Page 1

Parts Manual

Large Frame

Walk-Behind Snowthrowers

9.5HP Snowthrowers

Mfg. No. Description

1694589 9560E, 9.5HP Snowthrower

1694597 9560M, 9.5HP Snowthrower (CE)

10HP Snowthrowers

Mfg. No. Description

1694590 1060E, 10HP Snowthrower

1694598 1060M, 10HP Snowthrower (CE)

11HP Snowthrowers

Mfg. No. Description

1694591 1170E, 11HP Snowthrower

1694599 1170M, 11HP Snowthrower (CE)

12HP Snowthrowers

Mfg. No. Description

1694592 1280E, 12HP Snowthrower

1694600 1280M, 12HP Snowthrower (CE)

13HP Snowthrowers

Mfg. No. Description

1694593 1390E, 13HP Snowthrower

1694601 1390M, 13HP Snowthrower (CE)

Rev.

1731160

11/2005

Part No.:

TP 400-4155-01-LW-S

Page 2

Page 3

Table Of Content

s

PRODUCT COMPONENTS PAGES

Handles and Controls Group - 1060, 1170, 1280 & 1390 Models ......................................................................

Handles and Controls Group - 9560 Models .......................................................................................................

Engine and Frame Group with Power Boost .......................................................................................................

Engine and Frame Group without Power Boost ..................................................................................................

Auger and Impeller Group ....................................................................................................................................

Auger Housing and Chute Group - 38" Models ...................................................................................................

Auger Housing and Chute Group - 9560, 1060, 1170 & 1280 Models ...............................................................

Traction Drive Group ............................................................................................................................................

Wheels & Tires Group ..........................................................................................................................................

Decal Group .........................................................................................................................................................

Headlight Group ...................................................................................................................................................

12

16

20

22

26

30

34

36

38

Torque Specification Chart ..................................................................... Inside Back Cover

4

8

Page 4

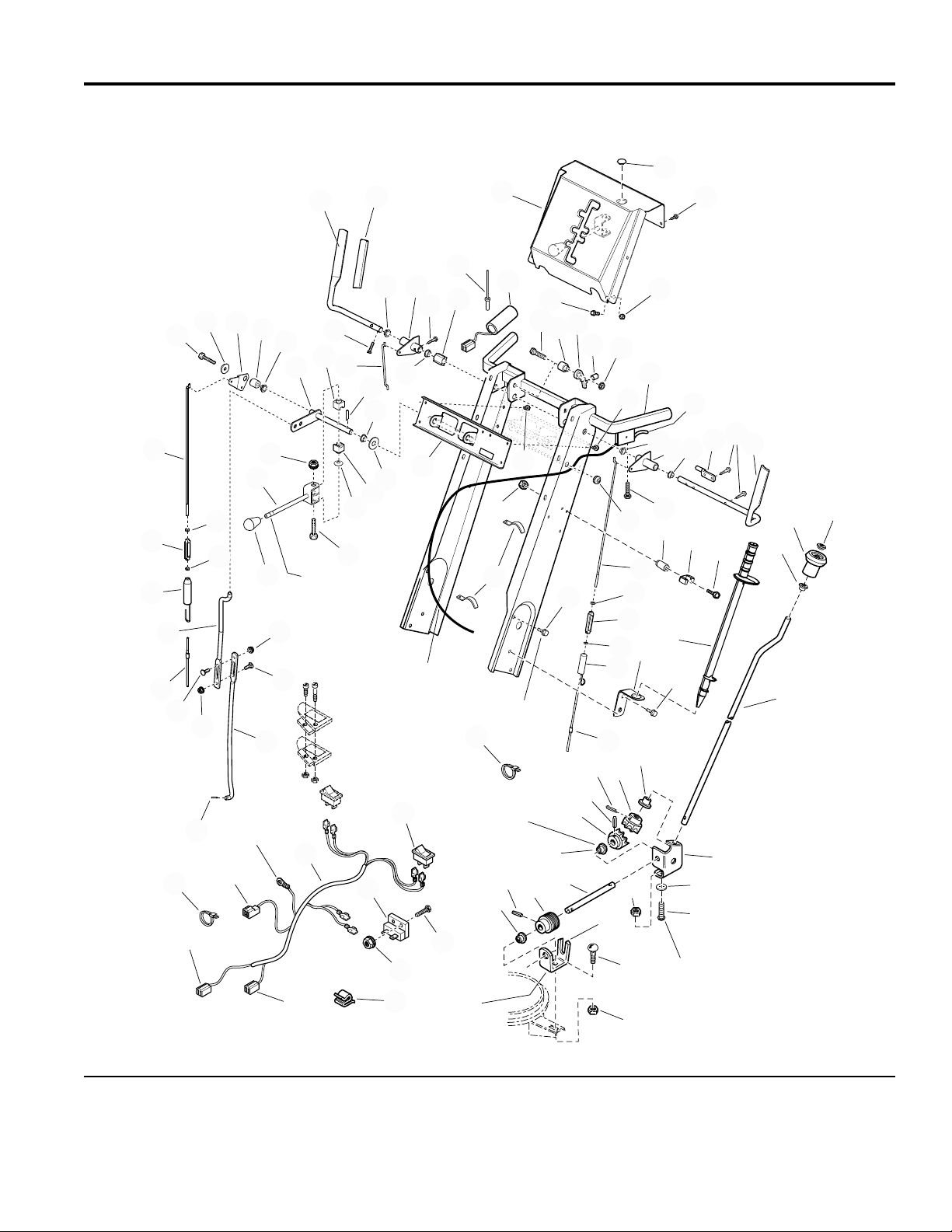

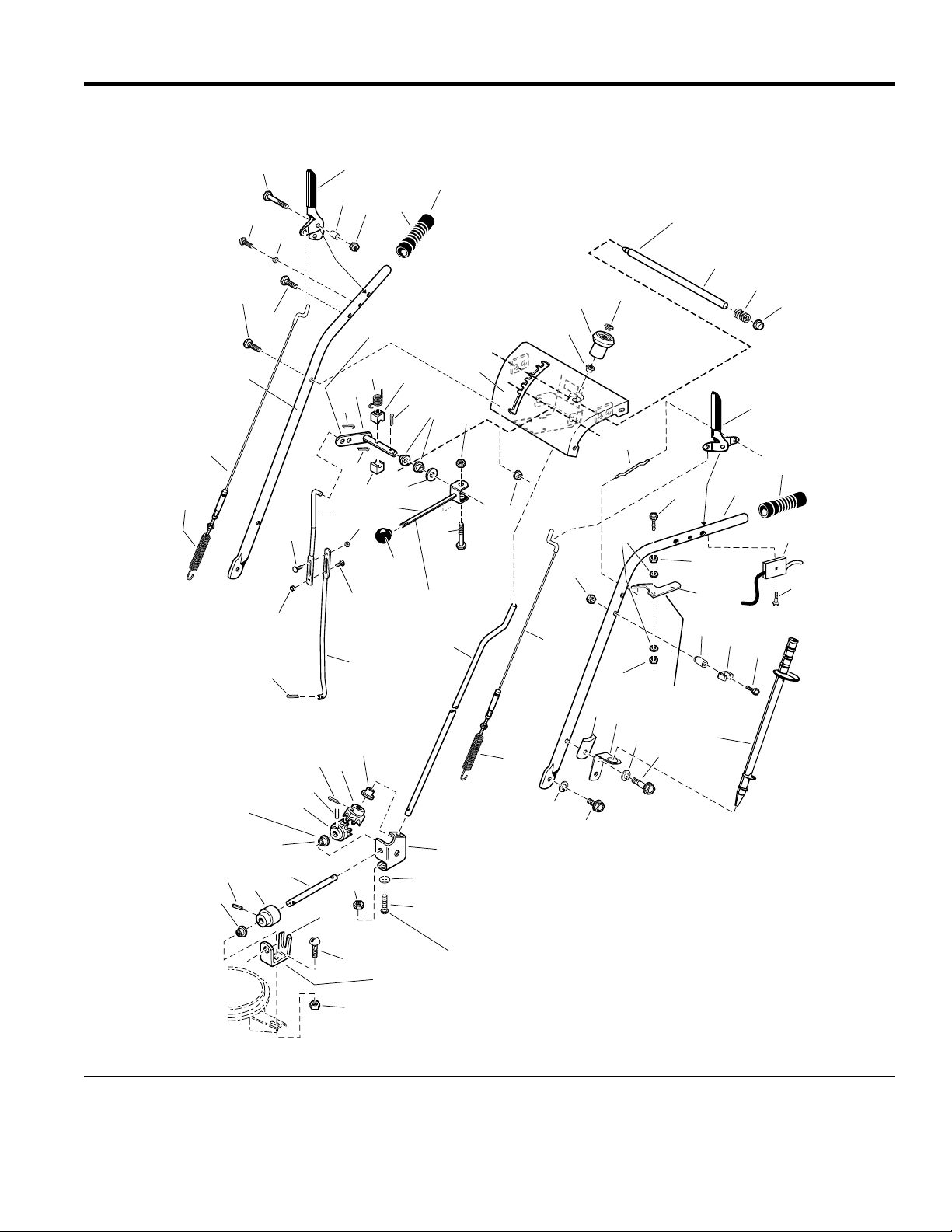

Handles and Controls Group - 1060, 1170, 1280 & 1390 Models

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

Linkage adjustment for traction and

auger drive with power boost: with

drive levers engaged, the bottom end of

lower rods (Ref. 40 & 66) should be flush

with bottom of springs (Ref. 39 & 68).

80

81

79

69

82

59

71

36

37

38

70

68

67

59

66

65

59

64

To engine

63

62

To headlight

To engine

plug

ground

1

4

74

76

Shift rod assembly

(Ref. 71) must pivot

freely on pivot blocks

(Ref. 21).

65

61

To spout

motor

2

4

5

6

3

78

4

77

4

21

75

74

73

72

Mount clutch cable

to cable support, see

Engine & Frame.

See Auger Housing and

Chute Group - 38"

56

58

59

60

10

8

7

28

2727

Torque to

19 - 29 ft-lbs.

84

Mount bushin gs (Ref . 78)

with flange on inside of

brackets, 3 places.

48

43

57

Slot towards

rear of unit.

986724

11

12

9

14

15

17

16

18

12

34

40

47

48

46

43

49

50

53

13

19

20

12

26

22

4

23

4

5

25

29

30

31

35

36

37

38

32

33

39

34

43

46

45

52

54

55

83

51

The holes in the frame for Ref. 51 are

slotted so the gear support (Ref. 45) can

be positioned to ensure the inside surface

of the gear support is tight against the

hub of the front gear (Ref. 50).

96

24

41

42

43

44

The above parts group applies to the following Mfg. Nos.:

1694590 - 1060E

1694591 - 1170E

1694592 - 1280E

1694593 - 1390E

1694598 - 1060M

1694599 - 1170M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

1694600 - 1280M

1694601 - 1390M

4

TP 400-4155-01-LW-S

Page 5

Handles and Controls Group - 1060, 1170, 1280 & 1390 Models

PART NO. DESCRIPTIONREF NO QTY.

1 1727128 1 HANDLE, Clutch R.H.

