Page 1

OPERATOR’S

MANUAL

Single Stage

Snowthrower

520M Models

Mfg. No. Description

1694585 520M, 5HP Snowthrower, Manual Start

7085663 SS5201R, 5HP Snowthrower, Manual Start

520E Models

Mfg. No. Description

1694586 520E, 5HP Snowthrower, Electric Start

7085664 SS5201E, 5HP Snowthrower, Electric Start

Manual No 7100194

I.R. 6/10/2005

TP 100-5072-IR-SX-N

Page 2

1

Table of Contents

Safety Rules & Information

Training ...................................................................2

Preparation .............................................................2

Operation ................................................................2

Children...................................................................3

Clearing a Clogged Discharge Chute .....................3

Service, Maintenance, and Storage........................3

Emissions................................................................3

Identification Numbers ............................................4

Safety Decals..........................................................5

International Symbols .............................................6

Assembling the Snowthrower ....................................7

Controls & Operation

Snowthrower Controls.............................................8

Engine & Starting Controls......................................9

General Operation ................................................10

Checks Before Each Start-Up...............................10

Mixing Fuel............................................................11

Starting the Engine ...............................................12

Stopping the Engine..............................................12

Operating the Snowthrower ..................................13

Snowthrowing Tips................................................13

After Each Use......................................................13

Off-Season Storage ..............................................13

Starting After Storage ...........................................11

Regular Maintenance

Removing Belt Cover ............................................14

Lubrication ............................................................14

Troubleshooting & Service

Troubleshooting ....................................................15

Removing Engine Cover .......................................15

Auger Control Cable Adjustment ..........................16

Carburetor Adjustment (Ref. only) ........................16

Replacing the Drive Belt .......................................17

Replacing the Scraper Blade ................................17

Servicing the Spark Plug.......................................17

Appendices

Specifications........................................................18

Parts & Accessories..............................................18

Technical Manuals ................................................18

Engine exhaust from this product contains

chemicals known, in certain quantities, to cause

cancer, birth defects, or other reproductive harm.

WARNING

Page 3

2

This machine is capable to amputating hands and feet and throwing objects. Read these safety rules and

follow them closely. Failure to obey these rules could result in loss of control of unit, severe personal injury

or death to you, or bystanders, or damage to property or equipment. The triangle in text signifies

important cautions or warnings which must be followed.

Safety Rules & Information

TP-600-3606-03-LW-UV

TRAINING

1. Read, understand, and follow all instructions on the

machine and in the manuals before operating this

unit. Be thoroughly familiar with the controls and the

proper use of the equipment. Know how to stop the

unit and disengage the controls quickly.

2. Never allow children to operate the equipment.

Never allow adults to operate the equipment without

proper instruction.

3. Keep the area of operation clear of all persons, particularly small children and pets.

4. Exercise caution to avoid slipping or falling especially

when operating in reverse.

PREPARATION

1. Thoroughly inspect the area where the equipment is

to be used and remove all doormat, sleds, boards,

wires, and other foreign objects.

2. Disengage all clutches and shift into neutral before

starting engine (motor).

3. Do not operate the equipment without wearing adequate winter outer garments. Wear footwear that will

improve footing on slippery surfaces. Avoid loose fitting clothing that can get caught in moving parts.

4. Handle fuel with care; it is highly flammable.

(a) Use an approved fuel container.

(b) Never add fuel to a running engine or hot engine.

(c) Fill fuel tank outdoors with extreme care. Never fill

fuel tank indoors. Replace fuel cap securely and

wipe up spilled fuel.

(d) Never fill containers inside a vehicle or on a truck

or trailer bed with a plastic liner. Always place containers on the ground, away from your vehicle, before

filling.

(e) When practical, remove gas-powered equipment

from the truck or trailer and refuel it on the ground. If

this is not possible, then refuel such on a trailer with a

portable container, rather than from a gasoline dispenser nozzle.

(f) Keep nozzle in contact with the rim of the fuel tank

or container opening at all times, until refueling is

complete. Do not use a nozzle lock-open device.

(g) Replace gasoline cap securely and wipe up spilled

fuel.

(h) If fuel is spilled on clothing, change clothing immediately.

5. Use extension cords and receptacles as specified by

the manufacturer for all units with electric drive

motors or electric starting motors.

6. Adjust the collector housing height to clear gravel or

crushed rock surfaces.

7. Never attempt to make any adjustments while the

engine (motor) is running (except when specifically

recommended by the manufacturer).

8. Let engine (motor) and machine adjust to outdoor

temperatures before starting to clear snow.

9. Always wear safety glasses or eye shields during

operation or while performing an adjustment or repair

to protect eye from foreign objects that may be

thrown from the machine.

OPERATION

1. Do not put hands or feet near or under rotating parts.

Keep clear of the discharge opening at all times.

2. Exercise extreme caution when operating on or

crossing gravel drives, walks, or roads. Stay alert for

hidden hazards or traffic.

3. After striking a foreign object, stop the engine (motor),

remove the wire from the spark plug, disconnect the

cord on electric motors, thoroughly inspect the

snowthrower for any damage, and repair the damage

before restarting and operating the snowthrower.

4. If the unit should start to vibrate abnormally, stop the

engine (motor) and check immediately for the cause.

Vibration is generally a warning of trouble.

5. Stop the engine (motor) whenever you leave the

operating position, before unclogging the

collector/impeller housing or discharge guide, and

when making any repairs, adjustments, or inspections.

6. When cleaning, repairing, or inspecting make certain

the collector/impeller and all moving parts have

stopped. Disconnect the spark plug wire and keep

the wire away from the plug to prevent accidental

starting.

7. Do not run the engine indoors except for starting the

engine or for transporting the snowthrower in or out of

the building. Open the outside doors; exhaust fumes

are dangerous.

8. Exercise extreme caution when operating on slopes.

Do not attempt to clear steep slopes.

9. Never operate the snowthrower without proper

guards plates, or other safety protective devices in

place and working.

