Page 1

Parts Manual

1170 Large Frame

Two-Stage Snowthrowers

11HP Snowthrowers

Mfg. No. Description

1694437 1170M, 11HP Snowthrower (CE)

1694441 1170E, 11HP Snowthrower

09/2003

Rev.

TP 400-3892-00-LW-S

Page 2

Page 3

Table Of Content

s

TRACTOR / MOWER DECK COMPONENTS PAGES

Handles and Controls Group .................................................................................................

Engine and Frame Group - 11HP Electric Start ....................................................................

Engine and Frame Group - 11HP Manual Start ....................................................................

Auger and Impeller Group - 28" .............................................................................................

Auger Housing and Chute Group - 28" ..................................................................................

Traction Drive Group .............................................................................................................

Wheels & Tires Group ..........................................................................................................

Decals Group - 1170 .............................................................................................................

Headlight Group ....................................................................................................................

12

16

18

22

26

28

30

Torque Specification Chart ..................................................................... Inside Back Cover

4

8

Page 4

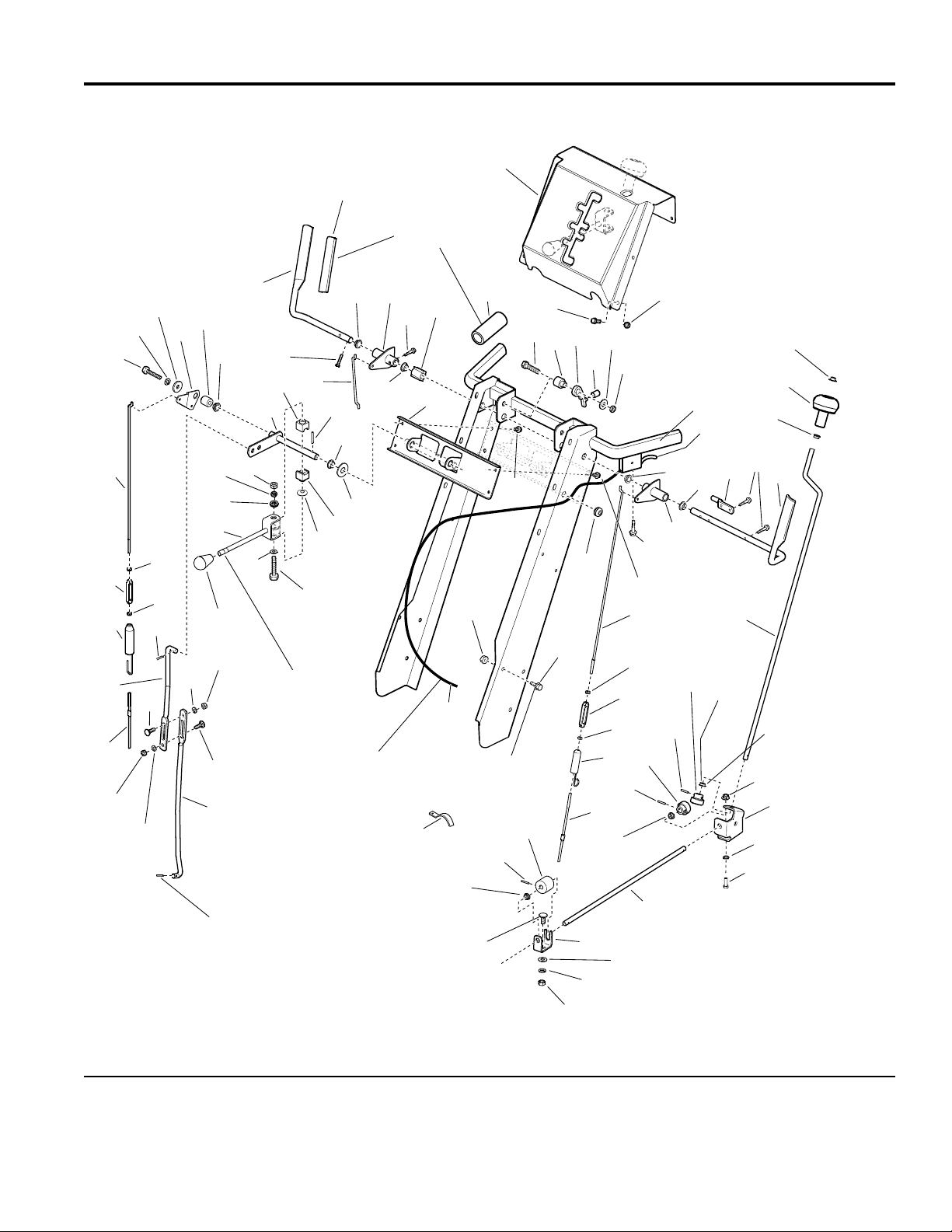

Handles and Controls Group

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

4

71

49

73

72

70

6

10

59

60

69

57

56

58

54

29

58

30

31

68

63

55

56

64

57

65

Shift rod assembly

(Ref. 54) must pivot

freely on pivot blocks

(Ref. 59).

67

65

56

66

57

63

Linkage adjustment for traction and auger drive

with power boost: with drive levers engaged, the

bottom end of lower rods (Ref. 33 & 67) should be

flush with bottom of springs (Ref. 32 & 68).

5

Apply adheasive to

secure grips.

6

8

11

9

7

38

6

13

6

62

59

24

61

Mount clutch cable to cable

support, see specific

Engine & Frame Grroup.

75

53

36

1

15

74

Torque to

19 - 29 ft-lbs.

46

47

12

45

16

986369

30

29

39

14

28

23

44

3

38

34

35

25

22

6

6

26

36

99

27

8

37

39

36

Mount bushings

(Ref. 36) with flanges

on inside of brackets

(Ref. 41 & 48).

40

41

42

43

2

18

19

20

21

17

51

52

31

32

38

33

36

48

20

49

50

The above parts group applies to the following Mfg. Nos.:

1694441- 1170E

1694437 - 1170M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

4

TP 400-3892-00-LW-S

Page 5

Handles and Controls Group

PART NO. DESCRIPTIONREF NO. QTY.

1 1667800 1 DASHBOARD

2 1935450 4 CAPSCREW, Hex Head, 1/4-20 x 3/4

3 1920397 4 NUT, Hex Lock, 1/4-20

4 1612165 1 HANDLE, Clutch, RH

5 1668608 2 GRIP

6 1668185 6 BUSHING, Nylon

7 1702663 1 ROD, Clutch

8 1725205 2 LEVER & TUBE ASSEMBLY, Clutch

9 1960471 4 CAPSCREW, Hex Washer Head, #12-24 x 1

10 1928732 1 CAPSCREW, Hex Washer Head, #10-24 x 1

11 1705899 1 GUIDE, Control

12 1927429 2 CAPSCREW, Hex Washer Head, 1/4-20 x 5/8

13 1723935 1 BRACKET, Shift Control

14 1925003 4 CAPSCREW, Hex Head, Taptite, 1/4-20 x 1/2

15 1725245 2 GRIP

16 1921221 1 CAPSCREW, Hex Head, 5/16-18 x 1-1/2

17 1678579 1 SPACER

18 1705898 1 LATCH, Control

19 1701342 1 SPRING, Compression

20 1919326 2 WASHER, 5/16

21 1923362 1 NUT, Hex, Center Lock, 5/16-18

22 1718804 1 TRIGGER ASSEMBLY, Easy Turn Clutch Cable

23 1725702 1 SCREW, Pan Head, #10 x 1/2

24 1668681 1 WASHER, Curved, 1/2

25 1725124 1 HANDLE ASSEMBLY

26 1677453 1 ROD, Control

27 1612167 1 HANDLE, Clutch, LH

28 1668121 1 ROD, 17-5/16 Long

29 928704 2 NUT, LH, Machine Screw, Hex, #10-24

30 108775 2 TURNBUCKLE

31 1916621 2 NUT, RH, Machine Screw, He x, #1 0-24

32 1707452 1 SPRING

33 1668526 1 ROD, Clutch

34 1960093 1 PUSH NUT

35 1714084 1 KNOB, Spinner

36 1667588 4 BUSHING, Nyl o n

37 1715658 1 ROD, Chute Co ntrol

38 1918452 3 PIN, Cotter

39 1718593 2 GEAR

40 1960294 2 NUT, Hex Flange, 1/4-20

Footnotes

The above parts group applies to the following Mfg. Nos.:

1694441- 1170E

1694437 - 1170M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

5

TP 400-3892-00-LW-S

Page 6

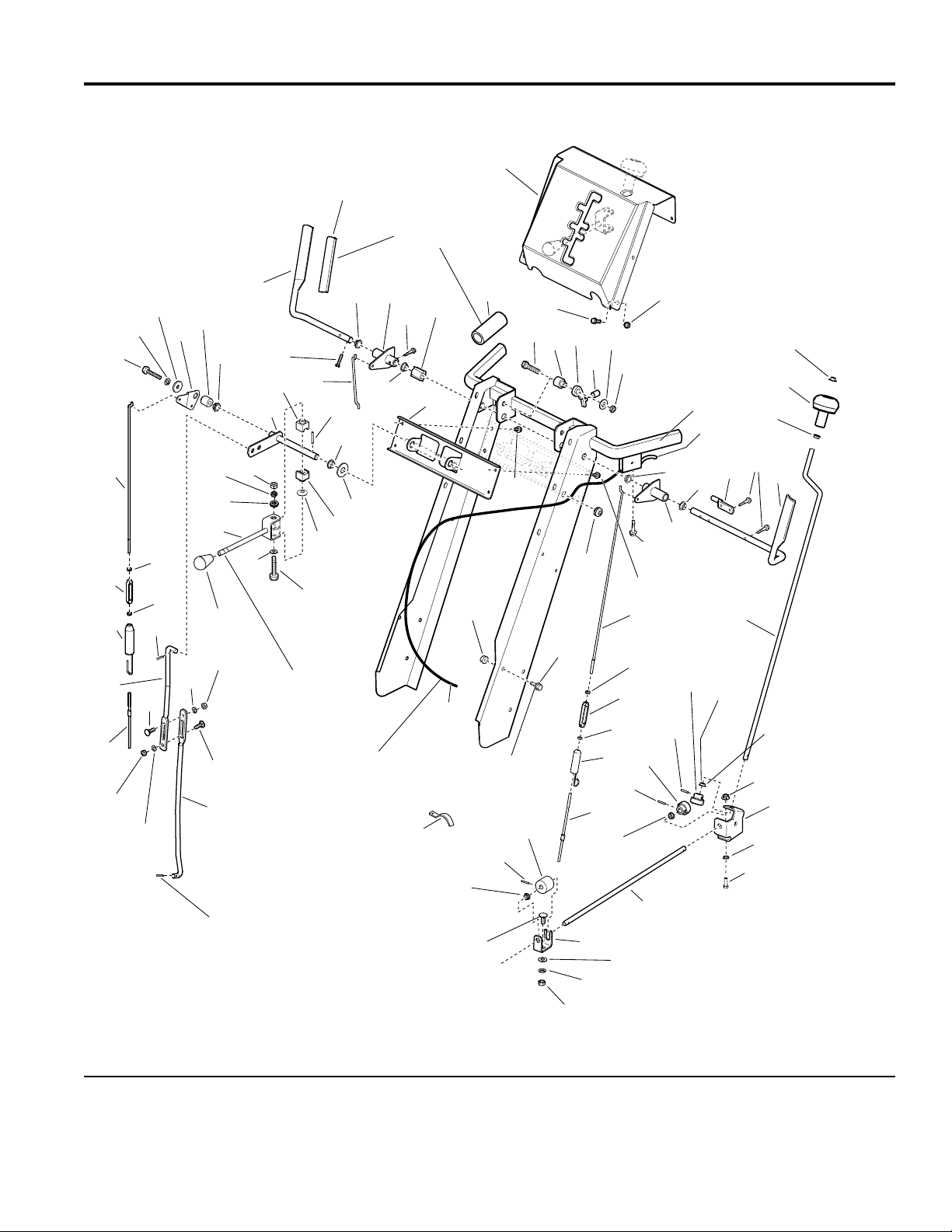

Handles and Controls Group

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

4

71

49

73

72

70

6

10

59

60

69

57

56

58

54

29

58

30

31

68

63

55

56

64

57

65

Shift rod assembly

(Ref. 54) must pivot

freely on pivot blocks

(Ref. 59).

67

65

56

66

57

63

Linkage adjustment for traction and auger drive

with power boost: with drive levers engaged, the

bottom end of lower rods (Ref. 33 & 67) should be

flush with bottom of springs (Ref. 32 & 68).

5

Apply adheasive to

secure grips.

6

8

11

9

7

38

6

13

6

62

59

24

61

Mount clutch cable to cable

support, see specific

Engine & Frame Grroup.

75

53

36

1

15

74

Torque to

19 - 29 ft-lbs.

46

47

12

45

16

986369

30

28

29

39

14

23

44

3

38

34

35

25

22

6

6

26

36

99

27

8

37

39

36

Mount bushings

(Ref. 36) with flanges

on inside of brackets

(Ref. 41 & 48).

40

41

42

43

2

18

19

20

21

17

51

52

31

32

38

33

36

48

20

49

50

The above parts group applies to the following Mfg. Nos.:

1694441- 1170E

1694437 - 1170M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

6

TP 400-3892-00-LW-S

Page 7

Handles and Controls Group

PART NO. DESCRIPTIONREF NO. QTY.

41 1718793 1 SUPPORT, Gear

42 1960518 2 PUSH NUT

43 1960252 2 CARRIAGE BOLT, 1/4-20 x 5/8

44 1725283 1 ROD, Chu te

45 1668186 1 GEAR, Worm

46 916168 2 PIN, Spring, 1/8 x 3/4

47 1931333 1 CARRIAGE BOLT, 5/16-18 x 3/4

48 1611911 1 SUPPORT, Worm

49 1917356 2 LOCKWASHER, Spring, 5/16

50 1917372 1 NUT, Hex, 5/16-1 8

51 1664022 1 GROMMET

52 1930591 6 CAPSCREW, Hex Whiz Lock, 5/16-18 x 3/4

53 1718791 1 CABLE & HANDLE ASSEMBLY, Clutch (Includes Reference Number 22)

54 1714120 1 SHIFT ASSEMBLY, Rod & Clevis

55 1713844 1 KNOB

56 1916622 3 NUT, Hex, 1/4-20

57 1916964 3 LOCKWASHER, Spring, 1/4

58 1921319 1 WASHER, 1/4

59 1668524 2 BLOCK, Pivot

60 1703043 1 ROD & ARM ASSEMBLY, Pivot

61 1921159 1 CAPSCREW, Hex Head, 1/4-20 x 2 1/4

62 1924361 1 WASHER, 1/2

63 1918447 3 PIN, Cotter

64 1720448 1 ROD, Shift, Up pe r

65 1931317 2 CARRIAGE BOLT, 1/4-20 x 3/4

66 1666255 1 ROD, Shift, Lo wer

67 1702004 1 ROD, Clutch, Lo w e r

68 1701996 1 SPRING

69 1702485 1 ROD, Clutch, Upper

70 1702552 1 SPACER

71 1919381 1 WASHER, 5/16

72 1702662 1 LEVER, Clutch

73 1922127 1 CAPSCREW, Hex Head, 5/16-18 x 3/4

74 1931277 6 NUT, Hex Flange, 5/16-18

75 934683 1 CLIP, Wire

Footnotes

The above parts group applies to the following Mfg. Nos.:

