Simplicity 1691975, 1691331, 1692491, 1691974, 1691973 Repair Information

...

How to use this file...(Labels & Miscellaneous Documents)

————————————————————————————————————————————–––

Instructions for

Print Vendors (Paper Manuals)

Paper: * Various...

Press: * Various...

Bindery: * Various...

General: * This instruction page is NOT part of the document and must NOT be printed.

• Pages labeled with the text “THIS PAGE INTENTIONALLY BLANK” are placement pages ONLY,

and should NOT be printed.

• THIS document will most likely be a unique piece -- either a label or certificate or

other such miscellaneous format.

• EXACT specifications on the print & job specs should already be known to

you. In you are uncertain of what these specifications are, please contact

Simplicity Technical Publications.

• (Note: We will do our best to answer your questions concerning this job, but may need to transfer

you to another department within our company for additional specifications and job

requirements).

————————————————————————————————————————————–––

If you have further questions on how to utilize this file, please contact

Simplicity Technical Publications Department at (262) 284-8647.

THIS PAGE INTENTIONALLY BLANK

Repair Information

Neutral

Adjustments

For Hydrostatic Drive Tractors

Volume I

Fifth Edition (1975 – 1997 Model Year)

TP 500-1220-06-XX-SMA

Rev. 7/1999

MANUFACTURING INC.

500 N. Spring Street / PO Box 997

Port Washington, WI 53074-0997 USA

www.simplicitymfg.com

© Copyright 1999, Simplicity Manfacturing, Inc.

All Rights Reserved. Printed in USA

Table of Contents

Page

Section 1. Commercial Front-Cut Riders with Dual Eaton Model 7 Hydrostatic ................................................6

SIMPLICITY AGCO ALLIS MASSEY FERGUSON

CFC Series/Procut 3000 Series

1691969 - 20 HP

1691968 - 20 HP

1691967 - 18 HP

1691966 - 18 HP

1691965 - 16 HP

1691964 - 16 HP

1691846 - 20 HP

1691845 - 20 HP

1691844 - 18 HP

1691843 - 18 HP

1691842 - 16 HP

1691841 - 16 HP

1691975 - 20 HP

1691974 - 18 HP

1691973 - 16 HP

1691972 - 20 HP

1691971 - 18 HP

1691970 - 16 HP

1691882 - 16 HP

1691876 - 18 HP

Section 2. Large-Frame Tractors with Shaft Drive - Sundstrand Model 15

Hydrostatic (Peerless 2600-002 or 2600-008) ........................................................................... 11

SIMPLICITY AGCO ALLIS MASSEY FERGUSON

18 & 20 GTH & SunStar Series 1900 & Ultima Series 2900 Series

1692521 - 18 HP

1692456 - 20 HP

1692454 - 20 HP

1692135 - 20 HP

1692133 - 20 HP

1692131 - 18 HP

1691953 - 20 HP

1691926 - 20 HP

1691924 - 18 HP

1691710 - 20 HP

1691528 - 18 HP

1691381 - 20 HP

1691380 - 18 HP

1691357 - 16 HP

1691250 - 14 HP

1691018 - 20 HP

1691017 - 18 HP

1692523 - 18HP

1692460 - 20 HP

1692458 - 20 HP

1692141 - 20 HP

1692139 - 20 HP

1692137 - 18 HP

1691955 - 20 HP

1691397 - 18 HP

1691392 - 20 HP

1691391 - 18 HP

1691389 - 16 HP

1691387 - 14 HP

1691307 - 18 HP

1691020 - 20 HP

1691019 - 18 HP

1692525 - 18 HP

1692507 - 20 HP

1692505 - 20 HP

Section 3. Large-Frame Tractors with Belt Driven - Sundstrand Model 15 Hydrostatic.................................12

SIMPLICITY

Sovereign, 17GTH-L, AGCO ALLIS MASSEY FERGUSON

7000 & 7100 Series, 7790 900 & 700 Series 2800 Series

1692798 - 18 HP

1692796 - 18 HP

1692450 - 18 HP

1692143 - 18 HP

1691957 - 17 HP

1691717 - 17 HP

1691382 - 16 HP

1690890 - 18.5 HP

1690723 - 14 HP

1690640 - 19 HP

1690638 - 19 HP

1690572 - 17 HP

1690571 - 17 HP

1690570 - 16 HP

Section 4.

