Simplex STS DAY TANK User Manual

STS DAY TANK

PACKAGED DAY TANK SYSTEMS

Last Revision Date: September 20, 2018

For the most up-to-date information for this product and others, please

contact Simplex, Inc. at (800) 637-8603 or visit us on the web at

http://www.simplexdirect.com.

Table of Contents

1 Warnings and Cautions ........................................ 1

Safety information symbols 1

Cautions 1

2 Nameplates and Placards ..................................... 3

3 Installation ...................................................... 5

Overview of use 5

Installation Operations 6

Vent Openings 9

Day Tank Pump Priming Procedure 10

4 Day Tank Operation ........................................... 11

Automatic Operation 12

High Level Fill Disabled 14

Fill Test Pushbutton 14

Low Level Alarm 15

Manual Operations 15

Lamp Test 15

Automatic Duplex Pump Controller, Option 345 16

Overflow-Return Tank, Option 383 17

Overflow-Return Pump/Controller Added to Day Tank, Option 390 18

5 Maintenance .................................................... 19

Each Year 19

After the First Three Years 19

6 Troubleshooting .............................................. 20

No Fuel Delivered 20

Insufficient Fuel Delivered 20

Rapid Pump Wear 20

Pump Delivers for Short Period and Quits 20

Pump Requires too Much Power 20

Noisy Operation 20

Pump Requires Frequent Re-Priming 21

Motor Does Not Turn or Turns Intermittently 21

Pump Leaks Fuel 21

7 Drawings and Parts List ..................................... 22

Abbreviation Index 22

Technical Data 23

Appendix A Product Warranty ................................. 25

1 WARNINGS AND CAUTIONS

1

Safety

information

SymbolS

CautionS

The following images indicate important safety information:

This General warning symbol points out important

information that, if not followed, could endanger

personal safety and/or property.

This Explosion warning symbol points out potential explosion hazards.

This Fire warning symbol points out potential fire

hazards.

This Electrical warning symbol points out potential

electrical shock hazards.

• Improper operation of this equipment such as neglecting its

maintenance or being careless can cause possible injury or

death. Permit only responsible and capable persons to install,

operate, and/or maintain this equipment.

• Potentially lethal voltages and amperages are present in these

machines. Ensure all steps are taken to render the machine

safe before attempting to work on the equipment.

• All hardware covered by this manual have dangerous electrical voltages and can cause fatal electrical shock. Avoid

contact with bare wires, terminals, connections, etc., on the

hardware, if applicable. Ensure all appropriate covers, guards,

grounds, and barriers are in place before operating the equipment. If work must be done around an operating unit, stand

on an insulated dry surface to reduce shock hazard.

• Do not handle any kind of electrical device while standing in

water, while barefoot, or while hands or feet are wet. DANGEROUS ELECTRICAL SHOCK MAY RESULT.

• If trained personnel must stand on metal or concrete while

installing, servicing, adjusting, or repairing this equipment,

place insulative mats over a dry wooden platform. Work on

the equipment only while standing on such insulative mats.

• The National Electrical Code (NEC), Article 250 requires the

frame of the equipment to be connected to an approved earth

ground and/or grounding rods. This grounding will help

prevent dangerous electrical shock that might be caused by a

ground fault condition or by static electricity. Never disconnect the ground wire.

• Wire gauge sizes of electrical wiring, cables, and cord sets

must be adequate to handle the maximum electrical current

(ampacity) to which they will be subjected.

2

• Before installing or servicing this (and related) equipment,

make sure that all power voltage supplies are completely

turned off at their source. Failure to do so will result in hazardous and possibly fatal electrical shock.

• In case of accident caused by electric shock, immediately shut

down the source of electrical power. If this is not possible,

attempt to free the victim from the live conductor. AVOID

DIRECT CONTACT WITH THE VICTIM. Use a nonconducting implement, such as a dry rope or board, to free the

victim from the live conductor. If the victim is unconscious,

apply first aid and seek immediate medical attention.

