Page 1

SATURN

1400KW3200KW

STATIONARY LOAD BANK

Page 2

Last Revision Date: March 15, 2016

For the most up-to-date information for this product and others, please

contact Simplex, Inc. at (800) 637-8603 or visit us on the web at

http://www.simplexdirect.com.

Page 3

Table of Contents

1 Warnings and Cautions ........................................................1

Safety information symbols 1

Cautions 1

2 Description and Specication .............................................. 4

Overview of Use 4

Control System 4

Cooling System 4

Load System 4

Safety 4

3 Unpacking ............................................................................. 6

Included Components 6

Primary Inspection 6

4 Installation ............................................................................ 7

Load Bank Placement 7

Installation Procedure 8

Remote HMI installation 9

Load Dump installation 10

Current Transformer installation 11

MODBUS installation 13

Heater installation 14

BMS/BAS Installation 15

5 Setup .................................................................................... 16

General Settings 16

Automatic Mode 16

6 Operating Instructions ....................................................... 17

Pre-operation checks 17

Setting up the test 17

Testing operation 18

Metering (if equipped) 18

Shutdown and cooling 18

7 Automatic Mode ................................................................. 19

Overview 19

Setting Up Automatic Mode 20

Entering Automatic Mode 20

Page 4

8 Maintenance/Troubleshooting .......................................... 21

General maintenance 21

Each Operation 21

Every 6 Months 21

Troubleshooting 22

9 Alarms and Warnings .......................................................... 23

Alarms 23

Warnings 23

APPENDIX A PARTS LISTINGS ...........................................................25

APPENDIX B MODBUS CONTROLS ...................................................41

Modbus Control Directions 44

APPENDIX C PRODUCT WARRANTY .................................................45

Page 5

Table of Figures

Current draw at specic resolutions (in kilowatts) ...............................5

Air Flow ................................................................................................................7

Ground Bus ......................................................................................................... 8

Main Load Bus ...................................................................................................8

Conduit Opening .............................................................................................. 8

HMI TBH................................................................................................................9

Serial Adapter ....................................................................................................9

TB-DC .................................................................................................................... 9

Load Dump Jumper ...................................................................................... 10

Current Transformers ................................................................................... 11

CT Orientation ................................................................................................ 11

TB-CT .................................................................................................................. 11

Current Transformer placement for Metering ..................................... 12

Current Transformer placement for Auto/Regen. Mode ................. 12

TB-COM ............................................................................................................. 13

Modbus Serial Converter ............................................................................ 13

TB-SH .................................................................................................................. 14

TBR ...................................................................................................................... 15

Setup Screen ................................................................................................... 16

General Settings............................................................................................. 16

HMI Information ............................................................................................. 18

Alarm History .................................................................................................. 18

Automatic/Regenerative Mode ................................................................ 19

Setup Screen ................................................................................................... 19

Automatic Mode Setup ............................................................................... 19

Automatic Mode Running .......................................................................... 20

Troubleshooting ............................................................................................ 22

Troubleshooting alarms .............................................................................. 24

Right Subpanel Layout ................................................................................ 25

Option D - Automation/Metering............................................................ 26

Page 6

Option B - Communication (TCP/IP Data Logging) ........................... 27

PLC Component list ...................................................................................... 28

Control Relays ................................................................................................. 30

Terminal Blocks ............................................................................................... 32

Option 010 - Space Heaters ....................................................................... 34

Center Subpanel ............................................................................................ 36

Phase A Detail ................................................................................................. 37

Phase B Detail ................................................................................................. 38

Phase C Detail ................................................................................................. 39

Load Control Terminal Blocks ................................................................... 40

Modbus Controls (Read/Write) ................................................................. 41

Modbus Indications (Read only) .............................................................. 42

Page 7

1 WARNINGS AND CAUTIONS

Safety

information

SymbolS

CautionS

e following images indicate important safety information:

is General warning symbol points out important

information that, if not followed, could endanger

personal safety and/or property.

is Explosion warning symbol points out

potential explosion hazards.

is Fire warning symbol points out potential re

hazards.

is Electrical warning symbol points out potential

electrical shock hazards.

is load bank is high-powered, technical, industrial

equipment operating at dangerous voltages and temperatures. It

is capable of damaging itself, property or personnel if improperly

used. It is not a consumer product.

It must be installed, connected and operated by personnel

properly trained and experienced in its use. An operator’s

manual is supplied with each load bank and available online at

www.simplexdirect.com. e operator must be familiar with its

contents and have access to it during operation.

• High Voltage: Turn o and disconnect power source before

opening this equipment

• High Temperature: Allow hardware to cool before servicing

or opening this equipment.

• Rotating Equipment: Ensure that the fans have stopped

before opening this unit.

• For Operator Safety: Make sure this equipment is properly

grounded when in use.

All compression-type connections on fuse blocks, load blocks,

and contactors should be checked for tightness frequently. is

check should be established as part of routine maintenance.

e following cautions should be observed before and during

operation:

• Check intake and exhaust screens as well as fan and load

elements for foreign objects.

• Position and install the load bank with consideration given

Warnings and Cauons — 1

Page 8

to large cubic airow requirements, exhaust temperature, and

velocity. Do not point exhaust at any nearby surface or object

that may be adversely aected by high temperature. is

includes but is not limited to painted surfaces, tar paper and

asphalt roofs, water sprinkler heads, re alarms, and volatile

material.

• Do not use in conned spaces. Do not allow the load bank’s

feet to sink into so surfaces thereby cutting o bottom air

intake. e load bank may have to compete with cooling air

requirements of a nearby running engine generator set where

cooling air intake to a conned space may not be adequate

for both engine and load bank. Be especially careful not

to bounce hot exhaust air o nearby obstructions for recirculation through the load bank.

• Verify that all control switch positions are set correctly for

your intended usage before connecting the load bank to the

source to be tested.

• e load cables carry high amperage. Be constantly aware of

possibility of inductively heating adjacent ferrous objects to

temperatures sucient to damage cable insulation.

• Always connect the safety ground cable to a proper ground.

Do not rely on a possible grounded neutral somewhere else

in the system.

• Do not let the load bank run unattended for long periods of

time.

• Do not store or operate in rain unless adequate protection is

provided.

• Routinely inspect all components and electrical connections

for tightness and integrity.

• Repair any damaged or degraded components and wiring

without delay.

• If technical assistance, service, or parts are needed, please call

800-837-8603 (24 Hours).

• All hardware covered by this manual have dangerous

electrical voltages and can cause fatal electrical shock. Avoid

contact with bare wires, terminals, connections, etc. Ensure

all appropriate covers, guards, grounds, and barriers are in

place before operating the equipment. If work must be done

around an operating unit, stand on an insulated dry surface

to reduce the risk of electrocution.

• Do not handle any kind of electrical device while standing

in water, while barefoot, or while your hands or feet are wet.

• If people must stand on metal or concrete while installing,

servicing, adjusting, or repairing this equipment, place

insulative mats over a dry wooden platform. Work on the

2 — Warnings and Cauons

Page 9

equipment only while standing on such insulative mats.

• e National Electrical Code (NEC), Article 250 requires

the frame to be connected to an approved earth ground

and/or grounding rods. is grounding will help prevent

dangerous electrical shock that might be caused by a ground

fault condition or by static electricity. Never disconnect the

ground wire while the load bank is in use.

