Page 1

FUEL OIL DAY T ANKS

See SRS Series for 50 gal and above.

SST Series - Engineering Submittal

SST Series Advanced Line

Day Tanks

Construction:

UL 142 aboveground steel tank

all seam welded, square, atmospheric tank of heavy gauge steel

with internal reinforcements,

tested to 5 PSI test pressure.

Welded flange pipe fittings for fuel

return, overflow, vent, drain. Submerged fuel oil supply drop tube.

Heavy gauge steel channel feet

with mounting holes. Separate

mechanical and electrical compartments, each with steel housing and removable access covers. Standard equipment:

•2 GPM SUPER-XL Pump

•SST Controller

MODELS

qq

q SST 10 10 gal.

qq

qq

q SST 25 25 gal.

qq

qq

q SST 50 50 gal.

qq

qq

q SST 75 75 gal.

qq

qq

q SST 100 100 gal.

qq

qq

q SST 150 150 gal.

qq

qq

q SST 200 200 gal.

qq

qq

q SST 275 275 gal.

qq

qq

q SST 325 325 gal.

qq

qq

q SST 400 400 gal.

qq

Secondary Containment

Option 190: UL142 Secondary

Containment Dike

Option 191: Leak Sensor

Super-XL Pump:

The SUPER-XL Pump consists of the following:

•2 GPM, high vacuum, positive displacement gear pump consisting of two pressure loaded, intermeshing, hardened

steel, precision ground gear assemblies

within a high strength die cast aluminum

housing. Mechanical shaft seal. Pressure

loaded to be self-compensating for internal wear .

• 1/3 HP, 120V, single-phase ODP motor.

Oversized for high starting torque.

•Motor overload protection

•Optional pumps-motors available.

SST Level Controller:

UL 508 LISTED

Indication Functions

Indicators are long life, extra-bright

large display, L.E.D.’s:

•Fuel level

•Power available

•Switch off (flashing)

•Pump running

•Low level alarm

•Overflow alarm/pump control

backup activated

Outputs

•Pump start-stop (1HP)

•Low level alarm (60W)

•High level alarm (60W)

