Page 1

How to use this file...(Operators Manuals)

————————————————————————————————————————————–––

Instructions for

Print Vendors (Paper Manuals)

Paper Size: * 11 x 17

* Body—50 lbs brilliant white offset or equivalent.

* Cover—on pre-printed two-tone “Swash” stock.

Press: * Body—1-color, 2-sided

* Cover imprint —1-color, 1-sided

Bindery:* Saddle Stitch, Face Trim

* Face Trim

COVERS: * This file contains several manuals, which differ only in their covers.

* Covers are all present at the beginning of this file.

* Back cover for a particular manual is the page IMMEDIATELY AFTER the front cover.

• Check the front cover for the individual part number (typically a 171xxxx number).

BODY: • The body of the manual is identical, regardless of the cover used.

* REMEMBER: ODD number pages are ALWAYS right hand pages, and EVEN number are ALWAYS

left hand pages.

General: * This instruction page is NOT part of the manual and must NOT be printed.

• Pages labeled with the text “THIS PAGE INTENTIONALLY BLANK” are placement pages ONLY,

and should NOT be printed.

————————————————————————————————————————————–––

If you have further questions on how to utilize this file, please contact

Simplicity Technical Publications Department at (262) 284-8647.

Page 2

THIS PAGE INTENTIONALLY BLANK

Page 3

Attachment

OPERATOR’S

MANUAL

Snowthrower & Hitch

36” Snowthrower

Mfg. No. Description

1691521 36” Snowthrower Attachment

42” Snowthrower

Mfg. No. Description

1691522 42” Snowthrower Attachment

Hitch

Mfg. No. Description

1692040 Hitch, Electric Lift (for Landlord / 1700 / 2700 Series)

1692041 Hitch, Manual Lift (for Broadmoor / 1600 / 2600 Series)

1692622 Hitch, Manual Lift (for Regent / 500 / 2500 Series)

1715020-05

Rev 6/1998

TP 100-2014-05-AT-SMA

Page 4

Simplicity Mfg. Inc.

500 N Spring Street / PO Box 997

Port Washington, WI 53074-0997 USA

© Copyright 1998, Simplicity Manufacturing, Inc.

All Rights Reserved. Printed in USA.

Page 5

1

General

Recommended Accessories

Tire chains and a weight box are recommended when installing

this attachment to your unit. These accessories will improve traction, thereby making the snowthrower more efficient. For additional traction, one wheel weight per wheel is recommended.

Weight added to the tractor should not exceed 35 lbs. per wheel

and 100 lbs. additional weight with the weight box.

For operation on slopes greater than 15% (8.5°), weight box, tire

chains and wheel weights are recommended. Never operate on

slopes greater than 30% (16.7°). See Operation on Slopes, page 3.

NOTE: Large Lift Lever Kit (part no. 1691832) is required for

Regent/2500/500 Series & Broadmoor/LT/2600/1600 Series tractors, if not already factory installed. The Landlord/GT/2700/1700

Series tractors come factory equipped with either the large lift

lever or an electric lift.

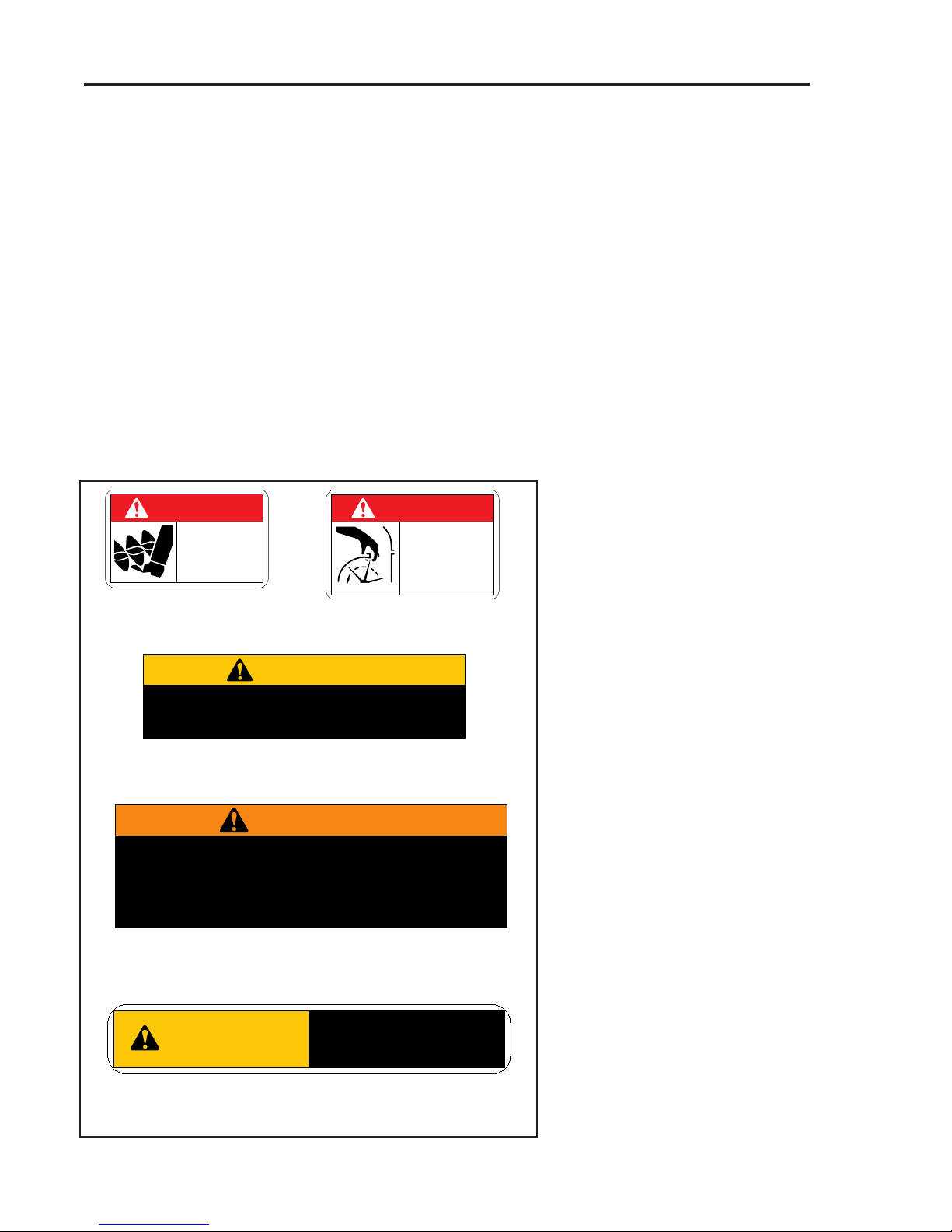

Safety Decals

Part No. 1716532

Auger Danger Decal

Part No. 1716533

Discharge Chute Danger Decal

Part No. 1716531

Main Operation Warning Decal

Part No. 1716536

Spring Tension Caution Decal

OPERATION AND USE

Recommended Accessories .......................1

Safety Decals ................................................1

Safety Rules..................................................2

Operation ......................................................3

Maintenance..................................................5

Belt Replacement .........................................7

Adjustments..................................................7

Belt Tension Adjustment............................7

Skid Shoe Adjustment ...............................7

Lift Rod Adjustment ...................................8

Troubleshooting ...........................................9

ASSEMBLY AND INSTALLATION

Regent / 500 / 2500 Series See Page 10-15

Snowthrower Assembly ...........................10

Hitch Installation ......................................12

Snowthrower Installation .........................14

Broadmoor / 1600 / 2600 Series See Pages 16-20

Snowthrower Assembly ...........................16

Hitch Installation ......................................18

Snowthrower Installation .........................20

Landlord / 1700 / 2700 Series See Pages 22-26

Snowthrower Assembly ...........................22

Hitch Installation ......................................25

Snowthrower Installation .........................26

Standard Torque Specifications ...............29

Standard Fastener Identification ..............30

Lift Lever Kit Installation Instructions......31

NOTE: In these instructions, “left” and “right”

are referred to as seen from the operating

position.

Part No. 1716887

Tire Fluid Caution Decal (Regent Series Only)

© Copyright 1997 Simplicity Manufacturing, Inc.

All Rights Reserved. Printed in USA.

TP 100-2014-05-AT-SMA

DANGER

AVOID INJURY

FROM ROTATING

AUGER!

Keep hands, feet,

1716532

and clothing away.

DANGER

AVOID INJURY

FROM ROTATING

BLOWER!

Shut off engine

before unclogging

1716533

discharge chute.

CAUTION

SPRING IS UNDER TENSION. RAISE

SNOWTHROWER BEFORE PULLING LEVER

BACK TO DISCONNECT SPRING.

WARNING

TO AVOID SERIOUS INJURY OR DEATH

• Refer to Operator's Manual for Safety and

Operating Instructions.

• Keep all guards and shields in place.

• Stop engine, remove key, and be sure all

moving parts have come to a complete

stop before servicing or unplugging.

CAUTION

• Do not use hands to unplug chute or auger.

• Always direct discharge so as to avoid injury

to persons —or damage to property.

• Never allow anyone in front of the machine

while it is operating.

WHEN OPERATING TRACTOR

WITHOUT SNOWTHROWER ATTACHED,

FLUID IN FRONT TIRES IS REQUIRED.