1690569 - 16 HP

1690480 - 17 HP

1690479 - 17 HP

1690478 - 16 HP

1690477 - 16 HP

1690473 - 12 HP

1690433 - 18 HP

1690431 - 18 HP

1690429 - 16 HP

1690427 - 16 HP

1690352 - 12 HP

1690342 - 16 HP

1690202 - 16 HP

1690006 - 16 HP

1692847 - 18 HP

1692845 - 18 HP

1692452 - 18 HP

1692144 - 18 HP

1691960 - 17 HP

1691718 - 17 HP

1691383 - 16 HP

1691139 - 18.5 HP

1691124 - 14 HP

1691122 - 16 HP

1690894 - 18.5 HP

1690727 - 14 HP

1690642 - 19 HP

1690575 - 16 HP

1690574 - 17 HP

1690519 - 17 HP

1690516 - 12 HP

1690367 - 18 HP

1690217 - 12 HP

1690214 - 12 HP

1690211 - 16 HP

1690076 - 12 HP

1690014 - 16 HP

1692852 - 18 HP

1692849 - 18 HP

1692503 - 18 HP

Tractors with Tuff Torq K215-A & HydroGear (Sundstrand) Hydrostatic, BDU-21L ........................

SIMPLICITY AGCO ALLIS MASSEY FERGUSON

Landlord, 18, 16GTH Series 1700 Series 2700 Series

1692631 - 16 HP

1692442 - 18 HP

1692440 - 16 HP

1692042 - 16 HP

1692006 - 18 HP

1692633 - 16 HP

1692448 - 18 HP

1692446 - 16 HP

1692044 - 16 HP

1692036 - 18 HP

1692501 - 18 HP

1

13

Table of Contents (Continued)

Page

Tractors with Hydro-Gear 216-3010L Hydrostatic Transaxle...............................................................................................

15

SIMPLICITY AGCO ALLIS MASSEY FERGUSON

Landlord Series 1700 Series 2700 Series

1692788 - 18 HP

1692786 - 17 HP

1692784 - 16 HP

1692576 - 18 HP

1692572 - 16 HP

1692841 - 18 HP

1692839 - 17 HP

1692837 - 16 HP

1692578 - 18 HP

1692574 - 16 HP

1692854 - 17 HP

1692843 - 18 HP

1692580 - 18 HP

Section 5. Tractors with Eaton 850 Transaxle..........................................................................................................17

SIMPLICITY AGCO ALLIS MASSEY FERGUSON

17, 16GTH & 6500 Series 1800 Series

1691824 - 17 HP

1691766 - 16 HP

1691732 - 17 HP

1691263 - 16 HP

1691769 - 16 HP

1691682 - 17 HP

1691560 - 14 HP

1691471 - 16 HP

1691470 - 13 HP

Section 6. Tractors with Tuff Torq K60 Hydrostatic Transaxle............................................................................ 18

SIMPLICITY AGCO ALLIS MASSEY FERGUSON

Broadmoor, 12.5 & 16LTH Series 1600 Series

1692182 - 14 HP

1692073 - 12.5 HP

1692071 - 16 HP

1692184 - 14 HP

1692076 - 13 HP

1692075 - 16 HP

Tractors with HydroGear 311-0750/311-0800 Transaxle ................................................................................................ 19

SIMPLICITY AGCO ALLIS MASSEY FERGUSON

Broadmoor Series 1600 Series 2600 Series

1692776 - 16 HP

1692774 - 15 HP

1692772 - 14 HP

1692609 - 15 HP

1692528 - 15 HP

1692420 - 16 HP

1692416 - 14 HP

1692414 - 14 HP

1692283 - 16 HP

1692279 - 14 HP

1692261 - 12.5 HP

1692813 - 16 HP

1692811 - 15 HP

1692809 - 14 HP

1692613 - 15 HP

1692530 - 15 HP

1692436 - 16 HP

1692432 - 14 HP

1692430 - 14 HP

1692285 - 16 HP

1692281 - 14 HP

1692265 - 12.5 HP

1692817 - 16 HP

1692815 - 15 HP

1692499 - 16 HP

1692497 - 14 HP

Lawn Tractors with Eaton 750 or 751 Hydrostatic Transaxle........................................................................................21

SIMPLICITY AGCO ALLIS MASSEY FERGUSON

Broadmoor, 12.5 & 16LTH Series 1600 Series

1691886 - 12.5 HP

1691807 - 16 HP

Section 7.

1691795 - 12.5 HP 1691888 - 13 HP 1691817 - 13 HP

Lawn Tractors with HydroGear (Formerly Agri-Fab) Sundstrand BDU10S Transaxle...........................