10. Never direct the discharge toward people or areas

where property damage can occur. Keep children

and others away.

11. Do not overload the machine capacity by attempting

to clear snow at too fast a rate.

12. Never operate the machine at high transport speeds

on slippery surfaces. Look behind and use care

when operating in reverse.

13. Disengage power to the collector/impeller when

snowthrower is transported or not in use.

14. Use only attachments and accessories approved by

the manufacturer of the snowthrower (such as wheel

weights, counterweights, or cabs).

15. Never operate the snowthrower without good visibility

or light. Always be sure of your footing, and keep a

firm hold on the handles. Walk, never run.

16. Never touch a hot engine or muffler.

17. Never operate the snowthrower near glass enclosures, automobiles, window wells, drop-offs, and the

like without proper adjustment of the discharge angle.

18. Never direct discharge at bystanders or allow anyone

in front of the unit.

19. Never leave a running unit unattended. Always disengage the auger and traction controls, stop engine,

and remove keys.

20. Do not operate the unit while under the influence of

alcohol or drugs.

Page 4

3

8. Always follow the engine manual instructions for storage preparations before storing the unit for both short

and long term periods.

9. Always follow the engine manual instructions for

proper start-up procedures when returning the unit to

service.

10. Maintain or replace safety and instruction labels as

necessary.

11. Keep nuts and bolts tight and keep equipment in

good condition.

12. Never tamper with safety devices. Check their proper

operation regularly and make necessary repairs if

they are not functioning properly.

13. Components are subject to wear, damage, and deterioration. Frequently check components and replace

with manufacturer’s recommended parts, when necessary.

14. Check control operation frequently. Adjust and service as required.

15. Use only factory authorized replacement parts when

making repairs.

16. Always comply with factory specifications on all settings and adjustments.

17. Only authorized service locations should be utilized

for major service and repair requirements.

18. Never attempt to make major repairs on this unit

unless you have been properly trained. Improper service procedures can result in hazardous operation,

equipment damage and voiding of manufacturer’s

warranty.

19. Check shear bolts and other bolts at frequent intervals for proper tightness to be sure the equipment is

in safe working condition.

EMISSIONS

1. Engine exhaust from this product contains chemicals

known, in certain quantities, to cause cancer, birth

defects, or other reproductive harm.

2. If available, look for the relevant Emissions Durability

Period and Air Index information on the engine emissions label.

Safety Rules

21. Keep in mind the operator is responsible for accidents occurring to other people or property.

22. Data indicates that operators, age 60 years and

above, are involved in a large percentage of power

equipment-related injuries. These operators should

evaluate their ability to operate the unit safely enough

to protect themselves and others from injury.

23. DO NOT wear long scarves or loose clothing that

could become entangled in moving parts.

24. Snow can hide obstacles. Make sure to remove all

obstacles from the area to be cleared.

CHILDREN

Tragic accidents can occur if the operator is not alert to the

presence of children. Children are often attracted to the

unit and the operating activity. Never assume that children

will remain where you last saw them.

1. Keep children out of the area and under the watchful

care of another responsible adult.

2. Be alert and turn unit off if children enter the area.

3. Never allow children to operate the unit.

4. Use extra care when approaching blind corners,

shrubs, trees, or other objects that may obscure

vision.

CLEARING A CLOGGED DISCHARGE

CHUTE

Hand contact with the rotating impeller inside the discharge chute is the most common cause of injury associated with snowthrowers. Never use your hand to clean

out the discharge chute.

To clear the chute:

1. SHUT OFF THE ENGINE.

2. Wait 10 seconds to be sure the impeller blades have

stopped rotating.

3. Always use a clean out tool, not your hands.

SERVICE, MAINTENANCE, AND STORAGE

1. Check shear bolts and other bolts at frequent intervals for proper tightness to be sure the equipment is

in safe working condition.

2. Never store the machine with fuel in the fuel tank

inside a building where ignition sources are present

such as hot water and spacer heaters, or clothes dryers. Allow the engine to cool before storing in any

enclosure.

3. Always refer to the operator’s manual for important

details if the snowthrower is to be stored for an

extended period.

4. Maintain or replace safety and instruction labels as

necessary.

5. Run the machine a few minutes after throwing snow

to prevent freeze-up of the collector/impeller.

6. If fuel is spilled, do not attempt to start the engine but

move the machine away from the area of spillage and

avoid creating any source of ignition until fuel vapors

have dissipated.

7. Always observe safe refueling and fuel handling practices when refueling the unit after transportation or

storage.