1716536

1716531

1716887

Page 6

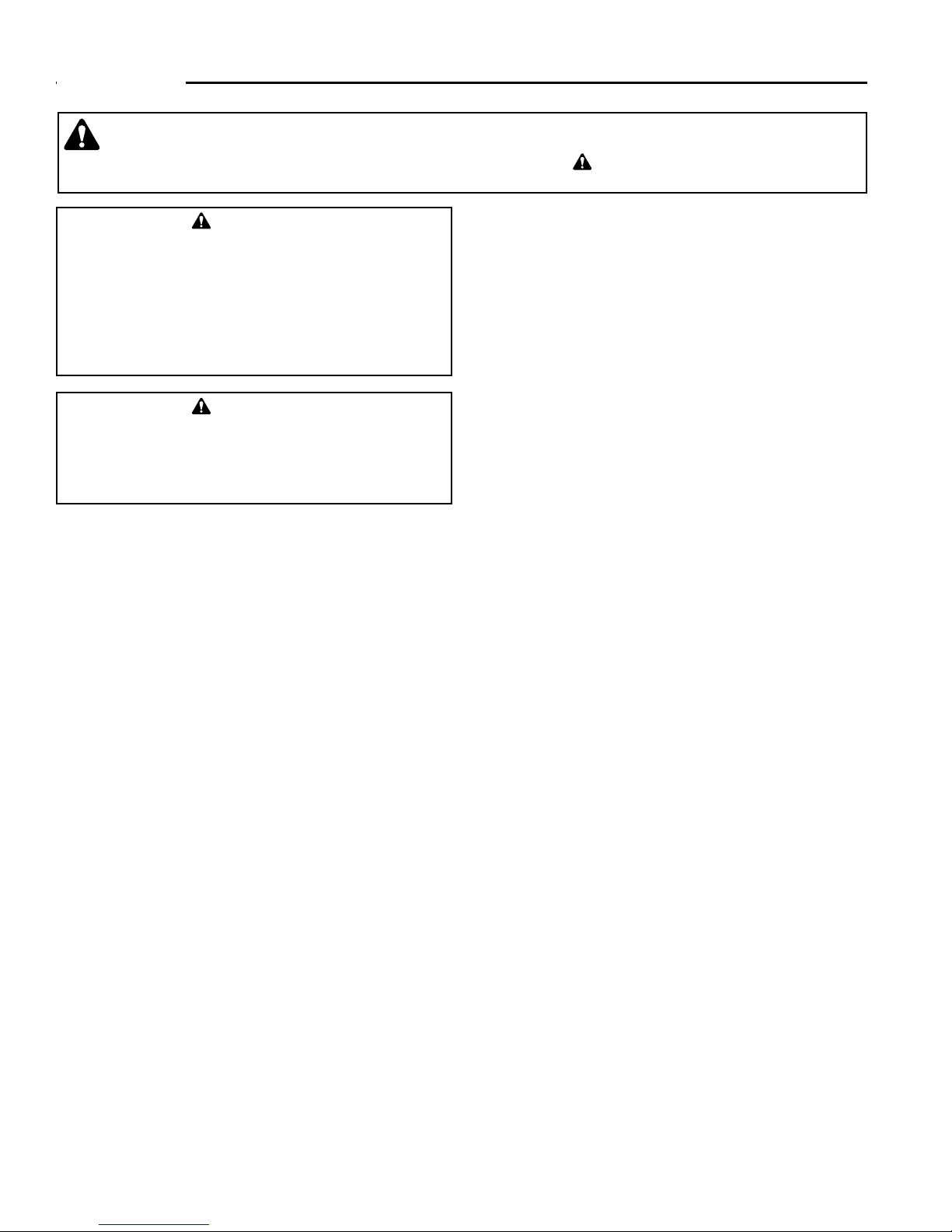

General

• Read this manual and the tractor Operator’s Manual

carefully. Be thoroughly familiar with the controls and

the proper use of the equipment.

• Never pull the spring-assist tension lever back unless

snowthrower is in fully raised position. The spring is

under tension when snowthrower is in lowered position.

• Never allow children to operate the machine. Do not

allow adults to operate it without proper instruction.

• Do not carry passengers.

• Use only attachments or accessories designed for

your machine. See your dealer for a complete list of

recommended attachments or accessories.

• Keep the area of operation clear of all persons, particularly small children, and pets.

• Never direct discharge chute towards bystanders.

• Make sure all hardware is secure and that

snowthrower is in good operating condition.

• Check to be sure all safety devices and shields are in

place.

• Check that all adjustments are correct before using

this unit.

2

Safety Rules

Read these safety rules, and the safety rules in your tractor Operator’s Manual, and follow them

closely. Failure to obey these rules could result in loss of control of vehicle, severe personal injury

to yourself, or damage to property or equipment. The triangle in the text signifies important cau-

tions or warnings which must be followed.

WARNING

If the auger stalls or the chute plugs, disengage the

electric clutch (PTO), stop the engine and remove the

key. set the parking brake. wait for moving parts to

stop. Remove the foreign object or clear the chute with

a piece of wood before restarting the engine. Never

place hands into blower housing to clear jammed

object. Auger may rotate when object is removed.

WARNING

For operation on slopes greater than 15% (8.5°),

weight box, tire chains and wheel weights are recommended. Never operate on slopes greater than 30%

(16.7°).

Preparation

• Never attempt to make any adjustments while engine

is running.

• Thoroughly inspect the area where the snowthrower

is to be operated and remove all foreign objects.

• Adjust the skid shoe height to clear gravel or crushed

stone surface. See the Maintenance and Adjustments

section for procedure.

Operation

• Always clear snow up and down the face of slopes,

never across the face. Exercise extreme caution

when changing direction on slopes. Do not attempt to

clear steep slopes.

• Exercise extreme caution when operating on, or

crossing, gravel drives, walks or roads. Stay alert for

hidden hazards or traffic.

• After striking an object or if unit starts to vibrate

abnormally, stop the engine, disengage the PTO, and

remove the key. Check for the cause and any damage before restarting. Before any inspection, make

sure all moving parts have stopped.

• Take all possible precautions before leaving operator’s position. Disengage the PTO, lower the attachment, set the parking brake, stop the engine and

remove the key.

• Never operate the snowthrower near glass enclosures, automobiles, window wells, dropoffs, etc.,

without proper adjustment of discharge angle.

• Do not overload machine capacity by attempting to

clear snow at too fast a rate.

• Never operate unit at high transport speeds on slippery surfaces. Use care when travelling in reverse.

• Disengage power to snowthrower when transporting

or not in use.

• Never operate the snowthrower without good visibility

or light. Always be sure your feet are properly placed

on the footrests and keep a firm hold on the steering

wheel.

Page 7

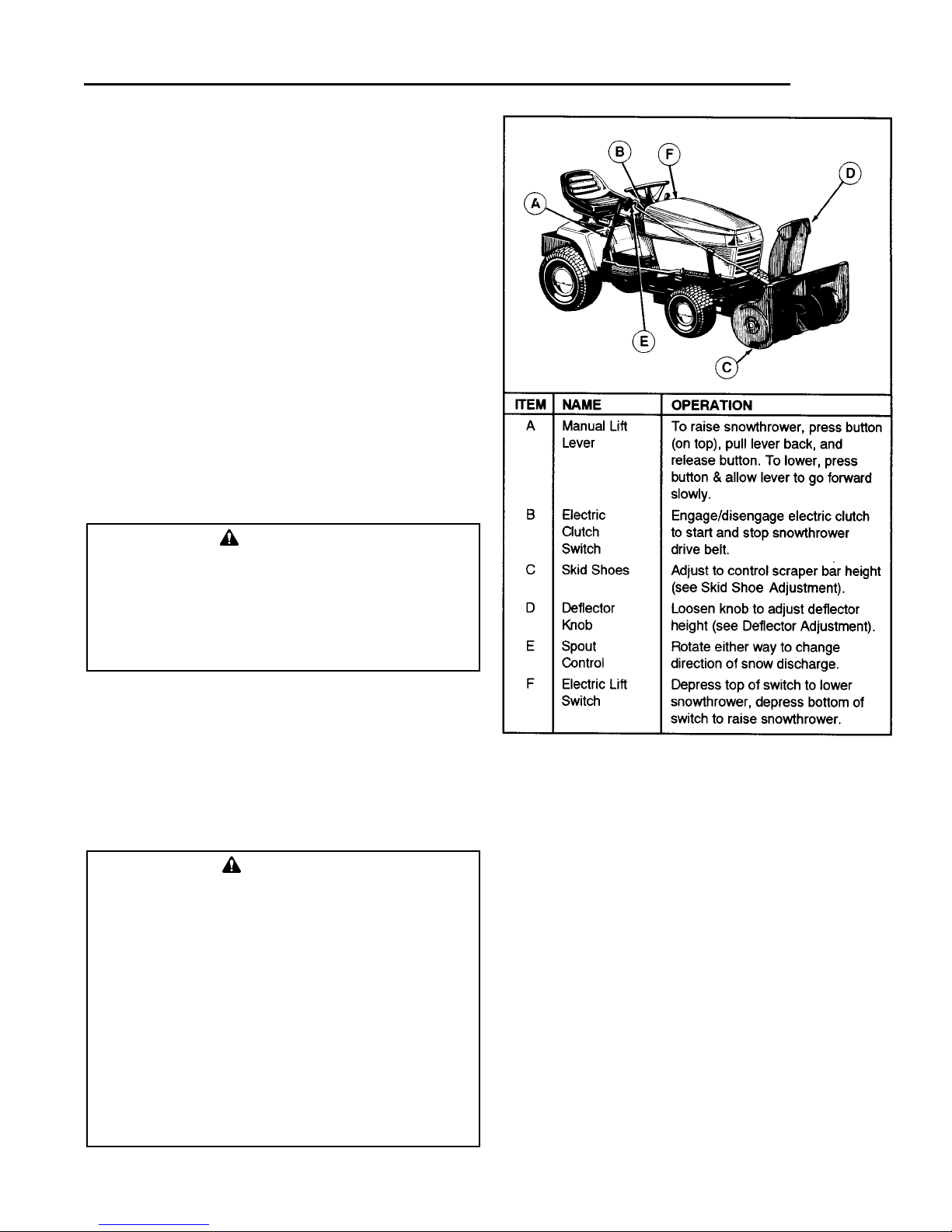

Controls

Read and understand the instructions in your tractor

Operator’s Manual.

See Figure 1 for location, name, and description of the

snowthrower controls.

Checks Before Starting

1. Refer to the Maintenance & Adjustments section of

this manual and perform any needed service. Also,

refer to the tractor Operator’s Manual and perform

any required service.

2. Remove any objects from the work area which might

be caught in, or thrown by, the auger.

3. Before starting the engine, clear the auger of any ice

particles which may cause damage to auger.

4. Adjust the deflector and skid shoes to desired height.

See Skid Shoe Adjustment and Deflector Adjustment.

5. Make sure all hardware is present and secure.

Figure 1. Snowthrower Controls

WARNING

• Never operate on slopes greater than 30%

(16.7o), which is a rise of three feet (.9m) vertically in 10 feet (3.1m) horizontally.

• When operating on slopes greater than 15%

(8.5o), one wheel weight on each rear wheel and

tire chains are recommended.

• Select slow ground speed before driving onto a

slope. Avoid using brakes to control speed.

• Drive up and down the face of the slopes, never

across the slope face.

• Use caution when changing directions and DO

NOT START OR STOP ON A SLOPE.

WARNING

Perform the Safety System Interlock test found in

your tractor Operator’s Manual. If tractor does not

pass the test, do not operate the tractor. See your

authorized dealer. Under no circumstances should

you attempt to defeat the safety system.

Operating On Slopes Transporting

1. Disengage the electric clutch and then raise the

snowthrower.

2. Adjust ground speed according to surface conditions.

3. Select a low ground speed when transporting on a

slippery surface.

Engine & Ground Speed Selection

Always run the engine at full throttle.

Normally, a low ground speed is best for throwing snow.

The deeper or heavier the snow, the slower the recommended ground speed.

3

Operation

Page 8

4

Operation

Starting & Stopping

1. Start the tractor engine. Set engine throttle at 1/2

speed.

