Page 1

0

sziip!c!g

OPERATOR’S

MANUAL

Chipper Vacuum

5125

Series

Mfg. No. Description

1692371

1692562 Model 5/25,5HP Chipper Vacuum

5125

Mfg. No. Description

1692373 Model 6/25,6HP Chipper Vacuum

1692564

8/25E

Mfg. No.

1692466 Model 6/25E, 6HP Chipper Vacuum, Electric Start

1692566

Model 5/25,5HP Chipper Vacuum

Series

Model

8/25,6HP Chipper Vacuum

Series

.Description

Mddel 6/25E, 6HP Chipper Vacuum, Electric Start

Page 2

MANUFACTURING, INC.

500 N Spring Street

Port Washington, WI 53074-0997

www.simplicitymfg.com

0

Copyright 1998, Simplicity Manufacturing, Inc.

All Rights Reserved. Printed in USA.

I

PO Box 997

Page 3

Baker

Chipper/Shredder

OPERATOR’S

MANUAL

Chipper Vacuum

5125

Series

Mfg. No. Description

1692372 Model 5/25,5HP Chipper Vacuum

1692583 Model

8125

Series

Mfg. No.

1692374

1692585 Model 8/25,8HP Chipper Vacuum

8/25E

Mfg. No., Description

1692467b Model 8/25E, 8HP Chipper Vacuum, Electric Stalt

1692587 Model 8/25E, 8HP Chipper Vacuum, Electric

Series

5/25,5HP Chipper Vacuum

Description

Model

8/25,8HP Chipper Vacuum

Start

Page 4

Baker

500 N. Spring Street \ P.O. Box 997

Port Washington, WI 53074.0997 USA

0

Copyright 1998, Simplicity Manufacturing, Inc.

All Rights Reserved. Printed in USA.

Page 5

INTRODUCTION

Model

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SAFETY RULES

General Safety

Safety Decals

Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

...................................................

NORMAL CARE

.7

STORAGE

Scheduled

Maintenance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Servicing the Chipper Vacuum

Bag

Care .

Battery

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

:.:.......................................... 21

. . . . . . . . . . . . . . . . . . . . . . . 19

Temporary Storage ........................................

FEATURES & CONTROLS

Major Components..

......................................... .8

Controls.. ...........................................................

OPERATION

Site Location

Checks Before

Start-Up..

Walk Behind

Chipping..

Flex Hose Vacuum/Shredding

Shutting Down..

Material Collection

Operator Adjustments

Seasonal Hints..

Performance Tips..

Waste Materials Guide..

...................................................

Starting..

................................

........................................................

Vacuum/Shredding..

..................

.......................................................

.......................

..............................................

&

Disposal..

.....................

....................................

.............................................

.........................................

.................................

g

TROUBLESHOOTING & REPAIR

10

.I0

.I0

.I1

.I2

.I3

.I4

.I5

.I6

.I7

OPTIONS & ACCESSORIES

.I7

.I8

Term/Seasonal

Long Storage

General Troubleshooting .......................................

Power

Electric

Optional

Shredding

Chipping Knives ......................................................

Drive

Drive

Vacuum

Clutch

Vacuum

Technical

Drive Troubleshooting ................................

Start Troubleshooting................................ .24

Vacuum Hose Troubleshooting..

Hammers.. ............................................

.............................................................

Belt..

Chains.. .........................................................

Nozzle Height Adjustment

Cable.. .........................................................

Attachment.......................................

Manuals .........................................

........................

....................... .34

.22

.22

.23

.24

............. .24

.25

23

.32

33

35

.36

.36

ADANGER

You must read, understand and comply with all

safety and operating instructions in this manual

before attempting to set-up and operate your

Chipper Vacuum

Failure to comply with all safety and operating

instructions can result in loss of machine control,

serious

and risk equipment and property damage. The

angle in the text signifies important cautions or

warnings which must be followed.

I

0

Copyright 1989 by Simplicity Manufactufing, Inc. All Rights Reserved.

TP L00-2Lb8-02-cv-sB

oersonal iniurv

to vou and /or bvstanders.

tri-

’

I

NOTICE

Upon start-up and shut down,

metal-to-metal sound of the triangular hammers posi-

tioning themselves on the rotor. This is a normal sound.

If this sound continues after the machine obtains full

speed, please contact your dealer for an inspection of

your unit.

I

1

you may hear the

Page 6

Introduction

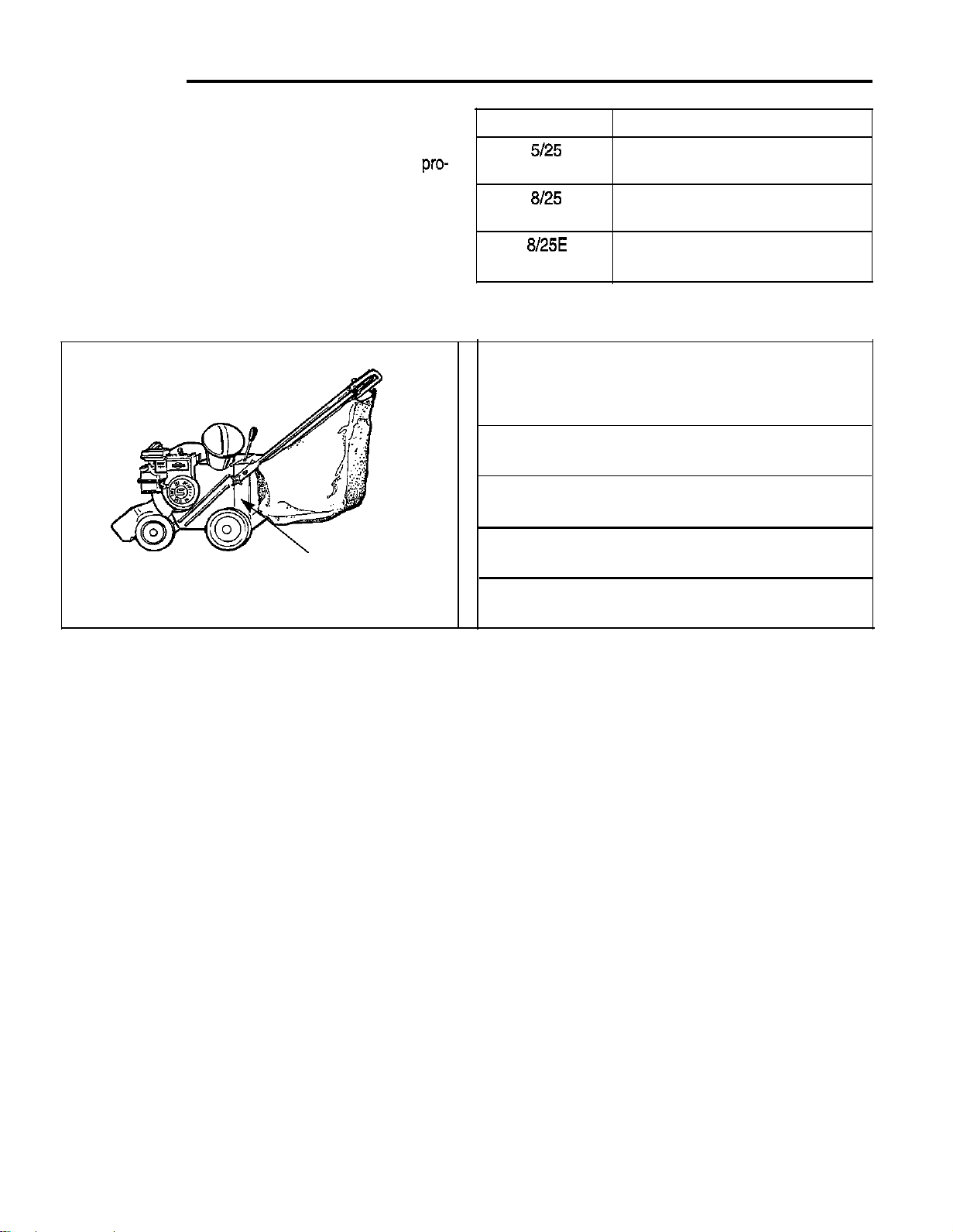

MODEL IDENTIFICATION

l

Record your model number, manufacturer number

and serial numberfrom the I.D. tag in the space

vided t for easy reference. The Chipper Vacuum I.D.

tag is located on the side of the unit as shown in the

illustration below.

l

Refer to the engine manufacturer’s owner’s manual

for the location of the engine serial number.

l

Be sure to fill out and return the Warranty

Registration Card supplied with your unit.

Identification Tag

Location

pro-

Model

5125

8125

8/25E

MODEL REFERENCE

Model Number:

Manufacturer Number:

Engine I.D. Number:

Dealer Name

Date Purchased:

Mfg. No.

1692371

1692582

1692372 1692583

1692373

1692584

1692374 1692585

1692466 1692586

1692467 1692587

2

Page 7

DESCRIPTION

General

The shredding chamber is designed to shred materials

that have been vacuumed directly into the unit through

the extra-wide vacuum intake nozzle or through the flexi-

ble vacuum hose, eliminating the need to manually load

or feed material into the shredder.

Selective vacuum-shredding can be performed with the

optional 20 foot long, large-diameter, quick-connect hose

while the unit is stationary, permitting

controlled vacuuming of areas such as flower or shrub

beds, or other confined or landscaped areas.

Large yard, garden, or other open, flat surface areas

can be cleaned up quickly and efficiently using the

Chipper Vacuum’s self-propelled feature, which permits

vacuuming of materials while the unit propels itself.

