Page 1

Print Vendor

Instructions

How to use this file

Operator’s Manuals

Paper Size: • 11x17

• Body - 50 lbs brilliant white offset or equivalent

• Cover - on pre-printed two tone “Swash” stock.

Press: • Body - 1 color, 2-sided

• Cover - 1 color, 1 sided

Bindery: • Saddle stitch, face trim *if too thick for saddle stitch, tape bind

Covers: • FRONT COVER is present at the beginning of the file.

• BACK COVER is the page immediately after the front cover.

• The part number for this manual (typically a 172_____ number) is

located on the front cover.

• This file may contain several manual which differ only by their covers.

See the part number at the bottom of the cover page. .

Body: • The body for all manuals is identical regardless of the cover.

• Odd number pages are always right hand pages, even number pages

are always left hand pages.

General: • This instruction sheet is NOT part of the manual and must not be

printed.

• Pages labeled “THIS PAGE INTENSIONALLY BLANK” are placement

pages and should NOT be printed.

Page 2

THIS PAGE INTENTIONALLY BLANK

(FOR PLACEMENT ONLY - DO NOT PRINT)

Page 3

OPERATOR’S

MANUAL

1726999

Revision 06

Revision Date 11/2005

TP 100-4089-06-RG-SMA

18HP Hydro Tractors

Mfg. No. Description

1694656 Regent, 18HP Hydro

1694659 Regent, 18HP Hydro (CE)

1694660 518H, 18HP Hydro

1694665 2518H, 18HP Hydro

1694749 Regent, 18HP Hydro

1694750 518H, 18HP Hydro

1694751 2518H, 18HP Hydro

1694802 Regent, 18HP Hydro

1694894 2518H, 18HP Hydro (CE)

1694903 Regent, 18HP Hydro (CE)

1694925 2518H, 18HP Hydro

2690322 Regent, 18HP Hydro & 38” Mower Deck

2690323 Regent, 18HP Hydro & 44” Mower Deck

2690326 Regent, 18HP Hydro

2690327 518H, 18HP Hydro & 38” Mower Deck

2690328 518H, 18HP Hydro & 44” Mower Deck

2690332 2518H, 18HP Hydro & 44” Mower Deck

2690336 2518H, 18HP Hydro & 38” Mower Deck

2690357 Regent, 18HP Hydro & 38” Mower Deck

2690358 518H, 18HP Hydro & 38” Mower Deck

2690359 2518H, 18HP Hydro & 38” Mower Deck

2690397 Regent, 18HP Hydro

2690426 Regent, 18HP Hydro (CE)

& 44” Mower Deck

18HP Hydro Tractors

Mfg. No. Description

2690446 2518H, 18HP Hydro (CE)

& 40” Mower Deck

2690453 Regent, 18HP Hydro

2690480 2518H, 18HP Hydro & 40” Mower Deck

38” Mower Decks

Mfg. No. Description

1693792 38” Mower Deck

1693794 38” Mower Deck (CE)

1693960 38” Mower Deck

40” Mower Decks

Mfg. No. Description

1694333 40” Mower Deck

1694334 40” Mower Deck (CE)

1694377 40” Mower Deck (CE)

44” Mower Decks

Mfg. No. Description

1693795 44” Mower Deck

1693885 44” Mower Deck (CE)

1693961 44” Mower Deck

Regent / 500 / 2500 Series

Page 4

MANUFACTURING, INC.

500 N Spring Street / PO Box 997

Port Washington, WI 53074-0997

www.simplicitymfg.com

© Copyright 2005 Simplicity Manufacturing, Inc.

All Rights Reserved. Printed in USA.

Page 5

1

Table of Contents

Safety Rules.........................................................2

General Operation ..................................................2

Transportation & Storage........................................2

Slope Operation ......................................................3

Children...................................................................3

Emissions................................................................3

Ignition System .......................................................3

Service & Maintenance ...........................................4

Identification Numbers........................................5

Decals .....................................................................6

CE Safety Icons ......................................................7

Features, Controls, & Operation ........................8

Control Functions....................................................8

Parking Brake .........................................................9

Safety Interlock System ........................................10

General Operation Safety .....................................10

Adding Fuel...........................................................10

Starting The Engine ..............................................10

Stopping The Tractor & Engine.............................11

Driving The Ttractor ..............................................11

Mowing..................................................................11

Mowing in Reverse ...............................................11

Attachment Operation in Reverse.........................11

Pushing the Tractor by Hand ...............................11

Using A Munching Mower .....................................12

Mower Installation & Removal ..............................13

Adjusting Mower Height and

Gauge Wheels 38” & 44” .....................................13

Adjusting Mower Height 40”..................................14

Storage .................................................................14

Regular Maintenance ........................................15

Schedule ...............................................................15

Tire Pressure ........................................................15

Raising the Hood & Seat ......................................16

Checking the Fuel Filter ........................................16

Safety Interlock System Check .............................16

Blade Brake Check ...............................................16

PTO Clutch Adjustment Check .............................16

Engine Maintance .................................................16

Lubrication ............................................................17

Lubricating Rear Axle Shafts ................................18

Transmission Identification ...................................19

Transmission Service............................................19

Battery Maintenance .............................................19

Servicing the Mower Blades .................................20

Check Mower Blade Timing - 40” Mowers ............21

Check Mower Belt Tension - 40” Mowers .............22

Troubleshooting, Adjustment, & Service ........24

Chart - Troubleshooting The Tractor.....................24

Chart - Troubleshooting The Mower .....................25

Battery Charging ...................................................26

Seat Adjustment....................................................26

Steering Gear Adjustment.....................................26

Brake & Brake Spring Adjustment ........................27

PTO Clutch Adjustment ........................................27

Mower Adjustments ..............................................28

Leveling The Mower......................................28

Blade Brake Check .......................................29

38” & 44”Mower Belt Replacement .......................29

40” Mower Belt Replacement................................30

40” Mower Arbor Drive Belt Replacement.............31

Tractor Drive Belt Replacement............................32

Transmission Purging ...........................................32

Specifications ....................................................33

Parts & Accessories..........................................34

Replacement Parts ...............................................34

Maintenance Items................................................34

Optional Accessories ............................................34

Lawn Care &

Mowing Information....................................LC—1

NOTE: In this manual, “left” and “right” are referred to as

seen from the operating position.

WARNING

Engine exhaust from this product contains

chemicals known, in certain quantities, to cause

cancer, birth defects, or other reproductive harm.

Page 6

2

GENERAL OPERATION

1. Read, understand, and follow all instructions in the

manual and on the unit before starting.

2. Do not put hands or feet near rotating parts or under

the machine. Keep clear of the discharge opening at

all times.

3. Only allow responsible adults, who are familiar with

the instructions, to operate the unit (local regulations

can restrict operator age).

4. Clear the area of objects such as rocks, toys, wire,

etc., which could be picked up and thrown by the

blade(s).

5. Be sure the area is clear of other people before mowing. Stop the unit if anyone enters the area.

6. Never carry passengers.

7. Do not mow in reverse unless absolutely necessary.

Always look down and behind before and while travelling in reverse.

8. Never direct discharge material toward anyone.

Avoid discharging material against a wall or obstruction. Material may ricochet back toward the operator.

Stop the blade(s) when crossing gravel surfaces.

9. Do not operate the machine without the entire grass

catcher, discharge guard (deflector), or other safety

devices in place.

10. Slow down before turning.

11. Never leave a running unit unattended. Always disengage the PTO, set parking brake, stop engine, and

remove keys before dismounting.

12. Disengage blades (PTO) when not mowing. Shut off

engine and wait for all parts to come to a complete

stop before cleaning the machine, removing the grass

catcher, or unclogging the discharge guard.

13. Operate the machine only in daylight or good artificial

light.

14. Do not operate the unit while under the influence of

alcohol or drugs.

15 Watch for traffic when operating near or crossing

roadways.

16. Use extra care when loading or unloading the unit

into a trailer or truck.

17. Always wear eye protection when operating this unit.

18. Data indicates that operators, age 60 years and

above, are involved in a large percentage of power

equipment-related injuries. These operators should

evaluate their ability to operate the equipment safely

enough to protect themselves and others from injury.

19. Follow the manufacturer’s recommendations for

wheel weights or counterweights.

20. Keep in mind the operator is responsible for accidents

occurring to other people or property.

21. All drivers should seek and obtain professional and

practical instruction.

22. Always wear substantial footwear and trousers.

Never operate when barefoot or wearing sandals.

23. Before using, always visually check that the blades

and blade hardware are present, intact, and secure.

Replace worn or damaged parts.

24. Disengage attachments before: refueling, removing

an attachment, making adjustments (unless the

adjustment can be made from the operator’s position).

25. When the machine is parked, stored, or left unattended, lower the cutting means unless a positive

mechanical lock is used.

26. Before leaving the operator’s position for any reason,

engage the parking brake (if equipped), disengage

the PTO, stop the engine, and remove the key.

27. To reduce fire hazard, keep the unit free of grass,

leaves, & excess oil. Do not stop or park over dry

leaves, grass, or combustible materials.

28. It is a violation of California Public Resource Code

Section 4442 to use or operate the engine on or near

any forest-covered, brush-covered, or grass-covered

land unless the exhaust system is equipped with a

spark arrester meeting any applicable local or state

laws. Other states or federal areas may have similar

laws.

Read these safety rules and follow them closely. Failure to obey these rules could result in loss of control

of unit, severe personal injury or death to you, or bystanders, or damage to property or equipment.

This mowing deck is capable of amputating hands and feet and throwing objects.

The triangle in text signifies important cautions or warnings which must be followed.

Safety Rules & Information

TRANSPORTING AND STORAGE

1. When transporting the unit on an open trailer, make

sure it is facing forward, in the direction of travel. If

the unit is facing backwards, wind lift could damage

the unit.

2. Always observe safe refueling and fuel handling practices when refueling the unit after transportation or

storage.

3. Never store the unit (with fuel) in an enclosed poorly

ventilated structure. Fuel vapors can travel to an

ignition source (such as a furnace, water heater, etc.)

and cause an explosion. Fuel vapor is also toxic to

humans and animals.

