Page 1

O

PERATOR

’

S

M

Sno-Away Models

ANUAL

Mfg. No. 1691411

Mfg. No. 1691413

Mfg. No. 1691414

Page 2

O

PERATOR

’

S

M

Model 7/22E

ANUAL

Page 3

500 N. Spring Street, P.O. Box 997

Port Washinnton, WI 53074-0997

Page 4

Page 5

Table Of Contents

General ...........................................................

Preparation.. .................................................. .2

Operation.. ..................................................... .2

Maintenance

Safety Decals ................................................

CONTROLS

Snowthrower Controls ................................. .4

Engine Controls.. ........................................... 4

Engine Speed.. ..............................................

Ground Speed Selector.. .............................. .4

Deflector.. ......................................................

Scraper Bar

OPERATION

General ..........................................................

Operation on Slopes .................................... .6

Checks Before Each Start-Up.. ....................

Starting The Engine.. .................................... .6

Operating The Snowthrower

After Each Use ..............................................

Storage.. .............................. .3

Skid Shoes ........................... .5

.......................

REGULAR MAINTENANCE

2

Normal Care Chart .........................................

Off-Season Storage .......................................

Starting After Storage .................................. .8

Checking Auger Gear Case.. ....................... .8

Lubrication ....................................................

Tire

Checking

SERVICE

Troubleshooting

Shift Control Adjustment

Drive Belts

Roller Chain Replacement.. ....................... .13

Shear Pin Replacement.. ............................ .13

Wheel Axle Bearing Replacement.. ............ 14

Auger Shaft Bearing Replacement ...........

SPECIFICATIONS.. ............................................ .15

COMMON REPLACEMENT PARTS .................

ACCESSORIES ................................................. .16

TECHNICAL MANUAL AVAILABILITY.............

Pressure ............................... .9

......................................... .lO

........................... .ll

................................................... .ll

8

8

This manual covers the following models:

Model

I

Record your model number, manufacturer number and

serial number in the space provided for easy reference.

The

frame.

Refer to the Engine Owner’s Manual for location of

engine serial number.

You must read, understand and comply with all safety and operating instructions in this manual before

attempting to set-up and operate your snowthrower.

Failure to comply with all safety and operating instructions can result in loss of machine control, serious

personal injury to you and /or bystanders, and risk equipment and property damage. The triangle in the

text signifies important cautions or warnings which must be followed.

I

Mfg. No.

1691411

1691413

1691414

1692615

WARNING

A

MODEL REFERENCE

Model Number:

I

Manufacturer Number:

Engine I.D. Number:

Dealer Name/Date Purchased:

WARNING

A

Engine exhaust from this product contains chemicals known, in certain quantities, to cause cancer, birth

defects, or other reproductive harm.

1

Page 6

Safety Rules

WARNING

This unit is a “two-stage” snowthrower. The first

stage is the auger, which feeds the snow back into

the impeller housing. The second stage is the

impeller, which throws the snow out the discharge

chute. If bodily contact is made with the auger or

impeller when they are rotating, severe personal

injury will occur. To avoid injury, keep others and

yourself away from the auger and the discharge

chute whenever the engine is running. Read and

follow all of the safety rules and warnings in this

manual.

A

WARNING

To avoid serious injury, do not put your hands into

the auger housing or discharge spout. If auger

stalls or spout becomes plugged, use the following

procedure to remove objects or clear the spout:

OPERATION

Release both drive levers.

2. Shut off the engine.

3. Wait for moving parts to stop.

4. Use a narrow board to remove foreign objects

and clear the spout or auger. Never put your

hands into the auger or discharge spout.

GENERAL

. Read the Operator’s Manual carefully. Be thoroughly

familiar with all controls and proper equipment use.

l Never allow children to operate the machine. Do not

allow adults to operate it without proper instruction.

. Keep the area of operation clear of all persons, par-

ticularly small children and pets.

l Never discharge material toward any person or pet.

l Make sure:

a. snowthrower is in good operating condition;

b. all safety devices and shields are in place and

working;

c. all adjustments are correct.

PREPARATION

l Never attempt to make any adjustment while engine

is running.

l Thoroughly inspect the area where the snowthrower

is to be used and remove all objects such as door

mats, sleds, boards, wires and sticks.

Disengage all clutches (release drive levers) before

starting engine.

l Do not operate snowthrower without wearing proper

winter clothing. Wear footwear which improves foot-

ing on slippery surfaces.

l Handle gasoline with care

it is highly flammable.

a. Use approved gasoline container.

b. Never remove the fuel tank cap or add gasoline to

a running or hot engine.

c. Never fill the fuel tank indoors.

d. Wipe up spilled gasoline.

l Adjust skid shoe height to clear gravel or crushed

rock surface.

. Do not run engine indoors. Exhaust fumes are dead-

ly.

l Keep hands and feet away from rotating parts. Keep

clear of discharge opening at all times.

l Always clear snow up and down the face of slopes,

never across the face. Use extreme caution when

changing direction on slopes. Do not attempt to clear

slopes over 17.7%

l Use extreme caution when operating on or crossing

gravel drives, walks or roads. Stay

for hidden

hazards and traffic.

. Be especially careful not to touch snowthrower parts

which might be hot from operation. Allow such parts

to cool before attempting to maintain, adjust or service.

l If unit starts to vibrate abnormally, disengage drives

and stop the engine. Check immediately for the

cause. Vibration is generally a warning of trouble.

l Before leaving operator’s position for any reason:

shut off engine,

remove the key and

wait for all moving parts to stop.

l Before cleaning, repairing or inspecting the unit,

make certain all moving parts have stopped. Remove

the key and then disconnect the spark plug wire to

prevent accidental starting.

. Always use a grounded, 3-wire plug receptacle for

electric starting.

. Adjust snow discharge angle for safe flow when oper-

ating near glass enclosures, automobiles, window

wells, dropoffs, etc.

Do not overload machine capacity by clearing snow

at too fast a ground speed.

2

Page 7

Safety Rules

l Never operate machine at high transport speeds on

slippery surfaces. Use care when backing up.

l Disengage auger drive when transporting or not in

use.

l Never operate the snowthrower without good

or light. Always be sure of your footing.

l Do not change the engine governor settings or

speed the engine.

MAINTENANCE

Keep all nuts, bolts and screws tight to ensure that

the equipment is in safe operating condition.

l Never store equipment with gasoline in the tank in a

building where fumes may reach an open flame or

spark. Allow the engine to cool before storing in any

enclosure.

STORAGE

l Always refer to the Operator’s Manual for important

details if snowthrower is to be stored for an extended

period.

l Run auger drive a few seconds after completion of

throwing snow to help clear out snow and prevent

freeze-up.

SAFETYDECALS

Safety warning decals are placed at strategic locations

on the snowthrower as a constant reminder to the operator of the most important safety precautions. All warning,

caution and instructional messages on your snowthrower

should be carefully read and obeyed.

If any of these decals are lost or damaged, replace them

at once. They can be purchased from your local dealer.

A DANGER

Avoid

rotating blower:

Shut

discharge chute.

---

Part No. 1677488

from

engine

Decal supplied by the engine manufacturer.

See your local Tecumseh dealer.

