Page 1

HYDRAULIC & MECHANICAL POWER

E

Q

U

I

P

M

E

N

T

S

E

R

V

I

C

E

A

S

S

O

C

I

A

T

I

O

N

R

E

B

U

I

L

D

E

R

S

O

F

T

O

O

L

S

&

E

Q

U

I

P

M

E

N

T

U

S

A

M

E

M

B

E

R

C

A

N

A

D

A

PAM & PGM SERIES

PRO - MAG

40 & 50 SERIES

AIR & GASOLINE POWER PUMPS

T

R

S

Y

N

I

G

N

I

V

R

E

SINCE - 1899

S

Te

m

U

D

pl

e

t

on

Q

U

W

I

T

H

P

R

I

D

E

.

c

n

I

.,

Co

y&

Ke

nl

Y

T

I

A

L

Operating & Maintenance Instructions

For 1

1/2 H.P. Air & Gasoline Pumps

and 8 H.P. Gasoline Pump.

1.5 H.P. Air Pumps

3.5 and 8 H.P.

Gas Pumps

Part Sheet #: 54393

Revised: 12-01

The world's most complete line of industrial, hydraulic and

mechanical lifting and positioning equipment.

SIMPLEX DIVISION OF TEMPLETON, KENLY & CO., INC.

2525 Gardner Road • Broadview, Illinois 60155 • (708) 865-1500 / Fax (708) 865-0894

www.tksimplex.com

Page 2

SAFETY

1-1. Working Pressure

The pump's maximum working pressure is 10,000 PSI (700 kg/cm

2

). Make sure

that all hydraulic equipment used with this pump are rated at 10,000 PSI operating pressure.

1-2. Hydraulic Connections

Never disconnect or connect any pressurized hydraulic hoses or fittings.

or open all hydraulic controls several times to assure that the system has been depressurized.

If the system includes a gauge, double check the gauge to assure pressure has been released.

When making connections with quick disconnect couplings,

are fully engaged

tightened and leak free.

CAUTION: Loose or improperly threaded fittings can be potentially dangerous if pressurized, however, severe over tightening can cause premature thread failure. Fittings need to be

tightened secure & leak free. Never hold or stand directly in line with any hydraulic connections while pressurizing. Never grab, touch or in any way come in contact with a hydraulic

!

pressure leak. Escaping oil can penetrate the skin and a serious injury can result.

Do not subject the hose to potential hazard such as sharp surfaces, extreme heat or heavy

*

impact. Do not allow the hose to kink & twist. Inspect each hose for wear before it is used.

. Threaded connections such as fittings, gauges, etc. must be securely

make sure the couplings

Shift,

Electrical Power for Solenoid valves (normally 12 or 24 volts)

1-3.

1. CHECK FOR PROPER ELECTRICAL SUPPLY BEFORE CONNECTING.

2. DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE OR IN THE PRESENCE OF

CONDUCTIVE LIQUIDS.

a. Do not use a power or extension cord that is damaged or has exposed wiring.

b. Solenoids come equipped with a three prong grounding type plug to fit the proper

grounded type electrical outlet. Do not use a two prong ungrounded extension cord as the

pump's motor must be grounded.

Jacking Safely

1-4.

You must know the weight of what you intend to lift and choose a ram with at least 10%

more capacity.

The ram should be placed on a

solid foundation so that the base of the ram is fully

supported. The load must be centered on the ram, or equally distributed on multiple rams. Off center loading can result in the ram slipping out and loss of the

load.

Never crawl or place any part of your body under any load at any time. Insert

blocking or cribbing under the load as you lift. Hydraulic rams are meant for lifting

only and should not be used to support the load for any period of time.

You should obtain and be familiar with the American National Standards Institute rules that

apply to hydraulic rams and jacks (ANSI B30.1).

- 2 -

Page 3

INSTRUCTIONS BEFORE USE

Read carefully. Most malfunctions in new equipment are the result of improper operation

and/or improper set-up assembly.

Preparation: Remove pump from shipping container -- but do not remove any plugs or

valves until the unit is ready to be fully assembled to prevent dirt or foreign matter from

contaminating system.

Inspection: Visually inspect all components for shipping damage. If any damage is found,

notify carrier immediately.

Electrical Connections: Solenoid valves only.

2-1.

Air Connections for AIR POWER PUMPS: Use only clean, dry, well lubricated air.

Gasoline Motor Oil and Fuel:

1. Above 32 degrees Fahrenheit use S.A.E. 10 W 30 (Motor only )

2. Below 32 degrees Fahrenheit use S.A.E. 5 W 20 (Motor only )

3. Oil sump capacity - -About 1.3 pints or check dip stick

4. Use clean, unleaded automotive gasoline ( without alcohol )

2-2. Hydraulic Connections:

Check hydraulic

located on reservoir plate. Oil level should be

oil level to prevent possible pump burnout. Open the red plastic fill plug

approximately 2" from top of reservoir

plate -- with cylinders retracted and motor off. Add Simplex oil as necessary. Do not

mix different grades of oil, or types of oil.