4. Always follow the engine manual instructions for

storage preparations before storing the unit for both

short and long term periods.

5. Always follow the engine manual instructions for

proper start-up procedures when returning the unit to

service.

6. Never store the unit or fuel container inside where

there is an open flame or pilot light, such as in a

water heater. Allow unit to cool before storing.

TP 600-2459-07-UV-SMA

Page 7

3

CHILDREN

Tragic accidents can occur if the operator is not alert to the

presence of children. Children are often attracted to the

unit and the mowing activity. Never assume that children

will remain where you last saw them.

1. Keep children out of the mowing area and under the

watchful care of another responsible adult.

2. Be alert and turn unit off if children enter the area.

3. Before and during reverse operation, look behind and

down for small children.

4. Never carry children, even with the blade(s) off. They

may fall off and be seriously injured or interfere with

safe unit operation. Children who have been given

rides in the past may suddenly appear in the mowing

area for another ride and be run over or backed over

by the machine.

5. Never allow children to operate the unit.

6. Use extra care when approaching blind corners,

shrubs, trees, or other objects that may obscure

vision.

EMISSIONS

1. Engine exhaust from this product contains chemicals

known, in certain quantities, to cause cancer, birth

defects, or other reproductive harm.

2. Look for the relevant Emissions Durability Period and

Air Index information on the engine emissions label.

IGNITION SYSTEM

1. This spark ignition system complies with Canadian

ICES-002.

Safety Rules and Information

SLOPE OPERATION

Slopes are a major factor related to loss-of-control and tipover accidents, which can result in severe injury or death.

Operation on all slopes requires extra caution. If you cannot back up the slope or if you feel uneasy on it, do not

operate on it.

Control of a walk-behind or ride-on machine sliding on a

slope will not be regained by the application of the brake.

The main reasons for loss of control are: insufficient tire

grip on the ground, speed too fast, inadequate braking, the

type of machine is unsuitable for its task, lack of awareness

of the ground conditions, incorrect hitching and load distribution.

1. Mow up and down slopes, not across.

2. Watch for holes, ruts, or bumps. Uneven terrain could

overturn the unit. Tall grass can hide obstacles.

3. Choose a slow speed so that you will not have to

stop or change speeds while on the slope.

4. Do not mow on wet grass. Tires may loose traction.

5. Always keep unit in gear especially when traveling

down slopes. Do not shift to neutral and coast downhill.

6. Avoid starting, stopping, or turning on a slope. If tires

lose traction, disengage the blade(s) and proceed

slowly straight down the slope.

7. Keep all movement on slopes slow and gradual. Do

not make sudden changes in speed or direction,

which could cause the machine to rollover.

8. Use extra care while operating machines with grass

catchers or other attachments; they can affect the

stability of the unit. Do not use on steeps slopes.

9. Do not try to stabilize the machine by putting your

foot on the ground (ride-on units).

10. Do not mow near drop-offs, ditches, or embankments. The mower could suddenly turn over if a

wheel is over the edge of a cliff or ditch, or if an edge

caves in.

11. Do not use grass catchers on steep slopes.

12. Do not mow slopes you cannot back up them.

13. See your authorized dealer/retailer for recommendations of wheel weights or counterweights to improve

stability.

14. Remove obstacles such as rocks, tree limbs, etc.

15. Use slow speed. Tires may lose traction on slopes

even through the brakes are functioning properly.

16. Do not turn on slopes unless necessary, and then,

turn slowly and gradually downhill, if possible.

TOWED EQUIPMENT (RIDE-ON UNITS)

1. Tow only with a machine that has a hitch designed

for towing. Do not attach towed equipment except at

the hitch point.

2. Follow the manufacturer’s recommendations for

weight limit for towed equipment and towing on

slopes.

3. Never allow children or others in or on towed equipment.

4. On slopes, the weight of the towed equipment may

cause loss of traction and loss of control.

5. Travel slowly and allow extra distance to stop.

6. Do not shift to neutral and coast down hill.

WARNING

Never operate on slopes greater than 17.6 percent

(10°) which is a rise of 3-1/2 feet (106 cm) vertically in

20 feet (607 cm) horizontally.

When operating on slopes use additional wheel

weights or counterweights. See your dealer/retailer

to determine which weights are available and

appropriate for your unit.

Select slow ground speed before driving onto slope.

In addition to front weights, use extra caution when

operating on slopes with rear-mounted grass

catchers.

Mow UP and DOWN the slope, never across the

face, use caution when changing directions and DO

NOT START OR STOP ON SLOPE.

Page 8

4

Safety Rules & Information

SERVICE AND MAINTENANCE

Safe Handling of Gasoline

1. Extinguish all cigarettes, cigars, pipes, and other

sources of ignition.

2. Use only approved gasoline containers.

3. Never remove the gas cap or add fuel with the engine

running. Allow the engine to cool before refueling.

4. Never fuel the machine indoors.

5. Never store the machine or fuel container where

there is an open flame, spark, or pilot light such as

near a water heater or other appliance.

6. Never fill containers inside a vehicle or on a truck bed

with a plastic bed liner. Always place containers on

the ground away from your vehicle before filling.

7. Remove gas-powered equipment from the truck or

trailer and refuel it on the ground. If this is not possible, then refuel such equipment on a trailer with a

portable container, rather than from a gasoline dispenser nozzle.

8. Keep nozzle in contact with the rim of the fuel tank or

container opening at all times until fueling is complete. Do not use a nozzle lock-open device.

9. If fuel is spilled on clothing, change clothing immediately.

10. Never over-fill the fuel tank. Replace gas cap and

tighten securely.

11. Use extra care in handling gasoline and other fuels.

They are flammable and vapors are explosive.

12. If fuel is spilled, do not attempt to start the engine but

move the machine away from the area of spillage and

avoid creating any source of ignition until fuel vapors

have dissipated.

13. Replace all fuel tank caps and fuel container caps

securely.

Service & Maintenance

1. Never run the unit in an enclosed area where carbon

monoxide fumes may collect.

2. Keep nuts and bolts, especially blade attachment

bolts, tight and keep equipment in good condition.

3. Never tamper with safety devices. Check their proper

operation regularly and make necessary repairs if

they are not functioning properly.

4. Keep unit free of grass, leaves, or other debris buildup. Clean up oil or fuel spillage. and remove any fuelsoaked debris. Allow machine to cool before storage.

5. If you strike an object, stop and inspect the machine.

Repair, if necessary, before restarting.

6. Never make adjustments or repairs with the engine

running.

7. Check grass catcher components and the discharge

guard frequently and replace with manufacturer’s recommended parts, when necessary.

8. Mower blades are sharp. Wrap the blade or wear

gloves, and use extra caution when servicing them.

9. Check brake operation frequently. Adjust and service

as required.

10. Maintain or replace safety and instructions labels, as

necessary.

11. Do not remove the fuel filter when the engine is hot

as spilled gasoline may ignite. Do not spread fuel line

clamps further than necessary. Ensure clamps grip

hoses firmly over the filter after installation.

12. Do not use gasoline containing METHANOL, gasohol

containing more than 10% ETHANOL, gasoline additives, or white gas because engine/fuel system damage could result.

13. If the fuel tank must be drained, it should be drained

outdoors.

14. Replace faulty silencers/mufflers.

15. Maintain or replace safety and instruction labels as

necessary.

16. Use only factory authorized replacement parts when

making repairs.

17. Always comply with factory specifications on all settings and adjustments.

18. Only authorized service locations should be utilized

for major service and repair requirements.

19. Never attempt to make major repairs on this unit

unless you have been properly trained. Improper service procedures can result in hazardous operation,

equipment damage and voiding of manufacturer’s

warranty.

20. On multiple blade mowers, take care as rotating one

blade can cause other blades to rotate.

21. Do not change engine governor settings or overspeed the engine. Operating the engine at excessive

speed can increase the hazard of personal injury.

22. Disengage drive attachments, stop the engine,

remove the key, and disconnect the spark plug

wire(s) before: clearing attachment blockages and

chutes, performing service work, striking an object, or

if the unit vibrates abnormally. After striking an

object, inspect the machine for damage and make

repairs before restarting and operating the equipment.

23. Never place hands near the moving parts, such as a

hydro pump cooling fan, when the tractor is running.

(Hydro pump cooling fans are typically located on top

of the transaxle).

24. Units with hydraulic pumps, hoses, or motors: WARNING: Hydraulic fluid escaping under pressure may

have sufficient force to penetrate skin and cause serious injury. If foreign fluid is injected into the skin it

must be surgically removed within a few hours by a

doctor familiar with this form of injury or gangrene

may result. Keep body and hands away from pin

holes or nozzles that eject hydraulic fluid under high

pressure. Use paper or cardboard, and not hands, to

search for leaks. Make sure all hydraulic fluid connections are tight and all hydraulic hoses and lines

are in good condition before applying pressure to the

system. If leaks occur, have the unit serviced immediately by your authorized dealer.

25. WARNING: Stored energy device. Improper release

of springs can result in serious personal injury.

Springs should be removed by an authorized technician.

26. Models equipped with an engine radiator: WARNING:

Stored energy device. To prevent serious bodily

injury from hot coolant or steam blow-out, never

attempt to remove the radiator cap while the engine is

running. Stop the engine and wait until it is cool.

Even then, use extreme care when removing the cap.