1694441- 1170E

1694437 - 1170M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

7

TP 400-3892-00-LW-S

Page 8

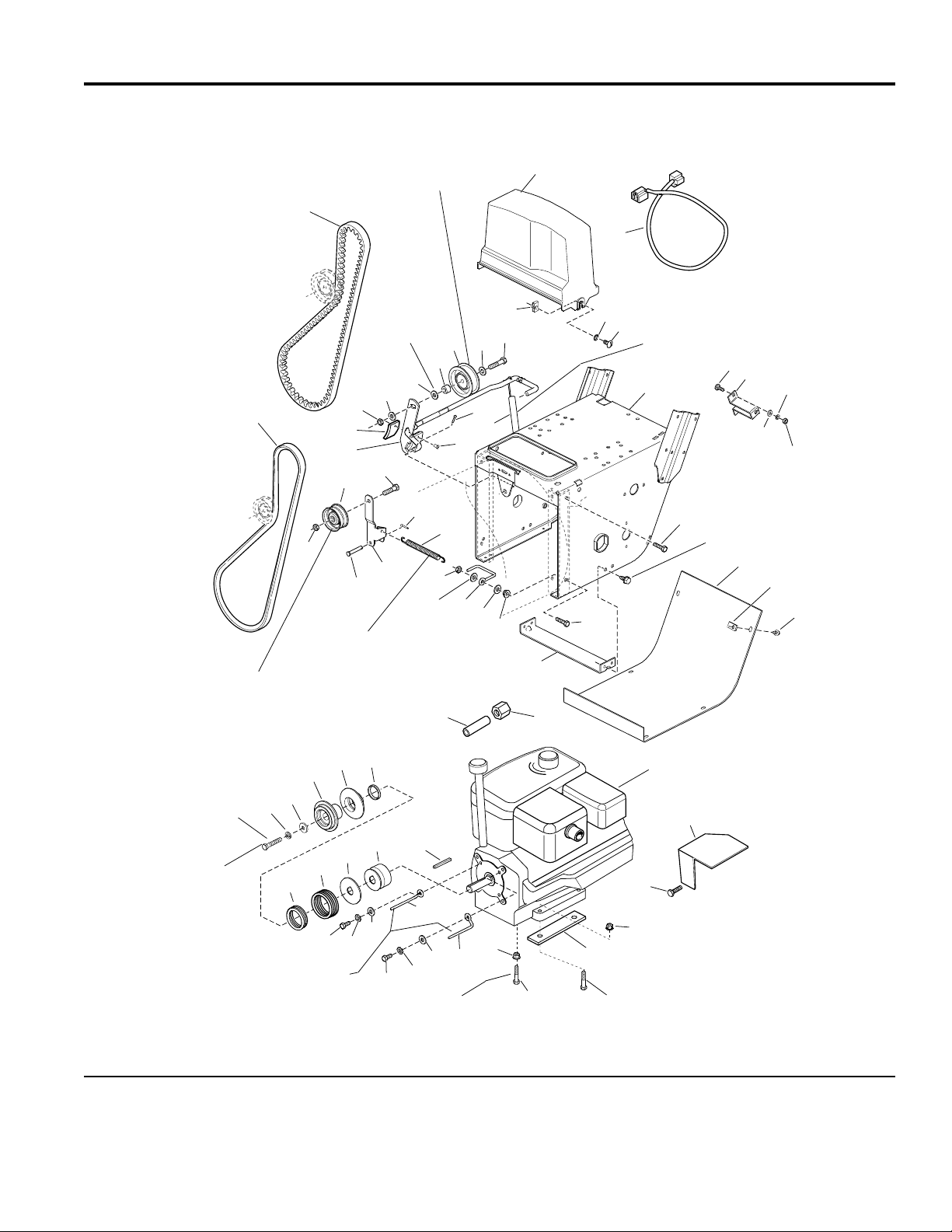

Engine and Frame Group - 11HP Electric Start

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

2

Long hub of idler pulley

(Ref. 27) to be toward

idler arm (Ref. 25).

Position idler pulley (Ref. 34) at

center of slot in clutch arm (Ref. 31).

1

Use 0-2

washers

between

Ref. 58 & 31

to assure a

centered

belt and no

interference

between

pulleys Ref.

27 & 34.

58

57

57

28

32

31

29

27

30

28

25

26

23

21

Hook one end of spring (Ref. 24)

into top hole of idler arm (Ref. 25)

and other end into top hole of the

pilot arm assembly in the Traction

Drive Grou p .

60

34

24

22

33

21

57

30

36

20

35

986373

3

59

Hook one end of spring

4

19

18

61

(Ref. 36) over clutch rod

5

assembly (Ref. 31)

6

between tabs and other

end into slot in frame.

7

13

14

8

9

11

10

12

15

16

17

50

51

52

53

54

55

46

47

Torque to

10 - 12 ft. lbs.

Position belt stop (Ref. 42)

1/16 to 1/8 inch from belt

when auger clutch is

engaged.

49

48

44

21

43

44

The above parts group applies to the following Mfg. Nos.:

1694441- 1170E

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

45

42

43

42

21

Right rear bolt

37

62

63

40

40

41

8

38

39

TP 400-3892-00-LW-S

Page 9

Engine and Frame Group - 11HP Electric Start

PART NO. DESCRIPTIONREF NO. QTY.

1 1676460 1 BE LT, Traction

2 1700415 1 BELT, Auger Drive

3 1725287 1 GUARD, Bel t

4 1935255 2 NUT, Speed, 5/16-18

5 920426 2 LOCKWASHER, Ext. Tooth, 5/16

6 1918249 2 SCREW, Truss Head, 5/16-18 x 3/4

7 1725270 1 F RA ME, Main

8 1931317 2 CARRIAGE BOLT, 1/4-20 x 3/4

9 1720404 1 SUPPORT, Clutch Cable

10 1921319 2 WASHER, 1/4

11 1916964 2 LOCKWASHER, Spring, 1/4

12 1916622 2 NUT, Hex, 1/4-20

13 1930591 2 CAPSCREW, Hex Head, Whizlock, 5/16-18 x 3/4

14 1664847 4 CAPSCREW, Hex Head, Taptite, 5/16-18 x 3/8

15 1666374 1 COVER, Botto m

16 1926018 6 NUT, Speed, 1/4-20

17 1925003 6 CAPSCREW, Hex Head, Taptite,1/4-20 x 1/2

18 1669198 1 SUPPORT, Tie Bar

19 1930595 2 CAPSCREW, Hex Head, Whizlock, 5/16-18 x 1-1/4

20 1927557 4 NUT, Hex, Whizlock, 5/1 6 - 1 8

21 1919326 6 WASHER, 11/32 x 3/4

22 1702969 2 GUIDE, Belt

23 1923362 2 NUT, Hex, Centerlock, 5/16-18

24 1672735 1 SPRING, Idler

25 1703046 1 ARM, Idler, Tracti o n

26 1665994 1 PIN

27 1668477 1 PULLEY, Idler

28 1928731 2 LOCKNUT, Jam, 3/8-16

29 1960647 1 CAPSCREW, Hex Head, 3/8-16 x 1-1/2

30 1918451 2 PlN,Cotter, 1/8 x 3/4

31 1612435 1 CLUTCH ROD & BRAKE ASSEMBLY

32 1669313 1 PAD, Brake

33 925160 2 RIVET, Pop

34 154534 1 PULLEY

35 1921971 1 CAPSCREW, Hex Head, 3/8-16 x 1-3/4

36 1724503 1 SPRING, Extension

37 * 1 ENGINE, Briggs & Stratton, 11 H.P. Electric Start - Engine Model

#204140111E1

38 1725326 4 SUPPORT, Engine Riser

39 1935159 3 CAPSCREW, Hex Head, 5/16-18 x 2-1/2, Black

40 1931277 1 NUT, Hex Flange, 5/16-18

Footnotes

* See your local Briggs & Stratton distributor for Parts & Service.