Make sure all desired gauge, valve, hose and quick coupler connections are tight and

secure before operating (See Section 1.2). The pumps pressure ports are 3/8 NPTF and are

located just below the control valve. (See Section 3-1).

The use of a

pumps and

Mounted on a gauge adapter between the pump and cylinder, the gauge permits the operator

to monitor loads on cylinders.

pressure gauge is strongly recommended for normal operation of these

required when the external adjustable relief valve pressures are changed.

Do not exceed rated capacity of equipment connected to pump. Where shock loading

or unsteady loads may cause overloading of cylinders, the operator must use larger capacity

cylinders to provide additional operating margin.

2-3.

Starting instructions ( Gasoline Motor )

• Hydraulic control valve in neutral ( center position ): • Throttle to choke position ( extreme

right ): Grasp STARTER HANDLE and pull rope out slowly to engagement: • Pull rope with

a rapid, continuous full stroke and let rewind slowly, and do not allow to snap back. • Move

the control lever to "HIGH SPEED" position then to "RUN" as the engine warms.

- 3 -

Page 4

OPERATING INSTRUCTIONS AT A GLANCE

Before Operating Pump:

1. If your pump is equipped with a SIMPLEX SOLENOID be sure the electrical connection

is grounded. Check that your power supply agrees with the requirements of the solenoid.

2. Use only cylinders, hoses and equipment rated at 10,000 PSI.

3. Make sure all hose and fitting connections are tight and secure. Hoses cannot be

kinked or twisted.

4. Oil level should be 1 to 2" from the top of the reservoir plate, with cylinders retracted

and motor off.

5. Never operate the pump with the directional control valve in advance or retract at

10,000 PSI without ram movement for more than 1 minute. Leaving the valve in the

advance or retract position without the rams piston rod moving will overheat the oil.

After Completing the Job:

1. Before disconnecting hoses, fittings, etc., first be sure the ram is retracted & unloaded,

then unplug the power cord and shift the hydraulic controls several times to release

system

pressure.

2. Store the pump in a clean, dry area.

Periodic Maintenance:

1. Completely change the hydraulic oil and clean the oil filter screen and magnet (located

in the reservoir) twice a year. (Use Simplex oil only, Model # AO1, 1 gallon). Change

the oil more frequently when used in extremely dusty areas or when the oil has been

overheated. Using oil other than Simplex Brand voids the pumps warranty.

2. Contact an AUTHORIZED SIMPLEX SERVICE CENTER if there are any problems with

the equipment.