2 1668608 2 GRIP, Handle Clutch, Black

3 1928732 1 CAPSCREW, Hex Washer Head Taptite #10-24 x 1

4 1668185 5 BUSHING, 1/2 ID x 3/4 OD x 1/4, Nylon

5 1725205A 2 LEVER & TUBE ASSEMBLY, Clutch

6 1960471 4 CAPSCREW, Hex Washer Head Taptite #12-24 x 1

7 1705899 1 GUIDE, Control

8 1726422 2 RIVET, Pop (1280 & 1390 Models Only)

9 1726317 2 GRIP, Black Soft 1" (9560, 1060 & 1170 Models Only)

9 1723965 2 HAND GRIP, Heated 1" (1280 & 1390 Models Only)

10 1667800C 1 DASHBOARD

11 1724489 1 PLUG, Button (1390 Models Only)

12 1925592 6 CAPSCREW, Hex Washer Head Taptite 1/4-20 x 3/4

13 1930641 4 NUT, Hex Flange Whiz Lock 1/4-20

14 1935450 4 CAPSCREW, Hex Washer Head, 1/4-20 x 3/4 G5

15 1933689 1 CAPSCREW, Hex Flange Whiz Lock, 5/16-18 x 1-1/2

16 1678579 1 SPACER, 21/64 ID x 13/16 OD x 15/16

17 1705898 1 LATCH, Control

18 1701342 1 SPRING, Compression

19 1960686 1 NUT, Hex Flange 5/16-18 ESNA

20 1726672C 1 HANDLE ASSEMBLY, Channel

21 1723935A 1 BRACKET, Shift Control

22 1718791 1 CABLE & HANDLE ASSEMBLY, Clutch L.H.

23 1677453 1 ROD, Control 2" Flat

24 1727127 1 HANDLE, Clutch L.H.

25 1725702 1 SCREW, Pan Head Torx #10 x 1/2 Thick Cut

26 1664022 1 GROMMET, 1/2

27 2834683 1 CLIP, Wire

28 1933896 1 NUT, Hex Lock 10-24 with Nylon Insert NC3B

29 1678392 1 SPACER, 17/64 ID x 3/8 OD x 21/64

30 1726728 1 CLIP, Clean Out Tool

31 1960589 1 SCREW, Phillips #10-24 x 3/4

32 7075909 1 TOOL, Clean Out

33 1726727A 1 BRACKET, Clean Out Tool

34 1930591 6 CAPSCREW, Hex Flange Whiz Lock, 5/16-18 x 3/4

35 1668121 1 ROD, Clutch, 17-5/16

36 2828704 2 NUT, Hex Machine Screw 10-24 NC-2B LH YEL

37 2108775 2 TURNBUCKLE, 2-1/4 Long #10-24NC (L.H. & R.H.)

38 1916621 2 NUT, Hex Machine Screw 10-24 NC-2B

39 1707452 1 SPRING, Extension 3-11/32 Long

40 1668526 1 ROD, Clutch, 6-5/16 Long

41 1960093 1 NUT, Push Pal (Used on all models Except 1390 Models)

42 1714084 1 KNOB, Spinner, Soft (9560, 1060, 1170 & 1280 Models Only)

43 1667588 4 BUSHING, 3/8 ID x 7/16 OD x 13/64, Nylon (9560, 1060, 1170 & 1280 Models Only)

Footnotes

The above parts group applies to the following Mfg. Nos.:

1694590 - 1060E

1694591 - 1170E

1694592 - 1280E

1694593 - 1390E

1694598 - 1060M

1694599 - 1170M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

1694600 - 1280M

1694601 - 1390M

5

TP 400-4155-01-LW-S

Page 6

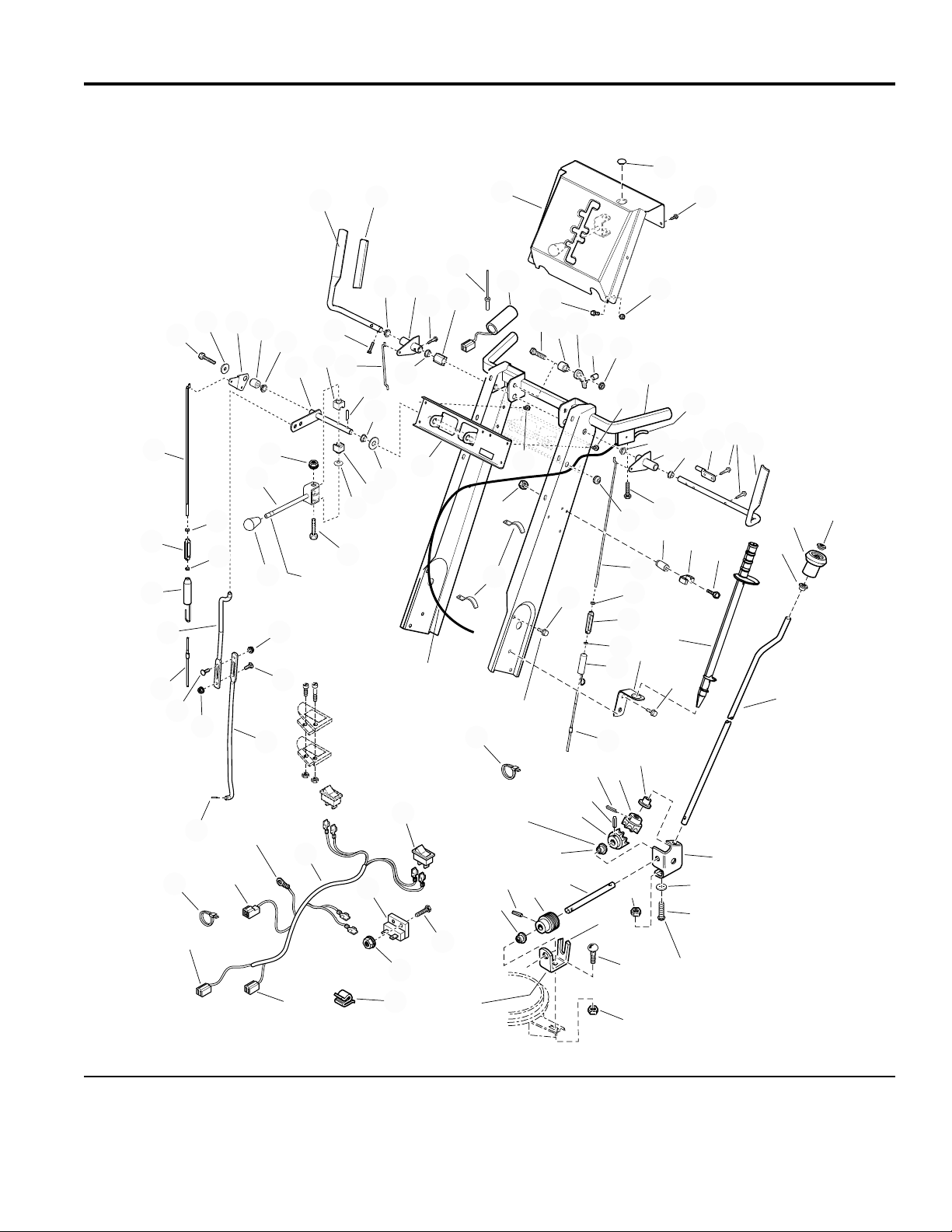

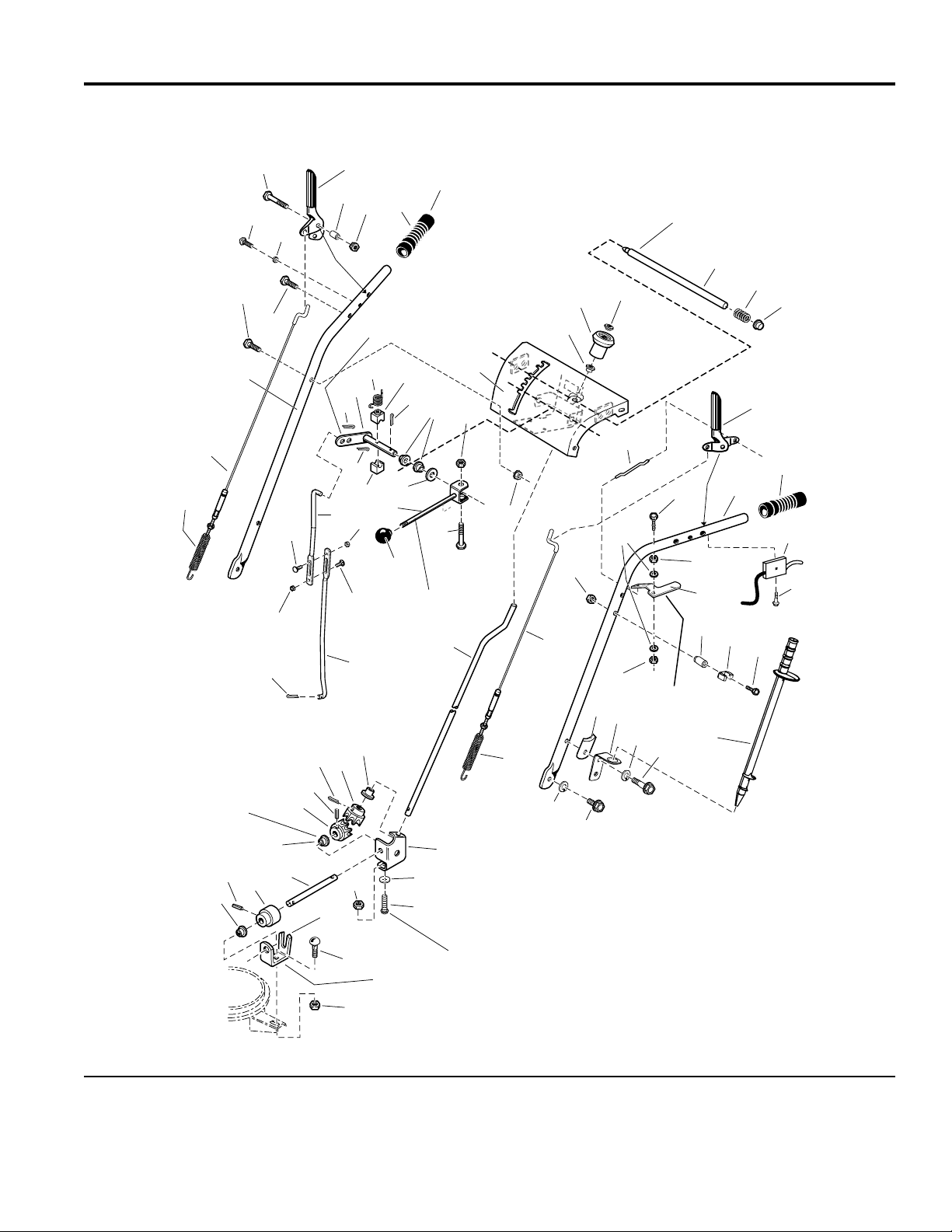

Handles and Controls Group - 1060, 1170, 1280 & 1390 Models

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

Linkage adjustment for traction and

auger drive with power boost: with

drive levers engaged, the bottom end of

lower rods (Ref. 40 & 66) should be flush

with bottom of springs (Ref. 39 & 68).

80

81

79

69

82

59

71

36

37

38

70

68

67

59

66

65

59

64

To engine

63

62

To headlight

To engine

plug

ground

1

4

74

76

Shift rod assembly

(Ref. 71) must pivot

freely on pivot blocks

(Ref. 21).

65

61

To spout

motor

2

4

5

6

3

78

4

77

4

21

75

74

73

72

Mount clutch cable

to cable support, see

Engine & Frame.

See Auger Housing and

Chute Group - 38"

56

58

59

60

10

8

7

28

2727

Torque to

19 - 29 ft-lbs.

84

Mount bushin gs (Ref . 78)

with flange on inside of

brackets, 3 places.

