Page 1

Film-Tech

The information contained in this Adobe Acrobat pdf

file is provided at your own risk and good judgment.

These manuals are designed to facilitate the

exchange of information related to cinema

projection and film handling, with no warranties nor

obligations from the authors, for qualified field

service engineers.

If you are not a qualified technician, please make no

adjustments to anything you may read about in these

Adobe manual downloads.

www.film-tech.com

Page 2

35mm UNITIZED PROJECTOR

STRONG

INTERNATIONAL

a division of Ballantyne of Omaha, Inc.

4350 McKinley Street

Omaha, Nebraska 68112 USA

Tel 402/453-4444 • Fax 402/453-7238

www.strong-cinema.com

INSTRUCTION MANUAL

and PARTS LIST

Page 3

SA VE THESE INSTRUCTIONS

This equipment is intended

FOR PROFESSIONAL USE ONLY

Read and understand all instructions before using

WARNING

To avoid risk of fire, do not use

nitrate or other flammable film.

Use safety film only.

EXERCISE CAUTION WHEN

WORKING AROUND MOVING

PARTS

Page 4

TABLE OF CONTENTS

PREFACE 1

FIGURE 1 3

FIGURE 2 4

INSTALLATION

Unpacking 5

Mounting 5

Lamphouse Alignment 6

Lamphouse Light Shield 6

Picture Changeover 6

Lens Turret 6

Projection Lenses 7

Flywheel 7

Sound Reader Assembly 8

Analog 9

Digital 10

START-UP PROCEDURES

Initial Oiling 15

Threading 16

Initial Operation 17

MAINTENANCE

Lubrication 18

Sprockets 18

Pad Rollers 18

Fastening Hardware 18

Film Gate 18

Film Trap 18

Lens Turret 19

Overall Appearance 19

i

Page 5

TABLE OF CONTENTS (continued)

FIGURE 3 20

FIGURE 4 21

ADJUSTMENTS & REPLACEMENTS

Intermittent Shoe Replacement 22

Film Trap & Aperture Changer 22

Pressure Strap Replacement 22

Studio Guide Replacement 22

Aperture Plate Adjustment 22

Gear Compartment Cover 23

Intermittent Movement 23

Intermittent Sprocket 24

Framing Light 24

Pad Roller Assemblies 24

Shutter Timing 25

Shutter Replacement 25

Film Gate Replacement 25

Film Sprocket Replacement 26

Sprocket Gear Replacement 26

Automatic Lens Turret 26

PARTS LISTS 28

STRONG INTERNATIONAL

a division of Ballantyne of Omaha, Inc.

Engineering/Sales

July 1, 2004

ii

Page 6

PREFACE

THE SIMPLEX APOGEE PROJECT OR, combining rugged construction with ease of operation, provides theatre owners with a superior mechanism, engineered to the high standards set for all Strong

International products. The following design features illustrate why the Simplex Apogee Projector is able

to provide continuously excellent performance throughout its long operating life:

UNIT DESIGN

Unit method of design simplifies part replacement and maintenance. All units may be quickly

removed and replaced. Components within a particular unit are just as easily handled.

SOUND READER

The analog and digital sound reader components are mounted to the same main frame as the optical

elements, insuring a straight film path. Minimal flutter and “wow” comply with all SMPTE standards.

MAIN DRIVE

The projector main drive is connected directly to the drive motor without pulleys and belts, eliminating the

need to adjust tension and/or replace these components.

OPTICS

A conical shutter, positioned close to the picture aperture, provides very high light efficiency. Optical

design is compatible to modern xenon lamphouse systems.

LENS TURRET

The Apogee Lens Turret is available in either Automatic or Manual configurations. The standard

turret accommodates (1) each 2-25/32" (71mm) diameter Wide Screen (flat) and Anamorphic (CinemaScope)

lens without use of a MagnaCom. A three-lens turret is available for export applications. Individual focus

controls permit concise focusing of each lens independently .

FILM COMPARTMENT

The roomy film compartment permits ease of threading and cleaning. The lens turret is hinged and

swings open for added convenience.

GEAR COMPARTMENT

The gear compartment has a removable cover, rounded corners, and an enameled finish which simplifies

cleaning and service.

1

Page 7

MAIN FRAME

The main frame casting forms a single unit that is noteworthy for its simplicity and strength. A single

thread path serves all film-handling elements for both precise projection and sound reproduction.

FILM SPROCKETS

The upper feed and lower holdback sprockets, having twenty-four teeth each, reduce shaft speeds to

prolong operating life, permit smoother wraparound, and lessen the danger of splice breakage. Exclusive use

of VKF

®

sprockets insures minimum film wear. The pad rollers are made of durable, lightweight nylon.

FILM TRAP

The film trap conforms to the curved film gate, and accommodates the multiple-aperture plate used

with the lens turret. Film tension can be easily adjusted while the machine is running. The trap is readily

removed and replaced for routine cleaning and maintenance.

FILM GATE

The curved gate, together with the film trap, controls the movement of the film past the aperture. Gate

curvature provides compensation for heat-induced warping of the film at the aperture, thus insuring a sharper

image on the screen. The film gate runner is easily removed, cleaned, and replaced.

INTERMITTENT MOVEMENT

The intermittent movement features a webbed starwheel for high strength, long life, and positive

registration. The VKF

®

intermittent sprocket is adjustable, making absolute alignment possible.

LUBRICATION

A Spray-O-Matic Lubrication System, with a gear-driven oil pump, completely lubricates all moving

components. The moving parts inside the gear compartment are visible through the full-vision, oil-sealed

plexiglass window on the off-operator side of the mechanism. The intermittent movement lubricates itself by

pump action, and the Spray-O-Matic system. An oil level sight glass in the film compartment permits a visual

check of the oil level.

COOLING

The Simplex Apogee Projector includes a heat sink positioned behind the shutter blade and aperture to

absorb radiant heat and protect the trap and film. Cooling fans further reduce heat at the film plane.

®

VKF

is a registered trademark of LaVezzi Precision, Inc. Elmhurst, Illinois

2

Page 8

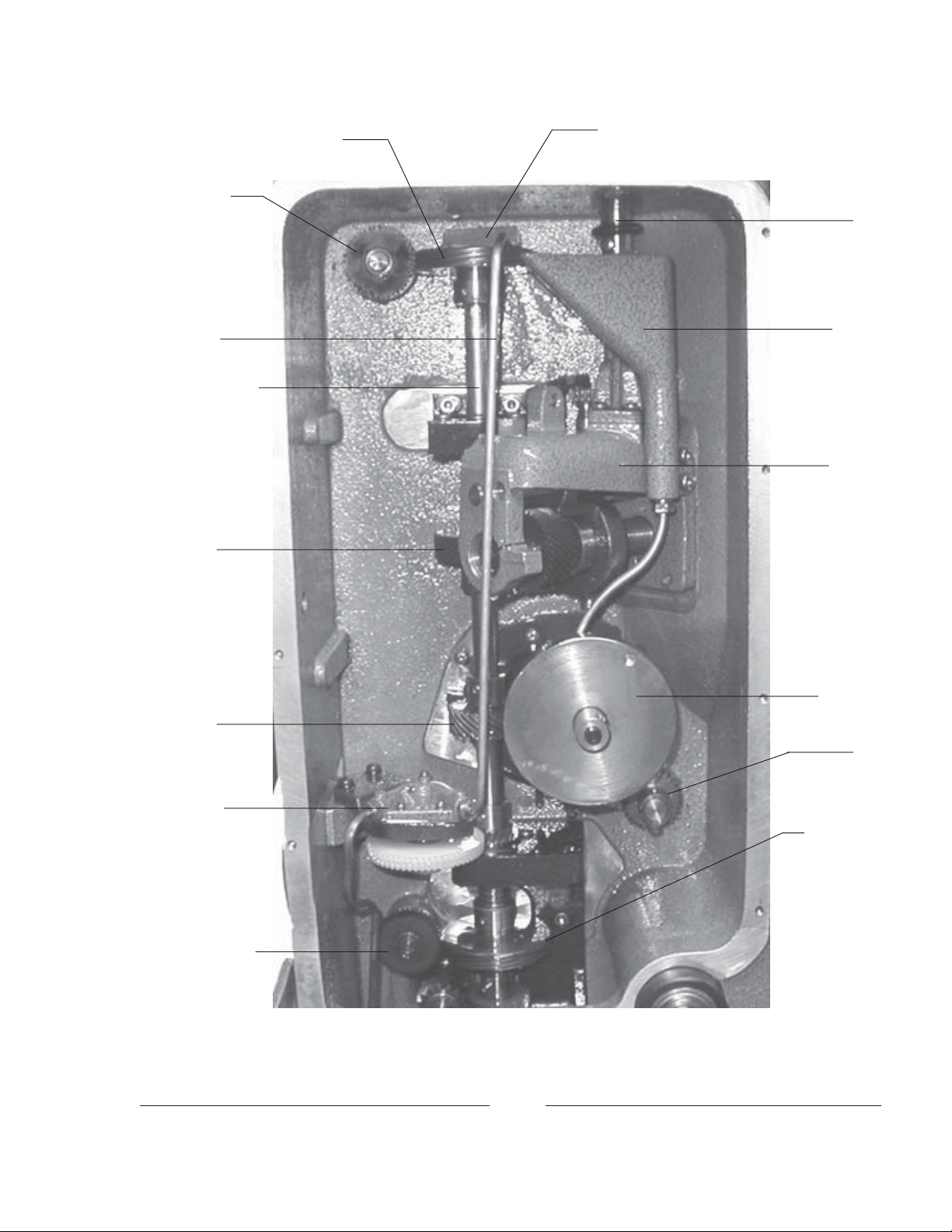

FOCUS

KNOB

FILM TRAP

COOLING FANS

SHUTTER ADJUSTING

KNOB

PICTURE

CHANGEOVER

DEVICE

TURRET “OPEN”