- 4 -

Page 5

OPERATION

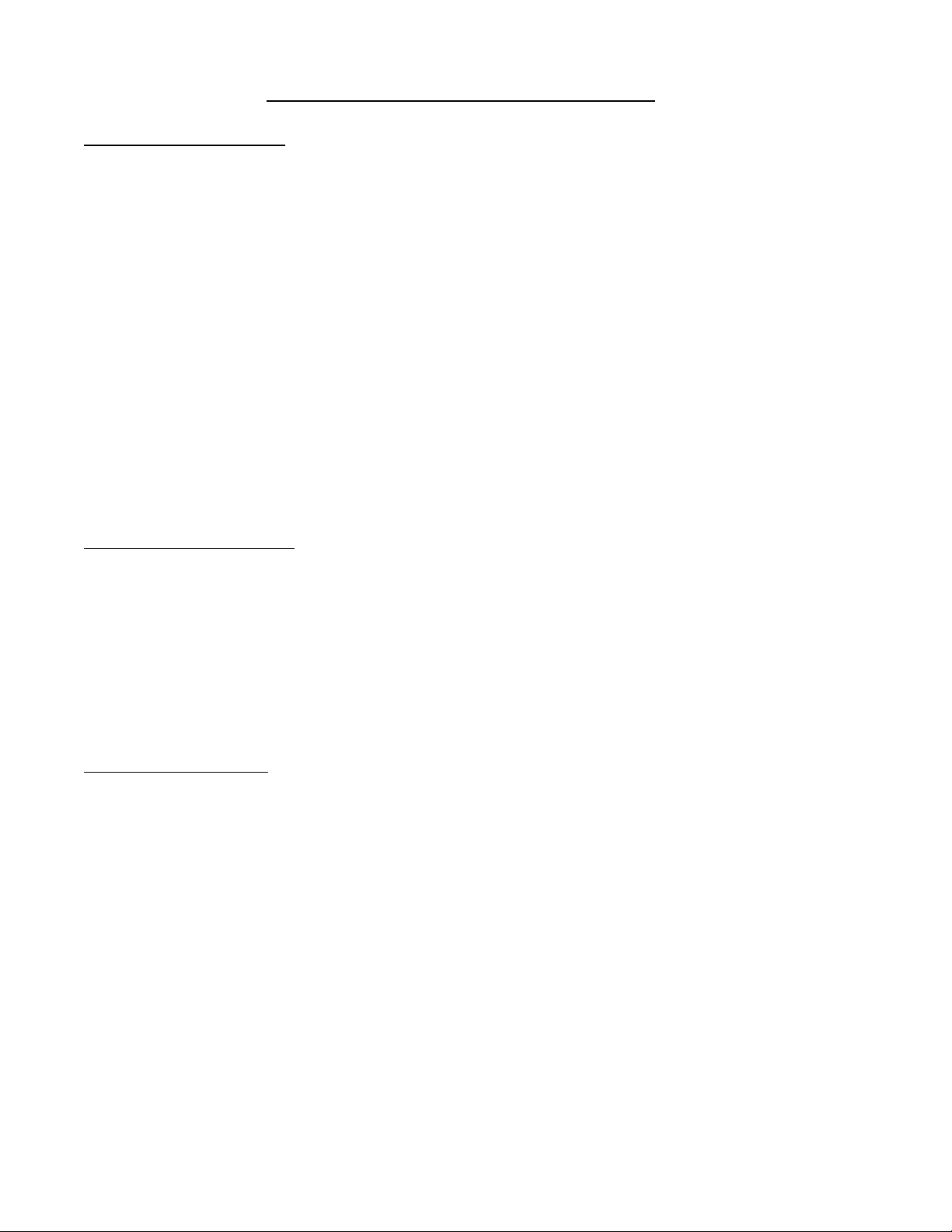

3-1. Control Valves:

a. 2-Way Valve for Single Acting Rams

To Advance.........turn lever to the right

& start motor.

To Hold................turn motor off.

To Retract............turn lever to the left.

b. 3-Way Valve for Single Acting Rams

To Advance..........push lever to right.

For Neutral/Hold...place lever in middle.

To Retract.............push lever to left.

c. 4-Way Valve for Double Acting Rams

Pushing lever to right directs pump output

to right-hand port.

Pushing lever to left directs pump output to

left-hand port.

Center position is neutral/hold. Pump

output is directed back to tank.

* Useable 3/8 NPTF port

*

Return ports

only.

(Marked T)

B *

B *

* A

* A

* A

* A

3-2.. Before starting pump,

prevent accidental lifting or moving of load. Start the pump and let the pump idle for a few

minutes.

Bleeding the Hydraulic System--air can be removed from the system by fully advancing

3-3.

and retracting the hydraulic cylinder several times with the pump elevated so its reservoir is

higher than the cylinder. Single-acting cylinder should be inverted, and double-acting on their

side with the coupling fitting up. When the trapped air is removed from the hydraulic circuit,

the cylinder will advance and retract smoothly. Sluggish cylinder action is usually the first sign

of air in the system.

3-4. Move lever to Advance position (as described above) to activate ram or cylinder. To hold

load, place lever into Neutral/Hold. Move lever to Retract position (as described above) to

release load.

3-5. Never operate the pump at 10,000 PSI without ram movement for more than 1 minute without

shifting the control valve to neutral.

place valve in Neutral/Hold position (as described above) to

Leaving the valve in the advance or retract posi-

tion without the piston rod moving will overheat the oil.

- 5 -

Page 6

MAINTENANCE

WARNING: THE ELECTRICAL POWER CORD MUST BE DISCONNECTED FROM ELECTRICAL OUTLETS BEFORE PERFORMING MAINTENANCE OR REPAIR

PROCEDURES.

4-1. Maintain Oil Level -- check hydraulic oil level every 30 hours of operation. Add Simplex oil

(Model # AO1 -- 1 gallon) when necessary. Oil level should be no more than 2" from top of

reservoir plate -- with cylinders retracted and motor off.

Completely change oil at least twice a year. The following conditions require more frequent

oil changes:

a. Rigorous duty, where oil temperature may reach 140 F.

b. High humidity environment and extreme changes in temperature that can result in con-

densation inside the reservoir.

c. Dirty or dusty environments that may contaminate the oil.

4-2. Clean Oil Filter Screen Once a Year

a. Loosen and remove reservoir plate bolts. Lift pump unit off the reservoir, being careful not

to damage the gasket.

b. Unscrew screen from bottom of pump unit and clean with nonflammable solvent.

c. Blow dry and reassemble.

4-3. Keep areas around pump unobstructed to provide good air flow around the motor and pump.

Keep the motor and pump as clean as possible.

4-4. Adjusting the External Relief Valve:

a. Install gauge and gauge adapter between pump and cylinder.

b. Remove cover to expose adjusting screw. Place valve lever in Neutral/Hold position and

start motor. Move lever to direct pump output to pressure port (Advance).

c. Insert allen wrench into adjusting screw in the hole on the lower left side of valve.

d. Turn adjusting screw clockwise to increase, or counter clockwise to decrease pressure .

(Do not exceed 10,000 PSI.)

e. Check valve setting by shifting the valve to advance and retract cylinder several times.

Maximum gauge reading should remain constant.

4-5. Flushing the Pump. If you suspect your pump has been contaminated or discover sludge or

other deposits on internal components, you should thoroughly flush the pump.

a. Remove the old oil from the reservoir, then thoroughly clean the reservoir and refill with a

clean, nonflammable flushing oil.

b. Reassemble the pump and motor to the reservoir.

c. Now run the pump in no load condition for 1 or 2 minutes maximum.

d. Unplug the pump and remove the motor and pump assembly again. Now drain the flush-

ing oil and reclean the inside of the reservoir. (Make sure flushing fluid is also drained

from pump assembly). Refill the reservoir with Simplex hydraulic oil and reassemble

the pump.