• Wire gauge sizes of electrical wiring, cables, and cord sets

must be adequate to handle the maximum electrical current

(ampacity) to which they will be subjected.

• Before installing or servicing this (and related) equipment,

ensure that all power voltage supplies are completely turned

o at their source. Failure to do so can result in hazardous

and possibly fatal electrical shock.

• In case of accident caused by electric shock, immediately

shut down the source of electrical power. If this is not

possible, attempt to free the victim from the live conductor.

AVOID DIRECT CONTACT WITH THE VICTIM. Use

a nonconducting implement, such as a dry rope or board,

to free the victim from the live conductor. If the victim is

unconscious, apply rst aid and seek immediate medical

attention.

• Never wear jewelry when working on this equipment. Jewelry

can conduct electricity resulting in electric shock or may get

caught in moving components causing injury.

• Keep a re extinguisher near the hardware at all times.

Do NOT use any carbon tetra-chloride type extinguisher.

Its fumes are toxic, and the liquid can deteriorate wiring

insulation. Keep the extinguisher properly charged and be

familiar with its use. If there are any questions pertaining to

re extinguishers, please consult the local re department.

• e illustrations in this manual are examples only and may

dier from your load bank.

• Load Bank warranty is void if incorrectly cooled.

Warnings and Cauons — 3

Page 10

2 DESCRIPTION AND SPECIFICATION

overview of

u

Se

Control

S

yStem

Cooling

S

yStem

Simplex Saturn load banks are precision test instruments

designed to apply a selectable load to a power source and measure

the source’s response. ey are used for routine maintenance

exercise to ensure the long-term reliability and readiness of the

standby generator. Load banks can also eliminate the detrimental

eects of unloaded operation of diesel engine generators as well

as prevent damage from reverse power generation.

Saturn load banks are available in models ranging from 1400

kilowatts up to 3200 kilowatts. All standard Saturn models have

a step resolution of 25 kilowatts.

Saturn load banks feature a Human-Machine Interface

(HMI) touchscreen, which controls load bank operation and

displays the unit’s status. With the HMI, the operator can apply

a desired load and measure the response of the test source.

e load bank can also be integrated into your facility’s BMS/

BAS system via standard Modbus RS-485 or optional Modbus

TCP/IP, as well as a set of dry contacts for status reporting.

Saturn load banks are cooled by forced air, delivered by an

aluminum fan blade directly driven by a TEFC motor. e air is

brought in on the bottom of the load bank and expelled through the

top. Optional equipment allows the exhaust to be driven through a

customer-installed duct, providing for indoor installation.

load SyStem

Safety

4 — Descripon and Specicaon

e load system comprises independently controlled Simplex

Powr-Web resistors, which have been designed specically for

use in load bank systems. e load elements are supported by

high-temperature, ceramic-clad, stainless-steel rods across their

entire length, virtually eliminating element-to-element short

circuits. e elements are arrayed in discrete trays, which are

independently serviceable.

e Saturn is protected by sensors to ensure that the load

bank is suciently cooled and that the exhaust does not exceed a

safe temperature, which could damage the load bank or present

a safety hazard to the operator. When a failure occurs, the safety

system immediately removes the load to protect the equipment

from permanent damage.

Page 11

1400 1500 1600 1700

416V

480V

600V

416V

480V

600V

416V

480V

600V

416V

1943A 2082A 2221A 2359A

1684A 1804A 1925A 2045A

1347A 1443A 1540A 1636A

1800 1900 2000 2100 2200

2498A 2637A 2776A 2915A 3053A

2165A 2285A 2406A 2526A 2646A

1732A 1828A 1925A 2021A 2117A

2300 2400 2500 2600 2700

3192A 3331A 3470A 3608A 3747A

2766A 2887A 3007A 3127A 3248A

2213A 2309A 2406A 2502A 2598A

2800 2900 3000 3100 3200

N/A N/A N/A N/A N/A

480V

600V

ese measurements are based on ideal numbers. ey do not take into account

control power draw, power cable resistance, voltage droop, etc.

3368A 3488A 3608A 3729A 3849A

2694A 2791A 2887A 2983A 3079A

Descripon and Specicaon — 5

Page 12

3 UNPACKING

.

inCluded

C

omponentS

primary

i

nSpeCtion

If any

problems

are observed

during

Primary

Inspection,

call Simplex

24 hours a

day at

800-637-8603

e following items are included with your load bank. If any

of the following are not included, please contact Simplex Direct

at 800-637-8603.

1. Load bank

2. Controller (remote or local)

3. Manual

4. Drawing package

Optional equipment

1. Additional controllers

2. Exhaust hood

3. Current transformers

4. Other optional equipment

Before installing your Saturn, inspect the shipping crate and

load bank. Physical or electrical problems could arise from

handling and vibration. Never apply power to a load bank before

performing this procedure. e following ve-point inspection

is recommended before installation and as part of a 6-month

maintenance schedule or when the load bank is relocated:

1. If the crate shows any signs of damage, examine the load

bank in the corresponding areas for signs of initial problems.

2. Check the entire outside of the cabinet for any visual damage,

which could cause internal electrical or mechanical problems

due to reduced clearance.

3. Open the control panel door and inspect all relays and

control modules. Make sure all components are secure in

their bases and safety bails are in place. Spot-check electrical

connections for tightness. If any loose connections are found,

inspect and tighten all remaining connections.

4. Examine all accessible internal electrical components such

as fuses, contactors, and relays. Check lugged wires at these

components.

5. Check the load element chamber for foreign objects, broken

ceramic insulators, and mechanical damage.

6 — Unpacking

Page 13

4 INSTALLATION

load bank

p

laCement

Improperly

installing

this unit may

result in

damage or

destruction

of the

load bank,

adjacent

equipment,

and the

building

housing the

unit.