Control Functions

120V AC or 24V DC

•“Auto-off-manual” pump control switch

•“Press to test” pump push-button

•Pump start-stop automatic level control

•Automatic disconnect of pump on

overflow/high level alarm

Page 2

FUEL OIL DAY TANKS - SST Series Engineering Submittal • page 2

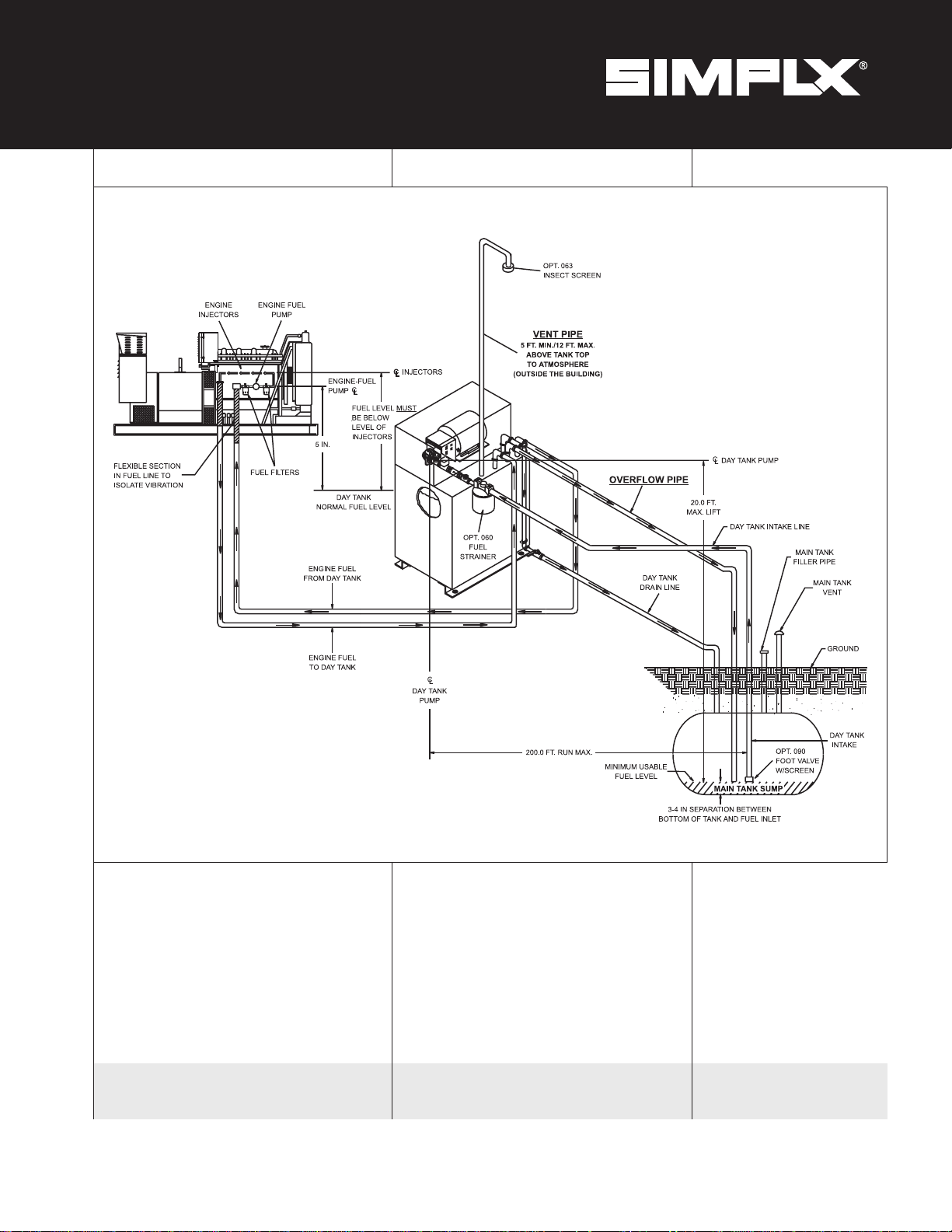

Fuel Supply

Network

This is an industrial product, not a consumer

product. It must be specified, installed, operated

and maintained by individuals equipped with the

appropriate training and skills. This tank conforms

to applicable portions of the following standards:

NFPA 30 and NFPA 37, UL 142, UL 508.

All fuel piping should be of black iron or copper

pipe. Pipe sizes should follow engine manufacturer’s recommendations based on KW of

generator set.

WARNING

A Dangerous Installation Will

Result If Properly Sized

Overflow And V ent Pipes Are

Not Connected To This Tank.

Overflow Pipe

Should the tank be overfilled as a result of

misadjustment of fuel level controls, fuel spillage

or overpressurization of the tank may result. An

overflow pipe back to the main storage tank of

at least double the size of the fill pipe must be

installed with consideration given to length of

run and vertical drop. (Use min. 1" I.D.)

Vent Pipe

A properly sized and installed vent pipe is mandatory. The vent provides a means for tank to

breathe when fuel is withdrawn or added to tank.

Venting also provides pressure relief in case of

overfill or rapid expansion or gasification of contents in event of fire. Portions of this tank may

become permanently distorted at pressures

above 5 PSI, and may rupture at pressures above

the designed maximum withstand pressure of

25 PSI. To avoid overpressurization a vent pipe

to atmosphere (outside of the building) of the

same diameter as the threaded vent fitting installed in the tank must be provided to extend a

minimum of 5 ft. above tank top, however, no

portion of this vent should extend or terminate

more than 12 ft. above this tank. There must be

no low portions or sags in the vent pipe which

can trap liquid. Protect the open end by suitable

means to prevent entry by insects, foreign matter and precipitation.

NOTE:

The emergency vent line capacity specified on

the placard at the top of the tank must be considered in order to maintain the fire safety factors established by NFPA 30 and UL 142. If installation is intended to conform and benefit from

the inherent safety advantages of the NFPA 30

and UL 142 installation standards, observance

of the value is mandatory. It may be necessary

to increase the vent pipe diameter if the run is

long, or install an emergency vent at the tank.

Maintenance

Every Six Months:

Inspect this tank at least every six months for

damage, leakage, or rust on both inside and

outside of the tank. Promptly repair or replace

any significantly damaged or deteriorated tank.