- 6 -

Page 7

TROUBLESHOOTING

If the procedures listed below do not remedy the problem -- the pump will require

service and should be taken to an authorized Simplex service center for repair

Problem Cause -- Solution

Sporadic Cylinder Action

Motor Will Not Start

Noisy Operation

Pump Oil is Over Heating

1. Air in the hydraulic system. See Sec. 3-3 for

correct bleeding procedure.

2. Check reservoir oil level.

Check manufacturer's operating instructions.

1. Air in system. (See Sec. 3-3 for bleeding

procedure).

2. Be sure the oil reservoir is filled to normal level.

3. Check all points where air might leak into

system.

1. Oil viscosity too high. Replace with Simplex #9.

2. Check for high pressure leakage on upper

pressure plate. (Leaking at plug).

3. Oil level is low. Fill reservoir to normal level, or

refit the pump with larger reservoir.

4. (See Section 3-5)

Pump Runs but Will Not Pump Oil

1. Pump is not primed. Run pump a few minutes

tipping from side to side.

2. Check to make sure that externally adjustable

relief valve set properly.

Check internal relief valve.

3. Damaged O-Rings. Take to nearest Simplex

service center for repair.

4. Defective control valve. (Troubleshoot

separately).

- 7 -

Page 8

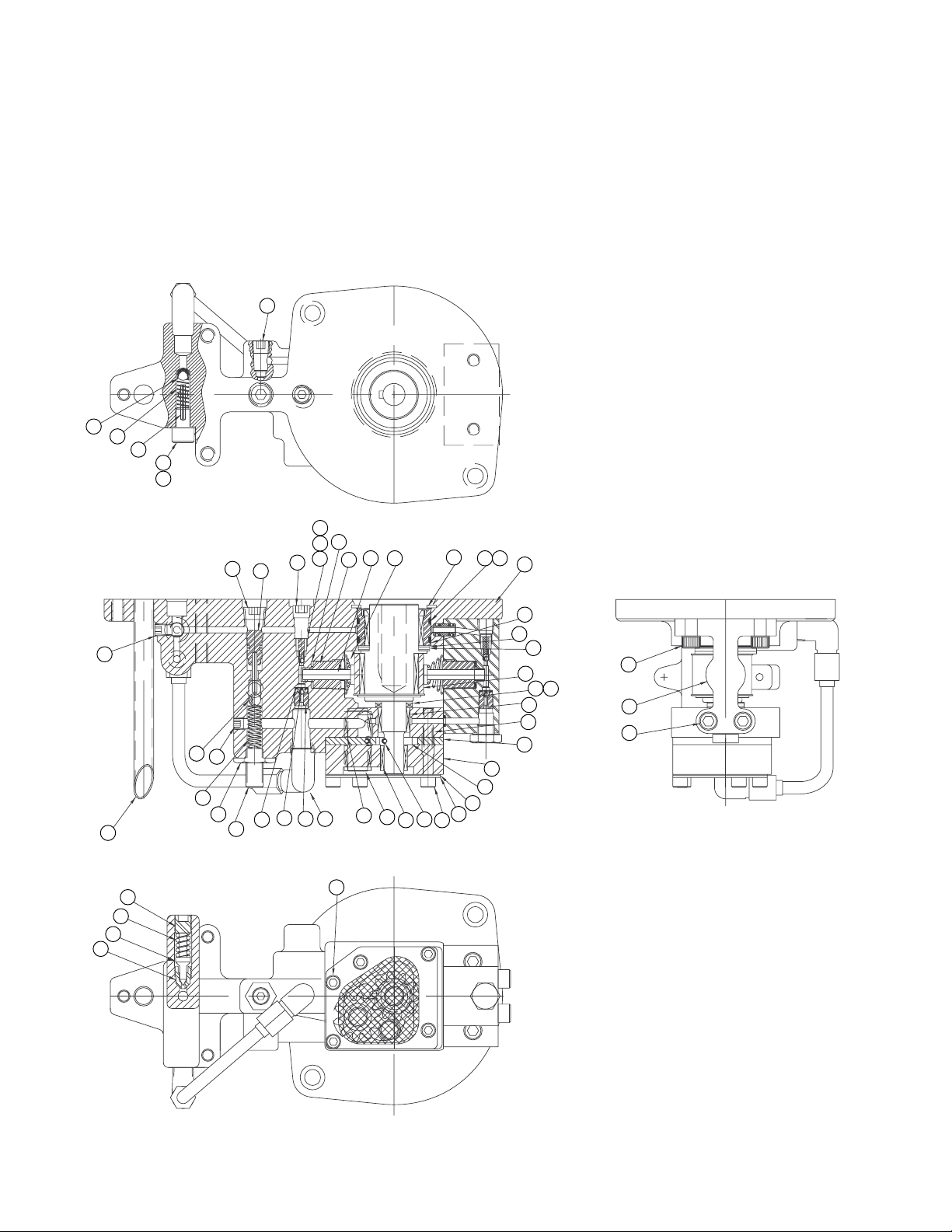

18948

PUMP ASSEMBIES 40 SERIES GAS PUMP

46

21

35

36

37

38

43

38

18

14

15

46

16

11

12 13

10

9 42

1

8

7

25

21

25

22

24

41

50

49

48

47

23

18

17

45

2019

34

29

18

44

28

30

33

32

6

5

3

4

2

31

26

27

55

53

54

- 8 -

Page 9

18948

PUMP ASSEMBIES 40 SERIES GAS PUMP

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

41

42

43

44

PART NO.

