Page 1

SST & SRS DAY TANK MANUAL

December 2010

Page 2

Day Tank Identifi cation

& Warranty Information

Attention Simplex Day Tank end user. This Day Tank Identifi cation Form and the en-

closed Day Tank Registration Card serves as your warranty registration. Please fi ll out

the enclosed registration card completely and mail it to Simplex Inc.

Simplex Day Tank Weld Tag Serial Number:

Simplex Work Order Number:

Date Purchased:

Date Shipped/Warranty Commencement:

Day Tank Sold To:

Customer Identifi cation Number:

SPECIFICATIONS:

Day Tank Model/Size:

Day Tank Pump/Motor Size:

Day Tank Options:

U.L. Number:

Simplex, Inc., 5300 Rising Moon Road, Springfi eld, IL 62711-6228 • 217-483-1600 • Fax 217-483-1616

© 2010 Simplex, Inc. All Rights Reserved. • Printed in the USA. • www.simplexdirect.com

Page 3

SST & SRS DAY TANK MANUAL • page 1 of 25

Contents

INSTALLATION ............................................................................ 2

Vent Openings ........................................................................ 5

Siphon-Drain .......................................................................... 7

Day Tank Pump Priming Procedure (Required) .................. 8

DAY TANK OPERATION .............................................................. 9

Automatic Operation ........................................................... 10

High Level Fill Disabled ....................................................... 11

Fill Test Pushbutton ............................................................ 11

Low Level Alarm .................................................................. 12

Manual Operation ................................................................. 12

Remote Operation ................................................................ 12

Lamp Test ............................................................................. 12

Automatic Duplex Pump Controller, Option 345 ............... 13

Overfl ow-Return Tank, Option 383 ..................................... 14

Overfl ow-Return Pump And Controller

Added To Day Tank, Option 390 ..................................... 15

MAINTENANCE .......................................................................... 16

Each Year .............................................................................. 16

After The First 3 Years ......................................................... 16

TROUBLESHOOTING ................................................................ 17

No Fuel Delivered ................................................................. 17

Insuffi cient Fuel Delivered .................................................. 17

Rapid Pump Wear ................................................................ 17

Pump Delivers for Short Period and Quits ........................ 17

Pump Requires Too Much Power ....................................... 17

Noisy Operation ................................................................... 17

Pump Requires Frequent Re-priming ................................ 17

Motor Does Not Turn or Turns Intermittently .................... 18

Pump Leaks Fuel ................................................................. 18

DRAWINGS AND PARTS LIST .................................................. 18

APPENDIX A - ABBREVIATIONS USED IN THIS MANUAL ..... 19

APPENDIX B - TECHNICAL DATA ............................................ 20

The information herein is the property of Simplex, Inc. and/or its subsidiaries.

Without written permission, any copying, transmitting to others, and other use

except that for which it is loaned, is prohibited.

Simplex, Inc., 5300 Rising Moon Road, Springfi eld, IL 62711-6228 • 217-483-1600 • Fax 217-483-1616

© 2010 Simplex, Inc. All Rights Reserved. • Printed in the USA. • www.simplexdirect.com

Page 4

SST & SRS DAY TANK MANUAL • page 2 of 25

INSTALLATION

Location of the Day Tank is of prime

importance and should be done by

trained personnel. It is one of the most

critical factors involved in reliable and

safe operation. The Day Tank must be

positioned and installed according to

the main fuel storage tank and engine

location. In general locate the Day Tank

as close to the engine as possible consistent with applicable local and national

plumbing and electrical codes. Always

position the Day Tank so that the highest

fuel level in the tank is lower than the

engine injectors. The Day Tank must be

located not farther than 200' from the

main fuel tank. The Day Tank must not

be more than 18' higher than the lowest

fuel level in the main fuel tank. Never

locate the Day Tank in a confi ned space

without consideration for accidental fuel

spillage and use a rupture basin when

necessary. Never locate the Day Tank

near a surface or object which may be

adversely affected by fuel oil. Never

locate a Day Tank system above a

residential living space.

If you have any questions regarding Day Tank installation,

call Simplex service at (217)

483-1600 (24 hrs.).

See dimensional drawing for port sizes.

All plumbing to and from the Day Tank

should be black iron pipe or copper tubing. All plumbing connections at the tank

should be made with pipe unions to facilitate installation and service. Special

attention must be given to pump suction

pipe connections to avoid possible air

leaks and subsequent loss of pump

prime. Never allow the Day Tank pump

to run “dry” as immediate pump damage

will occur. Before applying power to the

pump/motor be sure all fuel connections

have been made and tightened and all

holes are plugged. Option 010 or 015,

auxiliary hand pump, is recommended

for installation on all Day Tanks with

motor-pumps. The hand pump is used

for initial priming of the fuel line from

the main tank and as a back up to the

motor-pump.

1. Remove the Day Tank top. Check

all visible hardware for tightness.

Attach the Vent Pipe. This is a NPT

internal connection. The vent pipe

allows equalization of internal Day

Tank pressure. DO NOT INSTALL A

VALVE IN THE VENT LINE! Venting

provides pressure relief in case of

overfi ll, rapid expansion, or gasifi ca-

tion of contents in the event of fi re.

The Day Tank may become permanently distorted at pressures above

5PSI (10 and 25 gallon) and 3PSI

IMPORTANT NOTE!! The system shall be for use with fuel oil as

described by NFPA321, “Basic Classifi cation of Flammable and Com-

bustible Liquids.” As defi ned by this standard, the fuel supply system

shall be for use with “combustible liquids,” those having a fl ash point

at or above 100°F and further defi ned as Class II or Class III liquids. In

no case shall a liquid having a fl ash point less than 100°F be used. In

every case, the system shall not be used or applied at a temperature in

excess of the fl ash point of the contents. Electrical equipment used in

the system shall be in accordance with NFPA30, section 5-7, wherein

it states “For areas where Class II or Class III liquids only are stored

or handled at a temperature below their fl ash points, the electrical

equipment may be installed in accordance with provisions of NFPA70,

National Electrical Code, for ordinary locations...”

Simplex, Inc., 5300 Rising Moon Road, Springfi eld, IL 62711-6228 • 217-483-1600 • Fax 217-483-1616

© 2010 Simplex, Inc. All Rights Reserved. • Printed in the USA. • www.simplexdirect.com

Page 5

(50–400 gallon) and may rupture at

pressures above the maximum withstand pressure of 25PSI (10 and 25

gallon) and 15PSI (50–400 gallon).

Day Tank operation without a vent

pipe is strictly not recommended.

The vent pipe should be at least 5

feet higher than any other pipe and

should terminate outdoors. The vent

pipe must not extend or terminate

more than 12' above the Day Tank.

There should be no low portions or

sags in the vent pipe which can trap

liquid. The end of the pipe should be

fi tted with a 180° weather protected

vent cap to shed water and should be

screened to keep out pests, leaves,

etc.