Annually:

Drain water and sediment from day tank sump

at least once each year, or more frequently

depending on usage and condition of the fuel.

Recommended Options

Main Storage Tank Is Underground:

When the main fuel storage tank is located

underground, one of the following options is

recommended to assure maintenance of day

tank pump prime. Option 070: Check valve on

pump intake, Option 080, 083: Solenoid valve

on pump intake, Option 090: Foot valve.

Initial Installation:

Hand pump is recommended for use as a backup to the motor pump and to prime the motor

pump on initial installation. Option 015: 5 GPM

(5 strokes/gallon) hand pump.

Special Requirements

Above Ground Storage Tank:

When the main fuel storage tank is located above

the level of the day tank, the following options

are required; Options 060, 080, 087: Solenoid

valve, with fuel strainer , on intake to prevent tank

flooding. Consider also: #190/191: Overflow

basin and overflow alarm, #383: Overflow-return

tank, #390: Overflow return pump and controller.

Simplex, Inc., 1139 North MacArthur Blvd., Springfield, IL 62702-2314 • 217-525-6995 (24 Hr.) • Fax 217-525-7984 • www.simplexdirect.com

© 2000 Simplex, Inc. All Rights Reserved. • Printed in the USA. • Design subject to change without notice. • 7A40225F

Page 3

FUEL OIL DAY TANKS - SST Series Engineering Submittal • page 3

Piping & Installation

Note:

All fuel piping should be of black iron or

copper pipe. Pipe sizes should follow engine

manufacturer’s recommendations based on

KW of generator set.

Emergency Vent:

For tanks equipped with emergency tank vent

(100-400 gallon), install weighted type emergency vent cap (Option #064) at this fitting. Install vent on 18-inch riser.

Simplex, Inc., 1139 North MacArthur Blvd., Springfield, IL 62702-2314 • 217-525-6995 (24 Hr.) • Fax 217-525-7984 • www.simplexdirect.com

© 2000 Simplex, Inc. All Rights Reserved. • Printed in the USA. • Design subject to change without notice. • 7A40225F

Page 4

FUEL OIL DAY TANKS - SST Series Engineering Submittal • page 4

Tank

10-25 Gallon Tanks

Dimensions

Size W" D" H" Wgt.

10 24.00 16.00 39.81 126 lbs.

10* 29.25 26.00 41.42 188 lbs.

25 24.00 16.00 52.56 169 lbs.

25* 29.25 26.00 54.17 277 lbs.

50 24.00 22.75 57.06 210 lbs.

50* 31.25 32.50 58.67 398 lbs.

75 24.00 22.75 72.31 212 lbs.

75* 31.25 32.50 73.81 360 lbs.

100 24.00 28.50 72.31 232 lbs.

100* 31.25 38.38 73.81 478 lbs.

150 32.13 28.00 76.56 550 lbs.

150* 42.00 35.00 78.06 826 lbs.

200 32.13 37.50 76.56 610 lbs.

200* 42.00 44.50 78.05 810 lbs.

275 32.13 52.00 76.56 700 lbs.

275* 42.00 59.00 78.05 820 lbs.

325 32.13 60.50 76.56 900 lbs.

325* 42.00 67.75 78.05 1090 lbs.

400 32.13 74.00 76.56 1000 lbs.

400* 42.00 81.25 78.05 1200 lbs.

*with rupture basin

50-400 Gallon Tanks

with rupture basin

with rupture basin

Simplex, Inc., 1139 North MacArthur Blvd., Springfield, IL 62702-2314 • 217-525-6995 (24 Hr.) • Fax 217-525-7984 • www.simplexdirect.com

© 2000 Simplex, Inc. All Rights Reserved. • Printed in the USA. • Design subject to change without notice. • 7A40225F

Page 5

FUEL OIL DAY TANKS - SST Series Engineering Submittal • page 5

10-25 Gal. 50-400 Gal.