Page 9

5

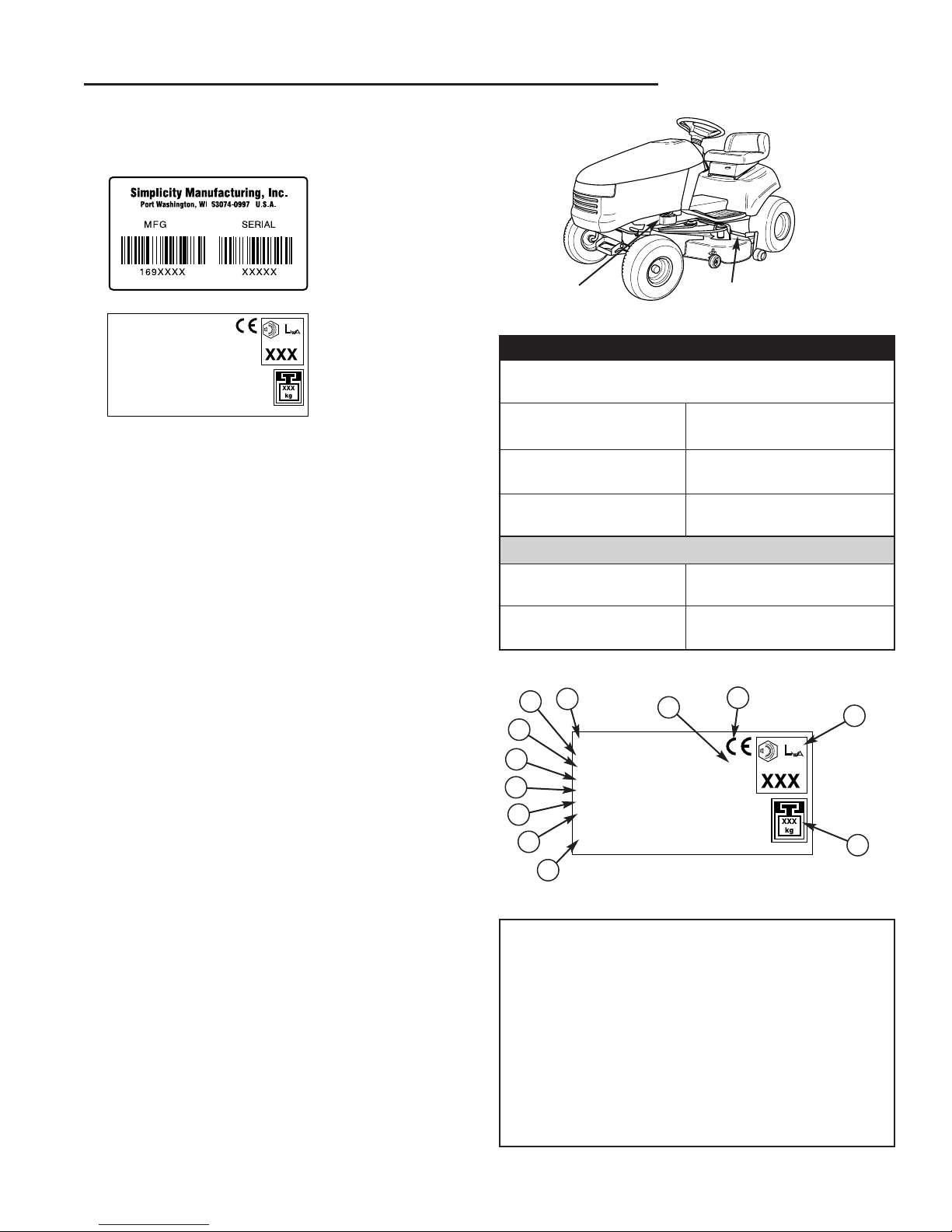

Identification Numbers

Tractor ID Tag

Mower ID Tag

When contacting your authorized dealer for replacement parts, service, or information you MUST have

these numbers.

Record your model name/number, manufacturer’s identification numbers, and engine serial numbers in the

space provided for easy access. These numbers can be

found in the locations shown.

NOTE: For location of engine identification numbers,

refer to the engine owner’s manual.

CE Models: Place the extra copy of the identification tag

in the manual

Mfg. No.: 169XXXX

Serial No.: XXXXX

kW: XXX

Engine RPM XXXX

LpA: XXX dB(A)

Vibration @ Wheel: XXX m/s²

Vibration @ Seat: XXX m/s²

2002

dB(A)

Port Washington, WI USA 53074-0997

Simplicity Mfg. Inc.

SSAAMMPPLLEE

SSAAMMPPLLEE

North American

Models

CE Models

ENGINE REFERENCE DATA

Model Description Name/Number

Unit MFG Number

PRODUCT REFERENCE DATA

Unit SERIAL Number

Dealer Name

Date Purchased

Engine Make

Engine Type/Spec

Engine Model

Engine Code/Serial Number

Mower Deck MFG Number

Mower Deck SERIAL

Number

Mfg. No.: 169XXXX

Serial No.: XXXXX

kW: XXX

Engine RPM XXXX

LpA: XXX dB(A)

Vibration @ Wheel: XXX m/s²

Vibration @ Seat: XXX m/s²

2002

dB(A)

Port Washington, WI USA 53074-0997

Simplicity Mfg. Inc.

CE IDENTIFICATION TAG MARKINGS

A. Manufacturer’s Identification Number

B. Manufacturer’s Serial Number

C. Power Rating in Kilowatts

D. Maximum Engine Speed in Rotations per Minute

E. Manufacturer’s Address

F. Year of Manufacture

G. CE Compliance Logo

H. Mass of Unit in Kilograms

I. Sound Power in Decibels ***

J. Sound Pressure at Operator’s Position in Decibels **

K. Vibration at the Steering Wheel *

L. Vibration at the Seat *

This unit complies with European Harmonized Lawn Mower

Standard EN 836, European Machinery Directive 98/37/EC,

and European EMC Directive 89/336/EC

* Tested according to EN 836:1997/A2:2001, EN 1032:

1996, EN 1033:1995

** Tested according to EN836:1997/A2:2001

*** Tested according to 2000/14/EC

A

B

C

D

J

K

L

E

F

G

H

I

CE Models:

Place copy of

Identification Tag here.

Identification Numbers

Page 10

6

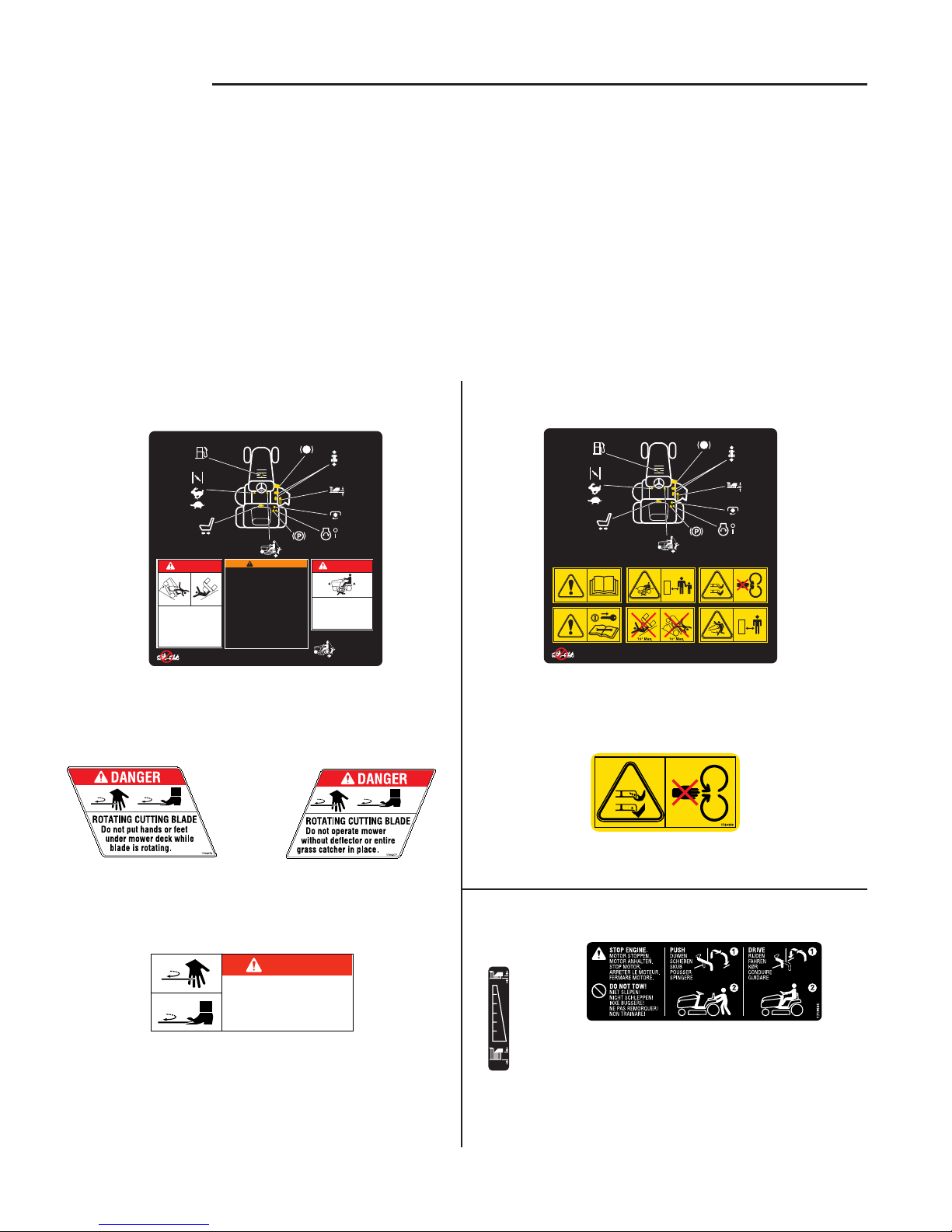

Safety Decals

SAFETY DECALS

This unit has been designed and manufactured to provide you with the safety and reliability you would expect

from an industry leader in outdoor power equipment

manufacturing.

Although reading this manual and the safety instructions

it contains will provide you with the necessary basic

knowledge to operate this equipment safely and effectively, we have placed several safety labels on the unit to

remind you of this important information while you are

operating your unit.

All DANGER, WARNING, CAUTION and instructional

messages on your rider and mower should be carefully

read and obeyed. Personal bodily injury can result when

these instructions are not followed. The information is for

your safety and it is important! The safety decals below

are on your rider and mower.

If any of these decals are lost or damaged, replace them

at once. See your local dealer for replacements.

These labels are easily applied and will act as a constant

visual reminder to you, and others who may use the

equipment, to follow the safety instructions necessary for

safe, effective operation.