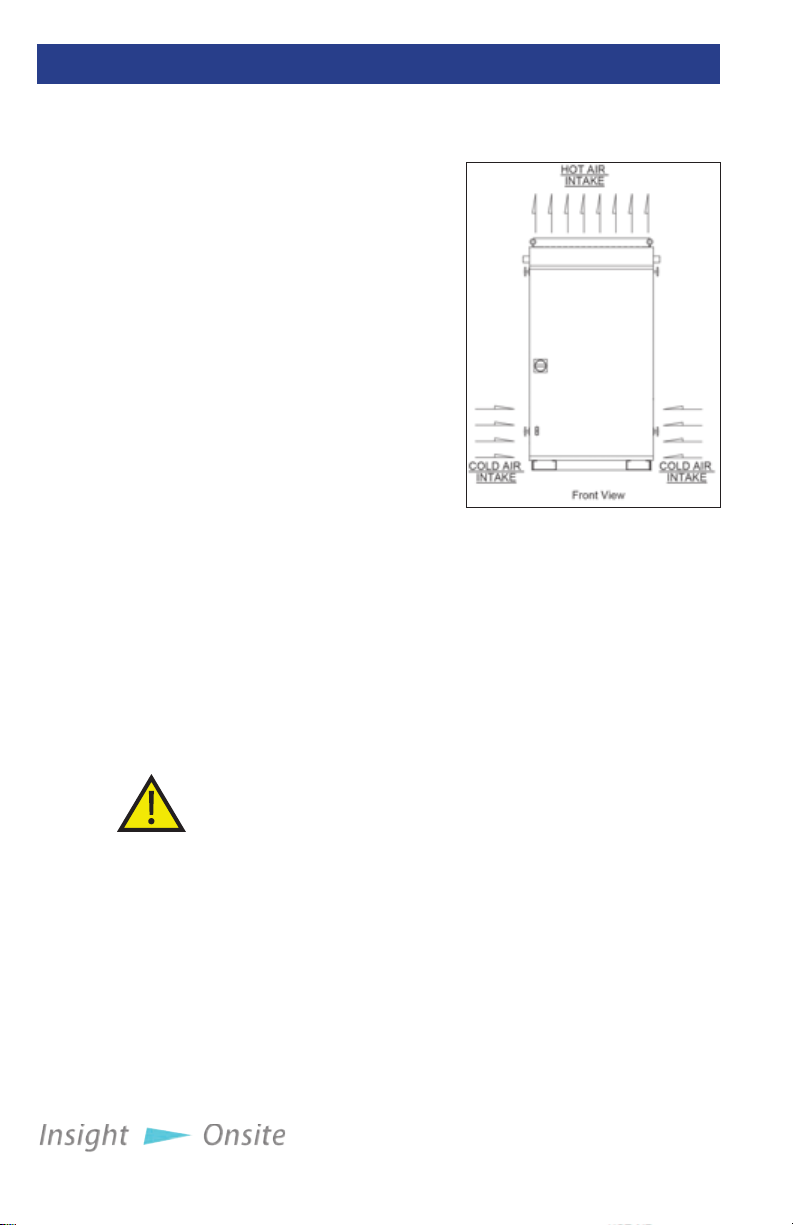

Normally equipped,

Saturn load banks are

intended for outdoor

installation. A forced air

system, which discharges

out of the top of the unit,

cools the load elements

(See Figure 1 Air Flow.)

Load banks require large

quantities of air circulation,

so it is essential to install the

unit in an area that provides

adequate airow. Before

conducting load tests, a

review of site conditions

by trained personnel is

recommended.

e load bank requires at least 20 feet of vertical clearance; 6

feet of clearance on the front, le, and right; and 1.5 feet of

clearance in the rear (see “Figure 2 Clearance requirements”

on page 11).

e load bank should be placed in a secure area accessible by

trained personnel only.

Figure 1 Air Flow

Because the unit generates a lot of heat, never operate near

sprinkler systems.

Operating the load bank in a conned space will recycle hot

exhaust air through the cooling system, which can cause severe

damage.

e load bank may compete with nearby generators for

cooling air.

Installaon — 7

Page 14

inStallation

p

roCedure

Saturn load

banks feature

a power

outlet in the

control panel

for your use.

This outlet is

limited to 2

amps.

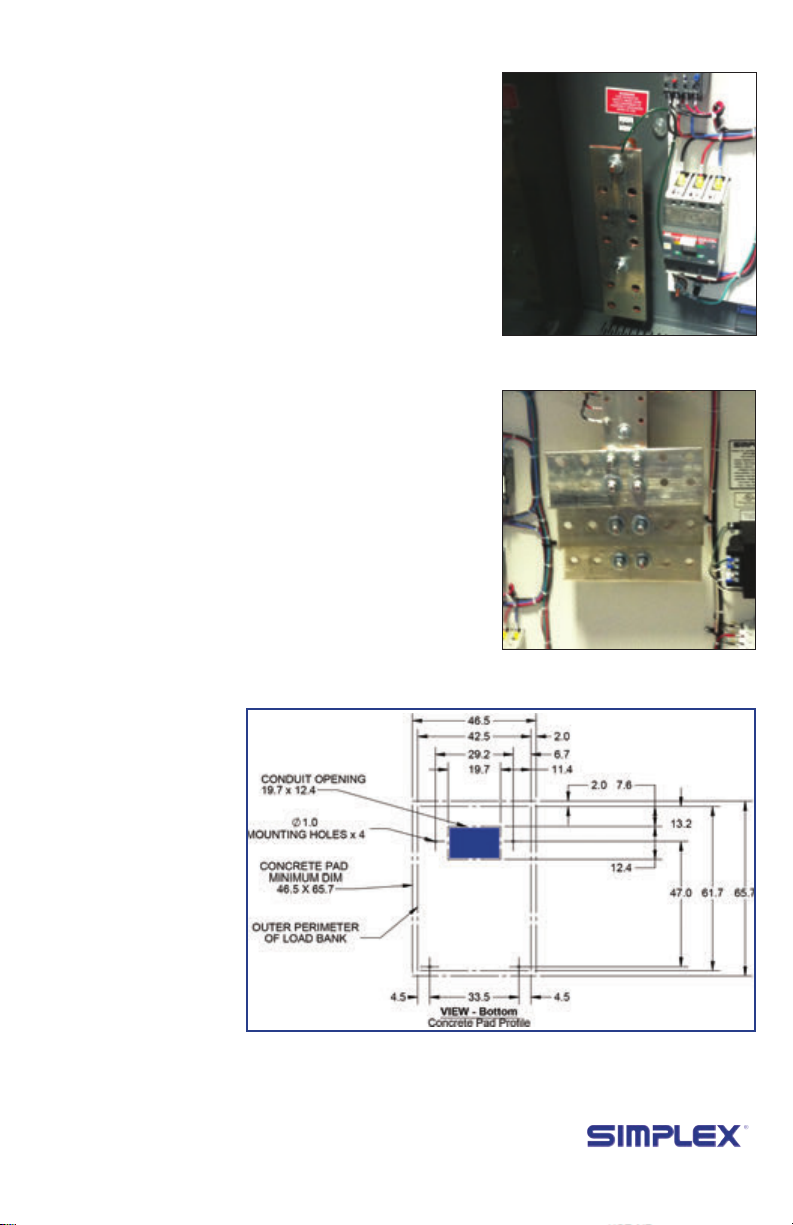

1. To bring in the source’s

power cables, pull holes

in the Conduit Opening,

located in the bottom of

the load bank’s control

panel enclosure (see

Figure 5 Conduit

Opening).

2. Conrm the test source is

properly grounded.

3. Ground the load bank

by connecting the

Grounding Bus to an earth

ground or grounding rod.

See Figure 3 Ground Bus

4. Connect the source’s

power output to the load

bank via the Main Load

Bus with appropriately

sized cables (see Figure 4

Main Load Bus).

Figure 2 Ground Bus

Figure 3 Main Load Bus

8 — Installaon

Figure 4 Conduit Opening

Page 15

remote Hmi

inStallation

If your HMI is installed

directly on the load bank,

skip to the next section.

1. Mount the HMI where

desired.

2. Connect the HMI to the

Load Bank by swinging

the HMI’s screen out to

expose the TB-H terminal

block (see Figure 6 HMI

TBH) and wiring it to the

Load Bank.

A. Using a Belden 9841

or equivalent cable,

make the following

connections between

the HMI’s TB-H

terminals to the Serial

Adapter (see Figure 7

Serial Adapter).