** Not a Servic e P ar t.

The above parts group applies to the following Mfg. Nos.:

1694441- 1170E

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

9

TP 400-3892-00-LW-S

Page 10

Engine and Frame Group - 11HP Electric Start

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

2

Long hub of idler pulley

(Ref. 27) to be toward

idler arm (Ref. 25).

Position idler pulley (Ref. 34) at

center of slot in clutch arm (Ref. 31).

1

Use 0-2

washers

between

Ref. 58 & 31

to assure a

centered

belt and no

interference

between

pulleys Ref.

27 & 34.

58

57

57

28

32

31

29

27

30

28

25

26

23

21

Hook one end of spring (Ref. 24)

into top hole of idler arm (Ref. 25)

and other end into top hole of the

pilot arm assembly in the Traction

Drive Grou p .

60

34

24

22

33

21

57

30

36

20

35

986373

3

59

Hook one end of spring

4

19

18

61

(Ref. 36) over clutch rod

5

assembly (Ref. 31)

6

between tabs and other

end into slot in frame.

7

13

14

8

9

11

10

12

15

16

17

50

51

52

53

54

55

46

47

Torque to

10 - 12 ft. lbs.

Position belt stop (Ref. 42)

1/16 to 1/8 inch from belt

when auger clutch is

engaged.

49

48

44

21

43

44

The above parts group applies to the following Mfg. Nos.:

1694441- 1170E

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

45

42

43

42

21

Right rear bolt

10

40

41

37

62

63

40

38

39

TP 400-3892-00-LW-S

Page 11

Engine and Frame Group - 11HP Electric Start

PART NO. DESCRIPTIONREF NO. QTY.

41 960551 1 CAPSCREW, Hex Head, 5/16-18 x 2-1/2, Black

42 1702970 2 GUIDE, Belt

43 1917356 2 LOCKWASHER, 5/16

44 1921515 2 CAPSCREW, Hex Head, 5/16-24 x 3/4

45 1672129 1 KEY, Parallel, 3/16 x 13/16 x 7/8

46 1724454 1 PULLEY, Traction

47 1701818 1 WASHER, Thrust

48 1702425 1 SPRING, Compression

49 1701849 1 SPRING, Compression

50 ** 1 WICK, Oil

51 1702017 1 PULLEY, Drive

52 1701776 1 PULLEY, Drive

53 1922755 1 WASHER,13/32 x 1

54 1916965 1 LOCKWASHER, Spring, 3/8

55 1922128 1 CAPSCREW, Hex Head, 3/8-24 x 1-1/2

56 1725398 1 DECAL, 11HP Briggs & Stratton (Not Shown)

57 1924940 3 WASHER, Flat, 13/3 2

58 157081 1 SPACER

59 ** 1 CORD, Electric, 3 Prong (Not a Service Part)

60 1724455 1 PIPE, Oil Drain

61 1724456 1 CAP, Hex, 1/2 x 18 NPT

62 1725664 1 GUARD, Muffler

63 1929477 3 CAPSCREW, Hex Washer Head, Taptite, #10-24 x 1/2

Footnotes

* See your local Briggs & Stratton distributor for Parts & Service.

** Not a Servic e P ar t.

The above parts group applies to the following Mfg. Nos.:

1694441- 1170E

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

11

TP 400-3892-00-LW-S

Page 12

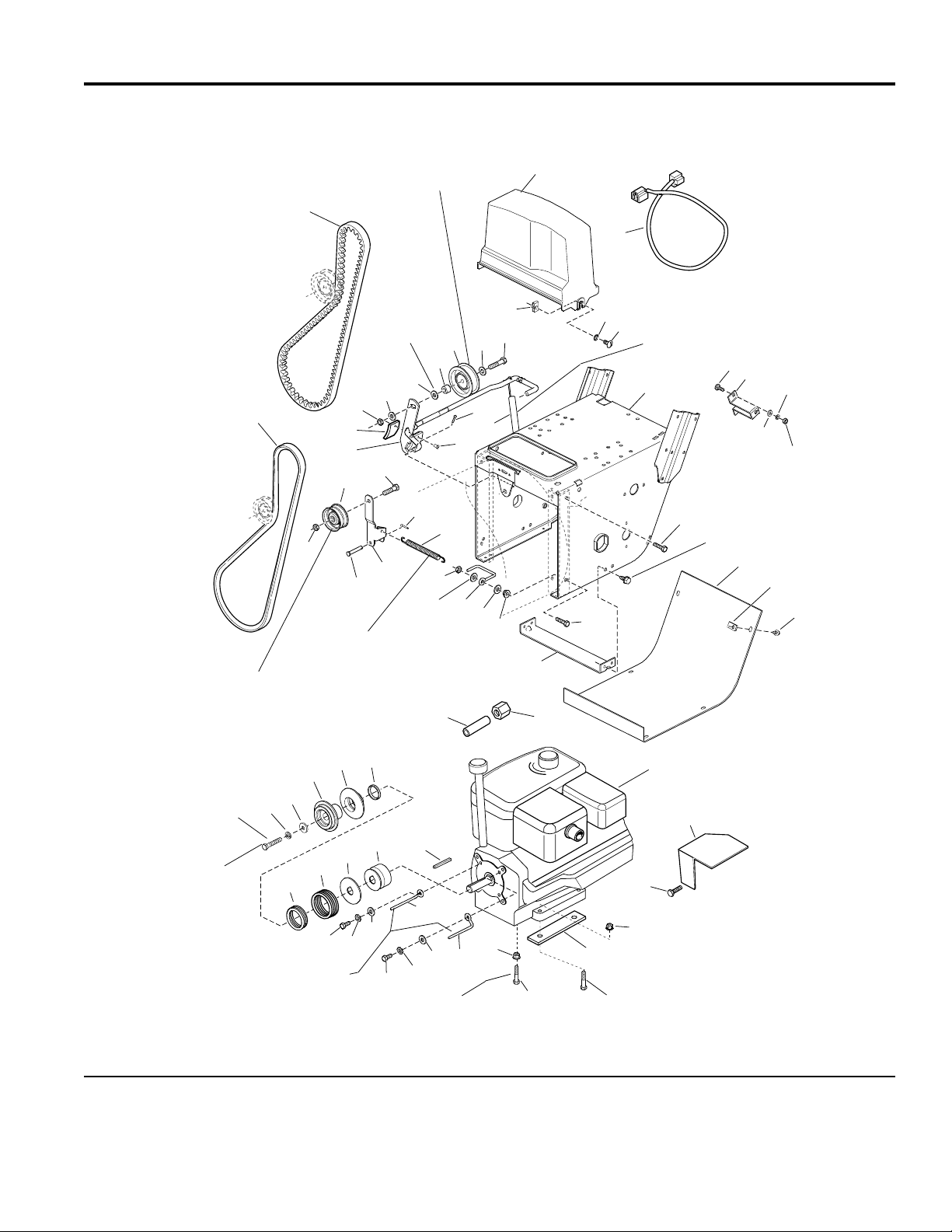

Engine and Frame Group - 11HP Manual Start

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

2

Long hub of idler pulley

(Ref. 27) to be toward

idler arm (Ref. 25).