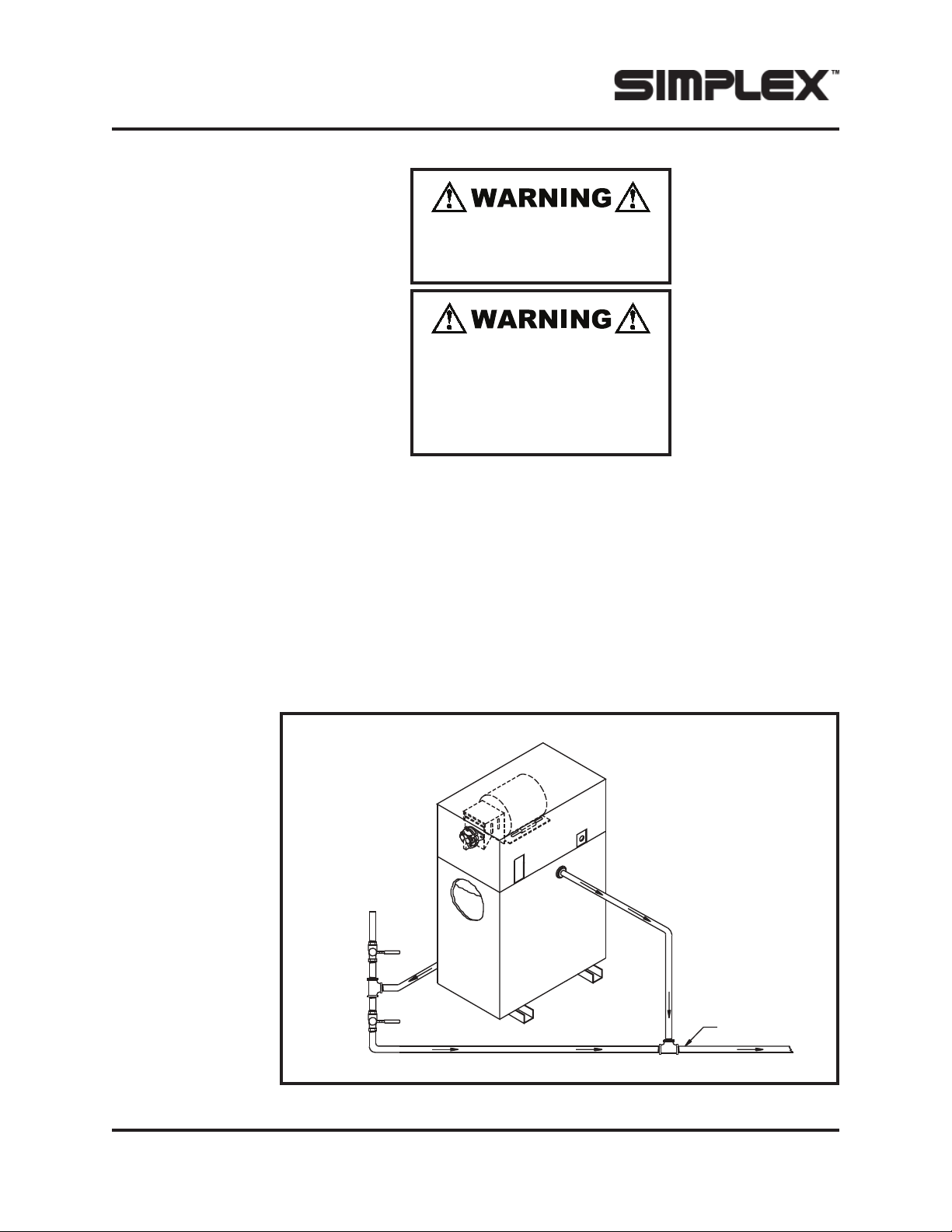

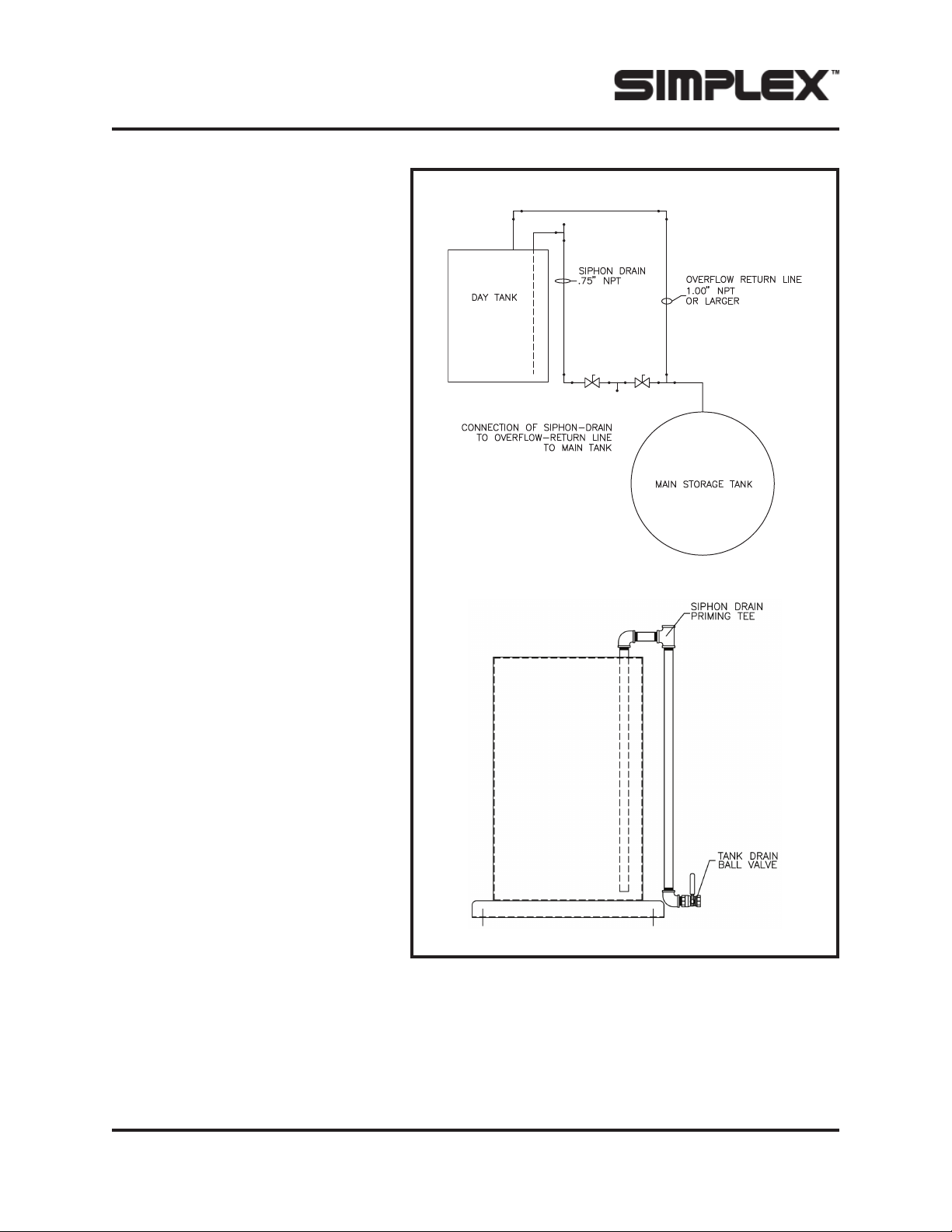

2. Attach the Overfl ow Pipe. This is a

NPT internal connection. Simplex

recommends the configuration

shown in the illustration below. The

overfl ow pipe runs from the Day Tank

back to the main storage tank and

allows for draining of the tank should

it become overfi lled. This pipe should

be sized at least twice the diameter of the pump fi ll pipe (minimum

1"I.D. for 10 and 25

gallon; minimum

2" I.D. for 50-500

gallon). If the tank

becomes overfi lled

and the overflow

line is not connected

or is obstructed the

tank will distort and

possibly rupture. In

installations where

the main fuel tank

is above ground

the overflow pipe

BALL VALVE

DRAIN FOR

WATER OR

SEDIMENT

should be connected to an Overfl ow

Tank (Option #390

Recommended).

PIPE TEE

BALL VALVE

TANK DRAIN

TO MAIN TANK

DO NOT INSTALL

A VALVE IN THE

OVERFLOW LINE!

SST & SRS DAY TANK MANUAL • page 3 of 25

The overfl ow connection is a

mandatory connection!

Always connect the Day Tank

to an earth ground before operating the Day Tank. Electrical shock can cause personal

injury or death!

3. Attach the Day Tank Intake Line (fi ll

pipe) from the main fuel tank to the

pump inlet. This is a NPT internal

connection. Use black pipe with a

union and size per the installation

drawing in this manual. Optional fuel

strainer (Option 060) with #60 mesh

is recommended.

4. Attach the Engine Supply Line. This is

a NPT external connection. Use black

pipe with a union and size per the

dimensioanl drawing in this manual.

DAY TANK

NORMAL

FUEL LEVEL

DRAIN LINE

OVERFLOW

DAY TANK DRAIN LINE

TO MAIN STORAGE TANK

Simplex, Inc., 5300 Rising Moon Road, Springfi eld, IL 62711-6228 • 217-483-1600 • Fax 217-483-1616

© 2010 Simplex, Inc. All Rights Reserved. • Printed in the USA. • www.simplexdirect.com

Page 6

5. Attach the Engine Return Line. This is

a NPT internal connection. Use black

pipe with a union and size per the

installation drawing in this manual.

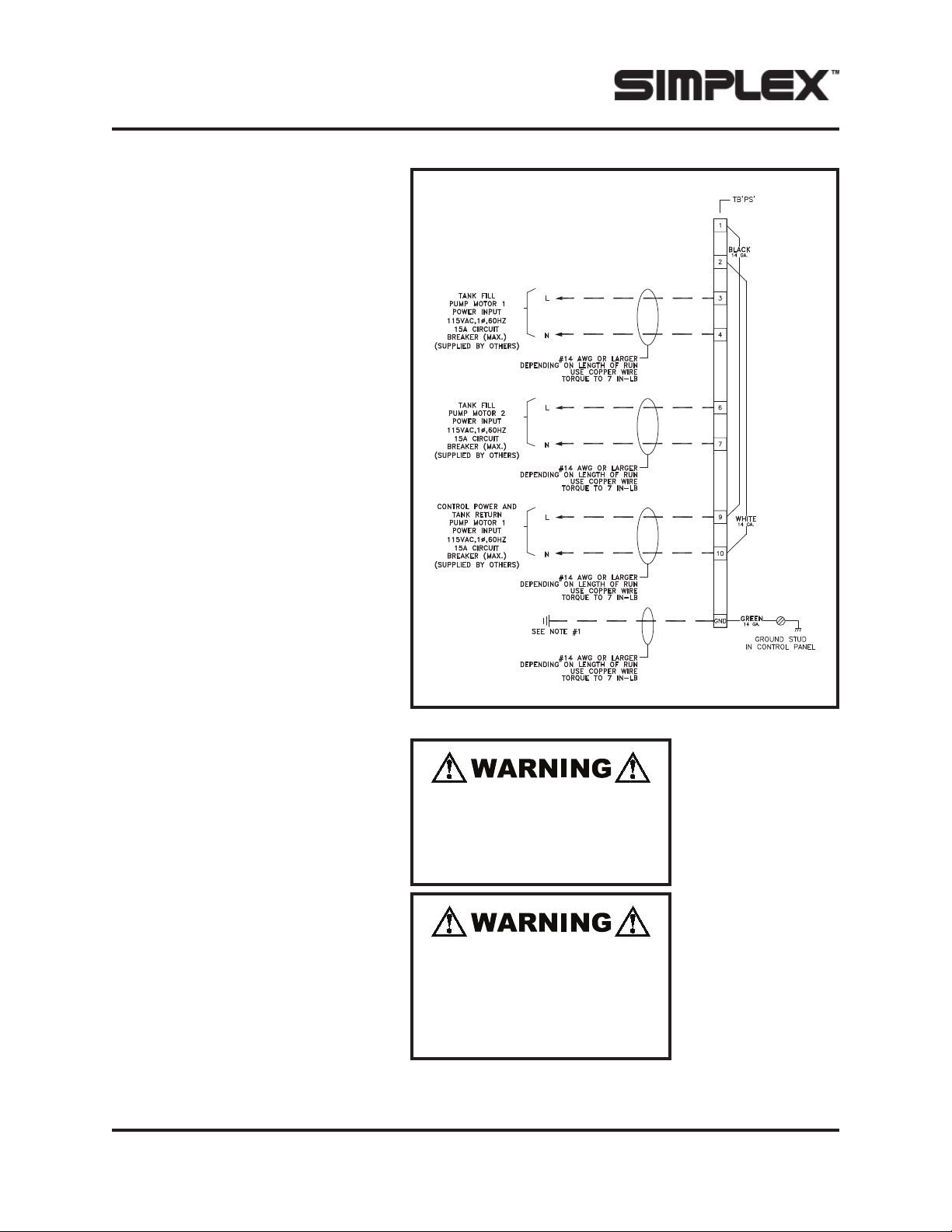

6. WARNING! Verify the Day Tank

mode selector switch is in the

“Off” position. Supply a 115-1-60,

15A, circuit breaker protected circuit

from a reliable power bus to the control power terminal board (TB”PS”)

at terminals 1 and 2. GROUND THE

DAY TANK! Secure the conduit end

to the left side of the cover at the

holes provided. Replace the cover.

