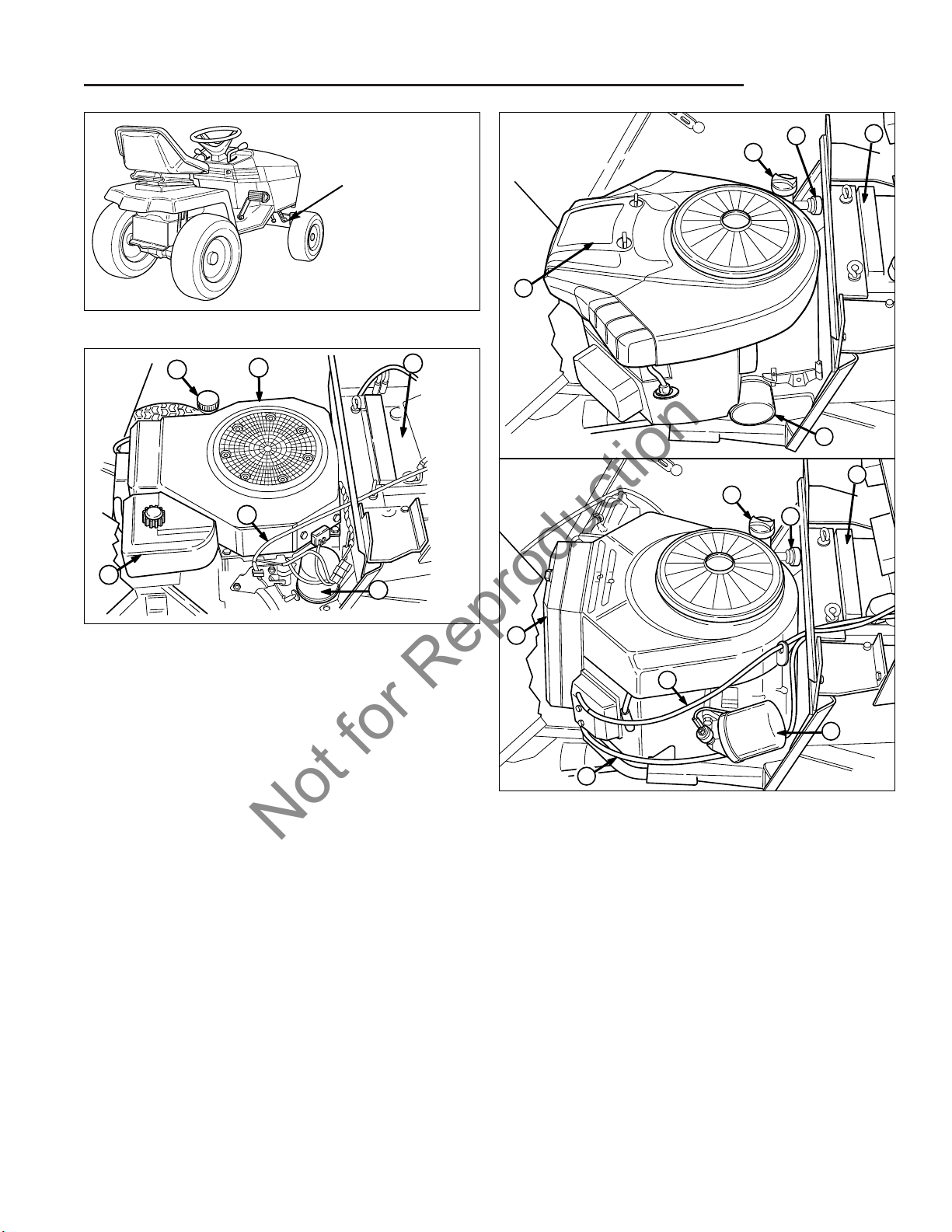

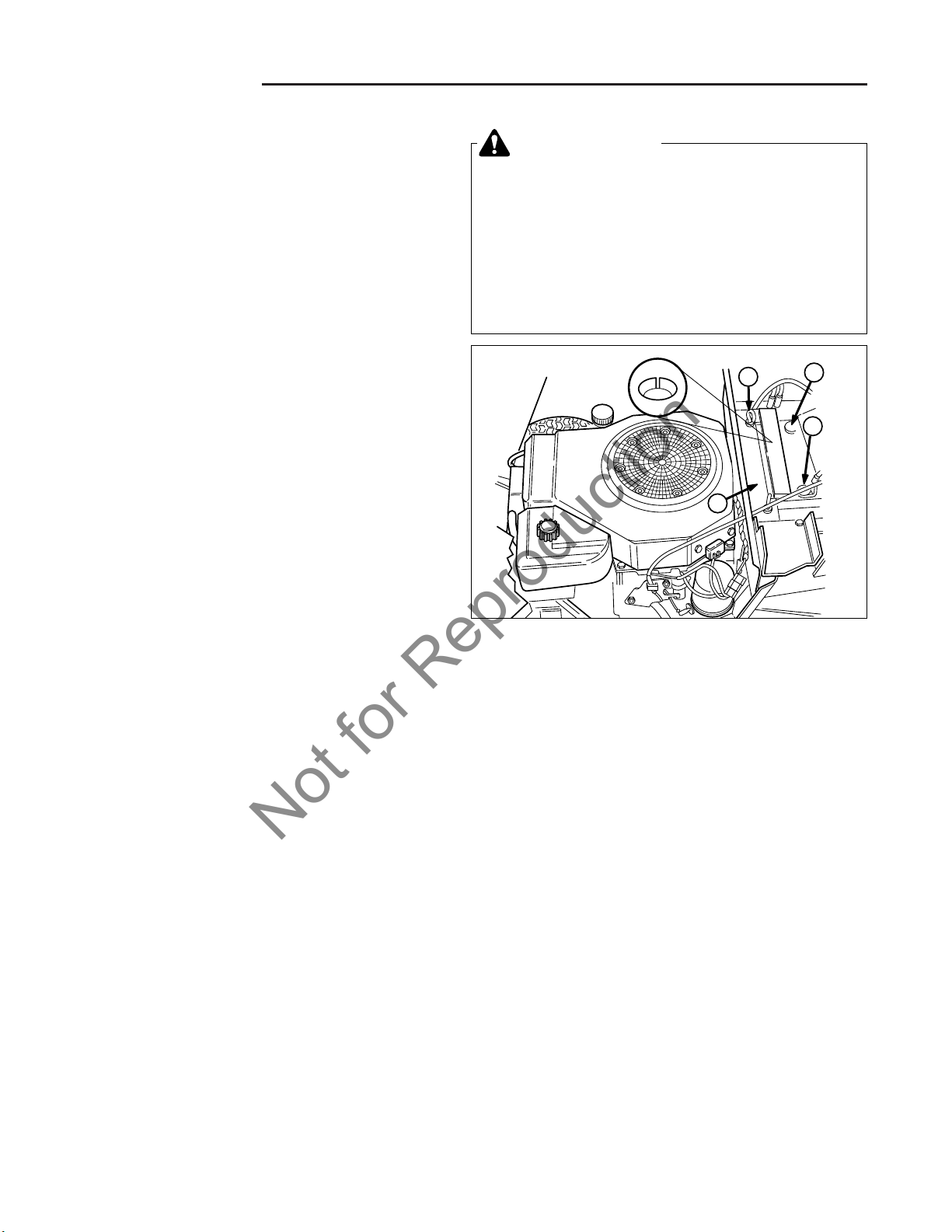

Figure 5. Engine Compartment

-Kohler Single Cylinder Engine

A. Battery D Oil Fill/Dipstick

B. Oil Filter E. Fuel Filter (Not Shown

C. Air Filter F. Throttle/Choke Cable

D

C

B

A

E

F

ACCESSING THE ENGINE

To gain access to the engine, unhook the rubber straps

(Figure 4) and tip the hood forward.

