Page 1

Setup Guide

Not for

Reproduction

Dual Stage Snow Thrower

WARNING: Always wear safety glasses or eye shields

when assembling the snow thrower.

Handle Assembly

1. Carefully unfold the handle while guiding the speed

control rod over the tire before cutting the orange ties.

2. Raise the upper handle (A, Figure 1) to the operating

position.

NOTE: Make sure the Z fi ttings at the ends of the cables are

secured in the holes on the control levers. Make sure

the cables are not caught between the upper and lower

handle.

3. Insert two bolts (B) into lower holes and fasten with two

lock washers and wing knobs (C) or nuts (if equipped).

Tighten all four fasteners securely.

4. Use the supplied ties to secure the EZ Steer™ cable (if

equipped) to the left handle and the wire harness to the

right handle.

Mfg. No.

1695734, 1695735, 1695820, 1695821, 1695824, 1695825,

1695826, 1695827, 1695843, 1695853, 1695906, 1695908,

1695964

E

G

FDH

Figure 2

A

Figure 1

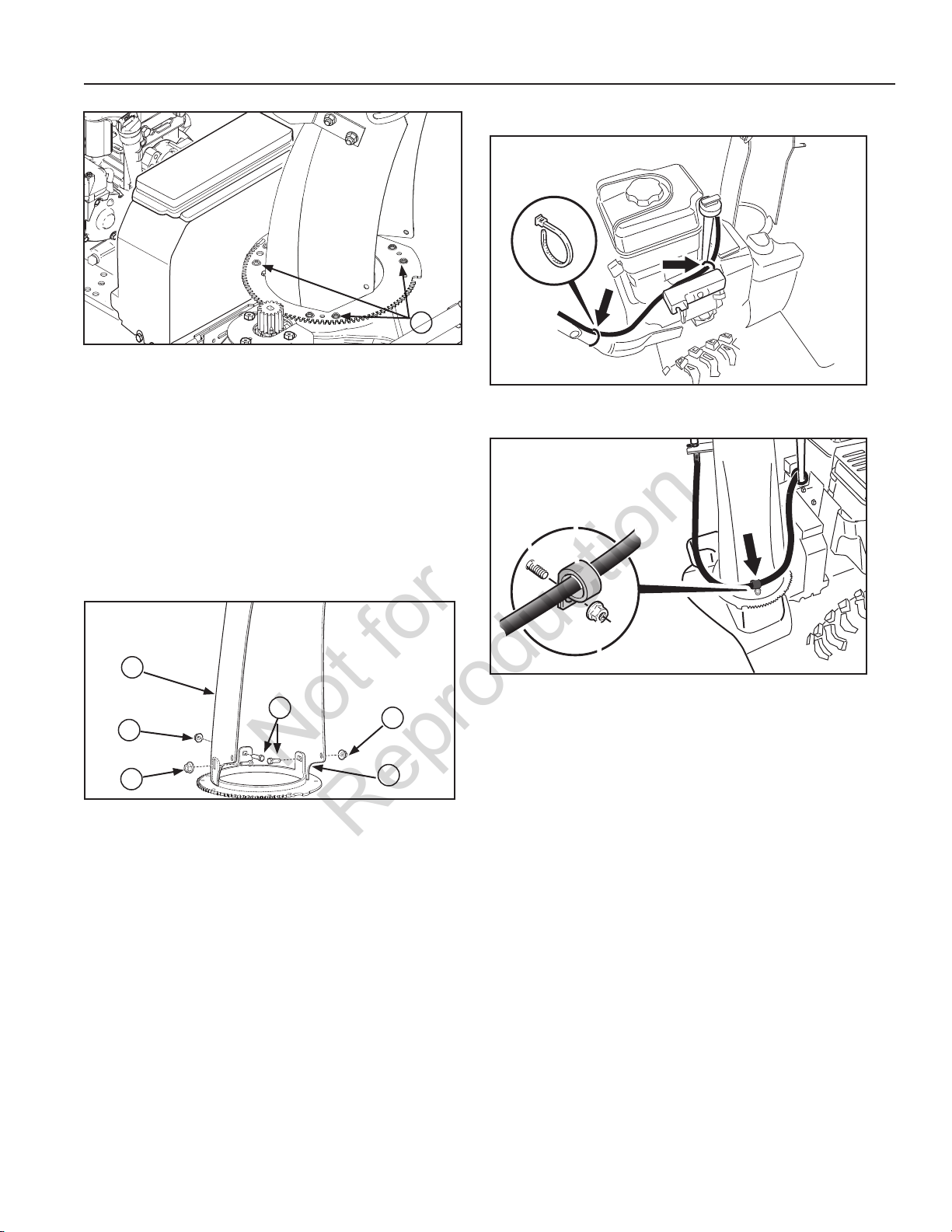

Install the Speed Control Rod

Attach the ball joint (D, Figure 2), located on the bottom end

of the speed control rod (E), to the shift yoke assembly (F)