2. Lower the snowthrower.

3. Engage the electric clutch switch. Snowthrower auger

should rotate. Disengage the electric clutch switch.

snowthrower auger should stop.

4. Adjust the engine speed to full speed. Select the

proper ground speed.

5. To stop the tractor, depress the clutch/brake pedal.

To stop the snowthrower, disengage the electric

clutch. Before leaving the seat, stop the engine, disengage the electric clutch, set the parking brake,

remove the key, and wait for all moving parts to stop.

Snow Removal Suggestions

• Determine the best snow removal pattern before

beginning.

• Wind direction is an important factor to consider.

Rotate the spout to discharge snow downwind.

• Plan the pattern so that you avoid throwing snow on

cleared areas and on yourself as your are operating.

• When land contour permits, it is best to travel in the

longest direction to minimize turning.

• In very deep or heavy snow, it may be necessary to

make the first pass with snowthrower partially raised,

backing up every few feet to clear the snow left on

the surface. Also, it may be necessary to slice off less

than the full width of the auger or reduce ground

speed.

• If snow stops flowing freely from the spout, back

away until the snowthrower clears itself.

CAUTION

Always raise the snowthrower before turning or

backing up, to prevent damage to the unit.

WARNING

If auger does not start and stop when

engaging/disengaging electric clutch, see your

authorized dealer. Under no circumstances should

you attempt to defeat the safety system.

WARNING

If the auger stalls or the chute plugs, DISENGAGE

THE ELECTRIC CLUTCH, STOP THE ENGINE AND

REMOVE THE KEY. SET THE PARKING BRAKE.

WAIT FOR MOVING PARTS TO STOP. Remove the

foreign object or clear the spout with a piece of

wood before restarting the engine. Never place

hands into auger housing or spout to clear

jammed object. Auger may rotate when object is

removed.

Snowthrower & Hitch Removal

Remove the snowthrower and hitch in the reverse order

of installation. Note the following:

• Always remove the 4-link chain from the spring assist

bracket to prevent interference with front steering

components.

• Use caution when removing the spring from the

spring-assist lever and chain. Snowthrower must be

in fully raised position to relieve spring tension.

• Whenever removed, install clevis pins, hitch pins,

clips and hardware onto snowthrower and hitch for

storage.

Daily Storage

1. Run the snowthrower a few minutes after blowing

snow to prevent freeze-up of auger and impeller.

2. Allow tractor engine to cool before storing in any

enclosure.

Off-Season Storage

1. Remove snowthrower from the tractor. Hitch can

remain installed if other attachments are to be used.

2. Use water pressure or a brush to thoroughly clean

the housing.

3. Paint, or lightly coat with oil, any area where paint

has been worn or chipped away.

4. Lubricate the snowthrower.

5. Store the snowthrower and hitch in a dry place.

WARNING

To prevent an explosion or fire, never store the

tractor with fuel in the tank inside a building where

an ignition source is present.

Page 9

5

Maintenance

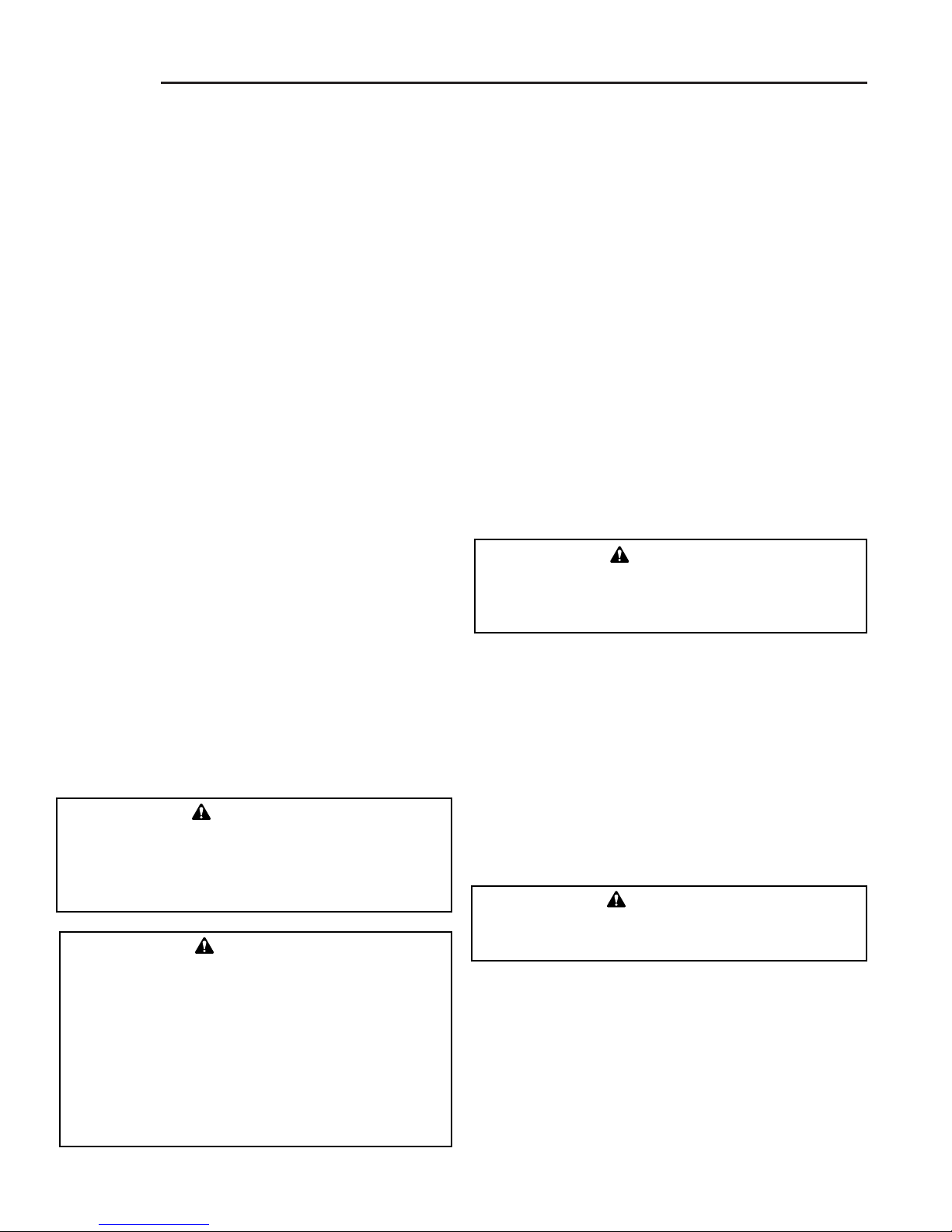

Figure 2. Drive Chain

A. Screws D. Screw G. Drive Shaft Sprocket J. Chain

B. Flange Nut E. Chain Guard H. Spacers K. Auger Sprocket

C. Clamps F. Nuts I. Nuts L. Drive Shaft Housing

Schedule For Normal Care

Care Required Schedule

Clean snow and ice from After each use.

snowthrower.

Lubricate snowthrower. Every 10 hours or at

least once a year.

Adjust belt tension. Every 25 hours or at

least once a year.

Inspect, adjust and Once a year or more

lubricate drive chain. often under frequent

use.

Inspect, Adjust & Lubricate Drive Chain

See Figure 2.

1. Remove the two nuts (F) and chain guard (E).

2. Check the chain for wear or damage. Replace chain

if worn or damaged.

3. There should be no slack in the chain, and the

sprockets (G and K) should be aligned. The drive

shaft housing (L) should be parallel with the auger

housing. If adjustment is required proceed with steps

4 - 7.

4. Loosen the four screws (A).

5. Pull rearward on the drive shaft housing (L) until all

slack is removed from chain. With drive shaft housing

parallel with auger housing, and sprockets aligned,

retighten the four screws (A). Torque to 40-50 ft. lbs.

6. Spread a coat of grease on the chain, working the

grease into the links.

7. Reinstall the chain guard (E) and two nuts (F).

WARNING

To avoid serious injury, perform maintenance on

the tractor or snowthrower only when the engine is

stopped, parking brake is set and all moving parts

have stopped. Always remove the ignition key

before beginning maintenance or adjustments to

prevent accidental starting of the engine.