25

SIMPLICITY AGCO ALLIS MASSEY FERGUSON

Regent, 12LT & 12RT Series 500 Series & 612H

1692156 - 12.5 HP

1692053 - 12 HP

1691931 - 12 HP 1692164 - 12.5 HP 1692057 - 12 HP

1691933 - 12 HP

2

Table of Contents (Continued)

Page

Section 7.

Lawn Tractors with HydroGear 310 - 0500 Transaxle (With Hand Control)..............................................................27

1692403 - 12.5 HP 1692259 - 12.5 HP 1692263 - 12.5 HP1692412 - 12.5 HP 1692495 - 12.5 HP

Lawn Tractors with HydroGear 318-0500/322-0500 Transaxle (With Foot Control) ................................................28

1692354 - 14 HP 1692591 - 14 HP

Lawn Tractors with HydroGear 322-0650 Transaxle (With Foot Control) ..................................................................28

1692762 - 16 HP

(Continued)

SIMPLICITY AGCO ALLIS MASSEY FERGUSON

Regent Series 500 Series 2500 Series

SIMPLICITY AGCO ALLIS MASSEY FERGUSON

Regent Series 500 Series 2500 Series

1692588 - 14 HP

SIMPLICITY AGCO ALLIS MASSEY FERGUSON

Regent Series 500 Series 2500 Series

1692831 - 16 HP

1692835 - 16 HP

Section 8.

Lawn Tractors with Eaton Model 7 Hydrostatic & Peerless 1300 Series Transaxle ...........................

30

SIMPLICITY AGCO ALLIS MASSEY FERGUSON

5200 & 4200 Series 600 Series

1691649 - 16 HP

1691473 - 12.5 HP

1691362 - 16 HP

1691340 - 12 HP

1691271 - 12 HP

1691235 - 12.5 HP

1691234 - 12.5 HP

1691033 - 16 HP

1691032 - 16 HP

1691029 - 11 HP

1690936 - 16 HP

1690919 - 16 HP

1690912 - 11 HP

1690881 - 16 HP

1690853 - 16 HP

1690846 - 11 HP

1690810 - 16 HP

1690759 - 11 HP

1691479 - 12 HP

1691477 - 13 HP

1691475 - 16 HP

1691432 - 13 HP

1691276 - 12 HP

1691237 - 13 HP

1691236 - 13 HP

1691044 - 16 HP

1691043 - 16 HP

1691040 - 11 HP

1690960 - 16 HP

1690954 - 16 HP

1690947 - 11 HP

1690887 - 16 HP

1690875 - 16 HP

1690868 - 11 HP

1690763 - 11 HP

Section 9. Later Model Front-Cut Riders with Eaton Model 7 Hydrostatic....................................................... 31

SIMPLICITY AGCO ALLIS MASSEY FERGUSON

FC Series Front-Cut 1300 Series Front-Cut 2300 Series

1692375 - 16 HP

1692311 - 16 HP

1692309 - 12.5 HP

1692014 - 12.5 HP

1691656 - 16 HP

1691655 - 12 HP

1692375 - 16 HP

1692312 - 16 HP

1692310 - 12.5 HP

1692022 - 12.5 HP

1691660 - 16 HP

1691659 - 12 HP

1692512 - 16 HP

Section 10. Early Model Front-Cut Riders with Eaton Model 7 Hydrostatic ...................................................32

SIMPLICITY AGCO ALLIS MASSEY FERGUSON

SunRunner Series Vanguard Series

1691331 - 12 HP 1691336 - 12 HP

3

Table of Contents (Continued)

Section 11. Mid-Engine Riding Mowers with HydroGear 311 - 0500 ................................................................33

SIMPLICITY AGCO ALLIS MASSEY FERGUSON

Coronet Series 400 Series 2400 Series

1692750 - 13 HP

1692515 - 12.5 HP

1692385 - 12.5 HP

1692130 - 12.5 HP

1692821 - 13 HP

1692519 - 12.5 HP

Transmission Purging

This procedure applies to the

following models:

Simplicity - Regent & Coronet Series

AGCO Allis - 500 & 400 Series

Massey Ferguson - 2500 & 2400 Series

The following is a purging procedure for

products that use the Hydro-Gear transmission. Use this procedure if air has become

trapped in the transmission during shipment,

storage, or during an oil change. Purge the

transmission if it lacks drive in forward or

reverse.

1. Park the tractor on a flat, level surface.

2. Place the hydro release lever in the PUSH

position by pulling rearward on the lever . The

lever is located under the rear right-hand corner

of the frame.

3. Start the tractor engine and run at low idle.

4. Move the ground speed control lever to the

neutral gate.