68507

68360

66033

66474

68906

66106

66108

68829

56020322

68978

68945

67868

68340

68810

93950

68535

66043

90906

66046

68851

91701

68981

68242

68920

97641

68848

68849

68883

68850

68921

68894

68255

68927

89148

68225

81332

68226

85726

68569

69513

66042

68891

QTY.

1

1

1

2

1

1

1

1

2

1

1

1

1

1

1

1

1

5

1

1

2

1

1

1

2

1

1

2

1

1

2

4

1

1

1

1

1

2

1

2

1

3

DISCRIPTION

2 Piston Pump Body

Roller Bearing

Thrust Bearing

Race Bearing

Ecc. Shaft Assm.

Thrust Bearing

Race Bearing

Adaptor Shaft Assm.

O-Ring

Retaining Ring

Adaptor Piston .225 Dia.

Piston .225 Dia

Piston Spring

Ball Stop

1/4 Socket Pipe Plug

Piston Unloading Assm.

Ball Retainer

803C-7D Ball Bearing

Intake Seat

Tube Assm.

R102-10B Ball Bearing

Spring

Set Screw

Nut-Hex Jam

Soc Pipe Plug Steel

Center Plate .11

Bottom Plate

Gear Pump

Shaft-Idler

Screen

Guide Tube

Screw

Plate-Screen Mount

Screw

Spring

Roll Pin 1/8 x 15/16

Ball Stop Screw

Gasket

Return Tube

Backup Washer

Spring

Bearing

ITEM

45

46

47

48

49

50

53

54

55

PART NO.

68892

81093

68004

68003

66085

66083

68502

82892

82687

QTY.

1

2

1

1

1

1

1

2

2

DISCRIPTION

Retaining Ring

PIpe Plug

Ext. Relief Seat

Ext. Relief Cone

Valve Relief Spring

Adjust Screw

Piston Block Assm.

SHCS 5/16-24 X 2

Screw

- 9 -

Page 10

18721

PUMP ASSEMBIES FOR 40 SERIES AIR PUMP

46

21

35

36

37

38

43

38

18

14

46

16

15

11

13

12

10

9 42

1

879 42

25

21

25

22

24

17

41

50

49

48

47

23

20

19

18

34

29

18

32

44

45

27

28

30

33

6

5

4

3

2

31

26

55

53

54

56

57

58

- 10 -

For 5 & 10 Gallon Reservoir.

Page 11

18721

PUMP ASSEMBIES FOR 40 SERIES AIR PUMP

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

41

42

43

44

PART NO.

68507

68360

66033

66474

69082

66106

66108

68829

56020322

68978

68915

68830

68340

68810

93950

68535

66043

90906

66046

68851

91701

68981

68242

68920

97641

68848

68849

68883

68850

68921

68894

68255

68927

89148

68225

81332

68226

85726

68569

69513

66042

68891

QTY.

1

1

1

2

1

1

1

1

2

1

1

1

1

1

1

1

1

5

1

1

2

1

1

1

2

1

1

2

1

1

2

4

1

1

1

1

1

2

1

2

1

3

DISCRIPTION

2 Piston Pump Body

Roller Bearing

Thrust Bearing

Race Bearing

Ecc. Shaft Assm.

Thrust Bearing

Race Bearing

Adaptor Shaft Assm.

O-Ring

Retaining Ring

Adaptor Piston .210 Dia.

Piston .210 Dia

Piston Spring

Ball Stop

1/4 Socket Pipe Plug

Piston Unloading Assm.

Ball Retainer

803C-7D Ball Bearing

Intake Seat

Tube Assm.

R102-10B Ball Bearing

Spring

Set Screw

Nut-Hex Jam

Soc Pipe Plug Steel

Center Plate .11

Bottom Plate

Gear Pump

Shaft-Idler

Screen

Guide Tube

Screw

Plate-Screen Mount

Screw

Spring

Roll Pin 1/8 x 15/16

Ball Stop Screw

Gasket

Return Tube

Backup Washer

Spring

Bearing

ITEM

45

46

47

48

49

50

53

54

55

*56

*57

*58

PART NO.

68892

81093

68004

68003

66085

66083

68832

82892

82687

88058

80240

68884

QTY.

1

2

1

1

1

1

1

2

2

1

1

1

DISCRIPTION

Retaining Ring

PIpe Plug

Ext. Relief Seat

Ext. Relief Cone

Valve Relief Spring

Adjust Screw

Piston Block Assm.