7. The pump has been pre-lubricated

with heavy oil prior to shipment. Prime

the system by using the hand pump

(Option 010 or 015) to transfer fuel

from the main tank to the Day Tank.

If the Day Tank is not equipped with

a hand pump, remove the tank inlet

priming tee plug and fi ll the entire inlet

line with fuel. Replace the tee plug.

Energize the Day Tank pump/motor

by placing the Day Tank mode selector switch in the automatic position.

Ensure that fuel is exiting the pump

by watching the clear pump outlet

tubing. If not, repeat this procedure

and prime the pump also at the pump

priming tee. Make sure all unused

Day Tank holes are plugged, all

pipe connections are secure and no

leaks are present. The Day Tank is

now ready for unattended automatic

operation. If the Day Tank has been

stored for extended periods of time

pre-lube the pump with oil at the

pump priming tee.

SST & SRS DAY TANK MANUAL • page 4 of 25

Typical- See enclosed drawing for your equipment

Risk of electric shock! More

than one Disconnect Switch

may be required to de-energize

the equipment before servicing.

Verify the Main Disconnect

Switch and pump Auto-Off-Run

switches are in the Off position

before performing installation

procedure.

Simplex, Inc., 5300 Rising Moon Road, Springfi eld, IL 62711-6228 • 217-483-1600 • Fax 217-483-1616

© 2010 Simplex, Inc. All Rights Reserved. • Printed in the USA. • www.simplexdirect.com

Page 7

VENT OPENINGS

SST & SRS DAY TANK MANUAL • page 5 of 25

Each tank and each compartment of a

compartment tank shall have provision

for both normal and emergency venting.

A vent opening shall be in addition to the

fi lling and withdrawal openings. A vent

opening that provides for both emer-

gency and normal venting shall have

a capacity not less than that specifi ed

in the Venting Capacity Table below.

The wetted area of a tank is calculated

on the basis of 75 percent of the total

exposed area.

VENTING CAPACITY

WETTED SURFACE, VENTING CAPACITY, MINIMUM OPENING,

SQUARE FEET

20 21,100 2

30 31,600 2

40 42,100 3

50 52,700 3

60 63,200 3

70 73,700 4

80 84,200 4

90 94,800 4

100 105,000 4

120 126,000 5

140 147,000 5

160 168,000 5

180 190,000 5

200 211,000 6

250 239,000 6

300 265,000 6

350 288,000 8

400 312,000 8

500 354,000 8

600 392,000 8

700 428,000 8

800 462,000 8

900 493,000 8

1000 524,000 10

1200 557,000 10

1400 587,000 10

1600 614,000 10

1800 639,000 10

2000 662,000 10

2400 704,000 10

2800 and over 742,000 10

b,c

CUBIC FEET PER HOUR

d,e

NOMINAL PIPE SIZE, INCHES

f

a At 14.7 psia and 60°F (101.4kPa and 16°C)

b Interpolate for intermediate values

c For SI units, m2 = ft2 /0.09.

d These values taken from NFPA 30

e For SI units, m3/s = ft/hr X 0.03

f These pipe sizes apply only to open vent pipes of the specifi ed diameter not more than 12 inches

(0.3m) long and a pressure tank of not more than 2.5 psig (17.1kPa). If tank is to be equipped with

venting device or fl ame arrestor, the vent opening is to accommodate the venting device or fl ame

arrestor sized in accordance with column 2 of this table.

Simplex, Inc., 5300 Rising Moon Road, Springfi eld, IL 62711-6228 • 217-483-1600 • Fax 217-483-1616

© 2010 Simplex, Inc. All Rights Reserved. • Printed in the USA. • www.simplexdirect.com

Page 8

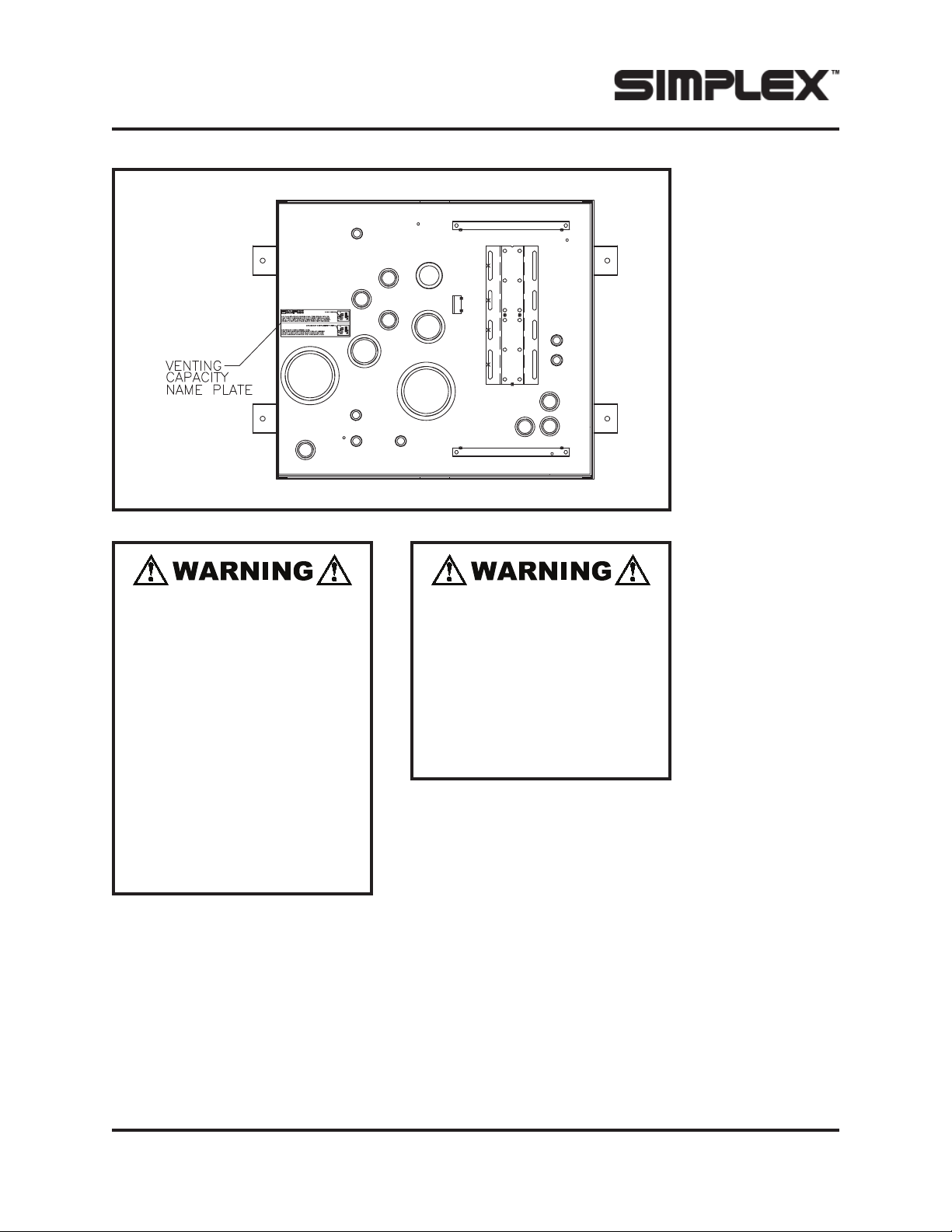

SST & SRS DAY TANK MANUAL • page 6 of 25

The emergency vent line capacity specifi ed on the placard

at the top of the tank must be

considered in order to maintain

the fi re safety factors estab-

lished by NFPA 30 and UL 142.

If installation is intended to

conform and benefi t from the

inherent safety advantages of

NFPA 30 and UL 142 installation standards, observance of

this value is mandatory. It may

be necessary to increase the

vent pipe if the run is excessively long.

Repairs or alterations of this

day tank without written approval from Simplex may void

the warranty and incur liability

for anyone making such repairs

or alterations. Alterations may

result in severe personal injury

or death due to electrical shock,

fi re or explosion.

Simplex, Inc., 5300 Rising Moon Road, Springfi eld, IL 62711-6228 • 217-483-1600 • Fax 217-483-1616

© 2010 Simplex, Inc. All Rights Reserved. • Printed in the USA. • www.simplexdirect.com

Page 9

SIPHON-DRAIN

The Siphon-Drain drop tube exits the

top of the tank and drops to nearly the

bottom of the tank. The siphon-drain

is used for service draining of the tank

and is the only means of draining the

tank. See dimensional drawing for the

location of the siphon-drain fi tting.

At the time of initial fi lling and start-up

of the tank, prime the siphon-drain as

follows:

1. Fill the tank to its normal maximum

full level.

2. Remove the plug in the siphon-drain

priming tee.

3. Be sure the lower end of the siphondrain tube is closed.

4. Using a funnel, manually fi ll the prim-

ing tube.

SST & SRS DAY TANK MANUAL • page 7 of 25

5. When the tube is full, plug the priming tee. Be sure to use pipe thread

sealant.

6. Test the siphon-drain by opening the

drain valve and drain into a bucket.

7. Repeat steps 1-6 if required to make

prime.

8. Close drain valve.

9. The siphon-drain should hold prime

and be available for tank draining at

any time.

Once primed, the siphon-drain may be

connected via a shut-off valve or solenoid valve to the overfl ow-return to the

main tank provided that the main tank is

below the level of the Day Tank and all

fl ow is by gravity. Any run of pipe above

the level of the drain termination may

require priming. With the siphon-drain

so connected to the Day Tank overfl ow-

return line, manual or automatic draining

of the Day Tank back to the main tank

is possible.