5. Return the control lever to the neutral gate.

6. Place the hydro release lever (A) in the DRIVE

position by pushing the lever fully forward.

7. Drive the tractor for at least five feet in forward

and reverse directions with full throttle and full

ground speed. Repeat this procedure three times

in the forward and reverse directions.

Repeat the above steps if the tractor has noisy or

erratic operation, lack of performance after

transmission warm up, or oil leakage from

transaxle vent tube.

1692399 - 12.5 HP

1692176 - 12.5 HP

1692491 - 12.5 HP

4

Introduction

■ This manual assumes all clutch and brake adjustments have been made, and that

transmission control linkages are in good serviceable condition.

■ Worn parts, broken or weak springs, fasteners, and bushings should be replaced as

necessary before attempting to make adjustments.

■ It is possible during adjustments to place yourself in a position which is more

hazardous than when the unit is in normal operation.

■ Safety is a matter of common sense . . . a matter of thinking before acting.

■ Familiarize yourself with the product and pay special attention to all safety warnings.

■ These adjustments are meant to minimize cr eep when controls are placed in the neutral

position.

■ Hydrostatic transmissions should never be relied upon to hold a tractor in a parked

position. The parking brake should be set and engine stopped whenever leaving the

tractor.

NOTE: PUSHING THE TRACTOR BY HAND

1. Disengage the PTO and turn the engine off.

2. Move the transmission release lever to PUSH position.

The tractor can now be pushed by hand. T owing the tractor with another vehicle is not

recommended, as the transmission may be damaged.

WARNING

When making adjustment, keep hands, hair, clothing, and tools away from rotating

belts. Careless or improper attention may result in serious injury.

5

Section 1.