1. TB-H 4 → TXD+

2. TB-H 5 → TXD-

3. Wire shielding →

COM B

Figure 5 HMI TBH

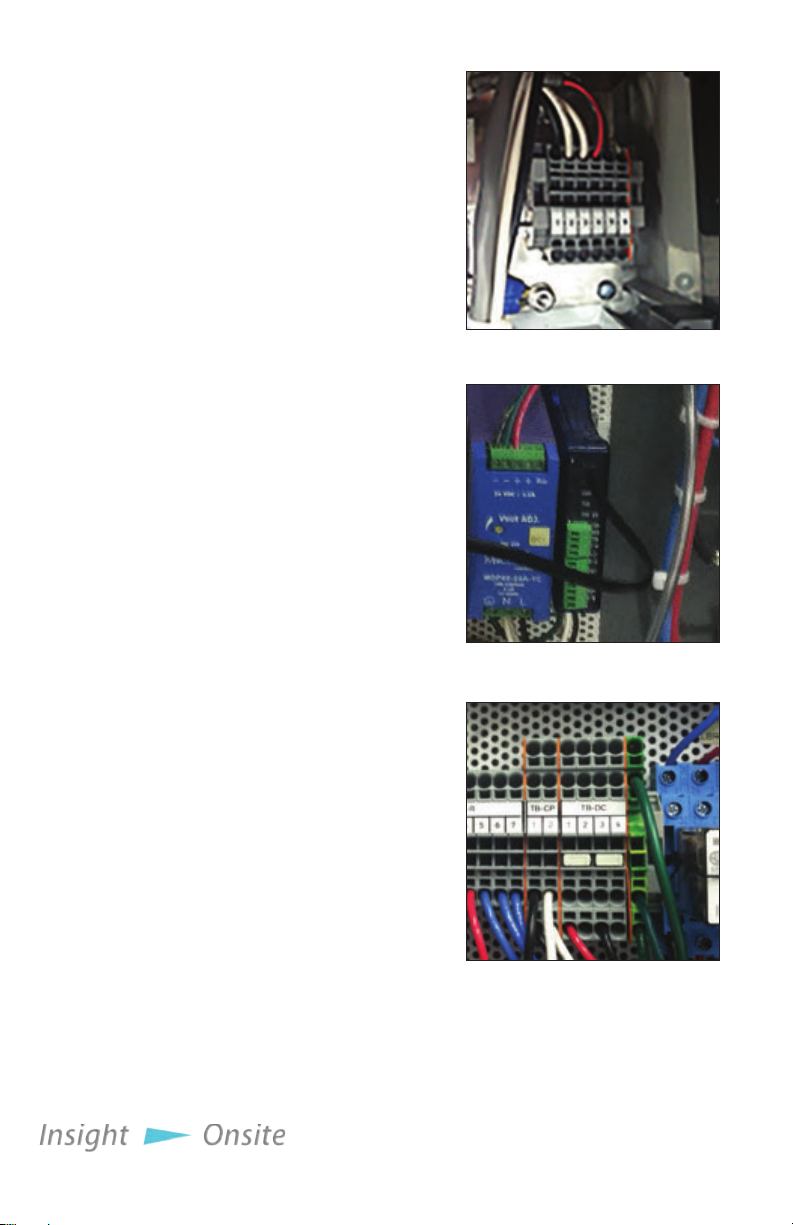

Figure 6 Serial Adapter

B. Using a copper wire,

14AWG or larger,

rated at 60C or

higher, connect the

HMI’s TBH 1 to the

load bank’s TB-DC

1 terminal and the

HMI’s TBH 2 to the

load bank’s TB-DC 3

terminal (see Figure 8

TB-DC).

Figure 7 TB-DC

Installaon — 9

Page 16

load dump

inStallation

If the Load Dump

feature is desired, remove

the factory-installed

jumper at TB-R 1–2 and

connect customer-supplied

Load Dump contacts to

TB-R 1–2 (See Figure 9

Load Dump Jumper). To

dump the load, open the

customer-supplied contact.

To enable load, close the

customer-supplied contact.

Load Dump Jumper

Figure 8

10 — Installaon

Page 17

Current

t

ranSformer

inStallation

The current

transformers

must be

placed and

oriented

correctly to

ensure they

accurately

detect the

current. The

rst current

transformer

must be

installed on

Phase A, and

the second

must be

installed on

Phase C.

If your load bank is

equipped with Metering,

Automatic Mode or

Regenerative Mode options,

you will have to install

current transformers on

your power cable.

• For metering mode,

install the current

transformers on the load

bank leg of your power

system (see “Figure 13

Current Transformer

placement for Metering”

on page 12.)

• For Automatic/

Regenerative Mode,

install the current

transformers on the power

source leg (see “Figure 14

Current Transformer

placement for Auto/

Regen. Mode” on page

12.)

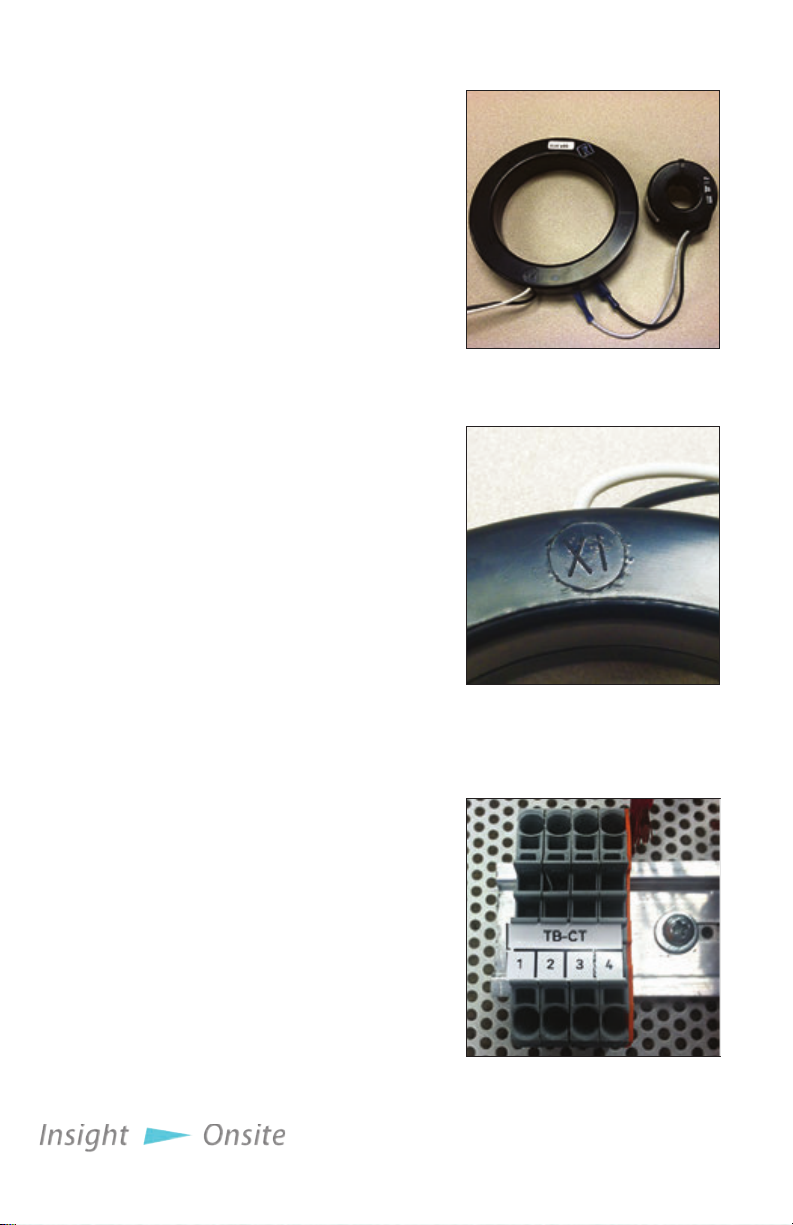

Orient the current

transformers so that the XI or

HI on each ring is facing the

power source (see Figure 11

CT Orientation.)