LEVER

CONTROL

CABINET

OIL FILL

CUP

DEADSTOP

ADJUST

DRIVE

MOTOR

FOCUS

KNOB

RESET LEVER, INDEX

STOP PIN

FIGURE 1

3

Page 9

FILM TENSION

ADJUSTING

KNOB

CHANGEOVER

DEVICE

FRAMING

LIGHT

GATE

RELEASE

PIN

UPPER FEED

SPROCKET

SHUTTER

GUARD

RELEASE,

APERTURE

MOTOR

COVER

FRAMING

HANDLE

APERTURE

CUE

ANALOG

SOUND

READER

DIGITAL

SOUND

READER

FIGURE 2

INTERMITTENT

SPROCKET

HOLDBACK

SPROCKET

OIL SIGHT

GLASS

OIL DRAIN

4

TURRET

RESET

SWITCH

APERTURE LOGIC

SENSING SWITCH

Page 10

INSTALLATION

EACH SIMPLEX APOGEE PROJECTOR is carefully inspected and film-tested before

leaving the factory. Carefully inspect the unit on receipt for any shipping damage, and file any damage

claims with the carrier immediately. It is the responsibility of the consignee, not Strong International or its

dealers, to file such claims.

THE FOLLOWING RECOMMENDATIONS should be studied carefully prior to installation. Even if received mounted and prewired to a Strong console, it is advisable to review and inspect the

following steps prior to energizing the system. Your Strong International Dealership may wish to assist in

installing those projection booth products supplied by their firm.

UNPACKING

The Simplex Apogee projector is shipped in a sturdy wooden crate. TOP and OPEN THIS SIDE are

marked on the carton. The projector is mounted to the base of the crate with (2) 5/16-18 hex head screws.

An accessory kit is shipped with each Simplex Apogee projector. The kit includes the following:

(1) Can Simplex Projector Oil

(1) Oiler

(1) Set Allen Wrenches

The tools and accessories are required for adjustments and routine maintenance after installation. Store

them in a secure location in the projection booth.

MOUNTING

Mount the Apogee to the mounting arm on the front of the console or pedestal. Some consoles will

require spacer block(s) to position the projector’s picture aperture at the correct working distance; see the

console installation instructions. Start the top two bolts, through the washers and spacer block (if required),

into the back of the main frame casting. The projector can then be lifted into place, and the top two bolts into

the casting lowered into the slotted holes in the projector mounting arm. In this manner, the mounting arm

will bear the weight of the projector while the two bottom bolts are started.

T o avoid crossthreading, the 3/8-16 mounting bolts should be screwed in fingertight as far as possible.

Before tightening the bolts, check that both the lamphouse/console and projector are on the same, level plane.

T erminals for the drive motor power leads are provided in the projector control cabinet. See the following

section detailing Electrical Connections.

5

Page 11

LAMPHOUSE OPTICAL ALIGNMENT

Carefully follow the lamphouse manufacturer’s instructions regarding correct optical alignment

between the lamphouse and projector. The lamphouse is generally aligned to the projector aperture, but

some consoles require positioning the projector to the optical center of the lamphouse. Never operate the

lamphouse with the douser open unless the projector is running.

LAMPHOUSE LIGHT SHIELD

Light shields, or nose cones, supplied by the lamphouse manufacturer, may be installed between the

projector shutter guard and the lamphouse snood. Make certain that the nose cone does not obstruct the rotation

of the shutter. T rim or otherwise modify the nose cone as required.

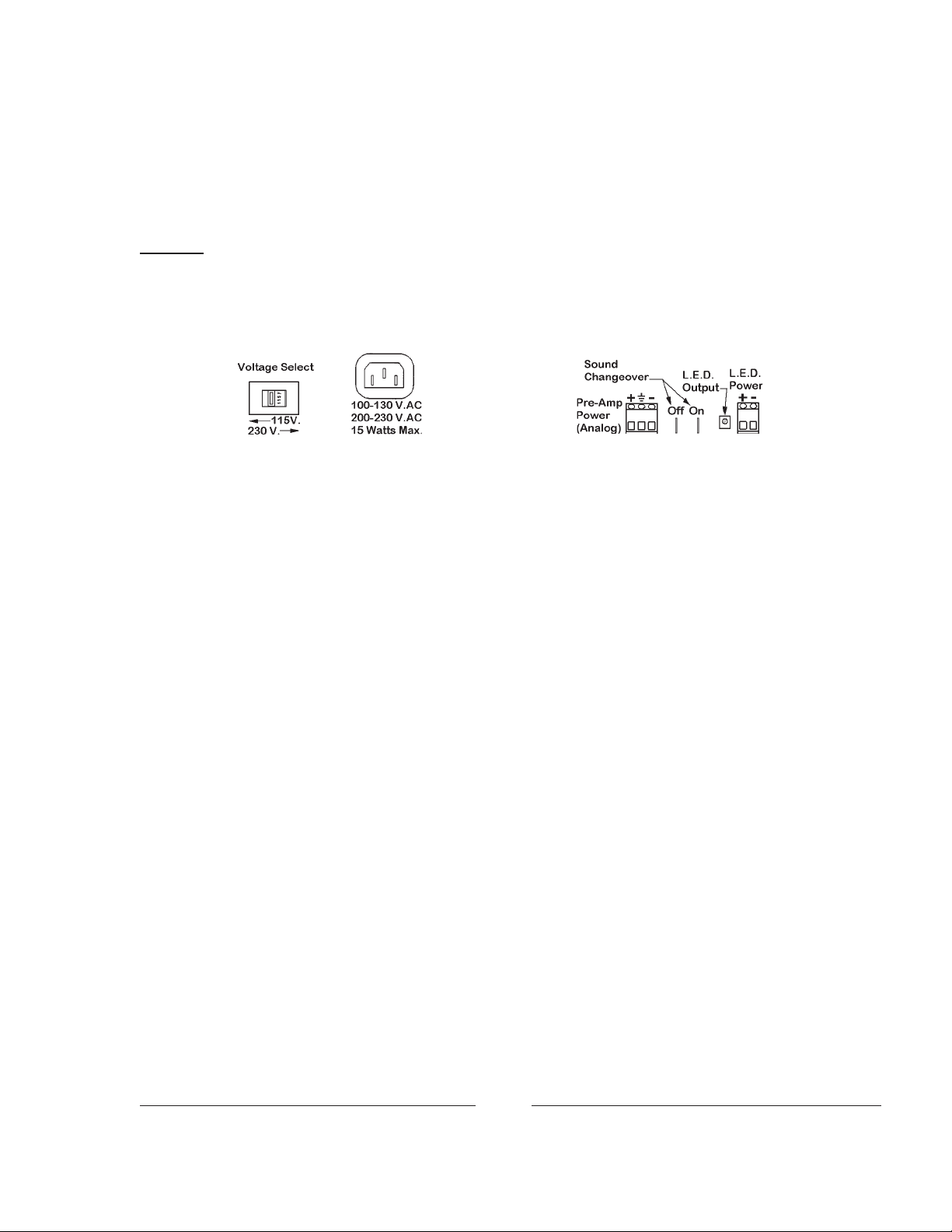

ELECTRICAL CONNECTIONS

All electrical connections to the Apogee terminate in the cabinet mounted on the side of the projector

adjacent to the gear compartment. Loosen the quarter-turn fastener and open the door to access the terminals.

Input voltage is user-selectable by connecting the transformer plug

to one of the two receptacles located on the top of the “Power” printed

circuit board. Connect the plug to J7 for 110 volt operation, or to J8 for

220 volt. After selecting the voltage, apply AC phase and neutral to the

two uppermost terminals on the right barrier strip. This AC input

powers the turret controller, the turret and aperture motors, and the L.E.D.

framing light. An earth ground must be connected to the ground lug at

the lower right corner of the cabinet.

The lower five terminals of the right barrier strip allow power

connections from the automation controller to the picture changeover

and the projector drive motor. The lower five terminals of the left

barrier strip provide connection points to the devices. Voltage to these

devices is generally supplied by, or switched through, the automation

controller. All NEUTRAL connections are common.

Turret inputs connect to the (4) marked terminals on the lower

part of the turret control PCB mounted to the cabinet door.