48

43

57

Slot towards

rear of unit.

986724

11

12

9

14

15

17

16

18

12

34

40

47

48

46

43

49

50

53

13

19

20

12

26

22

4

23

4

5

25

29

30

31

35

36

37

38

32

33

39

34

43

46

45

52

54

55

83

51

The holes in the frame for Ref. 51 are

slotted so the gear support (Ref. 45) can

be positioned to ensure the inside surface

of the gear support is tight against the

hub of the front gear (Ref. 50).

96

24

41

42

43

44

The above parts group applies to the following Mfg. Nos.:

1694590 - 1060E

1694591 - 1170E

1694592 - 1280E

1694593 - 1390E

1694598 - 1060M

1694599 - 1170M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

1694600 - 1280M

1694601 - 1390M

6

TP 400-4155-01-LW-S

Page 7

Handles and Controls Group - 1060, 1170, 1280 & 1390 Models

PART NO. DESCRIPTIONREF NO QTY.

44 1715658 1 ROD, Chute Control, 27" Long (9560, 1060, 1170 & 1280 Models Only)

45 1718793 1 SUPPORT, Gear (9560, 1060, 1170 & 1280 Models Only)

46 1718593 2 GEAR, Powered Metal (9560, 1060, 1170 & 1280 Models Only)

47 1918452 1 PIN, Cotter 1/8 x 1 (9560, 1060, 1170 & 1280 Models Only)

48 2816168 2 PIN, Spring 1/8 x 3/4 (9560, 1060, 1170 & 1280 Models Only)

49 1725283 1 ROD, Chute Worm, 18 Long (9560, 1060, 1170 & 1280 Models Only)

50 1668186 1 WORM, Chute, L.H. (9560, 1060, 1170 & 1280 Models Only)

51 1960252 2 CARRIAGE BOLT, 1/4-20 x 5/8 G5 (9560, 1060, 1170 & 1280 Models Only)

52 1960294 2 NUT, Hex Flange Whiz Lock, 1/4-20 Small (9560, 1060, 1170 & 1280 Models Only)

53 1611911 1 SUPPORT, Worm (9560, 1060, 1170 & 1280 Models Only)

54 1931333 1 CARRIAGE BOLT, 5/16-18 x 3/4 G5 (9560, 1060, 1170 & 1280 Models Only)

55 1960684 1 NUT, Hex KEPS Conical Washer, 5/16-18 (9560, 1060, 1170 & 1280 Models Only)

56 1723967 1 SWITCH, Hand Warmer (1280 & 1390 Models Only)

57 1923341 1 CAPSCREW, Hex Head, 1/4-20 x 3/4 G5 (1280 & 1390 Models Only)

58 1724037 1 RESISTOR BLOCK, Male Terminal (1280 & 1390 Models Only)

59 1960685 4 NUT, Hex KEPS, 1/4-20 Conical Washer

60 2172434 1 CLIP, Wire (Spout Rotator Models Only)

61 1725439 1 HARNESS, Wiring (Handwarmer Models Only)

61 1725409 1 HARNESS, Wiring (Handwarmer & Spout Rotator Models Only)

62 2825094 3 TIE, Self Locking 7-5/16 (1280 & 1390 Models Only)

63 1722460 1 PIN, Quick

64 1666255 1 ROD, Lower Shift 15-21/64 Long

65 1931317 2 CARRIAGE BOLT, 1/4-20 x 3/4 G5

66 1702004 1 ROD, Lower Clutch

67 1726304 1 ROD, Upper Shift 11-3/8 Long

68 1701996 1 SPRING, Extension 4-3/4 Long

69 1702485 1 ROD, Upper Clutch

70 1713844 1 KNOB, Hole

71 1714120 1 ROD & CLEVIS ASSEMBLY, Shift

72 1960705 1 CAPSCREW, Hex Flange Whiz Lock 1/4-20 x 2-1/4

73 1668681 1 WASHER, Curved

74 1668524 2 BLOCK, Pivot, Powdered Metal

75 1924361 1 WASHER, 1/2

76 1703043 1 ROD & ARM ASSEMBLY, Pivot

77 1960074 1 CLIP, Hair Pin

78 1702663 1 ROD, Clutch 5-11/32 Long

79 1933689 1 CAPSCREW, Hex Flange Whiz Lock 5/16-18 x 1-1/2

80 1919326 1 WASHER, 5/16

81 1702662 1 LEVER, Clutch

82 1702552 1 SPACER, 21/64 ID x 3/4 OD x 53/64, Powdered Metal

83 1960518 2 NUT, Push for 1/4 Diameter Thread

84 1701011 1 TIE, Self Locking, 15" (Spout Rotator Models Only)

Footnotes

The above parts group applies to the following Mfg. Nos.:

1694590 - 1060E

1694591 - 1170E

1694592 - 1280E

1694593 - 1390E

1694598 - 1060M

1694599 - 1170M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

1694600 - 1280M

1694601 - 1390M

7

TP 400-4155-01-LW-S

Page 8

Handles and Controls Group - 9560 Models

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

8

6

4

5

3

1

2

986728

9

10

11

7

Insert shift rod (Ref. 58)

into outter hole of Ref. 64.

65

64

54

54

63

58

57

56

12

63

62

61

Apply adhesive to

secure grips.

13

66

35

67

56

60

Must slide freely in

dash assembly (Ref 13).

Apply lubricant as required.

17

15

14

68

16

20

23

1625

18

19

21

12

22

28

Mount bushings (Ref. 14)

with flange on inside of

brackets, 3 places.

49

50

14

59

Shift rod assembly (Ref. 61)

57

must pivot freely on

56

54

53

52

49

52

14

51

46

pivot blocks, (Ref. 63).

55

14

45

47

Slot towards

rear of unit.

48

41

40

42

43

44

The holes in the frame for Ref. 44 are

slotted so the gear support (Ref. 42) can

be positioned to ensure the inside surface

of the gear support is tight against the

hub of the front gear (Ref. 50).

26

39

24

Must pivot freely

34

36

38

on capscrew (Ref 27).

35

Apply lubricant as required.

36

24

27

30

31

33

37

29

32

The above parts group applies to the following Mfg. Nos.:

1694589 - 9560E

1694597 - 9560M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

8

TP 400-4155-01-LW-S

Page 9

Handles and Controls Group - 9560 Models

PART NO. DESCRIPTIONREF NO QTY.

1 1726833 1 CABLE AND SPRING ASSEMBLY, R.H. Auger

2 1701996 1 SPRING, Torsion

3 1727087A 1 HANDLE, Tube, R.H.

4 1922127 1 CAPSCREW, Hex Head, 5/16-18 x 1-3/4 G5

5 1921221 3 CAPSCREW, Hex Head, 5/16-18 x 1-1/2 G5

6 1960671 2 SCREW, Pan Head Torx, 1/4-20 x 3/4, Thread Cutting

7 1715654 2 SPACER, 1/4ID x 25/64OD x 11/64LG

8 1922837 2 CAPSCREW, Hex Head, 1/4-20 x 1-1/2 G5

9 1722638 1 HANDLE, Clutch R.H.

10 1715655 2 SPACER

11 1923358 2 NUT, Hex Centerlock, 1/4-20

12 1726317 2 GRIP

13 1726983A 1 DASH AND SUPPORT ASSEMBLY, Tubular

14 1667588 4 BUSHING, 47/125ID x 437/1000OD x 1/5LG

15 1714084 1 KNOB, Spinner

16 1960093 1 NUT, Push Pal, 3/8" Diameter Stud Capped

17 1722633 1 ROD AND SPRING ASSEMBLY, w/Pin

18 1722690 1 SPRING, Complete

19 1960519 1 PUSH NUT, Stud Cap, 1/2

20 1722630 1 ROD, 4/25" Diameter, E-Coat

21 1722667 1 HANDLE, Clutch L.H.

22 1727086A 1 HANDLE, Tube, L.H.

23 1960662 1 CAPSCREW, Hex Head, 1/4-20 x 2 G5

24 1920397 2 NUT, Hex Lock ESNA Light, 1/4-20NC-3B

25 1921319 2 WASHER, 1/4

26 1933896 1 NUT, Hex Lock, 10-24

27 1722631A 1 LEVER, Pivot

28 1718791 1 CABLE AND HANDLE ASSEMBLY, Clutch

29 1725702 1 SCREW, Pan Head Torx, #10 x 1/2 Thread Cut

30 1726995 1 SPACER, 1-1/4 LG Beveled End

31 1726728 1 CLIP, Snow Stick

32 1960727 1 SCREW, Hex Flange Slot, #10-24 x 2-1/2

33 7075909 1 STICK, Snow Removal

34 1720452 2 CLAMP, Saddle Snow Handle E-Coat

35 1726727A 1 BRACKET, Clean Out Tool

36 1917356 4 LOCKWASHER, Spring, 5/16

37 1921978 2 CAPSCREW, Hex Head 5/16-18 x 2 G5

38 1930591 2 SCREW, Hex Whiz Lock Flange, 5/16-18 x 3/4

39 1726832 1 CABLE AND SPRING ASSEMBLY, L.H. Traction

40 1707452 1 SPRING, Extension

41 1727088 1 ROD, 3/8" Diameter, 26" Long

42 1718793 1 SUPPORT, Gear

43 1960518 2 NUT, Push for 1/4 Diameter Thread

44 1960252 2 CARRIAGE BOLT, 1/4-20 x 5/8 G5

Footnotes

The above parts group applies to the following Mfg. Nos.:

1694589 - 9560E

1694597 - 9560M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

9

TP 400-4155-01-LW-S

Page 10

Handles and Controls Group - 9560 Models

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

8

6

4

5

3

1

2

986728

9

10

11

7

Insert shift rod (Ref. 58)

into outter hole of Ref. 64.

65

64

54

54

63

58

57

56

12

63

62

61

Apply adhesive to

secure grips.

13

66

35

67

56

60

Must slide freely in

dash assembly (Ref 13).

Apply lubricant as required.

17

15

14

68

16

20

23

1625

18

19

21

12

22

28

Mount bushings (Ref. 14)

with flange on inside of

brackets, 3 places.

49

50

14

59

Shift rod assembly (Ref. 61)

57

must pivot freely on

56

54

53

52

49

52

14

51

46

pivot blocks, (Ref. 63).

55

14

45

47

Slot towards

rear of unit.

48

41

40

42

43

44

The holes in the frame for Ref. 44 are

slotted so the gear support (Ref. 42) can

be positioned to ensure the inside surface

of the gear support is tight against the

hub of the front gear (Ref. 50).

26

39

24

Must pivot freely

34

36

38

on capscrew (Ref 27).

35

Apply lubricant as required.

36

24

27

30

31

33

37

29

32

The above parts group applies to the following Mfg. Nos.:

1694589 - 9560E

1694597 - 9560M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

10

TP 400-4155-01-LW-S

Page 11

Handles and Controls Group - 9560 Models

PART NO. DESCRIPTIONREF NO QTY.

45 1960294 2 NUT, Hex Flange, 1/4-20, Whiz Lock Small

46 1611911 1 SUPPORT, Worm

47 1931333 1 CARRIAGE BOLT, 5/16-18 x 3/4 G5

48 1960684 1 NUT, Hex Keps, 5/16-18, Conical Washer

49 2816168 2 PIN, Spring 1/8 x 3/4

50 1668186 1 WORM, Chute, L.H.