with 5/16” lock washer (G) and 5/16” nut (H). Tighten nut

securely.

B

B

C

Install the Chute Control Rod

NOTE: Some models have the chute control already installed.

Models with an electric chute do not have a control rod.

Insert the chute control handle (if equipped) through the 1.

opening in the upper handle control panel.

Insert the end of the chute control rod (2. I) into the universal joint assembly (J) located next to the chute gear.

Secure with hair pin (K).

K

I

J

Figure 3

Copyright Briggs & Stratton Corporation 1739435 (Rev. B)

Page 2

Figure 4

Not for

Reproduction

Route Defl ector Cable & Clip (if included)

L

NOTE: If the chute rotation is slow or binding, loosen the

chute rotation screws (L, Figure 4) 1/4 turn.

Install the Discharge Chute

NOTE: Some models have the discharge chute already

installed.

Place discharge chute (1. M, Figure 5) over tabs on chute

ring (N) as shown.

Secure discharge chute with three carriage bolts (2. O) and

nuts (P).

M

O

P

P

Figure 5

P

N

Figure 6

Figure 7

3. Tighten hardware to 66 in-lbs (7.6 Nm).

4. Connect the wire harness (electric chute models only).

NOTE: Check all bolts and nuts in fl ange for tightness. Do not

overtighten.