A

q -zjzJEJ

Part No. 1677485

3

Page 8

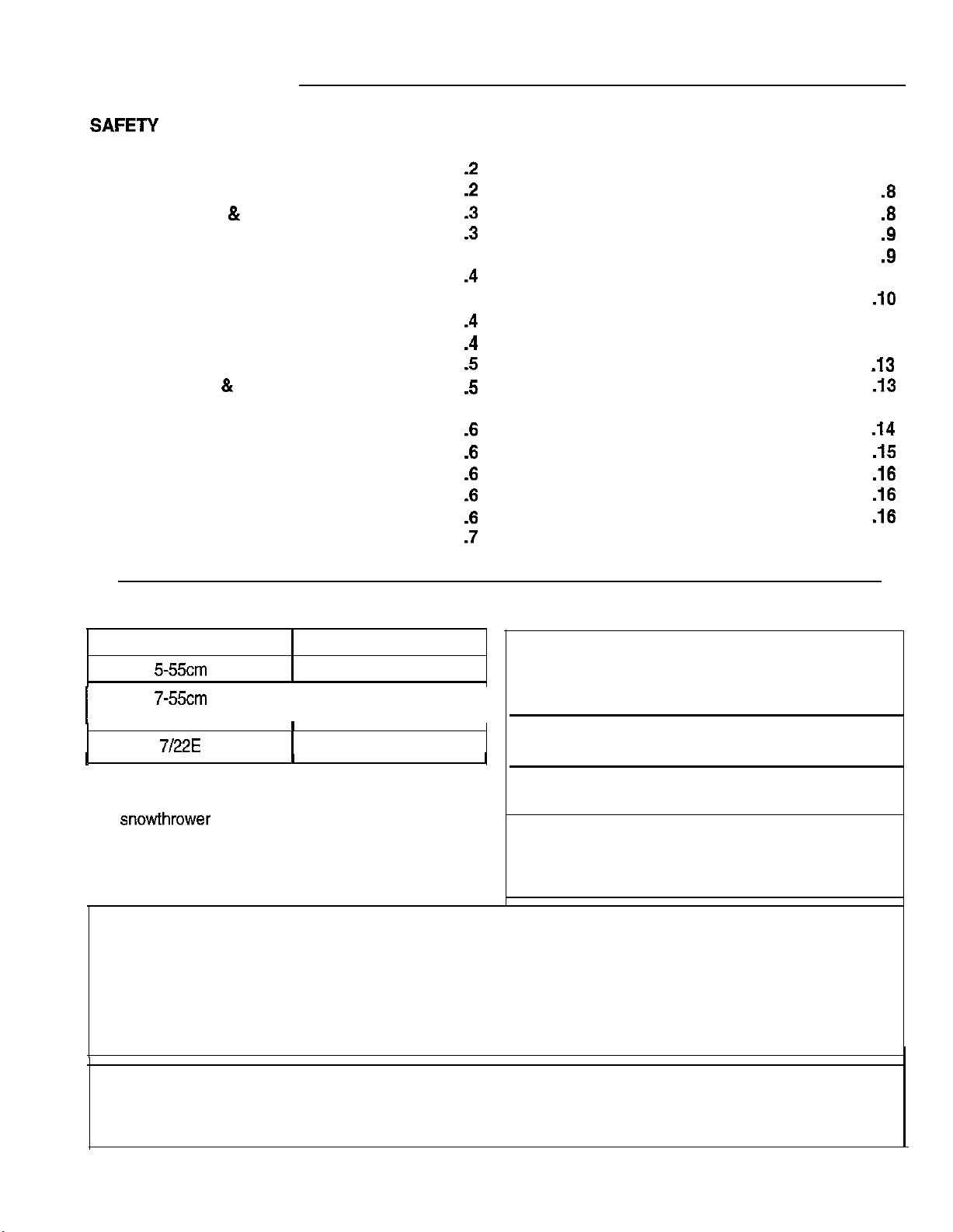

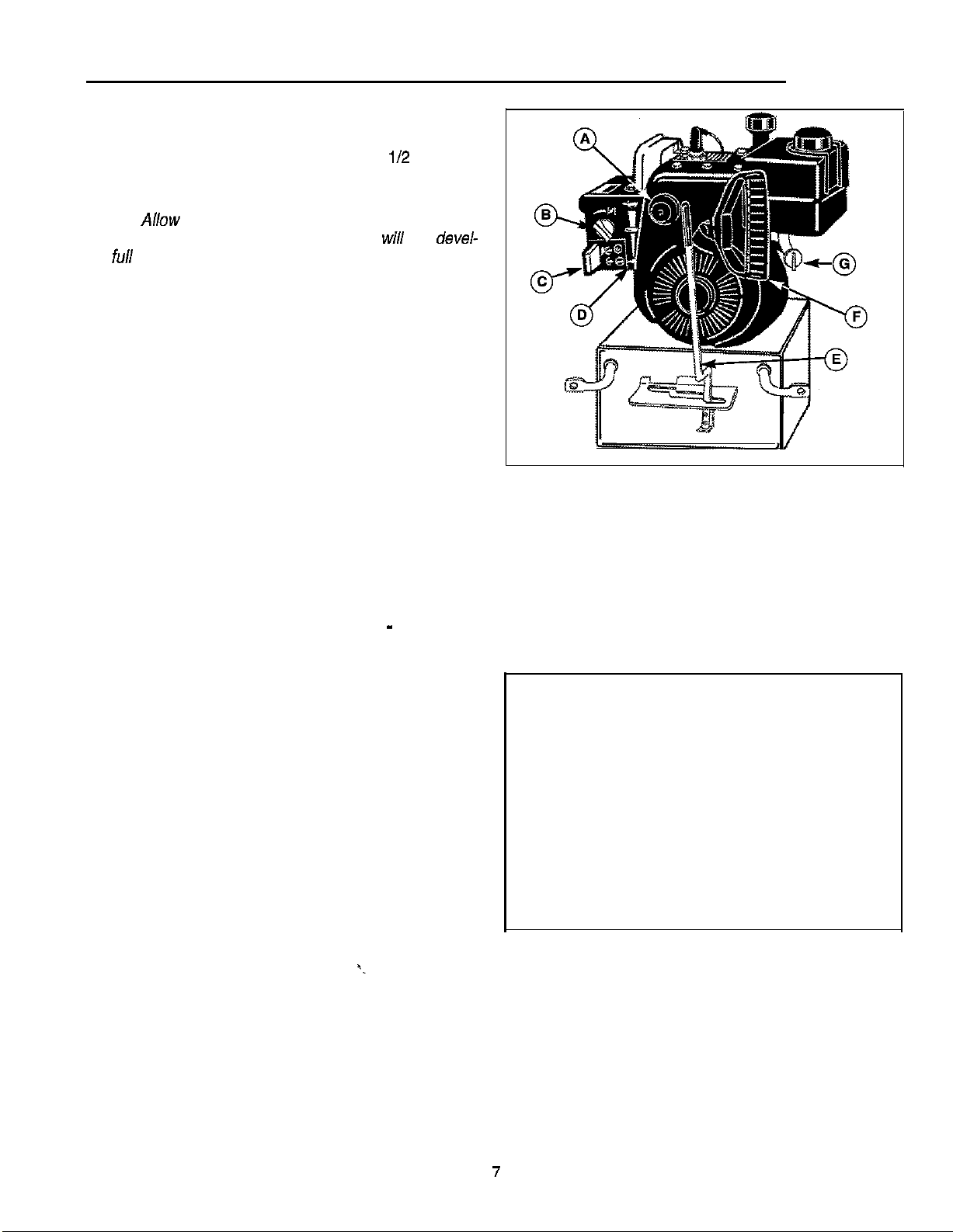

SNOWTHROWER CONTROLS

(Figure 1)

Ref

Name

A

Auger Control

Clutch Lever

B

Drive Control

Clutch Lever

Engages auger/impeller when

depressed; disengages when

released.

Engages drive

depressed; disengages when

Function

to

released.

C

Chute Control

Rod

D

Chute

Deflector

E

Skid Shoes

Controls direction snow is

thrown.

Controls angle snow is

thrown.

Controls height of scraper

bar.

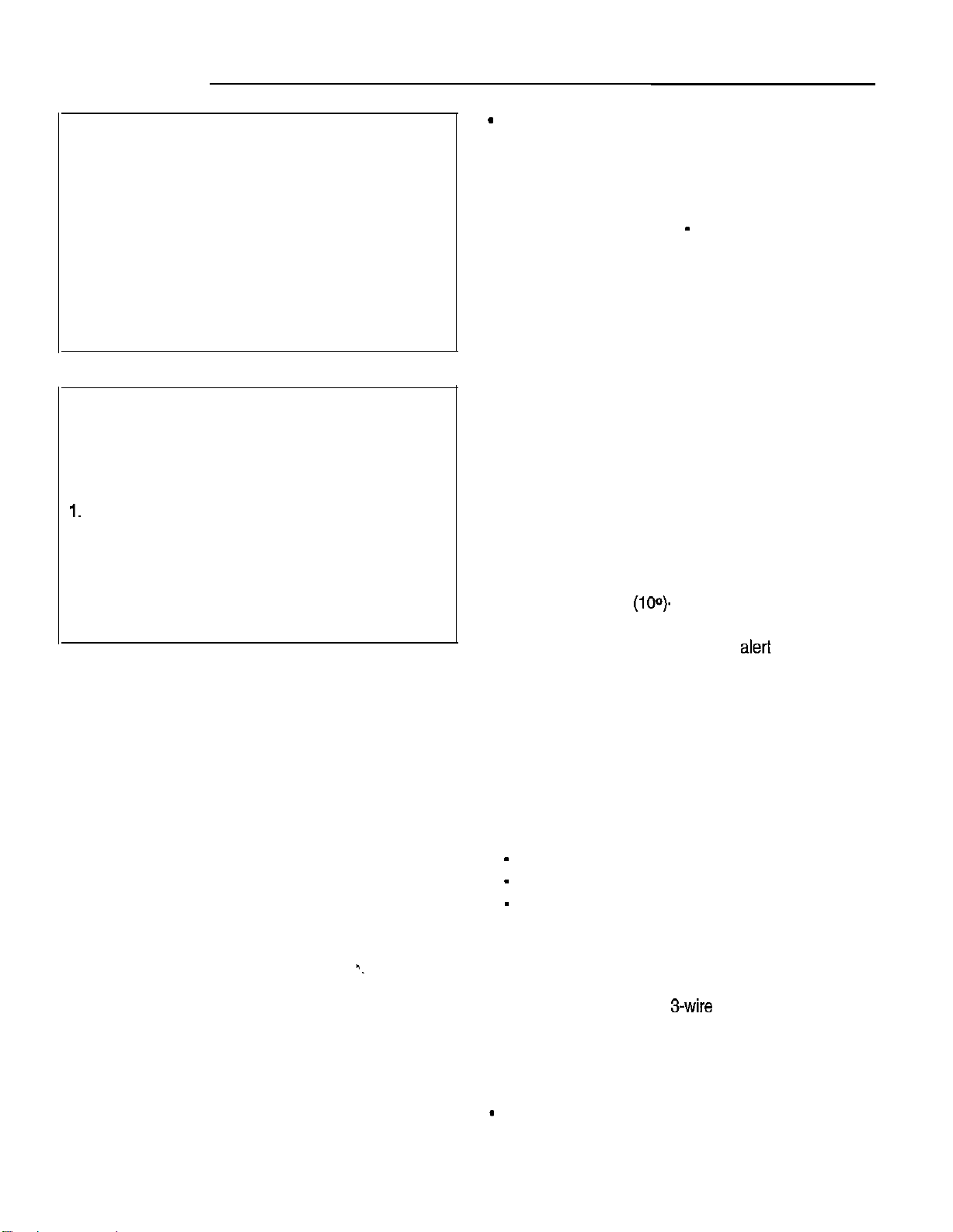

ENGINE CONTROLS

(Figure 2)

wheels when

Figure 1. Snowthrower Controls

Ref Name

Button

B 1 Choke

C Ignition

Switch

Throttle

Lever

Shift Lever

F Starter

Handle

G Fuel Valve

The engine can be started with the rewind (rope) starter

or optional

stopped by moving the throttle lever (D,figure 2) all the

way down, or by pulling out on the ignition key.

Refer to the engine Owner’s Manual for maintenance

and service instructions, along with important safety

information.

electric starter. The engine can be

Enriches fuel sutmlv.

Allows starting and stopping

of the engine.

Controls engine

Controls ground speed and

direction.

Used to start engine.

Turns fuel

Function

speed.

on or off.

ENGINE SPEED

For overall best performance, run the snowthrower at full

operating engine speed. Use the engine throttle lever (D,

figure 2) to set the engine speed.

I

Figure 2. Engine Controls

GROUND SPEED

Use the ground speed shift lever (E, figure 2) to control

the drive speed of the snowthrower. There are three

ward speeds and one reverse speed. Position 1 is for

extra deep, wet, heavy snow. Positon 2 is for deep, wet,

heavy snow. Position 3 is for light, fluffy snow and to

drive the snowthrower without blowing snow. To change

speeds, first release the drive control clutch lever (B,

I), then move the ground speed shift lever to the

desired speed setting.

