Page 1

1-1

TrueAlert

™

Addre ssable Controller

Insta lla tio n Guid e

574-762

Rev. E

Page 2

1-2

Page 3

Copyright © 2005, 2007 Tyco Safety Products Westminster, Westminster, MA 01441-0001 USA.

All rights reserved.

Printed in the United States of America.

Information in this document is subject to change without notice. No part of this document may be

reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose,

without the express written consent of Tyco Safety Products.

Tyco, Simplex, the Simplex logo, IDNet and TrueAlert are trademarks of Tyco International

Services AG or its affiliates in the U.S. and/or other countries.

Copyrights and Trademarks

Page 4

Page 5

Chapter 1 Introduction to the TrueAlert Addressable Controller.... 1-1

Introduction .............................................................................................................. 1-1

In this Chapter ......................................................................................................... 1-1

Introduction to TrueAlert .............................................................................................. 1-2

Overview.................................................................................................................. 1-2

The 4009 TrueAlert Addressable Controller................................................................ 1-3

Overview.................................................................................................................. 1-3

Control Types .............................................................................................................. 1-5

Overview.................................................................................................................. 1-5

Addressable TrueAlert 4009 Control (IDNet and RUI) ........................................... 1-5

Hardwired 4009 TrueAlert Control.......................................................................... 1-5

Hardware Components................................................................................................ 1-6

Overview.................................................................................................................. 1-6

TrueAlert SLC Channels.......................................................................................... 1-6

Battery Charger ....................................................................................................... 1-6

IDNet and RUI Ports................................................................................................ 1-6

DIP Switches ........................................................................................................... 1-6

System Trouble Indicators (LEDs E-A) ................................................................... 1-8

System Trouble Messages ...................................................................................... 1-9

Isolating Earth Grounds......................................................................................... 1-10

AC Power Indicator (LED 9) .................................................................................. 1-10

Chapter 2 System Configuration and Installation.............................. 2-1

Overview.................................................................................................................. 2-1

In this Chapter ......................................................................................................... 2-1

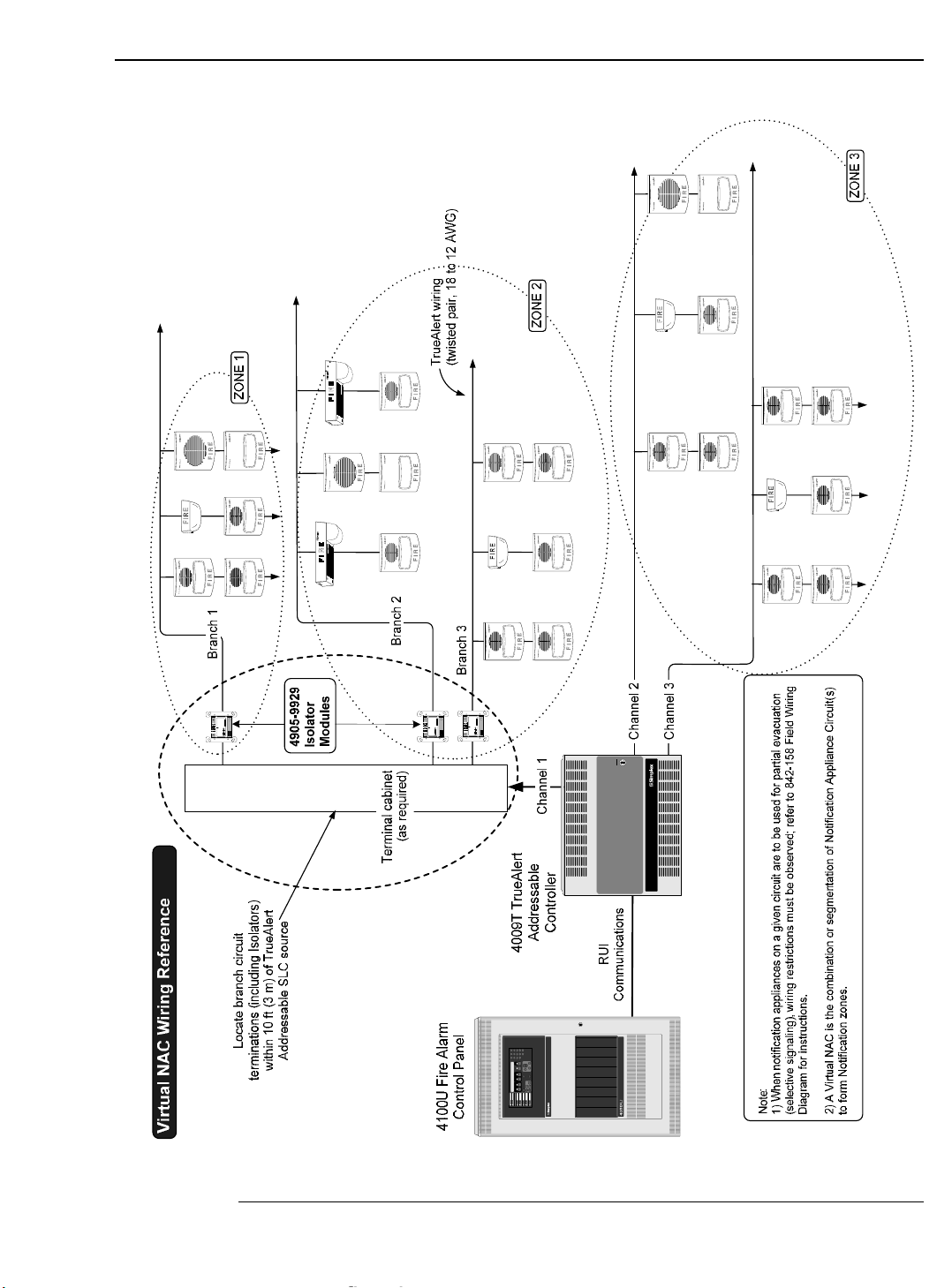

System Overview: Applications Diagram .................................................................... 2-2

Illustration ................................................................................................................ 2-2

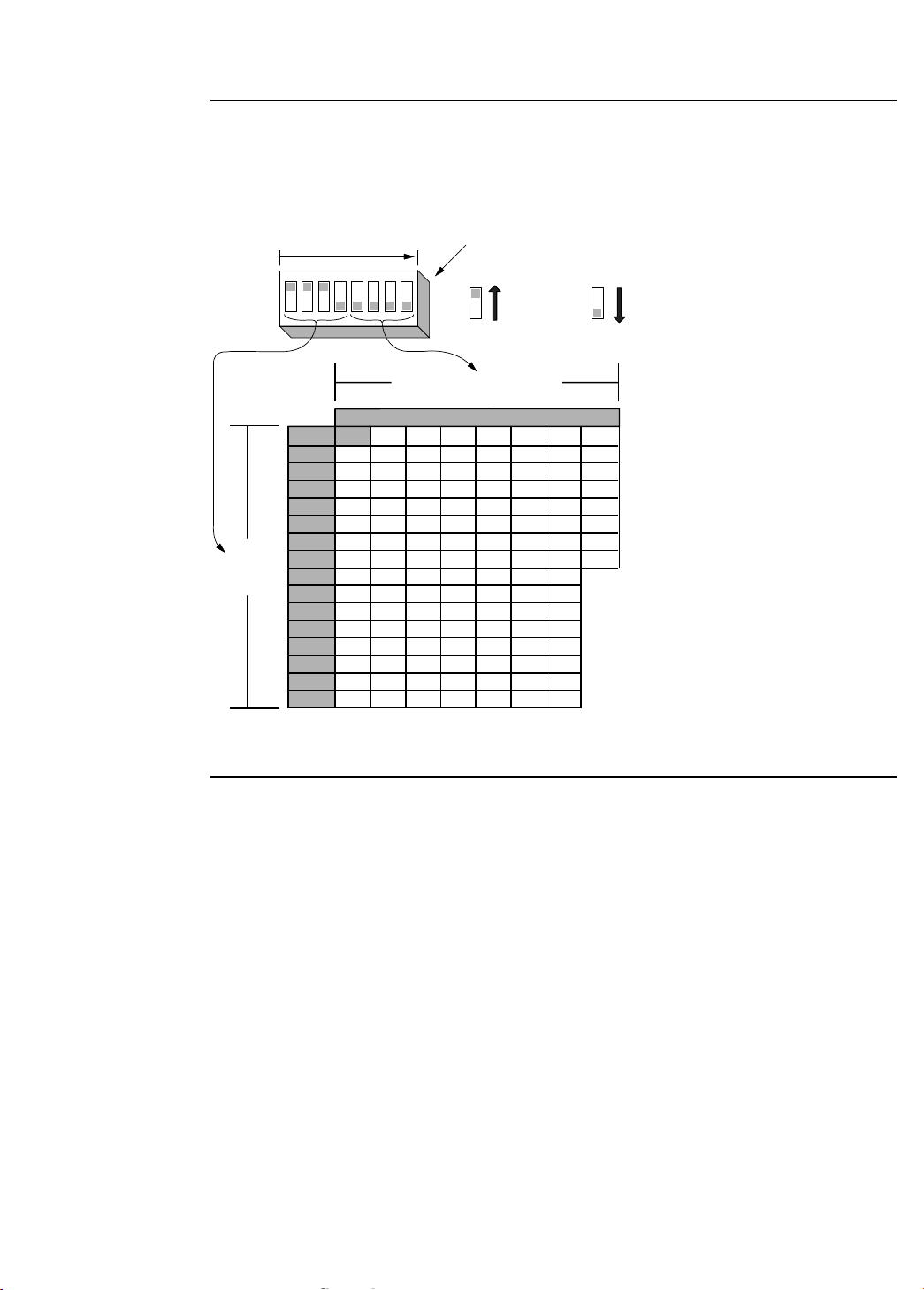

System Overview: Selective Signaling ........................................................................ 2-3

Illustration ................................................................................................................ 2-3

System Configuration .................................................................................................. 2-4

Overview.................................................................................................................. 2-4