Shredding Action

Material is drawn into the shredding chamber by the

vacuum action of the spinning rotor, and is pulled into

the path of patented shredding hammers that are rotat-

ing at the same high speed as the rotor. The hammers

cut and grind the material into progressively smaller

pieces, and the flow of air then conveys the fully

ded,reduced waste into the discharge bag.

Vacuum Action

precisely-

shred-

rocks, gravel, and other debris before use. All materials and other debris that could damage the shredding hammers should be removed and properly dis-

posed of before starting the unit.

l Se particularly watchful for small, sharp objects such

as old nails, pieces of glass, and small metal objects

such as cans, can lids, bottle tops, etc.

l Review all operating safety instructions in this manu-

al before proceeding.

l Determine where the discharge bag will be emptied,

and if possible, plan a vacuum path that will allow

you to access this area easily while vacuuming.

Chipper Operation

The chipper is designed to handle tree limbs and

branches up to

up to 3” diameter on 13 HP models. The unit can also

process tough organic matter such as corn stalks and

berry canes.

Chipping operations should be performed while the unit

is stationary, and positioned so that the operator has

firm footing and easy access to the chipper cone area.

Tree limbs and branches should be inserted “butt end”

first into the chipper cone, and are fed into the chipper

block. The sharp cutting edges and angle of the blades

actually pull the tree limbs and branches into the chipper

block, cutting the material into small chips.

2-l/2” in diameter on 5 HP models, and

In addition to the shredding hammers and chipping

knives, the rotor has fan blades integrated into its

design. When the rotor is spinning, a constant, powerful

vacuum action is created, which aggressively pulls

waste into the shredder chamber for shredding.

These spinning fan blades also create a blowing force

that ejects the shredded or chipped material out of the

discharge chute and into the discharge bag, making

room for more material to be pulled in and processed.

Vacuum/Shredding

l Vacuum/Shredding can be performed in confined

areas using the vacuum hose attachment, or on

large, flat areas using the

extra-wide vacuum intake nozzle.

l Areas containing rocks, gravel, or other hard materi-

als should be avoided, as these types of materials

will damage the shredding hammers or reduce their

service life. Use of the unit to vacuum non-organic

materials will void the product warranty.

l Areas to be vacuumed should be inspected for

3-speed

power drive and

The chips of material then pass through a slot in the

rotor behind the chipper knives, where air flow conveys

them through the fan chamber and into the discharge

bag.

Blower Operation

The vacuum force makes it possible to use the unit as a

large-area, self-driven blower for clean-up of grass clip-

pings or other debris that you may not want to collect for

disposal or recycling.

Using the Chipper Vacuum in this mode requires the

removal of the discharge bag, and the attachment of the

optional deflector elbow. The deflector elbow is needed

to direct the powerful exhaust stream to either side of

the unit.

When used in this manner, the operator walks behind

the unit, allowing the discharge deflector elbow to blow

the lightweight debris toward an area where it can be

easily gathered later for disposal, or, as in the case of

grass clippings or other organic matter, be allowed to

decompose naturally as an added nutrient for the soil.

3

Page 8

The Safety Alert symbol shown to the left is used to alert you to important safety information that must be

A

read, fully understood, and followed at all times when handling, transporting, operating, servicing, or storing

your Chipper Vacuum.

intensity, or level, of the hazard the safety alert instructions pertain to. The following list of signal words is being

provided to help you understand the hazard levels associated with each signal word used in this manual.

The signal word “DANGER” is used when a serious

injury or fatality will result if the safety instructions

that follow this signal word are not obeyed.

e

A

The signal word “WARNING” is used when a serious injury or fatality could result if the safety

instructions that follow this signal word are not

obeyed.

A

The signal word “CAUTION” is used when personal injury, or property or equipment damage could

result if the safety instructions that follow this signal word are not obeyed.

Each safety alert symbol is followed by a “signal word” that advises you of the relative

A

DANGER

You must read and understand this manual and all

safety instructions and labeling completely, before

attempting to assemble, set-up, transport, operate,

service, or install any options or accessories on

WARNING

CAUTION

this unit.

This Chipper Vacuum is a powerful machine

designed for chipping of tree limbs and branches

up to 2

capable of amputating or causing serious injury to

fingers, hands, feet, and other extremities if acci-

dental contact with rotating chipper or shredder

blades should occur.

Always keep hands, feet, and other extremities out

of the chipper cone and vacuum intake areas, and

never wear loose fitting clothing or jewelry that

could get caught on tree limbs or branches, and

pull your hands, or other body parts into the rotat-

ing chipper blades.

l/2” in diameter (3” on 8 HP models), and is

GENERAL

Safe operation of the Chipper Vacuum requires that all

operating and safety instructions be obeyed by everyone

who uses, services, or otherwise handles the unit.

Although the instructions and warnings appearing in

this manual cover most normal operating conditions,

everyone using the Chipper Vacuum must also always

follow safe work practices while operating, servicing, or

handling the Chipper Vacuum unit under any conditions

not specifically covered in this manual.

The primary operator of the Chipper Vacuum must

always be alert for the presence of bystanders, who are

likely to be unaware of the operating and safety requirements necessary for safe operation. It is the operator’s

responsibility to prevent bystanders from being exposed

to potential hazards whenever the Chipper Vacuum is

being used.

If you do not understand any portion of these safety

instructions, or any other

manual, contact your local factory-authorized dealer for

help, or request factory assistance by calling: Customer

Service Department

NOTE: DO NOT use the Chipper Vacuum unless

are sure that you know how to comply with

and operating instructions.

part

of the instructions in this

-

414/284-3786

a//

safety

you

BEFORE START-UP

l Inspect the chipper cone for any debris, or other

material that may have fallen in during unpacking

and assembly. Always disconnect the spark plug

wire trom me spark plug

any objects from the chipper cone.

l Never fill the fuel tank indoors! Gasoline vapors are

explosive, and can easily travel unnoticed to sources

of ignition, such as pilot lights or open flames on

water heaters, furnaces, stoves, dryers or sparks

from electric motors and other electrical appliances,

or smoking materials. Contact with these or any

other ignition sources will cause an explosion or fire,

serious personal injury, and damage to property and

equipment.

l Gas cap shall never be removed or fuel added with

the engine running.

l Never overfill the fuel tank. Fuel may run out of the

tank and contact hot engine surfaces and ignite,

causing a fire and/or risk of an explosion. Always fill

the fuel tank to

l Use only an approved container for fuel, and always

handle the container with extreme care. Never

smoke while fueling or transporting the fuel container.

i/2” below bottom of filler neck only.

betOre

attempting to remove

4

Page 9

l Never store the fuel container or Chipper Vacuum

indoors where there is a possibility of contact with

any ignition source such as a spark, open flame,

pilot light, heating element, or smoking materials.

l Never attempt to test or operate the unit indoors or in

an enclosed area. Engine exhaust contains carbon

monoxide, an odorless, colorless, and tasteless gas.

If inhaled, carbon monoxide can cause dizziness or

nausea, and if prolonged contact occurs, uncon-

sciousness, brain damage, or death can result.

l Check all parts to ensure that they are properly

attached and that all hardware is secure.

l Make sure the discharge bag is securely attached to

the discharge chute and is properly supported by the

bag supports on the bottom of the handle, and the

sides of the rear frame.

l Make sure you have read and understand the engine

manual accompanying the Chipper Vacuum, and

know the location and function of all operating con-

trols for your model Chipper Vacuum. You must

understand how to start and stop the unit safely

before proceeding.

OPERATING LOCATION

l Always operate the Chipper Vacuum outdoors only,

on a firm, level, earthen or grassy area where the

unit will be stable and will stay in position. Never

attempt to operate the unit on a slope greater than

20 degrees, or on wet or slippery surfaces where

you or someone else could slip and fall toward the

chipper cone opening.

l Never operate the unit on rocky, gravel, or

covered surfaces, as this material could be sucked in

to the shredder housing through the vacuum intake

openings and cause damage to the shredder.

l This equipment shall not be operated in the vicinity

of bystanders. Never operate the unit where children,

pets, or others who may be unaware of the potential

hazards associated with chipping, shredding, or vacuuming operations could enter the area unexpectedly

and be exposed to these hazards.

l Never use the optional hose kit to vacuum up rocky,

gravel, or stone-covered surfaces,, as this material

will cause damage to the shredderand other internal

components.

l Never operate in an area where sparks from the

muffler could ignite surrounding dry brush or other

flammable materials. See following Fire Hazard

Warning!

l Wear hearing protection when the Chipper Vacuum

is to be used for prolonged periods of time, or when-

ever noise reaches an uncomfortable level.

stone-

A

CAUTION

SPARK/FIRE HAZARD

GAS ENGINES MAY REQUIRE A SPARK

ARRESTER FOR SAFE OPERATION

If the engine on this unit is not equipped with a

spark arrester and is to be used on any forest,

brush, or grass-covered unimproved land, a spark

arrester must be added to the muffler before using

the engine on such land. The arrester must be

maintained in effective working order by the opera-

tor. In the State of California, the above is required

by law (Section 4442 of the California Public

Resources Code.) Other states may have similar

laws. Federal laws apply on federal lands. See your

authorized engine service center for muffler spark

arrester options.