4

Page 9

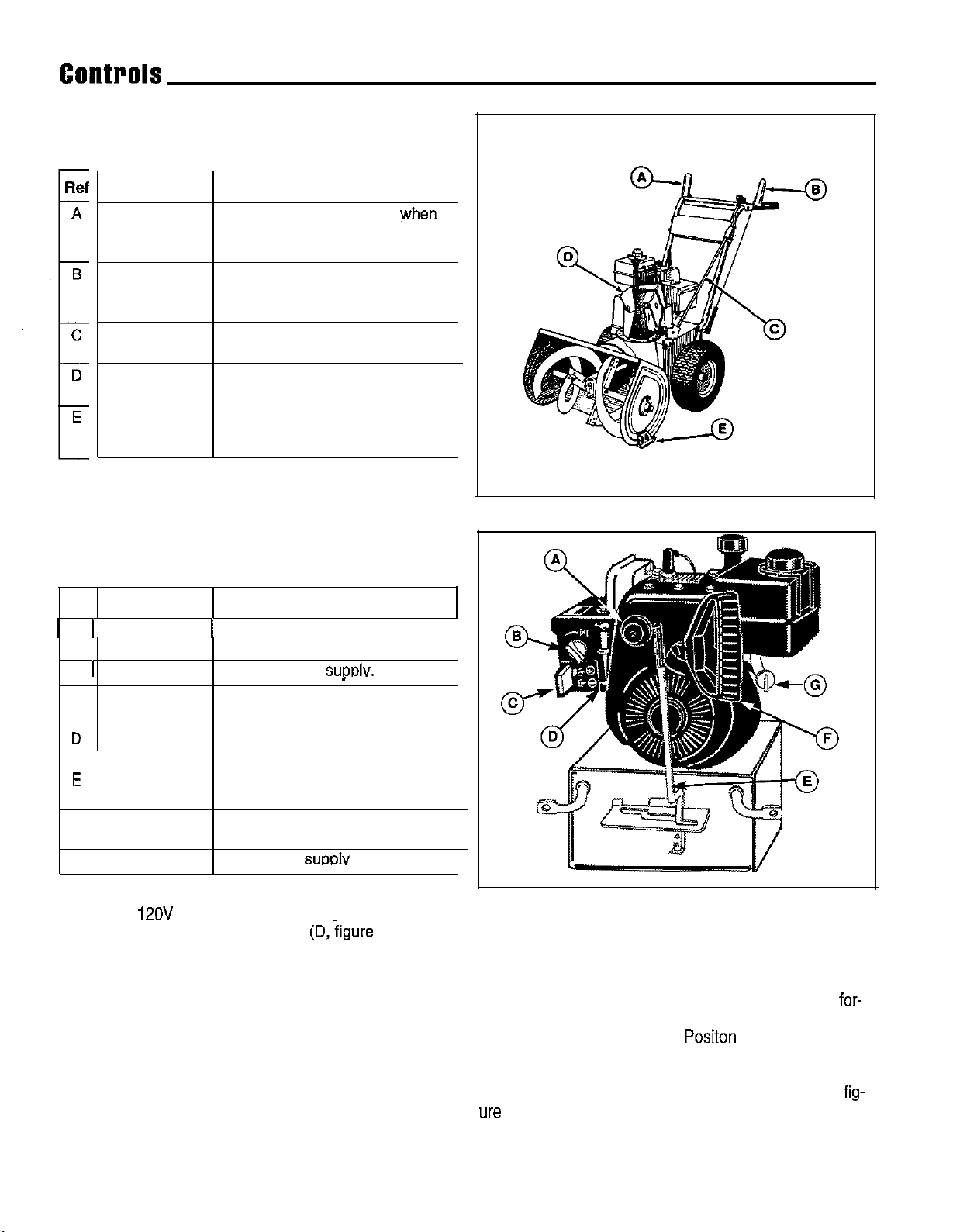

DEFLECTOR

The angle and distance of the discharged snow is controlled by the position of the deflector. Engine speed also

affects distance of discharge.

The more the deflector is tilted back, the farther snow will

be thrown. Loosen the knob (figure 3) to tilt the deflector

back or forward, then retighten the knob.

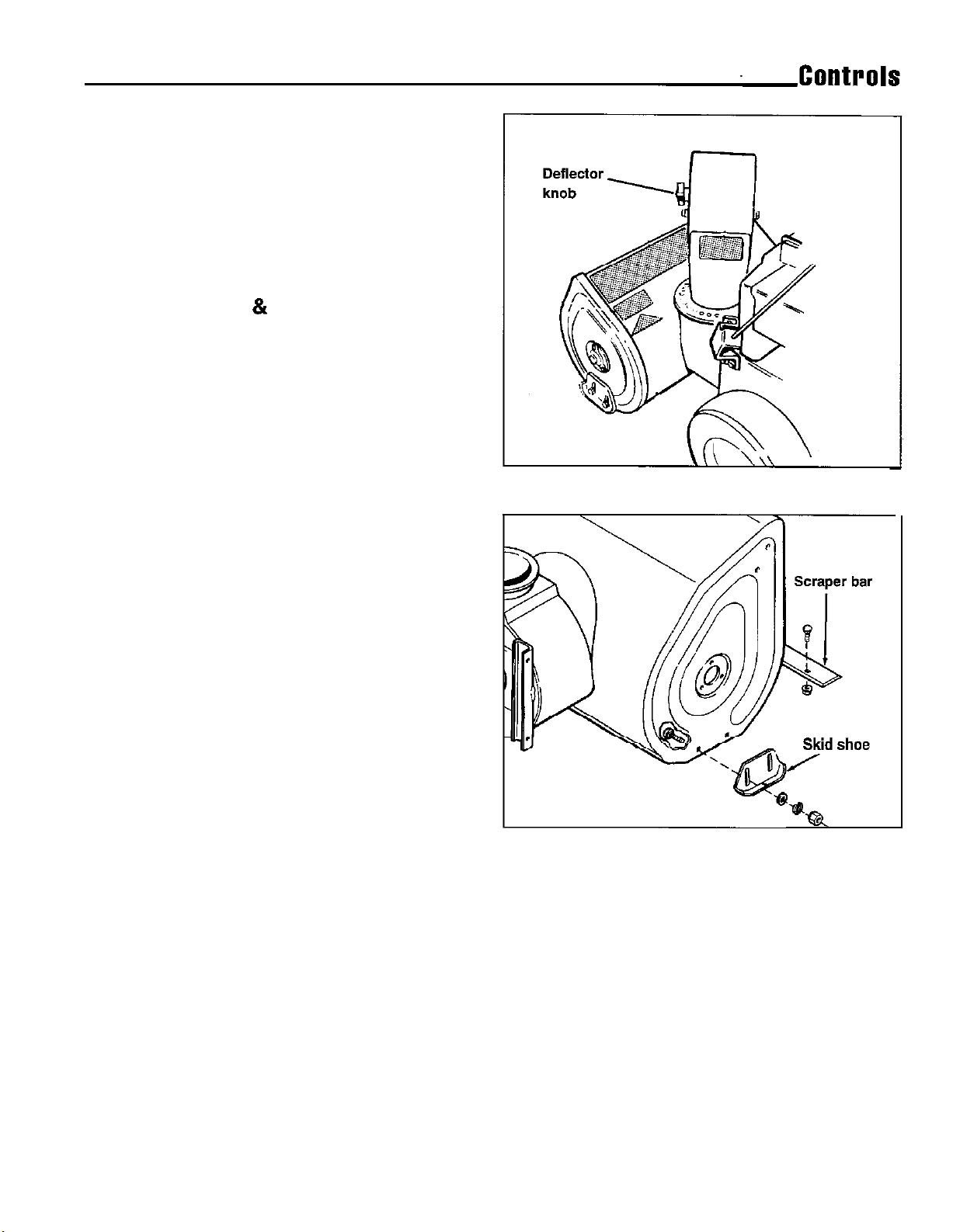

SCRAPER BAR

On smooth surfaces such as concrete or asphalt, the

scraper bar should scrape the surface. On surfaces such

as gravel, the scraper bar should be high enough so that

it will not pick up gravel or debris.

The height of the scraper bar is controlled by raising or

lowering the skid shoes as shown in figure 4.

1. To raise the scraper bar height, rest the scraper bar

on a piece of wood, equal in thickness to the desired

height.’

2. Make sure the scraper bar is parallel to the ground

surface.

3. Loosen the skid shoe nuts and let the skid shoes

drop to the surface.

4. Tighten the nuts, making sure the skid shoes are

adjusted equally and are parallel to the surface.

5. To lower the height of the scraper bar, raise the skid

shoes.

6. If the scraper bar becomes worn, it can be replaced

by removing the hardware attaching it to the

snowthrower, installing a new one and then tightening the hardware.

SKID SHOES

Figure 3. Deflector Adjustment

Figure 4. Skid Shoe Adjustment

Page 10

Operation

GENERAL

Gasoline is highly flammable and must be handled

A

WARNING

Before leaving the operator’s area for any reason,

stop the engine and remove the key. Disconnect

the spark plug wire and secure it away from the

plug to prevent accidental start-up of the

snowthrower.

A

WARNING

To avoid serious injury, do not put your hands into

the auger housing or discharge spout. If auger

stalls or spout becomes plugged, use the following

procedure to remove objects or clear the spout:

1. Release both drive levers.

2. Shut off the engine.

3. Wait for moving parts to stop.

4. Use a narrow board to remove foreign objects

and clear the spout or auger. Never put your

hands into the auger or discharge spout.

OPERATION ON SLOPES

A

WARNING

For your safety, operation on slopes should be in

an up and down direction only. If it becomes necessary to move across the face of a slope, use caution and do not blow snow. Be very careful when

changing direction on a slope.

Proper winter footwear is recommended for the

operator to help prevent slipping.

Never attempt to clean snow from excessively

steep slopes. The maximum slope for any operation is 17.7% (10’).

CHECKS BEFORE EACH START-UP

1. Make sure all safety guards are in place. and all nuts,

bolts and clips are secure.

2. Check the engine oil level. See your engine Owner’s

Manual for procedure and specifications.

3. Check the fuel supply. Fill the tank to within

inch of top of tank to provide space for expansion.

See your engine Owner’s Manual for fuel recommendations.

to

with care. Never fill the tank when the engine is hot

or runnmg. Always move outdoors to fill the tank.

4.

5. Check the auger control clutch lever (A, figure

6.

7.

8. Check to make sure spark plug wire is attached and

9. After servicing engine and before beginning snow

STARTING THE ENGINE

2. Turn the fuel valve (G, figure 5) to the ON position.

3. Insert the ignition key (C, figure 5) into the ignition

4. Move the throttle lever (D, figure 5) fully up to the

4. Turn the choke knob (B, figure 5) fully counterclock-

5. Push the primer button (A, figure 5) two times if

6. Pull starter handle (F, figure 5) rapidly or push starter

WARNING

Keep snowthrower and gasoline away from open

Position the deflector at the desired angle and the

scraper bar at the desired height.

drive control clutch lever (B, figure 1) and discharge

chute deflector (D, figure 1) for proper operation. If

adjustment is required, sea the Service Section for

procedures.

Check the discharge chute control rod (C, figure 1)

for proper function. Check to make sure sprocket

teeth on lower chute control rod fully engage holes in

flange around bottom of discharge chute. The bracket

that holds lower chute control rod is slotted and can

be moved up or down to obtain full engagement of

sprocket teeth.

Check shift lever (E, figure 5) for proper position. If

adjustment is required, see SHIFT CONTROL

ADJUSTMENT in the Service Section.

spark plug is tightened securely into engine. If

torque spark plug to 15 ft. Ibs.

removal, check controls again with engine running.

Move the ground speed shift lever (E, figure 5) to the

Neutral position.

switch and push fully in to the RUN position.

FAST position.

wise if engine is cold. Do not choke a warm engine.

engine is cold. Do not prime a warm engine.

button if equipped with the electric start. Do not allow

starter handle to snap back. Let the starter rope

rewind slowly while keeping a firm hold of the starter

handle.

6

Page 11

7. As the engine warms up and begins to operate evenly, turn the choke knob slowly counterclockwise to the

OFF position. If engine falters, return to

position until it runs smoothly, then turn it to the

choke OFF position.