Position idler pulley (Ref. 34) at

center of slot in clutch arm (Ref. 31).

1

Use 0-2

washers

between

Ref. 58 & 31

to assure a

centered

belt and no

interference

between

pulleys Ref.

27 & 34.

58

57

57

28

32

31

29

27

30

28

25

26

23

21

Hook one end of spring (Ref. 24)

into top hole of idler arm (Ref. 25)

and other end into top hole of the

pilot arm assembly in the Traction

Drive Grou p .

59

34

24

22

33

21

57

30

36

20

35

986381

3

Hook one end of spring

4

19

18

60

(Ref. 36) over clutch rod

5

assembly (Ref. 31)

6

between tabs and other

end into slot in frame.

7

13

14

8

9

11

10

12

15

16

17

50

51

52

53

54

55

46

47

Torque to

10 - 12 ft. lbs.

Position belt stop (Ref. 42)

1/16 to 1/8 inch from belt

when auger clutch is

engaged.

49

48

44

21

43

44

The above parts group applies to the following Mfg. Nos.:

1694437 - 1170M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

45

42

43

42

21

Right rear bolt

12

40

41

37

40

38

39

TP 400-3892-00-LW-S

Page 13

Engine and Frame Group - 11HP Manual Start

PART NO. DESCRIPTIONREF NO. QTY.

1 1676460 1 BE LT, Traction

2 1700415 1 BELT, Auger Drive

3 1725287 1 GUARD, Bel t

4 1935255 2 NUT, Speed, 5/16-18

5 920426 2 LOCKWASHER, Ext. Tooth, 5/16

6 1918249 2 SCREW, Truss Head, 5/16-18 x 3/4

7 1725270 1 F RA ME, Main

8 1931317 2 CARRIAGE BOLT, 1/4-20 x 3/4

9 1720404 1 SUPPORT, Clutch Cable

10 1921319 2 WASHER, 1/4

11 1916964 2 LOCKWASHER, Spring, 1/4

12 1916622 2 NUT, Hex, 1/4-20

13 1930591 2 CAPSCREW, Hex Head, Whizlock, 5/16-18 x 3/4

14 1664847 4 CAPSCREW, Hex Head, Taptite, 5/16-18 x 3/8

15 1666374 1 COVER, Botto m

16 1926018 6 NUT, Speed, 1/4-20

17 1925003 6 CAPSCREW, Hex Head, Taptite, 1/4-20 x 1/2

18 1669198 1 SUPPORT, Tie Bar

19 1930595 2 CAPSCREW, Whizlock, 5/16-18 x 1-1/4

20 1927557 4 NUT, Hex, Whizlock, 5/1 6 - 1 8

21 1919326 6 WASHER, 11/32 x 3/4

22 1702969 2 GUIDE, Belt

23 1923362 2 NUT, Hex, Centerlock, 5/16-18

24 1672735 1 SPRING, Idler

25 1703046 1 ARM, Idler, Tracti o n

26 1665994 1 PIN

27 1668477 1 PULLEY, Idler

28 1928731 2 LOCKNUT, Jam, 3/8-16

29 1960647 1 CAPSCREW, Hex Head, 3/8-16 x 1-1/2

30 1918451 2 PlN, Cotter, 1/8 x 3/4

31 1612200 1 CLUTCH ROD & BRAKE ASSEMBLY

32 1669313 1 PAD, Brake

33 925160 2 RIVET, Pop

34 154534 1 PULLEY

35 1921971 1 CAPSCREW, Hex Head, 3/8-16 x 1-3/4

36 1724503 1 SPRING, Extension

37 * 1 ENGINE, Briggs & Stratton, 11 H.P. Manual Start - Engine Model

#20G4160110E1

38 1725326 4 SUPPORT, Engine Riser

39 1935159 3 CAPSCREW, Hex Head, 5/16-18 x 2-1/2, Black

40 1931277 1 NUT, Hex Flange, 5/16-18

Footnotes

* See your local Briggs & Stratton distributor for Parts & Service.

** Not a Servic e P ar t.

The above parts group applies to the following Mfg. Nos.:

1694437 - 1170M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

13

TP 400-3892-00-LW-S

Page 14

Engine and Frame Group - 11HP Manual Start

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

2

Long hub of idler pulley

(Ref. 27) to be toward

idler arm (Ref. 25).

Position idler pulley (Ref. 34) at

center of slot in clutch arm (Ref. 31).

1

Use 0-2

washers

between

Ref. 58 & 31

to assure a

centered

belt and no

interference

between

pulleys Ref.

27 & 34.

58

57

57

28

32

31

29

27

30

28

25

26

23

21

Hook one end of spring (Ref. 24)

into top hole of idler arm (Ref. 25)

and other end into top hole of the

pilot arm assembly in the Traction

Drive Grou p .

59

34

24

22

33

21

57

30

36

20

35

986381

3

Hook one end of spring

4

19

18

60

(Ref. 36) over clutch rod

5

assembly (Ref. 31)

6

between tabs and other

end into slot in frame.

7

13

14

8

9

11

10

12

15

16

17

50

51

52

53

54

55

46

47

Torque to

10 - 12 ft. lbs.

Position belt stop (Ref. 42)

1/16 to 1/8 inch from belt

when auger clutch is

engaged.

49

48

44

21

43

44

The above parts group applies to the following Mfg. Nos.:

1694437 - 1170M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

45

42

43

42

21

Right rear bolt

14

40

41

37

40

38

39

TP 400-3892-00-LW-S

Page 15

Engine and Frame Group - 11HP Manual Start

PART NO. DESCRIPTIONREF NO. QTY.

41 960551 1 CAPSCREW, Hex Head, 5/16-18 x 2-1/2, Black

42 1702970 2 GUIDE, Belt

43 1917356 2 LOCKWASHER, 5/16

44 1921515 2 CAPSCREW, Hex Head, 5/16-24 x 3/4

45 1672129 1 KEY, Parallel, 3/16 x 13/16 x 7/8

46 1724454 1 PULLEY, Traction

47 1701818 1 WASHER, Thrust

48 1702425 1 SPRING, Compression

49 1701849 1 SPRING, Compression

50 ** 1 WICK, Oil (Not a Service Part)

51 1702017 1 PULLEY, Drive

52 1701776 1 PULLEY, Drive

53 1922755 1 WASHER, 13/32 x 1

54 1916965 1 LOCKWASHER, Spring, 3/8

55 1922128 1 CAPSCREW, Hex Head, 3/8-24 x 1-1/2

56 1725398 1 DECAL, 11HP Briggs& Stratton (Not Shown)

57 1924940 3 WASHER, Flat, 13/3 2

58 157081 1 SPACER

59 1724455 1 PIPE, Oil Drain

60 1724456 1 CAP, Hex, 1/4-18NPT

Footnotes

* See your local Briggs & Stratton distributor for Parts & Service.

** Not a Servic e P ar t.

The above parts group applies to the following Mfg. Nos.:

1694437 - 1170M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

15

TP 400-3892-00-LW-S

Page 16

Auger and Impeller Group - 28"

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

16

14

15

17

18

985467

End of hub to be flush

with end of rolled down

4

shaft (Ref. 9).

2

Torque to 30 -34 ft -lbs.

40 - 46 Nm.

5

7

10

10

10

11

19

6

12

13

6

8

9

Impeller to be positioned

against bearing before

tightening set screw.

3

1

2

Torque to

18-21 ft-lbs.

24 - 28 Nm.