Picture Changeover

The Apogee is normally shipped with a Strong International

115 V.AC (52-60325) or 230 V.AC (52-60326) picture changeover de-

vice. If ordered separately, connect the changeover leads as follows:

Blk - OPEN Wht - COMMON

Red - CLOSE Grn - GROUND

NOTE: These changeover devices require an AC pulse to operate.

Connecting the changeover device to a sustained AC circuit will destroy

the electrical coil(s). Check carefully the instructions supplied with the

automation controller and/or the (installer-supplied) switching circuit.

6

Page 12

Lens Turret

The MANUAL lens turret requires no electrical connections. Installer connections to the AUTO-

MA TIC turret are made to the J4 terminals located on the printed circuit board on the control box door adjacent

to the gear compartment cover on the side of the projector. The inputs (FEED, SPECIAL, FLA T , and SCOPE)

are derived from an automation controller and/or other installer-supplied circuitry . NOTE: “SPECIAL” input

applies only to a third lens in a three-lens turret.

LENS INSTALLATION

The lens barrels are individually marked to designate their screen format. The barrels of the standard

two-lens turret are marked SCOPE (CinemaScope, or anamorphic) and FLAT (“wide screen,” or nonanamorphic). Lens barrels on the three-lens turret are marked SC (CinemaScope), FL (Flat), and SP (Special).

The lenses must be installed in their designated barrels for correct aperture logic. Magnacom lenses are not

required in any configuration.

Rotate the turret to the SCOPE position. The automatic turret can be indexed to this position by pressing

the reset switch; the manual turret must be indexed by hand. Make certain the SCOPE aperture plate is in

position. Center the focus adjustment screw, allowing equal travel forward and back. Insert the CinemaScope

lens and anamorphic adapter into the SCOPE barrel. Start the projector , ignite the lamphouse, and project

a picture to the screen. Move the lens inside the barrel until a sharply focused picture is projected, and rotate

the lens and adapter to set the anamorphic correction on the horizontal plane. Securely tighten the lens locking

knob on the top of the SCOPE barrel. Close the lamphouse douser.

Reset the turret to FLAT format, and make certain the FLAT aperture is in position. Install the FLA T

lens, and center its focus adjustment screw. Open the lamphouse douser and move the lens inside the barrel

until a sharply focused picture is projected. T ighten the lens locking knob above the FLAT barrel.

Repeat the above procedures as required for the “special” lens used in a three-lens turret. Once

installed, DO NOT remove the lenses for cleaning. The turret is hinged, and opens to permit cleaning the rear

surfaces of the lenses.

File the aperture plates to size the picture to the screen and/or masking. NOTE: When projecting a

white light while filing apertures, close the lamphouse douser frequently to allow the lens to cool.

DO NOT attempt to correct “keystoning” by shimming the turret or offsetting the position of the lenses.

The lenses must be positioned on optical center to project an acceptable image.

SOUND READER FLYWHEEL INSTALLATION

Spring Washer

Shaft

The sound reader flywheel is dismounted for

shipping to avoid damage to the impedance drum shaft.

Assemble the flywheel to the end of the impedance drum

shaft using the wave spring washer and spacer in the

sequence shown (spring washer against the flywheel,

Spacer

Flywheel

spacer next to bearing seal). Secure the flywheel to the

shaft with the 1/4 inch hex head screw. Note LEFT-

HAND THREAD; turn counterclockwise to tighten.

7

Page 13

SOUND READER ASSEMBLY

ADJUSTMENTS to those components relevant to scanning the optical soundtrack are best

performed by qualified personnel equipped with the necessary test equipment. Attempts to effect field repairs

without use of the required test equipment are generally detrimental to sound quality.

1. An L.E.D. (Light Emitting Diode) is positioned directly behind the film plane to illuminate the soundtrack.

The horizontal and vertical positioning is adjustable. The distance of the L.E.D. from the film plane is

factory set. The L.E.D. is powered by a remote, low-voltage, current regulated power supply.

2. An Analog Signal Pick-Up Assembly is mounted in front of the film plane, and contains the lensing, the

solar cells, pre-amps, and terminals for the cell output. This assembly is factory-set to maximize the

reception of the signal generated by the L.E.D.

3. A second L.E.D. illuminator and signal pick-up are required for scanning Dolby

®

digital prints. These

components are mounted adjacent to the analog elements, 45° off the analog axis. A second L.E.D. power

supply is also required.

An L.E.D. features a much longer life than an incandescent exciter lamp, and eliminates signal loss

because of sagging or aging bulb filaments. The one-piece Signal Pick-Ups detect only L.E.D. inputs, and

stray booth lighting does not affect the solar cell output. Channel separation is enhanced by incorporating the

solar cells within the sealed lens assembly.

Signal Pick-Up Assembly, ANALOG

L.E.D. Illuminators

Impedance Drum

Signal Pick-Up Assembly, DIGITAL

Film Path IN

Holdback

Sprocket

Film Path OUT

8

Page 14

The duty cycle (time ON) of the L.E.D. is the same as the projector motor and should parallel that of the

xenon bulb; the lamphouse elapsed hour meter should indicate approximate L.E.D. hours. L.E.D. manufacturers have noted a 10-20% drop in light output after prolonged operation. If a sound signal loss cannot be

corrected by fader gain, it may be necessary to replace the L.E.D. head.

WIRING

Install the LS-40 L.E.D. Power Supply to the projection console, pedestal, or to a rack adjacent to the

soundhead. Set the slide switch for the desired AC power , and connect to AC source. Route the power leads to the

soundhead-mounted L.E.D. illuminator assembly using 18 gauge wires for short runs; 16 gauge wires for excessively long runs. Other installer connections are made to the clearly-marked terminals on the back of the unit.

The L.E.D.’s are bipolar; the power supply cannot damage an L.E.D. through reversed polarity . It is safe

to try reversing the polarity if you have power but no light. Accidental connection of the L.E.D. to the pre-

amp power terminals will damage the L.E.D. The pre-amp power to the analog reader (Signal Pick-Up) is 12

V .DC+, ground, and 12 V.DC-. The ground must be connected at both ends as it is circuit reference zero volts.

It is recommended to use (2) shielded two-conductor cables to connect the solar cell outputs, but

use of a three-conductor, single-shield cable is permitted. If using three-conductor cable, strap the two “LO”

terminals together. Since very little current is required, 22 gauge wire is adequate. DO NOT interconnect

input and output grounds.

Digital readers utilize a second LS-40 Power Supply. Use 16 or 18 gauge hookup wire between the

L.E.D. and the LS-40 power supply , depending on the length of the run. Pre-terminated digital output cables

(51-98272) are supplied, and should be connected to the processor as instructed in the Dolby manual.

ANALOG ALIGNMENT

Energize the LS-40 and check for 450 mA output to the analog (inner) L.E.D. Connect test equipment to

solar cell output terminals. Turn the sound processor ’s level and high frequency adjustment to minimum

settings.

Loosen, but do not remove, the socket head screw clamping the inner L.E.D. head to its mounting post and

bracket. Loosening this screw permits moving the L.E.D. head up and down, and on the horizontal plane (in

and out). Position the L.E.D. head to visually locate the light source directly opposite the lens opening of the

analog signal pickup assembly .

Run a loop of level set (“Dolby Tone”) film and observe the output of the LEFT and RIGHT channels.

When the highest output is seen, move the L.E.D. head horizontally (in and out) inside the impedance drum.

DO NOT permit the L.E.D. head to touch the inside of the impedance drum. Observe the output and secure the

L.E.D. head when the highest output is achieved. Refer also to the sound processor manual.

Run a “Buzz Track” (SMPTE No. 35-BT) loop and check for correct sound track alignment. It is recommended to splice together a loop of half “Buzz Track” film and half “Left/Right Alignment” (Dolby Cat. No. 97)

test film. This permits centering the soundtrack and checking for cross-talk simultaneously. If correction is

required, loosen or tighten the 1/4-20 locknut to move the spring-loaded pickup assembly horizontally .

9

Page 15

Focus/Azimuth

Analog Signal

Pickup Assembly

Azimuth Adjust

Focus Adjust

Horizontal

Positioning

Locknut

Clamping Screw

L.E.D. Head

Clamping Screw

Impedance Drum

Loosen the focus/azimuth clamping screw and set the focus and azimuth by running the “pink noise” loop

and adjusting the signal pickup assembly in the same manner as a conventional slit lens. Finalize the “A”

chain installation by again checking the L.E.D. adjustment using Dolby Cat. No. 566 “illumination uniformity” test film. Perform a final “Dolby” level set, and complete any other steps specified by the manufacturer

of the sound processor.

DIGIT AL ALIGNMENT

Preliminary Adjustment

• Power up the second LS-40 Power Supply and the Audio Processor.

• Check for 550 mA output to the digital (outer) L.E.D.

• Connect a dual-trace oscilloscope to the left and right test points of the

Analog Soundtrack

processor pre-amp.

• Thread and run Dolby Tone Test film (Cat. No. 96t).

• Observe oscilloscope traces and “Dolby” level indicators in the processor.

• If tone is visible on both channels, set to “Dolby” level.

• If not, check the L.E.D. alignment and focus the optics. Then set

“Dolby” level.

• Thread and run SMPTE “Buzz” track.