Page 10

6

Maintenance

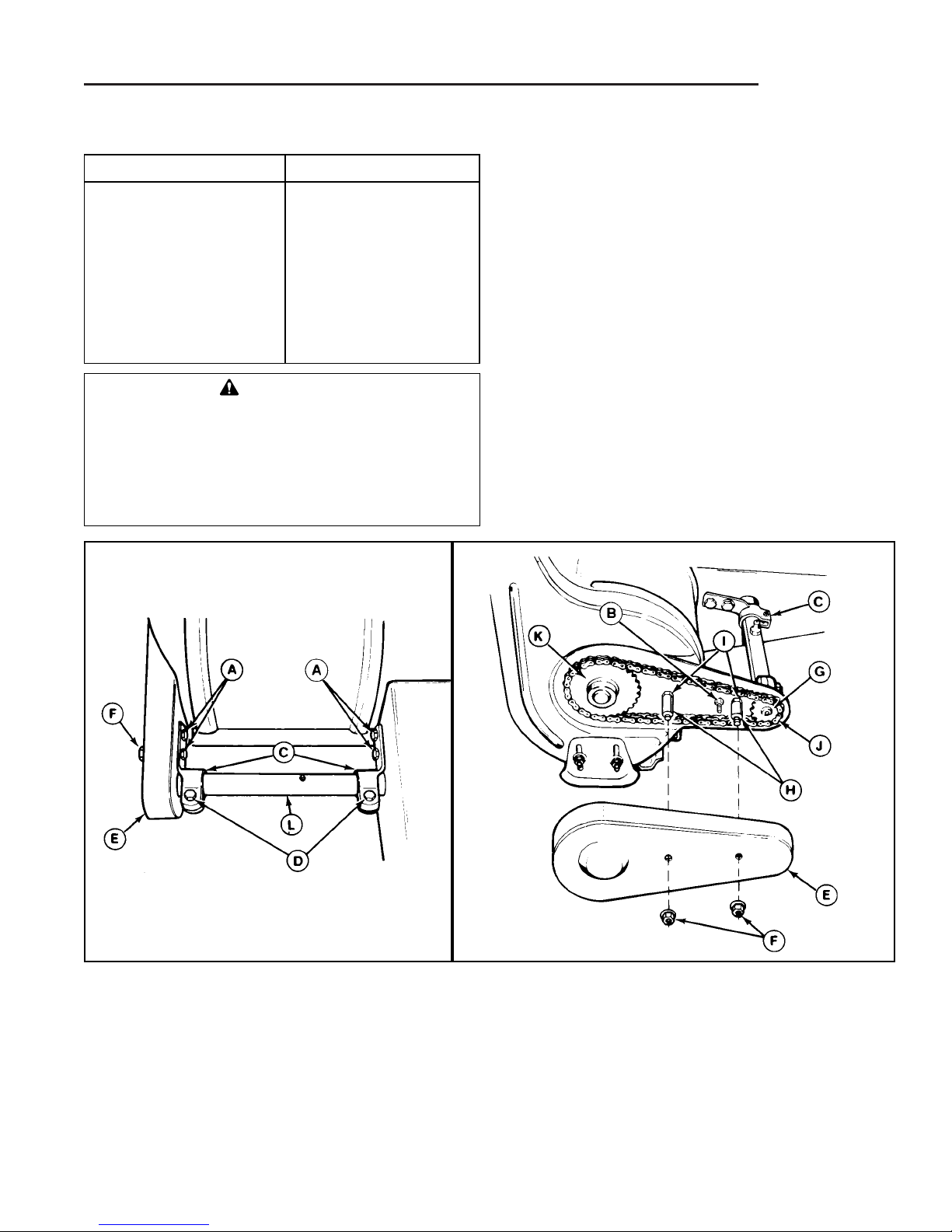

Figure 3. Lubricate Drive Shaft & Auger Shaft

Lubricate Snowthrower

Page 11

7

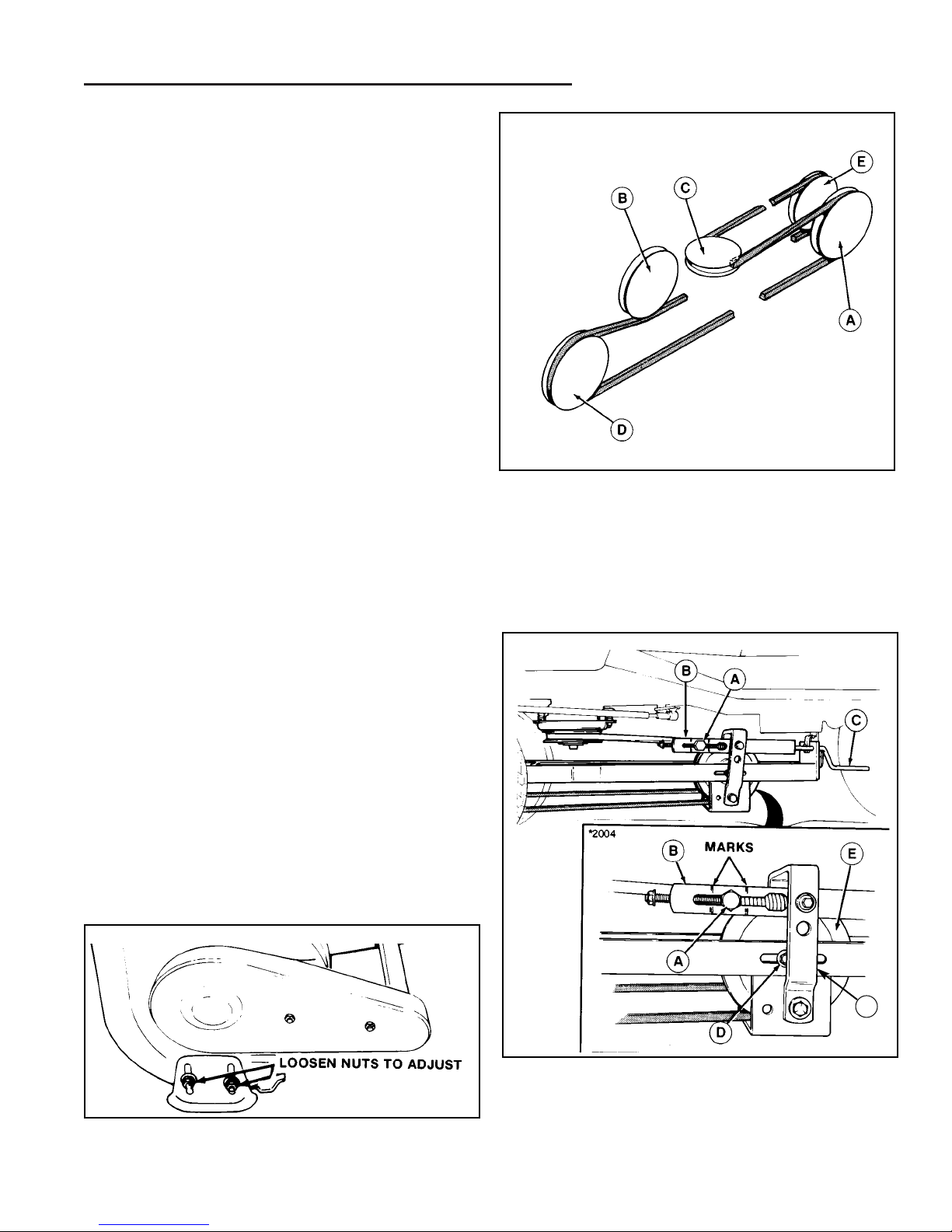

Belt Replacement / Adjustment

Figure 6. Adjusting Skid Shoes

Figure 4. Belt Routing

A. V-Pulley

B. Idler Pulley

C. Electric Clutch Pulley (V-pulley)

D. Snowthrower Pulley (V-pulley)

E. Idler Pulley

Figure 5. Adjusting Belt Tension

A. Trunion D. Capscrew

B. Spring Tension Bracket E. Idler Pulley

C. Handle F. Pivot Bracket

F

BELT REPLACEMENT

1. Loosen the drive belt by turning the handle (C, Figure

5).

2. Remove the belt from the pulley (D, Figure 4) inside

the snowthrower and remove the snowthrower from

the tractor.

3. Loosen the lockwashers and nuts securing two belt

stops on idler pulleys (A and E, Figure 4).

4. Install new belt as shown.

5. Retighten belt stops and adjust the belt tension.

ADJUSTMENTS

Belt Tension Adjustment

See Figure 5.

1. With the snowthrower drive belt installed, trunion (A)

should be between marks on spring tension bracket

(B) for correct belt tension.

2. Turn belt tension handle (C) to move trunion forward

or rearward until within between marks.

3. If trunion cannot be placed between marks, loosen

capscrew (D) and reposition idler pulley (E) as necessary. The pivot bracket (F) should be perpendicular to

snowthrower hitch. Retighten capscrew (D) and

repeat step 2.

Skid Shoe Adjustment

On smooth surfaces such as concrete or asphalt, the

scraper bar should scrape the surface. On surfaces

such as gravel, the scraper bar should be set high

enough so that it will not pick up debris.

1. Loosen the nuts securing the skid shoes (see Figure

6).

2. Raise or lower the scraper bar to the desired height.

Use wood blocks to hold the snowthrower in position.

3. Set the skid shoes so that they are in contact with the

ground and tighten the skid shoe nuts.

Page 12

8

Adjustment

Lift Rod Adjustment

MANUAL LIFT MODELS

The lift lever can be placed in one of three notches and

is held in position by the lever latch. (see Figure 8).

When the lever latch is placed in notch 1 the lift lever

should be applying downward pressure on the

snowthrower. In position 2, the “float” position, the

snowthrower/plow should experience negligible upward

or downward pressure. Position 3 should raise the

snowthrower approximately 3 to 3-1/2 “ above the

ground.

ELECTRIC LIFT MODELS:

In the fully raised position the snowthrower should be 3

to 3-1/2” off the ground. In the fully lowered position, the

lift rod should slightly compress the spring (C, Figure 7)

creating downward pressure on the snowthrower. If the

snowthrower tilts excessively to one side you may want

to install the spring assist (see installation instructions).

The spring assist is not required on electric lift models.

NOTE: Always adjust the lift height before and after

adjusting the downward pressure.

Lift Height Adjustment

1. Place the lever latch in notch 3 or fully raise the electric lift (see Figure 8). The snowthrower should be

approximately 3 to 3-1/2” off the ground. If not, go to

step 2.

2. Lower the snowthrower and adjust the front set collar

(A, Figure 7) to achieve the correct lift height.

Downward Pressure Adjustment

1. Move the lever latch from notch 2 to notch 1 (See

Figure 8) or fully lower the electric lift.

2. The spring (C, Figure 7) should be slightly compressed applying downward pressure to the

snowthrower. If not, adjust the rear set collar (D,

Figure 7) to achieve the desired amount of downward

force. Do not over-compress the lift rod spring.

Figure 7. Adjusting Lift Rod

A. Front Set Collar

B. Rod Guide

C. Spring

D. Rear Set Collar

E. Spring Clip

Figure 8. Lift Lever Quadrant - Side View

Notch 1

Notch 2

Notch 3

CAUTION

Do not over-compress the lift rod spring. In addition

to providing downward pressure, the spring is an

elastic medium that absorbs shocks caused by

bumps and cracks in ground surfaces. Over-compressing the spring defeats this and could cause

damage to the unit.

Page 13

9

Troubleshooting

PROBLEM

1. Snowthrower auger does not rotate.

2. Auger does not stop when electric clutch is

disengaged.

3. Auger rotates, but snow is not thrown far

enough.

4. Scraper bar does not clean down to hard

surface.

5. Snowthrower picks up and throws stones on

gravel drive.

6. Tractor does not have sufficient traction.

7. Tractor not stable on sloping surfaces.

Locate the problem you’ve encountered in the chart below. Check the possible causes one at a time in the order listed. Correct any problems that are found and operate the snowthrower to see if you have eliminated the problem.

WARNING

To avoid serious injury, perform maintenance on the tractor or snowthrower only when the engine is

stopped, parking brake is set, and all moving parts have stopped. Always remove the ignition key before

beginning maintenance or adjustments to prevent accidental starting of the engine.

CAUSE/SOLUTION

A. Electric clutch not engaged. Engage electric clutch.

B. Foreign material is blocking auger. STOP engine. Remove key.

Unplug auger with piece of wood. Read WARNING on page 4.

C. Snowthrower drive belt slipping. Adjust drive belt tension.

D. Drive chain broken. Replace parts as required.

A. Electric clutch brake not operating properly. See your local

dealer. See WARNING under Stopping & Starting, page 4.

A. Engine RPM too slow. Operate engine at full speed.

B. Ground speed too fast. Use slow ground speed.

C. Snowthrower discharge spout clogged. STOP engine. Remove

key. Unplug discharge spout. Read WARNING on page 4.

A. Skid shoes not properly adjusted. Adjust skid shoes.

B. Lift rod out of adjustment. Adjust lift rod.

A. Skid shoes not properly adjusted for ground surface. Adjust

skid shoes.

B. Too much downward pressure on snowthrower. Raise

snowthrower slightly.

C. Lift rod out of adjustment. Adjust lift rod.

A. Tractor too light at rear wheels. Use wheel weights and chains.

A. Ground speed too fast. Reduce speed.

B. Tractor not properly weighted. See Recommended

Accessories, page 1.