NOTE: For engine service item locations see Figure

6 for models with Briggs & Stratton engines and

Figure 5 for models with Kohler engines

FUEL FILTER REPLACEMENT

The fuel filter (E, Figures 5 & 6) is located in the fuel line

between the fuel tank and the carburetor.

If filter is dirty or clogged, replace as follows:

1. Disconnect the negative battery cable.

2. Place a container below the filter to catch spilled fuel.

3. Using a pliers, open and slide hose clamps from fuel

filter.

4. Remove hoses from filter.

5. Install new filter in proper flow direction in fuel line.

6. Secure with hose clamps.

7. Reconnect the negative battery cable when finished.

D

C

B

A

E

G

F

Figure 6. Engine Compartment

- Briggs & Stratton Twin Cylinder Engines

A. Battery E. Fuel Filter

B. Oil Filter F. Throttle Cable

C. Air Filter G. Choke Cable

D Oil Fill/Dipstick

Figure 4. Engine Access

Undo Hood

Straps (Both

Sides) and Lift

Hood to access

Engine

D

C

B

A

E

OIL & FILTER CHANGE

Refer to engine manual for specific oil and filter recommendations and oil draining procedures.

CHECK / CHANGE AIR FILTER

Refer to the engine manual for specific air filter service

procedures.

INSPECT & REPLACE SPARK PLUGS

Refer to the engine manual for specific spark plug

replacement procedures.