• Adjust horizontal positioning locknut as required to obtain (2) very low ,

equal residual signals.

Analog L.E.D. Alignment

The analog L.E.D. must be aligned before the digital.

• Turn both left and right channel pre-amp gain adjustments on your cinema

processor to full down; if using a Dolby CP-500, turn to 50%. The goal is to

have equal gain on both channels.

• Thread and run Dolby Tone Test film (Cat. No. 96t).

• View the pre-amp outputs on the oscilloscope screen.

• Rotate the analog L.E.D. mount assembly to reach the maximum ampli-

tude of both traces.

• Move the assembly laterally to get both traces as high and equal as possible.

• Complete the standard “A” chain alignment.

Digital Soundtrack

10

Page 16

T o minimize microphonics, the L.E.D. must be very accurately aligned.

• With the power amplifiers OFF , turn the processor and monitor gains FULL UP. Select a film format and

the correct projector on the processor. Run the projector with no film. Fine-adjust the L.E.D. mount

rotation to a point where the sound of the projector running is not heard through the sound system. The

optimal adjustment will be found between two positions where the projector vibration can be heard quite

clearly . Run Dolby Tone again to give the system a final adjustment. The final result will be projector

noise that is below the noise floor of the processor.

• Optionally, connect an AC millivolt meter to one of the pre-amp test points. Rotate the L.E.D. mount to

achieve highest output to three decimal places on the AC millivolt meter . Careful peaking will achieve

the same result.

Digital Reader Alignment

• Thread and run a reel of Dolby-encoded film.

• Connect a dual-trace oscilloscope to the Dolby Digital Processor per the following instructions.

• Refer to the oscilloscope traces “A” - “D” on the following page in reference to the following instructions:

Figure B is in optimal alignment.

• In Figure A, the top of the sprocket hole has (12) large saw teeth. The differential between the high and

low points is 1/3 volt.

• Figure B shows more saw teeth with less differential. This is obtained by fine-adjusting the rotation of the

L.E.D. holder.

• In Figure C, the sprocket hole is falling off on the left, indicating uneven light. This is improved by

moving the L.E.D. holder laterally until a flatter trace is obtained.

• In Figure D, the CCD board is misaligned laterally. Dimension X2 is smaller than X1. This can be

improved by loosening the moving the board until the X1 and X2 dimensions look like Figure B. The correct

alignment is offset to the left by one minor division. That is, the sprocket hole will be 1/5 of a square offcenter toward the left “goal post”on the ‘scope screen.

Instructions for Alignment of Readers for Dolby Digital

1. Connect a dual-trace oscilloscope to test points on V ideo Acquisition Card (Cat. No. 605 or 670). Oscillo-

scope should be 20 MHz. minimum.

a) Connect Channel 1 to Video test point; connect this probe ground only to Gnd. test point.

b) Connect Channel 2 to Clamp test point.

c) Set both channels Volt/Div. controls to 1 volt/div. Set vernier to calibrate. Ensure that probes are

not at X10.

d) Set horizontal sweep rate to 2 usec/div.

e) Set trigger to channel 2 and positive polarity, adjust trigger level, and lock on signal.

11

Page 17

(Figure B is in optimal alignment)

12

Page 18

2. Calibrate oscilloscope to processor:

a) Thread a loop of Cat. No. 69P test film into projector and reader; start machine.

b) Select Channel 2 for display .

c) Adjust the horizontal position to line up the inside edge of the left “goal post” with the left edge

of the graticule.

d) Adjust the sweep vernier to line up the inside edge of the right “goal post” with the right edge of the

graticule.

e) Adjust the vertical position for the baseline of the clamp signal (Channel 2) to coincide with

a line in the lower section of the graticule.

f) Select either Alternate or Chop to give the brightest display of both channels.

g) Adjust the vertical position of the video signal (Channel 1) to coincide with the same line as the

clamp signal.

3. Alignment of the Reader:

a) Rotate the horizontal positioning locknut and roughly adjust the lateral position of the CCD board

so that the outer trace (perf) is centered between the “goal posts.” This is approximate, and will

be repeated later for accurate positioning.

b) Rotate the L.E.D. mounting assembly for maximum amplitude on the upper trace without

sacrificing flatness. The trace should vary one block or less (± .5 volt). As shown, Figure B is

improved from Figure C. Amplitude, as measured with the top trace, should be between 2-5

volts from baseline. Adjust the digital L.E.D. for minimum ripple on the upper trace of the video

signal. As shown, Figure B is improved from Figure A.

c) If available, use DRAS10 software and a laptop computer to view the adjustment of azimuth for a

zero degree reading. Or, center the reader rotation between sync lost points using the error rate

of the Digital Processor to indicate lost sync.

d) Adjust focus for darkest center in area of bits (grass). Confirm highest reading with DRAS.

e) Confirm calibration of oscilloscope as above. Readjust the lateral position to align the outer

trace to one minor division (2/10) left of center between the “goal posts.” Figure B is improved

from Figure D.

4. Final Analog:

Check the lateral alignment, as initially set using the “Buzz T rack,” and correct as required.

Confirm the L.E.D. positioning by setting the oscilloscope for “X-Y” display and running the

Dolby Cat. No. 97 loop. A “cross” should appear on the screen. When both the horizontal and

vertical lines are straight and of uniform length, the optimum position has been reached. Repeat

the tests for focus, azimuth, equalization, and “Dolby” level set. A dif ference may be noted in that

the high frequency range is extended, and very little high frequency boost will be required.

13

Page 19

Focus/Azimuth

Clamping Screw

Azimuth Adjust

Digital Signal Pickup

Assembly

Focus Adjust

L.E.D. Head

Clamping Screw

Impedance Drum

Horizontal Positioning Locknut

14

Page 20

START-UP PROCEDURES

ALL SIMPLEX PROJECTORS are carefully “run-in” at the factory before shipping. No

“run-in” period at the installation site is required. Some gear whine may be noticed initially, but should

disappear after a few hours of operation.

INITIAL OILING

One quart of Simplex Projector Oil is included in the accessory kit supplied with new equipment. USE

ONLY GENUINE SIMPLEX PROJECTOR OIL IN THE MECHANISM. Use of other lubricants may

inhibit oil pump operation and damage moving parts. Additional oil is available through authorized Strong

International Dealers; order Simplex Part No. 52-00400 for one-quart quantities, 52-00410 for a half-gallon

can, or 52-00420 for a one-gallon can.

DO NOT, at any time, operate the projector without oil.

With the projector level (0° projection angle), add oil through the filler located at the front of the gear

compartment. Look into the gear compartment while adding oil; the correct amount of oil will touch the bottom

of the horizontal drive shaft. No air bubble should be visible in the sight glass inside the film compartment.

Unless the machine is operated at a severe upward angle, no air should be visible in the sight glass. If

bubbles are seen, add oil to maintain a safe level. Always check the oil level with the motor off.

Normal Add Oil

Rotate the motor flywheel by hand to turn the projector mechanism. It should turn freely and smoothly .

Start the projector motor and run for at least one minute. Check for an oil splash against the gear compartment

cover glass.

15

Page 21

THREADING

Threading the projector correctly is one of the operator’s most important duties. Careful attention

during this operation pays off in improved performances and long print life.

Unlatch and open the turret. Rotate the framing handle (A)

to position the intermittent sprocket (B) at the center of its adjustment range. Using the motor flywheel, turn the mechanism by

hand to rotate the intermittent sprocket (B) to its “rest” position.

In the “rest” position, the intermittent sprocket is in a locked,

stationary stage while the other sprockets continue to rotate.

Open the feed (C) and holdback (D) sprocket pad roller assemblies. Open the film gate by pulling the gate opening pin (E)

and sliding the film gate forward to the threading position. Open

the intermittent sprocket roller arm (F).

At this time, it is advisable to dismount the film gate

pressure pad by sliding the gate to its full forward position, and

loosening the thumb screw (G). W ithdraw the pressure pad runner

from the film compartment and use a clean, dry cloth to wipe

down all film-bearing surfaces of the gate and trap. Replace the

pressure pad after cleaning and secure thumb screw (G). This

procedure should be performed at least once every day .

Thread the film as illustrated. Engage first the intermittent

sprocket (B), and check for correct frame position at the lighted

framing aperture (H). When correct, close the intermittent roller

arm (F). Secure the gate by pushing the gate into the trap until the

spring-loaded gate latching pin (E) engages. Form a two-finger

loop above the gate as illustrated, and on the loop chute below the

intermittent sprocket. Draw the film over the impedance drum (I)

and close the pad rollers over sprockets (C) and (D).

Rotate the motor flywheel by hand to advance a few frames of film. Do not “inch” the mechanism by

momentarily switching the drive motor on and off; in the event of a threading error , film may be damaged. Run

fingers over each sprocket (B, C, & D) to insure that the sprocket teeth are centered in the film perforations,

and the film is centered between the flanges of the pad rollers. Check again the position of the film in the

framing aperture (H). With the intermittent sprocket in its “rest” position, a correct frame image in the framing

aperture insures correct frame positioning in the picture aperture and on the screen. Use the framing handle (A)

to correct misframes. Close and latch the lens turret.