SHCS 5/16-24 X 2

Screw

Tube

Coupling

Screen & Tube

* For 5 & 10 Gallon

Reservoir Only.

- 11 -

Page 12

21

35 36

38

37

15

16

43

46

# 69296

8 HP Gasoline Motor

18

14

39

11

12

13 10

42

1

9

47

25

49

41

48

50

22

21

25

24

23

20

17

18

19

20

32

45

29

44

18

32

28

27

8

7

6

3

31

26

5

4

55

2

30

54

53

56

57

58

- 12 -

Page 13

# 69296

8 HP Gasoline Motor

Item #

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

35

36

37

38

41

42

43

44

45

46

47

48

49

50

53

54

55

56

57

58

Part #

68529

68360

66033

66474

68906

66106

66108

68829

56020322

68978

68915

68830

68340

68810

93950

68535

66043

90906

66046

68851

91701

68981

68242

68920

97641

68855

68849

68896

68850

68898

68922

68255

68225

81332

68226

95726

68569

69513

66042

68891

68892

81093

68004

68003

66085

66083

68832

69392

82687

88058

80240

68884

Descreption

4Piston Pump Body

Roller Bearing

Bearing

Bearing Race

Eccentric Asm.

Thrust Bearing

Bearing Race

Adapter Shaft Asm.

O-Ring

Retaining Ring

.210 Piston Adapter

Piston .210

Piston Spring

Ball Stop

Pipe Plug

Piston Unloading Asm.

Ball Retainer

Ball

Intake Seat

Tube Asm.

Ball

Unloading Valve Spring

Set Screw

Hex Jam Nut

Socket Pipe Plug

Center Plate

Bottom Plate

Gear (Pump)

Idler Shaft

Piston Block Asm.

Guide Tube

Screw

Spring

Roll Pin

Ball Stop Screw

Gasket

Return Tube

Back Up Washer

Spring

Bearing

Retaining Ring

Pipe Plug

Seat - Relief

Cone - Relief

Spring - Relief

Adj. Screw

Piston Block Asm.

S.H. Cap Screw

S.H. Cap Screw

Tube / nipple

coupling

screen and tube

Quantity

1

1

1

2

1

1

2

1

2

1

1

1

1

1

1

1

1

9

1

1

2

1

1

1

2

1

1

2

1

2

2

4

1

1

1

2

1

2

1

3

1

2

1

1

1

1

1

6

6

1

1

1

- 13 -

Page 14

4

29

33

30

25

32

3

31

25

35

36

9

13

38

16

13

11

2

7

37

23

17

42

28

27

19

26

34

21

20

5

28

18

8

15

24

1

GASOLINE

POWER PUMPS

- 14 -

7

12

6

9

Page 15

16

13

4

3

19

22

10

11

14

2

23

17

21

12

20

5

6

15

8

9

24

40 SERIES AIR POWER

PUMPS

- 15 -

18

7

Page 16

PGM & PAM POWER PUMPS

DESCRIPTION

NUMBER

PART

ITEM

1

18135

2

68000

3

66012 MOTOR GASKET

4

68231

5

66014

6

68251

68258

7

8

68551

69090

18388

9

18389

10

69042

11

87492

68433

12

68392

13

93594

14

68571

15

68963

18721

18874

18948

16

68116

69296

86095

17

65891

18

87145

88559

19

68311

84579

20

93599

68349

21

18379

22

69026

23

65892

24

66021 MAGNET

25

66121 MOTOR RISER PLATE

26

97268

27

86513

28

68682 COVER PLATE

29

85454 GAS ENG ADPT

30

68163 SPACER - COUPLING

31

68124 MTROR ADPT

32

93544 SCREW

33

93943 LOCK WASHER

34

68164 FLEX CPLG

35

69294 STUB SHAFT

36

68119 KEY

37

96550 RETAIN'G KEY

38

69298 SPACER CPLG

OIL / GAL.

BREATHER VENT

PUMP GASKET

RES. GASKET

VALVE GASKET

PLUG SAE #4

PUMP GASKET

RESERVOIR

HANDLE

PIPE PLUG

MANIFOLD

SCREW-MOTOR

FILLER PLUG

VALVE ADAPTER ASM

PUMP ASM

SCREW - COVER

PLUG - SHIPP'G

AIR MOTOR

GAS MOTOR

MANIFOLD SCREW

VALVE

PIN - DOWEL

WASHER

SCREW

SCREW

PGM5036

PGM4045

PGM4042

PGM4035

PGM4032

PAM4045

PAM4042

PAM4035

PAM4032

22 2266 66

1111 1111 11

1111 1111

1111 1111

1111 1111

1111 1111

1111 1111

1111 1111

11 11

11 11

11 11

1111 1111 11

11 11 1

11

1111 1111 11

1111 1111 11

11

11

11

11

11 1122 22

1111

3333 3333

11 11

11 11

1111 1111

12 12 12 12

11 11

1111 1111 11

1

11

11

11 11

12

1111

1111

2222

1111

11 11

11

11

11

11

11

11

11

11

2222222222

11

121212

12 12

11

33

1

12 12

11

4

11

11

11

33

33

11

11

11

11

11

PGM5046

21

1

11

4

- 16 -

Page 17

PGM & PAM POWER PUMPS

2

Assembly #68829

Item

1

3

Item

Part

No.