NORTH AMERICAN MODEL DECALS CE MODEL DECALS

Decal - North American

Operating Instructions

Part No. 1726986

Decal - Danger

Part No. 1704276

Decal - Danger

Part No. 1704277

Decal - Hydro Release Valve

Part No. 1719635

Decal - CE Operating

Instructions

Part No. 1726988

Decal - Danger, Mulching Models

Part No. 1720389

ALL MODELS

Decal - Cutting Height,

(Mulching Models)

Part No. 1723470

1723470

Decal - Danger, Rotating Blades

Part No. 1720389

DANGER

OPERATING ON SLOPES

CAN BE DANGEROUS

SEE OPERATOR'S MANUAL. IF YOU

CANNOT BACK-UP A HILL, DO NOT

DRIVE ON IT.

DO NOT TOW TRACTOR! DAMAGE MAY RESULT TO TRANSMISSION.

WARNING

AVOID SERIOUS INJURY OR DEATH

• READ OPERATOR'S MANUAL(S).

• KNOW LOCATION AND FUNCTION OF ALL CONTROLS.

• KEEP SAFETY DEVICES (GUARDS, SHIELDS, SWITCHES, ETC.)

IN PLACE AND WORKING.

• REMOVE OBJECTS THAT COULD BE THROWN BY THE BLADE.

• DO NOT MOW WHEN CHILDREN OR OTHERS ARE AROUND.

• NEVER CARRY CHILDREN EVEN WITH BLADES OFF.

• LOOK DOWN AND BEHIND BEFORE AND WHILE BACKING.

• AVOID SUDDEN TURNS.

• IF YOU CANNOT BACK UP A HILL, DO NOT OPERATE ON IT.

• GO UP AND DOWN SLOPES, NOT ACROSS.

• IF MACHINE STOPS GOING UPHILL, STOP BLADE AND

BACK DOWN SLOWLY.

• BE SURE BLADE(S) AND ENGINE ARE STOPPED BEFORE

PLACING HANDS OR FEET NEAR BLADE(S).

• WHEN LEAVING MACHINE, SHUT OFF ENGINE, REMOVE KEY,

AND SET PARKING BRAKE.

DANGER

ROTATING BLADES CUT

OFF ARMS AND LEGS

STOP MOWER WHEN CHILDREN

ARE NEAR.

NO RIDERS — THEY FALL OFF.

This product is equipped with

RMO™ System:

the RMO system. Refer to the

operator's manual for a full

explanation of the RMO

system and for important

safety messages.

1726986

1726988

DANGER

ROTATING CUTTING BLADE

Do not put hands or feet

under mower deck while

blade is rotating.

1720660

Page 11

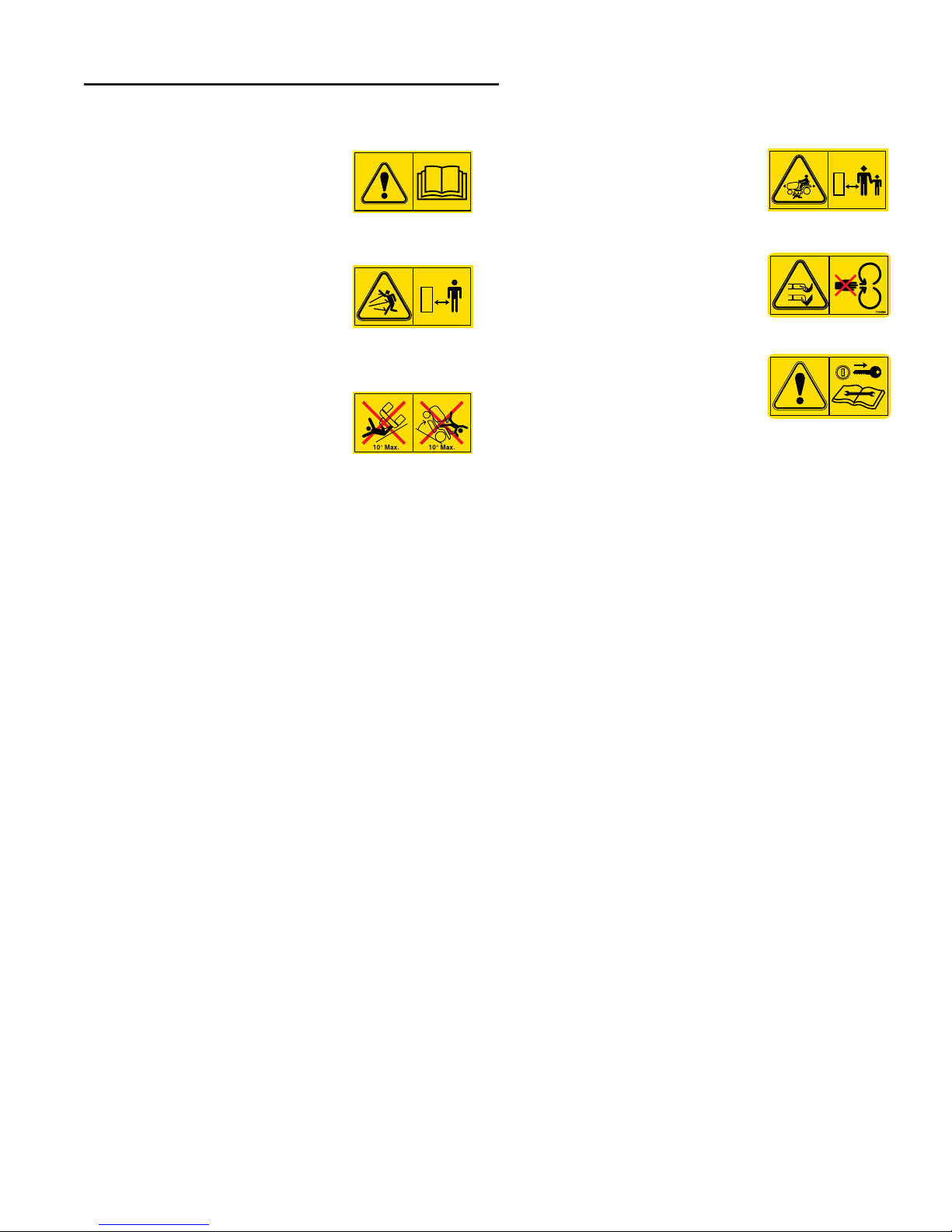

7

CE Safety Icons / Directive Compliance

Warning: Read Operator’s

Manual.

Read and understand the

Operator’s Manual before using

this machine.

Danger: Thrown Objects.

This machine is capable of throwing

objects and debris. Keep

bystanders away.

Danger: Machine Rollover.

Do not use this machine on slopes

greater than 10°.

Danger: Dismemberment.

This machine can amputate limbs.

Keep bystanders and children away

when engine is running.

Danger: Dismemberment.

This mower deck can amputate

limbs. Keep hands and feet away

from blades.

1723824

Danger: Remove Key & Read

Manual Before Servicing

Remove the key and read the operator’s manual before performing service procedures involving components in this area.

SAFETY ICONS

Page 12

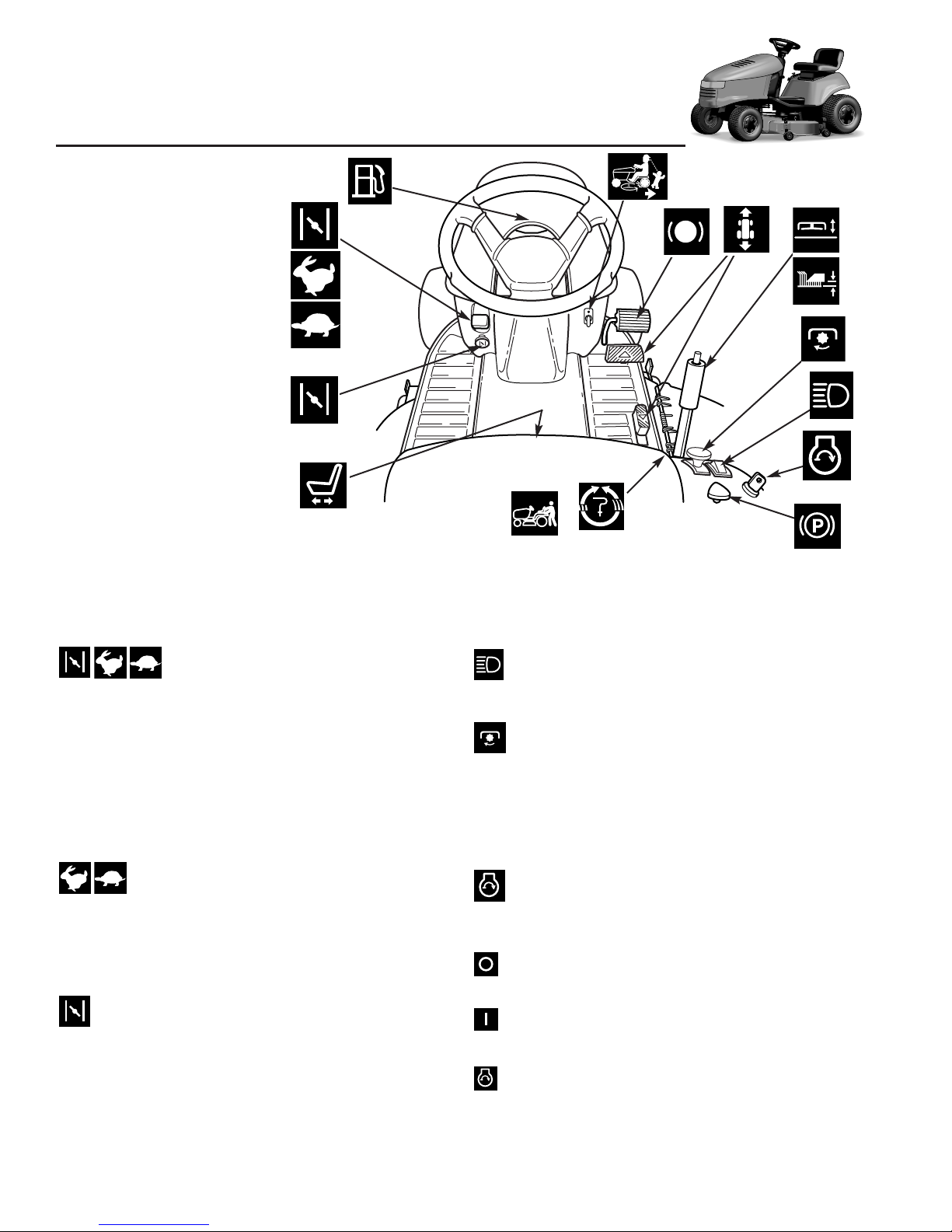

8

Features & Controls

Please take a moment and

familiarize yourself with the

name, location, and function

of these controls so that you

will better understand the safety

and operating instructions provided in this manual.