51 1725283 1 ROD, 3/8" Diameter, Chute Worm E-Coat

52 1718593 2 GEAR, Powdered Metal, Metafusion

53 1918452 1 PIN, Cotter 1/4 x 1

54 1722460 1 PIN, Quick

55 1666255 1 ROD, 3/4" Diameter

56 1960685 3 NUT, Hex KEPS, 1/4-20, Conical Washer

57 1931317 2 CARRIAGE BOLT, 1/4-20 x 3/4 G5

58 1726304 1 ROD, 3/4" Diameter, Shift Upper, 11-19/50 Long

59 1726734 1 KNOB, Intermediate Thread, 3/8-16

60 1960705 1 SCREW, Hex Whiz Lock Flange, 1/4-20 x 2-1/4

61 1668523 1 ROD AND CLEVIS ASSEMBLY, Shift, Threaded

62 1924361 1 WASHER, 1/2

63 1668524 2 BLOCK, Pivot, 3/4 x 3/4, Powdered Metal

64 1720240 1 ROD AND ARM ASSEMBLY, Pivot

65 1715123 1 SPRING, Torsion

66 1960074 1 CLIP, Hair Pin

67 1668185 2 BUSHING, 1/2ID x 3/4OD x 1/4LG

68 1960686 4 NUT, Hex Flange, 5/16-18 ESNA

Footnotes

The above parts group applies to the following Mfg. Nos.:

1694589 - 9560E

1694597 - 9560M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

11

TP 400-4155-01-LW-S

Page 12

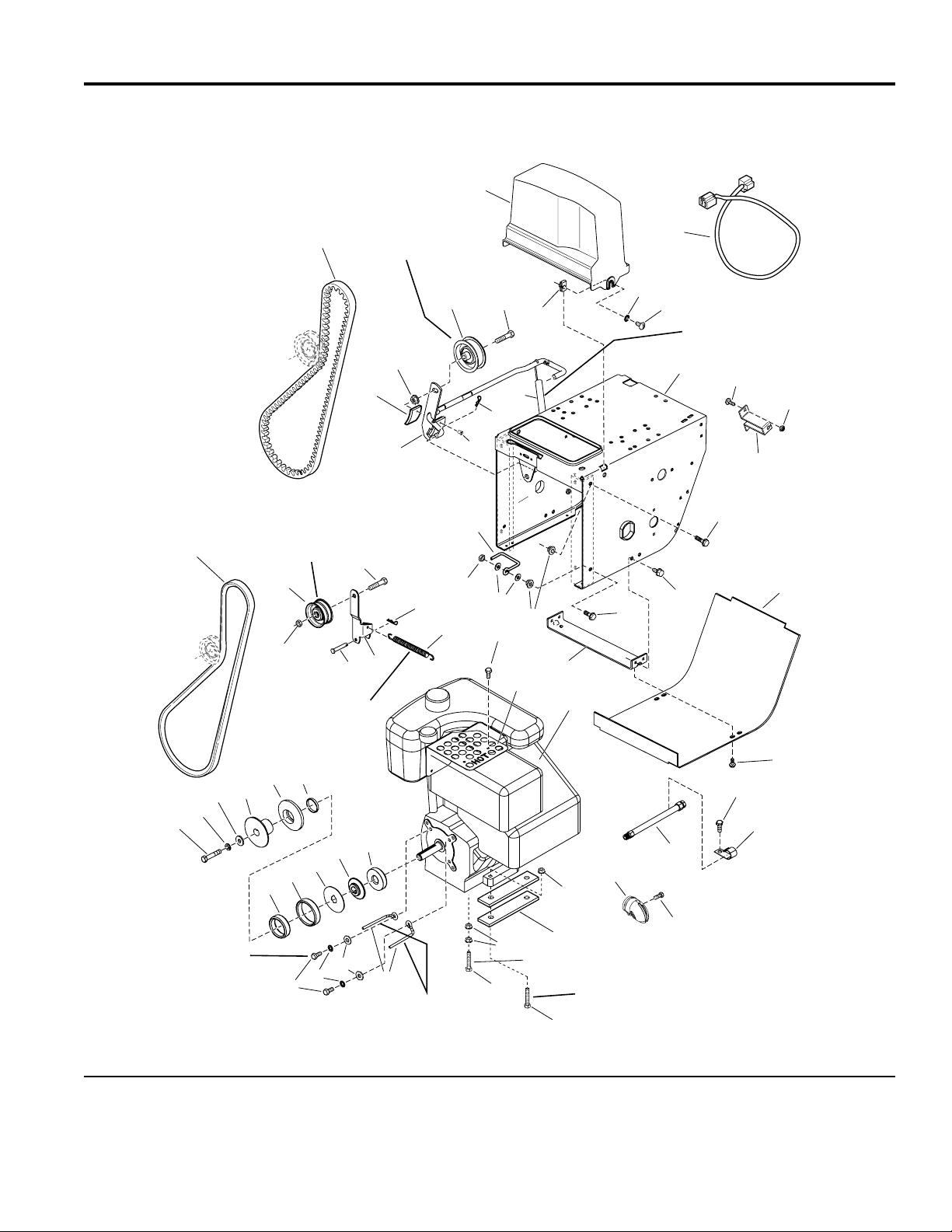

Engine and Frame Group with Power Boost

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

Long hub of idler

pulley (Ref. 3) to

1

2

Hook one end of spring (Ref. 7)

into top hole of roller arm (Ref. 6)

and other end into top hole of

the idler arm assembly in the

Traction Drive Group.

61

60

59

58

57

52

9

be toward idler

arm (Ref. 6).

3

62

55

54

53

Position idler pull ey (Ref. 14 )

at center of slot in clutch arm

(Ref. 10).

14

13

11

10

4

34

8

7

6

5

56

986732

17

21

43

19

20

Hook one end of spring (Ref. 16)

over clutch rod assembly (Ref. 10)

between tabs and other end into

slot in frame.

22

27

28

39

23

24

25

26

29

30

40

41

15

18

16

8

12

35

1433

1432

36

31

37

38

44

Torque to

10-14 ft. lbs. or

14-20 N m

3551

3549

3550

45

48

Position belt stops 1/16 - 1/8

from belt when auger clutch is engaged.

The above parts group applies to the following Mfg. Nos.:

1694590 - 1060E

1694591 - 1170E

1694592 - 1280E

1694593 - 1390E

1694598 - 1060M

1694599 - 1170M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

1694600 - 1280M

1694601 - 1390M

12

47

29

44

45

Right rear bolt.

46

Torque (4) Engine

Bolts to 17 - 21 ft. lbs.

or 23 - 29 N m

42

TP 400-4155-01-LW-S

Page 13

Engine and Frame Group with Power Boost

PART NO. DESCRIPTIONREF NO QTY.

1 1700415 1 V-BELT, 3L (Used on all models Except 1390 Models)

1 1672732 1 V-BELT, 3L (Used Only on 1390 Models)

2 1928731 1 NUT, Hex, Toplock, Jam, 3/8-16

3 1668477 1 PULLEY, Idler

4 1960647 1 SCREW, Hex Head, 3/8-16 x 1-1/2

5 1665994 1 PIN, Flat Head Drilled

6 1703046A 2 ARM, Idler, 5-3/4 LG

7 1727149 1 SPRING, Extension

8 1722460 1 PIN, Quick

9 1676460 2 V-BELT, HA (Used on all models Except 1390 Models)

9 1701257 1 V-BELT, HA (Used Only on 1390 Models)

10 1727058A 1 ROD AND ARM ASSEMBLY, Clutch, Brake w/Pad

11 1669313 1 PAD, Brake

12 2825160 1 RIVET, Pop

13 1928352 1 NUT, Hex Flange, 3/8-16 Whiz Lock Large

14 1726348 1 PULLEY, Idler

15 2860709 1 SCREW, Hex Whiz Lock Flange, 3/8-16 x 1-3/4

16 1727059 1 SPRING, Extension

17 1725287 2 COVER, Belt

18 1935255 1 NUT, Speed, 5/16-18, Lug Type

19 2820426 2 LOCKWASHER, External Tooth, 5/16

20 1918249 2 SCREW, Truss head Slotted, 5/16-18 x 3/4

21 1724064 1 CORD, Electric Extension

22 1726568C 4 FRAME ASSEMBLY, Chain/Tube Handles

23 1931317 1 CARRIAGE BOLT, 1/4-20 x 3/4 G5

24 1960685 2 NUT, Hex KEPS, 1/4-20, Conical Washer

25 1720404A 4 SUPPORT, Clutch Cable, 16GA

26 1930591 1 SCREW, Hex Whiz Lock Flange, 5/16-18 x 3/4

27 1664847 1 SCREW, Hex Washer Head Taptite, 5/16-18 x 3/4

28 1930595 1 SCREW, Hex Whiz, 31/100-18 x 1-1/4

29 1726870C 4 COVER, Bottom Frame, 20GA

30 1925003 1 SCREW, Hex Washer Head Taptite, 1/4-20 x 1/2

31 1727004A 2 SUPPORT, Tie Bar

32 1927557 4 NUT, Hex Flange, 5/16-18, Whiz Lock Large

33 1919326 1 WASHER, Flat, 11/32 x 3/4 x 1/16

34 1923362 1 NUT, Hex Centerlock, 5/16-18

35 1702969 1 BELT STOP

36 1929477 1 SCREW, Hex Washer Head Taptite, #10-24 x 1/2

37 1725664A 1 GUARD, Muffler, 18GA

38 * 1 ENGINE, 9.5HP B&S Electric Start Model: 20G4140 Type: 111E1

38 * 1 ENGINE, 9.5HP B&S Electric Start (CE) Model: 20G4160 Type: 110E1

39 1726942 2 HOSE, Oil Drain, w/Fittings

40 1664847 1 CAPSCREW, Hex Washer Head, 5/16-18 x 3/4

41 1727068 1 CLIP, "J"

Footnotes

Note* See your local Briggs & Stratton distributor for Parts & Service.

The above parts group applies to the following Mfg. Nos.:

1694590 - 1060E

1694591 - 1170E

1694592 - 1280E

1694593 - 1390E

1694598 - 1060M

1694599 - 1170M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

1694600 - 1280M

1694601 - 1390M

13

TP 400-4155-01-LW-S

Page 14

Engine and Frame Group with Power Boost

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

Long hub of idler

pulley (Ref. 3) to

1

2

Hook one end of spring (Ref. 7)

into top hole of roller arm (Ref. 6)

and other end into top hole of

the idler arm assembly in the

Traction Drive Group.

61

60

59

58

57

52

9

be toward idler

arm (Ref. 6).

3

62

55

54

53

Position idler pull ey (Ref. 14 )

at center of slot in clutch arm

(Ref. 10).

14

13

11

10

4

34

8

7

6

5

56

986732

17

21

43

19

20

Hook one end of spring (Ref. 16)

over clutch rod assembly (Ref. 10)

between tabs and other end into

slot in frame.

22

27

28

39

23

24

25

26

29

30

40

41

15

18

16

8

12

35

1433

1432

36

31

37

38

44

Torque to

10-14 ft. lbs. or

14-20 N m

3551

3549

3550

45

48

Position belt stops 1/16 - 1/8

from belt when auger clutch is engaged.

The above parts group applies to the following Mfg. Nos.:

1694590 - 1060E

1694591 - 1170E

1694592 - 1280E

1694593 - 1390E

1694598 - 1060M

1694599 - 1170M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

1694600 - 1280M

1694601 - 1390M

14

47

29

44

45

Right rear bolt.

46

Torque (4) Engine

Bolts to 17 - 21 ft. lbs.

or 23 - 29 N m

42

TP 400-4155-01-LW-S

Page 15

Engine and Frame Group with Power Boost

PART NO. DESCRIPTIONREF NO QTY.