A manual or electric pump may be

connected to the siphon-drain at either

the lower termination or at the priming

tee plug.

Simplex, Inc., 5300 Rising Moon Road, Springfi eld, IL 62711-6228 • 217-483-1600 • Fax 217-483-1616

© 2010 Simplex, Inc. All Rights Reserved. • Printed in the USA. • www.simplexdirect.com

Page 10

DAY TANK PUMP PRIMING

PROCEDURE (REQUIRED)

SST & SRS DAY TANK MANUAL • page 8 of 25

The Day Tank pump is shipped from

the factory pre-primed with SAE 30 oil.

On initial start-up the pump must be

manually pre-primed. Do not prime the

system by running the pump motor!

Normally it is not necessary to fi ll the

supply line with fuel to prime the pump.

1. Remove the steel plug from the pump

priming tee, insert a short piece of

pipe in the pump priming tee and

attach a reducing coupler or funnel.

2. Fill the line from the check valve to

the pump with fuel oil or lube oil. Energize the pump/motor and observe

fuel fl owing through the clear fl ex

hose. Allow the pipe to drain about

halfway then hold your hand on the

top of the pipe to temporarily seal

the open tee. The oil drawn into the

pump will act to seal the pump and

allow a large vacuum to be generated. Repeat as required until line is

primed. After pump is primed remove

pipe/funnel and replace plug in pump

priming tee.

Attempting to pre-prime the

Day Tank fuel delivery system

by running the pump will cause

serious damage to the pump!

This is an industrial product, not

a consumer product. It must be

specifi ed, installed, operated,

and maintained by individuals

equipped with the appropriate

training and skills

Never operate or service a

Day Tank that is not properly

connected to an earthground.

Electrical shock can cause

personal injury or death!

Simplex, Inc., 5300 Rising Moon Road, Springfi eld, IL 62711-6228 • 217-483-1600 • Fax 217-483-1616

© 2010 Simplex, Inc. All Rights Reserved. • Printed in the USA. • www.simplexdirect.com

Page 11

DAY TANK OPERATION

The control nameplate consists of a

durable, fuel oil resistant, lexan membrane which contains the Day Tank

control pushbutton, switch and status

indicators. The control panel contains a

Fill Test pushbutton (hold to test L.E.D.

lamps), a three position Day Tank AutoOff-Manual switch, and the following

L.E.D. lamps: Power Available, Tank

Filling, Tank Leak, Not In Auto (blinking),

High Level Alarm, Tank Full, Normal

Operating Range, Fill Start, and Low

Level Alarm. Day Tank operation is

represented by the diagram in the lower

center of the nameplate.

The Day Tank control circuitry contains

the following serviceable components:

motor starting contactor, and control

fuses. Control fuses are 2A, 250VAC,

ABC type, and the standard motor starting contactor is a double pole, 24VDC

coil, rated at 20A. The prime controller in

the Day Tank is the printed circuit board.

The Day Tank printed circuit board is

powered by a fused internal 24VDC, 2A,

power supply. The printed circuit board

utilizes 24VDC components to analyze

the fuel level data it receives from the

four Day Tank fuel level sensors. The

four fuel level sensors together with the

sensor mounting plate comprise the fuel

level sensor assembly. When 120VAC,

single phase, 60Hz control power is supplied to the Day Tank control system the

Power Available L.E.D. is illuminated.

See Parts Legend Drawing for specifi c

components used.

During automatic operation, the

printed circuit board energizes and

de-energizes control relays, the motor

starter contactor, and the pump/motor

to automatically refi ll the Day Tank as

fuel is consumed by the prime mover.

SST & SRS DAY TANK MANUAL • page 9 of 25

Never use a Day Tank to transfer

or store class I, fl ammable, or

liquids with a fl ash point less

than 100°F. Ignition of fuel can

cause severe personal injury or

death! Day Tanks are approved

for use with combustible liquids

(class II or class III liquids)

with a fl ash point at or above

100°F provided they are stored

below the fl ash point ambient

temperature!

Dry contacts for Low Fuel Level, High

Fuel Level, Leak Alarm, and Not In Auto

relays are wired to terminals 1-12 of

terminal block TB‘A’ for customer use.

The customer may utilize these contacts

to annunciate low fuel level and high

fuel level. Contacts are rated at the

following specifi cations: 5A@30VDC,

5A@125VAC.

Simplex, Inc., 5300 Rising Moon Road, Springfi eld, IL 62711-6228 • 217-483-1600 • Fax 217-483-1616

© 2010 Simplex, Inc. All Rights Reserved. • Printed in the USA. • www.simplexdirect.com

Page 12

SST & SRS DAY TANK MANUAL • page 10 of 25

AUTOMATIC OPERATION

The Day Tank mode selector switch

should be left in the automatic position

for normal unattended operation. Regardless of operating mode, the Pump

Running L.E.D. will be illuminated any

time the pump/motor is energized. The

standard Day Tank motor is thermally

protected. See Parts Legend Drawing

for the pump/motor supplied with this

work order. As the prime mover con-

sumes fuel the Day Tank pump and

motor will cycle through the normal

operating range as determined by the

fuel level sensors. The control panel

L.E.D. lamps will continuously visually

annunciate fuel level in the Day Tank.

The Day Tank operator selects the

Day Tank operating mode via the three

position Day Tank mode selector toggle

switch. The operator may choose Automatic, Manual, or Off. To alert the Day

Tank operator, the red Not In Auto lamp

fl ashes continuously when the Day Tank

mode selector switch is not in the Auto

position. This is the only fl ashing lamp

on the control panel. Normally the mode

selector switch is left in the automatic

position. After initial Day Tank installation, priming, and fi ll, the controller

printed circuit board will energize and

de-energize the Day Tank pump/motor

as determined by the opening and closing of the fuel level sensors (25%-FS1,

50%-FS2, 90%-FS3, 95%-FS4).

As the Day Tank continues to fi ll and

the fuel level reaches 50% capacity the

Normal Operating Range L.E.D. will

be illuminated. The Day Tank pump/

motor will de-energize when the fuel

level reaches 90% (the Normal Operating Range L.E.D. is extinguished and

the Normal Maximum L.E.D. is illuminated). During normal operation fuel is

consumed by the prime mover and the

Day Tank cycles between 50 and 90%

capacity, energizing and de-energizing

the motor/pump as necessary. If the

pump/motor continues to run past the

90% capacity level, normally open fuel

level sensor FS4 will close when 95%

capacity is reached. At this point the

High Level Alarm L.E.D. will be illuminated and the pump will de-energize.

The fuel level sensors are shown below.

Day Tank operation is automatic

and the day tank motor may

start at any time! After a motor thermal overload reset the

motor may restart at any time!

Simplex, Inc., 5300 Rising Moon Road, Springfi eld, IL 62711-6228 • 217-483-1600 • Fax 217-483-1616

© 2010 Simplex, Inc. All Rights Reserved. • Printed in the USA. • www.simplexdirect.com

Page 13

HIGH LEVEL FILL DISABLED

A High Level alarm causes the Day

Tank to enter a new mode of operation

dependent on the position of the mode

selector switch.

Regardless of the operation mode,

High Level indicates that fuel level has

reached or exceeded 95% capacity. The

pump/motor is de-energized and will remain locked-out until the Day Tank fuel

level is decreased to 90% capacity or

less. The High Level L.E.D. will remain

illuminated until reset by the operator

regardless of Day Tank fuel level.

If a High Level Alarm condition occurs

and the Day Tank fuel level is reduced

to normal levels the High Level L.E.D.

will remain illuminated until it is reset by

the operator. The operator must place

the Day Tank mode selector switch in

the Off position and then return it to the

Manual or Automatic position to reset

the High Level failure.

SST & SRS DAY TANK MANUAL • page 11 of 25

When High Level is initiated while in

Automatic Mode the Day Tank will

continue to operate normally and cycle

from 50 to 90% but the High Level L.E.D.

will remain illuminated until it is reset.

When the High Level mode is initiated

while in Manual Mode the Day Tank

pump/motor will cycle between the 90%

and 95% levels as determined by fuel

level sensors FS3 and FS4. After the

condition is corrected and the control

circuitry is returned to Auto the pump/

motor will resume normal operation and

cycle between 50% and 90%.

Fuel level sensors FS1-FS3 (Low Fuel

Level Alarm, Fill Start, and Tank Full,

respectively) have normally closed

contacts. FS4 (High Level Alarm) is

the only fuel level sensor with normally

open contacts.

FILL TEST PUSHBUTTON

The Fill Test pushbutton is a momentary type. It may be used to provide a

quick verifi cation of overall pump/motor/

fuel level sensor operation when the

system is in the Auto mode. When the

mode selector switch is placed in the

Off position, the Fill Test pushbutton

is disabled. When the mode selector

switch is in the Automatic position, the

Fill Test pushbutton is enabled.

Simplex, Inc., 5300 Rising Moon Road, Springfi eld, IL 62711-6228 • 217-483-1600 • Fax 217-483-1616

© 2010 Simplex, Inc. All Rights Reserved. • Printed in the USA. • www.simplexdirect.com

Page 14

SST & SRS DAY TANK MANUAL • page 12 of 25

The operator may energize the pump/

motor with the Test Fill pushbutton to

test and cycle the Day Tank through

the specifi ed capacity range. When

the pump is operated by continuously

holding the Fill Test pushbutton the

pump/motor will continue to run past the

normal stop level until 95% capacity is

reached, at which point the pump/motor

is de-energized and locked out by fuel

level sensor FS4. The High Level L.E.D.

will be illuminated and the High Level

alarm relay will be energized. Contact

rated 5A @ 30 VDC, 5A @ 125VAC

maximum.