1

68219

2

66030

3

68901

Assembly #68535

Part

Description

Adapter-Shaft

Bearing

Seal

Description

Qty.

1

1

1

Qty.

No.

1

68209

2

5602010

3

1

3

2

4

3

2

4

1

Item

68145

4

93837

Part

Piston

O-Ring

Back-Up Ring

Roll Pin

Assembly #69082 - AIR

Assembly #68906 - GAS

Description

1

1

1

1

Qty.

No.

1

68859

1

68907

2

69081

3

66108

4

67863

Shaft Ecc. - AIR

Shaft Ecc. - GAS

Ecc. Bearing Assembly

Race Bearing

Retaining Ring

1

1

1

1

1

1

16

14

13

15

4

Item

1

3

2

3

2

4

5

12

11

10

5

2

6

6

7

8

9

10

11

12

7

14

9

8

13

14

15

16

Assembly #68832 & #68502

Part No.

68832

68501

90906

66042

68810

66043

66046

86269

68825

85727

68915

68340

68830

68970

5602008

93949

56080087

Part No.

68502

68501

90906

66042

68810

66043

66046

86269

68825

85727

68945

68340

67868

68970

5602008

93949

56080087

Piston Block

Ball St 803C-7D

Spring

Ball Stop

Ball Retainer

Intake Seat

Gasket

Screw

Gasket

Adapter

Spring Piston

Piston (Pump)

Adapter Assembly

O-Ring

SOC Pipe Plug 1/8

Back-Up Ring

Description

Qty.

1

2

1

1

1

1

1

1

1

1

1

1

1

3

1

2

- 17 -

Page 18

3 WAY & 4 WAY VALVE MANIFOLD

7

8

SECTION A-A

A

A

9

2

AR

10

6

5

11

SECTION B-B

B

B

34

8

R

1

Assembly #69570 3 Way Manifold

Item

Part No.

Description

Qty.

69570

1

69569

2

68197

3

68004

4

7

5

6

7

8

9

10

11

68003

66085

69104

84084

97641

5602014

69124

69105

Ret. Valve Manifold

Nozzle-Valve

Seat-Ext. Relief

Cone-Ext. Relief

Spring Rel. Valve

Adjusting Screw

Flush SOC 3/8-18 PTF

1/16 SOC Pipe Plug

O-Ring

Washer 7/16 Nylon

Acorn Nut

1

1

1

1

1

1

3

2

1

1

1

Assembly #69100 4 Way Manifold

Part No.

Item

Description

69100

69099

1

69104

2

69105

3

69124

4

66085

5

68003

6

68004

7

84084

8

8

B AA

4

3

2

1

4 Way Valve Manifold

Adjusting Screw

Acorn Nut

Washer 7/16 Nylon

Spring Rel. Valve

Cone - Ext. Relief

Seat - Ext. Relief

Flush SOC 3/8-18 NPTF

6 7

5

- 18 -

Qty.

1

1

1

1

1

1

1

2

8

Page 19

3 WAY & 4 WAY LOCKING VALVE MANIFOLD

2

1

3

4

5

Assembly #68581 4 Way Lock Valve Manifold

Item

Part

Description

Qty.

No.

1

68591

2

92549

3

68637

4

5602113

5

89435

6

8

6

2

14

15 16

17

8

9

10

11

12

13

14

15

16

17

56021115

5602010

66083

66085

68003

68004

5608106

68589

5602106

68636

68590

Valve Body

Ball - 1/4

Release Gland

O-Ring 2-113

Release Screw Assm.

O-Ring 2-111

O-Ring 2-010

Adjusting Screw

Relief Valve Spring

Relief Valve Cone

Relief Valve Seat

Back-Up Washer 8-106

Ball retainer

O-Ring 2-106

Spool

Ball Seat

1

3

1

1

1

1

1

1

1

1

1

2

2

1

1

2

9

10

12 13

11

2

Assembly #69077 3 Way Lock Valve Manifold

Item

Part

Description

Qty.

No.

1

21

18

11

13

14

7

5

4

6

12

10

23

18

19

20

9

8

15

17

16

23

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

69112

68004

68003

66085

66083

5603908

69113

5602010

68145

5602012

65881

68189

68183

68184

92550

68080

68187

5602014

68197

69114

81093

97641

68188

5602008

Valve Body Lock Valve

Seat-External Relief

Cone-External Relief

Spring Release Valve

Adjustable Screw

O-Ring

Retainer

O-Ring

Back-Up Washer

O-Ring

Back-Up Ring

Pilot-Spool

Gasket-Plug

Plug-Spool

3HJ-23C Ball Bearing

Gasket Washer

Port Adapter

O-Ring

Nozzle-Valve

Diffuser

Pipe Plug

Plug (Not Shown)

Compression Spring

O-Ring

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

3

1

1

1

- 19 -

Page 20

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

Qty.

1

Description

2 Way Valve Block

Valve Stem

No.