Page 5

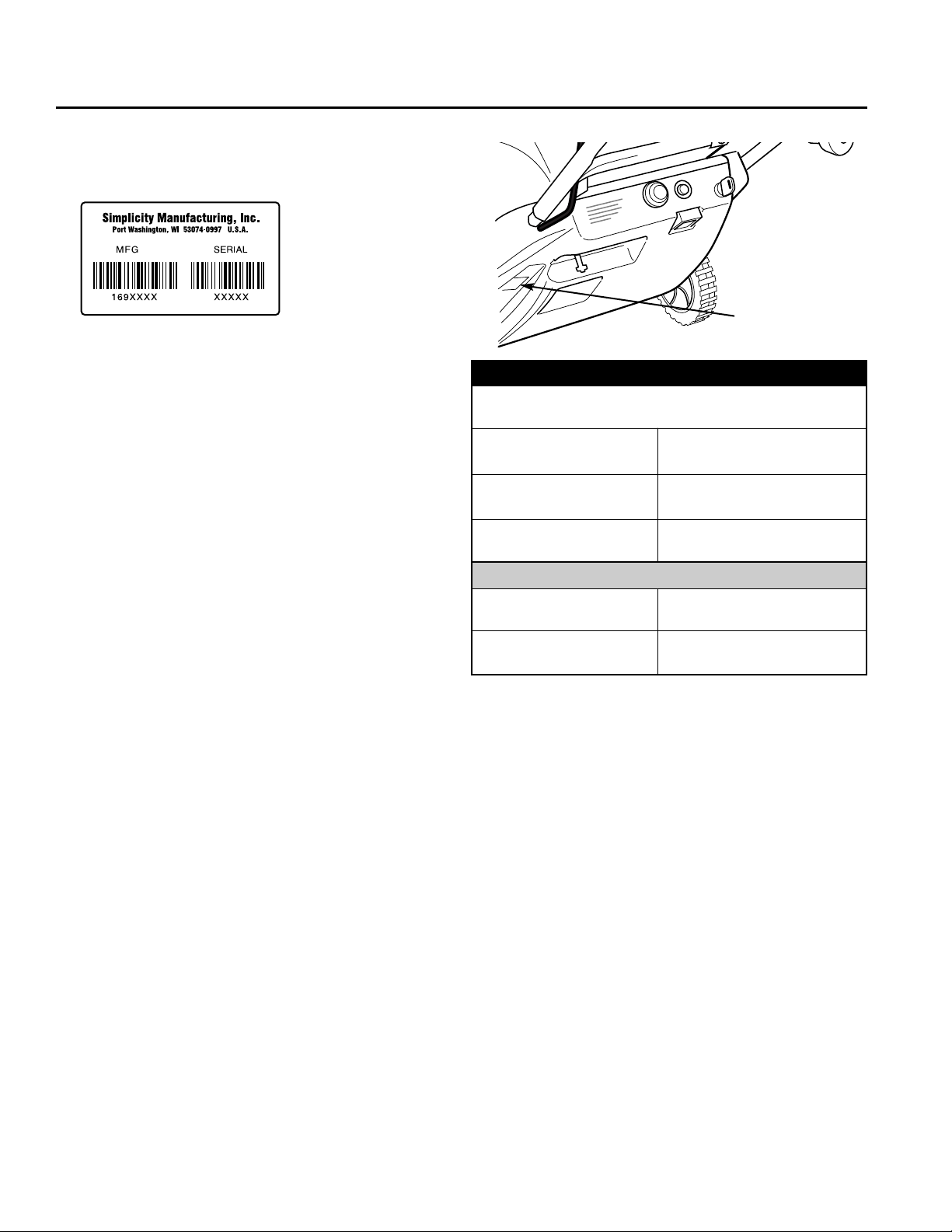

4

Product Identification

ID Tag

When contacting your authorized dealer for replacement parts, service, or information you MUST have

these numbers.

Record your model name/number, manufacturer’s identification numbers, and engine serial numbers in the

space provided for easy access. These numbers can be

found in the locations shown.

NOTE: For location of engine identification numbers,

refer to the engine owner’s manual.