A slight degree of film tension is required above the upper feed sprocket (C) and below the holdback

sprocket (D). This measure prevents the film from snapping upon motor start.

16

Page 22

INITIAL OPERATION

CLEAN ALL FILM-BEARING SURF ACES BEFORE EACH THREADING OPERATION. Check

all sprocket teeth for hooks or burrs; replace if required. Keep all pad rollers clean and operating freely.

Make certain the turret is set to the correct lens and aperture for the desired screen format. FLAT format is

generally used for initial setup of the projection system.

The Film T rap Tension Knob is located at the top of the film trap, and is graduated from “minus” (-) to

“plus” (+). Rotate this knob counterclockwise to its stop. The “minus” (-) setting indicates minimum trap

tension. Thread film into the projector, ignite the lamp, and project a picture to the screen. Use of RP-40 test

film is highly desirable for this stage of machine set-up. This test film may be purchased directly from the

Society of Motion Picture and T elevision Engineers:

SMPTE Test Film Department

595 W est Hartsdale Avenue

White Plains, New York 10607

or

www.smpte.org

Order: 35 PA-50 (50 ft.) or 35 PA-200 (200 ft.)

Install the lenses and set focus as detailed in the preceding INST ALLATION section. File the apertures

to fit screen or masking parameters.

If the projected picture is unsteady , rotate the film trap tension knob clockwise one step at a time, while

the film is running. Always adjust for the minimum tension required to project a steady picture. Excessive

tension not only increases wear on projector parts, but in extreme cases may cause torn perforations and

film breakage.

Check the projected picture for travel ghost. “Travel Ghost” is the term commonly applied to vertical

streaking of lighter areas against a darker area, and is particularly noticeable during opening or closing titles

and credits. If ghosting is apparent, rotate the shutter adjustment knob on the top of the projector until the

ghosting disappears. If the ghost cannot be eliminated by means of this knob, see “Shutter Timing” in the

ADJUSTMENTS AND REPLACEMENTS section of this manual.

The rotation travel of the lens turret is limited by the indexing stop pin mounted to the outer ring of the

turret. The automated turret on the Apogee includes a solenoid which pulls the pin when the turret is in motion.

A compression spring seats the pin when the turret is at rest. When first energized, the autoturret will

automatically index to FLA T mode, if not already in FLA T . The proximity switch on the turret ring will sense

the cueing magnet mounted to the index stop bracket and set the correct picture aperture: one magnet mounted

inboard = FLAT, one magnet mounted outboard = SCOPE, two magnets = SPECIAL (third lens).

In the event of a turret or aperture motor failure, the automatic turret can be operated manually until a

replacement motor is obtained. It is advisable to de-energize the turret control until the replacement motor is

installed. The dual aperture plate can be pushed in or pulled out manually to set the correct format.

17

Page 23

MAINTENANCE

THE PROJECTOR MECHANISM should periodically undergo a careful and thorough

inspection. A regular schedule of adjustments and replacement of wearing parts will insure long life, provide

reliable performance, and minimize downtime.

LUBRICATION

Drain and discard the projector oil after six months of initial operation, and at least annually thereafter.

Clean the oil pump intake filter and the oil reservoir. Replace with genuine Simplex Projector Oil (Part No.

52-00400 Quart; 52-00410 Half Gallon; 52-00420 Gallon) available from Strong International Dealers.

SPROCKETS

Clean sprocket teeth daily with a typewriter brush or used toothbrush (with softened bristles). Examine

each sprocket carefully for wear, undercutting (“hooks”), and/or looseness. Replace as required. Assuming the projector is used for forward-running only , hooked sprockets can be re-used by reversing the sprocket on

its shaft. Check the alignment of the intermittent sprocket to the film trap.

PAD ROLLERS

Check pad rollers for grooves, flat spots, and/or looseness. Clean rollers and shafts thoroughly to relieve

binding; replace as required. Inspect alignment of pad rollers to sprockets; centered, flanges not rubbing,

spaced (2) film thicknesses above sprocket face.

FASTENING HARDWARE

Check all fasteners (screws, nuts) for tightness. Normal operating vibration over prolonged periods may

cause fasteners to loosen. Tighten as required.

FILM GATE

Remove all foreign matter (dirt, wax) by cleaning thoroughly. Examine film runners and straps for wear;

replace if required. Check gate opening and closing slide for smooth operation; clean linear bearing to relieve

binding. The gate mount is adjustable horizontally by means of slotted mounting holes; check periodically to

insure secure gate closure.

FILM TRAP

Examine the inboard spring-loaded studio guides for free motion. Clean carefully , adjust, or replace if

grooved. Remove all foreign material from tension straps. Inspect for wear; replace if required.

To remove the trap from the main frame, release the quarter-turn fastener securing the aperture motor

cover to the shutter guard. Loosen the slotted head of the trap mounting screw. This screw is captive, and

cannot be removed. When the trap mounting screw is loose, grasp the trap plate and withdraw the trap from the

film compartment. Carefully align the electrical pins before replacing the trap.

18

Page 24

MAINTENANCE (continued)

LENS TURRET

Periodically check the condition of the (2) O-ring drive tires on the auto turret drive wheel. Clean the

surfaces of the O-rings and replace if worn or cracked. DO NOT LUBRICA TE. Check the tension of the motor

mount expansion spring and replace if stretched.

The indexing plate of the lens turret rotates on (3) grooved ball bearings mounted to the turret ring

casting. The uppermost bearing is retained by means of an eccentric bushing, allowing a degree of adjustment.

To adjust, loosen the socket head bearing screw, and increase or decrease bearing pressure by rotating the

eccentric bushing with a 9/16 inch end wrench. Do not apply excessive pressure; allow the index plate to rotate

freely , but without “play” between the plate and ring.

On both AUT O and MANUAL turrets, the index stop is actuated by the a compression spring mounted

between the stop pin and the solenoid (or lever). Make certain the spring is correctly installed. Replace

immediately if worn; the correct spring tension is required to seat the index stop pin. The index stops on the

lens indexing plate are mounted with (3) screws each. Two of the mounting holes are slotted to provide a

degree of fine adjustment of the lens position. Securely tighten all (3) screws when the lens is correctly

positioned. See the following ADJUSTMENTS & REPLACEMENTS section for detailed information regarding lens alignment and positioning.

Magnets are mounted to brackets on the index stops to actuate the ring-mounted proximity switch and

establish lens/aperture logic. Periodically clean the exposed surfaces of these magnets to insure good magnetic

conduction. Keep mounting hardware tight to maintain correct alignment.

L.E.D. indicators next to the reset switch display operation of the aperture-sensing proximity switch.

When the center L.E.D. is illuminated, the proximity switch is sensing the inboard magnet, and setting the

FLAT aperture. The lower L.E.D. glows when the proximity switch senses the outboard magnet, and actuates

the SCOPE aperture. The uppermost L.E.D. glowing indicates that the proximity switch senses two magnets,

thereby setting the SPECIAL aperture (third lens, when used).

Clean the turret hinge to allow free operation. Make certain that the turret is fully closed when latched.

The deadstop screw in the front center of the turret casting can be adjusted to remove “play .” Do not shim the

turret, or offset the index stops in an attempt to correct “keystoning.” Keep lenses on correct optical centers.

Clean the lenses as recommended by the lens manufacturer. Do not remove the lenses from the turret for

cleaning; doing so would alter the preset focus of the lenses. Swing the turret open to the THREAD position for

easy access to the rear surfaces of the lenses. Close and latch the turret after cleaning the lenses.

OVERALL APPEARANCE

Clean all enameled surfaces of the projector regularly . Surfaces coated with oil will attract and hold dust

and film particles.