Port Description Size " Size "

A Engine Supply Drop Tube 0.50 0.75

B Siphon Drain Drop Tube 0.50 0.75

C Overflow Port 1.00 1.00

D Engine Return Port 1.00 1.00

E Extra Pipe Flange 1.00 1.00

F Tank Vent Port 1.50 2.00

G Manual Fill Port 2.00 2.00

H Hand Pump Mounting Port 0.75 0.75

J Pump Connection To Tank Drop Tube 0.50 0.50

K Floatswitch Mtg./Inspection Port 3.50 3.50

L Pump Motor Mounting Bracket

M Emergency Tank Vent (100-400 gal.) 4.00

Tank

Fittings

10 - 25 GALLON

TANK FITTINGS - TOP VIEW

50 - 75 GALLON

TANK FITTINGS - TOP VIEW

100 - 400 GALLON

TANK FITTINGS - TOP VIEW

Finish

Rust-inhibitor coated interior . Exterior of tank chemically

treated to resist corrosion, primed and finish

painted light gray. Top cover painted blue.

Simplex, Inc., 1139 North MacArthur Blvd., Springfield, IL 62702-2314 • 217-525-6995 (24 Hr.) • Fax 217-525-7984 • www.simplexdirect.com

© 2000 Simplex, Inc. All Rights Reserved. • Printed in the USA. • Design subject to change without notice. • 7A40225F