SAFE WEARING APPAREL

l Always wear safety goggles to protect your eyes

from flying debris when operating the Chipper

Vacuum. One pair of safety goggles has been provided with the unit for your immediate use. All oth-

ers in and around the immediate area must also

wear approved safety glasses to protect their eyes

from flying debris.

l Always wear properly-fitted leather work gloves to

protect your hands from cuts and scratches caused

by tree limbs and branches. Never wear gloves with

pull-ties or straps, as these straps could get entan-

gled with branches and draw your hands into the

chipper cone cutting areas.

l Never wear loose-fitting clothing, hanging jewelry,

ties, scarves, or other items that could get caught on

tree limbs or branches, and draw body parts into the

cutting areas of the chipper cone.

l Always tie up long hair and prevent it from hanging

down, where it could become tangled in branches or

get caught in rotating parts and pull you into the cut-

ting areas.

l Even if you are wearing heavy-duty leather work

gloves, never, ever place your hands in the chipper

cone while the unit is running. If you must reach in

to clear a jam or free up branches, shut the unit off,

allow the rotor to come to a complete stop, discon-

nect the spark plug wire at the spark plug, and care-

fully remove or clear the jammed material.

OPERATING SAFETY

l Always obey the size limitations for tree limbs and

branches stated in the Waste Materials Guide sec-

tion of this manual.

5

Page 10

Safety Rules

l Never leave the machine running unattended.

Always turn off the engine, wait

ior the rotor to come

to a complete stop, and disconnect the spark plug

before leaving the area. Always move the unit to a

safe storage area for prolonged idle periods.

l Never allow children to operate the machine. Do not

allow adults to operate it without proper instruction.

l Always maintain secure footing and solid balance

while starting or operating the Chipper Vacuum.

Never lean directly over the machine.

l Select a speed suitable for operating conditions, and

stay clear‘of hazards such as large bushes, trees,

fences and anything else that could become caught

on or entangled with any part of the unit. Sudden

contact with these obstacles could cause a momentary loss of control of the unit, or cause you to lose

your balance and fall.

l Although the engine is powerful, never attach any

kind of cart or riding attachment to your Chipper

Vacuum. This is a walk-behind unit only, which will

provide years of reliable service when used properly.

l Always stand to one side of the chipper cone when

feeding tree limbs and branches. They may

occa-

sionally whip around forcefully or “kickback” while

being chipped.

l Always keep hands out of the chipper cone when

feeding materials. Never wrap fingers tightly around

branches as you are feeding them into the unit, as a

sudden inward surge could

pull your hands and arms

into the unit.

* If you are not using the discharge bag to collect

chipped debris, always direct the debris flow away

from yourself and others, and always stay clear of

the discharge area to avoid being struck by ricochets

or material being ejected from the machine.

l Never force material as it is being fed into the

machine, as this may result in a sudden kickback of

the material with sufficient force to injure you or other

bystanders.

l Never allow material to build up around the engine

during Chipper Vacuum operation. This could result

in a fire, or overheating of the engine.

l When using the Chipper Vacuum as a walk-behind,

large-area blower, always make sure the area to be

cleared of debris is free of gravel, stones, and other

hard debris that could be propelled with great force

by the powerful blowing action possible with this unit.

l Never continue to operate the machine if it starts

making unusual noise or vibration. Shut the engine

off immediately, allow the rotor to stop, disconnect

the spark plug wire from the spark plug, and do the

followina:

a. Inspect the unit for any signs of damage or for-

eign material in the chipping or shredding areas.

Remove any solid material that may be prevent-

ing the unit from operating properly.

b. Check for loose parts, and loose or missing hard-

ware, and repair or replace as reauired.

c. Check the oil level in the engine crankcase. See

the engine manual for the specific location of the

oil dipstick, the correct

the

t&e

of oil to add if the oil

checkina procedure. and

level

is low.

Never attempt to clear clogs from the chipper cone

or discharge area while the unit is running. Always

shut the engine off, allow the motor to come to a

complete stop, and remove the spark plug wire from

the spark plug before removing excess materials,

Never fill the fuel tank while the machine is running

or while the engine is hot. An unexpected spillover

of fuel could contact a hot surface and ignite, caus-

ing fire or explosion. Turn off the engine, and allow

the engine to cool before attempting refilling.

l Never attempt to perform any maintenance, repairs,

or attachment of accessories while the unit is

run-

ning. Always shut the unit off, allow the engine to

come to a complete stop, and remove the spark plug

wire from the spark plug before beginning these.

activities. See engine manufacturer’s owner’s

al for anv exceptions.

l Never remove covers, deflectors, or warning labels

.

manu-

from the unit. If any of these are found to be miss-

ing, take the unit out of service until the appropriate

repairs can be made. Tag the machine so others do

not mistakenly attempt to use it while awaiting parts

or repairs.

l Always make sure that the chipper cone area is

empty before restarting the unit after it has been idle.

Attempting to start the unit with material in this area

could cause the engine starting cord to jerk or stop

suddenly, causing a risk of injury to your hand or

arm.

l Never tamper with any engine controls to alter or

increase maximum unit running speed. An

over-

speeding condition could cause the engine to over-

heat, resulting in risk of fire, permanent engine dam-

age, and voiding of your product warranty.

l Always comply with the engine manual instructions

for operating and periodic maintenance require-

ments. Make sure the oil level is always in the safe

zone, and keep the air filter element clean.

l Never attempt to defeat, bypass, or disable Chipper

Vacuum safety features. Making alterations to this

-

6

Page 11

Safety Rules

equipment can result in serious injury, damage to

equipment, and voiding of your warranty.

TRANSPORTING AND STORAGE

l If you must travel across rock, gravel, or other

debris-covered terrain, set the engine speed control

to Wow”, and close the variable suction control flap

by moving the selector lever to the “closed” position.

l Never lift the unit using the fuel tank, vacuum intake

areas, or covers for support. If the unit must be lifted

for vehicular transportation, always use at least two

people, and always grip the unit securely using the

units rigid steel frame. The power drive feature

should only be used for loading by experienced

operators using ramps designed to ensure that the

unit stays properly positioned on the ramps while the

Chipper Vacuum is moving.

l If the unit must remain tilted for transportation, con-

sult the engine manual for required preparation,

Normally, engine fuel and oil must be drained to prevent dangerous fuel leakage, and unwanted transfer

of the sump oil into the cylinder head area.

l Always refill the oil sump with the recommended oil

before attempting to use the unit again after it has

been drained for transportation.

l Always observe safe refueling and fuel handling

practices when refueling the unit after transportation

or storage.

l Always follow the engine manual instructions for

storage preparations before storing the unit for

pro-

longed periods.

l Always follow the engine manual instructions for

proper pre-use start-up procedures when returning

the unit to service.

SERVICE AND MAINTENANCE

l Always follow recommended engine and Chipper

Vacuum procedures when performing required service and maintenance on the unit.

l Use only factory-authorized replacement parts for

repair along with recommended factory specifications

on all settings and adjustments.

l Never attempt to make major repairs on this unit

unless you have been properly trained and certified

to work on high-capacity gasoline powered Chipper/

Shredder or Chipper Vacuum units. Improper service procedures can result in hazardous operation,

equipment damage, and voiding of the product war-

ranty.