C. Tire pressure incorrect. Front tires should be inflated to 20 psi

(138 kPa) for snowthrower use.

D. Slope grade too steep. See Operation On Slopes, page 3.

Page 14

10

Figure 9. Discharge Chute & Controls

A. Discharge Chute F. 1" Capscrew & Locknut

B. Rod Guide Liner G. Clip

C. Rod Guide H. Dis. Chute Control Rod

D. Pivot Bearing I. Notch

E. Support Arm J. 3-1/2" Capscrew & Locknut

K. Spacer

CAUTION

Do not let the pivot bearing (D, Figure 9) support

the weight of the control rod or the bearing could

be damaged.

SNOWTHROWER ASSEMBLY

Assemble Support Arm and Control Rod

1. See Figure 9. Attach the support arm (E) to the

frame with the 1" capscrews and locknuts (F) supplied.

2. See Figure 9. Place the the thin, plastic liner (B)

inside the rod guide (C). Place the rod guide (C) over

the discharge chute control rod (H) and loosely

attach the guide to the support arm (E) in either of

the top two mounting holes. Use the capscrew and

locknut (J) and spacer (K) provided.

3. See Figure 9. Install the discharge chute control rod

(H) through the plastic pivot bearing (D) on the auger

housing. Place a cotter pin into the lowest rod hole

on the inside of the housing, and spread the cotter

pin fully around the rod.

4. Pull the rod back so the cotter pin is resting against

the bearing (D), then insert a second cotter pin

through the rod, just above the bearing. Spread the

cotter pin fully around the rod.

5. Tighten the locknut and capscrew (J) securing the

control rod guide. Do not overtighten. This nut and

capscrew are used to set the control rod rotation

resistance.

Assemble Discharge Chute & Control Cable

1. See Figure 9. Install the discharge chute (A) so the

clip (G) on the housing is positioned in the notch (I).

Lubricate the discharge chute so it turns freely.

2. See Figure 10. With the discharge chute facing

slightly left, wind the cable around the control rod

spool. Wind it three turns on the rear part of the

spool so that the cable leaves the spool on the lower

edge as shown. Wind two turns on the front part of

the spool so the cable leaves the spool on the upper

edge as shown.

3. See Figure 10. Place the looped end of the cable

over the stud on the discharge chute. Place the small

flat washer (E) provided on the stud. Pull the other

end of the cable around the stud using locking pliers.

While holding the cable tight, install the cup washer

(B) (cup facing inward), lockwasher (C) and nut (D).

Tighten the nut and tape the cable end to the taut

section of the cable.

Figure 10. Control Cable

A. Cotter Pin C. Lockwasher

B. Cup Washer` D. Nut

E. Flat Washer

K

Regent Snowthrower Assembly

Page 15

11

Regent Snowthrower Assembly

Assemble Hitch Brackets and Up-Stops

Refer to Figure 11 for up-stop orientation.

1. Mount the hitch bracket to the inside of the

snowthrower and the up-stop bracket to the outside

of the snowthrower using capscrews and flange locknuts as shown in Figures 11 - 14.

Be sure the up-stop bracket is oriented correctly (see

Figure 11).

Figure 12. Hole Pattern - Left Side

Figure 13. Hole Pattern - Right Side.

NOTE: Support Arm Removed For Clarity

Figure 14. Install the Hitch Brackets and Stop

Brackets

A. Hitch Brackets C. Flange Locknut

B. Capscrew, 1" D. Up-Stop Bracket

Figure 11. Up-stop Bracket Orientation

Hitch Bracket

(Mounted On

Inside)

Hitch Bracket

(Mounted On

Inside)

Up-stop

Up-stop

Up-stop

Page 16

12

Figure 15. Spout Deflector

A. Washer, 5/16 F. Spacer

B. Knob G. Washer, 5/16

C. Deflector H. Screw, 5/16

D. Nut, 5/16 I. Carriage Bolt, 5/16

E. Lockwasher, 5/16

Assemble the Deflector

Refer to Figure 15.

1. Attach the deflector (C) to the discharge chute with

two screws (H), washers (G), spacers (F), washers

(A), lockwashers (E) and nuts (D).

2. Position the bolt (I) and washer (A), then thread the

knob (B) onto the bolt (I).

Figure 16. Installing Hitch to Front of Tractor

A. Hitch Bar D. Tractor Brackets

B. Hitch Pin E. Up-Stop Brackets

C. Safety Clip

HITCH INSTALLATION

NOTE: If your tractor is not equipped with the Large Lift

Lever, part no.1692623, install it at this time. Follow the

instructions supplied with the kit (a copy of the instruction sheet can be found in the back of this manual). The

rear hitch bracket, washers, and hairpin clips (B, C, D,

Figure 17) need to be installed with the left lever kit. The

pivot bar of the lift lever kit goes through the rear hitch

bracket and washers.

1. Increase front tire pressure to 20 psi (138 kPa) to

compensate for added weight. Be sure both tires

have equal pressure.

2. From the front of tractor, slide the hitch under the

tractor.

3. See Figure 16. Turn the wheels fully left and lift the

front hitch bar (A) up onto the tractor bracket (D).

Make sure it is seated fully into the tractor bracket.

Install the long hitch pin (B) through the up-stop

brackets (E, one on each side) and hitch. Secure the

pin with a safety clip (C).

E

D

Regent Hitch Installation

Page 17

13

Figure 17. Hitch Assembly

A. Hitch Assembly

B. Rear Hitch Bracket

C. Washers (Qty. 2)

D. Hairpin Clip (Qty. 2)

E. Pin

F. Spring Clip (Qty. 4)

G. Clevis Pin, 3/8 (Qty. 2)

H. Rod

I. Reflectors (Qty. 2)

J. Capscrew, 3/8-16 x 2

K. Spacer, 25/64 x 5/8 x 17/64

L. Spacer, 13/32 x 1 x 13/16

M. Nut, Whizlock, 3/8-16

N. Up-Stop Bracket (Qty. 2)

Attach reflectors (I) to rear lip

of seat deck. If snow cab is

installed, make sure reflectors

are not obstructed.

G

F

I

A

E

M

L

K

J

D

C

F

D

C

B

F

G

H

Figure 18. Installing Hitch to Rear Bracket

A. Rear Hitch Bracket F. Clevis Pin

B. Lift Lever Rod G. Capscrew, 3/8-16 x 2

C. Spring Clip H. Spacer, 25/64 x 5/8 x 17/64

D. Washer I. Spacer, 13/32 x 1 x 13/16

E. Hitch J. Nut, Whizlock, 3/8-16

4. See Figure 17. Install the rear hitch bracket (B), hair-

pin clips (D) and washers (C) onto the lift lever shaft,

if not done already.

5. Attach the hitch assembly to the rear hitch bracket

using the clevis pin (F) as shown in Figure 18.

6. Install the capscrew(G), spacers (I, H), and nut (J) as

shown in the Figure 18 inset.

The hitch assembly is now installed on the tractor and

you may proceed to Snowthrower Installation.

N

N

Regent-Hitch Installation

Page 18

14

SNOWTHROWER INSTALLATION

1. See Figure 19. Align snowthrower bracket (D) with

front tractor hitch arms (B). Lift snowthrower so that

up-stop brackets (E) rest on hitch arms (B).

2. Before attaching snowthrower bracket to the hitch,

install the belt from the hitch idler pulley (B, Figure

20) to the snowthrower pulley as shown in Figure 20.

Do not attempt to install the belt on electric clutch pulley at this time.

3. See Figure 19. Attach snowthrower bracket (D) to

hitch using clevis pins (B) and safety clips (A).

Figure 19. Snowthrower Installation

A. Safety Clips D.Snowthrower Bracket

B. Hitch Arms E. Up-Stop Brackets

C. Clevis Pin

Figure 20. Belt Routing

A. V-pulley C. Electric Clutch Pulley (V-Pulley)

B. Idler Pulley D. Snowthrower Pulley (V-Pulley)

E. Backside Idler Pulley

D

B

A

C

PTO Belt Installation and Trunion

Adjustment.

1. See Figure 21. To install the belt on the electric

clutch pulley, the trunion (A) on the tension spring

assembly (B) must be fully forward. Turn the handle

(C) to move the trunion forward and slacken the belt.

If the belt is still too tight, loosen the capscrew (D)

and slide the pulley (E) forward to further slacken the

belt. Install belt on electric clutch pulley. Refer to

Figure 20 for belt routing.

2. See Figure 21. Re-tighten the pulley (E) and capscrew (D) if they were loosened. Turn the handle (C)

so that the trunion (A) is centered between the marks

as shown.

NOTE: If trunion cannot be centered between marks,

loosen the trunion (A), loosen the capscrew (D) and

reposition the pulley (E) further rearward. Re-tighten capscrew (D) and center the trunion.

Figure 21. Belt Installation & Adjustment

A. Trunion D. Capscrew

B. Tension Spring Assembly.. E. Pulley

C. Handle

CAUTION

After snowthrower installation if the tractor hood is

opened, it will come into contact with the

snowthrower. To protect the hood finish cover the

discharge chute with a towel or blanket.

E

E

Regent-Hitch Installation

Page 19

15

Figure 22. Installing Lift Rod to Manual Lift Lever

A. Front Attachment Lift Rod C. Hair Pin Clip

B. Manual Lift Lever

A

B

C

Figure 23. Installing Lift Rod to Snowthrower

A. Rod Guide Assembly

B. Hair Pin Clip

Install lift rod to inside of bracket as shown.

Install the Lift Rod

1. Attach the lift rod assembly to the manual lift lever as

shown in Figure 22 and secure with a hairpin clip.

2. Install the front attachment lift rod to the snowthrower

as shown in Figure 23 and secure with a hair pin clip.

The rod guide assembly (A) may need to be removed

and oriented correctly.

Spring Assist Installation

NOTE: The parts described in the following steps (and

shown in Figures 24 & 25) are packaged with the hitch

assembly.

1. Place the snowthrower in the down position.

2. See Figure 24. Install the spring assist bracket (A)

using the capscrew (D), lockwasher (C), and nut (B)

as shown in Figure 24

3. Place spring assist lever (A Figure 25) in rearward

position. Install spring (B) directly onto spring assist

bracket (A) and on the spring assist lever. No chain

is required.

4. Rotate lever forward so that it travels “over center” to

the fully forward position.

Adjust, Lubricate, and Test Run

1. Adjust the Lift Rod-See Adjustments

2. Adjust the Skids-See Adjustments

3. Lubricate the Snowthrower-See Maintenance.

4. Install the reflectors on the on the rear lip of the seat

deck. If a snowcab is also installed, make sure the

reflectors are not obstructed.

