Page 1

SIMPLICITY MANUFACTURING COMPANY.

INC.,

LIT”0

IN

U.S.A.

SNO-AWAY

Page 2

PACKING

The 4 and 6 H.P.

Sno-Aways

are delivered

complete in their separate cartons. The carton contains:

2

1 - Frame, Rotor, Engine and Wheel Assembly

1 - Handle

Assembly

1 - Spout Adjusting Rod

2 - Skid Shoes

1 - Bag of Hardware

Should shortages of any of the above items

occur, advise by stating packers number listed on

the green packing slip,.sarial number of Sno-Away,

part number and description of items missing.

ASSEMBLY

1. Fasten the handle assembly to the mount-

ing brackets as shown at

(l),

Figure 1, using the (4)

3/8-16 x 2’: capscrews, 3/8” plain washers, 3/8”

lockwashers and

3/8”

hex nuts.

2. The throttle cable assembly is coiled around

the engine

for

shipping purposes. Uncoil the cable

and attach ‘to the housing

a&nbly

using the (2)

32” x

l/2

self-tapping screws. The cable is held in

place by the clamp on the lower portion of the

right handle as shown at

(2),

Figure 1.

Figure 1.

Figure 2.

3. Insert the lower end of transmission shift

rod through the hole in the shift lever and fasten in

place with a cotter pin as shown in Figure 1.

4. Insert the Touch-0-Matic extension wire

through the wire clamp. For proper belt tension,

adjust as shown in Figure 2.

5. Attach the spout control cable as shown in

Figure 3. Insert the lower end of the spout control

rod in the nylon bearing on the ,blower housing and

hold in place with (2)3/32x 5/8”cotter pins.

Tli

spout control rod support bracket is mounted in

a..

reverse position for shipping purposes. Detach and

mount as shown in Figure 4. Tighten clamp as nec-

essary to hold spout in desired position.

Figure

3,.

Page 3

Figure 4.

4 H.P. SNO-AWAY

LUBRICATION

DRAlNlNG OIL - 6 H.P. SNO-AWAY

The 4 KP. Sno-Away is

cquipprd wilh 4

gxase fittings that

requirr

occasional lubrication

with

n

gcncral

purposr automotiw grcaac.

The

10.

ration of thrse fittings is shown in Figures 1.6 & 9.

Thr 6

t1.P.

Sue-Away has an additional

fitling

on

the 2.spwd

axlct

cowr.

The bcarings*on thr rotor shaft arc a

walul

type

and do not

rrquiw furlhcr lubrivation. An

occasional application of light motor oil to thv cwdr

of

the

rotor shaft will aid in prolonging thr

lift

ol

thr

braring s&r.

DRAINING OIL - 4 H.P. SNO-AWAY

5.

Rrfw to cngirw manufacturer’s manual for

proper

gradr

and volurm: of oil for

refilling

engine

crankraw.

4. When

the

plastic

lubing

is firmly

owr the

thrcadcd end of

thea

elbow. wturn thv Stw-.4way

lo

its normal

attitude

and allow

the

oil IO drain

inlo

a

suitable wntaiwr.

C,.W

tub. into

.Ib.r

6 H.P. SNO-AWAY

^

Figure 6.

5. Rrfcr to

mginc

manufacturrr’s manual for

proper

grade and

\-olumr

of oil for

wfillinp.nnginc

cmw tubs

OY,, .,box

3

Page 4

.,~A

BELT TENSION ADJUSTMENT

Belt tension for the rotor drive is regulated by

the position of the set collar on

,the

rotor clutch

rod. NormaRy

a clearance of 1iZ” between the

set

collar and

the clutch rod clip will properly tension

this belt. Check this adjustment when the rotor

clutch is engaged.

Refer30

Figure 7.

Belt tensiop for transmission drive belt is reg-

ulated by the position of the wire clamp on the ex-

tension spring.

Figure 7.