Page 3

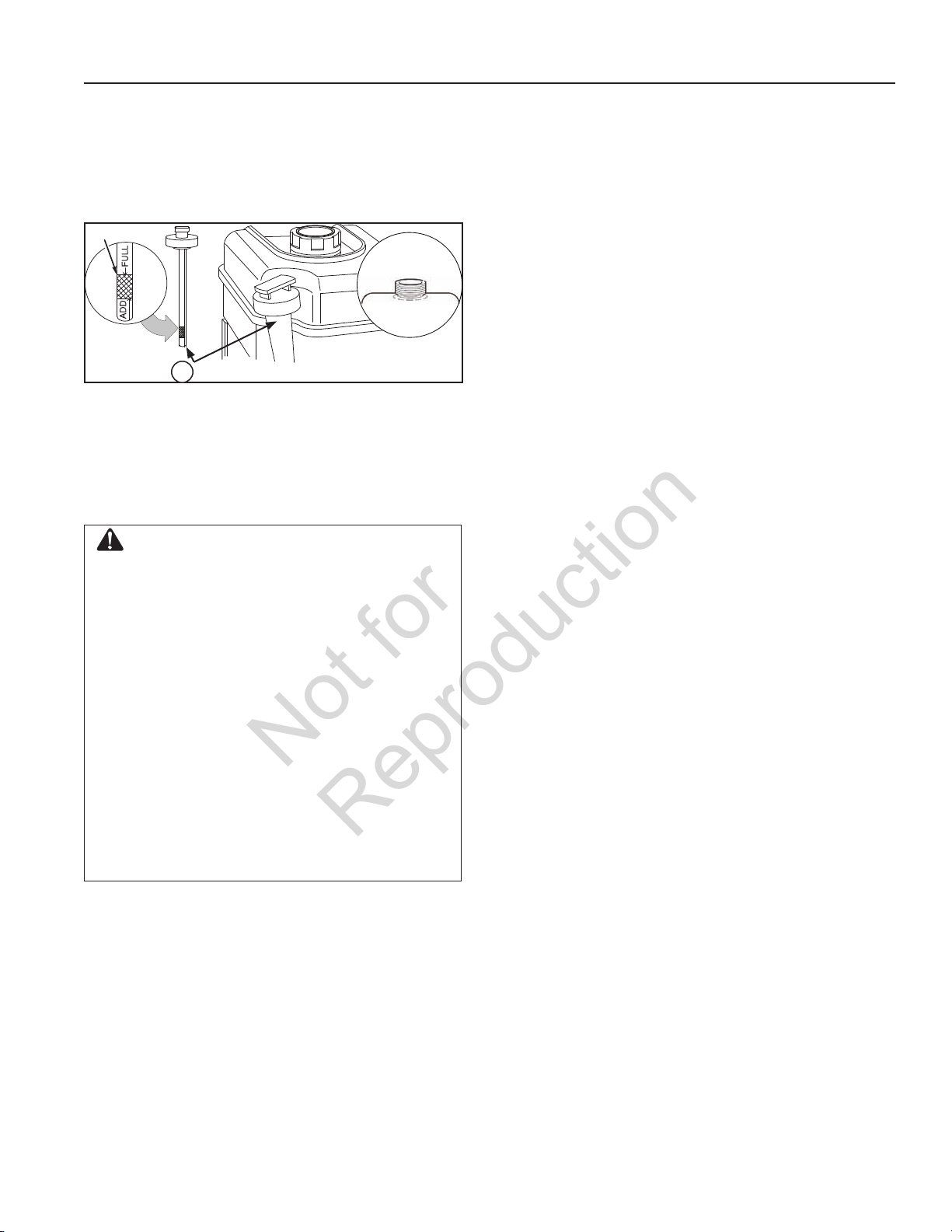

CHECK OIL LEVEL

Not for

Reproduction

Remove oil dipstick (Q, Figure 8). Check oil level. Oil level

should be between FULL and ADD marks. Add oil if required

(See Operator’s Manual). Reinstall oil dipstick.

FULL

Q

Figure 8

Check the Tires

Check tires for damage. Check the air pressure in the tires

with an accurate gauge. See the sidewall of the tire for the

proper infl ation.

WARNING: Avoid Injury! Explosive separation of

tire and rim parts is possible when they are serviced

incorrectly.

• Do not attempt to mount a tire without the proper

equipment and experience to perform the job.

• Do not infl ate the tires above the recommended

pressure.

• Do not weld or heat a wheel and tire assembly. Heat can

cause an increase in air pressure resulting in an

explosion. Welding can structurally weaken or deform

the wheel.

• Do not stand in front or over the tire assembly when

infl ating. Use appropriate tool that allows you to stand

to one side.

NOTICE: Check side of tire for maximum tire pressure.

DO NOT exceed maximum.

Remove Snow Thrower from Pallet

1. Remove straps that secure snow thrower to pallet.

2. Remove snow thrower from pallet.

3. Adjust the skid shoes so that the scraper bar has 1/83/16” clearance above the ground.

Page 4

Guide d'installation rapide

Not for

Reproduction

AVERTISSEMENT : Portez toujours

des lunettes de sécurité ou des écrans

protecteurs lors de l’assemblage de la

souffleuse à neige.

Mfg. No.

1695734, 1695735, 1695820, 1695821, 1695824, 1695825,

1695826, 1695827, 1695843, 1695853, 1695906, 1695908,

1695964

E

ASSEMBLAGE DES POIGNÉES

1. Dépliez soigneusement la poignée tout en guidant la

tige de commande de vitesse au-dessus du pneu avant

de couper les liens orange.

2. Ramener le levier (A, Figure 1) supérieur à sa position

de marche.

REMARQUE : S'assurer que les raccords aux extrémités

des câbles soient sécurisés dans les trous des leviers de

contrôle. Assurez-vous que les câbles ne sont pas coincés

entre la poignée supérieure et inférieure.

3. Insérez deux boulons (B) dans les trous inférieurs et

attachez à l’aide des deux rondelles (C) et des boutons

à ailettes (éventuellement). Serrez à fond les quatre

boutons.