Marked side of worm

gear must contact against

left thrust washer to assure

proper gear mesh.

Auger assembly

stamped "R".

28

Apply grease until

it appears at ends

of auger assemb ly

(2 places).

Auger assembly

stamped "L".

20

2929

21

26

22

18

25

23

Torque to 9 - 11 ft-lbs.

12 - 15 Nm.

14

24

27

The above parts group applies to the following Mfg. Nos.:

1694437 - 1170M

1694441- 1170E

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

16

TP 400-3892-00-LW-S

Page 17

Auger and Impeller Group - 28"

PART NO. DESCRIPTIONREF NO. QTY.

1 1679293 1 PULLEY, Auger Input

2 1928721 2 SETSCREW, Square Head, 5/16-18 x 1/2

3 1612187 1 IMPELLER ASSEMBLY

4 1960474 1 SETSCREW, Square Head, 3/8-16x 1/2

5 1612093 1 SEAL, Oil

6 1612149 2 BUSHING, Flange

7 1612127 1 C OL LA R, Thrust

8 936098 1 PIN, Drivelok, 3/16 x 1-1/2

9 1612129 1 SHAFT, Worm

10 918312 3 KEY, Woodruff, 3/16 x 5/8

11 1612111 1 TUBE

12 1612142 1 GEAR, Rolled Worm

13 168111 1 WASHER, Thrust

14 118118 2 SEAL

15 1923358 6 LOCKNUT, Hex, 1/4-20

16 1612137 1 CASE, Gear, RH

17 1612124 1 GASKET

18 118315 2 WASHER, Thrust

19 1612117 1 SHAFT, Auger

20 930246 1 KEY, Woodruff, 1/4 x 3/4

21 1612141 1 GEAR, Worm

22 1612136 1 CASE, Gear, LH

23 1668971 1 PLUG, Pipe, Tapered, 1/8

24 1960346 6 CAPSCREW, Hex Head, 1/4-20 x 7/8

25 1668344 2 PIN, Shear

26 1918447 2 PIN, Cotter, 3/32 x 3/4

27 1718784 1 AUGER ASSEMBLY, LH, 28"

28 1718785 1 AUGER ASSEMBLY, RH, 28"

29 921133 2 FITTING, Lube, 1/4

Footnotes

The above parts group applies to the following Mfg. Nos.:

1694437 - 1170M

1694441- 1170E

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

17

TP 400-3892-00-LW-S

Page 18

Auger Housing and Chute Group - 28"

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

5

4

3

Plastic washer

(Ref. 3) goes

between chute

and deflector.

and deflector.

2

1

Decal must cover

gap at hinge pivot.

6

1

985639

22

21

13

10

1

19

20

14

16

18

17

15

9

1

7

10

9

12

8

Mount cable bracket (Ref. 20)

on right hand side of handle

using shift control bracket

hardware.

32

33

31

Scraper blade should

be on inside of housing.

25

43

45

24

23

46

11

44

28

42

Coat top and bottom of

chute ring with grease.

26

41

40

37

39

30

When installing cable,

27

make sure it does not

come into contact with

muffler.

muffler.

28

29

32

36

35

34

38

15

OHV

Mount cable

to lift eye.

33

The above parts group applies to the following Mfg. Nos.:

1694441- 1170E

1694437 - 1170M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

18

TP 400-3892-00-LW-S

Page 19

Auger Housing and Chute Group - 28"

PART NO. DESCRIPTIONREF NO. QTY.

1 1960126 2 P U S H NU T, 1/4

2 1931333 1 CARRIAGE BOLT, 5/16-18 x 3/4

3 960210 1 WASHER, Nylon

4 1919326 1 WASHER, Flat, 11/32

5 933126 1 WINGNUT, 5/16-18

6 1720671 1 CHUTE & DEFLECTOR ASSEMBLY

7 1706085 2 SEAL, Hinge Decal

8 1960001 3 CAPSCREW, Hex, Washer Head, Plastite 10-14 x 5/8

9 1702219 3 SPACER,

10 1921319 2 WASHER, Flat

11 1931332 5 CARRIAGE BOLT, 5/16-18 x 5/8

12 1611945 1 ROD, Spring

13 1611939 1 SPRING

14 1700048 1 BOOT, Water

15 1701011 2 TIE, Self-Locking

16 932474 2 TIE, Self-Locking

17 1720446 1 CABLE, Assembly, 67" Long (Includes Ref. Nos. 14, 21, 20 & 22)

18 1922014 2 NUT, 5/16-18

19 1705920 1 BRACKET, Cable

20 1719139 1 SEAL, Rod, Chute Deflector Cable

21 1719138 1 HANDL E , Cable

22 1960600 1 SCREW, Pan Head, #8-32 x 11/16

23 1667865 3 SPRING

24 1666613 3 HOLD DOWN, Chute, Black Nylon

25 1612455 1 GUARD & SUPPORT ASSEMBLY, Chute

26 1930659 3 NUT, Reta i ner, 5/16-18

27 1925205 3 CAPSCREW, Hex Head, 5/16-18 x 17/64

28 1917356 7 LOCKWASHER, 5/16

29 1665982 1 RETAINER, Bearing

30 108202 1 BEARING, Ball

31 1612185 1 HOUSING ASSEMBLY, Auger, 28"

32 1715787 2 CUTTER, Drift

33 1921332 4 CAPSCREW, Hex Head, 5/16-18 x 3/4

34 1923325 6 CAPSCREW, Hex Head, 5/16-18 x 7/8

35 1668639 2 BEARING, Cap

36 1665980 2 BEARING, Auger, Flange

37 1663189 2 SPACER

38 1916950 4 NUT, Hex, 3/8-16

39 1916965 4 LOCKWASHER, 3/8

40 1924940 4 WASHER, Flat, 13/3 2

Footnotes

The above parts group applies to the following Mfg. Nos.:

1694441- 1170E

1694437 - 1170M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

19

TP 400-3892-00-LW-S

Page 20

Auger Housing and Chute Group - 28"

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

5

4

3

Plastic washer

(Ref. 3) goes

between chute

and deflector.

and deflector.

2

1

Decal must cover

gap at hinge pivot.

6

1

985639

22

21

13

10

1

19

20

14

16

18

17

15

9

1

7

10

9

12

8

Mount cable bracket (Ref. 20)

on right hand side of handle

using shift control bracket

hardware.

32

33

31

Scraper blade should

be on inside of housing.

25

43

45

24

23

46

11

44

28

42

Coat top and bottom of

chute ring with grease.

26

41

40

37

39

30

When installing cable,

27

make sure it does not

come into contact with

muffler.

muffler.

28

29

32

36

35

34

38

15

OHV

Mount cable

to lift eye.

33

The above parts group applies to the following Mfg. Nos.:

1694441- 1170E

1694437 - 1170M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

20

TP 400-3892-00-LW-S

Page 21

Auger Housing and Chute Group - 28"

PART NO. DESCRIPTIONREF NO. QTY.

41 177434 2 SKID

42 1709947 1 BLADE, Scraper, 28"

43 1935048 5 NUT, Hex Flange, 2-Way Lock, 5/16-18

44 1931348 4 CARRIAGE BOLT, 3/8-16 x 3/4

45 1923362 6 NUT, Hex, Center Lock, 5/16-18

46 1917372 4 NUT, Hex, 5/16-1 8

Footnotes

The above parts group applies to the following Mfg. Nos.:

1694441- 1170E

1694437 - 1170M

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

21

TP 400-3892-00-LW-S

Page 22

Traction Drive Group

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

4

1

2

3

Apply loctite

4

(2 places).

5

26

Mounted outside

of frame.

Be sure tie bar support is in place. Move axle to

left (as viewed from back) to take up end play.