42 1727033 1 SCREW, Muffler Deflector

43 1727032 3 DEFLECTOR, Rain Guard, B&S Snow Muffler

44 2831277 3 NUT, Hex Flange, 5/16-18, Whiz Lock Small

45 1725326C 1 SUPPORT, Engine Riser (Used on all models Except 1390 Models)

46 1935159 1 CAPSCREW, Hex Whiz Lock Flange, 5/16-18 x 2-1/4 (Used on all models Except

1390 Models)

46 1921221 1 CAPSCREW, Hex Head, 5/16-18 x 1-1/2 G5 (Used Only on 1390 Models)

47 2860551 4 CAPSCREW, Hex Washer Head Taptite, 5/16-18 x 2-1/2 (Used on all models Except

1390 Models)

47 2822127 3 CAPSCREW, Hex Head 5/16-18 x 1-3/4 G5 (Used Only on 1390 Models)

48 1668174 1 STOP, Belt

49 1919326 2 WASHER, 5/16

50 1917356 2 LOCKWASHER, Spring, 5/16

51 1921515 1 CAPSCREW, Hex Head, 5/16-24 x 3/4 G5

52 1701849 1 SPRING, Compression

53 1702425 1 SPRING, Compression

54 1701818 1 WASHER, Thrust

55 1726869 1 PULLEY HALF, Middle

56 1726868 1 PULLEY HALF, Inside

57 1922128 1 CAPSCREW, Hex Head, 3/8-24 x 1-1/2 G8

58 1916965 1 LOCKWASHER, Spring, 3/8

59 1922755 1 WASHER, 3/8

60 1726864 1 PULLEY HALF, Outside

61 1726863 1 PULLEY HALF, Middle

62 1701825 1 WICK, Felt, Oil

Footnotes

Note* See your local Briggs & Stratton distributor for Parts & Service.

The above parts group applies to the following Mfg. Nos.:

1694590 - 1060E

1694591 - 1170E

1694592 - 1280E

1694593 - 1390E

1694598 - 1060M

1694599 - 1170M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

1694600 - 1280M

1694601 - 1390M

15

TP 400-4155-01-LW-S

Page 16

Engine and Frame Group without Power Boost

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

Long hub of idler

pulley (Ref. 3) to

1

3

2

9

be toward idler

arm (Ref. 6).

Position idler pull ey (Ref. 14 )

at center of slot in clutch arm

(Ref. 10).

14

13

11

10

4

8

7

6

5

12

17

15

8

32

986730

21

19

20

18

16

31

30

33

34

Hook one end of spring (Ref. 16)

over clutch rod assembly (Ref. 10)

between tabs and other end into

slot in frame.

22

27

23

24

25

26

28

Hook one end of spring (Ref. 7)

into top hole of roller arm (Ref. 6)

and other end into top hole of the idler

arm assembly in the Traction Drive Group.

53

52

51

50

49

48

Torque to

10-14 ft. lbs. or

14-20 N m

3547

3545

3546

The above parts group applies to the following Mfg. Nos.:

1694589 - 9560E

1694597 - 9560M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

44

Right rear bo lt.

16

43

29

36

37

35

39

40

29

40

41

Torque (4) Engine

Bolts to 17 - 21 ft. lbs.

or 23 - 29 N m

42

38

TP 400-4155-01-LW-S

Page 17

Engine and Frame Group without Power Boost

PART NO. DESCRIPTIONREF NO QTY.

1 1700415 1 V-BELT, 3L (Used on all models Except 1390 Models)

1 1672732 1 V-BELT, 3L (Used Only on 1390 Models)

2 1928731 1 NUT, Hex, Toplock, Jam, 3/8-16

3 1668477 1 PULLEY, Idler

4 1960647 1 SCREW, Hex Head, 3/8-16 x 1-1/2

5 1665994 1 PIN, Flat Head Drilled

6 1703046A 2 ARM, Idler, 5-3/4 LG

7 1727149 1 SPRING, Extension

8 1722460 1 PIN, Quick

9 1725416 2 V-BELT, HA (Used on all models Except 1390 Models)

9 1666655 1 V-BELT, HA (Used Only on 1390 Models)

10 1727058A 1 ROD AND ARM ASSEMBLY, Clutch, Brake w/Pad

11 1669313 1 PAD, Brake

12 2825160 1 RIVET, Pop

13 1928352 1 NUT, Hex Flange, 3/8-16 Whiz Lock Large

14 1726348 1 PULLEY, Idler

15 2860709 1 SCREW, Hex Whiz Lock Flange, 3/8-16 x 1-3/4

16 1727059 1 SPRING, Extension

17 1725287 2 COVER, Belt

18 1935255 1 NUT, Speed, 5/16-18, Lug Type

19 2820426 2 LOCKWASHER, External Tooth, 5/16

20 1918249 2 SCREW, Truss head Slotted, 5/16-18 x 3/4

21 1724064 1 CORD, Electric Extension

22 1726568D 4 FRAME ASSEMBLY, Chain/Tube Handles

23 1931317 1 CARRIAGE BOLT, 1/4-20 x 3/4 G5

24 1960685 2 NUT, Hex KEPS, 1/4-20, Conical Washer

25 1720404A 4 SUPPORT, Clutch Cable, 16GA

26 1930591 1 SCREW, Hex Whiz Lock Flange, 5/16-18 x 3/4

27 1664847 1 SCREW, Hex Washer Head Taptite, 5/16-18 x 3/4

28 1726870D 4 COVER, Bottom Frame, 20GA

29 1925003 1 SCREW, Hex Washer Head Taptite, 1/4-20 x 1/2

30 41727004 2 SUPPORT, Tie Bar

31 1927557 4 NUT, Hex Flange, 5/16-18, Whiz Lock Large

32 1725664A 1 GUARD, Muffler, 18GA

33 1929477 1 SCREW, Hex Washer Head Taptite, #10-24 x 1/2

34 * 1 ENGINE, 9.5HP B&S Electric Start Model: 20G4140 Type: 111E1

34 * 1 ENGINE, 9.5HP B&S Electric Start (CE) Model: 20G4160 Type: 110E1

35 1726942 2 HOSE, Oil Drain, w/Fittings

36 1664847 1 CAPSCREW, Hex Washer Head, 5/16-18 x 3/4

37 1727068 1 CLIP, "J"

38 1727033 1 SCREW, Muffler Deflector

39 1727032 3 DEFLECTOR, Rain Guard, B&S Snow Muffler

40 2831277 5 NUT, Hex Flange, 5/16-18, Whiz Lock Small (Quantity 4 used only on 9560 Models)

41 1725326C 1 SUPPORT, Engine Riser (Used on all models Except 1390 Models)

Footnotes

Note* See your local Briggs & Stratton distributor for Parts & Service.

The above parts group applies to the following Mfg. Nos.:

1694589 - 9560E

1694597 - 9560M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

17

TP 400-4155-01-LW-S

Page 18

Engine and Frame Group without Power Boost

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

Long hub of idler

pulley (Ref. 3) to

1

3

2

9

be toward idler

arm (Ref. 6).

Position idler pull ey (Ref. 14 )

at center of slot in clutch arm

(Ref. 10).

14

13

11

10

4

8

7

6

5

12

17

15

8

32

986730

21

19

20

18

16

31

30

33

34

Hook one end of spring (Ref. 16)

over clutch rod assembly (Ref. 10)

between tabs and other end into

slot in frame.

22

27

23

24

25

26

28

Hook one end of spring (Ref. 7)

into top hole of roller arm (Ref. 6)

and other end into top hole of the idler

arm assembly in the Traction Drive Group.

53

52

51

50

49

48

Torque to

10-14 ft. lbs. or

14-20 N m

3547

3545

3546

The above parts group applies to the following Mfg. Nos.:

1694589 - 9560E

1694597 - 9560M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

44

Right rear bo lt.

18

43

29

36

37

35

39

40

29

40

41

Torque (4) Engine

Bolts to 17 - 21 ft. lbs.

or 23 - 29 N m

42

38

TP 400-4155-01-LW-S

Page 19

Engine and Frame Group without Power Boost

PART NO. DESCRIPTIONREF NO QTY.

42 1935159 1 CAPSCREW, Hex Whiz Lock Flange, 5/16-18 x 2-1/4 (Used on all models Except

1390 Models)

42 1921221 1 CAPSCREW, Hex Head, 5/16-18 x 1-1/2 G5 (Used only on 1390 Models)

43 2860551 4 CAPSCREW, Hex Washer Head Taptite, 5/16-18 x 2-1/2 (Used on all models Except

1390 Models)

43 2822127 3 CAPSCREW, Hex Head 5/16-18 x 1-3/4 G5 (Used only on 1390 Models)

44 1668174 1 STOP, Belt

45 1919326 2 WASHER, 5/16

46 1917356 2 LOCKWASHER, Spring, 5/16

47 1921515 1 CAPSCREW, Hex Head, 5/16-24 x 3/4 G5

48 1922128 1 CAPSCREW, Hex Head, 3/8-24 x 1-1/2 G8

49 1916965 1 LOCKWASHER, Spring, 3/8

50 1922755 1 WASHER, 3/8

51 1726867 1 PULLEY, Engine Outside, Powdered Metal

52 1726866 1 PULLEY, Engine Middle, Powdered Metal

53 1726865 1 PULLEY, Half Powdered Metal

Footnotes

Note* See your local Briggs & Stratton distributor for Parts & Service.

The above parts group applies to the following Mfg. Nos.:

1694589 - 9560E

1694597 - 9560M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

19

TP 400-4155-01-LW-S

Page 20

Auger and Impeller Group

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

16

14

15

17

18

985466

End of hub to be flush

with end of rolled down

shaft (Ref. 9).

4

2

Torque to 30 -34 ft-lbs.

40 - 46 Nm.

5

7

10

10

10

11

19

6

12

13

6

8

9

Impeller to be positioned

against bearing before

tightening set screw.

3

1

2

Torque to

18-21 ft-lbs.

24 - 28 Nm.

Marked side of worm

gear must contact against

left thrust washer to assure

proper gear mesh.

Auger assembly

stamped "R".

28

Apply grease until

it appears at ends

of auger assembly

(2 places).

Auger assembly

stamped "L".

20

2929

21

26

22

18

25

23

Torque to 9 - 11 ft-lbs.

12- 15 Nm.

14

24

27

The above parts group applies to the following Mfg. Nos.:

1694589 - 9560E

1694590 - 1060E

1694591 - 1170E

1694592 - 1280E

1694593 - 1390E

1694597 - 9560M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

1694598 - 1060M

1694599 - 1170M

1694600 - 1280M

1694601 - 1390M

20

TP 400-4155-01-LW-S

Page 21

Auger and Impeller Group

PART NO. DESCRIPTIONREF NO QTY.

1 1679293 1 PULLEY, w/Hub

2 1928721 2 SCREW, Set Square Head Cup Point, 5/16-18 x 1/2 G8

3 1612187A 1 IMPELLER ASSEMBLY

4 1960474 1 SCREW, Set Square Head Cup Point, 3/8-16 x 1/2 G8

5 1612093 1 SEAL, Oil 1/4" Thick

6 1612149 2 BUSHING, 377/500 ID x 1-1/10 OD x 1-1/100 LG Powerdered Metal

7 1612127 1 COLLAR, Thrust 3/4 LG

8 2836098 1 PIN, Drive Lock Type A 3/16 x 1-1/2

9 1612129 1 SHAFT, Worm 18-1/10 LG

10 2818312 3 KEY, Woodruff, 47/250 x 5/8

11 1612111 1 TUBE, 9/10 OD 39/50 ID, 7-1/2 LG

12 1612142 1 GEAR, Worm 1-3/8 LG

13 2168111 1 WASHER, Thrust

14 2118118 2 SEAL, Oil, 1/4" Thick

15 1923358 6 LOCKNUT, Hex, 1/4-20 Qauntity 8 used on 38 in. Models

16 1612137 1 CASE, Gear R.H.