LOW LEVEL ALARM

During normal operation, the pump/motor is energized and the Fill Start L.E.D.

is illuminated when the Day Tank fuel

level reaches 50% capacity. If the pump/

motor does not energize a low fuel level

alarm will be initiated when Day Tank

fuel capacity reaches the 25% level. The

low fuel alarm relay LFR energizes, the

Low Level Alarm L.E.D. is illuminated,

and LFR dry contacts close. The Day

Tank user may utilize these contacts to

sound an alarm horn or provide an input

to a remote annunciator. Contacts are

5A @ 30VDC, 5A @ 125VAC maximum.

to fi ll until 95% capacity is reached at

which time the High Level mode will be

initiated. The Day Tank pump/motor

will be de-energized and locked out

until Day Tank fuel level is reduced to

90% capacity and fuel level sensor FS3

changes state. Until the alarm condition

is corrected and the control circuitry is

reset to Auto the Day Tank pump/motor

will continue to cycle between the 90%

and 95% levels. Upon return to Auto, the

control circuitry is reset and the pump/

motor will resume normal operation and

cycle between 50% and 90%.

REMOTE OPERATION

See Electrical Drawing. These Day

Tanks are shipped with a jumper installed on terminals TB‘2’ 8 and TB‘3’ 1

on the printed circuit board. Removing

this jumer disables the pump/motor

when in Auto mode. The Day Tank user

has the option of installing a switch,

remote disconnect, or overload relay to

enable or disable the Day Tank pump/

motor when in Auto mode. For example,

a fuel sensor located in the Day Tank

secondary containment (SST Options

190 and 191, SRS Standard) could be

wired across these contacts to disable

the pump/motor in the event of a Day

Tank leak.

MANUAL OPERATION

For manual (continuous run) operation,

the Day Tank operator must place the

Day Tank mode selector toggle switch

in the Manual position. Manual operation

allows the Day Tank operator to energize and run continuously the pump/

motor independent of fuel level sensors

FS1-FS3. During manual operation the

control panel L.E.D. lamps will continue

to annunciate fuel level to the Day Tank

operator. The Day Tank will continue

Simplex, Inc., 5300 Rising Moon Road, Springfi eld, IL 62711-6228 • 217-483-1600 • Fax 217-483-1616

© 2010 Simplex, Inc. All Rights Reserved. • Printed in the USA. • www.simplexdirect.com

LAMP TEST

The momentary Fill Test pushbutton is

also used to test L.E.D. lamps on the

control board. To use this feature, press

and hold the the Fill Test pushbutton to

illuminate the L.E.D. lamps. If desired,

the lamps may be tested without fi lling

the tank further by placing the mode

switch in the “Off” position before pressing the Fill Test pushbutton.

Page 15

SST & SRS DAY TANK MANUAL • page 13 of 25

AUTOMATIC DUPLEX PUMP

CONTROLLER, OPTION 345

Duplex pump options are used to increase the reliability of a day tank system

through the addition of a second, backup pump and level control. In a duplex

system, one pump is designated the

“lead” pump and the other is the “lag”

pump. The lead pump automatically

refi lls the day tank over the tank’s normal

operating range of 50% to full. Normally,

once the tank has been initially fi lled,

the fuel level should never drop below

50%. Less than 50% is indicative of

either a failure of the lead pump or consumption in excess of pump capacity.

The lag pump and its separate level

controller, acting as a backup senses a

drop in fuel level below 50% and starts

the lag pump, which then continues to

run, along with the lead pump, until the

tank is full.

Multi-function duplex pump controller

system providing selectable operating

modes, including:

• Automatic lead pump alternating with

automatic lag pump back-up

• Automatic twin pump operation

(both pumps run simultaneously)

automatic level control back-up

• Manual operation

Basic System includes the following:

• All controller features

• Duplex switch

• Mode Selector switch

• Pump running indicators for each

pump

• Two pumps, each with check

valves

Operation: With the Duplex switch in the

Alternate position, Pump 1 will start at

50% and shut off at the 90% level. For

utilization of both Pump 1 and Pump 2

simultaneously, switch to Both position.

In this position Pump 1 and Pump 2 will

start at the 50% level and shut off at

the 90% level.

When the Mode Selector switch is in the

Manual position all fl oatswitches, except

the high fuel level fl oatswitch are over-

ridden, and either position (Alternate

or Both) may be selected. The pumps

will continue to run until Switch #1 is

returned to the Off or Auto position or

if a high fuel condition occurs.

For standard duplex operation, the Duplex switch should be in the Alternate

position and Mode Selector switch

should be in the Auto position. Pump #1

will then start at 50% level and stop at

the 90% level. The next time fuel drops

back to the 50% level Pump #2 will start

and then stop at the 90% level. Continuing operation alternates between Pump

#1 and Pump #2.

When the fuel drops to the 25% level,

both pumps will run simultaneously

until the fuel level returns to the 90%

fuel level.

Simplex, Inc., 5300 Rising Moon Road, Springfi eld, IL 62711-6228 • 217-483-1600 • Fax 217-483-1616

© 2010 Simplex, Inc. All Rights Reserved. • Printed in the USA. • www.simplexdirect.com

Page 16

OVERFLOW-RETURN TANK,

OPTION 383

Operation: The control switch should

normally be in the Auto position and

the Power Available L.E.D. should be

illuminated. The level controller is set to

pump the tank to virtually empty. Therefore, normally the tank is empty and the

Tank Empty L.E.D. is illuminated. If the

adjacent Day Tank should overfi ll and

overfl ow, oil will fl ow from the overfl ow

line of the Day Tank to the inlet port of

the overfl ow-return tank. Above empty

level, fl oat switch FS3 will close. At

20% level in the overfl ow-return tank,

fl oat switch FS2 will close, activating

the overflow-return pump which is

installed on the tank. The Pump Start

L.E.D. will illuminate and the tank will be

pumped-down to empty. At empty level,

fl oat switch FS3 will open and stop the

pump. If the level in the overfl ow-return

tank should continue to rise above the

pump start level, fl oat switch FS1 will

close at the 30% level activating the

“high fuel level” alarm indicator and

remote signal contacts.

SST & SRS DAY TANK MANUAL • page 14 of 25

Day Tank operation is automatic

and the day tank motor may

start at any time! After a motor thermal overload reset the

motor may restart at any time!

Simplex, Inc., 5300 Rising Moon Road, Springfi eld, IL 62711-6228 • 217-483-1600 • Fax 217-483-1616

© 2010 Simplex, Inc. All Rights Reserved. • Printed in the USA. • www.simplexdirect.com

Page 17

SST & SRS DAY TANK MANUAL • page 15 of 25

OVERFLOW-RETURN PUMP

AND CONTROLLER ADDED

TO DAY TANK, OPTION 390

Normally the Day Tank operates

automatically to control the fuel level

between the 50% and normal full

level, which is set at the position of the

overfl ow or vent fi tting on the tank. An

overfi ll can occur if the control switch is

left in the Manual position, if there is a

leak in a control valve permitting gravity

or siphon fl ow of oil into the tank, or if

there is a control failure. In the event of

an overfi ll, fl oat switch FS4 will close,

activating the High Level Alarm L.E.D.

lamp on the control panel. In addition,

the fi ll pump will be disabled. The tank

should not fi ll above this point, which

is approximately 1.0” above the normal

full level but 1.0-2.0” below the top of

the tank. With the addition of option

390, the overfl ow-return pump will be

activated by the overfl ow alarm circuit

and will operate as described below.

Above 70% level, fl oat switch closes

and arms the overfl ow-return controller,

illuminating the “overfl ow return armed”

indicator and enabling the overfl ow

pump test push-button. Upon activation

of the overfl ow alarm by fl oat switch FS4,

as described above, the over fl ow pump

contactor will be energized and the

overfl ow pump will run. The contactor

is latched-in via 70% level fl oat switch

and the tank will be pumped down to

the 70% level. This is intermediate in

the normal operating range of 50% to

full and the tank should remain at this

level; the refi ll pump will not start until

the tank reaches the 50% level. As the

overfl ow pump is running, the “pump

running” L.E.D. will be illuminated.

To test the overfl ow-return pump, press

the Test pushbutton. This pushbutton is

armed only above the 70% level, when

the L.E.D. is illuminated. The overfl ow

pump will pump-down the tank to the

70% level. If desired, the tank can be

refi lled to normal full by pressing the

test pushbutton on the control panel.

Simplex, Inc., 5300 Rising Moon Road, Springfi eld, IL 62711-6228 • 217-483-1600 • Fax 217-483-1616

© 2010 Simplex, Inc. All Rights Reserved. • Printed in the USA. • www.simplexdirect.com

Page 18

MAINTENANCE

The Simplex Day Tank has been

designed to require minimum maintenance. All components have been

chosen for a long, reliable life. The

Day Tank is constantly lubricated by

the diesel fuel it transfers. Inspect this

tank at least once every year for damage, leakage, or rust on both inside

and outside the tank. Promptly repair

or replace any signifi cantly damaged

or deteriorated Day Tank. Two basic

intervals of maintenance are required:

each year and after the fi rst 3 years.

EACH YEAR

1. Water and sediment should be

drained from the tank each year.

If normal engine/generator testing

does not consume one tank full of

fuel each year the tank should be

drained and refi lled with fresh fuel.

2. Remove the inspection port from the

Day Tank. The port is shown in the illustration below. Examine the interior

of the Day Tank. Using an inspection

lamp examine all internal Day Tank

components. With tank drained test

sending unit operation. Install a new

inspection port gasket and replace

the inspection port cover.

3. Press the Test Fill pushbutton and observe pump and motor performance.

SST & SRS DAY TANK MANUAL • page 16 of 25

Repairs or alterations of this

day tank without written approval from Simplex may void

the warranty and incur liability

for anyone making such repairs

or alterations. Alterations may

result in severe personal injury

or death due to electrical shock,

fi re or explosion.

If you have any questions regarding Day Tank maintenance,

call Simplex service at (217)

483-1600 (24 hrs.).