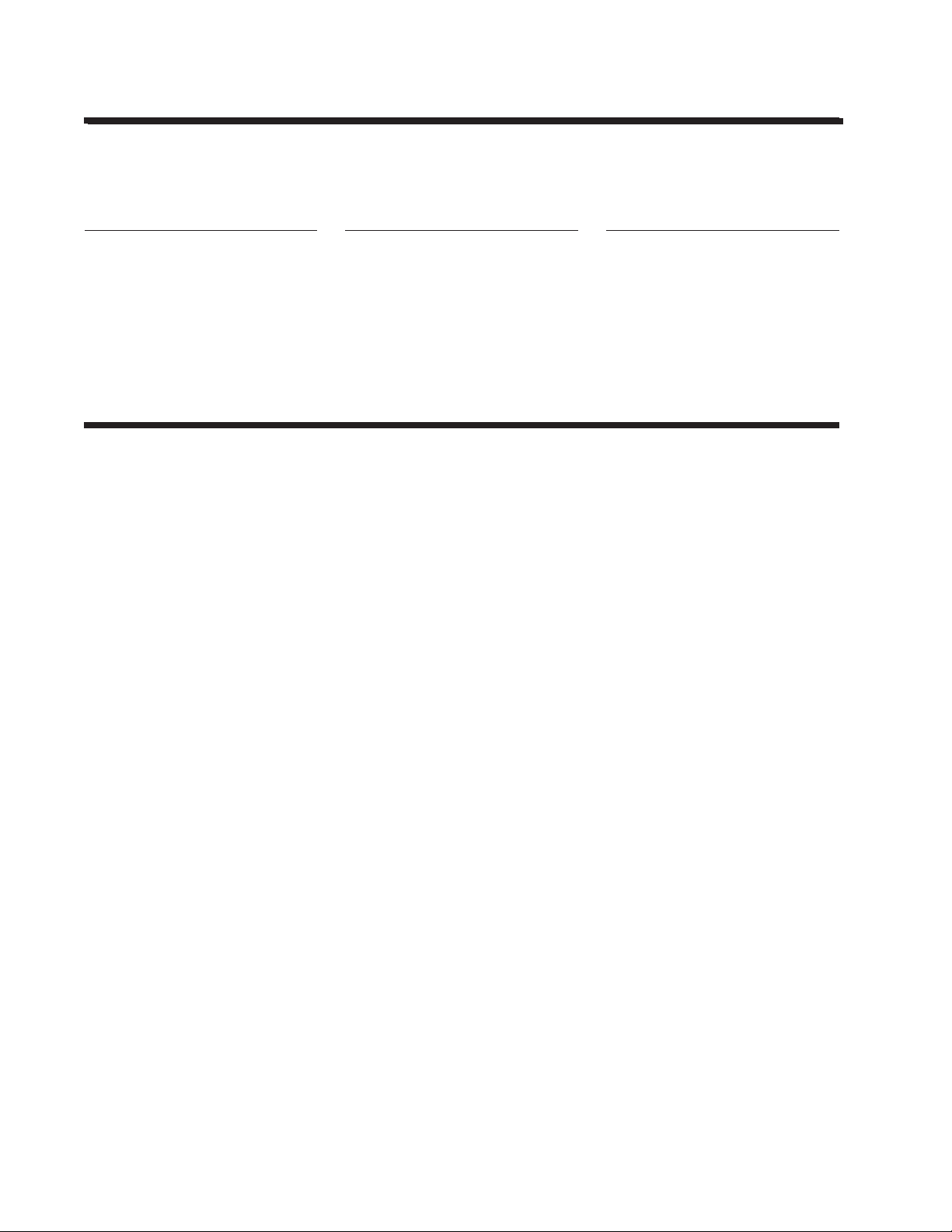

Commercial Front-Cut Rider with Dual Eaton Model 7 Hydrostatic

Wheel-Steer Adjustments

Neutral

1. Make sure that the steering wheel is springcentered in the straight-forward position. If

spring pulls steering wheel off-center, loosen

the nut securing the anchor bolt (G) and move

bolt in slot until wheel is pointing straight

ahead. Retighten nut and recheck steering

wheel alignment.

2. Check the alignment of the rear edges of bars

(I, figure 1-1) and transmission control shafts

(C and D). Rear edges should be aligned as

shown in figure 1-1. To adjust linkage, first loosen

jamnuts (A), remove the nut securing the ball

joint (H), and rotate ball joint until alignment is

correct. Retighten all hardware.

3. Block frame so that wheels are off the ground.

Increase the engine RPM level and move foot

pedal forward and reverse several times. Spring

tension should return foot pedal to neutral.

4. If wheels rotate in neutral, loosen nuts

(B, figure 1-1) on each side of the hydro pump

linkage (F). Turn either front or rear nut until

wheel stops rotating.

5. Tighten nuts, making sure control rods do not

change position. This may take several times to

position rods at exact neutral.

6. Remove frame blocking and test operate.

Rider should not move with foot pedal in

neutral position.

Figure 1-1.