SSAAMMPPLLEE

ENGINE REFERENCE DATA

Model Description Name/Number

Unit MFG Number

PRODUCT REFERENCE DATA

Unit SERIAL

Number

Dealer Name

Date Purchased

Engine Make

Engine Type/Spec

Engine Model

Engine Code/Serial Number

Mower Deck MFG Number

Mower Deck SERIAL

Number

Identification Numbers

Page 6

5

Safety Rules & Information

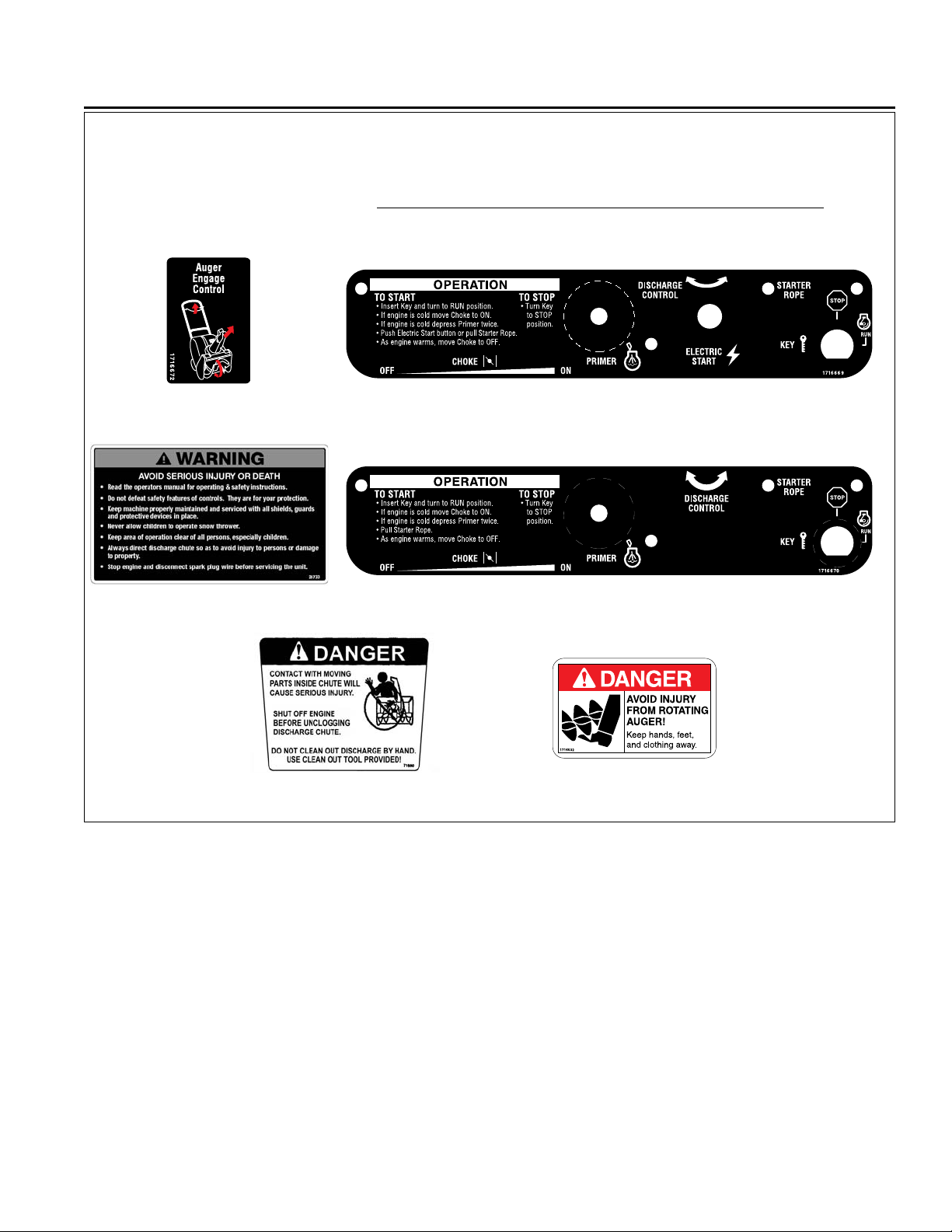

SAFETY DECALS

Safety warning decals are placed at strategic locations on the snowthrower as a constant reminder to the operator of the most important safety precautions. All warning, caution and instructional messages on your snowthrower should be carefully read and obeyed. If any of these decals are lost or damaged, replace them at once. They

can be purchased from your local dealer.

Part No. 7071880

Discharge Chute Danger Decal

Part No. 1716669

Main Dash Decal (Electric Start Models)

Part No. 1716532

Auger Danger Decal

Part No. 1716670

Main Dash Decal (Manual Start Models)

Part No. 1716672

Auger Control Decal

Part No. 7026733

Warning Decal

Page 7

6

Safety Rules & Information

International Symbols

FAST

SLOW

STOP

CHOKE

PRIMER

ELECTRIC START

IGNITION KEY

RUN

Page 8

7

Assembling

the Snowthrower

TOOLS REQUIRED

• Socket or Wrench Set

• Pair of Pliers

ASSEMBLY PROCEDURE

If your unit was not previously assembled, see Figures 1

and 2, and follow the steps below to assemble the unit:

1. Install the discharge chute on to the rotating ring

located on the auger housing. Secure with the three

5/16 inch carriage bolts, flat washers and nylock nuts

found in the parts bag (the bolt heads go to inside of

of the rotating ring, with washers and nuts on the outside). Note, install the rear bolt first for easier alignment.

2. Tighten bolts securely with a wrench.

3. Lift up folding handle to align it with lower handle and

tighten the wing knobs securely as shown in Figure 3.

4. Insert clean-out tool into holders on left handle.

Figure 1. Assembly of Discharge Chute

A. Discharge Chute D. Nuts

B. Carriage Bolts E. Rotating Ring

C. Washers

A

B

C

D

E

Figure 2. Handles

A. Handle B. Wing Knobs C. Clean-out Tool

A

B

Figure 3. Lift Handles and Lock Wing Knobs

C

Page 9

8

Controls

& Operation

Auger

Control

Chute

Direction

Control

Chute

Deflector

Clean-Out

Tool

A

B

C

D

Engages auger when pulled

back, and disengages auger

when released.

Rotates discharge chute to

desired direction

Controls vertical angle snow is

thrown.

Use to remove objects and clear

the chute or auger.

Figure 5. Snowthrower Controls

A

B

C

SNOWTHROWER CONTROLS

Auger Control

A. Auger Control - This control engages and disen-

gages the auger. Pull the control back against handle

to engage the auger, (this will pull snowthrower forward if auger is in contact with the ground). Release

the auger control to stop rotation of auger.

Deflector Controls

B. Chute Direction Control - The chute direction con-

trol (B, Figures 4 & 5) allows the discharge chute to

be rotated to throw snow in the desired direction.

Snow may be thrown at any angle from straight left to

straight forward, to straight right.

The length of the chute direction control can be

adjusted. Remove the cotter pin (A, Figure 5) to

extend or shorten the rod to desired length, then reinstall the pin.

C. Chute Deflector - Controls the distance snow is

thrown. Tilting the chute deflector (C, Figure 4) UP

provides a higher stream and greater distance, while

tilting the deflector DOWN provides a lower stream

and less distance.

Figure 4. Discharge Chute Control Adjustment

A. Cotter Pin

B. Chute Direction Control

A

B

D

Clean-Out Tool

D. Clean-Out Tool - Use to remove objects and clear

the discharge chute or auger.

DO NOT clean out discharge chute with hands.

Contact with moving parts in the chute will cause

serious injury. Use clean-out tool provided with

machine.

DANGER

Page 10

9

Controls & Operation

ENGINE & STARTING CONTROLS

NOTE: Throttle -

This snow thrower does NOT have a

throttle for controlling operating speed of engine.

The

engine governor maintains operating speed for varying snow removal conditions.

Electric Start Units Only

A. Electric Start Button - The electric start Button (A,

Figure 6) activates an electric starter mounted to the

engine, eliminating the need to pull the starter handle. The electric start button operates on 120 Volts

AC, which is provided by connection to the extension

cord provided with units equipped with this feature.

Connect this extension cord ONLY to a properly

grounded 3 prong electrical outlet.

All Models

B. Fuel Tank Cap - Cover fuel tank & provides venting

ability to prevent vapor lock.

C. Starter Handle - The starter handle (C, Figure 6)

connects to a starter cord to manually start the

engine. Pulling starter handle rapidly spins the engine

crankshaft, cycles the engine, and generates the

spark necessary for starting the engine.

D. Primer Button - When pressed, the primer button (D,

Figure 6) provides initial fuel to help start a cold

engine. Normally, pressing the primer button twice

will provide enough fuel to start a cold engine.

E. Engine Key - Insert key in switch and turn key to ON

position when starting engine. To stop engine, turn

key to OFF position.

F. Choke Control - The is control (F, Figure 6) adjusts

the fuel/air mixture, and is used to help start a cold

engine by providing a richer mixture.Once the engine

is warm and running smoothly, the choke control

should be set to the off position to provide a normal

air/fuel mix.