5. Test run and recheck belt tension.

WARNING

Never release the spring assist lever unless the

snowthrower is in the fully raised position. The

spring is under tension when the snowthrower is

in the lowered position.

Figure 25. Spring-Assist Lever

A. Lever B. Spring

A

B

C

D

Figure 24. Spring Assist Bracket

A. Spring Assist Bracket C. Lockwasher

B. Nut D. Capscrew

A

B

Regent-Snowthrower Installation

Page 20

16

16

SNOWTHROWER ASSEMBLY

Assemble Support Arm and Control Rod

1. See Figure 26. Attach the support arm (E) to the

frame with the 1" capscrews and locknuts (F) supplied.

2. See Figure 26. Place the the thin, plastic liner (B)

inside the rod guide (C). Place the rod guide (C) over

the discharge chute control rod (H) and loosely attach

the guide to the support arm (E) in any of the three

mounting holes. Use the 3-1/2" capscrew, locknut

(J), and spacer (K) provided.

3. See Figure 26. Install the discharge chute control rod

(H) through the plastic pivot bearing (D) on the auger

housing. Place a cotter pin into the lowest rod hole on

the inside of the housing, and spread the cotter pin

fully around the rod.

4. Pull the rod back so the cotter pin is resting against

the bearing (D), then insert a second cotter pin

through the rod, just above the bearing. Spread the

cotter pin fully around the rod.

5. Tighten the locknut and capscrew (J) securing the

control rod guide. Do not overtighten. This nut and

capscrew are used to set the control rod rotation

resistance.

Assemble the Discharge Chute and Control

Cable

1. See Figure 26. Install the discharge chute (A) so the

clip (G) on the housing is positioned in the notch (I).

Lubricate the discharge chute so it turns freely.

2. See Figure 27. With the discharge chute facing slightly left, wind the cable around the control rod spool.

Wind it three turns on the rear part of the spool so

that the cable leaves the spool on the lower edge as

shown. Wind two turns on the front part of the spool

so the cable leaves the spool on the upper edge as

shown.

3. See Figure 27. Place the looped end of the cable

over the stud on the discharge chute. Place the small

flat washer (E) provided on the stud. Pull the other

end of the cable around the stud using locking pliers.

While holding the cable tight, install the cup washer

(B) (cup facing inward), lockwasher (C) and nut (D).

Tighten the nut and tape the cable end to the taut

section of the cable.

Figure 26. Discharge Chute& Controls

A. Discharge Chute F. 1" Capscrew & Locknut

B. Rod Guide Liner G. Clip

C. Rod Guide H. Dis. Chute Control Rod

D. Pivot Bearing I. Notch

E. Support Arm J. 3-1/2" Capscrew & Locknut

K. Spacer

Figure 27. Control Cable

A. Cotter Pin C. Lockwasher

B. Cup Washer` D. Nut

NOTICE

Do not let the pivot bearing (D, Figure 26) support

the weight of the control rod or the bearing could

be damaged.

Broadmoor-Snowthrower Assembly

K

Page 21

Assemble the Deflector

1. See Figure 28. Attach the deflector (C) to the discharge chute with two screws (H), washers (G), spacers (F), washers (A), lockwashers (E) and nuts (D).

2. Position the bolt (I) and washer (A), then thread the

knob (B) onto the bolt (I)

Assemble the Hitch Brackets and Spacers

1. Mount the hitch brackets and spacer to the inside of

the snowthrower capscrews and flange locknuts as

shown in Figures 29 - 31.

17

Broadmoor Snowthrower Assembly

Figure 28. Discharge Chute

A. Washer, 5/16 F. Spacer

B. Knob G. Washer, 5/16

C. Deflector H. Screw, 5/16

D. Nut, 5/16 I. Carriage Bolt, 5/16

E. Lockwasher, 5/16

Figure 29. Installing the Hitch Brackets and Spacers

A. Hitch Brackets E. Capscrew, 1-1/4"

B. Capscrew, 1" F. Lockwasher

C. Locknut, Flange G. Nut

D. Spacers

Figure 30 Hole Pattern - Left Side

Figure 31. Hole Pattern - Right Side.

NOTE: Support Arm Removed For Clarity

Hitch Bracket

(Mounted On

Inside)

Hitch Bracket

(Mounted On

Inside)

Spacer

(Mounted On

Inside)

Spacer

(Mounted On

Inside)

Page 22

HITCH INSTALLATION

NOTE: If your tractor is not equipped with the Large Lift

Lever, part no.1691832, install it at this time. Follow the

instructions supplied with the kit (a copy of the instruction sheet can be found in the back of this manual). The

rear hitch bracket, washers, and hairpin clips (B, C, D,

Figure 34) need to be installed with the left lever kit. The

pivot bar of the lift lever kit goes through the rear hitch

bracket and washers.

1. Increase front tire pressure to 20 psi (138 kPa) to

compensate for added weight. Be sure both tires

have equal pressure.

2. From the front of tractor, slide the hitch under the

tractor.

3. See Figure 33. Turn the wheels fully left and lift the

front hitch bar (A) up onto the tractor brackets (D).

Make sure it is seated fully into the tractor brackets.

Install the long hitch pin (B) through the bracket (bottom rear holes) and secure it with the safety clip (C).

Figure 33. Installing Hitch to Front of Tractor

A. Hitch Bar C. Safety Clip

B. Hitch Pin D. Tractor Brackets

D

18

Position shield 1/8"

from “T” on grille.

Figure 32. Heat Shield Installation

A. Heat Shield C. Clip

B. Carriage Bolt D. Lockwasher, 1/4

1/4-20 x 7/8 E. Nut, 1/4-20

CAUTION

The heat shield shown in Figure 32, is supplied

with the hitch assembly and must be installed

before installing hitch assembly. Damage to

snowthrower could occur if heat shield is not

installed.

Remove heat shield when removing snowthrower

and hitch assembly.

E

D

A

C

B

Install the Heat Shield

1. Install the heat shield as shown in Figure 32.

Position the shield 1/8” right of the “T” of “HOT”.

Broadmoor Hitch Installation

Page 23

Figure 34. Hitch Assembly..

Part No. 1692040 for Electric Lift

Part No. 1692041 for Manual Lift; Broadmoor/LT/2600/1600 Series

A. Hitch Assembly

B. Rear Hitch Bracket

C. Washers (Qty. 2)

D. Hairpin Clip (Qty. 2)

E. Pin

F. Spring Clip (Qty. 4)

G. Clevis Pin, 3/8 (Qty. 2)

H. Rod

I. Reflectors (Qty. 2)

Attach reflectors (I) to rear lip of

seat deck. If snow cab is installed,

make sure reflectors are not

obstructed.

Insert Pin “E” Through

the Top Hole

G

F

I

A

E

D

C

F

D

C

B

F

G

H

4. See Figure 34. Install the rear hitch bracket (B),

spring clips (D) and washers (C) onto the lift lever

shaft, if not done already.

5. See Figure 34 & 35. Secure the hitch assembly to

the rear bracket inserting pin “E” through the top hole

and securing with Spring Clip (F).

The hitch assembly is now installed to the tractor and

you may proceed to Snowthrower Installation.

19

Figure 35. Installing Hitch to Rear Bracket

A. Rear Hitch Bracket D. Washer

B. Lift Lever Rod E. Hitch

C. Spring Clip F. Clevis Pin

Broadmoor-Hitch Installation

Page 24

Figure 37. Belt Routing

A. V-pulley C. Electric Clutch Pulley (V-Pulley)

B. Idler Pulley D. Snowthrower Pulley (V-Pulley)

E. Backside Idler Pulley

20

SNOWTHROWER INSTALLATION

1. See Figure 36. Align snowthrower bracket (E) with

front tractor hitch arms (B). Lift snowthrower so that

spacers (A) rest on hitch arms (B).

2. Before attaching snowthrower bracket to the hitch,

install the belt from the hitch idler pulley (B, Figure

37) to the snowthrower pulley as shown in Figure 37.

Do not attempt to install belt on electric clutch pulley

at this time.

3. See Figure 36. Attach snowthrower bracket (C) to

hitch using clevis pins (C) and safety clips (D).

PTO Belt Installation and Trunion

Adjustment

1. See Figure 38. To install belt on the electric clutch

pulley, the trunion (A) on the tension spring assembly

(B) must be fully forward. If it is not, turn handle (C) to

move it forward. Install the belt on electric clutch pulley. Refer to Figure 37 for belt routing.

2. See Figure 38. Turn handle (C) so that trunion (A) is

centered between the marks as shown.

NOTE: If trunion cannot be centered between marks,

loosen capscrew (D, Figure 38) and reposition pulley

(E) rearward. Retighten capscrew (D) and center trunion.

Figure 36. Attaching the Snowthrower

A. Spacers D. Safety Clips

B. Hitch Arms E. Snowthrower Bracket

C. Clevis Pin

Figure 38. Belt Installation & Adjustment

A. Trunion D. Capscrew

B. Tension Spring Assembly. E. Pulley

C. Handle

Install the Lift Rod

1. Install the lift rod assembly to the manual lift lever as

shown in Figure 39 and secure with a hair pin clip.

2. Install the front attachment lift rod to the snowthrower

as shown in Figure 40 and secure with a hair pin clip.

The rod guide assembly (A, Figure 40) may need to

be removed and oriented correctly.

CAUTION

After snowthrower installation if the tractor hood is

opened, it will come into contact with the

snowthrower. To protect the hood finish cover the

discharge chute with a towel or blanket.

Broadmoor-Hitch Installation

Page 25

21

Figure 39. Installing Lift Rod to Manual Lift Lever

A. Front Attachment Lift Rod C. Spring Clip

B. Manual Lift Lever

A

B

C

Install the Spring Assist

NOTE: The parts described in the following steps (and

shown in Figures 42 & 41) are packaged with the hitch

assembly.

NOTE: 4-link chain replaces 3-link chain supplied with

snowthrower.

1. Place snowthrower in the down position.

NOTE: On single cylinder engines, the clevis pin (B,

Figure 41) must be installed to the bracket before mounting onto the tractor frame.

2. See Figure 41. Install the spring assist bracket (A)

into the underside of the frame as shown using a 11/4” long capscrew, lockwasher, and nut.

3. See Figure 41. Place the clevis pin (B) through the

spring assist bracket from the back. Install a flat

washer (C), the 4 link chain (D), another flat washer

(C), and safety clip (E) as shown.

4. Place snowthrower in fully raised position.

5. Rotate the spring assist lever (A, Figure 42) fully back

and install the spring (B) on the lever and through the

chain. See Figure 42.

7. Rotate lever forward so that it travels “over center” to

the fully forward position.