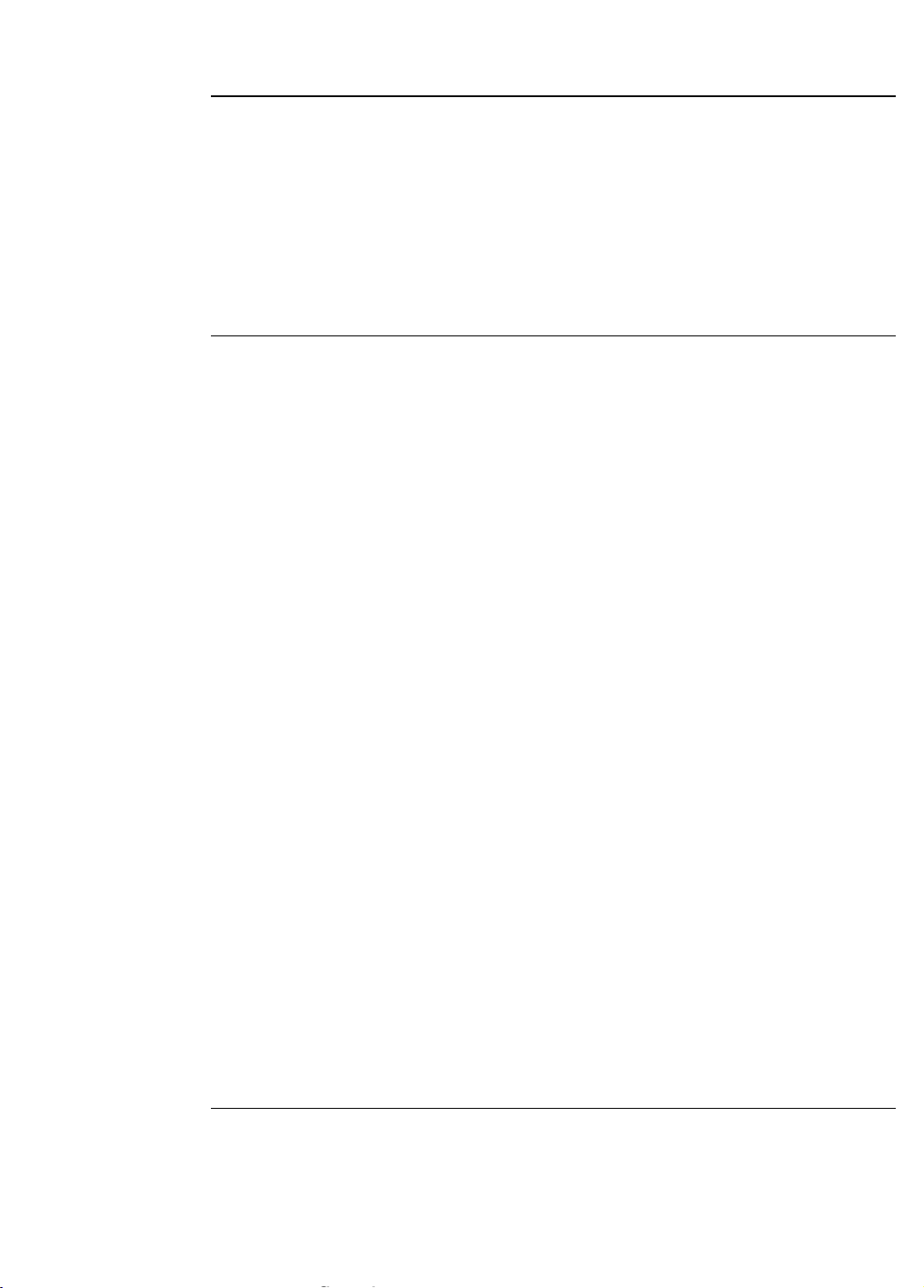

SLC Appliance DIP Switches (SW1, SW2, SW3) .................................................. 2-4

Hardware Configuration DIP Switch (SW4)............................................................. 2-5

Address/Software Configuration DIP Switch (SW5)................................................ 2-8

System Installation .................................................................................................... 2-11

General Information............................................................................................... 2-11

Tools and Equipment Required............................................................................. 2-11

Required Documentation....................................................................................... 2-12

General Notes........................................................................................................ 2-12

Mounting the 4009 TrueAlert Addressable Controller ........................................... 2-13

Wiring the 4009 TrueAlert Addressable Controller................................................ 2-14

System Power Requirements ................................................................................ 2-15

Table of Contents

Page 6

Mounting and Wiring Peripheral Appliances ......................................................... 2-16

Installing Option Interfaces ........................................................................................ 2-17

Overview................................................................................................................ 2-17

Chapter 3 4010 Panel Programming ................................................... 3-1

Overview.................................................................................................................. 3-1

In this Chapter ......................................................................................................... 3-1

Overview.................................................................................................................. 3-2

Step 1: Starting the Programmer............................................................................. 3-2

Step 2: Adding an IDNet Point for the 4009 TrueAlert Addressable Controller ...... 3-3

Step 3: Configuring 4009 SLC Point Types............................................................. 3-4

Step 4: Editing Point Labels .................................................................................... 3-4

Step 5: Saving a Configuration................................................................................ 3-5

Step 6: Specifying Signal Operation........................................................................ 3-5

Deleting the 4009 TrueAlert Addressable Controller................................................... 3-6

Overview.................................................................................................................. 3-6

4010 Quick CFIG......................................................................................................... 3-7

Overview.................................................................................................................. 3-7

Quick CFIG Steps.................................................................................................... 3-7

Page 7

Figure 1-1. Simplex 4009 TrueAlert Addressable Controller .......................................... 1-3

Figure 1-2. 4009 TrueAlert Addressable Controller System Board ................................ 1-7

Figure 1-3. System Trouble Indicators ............................................................................ 1-8

Figure 2-1. 4009 TrueAlert Applications Diagram........................................................... 2-2

Figure 2-2. Selective Signaling Example ........................................................................ 2-3

Figure 2-3. SLC Appliance Settings (SW1, SW2, SW3) ................................................. 2-4

Figure 2-4. IDNet Address Settings (SW5) ..................................................................... 2-8

Figure 2-5. RUI Address Settings (SW5) ........................................................................ 2-9

Figure 2-6. Installing the 4009 Back Box ...................................................................... 2-13

Figure 2-7. 4009 TrueAlert Addressable Controller Connection Diagram .................... 2-15

List of Figures

Page 8

Page 9

1-1

The 4009-9401 TrueAlert

™

Addressable Controller is a self-contained adjunct panel for use with

TrueAlert addressable notification appliances. The base version of the Addressable Controller is a

single-board system consisting of three Signaling Line Circuit (SLC) channels, a power supply

and charger, slave interfaces for IDNet

™

and RUI protocols, and two conventional Notification

Appliance Circuit (NAC) inputs for hardwired control. Option cards are available to provide the

following additional capabilities:

• 4009-9812 Class A Adapter Option Card. Allows fault tolerance in the case of

open circuit wiring faults on the three TrueAlert SLCs.

• 4009-9809 IDNet Repeater Option Card. 4010 only. Regenerates and provides a

power and distance boost for the IDNet channel. The 4009-9809 takes the IDNet signal

from the 4009 receiver and retransmits it on its output side at host panel IDNet levels.

When the IDNet Repeater Option Card is used, the Fiber Optic Receiver Option Card is

not available for the 4009 TrueAlert Addressable Controller.

• 4009-9810 (Class B)/4009-9811 (Class A) Fiber Optic Receiver Option Card.

4010 only. Receives IDNet communication over a fiber optic link and regenerates the

IDNet signal. The Fiber Optic Receiver Option Card is used with the 4090-9105

(Class B)/4090-9107 (Class A) Fiber Optic Card to form an IDNet fiber optic link.

The table below lists the topics in this chapter.

Topic See Page

Introduction to TrueAlert 1-2

The 4009 TrueAlert Addressable Controller 1-3

Control Types 1-5

Hardware Components 1-6

Chapter 1

Introduction to the TrueAlert

Addressable Controller

Introduction

In this Chapter

Page 10

1-2

TrueAlert notification appliance operation provides power, control, and supervision of horns and

strobes over a single pair of wires. The controlling TrueAlert channel digitally communicates with

each appliance and receives a response to verify the appliance’s presence on the channel. When

required, the TrueAlert channel provides a digital command to control appliance operation.

(Typical operation would be for both horns and strobes to be initially activated upon alarm and

then, when desired, horns can be silenced while the strobes continue to flash. When the alarm

condition is over, both appliance types can be de-energized.)

Due to the supervision provided, TrueAlert notification appliances can be wired in a Class B

(Style 4) configuration without requiring traditional in/out wiring methods. Both separate branch

wiring and T-tapping are allowed in these cases. Class A (Style 6) operation does require

traditional in/out wiring methods. Up to 63 appliances can be supported on a single TrueAlert

channel.

Each TrueAlert notification appliance contains an electronic module and a selectable address

setting (in addition to its notification appliance) that allows it to occupy a unique location on the

TrueAlert channel. This on-board module also allows the TrueAlert channel to perform appliance

diagnostics that assist with installation and subsequent test operations. A visible LED at each

TrueAlert appliance can be set up to provide verification of communication, and flashes with the

appliance’s address setting when locally requested using a magnetic test tool.

Introduction to TrueAlert

Overview

Page 11

1-3

Figure 1-1 is an illustration of the TrueAlert Addressable Controller.

Figure 1-1. Simplex 4009 TrueAlert Addressable Controller

The TrueAlert Addressable Controller provides the TrueAlert channel interface between fire

alarm control panels (FACPs) that do not support TrueAlert operation, and the TrueAlert

appliances. It provides three TrueAlert channels that supply 2.5 amperes of alarm current each,

and an auxiliary 0.5-amp output. Panels that do not support TrueAlert operation cannot take

advantage of all the features of TrueAlert notification appliances, but the TrueAlert Addressable

Controller provides these panels with various capabilities that depend on the interface being used.

There are three possible interfaces to the TrueAlert Addressable Controller that the FACP can use

to control operation of the appliances.

The Simplex 4010 FACP can interface to the TrueAlert Addressable Controller via an IDNet

Interface. When using this interface, the TrueAlert Addressable Controller appears to the 4010 as

an IDNet addressable peripheral. Each of the three TrueAlert SLC channels looks to the 4010 like

a TrueAlert Non-Addressable NAC with independent control of horns and strobes. This provides

greater selective control. Diagnostic features are enabled and disabled via DIP switches in the

panel. Up to five TrueAlert Addressable Controllers can be used with a 4010 host (see Field

Wiring Diagram

842-158).

The Simplex 4100 or 4020 FACPs can interface to the TrueAlert Addressable Controller via a

Remote Unit Interface (RUI). Diagnostic features are enabled and disabled through the front panel

user interface. The quantity of TrueAlert Addressable Controllers that can be used is limited only

by the number of card addresses available (out of the total of 119).

Continued on next page

The 4009 TrueAlert Addressable Controller

Overview

Page 12

1-4

The Hardwired NAC Interface uses two conventional NACs from the host FACP. One NAC is

used to enable operation of the strobe appliances (so that they are On Until Silenced), and a

second NAC is used to enable operation of the horn appliances (so that they are On Until Reset).