Part

69092

69095

1

Item

2

O-Ring

Back-Up Washer 8-111

Ball 5/16 R102

91701

5602111

5608111

3

4

5

Pin Roll 1/8 x 1/2 LG

Valve Handle

Screw

Seat-External Relief

Cone-External Relief

Spring Relief Valve

Adjusting Screw

93835

69091

85961

68004

68003

66085

69104

6

7

8

9

1

10

12

Spring

Adapter Assembly

1/16 Pipe Plug Flush

Acorn Nut

Hex St. Pipe Plug

68963

40049

69105

17

18

87145

19

5623007

13

14

7

Washer 7/16 Nylon

69124

20

0

6

8

2

12

9

3

4

5

13

11

10

14

1

13

69094

2 WAY VALVE

19

17

- 20 -

Page 21

18379 VALVE ASSEMBLY

68349 RETRACTOR VALVE ASSEMBLY

18

17

16

15

7

14

13

12

11

1

2

10

9

8

5

6

5

4

3

19

20

A

"A" "A"

View "A-A"

21

22

2

23

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

PART NO.

68160

56020112

68180

5602225

68026

68155

5602012

68035

68024

93804

5602011

65882

68181

68028

68025

92549

68032

68157

68033

68034

85317

5602008

93598

QTY.

18379

1

4

1

1

2

1

1

1

1

1

3

3

3

3

1

1

1

1

1

1

2

1

4

QTY.

68349

1

2

1

1

2

1

1

1

1

1

6

4

4

4

1

1

1

1

1

1

2

1

4

68349 - Use

18379 - Use

11

2

DESCRIPTION

Rotor Assembly

O-Ring

Subplate-Valve.

O-Ring

Thrust Washer

Thrust Bearing

O-Ring

Upper Valve Blk.

Detent & Stop Plt.

Driv-Lok Pin

O-Ring

Back-up Washer

Shear Seal

Spring Washer

Detent Spring

Ball .250 Dia.

Washer-Handle

Flat Grip

Handle

Acorn Nut 1/2-20

Soc. Hd. Capscrew

O-Ring

Valve Mounting

- 21 -

Page 22

43022 VALVE AIR TORQUE OC

7

3

4

8

2

5

1

6

ITEM

1

2

3

4

5

6

7

PART NO.

68725

41954

68388

68389

68711

56020112

43358

433598

DESCRIPTION

VALVE ASSY.

AIR CYL ASSY

COVER

GASKET

SPRING

O'RING

SCREW

SCREW

QTY

1

2

1

1

2

4

4

8

- 22 -

Page 23

41950 MOTOR PENDANT AIR ASSEMBLY

4

1

ITEM

2

3

7

PART NO.

1

41968

41969

41963

2

3

5

6

DESCRIPTION

BODY-PENDANT

BLOCK-AIR PENDANT

CARTRIDGE-AIR

QTY

1

1

2

4

5

6

7

41964

68808

41970

6069613

SWIVEL FITTING

RETAINING RING

CARTRIDGE-CAP

SAFETY VAL BALL

3

2

2

3

- 23 -

Page 24

AIR VALVE ASSEMBLY

ADVANCE

COIL

14

12

5

13

12

11

5101

MOTOR

7

B

2

5

RETRACT

COIL

42

1

1

7" LG

8

2

4

1

P

A

6

31

2

9

3

TUBE FROM

FILTER/LUBE

8

ITEM

1

2 42380

3 86872

4 42968

5 42667

6 42668

7

8 69361

9 43514

10 69852

11 4100067

12 68794

13 68797

PART NO. DESCRIPTION

69362

69547

4351514 AIR VALVE 4W / 2POS 1

SWIVEL NUT ELBOW

SWIVEL ADP 1/8 90 2

SWIVEL ELBOW 1/4 1

SWIVEL TEE 1/8

REDUCER

BRANCH TEE 1

HOSE BARB

NYLON TUBING

AIR VALVE 3W / 2POS 1

MALE RUN TEE

NIPPLE

MALE ELBOW TUBE

MALE CONNECT TUBE

QTY

- 24 -

5

1

3

1

2

1

1

2

1

Page 25

68790 FILTER / LUBE ASSEMBLY

ASSEMBLE WITH LOCTITE 242

6

4

1

3

2

5

7

ITEM

1

2

3

4

5

6

7

PART NO.

86241

86242

87320

68791

69936

85851

68798

DESCRIPTION

AIR FILTER

AIR LUBRICATOR

PIPE NIPPLE

BRACKET WELD'M

REDUCER

AIR VALVE

HOSE BARB ELBOW

QTY

1

1

1

1

1

1

1

- 25 -

Page 26

69470 FILTER BLOCK ASSEMBLY

4

5

2

3

1

ITEM

2

3

4

5

6

6

PART NO.

1

69546

69670

69144

93950

56020112

5602008

DESCRIPTION

FILTER BLOCK

OIL FILTER

ADAPTER-FILTER

PIPE PLUG 1/4

O'RING

O'RING

QTY

1

1

1

2

4

1

- 26 -

Loading...

Loading...