NOTE: Allow the engine to warm up for a few minutes

before operating the snowthrower. Engine will not devel-

op

8. Run the engine at or near top speed during

snowthrower operation.

choke

OPERATING THE SNOWTHROWER

1. Position the discharge chute to the desired angle and

direction.

2. Set the ground speed control lever to the desired for-

ward or reverse position.

3. Press the auger clutch lever on the right-hand grip to

begin auger rotation.

4. Press the drive clutch lever on the left-hand grip to

begin moving the snowthrower.

5. To disengage the drive mechanism, release both

clutch levers. Set the ground speed control lever to

the NEUTRAL position.

NOTE: After a normal break-in period of 2

use, it may be necessary to adjust the drive belt. See

DRIVE BELTS in the Service Section for the adjustment

procedure,

4 hours of

AFTER EACH USE

1. Before stopping engine, pull the starter rope twice

and allow it to rewind slowly, then stop the engine by

moving the throttle lever (D, figure 5) all the way

down or by pulling out on the ignition key. This will

prevent freeze-up.

2. The engine Owner’s Manual contains further information on preventing engine freeze-up.

3. Always remove the key to prevent unauthorized use.

Operation

Figure 5. Engine Controls

A. Primer Button

B. Choke Knob E. Shift Lever

C. Ignition Key/Switch F. Starter Handle

4. Clean snow and ice from the snowthrower.

5.

If the snowthrower is kept in a cold shelter, fill the fuel

tank to prevent condensation. Do not store near

sparks or flame.

Never store snowthrower, with gasoline in engine

or fuel tank, in a heated shelter or in enclosed,

poorly ventilated enclosures. Gasoline fumes may

reach an open flame, spark or pilot light (such as a

furnace, water heater, clothes dryer, etc.) and

cause an explosion.

Handle gasoline carefully. It is highly flammable

and careless use could result in serious fire damage to your person or property.

Drain fuel into an approved container outdoors

away from open flame or sparks.

D. Throttle Lever

G. Fuel Valve

A

WARNING

Page 12

Regular Maintenance

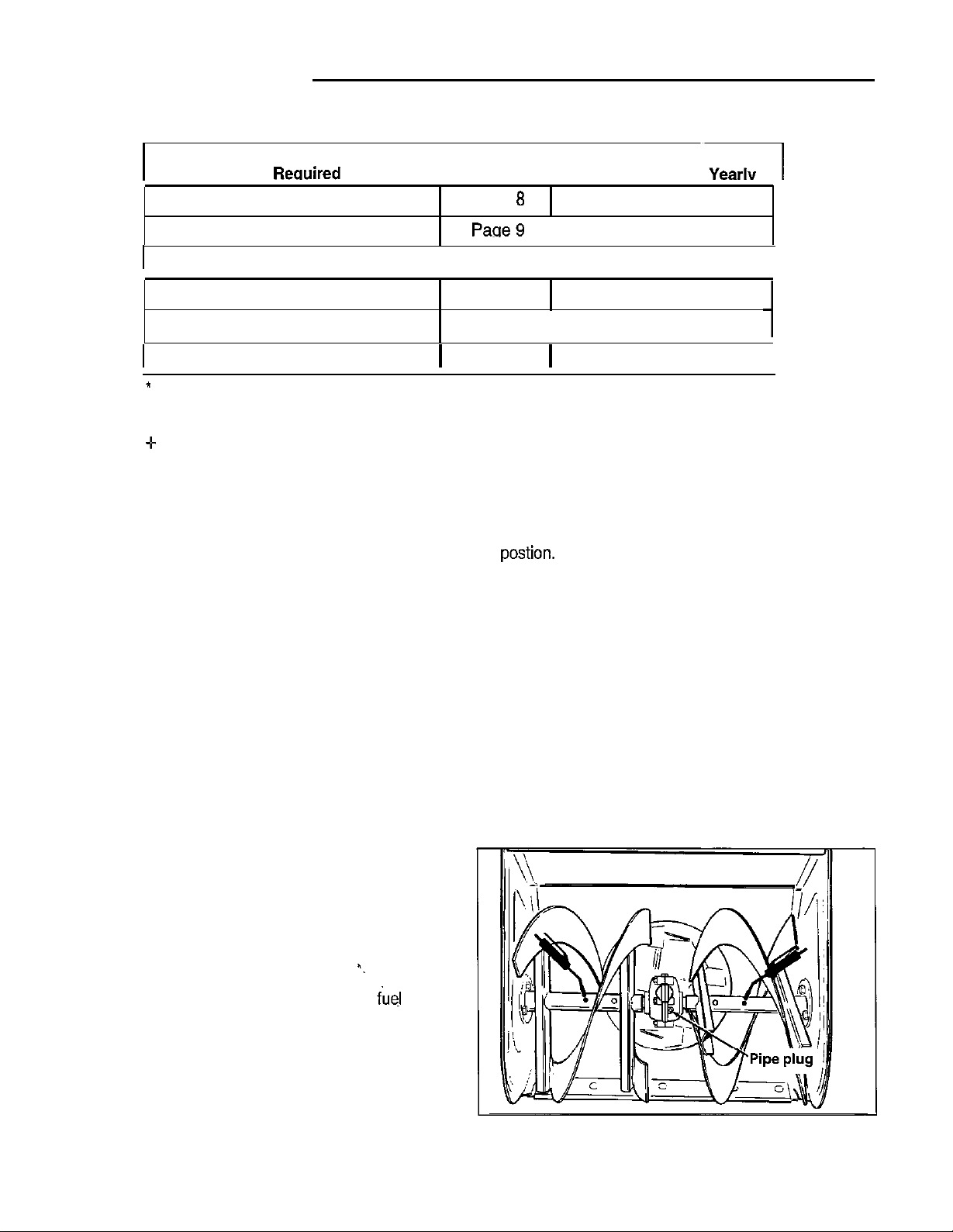

NORMAL CARE

Care Reauired

Check auger gear case lubrication.*

Lubricate snowthrower.

Every 25

See Paae

Page

I

I

Paae 9 I l I

Hours

.

I

.

1

Change engine oil.**+

Clean or replace spark plug.+

Check discharge control.

The transmission and auger gear case have been factory lubricated for life. If lubricant should leak

out, have transmission or auger gear case inspected by your dealer.

**Change original oil after two hours of operation.

See your engine Owner’s Manual.

OFF-SEASON STORAGE

Before you store your snowthrower for the off-season,

read the Maintenance and Storage instructions in the

Safety Rules section and take the following precautions:

NOTE: Gasoline, if permitted to stand unused for extended periods (30 days or more), may develop gummy

deposits which can adversely affect the engine carburetor and cause engine malfunction. To avoid this condition, add a gasoline stabilizer to the fuel tank or drain all

fuel from the system before placing unit in storage.

1. Prepare your snowthrower engine for storage according to the instructions found in the engine Owner’s

Manual.

2. Lubricate the snowthrower as described in the

LUBRICATION section.

3.. Clean the snowthrower thoroughly. Coat all exposed

bare metal parts with a good quality paint (available

from you dealer) or a light film of grease, oil or auto-

motive wax.

.

I

Page 14

6. Check the operation of the controls. If necessary,

lubricate the snowthrower to improve operation of the

spout control.

7. Store snowthrower in the wheels down, operating

If stored in any other position, oil from

crankcase could enter cylinder head, causing a service problem. Store in a protected area and cover for

additional protection.

I

.

I * I

CHECK AUGER GEAR CASE

LUBRICATION

1. Place the snowthrower on a level surface.

2. Remove the pipe plug (A, figure 6). The lubricant

should be level with the hole. If not, add Simplicity

Winter Weight Worm Gear Oil (available from your

dealer).

3. Re-install pipe plug.

STARTING AFTER STORAGE

1. Remove the spark plug and wipe dry. Crank engine a

few times to blow excess oil out of plug hole. Then

reinstall plug.

2. Fill fuel tank with fresh gasoline (unless a

er was used).

3. Check to be sure engine fins are clean and air flow is

unobstructed.

4. Check engine oil and lubricate snowthrower.

5. Start the engine outdoors. Do not run engine at high

speeds immediately after starting.

stabiliz-

Figure 6. Checking Auger Gear Case Lubrication

8

Page 13

Regular- Maintenance

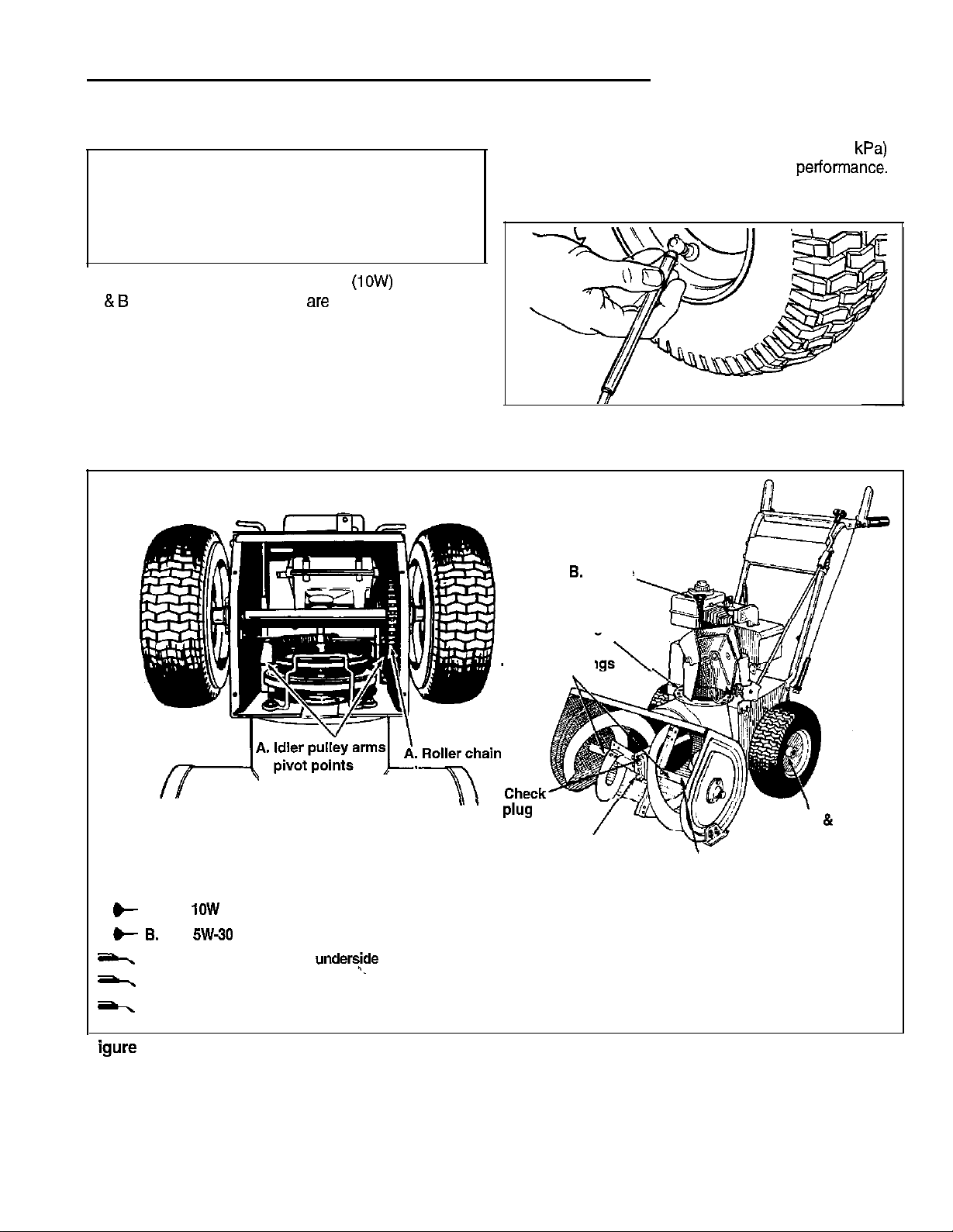

LUBRICATION CHECKING TIRE PRESSURE

The air pressure in each tire should be 20 psi (136

A

CAUTION

It is very important that grease fittings on auger

shaft (figure 6) are lubricated regularly. If auger

rusts to shaft, damage to worm gear may occur if

shear pins do not break.