When the current

transformers are installed,

connect them to the load

bank by connecting the

white wire of the current

transformer on Phase A to

TB-CT 1 and the black wire

to TB-CT 2. If a second

current transformer is

installed on Phase C, connect

its white wire to TB-CT 3

and its black wire to TB-CT

4 (see Figure 12 TB-CT.)

Make sure the XI or HI on the

ring faces the power source.

Figure 9

Current Transformers

Figure 10

CT Orientation

Figure 11 TB-CT

Installaon — 11

Page 18

Figure 12

Current

Transformer

placement for

Metering

Figure 13

Current

Transformer

placement for

Auto/Regen.

Mode

e rst current transformer must be installed on Phase A, and the second must be

installed on Phase C.

12 — Installaon

Page 19

modbuS

inStallation

e Saturn load bank

supports the Modbus

protocol, implemented

either as RS485 or TCP/

IP (which is an optional

upgrade).

To implement Modbus

control and monitoring,

connect the load bank to

your facility’s systems as

follows:

For RS485:

Figure 15 Modbus Serial

1. Connect the RS485+ line

to TB-COM 1

2. Connect the RS485- line

to TB-COM 2

3. Connect the wire

shielding to TB-COM

Terminal 3

For Optional Modbus

TCP/IP

Figure 14 TB-COM

Converter

1. Plug a CAT5e cable

into the ethernet jack

on the MODBUS Serial

Converter (see Figure 16 Modbus Serial Converter.)

e Polaris Modbus control set is implemented as detailed in

“Appendix B — Modbus controls” on page 41

Installaon — 13

Page 20

Heater

inStallation

Saturn load banks are

equipped with space heaters

for cold weather operation

and to prevent condensation,

which can damage the

unit. e heaters require

a dedicated power source

independent of control

power at all times to prevent

startup failure due to cold

environments.

To run power to the

heaters:

1. Run a 120V, 15A, 1-phase power cable into the control panel.

2. Connect the Line leg of the power cable to SH-1

3. Connect the Neutral leg of the power cable to SH-2

4. Connect the Ground leg of the power cable to SH-3

e heaters are set at 50 degrees Fahrenheit. If a dierent

temperature is required, adjust the red thermostat on the front

of the heater.

Figure 16 TB-SH

14 — Installaon

Page 21

bmS/baS

inStallation

e Polaris provides a

set of Remote Signal Dry

Contacts, which allow you to

integrate the load bank into

your Building Management

System (BMS) or Building

Automation System (BAS)

e dry contacts provide an

alarm message, letting you

know if the load bank has

failed.

To enable BMS/BAS

functionality, wire three

cables to TBR 5-7. Continuity between TBR 5 and TBR 6 indicate

normal load bank operation, and continuity between TBR 5 and

TBR 7 indicate load bank failure.

Figure 17 TBR

Installaon — 15

Page 22

5 SETUP

Saturn load

banks feature

a power

outlet in the

control panel

for your use.

This outlet is

limited to 2

amps.

general

S

ettingS

e Saturn load bank

oers a number of

conguration options

through its setup screens.

You can access the setup

screens by pressing “F4 Setup” or the F4 function

ke y.

At the main setup screen,

you are presented with four options:

1. General Settings

2. Automatic Mode Settings

3. Test Mode (Intended only for Simplex engineers)

4. Factory Setup (Intended only for Simplex engineers)

You can access General Settings and Automatic Mode

Settings by pressing their respective buttons.

General Settings presents

three elds:

1. Cooldown Delay (sec)

2. Intake Temp Warning (F)

3. Exhaust Temp Alarm (F)

Figure 18 Setup Screen

Figure 19 General

Settings

Cooldown

Delay should

not normally

be changed.

automatiC

m

ode

16 — Setup

Cooldown Delay

determines how long the

load bank fans will continue

running aer an operation has been concluded. Intake Temp

Warning determines at what temperature the load bank will

present a warning that the air being used for the forced air

cooling system is too hot.

Exhaust Temp Alarm determines how hot the exhaust must

be before the load bank will trigger an Exhaust Temp High alarm

and remove the load. is and Intake Temp Warning may need

to be changed at installation, depending on the climate.

Automatic Mode Settings specify the operation of Automatic/

Regenerative Mode. For information about how to set them up,

see “Setting Up Automatic Mode” on page 20.

Page 23

6 OPERATING INSTRUCTIONS

pre-operation

CHeCkS

Saturn load

banks feature

a power

outlet in the

control panel

for your use.

This outlet is

limited to 2

amps.

1. Start the generator or

source being tested.

2. Ensure the load bank’s

Fan/Control Power

Disconnect Switch,

located on the unit’s door,

is in the on position (see

Figure 21 Fan/Control

Power Disconnect

Switch.)

3. Check the load bank’s

intake areas, located on

the bottom of the unit, to

ensure that the vents are

not blocked by paper or

other debris that would

prevent the cooling fan

from pulling in air.

4. On the HMI, turn on the

load bank by pressing the

Control Power button in

the upper le corner of

the screen (see Figure 22

Control Power Button.)

5. Listen to the load

bank’s fan to ensure it is

operating normally.

Figure 20 Fan/Control

Power Disconnect Switch

Figure 21 Control Power

Button

Figure 22 HMI - Manual

Mode

Setting up tHe

teSt

When the fan is running

properly, you are ready to

begin testing.

Press the F1 function

key or “F1 - Manual Mode”

on the screen to bring up

Manual Mode (See Figure

23 HMI - Manual Mode). In

the upper right area of this

screen is a display indicating

the load to be applied,

measured in kilowatts. To

change this value, touch the

Figure 23 HMI -

Numeric keypad

Operang Instrucons — 17

Page 24

number and enter the new

value on the numeric keypad

that appears (see Figure 24

on page 17). Enter the

desired value and press the

↵ button to return to the

previous screen, or press

“E” to return to the main

screen without changing the

value.

In the lower right quadrant of the screen is the KW Jog

value. is indicates by how many kilowatts you will increase

or decrease the load by pressing the “-” and “+” buttons,

respectively. To change this value, press the number and enter

your choice using the numeric keypad.

Figure 24 HMI

Information

teSting

operation

metering (if

equipped)

SHutdown and

Cooling

To begin testing, press the “Master Load” button. is will

activate the load bank and begin applying the load displayed

in the upper right area of the screen. To quickly decrease or

increase the load, press the “-” and “+” buttons.

If you have purchased the

metering upgrade, pressing

the F3 function key or “F3 Information” on the screen

while the test is running will

bring up the metering screen

(see Figure 26). Here you can

monitor the voltage, current,

load applied to the source,

and the frequency of the electricity. is screen also displays the

temperatures registered by the load bank’s three sensors.