17 1612124 1 GASKET, Gear Case

18 2118315 2 WASHER, Thrust

19 1612117 1 SHAFT, 16 LG Auger 3 Holes

20 2830246 1 KEY, Woodruff 1/4 x 3/4

21 1612141 1 GEAR, Worm 7/8 LG

22 1612136 1 CASE, Gear L.H.

23 1668971 1 PLUG, Pipe, Tapered, 1/8 Used on 38 in. Models

24 1960346 6 CAPSCREW, Hex Head, 1/4-20 x 2-1/4 G5 Quantity 4 used on 38 in. Models

25 1668344 2 PIN, Flat Head Drilled

26 1918447 2 PIN, Cotter 47/50 x 3/4

27 1718782A 1 AUGER ASSEMBLY, L.H. 9-1/2 LG Used on 24 in. Models

27 1718784A 1 AUGER ASSEMBLY, L.H. 11-1/2 LG Used on 28 in. Models

27 1718786A 1 AUGER ASSEMBLY, L.H. 13-1/2 LG Used on 32 in. Models

28 1718783A 1 AUGER ASSEMBLY, R.H. 9-1/2 LG Used on 24 in. Models

28 1718785A 1 AUGER ASSEMBLY, R.H. 11-1/2 LG Used on 28 in. Models

28 1718787A 1 AUGER ASSEMBLY, R.H. 13-1/2 LG Used on 32 in. Models

29 2821133 2 FITTING, Lube 1/4 Drive, No Check Ball

Footnotes

The above parts group applies to the following Mfg. Nos.:

1694589 - 9560E

1694590 - 1060E

1694591 - 1170E

1694592 - 1280E

1694593 - 1390E

1694597 - 9560M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

1694598 - 1060M

1694599 - 1170M

1694600 - 1280M

1694601 - 1390M

21

TP 400-4155-01-LW-S

Page 22

Auger Housing and Chute Group - 38" Models

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

11

8

7

5

4

Plastic washer

(Ref. 3) goes

between chute

and deflector.

3

2

47

46

48

45

986720

10

9

22

252513

14

14

12

6

15

16

1

Mount cable bracket (Ref. 23)

on right hand side of handle

using shift control bracket

hardware.

26

49

25

27

28

Coat top and bottom of

chute ring with grease.

50

32

2

44

21

20

23

18

19

17

24

When installing cable,

make sure it does not

come into contact with

muffler.

29

30

See Handles and Controls

group for Wiring Harness.

31

33

34

35

51

43

Scraper blade should

be on inside of housing.

The above parts group applies to the following Mfg. Nos.:

1694593 - 1390E

1694601 - 1390M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

42

41

22

40

36

39

37

38

29

TP 400-4155-01-LW-S

Page 23

Auger Housing and Chute Group - 38" Models

PART NO. DESCRIPTIONREF NO QTY.

1 1960001 3 SCREW, Hex Washer Head Pastite, 10-14 x 5/8

2 1931333 10 CARRIAGE BOLT, 5/16-18 x 3/4 G5

3 2860210 1 WASHER, Special, 97/250ID x 1-3/25OD x 3/100 Thick

4 1919326 1 WASHER, 5/16

5 1919438 1 NUT, Hex Lock ESNA Light, 5/16-18NC-3B

6 1933896 2 NUT, Hex Nylon 10-24

7 1725427C 1 BRACKET, Mounting Switch Bottom

8 1725426C 1 BRACKET, Mounting Switch Top

9 1960725 1 SCREW, 10-24 x 1.75

10 1724205 1 SWITCH, Rocker Chute

11 1725696 1 BOOT, Rocker Switch

12 1727194C 1 CHUTE AND DEFLECTOR ASSEMBLY, Riveted, w/Pigtail

13 1702219 3 SPACER, Heat Treated

14 1960126 2 NUT, Push Pal, 1/4" Diameter Stud Capped

15 1611945 1 ROD, 5/16" Diameter, Spring Guide

16 1611939 1 SPRING, Complete

17 1720446 1 CABLE AND KNOB ASSEMBLY, Chute (Includes Ref. No. 18, 19, 20, 21 & 22)

18 1611989 1 BOOT, Bellows

19 1719140 1 COLLET

20 1719139 1 SEAL, Rod

21 1719138 1 KNOB

22 1960600 1 SCREW, 8-32

23 1726411A 1 SUPPORT, Cable

24 2825094 1 TIE, Self Locking

25 2860664 3 SCREW, Hex Sems Washer, 1/4-20 x 7/8

26 1724553 1 CAPLUG, For 3/4" Hole

27 1960685 1 NUT, Hex KEPS, 1/4-20, Conical Washer

28 1724604 1 PINION, 1-3/20 LG

29 1925205 9 CAPSCREW, Hex Head, 5/16-18 x 5/8 G5

30 1917356 3 LOCKWASHER, Spring, 5/16

31 1665982A 1 RETAINER, Bearing

32 2108202 1 BEARING, Ball

33 1723930A 1 COVER, Pinion, 18GA

34 1925003 2 CAPSCREW, Hex Washer Head Taptite, 1/4-20 x 1/2

35 1715885 1 MOTOR, Electric 60" Mower Rocky

36 2172279A 2 FLANGE, Bearing, w/Fitting

37 2173934 2 BEARING, Cartridge

38 2172278A 2 FLANGE, Bearing, 3/8" Deep

39 1960687 4 NUT, Hex Flange, 3/8-16 ESNA

40 1725747A 2 SKID SHOE, 7GA Formed, Heat Treated

41 61723921 1 BLADE, Scraper, 35-3/4 for 38"

42 1960702 4 CARRIAGE BOLT, 3/8-16 x 1 G5

43 1935048 15 NUT, Hex Flange, 5/16-18, Two-Way Lock GA

44 1960684 4 NUT, Hex Keps, 5/16-18, Conical Washer

Footnotes

The above parts group applies to the following Mfg. Nos.:

1694593 - 1390E

1694601 - 1390M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

23

TP 400-4155-01-LW-S

Page 24

Auger Housing and Chute Group - 38" Models

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

11

8

7

5

4

Plastic washer

(Ref. 3) goes

between chute

and deflector.

3

2

47

46

48

45

986720

10

9

22

252513

14

14

12

6

15

16

1

Mount cable bracket (Ref. 23)

on right hand side of handle

using shift control bracket

hardware.

26

49

25

27

28

Coat top and bottom of

chute ring with grease.

50

32

2

44

21

20

23

18

19

17

24

When installing cable,

make sure it does not

come into contact with

muffler.

29

30

See Handles and Controls

group for Wiring Harness.

31

33

34

35

51

43

Scraper blade should

be on inside of housing.

The above parts group applies to the following Mfg. Nos.:

1694593 - 1390E

1694601 - 1390M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

42

41

24

40

36

39

37

38

29

TP 400-4155-01-LW-S

Page 25

Auger Housing and Chute Group - 38" Models

PART NO. DESCRIPTIONREF NO QTY.

45 1723902C 1 HOUSING AND IMPELLER ASSEMBLY, 38"

46 1921332 4 CAPSCREW, Hex Head, 5/16-18 x 3/4 G5

47 1715787C 2 CUTTER, Drift, 1/4" Thick, 20LG

48 1666613 3 HOLD DOWN, Chute

49 1717477A 1 GEAR, Chute

50 1930659 3 NUT, Retainer Speed, 5/16-18

Footnotes

The above parts group applies to the following Mfg. Nos.:

1694593 - 1390E

1694601 - 1390M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

25

TP 400-4155-01-LW-S

Page 26

Auger Housing and Chute Group - 9560, 1060, 1170 & 1280 Models

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

5

4

3

2

Plastic washer

(Ref. 2) goes

between chute

and deflector.

and deflector.

1

Decal must cover

gap at hinge pivot.

6

986713

21

20

252511

14

7

12

22

17

13

14

16

8

Mount cable bracket (Ref. 22)

on right hand side of handle

using shift control bracket

hardware.

15

19

18

41

40

Scraper blade should

be on inside of housing.

39

42

35

37

10

9

Coat top and bottom of

chute ring with grease.

When installing cable,

23

make sure it does not

come into contact with

muffler.

muffler.

24

27

25

26

38

36

28

29

30

31

34

33

32

The above parts group applies to the following Mfg. Nos.:

1694589 - 9560E

1694590 - 1060E

1694591 - 1170E

1694592 - 1280E

1694597 - 9560M

1694598 - 1060M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

1694599 - 1170M

1694600 - 1280M

26

TP 400-4155-01-LW-S

Page 27

Auger Housing and Chute Group - 9560, 1060, 1170 & 1280 Models

PART NO. DESCRIPTIONREF NO QTY.

1 1931333 1 CARRIAGE BOLT, 5/16-18 x 3/4 G5

2 2860210 1 WASHER, Nylon

3 1919326 1 WASHER, 5/16

4 1919438 1 NUT, Hex Lock ESNA Light, 5/16-18NC-3B (Used on all models Except 9560

Models)

5 1670578 1 KNOB, Internal Thread, 5/16 (Used Only on 9560 Models)

6 1704161C 1 CHUTE AND DEFLECTOR ASSEMBLY, Manual (Used Only on 9560 Models)

6 1720671C 1 CHUTE AND DEFLECTOR ASSEMBLY, w/Remote (Used on all models Except 9560

Models)

7 1706085 2 DECAL, Orange Strip

8 1960001 3 SCREW, Hex Washer Head Pastite, 10-14 x 5/8

9 1667865 3 SPRING, Flat

10 1666613 3 HOLD DOWN, Chute

11 1702219 3 SPACER, 17/64 ID x 3/8 OD

12 1960126 2 NUT, Push 1/4

13 1611945 1 ROD, Spring

14 1611939 1 SPRING, Compression

15 2825094 1 TIE, Self Locking (Used on all models Except 9560 Models)

16 1720446 1 CABLE AND KNOB ASSEMBLY, Chute (Includes Ref. No. 17, 18, 19, 20 & 21)

17 1611989 1 BOOT, Bellows

18 1719140 1 COLLET

19 1719139 1 SEAL, Rod

20 1719138 1 KNOB

21 1960600 1 SCREW, 8-32

22 1726411A 1 BRACKET, Cable

23 1925205 3 CAPSCREW, Hex Head, 5/16-18 x 5/8 G5

24 1917356 3 LOCKWASHER, Spring, 5/16

25 1665982A 1 RETAINER, Bearing

26 2108202 1 BEARING, Ball

27 1930659 3 NUT, Retainer Speed, 5/16-18

28 1663189 2 SPACER, Low

29 1665980 1 BEARING, Flange

30 1668639C 2 CAP, Bearing, 3-3/4OD

31 1923325 6 CAPSCREW, Hex Head 5/16-18 x 7/8 G5

32 1960687 6 NUT, Hex Flange 3/8-16 ESNA

33 1726725 2 SKID SHOE, Reversible

34 1709946A 1 BLADE, Scraper, 24" (Used Only on 9560 & 1060 Models)

34 1709947A 1 BLADE, Scraper, 28" (Used Only on 1170 Models)

34 1709948A 1 BLADE, Scraper, 32" (Used Only on 1280 Models)

35 1935048 5 NUT, Hex Flange, 5/16-18, Two-Way Lock GA (Quantity 7 Only on 1280 Models)

36 1960711 4 CARRIAGE BOLT, 3/8-16 x 3/4

37 1923362 6 NUT, Hex Centerlock, 5/16-18

38 1960699 5 CARRIAGE BOLT, 5/16-18 x 5/8 G5 (Quantity 7 Only on 1280 Models)

39 1960684 4 NUT, Hex Keps, 5/16-18, Conical Washer (Used on all models Except 9560 Models)

40 1921332 2 CAPSCREW, Hex Head, 5/16-18 x 3/4 G5 (Used on all models Except 9560 Models)

Footnotes

The above parts group applies to the following Mfg. Nos.:

1694589 - 9560E

1694590 - 1060E

1694591 - 1170E

1694592 - 1280E

1694597 - 9560M

1694598 - 1060M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

1694599 - 1170M

1694600 - 1280M

27

TP 400-4155-01-LW-S

Page 28

Auger Housing and Chute Group - 9560, 1060, 1170 & 1280 Models

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

5

4

3

2

Plastic washer

(Ref. 2) goes

between chute

and deflector.

and deflector.