A. Steering Linkage Adjustment Nuts

B. Neutral Adjustment Nuts

C. Left Hand Transmission Control Shaft

D. Right Hand Transmission Control Shaft

E. Steering Linkage

F. Hydro Pump Linkage

G. Spring-Centering Bolt

H. Ball Joint

I. Bar

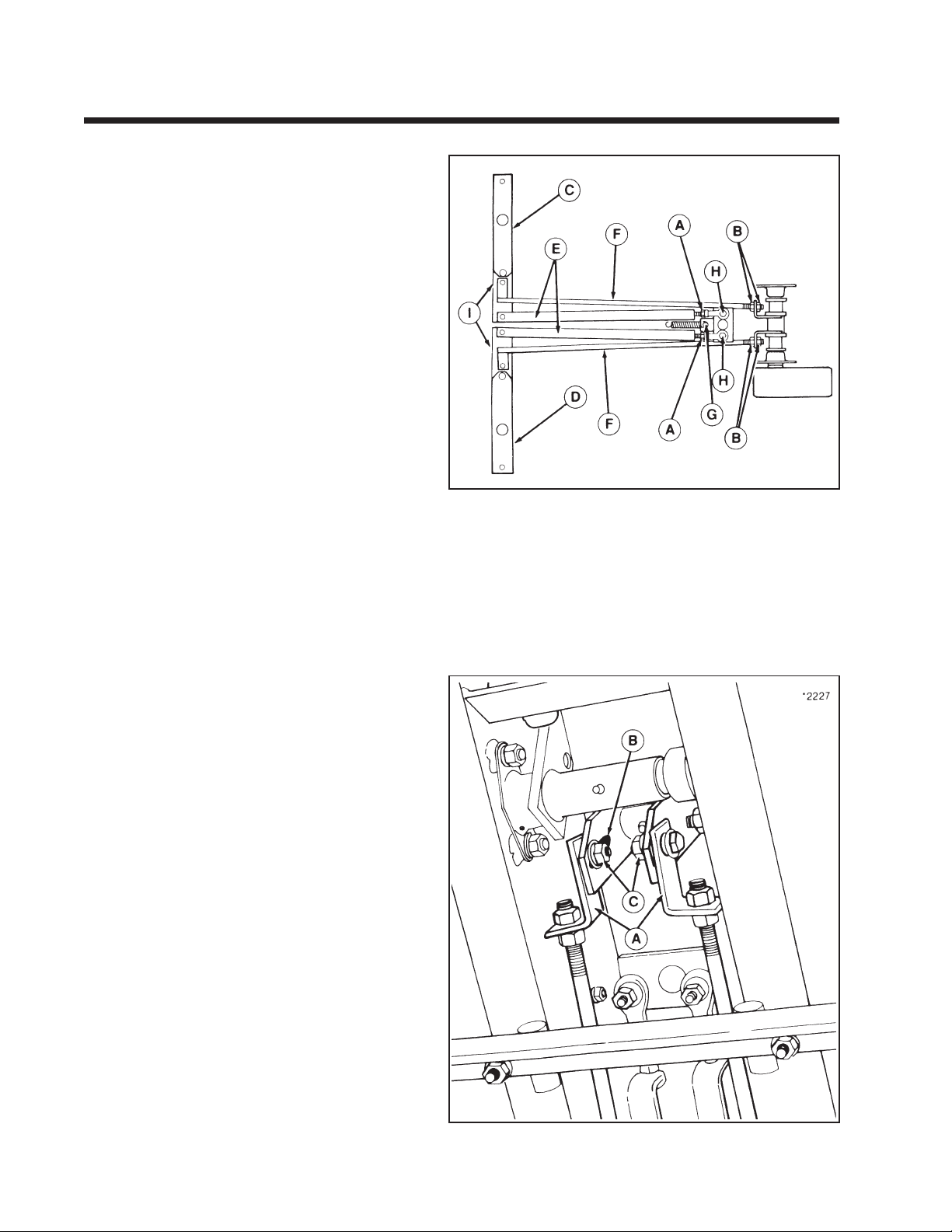

Transmission Speed Variation

If rider pulls to one side with the steering wheel in a

straight forward position, the hydro pump linkage

can be adjusted to correct for unequal pump output.

This adjustment limits the output of a faster hydro

pump at less than maximum forward speed. Refer to

“Forward Travel Stop Adjustment” for maximum

forward speed adjustment.

To adjust hydro pump linkage (A, figure 1-2), loosen

retaining hardware and move linkage upward in slot

(B) to reduce hydro pump output. Retighten flange

locknut (C) after adjustment is complete.

Figure 1-2.

A. Hydro Pump Linkage

B. Adjustment Slot

C. Flange Locknut

6

Section 1. (Continued)