19

Page 25

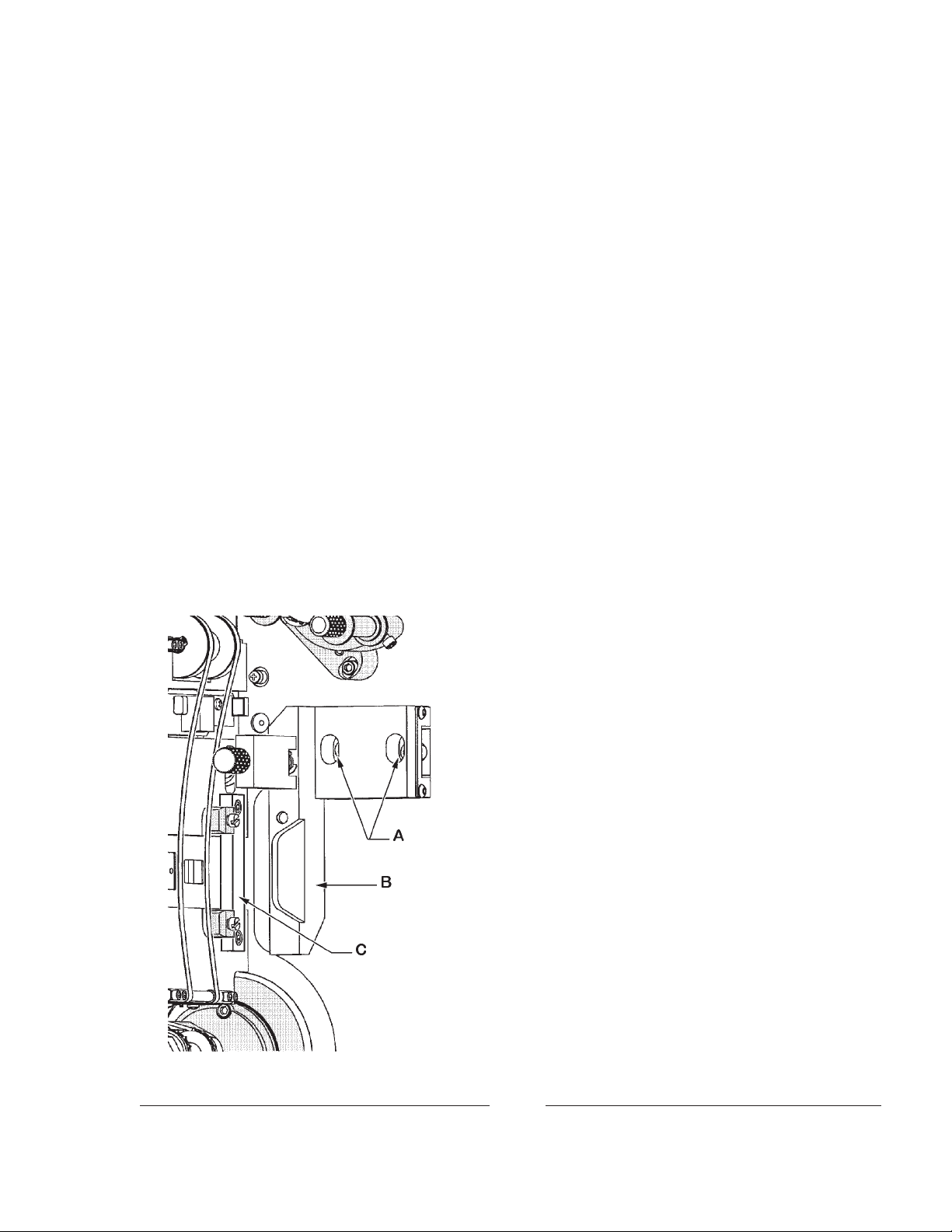

CHANGEOVER

DOUSER

HEAT

SHIELD

CHANGEOVER

DOUSER

PIVOT

DOUSER LINKAGE

ARM

SHUTTER

BLADE

FIGURE 3

COVER, APERTURE

MOTOR

FILM TRAP

20

Page 26

UPPER FEED

SPROCKET

DRIVEN GEAR

MAIN OIL

SUPPL Y LINE

VERTICAL SHAFT

SHUTTER

SHAFT

DRIVE GEAR

UPPER FEED

SPROCKET

DRIVE GEAR

OIL SLINGER

SHUTTER

ADJUSTMENT

KNOB

INTERMITTENT

MOVEMENT

OIL TRAP

SHUTTER

SHAFT

SUPPORT

INTERMITTENT

DRIVE GEAR

OIL PUMP

HOLDBACK

SPROCKET

DRIVEN GEAR

INTERMITTENT

MOVEMENT

FLYWHEEL

FRAMING

GEAR

HOLDBACK

SPROCKET

DRIVE GEAR

FIGURE 4

21

Page 27

ADJUSTMENTS AND REPLACEMENTS

REFER TO THIS SECTION in conjunction to performing the steps in the MAINTENANCE

section. Conscientious maintenance and service of the Simplex Apogee Projector Mechanism will insure many

years of excellent performance.

ADJUSTMENTS are quickly accomplished, and replacements performed, as all units and

components are readily removed. Adjustments and replacements described below may be performed by

qualified projection booth personnel. Any elements of maintenance and service not detailed below should be

referred to an authorized Strong International Dealer .

FILM TRAP AND APERTURE CHANGER ASSEMBLY

Dismount the aperture motor cover plate (see Parts List, “Film Trap” drawing, Item 53) by releasing the

quarter-turn fastener (Item 54) and loosening the (2) phillips head screws (Item 44). Loosen the captive, slot

head mounting screw (Item 34) and remove the trap assembly from the film compartment.

T o replace, make certain that the contacting surfaces on both the mounting plate and the trap casting are

clean. Align the pins of the electical connector pins and slide the film trap in so that it registers with the (2)

dowel pins in the main frame. Carefully guide the electrical plug into its receptacle for the the aperture change

motor and framing light PC board connection. Securely tighten the captive mounting screw.

Check the alignment of the intermittent sprocket to the film trap (see INTERMITTENT MOVEMENT

section following).

PRESSURE STRAP REPLACEMENT

Dismount the film trap and associated components. Rotate the trap tension knob fully counterclockwise

to the “minus” (–) position. Remove the (2) screws from each strap, and remove the straps. Replace with new

straps and reassemble. NOTE: Project film to reset gate pressure (see START-UP PROCEDURES).

STUDIO GUIDE REPLACEMENT

Remove the film gate runner and open the turret assembly. Remove the (2) socket head screws to dismount the fixed, outboard studio guide. Position and install the replacement outboard studio guide. The two

spring-loaded inboard studio guides, which serve as lateral guides, can be dismounted by removing the (2) slotheaded shoulder screws. Clean the spring channels and inspect the springs for proper tension before replacing.

Close the turret and replace the film gate.

APERTURE PLATE ADJUSTMENT

Gear mesh between the aperture drive motor spur gear and the rack gear on the aperture slide can be set

by loosening the (2) 10-32 socket head screws and moving the motor, on its mounting plate, up or down. The

motor plate mounting holes are slotted for this purpose.

22

Page 28

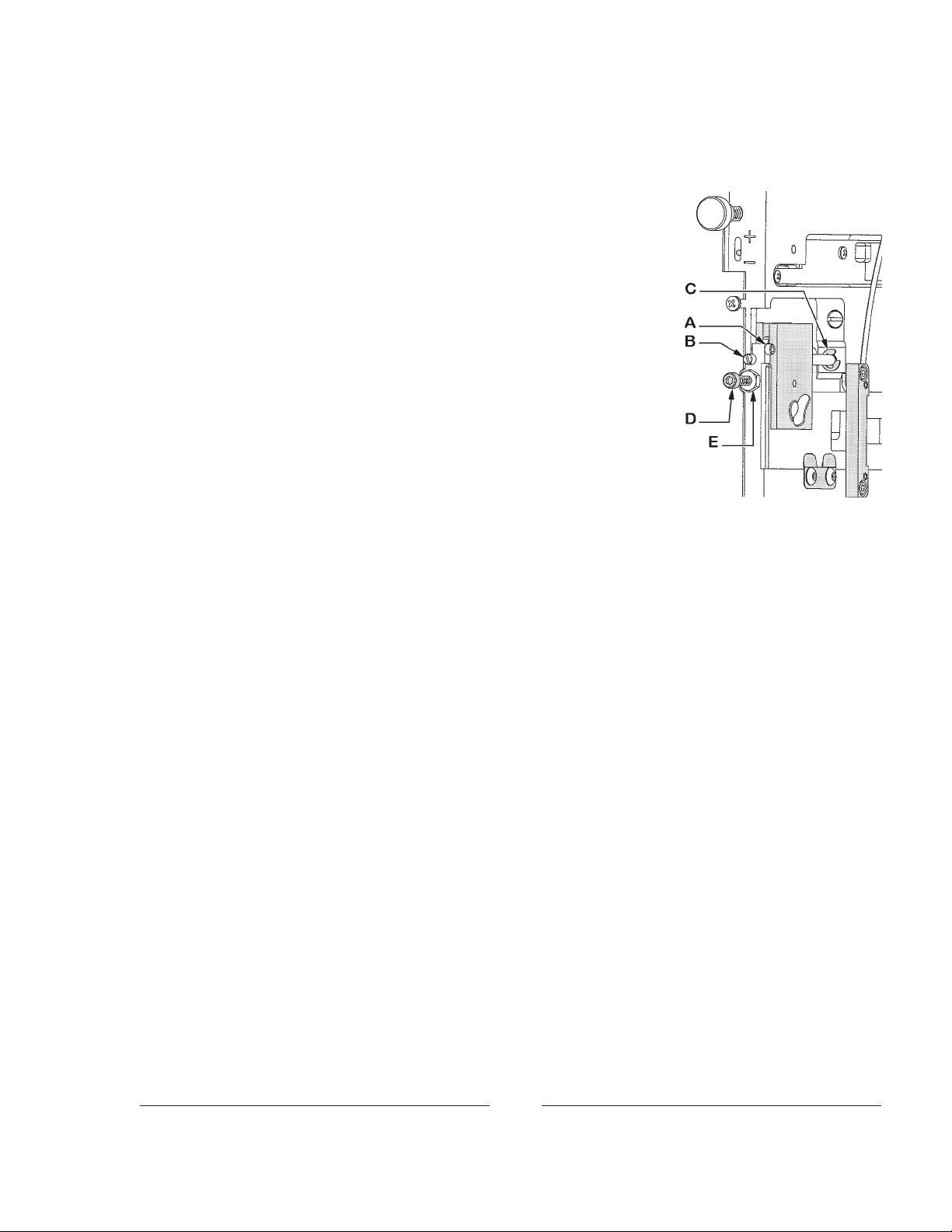

APERTURE PLATE ADJUSTMENT (continued)

Horizontal travel of the aperture plate is also adjustable. The inboard

stop is set by loosening the clamping screw (A) and rotating the slotted end of

the slide shaft (B) to position the snap ring (C) at the desired stop point.