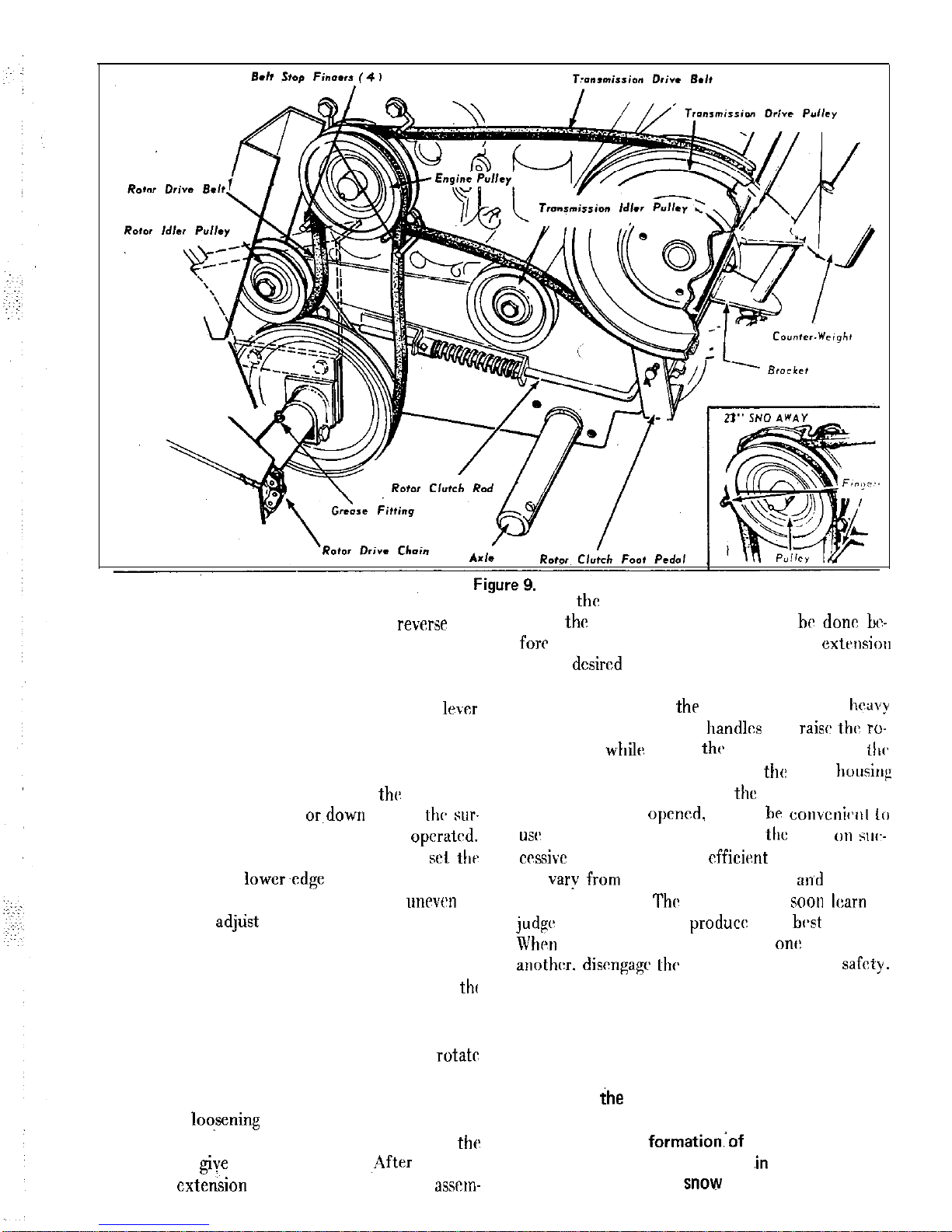

BELT STOPS ADJUSTMENT

On the drive pulley side of the engine, belt

stops arc mounted as shown in Figure 9.