Figure 6. Engine Controls

A Electric Start

Button

(Optional)

Activates electric starter

B Fuel Tank

Cap

Covers fuels tank and provides

venting to prevent vapor lock

C Starter Handle Used to start engine

D Primer Button Primes carburetor for faster cold

starting.

E Engine Key Prevents starting of engine with-

out key. Stops engine when

removed.

F Choke Control Adjusts air/fuel mixture

E

A

B

D

F

C

Page 11

10

GENERAL OPERATION

CHECKS BEFORE EACH START-UP

1. Make sure all safety guards are in place and all nuts,

bolts and clips are secure.

2. Check the fuel supply. Fill the tank no closer than 1/4

to 1/2 inch of top of tank to provide space for expansion. See your engine owner’s manual for fuel recommendations.

3. Check the auger control (see A, Figure 4) for proper

operation. If adjustment is required, see the service

section (pages 13-15) for procedures.

4. Check the chute direction control (B, Figure 4) for

proper operation. The discharge chute should rotate

freely in both directions. See the service section for

adjustment procedures and troubleshooting.

5. Check the chute deflector (C, Figure 4) for proper

operation. The deflector should pivot freely up and

down. See the service section for procedures.

6. Position the chute at the desired starting direction

and set the deflector at the desired angle.

7. Make sure the clean-out tool is mounted in the storage position on the snow thrower.

Controls & Operation

OPERATIONAL WARNINGS

Clearing The Discharge Chute

To avoid serious injury, do not put your hands

into the auger housing or discharge chute. If the

auger stalls or chute becomes plugged, use the

following procedure to remove objects or clear

the chute:

1. Release the auger control.

2. Shut off the engine.

3. Remove the key.

4. Wait for all moving parts to stop.

5. Use the clean-out tool to remove foreign

objects and clear the chute or auger. Never

put your hands into the auger or discharge

chute.

6. If servicing is needed, remove cover and

disconnect spark plug wire.

Discharge Chute Adjustment

Release the auger control and make sure the

auger has STOPPED before rotating the

discharge chute or adjusting the deflector. DO

NOT place hands near the auger while the engine

is running.

Thrown Objects

Objects can be thrown by the snowthrower while

it is in operation. Thrown objects could cause

serious injury to the operator or bystanders.

Always wear safety goggles or other suitable eye

protection. Keep people and pets away from the

area.

Slope Operation

For your safety, operation on slopes should be in

an up and down direction only. If it becomes

necessary to move across the face of a slope,

use caution and do not activate the auger. Be

very careful when changing direction on a slope.

Proper winter footwear is recommended for the

operator to help prevent slipping. Never attempt

to clean snow from slopes. The maximum slope

for any operation is 17.7% (10º).

Do not use the snowthrower on surfaces above

ground level such as the roof of a building.

WARNING

DO NOT clean out discharge chute with hands.

Contact with moving parts in the chute will cause

serious injury. Use clean-out tool provided with

machine.

DANGER

Never run engine indoors or in enclosed, poorly

ventilated areas. Engine exhaust contains

CARBON MONOXIDE, an ODORLESS and

DEADLY GAS.

DANGER

Page 12

11

FUEL AND OIL MIXTURE

The snowthrower uses a two cycle engine that requires a

mixture of fuel (gasoline) and oil for lubrication of engine

bearings and other moving parts.

The correct fuel/oil mixture ratio is 50 to 1. Use fuel/oil

mixture chart shown.

NOTE: To prevent damage to engine, carefully

observe recommended fuel to oil mixing ratio and

procedures.

• Gasoline and oil must be premixed in a clean fuel

container.

• Always use fresh, unleaded, winter grade fuel.

• Never put plain, unmixed fuel into fuel tank. Shake

fuel container each time before filling fuel tank.

• Never use “stale” fuel left over from last season or

stored for long periods.

• DO NOT USE MULTI VISCOSITY OILS, SUCH AS

10W-30 or 10W-40.

PROPER FUEL MIXING PROCEDURE

1. Fill approved clean fuel container one quarter full with

fresh unleaded fuel - one quart (one liter) in a one

gallon (4 liter) container.

2. Pour recommended amount of high quality two

cycle oil — 2.5 ounces (80 ml) into fuel container for

one gallon (4 liters) of fuel. (NOTE: DO NOT USE

MULTI VISCOSITY OILS, SUCH AS 10W-30 or

10W-40.)

3. Reinstall cap on the fuel container and shake container vigorously so oil mixes with gasoline.

4. Unscrew cap and fill container with fuel. Shake container again.

5. Remove fuel tank cap and carefully pour mixed fuel

into the fuel tank, filling to 1/2 inch (1.5 cm) below

filler neck to allow room for expansion. Never put

plain, unmixed fuel into fuel tank. Shake fuel container each time before filling fuel tank.

Controls & Operation

Gasoline is highly flammable and must be

handled with care. Follow these fuel handling

precautions:

• Use an approved fuel container.

• DO NOT run the unit indoors. DO NOT fill fuel

tank indoors or while engine is running.

• Allow engine to cool for at least ten minutes

before refueling.

• Wipe up any spilled fuel before starting the

engine.

• Fuel vapors can travel to distant ignition

sources. Keep fuel and fuel vapors away from

ignition sources.

WARNING

FUEL TO OIL MIXTURE CHART (50:1)

U.S. Imperial Metric

Gasoline 2 Cycle Oil Gasoline 2 Cycle Oil Gasoline 2 Cycle Oil

Gallons Ounces Gallons Ounces Liters Milliliters

1 2.5 1 2.8 4 80 ml

2 5 2 5.6 8 160 ml

5 13 5 14.1 20 400 ml

Figure 7. Proper Fuel Mixing Procedure

A. Fill Container with 1 Quart (1 Liter) of fuel

B. 2.5 Ounces (80 ml) of two-cycle oil

C. Combine in container, then shake container

D. Additional fuel brings total to 1 Gallon (4 liters)

A

B

D

C

Page 13

12

Controls & Operation

STARTING THE ENGINE

NOTE: The snowthrower engine is designed to operate

at cold temperatures. Avoid operating the snowthrower if

air temperature is 40° C or warmer since engine may

vapor lock and stop running after a short time. Engine

will be difficult to start in warm weather.