Trans. Release

Lever on Rear

Of Tractor

Throttle/Choke Control

(Single Lever Models)

The throttle/choke lever controls engine speed and

choke. Move the throttle forward to increase engine

speed and back to decrease engine speed. Always

operate at FULL throttle. Move the control fully forward

(past the detent) to close the choke. Close the choke for

cold starting. Open the choke once the engine starts. A

warm engine may not require choking.

Throttle Control

(Twin Lever Models)

The throttle controls engine speed. Move the throttle forward to increase engine speed and back to decrease

engine speed. Always operate at FULL throttle.

Choke

(Twin Lever Models)

Close the choke for cold starting. Open the choke once

the engine starts. A warm engine may not require choking. Move the lever forward to close the choke.

Headlights

The light switch turns the tractor headlights on and off.

PTO Switch

The PTO (Power Take-Off) switch engages and disengages attachments that use the PTO. To engage the

PTO, pull UP on the switch. Push DOWN to disengage.

Note that the operator must be seated firmly in the tractor seat for the PTO to function.

Ignition Switch

The ignition switch starts and stops the engine, it has

three positions:

OFF Stops the engine and shuts off the

electrical system.

RUN Allows the engine to run and powers the

electrical system.

START Cranks the engine for starting.

NOTE: Never leave the ignition switch in the RUN position with the engine stopped–this drains the battery.

CONTROL FUNCTIONS

The information below briefly describes the function of individual controls. Starting, stopping, driving, and mowing

require the combined use of several controls applied in specific sequences. To learn what combination and sequence

of controls to use for various tasks see the OPERATION section.

Page 13

9

Operation

Seat Adjustment Lever

The seat can be adjusted forward and back. Move the lever,

position the seat as desired, and release the lever to lock

the seat into position.

Transmission Release Valve Lever

The transmission release valve lever deactivates the transmission so that the tractor can be pushed by hand. See

PUSHING THE TRACTOR BY HAND for operational information.

Fuel Tank

To remove the cap, turn counterclockwise. On models with

a dashboard display, the fuel gauge is part of the dashboard. Model without a dashboard display have a fuel

gauge located under the seat.

Attachment Lift Control Lever

When using the mower deck, lift the deck off the ground

while transporting to and from the job site. DO NOT cut

with the mower in the raised, transport position.

The attachment lift control lever raises and lowers attachments that utilize the tractor’s manual lift linkage. To lower

an attachment: pull the lever back slightly, depress the

release button, and push the lever forward until it locks in

the lowered position. To raise an attachment: push the

lever forward slightly, depress the release button, then pull

the lever back until it locks in the raised position.

Reverse Mowing Option (RMO)

The Reverse Mowing Option allows for mowing (or use of

other PTO driven attachments) while traveling in reverse. If

you choose to mow or operate another attachment in

reverse, turn the RMO key after the PTO is engaged. The

L.E.D. light will illuminate, and the operator can then mow in

reverse. Each time the PTO is disengaged the RMO needs

to be reactivated if desired.

Brake Pedal

Depressing the brake pedal applies the tractor brake.

Ground Speed Pedals

The tractor’s forward ground speed is controlled by the forward ground speed control pedal. The tractor’s reverse

ground speed is controlled by the reverse ground speed

control pedal.

Depressing either pedal will increase ground speed. Note

that the further down the pedal is depressed, the faster the

tractor will travel.

Parking Brake

The parking brake knob is used to lock the parking brake

when the tractor is stopped. Fully depressing the brake

pedal and pulling up on the knob engages the parking

brake. Refer to page 10 for a full explanation of parking

brake functions.

Mower Height of Cut Adjustment

When using the mower deck, lift the deck off the ground

while transporting to and from the job site. DO NOT cut

with the mower in the raised, transport position.

38” & 44” MOWER DECKS

The cutting height adjustment knob controls the mower cutting height. The cutting height is infinitely adjustable

between 1” and 3-5/8.”

40” MOWER DECKS

The cutting height adjustment lever controls the mower cutting height. Push down on the button to release the lever,

move to the desired cutting height, and release the button to

lock. The cutting height is infinitely adjustable between 1”

and 3-5/8.”

Cutting Height Fine Tuning Adjustment

(40” Mower Decks Only)

The cutting height fine tuning adjustment is used to set the

mower cutting height between two of the preset cutting positions.

PARKING BRAKE FUNCTION

Applying the Parking Brake - See Figure 1. To lock

the parking brake, release the ground speed pedals (A),

fully depress the brake pedal (B), pull UP on the parking

brake knob (C), and then release brake pedal.

Releasing the Parking Brake - See Figure 1. To

release the parking brake, fully depress the brake pedal

(B) and push the parking brake knob (C) DOWN.

IMPORTANT NOTE: The tractor’s hydraulic attachment

lift will not work when the parking brake is engaged.

B

C

A

Figure 1. Engaging the Parking Brake

A. Ground Speed Pedals C. Parking Brake Knob

B. Brake Pedal

Page 14

10

Operation

SAFETY INTERLOCK

SYSTEM TESTS

This unit is equipped with safety interlock

switches and other safety devices. These safety systems are present for your safety: do not attempt to

bypass safety switches, and never tamper with safety

devices. Check their operation regularly.

Operational SAFETY Checks

Your unit is equipped with a seat switch safety system.

Check the seat switch operation every fall and spring

with the following tests.

Test 1 — Engine should NOT crank if:

• PTO switch is ON, OR

• Brake pedal is NOT fully depressed (parking brake

OFF), OR

• The cruise control lever is NOT in NEUTRAL.

Test 2 — Engine SHOULD crank if:

• PTO switch is OFF, AND

• Brake pedal is fully depressed (parking brake ON),

AND

• The cruise control lever is in NEUTRAL.

Test 3 — Engine should SHUT OFF if:

• Operator rises off seat with PTO engaged, OR

• Operator rises off seat with brake pedal NOT fully

depressed (parking brake OFF).

Test 4 — Blade Brake Check

Mower blades and mower drive belt should come to a

complete stop within five seconds after electric PTO

switch is turned OFF (or operator rises off seat). If

mower drive belt does not stop within five seconds,

readjust the PTO clutch as described in the ADJUSTMENTS section or see your dealer.

Test 5 — Reverse Mow Option (RMO) Check

• Engine should shut off if reverse travel is attempted

if the PTO has been switched on and RMO has not

been activated.

• RMO light should illuminate when RMO has been

activated.

NOTE: Once the engine has stopped, the PTO switch

must be turned off after the operator returns to the seat

in order to start the engine.

WARNING

If the unit does not pass a safety test, do not

operate it. See your authorized dealer. Under no

circumstance should you attempt to defeat the

purpose of the safety interlock system.

GENERAL OPERATING SAFETY

Be sure to read all information in the Safety and

Operation sections before attempting to operate this unit.

Become familiar with all of the controls and how to stop

the unit.

ADDING FUEL

To add fuel:

1. Remove the fuel cap.

2. Fill the tank. Do not overfill. Leave room in the tank

for fuel expansion. Refer to your engine manual for

specific fuel recommendations.

3. Install and hand tighten the fuel cap.

STARTING THE ENGINE

1.While sitting in the operator’s seat, fully depress the

brake pedal or set the parking brake.

2. Make sure that your feet are not depressing the

ground speed control pedals and that the cruise control lever is in neutral.

3. Disengage the PTO clutch.

4. Set the throttle to FULL.

5. Close the choke.

NOTE: A warm engine may not require choking.

6. Insert the ignition key and turn it to START.

7. After the engine starts, move the engine throttle control to SLOW. Warm up the engine by running it for at

least a minute.

8. Set throttle to FULL.

NOTE: In the event of an emergency the engine can be

stopped by simply turning the ignition switch to STOP.

Use this method only in emergency situations. For normal engine shut down follow the procedure given in

STOPPING THE TRACTOR.

WARNING

Gasoline is highly flammable and must be

handled with care. Never fill the tank when the

engine is still hot from recent operation. Do not

allow open flame, smoking or matches in the

area. Avoid over-filling and wipe up any spills.

Do not use gasoline containing METHANOL,

gasohol containing more than

10% ETHANOL, gasoline additives, or white

gas because engine/fuel system damage

could result.

Page 15

11

Operation

Figure 2. Release Lever - Hydro Models

Release Lever

STOPPING THE TRACTOR & ENGINE

1. Return the ground speed control(s) to neutral.

2. Disengage the PTO and wait for all moving parts to

stop.

3. Place the throttle control in the position specified in

the engine owner’s manual provided in the operator's

packet shipped with your tractor. Follow any recommended stopping procedures.

4. Turn the ignition switch to OFF. Remove the key.

DRIVING THE TRACTOR

1. Sit in the seat and adjust the seat so that you can

comfortably reach all the controls and see the dashboard display.

2. Engage the parking brake.

3. Make sure the PTO switch is disengaged.

4. Start the engine (see STARTING THE ENGINE).

5. Disengage the parking brake and release the brake

pedal.

6. Depress the forward ground speed control pedal to

travel forward. Release the pedal to stop. Note that

the further down the pedal is depressed the faster the

tractor will travel.

7. Stop the tractor by releasing the ground speed control pedals, setting the parking brake, and stopping

the engine (see STOPPING THE TRACTOR AND

ENGINE).

MOWING

1. Set the mower cutting height to the desired level and

set the gauge wheels to the appropriate position (if

equipped).

2. Engage the parking brake. Make sure the PTO

switch is disengaged.