5. Re-tighten hose clamps at pump/

hose connections. Re-tighten the

pump bracket, motor bracket, and

pump/motor coupler hardware.

6. Inspect all plumbing connections for

leaks. Test all options and fuel level

alarms for proper operation.

7. Re-tighten all electrical connections.

AFTER THE FIRST 3 YEARS

After three years of normal use re-oil the

Day Tank motor with 10 drops of 5W30

or 10W oil. Do not over oil the motor.

4. Inspect pump/motor alignment and

wear. Inspect the pump for leaks.

Simplex, Inc., 5300 Rising Moon Road, Springfi eld, IL 62711-6228 • 217-483-1600 • Fax 217-483-1616

© 2010 Simplex, Inc. All Rights Reserved. • Printed in the USA. • www.simplexdirect.com

Page 19

TROUBLESHOOTING

SST & SRS DAY TANK MANUAL • page 17 of 25

NO FUEL DELIVERED

1. Pump not primed.

2. Lift is too high.

3. Rotation direction incorrect.

4. Check valve installed backwards.

INSUFFICIENT FUEL

DELIVERED

1. Air leak at inlet.

2. Defective solenoid valve or check

valve.

3. Lift too high.

4. Pump worn.

5. Inoperative foot valve.

6. Piping improperly installed.

7. Fuel strainer plugged.

RAPID PUMP WEAR

1. Dirt or grit in fuel.

2. Pipe strain on pump causing bind.

3. Worn pump/motor coupler.

4. Pump has been run dry or with insuffi cient fuel.

Never operate or service a

Day Tank that is not properly

connected to an earthground.

Electrical shock can cause

personal injury or death!

PUMP REQUIRES TOO

MUCH POWER

1. Air in plumbing lines.

2. Liquid heavy or too viscous.

3. Bent pump shaft, binding rotating

element.

4. Misalignment of pump/motor coupler.

NOISY OPERATION

1. Insuffi cient fuel supply.

2. Air leaks in the inlet pipe.

3. Air or gas at the inlet connection.

4. Pump and motor out of alignment.

5. Worn out spider coupling.

6. Pump coupler out of balance.

PUMP DELIVERS FOR

SHORT PERIOD AND QUITS

PUMP REQUIRES

FREQUENT RE-PRIMING

1. Leak at inlet.

2. End of inlet not deep enough.

3. Air or gas in fuel.

4. Supply exhausted.

5. Vaporization of fuel at inlet.

6. Air or gas in inlet line.

7. Sand or abrasives in fuel.

Simplex, Inc., 5300 Rising Moon Road, Springfi eld, IL 62711-6228 • 217-483-1600 • Fax 217-483-1616

© 2010 Simplex, Inc. All Rights Reserved. • Printed in the USA. • www.simplexdirect.com

1. Inoperative foot valve.

2. Inoperative check valve.

3. Inoperative solenoid valve.

4. Pump cavitation.

5. Plumbing air leaks.

6. Lift too high.

7. Pump seals leaking.

Page 20

MOTOR DOES NOT TURN OR

TURNS INTERMITTENTLY

1. Control power not available.

2. Motor thermal overload condition.

3. Pump failed and seized.

4. Motor failure.

PUMP LEAKS FUEL

1. Loose pump plumbing fi ttings.

2. Worn pump shaft seal.

3. Pump pressure relief valve failure.

4. Fuel leak elsewhere running towards

pump area.

5. Excessive head from overhead storage tank.

6. Worn pump O-rings.

DRAWINGS AND

PARTS LIST

The drawings included in this manual

are the most accurate source of part

numbers for your Fuel Supply System.

When ordering replacement parts always consult the Parts Legend. When

contacting the Simplex Service Department always have your work order and

drawing number ready for reference.

The Work Order Number and the Drawing Numbers are located on each drawing legend. A typical drawing legend and

parts list is illustrated at right.

SST & SRS DAY TANK MANUAL • page 18 of 25

ASSEM BLY

ITE M

NO. QTY.

1 1 196781 DT FUEL OIL DAY TANK SST-25C

2 1 196782

3 1 196783

4 1 22918050 BV1 BALL VALVE 0.50” NPT.

5 1 25242920 FS1-4 25 GALLON 4 FLOAT ASSEMBLY

6 1 25242140 LS TANK LEAK SENSOR FLOATSWITCH

7 1 24626100 MOT1S FILL PUMP MOTOR 0.33HP, 115VAC,

8 1 24741020 PUMP PUMP 2 G.P.M. SUPER XL

9 2 24649510 SC PUMP/MOTOR SHAFT COUPLER HUB 0.50”

10 1 24650000 [SC] SHAFT COUPLER SPIDER (L050)

11 1 24748300 MHP MANUAL HAND PUMP 1.00” NPT.

12 1 22925002

13 1 22918010 BV2 BALL VALVE 1.00” NPT.

14 1 21704100A SOL SOLENOID VALVE 0.75” NPT. 115VAC

15 1 24010040 BV3 BALL VALVE NEXUS UNION

16 1 22923105 CV CHECK VALVE 0.50” NPT.

PART

NUMBER

[8BD73671]

[8BD83854B]

PAR TS LIST/LEG END

COMP

DESIG. DESCRIP TION

WITH OVERFLOW BASIN, UL LABELED

OP TION 19 0

CP TANK CONTROL BOX WRAPPER

6.00" POWDER COATED WHITE NEMA 1

CBP SST – OPTION CONTROL PANEL

POWDER COATED BONE WHITE

OP TION 06 5

OP TION 19 1

1PH, 60HZ, ODP.

OP TION 60 0

OP TION 39 9

(L050)

20 GALLONS PER 100 STROKES

OP TION 01 5

SCV SWING CHECK VALVE 1.00” NPT.

OP TION 01 5

OP TION 01 5

NORMALLY CLOSED

OP TION 08 0

1.00” NPT. FEMALE INLET,

0.75” NPT. FEMALE OUTLET

OP TION 08 7

OP TION 07 0

Simplex, Inc., 5300 Rising Moon Road, Springfi eld, IL 62711-6228 • 217-483-1600 • Fax 217-483-1616

© 2010 Simplex, Inc. All Rights Reserved. • Printed in the USA. • www.simplexdirect.com

Page 21

SST & SRS DAY TANK MANUAL • page 19 of 25

APPENDIX A - ABBREVIATIONS USED IN THIS MANUAL

Listed below are abbreviations of terms found on Fuel Supply Systems. When following a drawing utilize this guide to defi ne abbreviated system and component

names. As this is a master list, drawings and text pertaining to your equipment may

not contain all these terms.

AC-Alternating Current

AHR-Alarm Horn Relay

AR-Alarm Horn

BPRV-Back Pressure Regulating

Valve

BRK-Motor/Pump Bracket

BV-Ball Valve

C-Contactor

CB-Ciruit Breaker

CSR-Check Strainer Relay

CV-Check Valve

DC-Direct Current

DPDT-Double Pole Double Throw

F-Fuse

FLS-Flowswitch

FS-Floatswitch

FSR-Simplex Fuel Strainer

GA-Gauge

GAL-Gallons

GPM-Gallons Per Minute

HFL-High Fuel Level Relay

HG-Mercury

HP-Horsepower

HZ-Hertz

I.D.-Inside Diameter

JB-Junction Box

Hz-Hertz

INHG-Inches of Mercury

L-Lamp

L.E.D.-Light Emitting Diode

LAFD-Los Angeles Fire Department

LFF-Loss of FLow Relay

LFL-Low Fuel Level Relay

LPR-Low Pressure Relay

MDB-Main Distribution Block

MDS-Main Disconnect Switch

MOT-Motor

N.C.-Normally Closed

NEC-National Electric Code

NEMA-National Electric

Manufacturers Association

NFPA-National Fire Protection As-

sociation

N.O.-Normally Open

NP-Nameplate

NPT-National Pipe Thread

O.D.-Outside Diameter

OLR-Over Load Relay

OPT-Option

PCB-Printed Circuit Board

PCRX-Pump Control Relays

PG-Pressure Gauge

PLR-Pipe Leak Relay

PRV-Pressure Relief Valve

PS-Pressure Switch

PSI-Pounds Per Square Inch

PSR-Pressure Switch Relay

PRR-Pump Running Relay

SC-Swing Check Valve

SOL-Solenoid

SST-Simplex Super Tank

TB-Terminal Block

T-Control Transformer

TDR-Time Delay Relay

TEFC-Totally Enclosed, Fan Cooled

THR-Tank Heater Control Relay

TS-Transducer Pressure Switch

V-Voltage

VAC-Voltage, Alternating Current

VDC-Voltage, Direct Current

VG-Vacuum Gauge

Simplex, Inc., 5300 Rising Moon Road, Springfi eld, IL 62711-6228 • 217-483-1600 • Fax 217-483-1616

© 2010 Simplex, Inc. All Rights Reserved. • Printed in the USA. • www.simplexdirect.com

Page 22

APPENDIX B - TECHNICAL DATA

SST & SRS DAY TANK MANUAL • page 20 of 25

Thermal expansion of oil is approximately

1 cubic inch per 1 gallon per 10°F rise in

temperature.

Hydraulic Formulas

Horsepower =

Torque (lb. in.) =

Torque (lb. in.) =

Flow (gpm) =

231

GPM x PSI

1714

CU IN./REV. x PSI

2

HP X 63025

RPM

CU IN./REV x RPM

Head and Pressure

Equivalents

When converting pressure from feet of water to

P.S.I., the specifi c gravity of the liquid must be

considered.

Here are some typical conversion fi gures:

1 P.S.I.=2.30 feet of water

(specifi c gravity 1.0)

1 P.S.I.=2.88 feet of oil

(specifi c gravity 0.8)

Conversion Factors

1HP = 33,000 ft. lbs. per minute

1HP = 42.4 btu per minute

1HP = 0.746 kwhr (kilowatt hours)

1 U.S. gallon= 231 cubic inches

Pipe Volume varies as the square of the diam-

eter; volume in gallons = 0.0034 D 2 L where:

D=inside diameter of pipe in inches;

L=length in inches

Velocity in feet per sec.=

where:

D=inside diameter of pipe in inches

Atmospheric pressure at sea level = 14.7PSI

Atmospheric pressure decreases

approximately 0.41PSI for each one thousand

feet of elevation up to 23,000 feet.