Page 6

FUEL OIL DAY TANKS - SST Series Engineering Submittal • page 6

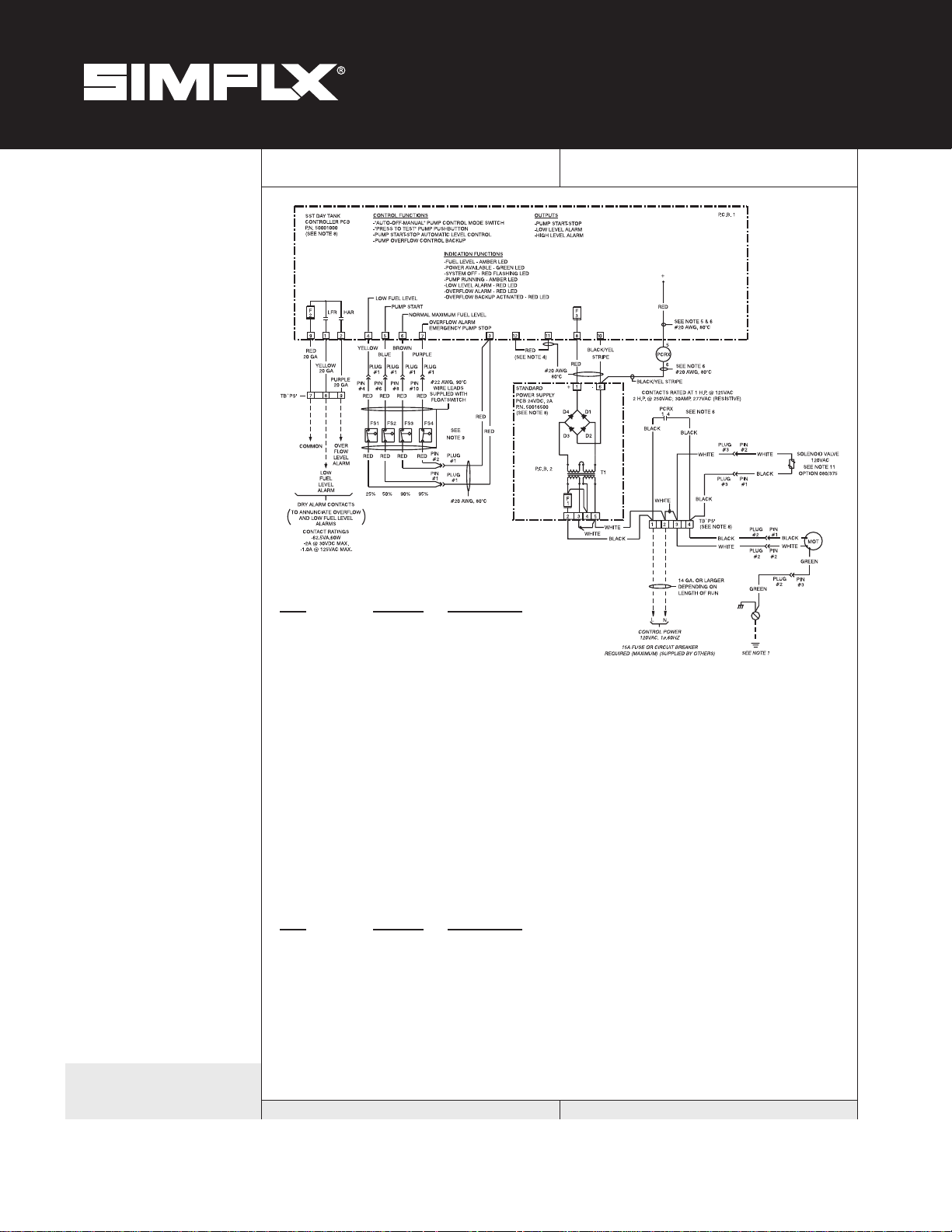

Control

Panel

Wiring

Legend/Parts List

ITEM PART NO. DESCRIPTION

FS1-FS4 ................25242150 .......Float Switch

MOT ...................... 24626100 ....... Motor

Standard 1/3 Hp, 115V, 1ø, 60 Hz, 6.6 Fla, thermally protected, auto reset

MOT ...................... 24630000 ....... Optional Motor

Option 700 1/2 Hp, 115V, 1ø, 60 Hz, 9.2 Fla, thermally protected, auto reset

TB‘PS’ ................... 25663400 ....... Terminal Block

SST Day T ank ....... 50001000 ....... Liquid Level Controller

P.C.B.1 printed circuit board, 24VDC input supply voltage, 4 liquid level inputs

Standard ...............50016500 ....... Power Supply

Power Supply printed circuit board

P.C.B.2 120 VAC input, 2 A fused, 24 DC output (full wave rectified), 56 VA

vertical float activation

SPST, 20 VA pilot duty

switch logic by reversing float

20A, 30V, 12 line

Serviceable SST PCB Component Parts

ITEM PART NO. DESCRIPTION

Indicators .............. 24249650 ....... Green LED, Socket Mount

PCRX ....................24832000 ....... Motor Starting Contactor

F1-F3 ....................14010000 ....... Fuse 2A, 250 VAC, AGC-2

SIMPLEX

24249700 Amber LED, Socket Mount

24249600 Red LED, Socket Mount

24 VDC Coil, 1 pole, normally open

Contacts rated at

1 Hp @ 125 VAC

2 Hp @ 250 VAC

30 Amp, 277 VAC (resistive)

Simplex, Inc., 1139 North MacArthur Blvd., Springfield, IL 62702-2314 • 217-525-6995 (24 Hr.) • Fax 217-525-7984 • www.simplexdirect.com

© 2000 Simplex, Inc. All Rights Reserved. • Printed in the USA. • Design subject to change without notice. • 7A40225F