3. Start the engine (see STARTING THE ENGINE).

4. Fully lower the mower using the attachment lift lever.

5. Set the throttle to FULL.

6. Engage the PTO (Mower Deck).

7. Begin mowing. See Section C for tips on mowing

patterns, lawn care, and troubleshooting information.

8. When finished, shut off the PTO and raise the mower

using the attachment lift control lever.

9. Stop the engine (see STOPPING THE TRACTOR

AND ENGINE).

DO NOT TOW TRACTOR

Towing the unit will cause transmission

damage. • Do not use another vehicle to

push or pull this unit. • Do not actuate the

transmission release valve lever while the

engine is running.

PUSHING THE TRACTOR BY HAND

1. Disengage the PTO and turn the engine off.

2. Pull the transmission release back approximately 2-1/2”

(6 cm) to lock into released position (Figure 2).

3. The tractor can now be pushed by hand.

MOWING IN REVERSE

If an operator chooses to mow in reverse, the RMO system can

be used. To use the Reverse Mowing Option (RMO) turn the

RMO key after the PTO is engaged. The L.E.D. light will illuminate, and the operator can then mow in reverse. Each time the

PTO is disengaged the RMO needs to be reactivated if desired.

The key should be removed to restrict access to the RMO feature.

ATTACHMENT OPERATION IN REVERSE

If an operator chooses to operate a PTO driven attachment in

reverse, the RMO system can be used. To use the Reverse

Mowing Option (RMO) turn the RMO key after the PTO is

engaged. The L.E.D. light will illuminate, and the operator can

then operate the attachment in reverse. Each time the PTO is

disengaged the RMO needs to be reactivated if desired. The

key should be removed to restrict access to the RMO feature.

WARNING

Mowing in reverse can be hazardous to

bystanders. Tragic accidents can occur if the

operator is not alert to the presence of children.

Never activate RMO if children are present.

Children are often attracted to the unit and the

mowing activity.

WARNING

The engine will shut off if the reverse ground

speed pedal is depressed while the PTO is on and

the RMO has not been activated. The operator

should always turn the PTO off prior to driving

across on roads, paths or any area that maybe

used by other vehicles. Sudden loss of drive

could create a hazard

Page 16

12

Operation

USING A MULCHING MOWER

Benefits of Proper Mulching

Mulching consists of a mower deck which cuts and

recuts clippings into tiny particles and then blows them

down into the lawn. These tiny particles decompose

rapidly into by-products that your lawn can use. Under

proper conditions your mulching mower virtually eliminate noticeable clippings on the lawn surface.

Limitations of Mulching Decks

Mulching mowers cannot function properly if the grass is

wet, or if the grass is simply too high. Even more than

normal mowing, mulching requires that the grass be dry

and no more than 1/3 of the height is cut.

Do not use the mower as a mulching mower during the

first two or three cuttings in the spring. The long grass

blades, quick growth, and often wetter conditions are

more suitable for broadcasting (side-discharging).

Correct Ground Speed & Engine Speed

Use full engine throttle to maximize mower blade tip

speed matched with a slow ground speed so that clippings will be finely cut. Ground speed while mulching

should be half the speed used when broadcasting (sidedischarging) under similar conditions. Since mulching

requires more horse power that broadcasting, using a

slower ground speed is vitally important for proper

mulching operation.

Correct Cutting Height

Cutting off too much at one time shocks the plants

growth system and weakens the grass plants. A good

rule of thumb is the 1/3 rule: to cut no more than one

third of the grass height, and never more than 1 inch at a

time.

The best mulching action typically results from cutting

only the top 1/2” to 3/4” of the grass blade. This provides

short clippings which decompose properly (much more

quickly than longer clippings). The ideal cutting height

will vary with climate, time of year, and quality of your

lawn. We recommend that you experiment with both the

cutting height and ground speed to achieve the best cut.

Start with a high cutting height and use progressively

lower heights until you find a cutting height that is

matched to your mowing conditions and preferences. For

best results, overlapping is recommended.

Using the Side Discharge Deflector

When to use the side discharge deflector: If you’ve

been on vacation or missed a mowing and the grass has

gotten very long, do not try to mulch at your normal cutting height. To handle these situations your mulching

mower is equipped with a side discharge deflector.

Installing the side discharge deflector allows you to

broadcast clippings. Broadcasting, or side-discharging,

disperses fine clippings evenly over the entire lawn.

Many golf courses use this method. Your mower has a

deep dish deck to allow freer circulation of clippings so

they are broadcast evenly over the lawn.

Always operate the engine at full throttle. Use an appropriate ground speed for the thickness and height of grass

you are cutting. If you hear the engine slowing down,

you are mowing too fast, use a slower ground speed.

Mow when the grass is 3”-5”long. Do not cut off more

than 1” in a single pass.

To install the side discharge chute:

1. Lift up the mulching cover (B, Figure 3).

2. Install the side discharge deflector (A) under the

mulching cover. The side discharge deflector hooks

onto the mulching cover hinge rod, and is held in

place by the mulching cover.

3. Release the mulching cover.

Figure 3. Installing the Side Discharge Deflector

A. Side Discharge Deflector

B. Mulching Cover

WARNING

Never operate the mower deck without either the

discharge chute or mulching deflector in place.

A

B

Page 17

13

Operation

MOWER INSTALLATION & REMOVAL

NOTE: Perform mower removal and installation on a

hard, level surface such as a concrete floor.

1. Turn the front wheels of the tractor full left.

2. Place the mower in lowest cutting position.

3. Move lever (C, Figure 5) to release belt tension, then

slide belt off of PTO pulley.

4. Remove clip (B, Figure 5) from the rod (A), and

remove the rod.

5. Disconnect the front hitch by pulling out on the

release rod (B, Figure 4) and lifting the mower hitch

off the tractor hitch (A). Slide the mower deck out

from under the right side of the tractor.

6. Install the mower in reverse order of removal.

NOTE: When installing rod (A, Figure 5), turning the front

wheels slightly left or right helps to align the holes.

Figure 6. Mower Deck - Right Side

A. Pin & Clip

B. Height Adjustment Lever

Figure 5. Mower Deck - Left Side (38” Deck Shown)

A. Rod C. Lever

B. Clip D. U-Bracket

Figure 4. Front Hitch

A. Hitch B. Release Rod

A

B

A

B

A

C

B

D

WARNING

Engage parking brake, disengage PTO, stop

engine and remove key before attempting to

install or remove the mower.

ADJUSTING MOWER CUTTING HEIGHT &

GAUGE WHEELS - 38” & 44”

NOTE: Perform adjustment on a hard, level surface such

as a concrete floor.

1. Set the mower height adjustment lever (B, Figure 6)

to the desired cutting height.

2. Remove the pin & clip (A, Figure 6) from each mower

deck front gauge wheel.

3. Adjust the gauge wheels to achieve the appropriate

mower deck-to-ground clearance, as shown in Figure

6. Reinstall pin & clip to each wheel. Between 3/4"- 1"

with Height Adjuster Lever in lower 3 slots, 2" with

Height Adjuster Lever in upper 3 slots

D

Page 18

14

Operation

Figure 7. Mower Cutting Height Adjustment

A. Cutting Height Lever

B. Fine Tuning Adjustment

ADJUSTING MOWER CUTTING

HEIGHT 40”

The cutting height adjustment lever (A, Figure 7) controls

the mower cutting height and has five positions. When

using the mower deck, lift the deck off the ground while

transporting to and from the job site. DO NOT cut with the

mower in the raised, transport position.

The lower four

positions are used when mowing.

Set this lever so that the deck is cutting off 1/3 the height

of the grass or less.

If the desired cutting height falls between two notches,

use the cutting height fine tuning adjuster (B) to achieve

the correct height.

A

B

STORAGE

Before you store your unit for the off-season, read the

Maintenance and Storage instructions in the Safety

Rules section, then perform the following steps:

• Disengage the PTO, set the parking brake, & remove

the key.

• Perform engine maintenance and storage measures

listed in the engine owner’s manual. This includes

draining the fuel system, or adding stabilizer to the

fuel (do not store a fueled unit in an enclosed structure - see above).

• Battery life will be increased if it is removed, put in a

cool, dry place and fully charged about once a month.

If the battery is left in the unit, disconnect the negative cable.

Before starting the unit after it has been stored:

• Check all fluid levels. Check all maintenance items.

• Perform all recommended check and procedures

found in the engine owner’s manual.

• Allow the engine to warm up for several minutes

before use.

WARNING

Never store the unit (with fuel) in an enclosed,

poorly ventilated structure. Fuel vapors can

travel to an ignition source (such as a furnace,

water heater, etc.) and cause an explosion.

Fuel vapor is also toxic to humans and animals.

Page 19

15

Operation

Regular

Maintenance

Tire Pressure

Front

12 - 15 psi (82 - 103 kPa)

Rear

10 - 12 psi (56 - 82 kPa)

TIRE PRESSURE

Tire pressure should be checked periodically, and maintained at the levels shown in the chart at right. Note that

these pressures differ slightly from the “Max Inflation”

stamped on the side-wall of the tires. The pressures

shown in the chart provide proper traction, improved cut

quality, and extended tire life.

MAINTENANCE SCHEDULE

The following schedule should be followed for normal care of your tractor and mower. Use the hour meter to determine your operating time.

* Change original engine oil after initial break-in period. Refer to engine owner’s manual.

** More often in hot (over 85° F: 30° C) weather or dusty operating conditions.

*** Service after the first 25 hours of operation, then every 250 hours of operation.

Before Every Every Every Every Spring

SAFETY ITEMS Each Use 5 Hours 25 Hours 100 Hours 250 Hours & Fall

Check Safety Interlock System ●

Check Tractor Brakes ●

Check Mower Blade Stopping Time ●●

Before Every Every Every Every Spring

TRACTOR MAINTENANCE ITEMS Each Use 5 Hours 25 Hours 100 Hours 250 Hours & Fall

Check Tractor/Mower for loose hardware ●

Check / Clean Cooling Fins ●

Check / Adjust PTO Clutch ***●●

Lubricate Tractor & Mower ** ●

Lubricate Rear Axle Shafts Yearly

Clean Battery & Cables ●

Check Tire Pressure ●

Clean Deck & Check/Replace Mower Blades ** ●

Perform Transmission Maint. (Varies by Model) ***●

Check Mower Blade Timing (40” Mowers) Yearly

Check Arbor Drive Belt Tension (40” Mowers) Yearly

Before Every Every Every Every Spring

ENGINE MAINTENANCE ITEMS Each Use 5 Hours 25 Hours 100 Hours 250 Hours & Fall

Check Engine Oil Level ●

Check / Change Engine Air Filter

Change Engine Oil & Filter *

Inspect Spark Plug(s)

Check / Replace Fuel Filter

These procedures and their service intervals can be found in the

engine manufacturer’s owner’s manual. Always refer to the

engine manual for engine-related information.