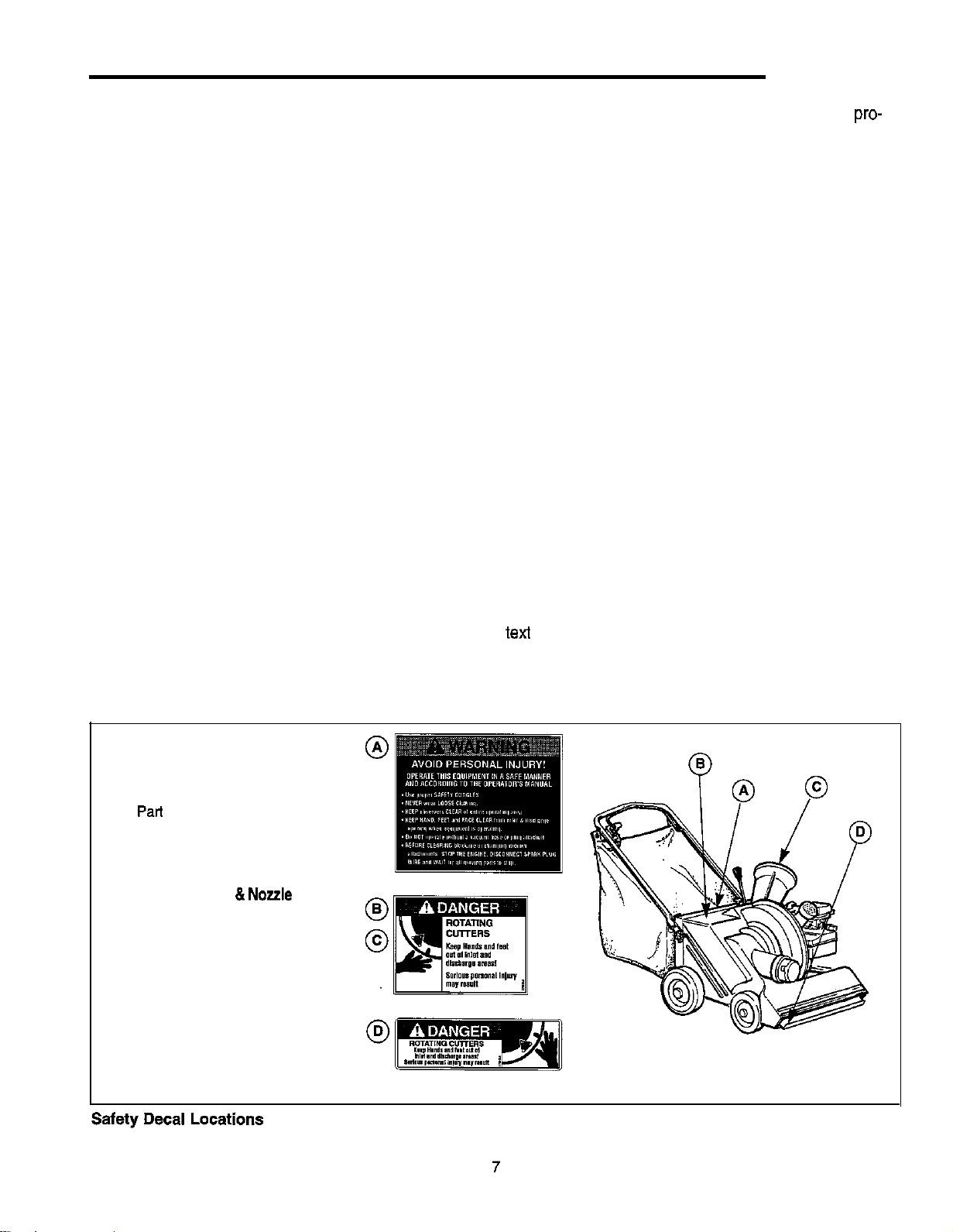

SAFETY DECALS

Important safety labels are shown in the following illustration. Please review these labels and if you have any

questions regarding their meaning or how to comply with

the instructions, re-read the complete safety instruction

text on the preceding pages, or contact your local dealer

or factory Customer Service Department. Use the pan

number information provided to order a replacement

label from your local factory-authorized dealer.

A. Operator Instruction Label

Part No. 1713665

B. Discharge Chute Danger Label

Part No. 5001612

C. Chipper Cone Danger Label

Pad No. 5001612

D.

Vacuum Hose & Nozzle Intake

Danger Label

Part No. 1709529

Page 12

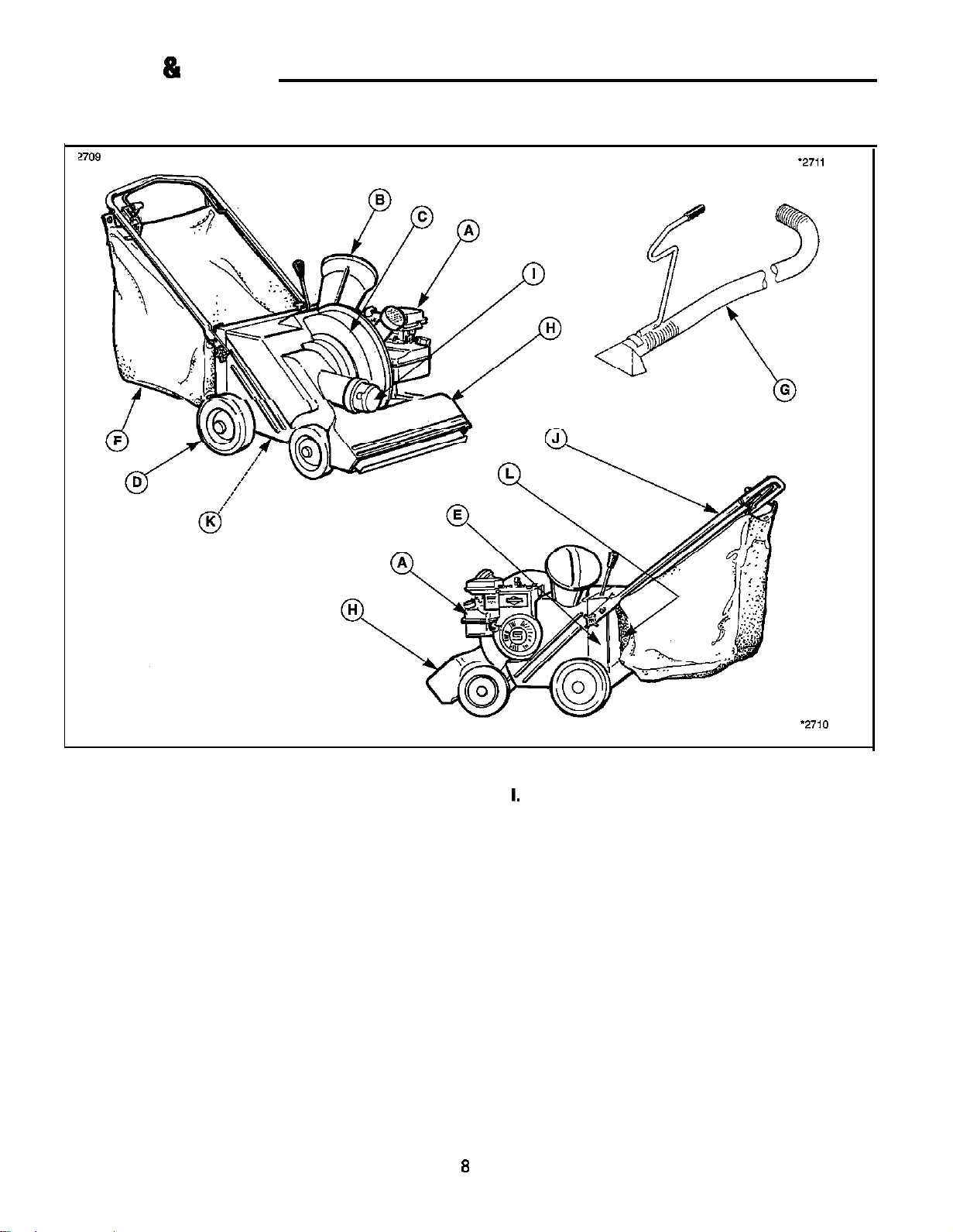

Features & Controls

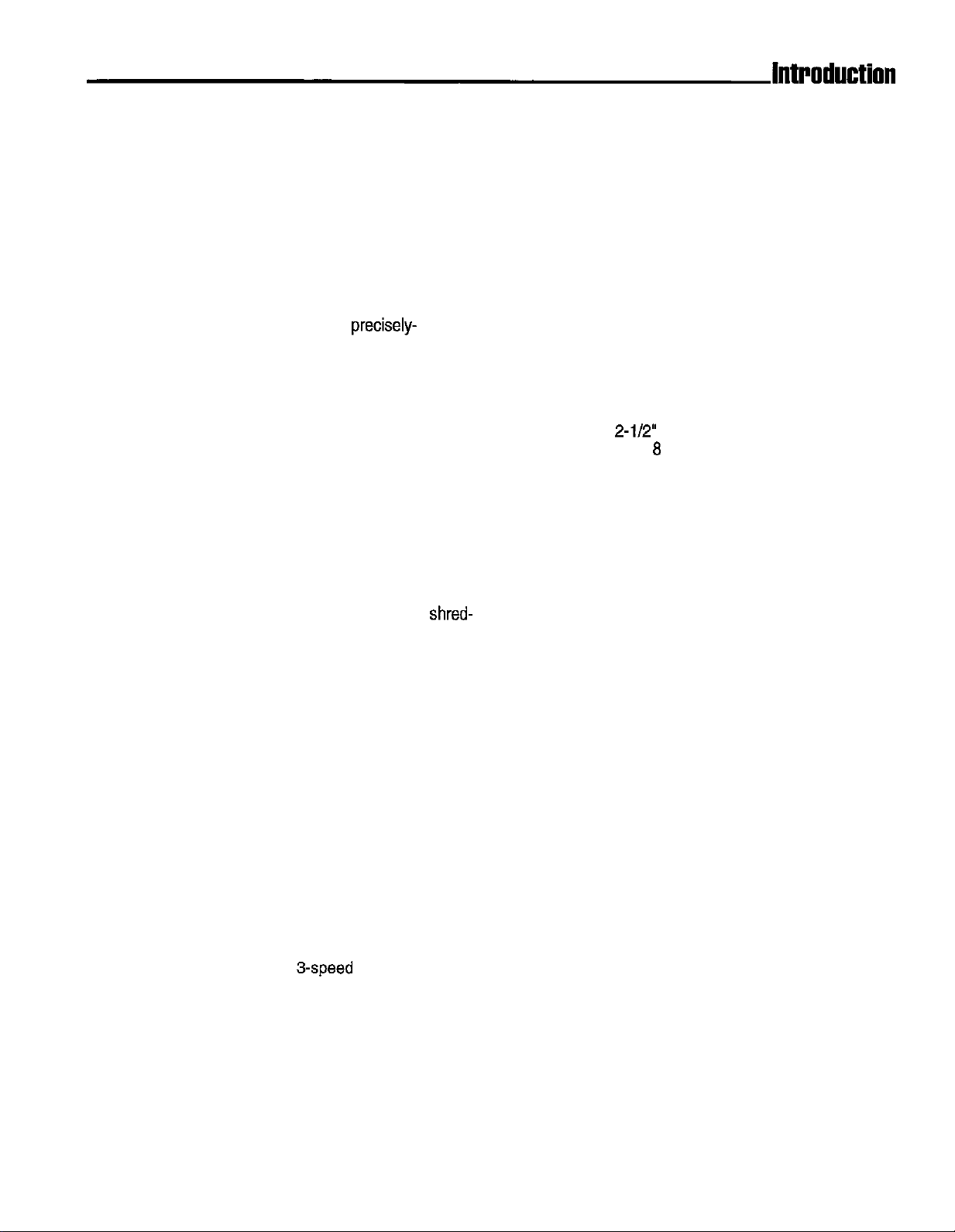

MAJOR COMPONENTS

OPTIONAL HOSE KIT ASSEMBLY

Engine

. Chipper Cone/Chipper Knives

. Shredding Chamber

. Drive Wheels

E. Frame

F. Discharge Bag

G. Vacuum Hose w/Nozzle (optional)

H.