If any of three voltage or current values are signicantly dierent

from the other two, check the load bank for a blown fuse. If no

blown fuse is found, contact Simplex service at 800-637-8603, ext. 4.

Pressing “Alarm History” on this screen will bring up a list of

registered alarms (See Figure 27.)

When the test is complete, press the Master Load button then

the Control Power button to remove the load from the test source.

e load bank’s fan will continue running for the duration of the

cooldown delay (see page 16 for more information).

Figure 25 Alarm History

18 — Operang Instrucons

Page 25

7 AUTOMATIC MODE

overview

e Saturn load bank can

Figure 26 Setup Screen

be equipped with an optional

automatic mode, which will

extend your generator’s life

by protecting it against wetstacking and reverse current.

Automatic Mode adds

load when the load bank

detects that your generator

isn’t operating in its optimal

range.

When your load bank

is installed, a set of current

transformers will be installed

on your generator’s power

lines to monitor the load on

your system. When the load bank detects that the power draw

has fallen below a preset range, it begins adding load until the

draw on the generator is within the designated range. Should the

load bank determine that the power draw has increased beyond

Figure 27 Automatic

Mode Setup

10%

10%

Figure 28 Automatic/Regenerative Mode

In this illustration, the load bank has been set up for an

800KW generator. e Target Load is set at 560KW, with 10%

Max Deviation. So long as the load remains in the green area,

the load bank will not add or drop load. But if the load moves

into the red area, the load bank will adjust the load to move it

back into the green.

Automac Mode — 19

Page 26

the preset maximum value,

it begins removing load until

the draw is back within the

designated range.

Figure 29 Automatic

Mode Running

Setting up

a

utomatiC

m

ode

The values

you will need

to set up

this mode

are specic

to your

generator.

For example,

if you have an

800 kilowatt

generator

with a 60% to

80% optimal

operating

range, you

might set

Target Load

to 560 (which

is 70% of its

capacity)

and Max

Deviation to

10%.

Before you activate

Automatic Mode, you must

congure the load bank to

interact with your generator.

Enter the Automatic mode

setup screen by pressing the “F4 Setup” button on the screen or

the F4 function key to reach the Setup Screen, then pressing the

Automatic Mode Settings button (see “Figure 28 Setup Screen” on

page 19.)

On the setup screen will be ve options specic to Automatic

Mode. (See “Figure 29 Automatic Mode Setup” on page 19.)

• Target load (KW): Sets the target load you want on your

generator, measured in whole kilowatts.

• Max Deviation (%): Determines how far above and below your

target load is acceptable, measured in whole percentage points.

• Step Up Delay (sec): Determines how fast the load bank will

add sequential load steps, measured in whole seconds.

• Step Down Delay (sec): Determines how fast the load bank

will remove sequential load steps, measured in whole seconds.

• Startup Delay (sec): Determines how long the load bank will

wait before adding load once the power draw has dropped below

the lower limits established by Target Load and Max Deviation,

measured in whole seconds.

To change any of the values, press the value and a numeric

keypad will come up. Use it to enter a new value the same way you

would enter a load to apply. (See page 17 for more information

about using the numeric keypad.)

entering

a

utomatiC

m

ode

20 — Automac Mode

When your load bank is congured, return to the main screen

by pressing the “Back” button. From the Main screen, press the

“F2 - Auto” button or the F2 function key to enter the Automatic

Mode screen (See Figure 31 Automatic Mode Running.)

On the Automatic Mode screen, press the “Auto Mode”

switch. Once this mode is enabled, the load bank will monitor

your generator and step the load up or down as necessary.

Once congured and enabled, your load bank can remain in

Automatic Mode indenitely.

Page 27

8 MAINTENANCE/TROUBLESHOOTING

general

maintenanCe

eaCH

o

peration

Remove all

power from

the load bank

before

servicing the

unit.

every 6

m

ontHS

e load bank has been designed to require minimum

maintenance. All components have been chosen for a long,

reliable life. Two basic intervals of maintenance are required:

each operation and every 6 months.

• Check the air intake screens and louvers, fan and cooling

chamber, and exhaust openings for any obstructions or

foreign objects.

• Check fan blades for stress fractures.

• Check the exhaust vent for obstructions

• Check the load branches for blown fuses or opened load

resistors.

To check the fuses or load resistors, operate the load bank

from a balanced 3-phase source and check the three line

currents. e three current readings should be essentially the

same. If a sizable dierence is noted, one or more load fuses or

load resistors may have malfunctioned.

Check the tightness of the electrical connections. e

expansion and contraction caused by load bank operation may

cause loose connections. For a detailed inspection guide, see

“Primary Inspection” on page 6.

Maintenance/Troubleshoong — 21

Page 28

trouble

SHooting

Although Saturn load banks are designed with trouble-free

operation in mind, some problems can arise. Please consult the

following table for solutions to the most common issues before

contacting a Simplex service representative.

Table 1 Troubleshooting

Problem Solution

Load bank

wired to

source but

won’t turn on

Load bank

overheating

HMI not

displaying data

Ensure load bank is wired to source correctly

Check for and replace any blown fuses

Tighten any loose relays, contactors, lugged wires, etc.

Clear intake and exhaust vents of any debris

Ensure load bank was not installed too close to generator

or any other source of exhaust

Ensure load bank was installed in a location that allows

sucient cool air intake

Make sure ambient temperature isn’t too high to allow for

cool air ow

Ensure HMI power connections are wired correctly

Check HMI serial cable connections

22 — Maintenance/Troubleshoong

Page 29

9 ALARMS AND WARNINGS

Saturn load banks are protected by four types of sensors.

1. Intake temperature, which checks the incoming air to ensure

the load elements can be adequately cooled.

2. Exhaust temperature, which checks the air temperature

coming out the load bank.

3. Fan pressure, when ensures the fan blades are forcing air into

the load element chamber.

4. Fan current, which ensures the fan motor isn’t overloaded or

jammed.

alarmS

Unresolved

cooling

issues may

result in

damage to

the load

bank.

warningS

e Saturn load bank’s HMI features ve status areas:

• Motor: Indicates the status of the cooling fan motor

• Fan: Indicates whether the fan is blowing air into the element

chamber

• Intake Temp: Indicates status of incoming cooling air

• Exhaust Temp: Indicates status of load bank’s exhaust

• Load Dump: Indicates whether the load dump feature has

been activated

With the exception of Intake Temp, any failure state will cause

the unit to dump the load until the problem is xed.

e load bank will alert you to alarms by turning the status

areas for the alarm on the home screen from green to red and

displaying the alarm signal in white text.

e Saturn features one warning: Intake Temp High. When

this warning is triggered, the Intake Temp status area will turn

yellow.

Saturn load banks do not dump load when a warning is

triggered, but the problem should be investigated as soon as

possible.

Alarms and Warnings — 23

Page 30

Table 2 Troubleshooting alarms

Alarm Cause Solution

Motor

Fan

Intake Temp

Fan blades blocked Clear obstruction

Intake vents blocked

by debris, paper, etc

Fan blades have come

loose from sha

Intake vents blocked

by debris, paper, etc

Load bank pulling

in exhaust from

generator, etc.