Not for Reproduction

3 Maintenance

Lubrication

3 - 6

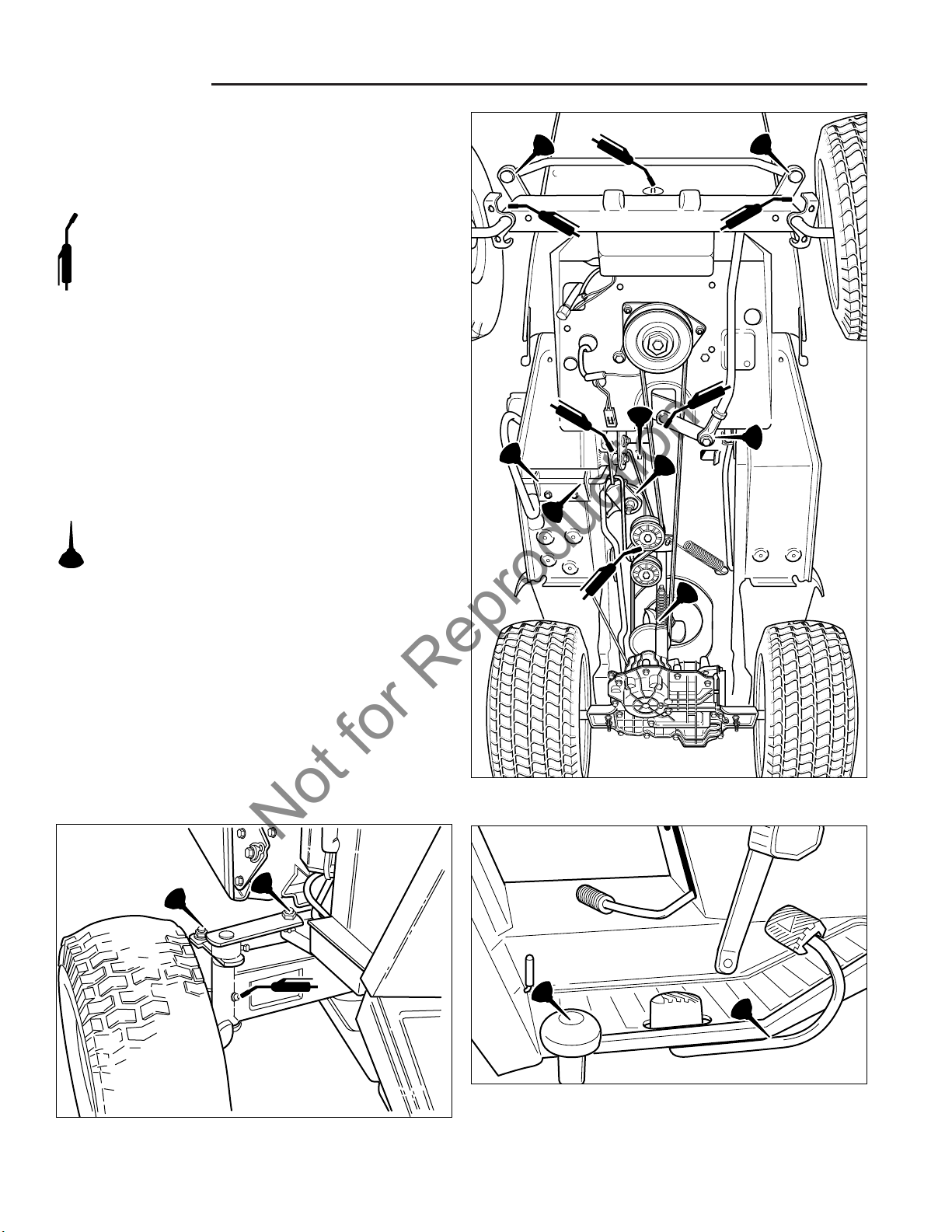

Figure 8. Lubricating the Tractor

LUBRICATION

Lubricate the unit at the locations shown in Figures 7-11

as well as the following lubrication points.

Grease:

• front axle pivot

• front axle grease fittings

• steering linkage

• foot pedal

• mower pivots

• mower arbors

• transmission idler assembly pivot

Use grease fittings when present. Disassemble parts

to apply grease to moving parts when grease fittings

are not present.

Not all greases are compatible. Simplicity Lithium

Grease is recommended, automotive-type lithium

grease may be used when this is not available.

Oil:

• hydro linkage

• seat adjustment assembly

• brake linkage

• frame pivot points

• mower deck height adjustment linkage

Generally, all moving metal parts should be oiled

where contact is made with other parts. Keep oil and

grease off belts and pulleys. Remember to wipe fittings and surfaces clean both before and after lubrication.