All three SLC channels of the TrueAlert Addressable Controller are controlled together.

Diagnostic features are enabled and disabled via DIP switches in the panel. Up to four hardwired

TrueAlert Addressable Controllers can be used with a single host panel (see Field Wiring

Diagram 842-158).

Alternatively, the first of the two host NACs can be set up to control audible and visible output for

TrueAlert SLC Channel 1, while the second host NAC controls audible and visible output for

TrueAlert SLC Channels 2 and 3. With this type of operation, there is no individual control of

audibles and visibles.

For any of the described applications, the TrueAlert Addressable Controller can minimize

transmission line losses associated with sending large currents for notification appliances long

distances within buildings. In a fire alarm system with the TrueAlert Addressable Controller, a

power supply and batteries for notification appliances are located near the actual notification

appliances, saving system power and battery capacity while minimizing line losses.

The 4009 TrueAlert Addressable Controller, Continued

Overview, continued

Page 13

1-5

The 4009 TrueAlert Addressable Controller can be used with addressable IDNet or RUI systems.

It can also be used with hardwired FACPs. This section discusses these general uses.

The TrueAlert Addressable Controller is addressable when configured as an IDNet or RUI

peripheral. In the IDNet or RUI modes, SW5 (see Figure 1-2) sets the address of the Addressable

Controller which is controlled and configured by the 4010 FACP (for IDNet) or the 4100/4020

(for RUI). The Addressable Controller monitors each SLC. If a trouble occurs, faults (including

appliance supervision, power, battery integrity, and earth) are communicated to the host panel as

IDNet or RUI messages.

When wired to a 4100U, visual synchronization is possible. A maximum of 39 multicandela

addressable visuals may be synchronized per SLC. All SLCs are synchronized across a 4009T. All

4009Ts are synchronized across the 4100U.

There are two hardwired NAC control inputs on the Addressable Controller which can be used to

activate the appliances connected to the Addressable Controller. The hardwired NAC control

inputs provide backward compatibility with other Simplex panels. In the hardwired mode, the

configuration of the Addressable Controller is configured via two DIP switches (Hardware

Configuration Switch (SW4) and Address/Software Configuration Switch (SW5)). Each input

(called Hardwire Control Channel 1 and Channel 2, respectively, on TB7) simulates a typical

hardwired notification appliance, as seen from the host panel. The host NAC that is connected to

Channel 1 sends general trouble messages to the host panel, while the NAC connected to Channel

2 sends SLC channel-related messages to the host panel.

An End Of Line Resistor (EOLR) may be directly connected to the hardwire control Channel 1

and 2 terminals, or NAC wiring can be continued on to the next termination point for that circuit.

See Field Wiring Diagram 842-158 for details.

A maximum of four TrueAlert Addressable

Controllers can be attached to the Hardwire Control Channel 1 and Channel 2 inputs.

Control Types

Overview

Addressable

TrueAlert 4009

Control (IDNet

and RUI)

Hardwired 4009

TrueAlert Control

Page 14

1-6

This section describes the hardware on the 4009 board. Use Figure 1-2 to locate the items

described on this page.

The Addressable Controller system board provides three TrueAlert SLC channels. Channels 1

through 3 are Class B TrueAlert signaling line circuits. Field wiring terminations are provided for

12 AWG to 18 AWG wire (twisted pair wire is required). Refer to Field Wiring Diagram 842-158

for complete wiring, compatible appliances, current, and line distance information. Each channel

is capable of being independently controlled by the TrueAlert 4009, as commanded by the host

panel and Dip Switch SW5 settings.

Each signaling line circuit is monitored for short and open circuit line faults when in the standby (not

energized) condition. In the event of a short circuit, the Addressable Controller will not activate the

SLC channel while the short circuit fault is present. Short and open circuit faults are reported to the

host panel via the command channel (IDNet, RUI, or hardwired) and can be identified by a steady

trouble LED on the Addressable Controller during the supervisory state.

The channels are configurable as Class A (Style 6) circuits with the addition of the

4009-9812 Class A Adapter Option Card. The Addressable Controller monitors for insertion of the

Class A Adapter Option Card, and detects it when it is configured properly via Hardware

Configuration Switch SW4 (see Table 2-1 in Chapter 2).

On power-up, or on controller reset via DIP switch SW4 (IDNet and Hardwired only) or SW5,

each channel momentarily disconnects its supervision, allowing earth fault isolation.

The battery charger charges lead acid batteries up to 18 AH (refer to Field Wiring Diagram

842-158 for details). Low, missing, and depleted batteries are detected through supervision. The

battery charger output remains disabled until a battery is sensed. The 4009 does not support

external chargers.

The control interfaces for IDNet and RUI are TB1 and TB2. Use these ports as described in Field

Wiring Diagram 842-158.

DIP switches are used to configure the system, as described in Chapter 2.

Continued on next page

Hardware Components

Overview

TrueAlert SLC

Channels

Battery Charger

IDNet and RUI Ports

DIP Switches

Page 15

1-7

Figure 1-2. 4009 TrueAlert Addressable Controller System Board

Continued on next page

Hardware Components, Continued

TB3, TB4, TB5

TRUEALERT SLC

CHANNELS

TB2

IDNet CONTROL INTERFACE

P4

IDNet REPEATER CARD

or FIBER RECEIVER

CARD

H1 (RED WIRE), H2 (BLACK W IRE)

MAIN POWER INPUTS FROM BRIDGE

RECTIFIER

TB8

BATTERY TERMINAL

P5 (ORANGE WIRE)

P6 (YELLOW WIRE)

CHARGER INPUTS

FROM TRANSF0RMER

TB7

NAC CONTROL

INTERFACE

(HOST NAC IN)

TB6

AUXILARY POWER

OUTPUT

(0.5 AMP AVAILABLE)

P2 AND P3

FOR CLASS A

ADAPTER CARD

LED 9

AC POWER

INDICATOR

LED(s) E-A

TROUBLE INDICATORS

SW4

HARDWARE

CONFIGURATION

DIP SWITCH

TB1

RUI CONTROL

INTERFACE

SW5

ADDRESS/SOFTWARE

CONFIGURATION

DIP SWITCH

SW1, SW2,

SW3

SLC DEVICE

SWITCHES

PB-SW6

TROUBLE SCROLL

PUSHBUTTON

SLC LEDs

(CH1-CH3)

Page 16

1-8

The system trouble indicators consist of a bank of five yellow LEDs (see Figure 1-2 for location

of LEDs) that are used to signify various trouble conditions within the Addressable Controller

system. Only one trouble at a time is indicated, with the highest trouble state indicated first. When

that trouble clears, the next highest trouble state is indicated.

Notes:

• Any trouble indication that applies to a specific SLC channel has the

corresponding LED (CH1 through CH3) for that channel lit.

• The on-board trouble scroll pushbutton (PB-SW6) allows an operator to scroll

through multiple troubles.

Figure 1-3 lists system troubles. LEDs are identifiable by the letter above each one (E through A).

EDCBA

TROUBLE

DESCRIPTION

SYSTEM CODES

SLC CHANNEL CODES

AC FAIL

LOW/MISSING BATTERY

RUNNING ON DEPLETED BATTERY

MEMORY CHECKSUM ERROR

RUI COMM FAIL

HARDWARE CONFIGURATION MISMATCH

CHANNEL CONTROLLER TROUBLE

NEGATIVE EARTH

POSITIVE EARTH

CHANNEL FAIL

SHORT CIRCUIT

DUPLICATE DEVICE

MISSING DEVICE

EXTRA DEVICE

CLASS A TROUBLE

EARTH TROUBLE

ISOLATOR TROUBLE

HARDWARE CONFIGURATION ERROR

MEMORY TEST ERROR

CHARGER TROUBLE

BAD DOWNLOAD

ADDRESS OUT OF RANGE

Figure 1-3. System Trouble Indicators

Continued on next page

Hardware Components, Continued

System Trouble

Indicators

(LEDs E-A)

Page 17

1-9

Tables 1-1 and 1-2, below, list the messages that appear on the FACP displays for each type of

trouble.

Note: On hardwired systems, all troubles are displayed as “Open Circuit Trouble.”

Table 1-1. System Trouble Messages

Trouble Description 4010 IDNet Display 4100/4020 RUI Display

AC Fail AC Power Fail AC Voltage Status

Low/Missing Battery Battery Fault Battery Low/Disconnected

Running on Depleted Battery Battery Fault Running on Depleted Battery

Memory/Checksum Error 4009A No Answer Card Missing/Failed

RUI Comm Fail -- Card Missing/Failed

Hardware

Configuration Mismatch

TrueAlert Non-Addressable NAC Open Hardware Configuration

Channel Controller Trouble 4009A No Answer Channel Comm. Failure

Negative Earth* Negative Earth Ground Negative Earth Ground

Positive Earth* Positive Earth Ground Positive Earth Ground

Hardware Configuration Error 4009A No Answer Card Missing/Failed

Memory Test Error 4009A No Answer Card Missing/Failed

Charger Trouble Battery Fault Battery Charger

Table 1-2. Channel Trouble Messages

Trouble Description 4010 IDNet Display 4100/4020 RUI Display

Channel Fail TrueAlert Non-Addressable NAC Open Card x Channel Fail

Short Circuit TrueAlert Non-Addressable NAC Short Card x Short Circuit

Duplicate Appliance TrueAlert Non-Addressable NAC Open Address, Channel Duplicate

Missing Appliance TrueAlert Non-Addressable NAC Open No Answer

Extra Appliance TrueAlert Non-Addressable NAC Open Extra Device

Class A Trouble Custom Label Common Class A Trouble

Earth Trouble* TrueAlert Non-Addressable NAC Open

Negative Earth Ground or Positive

Earth Ground

Isolator Trouble TrueAlert Non-Addressable NAC Open Isolator Short

Bad Download† TrueAlert Non-Addressable NAC Open --

Address Out of Range TrueAlert Non-Addressable NAC Open Extra Device

*Refer to “Isolating Earth Grounds” on the next page.

†

Occurs for all circuits not assigned to the TrueAlert point type of QALERT or SQALERT.

Continued on next page

Hardware Components, Continued

System Trouble

Messages

Page 18

1-10

To determine which channel is in an Earth Ground trouble condition in any wiring mode,

1. When the Addressable Controller LEDs indicates a system trouble of Positive or

Negative Earth Ground, reinitialize the Addressable Controller (typically by switching

any DIP switch on the board).