1

Decal must cover

gap at hinge pivot.

6

986713

21

20

252511

14

7

12

22

17

13

14

16

8

Mount cable bracket (Ref. 22)

on right hand side of handle

using shift control bracket

hardware.

15

19

18

41

40

Scraper blade should

be on inside of housing.

39

42

35

37

10

9

Coat top and bottom of

chute ring with grease.

When installing cable,

23

make sure it does not

come into contact with

muffler.

muffler.

24

27

25

26

38

36

28

29

30

31

34

33

32

The above parts group applies to the following Mfg. Nos.:

1694589 - 9560E

1694590 - 1060E

1694591 - 1170E

1694592 - 1280E

1694597 - 9560M

1694598 - 1060M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

1694599 - 1170M

1694600 - 1280M

28

TP 400-4155-01-LW-S

Page 29

Auger Housing and Chute Group - 9560, 1060, 1170 & 1280 Models

PART NO. DESCRIPTIONREF NO QTY.

42 1612184C 1 HOUSING AND IMPELLER ASSEMBLY, 24" (Used on 9560 & 1060 Models)

42 1612185C 1 HOUSING AND IMPELLER ASSEMBLY, 28" (Used on 1170 Models)

42 1612186C 1 HOUSING AND IMPELLER ASSEMBLY, 32" (Used on 1280 Models)

Footnotes

The above parts group applies to the following Mfg. Nos.:

1694589 - 9560E

1694590 - 1060E

1694591 - 1170E

1694592 - 1280E

1694597 - 9560M

1694598 - 1060M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

1694599 - 1170M

1694600 - 1280M

29

TP 400-4155-01-LW-S

Page 30

Traction Drive Group

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

2

1

1

Mount ed outside

of frame.

Be sure tie bar support is in place. Move axle to

left (as viewed from back) to take up end play.

Move set collar (Ref. 49) to right to remove end

play in pivot arm (Ref. 40). Torque set screw

(Ref. 43) to 10 - 14 ft-lbs.

48

49

2

Apply loctite

(2 places).

3

20

22

Apply grease to

bearing areas.

Mounted inside of frame.

3

Lubricate with

4

5W 50 Synthetic oil.

21

Grease I.D. teeth•

and flange.

46

44

23

45

986712

Pack groove

with grease.

5

Mount to bracket in

6

frame weldment.

10

7

8

9

18

15

24

25

16

27

15

17

8

26

28

29

20

40

41

43

42

13

12

11

14

Apply Loctite and•

Torque to 55 - 60

in-lbs. when all parts

are against hub.

19

30

3

31

32

3

Mounted

outside of

2

frame.

33

Must pivot

freely.

Hook end to

top left corner

slot of frame.

Mount ed outside

of frame.

2

1

Mount in

hole at

upper rear

corner of

frame.

34

35

1

50

Torque to•

18 - 21 ft-lbs.

52

47

Torque to

10 - 14 ft-lbs.

Assemble Ref. 40, 44 & 51

with no end play. Parts

must rotate freely.

51

The above parts group applies to the following Mfg. Nos.:

1694589 - 9560E

1694590 - 1060E

1694591 - 1170E

1694592 - 1280E

1694593 - 1390E

1694597 - 9560M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

1694598 - 1060M

1694599 - 1170M

1694600 - 1280M

1694601 - 1390M

50

53

30

33

46

54

26

39

38

57

38

55

Grease bearing

area of Ref. 57.

37

58

36

59

56

Apply anti-seize

compound to wheel hub

area of Ref. 49 & 57.

TP 400-4155-01-LW-S

Page 31

Traction Drive Group

PART NO. DESCRIPTIONREF NO QTY.

1 1930601 8 SCREW, Hex Washer Head Taptite, 5/16-18 x 5/8

2 1667341 4 RETAINER, Bearing

3 1722703 4 BEARING, Ball

4 1726856 1 SHAFT, Hex

5 1921332 3 CAPSCREW, Hex Head, 5/16-18 x 3/4 G5

6 1725428 1 DISC, Friction with Insert

7 1665995 1 HUB, Friction Disc

8 1960684 6 NUT, Hex Keps, 5/16-18, Conical Washer

9 1960687 1 NUT, Hex Flange, 3/8-16 ESNA

10 1669256 1 ARM ASSEMBLY, Shift w/Bushing

11 1666114 1 BUSHING, 19/50 ID x 3/4 OD x 1-3/100 LG

12 1924940 1 WASHER, 3/8

13 1923701 1 CAPSCREW, Hex Head, 3/8-16 x 2 G5

14 1668255 1 SPRING, Extension

15 1678956 2 COLLAR, Thrust

16 1666207 1 PIN, Loop

17 1667335 1 COLLAR, Set

18 1724333 2 SCREW, Set Square Head Cup Point, 1/4-20 x 1/2

19 1726931 1 SPROCKET, 10 Tooth

20 2860164 4 WASHER, 5/8

21 1718752 1 JACKSHAFT, Double D

22 1720298 1 SPRING, Complete

23 1718689 1 CLUTCH, Sliding, 1/5LG, Powdered Metal

24 1720078A 1 ARM, Clutch

25 2827732 1 RING, Retaining Extension

26 1960114 3 WASHER, 3/4

27 1718688 1 GEAR, Stationary Clutch

28 1679556 1 SPACER, Heat Treated, 31/100 LG

29 1667330 1 SPROCKET

30 1666980 1 CHAIN, Roller

31 1718687 1 GEAR, Double D

32 1921333 3 CAPSCREW, Hex Head, 5/16-18 x 1 G5

33 1960686 2 NUT, Hex Flange, 5/16-18 ESNA

34 1700473 1 BELLCRANK

35 1666106 1 BUSHING, 11/32 ID x 3/4 OD x 1-3/50 LG

36 1922127 1 CAPSCREW, Hex Head, 5/16-18 x 1-3/4 G5

37 1726467 1 ROD, Pivot, 9-15/100 LG

38 1722460 1 PIN, Quick

39 1725666 1 SPRING, Extension

40 1719879 1 DRIVE DISC with SPINDLE

41 2818312 1 KEY, Woodruff, 47/250 x 5/8

42 1960114 1 WASHER, 3/4

43 1924366 1 WASHER, 5/8

44 1670849 1 ARM, Pivot with Bushings & Bearings (Includes Ref. Nos. 45, 46, 47 & 48)

Footnotes

The above parts group applies to the following Mfg. Nos.:

1694589 - 9560E

1694590 - 1060E

1694591 - 1170E

1694592 - 1280E

1694593 - 1390E

1694597 - 9560M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

1694598 - 1060M

1694599 - 1170M

1694600 - 1280M

1694601 - 1390M

31

TP 400-4155-01-LW-S

Page 32

Traction Drive Group

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

2

1

1

Mount ed outside

of frame.

Be sure tie bar support is in place. Move axle to

left (as viewed from back) to take up end play.

Move set collar (Ref. 49) to right to remove end

play in pivot arm (Ref. 40). Torque set screw

(Ref. 43) to 10 - 14 ft-lbs.

48

49

2

Apply loctite

(2 places).

3

20

22

Apply grease to

bearing areas.

Mounted inside of frame.

3

Lubricate with

4

5W 50 Synthetic oil.

21

Grease I.D. teeth•

and flange.

46

44

23

45

986712

Pack groove

with grease.

5

Mount to bracket in

6

frame weldment.

10

7

8

9

18

15

24

25

16

27

15

17

8

26

28

29

20

40

41

43

42

13

12

11

14

Apply Loctite and•

Torque to 55 - 60

in-lbs. when all parts

are against hub.

19

30

3

31

32

3

Mounted

outside of

2

frame.

33

Must pivot

freely.

Hook end to

top left corner

slot of frame.

Mount ed outside

of frame.

2

1

Mount in

hole at

upper rear

corner of

frame.

34

35

1

50

Torque to•

18 - 21 ft-lbs.

52

47

Torque to

10 - 14 ft-lbs.

Assemble Ref. 40, 44 & 51

with no end play. Parts

must rotate freely.

51

The above parts group applies to the following Mfg. Nos.:

1694589 - 9560E

1694590 - 1060E

1694591 - 1170E

1694592 - 1280E

1694593 - 1390E

1694597 - 9560M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

1694598 - 1060M

1694599 - 1170M

1694600 - 1280M

1694601 - 1390M

50

53

32

33

46

54

26

39

38

57

38

55

Grease bearing

area of Ref. 57.

37

58

36

59

56

Apply anti-seize

compound to wheel hub

area of Ref. 49 & 57.

TP 400-4155-01-LW-S

Page 33

Traction Drive Group

PART NO. DESCRIPTIONREF NO QTY.

45 1665521 1 BEARING, Ball

46 1666425 2 BUSHING, 3/4 ID x 1 OD x 3/4 LG, Powder Metal

47 1666855 1 BUSHING, 5/8 ID x 13/16 OD x 3/4 LG, Powder Metal

48 1666001 1 BUSHING, 377/100 ID x 1-13/100 OD x 1 LG, Powdered Metal

49 1720299 1 AXLE, Round

50 1928721 2 SCREW, Set Square Head Cup Point, 5/16-18 x 1/2 G8

51 1672595A 1 PULLEY AND HUB ASSEMBLY

52 1919394 1 WASHER, 1

53 1729254 1 COLLAR, Set

54 1720300 1 GEAR AND HUB ASSEMBLY- RH

55 1930570 1 CAPSCREW, Hex Head, 5/16-18 x 1-1/2 G8

56 2821133 1 FITTING, Lube 1/4 Drive, No Check Ball

57 1720716 1 GEAR AND HUB ASSEMBLY, with Bushings

58 2860169 1 WASHER, 1-47/250

59 1720305 1 BUSHING, 1-27/200 ID x 1-157/250 OD x 3/4 LG

Footnotes

The above parts group applies to the following Mfg. Nos.:

1694589 - 9560E

1694590 - 1060E

1694591 - 1170E

1694592 - 1280E

1694593 - 1390E

1694597 - 9560M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

1694598 - 1060M

1694599 - 1170M

1694600 - 1280M

1694601 - 1390M

33

TP 400-4155-01-LW-S

Page 34

Wheels & Tires Group

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

1

2

4

5

986549

3

6

10

7

6

8

4

9

The above parts group applies to the following Mfg. Nos.:

1694589 - 9560E

1694590 - 1060E

1694591 - 1170E

1694592 - 1280E

1694593 - 1390E

1694597 - 9560M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

1694598 - 1060M

1694599 - 1170M

1694600 - 1280M

1694601 - 1390M

34

TP 400-4155-01-LW-S

Page 35

Wheels & Tires Group

PART NO. DESCRIPTIONREF NO QTY.