Engage

the rotor clutch and

transmissioh

clutch and check

clearance between belts and

belt

stops. The belt

stops

will

be properly

,adjusted

when

l/16”

clear-

ance is visible between

the

stops and the belts. To

adjust, loosen the hex capscrews and reposition the

stops to proper clearance. Retigbten hex capscrews

to hold stops in proper position. Refer to Figure 9.

-.

-

OPERATION

Before attempting to start the engine or to op-

erate the Sno-Away, refer to the engine manufac-

turer’s owner’s manual for the proper fuel, oil, and

procedure for starting the engine.

The

operation of the rotor is controlled by the

rotor clutch. To engage the rotor clutch, raise the

foot pedal shown in Figure 9.

To disengage the

clutch, depress the foot pedal.

Bear

in mind that

the rotor will operate independently~of the forward

travel of the Sno-Away, as long as the engine is run-

ning and the clutch is engaged. Exercise caution at

all times, and

never attempt to remove snow or ice

from the r&or housing or discharge spout unless

the engine is stopped and rotor clutch is disengaged.

To stop the engine,

mow

the throttle control lever

all the way to the shut-off position.

If the engine fails to shut-off after moving the

throttle control lever to the shut-off position, re-

position the “shorting-wire” to make contact with

the ignition shorting lever located on engine at end

of throttle cable.

The direction of travel of the Sno-Away is

controlled by the position of the transmission shift

lever. Refer to Figure 2. When shifting the transmission, always release Touch-0-Matic control.

With the clutch disengaged, push down on the trans-

mission shift lever and

the

transmission will shift

j.

Page 5

into forward position and Sno-Away will travel forward when the clutch is engaged. To reverse the

Sno-Away, disengage the clutch and pull up on

shift lever and transmission will shift into the reverse position. Neutral position of the shift lever is

half way between forward and reverse and thr

lever

will be held in this position by a detent lever on the

left side of the Sno-Away frame.

The skid shoes on each side of

thcr

rotor hous-

ing are adjustable either up or.down to suit

thr LUP

face over which the Sno-Away is to be operated.

For smooth surface, loosen the nuts and

set thr

shoes so that the lower~edge of the rotor housing

rides near the surface. For use over an unewn or

rough surface

adjdst the shoes for maximum lift.

When using the Sno-Away, adjust the discharge

spout so that the snow will be thrown with th(

wind and never into the wind. Throwing snow into

the wind will be a source of discomfort to the operator. To alter the direction of discharge,

rotate

the spout by means of the spout adjusting handle.

The distance that the snow may be thrown may be

adjusted by

loq,sening the two wing nuts on the dis-

charge spout extension and raising or lowering.

the:

extension to give the desired angle. ,After adjusting,

push the

exten&n

snugly against the spout asscm

bly to prevent snow from being blown backwards

against

the

engine and operator. Slotted holes be-

neath

the

wing nuts will allow this to br

done bc-

forr tightening the wing nuts to hold thr

exttmiou

in the dcsircd position,

When operating

thr

Sno-Away through

hcsv~y

drifts of snow, depress the handles and

raiser the

ro-

tor housing

while

taking

thcb

first pass through tiw

drift.

Then back off and lower

the

rotor housing

and go through again. After

the

first path through

thr drift has been

openrd,

it may be

convcniwl

to

USC

only a portion of thr width of

the

plow on w,--

crssive passes. Naturally, efficient plowing method-

will

vary from one snowfall to another

an’d

from lo-

cation to location.

The:

operator w-ill soon

Icarn

to

judge

which mrthods

product

the

b(‘st

results.

When transporting the plow from one location to

anothw.

discngagc

Lhv

rotor clutch for safety.

IMPORTANT

After completion of plowing operation,

allow the engine to operate in a sheltered

area for about 5 minutes to dry itself and

prevent the

formation.‘of ice. When pos-

sible, store the Sno-Away

,in

a cold area

so that clinging

snow

will not melt and

refreeze into ice.