2. The Addressable Controller LEDs should now display the channel-specific Earth

Trouble. If you still see the system trouble without any channel indication, hit the

Trouble Scroll button (PB-SW6) on the system board until the channel-specific trouble is

displayed. Refer to Figure 1-2 for the Trouble Scroll button location.

3. The system trouble will clear automatically once you correct the trouble condition. To

clear the channel trouble message, reinitialize the Addressable Controller once again.

This green LED indicates that AC power is present and is being used as the 4009 TrueAlert

Addressable Controller power source. The 4009 switches to the battery whenever the green LED

is OFF.

CAUTION: The green AC LED indicates “Good AC Power.” In the event of a

brownout condition, the unit will switch to battery power but lethal

voltages may still exist. DISCONNECT POWER BEFORE SERVICING.

Hardware Components, Continued

Isolating Earth

Grounds

AC Power Indicator

(LED 9)

Page 19

2-1

The 4009 TrueAlert Addressable Controller can be configured to work with IDNet, RUI, or

hardwired systems. This chapter describes how the DIP switches can be used to set up

configurations, and goes on to describe the installation process common to all configurations.

The table below lists the topics in this chapter.

Topic See Page

System Overview: Applications Diagram 2-2

System Overview: Selective Signaling 2-3

System Configuration 2-4

System Installation 2-11

Installing Option Interfaces 2-17

Chapter 2

System Configuration and Installation

Overview

In this Chapter

Page 20

2-2

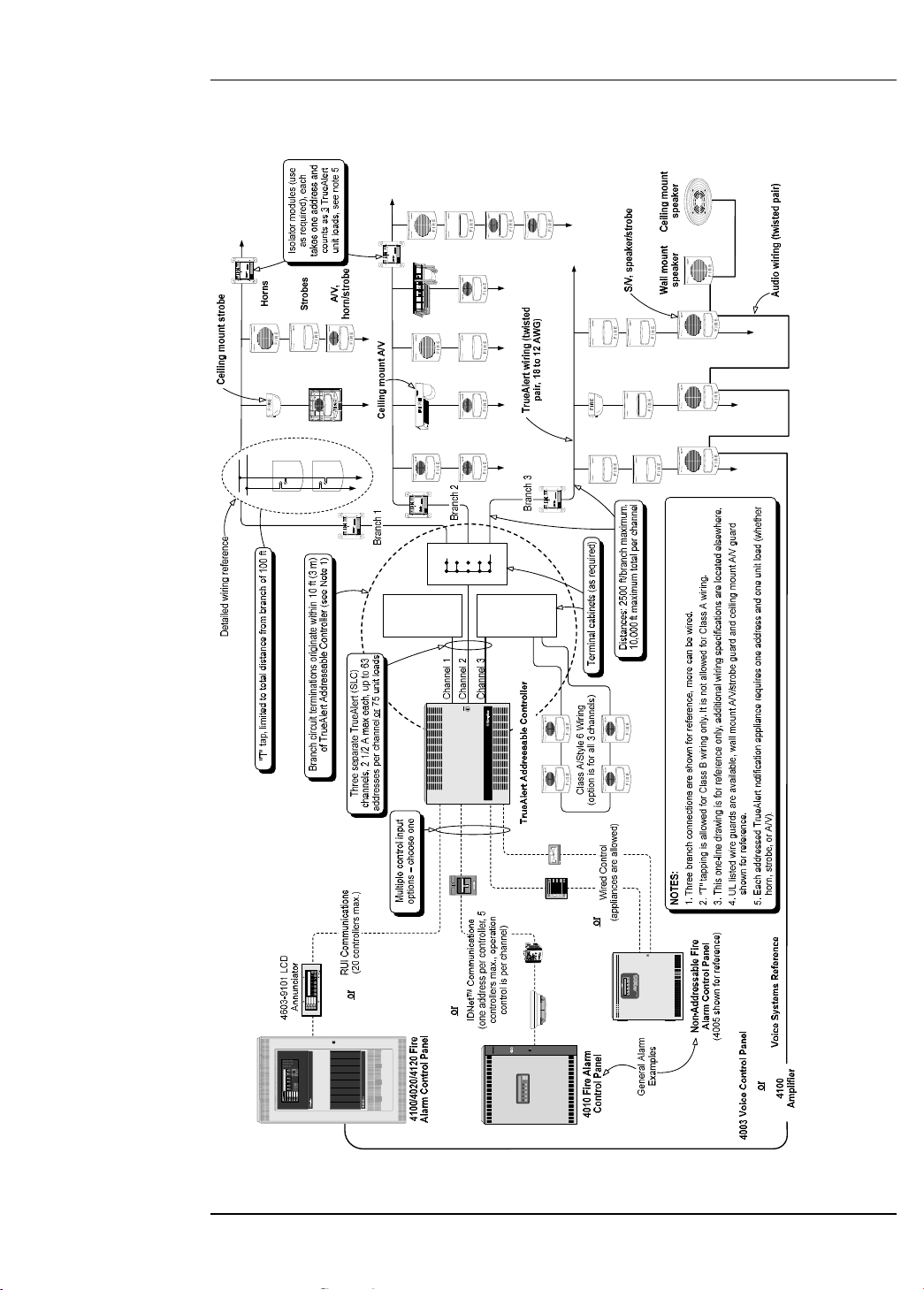

Figure 2-1 summarizes the connections between the 4009 TrueAlert Addressable Controller,

FACPs, and peripheral appliances. The figure shows example connections. Refer to 842-158 Field

Wiring Diagram for instructions.

**SYSTEM IS NO RM AL**

12:02:15pm Fri 19-Feb-99

ALARM

ACK

SUPV

ACK

TROUBLE

ACK

ALARM

SILENCE

SYSTEM

RESET

FIRE

ALARM

SYSTEM

SUPERVISORY

SYSTEM

TROUBLE

ALARM

SILENCED

AC

POWER

FIRE ALARM

CONTRO L

DISCO NNEC

POW ER BEF

SERVICING

CAUTIO N

** SYSTEM I S NO RM AL * *

12:02:15pm Mon 8-Mar-99

SUPV

ACK

SYSTEM

SUPERVISORY

ALARM

ACK

FIRE

ALARM

TROUBLE

ACK

SYSTEM

TROUBLE

ALARM

SILENCE

ALARM

SILENCED

SYSTEM

RESET

AC

POW ER

POWER

BEFORE

SERVICING

CAUTION

DISCONNECT

Tru eAlert Addr essable Contr oller

TM

Simplex Time Recorder Co.

Gardner, MA 01441

ON

ADDRESS

MSB

4905-9929 TRUEALERT ISOLATOR

INST. INSTR. 574-769 REV

RELAY CONTACTS

3 AMP, 30 VDC

MODULE

15 mA MAX 24 VDC

576-733

PORT 1

+ -

PORT 2

+ -

Simplex Time Recorder Co.

Gardner, MA 01441

ON

ADDRESS

MSB

4905-9929 TRUEALERT ISOLATOR

INST. INSTR. 574-769 REV

RELAY CONTACTS

3 AMP, 30 VDC

MODULE

15 mA MAX 24 VDC

576-733

PORT 1

+ -

PORT 2

+ -

FIRE

ALARM

ALARM

SILENCED

PRIORITY 2

ALARM

SYSTEM

SUPERVISORY

SYSTEM

TROUBLE

POWER

ON

ALARM

ACK

SUPV

ACK

TBL

ACK

ALARM

ACK

ALARM

SILENCE

SYSTEM

RESET

DISPLAY

TIME

SYSTEM IS NORMAL

12:35:15 am MON 22 NOV 99

ALARMFIRE

PULL DOWN

-

I

D

N

E

T

I

N

+

+

I

D

N

E

T

I

N

-

Simplex Time Recorder Co.

Gardner, MA 01441

ON

ADDRESS

MSB

4905-9929 TRUEALERT ISOLATOR

INST. INSTR. 574-769 REV

RELAY CONTACTS

3 AMP, 30 VDC

MODULE

15 mA MAX 24 VDC

576-733

PORT 1

+ -

PORT 2

+ -

Simplex Time Recorder Co.

Gardner, MA 01441

ON

ADDRESS

MSB

4905-9929 TRUEALERT ISOLATOR

INST. INSTR. 574-769 REV

RELAY CONTACTS

3 AMP, 30 VDC

MODULE

15 mA MAX 24 VDC

576-733

PORT 1

+ -

PORT 2

+ -

Simplex Time Recorder Co.

Gardner, MA 01441

ON

ADDRESS

MSB

4905-9929 TRUEALERT ISOLATOR

INST. INSTR. 574-769 REV

RELAY CONTACTS

3 AMP, 30 VDC

MODULE

15 mA MAX 24 VDC

576-733

PORT 1

+ -

PORT 2

+ -

FIRE

Fire Control

Figure 2-1. 4009 TrueAlert Applications Diagram

System Overview: Applications Diagram

Illustration

Page 21

2-3

Figure 2-2 shows that selective signaling can only be done with an RUI connection to a 4100U fire Alarm Control

Panel.

Simplex Time Recorder Co.

Gardner, MA 01441

ON

ADDRESS

MSB

4905-9929 TRUEALERT ISOLATOR

INST. INSTR. 574-769 REV

RELAY CONTACTS

3 AMP, 30 VDC

MODULE

15 mA MAX 24 VDC

576-733

PORT 1

+ -

PORT 2

+ -

Simplex Time Recorder Co.

Gardner, MA 01441

ON

ADDRESS

MSB

4905-9929 TRUEALERT ISOLATOR

INST. INSTR. 574-769 REV

RELAY CONTACTS

3 AMP, 30 VDC

MODULE

15 mA MAX 24 VDC

576-733

PORT 1

+ -

PORT 2

+ -

Simplex Time Recorder Co.

Gardner, MA 01441

ON

ADDRESS

MSB

4905-9929 TRUEALERT IS O LAT OR

INST. INSTR. 574-769 REV

RELAY CONTACTS

3 AMP, 30 VDC

MODULE

15 mA MAX 24 VDC

576-733

PORT 1

+ -

PORT 2

+ -

Fire Control

POWER

BEFORE

SERVICING

CAUTION

DISCONNECT

TrueAlert Addressable Controller

TM

Figure 2-2. Selective Signaling Example

System Overview: Selective Signaling

Illustration

Page 22

2-4

This section describes how to use the DIP switches on the 4009 TrueAlert Addressable Controller

board for setting addresses and optional features.