Electric Starting Steps

Note: The electric starter is designed to operate on 120V

AC household current, using power cord supplied with

electric start snowthrower. When using power cord,

match wide blade of plug to wide slot of receptacle.

1. Insert engine key in switch and turn key to the ON

position.

2. If engine is cold, move choke control lever to the ON

position. (Do not choke a warm engine).

3. Push the primer button two times if engine is cold.

(Do not prime a warm engine.)

4. Plug power cord for starter into receptacle on starter

switch, then plug other end into a 120Volt AC household receptacle. DO NOT use an extension cord with

the electric start power cord supplied.

5. Push starter button to crank engine. DO NOT crank

engine for more than a total of 15 seconds without

allowing electric starter to cool for 10 minutes before

additional cranking is attempted. Electric starter can

be severely damaged if recommended starter operating limitations are not observed.

NOTE: Do not push primer button while engine is

being cranked.

6. Release starter button when engine starts and gradually move choke lever to the OFF position.

NOTE: Always disconnect power cord from

household receptacle first, then unplug from

starter switch.

7. Disconnect power cord from household receptacle

and then from starter switch on snowthrower. Store

cord in a dry, convenient place.

8. To stop engine, turn engine key to the OFF position.

Manual (Recoil) Starting Steps

1. Insert engine key in switch and turn key to the ON

position.

2. If engine is cold, move choke control lever to the ON

position. (Do not choke a warm engine).

3. Push the primer button two times if engine is cold.

(Do not prime a warm engine.)

4. Grasp starter rope handle and slowly pull out rope

until resistance is felt. Allow rope to rewind slowly,

then pull rope out rapidly to start engine. Let rope

return slowly to starter.

NOTE: If engine does not start after three pulls,

push primer bulb once and again pull starter

rope.

5. After engine starts and gradually warms up, move

choke lever to the OFF position. Be prepared to

move choke lever to the ON position if engine falters

during warm up.

6. Allow engine to warm up before beginning

snowthrower operations. The engine will operate at

full throttle when thoroughly warmed up.

7. To stop engine, turn engine key to the OFF position.

STOPPING THE ENGINE

1. Release the auger control.

2. Turn engine key to the OFF position.

3. Remove the key from the switch if you are leaving the

operating position or will be making adjustments or

repairs. (NOTE: Allow the unit to cool before storing

or making any adjustments or repairs.)

If you will be storing the unit for the season, see the

STORAGE section for instructions on properly preparing

the unit for long-term storage.

Electric start precautions:

• Use only with a grounded, polarized 120V AC

outlet. Do not modify the plug to fit into any

other type of outlet.

• Use only the power cord supplied with the unit.

DO NOT use a damaged cord.

• Be sure there is no moisture present on the

cord ends or receptacles when connecting to

an outlet or to the unit.

WARNING

Never run engine indoors or in enclosed, poorly

ventilated areas. Engine exhaust contains

CARBON MONOXIDE, an ODORLESS and

DEADLY GAS.

DANGER

Page 14

13

OPERATING THE SNOWTHROWER

Before operating snowthrower, review the

Checks Before

Each Use

under General Operation on page 8 of this

manual.

1. Rotate the discharge chute to the desired direction.

2. Pull the Auger Control back against the handle to

engage the auger.

NOTE: The snowthrower will be pulled forward by the

auger when the auger contacts the ground or with the

snow to be thrown.

3. Begin snow removal by clearing a path down the center of walk or driveway, then gradually widen path,

throwing snow off to both sides.

4. Release the auger control to stop both the auger and

the forward motion of the snowthrower.

SNOWTHROWING TIPS

Discharge chute plugging may occur as the result of

snow build up inside the chute. DO NOT use your hands

to clear the blockage, only use the clean-out tool. DO

NOT place your hands near the auger or discharge chute

any time the engine is running. Turn the engine OFF, be

sure all moving parts have stopped, and clear the blockage using the clean-out tool, or put the unit indoors and

allow the blockage to melt.

Varying snow conditions will affect performance of

snowthrower. The snowthrower should be allowed to

move into the snow at it's own pace.

Wet, heavy snow — When clearing wet, heavy snow,

the forward movement of the snowthrower may have to

be slowed by pushing down on handle while allowing

engine to operate at full throttle.

Do not operate on gravel or crushed rock surfaces.

Avoid picking up this type of material with auger since

damage to unit could result and particles can be discharged with considerable force that could cause serious

injury.

Always be alert to hidden hazards that might be struck

by the auger. Should a foreign object be struck by the

auger, immediately stop the engine and inspect machine

for any damage. Repair damage before continuing operation.

Controls & Operation

AFTER EACH USE

Allow snow thrower to run a few minutes after clearing

snow to reduce the likelihood of parts freezing while

machine is not is use.

If you will be storing the unit for the season, see the

STORAGE section for instructions on properly preparing

the unit for long-term storage.

OFF-SEASON STORAGE

Before you store your snowthrower for the off-season,

read the Service, Maintenance and Storage instructions

in the Safety Rules section and take the following precautions:

NOTE: Gasoline, if permitted to stand unused for extended periods (30 days or longer), may develop gummy

deposits which can adversely affect the engine carburetor and cause engine malfunction. To avoid this condition, add Dealer Line Gasoline Stabilizer to the fuel tank,

or drain all fuel from the system before placing unit in

storage.

NOTE: Refer to the engine manufactur’s owner’s manual

for engine storage information.

1.Drain fuel from the fuel tank and let the engine run until

all fuel is consumed and the engine stops. Allow the

unit to cool.