Vacuum Nozzle w/Variable Suction Control

I.

Vacuum Hose Intake

J. Handle Assembly

K. Transmission (not shown)

L. Discharge Tube.

8

Page 13

CONTROLS

A. Choke

The choke controls the fuel to air ratio, and helps make

cold starts easier by providing a rich, easily-ignited fuel

mixture.

B. Throttle

The throttle controls engine speed, and allows you to

conserve fuel by powering down during idle periods, or

to achieve optimal chipping/shredding/vacuuming power

by running the engine at full speed.

C. Vacuum Nozzle Variable Suction

The vacuum nozzle Variable Suction Controlru is direct-

ly above and behind the vacuum nozzle, and has four

quick-set opening settings for variable nozzle suction

control:

l closed (for vacuuming with the optional hose

attachment)

l

113

open,

*

213 open

l full open.

Smaller nozzle openings provide the necessary vacuum

force for smaller debris, while a larger opening provides

the suction necessary for larger debris like large leaves.

D. Vacuum Nozzle Height Control

The vacuum nozzle height control lever is located at the

rear frame in front of the discharge bag. Three height

settings are available: Low, Medium, and High.

The low setting is suitable for smooth, hard surfaces,

while the medium and high settings are used for different terrain conditions. Settings are easily changed by

simply positioning the control lever into one of three different slots.

The height adjustment control may be fine-tuned by

means of an rod adjustment that permits precise position control for vacuuming of smooth surfaces. See the

adjustment procedure in the TROUBLESHOOTING

REPAIR section.

ControW

&

Operating Controls Locations (5 HP model shown)

E. Drive Speed Control

The Chipper Vacuum is self-propelled, and features

three forward speeds to help match vacuuming action to

surface conditions The drive speed control lever is

mounted on the handle within easy reach of the operator, permitting quick changes in travel speed. This feature allows you to rapidly adjust to changing conditions.

F. Power Drive Bail Lever

The power drive bail lever operates the clutch, the

mechanism that transfers power from the drive shaft to

the transmission.

Pulling the bail lever down against the Chipper Vacuum

handle engages the transmission, which drives the unit

forward for vacuum/shredding or moving the unit around

your yard and garden.

Releasing the lever disengages the transmission, stopping the power drive motion, and allowing the unit to

come to a stop to make adjustments, empty the bag, or

perform chipping or hose vacuuming operations.

Page 14

Operation

SITE LOCATION

1. Select an area that will provide stable footing for

both the Chipper Vacuum and the operator. Do not

operate on wet, slippery surfaces, or in areas with

heavy pedestrian traffic that may distract you from

alert operation of the unit.

2. Locate the Chipper Vacuum near the waste materials

to be chipped to reduce unnecessary lifting and

carrying.

3. Trim and stack the materials to be chipped for more

efficient and safe operation of the Chipper Vacuum.

4. Provide sufficient room for maneuvering around the

Chipper Vacuum. Never set up the work area so that

operators must over-reach or have to step over

materials to be processed.

5. Review all operating safety instructions before

proceeding.

6. Determine whether you wish to

bag to collect the chipped material, or the discharge

deflector elbow to direct the chipper discharge to a

safe area.

7. The optional discharge deflector elbow should only

be used when the unit is positioned over a sofi

surface such as soft dirt or grass, and should always

be directed to the side and away from the operator.

8. If the discharge bag is to be used, be sure to allow

adequate access around the Chipper Vacuum for

bag removal and reattachment.

A

DANGER

Internal combustion engines produce Carbon

Monoxide, a colorless, odorless, and tasteless gas

that can cause dizziness, nausea, unconsciousness, and even brain damage or death if breathed.

Operate the Chipper Vacuum outdoors in a well

ventilated location only.

Keep children, pets, and bystanders away from the

operating and discharge areas.

Failure to follow these instructions may result in

serious injury or death to you or bystanders.

use

the discharge

2. Inspect the chipper cone and make sure that it is

firmly attached to the shredder housing.

3. Check all parts to ensure that they are properly

attached and that all fasteners are properly tightened.

4. If a discharge bag is not going to be used to accu-

mulate waste material, make sure the discharge

deflector elbow is directed away from the operator,

and that the area selected for accumulation of

chipped or shredded material will not cause ejected

material to be deflected toward the operator or

bystanders.

5. If a discharge bag is being used, make sure it is

attached to the discharge chute securely, and is

correctly supported by using all four support straps.

6. Open the Variable Suction

ControlrM

intake flap on

the nozzle, and check to make sure no unwanted

debris or other objects are stuck in the nozzle.

7. Fill the fuel tank to a level no closer than

l/2”

from

the bottom of the filler neck. Obey all safety precautions while handling and fueling the unit. Use regular,

unleaded gas only.

8. Check oil level if unit has not been operated since

initial set-up.

9. Before attempting to start the unit, make sure:

l fuel cap is attached securely,

l oil dipstick is fully inserted in dipstick port,

l chipper cone cap is installed over chipper cone

opening if chipping is not to be performed,

l speed control lever is in normal, disengaged posi-

tion, and speed control selector is in position

#l,

iO.To use self-powered vacuum/shredding mode vacu-

um hose intake opening plug must be fully inserted

into intake opening.

Il.

To use

l hose end must be fully inserted in hose intake

20’

flexible hose for vacuuming:

opening.

l

Variable Suction

ControlrM

setting is set to closed

position.

l

area to be vacuumed is clear of rocks, gravel,

other hard or sharp debris, and small animals and

pets.

CHECKS BEFORE STARTING

1.

Inspect the chipper cone for debris and other objects

that may have fallen into the machine while the unit

was idle, and remove them before starting the unit.

Before reaching into the chipper cone, always

disconnect the spark plug wire first to prevent

accidental starting of the unit.

START-UP

The controls required to start the Chipper Vacuum are

located on the engine, and are marked “Choke” and

“Throttle” (Figure 1). A more detailed description of

engine operation and all related precautions and proce-

dures can be found in the engine manufacturer’s manual

supplied with each Chipper Vacuum.

10

Page 15

Starting The Engine - Manual Start Units

1. Move choke lever to full choke position.

2. Move throttle lever to “fast”.

3. Place foot on front wheel to hold unit firmly in place,

and adopt a stable stance.

4. Pull starting rope out slowly one time and allow to

return normally.

5. Pull starting rope out with a steady pull, and allow

rope to return normally.

6. When engine starts, gradually move choke lever to

“no choke” position.

7. Maintain throttle speed at ‘fast” for best performance.

Starting The Engine - Electric Start Units

I.

Move choke lever to full choke position.

2. Move throttle lever to “fast”.

3. Turn key to

4. Release key when engine starts, allowing key to

return to “on’ position.

5. When engine starts, gradually move choke lever to

“no choke” position.

6. Maintain throttle speed at ‘fast” for best performance.

“stall

position

Operation

Choke

throttle

controls

Figure 1. Typical Choke And Throttle Controls

--&

Bail Lever

Jx-A

&

Idle Speed

Use the “idle” position on the throttle lever to reduce

stress on the engine when chipping or

ding is not being performed. Lowering the engine speed

to “idle” will help extend engine life, as well as conserve

fuel and reduce the noise level of the equipment.

vacuumfshred-

WALK BEHIND VACUUM/SHREDDING

Normal operator position for power-drive, walk-behind

vacuum/shredding is directly behind the unit holding the

units handle securely with two hands. This position provides the best combination of unit control, forward and

side

vrsrbrlrty,

and overall operator safety (Figure 2).

Figure 2. Pull Bail Lever Down And Grip Against

Handle To Engage Transmission

The powered wheel drive is engaged by pulling the

width bail lever down where it can be comfortably

gripped against the chipper vacuum handle. Releasing

the bail stops the forward movement and disengages

the transmission, making it easier to turn or maneuver

the unit.

full-

11

Page 16

Operation

Drive Speed Selector

Forward speed is selected using the speed control lever

mounted on the right side of the handle. The speed

control lever has three positions: slow, medium or fast

(Figure 3).

The ability to select different speeds for differing types of

waste material pick-up and varying surface conditions

helps give you precise control over the unit, which is fur-

ther enhanced by the 3-position vacuum height adjust-

ment and

(These adjustment features will be covered later.)

SLOW SPEED - POSITION #l

Slow drive speed is selected when the lever is pulled all

the way back toward the operator into position number

one (Figure 3).

Slow speed is recommended for initial use to help the

operator get accustomed to the driving characteristics of

the unit, and to move the unit very short distances, or for

using the flexible vacuum hose.

Slow speed is also recommended for vacuum/shredding

of wet leaves on heavy density ground cover such as

long, wet grass or thick weeds, or wherever heavier

materials or rougher ground covering requires concen-

trated vacuuming action.

MEDIUM SPEED

Medium drive speed is selected by moving the lever to

position

Medium speed is used when vacuuming leaves that may

be moist, or clinging to medium length ground cover.

FAST SPEED - POSITION #3

Fast drive speed is selected by moving the speed selec-

tor lever to position #3 (Figure 3).