Secure the clamping screw (A) after the adjustment is correct. The outboard

stop is fixed by tightening or loosening stop screw (D) against the aperture

slide bracket. Secure lock nut (E) after the outer stop adjustment is correct.

GEAR COMPARTMENT COVER REMOVAL

Remove the gear compartment cover only when absolutely necessary ,

and only after the machine has been at rest for at least (10) minutes to allow all

oil to drain into the reservoir. Remove the cover fastening screws. Make

certain no foreign material deposits in the gear compartment while the cover

is removed. Before replacing the cover, wipe all oil from the cover gasket and

the mating surface on the projector main frame. Any oil remaining on these

surfaces will provide an oil seepage path after the cover is replaced. Tighten all

screws equally and in sequence, and secure enough to form an oil-tight seal.

INTERMITTENT MOVEMENT REPLACEMENT

1. Open the film gate. Rotate the framing handle fully clockwise.

2. Set the shutter adjusting knob in mid-position. The shutter adjusting knob travels three complete turns.

T o locate mid-position, rotate the knob to either stop, and reverse 1½ turns.

3. Remove the gear compartment cover (see above).

4. Rotate the vertical shaft until the intermittent drive gear mounting screw is visible. Remove the mounting

screw and slide the gear downward.

5. Loosen the (2) intermittent retaining clamp screws on the framing cam and position the clamps to clear the

intermittent case.

6. W ithdraw the intermittent assembly from the gear compartment side, taking care not to strike the inter-

mittent oil feed tube positioned above the intermittent assembly.

7. Slide the replacement intermittent movement into position. The keyway in the intermittent case is aligned

with the key in the framing cam. Press firmly to seat the O-ring.

8. Rotate the intermittent retaining clamps to retain the intermittent assembly and tighten the fastening

screws securely .

9. Rotate the shutter counterclockwise (from the rear of projector) until its leading edge is exactly in line

with the upper edge of the picture aperture (aperture just completely blocked).

10. Rotate the intermittent flywheel until the intermittent sprocket turns clockwise; (1) of the (4) index lines

on the outboard collar will align with the index line on the outboard bearing support arm.

11. Continue to rotate the flywheel in the same direction until the intermittent sprocket just begins to move.

12. Reverse rotation of the flywheel until the sprocket stops. Then, rotate the flywheel counterclockwise

until the start of sprocket rotation is felt.

13. Continue to rotate the flywheel until the precise point at which the sprocket is about to move is reached.

Retain that setting.

14. Raise the intermittent drive gear and rotate it tooth by tooth until it meshes with the intermittent driven

gear. At this time, the mounting hole in the drive gear should align with the hole in the vertical shaft. Do

not rotate the vertical shaft or driven gear. Replace the gear mounting screw.

15. Align the intermittent sprocket with the film trap (see below).

23

Page 29

INTERMITTENT SPROCKET REPLACEMENT

1. Remove the film gate runner . Dismount the film trap. Open the intermittent sprocket pad arm.

2. Rotate the framing knob to its extreme clockwise position to expose the intermittent sprocket film stripper

mounting screw . Remove the screw and stripper .

3. Turn the projector mechanism by hand so that one of the collar index lines (A) aligns with the index mark

on the outboard arm (B), and the sprocket mounting screw is exposed.

4. Remove the intermittent sprocket mounting screw and nut.

5. Loosen the (2) intermittent outboard collar set screws and remove the collar (C).

6. Remove the (2) outboard arm socket head mounting screws and dismount the outboard arm (D).

7. Remove the worn intermittent sprocket. Slide the replacement sprocket onto shaft.

8. Position the intermittent outboard bearing arm (D) on the intermittent sprocket shaft and start the (2)

socket head mounting screws finger tight. Adjust the bearing arm, as required, so that the bearing is

precisely centered with respect to the intermittent shaft. Tighten the (2) mounting screws.

9. Fasten the replacement intermittent sprocket to the intermittent shaft using the screw and nut supplied.

10. Slide the intermittent outboard collar (C) onto the intermittent shaft and align one of its index lines (A) to

the index mark on the outboard bearing arm (B). Pull the intermittent sprocket out while pressing the

outboard collar in, so that shaft end play is just perceptible.

11. Securely tighten the (2) set screws in collar (C). Check that the

shaft end play is just perceptible.

12. Replace intermittent sprocket film stripper .

13. Align the intermittent sprocket (see below).

14. Replace film trap and install the film gate runner .

INTERMITTENT SPROCKET ALIGNMENT

Loosen the intermittent sprocket fastening screw and slide the sprocket, as required, until the outside face

of the sprocket is flush with a straight edge (i.e. machinist’s steel pocket ruler) placed on the outside face of the

lower holdback sprocket. Securely tighten the intermittent sprocket fastening screw . Thread a length of scrap

film through the trap between the upper sprocket and the intermittent sprocket to verify correct alignment.

FRAMING LIGHT REPLACEMENT

Remove the film trap. Dismount the L.E.D. Printed Circuit Board assembly from the trap plate (three

screws); replace with new unit (Part No. 52-00353). Align the pins of the electical connectors and slide the film

trap in so that it registers with the (2) dowel pins in the main frame; secure the captive mounting screw.

FEED AND HOLDBACK SPROCKET PAD ROLLER ADJUSTMENT

For coarse adjustment, loosen the three socket head mounting screws securing the pad roller assembly to

the main frame. Position the pad roller assembly so the rollers are at an equal distance from the face of the film

sprocket. Secure the three screws.

For fine adjustment, loosen the socket head screws securing the roller shafts to the roller arm. The shafts

are eccentric; rotating the shaft will move the roller closer to or farther from the sprocket face. Rotate each

roller shaft to position each roller (2) film thicknesses from the face of the sprocket. If the roller cannot be

placed at this position, reset the coarse adjustment. Secure the shafts after reaching the correct setting.

24

Page 30

SHUTTER TIMING

1. Place the shutter adjusting knob in its mid-position. To locate mid-position, rotate the knob to its stop,

and reverse 1½ turns. Remove the shutter guard.

2. Turn the projector mechanism by hand so that the index mark on the intermittent outboard bearing arm

is centered between two of the collar index lines.

3. Loosen the (2) socket head shutter hub clamping screws. With the screws loosened, the shutter blade

should rotate freely on its shaft while the shaft remains stationary.

4. Hold the motor flywheel to “freeze” the mechanism, so the shutter shaft remains stationary . Rotate the

shutter to the fully closed position (one blade completely covering the picture aperture).

5. Tighten the (2) hub clamping screws while the shutter shaft remains stationary.

6. Replace the shutter guard. Project a picture and check the screen; a slight adjustment of the shutter fine

adjustment knob on the top of the projector may be required to eliminate travel ghost (see preceding

START-UP PROCEDURES).

SHUTTER REPLACEMENT

Remove the shutter guard. Disconnect the linkage to the changeover douser. Remove the (4) socket

head mounting screws from the rear cover casting, and dismount the cover. Loosen the (2) shutter hub

clamping screws and dismount shutter. Install the replacement shutter and set shutter time as detailed in the

preceding section. Replace the rear cover, douser linkage, and shutter guard.

FILM GATE PRESSURE PAD & CARRIAGE REPLACEMENT

1. Open the turret. Dismount the gate pressure pad runner

by loosening the captive thumb screw and removing the

runner from the gate carriage.

2. Remove the sliding gate carriage and bearing assembly

after dismounting the pressure pad runner. Slide the film

gate carriage back to the “closed” position to expose the

two socket head mounting screws (A). Remove the

mounting screws and withdraw the carriage and bearing

assembly (B) from the film compartment.

3. To replace the film gate carriage assembly , install it to the

main frame using the two socket head mounting screws

(A). Do not tighten the mounting screws until aligning the

gate carriage (B) to the trap.

4. Close the film gate carraige and check the alignment between the gate carriage and the trap. The pressure pad

plate must be parallel to the trap. Set the spacing between

the gate carriage and the trap by placing a 9/64 inch allen

wrench between the face of the inner studio guide spring

block (C) and the gate carriage (B) with the carriage closed.

Hold the carriage in place (against the allen wrench) and

securely tighten the two mounting screws (A).

5. Replace the pressure pad runner. Close and latch the

turret. Set the trap tension to “minus” (–). Project some

film and check the picture for stability . Reset trap tension

as required.

25

Page 31

FILM SPROCKET REPLACEMENT

1. Open the pad roller arm.

2. Remove the hex head sprocket fastening screw from the outboard end of the sprocket shaft and slide the

sprocket from the shaft. Leave the spring washer and flat washer on the shaft.

3. Slide the replacement sprocket onto the sprocket shaft, aligning the key in the sprocket with the keyway in

the shaft. Secure with the sprocket fastening screw .