The SLC Appliance Switches (SW1, SW2, SW3) are 8-position DIP switches. Use these switches

to set the number of appliances connected to each SLC. SW1 corresponds to SLC 1, SW2

corresponds to SLC 2, and SW3 corresponds to SLC 3. A maximum of 63 appliances or 2.5 amps

of power may be specified per SLC channel (refer to Field Wiring Diagram 842-158). Refer to

Figure 1-2 to locate the switches on the system board. Refer to Figure 2-2, below, to specify the

correct number of appliances for each SLC channel.

Use a small screwdriver or pen to set the switches.

Notes:

• DIP switch in “1” position is ON while DIP switch in “0” position is OFF.

• SW1, SW2, and SW3 are disabled when the RUI host interface is selected.

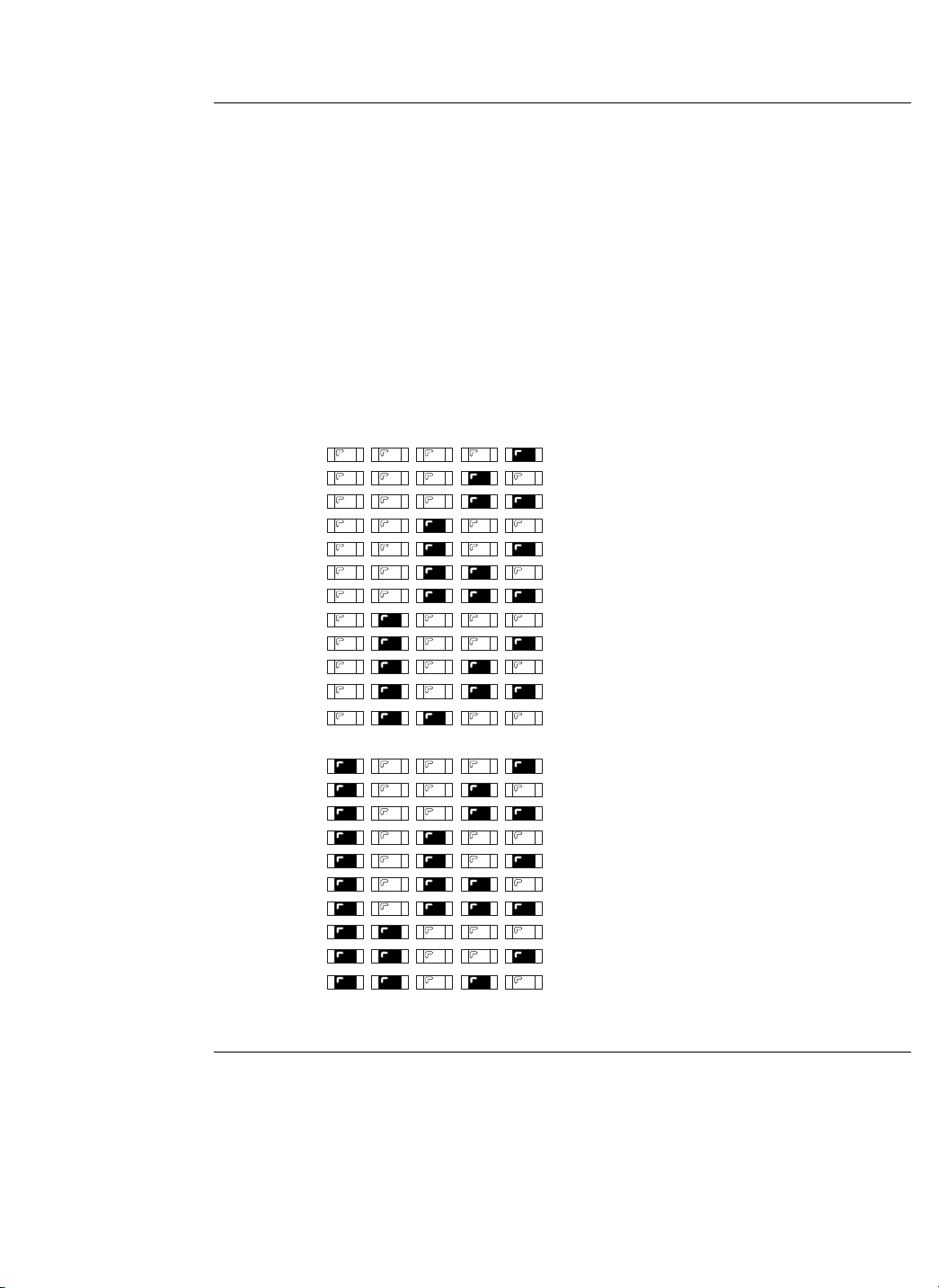

0000 1000 0100 1100

0000

0 163248

1000

1 173349

0100

2 183450

1100

3 193551

0010

4 203652

1010

5 213753

0110

6 223854

1110

7 233955

0001

8 244056

1001

9 254157

0101

10 26 42 58

1101

11 27 43 59

0011

12 28 44 60

1011

13 29 45 61

0111

14 30 46 62

15 31 47 63

LSB

MSB

1 2345678

1111

DIP SWITCHES 5 AND 6

DIP

SWITCHES

1 THRU 4

RESERVED FOR

FUTURE USE

NOT USED

ON

OFF

1 = ON 0 = OFF

DIPSWITCH IS SHOWN

SET AT ADDRESS 7.

Figure 2-3. SLC Appliance Settings (SW1, SW2, SW3)

Continued on next page

System Configuration

Overview

SLC Appliance DIP

Switches

(SW1, SW2, SW3)

DIP SWITCH IS SHOWN

SET AT ADDRESS 7.

Page 23

2-5

The 8-position Hardware Configuration DIP Switch (SW4) is used to configure what hardware is

present and supervised by the Addressable Controller, and how the hardware is used. The

Hardware Configuration Switch is located to the right of the channel indicator LEDs

(E-A indicators) on the system board (see Figure 1-2).

Table 2-1, below, lists the SW4 settings.

IMPORTANT: All settings, including “N/A,” will reinitialize the TrueAlert

Addressable Controller.

Table 2-1. Hardware Configuration Switch (SW4)

Switch

Number

Setting

IDNet/Hardwired Selection RUI Selection

OFF, OFF Normal Operation

ON, OFF Global Silent Appliance Test

OFF, ON Manual Real Appliance Test

1, 6

ON, ON Manual Silent Appliance Test

OFF No Class A Adapter Card Present

2

ON Class A Adapter Card Present

N/A

OFF, OFF RUI Host RUI Host

ON, OFF IDNet Host N/A

OFF, ON Reserved

3, 4

ON, ON Dual NAC Host

OFF No IDNet Repeater Card Present

5

ON IDNet Repeater Card Present

N/A

6 See first row of table

OFF Appliance Blink on Poll Disabled

7

ON Appliance Blink on Poll Enabled

OFF Horn Volume: Low

8

ON Horn Volume: High

N/A

Normal Operation. The Addressable Controller runs under normal operation only when both

switches 1 and 6 are set of OFF. Any other combination between the two switches puts the

Addressable Controller into one of the test modes described below and on the next page.

Global Silent Appliance Test. Sets all TrueAlert notification appliances so that alarms are

silent. If the system goes into alarm, appliances will illuminate their LEDs in a Steady On state

without audibles or strobes.

Continued on next page

System Configuration, Continued

Hardware

Configuration DIP

Switch (SW4)

Page 24

2-6

Manual Real Appliance Test. Activates a test mode so that appliances can be manually tested

one at a time. The manual real appliance test makes a given notification appliance report its

address and emits an alarm. Place a magnet on the appropriate area of the notification appliance to

initiate a real appliance test. The LED emits one long flash denoting the test acknowledge signal,

and then another long flash denoting the first digit (always zero) of the appliance address. The

LED then flashes one to six times to denote the second digit of the address, pauses, and flashes

one to nine times to indicate the third digit of the address. A zero is always indicated by one long

flash. After the LED flashes, the appliance goes into alarm for 2 to 3 seconds.

Manual Silent Appliance Test. Like the real appliance test mode, this allows appliances to be

manually tested, one at a time. The manual silent appliance test makes a given notification

appliance report its address without emitting an alarm. Place a magnet on the appropriate area of

the appliance to initiate a silent appliance test. The LED emits one long flash denoting the test

acknowledge signal, and then another long flash denoting the first digit (always zero) of the

appliance address. The LED then flashes one to six times to denote the second digit of the address,

pauses, and flashes one to nine times to indicate the third digit of the address. A zero is always

indicated by one long flash. When the address is done, the LED illuminates once more for 2 to 3

seconds.

Class A Adapter Card Options. Refer to Table 2-2, below, for a description of what happens

when switch 2 is set.

Note: In Table 2-2, “Yes” denotes the Class A Option Card has been correctly wired and

installed in the Addressable Controller.

Table 2-2. (SW4) Switch 2

(SW4) Switch 2

Setting

Class A Card Connected

to Addressable

Controller?

System Status

Yes Normal

ON

No Class A Trouble*

Yes Configuration Mismatch Trouble

OFF

No Normal

*In Hardwired mode, this condition clears once a Class A Card is correctly installed and the Addressable

Controller is reinitialized. In the 4010 and 4100, the message clears only after the Class A Card is correctly

installed and the SYSTEM RESET button is pressed at the host panel.

RUI Host. Selected when the TrueAlert Addressable Controller is used with a 4100 or 4020

FACP. The Addressable Controller LEDs will display a Comm Trouble if the RUI channel is not

connected.

IMPORTANT: The Addressable Controller cannot be connected to hardwired NAC

channels (TB7) and a RUI host (TB1) at the same time.

Continued on next page

System Configuration, Continued

Hardware

Configuration DIP

Switch (SW4),

continued

Page 25

2-7

IDNet Host. Selected when the TrueAlert Addressable Controller is used with a 4010 FACP.

IMPORTANT:

• The Addressable Controller cannot be connected to hardwired NAC

channels (TB7) and an IDNet host (TB2) at the same time. Make sure only

one interface is selected (IDNet, RUI, or Hardwired).

• The Addressable Controller LEDs do not indicate a trouble if the IDNet

channel is disconnected. The only trouble indication is at the host panel.

Dual NAC Host. Selected when the Addressable Controller is hardwired to the host FACP using

TB7 on Figure 1-2. The Addressable Controller can be hardwired to any compatible FACP.

IMPORTANT:

• The Addressable Controller cannot be connected to a RUI host (TB1) or an

IDNet host (TB2) while it is connected to hardwired NAC channels (TB7) at

the same time. Make sure only one interface is selected.

• The Addressable Controller LEDs do not indicate a trouble if the hardwired

channels are disconnected. The only trouble indication is at the host panel.