Page 6

WARRANTY

The company

warrant8

Simplicity

Products

tc be free

from

defects in material and

workmanship

except

the

conipany

makes M warranty

expn?ss

or

Implied

with respect to tires. engines and engine accessc-

rles which generally

are

warranted by their respective mamfaoturers. Any part covered by

this

war-

ranty

which

is prcvendefmtive

wfthin

cm year, under

normal use,

from date of purchase, will be re-

placed free of charge,

f.c.b.

Port Washiwtcn, Wisconsin, provided such part is returned

to.

factory

transpcrtatfcn-charges

prepaid and is found tc be defective

upon examination

at the factory. The ccm-

pany

is not obligated

undei

this warranty to bear cost of labor

01’

delivery charges in replacement of

defective parts.

Thfa

warranty does not apply to any Simplicity Products

altered

outside of Simplicity’s

factory. Such replacement of defective parts shall be tlie exclusive remedy

and in no

event shall Sim-

plicity be liable for

ccnssquentisl

damages. EXCEPT AS SPECIFICALLY PROVIDED HEREIN, THERE

ARE NO WARRANTIES

WHICH

EXTEND BEYOND THE DESCRIPTION ON ANY SIMPLICITY PRODUCT.

SAFE SNOW REMOVAL IS NO ACCIDENT

Page 7

.,...

SPOUT GROUP

G

106785

H

720001

J

717001

K

106881

L

106491

M

705015

N

720003

p 717005

Q

106870

R

106516

S

715067

T 722016

u 152050

V

121175

w

705018

X

717511

Y 106521

Z 705053

AA

720003

AB

717005,

AC

106867

AD

722015

AE

106Sl2

JMBER

1

DESCRIPTION

21"

StWAWW

106762 Spout Assembly

703005

Carriage

Bolt, 5/16 - 18 x 3/4”

lg.

106760

Spout Extension

719001

Plain Washer,

318”

721601

Lock Washer,

318”

106229

Wing Nut

106785

Cup Washer

717001

106881

106491

705015

720003

717005

106870

106516

715067

722016

152050

121175

705018

717511

!06521

705053

720003

717005

106867

722015

106512

Lock Washer, 5116

Hex Nut,

Full,

5/16 - 18

Cable

Assembly

Bearing

Hex

Capscrew, l/4.20 x

5/B”

,g.

Lock

Washer,

l/4”

Hex Nut,

Full, l/4”.

20

Spout Control, Tube Assembly

Handle Cover

Self-Tapping Screw,

114 -

20 x 3/B” lg.

cotter pin,3/32 x 5/8"Ig.

Rod Guide

Guide

Liner

Hex

Capscrew,

5/16 - 18 x 1.112”

lg.

Hex Nut, Full, Lock,

5116

18

Spout Adjusting Rod Support

Hex Capsqw, 114 - 20 I

l-3/4” lg.

Lock Washer,

114”

Hex Nut,

Full, 114

20

llandle Aswnbly

cuttrr

Pin,5/32 x

1”

lg.

D%Xl

Page 8

ROTOR BODY and FRAME

1

Page 9

i

ROTOR BODY and FRAME

REF. PART NUMBER

DESCRIPTION

LET. 26”

21”

Sac-Away SnoAway

A

106832 106814

Hody Framr Assembly

II

IO6745 106745

Side Plate

I:

106X38

lOhB31

Scraper - Body

II

715071 715071

llrx

Capscrew, S/16 - I8 x

5/8”

lg.

K

717511 717511

llrx

Nut Fult Lock, 5116. 18

F

71.5018 715018

Ilcx Capscrew.

114

20 I 5/E-‘lg.

,: 72ono3 720003

Lock Washer,

l/4”

II

71700s 717005

tlrx Nut Full:

l/4

20

1’

106747 106747

Skid

Ii 7n3004 703004 Carriage Bolt,

318

16 x

3/4”

lg.

I,

710001 719001

Plain Washer,

3/8”

Jl

720002 720002

Lock Washer, 3/B”

u 717003 717003

llrx

Nut Full, 3/B I6

I’

10683’)

lO68%3

Rotor Assmbly

0

106732 106732

Braring Cartridge

II

7lBSO9 713509

Srt

Screw,

l/4

28 x

114”

lg.