• Never wear jewelry when working on this equipment. Jewelry can conduct electricity resulting in electric shock or may

get caught in moving components causing injury.

• Keep a fire extinguisher near the hardware at all times. Do

NOT use any carbon tetra-chloride type extinguisher. Its

fumes are toxic, and the liquid can deteriorate wiring insulation. Keep the extinguisher properly charged and be familiar

with its use. If there are any questions pertaining to fire extinguishers, please consult the local fire department.

• The illustrations in this manual are examples only and may

differ from your unit.

3

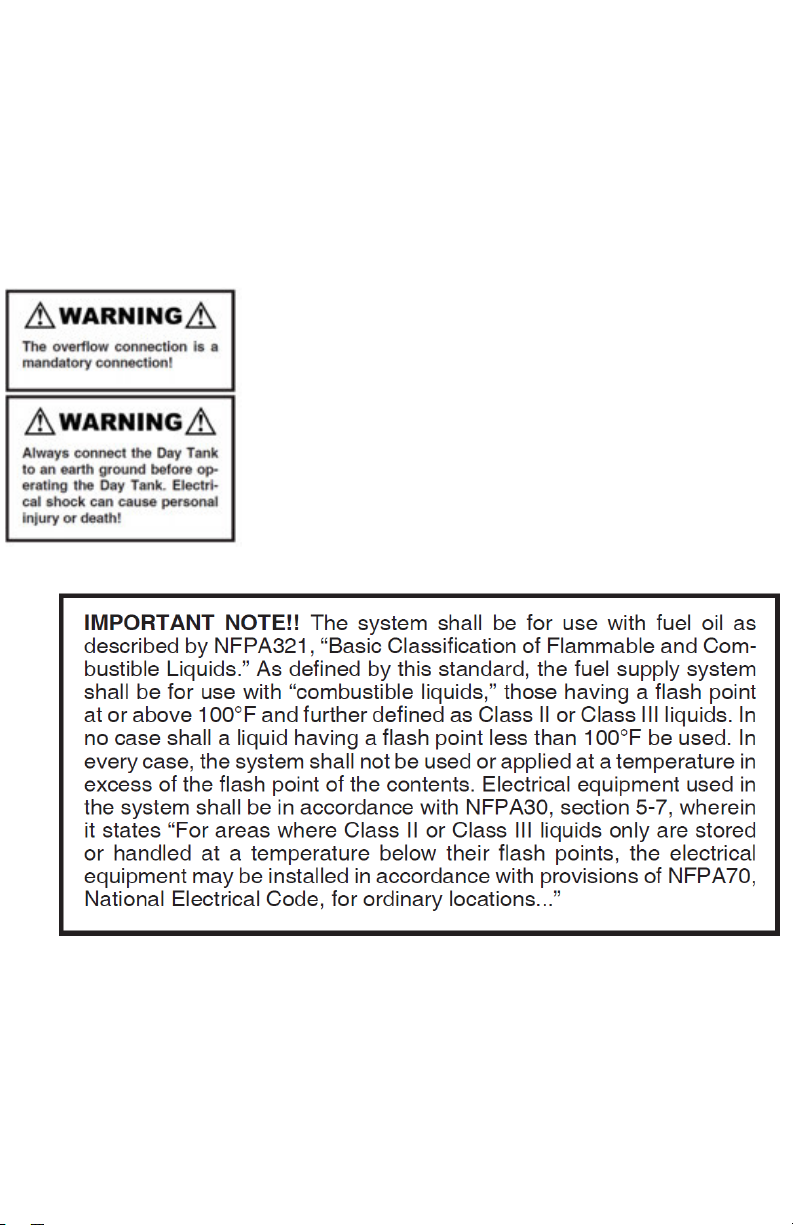

2 NAMEPLATES AND PLACARDS

Nameplates and Placards — 3

4 — Nameplates and Placards

4

If you have any questions regarding Day Tank

installation, call Simplex service at (800) 637-8603

(24 hrs.).