IDNet Repeater Card Options. Refer to Table 2-3, below, for a description of what happens

when Switch 5 is set.

Note: In Table 2-3, “Yes” denotes the IDNet Repeater Card has been correctly wired

and mounted to the Addressable Controller.

Table 2-3. (SW4) Switch 5

(SW4) Switch 5

Setting

IDNet Repeater Card

Connected to

Addressable Controller?

System Status

Yes Normal

ON

No

Yes

Configuration Mismatch Trouble

OFF

No Normal

Appliance Blink on Poll Disabled. Stops notification appliance LEDs from blinking when the

appliances are polled during normal operation.

Appliance Blink on Poll Enabled. Forces notification appliance LEDs to blink whenever they

are polled (i.e., every few seconds). Note that a blinking LED at the appliance indicates that

polling was successful, and does not indicate whether the system detected a problem with the

appliance (the host panel must be used to determine appliance status).

Horn Volume: Low. Sets the horn volume at Low for all A/Vs and Horns connected to the

Addressable Controller. Horn volume is not configurable on an appliance-by-appliance basis.

Horn Volume: High. Sets the horn volume at High for all A/Vs and Horns connected to the

Addressable Controller. Horn volume is not configurable on an appliance-by-appliance basis.

Continued on next page

System Configuration, Continued

Hardware

Configuration DIP

Switch (SW4),

continued

Page 26

2-8

The Address/Software Configuration Switch (SW5) is an 8-position DIP switch. The

Address/Software Configuration Switch is located to the right of the Hardware Configuration

Switch (SW4) on the system board.

When the Addressable Controller is operating as an addressable IDNet or RUI peripheral, this

switch sets the Addressable Controller address. Set the Addressable Controller address using

Figure 2-3 (IDNet) or Figure 2-4 (RUI) as a reference.

When the Addressable Controller operates in a hardwired configuration (without addresses), this

switch is used to control the configuration as described in Table 2-1.

• The Addressable Controller can be assigned address number 1 through 250 in IDNet

interface mode. See Figure 2-3.

• The Addressable Controller can be assigned address number 1 through 119 in RUI

interface mode. See Figure 2-4.

Figure 2-3, below, applies to IDNet mode only.

Use a small screwdriver or pen to set the switches.

Note: DIP switch in “1” position is ON while DIP switch in “0” position is OFF.

0000 1000 0100 1100 0010 1010 0110 1110 0001 1001 0101 1101 0011 1011 0111 1111

0000

0 16 32 48 64 80 96 112 128 144 160 176 192 208 224 240

1000

1 17 33 49 65 81 97 113 129 145 161 177 193 209 225 241

0100

2 18 34 50 66 82 98 114 130 146 162 178 194 210 226 242

1100

3 19 35 51 67 83 99 115 131 147 163 179 195 211 227 243

0010

4 20 36 52 68 84 100 116 132 148 164 180 196 212 228 244

1010

5 21 37 53 69 85 101 117 133 149 165 181 197 213 229 245

0110

6 22 38 54 70 86 102 118 134 150 166 182 198 214 230 246

1110

7 23 39 55 71 87 103 119 135 151 167 183 199 215 231 247

0001

8 24 40 56 72 88 104 120 136 152 168 184 200 216 232 248

1001

9 25 41 57 73 89 105 121 137 153 169 185 201 217 233 249

0101

10 26 42 58 74 90 106 122 138 154 170 186 202 218 234 250

1101

11 27 43 59 75 91 107 123 139 155 171 187 203 219 235

0011

12 28 44 60 76 92 108 124 140 156 172 188 204 220 236

1011

13 29 45 61 77 93 109 125 141 157 173 189 205 221 237

0111

14 30 46 62 78 94 110 126 142 158 174 190 206 222 238

15 31 47 63 79 95 111 127 143 159 175 191 207 223 239

LSB

MSB

1 2345678

1111

DIP SWITCHES 5 THRU 8

ON

OFF

1 = ON 0 = OFF

251

252

253

254

255

DIPSWITCH IS SHOWN SET AT ADDRESS 7.

Figure 2-4. IDNet Address Settings (SW5)

Continued on next page

System Configuration, Continued

Address/Software

Configuration DIP

Switch (SW5)

DIP SWITCH IS SHOWN SET AT ADDRESS 7.

Page 27

2-9

Figure 2-4, below, applies to RUI mode only.

Use a small screwdriver or pen to set the switches.

Note: DIP switch in “1” position is ON while DIP switch in “0” position is OFF.

0000 1000 0100 1100 0010 1010 0110 1110

0000

0 163248648096112

1000

1 173349658197113

0100

2 183450668298114

1100

3 193551678399115

0010

4 2036526884100116

1010

5 2137536985101117

0110

6 2238547086102118

1110

7 2339557187103119

0001

8 2440567288104

1001

9 2541577389105

0101

10 26 42 58 74 90 106

1101

11 27 43 59 75 91 107

0011

12 28 44 60 76 92 108

1011

13 29 45 61 77 93 109

0111

14 30 46 62 78 94 110

15 31 47 63 79 95 111

LSB

MSB

1 2345678

1111

DIP SWITCHES 5 THRU 8

DIP

SWITCHES

1 THRU 4

ON

OFF

1 = ON 0 = OFF

DIPSWITCH IS SHOWN SET AT ADDRESS 7.

Figure 2-5. RUI Address Settings (SW5)

Continued on next page

System Configuration, Continued

Address/Software

Configuration DIP

Switch (SW5),

continued

DIP SWITCH IS SHOWN SET AT ADDRESS 7.

Page 28

2-10

When the 4009 operates as a non-addressable NAC extender, Switch SW5 configures the

operation of the output SLCs, based on the state of the two NAC control inputs. Refer to

Table 2-2 for SLC control operation settings.

Table 2-4. Software Configuration Settings for Hardwired Control (SW5)

Switch

Number

Setting Mode of Operation

1-3 Reserved

OFF Visuals Flash Once Per Second

4

ON Visuals Flash Temporal with Audibles

OFF, OFF

Temporal Audibles

ON, OFF March Time Audibles

OFF, ON Fast March Time Audibles

5, 6

ON, ON Audibles Steady On

7 Reserved

OFF

Channel 1 Controls All Visibles

Channel 2 Controls All Audibles

8

ON

Channel 1 Controls All Appliances on SLC 1

Channel 2 Controls All Appliances on SLCs 2 and 3

System Configuration, Continued

Address/Software

Configuration DIP

Switch (SW5),

continued

Page 29

2-11

IMPORTANT: Notify the appropriate personnel (building occupants, fire

department, monitoring facility, etc.) of the installation.

The following sections contain installation information which is applicable to the 4009 TrueAlert

Addressable Controller. Be sure that you are thoroughly familiar with this information before

installing the 4009 TrueAlert Addressable Controller.

To help you with installation of this and other Simplex Fire Alarm equipment, use How to Wire a

Building for a Fire Alarm System (FA2-91-001 or 575-892) for general reference.

The following tools and equipment are required to install the 4009 TrueAlert Addressable

Controller:

• 1/4-inch flat-tip screwdriver (Phillips screwdriver optional)

• 1/8-inch flat-tip screwdriver

• Volt-Ohmmeter

• Diagonal cutting pliers

• Wire strippers

Continued on next page

System Installation

General Information

Tools and

Equipment Required

Page 30

2-12

The following documentation may be required:

• Field Wiring Diagram 842-158

• 4009-9812 Class A Adapter Option Card Installation Instructions (574-763)

• 4009-9809 IDNet Repeater Option Card Installation Instructions (574-327)

• 4009-9810/-9811 Fiber Optic Link Option Installation Instructions

(574-182)

• 4901 TrueAlert Horn Installation Instructions (574-764)

• 4902 TrueAlert Ceiling-Mount and Wall-Mount Speaker Installation Instructions

(574-765)

• 4903 TrueAlert Ceiling-Mount A/V Installation Instructions (574-929)

• 4903 TrueAlert S/V Installation Instructions (574-766)

• 4903 TrueAlert A/V Installation Instructions (574-768)

• 4904 TrueAlert Ceiling-Mount Strobe Installation Instructions (574-928)

• 4904 TrueAlert Strobe Installation Instructions (574-767)

• 4905 TrueAlert Isolator Module Installation Instructions (574-769)

• 4906 TrueAlert Multi-Candela Notification Appliances Installation Instructions

(579-808)

• 4906 TrueAlert Multi-Candela Amber Strobe Installation Instructions (579-828)

• All wiring must be installed in accordance with local codes.

• A minimum of 6 inches (15.24 cm) of free conductor is required at each electrical box to

facilitate terminations.

• A 12-inch (30.48 cm) service loop of cable is required for all continuous pulls through an

electrical box.

• All system wiring subject to physical damage must be mechanically protected based on

the environment to which the cable is subjected.

• A neatly wired system helps assure an accurate inspection of all connections and simplify

troubleshooting.

• Field adjustments may not be made to the TrueAlert Addressable Controller board.

Continued on next page

System Installation, Continued

Required

Documentation

General Notes

Page 31

2-13

A

Use the following procedure when mounting a TrueAlert Addressable Controller.

CAUTION: Read all instructions carefully before cutting conduit/service entrances

and installing back box. Failure to comply with all installation

requirements may result in a violation of UL or FCC regulations.

1. Lay the TrueAlert Addressable Controller on a flat surface.

2. Unlock and open the panel door. Disconnect the AC wiring harness from the card cage.

Remove the electronic card cage assembly and store it in a safe, dry area.

3. Determine the amount and proper location of conduit/service entrances (see Figure 2-5).

Make all appropriate entrances into the back box. Power limited and non-power limited

wiring must enter through separate conduit/service entrances. AC power entrance into the

back box is recommended at the bottom right side of the back box.

Note: Maximum intrusion into back box for conduit is ½ inch (1.27 cm).

Recommended Conduit Locations

Locate conduit entry approximately where shown.

A. Class B or Class A Fiber Feed and AC Power

B. Signaling Line Circuits, IDNet and RUI

C. IDNet, RUI, or Class A Fiber Return

D. SLCs, NACs, IDNet, and RUI or Class A Fiber Return

E. Control Inputs: IDNet, RUI, or Notification Appliance Circuits

Figure 2-6. Installing the 4009 Back Box

Continued on next page

System Installation, Continued

Mounting the 4009

TrueAlert

Addressable

Controller

B

BATTERY

MOUNTING

AREA (NO

CONDUIT

ENTRY)

KNOCKOUT

SCREW/NAIL

HOLES for

SEMI-FLUSH

MOUNTING

TOP VIEW

NON-POWER LIMITED WIRING ONLY

C

D

E

A

Page 32

2-14

4. Mount the back box to the wall so that the top of the enclosure is no more than eight feet

above the floor. The back box must be level and plumb. For surface mounting, use the

teardrop and clearance holes located in the rear of the box and screw to wall.