Page 7

FUEL OIL DAY TANKS - SST Series Engineering Submittal • page 7

Mechanical

qq

q 010 Auxiliary hand pump

qq

qq

q 015 Auxiliary hand pump

qq

qq

q 025 Locking manual fuel fill cap

qq

qq

q 040 Wall-mounting brackets

qq

qq

q 050 Pipe stand adapter

qq

qq

q 060 Fuel strainer

qq

qq

q 062 Duplex strainer

qq

qq

q 063 Vent cap

qq

qq

q 064 Emergency vent

qq

qq

q 065 Drain hand valve

qq

qq

q 068 Emergency quick-drain

qq

qq

q 070 Priming tee & check valve assembly

qq

qq

q 080 AC Solenoid valve

qq

qq

q 083 DC Solenoid valve

qq

qq

q 087 Manual shut-off valve, bronze

qq

qq

q 088 Manual shut-off valve, fire rated

qq

qq

q 090 Foot valve

qq

qq

q 093 Fusible link valve

qq

qq

q 095 Pressure relief valve

qq

qq

q 100 Pressure gauge

qq

qq

q 101 Vacuum gauge

qq

qq

q 103 Flow gauge

qq

qq

q 104 Ball motion flow indicator

qq

qq

q 120 Extra 1” NPT pipe connection

qq

qq

q 125 Extra supply suction tube

qq

qq

q 130 Oversize pipe connection,

qq

qq

q 131 Oversize pipe connection,

qq

qq

q 140 Special paint color

qq

qq

q 141 Epoxy primer

qq

qq

q 150 Extra-heavy tank construction

qq

qq

q 180 Weatherproof Modification

qq

qq

q 185 2 or 3 complete day tanks

qq

qq

q 190 Overflow basin

qq

qq

q 191 Rupture float switch

qq

qq

q 192 Basin drain hand valve

qq

qq

q 194 Gravity drain for overflow basin,

qq

qq

q 195 Screen top for overflow basin

qq

qq

q 196 Weatherproof cover

qq

1 ¼" to 2 ½" NPT

3” to 6” NPT

mounted on common base

use with option 190

for overflow basin

Control Devices and Alarms

qq

q 260 Disconnect switch

qq

qq

q 261 System circuit breaker

qq

qq

q 262 Control power transformer

qq

qq

q 265 Day tank heater

qq

qq

q 270 Power available green pilot light

qq

qq

q 280 Operation mode selector switch

qq

qq

q 285 Loss of flow alarm

qq

qq

q 295 Remote low fuel level alarm

qq

dry signal contacts

080 Solenoid valve

376 Manual reset

solenoid valve

180 Weatherproof Modification

190 Overflow basin

196 Weatherproof cover

qq

q 297 Remote high fuel level alarm

qq

qq

q 299 Auxiliary relay, use w/options 295

qq

qq

q 311 Local/remote low fuel level alarm,

qq

qq

q 312 Local/remote high fuel level alarm,

qq

qq

q 325 High fuel level emergency

qq

qq

q 326 High level cutout for

qq

qq

q 329 Low fuel level red light

qq

qq

q 333 Critical low fuel level

qq

qq

q 334 Alarm horn

qq

qq

q 340 “Pump Running” amber light

qq

Options

Checklist

dry signal contacts

& 297 above

sensing 30% of capacity

sensing 103% of capacity

pump-stop switch

SDE Series only

alarm-engine shut down

Simplex, Inc., 1139 North MacArthur Blvd., Springfield, IL 62702-2314 • 217-525-6995 (24 Hr.) • Fax 217-525-7984 • www.simplexdirect.com

© 2000 Simplex, Inc. All Rights Reserved. • Printed in the USA. • Design subject to change without notice. • 7A40225F

Page 8

FUEL OIL DAY TANKS - SST Series Engineering Submittal • page 8

qq

q 6151/3 HP, 110V AC, 1ø, 50 Hz motor, ODP

Options

Checklist

cont’d

Duplex Pump Systems

qq

q 345 Multifunction duplex pump

qq

qq

q 346 Two running time meters

qq

qq

q 347 Manual duplex pump selector switch

qq

controller

Gravity Fed Day Tanks

qq

q 060, Solenoid valve,

qq

080, with fuel strainer, on

087 intake to prevent tank flooding

qq

q 376 Manual reset, normally open,

qq

qq

q 377 Siphon-break solenoid valve

qq

qq

q 378 Anti-siphon valve

qq

qq

q 383 Overflow-return tank

qq

qq

q 390 Overflow return pump & controller

qq

qq

q 150 Extra-heavy tank construction

qq

qq

q 190, Overflow basin and

qq

electrically operated valve

for remote installation

191 Overflow alarm

Sight Glasses

qq

q 211 Safety sight glass

qq

qq

q 212 Electric level gauge on tanks,

qq

qq

q 214 Digital fuel flow indicator

qq

without rupture basins

12" min. tank depth

Fuel Oil Coolers

qq

q 396 Radiator with electric fan,

qq

flow switch

Pumps and Motors

qq

q 002 Deletion of Standard Pump & Motor.