1 1921978 1 CAPSCREW, Hex Head 5/16-18 x 2 G5

2 1919438 1 NUT, Hex Lock ESNA Light 5/16-18 NC-3B

3 1726743 1 WHEEL & TIRE ASSEMBLY, Snow R.H. (Used on 24 & 28 in. Models)

3 1726745 1 WHEEL & TIRE ASSEMBLY, Snow R.H. (Used on 32 & 38 in. Models)

4 2172353 2 VALVE STEM & CAP ASSEMBLY, Air

5 1714242 1 HUB, Wheel R.H., 3-3/4 Wide 8 Diameter 3/4 ID (Used on 24 & 28 in. Models)

5 1722762 1 HUB, Wheel, 5-3/8 Wide 8 Diameter 3/4 ID (Used on 32 & 38 in. Models)

6 1727074 2 TIRE, 4.80/4.00-8, X-TRAC TL (Used on 24 & 28 in. Models)

6 1727075 2 TIRE, 16 x 6.5-8 X-TRAC TL (Used on 32 & 38 in. Models)

7 1726742 1 WHEEL & TIRE ASSEMBLY, Snow L.H. (Used on 24 & 28 in. Models)

7 1726744 1 WHEEL & TIRE ASSEMBLY, Snow L.H. (Used on 32 & 38 in. Models)

8 1720307 1 HUB, Wheel L.H., 3-3/4 Wide 8 Diameter 1-1/8 ID (Used on 24 & 28 in. Models)

8 1722761 1 HUB, Wheel 5-3/8 Wide 8 Diameter 1-1/8 ID (Used on 32 & 38 in. Models)

9 2153038 2 TUBE, Tire

10 1666969 1 PIN, KLIK, Ring

Footnotes

The above parts group applies to the following Mfg. Nos.:

1694589 - 9560E

1694590 - 1060E

1694591 - 1170E

1694592 - 1280E

1694593 - 1390E

1694597 - 9560M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

1694598 - 1060M

1694599 - 1170M

1694600 - 1280M

1694601 - 1390M

35

TP 400-4155-01-LW-S

Page 36

Decal Group

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

Free Hand

Free Hand

Unlocked

Locked

Traction

Traction

1727020

Disengage

Engage

1727021

• Read the operat or's m anu al fo r oper atin g and safet y

instructions.

• Do not defeat the safety features of control. They are

for your protection.

• Keep machine properly maintain ed and serviced with

all shi eld s, g uards, and prot ecti ve devi ces in pl ace.

• Never allo w ch ild ren t o op erate sn owth rower.

• Keep area of operation clear of all persons,

especially children.

2

WAR NI N G

AVOID SERIOUS INJURY OR DEATH

• Always direct discharge chute so as to avoid

injury to persons or damage to property.

• Stop engine and disconnect spark plug wire

before servicing the unit.

• When tracti on and au ger co ntro ls are d epressed ,

the Free Han d™ control is activated. This allows

the auger co ntr ol t o be re leased , yet a uger

rotatio n wi ll cont inu e un til th e Free Han d co ntro l

is released.

4

5

986738

3

Auger

Engage

Auger

Disengage

1726946

1

3

1727023

5

6

6

1

2

4

6

7

8

7

8

9

10

9

11

12

13

10

11

1716532

15

16

15

14

The above parts group applies to the following Mfg. Nos.:

1694589 - 9560E

1694590 - 1060E

1694591 - 1170E

1694592 - 1280E

1694593 - 1390E

1694597 - 9560M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

1694598 - 1060M

1694599 - 1170M

1694600 - 1280M

1694601 - 1390M

36

TP 400-4155-01-LW-S

Page 37

Decal Group

PART NO. DESCRIPTIONREF NO QTY.

1 1726945 1 DECAL, Dashboard EZ Turn L.H. (Tube Handle Models Only)

1 1727022 1 DECAL, Dashboard EZ Turn L.H. (CE)

2 1715557 1 DECAL, 5 4 3 2 1 R1 R2, Shift Pattern (Tube Handle Models Only)

3 1726946 1 DECAL, Auger Control R.H. (Tube Handle Models Only)

3 1727023 1 DECAL, Auger Control R.H. (CE)

4 1715558 1 DECAL, Simplicity (Tube Handle Models Only)

5 1722867 1 DECAL, Handle Lubrication (Tube Handle Models Only)

6 1726947 1 DECAL, Dashboard EZ Turn (Channel Handles)

6 1727024 1 DECAL, Dashboard EZ Turn (Channel Handles) (CE)

7 1714245 1 DECAL, 4 2 R1 Ground Speed, R.H. (Channel Handle Models Only)

8 1714246 1 DECAL, 5 3 1 R2, Shift Pattern, L.H. (Channel Handle Models Only)

9 1727019 1 DECAL, Stripe, 9560

9 1725376 1 DECAL, Stripe, 1060

9 1725377 1 DECAL, Stripe, 1170

9 1725378 1 DECAL, Stripe, 1280

9 1724075 1 DECAL, Stripe, 1390

10 7071880 1 DECAL, DANGER Chute Cleaning

10 1727207 1 DECAL, WARNING Chute Cleaning (CE)

11 1716532 1 DECAL, DANGER Avoid Injury from Auger

11 1727208 1 DECAL, WARNING Impeller (CE)

12 * 1 DECAL, OPEI Certified

13 1725507 1 DECAL, Power Boost (1060, 1170, 1280 & 1390 Models Only)

14 * 1 DECAL, Patent

14 * 2 LABEL, Decibel, Power MASS (CE)

15 1720454 1 DECAL, Touch Up Paint, Orange

16 * 1 DECAL, Serial I.D. Tag

Footnotes

The above parts group applies to the following Mfg. Nos.:

1694589 - 9560E

1694590 - 1060E

1694591 - 1170E

1694592 - 1280E

1694593 - 1390E

1694597 - 9560M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

1694598 - 1060M

1694599 - 1170M

1694600 - 1280M

1694601 - 1390M

37

TP 400-4155-01-LW-S

Page 38

Headlight Group

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

986371

1

7

2

4

6

Existing

Hardware

5

3

The above parts group applies to the following Mfg. Nos.:

1694589 - 9560E

1694590 - 1060E

1694591 - 1170E

1694592 - 1280E

1694593 - 1390E

1694597 - 9560M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

1694598 - 1060M

1694599 - 1170M

1694600 - 1280M

1694601 - 1390M

38

TP 400-4155-01-LW-S

Page 39

Headlight Group

PART NO. DESCRIPTIONREF NO QTY.

1 1725291 1 HEADLIGHT ASEMBLY

2 1701011 2 TIE, Self Locking

3 2834683 1 CLIP, Wire

4 1709256A 1 LOCKWSHER, 5/16

5 1917372 1 NUT, Hex, 5/16-18

6 1725292C 1 BRACKET

7 1931333 1 CARRIAGE BOLT, 5/16-18 x 3/4

Footnotes

The above parts group applies to the following Mfg. Nos.:

1694589 - 9560E

1694590 - 1060E

1694591 - 1170E

1694592 - 1280E

1694593 - 1390E

1694597 - 9560M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2005

1694598 - 1060M

1694599 - 1170M

1694600 - 1280M

1694601 - 1390M

39

TP 400-4155-01-LW-S

Page 40

Page 41

Hardware Identification & Torque Specifications

Common Hardware Types

Hex Head Capscrew

Carriage Bolt

Standard Hardware Sizing

When a washer or nut is identified as 1/2”, this is the

Nominal size

second number is present it represent the

When bolt or capscrew is identified as 1/2 - 16 x 2”, this

means the

second number represents the

example, and the final number is the

bolt or screw (in this example 2 inches long).

, meaning the

Nominal size

inside diameter

, or

body diameter

threads per inch

body length

Washer

Lockwasher

Hex Nut

is 1/2 inch; if a

threads per inch

is 1/2 inch; the

(16 in this

of the

The guides and ruler furnished below are designed to

help you select the appropriate hardware and tools.

0

1/4 3/4

1/2

Nut, 1/2”

Inside

Diameter

1

1/4 3/4

1/2

Screw, 1/2 x 2

2

1/4 3/4

1/2

3

1/4 3/4

1/2

4

Body

Diameter

Body

Length

Torque Specification Chart

FOR STANDARD MACHINE HARDWARE (Tolerance ± 20%)

Hardware

Grade

Size Of

Hardware ft/lbs Nm. ft/lbs Nm. ft/lbs Nm.

8-32

8-36

10-24

10-32

1/4-20

1/4-28

5/16-18 11 15.0 17 23.1 25 34.0

5/16-24 12 16.3 19 25.8 27 34.0

3/8-16 20 27.2 30 40.8 45 61.2

3/8-24 23 31.3 35 47.6 50 68.0

7/16-14 30 40.8 50 68.0 70 95.2

7/16-20 35 47.6 55 74.8 80 108.8

1/2-13 50 68.0 75 102.0 110 149.6

1/2-20 55 74.8 90 122.4 120 163.2

9/16-12 65 88.4 110 149.6 150 204.0

9/16-18 75 102.0 120 163.2 170 231.2

5/8-11 90 122.4 150 204.0 220 299.2

5/8-18 100 136 180 244.8 240 326.4

3/4-10 160 217.6 260 353.6 386 525.0

3/4-16 180 244.8 300 408.0

7/8-9 140 190.4 400 544.0 600 816.0

7/8-14 155 210.8 440 598.4 660 897.6

1-8 220 299.2 580 788.8 900 1,244.0

1-12 240 326.4 640 870.4 1,000 1,360.0

1. These torque values are to be used for all hardware

excluding: locknuts, self-tapping screws, thread forming

screws, sheet metal screws and socket head setscrews.

2. Recommended seating torque values for locknuts:

a. for prevailing torque locknuts - use 65% of grade 5

torques.

b. for flange whizlock nuts and screws - use 135% of

grade 5 torques.

3. Unless otherwise noted on assembly drawings, all torque

values must meet this specification.

No

Marks

SAE Grade 2 SAE Grade 5 SAE Grade 8

in/lbs in/lbs

19

20

27

31

66

76

2.1

2.3

3.1

3.5

7.6 8 10.9 12 16.3

8.6 10 13.6 14 19.0

30

31

43

49

NOTES

3.4

3.5

4.9

5.5

in/lbs

41

43

60

68

420 571.2

4.6

4.9

6.8

7.7

Wrench & Fastener Size Guide

1/4

1/4” Bolt or Nut

Wrench—7/16”

5/16

5/16” Bolt or Nut

Wrench—1/2”

3/8

3/8” Bolt or Nut

Wrench—9/16”

7/16

DIA.

7/16” Bolt or Nut

Wrench (Bolt)—5/8”

Wrench (Nut)—11/16”

1/2

DIA.

1/2” Bolt or Nut

Wrench—3/4”

Page 42

MANUFACTURING, INC.

500 N. Spring Street / PO Box 997

Port Washington, WI 53074-0997 USA

www.simplicitymfg.com

© Copyright Simplicity Manufacturing, Inc.

All Rights Reserved. Printed In USA.

2005

Loading...

Loading...