5. Wire non-power limited wiring in the shaded areas only (see Figure 2-5), this includes AC

input and battery connections. All other wiring is power limited. Maintain at least ¼-inch

(0.63 cm) spacing between all power limited and non-power limited wiring.

6. Connect the AC wiring harness and install the electronic card cage assembly to the 4009

cabinet.

When wiring the 4009 TrueAlert Addressable Controller, refer to Field Wiring Diagram

842-158, the 4009 TrueAlert Applications Diagram (Figure 2-1), and the following system wiring

requirements.

• All wiring, except incoming power and ground connecting wires, must be free from

grounds or shorts and have a resistance of one megohm, or higher, to earth.

• All wires are to be copper conductors only, except fiber cables. All equipment must be

installed in accordance with the manufacturer’s recommendations and the specifications

and standards of the Authority Having Jurisdiction (AHJ). The installation of all wiring,

cable, and equipment must be in accordance with NFPA 70 National Electrical Code.

• If shielded wire is used, the metallic continuity of the shield must be maintained and

insulated throughout the entire length of the cable. The entire length of the cable must

have a resistance greater than one megohm to earth.

• Splicing is permitted in accordance with NFPA 70 National Electrical Code. All wiring

must be terminated with UL listed appliances (e.g., wire nuts, pressure connectors).

Wiring terminated with only electrical tape is not permitted. All splicing (free ends of

conductors) must be covered with an insulation equivalent to that of the conductors.

• An appropriate system ground must be provided for earth detection and lightning

protection appliances. The connection must be an approved dedicated earth connection

per NFPA 70 National Electrical Code.

• When running wires to the 4009, identify the wires appropriately. Only system wiring

can be run in the same conduit which includes SLC wiring, NAC wiring, IDNet wiring,

RUI wiring, 24 V AUX wiring, and FACP speaker circuits.

• Input power and external battery power are non-power limited and cannot be run

with power limited system wiring.

IMPORTANT: If the 4009T is powered up with zero devices connected, the 4009T will

indicate channel failure for those channels that are programmed to support

devices. The 4009T will not sense devices as they are connected when the

4009T has been powered up with zero devices connected. After at least one

valid device is connected, the unit must be reset by toggling dipswitches on

Hardware Configuration Switch SW4 (SW4-2 for example) and then the

4009T will communicate with devices as they are added.

Continued on next page

System Installation, Continued

Mounting the 4009

TrueAlert

Addressable

Controller, continued

Wiring the 4009

TrueAlert

Addressable

Controller

Page 33

2-15

AC Input - 120VAC, 3 amperes, 60Hz

Battery Input - 24VDC, 8 amperes

4009 TRUEALERT

ADDRESSABLE

CONTROLLER

(SEE

NOTE 2)

AC INPUT

POWER

EXTERNAL

BATTERY

CONNECTION

(IF REQUIRED)

IDNet

INPUT

RUI

INPUT

TO AUDIBLE AND/OR VISIBLE

NOTIFICATION APPLIANCES

TRUEALERT CHANNEL

SIGNALING LINE CIRCUITS:

THREE CLASS B/STYLE 4 CIRCUITS STANDARD

(CLASS A/STYLE 6 CIRCUITS AVAILABLE)

CIRCUITS RATED AT

2 1/2A @ 24 VDC PER CIRCUIT,

POWER LIMITED 8A TOTAL POWER AVAILABLE

#18 AWG MIN

NAC OF

HOST FACP

HARDWIRED

NAC

CONTROL

AUXILIARY

POWER

OUTPUT

Notes:

1. Refer to the Field Wiring Diagram (842-158) for detailed information on 4009 System Wiring

Configurations.

2. External Battery requires splicing into existing Battery Harness (733-945), see Note 1.

Figure 2-7. 4009 TrueAlert Addressable Controller Connection Diagram

Continued on next page

System Installation, Continued

System Power

Requirements

Page 34

2-16

Refer to Field Wiring Diagram 842-158 for detailed information and the installation instructions

for each appliance during peripheral appliance installation. The procedure listed below is a

general outline for installing the 4009 peripheral appliances.

1. Determine the mounting locations of the peripheral appliances and install system wires from

the mounting location of each peripheral appliance to the 4009 system board. All wiring must

be minimum 18 AWG, supervised, and power limited.

2. Install all peripheral appliances and connect them to appropriate wires. (Refer to the

installation instructions packed with the appliances.)

System Installation, Continued

Mounting and Wiring

Peripheral

Appliances

Page 35

2-17

The 4009 TrueAlert Addressable Controller supports several option add-on cards:

4009-9812 Class A Adapter Option Card. Allows fault tolerance in the case of open circuit

wiring faults. One card provides Class A/Style 6 functionality for three TrueAlert SLCs. See

4009-9812 Class A Adapter Option Card Installation Instructions (574-763).

4009-9809 IDNet Repeater Option Card. Regenerates and provides a power and distance

boost for the IDNet channel. Takes the IDNet signal from the 4009 receiver and retransmits it on

its output side at host panel IDNet levels. See IDNet Repeater Option Card Installation

Instructions (574-327).

4009-9810/-9811 Fiber Optic Receiver Option Card. Works with the IDNet Fiber

Transmitter to form a fiber optic link from an IDNet channel to a remote TrueAlert Addressable

Controller. The fiber optic link allows remote buildings (within 3,000 ft (914.4 m)) to connect to

the IDNet channel, and to minimize susceptibility to electrical transients. See Fiber Optic Link

Option Installation Instructions (574-182).

Connectors are provided on the base assembly of the 4009 system board to support the available

option cards. Optional hardware must be configured with the Hardware Configuration DIP

Switch (SW4), described in Table 2-1 on page 2-4, for proper system operation.

Installing Option Interfaces

Overview

Page 36

Page 37

3-1

The 4009 TrueAlert Addressable Controller can be configured to work with the 4010 via

programming at the 4010 panel.

The panel programmer has the capability of auto-detecting new hardware, so that a 4009

TrueAlert Addressable Controller can be added to an existing configuration. Alternatively, the

panel programmer can be used to manually add the 4009 TrueAlert Addressable Controller to the

system setup. This chapter describes both methods.

The table below lists the topics in this chapter.

Topic See Page

4010 Programming Steps 3-2

Deleting the 4009 TrueAlert Addressable Controller 3-6

4010 Quick CFIG 3-7

Chapter 3

4010 Panel Programming

Overview

In this Chapter

Page 38

3-2

Each step in this section is intended to be read sequentially, so that the last instruction from

“Step 1. Starting the Programmer,” for example, leads directly to the first instruction in

“Step 2. Adding an IDNet Point…” Read the entire section to make sure you make all the

necessary configurations.

These programming instructions can be used to:

• Add a 4009 TrueAlert Addressable Controller to a 4010

• Modify settings for already programmed 4009 TrueAlert Addressable Controllers

The instructions below describe how to log in and start the 4010 panel programmer.

1. Press the MENU button so that the display reads Menu:[Control/View Points].

Then press the NEXT button. The display reads Menu:[Login/Logout].

2. Press the ENTER button. The display reads <Enter> to [Login]. Press ENTER

again.

3. The display reads Passcode:[0]. Enter your passcode. The passcode must have

access to programming and all other menus mentioned in these instructions. Use the

PREVIOUS and NEXT buttons to select numbers 0 through 9. When you have selected

the correct number, use the right arrow button to move to the next digit. When you move

to a different digit, numbers that have already been entered will appear as asterisks (*). If

you make an error, use the left arrow button to backspace. When you are done, press

ENTER. At this point the display reads **Login is Accepted** and displays your

current access level.

4. When the display returns to normal, press NEXT until you reach

Menu: [Programming]. Press ENTER.

5. The display reads Please Wait… Fire Alarm Operation Suspended. After

a moment, it reads Press <ENTER> for Programming Press <EXIT> to

resume operation. Press ENTER.

Continued on next page

4010 Programming Steps

Overview

Step 1:

Starting the

Programmer

Page 39

3-3

Use the following instructions to add a 4009 IDNet point for the 4009 TrueAlert Addressable

Controller.

1. From the Programming: [Configure Points] menu item, press ENTER.

2. Press NEXT until the Configure Point: [ZAMS/IAMS/RIAMS] menu item comes up.

Press ENTER.

3. The IDNet: [Add IDNet Point] menu item appears. Press ENTER.

4. The display now reads IDNet Device: M1-x where x is the first available IDNet address.

If needed, use the PREVIOUS or NEXT buttons to scroll through the addresses. Press

ENTER on the address to which you want to add the 4009 TrueAlert Addressable

Controller.

5. You now have to tell the 4010 that the IDNet device type will be a 4009. Press ENTER

on the menu item Point Label Function: [Edit Device Type]. When the display reads

Point Label: [PHOTO], use the PREVIOUS key to scroll to the appropriate device type.

The 4010 sees a 4009 TrueAlert Addressable Controller as a 4009 IDNet NAC Extender.

This means only the 4009 IDNet NAC Extender is available on the list of device types.

There are four 4009 IDNet NAC Extender device types, and only two that you can use.

Press ENTER on one of the following:

• [4009A (4 NAC)]. Normally used for the 4009 IDNet NAC Extender, this also

denotes the 4009 TrueAlert Addressable Controller.

• [R4009A (4 NAC)]. Normally used for the 4009 IDNet NAC Extender with

Repeater Option, this also denotes the 4009 TrueAlert Addressable Controller with

Repeater Option.

Note: [4009A (8 NAC)] and [R4009A (8 NAC)] cannot be used for the 4009

TrueAlert Addressable Controller.

6. When prompted, press ENTER to confirm your selection. The display reads

** Operation Complete **, and you are returned to the

IDNet Device: M1-x display, which shows the next available IDNet address. Note

that if you press the PREVIOUS button, the address you just configured has disappeared

because it is now being used.

7. At this point, repeat steps 4 through 6 for each 4009 TrueAlert Addressable Controller

you need to add. A total of five can be used. When you are done, press EXIT twice so

that the display reads Configure Point: [ZAMS/IAMS/RIAMS].