Move set collar (Ref. 51) to right to remove end

play in pivot arm (Ref. 42). Torque set screw

(Ref. 45) to 10 - 14 ft-lbs.

39

40

Apply grease to

bearing areas.

45

Torque to•

18 - 21 ft-lbs.

Assemble Ref. 42, 44 & 49

with no end play. Parts

must rotate freely.

29

Mounted inside of frame.

5

6

27

28

Grease I.D. teeth•

and flange.

41

43

Torque to

10 - 14 ft-lbs.

44

Lubricate with

5W 50 Synthetic oil.

7

30

67

42

46

50

45

51

55

31

41

33

Mount to bracket in

8

frame weldment.

9

17

32

48

47

60

18

35

34

33

2

36

49

17

Pack groove

with grease.

3

19

3

2

52

53

62

12

11

10

20

21

56

53

61

Grease bearing

area of Ref. 62.

15

14

13

16

Apply Loctite and•

Torque to 55 - 60

in-lbs. when all parts

are against hub.

3

22

66

37

2

4

38

5

27

4

Mounted

outside of

frame.

55

Must pivot

freely.

63

Apply anti-seize

compound to wheel hub

area of Ref. 40 & 62.

64

Hook end to

top left corner

slot of frame.

Mounted

outside of

frame.

23

24

26

Mount in

hole at

upper rear

corner of

frame.

57

54

59

65

1

5

25

58

SC985638

Apply locktite,

torque to

8 - 10 ft-lbs.

The above parts group applies to the following Mfg. Nos.:

1694437 - 1170M

1694441- 1170E

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

22

TP 400-3892-00-LW-S

Page 23

Traction Drive Group

PART NO. DESCRIPTIONREF NO. QTY.

1 1925205 4 CAPSCREW, Hex Head, 5/16-18 x 5/8

2 1917356 10 LOCKWASHER, 5/16

3 1917372 10 NUT, Hex, 5/16-18

4 1667341 4 RETAINER, Bearing

5 1705897 4 BEARING

6 1667340 1 SHAFT, Hex

7 1921332 3 CAPSCREW, Hex Head, 5/16-18 x 3/4

8 1725428 1 DISC, Friction

9 1665995 1 HUB, Friction Disc

10 1916950 1 NUT, Hex, 3/8-16

11 1916965 1 LOCKWASHER, 3/8

12 1669256 1 ARM ASSEMBLY, Shift w/Bushings

13 1666114 1 BUSHING, Spa c e r

14 1924940 1 WASHER, Flat, 13/3 2

15 1923701 1 CAPSCREW, Hex Head, 3/8-16 x 2

16 1668255 1 SPRING

17 1678956 2 COLLAR, Thrust

18 1666207 1 PIN, Slide

19 1667335 1 SET COLLAR

20 1724333 2 SETSCREW, Square Head, 1/4-20 x 1/2

21 1720409 1 SPACER

22 1667331 1 SPROCKET, 10 Tooth

23 1960353 1 WASHER, Flat, 1/4

24 1916964 1 LOCKWASHER, 1/4

25 1921959 1 CAPSCREW, Hex Head, 1 /4-20 x 5/8

26 1924856 4 CAPSCREW, Hex Head Taptite, 5/16-18 x 1/2

27 960164 4 WASHER

28 1718752 1 JACKSHAFT

29 1720298 1 SPRING, Compression

30 1718689 1 CLUT CH, Sliding

31 1720078 1 ARM, Clutch

32 927732 1 RING, Retaining

33 1960114 2 WASHER, 3/4

34 1718688 1 GEAR, 10 Tooth, Stationary, Clutch

35 1679556 1 SPACER

36 1667330 1 SPROCKET, 36 Tooth

37 1718687 1 GEAR, 10 Tooth, Double D

38 1921333 3 CAPSCREW, Hex Head, 5/16-18 x 1

39 1666001 1 BUSHING

40 1720299 1 AXLE

Footnotes

The above parts group applies to the following Mfg. Nos.:

1694437 - 1170M

1694441- 1170E

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

23

TP 400-3892-00-LW-S

Page 24

Traction Drive Group

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

4

1

2

3

Apply loctite

4

(2 places).

5

26

Mounted outside

of frame.

Be sure tie bar support is in place. Move axle to

left (as viewed from back) to take up end play.

Move set collar (Ref. 51) to right to remove end

play in pivot arm (Ref. 42). Torque set screw

(Ref. 45) to 10 - 14 ft-lbs.

39

40

Apply grease to

bearing areas.

45

Torque to•

18 - 21 ft-lbs.

Assemble Ref. 42, 44 & 49

with no end play. Parts

must rotate freely.

29

Mounted inside of frame.

5

6

27

28

Grease I.D. teeth•

and flange.

41

43

Torque to

10 - 14 ft-lbs.

44

Lubricate with

5W 50 Synthetic oil.

7

30

67

42

46

50

45

51

55

31

41

33

Mount to bracket in

8

frame weldment.

9

17

32

48

47

60

18

35

34

33

2

36

49

17

Pack groove

with grease.

3

19

3

2

52

53

62

12

11

10

20

21

56

53

61

Grease bearing

area of Ref. 62.

15

14

13

16

Apply Loctite and•

Torque to 55 - 60

in-lbs. when all parts

are against hub.

3

22

66

37

2

4

38

5

27

4

Mounted

outside of

frame.

55

Must pivot

freely.

63

Apply anti-seize

compound to wheel hub

area of Ref. 40 & 62.

64

Hook end to

top left corner

slot of frame.

Mounted

outside of

frame.

23

24

26

Mount in

hole at

upper rear

corner of

frame.

57

54

59

65

1

5

25

58

SC985638

Apply locktite,

torque to

8 - 10 ft-lbs.

The above parts group applies to the following Mfg. Nos.:

1694437 - 1170M

1694441- 1170E

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

24

TP 400-3892-00-LW-S

Page 25

Traction Drive Group

PART NO. DESCRIPTIONREF NO. QTY.

41 1666425 2 BUSHING

42 1670849 1 ARM ASSEMBLY, Pivot w/Bushings (Includes Reference Numbers 41, 43 &

46)

43 1666855 1 BUSHING

44 1672595 1 PULLEY, Traction

45 1928721 2 SETSCREW, Square Head, 5/16-18 x 1/2

46 1665521 1 BEARING

47 1960114 1 WASHER

48 918312 1 KEY, Woodruff, 3/16 x 5/8

49 1719879 1 DRIVE DISC W/SPINDLE

50 1919394 1 WASHER

51 8021010 1 SET COLLAR

52 1725666 1 SPRING

53 1918451 2 PIN, Cotter, 1/8 x 3/4

54 1666105 1 ROD, Pivot

55 1919438 3 NUT, Hex, Lock, 5/16- 1 8

56 1919326 1 WASHER, Flat, 11/3 2

57 1700473 1 BELLCRANK

58 1666106 1 BUSHING, Pivot

59 1922127 1 CAPSCREW, Hex Head, 5/16-18 x 1 -3/4

60 1720300 1 GEAR & HUB ASSEMBLY, 50 Tooth

61 1930570 2 CAPSCREW, Hex Head, 5/16-18 x 1-1/2

62 1720716 1 GEAR & HUB ASSEMBLY, w/Bushing, 50 Tooth

63 921133 1 FITTING, Lube

64 960169 1 WASHER

65 1720305 1 BUSHING

66 1666980 1 CHAIN, Drive, #40

67 1924366 1 WASHER

Footnotes

The above parts group applies to the following Mfg. Nos.:

1694437 - 1170M

1694441- 1170E

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

25

TP 400-3892-00-LW-S

Page 26

Wheels & Tires Group

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

1

2

3

4

W985644

6

5

8

5

10

7

3

9

The above parts group applies to the following Mfg. Nos.:

1694437 - 1170M

1694441- 1170E

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

26

TP 400-3892-00-LW-S

Page 27

Wheels & Tires Group

PART NO. DESCRIPTIONREF NO. QTY.