Fast speed is recommended for vacuum/shredding of

light, dry leaves or debris on short or light density

ground cover. It may also be used by experienced oper-

ators to move the Chipper Vacuum long distances.

Changing drive speed should only be done while

the unit is stopped and the bail lever,+ completely

released. Attempting to change drive speed while

the unit is running may damage the transmission or

cause premature wear of transmission and clutch

components.

4-position vacuum intake opening adjustment.

- POSITION #2

#2

(Figure 3).

A

CAUTION

Figure 3. Speed Selector Lever And Positions

CHIPPING

General

Variations in the size and hardness of the materials

being chipped will affect how quickly the material is

pulled in to the chipping knives. Small diameter

softwood branches will

diameter hardwood tree limbs, so be prepared for

different feeding speeds when changing the type of

material you are chipping. Kiln-dried dimensional

lumber may be too hard to chip properly.

Speed Selector Lever

A

WARNING

Release the bail lever immediately to stop the for-

ward travel of the unit if you see, step on, or sus-

pect to encounter any dangerous debris such as

rocks, gravel, glass, or other hard or sharp objects

anywhere in the path of the Chipper Vacuum.

Clear the debris before proceeding, and dispose of

the material properly to prevent contact with it

again later.

Allowing the Chipper Vacuum to vacuum these

types of materials may result in personal injury to

the operator or bystanders, and will damage the

shredding hammers, reducing shredding efficien-

cy, and voiding the warranty.

chip more readily than larger

l Always maintain a stable, well-balanced stance to

one side of the unit when operating the chipper

(Figure 4).

l Never stand directly in front of the chipper cone

when performing chipping operations, since occasional kick-backs or twirling of branches and limbs

may occur, resulting in

limb or branches.

you

being struck by the tree

12

Page 17

l Hold tree limbs and branches carefully as they are

being put into the chipper cone, releasing your grip

as soon as the self-feeding action of the chipper

knives begin to pull the material in.

l Longer pieces may have a tendency to twirl around

forcefully as they are being drawn into the chipping

knives. Hold the material safely away from the chipper cone area until the material is properly controlled

by the chipper cone.

l Never wrap your fingers around tree limbs and

branches, or hold so tightly that you can’t let go

quickly if the tree limb or branch is suddenly and

forcefully pulled into the chipper block chipping

knives. Short pieces may be pushed into the chipper

using longer limbs and branches. Stand to the side

when feeding shod pieces, since they may kick back.

Operation

Figure 4. Proper Operator Stance For Chipping

Feeding Material

1. Prune tree limbs and large branches to limit size to

the maximum diameter allowed. Pruning tree limbs

and branches close to the main portion of the limb or

branch will make feeding into the chipper cone

er, and will help you maintain control as the material

is drawn into the chipper block.

2. Large, hard or dried-out tree limbs that tend to resist

chipping can be processed by rotating them manually as you alternately insert and retract them in the

chipper cone.

3. If the material to be chipped is extremely hard and

kicks back forcefully, or cannot be easily controlled

while it is being fed into the unit, remove the material

immediately and set it aside. You may need to sharpen

the chipper blades to process the material. Consult

the repair section of this manual for sharpening instructions, or take your unit to an authorized service center.

4. If normal chipping operation begins to require additional feeding force to process material, the chipper

knives may be in need of routine sharpening. See the

repair section of this manual for sharpening instruc-

tions, or take your unit to an authorized service center.

5. Always try to maintain adequate control of the tree

limbs and branches being fed into the chipper cone

to prevent them from whipping around and causing

injury to you or damage to the cone. Larger limbs

and branches may have a tendency to kick back

toward the operator, so always be alert as you feed

materials into the cone. Always, feed the large end of

the limb in first.

6. Avoid chipping limbs or branches that you suspect

may have imbedded objects such as hooks, eyelets,

nails, screws, or other metal items that could dam-

age the chipping knives. If possible dispose of them

easi-

using another means.

7. Check the chipper cone periodically to make sure it

is securely fastened to the housing.

cone become loosened, stop the unit, and tighten

assembly hardware securely.

FLEX HOSE VACUUM/SHREDDING

Vacuum/shredding of confined areas such as plant beds

and decorative landscaping can be performed quickly

and effectively using the 15’ flexible vacuum hose available for your Chipper Vacuum.

Changing over to flex hose vacuuming can be done

quickly and requires no tools.

To convert your unit for use with the

hose, just follow these easy steps:

1. Shut the unit off if it is running, and allow the rotor to

come to a complete stop. (Make sure any material

being shredded or chipped is completely processed

before stopping the unit.) When the rotor is fully

stopped, no noise or vibration will be noticeable.

2. Set the vacuum intake nozzle flap adjustment to the

closed position.

3. Remove the vacuum hose intake plug from the

vacuum hose opening, and store it where it won’t get

damaged or lost (Figure 5). Placing the plug into the

chipper cone opening will keep it readily available

when you want to resume walk-behind vacuuming.

NOTE: When removing the vacuum hose intake plug or

hose connector end, align the seam on the cap or hose

connector with the seam on the

then pull out to snap it out of the intake opening groove,

and unscrew to remove.

If the chipper

20’

flexible vacuum

vacuum intake opening,

13

Page 18

Operation

4. lnserl the connector end of the vacuum hose into the

intake opening, using care to fully seat the connector

in the opening. If the connector is not fully inserted,

and electrical interlock switch will keep the unit from

starting or running (Figure 6).

5. Place the hand-held vacuum intake nozzle in the

area to be vacuumed, using care to avoid twisting

and minimize bends in the hose.

6. Visually inspect the area to be vacuumed to make

sure it is clear of small pets, non-shreddable materials, and any other hazards that could damage the

shredding hammers if vacuumed into the unit.

7. Perform the Checks Before Start-Up described earlier in this manual.

8. Stan the unit in accordance with standard starting

instructions for the type of unit you have.

9. For maximum vacuum force, set the throttle control

on the engine to the maximum speed setting.

lO.To reduce vacuum force, adjust the moveable ring to

gradually open the vacuum adjustment port

(Figure 7).

11. Using the vacuum intake nozzle, vacuum the area

you wish to clear, using care to avoid vacuuming

rocks, gravel, and other hard or sharp objects that

are not shreddable.

12.

Use extra care near landscape borders that may be

separating grassy areas from landscape rock or

stone.

13. Se watchful for small children, pets or other animals

that may enter the area.

Figure 5. Remove Vacuum Hose Intake Cap

‘2708

Insert Hose

Figure 6. Insert Vacuum Hose Connector Into Hose

Intake Opening

Vacuum Force

’

A

WARNING

The chipper vacuum is equipped with an electrical

safety interlock switch which prevents the unit from

operating when the vacuum intake cap or hose is

removed from the inlet opening. See your dealer if

the safety interlock switch is not operating properly.

A

DANGER

Never reach into the shredding chamber area of an

electric start unit unless the start key has been

removed and the spark plug wire has been disconnected.

Always wear work gloves to protect your hands

from sharp edges and objects that may have been

vacuumed into the unit.

Figure 7. Vacuum Force Adjustment

SHUTTING DOWN

When you’re done using the Chipper Vacuum, following

these simple but worthwhile steps will help you shut

down the unit properly so ihat your next use will be

trouble-free.

A

DANGER

The engine and surrounding parts become

extremely hot during normal use, and will cause

serious burn injuries if touched before the engine

has cooled. Allow the engine to cool completely

before touching these hot surfaces.

1. When you have completed processing the materials

to be chipped or vacuum/shredded, shut the unit off

and allow the rotor to come to a complete stop

before proceeding

14

Page 19

2. Remove the spark plug wire from the spark plug to

prevent the possibility of inadvertent starting. On

electric-start models, remove the key to prevent anyone from inadvertently activating the electric start

feature. Although the unit won’t start with the spark

plug removed, the rotor will turn, and serious injury

could result if your hands are in the area of the rotor

or chipper knives.

3. Inspect the following areas for any remaining materials that may have built up or become caught during

operations:

l vacuum intake nozzle

l vacuum hose intake opening

l chipper cone

l discharge chute

l engine air intake area

l transmission/clutch area

NOTE: Do not spray water on the transmission to clean

it, A/though it is sealed to protect it during normal use,

doing so may force water into the transmission housing,

causing corrosion or transmission failure. Use a small

brush or air stream to clear debris away from this area.

Figure 8. Unhook Support Straps

I

Figure 9. Loosen Cinch Strap

Operation

/

I\

MATERIAL COLLECTION & DISPOSAL

Direct Bagging

Chipped material may be collected using the discharge

collection bag. Check the bag frequently to make sure it

is filled to a level you can comfortably handle when

removing and emptying the bag.

1. To remove the bag, shut the unit off, and let the

rotor come to a complete stop. Unhook the rear and

front support straps, (Figure

strap that holds the bag opening to the discharge

chute. (Figure 9)

2. Pull the bag off and away from the discharge tube

(Figure

lo), and using both hands, grip the bag

securely at the front and rear to balance the weight

as you lift it.

3. Place the bag down in the disposal area, and unzip

the zipper opening completely. Lift the bag by the

other end and the contents of

out easily.

4. Zip the bag closed, and reinstall in the reverse

sequence followed for bag removal. Tighten cinch

strap securely (Figure 11).

NOTE: The discharge bag may be emptied without

removing the bag from the Chipper Vacuum by simply

unzipping it and raking the material out by hand. This

method is ideal for heavier debris that may make lifting

and carrying the bag difficult.