3

I6 IO6’J

161069

Bearing Flange

1

70.5” I7

7n5017

,,vxCa,,swcw,5/16-

18 x 314”Ig.

I

720001 720001 Lock

Wil-Fher,

5116”

\ 717001 717001

Hex Nut Full. 5116 -

I8

\\ IO6633 IO6653 Rotor Sprocket

\

;I35033 713503 Set Scrrw. .5/16. 18 x S/16” lg.

1

I .i I

040 ISIO40

KC!

%

IO6376

106176

Clamp Support Assembly

.\:\

705005 705003

llra

Caprcrw. 3/E 16 x 1”

lg.

,111

;I

‘JO0 I

:I0001

Plain

Wahcr.

3/R”

~\I:

;““00’

71000’ Lark Washer, 3/B”

\I)

7

I 7003

71

7003 ttrx Nut Full. 3/B 16

,\I:

Iilh;:l

106771 Stud

,\

F

;

I1tm.i

71 m:t.i

Flang

Nut. “Whiz Lock”. 3/8 16

,\I;

717SlO 717310 tlrx Nut Full Lock, 3/8 16

.,\I I 70.501 I,

in.50 1

II

tlrx Capscnw. 5116. 18 x l-1/2” lg.

,\1

7’0001 72000

I

Lock Washrr. 5116”

:\

Ii

717001

71 iOOl

lb-x Nut Full_ 5116 -

I8

.\I. 106X43

I

06t1’6

Ikxrinp Ilousing

It \I

I.x?.58

I

.5458

Nwdtc tkaring

.,\U

;“:,I”2

727002

Crcan Fit&g

;\

I’

11061012 tw6

IO I

2

WBPIIW

\O

1068U

I

lJ6B27 Sbaf, Assrmbly

,,\R IO60511

10605H Chain

:,s

IO6;.5’)

1

D6750 Chain Guard

-\‘I

720002

720002 Lock Washvr. 3/B”

:\ I

71 io0:i

71

7003

lt<~x

Nut Full.

310

I6

-\

\

I

0666R IO6663

PUIIC~)

\

n

;I:3503 71350:3

Srt

Scww 5/16 18

x5/16”

lg.

:\

I

7’5003

:“xto,

Kry

.\\

10677-L

106:7-t Ih.tlw10r

.I%

:o.iot

2 705012

Ilrr

Crpwnw. 5/16 I8 x S/B”

Iz.

II:\

;“ooot

;200,,1 I.wk

\V&vr.

5/16”

1ttt

71

700

I

:I-001

It,:

t0688”

‘

IIVX

Nlll Pull. 5/16 -

IB

I068X0 Spwd ,:litj

111)71 w,tf,

7 I

ulo6

Self Tapping Srww. No. IO x

l/2” lg.

BE

7

I l100l1 7 I

R,,,“, S,rwl Nut

9

:

Page 10

--------a

- -------_-

HANDLES & CONTROLS

106546

r

i

----_.

10

Page 11

REF.

LET.

A

B

C

D

E

F

G

J”

K

L

M

N

P

Q

R

S

T

U

V

W

X

Y

Z

AA

AB

AC

AD

A!?.

AF

AG

AH

Al

AK

AL

AM

AN

AP

AQ

AR

As

AT

AU

AV

AW

HANDLES & CONTROLS

PART

26”

Sno-Away

IJMBER

21”

SneAway

106781 106781

106782 106782

106558 106558

705006 705006

7i9001 719001

720002

720002

717003 717003

146559 I,06559

705025 705025

720003 720003

717005 717005

106780 106780

106524 106524

714003 714003

718019 718019

106563 106563

714005 714005

106564 106564

106778 106778

717003 717003

154534 154534

717524 717524

705010 705010

717510 717510

106776 106776

722001 722001

106572 106572

106201 106201

8171073 8171073

705010 705010

154534 154534

106829 106829

8191045 8191045

8191022 8191022

713001 713001

705031 705031

106223 106223

717003 717003

108418 108418

106204 106204

717513 717513

118056 118056

106786 106786

8081503 8081503

8161215 8161215,

DESCRIPTION

Handle, LH

Handle, RH

Grip

Hex Capscrew, 3/8 - 16 x 2”