Commercial Front-Cut Rider with Dual Eaton Model 7 Hydrostatic

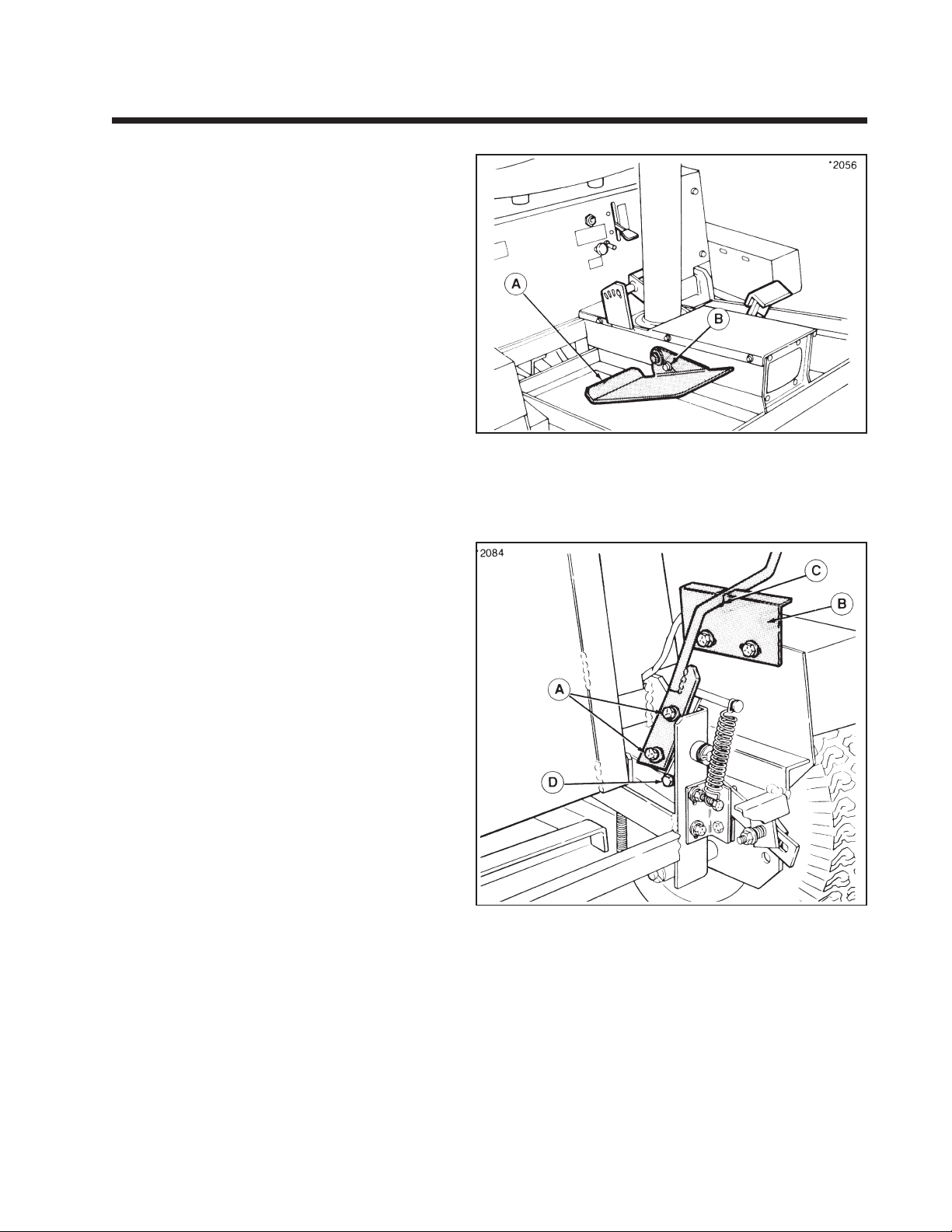

Ground Speed Control

The position and angle of the foot pedal (A, figure

1-3) can be adjusted by loosening taptite screw (B)

and moving pedal in slot. This adjustment should

not affect rider speed or neutral adjustment.

Figure 1-3.

A. Foot Pedal

B. Adjustment Capscrew

Lever-Steer Adjustments

Control Levers

The control levers have slotted holes for mounting

and can be positioned for the most comfortable

operating position. When in neutral, the handles

should be opposite each other.

To adjust the angle of lever, loosen capscrew

(A, figure 1-4). Adjust lever position and retighten

capscrew. Neutral gate brackets (B) must be adjusted

so that new position of lever will be aligned with

neutral gate (C) when rider is in neutral.

In the operating position, handles should have about

1/2" between them so they will not contact each

other with the weight of the operator’s hands on

handles. To adjust distance, loosen locknut and turn

adjusting bolt (D) in or out. Retighten nut after

adjustment.

After handle adjustment, check the neutral adjustment to make sure there is no creep with levers in

neutral position. Readjust spring-centered lever

position. (Refer to following adjustments.)

Figure 1-4.

A. Capscrew

B. Brackets

C. Neutral Gate

D. Adjustment Bolt

7

Section 1. (Continued)

Commercial Front-Cut Rider with Dual Eaton Model 7 Hydrostatic

Neutral

Exact neutral position of transmission control

linkage (A, figure 1-5) can be adjusted by changing

position of linkage on frame bracket (B). With

control levers in neutral position, wheels should not

turn in forward or reverse direction. To adjust

neutral:

1. Block frame up so both drive wheels are off the

ground.

2. Place weight in operator’s seat to start engine.

3. With control levers in neutral gate, start engine

and leave in fast throttle position. If either wheel

turns in forward or reverse direction, perform

steps 4 and 5.

4. Loosen capscrew (C) and nut securing transmission control linkage (A). Move linkage forward or

backwards until wheel stops moving.

5. Retighten hardware, making sure wheel does not

rotate after hardware is tightened. Repeat steps

for opposite wheel if necessary.

6. Shut engine off and remove weight from seat.

Lower rider to the ground.

Figure 1-5.