8. Lower the snowthrower.

Adjust, Lubricate, and Test Run

1. Adjust the Lift Rod- See Adjustments

2. Adjust the Skids-See Adjustments

3. Lubricate the Snowthrower-See Maintenance.

4. Install the reflectors on the on the rear lip of the seat

deck. If a snowcab is also installed, make sure the

reflectors are not obstructed.

5. Test run and recheck belt tension.

Figure 40. Installing Lift Rod to Snowthrower

A. Rod Guide Assembly

B. Hair Pin Clip

Install lift rod to inside of bracket as shown.

A

B

WARNING

Never pull spring-assist tension lever back unless

snowthrower is in fully raised position.

Figure 42. Spring-Assist Lever

A. Lever B. Spring

Broadmoor-Snowthrower Installation

Frame hole is located on front, left side; in front of engine

Figure 41. Spring Assist Bracket

A. Bracket D. 4-link Chain

B. Clevis Pin E. Safety Clip

C. Flat Washer

A

B

D

C

C

E

Page 26

22

SNOWTHROWER ASSEMBLY

Assemble the Support Arm and Control Rod

1. See Figure 43. Attach the support arm (E) to the

frame with the 1" capscrews and locknuts (F) supplied.

2. See Figure 43. Place the the thin, plastic liner (B)

inside the rod guide (C). Place the rod guide (C) over

the discharge chute control rod (H) and loosely attach

the guide to the support arm (E) in any of the three

mounting holes. Use the 3-1/2" capscrew, locknut

(J), and spacer (K) provided.

3. See Figure 43. Install the discharge chute control rod

(H) through the plastic pivot bearing (D) on the auger

housing. Place a cotter pin into the lowest rod hole on

the inside of the housing, and spread the cotter pin

fully around the rod.

4. Pull the rod back so the cotter pin is resting against

the bearing (D), then insert a second cotter pin

through the rod, just above the bearing. Spread the

cotter pin fully around the rod.

5. Tighten the locknut and capscrew (J) securing the

control rod guide. Do not overtighten. This nut and

capscrew are used to set the control rod rotation

resistance.

Assemble the Discharge Chute and Control

Cable

6. See Figure 43. Install the discharge chute (A) so the

clip (G) on the housing is positioned in the notch (I).

Lubricate the discharge chute so it turns freely.

7. See Figure 44. With the discharge chute facing slightly left, wind the cable around the control rod spool.

Wind it three turns on the rear part of the spool so

that the cable leaves the spool on the lower edge as

shown. Wind two turns on the front part of the spool

so the cable leaves the spool on the upper edge as

shown.

8. See Figure 44. Place the looped end of the cable

over the stud on the discharge chute. Place the small

flat washer (E) provided on the stud. Pull the other

end of the cable around the stud using locking pliers.

While holding the cable tight, install the cup washer

(B) (cup facing inward), lockwasher (C) and nut (D).

Tighten the nut and tape the cable end to the taut

section of the cable.

Figure 43. Discharge Chute & Controls

A. Discharge Chute F. 1" Capscrew & Locknut

B. Rod Guide Liner G. Clip

C. Rod Guide H. Dis. Chute Control Rod

D. Pivot Bearing I. Notch

E. Support Arm J. 1-1/2" Capscrew & Locknut

K. Spacer

Figure 44. Control Cable

A. Cotter Pin C. Lockwasher

B. Cup Washer` D. Nut

E. Flat Washer

CAUTION

Do not let the pivot bearing (D, Figure 43) support

the weight of the control rod or the bearing could

be damaged.

Landlord-Snowthrower Assembly

K

Page 27

23

Landlord-Snowthrower Assembly

Assemble the Deflector

1. See Figure 45. Attach the deflector (C) to the discharge chute with two screws (H), washers (G), spacers (F), washers (A), lockwashers (E) and nuts (D).

2. Position the bolt (I) and washer (A), then thread the

knob (B) onto the bolt (I).

Assemble the Hitch Brackets

1. Mount the hitch brackets to the inside of the

snowthrower capscrews and flange locknuts as

shown in Figures 46 - 48.

Figure 45. Deflector

A. Washer, 5/16 F. Spacer

B. Knob G. Washer, 5/16

C. Deflector H. Screw, 5/16

D. Nut, 5/16 I. Carriage Bolt, 5/16

E. Lockwasher, 5/16

Figure 46. Installing the Hitch Brackets

A. Hitch Brackets C. Flange Locknut

B. Capscrew, 1"

Figure 47. Hole Pattern - Left Side

Figure 48. Sketch 2. Hole Pattern - Right Side

NOTE: Support Arm Removed For Clarity

Hitch Bracket

(Mounted On

Inside)

Hitch Bracket

(Mounted On

Inside)

Page 28

24

Install the Heat Shield

1. Install the heat shield as shown in Figure 49.

Position the shield 1/8” right of the “T” of “HOT”.

Install the Lift Linkage and Rear Hitch

Bracket

ELECTRIC LIFT MODELS

1. Remove the hair pin clip (A, Figure 50) and slide the

shaft assembly (C) out far enough to remove the lift

tube assembly.

2. Push the shaft assembly back through the lift support

far enough to mount the rear hitch bracket (A, Figure

53), washers (D), and hairpin clips (C).

3. Push the shaft assembly (D, Figure 50) back through

the lift support and reinstall the hair pin clip (A).

4. Install the lift lever extension (D, Figure 51) onto the

shaft assembly (C, Figure 50) and secure to the lift

arm assembly (E, Figure 50) with the clevis pin (B,

Figure 51) and hair pin clip (C, Figure 51).

5. Install the front lift rod(A, Figure 51) into the lift lever

extension (D) and secure with a hair pin clip.

Figure 51. Electric Lift Models

A. Front Lift Rod

B. Clevis Pin

C. Hairpin Clip

D. Lift Lever Extension

Figure 49. Heat Shield Installation

A. Heat Shield C. Clip

B. Carriage Bolt D. Lockwasher, 1/4

1/4-20 x 7/8 E. Nut, 1/4-20

CAUTION

The heat shield shown in Figure 49, is supplied

with the hitch assembly and must be installed

before installing hitch assembly. Damage to

snowthrower could occur if heat shield is not

installed.

Remove heat shield when removing snowthrower

and hitch assembly.

E

D

A

C

B

Position shield 1/8"

from “T” on grille.

Figure 50. Electric Lift Assembly

A Hair Pin Clip D. Lift Support

B Lift Tube E. Lift Arm Assembly

C Shaft Assembly

C

D

B

A

E

Landlord-Snowthrower Assembly

Page 29

25

Landlord-Hitch Installation

Figure 54. Installing Lift Rod to Manual Lift Lever

A. Front Attachment Lift Rod C. Spring Clip

B. Manual Lift Lever

A

B

C

MANUAL LIFT MODELS

1. Loosen the hardware securing the lift guide bracket

(B, Figure 52) and remove the hair pin clip (C, Figure

52) from the left side of the lift lever assembly.

2. Partially remove the lift lever assembly from the

frame and install the rear hitch bracket (A, Figure 53),

washers (D), and hair pin clips (C).

3. Reinstall the lift lever assembly.

HITCH INSTALLATION

1. Increase front tire pressure to 20 psi (138 kPa) to

compensate for added weight. Be sure both tires

have equal pressure.

2. From the front of tractor, slide the hitch under the

tractor.

3. See Figure 55. Turn the wheels fully left and lift the

front hitch bar (A) up onto the tractor brackets (B).

Make sure it is fully seated into the tractor brackets.

Install the long hitch pin (C) through the bracket (bottom rear holes) and secure it with the safety clip (D).

4. See Figure 53. Install the rear bracket (A), spring

clips (C) and washers (D) onto the lift lever shaft, if

not done already.

5. Secure the hitch assembly (E, Figure 53) to the rear

bracket (A) inserting pin (F) through the top hole.

The hitch assembly is now installed to the tractor and

you may proceed to Snowthrower Installation.

Figure 53. Installing Hitch to Rear Bracket

A. Rear Hitch Bracket D. Washer

B. Lift Lever Rod E. Hitch

C. Hair Pin Clip F. Clevis Pin

Figure 52. Manual Lift Lever Assembly

A. Lift Lever Assembly. C. Hair Pin Clip

B Guide Bracket D. Shaft Assembly.

Figure 55. Installing Hitch to Front of Tractor

A. Hitch Bar C. Safety Clip

B. Hitch Pin D. Tractor Brackets

D

A

B

C

D

Page 30

26

SNOWTHROWER INSTALLATION

1. See Figure 57. Align snowthrower bracket (A) with

front tractor hitch (B).

2. Before attaching the snowthrower bracket to the

hitch, install the belt from the hitch idler pulley (B,

Figure 58) to the snowthrower pulley as shown in

Figure 58.

Do not attempt to install belt on electric clutch pulley

at this time.

3. See Figure 57. Attach snowthrower bracket (A) to

hitch using clevis pins (C) and safety clips (D).

Figure 57. Landlord/GT/2700/1700 Series

A. Snowthrower Bracket C. Clevis Pin

B. Hitch Arms D. Safety Clips

26

Figure 56. Hitch Assembly..

Part No. 1692040 for Electric Lift

A. Hitch Assembly..

B. Rear Support Assembly..

C. Washers (Qty. 2)

D. Hairpin Clip (Qty. 2)

E. Pin

F. Spring Clip (Qty. 4)

G. Clevis Pin, 3/8 (Qty. 2)

H. Rod

I. Reflectors (Qty. 2)

Attach reflectors (I) to rear lip of

seat deck. If snow cab is installed,

make sure reflectors are not

obstructed.

Install Pin “E” Through

the Bottom Hole.

G

F

I

A

E

D

C

F

D

C

B

F

G

H

CAUTION

After snowthrower installation if the tractor hood is

opened, it will come into contact with the

snowthrower. To protect the hood finish cover the

discharge chute with a towel or blanket.

Landlord-Snowthrower Installation

Page 31

27

Landlord -Snowthrower Installation

27

Figure 58. Belt Routing

A. V-pulley C. Electric Clutch Pulley (V-Pulley)

B. Idler Pulley D. Snowthrower Pulley (V-Pulley)

E. Backside Idler

Figure 60. Installing Lift Rod to Snowthrower

A. Rod Guide Assembly

B. Hair Pin Clip

Install lift rod to inside of bracket as shown.

A

B

Install the Belt

1. See Figure 59. To install the belt on the electric

clutch pulley, the trunion (A) on the tension spring

assembly (B) must be fully forward. If it is not, turn

handle (C) to move it forward. Install belt on electric

clutch pulley. Refer to Figure 58 for belt routing.

2. See Figure 59. Turn handle (C) so that trunion (A) is

centered between the marks as shown.

NOTE: If trunion cannot be centered between marks,

loosen capscrew (D, Figure 59) and reposition pulley

(E) rearward. Retighten capscrew (D) and center trunion.