Plain Washer,

3/8”

Lock Washer,

3/8”

Hex Nut,

Full, 3/8”

16

Handle Cover

Hex Capscrew,

l/4 -

20 x

l-1/2”

Lock Washer,

l/4”

Hex Nut,

FuII, l/4” -

20

Housing Assembly

Support, Throttle Control

Hex Screw, self-tap. No.10 32 x

l/2”

Speed Nut, Tinnerman

Throttle Control Assembly

Screw, self-tap. No.10 -24 x

l/2”

Lever Pin

Spring Assembly

Hex Nut,

Full, 3/8” -

16

Idler Pulley (Trans. Drive)

Hex Jam Nut

Hex Capscrew, 3/8”- 16 x 314”

Hex Nut,

Full,

Lock,

3/8” -

16

Reverse Rod

Cotter Pin, 3132” x 314”

Grip, Reverse Rod

Idler Lever Assembly

Bearing Race, Inner

Hex Capscrew, 3/8 16 x l-3/4

Idler Pulley (Rotor Drive)

Rotor Clutch Rod

Spring

set Collar

Set Screw, Sq. Hd.

114 -

20 x 3/8

Hex Capscrew, 3/8 - 16 x

7/8”

lg.

Foot Clutch

Pedal

Hex Nut, Full,

3/8” -

16

Special Capscrew

Idler Lever Assembly

Hex Nut, Full, Lock,

114 -

20

Clutch Grip

Clip

Clutch Rod Guide Assembly

Bushing

11

Page 12

Page 13

:

n

B

C

D

E

F

G

H

J

K

L

M

N

i

R

S

T

u

v

w

x

H

J

,K

,L

,M

,N

,P

,Q

IR

;s

;T

;xJ

x

,W

Ix

IY

-

PART

26”

no dr.y

______

153089

727002

---___

061046

713006

153114

153105

705012

720001

7 1700 1

106193

12 1044

705005

719001

720002

7 17003

153124

153079

121306

153078

106199

727002

051038

121115

153079

153124

121118

121107

121163

121139

153094

719002

7 15033

153090

153115

153106

714006

716008

106215

106217

106216

720001

7 1700 1

718021

7 140 14

719006

TRANSMISSION, WHEELS

no

*my

106777 Guide, Clutch Wire

(4hp

only)

153069 Bearing

727002 Grease Fitting

106435 Axle

d Gear Assembly

061046 Set Collar

713006 Set Screw,

SqHd,5/16-18x1,

153 114 Gasket, Bearing Hous,ing

153 105 Gear Case

705012 Hex

Capscrew, S/16-18

x

5/

720001 Lock Washer,

S/16”

717001 Hex Nut. Full,

6/16”-18

106193 Shaft, Intermediate

12 1044 Lock Pin.

705005 Hex Capscrew, 3/S”-16 x 1”

719001

Plain

Washer,

3/S”

720002 Lock Washer,

3/E”

717003 Hex Nut, Full,

3/E”-16

153124 Retaining Ring

153079 Washer

12 130 6

Gear Assembly, Internwdfate

153078 Bearing, Intermediate

106199 HousIng Assembly, Bearing

727002 Grease Fitting

051038 Bearing

121115 Pulley Shaft Assembly

153079 Washer

153124

Retalnfng Ring

12 1118 Reverse

Pini””

12 1

lC7 Reverse Pinto” Spacer

121163 Pinion Spacer

121139 Lock Plate

1530 94 Shield

719002

Plain

Washer,

S/16”

715033 Hex Head Bolt, L.H.

153090 Nut, Hex, Full, L.H.

153115 Gear Case Gasket

153106 Gear Case Cover Assembly

714006 screw.