With an oil can, apply medium weight (IOW) oil to points

A

shown in figure 7. There

the auger shaft (figure 6). Wipe fittings clean and apply

two or three shots of grease. Also, use grease on other

points shown.

Generally, all moving metal parts should be oiled where

contact is made with other parts. Keep oil and grease off

belts and pulleys.

Transmission

two grease fittings in

and should be equal for both tires for best petiormance.

Be sure to keep caps on valves to prevent entry of mois-

ture.

I

Figure 8. Checking Tire Pressure

C. Discharge chute

E. Grease fittings

Auger gear case

Auger shaft

A. Use 1OW oil every 10 hours of use and at beginning of each season.

Add

C. Remove chute and coat unders$te of flange with clinging type grease annually.

D. Remove wheels and coat axles with clinging type grease annually.

E. Add grease to two grease fittings annually.

7. Lubrication Points

oil as required. Check engine every 5 hours of use and before each use.

D. Wheeis

axles

9

Page 14

WARNING

A

Before performing any adjustment or service to

snowthrower, stop the engine and wait for moving

parts to stop. Remove the key. To prevent accidental starting, disconnect the spark plug wire and

fasten away from the plug.

This section provides troubleshooting and service

instructions. For problems not covered here, contact your

dealer.

4. Broken belt. Replace belt.

5. Shear pin broken. Replace pin.

Auger rotates, but snow not thrown far enough.

2. Engine speed too slow. Set to full throttle.

3. Ground speed too fast. Use slower speed.

4. Snowthrower discharge spout clogged. STOP engine

TROUBLESHOOTING

Locate the problem and check the possible cause/reme-

dy in the order listed. Also, refer to the engine manufacturer’s Owner’s Manual for other information. If problem

cannot be remedied, see your dealer.

Engine fails to start.

1. Key off. Push key in to the ON position.

2. Fuel valve closed. Turn valve to open position.

3. Out of fuel. Fill fuel tank.

4. Choke not on. Turn choke fully clockwise to ON position and set throttle up to FAST position.

5. Engine flooded. Move choke to counterclockwise to

OFF position and try starting engine again.

6. Spark plug faulty, fouled or poorly gapped. Clean and

gap or replace.

7. Water in fuel. Drain tank and refill with fresh fuel.

8. Old stale gas. Drain tank and refill with fresh fuel.

Engine starts hard or runs poorly.

Fuel mixture too rich. Move choke to OFF position.

2. Carburetor adjusted incorrectly. See your dealer.

3. Spark plug faulty, fouled or poorly gapped. Clean and

gap or replace.

4. Fuel cap vent blocked. Clear vent.

Auger does not rotate.

Auger control clutch lever not engaged. Engage

1.

auger control lever.

2.

Foreign matter blocking auger. STOP.engine and

REMOVE the key. DISCONNECT the spark plug

wire. Clear auger using a narrow board. See warning

in SAFETY RULES.

Auger drive belt slipping. Check auger drive belt

3.

Scraper bar does not clean hard surface.

Snowthrower picks up and throws stones on gravel

drive.

Poor traction.

Auger does not stop when auger lever is released.

Snowthrower does not stop when drive lever is

released.

Snowthrower does not drive when drive lever is

engaged.

Discharge control is difficult to operate.

Cannot shift into all speeds.

Snowthrower veers to one side.

Spout deflector too low. Adjust deflector as neces-

sary.

and REMOVE the key. DISCONNECT the spark plug

wire. Clear auger using a narrow board. See warning

in SAFETY RULES.

Skid shoes improperly adjusted. Adjust.

1. Skid shoes improperly adjusted. Adjust.

Tires slipping. Check tire pressure and tread.

1. Drive belts loose, broken or stretched. Adjust or

2. Drive roller chain damaged. Replace chain.

1. Gears need lubrication. Oil as required.

1. Tire pressure not equal; should be 20 psi

Excessive vibration.

drive belt out of adjustment. Adjust auger belt.

Unit drive belt out of adjustment. Adjust drive belt.

replace.

See SHIFT CONTROL ADJUSTMENT.

(136

Loose parts or damaged auger. STOP engine and

REMOVE the key. DISCONNECT the spark plug

wire. Tighten all hardware. Replace auger if neces-

sary. If vibration continues, see your dealer.

each side.

10

Page 15

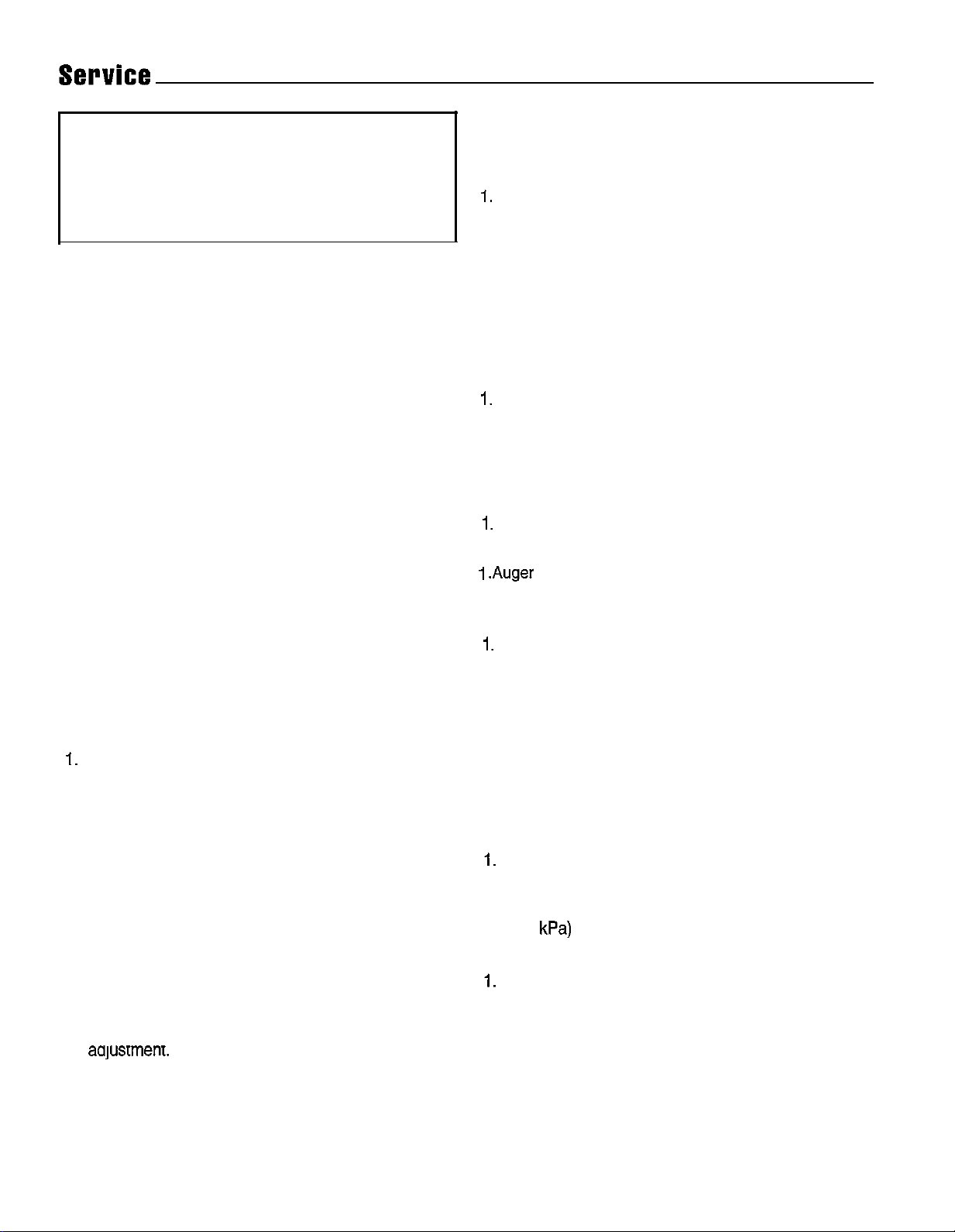

SHIFT CONTROL ADJUSTMENT

If any of the following conditions exist, it will be neces-

sary to adjust the shift control.

l Snowthrower is not in neutral when shift lever is in

NEUTRAL position.

l Reverse position cannot be fully reached.

l 3rd gear cannot be fully reached.

Adjust as follows:

1. Locate neutral position of shift lever by moving unit

back and forth with traction lever engaged. Unit will

move easily when in neutral.

2. Leave shift lever in position where neutral was

obtained.

3. Loosen screws in shift control bracket (figure 9) at

rear of snowthrower.

4. Slide shift control bracket left or right until shift lever

is properly aligned in neutral position. Tighten screws

in control bracket.

5. Check adjustment by moving lever to each position.

Be sure to check to see that NEUTRAL is properly

reached from both forward and reverse directions.