Insucient airow

Ambient temperature

too high

Clear intake vents

Tighten fan blade hub.

Clear intake vents

Ensure load bank was

not installed too close

source of exhaust

Ensure load bank has

access to sucient

cool air intake

Conduct operation on

cooler day, if possible

Exhaust Temp

Load Dump

24 — Alarms and Warnings

Air not being forced

over load elements

Load dump switch

activated

Load dump jumper

fell out of TB-LD 1-2

Ensure fan and fan

motor are working

correctly and rotating

in correct direction

Deactivate load dump

switch

Replace load dump

jumper

Page 31

APPENDIX A PARTS LISTINGS

Figure 30 Right Subpanel Layout

Opon D - Automaon/

Metering page 26

Opon E - Communicaon

(TCP/IP Data Logging)

page 27

PLC

page 28

Control Relays

page 30

Terminal blocks/Service Outlet

page 32

Opon 010 - Space Heaters

page 34

Parts lisngs - 25

Page 32

Table 3 Option D - Automation/Metering

Label Description Part Number

TB-M 1

TB-M 2

TB-M 3

TB-M 4, 6

TB-M 5, 7

DMP1

26 - Parts lisngs

Terminal Block, 4

Connections, Black

Terminal Block, 4

Connections, Red

Terminal Block, 4

Connections, Blue

Terminal Block, 4

Connections, Grey

Terminal Block, 4

Connections, Green

Digital Metering

Package, RS232

25678547

25678546

25678557

25678536

25678537

24345050

Page 33

Table 4 Option B - Communication (TCP/IP Data Logging)

Label Description Part Number

Modular Controller

CM1

and Protocol

Converter

24955043

NS1

Ethernet Switch, 5

Port, Unmanaged

24955074

Parts lisngs - 27

Page 34

Table 5 PLC Component list

Label Description Part Number

PLC1

EX1

EX2

DC1

CM2

TB-COM1-6

28 - Parts lisngs

PLC 24955113

8PT Relay Output

Module

4PT ermocouple

Input Module

DC Power Supply,

60W, 24VDC

RS232/RS485

Converter, RJ12 Port

Terminal Block,

Spring Type,

20A, 600Vac, 2

Connections, Grey

24955008

24955023

25457900

24953500

25678532

Page 35

Parts lisngs - 29

Page 36

Table 6 Control Relays

Label Description Part Number

F4

F5

SR9

SR8

SR7

SR6

SR5

SR4

SR3

Fuse, 2A, 600V, Instantaneous 14014500

Fuse, 2A, 600V, Time Delay 14012000

Relay, 24VDC Coil, 3PDT 24827045

Relay, 24VDC Coil, 3PDT 24827045

Relay, 24VDC Coil, 3PDT 24827045

Relay, 24VDC Coil, 3PDT 24827045

Relay, 24VDC Coil, 3PDT 24827045

Relay, 24VDC Coil, 3PDT 24827045

Relay, 24VDC Coil, 3PDT 24827045

SR2

SR2

NOR1

NOR2

LBR1

30 - Parts lisngs

Relay, 24VDC Coil, 3PDT 24827045

Relay, 24VDC Coil, 3PDT 24827045

Relay, 24VDC Coil, 3PDT 24827045

Relay, Large, 24VDC Coil 24816000

Relay, Large, 24VDC Coil 24816000

Page 37

2A

Parts lisngs - 31

Page 38

Table 7 Terminal Blocks

Label Description Part Number

Terminal Block, Spring Type,

TB-CP 1-4

TB-C 14-26

TB-DC 1-2

TB-DC 3-4

TB-C 1-13

20A, 600Vac, 4 Connections,

Grey

Terminal Block, Spring Type,

20A, 600Vac, 2 Connections,

Grey

Terminal Block, Spring Type,

20A, 600Vac, 4 Connections,

Red

Terminal Block, Spring Type,

20A, 600Vac, 4 Connections,

Black

Terminal Block, Spring Type,

20A, 600Vac, 4 Connections,

Grey

25678536

25678532

25678546

25678547

25678536

TB-R 1-2

TB-R 3-6

CO1

32 - Parts lisngs

Triple Deck Terminal Block,

Spring Type, 24A, Blue

Terminal Block, Spring Type,

20A, 600Vac, 4 Connections,

Grey

Outlet, 120Vac, DIN Rail

Mount, 15A

25678550

25678536

25629900

Page 39

Parts lisngs - 33

Page 40

Table 8 Option 010 - Space Heaters

Label Description Part Number

TB-SH 1-3

HF1

HTR1

Terminal Block, 2

Connections, Grey

Fuse, 7A, Time Delay 14039000

Enclosure Heater,

120Vac, 550W w/

ermostat

25678532

25309211

34 - Parts lisngs

Page 41

Phase C

page 39

Subpanel

Phase A

page 37

Phase B

page 38

Load

control

terminal

blocks

page 40

Parts lisngs - 35

Page 42

Table 9 Center Subpanel

Label Description Part Number

RC 1-6

RC5-15

FMC1

OLR1

CB1

T1

Subpanel

Contactor, 40A

Resistive

Contactor, 65A

Resistive

Contactor, 40A

Resistive

Overload Relay, 5.7-

18.9A

Circuit Breaker, 15A

Trip

Transformer, 300VA,

480/240:240/120Vac

Subpanel, Saturn,

Rear

13011040

13011065

13011040

24827710

12046615

25457650

PRT-00025390

36 - Parts lisngs

Page 43

Table 10 Phase A Detail

Label Description Part Number

Bus Bar (vertical)

RF4

RF7-34

Bus Bar (horizontal)

RF1

Bus Bar, Single Pole,

750A, Phase A

Fuse, 35A, Class T,

Fast Acting

Fuse, 70A, Class T,

Fast Acting

Bus Bar, Nept/Mars,

0.250” x 4.00” x10.50”

Fuse, 35A, Class T,

Fast Acting

60044465G

14074000

14087000

60063693

14074000

Parts lisngs - 37

Page 44

Table 11 Phase B Detail

Label Description Part Number

Bus Bar (vertical)

RF5

RF8-35

Bus Bar (horizontal)

RF2

38 - Parts lisngs

Bus Bar, Single Pole,

750A, Phase B

Fuse, 35A, Class T,

Fast Acting

Fuse, 70A, Class T,

Fast Acting

Bus Bar, Nept/Mars,

0.250” x 4.00” x10.50”

Fuse, 35A, Class T,

Fast Acting

60044466E

14074000

14087000

60063693

14074000

Page 45

Table 12 Phase C Detail

Label Description Part Number

Bus Bar (vertical)

RF6

RF9-36

Bus Bar (horizontal)

RF3

Bus Bar, Single Pole,

750A, Phase C

Fuse, 35A, Class T,

Fast Acting

Fuse, 70A, Class T,

Fast Acting

Bus Bar, Nept/Mars,

0.250” x 4.00” x10.50”