Continued on next page

4010 Programming Steps, Continued

Step 2:

Adding an IDNet

Point for the 4009

TrueAlert

Addressable

Controller

Page 40

3-4

1. Press NEXT until the Configure Point: [NACs] menu item appears. Press ENTER.

2. The display reads NAC Circuit: SIG 1 with a point type of Signal Circuit.

Press NEXT or PREVIOUS until IDNET M1-x: 4009A NAC 1 with a point type of

Signal Circuit appears. Press ENTER.

3. The Function: [Edit Device Type] menu item appears. Press NEXT so that

Function: [Edit Point Type] comes up. Press ENTER.

4. The display now reads [SSIGNAL: Fire Signal (On Til Silence)]. This is

only one of the available point types. Press PREVIOUS to display other point types.

Press ENTER on one of the two point types that apply to 4009 SLCs:

• [QALERT: TrueAlert Non Adr. (Gen)]. Makes the SLC respond to

Custom Control commands.

• [SQALERT: TrueAlert N.A. Horn(On Til Sil)]. Makes the SLC

respond to normal system control.

5. When prompted, press ENTER to confirm your selection. The display reads

** Operation Complete **, and you are returned to the

Configure Point: [NACs] display.

6. At this point, repeat steps 1 through 5 for each 4009 TrueAlert Addressable Controller

you need to add.

1. From the Configure Point: [NACs] menu item, scroll up to the

4009 NAC points you just modified. Each one displays an M1-x address and reads

TrueAlert N.A.NAC under it. Press ENTER on the first SLC point you want to edit.

2. The Function: [Edit Device Type] menu item comes up. Press NEXT until

the display reads Function: [Edit Point Label], and then press ENTER.

3. The part of the display that says IDNet M1-x: 4009A NAC 1 is now editable. Use

the PREVIOUS and NEXT buttons to select alphanumeric characters. When you have

selected the correct character, use the right and left arrow buttons to move to other

characters. When you are done, press ENTER and then press ENTER again to confirm

your selection. The display will then read **Operation Complete**.

4. Repeat steps 1 through 3 for every 4009 TrueAlert SLC.

5. Change IDNet M1-x: 4009A NAC 1 to say “4009T COMMON CLASS A

TROUBLE”.

Note: An alternate way to edit labels is to clear the point label completely and then

add text. To do this, press ENTER on the Configure Point: [NACs]

menu item, use the NEXT or PREVIOUS buttons to scroll to the

Function: [Clear Point Label] item, press ENTER, select an

IDNet M1-x entry, and press ENTER again. This deletes all the characters

on the top line of the display and lets you enter and save text as described in

step 3.

6. Press EXIT to return to Programming: [Configure Points].

Continued on next page

4010 Programming Steps, Continued

Step 3:

Configuring 4009

SLC Point Types

Step 4:

Editing Point Labels

Page 41

3-5

1. Press NEXT until you get to Programming: [Save CFIG], and press ENTER. Press

ENTER again at the prompt.

2. The display indicates the panel is saving and then restoring the CFIG and the labels.

When the system is done saving, it reboots. Your passcode is cleared from the system,

and you have to log in again if you want to continue programming (i.e., to add, edit, or

delete points).

To set audible signal types for audible notification appliances,

1. Log in and open the Programming menu.

2. Press NEXT until the Programming: System Options menu item appears. Press

ENTER.

3. Press NEXT until System Options: TrueAlert Non Adr. Horn appears,

and press ENTER.

4. Use the NEXT and PREVIOUS buttons to scroll through the list of options for TrueAlert

Non-Addressable NACs (in this case, TrueAlert SLCs) that appear in the New: field.

The choices are Temporal, Steady, and Slow March. When you make your

selection, press ENTER. Press ENTER a second time to confirm your choice.

4010 Programming Steps, Continued

Step 5:

Saving a

Configuration

Step 6:

Specifying Signal

Operation

Page 42

3-6

To delete a 4009 TrueAlert Addressable Controller from the list of device types from the

Programming menu:

1. From the Programming: [Configure Points] menu item, press ENTER.

2. Press NEXT until the Configure Point: [ZAMS/RIAMS/IAMS] menu item

comes up. Press ENTER.

3. Press PREVIOUS until you reach the IDNet: [Delete IDNet Point] menu

item. Press ENTER.

4. The display now reads IDNet Device: M1-x where x is the first available IDNet

address. If needed, use the PREVIOUS or NEXT buttons to scroll through the addresses.

Press ENTER on the address you want to delete.

5. Press ENTER again to verify your selection. The display reads

** Operation Complete ** when you are done.

Deleting the 4009 TrueAlert Addressable Controller

Overview

Page 43

3-7

The Quick CFIG option can be used instead of manual programming. Quick CFIG automatically

detects new hardware, and assigns default settings which you can modify later by using the

programmer manually.

To add one or more 4009 TrueAlert Addressable Controllers using Quick CFIG:

1. Press the MENU button, and then press NEXT until the display reads Menu: [Quick CFIG].

Press ENTER.

Note: The Quick CFIG menu item does not appear unless you have entered a valid

password with the appropriate access level. See “Step 1: Starting the

Programmer,” in this chapter.

2. The display reads Please Wait… Fire Alarm Operation Suspended. After

a moment, it reads Press <ENTER> for Programming. Press <EXIT> to

resume operation. Press ENTER.

3. The Quick CFIG: [Reconfigure All Hardware] menu item appears.

• If you are configuring a new job, press ENTER.

• If you are configuring an existing job, press NEXT so that

Quick CFIG: [Auto Detect NEW Hardware] comes up, and press ENTER.

4. Press ENTER at the prompt warning you that this will delete or change the existing

configuration.

5. Press ENTER once again to begin automatically detecting new hardware. The display

reads ** Detecting new Hardware **, and soon changes to

** Scanning for IDNet Devices **. After a few minutes, the display reads

Automatic Hardware Detection Completed, along with the number of

IDNet devices that were added. Finally, you are prompted to either press ENTER to go

back to the Quick CFIG menu, or EXIT.

• To go back to the Quick CFIG menu, press ENTER and skip the rest of the

instructions below.

• To stop programming and save your changes, press EXIT and continue to step 6.

6. The display notifies you that the configuration has changed, and prompts you to either

restore, save, or continue. Use the arrow buttons, and press ENTER on your selection.

• To save your latest changes, select Save and skip the rest of these instructions.

• To cancel your latest changes and restore the 4010 back to the previous

configuration, select Restore and skip the rest of these instructions.

• To go back to the previous screen, which allows you to enter the manual programming

menu, select Continue and refer to the “4010 Programming Steps” section.

7. From the Programming: [Configure Points] menu item, press NEXT until

the Configure Point: [NACs] menu item comes up. At this point, refer to

“Step 3: Configuring 4009 SLC Point Types” to set the correct point types. When you

finish “Step 3,” you will be done with the configuration. You can continue on to

“Step 4: Editing Point Labels,” or to “Step 5: Saving a Configuration.”

4010 Quick CFIG

Overview

Quick CFIG Steps

Page 44

3-8

Page 45

I-1

A

Addressable Controller, 1-1

block diagram, 2-2

deleting, 3-6

description, 1-3

hardwired interface, 1-4

IDNet interface, 1-3

mounting,

2-13

power requirements, 2-15

RUI interface, 1-3

system board illustration, 1-7

TrueAlert channels, 1-6

wiring, 2-14

Appliance Blink on Poll settings, 2-7

B

battery charger, 1-6

Blink on Poll settings, 2-7

C

Class A Adapter Option Card, 1-1

DIP switch settings, 2-6

D

DIP switch

address settings, 2-8

Appliance Blink on Poll settings, 2-7

Class A Adapter Option Card settings, 2-6

configuration for Addressable Controller, 2-10

Global Silent Appliance Test setting, 2-5

hardware configuration, 2-5

hardwired interface setting, 2-7

Horn volume settings, 2-7

IDNet interface setting, 2-7

IDNet Repeater Option Card setting, 2-7

Manual Real Appliance Test setting, 2-6

Manual Silent Appliance Test setting, 2-6

RUI interface setting, 2-6

SLC appliance addresses, 2-4

F

Fiber Optic Receiver Option Card, 1-1

G

Global Silent Appliance Test, 2-5

H

hardwired interface

description, 1-4, 1-5

DIP switch configuration settings, 2-10

DIP switch settings, 2-7

Horn volume settings, 2-7

I

IDNet interface

adding points, 3-3

address settings, 2-8

description, 1-3, 1-5

DIP switch settings, 2-7

point label programming, 3-4

point type programming, 3-4

Quick CFIG,

3-7

saving a configuration, 3-5

signal programming, 3-5

IDNet Repeater Option Card, 1-1

DIP switch setting, 2-7

installation

appliances, 2-16

Class A Adapter Option Card, 2-17

equipment needed,

2-11

Fiber-Optic Receiver Option Card, 2-17

IDNet Repeater Option Card, 2-17

mounting,

2-13

power requirements, 2-15

wiring, 2-14

L

LEDs

AC power, 1-10

Appliance Blink on Poll settings, 2-7

Earth Ground indication on, 1-10

Global Silent Appliance Test, 2-5

Manual Real Appliance Test, 2-6

Manual Silent Appliance Test, 2-6

trouble, 1-8

M

Manual Real Appliance Test, 2-6

Manual Silent Appliance Test, 2-6

mounting

Addressable Controller,

2-13

appliances, 2-16

N

notification appliances

overview, 1-2

P

panel programming (4010), 3-1

adding IDNet points, 3-3

deleting the Addressable Controller, 3-6

IDNet point labels, 3-4

IDNet point type, 3-4

Index

Page 46

point labels, 3-4

point types, 3-4

Quick CFIG, 3-7

saving, 3-5

signals, 3-5

starting up, 3-2

point label programming, 3-4

point type programming, 3-4

programming

4010 panel. See panel programming (4010)

Q

Quick CFIG, 3-7

R

Real Appliance Test, 2-6

related documentation, 2-12

RUI interface

address settings, 2-9

description, 1-3, 1-5

DIP switch settings, 2-6

S

saving a configuration, 3-5

signal programming

4010 (panel), 3-5

Silent Appliance Test

Global, 2-5

Manual, 2-6

SLC channels

on Addressable Controller, 1-6

overview, 1-2

T

trouble indicators, 1-8

Earth Ground, 1-10

TrueAlert Addressable Controller. See

Addressable Controller

TrueAlert channels

on Addressable Controller, 1-6

overview, 1-2

W

wiring

Addressable Controller, 2-14

appliances, 2-16

I-2

Page 47

Page 48

574-762

Rev. E

© 2005, 2007 Tyco Safety Products Westminster, Westminster, MA 01441-001 USA. Specifications and other information shown were current as of publication and are subject to change without notice.

Loading...

Loading...