1 1921978 1 CAPSCREW, Hex Head, 5/16-18 x 2

2 1919438 1 NUT, Hex Lock ESNA Light, 5/16-18

3 172353 2 VALVE STEM & CAP

4 1714242 1 HUB, Wheel, RH

5 1612000 2 TIRE, 4.80-4.00-8

6 1714235 1 WHEEL & TIRE ASSEMBLY, RH (Includes Reference Numbers 3, 4 & 5)

7 1720307 1 HUB, Wheel, LH

8 1720306 1 WHEEL & TIRE ASSEMBLY, LH (Includes Reference Numbers 3, 5 & 7)

9 153038 2 TUBE, Tire

10 1666969 1 KLIK-PIN

Footnotes

The above parts group applies to the following Mfg. Nos.:

1694437 - 1170M

1694441- 1170E

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

27

TP 400-3892-00-LW-S

Page 28

Decals Group - 1170

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

3

D986372

2

2

2

3

1

1

12

5

4

6

7

10

4

11

171653 2

6

5

8

9

9

The above parts group applies to the following Mfg. Nos.:

1694437 - 1170M

1694441- 1170E

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

28

TP 400-3892-00-LW-S

Page 29

Decals Group - 1170

PART NO. DESCRIPTIONREF NO. QTY.

1 1714245 1 DECAL, Shift Pattern, RH

2 1720674 1 D E CA L , Da s h

2 1722688 1 DECAL, Dash (Export)

3 1714246 1 DECAL, Shift Pattern, LH

4 1725377 1 DECAL, Stripe 1170

5 1722641 1 DECAL, Discharge Chute Danger (Export)

5 1722674 1 DECAL, Discharge Chute Warning

6 1716532 1 DECAL, Auger Danger

6 1722642 1 DECAL, Auger Danger (Export)

7 * 1 DECAL, OPEI (Not Serviced)

8 * 1 DECAL, Decibel (Export)

8 * 1 DECAL, Patent

9 1720454 1 DECAL, Touch Up Paint Deep Orange

10 * 1 I.D. Tag (Not Serviced)

11 1725507 1 DECAL-Power Boost

12 1706085 2 DECAL, Hinge, Orange

Footnotes

* Not a Service Part.

The above parts group applies to the following Mfg. Nos.:

1694437 - 1170M

1694441- 1170E

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

29

TP 400-3892-00-LW-S

Page 30

Headlight Group

NOTE: Unless noted otherwise,

use the standard hardware torque

specification chart.

986371

1

7

2

4

6

Existing

Hardware

5

3

The above parts group applies to the following Mfg. Nos.:

1694437 - 1170M

1694441- 1170E

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

30

TP 400-3892-00-LW-S

Page 31

Headlight Group

PART NO. DESCRIPTIONREF NO. QTY.

1 1725291 1 HEADLIGHT ASEMBLY

2 1701011 2 T I E , S el f L o ck in g

3 934683 1 CLIP, Wire

4 1709256 1 LOCKWSHER, 5/16

5 1917372 1 NUT, Hex, 5/16-18

6 1725292 1 BRACKET

7 1931333 1 CARRIAGE BOLT, 5/16-18 x 3/4

Footnotes

The above parts group applies to the following Mfg. Nos.:

1694437 - 1170M

1694441- 1170E

© Copyright Simplicity Manufacturing, Inc. All Rights Reserved.

2003

31

TP 400-3892-00-LW-S

Page 32

Page 33

Hardware Identification & Torque Specifications

Common Hardware Types

Hex Head Capscrew

Carriage Bolt

Standard Hardware Sizing

When a washer or nut is identified as 1/2”, this is the

Nominal size

second number is present it represent the

When bolt or capscrew is identified as 1/2 - 16 x 2”, this

means the

second number represents the

example, and the final number is the

bolt or screw (in this example 2 inches long).

, meaning the

Nominal size

inside diameter

, or

body diameter

threads per inch

body length

Washer

Lockwasher

Hex Nut

is 1/2 inch; if a

threads per inch

is 1/2 inch; the

(16 in this

of the

The guides and ruler furnished below are designed to

help you select the appropriate hardware and tools.

0

1/4 3/4

1/2

Nut, 1/2”

Inside

Diameter

1

1/4 3/4

1/2

Screw, 1/2 x 2

2

1/4 3/4

1/2

3

1/4 3/4

1/2

4

Body

Diameter

Body

Length

Torque Specification Chart

FOR STANDARD MACHINE HARDWARE (Tolerance ± 20%)

Hardware

Grade

Size Of

Hardware ft/lbs Nm. ft/lbs Nm. ft/lbs Nm.

8-32

8-36

10-24

10-32

1/4-20

1/4-28

5/16-18 11 15.0 17 23.1 25 34.0

5/16-24 12 16.3 19 25.8 27 34.0

3/8-16 20 27.2 30 40.8 45 61.2

3/8-24 23 31.3 35 47.6 50 68.0

7/16-14 30 40.8 50 68.0 70 95.2

7/16-20 35 47.6 55 74.8 80 108.8

1/2-13 50 68.0 75 102.0 110 149.6

1/2-20 55 74.8 90 122.4 120 163.2

9/16-12 65 88.4 110 149.6 150 204.0

9/16-18 75 102.0 120 163.2 170 231.2

5/8-11 90 122.4 150 204.0 220 299.2

5/8-18 100 136 180 244.8 240 326.4

3/4-10 160 217.6 260 353.6 386 525.0

3/4-16 180 244.8 300 408.0 420 571.2

7/8-9 140 190.4 400 544.0 600 816.0

7/8-14 155 210.8 440 598.4 660 897.6

1-8 220 299.2 580 788.8 900 1,244.0

1-12 240 326.4 640 870.4 1,000 1,360.0

1. These torque values are to be used for all hardware

excluding: locknuts, self-tapping screws, thread forming

screws, sheet metal screws and socket head setscrews.

2. Recommended seating torque values for locknuts:

a. for prevailing torque locknuts - use 65% of grade 5

torques.

b. for flange whizlock nuts and screws - use 135% of

grade 5 torques.

3. Unless otherwise noted on assembly drawings, all torque

values must meet this specification.

No

Marks

SAE Grade 2 SAE Grade 5 SAE Grade 8

in/lbs in/lbs

19

2.1

20

2.3

27

3.1

31

3.5

66

7.6 8 10.9 12 16.3

76

8.6 10 13.6 14 19.0

NOTES

30

31

43

49

3.4

3.5

4.9

5.5

in/lbs

41

43

60

68

4.6

4.9

6.8

7.7

Wrench & Fastener Size Guide

1/4

1/4” Bolt or Nut

Wrench—7/16”

5/16

5/16” Bolt or Nut

Wrench—1/2”

3/8

3/8” Bolt or Nut

Wrench—9/16”

7/16

DIA.

7/16” Bolt or Nut

Wrench (Bolt)—5/8”

Wrench (Nut)—11/16”

1/2

DIA.

1/2” Bolt or Nut

Wrench—3/4”

Page 34

MANUFACTURING, INC.

500 N. Spring Street / PO Box 997

Port Washington, WI 53074-0997 USA

www.simplicitymfg.com

© Copyright Simplicity Manufacturing, Inc.

All Rights Reserved. Printed In USA.

2003

Loading...

Loading...