Fuse, 35A, Class T,

Fast Acting

660044467G

14074000

14087000

60063693

14074000

Parts lisngs - 39

Page 46

Table 13 Load Control Terminal Blocks

Label Description Part Number

F1-2

F3

TB-L 1

TB-L 2

TB-L 3

TB-L 4-19

40 - Parts lisngs

Fuse, 1.5A, Time

Delay

Fuse, 3.5A, Time

Delay

Terminal Block, 4

Connections, Black

Terminal Block, 4

Connections, Red

Terminal Block, 4

Connections, Blue

Terminal Block, 2

Connections, Grey

14009500

14019775

25678547

25678546

25678557

25678532

Page 47

APPENDIX B MODBUS CONTROLS

Table 14 Modbus Controls (Read/Write)

Name Type

Activate

Fan

Apply Load

Cancel

Cooldown

KW To

Apply

Function

Address

Code

Coil 01 16586

Coil 01 16704

Coil 01 16487

Floating Point 03 28911

Modbus controls - 41

Page 48

Table 15 Modbus Indications (Read only)

Name Type

Exhaust Alarm

Fan Failure

Alarm

Load Dump

Activated

Fan Running

Applied Load

Regulate Mode

Active

Regenerative

Sensing Mode

Active

Function

Code

Coil 01 16484

Coil 01 16485

Coil 01 16486

Coil 01 8193

Floating

Point

Coil 01 16705 (a)

Coil 01 16706 (b)

03 29077

Address Notes

Vab

Vbc

Vac

(a) Load Banks with Automatic Load Regulation Only

(b) Load Banks with Regenerative Power Sensing Only

(c) Load Banks with Any Automation Option Only

42 - Modbus controls

Floating

Point

Floating

Point

Floating

Point

03 28673 (c)

03 28675 (c)

03 28677 (c)

Page 49

Table 15 Modbus Indications (Cont.)

Name Type

Va

Vbc

Vc

Ia

(a) Load Banks with Automatic Load Regulation Only

(b) Load Banks with Regenerative Power Sensing Only

(c) Load Banks with Any Automation Option Only

Floating

Point

Floating Point 03 28681 (c)

Floating Point 03 28683 (c)

Floating Point 03 28685 (c)

Function

Code

03 28679 (c)

Address Notes

Modbus controls - 43

Page 50

modbuS

C

ontrol

d

ireCtionS

1. Ensure that “Regulate Mode Active” (16705) and

“Regenerative Sensing Mode Active” (16706) are OFF,

indicating that the load bank is ready for Modbus Control

2. Turn “Activate Fan” (16586) ON to energize the cooling fan

3. Verify fan is running by checking that “Fan Running” (8193

is ON

4. Write the desired amount of KW to apply to “KW To Apply”

(28911)

5. Turn “Apply Load” (16704) ON to energize the desired

amount of load

6. Verify applied load by reading value at “Applied Load” 29077.

e load bank will apply as much load as possible to reach the

“KW To Apply” value, without exceeding it.

7. Monitor other values as desired.

8. Turn “Apply Load” o to de-energize the load

9. Turn “Activate Fan” OFF to stop the cooling fan. Load bank

will continue to operate cooling fan for Cooldown Time set

on HMI.

10. Cooldown mode has ended and cooling fan has stopped

when “Fan Running” is OFF

11. Cooldown mode can be stopped by writing ON then OFF to

“Cancel Cooldown” (16487)

44 - Modbus controls

Page 51

APPENDIX C PRODUCT WARRANTY

SIMPLEX, Inc., warrants the industrial electrical control, test and accessory equipment

and parts and accessories thereof to be the kind and quality described in SIMPLEX’s

specications and to be free from defects in material or workmanship under normal

service, its obligations under this warranty being limited to repairing or replacing, at its

option, any part or parts which shall, within twelve (12) months from date of shipment

from its factory, as indicated by serial date code on the nameplate or sales records, be

returned to SIMPLEX or an authorized SIMPLEX repair station, with transportation

costs prepaid, and which its examination shall disclose to its satisfaction to have been

thus defective.

e provisions of this warranty shall not apply to any equipment, part or accessory

which

(a) has been improperly specied by buyer;

(b) has been improperly stored or handled prior to placing in service;

(c) has been improperly mounted or connected;

(d) has not been operated within specications stated on its nameplate, label or

placard;

(e) has not been properly maintained;

(f) parts supplied by buyer for inclusion in nished equipment are not covered by

this warranty;

(g) components or assemblies specied by buyer with no substitution permissible

that are not normally used by SIMPLEX.

SIMPLEX reserves the right to reject warranty claims of any kind against assembled

equipment, parts or material for which SIMPLEX has not received payment in full.

Should buyer, at his own risk, elect to replace defective equipment or parts in the

eld rather than return equipment to SIMPLEX’s factory or authorized repair station,

SIMPLEX will supply and invoice parts at normal prices upon receipt of buyer’s bonade purchase order. Defective equipment or parts returned for in-warranty crediting in

exchange for replacement parts must be returned within 45 days from date of shipment

of replacement in order to qualify for warranty consideration. Defective equipment or

parts returned aer 45 days may be subject to a restocking charge of 20% or a minimum

charge of $50.00, whichever is greater.

is warranty is in lieu of all other warranties, express or implied, and all other

obligations or liabilities on the part of SIMPLEX, and SIMPLEX neither assumes nor

authorizes any other person to assume for it any other liability in connection with any

such electrical control, test or accessory equipment or accessories or parts.

Product Warranty - 45

Page 52

WE WELCOME YOUR FEEDBACK!

Simplex designs and manufactures Load Banks and

Fuel Supply systems for power generation and liquid

automation. Simplex is certified to ISO 9001:2015.

Used world-wide for mission critical environments in

manufacturing, technology, transportation, hospitals,

schools, public utilities and the U.S. military,

Simplex products provide solutions meeting exact

requirements, from the simplest testing and proving

equipment for backup generators to custom-designed

and engineered mission-critical fuel systems. At

Simplex, we are experts at building products that meet

our customers’ exact requirements. For a complete

listing of Simplex products visit

www.simplexdirect.com.

Simplex welcomes your questions, comments,

suggestions, compliments, and complaints as a way to

continuously improve our service to you.

Please call us at 800-637-8603 (24 hours a day)

or visit www.simplexdirect.com.

Page 53

LOAD BANK RENTAL AND SERVICE CENTERS

Simplex Onsite can place Load Banks, Cables, Transformers, and Fuel Polishers rentals as well as service technicians at your ngerps anywhere in the

United States quickly and cost eecvely.

For informaon call 855-767-5483 or visit www.simplexonsite.com.

COLORADO

Serving Colorado, Idaho, Montana, Nevada, Utah and Wyoming

GEORGIA

Serving Alabama, Florida, Georgia, North Carolina and South Carolina

ILLINOIS

Serving Illinois, Indiana, Kentucky, Michigan, Missouri and Tennessee

MASSACHUSETTS

Serving Conneccut, Delaware, Maine, Maryland, Massachuses, New

Hampshire, New Jersey, New York, Pennsylvania and Vermont

MINNESOTA

Serving Iowa, Minnesota, North Dakota, South Dakota and Wisconsin

OHIO

Serving Indiana, Michigan, Ohio, Pennsylvania (western) and West Virginia

TEXAS

Serving Arkansas, Louisiana, New Mexico, Oklahoma and Texas

Page 54

Simplex, Inc.

5300 Rising Moon Road

Springfield, IL 62711-6228

(800) 637-8603

www.simplexdirect.com

Loading...

Loading...