Self-Tapping.

#lo

x

l/2’

718008 Speed Nut

106215 Plate, Friction, Stop

1062 17 Spacer, Frame

106216 Bolt, Frame

720001 Washer, Lock,

S/16”

717001 Hex Nut, Full,

5/16”-18

718021 Detent, Neutral

7 14014 Screw,

Self-TappI”g,#lO

X 3,

719006 Washer, Plain,

l/4”

REF.

MRT

“UMBER

LET.

26” 21”

DESCR,PT,ON

,

Sno A*c.)r

Sn.A*.y

BZ

716018 715018 Hex capscrew,

l/4%20

x 5/S

CA 153121 153121 Spring, Reverse Lever

CB 153011 153011 Extension,

Spdng

cc

lill87

------ Sun Gear Assembly

CD 121167 ------ snap Ring

CE

106394 ------ Key

CF 106410 ------ Shift Rod Assembly

CG 121169 ------ Shift Block

CH 106572 ------

Clevis

Rod Grip

CJ 121146 ------ Housing Assembly

CK

720003

---_--

Lock Washer,

l/4”

CL 717005 ------ Hex Nut, Full,

l/4”-20

CM 121148 ------ Cover Assembly

CN 121151 ------ Ring Gear

:‘,

121118

121163

------ ------

Pinlo* pinion

spacer

CR 121162 ------ Bolt Ring

:;

121184 106416

------ ------ Hex Head Bolt

‘Spider

cu 72 1004

---_--

Lock Washer,

3/S”

Shakeproof

cv 718015 ------ Hex Nut, Full,

3/E”-24

CW 121185 ------

Th,vst.Plate

cx 121186 ------ Seal, Housing Assembly

CY 106407 ------ Carrier Assembly

cz

705015

---___

Hex capscrew,

l/4”-20

x 5/a

DA 10639:

_____-

WaSher’

DB 106406 ------ Axle Shaft

DC 106405 ------Axle Plate, R.H.

DD 154291 ------ snap Fd.,g

DE 727002 ------ Grease Fitting

DF 7 19002

---_-_

Plain Washer,

S/16”

DG 106392 ------ spacer

DH 720002

----__

Lock Washer,

3/S”

DJ

717003

--__--

Hex Nut, Full,

3/S”-16

DK 153068 ------ Bearings

DL 106414 ------ Gear 6 Tube Assembly

DM 121144 ------ Cover, Gear Case Assembly

DN 715017 ------ Hex

Capscrew,5/16-16x

l-l,,

DP 7 19002 ------ Plain Washer,

5/16

DQ 717511 ------ Hex Nut, Full,

5/16”

DR 153074 ------ Guide, Rod

DS 121175 ------ Liner

DT 106419 106419 Wheel & Tire Assembly

DU 118053 118053

P,”

DV 8161045 8161045 Spring Clip

DW 106420 106420 Steel Wheels

DX 8061055 6061055 seal. Felt

I

Page 14

SHIELD, DRIVE

PULLEYS, ENGINE

si

cil

Page 15

A

B

C

D

E

F

G

H

J

K

L

M

N

L

R

s

T

u

v

W

X

Y

2

aA

BB

ac

3D

BE

3F

3G

3H

3J

3K

3L

3M

3N

3P

30

3R

3s

BT

3u

BV

BW

Bx

BY

B2

3A

3B

JC

ZD

3E

3F

:G

x-l

:J

3K

31

xl

CN

CP

CQ

:s”

CT

CU

SHIELD, DRIVE PULLEYS, ENGINE

PART

26”