Pressure (PSI) = feet head x 0.433 x specifi c

gravity

Specifi c gravity of oil is approximately 0.85.

0.408 x fl ow (gpm)

2

D

PRESSURE AND

CONVERSION TABLE

Feet PSI PSI

Water Oil Water

1 .35 .43

2 .70 .87

3 1.05 1.3

4 1.4 1.73

5 1.75 2.17

10 3.5 4.33

15 5.2 6.5

20 7.0 8.66

25 8.7 10.8

30 10.5 13.0

35 12.2 15.2

40 14.0 17.3

45 15.7 19.5

50 17.5 21.7

55 19.2 23.9

60 21.0 26.0

65 22.7 28.1

70 24.5 30.5

75 26.2 32.5

80 28.0 34.6

85 29.7 36.8

90 31.5 39.0

SUPER X-L PUMP

Flow, GPM (LPM)

PUMP DISPLACEMENT RPM 100 PSI 1000 PSI 1500 PSI 2000 PSI 2500 PSI

MODEL IN3 (CC/REV.) (6.9 Bar) (69 Bar) (103 Bar) (138 Bar) (172 Bar)

SUPER .262 1800 1.99 1.86 1.79 1.73 1.66

XL-11 (4.29) (7.54) (7.05) (6.78) (6.56) (6.29)

SUPER .942 1800 7.08 6.87 6.77 6.66 6.56

XL-39 (15.44) (26.83) (26.04) (25.66) (25.24) (24.86)

SUPER 1.47 1800 11.10 10.81 10.70 10.60 10.40

XL-62 (24.14) (42.07) (40.97) (40.55) (40.17) (39.42)

SUPER 2.23 1800 16.70 16.50 16.30

XL-90 (36.5) (63.29) (62.54) (61.78)

SUPER 3.35 1800 25.30 24.90 24.60 24.40

XL-114 (54.9) (95.89) (94.37) (93.23) (92.48)

Simplex, Inc., 5300 Rising Moon Road, Springfi eld, IL 62711-6228 • 217-483-1600 • Fax 217-483-1616

© 2010 Simplex, Inc. All Rights Reserved. • Printed in the USA. • www.simplexdirect.com

Page 23

SST & SRS DAY TANK MANUAL • page 21 of 25

PUMP PERFORMANCE DATA

40 SSU • 200 SSU • 500SSU

(SERIES 420)

40SSU 200SSU

0 PSI 50 PSI 100 PSI 0 PSI 50 PSI 100 PSI 200 PSI 300 PSI 500 PSI

MODEL RPM GPM HP GPM HP GPM HP GPM HP GPM HP GPM HP GPM HP GPM HP GPM HP

420 1200 1.9 ¼ 1.7 ¼ 1.5

1

/3 1.9

1800 2.9 ¼ 2.7 ½ 2.5 ½ 2.9

422 1200 3.7

1

/3 3.4 ½ 3.1 ¾ 3.7

1800 5.4 ½ 4.9 ¾ 4.8 1 5.5 ¼ 4.9

424 1200 9.0 ¼ 7.6 ¾ 6.0 1 9.0

1800 11.5

426 1200 10.0 ¾ 8.2 1 6.3 1½ 12.0 ¾ 11.0 1 10.5 1½ - - - - - -

1

/3 11.1 1 10.7 1½ 13.7 ½ 13.3 1 12.9 1½ 10.9 3 10.2 5 - -

1800 15.0 1 12.2 1½ 9.5 3 18.0 1 17.0 1½ 16.0 3 - - - - - -

1

/8 1.9

1

/8 2.8 ¼ 2.7

1

/8 3.4 ¼ 3.1 ¼ 2.8 ½ 3.0 1 2.8 1½

1

/3 8.6 ½ 8.2 1 7.7 2 7.1 3 - -

1

/8 1.7 ¼ 1.5

1

/3 4.9 ½ 4.6 ¾ 4.3 1½ 3.8 2

1

/3 2.5 ½ 2.3 ¾ 2.1 1½

1

/3 1.4 ½ 1.2 ¾

428 1200 20.9 ¾ 17.4 1½ 14.0 3 24.5 ¾ 23.8 1½ 23.0 3 - - - - - -

1800 31.2 1½ 26.1 3 21.0 5 37.0 1½ 36.0 3 35.0 5 - - - - - -

429 1200 34.0 1½ 29.0 3 22.0 5 41.0 1½ 40.0 3 38.5 5 - - - - - -

1800 53.0 3 45.0 5 36.0 7½ 61.7 3 61.0 5 60.0 7½ - - - - - -

500SSU

0 PSI 50 PSI 100 PSI 200 PSI 300 PSI 500 PSI

MODEL RPM GPM HP GPM HP GPM HP GPM HP GPM HP GPM HP

420 1200 1.8

1

/8 1.8

1800 2.7 ¼ 2.7 ¼ 2.6

422 1200 3.6

1

/8 3.5 ¼ 3.3

1800 5.3 ¼ 5.2

1

/8 1.7 ¼ 1.6

1

/3 4.9 ½ 4.4 1 4.0 1½ 3.0 2

1

/3 2.5 ½ 2.4 1 2.2 1½

1

/3 2.8 ½ 2.7 ¾ 2.0 1½

1

/3 1.4 ½ 1.1 1

424 1200 8.7 ½ 8.6 ¾ 8.5 1½ 8.2 2 7.8 3 - -

1800 2.9 1 12.8 1½ 12.7 2 12.5 3 12.0 5 - -

426 1200 12.0 1 11.5 1½ 11.0 2 - - - - - -

1800 18.1 1½ 18.0 2 16.3 3 - - - - - -

428 1200 24.5 1½ 24.0 2 23.7 3 - - - - - -

1800 37.0 3 36.5 5 36.0 5 - - - - - -

429 1200 41.0 2 40.0 5 39.5 5 - - - - - -

1800 61.7 5 61.0 5 60.0 7½ - - - - - -

Simplex, Inc., 5300 Rising Moon Road, Springfi eld, IL 62711-6228 • 217-483-1600 • Fax 217-483-1616

© 2010 Simplex, Inc. All Rights Reserved. • Printed in the USA. • www.simplexdirect.com

Page 24

PUMP PERFORMANCE DATA

1000 SSU • 5000 SSU • 10000SSU

(SERIES 420)

1000SSU

0 PSI 50 PSI 100 PSI 200 PSI 300 PSI 500 PSI

MODEL RPM GPM HP GPM HP GPM HP GPM HP GPM HP GPM HP

420 1200 1.9

1800 2.8 ¼ 2.7 ¼ 2.7 ¼ 2.6 ½ 2.5 ¾ 2.2 1½

422 1200 3.5 ¼ 3.4 ¼ 3.3

1800 5.0

424 1200 8.8 ¾ 8.7 1 8.5 1½ 8.2 2 7.8 3 - -

1800 13.0 1½ 12.7 2 12.5 2 10.2 3 9.9 5 - -

426 1200 12.5 1½ 12.0 1½ 11.8 2 - - - - - -

1800 18.7 2 18.5 2 17.0 3 - - - - - -

428 1200 24.9 2 24.5 3 24.0 5 - - - - - -

1800 37.4 5 37.2 5 36.5 5 - - - - - -

1

/8 1.9

1

/3 4.9 ½ 4.9 ¾ 4.7 1 4.2 1½ 3.4 2

1

/8 1.8 ¼ 1.7

1

/3 3.0 ¾ 2.6 ¾ 1.8 1½

SST & SRS DAY TANK MANUAL • page 22 of 25

1

/3 1.6 ½ 1.4 ¾

429 1200 41.7 3 41.7 5 41.0 5 - - - - - -

1800 61.7 5 61.7 7½ 61.0 7½ - - - - - -

5000SSU 10000SSU

0 PSI 50 PSI 100 PSI 200 PSI 300 PSI 0 PSI 50 PSI 100 PSI

MODEL RPM PM HP GPM HP GPM HP GPM HP GPM HP GPM HP GPM HP GPM HP

420 1200 - - - - - - - - - - - - - - - -

1800 - - - - - - - - - - - - - - - -

422 1200 - - - - - - - - - - - - - - - -

1800 - - - - - - - - - - - - - - - -

424 1200 8.2 1 8.0 1½ 7.8 2 7.6 3 7.4 3 - - - - - -

1800 11.2 2 11.0 3 10.7 3 10.2 5 9.9 5 - - - - - -

426 1200 12.5 2 12.4 2 11.6 3 - - - - - - - - - -

1800 18.7 3 18.5 3 17.5 5 - - - - - - - - - -

428 1200 24.9 5 24.9 5 24.5 5 - - - - 23.3 5 23.0 5 22.8 5

1800 37.4 7½ 37.4 7½ 37.0 7½ - - - - - - - - - -

429 1200 41.7 5 41.0 5 40.0 7½ - - - - - - - - - -

1800 61.7 7½ 61.7 7½ 61.0 10 - - - - - - - - - -

Simplex, Inc., 5300 Rising Moon Road, Springfi eld, IL 62711-6228 • 217-483-1600 • Fax 217-483-1616

© 2010 Simplex, Inc. All Rights Reserved. • Printed in the USA. • www.simplexdirect.com

Page 25

SST & SRS DAY TANK MANUAL • page 23 of 25

MOTORS FOR PUMP DRIVE CONTINUOUS DUTY, 40°C, UL RECOGNIZED

Single Phase Motors

Split Phase Start, Drip Proof, Rigid Base, Class B

Insulation, Moderate Starting Torque, Sleeve Bearing

NEMA Thermal Service Approx.