6. Check shift lever movement from reverse to 3rd and

make sure lever does not contact handles. To adjust,

loosen two screws indicated in figure 9, move lever

slightly, then tighten the screws and check again.

control

b

for step 6

Figure 9. Shift Control Adjustment

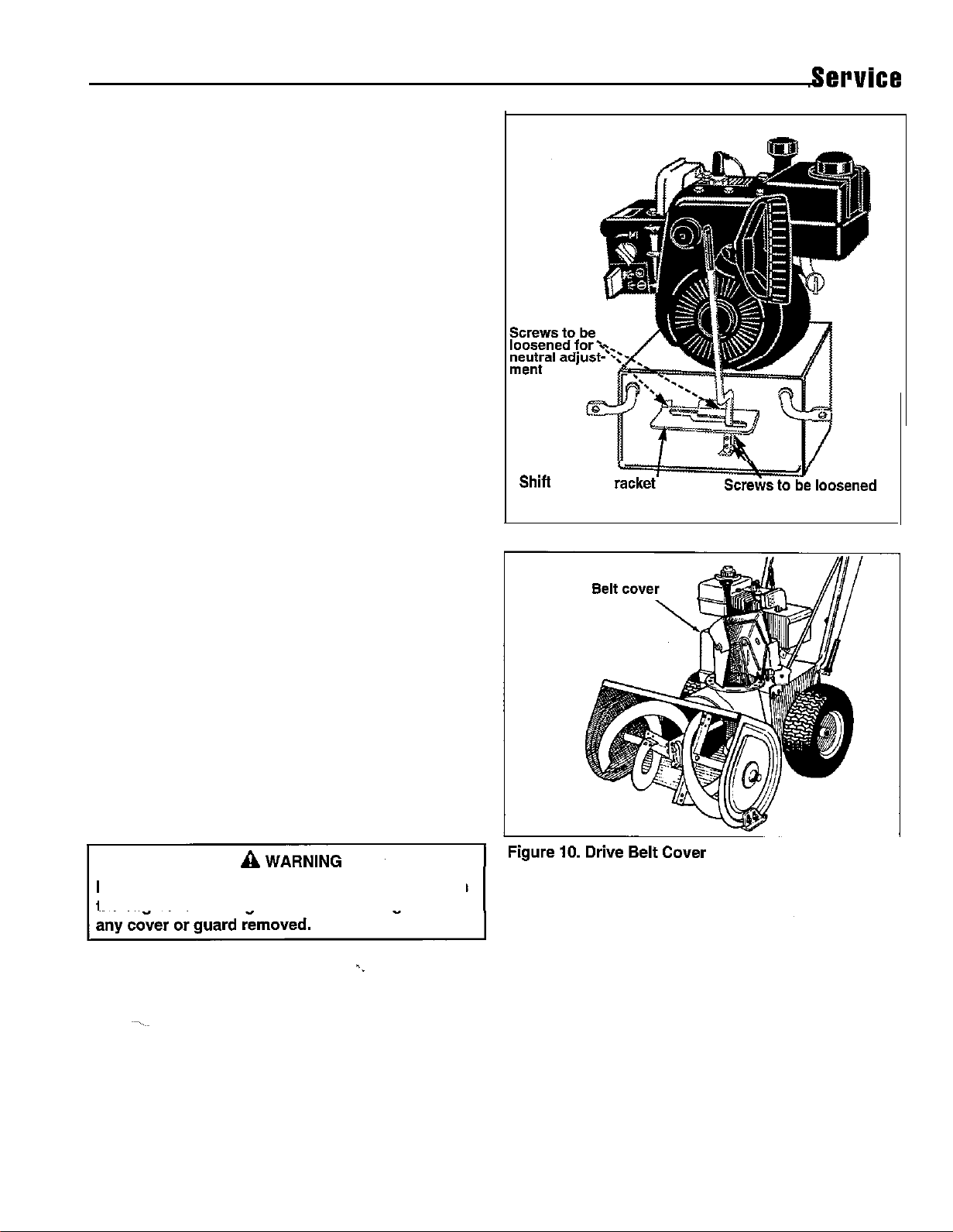

DRIVE BELTS

The snowthrower is equipped with two drive belts located

just in front of the engine under the belt cover (figure 10).

Figure 11 shows both belts and idler pulleys. The belt

nearest the engine is the unit drive (wheels) belt. The

belt farthest from the engine is the auger/impeller drive

belt.

Do not go near the discharge chute or auger when

the engine is running. Do not run the engine with

11

Page 16

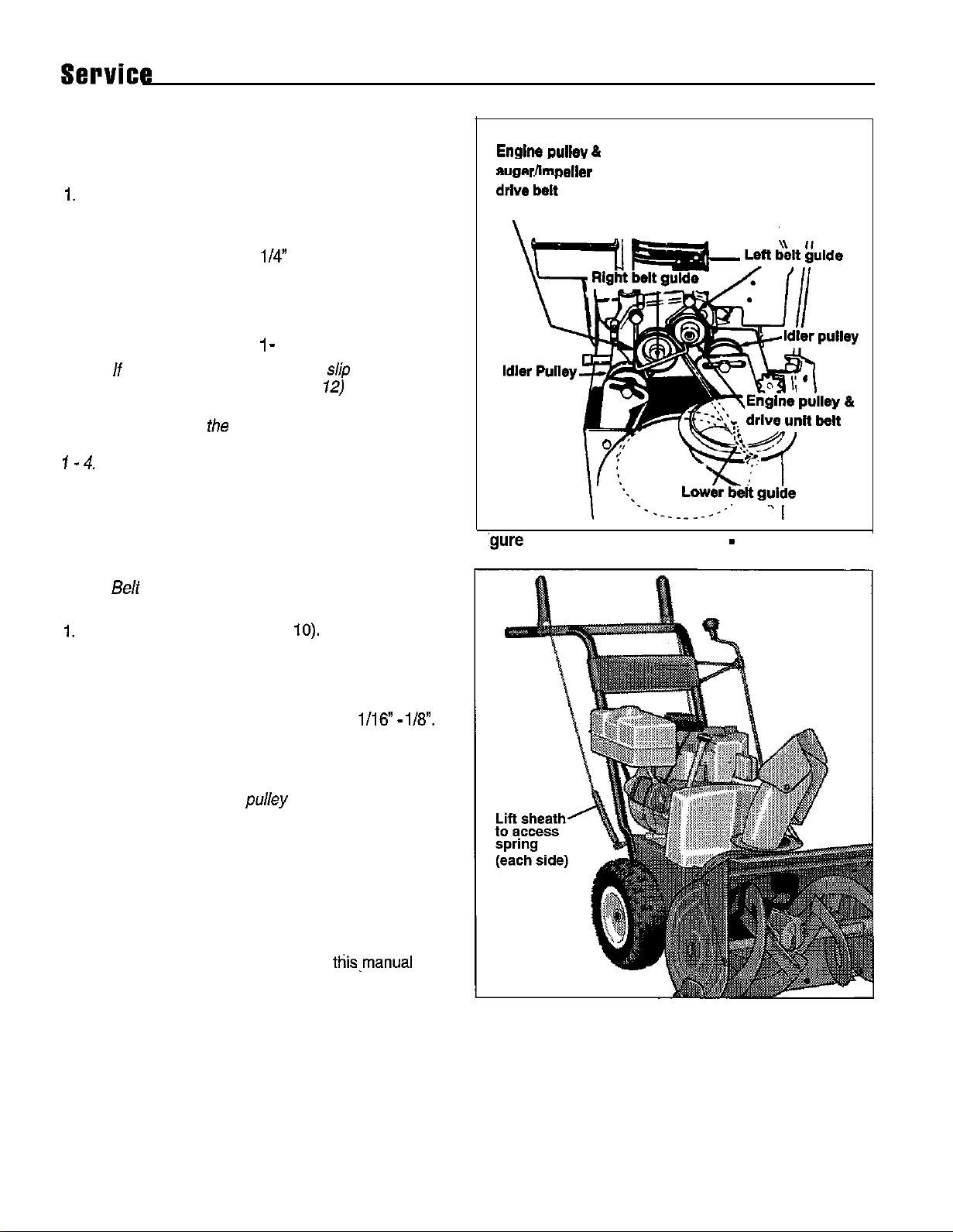

Adjusting Drive Belts

If the auger or wheels slip under load, belts could be

stretched or worn. Adjust as follows:

Remove the belt cover (figure 10). Determine which

belt requires adjustment.

2. Loosen the locknut on the appropriate idler pulley

and move the idler pulley i/4” toward the belt (figure

11). Tighten the locknut.

3. Re-install the belt cover.

4. Determine if additional adjustment is required by trying the unit. Repeat step

NOTE: If auger or wheels continue to slip after adjust-

ing the idler pulleys, the spring (figure

trol rod might be stretched and worn and require replace-

ment. Replace either

drive control rod spring as necessary, then repeat steps

3 if necessary.

on either con-

auger control rod spring or

Adjusting Belt Guides

Check each belt guide for proper clearance using the following procedure.

NOTE: Belt guides on 7 HP mode/s are slight//y different

than shown, but adjustment is the same.

Remove the belt cover (figure

2. Have someone hold both the auger and drive clutch

levers tight against the handgrips (figure 12).

3. Loosen the screw securing the belt guide (figure 11).

Adjust the guide so it clears the belt by

The clearance should be equal on both side of the

pulley. Tighten the screw securely.

NOTE: When adjusting the right belt guide, make sure

guide does not contact the

4. Re-install the belt cover.

l/8”.

\

Belt Cover Off

Replacing Drive Belts

The drive belts on this snowthrower are of special con-

struction and should be replaced with original equipment

belts available from your dealer. See COMMON

REPLACEMENT PARTS at the back of tfiis.manual for

part numbers.

Use the following procedure to replace either drive belt.

1. Remove gas from fuel tank and run engine until it

stops running from lack of fuel.

2. Disconnect spark plug wire and fasten it away from

the spark plug.

3. Remove belt cover (figure 10).

Figure 12. Drive Control Spring

4. Loosen the screw securing the belt guide (figure 11).

Pivot the belt guide as necessary and remove the

drive belt from the pulley.