Figure 9. Brake Pedal Pivot Point

Figure 7. Lubricate Steering Linkage

Not for Reproduction

3 - 7

3 Maintenance

Lubricate Rear Axles

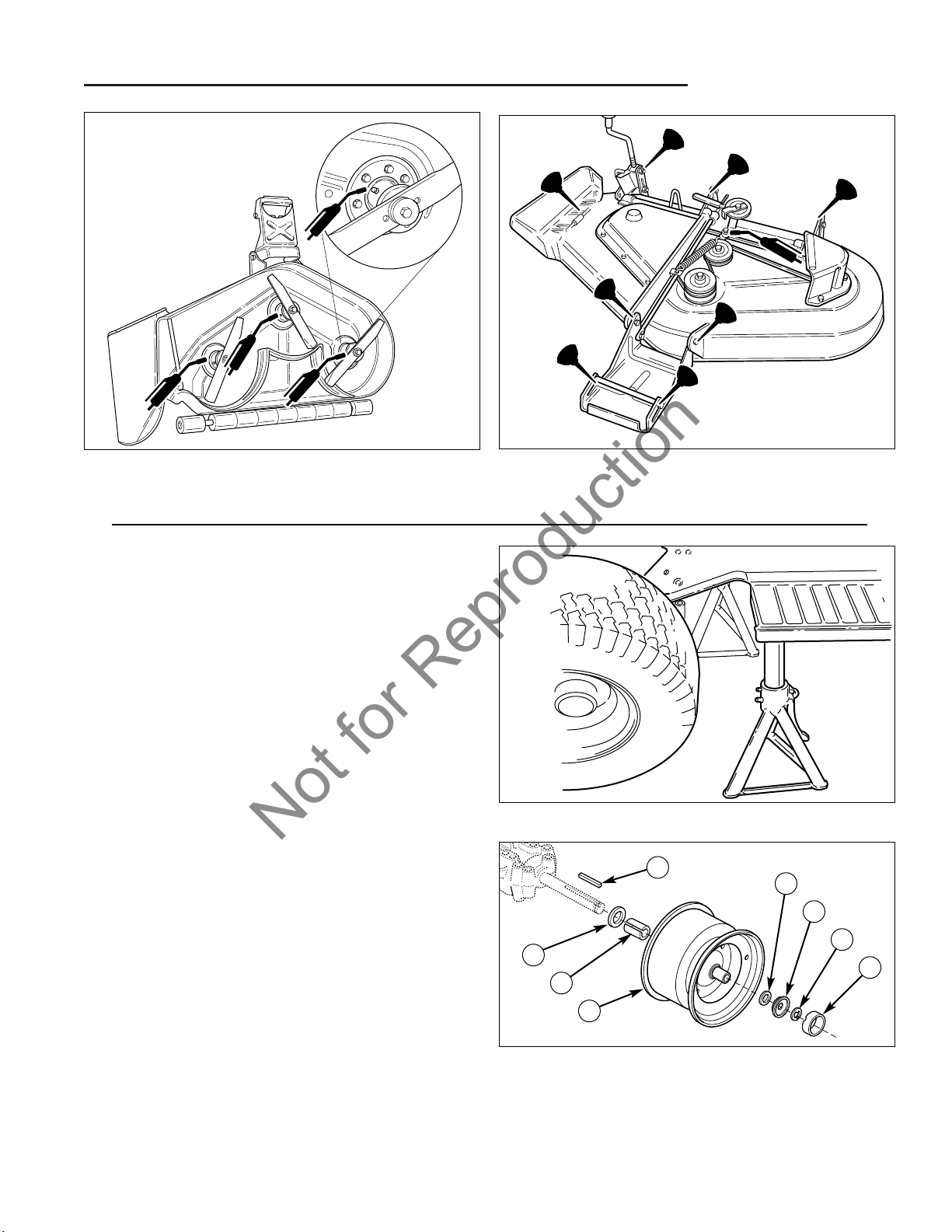

Figure 11. Mower Lubrication Points

Figure 10. Arbor Lubrication Points

LUBRICATE REAR AXLES

We recommend removing the rear wheels and lubricating the axle shafts yearly. This prevents the wheel from

seizing onto the axle shaft, making future service easier.

1. Remove the key and disconnect the spark plug

wire(s) while working on the unit.

2. Engage the parking brake and block the front wheels.

3. Using a jack or chain hoist positioned at the center of

the rear frame, carefully jack the unit up until the rear

tires are approximately 1" - 2" off the ground.

NOTE: For overall unit stability during service, do not

jack rear end higher than required for wheel removal.

4. Support the rear of the unit on jack stands positioned

under the rear frame (see Figure 12).

5. Remove the plastic hub cap (G, Figure 13).

6. Remove e-ring (F) using a screwdriver.

7. Remove the washers (D) and wheel (C).

NOTE: Your axle assembly may differ slightly from the

assembly pictured: washer (D, Figure 13) may be missing or doubled. This is adjusted on a tractor by tractor

basis during assembly to allow a small amount of axle

end-play.

8. Lubricate the axle shaft with anti-seize compound or

lithium grease.

9. See Figure 13 for assembly. Reinstall components in

reverse order of disassembly and lower the unit. Be

sure the key (H) is in place in the axle key-way.

Figure 12. Elevate the Rear End

Figure 13. Wheel and Axle Assembly

A. Washer E. Hub Cap Retainer

B. Spacer F. E-Ring

C. Wheel G. Hub Cap

D. Washer H. Key

A

B

C

D

E

F

G

H

Not for Reproduction

3 Maintenance

Battery Maintenance

3 - 8

BATTERY MAINTENANCE

Checking the Battery Fluid

Note: Does not apply to maintenance-free batteries.

1. Raise the hood to access battery.