4 À l’aide des liens noirs fournis, attachez le câble EZ

Steer™ à la poignée gauche et le faisceau de câbles

à la poignée supérieure droite.

A

B

B

G

H

D

Figure 2

INSTALLER LA TIGE DE COMMANDE CHUTE

REMARQUE :Certains modèles sont munis d'une commande de

goulotte pré-installée. Les modèles munis de goulotte électri-

que n'ont pas de tige de contrôle.

Insérer le guidon de contrôle de goulotte (si équipé) dans 1.

l'ouverture du panneau de commande du guidon supérieur.

Insérer l'extrémité de la tige de contrôle de goulotte (2. I) dans

l'ensemble de joint universel (J) situé près de l'engrenage de

la goulotte. Sécuriser avec une goupille en épingle à cheveux

(K).

K

F

I

C

C

Figure 1

INSTALLATION DE LA TIGE DE COMMANDE DE VITESSE

Attachez le joint sphérique (D, Figure 2), situé à l’extrémité

inférieure de la tige de commande de vitesse (E) à

l’assemblage de fourchette de boîte (F) avec une rondelle

frein de 5/16 po (G) et un écrou de 5/16 po (H). Serrez

l’écrou à fond..

J

Figure 3

Page 5

L

Not for

Reproduction

Figure 4

REMARQUE : Si la rotation de la goulotte est lente

ou grippée, desserrez les vis de rotation de goulotte

(L, Figure 4) d’un 1/4 de tour.

Placez la goulotte d’éjection (1. M, Figure 5) sur les

pattes de l’anneau de goulotte (N) selon l’illustration.

Attachez la goulotte d’éjection à l’aide de trois boulons 2.

de carrosserie (O) et des écrous (P).

Acheminer le câble du dé ecteur et le clip

(si inclus)

Figure 6

M

P

P

Figure 5

3. Serrez la quincaillerie avec 66 in-lb (7.6 Nm).

4. Connecter le faisceau de câbles (modèles à gou-

lotte électrique uniquement).

NOTE: Véri ez tous les boulons et les écrous une fois

apposés pour serrage. NE PAS trop serrer.

O

P

N

Figure 7

Page 6

VÉRIFIEZ LE NIVEAU D’HUILE

FULL

Not for

Reproduction

1. Retirez la jauge d’huile (Q, Figure 8). Véri ez le niveau

d’huile. Le niveau d’huile doit être entre les marques

PLEIN et AJOUTER. Réinstaller la jauge d'huile.

Q

Figure 8

VÉRIFICATION DES PNEUS

Véri ez les pneus pour dommage. Véri ez la pression d’air

des pneus avec une jauge. Veuillez voir le anc de pneu

pour le gon age adéquat.

AVERTISSEMENT : Évitez les blessures! Lorsqu’elles sont mal

entretenues les pièces des pneus et des jantes risquent de se

séparer avec une force explosive.

• N’essayez pas de monter une roue sans

l’équipement approprié et l’expérience pour

exécuter le travail.

• Ne gon ez pas les pneus plus que la pression

recommandée.

• Ne soudez ou ne chauffez pas la roue complète.

La chaleur peut causer une augmentation de

pression d’air résultant en une explosion. La

soudure peut faiblir ou déformer la structure de

la roue.

• Ne restez pas debout devant ou ne penchez

pas au-dessus de la roue complète lors du

gon age. Utilisez des outils appropriés qui vous

permet de tenir debout latéralement.

AVIS: Véri ez le anc du pneu pour pression d’air

maximum. NE PAS excéder le maximum.

ENLEVER LA SOUFFLEUSE À NEIGE DE LA PALETTE

1. Retirez les sangles qui xent la souffleuse à neige à la

palette.

2. Retirez la souffleuse à neige de la palette.

3. Réglez les patins pour que la barre de raclage ait un

dégagement de 3,2 mm à 4,8 mm (1/8 po à 3/16 po)

au-dessus du sol.

Page 7

Not for

Reproduction

Page 8

Not for

Reproduction

Loading...

Loading...