2. Disconnect the spark plug wire and secure away from

the spark plug.

3. Tape all openings to prevent spraying water into the

exhaust or air intakes.

4. Tilt the snowthrower up on its wheels and thoroughly

clean the underside.

5. Lubricate all exposed metal with a light coating of oil.

DO NOT place any type of lubrication on the drive

belt or pulleys.

6. Store the unit in a shelter or other dry area protected

from the weather.

STARTING AFTER STORAGE

1. Remove the spark plug and wipe dry. Then reinstall

plug.

2. Fill fuel tank with fresh gasoline (unless a fuel stabilizer was used).

3. Check to be sure engine fins are clean and air flow is

unobstructed.

4. Start the engine outdoors. Allow the engine to warn

up before blowing snow.

5. Check the operation of all the controls.

DO NOT clean out discharge chute with hands.

Contact with moving parts in the chute will cause

serious injury. Use clean-out tool provided with

machine.

DANGER

Page 15

Figure 11. Grease the Discharge Chute Ring

Lubricate

Flange

Regular

Maintenance

14

Removing Belt Cover

In order to perform proper lubrication, it is necessary to

remove the Belt cover from the lower left of the

snowthrower.

1. Remove the Engine Key from the switch.

2. Remove the fours screws securing the belt cover

(see Figure 8).

3. Remove the cover.

4. Perform lubrication (see below).

5. Reinstall belt cover (reverse steps 3 to 1 above.)

Figure 8. Removing Belt Cover

Figure 10. Lightly oil pivot point

LUBRICATION

Note: The drive pulley end of auger shaft is supported by

a sealed ball bearing and requires no lubrication. The

ball bearing on other end of auger shaft is also sealed,

and will not require lubrication.

Lightly Oil

• A few drops of oil should be placed on wheel

hubs occasionally to keep wheels turning

freely.

• Apply oil to pivot points of auger control periodically, wiping off any excess oil.

• A couple of drops of light machine oil applied to

upper end of auger control cable will assure free

movement of cable through outside casing. Wipe off

any excess oil.

• Remove belt cover and lightly apply oil to the pivot

point for idler pulley arm. BE CAREFUL NOT TO

GET OIL ON BELT OR PULLEYS.

Grease

• At the beginning of each snow throwing season, remove discharge chute and generously

lubricate steel flange at back of rotating ring

with light grease. Rotate ring with crank to distribute grease.

Engine Lubrication

The two cycle engine used in this snowthrower is lubricated by the fuel and oil mixture. Observe recommended

fuel to oil mixture ratio shown on page 9.

Figure 9. Lubrication points

Pivot Point

Screws

Page 16

TROUBLESHOOTING

Problem Possible Cause Remedy

Engine fails to start 1. Key is OFF 1. Turn Key to the ON position

2. Failure to prime cold engine 2. Press primer button twice and restart.

3. Out of fuel 3. Fill fuel tank

4. Choke OFF - cold engine 4. Turn Choke to ON.

5. Engine flooded 5. Turn Choke to OFF; try starting

6. Spark Plug not sparking 6. Check Gap. Gap plug, clean electrode,

or replace as necessary

7. Water in fuel, or old fuel 7. Drain tank (Dispose of fuel at an authorized

waste facility). Fill with fresh fuel mixture.

Engine starts hard or runs poorly 1. Fuel mixture too rich 1. Move choke to OFF position

2. Spark plug faulty, fouled, 2. Clean and gap, or replace

or gapped incorrectly

3. Water in fuel, or old fuel 3. Drain tank (Dispose of fuel at an authorized

waste facility). Fill with fresh fuel mixture.

4. Gas cap vent hole plugged 4. Clean vent hole or replace cap

Unit does not throw snow 1. Loose or broken drive belt 1. Adjust or replace belt

2. Incorrect control cable 2. Adjust Auger Control cable

adjustment

3. Discharge chute clogged, 3. Stop engine, remove key and

foreign object lodged in auger

clean out discharge chute

4. Broken control cable 4. Replace cable

Auger does not stop turning 1. Incorrect control cable 1. Adjust Auger Control cable

when control is released adjustment

Excessive vibration 1. Loose parts or damaged 1. STOP engine and REMOVE the key,

auger tighten all hardware. If vibration

continues, see your dealer.

Note: For repairs beyond the minor adjustments listed above, please contact your local authorized dealer.

Figure 12. Remove and/or Loosen Cover Screws

Remove two

rear fasteners

securing

cover

Remove

Fuel Tank

Cap

15

Troubleshooting

& Service

REMOVING ENGINE COVER

Note: In many of the following adjustment and service

tasks, it will be necessary to remove and reinstall the

engine cover. To remove the cover, proceed as follows:

1. Remove the engine key from the switch.

2. Remove the two rear fasteners securing the back of

the cover housing. (Figure 12).

3. Remove the fuel tank cap.

4. Remove the cover (see Figure 13 on page 14).

5. Temporarily reinstall the fuel tank cap.

6. Perform the adjustments or service desired.

7. Reinstall the cover by reversing the removal steps.

Note: The tabs at the lower front of the cover must be

positioned correctly.

Before beginning any repair stop the engine,

remove the key, disconnect the spark plug wire,

and wait for all moving parts to stop.

WARNING

Page 17

16

Troubleshooting & Service

Adjusting the Cable

1. Remove the engine cover.

2. Locate and loosen the lower locknut securing the

auger control cable (shown in Figure 14).

3. To change the slack in the cable, turn the upper locknut slightly just until the slack between the spring

and the exposed cable has been eliminated.

4. Tighten the lower locknut.

5. Test the units to make certain that the cable has

been adjusted properly.

Testing the Auger Control Cable

Start the snowthrower engine and pull back on auger

control to operate auger. Release auger control and

check to be sure auger stops turning.

If auger continues to turn after auger control is

released, cable is too tight and will have to be adjusted to make it longer. Cable must be slightly slack

when auger control is released (away from handle).