5. Stand the snowthrower up onto the auger end.

12

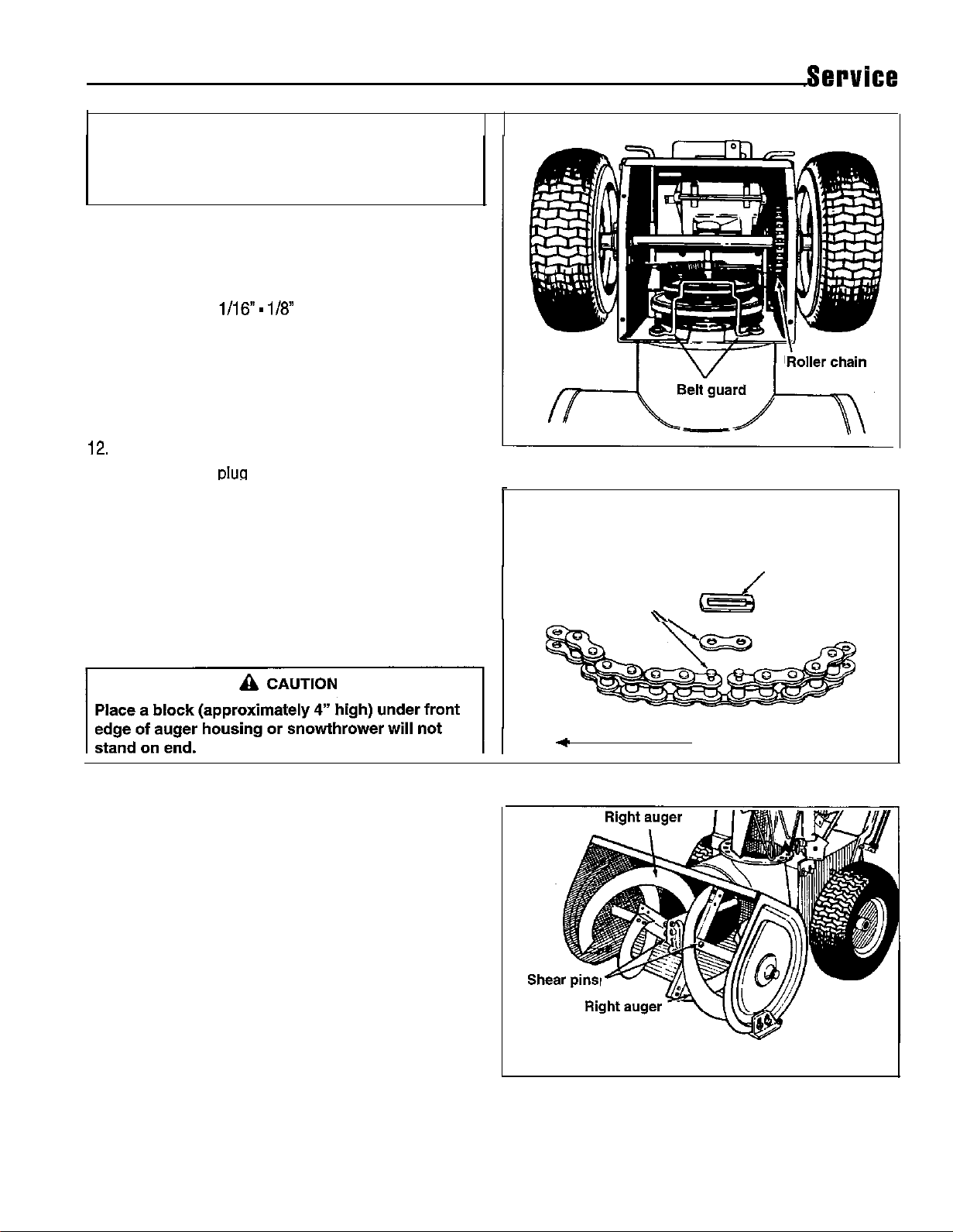

Page 17

A

CAUTION

Place a block (approximately 4” high) under front

edge of auger housing or snowthrower will not

stand on end.

6. See figure 13. Loosen nuts holding lower belt guard

and slide guard away from belt.

7. Remove belt from between large pulleys.

13. Slide new belt onto pulley and position lower belt

guard to within l/16”

Tighten nuts securing lower belt guard.

9. Return snowthrower to upright operating position.

10. Place new belt onto engine pulley.

11. Adjust guides as described under ADJUSTING BELT

GUIDES.

Install belt cover.

13. Connect spark

i/8” of large drive pulley.

wire and fill fuel tank.

Figure 13. Lower Belt Guard

ROLLER CHAIN REPLACEMENT

1. Remove gas from fuel tank and run engine until it

stops running from lack of fuel.

2. Disconnect spark plug wire and fasten it away from

the spark plug.

3. Stand the snowthrower up onto the auger end.

4. Rotate the wheel (figure 13) to locate the roller chain

master link (figure 14).

5. Remove the keeper link, master link and chain.

6. Install new chain and keeper link as shown in figure

14.

7. Return snowthrower to upright operating position.

8. Connect spark plug wire and fill fuel tank.

Keeper link

(Must install towards wheel side

with open end trailing.)

Master link

Direction of

Figure 14. Roller Chain Master Link

travel

SHEAR PIN REPLACEMENT,

If the auger strikes an object which could cause damage

to the unit, the shear pin will break. This protects the

gear box and other parts from damage. The shear pins

are shown in figure 15. To replace, install a new shear

pin and cotter pin. Spread the legs of the new cotter pin

fully. Do not replace shear pins with bolts, screws or a

harder shear pin.

Figure 15. Shear Pin Replacement

13

Page 18

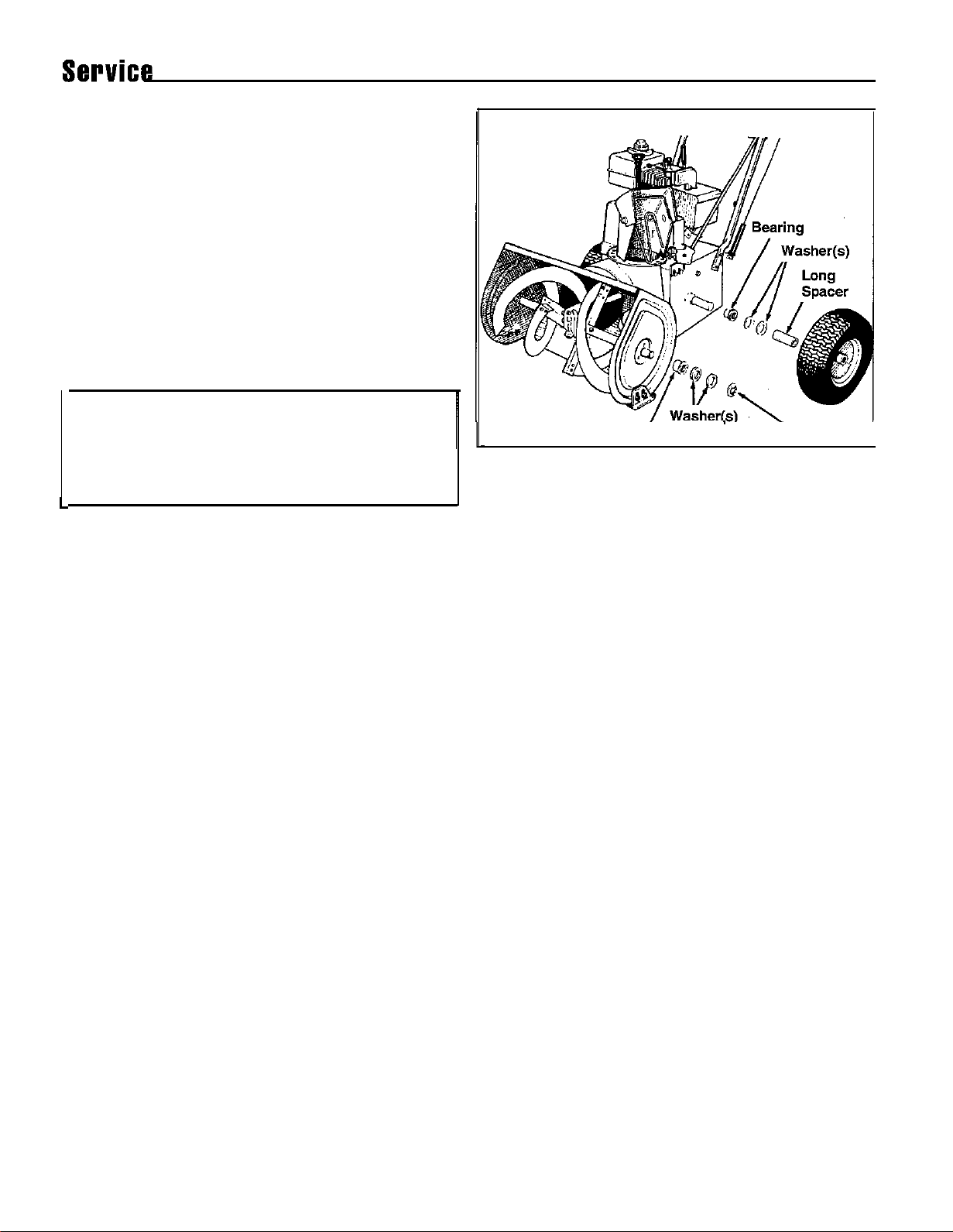

WHEEL AXLE BEARING

REPLACEMENT

After approximately 100 hours of use (about 5 years), or

if drive chain jumps off sprockets, wheel axle bearings

may need to be replaced.

1. Disconnect spark plug wire and fasten it away from

the spark plug.

2. Place a block under the snowthrower so the wheels

are just off the ground.

3. See figure 16. Remove the ring pin and wheel from

each axle.

4. Slide off the washers and long spacer.

A

CAUTION

Note the number and placement of washers used

between wheel and long spacer, or between long

spacer and bearing. An even number of washers

must be used on each side of the shaft.

5. Pull bearing out of housing opening and off of the

shaft.

6. Install new bearing by aligning bearing flat sides with

flat sides in housing.

7. Install washers and long spacer.

8. Install wheel and ring pin.

Bearing

Figure 16. Wheel and Auger Bearings

. ,

E-ring

AUGER SHAFT BEARING

REPLACEMENT

If auger shaft bearings need replacement, proceed as

follows:

1. Pry off the E-ring (figure 16).

2. Remove the washers, then pull the bearing out of the

housing and off the shaft.

3. Install new bearing by aligning bearing flat sides with

flat sides in housing.

4. Install washers. Install a new E-ring securely in shaft

groove.