8) then loosen the cinch

the,bag should empty

Figure IO. Pull Discharge Bag Off Discharge Tube

Figure 11. Tighten Cinch Strap Securely

Direct Discharge

Chipped material may be discharged directly into a

selected collection area by installing the discharge

deflector elbow on the discharge chute. When direct

charge is being used, the deflector elbow must always

be directed away from the operator.

15

pre-

dis-

Page 20

Operation

A safe collection area should be located where children,

pets, and bystanders will not come into contact with

chipped material as it is being discharged, or be hit by

deflected pieces that may ricochet away from the collection area with great force.

When using direct discharge, check the discharge area

frequently for accumulation of material near the discharge port, and make sure the material can be safely

ejected away from the unit. Letting material accumulate

directly in front of the units discharge port may cause a

jam.

Direct Discharge Blowing

The direct discharge method of clearing debris can also

be used to clear driveways or other large areas. Make

sure the discharge deflector elbow is directed to one

side of the unit, then blow debris away from the center

of the area toward the outer edges.

Do not discharge against a fence or wall where

charged material may deflect back toward you and possibly cause injury. If a wall, fence, or other obstacle is

encountered while clearing an area, stop the unit,

change the direction of the discharge stream, and blow

debris away from the obstruction.

A

WARNING

Never attempt to move the unit while material is in

chipper cone being chipped.

Always allow limbs and branches to be completely

processed before engaging the power drive bail

lever.

Failure to obey these instructions may result in

jamming of the chipper, or erratic power drive performance causing sudden starting and stopping of

the power drive.

dis-

FIGURE 9. Variable Suction Control Adjustment

A. Closed Flap Opening - used with flexible hose

B. Narrow Flap Opening - light debris

C. Medium Flap Opening - small leaves

D. Wide Flap Opening - large leaves

-.

Figure 10. Vacuum Intake Nozzle Height Adjustment

A. High Height Adjustment

B. Medium Height Adjustment

C. Low Height Adjustment

Height

Adjustment Lever

/;;\

a7

Selecting the right combination of vacuum nozzle

height and flap opening position may require a little

experimenting to find the settings that work the best for

off and allow the rotor to come to a complete stop.

Never start the unit without securely attaching the

discharge bag or installing the discharge elbow in

a safe direction. Failure to obey these instructions

may result in serious injury.

OPERATOR AU

OPERATOR ADJUSTMENTS

Three different suction control settings and three nozzle

Three different suction

height positions provide a total of nine

height positions provide a total of nine different positions

for handling virtually any type of lawn

for handling virtually any type of lawn surface and yard

1

waste conditions.

I”-‘l

contror senrngs

r

s

you.

Variable Suction Control Adjustment

The variable suction control adjustment is located just

above and to the rear of the vacuum intake nozzle. This

adjustment sets the size of the intake opening, allowing

you to match the vacuum suction force to the type of

aeDnS ana

The vacuum intake nozzle flap has four easily-set

tions: closed (for vacuuming using the flexible 20

hose), small, medium, and large. These positions are

set and maintained by the vacuum nozzle flap adjust-

ment bracket, using a simple pull-and-place lever that

16

1..

grouna cover Deing vacuumed.

posi-

Page 21

Operation

slides smoothly into place in one of four slots (Figure 9).

To adjust the opening of the vacuum intake nozzle flap:

1. Grip the curved portion of the lever arm,

2. Pull the lever out of the present slot,

3. Slide the lever into the desired slot.

Vacuum Intake Nozzle Height Position

The vacuum intake nozzle height adjustment is located

at the rear of the frame on the left side of the unit

(Figure 10). This adjustment controls the height of the

vacuum intake nozzle above the ground.

SEASONAL HINTS

l Keep the lawn cut short during leaf clean-up season.

Although your Chipper Vacuum is designed to handle

tough clean-up jobs, you will save time and effort

when the ground cover gets moist or matted if your

lawn is mowed short.

l Vacuum frequently if your lawn is subject to a heavy

deposit of leaves. Attempting to vacuum extremely

thick deposits of leaves may require frequent stop-

ping and starting to allow the unit to fully process the

material in the shredding chamber.

l On extremely damp ground cover, leaves sometimes

get vacuumed into the unit in lame clumos. Go slow

to

avoid clogging the vacuum intake housing, and let

the shredder fully process material before vacuuming

additional debris.

l Frozen ground cover will require raking before

vacu-

uming can be performed. Break up frozen clumps of

leaves or other debris before attempting to vacuum

the material.

l Extremely wet ground surfaces may impede wheel

traction and make maintaining secure operator foot-

ing difficult. Allow surfaces to dry out before

vacu-

uming if it is hard to maintain positive control of the

unity

_.....

l Operation on wet surfaces may result in a rapid

build-up of debris on wheels and on the underside of

the unit. Be sure to remove any build-up before

putting the Chipper Vacuum away. Moist debris will

be easier to remove than material that has been

allowed to cake on the unit and dry.

* A light coating of WD-40 on drive chains will help

prevent corrosion between uses if the unit has been

subjected to extremely wet operating conditions.

17

Page 22

WASTE MATERIALS GUIDE

Your Chipper Vacuum is designed to efficiently process

a wide variety of organic yard and garden waste

als. To obtain consistent performance, extend the life of

your unit, and help ensure safe operation, do not

attempt to process non-organic materials, and always

follow the material requirements shown in the Waste

Materials Guide below.

materi-

If you are unsure about processing a material not covered in the guide below, contact your local authorized

dealer, or call our

414-284-6786

If you encounter any difficulties while processing any of

these recommended materials, consult the

ing sections of this manual for guidance and

mended corrective action,

Customer Service Department at

for assistance before proceeding.

troubleshoot-

recom-

Power

Drive

Vacuum/

Shredding

Chipping

Dry, moist, or wet organic

material, including leaves, clippings,

seeds, pine needles, cones,

and other organic lawn

debris that is shreddable

Vacuum at drive speed

and nozzle settings that

consistently provide

thorough material pick-up

Tree limbs, large branches,

or small branches grouped

together for ease of handling.

Never use the chipper

to chip very hard, dry materials

such as kiln-dried dimensional

lumber

building and lumber yard materials.

Never use the Chipper Vacuum to

chip pressure-treated wood products

such as landscape timbers, fence

posts, or other outdoor building or

landscaping lumber products.

(2x43, 1x2’s etc.), or other

Branches and twigs

up

to l/4” diameter

and 4” long.

Fruit and vegetable

waste that will pass

through vacuum intake

nozzle

3” Diameter limbs,

branches, or small

groups of branches.

Avoid long pieces

(over

6’)

as the

outer end can twirl

in a circular motion

and strike you or

bystanders, causing

personal injuries.

Maximum Diameter:

Model

Model

5/25

8/25

(2-i/2”)

(3”)

Rake very wet materials

to separate them from

ground cover that may

impede normal vacuuming

operations.

If time permits, allow wet

material to dry out for a few

days prior to vacuum/

shredding.

Bulky tree limbs and

branches should be

pruned close to the main

stem to pass through the

chipper cone properly.

As the material is chipped,

short

lengths may be

pushed into the chipper

with another tree limb or

batch of branches.

Never attempt to chip

material suspected of

containing nails, hooks, o

other metal objects.

Vacuum

Hose

Operation

Loose, dry waste such as

leaves, grass clippings, seeds,

pine needles, cones, and other

organic lawn and yard debris.

Avoid vacuum operation on areas

where hard, non-organic materials

such as gravel, dirt clumps, or

other hard objects could get

vacuumed into the shredder chamber.

Smaller materials that

will not obstruct the

vacutrm

being vacuumed.

18

hose as its

The

hose is designed

for small, loose waste and

for cleaning around decorative

landscaping and

flower beds.

Page 23

Normal Care

. I

SCHEDULED MAINTENANCE

Your Chipper Vacuum has been designed to provide you with years of reliable operation. Keeping your Chipper

Vacuum in top running condition will prolong its life, and help you obtain optimum performance whenever you wish to

chip or shred yard or garden waste.

operating intervals to extend the life of your unit.

Please read this normal care schedule, and observe these recommended care

ITEM

Check For Loose Pans

Check Oil Level And Add As Req’d

Change Oil

Change Spark Plug

Clean Engine Air Intake Area

Clean/Oil Air Filter Element

I

Inspect/Rotate Shredding Hammers

I

Inspect/Sharpen Chipping Knives

Inspect/Adjust Drive Chains

Inspect Drive Belt

Inspect Starter Rope/Handle

Inspect Chipper Cone

I

&

Hardware

Page Each Use 5 Hrs 25 Hrs

19

*

f

*

20

I

*

I I l I

20

I I

20

33

32

20

20

I

I.17

0

.

I

l

I

l

l

.

I

l

.

l

Inspect Vacuum Nozzle & Housing

&

Lubricate Wheels, Pulleys,

Check All Safety Labels

Battery Maintenance (Electric Start Only)

Optional Vacuum Hose

* See engine manufacturer’s owner’s manual supplied with the unit.

Sprockets

SERVICING THE CHlPPEq VACUUM

21

20

20

21

21

Read the engine manufacturer’s owner’s manual for any

engine maintenance required.

General

The following information will help you make the

necessary checks and perform the procedures required

to follow the normal care recommendations made for

your Chipper Vacuum unit,

If you prefer, your local authorized dealer can make these

checks and perform the required procedures for you.