Page 20

16

Figure 8. Gas Tank Located Under Hood

Hood recess

RAISING THE HOOD & SEAT

1. To raise the hood, grasp the hood recess (Figure 8)

on top, then pivot the hood up and forward.

2. To raise the seat for battery access, tilt the seat forward.

CHECKING FUEL FILTER

The fuel filter (C, Figure 9) is located in fuel line between

fuel tank and carburetor. If filter is dirty or clogged,

replace as follows. Place a container below filter to catch

spilled gasoline.

1. Using a pliers, open and slide hose clamps from fuel

filter.

2. Remove hoses from filter.

3. Install new filter in proper flow direction in fuel line.

Secure with hose clamps. See warning at beginning

of procedure.

SAFETY INTERLOCK SYSTEM

CHECK

Service Interval: Every Fall & Spring

Check the function of the safety interlock system using

the test procedure found on page 10 of this manual. If

the tractor fails any of the tests, see your dealer.

BLADE BRAKE CHECK

Service Interval: Every 100 Hours or Fall & Spring

Mower blades and mower drive belt should come to a

complete stop within five seconds after electric PTO

switch is turned off.

1. With tractor in neutral, PTO disengaged and operator

in seat, start the engine.

2. Look over the left-hand footrest at the mower drive

belt. Engage the PTO and wait several seconds.

Disengage the PTO and check the amount of time it

takes for the mower drive belt to stop.

3. If mower drive belt does not stop within five seconds,

re-adjust the clutch or see your dealer.

CAUTION

Do not run the engine with the hood raised.

Engine heat will cause damage to the headlight

bezel and hood.

Regular Maintenance

Figure 9. Engine Compartment

A. Oil Fill D. Air Filter

B. Gas Tank E. Spark Plug

C. Fuel Filter

B

A

A

D

D

E

E

C

C

WARNING

Do not remove fuel filter when engine is hot, as

spilled gasoline may ignite. DO NOT spread hose

clamps further than necessary. Ensure clamps

grip hoses firmly over filter after installation.

PTO CLUTCH ADJUSTMENT CHECK

Service Interval: After 25 Hrs, Then Every 250 Hrs

Check the PTO clutch adjustment after the initial 25 hour

break-in period and then after every 250 hours of operation–or if the clutch starts slipping or will not engage.

Check and adjust the clutch using the procedure outlined

in the Adjustments section of this manual.

ENGINE MAINTENANCE

Refer to the engine owner’s manual for all engine maintenance procedures and recommendations.

Page 21

Figure 11. Lubricating Tractor

Grease Axle

Shafts Yearly

Figure 12. Arbor Lubrication Points

Figure 10. Lubricate Deck Linkage (38” shown)

17

Regular Maintenance

LUBRICATION

Service Interval: Every 25 Hours

Lubricate the unit at the locations shown in Figures 1012 as well as the lubrication points listed. Generally, all

moving metal parts should be oiled where contact is

made with other parts. Keep oil and grease off belts and

pulleys. Wipe surfaces clean before and after lubrication.

Grease:

• steering linkage

• foot pedal

• mower linkage

• transmission idler assembly pivot

• rear axle shafts (remove wheel hubs)

Use grease fittings when present. Automotive lithium

grease is recommended.

Oil:

• control linkage

• seat adjustment assembly

• brake linkage

• mower deck height adjustment linkage

• manual lift lever

Page 22

18

Regular Maintenance

LUBRICATE REAR AXLE SHAFTS

Service Interval: Yearly

We recommend removing the rear wheel hubs and lubricating the axle shafts yearly. This prevents the wheel

hubs from seizing onto the axle shaft and makes future

service easier.

1. Turn off the ignition, turn off the PTO, engage the

parking brake, and block the front tires.

2. Using a jack or chain hoist positioned at the center of

the rear frame, carefully jack the unit up until the rear

tires are approximately 1" - 2" (2.5-5cm) off the

ground.

NOTE: For overall unit stability during service, do not

jack rear end higher than required for wheel removal.

3. Support the rear of the unit on jackstands positioned

under the rear frame.

NOTE: Your axle assembly may differ slightly from the

assembly pictured: the quantity of washers is adjusted

on a tractor by tractor basis during assembly to allow a

small amount of axle end-play.

4. Remove the hardware retaining the wheel assembly

to the axle and lubricate the axle shaft using antiseize compound or lithium grease.

5. Reinstall the components in reverse order of disassembly and lower the unit. Be sure the key (A,

Figure 13) is in place in the axle keyway.

A

B

C

D

B

E

F

G

x3

Figure 13. Rear Wheel (Models with Axle Caps)

A. Key E. Small Washer (A.R.)

B. Large Washers F. E-Ring

C. Spacer G. Hub Cap

D. Wheel Assembly

WARNING

PREVENT SERIOUS INJURY OR

DEATH FROM FALLING UNIT

Always use a properly working lifting device with

a capacity suitable for the weight of the unit being

serviced.

Always use a jack stand to support the unit while

performing service, and chock remaining wheels

to prevent the unit from rolling off the supports.

Never work under or around an elevated unit that

is not properly supported and secured in position

with wheel chocks.

Page 23

19

Regular Maintenance

BATTERY MAINTENANCE

Cleaning the Battery and Cables

1. Disconnect the cables from the battery, negative

cable(s) first (A, Figure 15).

2. Remove the battery and clean the compartment with

a solution of baking soda and water.

3. Clean the battery terminals and cable ends with a

wire brush until shiny.

4. Reinstall the battery and reattach the battery cables,

positive first.

5. Coat the cable ends and battery terminals with

grease or petroleum jelly.

TRANSMISSION IDENTIFICATION

Several service procedures within this book are identified

by, and vary by, transmission type. To determine what

transmission is in your tractor, check the identification

tag attached to the axle of the transmission (Figure 14),

or check your tractor’s parts book.

TRANSMISSION MAINTENANCE

K46 Maintenance

The K46 is a sealed unit and does not require regular

maintenance. If the transmission lacks drive or is excessively noisy, it may need to be purged. See TRANSMISSION PURGING in the Troubleshooting, Adjustments, &

Service Section.

Figure 14. Transmission ID Tag Location

TUFF TORQ K61

1001010101010010101

ID Tag

WARNING

Be careful when handling the battery. Avoid

spilling electrolyte. Keep flames and sparks away

from the battery.

When removing or installing battery cables,

disconnect the negative cable FIRST and reconnect

it LAST. If not done in this order, the positive

terminal can be shorted to the frame by a tool.

Figure 15. Battery

A. Negative Cable(s)

B. Positive Cable & Cover

B

A

A

FRONT

Page 24

20

Regular Maintenance

SERVICING THE MOWER BLADES

Service Interval: Every 100 Hours or As Required

NOTE: Mower blades must be timed perpendicular to

each other.

1. Remove mower deck (see “Mower Deck Removal”).

2. See Figure 16. To remove blade for sharpening, use

a block of wood to prevent blade rotation while loosening the capscrew.

3. 38” & 44” Mowers: Remove the capscrew (D, Figure

18), spring washer (C), hex washer (B), and blade.

40” Mowers: Remove the capscrew (A, Figure 19),

spring washer (F), spline washer (G), alignment pin

(E) and blade (D). Do not remove the blade adapter

(C).

4. Use a file to sharpen blade to a fine edge. If blade is

severely damaged, it must be replaced.

5. Balance the blade as shown in Figure 17. Center the

blade’s hole on a nail lubricated with a drop of oil. A

balanced blade will remain level.

6. Reinstall the blade (Figures 18 & 19) with the tabs

pointing up toward the mower deck as shown.

Reinstall the alignment pin (E).

7. 38” & 44” Mowers: Reinstall the hex washer (B,

Figure 18), spring washer (C) and capscrew (D). Use

a wooden block (A) to prevent blade rotation while

tightening the capscrew (D) to 61-75 N.m (45-55 ft.

lbs.).

40” Mowers: Be sure the blades are positioned perpendicular to each other as shown in Figure 19. If

not, perform the Mower Blade Timing procedure

found in this section. Reinstall the spline washer (G),

spring washer (F) and capscrew (A). Use a wooden

WARNING

For your personal safety, do not handle the sharp

mower blades with bare hands. Careless or

improper handling of blades may result in serious

injury.

WARNING

For your personal safety, blade mounting

capscrews must each be installed with a

hex/spline washer and spring washer, then

securely tightened. Torque blade mounting

capscrew to 45 - 55 ft. lbs. (61 - 75 N.m.)

Figure 17. Balancing The Blade

Workbench

Nail

Figure 16. Blade Removal

Figure 18. Installing The Blade - 38” & 44” Models

A. 4x4 Wood Block C. Spring Washer

B. Hex Washer D. Blade Bolt

block (B) to prevent blade rotation while tightening

the capscrew (A) to 61-75 N.m (45-55 ft. lbs.).

B

A

TIGHTEN

C

D

Page 25

21

Regular Maintenance

CHECK MOWER BLADE TIMING 40” MOWERS

Service Interval: Yearly

1. Turn the PTO to the off position, engage the parking

brake, turn the engine off, and remove the key.

Remove the mower deck (see “Mower deck

removal”).

2. Turn the mower deck over and check the position of

the blades. The blades must be positioned perpendicular to each other as shown in Figure 20. If not,

proceed to step 3.

3. Use a block of wood (B, Figure 19) to prevent blade

rotation while loosening the capscrew.

4. Remove the capscrew (A, Figure 19), spring washer

(F), and spline washer (G).