A. Transmission Control Linkage C. Capscrew

B. Frame Bracket

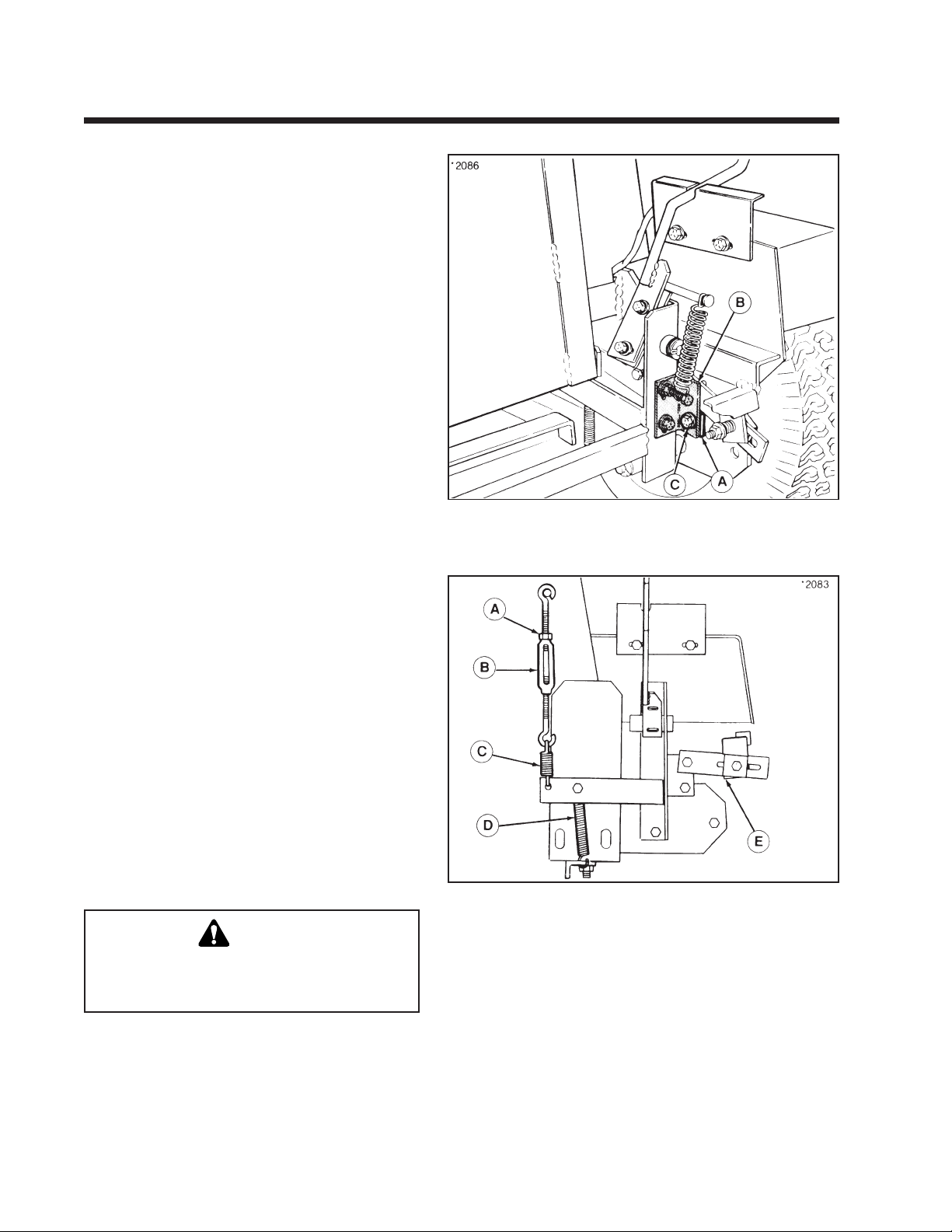

Spring-Centered Lever

Control levers should be adjusted so that levers

automatically return to neutral position when

released. Before performing adjustment, make sure

“Control Lever Adjustment” and “Neutral Adjustment” have been performed.

1. Block frame up so both drive wheels are off the

ground.

2. Place weight in operator’s seat to start engine. Do

not start engine.

3. Make sure that “Control Lever Adjustments” and

“Neutral Adjustment” are correct (refer to

preceding adjustments).

4. Loosen spring tension completely on friction pad

(refer to following adjustment).

5. Loosen nut (A, figure 1-6) on top of turnbuckle

(B) and adjust turnbuckle up or down.

WARNING

Do not adjust turnbuckle with engine running.

Hydro pump fan is too close to turnbuckle to

safely perform adjustment.

6. Restart engine and check control lever position.

Move control lever forward and backward and

check if lever returns to neutral position and

wheel does not rotate. If wheel rotates forward,

turnbuckle assembly must be lengthened (turnbuckle will move down). If wheels rotate backwards, turnbuckle assembly must be shortened

(turnbuckle will move up).

Figure 1-6.

A. Nut D. Stationary Spring

B. Turnbuckle E. Friction Pad

C. Tension Spring

7. Repeat turnbuckle adjustment until control lever automatically returns to neutral position. Tighten nut (A)

when adjustment is correct.

8. Tighten spring tension on friction pad (refer to following

adjustment).

9. Remove weight from seat and lower rider to the ground.

8

Loading...

Loading...