Attach the Lift Rod to the Snowthrower

1. Install the front attachment lift rod to the snowthrower

as shown in Figure 60 and secure with a hair pin clip.

The rod guide assembly (A) may need to be removed

and oriented correctly.

Figure 59. Belt Installation & Adjustment

A. Trunion D. Capscrew

B. Tension Spring Assembly.. E. Pulley

C. Handle

Page 32

28

WARNING

Never pull spring-assist tension lever back unless

snowthrower is in fully raised position. Spring is

under tension when snowthrower is in lowered

position.

Figure 62. Spring-Assist Lever

A. Lever B. Spring

Landlord/GT/2700/1700 Series

Frame hole is located on front, left side; in front of engine

Install the Spring Assist

NOTE: The spring assist is not required on models

equipped with electric lift. However, if the snowthrower

leans to one side the spring assist can be installed to

correct this. The spring assist is required on all manual

lift models.

NOTE: The parts described in the following steps (and

shown in Figures 61 & 62) are packaged with the hitch

assembly.

NOTE: 4-link chain replaces 3-link chain supplied with

snowthrower.

1. Place snowthrower in the down position.

2. See Figure 61. Install the spring assist bracket (A)

into the underside of the frame as shown using a 11/4” capscrew, lockwasher, and nut.

3. See Figure 61. Place the clevis pin (B) through the

spring assist bracket from the back. Install a flat

washer (C), the 4 link chain (D), another flat washer

(C), and safety clip (E) as shown.

NOTE: On single cylinder engines, the clevis pin must be

installed to the bracket before mounting onto the tractor

frame.

4. Place snowthrower in fully raised position.

5. Rotate the spring assist lever (A, Figure 62) fully back

and install the spring (B) on the lever and through the

chain. See Figure 62.

6. Rotate lever forward so that it travels “over center” to

the fully forward position.

7. Lower the snowthrower.

Adjust, Lubricate, and Test Run

1. Adjust the Lift Rod- See Adjustments

2. Adjust the Skids-See Adjustments

3. Lubricate the Snowthrower-See Maintenance.

4. Install the reflectors on the on the rear lip of the seat

deck. If a snowcab is also installed, make sure the

reflectors are not obstructed.

5. Test run and recheck belt tension.

Landlord-Snowthrower Installation

Figure 61. Spring Assist Bracket

A. Bracket E. Safety Clip

B. Clevis Pin

C. Flat Washer

D. 4-link Chain

A

B

D

C

C

E

Page 33

29

Torque Specifications

TORQUE SPECIFICATIONS FOR

STANDARD MACHINE HARDWARE

(Tolerance ± 20%)

SIZE SAE GRADE #2 SAE GRADE #5 SAE GRADE #8

in/lbs

in/lbs in/lbs

ft/lbs Nm. ft/lbs Nm. ft/lbs Nm.

8-32 19 2.1 30 3.4 41 4.6

8-36 20 2.3 31 3.5 43 4.9

10-24 27 3.1 43 4.9 60 6.8

10-32 31 3.5 49 5.5 68 7.7

1/4-20 66 7.6 8 10.9 12 16.3

1/4-28 76

8.6 10 13.6 14 19.0

5/16-18 11 15.0 17 23.1 25 34.0

5/16-24 12 16.3 19 25.8 27 34.0

3/8-16 20 27.2 30 40.8 45 61.2

3/8-24 23 31.3 35 47.6 50 68.0

7/16-14 30 40.8 50 68.0 70 95.2

7/16-20 35 47.6 55 74.8 80 108.8

1/2-13 50 68.0 75 102.0 110 149.6

1/2-20 55 74.8 90 122.4 120 163.2

9/16-12 65 88.4 110 149.6 150 204.0

9/16-18 75 102.0 120 163.2 170 231.2

5/8-11 90 122.4 150 204.0 220 299.2

5/8-18 100 136 180 244.8 240 326.4

3/4-10 160 217.6 260 353.6 386 525

3/4-16 180 244.8 300 408.0 420 571.2

7/8-9 140 190.4 400 544.0 600 816.0

7/8-14 155 210.8 440 598.4 660 897.6

1-8 220 299.2 580 788.8 900 1,244.0

1-12 240 326.4 640 870.4 1,000 1,360.0

NOTES

1. These torque values are to be used for all hardware excluding: locknuts,

self-tapping screws, thread forming screws, sheet metal screws and socket

head setscrews.

2. Recommended seating torque values for locknuts:

a. for prevailing torque locknuts - use 65% of grade 5 torques.

b. for flange whizlock nuts and screws - use 135% of grade 5 torques.

3. Unless otherwise noted on assembly drawings, all torque values must meet

this specification.

Page 34

30

Standard Hardware

STANDARD

FASTENER

IDENTIFICATION

CHART

Hardware sizes given in the

illustrations throughout this

manual.

If a washer or nut is identified as

“washer, 1/2” or “nut, 1/2”, this

means the inside diameter is 1/2

inch

If a screw is identified as “screw,

1/2 x 2”, this means the shaft

diameter is 1/2 inch and the

shaft of the screw is 2 inches

long. If a screw is identified as

“screw, 1/2 - 16 x 2”, the number

“16” means that the screw has

16 threads per inch.

SAMPLE: SCREW IDENTIFICATION

HEX CAPSCREW IDENTIFICATION

Shown below

are actual size heads for standard screw sizes.

Example: a 1/4 screw has 7/16 head and thus requires a 7/16

wrench. To measure length, use the scale below.

WASHER AND NUT IDENTIFICATION

Place the washer or nut on the above scale to

determine the inside diameter. The actual inside

diameter can vary 1/16 inch. Use the scale for

comparison.

3/4” Head

screw with

1/2” S.D.

5/8” Head

screw with

7/16” S.D.

9/16” Head

screw with

3/8” S.D.

1/2” Head

screw with

5/16” S.D.

7/16” Head

screw with

1/4” S.D.

PLAIN WASHER

HEX CAPSCREW

CARRIAGE BOLT

LOCKWASHER

NUT

01234

1/2 1/2 1/2 1/2

1/4 1/4 1/4 1/4

3/4 3/4 3/4 3/4

Shaft

Diameter

SAMPLE: NUT IDENTIFICATION

Inside

Diameter

Screw Length

Shaft

Diameter

Screw 1/2 x 2

Shaft

Length

Nut, 1/2

Inside

Diameter

Page 35

31

1. Remove the mower deck.

2. Pry up and discard the two rear plastic ratchet fasteners holding the foot rest mat on the left and right

footrests.

3. Install the pivot bracket (A) to the underside of the left

footrest using capscrews (B) and nuts (C). Tighten

securely.

4. Assembly bracket (D) to the underside of the right

footrest using capscrews (B) and nuts (C). Tighten

securely.

5. Loosely assemble the guide (E) to the quadrant (F)

using two capscews (H), spacers (I), and nuts (C).

6. For snowthrower and plow use, install the rear hitch

bracket, hairpin clips and washers on the pivot rod

(parts supplied with hitch).

7. Slide the pivot rod through the pivot bracket (A) and

install the washer (J) and hairpin clip (K).

8. Mount the quadrant (F) onto the lift bracket (D).

9. Tighten the capscrews (H) and nuts (C) mounting the

guide (E) to the lift lever assembly. Be sure lift lever

assembly is securely clamping the foot rest and the

lever latch is unobstructed.

WARNING

Before performing any installation or adjustment,

turn off the engine and let the unit come to a complete stop. Remove the key and disconnect the

spark plug wire to prevent the unit from accidentally starting and causing personal injury.

Kit Contents:

Ref. Qty. Part No. Description

A 1 1704712 Pivot Bracket

B 4 1923325 Capscrew, 5/16-18 x 7/8

C 6 1924433 Nut, 5/16-18

D 1 1704713 Lift Bracket

E 1 1704715 Guide

F 1 1665591 Quadrant

G 1 1704718 Lift Lever Assy.

H 2 1921977 Capscrew, 5/16-18 x 1-1/4

I 2 1704716 Spacer

J 1 911386 Flat Washer

K 1 106788 Clip

Not shown

4 1704351 Fastener, Footrest Mat

Lift Lever Installation

G

H

F

E

I

C

B

C

D

A

B

K

J

Studs

Rear

Hitch Bracket

A

J

K

B

C

B

D

G

E

C

F

H

Installation

Instructions

Lift Lever Kits

Mfg. Nos. 1691832 & 1692623

BROADMOOR / 1600 / 2600 SERIES INSTALLATION - 1691832

Page 36

32

Kit Contents:

Ref. Qty. Part No. Description

A 1 1704715 Guide

B 1 1665591 Quadrant

C 3 1921977 Capscrew, 5/16-18 x 1-1/4

D 1 1921719 Capscrew, 5/16-18 x 2-1/2

E 1 1704716 Spacer,

11/32 ID x 3/4 OD x 7/16

F 3 1675795 Spacer

21/64 ID x 5/8 OD x 1/2

G 1 1674669 Spacer

25/64 ID x 5/8 OD x 1-5/32

H 4 1919438 Nut, Esna, Lock, 5/16-18

I 1 1704718 Lift Lever Assy.

1. Remove the mower deck.

2. Remove and retain the up-stop bracket and mounting

hardware.

NOTE: Reinstall the up-stop bracket for mower use.

3. Loosely assemble the guide (A) to the quadrant (B)

using capscrews (C, D), spacers (E, F, G), and nuts

(H).

4. Slide the lift lever pivot rod through the hole in the

right side of the frame.

5. Install the rear support assembly, washers, and hair

pin clips (supplied with snowthrower or dozer blade)

on the lift lever pivot rod.

6. Slide the lift lever pivot rod through the hole in the left

side of the frame.

7. Secure the quadrant to the frame using spacers (F),

capscrews (C), and nuts (H).

8. Tighten the guide plate (A) and quadrant (B) hardware making sure the lever latch movement is unobstructed.

WARNING

Before performing any installation or adjustment,

turn off the engine and let the unit come to a complete stop. Remove the key and disconnect the

spark plug wire to prevent the unit from accidentally starting and causing personal injury.

Lift Lever Installation

A

I

A

E

G

H

C

F

H

B

C

D

F

I

B

C

H

C

F

D

Rear Hitch Bracket

Frame

Bracket

Upstop Bracket Location

Up-Stop Bracket

Located Under

Right Side of

Frame

REGENT / 500 / 2500 SERIES INSTALLATION - 1692623

Form No. 1715019

Rev. 6/97

© 1997 Simplicity Manufacturing, Inc. All Rights Reserved

TP 200-2069-02-AT-SMA

MASimplicity Mfg. Inc.

500 N Spring Street / PO Box 997

Port Washington, WI 53074-0997 USA

Installation Instructions Lift Lever Kit

Loading...

Loading...