5. Remove the alignment pin (E, Figure 19). Rotate the

blade (D) manually until the blades are perpendicular

to each other as shown in Figure 20. It may be necessary to remove and rotate the blade adapter (C) to

align the blade hole and adapter hole.

6. Reinstall the alignment pin (E), spline washer (G),

spring washer (F) and capscrew (A). Use a wooden

block (B) to prevent blade rotation while tightening

the capscrew (A) to 61-75 N.m (45-55 ft. lbs.).

Figure 20. Check Blade Timing

A

B

C

D E

G

F

A

Figure 19. Blade Installation & Hardware

A. Blade Mounting Capscrew

B. 4x4 Wood Block

C. Blade Adapter

D. Blade

E. Alignment Pin

F. Spring Washer

G. Spline Washer

Page 26

22

Regular Maintenance

CHECK MOWER BELT TENSION -

40” MOWERS

Service Interval: Yearly

1. Turn the PTO to the off position, engage the parking

brake, turn the engine off, and remove the key.

Remove the mower deck (see “Mower deck

Removal”).

2. Remove the screws securing the belt covers.

Remove the belt covers.

3. Loosen the idler assembly capscrew (A, Figure 21).

4. Using a 3/8" drive ratchet and extension (Figure 22),

insert the square end of the extension into the square

hole (D) and rotate the spring-loaded idler assembly

(B, Figure 21) to relieve tension on the belt (C). .

5. Remove the belt (C) and inspect it for cracks, missing

teeth and wear. Replace belt if worn or damaged.

6. Reinstall the belt (C). Releasing the idler assembly

(B) allows the spring to automatically tension the

cogged belt.

7. Tighten the idler assembly capscrew (A) and reinstall

the belt covers.

8. Check the mower blade timing.

WARNING

Mower blades are sharp. For your personal

safety, do not handle mower blades with bare

hands. Careless or improper handling of blades

may result in serious injury.

Figure 21. Mulching Deck (Belt Covers Removed)

A. Idler Assembly Capscrew

B. Spring-Loaded Idler Assembly

C. Belt

D. Square Hole

Figure 22. Release Cogged Belt Tension

A. 3/8” Ratchet and Extension

A

B

D

C

A

Page 27

23

Notes

Page 28

24

Troubleshooting,

Adjustment, & Service

TROUBLESHOOTING

While normal care and regular maintenance will extend

the life of your equipment, prolonged or constant use

may eventually require that service be performed to

allow it to continue operating properly.

The troubleshooting guide below lists the most common

problems, their causes and remedies.

See the information on the following pages for instructions on how to perform most of these minor adjustments

and service repairs yourself. If you prefer, all of these

procedures can be performed for you by your local

authorized dealer.

TROUBLESHOOTING THE TRACTOR

PROBLEM CAUSE REMEDY

Engine will not turnover or start. 1. Brake pedal not depressed. Fully depress brake pedal.

2. PTO (electric clutch) switch Place in OFF position.

in ON position.

3. Cruise control engaged. Move lever to Neutral position.

4. Out of fuel. If engine is hot, allow it to cool, then refill

the fuel tank.

5. Engine flooded. Disengage choke.

6. Circuit breaker tripped. Wait one minute for automatic reset.

Replace if defective.

7. Battery terminals require See Battery Maintenance Section.

cleaning.

8. Battery discharged or dead. Recharge or replace.

9. Wiring loose or broken. Visually check wiring & replace broken or

frayed wires. Tighten loose connections.

10. Solenoid or starter motor faulty. See your dealer.

11. Safety interlock switch faulty See your dealer.

12. Spark plug(s) faulty, fouled Clean and gap or replace.

or incorrectly gapped. See engine manual.

13. Water in fuel. Drain fuel & refill with fresh fuel. Replace fuel filter.

14. Gas is old or stale. Drain fuel & refill with fresh fuel. Replace fuel filter.

Engine starts hard or runs poorly. 1. Fuel mixture too rich. Clean air filter. Check choke adjustment

2. Spark plug(s) faulty, fouled, or Clean and gap or replace.

incorrectly gapped. See engine manual.

Engine knocks. 1. Low oil level. Check/add oil as required.

2. Using wrong grade oil. See engine manual.

Excessive oil consumption. 1. Engine running too hot. Clean engine fins, blower screen and

air cleaner. Clean radiator screen.

2. Using wrong weight oil. See engine manual.

3. Too much oil in crankcase. Drain excess oil.

Engine exhaust is black. 1. Dirty air filter. Replace air filter. See engine manual.

2. Choke closed. Open choke.

Engine runs, but tractor will 1. Ground speed control pedals Depress pedals.

not drive. not depressed.

2. Transmission release lever Move into drive position.

in “push” position.

3. Drive belt is broken. See Drive Belt Replacement.

4. Drive belt slips. See cause and remedy below.

5. Parking brake is engaged. Disengage parking brake.

WARNING

To avoid serious injury, perform maintenance on

the tractor or mower only when the engine is

stopped and the parking brake engaged.

Always remove the ignition key, disconnect the

spark plug wire and fasten it away from the plug

before beginning the maintenance, to prevent

accidental starting of the engine.

Page 29

25

Troubleshooting, Adjustment, & Service

Tractor Troubleshooting Cont.

Tractor drive belt slips. 1. Clutch/brake is out of adjustment. See Adjustments Section.

2. Pulleys or belt greasy or oily. Clean as required.

3. Belt stretched or worn. Replace with new belt.

4. Idler pulley pivot bracket Remove idler pulley bracket, clean and lubricate.

“frozen” in declutched position.

Brake will not hold. 1. Brake is incorrectly adjusted. See Brake Adjustment.

2. Internal brake worn. See your dealer.

Tractor steers hard or 1. Steering linkage is loose. Check and tighten any loose connections.

handles poorly. See Steering Gear Adjustment.

2. Improper tire inflation. Check and correct.

3. Front wheel spindle Grease spindles. See Lubricating the

bearings dry. Tractor.

TROUBLESHOOTING THE MOWER

PROBLEM CAUSE REMEDY

Mower will not raise. 1. Lift linkage not properly attached Attach or repair.

or damaged.

2. Dirt in hydraulic lines. Change hydraulic system filter.

3. Brake pedal depressed. Release brake pedal to power transmission.

Mower cut is uneven. 1. Mower not leveled properly. See Mower Adjustment.

2. Tractor tires not inflated See Maintenance Section.

equally or properly.

Mower cut is rough looking. 1. Engine speed too slow. Set to full throttle.

2. Ground speed too fast. Slow down.

3. Blades are dull. Sharpen or replace blades.

See Mower Blade Service.

4. Mower drive belt slipping Clean or replace belt as necessary.

because it is oily or worn.

5. Check PTO (Electric Clutch) See Adjustments Section.

Adjustment.

6. Blades not properly fastened See Servicing the Mower Blades.

to arbors.

Engine stalls easily with 1. Engine speed too slow. Set to full throttle.

mower engaged. 2. Ground speed too fast. Slow down.

3. Carburetor improperly adjusted. See Engine Manual.

4. Cutting height set too low. Cut tall grass at maximum cutting

height during first pass.

5. Discharge chute jamming Cut grass with discharge pointing toward

with cut grass. previously cut area.

6. Engine not up to operating Run engine for several minutes to warm-up.

temperature.

7. Starting mower in tall grass. Start the mower in a cleared area.

Excessive mower vibration. 1. Blade mounting screws Tighten to 45-55 ft.lbs. (61-75 N.m.).

are loose.

2. Mower blades, arbors, Check and replace as necessary.

or pulleys are bent.

3. Mower blades are out Remove, sharpen, and balance blades.

of balance. See Servicing the Mower Blades.

4. Belt installed incorrectly. Reinstall Correctly.

Excessive belt wear or breakage. 1. Bent or rough pulleys. Repair or replace.

2. Using incorrect belt. Replace with correct belt.

Mower drive belt slips 1. Idler pulley spring broken or not Repair or replace as needed.

or fails to drive. properly attached.

2. Belt stops out of adjustment. Check belt stops.

3. Mower drive belt broken. Replace drive belt.

4. PTO clutch out of adjustment. Adjust PTO clutch.

Mower blades collide (40” Mower). 1. Blade shear pin broken. Replace shear pin.

Page 30

26

Troubleshooting, Adjustment, & Service

BATTERY CHARGING

A dead battery or one too weak to start the engine may

be the result of a defect in the charging system or other

electrical component. If there is any doubt about the

cause of the problem, see your dealer. If you need to

replace the battery, follow the steps under Cleaning the

Battery & Cables in the Regular Maintenance Section.

To charge the battery, follow the instructions provided by

the battery charger manufacturer as well as all warnings

included in the safety rules sections of this book. Charge

the battery until fully charged (until the specific gravity of

the electrolyte is 1.250 or higher and the electrolyte temperature is at least 60° F). Do not charge at a rate higher than 10 amps.

WARNING

Keep open flames and sparks away from the

battery; the gasses coming from it are highly

explosive. Ventilate the battery well during

charging.

SEAT ADJUSTMENT

The seat can be moved forward and back by moving the

lever (A, Figure 23) underneath the front of the seat, then

positioning the seat as desired.

Figure 23. Seat Adjustment

A. Seat Adjustment Lever

STEERING GEAR ADJUSTMENT

If there is excessive slack in the steering system, the

steering gear backlash can be removed.

1. See Figure 24. Locate the steering gear assembly on

the underside of the tractor. Loosen the two nuts and

adjust the bracket so the gear teeth are closely

meshed.

2. Tighten nuts (A, Figure 24) to 36-44 ft. lbs. (49-59

Nm) after adjustment.

WARNING

To avoid serious injury, perform adjustments only

with engine stopped, key removed and tractor on

level ground.

A

Figure 24. Steering Gear Adjustment

A. Nuts

A

Page 31

01

BRAKE & BRAKE SPRING

ADJUSTMENT

1. Disengage the PTO, stop the engine, block the

wheels, remove the ignition key, and engage the

parking brake.

2. Remove the mower deck (see Mower Deck

Removal).

3. Locate the brake spring (A, Figure 25) and adjustment nut (B).