qq

qq

q 400 7 GPM pump

qq

qq

q 410 10 GPM pump

qq

qq

q 415 17 GPM pump

qq

qq

q 417 25 GPM pump

qq

qq

q 420 3 GPM pump

qq

qq

q 422 5 GPM pump

qq

qq

q 424 11 GPM pump

qq

qq

q 426 13 GPM pump

qq

qq

q 428 36 GPM pump

qq

qq

q 430 45 GPM pump

qq

qq

q 432 61 GPM pump

qq

qq

q 510 Transformer,

qq

qq

q 511 Transformer,

qq

qq

q 6051/3 HP, 230V AC, 1ø, 60 Hz motor, ODP

qq

10A @ 125/250V AC,

10A @ 30V DC, Form C

contacts provided

480/120V AC, 1ø, 50-60 Hz

480/120V AC, 1ø, 50-60 Hz

qq

qq

q 6161/3 HP, 220V AC, 1ø, 50 Hz motor, ODP

qq

qq

q 6211/3 HP, 230/460V AC, 3ø motor,

qq

qq

q 6221/3 HP, 230/460V AC, 3ø motor,

qq

qq

q 6301/3 HP, 12V DC motor

qq

qq

q 6351/3 HP, 24V DC motor

qq

qq

q 6451/3 HP, 115V AC, 1ø, 60 Hz, motor, TEFC

qq

qq

q 700 ½ HP, 115V AC, 1ø, 60 Hz motor, ODP

qq

qq

q 705 ½ HP, 230V AC, 1ø, 60 Hz motor, ODP

qq

qq

q 715 ½ HP, 110V AC, 1ø, 50 Hz motor, ODP

qq

qq

q 716 ½ HP, 220V AC, 1ø, 50 Hz motor, ODP

qq

qq

q 721 ½ HP, 230/460V AC, 3ø motor, ODP

qq

qq

q 722 ½ HP, 230/460V AC, 3ø motor,

qq

qq

q 730 ½ HP, 12V DC motor

qq

qq

q 735 ½ HP, 24V DC motor

qq

qq

q 745 ½ HP, 230/115V AC, 1ø, 60 Hz

qq

qq

q 768 Single phase magnetic

qq

qq

q 770 3-phase magnetic motor starter

qq

qq

q 800 ¾ HP, 115V AC, 1ø, 60 Hz motor, ODP

qq

qq

q 805 ¾ HP, 230V AC, 1ø, 60 Hz motor, ODP

qq

qq

q 825 ¾ HP, 230/460V AC, 3ø, 60 Hz

qq

qq

q 900 1 HP, 115V AC, 1ø, 60 Hz motor, ODP

qq

qq

q 905 1 HP, 230V AC, 1ø, 60 Hz motor, ODP

qq

qq

q 925 1 HP, 230/460V AC, 3ø, 60 Hz motor,

qq

Optional motors requiring SPS/SKS Pump Set

when used with 10 through 400 gallon models

qq

q 1000 1½ HP, 115V AC, 1ø, 60 Hz motor , ODP

qq

qq

q 1005 1½ HP, 230V AC, 1ø, 60 Hz motor , ODP

qq

qq

q 1025 1½ HP, 230/460V AC, 3ø, 60 Hz

qq

qq

q 1100 2 HP, 115V AC, 1ø, 60 Hz motor , ODP

qq

qq

q 1105 2 HP, 230V AC, 1ø, 60 Hz motor , ODP

qq

qq

q 1125 2 HP, 230/460V AC, 3ø, 60 Hz

qq

qq

q 1200 3 HP, 115V AC, 1ø, 60 Hz motor , ODP

qq

qq

q 1205 3 HP, 230V AC, 1ø, 60 Hz motor , ODP

qq

qq

q 1225 3 HP, 230/460V AC, 3ø, 60 Hz

qq

qq

q 1305 5 HP, 230V AC, 1ø, 60 Hz motor , ODP

qq

qq

q 1322 5 HP, 230V AC, 3ø, 60 Hz motor, TEFC

qq

qq

q 1325 5 HP, 230/460V AC, 3ø, 60 Hz

qq

qq

q 1405 7½ HP, 230V AC, 1ø, 60 Hz motor, ODP

qq

qq

q 1422 7½ HP, 208V AC, 3ø, 60 Hz motor, ODP

qq

qq

q 1425 7½ HP, 230/460V AC, 3ø, 60 Hz

qq

ODP, w/starter

TEFC, w/starter

TEFC, w/starter

motor, TEFC

motor starter

motor, ODP, w/starter

ODP, w/starter

motor, ODP, w/starter

motor, ODP, w/starter

motor, ODP, w/starter

motor , ODP, w/starter

motor , ODP, w/starter

Simplex, Inc., 1139 North MacArthur Blvd., Springfield, IL 62702-2314 • 217-525-6995 (24 Hr.) • Fax 217-525-7984 • www.simplexdirect.com

© 2000 Simplex, Inc. All Rights Reserved. • Printed in the USA. • Design subject to change without notice. • 7A40225F

Loading...

Loading...