I

14

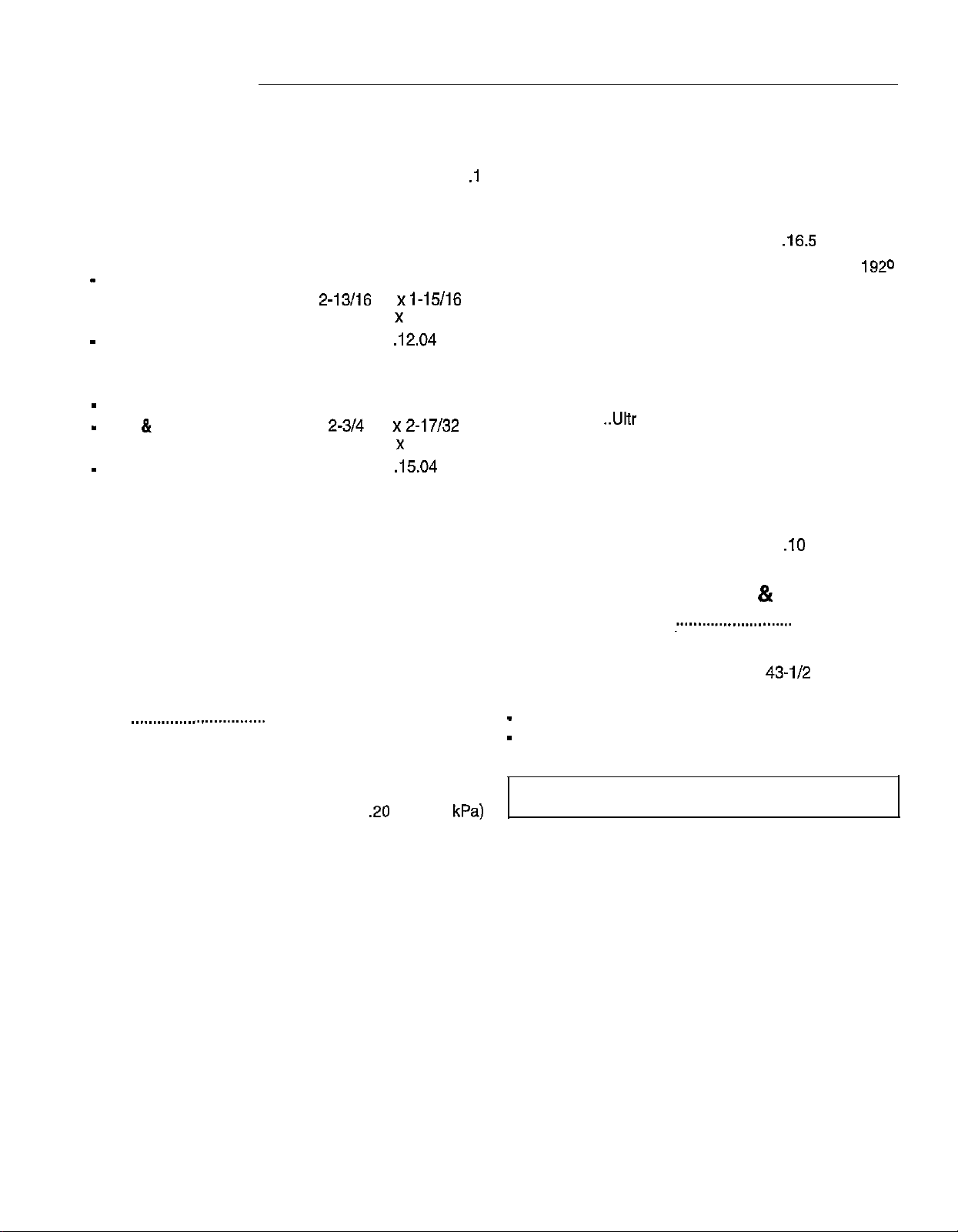

Page 19

Specifications

ENGINE

in.

in. x

Splash

Tecumseh

I.D. plate

(197.34 cc)

(246.5 cc)

Magneto

Mechanical

Manual

system

manual

Make

................................................................

Cylinders.......................................................................

Cycles.............................................................................

Crankshaft

5HP

Model

-Bore&Stroke..

Displacement..

7HP

Model No. .....................................See engine I.D. plate

Bore

Displacement..

Ignition

Governor..

Choke ...................................................................

Lubrication.. .............................................

Oil

Capacity ......................................

Fuel

Capacity..

....................................................... Horizontal

.....................................

No.

........................ Z-13/16

...........................................12.04 cu.

Stroke

...............................................................

............................ 2-314

...........................................15.04 cu.

......................................................

..................................See engine

See engine

(71.44 mm x 49.23 mm)

(69.86 mm

See engine manual

AUGER HOUSING

Construction..

Effective Width

4

Auger Opening Height

with Extension.. .....................................

Spout Rotation

Scraper

in.

Skid Shoes..

in.

............................

.....................................

........................................................

....................................

Bar..

......................

Adjustable,

AUGER

in.

in.

Construction..

Bearings..

IMPELLER

Construction..

Bearings..

Diameter.. ...............................................

...........................Ribbon

.....

............ Pre-lubricated

a high

............................................

Molecular Weight Polyethylene

OVERALL DIMENSIONS

Length ........................... ~.......................... 51

Width

.....................................................

Welded

and sealed ball bearing

steel

stampings

22 in. (55.88 cm)

in. (42 cm)

Wear

resistant steel

heat-treated steel

flite welded

4 steel blades

in. (25.4 cm)

steel

WEIGHT

in. (132 cm)

24

in. (60.96 cm)

DRIVE

Type

Speeds.. ..........................

.........................................................................

Axle..

Tire Inflation

.........................................

Gear drive transmission w/chain

and speed selection

Three forward and one reverse

psi

(136

Solid

Height .................................................

Weight

,158

5-55

.......................................................

7-55

........................................................

SPECIFICATIONS ARE CORRECT AT TIME OF PRINTING

AND ARE SUBJECT TO CHANGE WITHOUT NOTICE.

Ibs. (72 kg)

178

Ibs. (80 kg)

15

Page 20

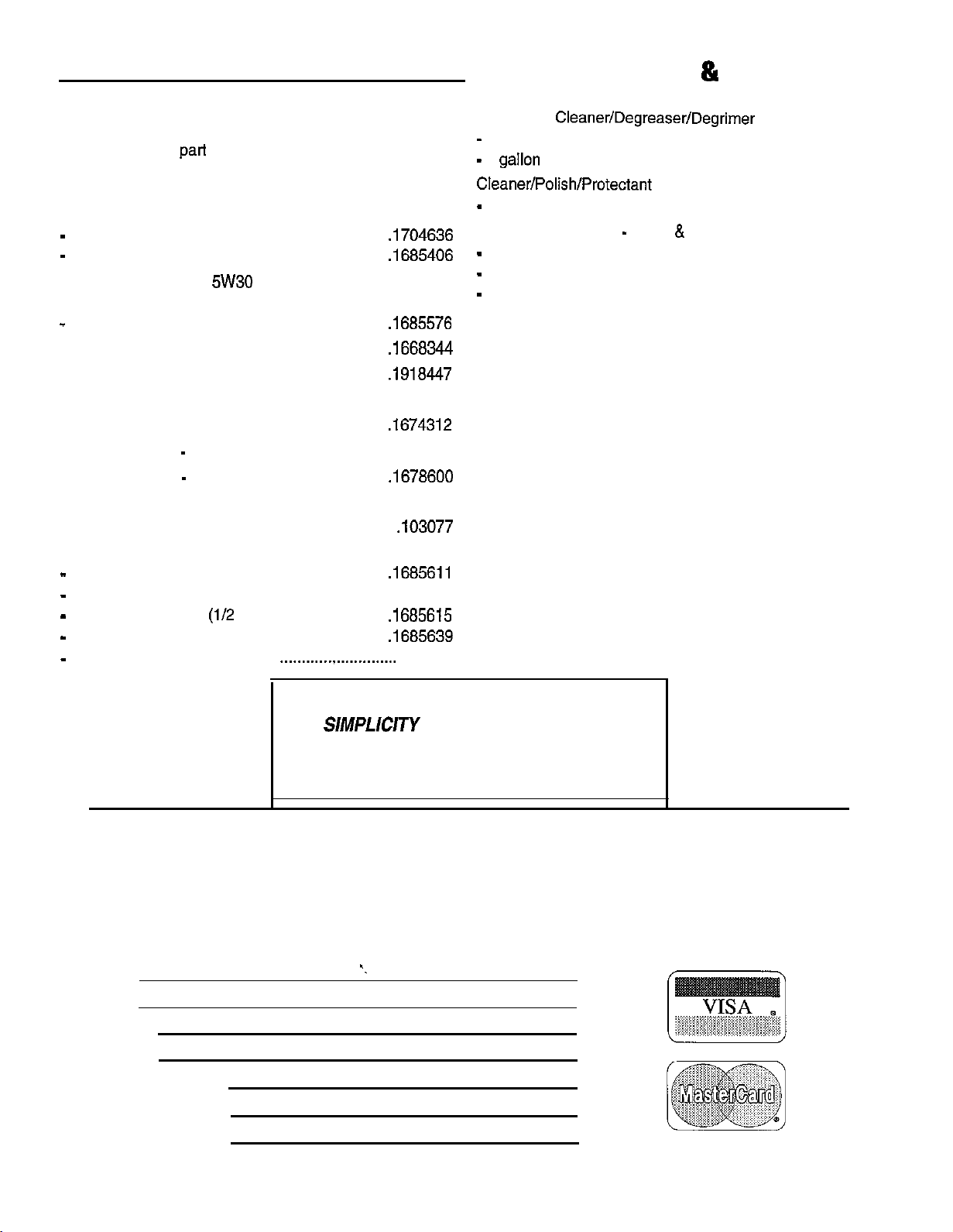

Replacement Parts

Accessories

COMMON REPLACEMENT PARTS

Listed below are

replacement parts. Use only genuine Simplicity replacement parts to assure optimum performance and safety.

Special Worm Gear Oil for Auger Gear Case

8 oz.

Container.. ..............................................

Case of 8 oz.

Simplicity Brand SAE 5W30 Cold

Weather Engine Oil

Case of

Shear

Cotter

Skid Shoes (set of 2)

Auger

Wheel Drive Belt

Wheel

Grease Gun Kit ...................................................

8

oz. Grease Tube.. .............................................

Touch-Up Paint

Deep Orange Spray Paint (13 oz. can)

Deep Orange Paint (1 qt. can)

Deep Orange Paint (i/2 oz. dauber)

Gloss Black Spray Paint (13 oz. can).

White Spray Paint (13 oz. can)

12 Qts..

Pin,

Auger ...............................................

Pin (for shear pin)

Drive Belt..

Drive

Belt

numbers for the more common

containers..

...............................................

............................................... .I674312

5 HP

7

................................

...................................

..........................................

......................................1674308

HP..

...................................

........... .1685611

.......................... 1685612

............... .1685615

............. .1685639

1685501

1685510

103049

Equipment

32

oz. Spray

1

oz.

bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1685697

Pneumatic Tire Seal

oz.

Case of 12

Case of 24

Bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1685619

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1685621

bottle

Stops

tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1685523

(11

oz.

tubes)

oz.

(11

tubes)

Prevents Leaks

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1685537

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1685525

ACCESSORIES

See your dealer to purchase any of the following acces-

sories for your snowthrower.

Light Kit

Light for late afternoon and early evening snowthrowing.

Electric Start Kit (120V AC)

Offers operator the convenience of electric starting.

Available for all models. Standard on some models.

Drift Cutters

Part No.1685189. Helps break through drifts.

Tire Chains

Increase traction on snowy surfaces (use with caution to

avoid marking surfaces). Available for all models. Not for

use with Snow Hog tires.

USE ONLY GENUINE

REPLACEMENT PARTS

Available through your local

authorized SIMPLICITY dealer.

TECHNICAL MANUAL AVAILABILITY

Parts and Repair Manuals are fully illustrated. All of the assemblies are shown in exploded views which show the

relationship of the parts and how they go together. Important assembly notes and special torque values are included

in the illustrations. Standard hardware and torque specification charts are also included.

For the manuals applicable for your model, contact the Simplicity Customer Publications Department at

414-284-8519. Have the following information available when phoning in your request.

Model:Model:

Mfg. No.:Mfg. No.:

Your Name:Your Name:

Address:Address:

City, State, Zip:

Vise/Mastercard No.:

Card Expiration Date:

16

Loading...

Loading...