5

3 INSTALLATION

O

verview of

Location of the Day Tank is of prime importance and

should be done by trained personnel. It is one of the

Use

most critical factors involved in reliable and safe

operation. The Day Tank must be positioned and

installed according to the main fuel storage tank and

engine location. In general, locate the Day Tank as close

to the engine as possible consistent with applicable local

and national plumbing and electrical codes. Always

position the Day Tank so that the highest fuel level in the

tank is lower than the engine injectors. The Day Tank

must be located not farther than 200' from the main fuel

tank. The Day Tank must not be more than 18' higher

than the lowest fuel level in the main fuel tank. Never

locate the Day Tank in a confined space without

consideration for accidental fuel spillage and use a

rupture basin when necessary. Never locate the Day

Tank near a surface or object which may be adversely

affected by fuel oil. Never locate a Day Tank system

above a residential living space.

See dimensional drawing for port sizes. All plumbing to

and from the Day Tank should be black iron pipe or copper

tubing. All plumbing connections at the tank should be

made with pipe unions to facilitate installation and service.

Special attention must be given to pump suction pipe

connections to avoid possible air leaks and subsequent loss

of pump prime. Never allow the Day Tank pump to run

“dry” as immediate pump damage will occur. Before

applying power to the pump/motor be sure all fuel

connections have been made and tightened and all holes are

plugged. Option 010 or 015, auxiliary hand pump, is

recommended for installation on all Day Tanks with motorpumps. The hand pump is used for initial priming of the

fuel line from the main tank and as a back up to the motor

pump.

I

6

nstallation

Operations

1. Remove the Day Tank top. Check all visible hardware for

tightness. Attach the Vent Pipe. This is an NPT internal

connection. The vent pipe allows equalization of internal

Day Tank pressure.

THE VENT LINE!

DO NOT INSTALL A VALVE IN

Venting provides pressure relief in case

of overfill, rapid expansion, or gasification of contents in

the event of fire. The Day Tank may become

permanently distorted at pressures above 5PSI (10 and 25

gallon) and 3PSI (50–400 gallon) and may rupture at

pressures above the maximum withstand pressure of 25PSI

(10 and 25 gallon) and 15PSI (50–400 gallon). Day Tank

operation without a vent pipe is strictly not recommended.

The vent pipe should be at least 5 feet higher than any

other pipe and should terminate outdoors. The vent pipe

must be installed per local building codes and per NFPA

30 including but not limited to Section 19.5.3. There should

be no low portions or sags in the vent pipe which can trap

liquid. The end of the pipe should be fitted with a 180°

weather protected vent cap to shed water and should be

screened to keep out pests, leaves, etc.