Sno **or

106519

106573

705012

720001

7 18030

------

106523

106576

106577

106525

710004

106578

720001

7 17001

------

106520

705007

720001

717001

106579

715037

_-__--

-----106779

106lJ65

715079

------

106SS2

7 13504

159129

154307

3021077

106522

8061089

706001

719002

106347

705017

106346

706016

106581

106385

------

------

--_---

------

106.585

106586

714003

7 19007

718031

7

180 19

106214

718041

725003

154381

728501

------

-----_

_----

713503

719002

106582

8081035

154247

715067

,YB.ER

21"

sno A*“~

106533

106534

705012

-----718030

106372

------

--_---

------

------

------

------

------

-----106541

----__

705007

720001

7 1700 1

106537

715037

106540

7 14007

106439

106866

------

715081

106227

713504

822 1042

154307

8021077

------

------

------

719002

------

------

------

------

------

-----106624

106545

706017

721506

106590

106591

114003

-----718031

718019

106214

718041

725003

154381

728502

106601

726502

106547

713503

------

__----

-----

-----______

-r-

DESCR,PT,O”

Hood Support

Hood Assembly

Hex

Capscrsw, 5116 -

18 x 5f8”lg.

Lock Washer,

5/16”

Tinnerman Nut,

ws31280-5618-i

Speed Clip

Rear Hood Support

Hood spacer, LH

Iiocd soacer. RI-I

Brace . .

Round Hd. Screw, X10-32 x

3/a”

Bolt, Hood Spacer

Lock Washer,

S/16”

Hex Nut, Full:

Lwk, 5116”-18

Belt Guard Support

Belt Guard Brace

Hex

CapSCrew,

5116 -

18 x 1”

t&

Lock Washer,

5/16”

Hex Nut, Full,

5/16”-18

Belt Guard Assambly:~

Thumb Screw

Belt Guard Bracket

Screw,Rec.

Hex. Hd.,Self-Tapping,

l/4/-20

x

3/8”1g.

EIl.XiI%Z

B&her

special capmw, 318 -

16 x 1.114”

b

special

Caprew,

318

16 x 1” lg.

Engine Pulley

Set Screw, Cup

Pt.,Socket Iid.,5/16”-18

x

3/a”

lg.

Key

V-Belt ( Rotor Drive )

V-Belt ( Transmission Drive

)

Guard Support

Belt Stop

Hex Capscrew,

5/16”-

24 x

3/4”

lg.

Plain

Washer,

S/16”

Belt Stop

Hex

Capscrew. S/16”-18

x

3/4”

lg.

Belt Stop

Hex Capscrew,

S/16”-24

x

5/a,,

lg.

Rubber

Tube

Tube Clamp

Belt Stop

Belt Stop

HEX

capscrew, l/Z”-20

x 1” lg.

Lo&

Washer, Int. Shakeproof,

l/2”

cover, Air cooling

Cover Bracket

screw,

Self-Tapping

x10 x

l/2”

lg.

Plain Washer,

3/16”

Speed Nut, Special

Speed Nut

Pulley, Transmission Drive

Nut

Reamer

Kay, woodruff

Tube, 011 Filler

Street Elbow,

90°

Nipple

Pipe

cap

Strip. White

screw. set

Plain

wisher. 5/l@’

Pelt Pad

Belt stop

Clamp

Hex

Capscrew. Self-tapping

Page 16

Figure 10.

COUNTER-WEIGHT KIT

Article No. 260

REF. PART NUMBER

LET. 26’

21”

Sno-Away

&o-Away

DESCRIPTION

1

A

106449

- _ _ - - _ - _

Bracket, Weight

~B

154322

-__---_-

Weight Assembly

C

118053

_ _ _ _ _ _ _ _

Pin

D

8161045 _i__ --

-_

Clip, Spring

COUNTER-WEIGHT KIT

Article No. 260

For added traction in extreme icy conditions, and

:j

added handling ease, the above counterweight kit

,~,

is available as optional equipment.

The bracket aid weight are attached as shown in

Figure 7.

Order Steel Lug Wheels by Article Number 257.

Order Rubber Tire Wheels by Article Number 258.

Order Tire Chains for Rubber Tire Wheels only, by

Article Number 259.

Loading...

Loading...