CARBURETOR ADJUSTMENT

The carburetor is properly calibrated and preset at the

factory for efficient cold weather operation. There are no

adjustments.

AUGER CONTROL

CABLE ADJUSTMENT

The length of the auger control cable is adjustable.

However, it will seldom be necessary to change the

cable length since the operating tension on the drive belt

is maintained by the spring on the end of the cable.

If the auger turns too slowly under heavy load or

momentary squealing of drive belt is heard when entering heavy snow, pressure applied to drive belt by idler

pulley must be increased by reducing the slack in the

cable.

If the auger continues to turn when the auger control

is released, the cable is too tight. The pressure applied

to the drive belt must be eliminated by increasing the

amount of slack to the cable adjustment.

Figure 14. Auger Control Cable

Locknuts

Spring

Checking the Adjustment.

1. Remove the cover. (See page 14.)

2. Measure the spring while the auger control on the

handle is disengaged. Record this measurement.

3. Pull the auger control against the handle and again

measure the spring. Record this measurement.

4. Compare the two measurements. The measurement

obtained with the spring extended should be 7/16

inch (11 mm) greater than with the spring at rest.

Figure 13. Cover Removal & Installation

Insert front

tabs first when

reinstalling

cover.

Align rear

tabs & side of

cover when

reinstalling.

Lift Cover

from Rear

of unit

Make certain the cable is not placing and tension

on the spring. If the cable places tension on the

spring, the auger may turn when the control has

not been engaged.

WARNING

Use extreme care when making adjustments that

require engine to be running. Keep hands, feet,

hair and loose fitting clothing away from moving

parts.

WARNING

Page 18

17

Troubleshooting & Service

REPLACING THE DRIVE BELT

1. Remove engine key from switch.

2. Remove belt and engine covers.

3. Move the auger control on the handle and slip the

belt out from between the brake lever and roller and

away from the idler pulley.

4. Remove the belt from the engine and auger pulleys.

5. Install new belt around engine and auger pulleys and

under idler pulley.

The ribbed side of the belt must be

to the inside, against auger and engine pulleys.

6. Slip the new belt into place between brake lever and

roller.

7. Start the engine and engage/disengage the auger

control several times. Make certain that auger stops

turning within 5 seconds after the control is released.

8. If the auger does not stop turning within 5 second

after the control is released, adjust the tension on the

control cable by following the Adjusting Control Cable

procedure in the Adjustments section of this manual.

9. Reinstall the belt and engine covers.

Figure 15. Drive Belt Replacement

REPLACING THE SCRAPER BLADE

1. Remove engine key from switch.

2. Remove the two bolts and nuts securing the scraper

blade to the auger housing. (Retain the bolts and

nuts for attaching the new blade.)

3. Remove the worn scraper blade.

4. Install the new scraper blade and secure it with the

three bolts and nuts saved in step 2 above.

Figure 16. Removing Scraper Blade

SERVICING THE SPARK PLUG

1. Remove engine key from switch.

2. Remove the engine cover. (See page 13.)

3. Disconnect the wire from the spark plug.

4. Inspect the spark plug and clean. If necessary,

replace the it with a new spark plug as recommended

in the engine owners manual.

5. Adjust the gap on the spark plug to .030 inches (.762

mm) using a gauge.

6. Reinstall the plug and tighten firmly.

7. Reconnect spark plug wire.

8. Reinstall engine cover.

Figure 17. Servicing Spark Plug

Spark Plug

Wire

Scraper Blade, Bolts & Nuts

Engine

Pulley

Idler

Pulley

Brake

Lever/Roller

Drive Belt

Auger Pulley

Page 19

18

ENGINE:

5 HP* Tecumseh

Make Tecumseh

Model HSK 850

Horsepower* 5 @ 4000 rpm

Displacement 8.46 Cu. in (139 cc)

Oil Mixture 50:1

CHASSIS:

Spout Rotation 220 Depress

Auger Diameter 9” (22.9cm)

Tire Size 7” x 1.5” (17.8cm x 3.8cm)

DIMENSIONS

Effective Clearing 20” (51cm)

Width

Length 42” (107cm)

Height 42” (107cm)

Weight 75 lbs (34kg)

NOTE: Specifications are correct at time of printing and are subject to change without notice.

* Actual sustained equipment horsepower will likely be lower due to operating limitations and environmental factors.

REPLACEMENT PARTS

Replacement parts are available from your authorized

dealer. Always use genuine Simplicity/Snapper Service

Parts.

TECHNICAL MANUALS

Additional copies of this manual are available, as well as

fully illustrated parts lists. These manuals show all of the

product’s components in exploded views (3D illustrations

which show the relationship of parts and how they go

together) as well as part numbers and quantities used.

Important assembly notes and torque values are also

included.

For applicable manuals currently available for your

Simplicity model, contact Customer Publications

Department at 262-284-8519 and for your Snapper

model contact 866-313-6682. Have the information listed in the box below available when phoning in your

request. Technical manuals can be downloaded from

www.simplicitymfg.com or www.snapper.com.

Engine Oil

Touch-Up Paint

Grease Gun Kit

8 oz. Grease Tube

Tire Sealant

Degrimer/Degreaser

Gas Stabilizer

MAINTENANCE ITEMS

Many convenient and helpful service and maintenance

items are available from you authorized dealer. Some of

these items include:

Model:

Mfg. No.:

Your Name:

Address:

City, State, Zip:

Visa/Mastercard No.:

Card Expiration Date:

Specifications

Parts & Accessories

Page 20

MANUFACTURING, INC.

500 N Spring Street / PO Box 997

Port Washington, WI 53074-0997

www.simplicitymfg.com

© Copyright 2005, Simplicity Manufacturing, Inc.

All Rights Reserved. Printed in USA.

PRODUCTS, INC.

McDonough, GA., 30253

www.snapper.com

Loading...

Loading...