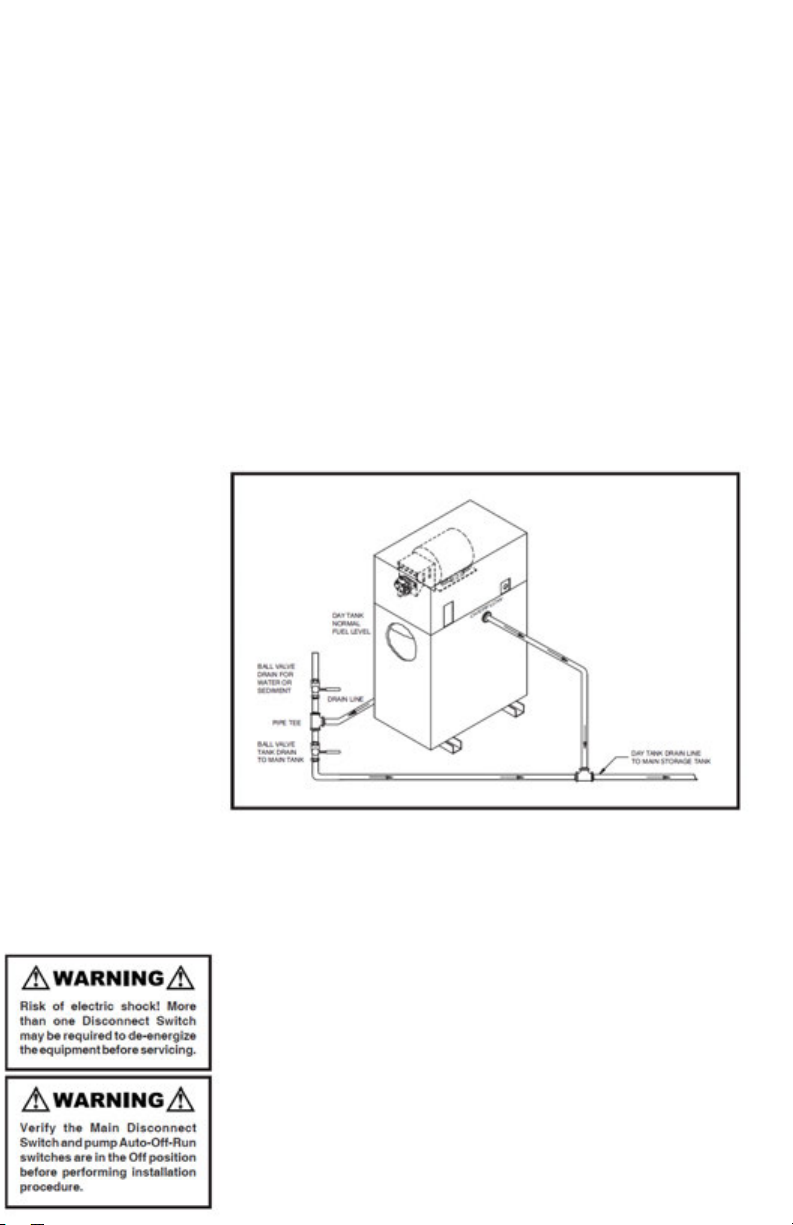

2. Attach the Overflow Pipe. This is an NPT internal

connection. Simplex recommends the configuration shown

in the illustration below. The overflow pipe runs from the

Day Tank back to the main storage tank and allows for

draining of the tank should it become overfilled. This pipe

should be sized at least twice the diameter of the pump fill

pipe (minimum 1"I.D. for 10 and 25 gallons; minimum 2"

I.D. for 50-500 gallon). If the tank becomes overfilled and

the overflow line is not connected or is obstructed the tank

I

7

nstallation

Operations

Contd

.

will distort and possibly rupture. In installations where the

main fuel tank is above ground the overflow pipe should

be connected to an Overflow Tank (Option #390

Recommended).

OVERFLOW LINE!

DO NOT INSTALL A VALVE IN THE

3. Attach the Day Tank Intake Line (fill pipe) from the main

fuel tank to the pump inlet. This is an NPT internal

connection. Use black pipe with a union and size per the

installation drawing in this manual. Optional fuel strainer

(Option 060) with #60 mesh is recommended.

4. Attach the Engine Supply Line. This is an NPT external

connection. Use black pipe with a union and size per the

dimensional drawing in this manual. Attach the Engine

Return Line. This is an NPT internal connection. Use black

pipe with a union and size per the installation drawing in

this manual.

5. Attach the Engine Return Line. This is a NPT internal

connection. Use black pipe with a union and size per the

installation drawing in this manual.

6.

WARNING! Verify the Day Tank mode selector switch is

in the “Off” position.

Supply a 115-1-60, 15A, circuit

breaker protected circuit from a reliable power bus to the

control power terminal board (TB”PS”) at terminals 1 and

2.

GROUND THE DAY TANK!

Secure the conduit end to

the left side of the cover at the holes provided. Replace the

cover.

7.

The pump has been pre-lubricated with heavy oil prior to

shipment. Prime the system by using the hand pump

(Option 010 or 015) to transfer fuel from the main tank to

Loading...

Loading...