HP RPM Voltage Frame Bearing Prot. Factor F.L. Amps

1/3 1800 115 48 Sleeve Auto 1.0 6.6

1/2 1800 115 56 Sleeve None 1.0 9.2

Capacitor Start, Drip Proof, Rigid Base, Class B Insulation,

High Starting Torque, Ball Bearing

NEMA Thermal Service Approx.

HP RPM Voltage Frame Bearing Prot. Factor F.L. Amps

1/3 1800 115/230 48 Sleeve Auto 1.0 7.0/3.5

1/2 1800 115/230 56 Sleeve Auto 1.0 9.2/4.6

3/4 1800 115/230 56 Sleeve Auto 1.0 10.4/5.2

Capacitor Start, Drip Proof, Rigid Base, Class B Insulation,

Moderate Starting Torque, Sleeve Bearing

NEMA Thermal Service Approx.

HP RPM Voltage Frame Prot. Factor F.L. Amps

1 1800 115/208-230 56 Auto 1.15 13.4/6.8-6.7

1 1/2 1800 115/208-230 56H Auto 1.15 18.0/9.3-9.0

2 1800 115/208-230 145T None 1.15 21.0/11.3-10.5

3 1800 115/208-230 184T None 1.15 33.0/16.5

5 1800 208-230 184T None 1.15 23.0-21.0

7 1/2 1800 208-230 215T None 1.15 35.2

Capacitor Start, Totally Enclosed, Fan-Cooled, Rigid

Base, Class B Insulation, NEMA-L (>1.0 HP) High Starting

Torque, Ball Bearing

NEMA Thermal Service Approx.

HP RPM Voltage Frame Prot. Factor F.L. Amps

1/3 1800 115/208-230 56 Auto 1.15 6.6/3.1-3.3

1/2 1800 115/208-230 56 Auto 1.15 8.8/4.2-4.4

3/4 1800 115/208-230 56 Auto 1.15 11.0/5.4-5.5

1 1800 115/208-230 56 Auto 1.15 13.4/6.8-6.7

1 1/2 1800 115/208-230 56H Auto 1.15 15.2/8.2-7.6

2 1800 115/208-230 145T None 1.15 18.8/9.4

3 1800 115/208-230 184T None 1.0 34.0/17.0

5 1800 208-230 213T None 1.0 27.5-26.0

7 1/2 1800 208-230 215T None 1.0 36.5-33.0

Simplex, Inc., 5300 Rising Moon Road, Springfi eld, IL 62711-6228 • 217-483-1600 • Fax 217-483-1616

© 2010 Simplex, Inc. All Rights Reserved. • Printed in the USA. • www.simplexdirect.com

Page 26

SST & SRS DAY TANK MANUAL • page 24 of 25

MOTORS FOR PUMP DRIVE CONTINUOUS DUTY, 40°C, UL RECOGNIZED

Three Phase Motors

Drip Proof, Rigid Base, Class B Insulation, NEMA B, High

Starting Torque, Ball Bearing

NEMA Thermal Service Approx.

HP RPM Voltage Frame Prot. Factor F.L. Amps

1/3 1800 208-230/460 56 Auto 1.35 1.5-1.6/0.8

1/2 1800 208-230/460 56 Auto 1.35 2.3-2.4/1.2

3/4 1800 208-230/460 56 Auto 1.25 2.9-3.0/1.5

1 1800 208-230/460 56 Auto 1.15 3.5-3.6/1.8

1 1/2 1800 208-230/460 145T Auto 1.15 4.8-4.8/2.4

2 1800 208-230/460 145T Auto 1.15 6.2-6.2/3.1

3 1800 208-230/460 145T Auto 1.15 9.2-8.6/4.3

5 1800 230/460 184T Auto 1.15 13.2/6.6

7 1/2 1800 230/460 213T Auto 1.15 20.0/10.0

10 1800 230/460 215T Auto 1.15 26.6/13.3

Totally Enclosed-Fan-Cooled, Rigid Base, Class B Insulation, Class F (182T -254T), NEMA B, High Starting Torque

NEMA Approx.

HP RPM Voltage Frame F.L. Amps

1/3 1800 208-230/460 56 1.5-1.6/0.8

1/2 1800 208-230/460 56 2.3-2.4/1.2

3/4 1800 208-230/460 56 2.9-3.0/1.5

1 1800 208-230/460 56 3.5-3.6/1.8

1 1/2 1800 208-230/460 145T 4.8-4.8/2.4

2 1800 208-230/460 145T 6.0-5.8/2.9

3 1800 208-230/460 145T 8.6/4.3

5 1800 230/460 184T 14.0-13.2/6.6

7 1/2 1800 230/460 213T 21.0-20.0/10.0

10 1800 230/460 215T 28.0-27.0/13.5

DC Motors - Ampere Ratings and Fuse Sizes

Ratings of DC Motors

HP Full-Load Amperes Recommended Values

120 Volts 240 Volts 120 Volts 240 Volts

1/8 1.4 .7 3 3

1/6 1.8 .9 3 3

1/4 2.9 1.5 5 3

1/3 3.6 1.8 5 3

1/2 5.2 2.6 7 3

3/4 7.4 3.7 10 5

1 9.4 4.7 15 7

1 1/2 13.2 6.6 20 10

2 17 8.5 25 12

3 25 12.2 30 15

5 40 20 50 25

7 1/2 5 8 29 8 0 40

10 76 38 100 50

Amp. Cap. of Fuses for Motors

Simplex, Inc., 5300 Rising Moon Road, Springfi eld, IL 62711-6228 • 217-483-1600 • Fax 217-483-1616

© 2010 Simplex, Inc. All Rights Reserved. • Printed in the USA. • www.simplexdirect.com

Page 27

SST & SRS DAY TANK MANUAL • page 25 of 25

Pipe Friction- Fuel Oil 2

Pressure Drop in PSI per 100 feet of Pipe and Tube

NOMINAL SIZES - INSIDE DIAMETERS

Pipe

Size, 2.0 7.0 10.0 17.0 23.0 30. 40.0 50.0

In. GPM GPM GPM GPM GPM GPM GPM GPM

.50 2.337 24.65 56.10 148.75 233.75 408.00

.75 3.61 7.31 21.25 39.53 64.6 93.5 182.75

1.00 .306 2.00 4.16 11.70 19.55 31.87 54.40 80.75

1.25 .10 .51 1.00 2.55 5.10 8.50 14.88 22.10

1.5 .23 .425 1.10 2.04 3.27 5.70 8.33

2.00 .13 .34 .60 .96 3.10 2.38

2.50 .10 1.62 .30 .51 .94 1.275

3.00 .10 1.74 3.06 4.93

NOTE: Pipe sizes shown apply to standard weight schedule 40 pipe.

Tube is standard copper tubing

Specifi c Gravity and Viscosity of Oils

*Specify Viscosities In SSU at Various Temperatures

Gravity

Oils At 60°F 30°F 60°F 80°F 100°F 130°F 170°F 210°F 250°F

Auto Lubricating

S.A.E.-

10 Max. .880 to .935 4,400 1,090 430 240 120 66

20 Max. .880 to .935 6,900 1,650 750 400 185 90 57

30 Max. .880 to .935 13,000 2,700 1,200 580 255 120 66 49

40 .880 to .935 25,000 4,850 2,000 950 380 150 80 55

50 .880 to .935 58,000 10,000 3,700 1,600 600 220 105 67

60 .880 to .935 100,000 15,000 5,300 2,300 800 285 128 76

70 .880 to .935 22,000 7,500 3,100 1,050 342 150 86

10W .880 to .935

20W .880 to .935

Fuel Oil-

Diesel No. 2D .82 to .95 138 70 53.6 45.5 39

Diesel No. 3D .82 to .95 390 145 92 65 48 39

Diesel No. 4D .82 to .95 4,400 700 280 140 70 44.2

Diesel No. 5D .82 to .95 16,500 3,500 1,500 750 320 136 76.5 54

No. 1 .82 to .95 35

No. 2 .82 to .95 104 56 45.5 40

No. 3 .82. to .95 126 68 53 45 39

No. 5A .82 to .95 1,480 420 215 125 72 48

No. 5B .82 to .95 850 600 490 400 315 235 178 141

No. 6 .82 to .95 72,000 21,500 7,800 2,150 590 225 110

Navy Spec. .989 Max. 3,300 1,100 600 360 190 100 66 50.2

Navy II 1.0 Max. 24,000 8,600 3,500 1,150 370 160 89

Turbine-

Heavy .91 Avg. 4,800 1,280 625 350 170 86 57

Light .91 Avg. 770 330 208 138 87 58.8

FLAMMABLE

LIQUIDS

FLASH POINTS

Excerpts from NFPA 325, “Fire

Hazards properties of Flammable

Liquids...”

Flash Points

°F(°C)

Diesel Fuel Oil 100 Min. (38)

No. 1-D or Legal

Diesel Fuel Oil 125 Min. (52)

No. 2-D or Legal

Diesel Fuel Oil 130 Min. (54)

No. 4-D or Legal

Fuel Oil No. 1

(Kerosene) 100-162

(Range Oil) (43-72)

(Coal Oil)

Fuel Oil 126-204

No.2 (52-96)

Fuel Oil 142-240

No. 4 (61-116)

Fuel Oil No. 5 156-336

Light (69-169)

Fuel Oil No. 5 160-250

Heavy (71-121)

Fuel Oil 150-270

No. 6 (66-132)

Jet Fuels 110-150

Jet A and A-1 (43-66)

Jet Fuels -10 to +30

Jet B (-23 to -1)

Jet Fuels -10 to +30

JP-4 (-23 to -1)

Jet Fuels 95-145

JP-5 (35-63)

Simplex, Inc., 5300 Rising Moon Road, Springfi eld, IL 62711-6228 • 217-483-1600 • Fax 217-483-1616

© 2010 Simplex, Inc. All Rights Reserved. • Printed in the USA. • www.simplexdirect.com

Loading...

Loading...