Loose Parts And Hardware

Check the following areas, and tighten as required:

l Chipper cone and cone mounting

l Vacuum intake housing mounting

l Discharge deflector mounting

l Top and side covers

19

.

.

a

.

l

Page 24

NormalCare

Clean Engine Air Intake Area

The engine is air-cooled, and requires unobstructed air

flow into and around the engine. The cooling fins on the

engine cylinder head area must also be kept clear of

chipper and shredding deposits, as well as any other

build-up of debris that could prevent heat from radiating

away from the engine (Figure 14).

To clean the air intake area, remove any external material build-up, and then blow out the area using a stream of

compressed air. If a compressor is not available, use a

stiff-bristle parts brush, which is available at most auto

parts supply stores.

To clean the cooling fins, brush the area between the

fins with a stiff bristle parts brush, and blow out any

remaining debris with a stream of compressed air. If the

cooling fins are caked with an oily build-up of debris,

using a commercially available engine cleaner aerosol

may help loosen and remove the deposits. If you use

such a product, you must follow all safety and use

instructions to prevent damage to the engine components and personal injury to you.

Using a stream of water to clean the engine requires

immediate drying of engine components to prevent

rusting and possible malfunctioning of the electrical

system. If a water stream is used to clean debris, start

the engine immediately, and allow engine heat to speed

drying.

Inspect Starter Rope/Handle

The recoil starter rope and handle should be inspected for

signs of abrasion or wear that could result in breakage.

Contact your local authorized dealer for replacement if

these parts need to be replaced.

Inspect/Rotate/Replace Shredding

Hammers

Consult the Troubleshooting and Repair Section of this

manual for complete disassembly, inspection, and

replacement instructions.

Your local authorized dealer can provide this service to

you if you do not wish to disassemble the unit and

inspect/repair it yourself.

Figure 14. Engine Air Intake Area

Inspect Chipper Cone

Check the cone to make sure that it hasn’t been damaged or worn excessively by constant use, and replace

it if it is cracked, worn out, or no longer fits securely on

the chipper cone mounting flange.

Cracks, worn areas, and loose attachment points can

cause material to jam or clog when feeding it into the

machine, and may result in kick-back or other hazard to

the operator.

Contact your local dealer for replacement parts if your

unit shows any evidence of these problems, and discon-

tinue use of the unit until the appropriate repairs can be

made.

Check Safety Labels

The safety labels located in various positions on the

Chipper Vacuum have been placed to help remind you

of important safety rules while you are operating or

transporting the Chipper Vacuum unit.

If any label can’t be read or is missing, contact your

local dealer for an immediate replacement. If you must

use the unit without the label, review the label informa-

tion in the “Safety Decals” section of this manual.

f

‘-

Clean

Around

Area

Inspect/Sharpen Chipping Knives

Consult the Troubleshooting and Repair Section of this

manual for complete disassembly, inspection, and

replacement instructions.

Your local authorized dealer can provide this service to

you if you do not wish to disassemble the unit and

inspect/repair it yourself.

Lubricate Wheels, Pulleys, and Sprockets

To lubricate, squirt 3-5 drops of SAE 30 oil on each

wheel axle at the wheel bearings, and at each bearing

on the pulleys and sprockets. Wipe up any run-off and

spin wheels briefly to work oil around entire axle

Inspect Vacuum Nozzle Housing

Check the vacuum nozzle housing for build-up of debris,

20

Page 25

Normal Care

and clean out if required. Always shut engine off and

remove the spark plug wire from the spark plug before

reaching into the housing to clear material.

For stubborn debris, the vacuum nozzle housing can be

removed from the unit following the steps in the hammer

service section of this manual, and hosed out with a garden hose.

fluid levels to run down below full may result in erratic

starting performance, or inability of the battery to provide

adequate power to operate the starter motor.

To check battery fluid:

Inspect Vacuum Hose (Optional)

Repetitive use may result in a build-up of debris on the

inner walls of the flexible vacuum hose. If this occurs,

remove the hose from the unit, and rinse out with a

den hose. Allow the hose to dry before reusing. Inspect

the hose for any sticks or small branches that may have

become lodged inside, and remove.

gar-

Checking/Cleaning Battery Cables

BAG CARE

The discharge bag is designed to allow air to pass freely

through the material, while safely retaining discharged

material from the chipper and shredding chamber. -Use

of the Chipper Vacuum in extremely dusty or dry conditions may cause a build-up of fine debris on the bag fab-

ric, reducing the air flow and the efficiency of the vacu-

um action. If this occurs, remove the bag from the unit

and turn it inside out, and brush or vacuum it clean. If

you have purchased the hose kit accessory, you can use

the hose kit to vacuum the bag clean.

BATTERY MAINTENANCE

(Electric Start Units Only)

Checking Battery Fluid Level

Check the battery fluid periodically to make sure that the

fluid level is maintained at the “full” mark. Allowing the

A

WARNING

When removing or installing battery cables, disconnect the negative cable FIRST, and reconnect it

LAST. If not done in this order, the positive terminal can be shorted to the frame by a tool, creating

a dangerous spark that can ignite fuel vapors or

escaping hydrogen from the battery.

I

1. Remove the top cover.

2. Remove battery filler cap. Battery fluid must be even

with split ring “full” mark. If necessary, add distilled

water to bring fluid level up to full level.

3. Reinstall battery filler cao

1. Disconnect the cables from the battery, negative

cable first.

batterv

2. Clean the

wire brush and battery post terminal cleaner.

3. Reconnect cables, positive cable first.

4. Coat cables and clamps with grease, petroleum jelly,

or a protective aerosol spray coating designed to

provide a protective barrier on electrical connections.

Lead-Acid batteries contain sulphuric acid, a high-

ly corrosive liquid that can cause severe chemical

burns if allowed to come into contact with skin, or

blindness if allowed to contact your eyes. Always

wear eye goggles and protective gloves when handling or servicing the battery.

Lead-acid batteries also produce hydrogen, a colorless, highly explosive gas that can be easily ignited by a single spark. Always disconnect the negative cable first and reconnect it last to prevent a

spark from occurring if a tool accidentally contacts

the positive terminal and any part of the machine

frame at the same time.

Never smoke or allow ignition sources to be near-

by while servicing the battery.

Never attempt to charge a discharged battery without first checking the fluid level and making sure

the fluid is to the full level.

terminals and cable clamos with a

A

WARNING

21

Page 26

Storage

TEMPORARY STORAGE

(30 Days Or Less)

Here’s a quick checklist of things to do when storing

your Chipper Vacuum temporarily, or between uses:

l Keep the unit in an area away from where children

may come into contact with it.

l When this equipment is stopped for service, inspec-

tion, or storage, or to change an accessory, operators shall make sure the spark plug wire is discon-

nected from the spark plug.

l Remember, the Chipper Vacuum fuel tank probably

will still contain some gasoline, so never store the

Chipper Vacuum indoors or in any other area where

fuel vapor could travel to any ignition source. Fuel

vapor is also toxic if inhaled, so never store the

Chipper Vacuum in any structure used for human or

animal habitation.

l Never put the unit away while the engine is still hot

from running. Let the engine cool down first to

prevent the chance of fire.

l Never try to lift or position the unit in the storage

area by holding the fuel tank. Always let the engine

and muffler cool completely before allowing yourself

to contact these parts.

l If the unit can’t be stored on a reasonably level

surface, use a block of wood to chock the wheels.

Never store the Chipper Vacuum where it will not be

in a stable position.

l Never tip the unit more than 45” from vertical, and

never lay the unit on its side, as this could cause fuel

leakage, and/or undesirable oil transfer into the

cylinder head and spark plug area. Excessive oil in

the cylinder head will prevent the engine from starting

properly.

l Cover the Chipper Vacuum unit to protect it from

debris and foreign objects.

l Avoid damp storage locations to prevent rusting of

metal parts.

l When this equipment is stopped for service, inspec-

tion, or storage, or to change an accessory, operators shall make sure the spark plug wire is discon-

nected from the spark plug.

l Drain fuel system completely following engine

manufacturer’s instructions or add fuel stabilizer to

prevent fuel from gumming up during extended

storage period.

l Clean external surfaces, engine and cooling fan.

l Remove spark plug, and squirt 1 ounce of SAE 30 oil

into spark plug hole.

l Plug hole and pull starter cord slowly or crank engine

briefly to distribute oil evenly in cylinder head area.

l Reinstall spark plug.

l Transport unit to a suitable storage location. If you

have chosen to use a fuel stabilizer and have not

drained the fuel system, follow all safety instructions

and storage precautions in this manual to prevent

the possibility of fire from the ignition of gasoline

fumes. Remember, gasoline fumes can travel to

distant sources of ignition and ignite, causing risk of

explosion and fire.

l For additional convenience and a reduction in the

amount of floor space required for storage, the

handle assembly may be moved to a vertical position

by removing the locking knobs and carriage bolts,

loosening the bag support cap screws, and rotating

the handle up toward the unit. Be sure to keep the

locking knobs and carriage bolts with the unit for

reinstallation when the unit is put back into service.

LONG TERM/SEASONAL STORAGE

(Longer Than 30 Days)

Your Chipper Vacuum can be safely stored during

seasons by following these simple storage instructions:

l For extended storage periods, run the unit dry of

gas.

off-

Electric Start Units Only

l Be sure the battery is fiiled to the proper level with

water and is fully,charged. Battery life will be

increased if the battery is removed and put in a cool,

dry place and fully charged about once a month. If