FILM SPROCKET DRIVEN GEAR REPLACEMENT

1. Remove the gear compartment cover (see previous).

2. Remove gear fastening screw and slide gear from shaft.

3. Hold the film sprocket in place and slide the replacement gear onto the shaft. Insert the fastening screw ,

position the gear to allow slight end play , and securely tighten the fastening screw.

4. Replace the gear compartment cover .

AUTOMATIC LENS TURRET

1. Check for correct contact between the turret drive tires and the driven indexing plate. Clean surfaces to

prevent dust and dirt build-up; replace O-ring tire(s) if cracked or worn. Do not lubricate.

2. Clean the grooves in the (3) indexing plate ball bearings. The top bearing is mounted to an eccentric

bushing to permit adjustment; take up any slack as required.

3. Check the compression spring on the index stop pin. Replace with

new, or stretch to length. Check the expansion spring on the motor

mount and replace if excessively stretched and allowing slippage.

4. A headless set screw in the front center of the turret casting (see Figure

1) acts as a deadstop for turret closure. Tighten this screw as required to

remove any play from the turret hinge when closed, yet allowing the

turret to latch securely . T ighten the hex nut to lock this adjustment.

NOTE: Do not attempt to correct “keystoning” by setting this deadstop

screw to offset the projection lenses. Lenses must remain on optical

center for correct focus.

5. Periodically check lens positions and correct as required. Project RP-40

Test Film to the screen and alternate between formats. If the picture

noticeably shifts up and down or left to right between formats, the lenses

should be re-positioned.

5a. The index stops are mounted to the inside of the lens indexing plate with

three screws. T wo of the screw holes are slotted to permit fine adjustment of the vertical lens position. Adjust the up-and-down position of

the picture on the screen by loosening the two locking screws (A) and

turning the slot-headed eccentric stud (B). When the up-and-down lens

position is correct, securely tighten the two locking screws (A).

5b. Left-to-right positioning of the picture on the screen is adjusted by setting the two button head socket

screws (C) adjacent to the lens on either side of the focus knob (D). Loosen the screws (C) slightly using

a 3/16" allen wrench, and adjust the side-to-side position using a 7/32" allen wrench to rotate the adjusting

screw (E). This moves the horizontal eccentric adjustment. Securely tighten the two button head screws

(C) when the picture is correctly positioned horizontally .

26

Page 32

AUTOMATIC LENS TURRET (continued)

6. If a lens change fails to execute when cued, press the reset switch until the desired format is in place.

Check the condition of the cuing material; foil tape may be worn, or bar code information may be

obscured by scratches or dirt. Check for faulty cue detector or failed contact in automation controller.

7. A malfunction in aperture/turret logic indicates a problem in the turret control board. Consult the factory .

There are no user-serviceable components on the printed circuit board.

8. Periodically check the condition of the magnets mounted to the index stops; clean the surfaces of the

magnets to allow good conduction. These magnets are sensed by the proximity switch on the turret ring to

determine aperture logic. A single magnet mounted inboard denotes FLAT, a single magnet on the

outboard edge denotes SCOPE, and two magnets (inboard and outboard) indicate SPECIAL (three-lens

turret only). The magnets are to be positioned close enough to the proximity switch to permit accurate

detection, but should not obstruct turret rotation.

9. L.E.D. indicators next to the reset switch display operation of the aperture-sensing proximity switch.

When the center L.E.D. is illuminated, the proximity switch is sensing the inboard magnet, and setting the

FLAT aperture. The lower L.E.D. glows when the proximity switch senses the outboard magnet, and

actuates the SCOPE aperture. The uppermost L.E.D. glowing indicates that the proximity switch senses

two magnets, thereby setting the SPECIAL aperture (third lens, when used). Failure of the L.E.D. indicator, and/or failure of the aperture to cycle, means that the magnet(s) or the proximity switch are loose or

out of alignment; adjust as required.

27

Page 33

PARTS LISTS

Simplex Apogee

Item Part No. Description

1 51-59005 Film Sprocket, Type VKF

®

- 51-51033 Sprocket Retaining Screw

- 51-70023 Wave Spring Washer

- 51-70024 Thrust Washer

- 51-52017 Sprocket Shaft, Upper & Lower

- 51-04025 Shaft Bearing, Film Side

- 52-00370 Shaft Bearing, Gear Side

- 51-00185 Driven Gear, Upper & Lower

2 52-00284 Gear Compartment Cover

- 31-71017 Oil Seal Cord (order 4 feet)*

- 4110751 Mounting Screw, 10-24 x 3/4"

- 41-07102 Black Fiber Washer, #10

3 52-00282 T urret Hinge Bracket (2 req’d.)

- 4250755 Mounting Screw, 1/4-20 x 3/4"

Item Part No. Description

4 52-00323 Turret Catch

- 52-00396 Lock Nut, 1/2-13 Hex

5 52-00291 Strike Plate, Deadstop Screw

- 4040253 Screw, 4-40 x 1/4"

6 21-38016 Brass Elbow, 90°

- 21-36005 Oil Fill Cup

- 21-38017 Threaded Nipple

7 51-37032 Turret Hinge Pin (2 req’d.)

- 425050A Set Screw, 1/4-20 x 1/2"

8 52-00050 Framing Cam

9 51-98201 Petcock, Oil Drain

- 51-26001 Drain Hose (order by foot)

10 51-98200 Oil Sight Glass

11 52-00325 Main Frame Casting

* T o prevent oil leakage, begin installing replacement cord at the top of the cover, and do not stretch the cord

28

Page 34

FILM GATE

Assembly No. 52-00214

Item Part No. Description

1 52-00209 Gate Carriage & Bearing Assembly

2 52-00212 Film Gate Runner

3 52-00211 Support Plate, Gate Release

4 52-00213 Gate Runner Retaining Screw

5 81-58016 Compression Spring, Gate Release

6 81-56012 Gate Release Spacer

7 52-00350 Pin Assembly, Gate Release

8 21-48016 Retaining Ring, 1/4" External

9 81-48007 Snap Ring, Truarc

10 21-37001 Dowel Pin, 1/2" x 1/4" Diameter

11 4060751 Screw , 6-32 x 3/4" Socket Head

29

Page 35

FILM TRAP

Assembly No. 52-00223

30

Page 36

FILM TRAP & APERTURE CHANGER

Parts List

Item Part No. Description

1 52-00215 Film Trap Base Plate

2 52-00217 Tension Strap Shaft, Lower

3 52-00218 Tension Strap Shaft, Upper

4 52-00219 Upper Tension Shaft Spacer

5 52-00220 Tension Spring Shaft

6 52-00221 Dual Aperture Plate

7 52-00222 Tension Strap (2 req’d.)

8 52-00224 Studio Guide, Fixed

9 82-00115 Slider Bracket

10 81-98141 Rack Gear

11 81-10016 Clamp Plate

12 52-00225 Tension Lever

13 52-00226 Tension Indicator

14 52-00227 Aperture Motor Mount

15 52-00228 Motor Cover

16 52-00229 Studio Guide, Movable (2 req’d.)

17 52-00230 Spring Holder, Studio Guides

18 52-00216 Upper Tension Strap Mount (2 req’d.)

19 71-37002 Dowel Pin, 1" x 1/4" Diameter

20 51-10013 Aperture Clamping Spring

21 52-00345 Dual Aperture Plate Slide Rod

22 4040621 Screw, 4-40 x 5/8" Socket Head

23 4040373 Screw, 4-40 x 3/8" Socket Head (8 req’d.)

24 4080253 Screw, 8-32 x 1/4" Button Head (2 req’d.)

25 4060372 Screw, 6-32 x 3/8" Socket Head (4 req’d.)

26 21-51032 Shoulder Screw, .25" x .25" 10-24 Thrd.

27 4040252 Screw, 4-40 x 1/4" Socket Head (2 req’d.)

28 4100500 Screw, 10-32 x 1/2" Socket Head (2 req’d.)

29 408037C Set Screw, 8-32 x 3/8"

30 21-37030 Roll Pin, 3/8" x 1/16" Diameter (4 req’d.)

31 21-48016 Snap Ring, Truarc 5100-25 (2 req’d.)

32 21-58032 Compression Spring (2 req’d.)

33 81-48002 Retaining Ring

34 52-00352 Trap Mounting Screw, Captive

35 51-48017 Retaining Ring (for Item 34)

36 52-00231 Tension Adjusting Knob

37 4252002 Set Screw, 1/4-20 x 2"

38 52-00232 Shoulder Screw, S tudio Guide (2 req’d.)

39 4040120 Screw, 4-40 x 1/8" Pan Head (7 req’d.)

40 52-00353 Printed Circuit Board Assembly, Motor/Frame Light

- 52-00357 Wire Harness, Trap PCB to Controller Cabinet

31

Page 37

FILM TRAP & APERTURE CHANGER, Parts List (continued)

Item Part No. Description

41 21-37008 Dowel Pin, 1/2" x 1/8" Diameter (2 req’d.)

42 52-00359 Aperture Plate Drive Motor Assembly

- 81-33017 Gear Motor; 12 V.DC, 72 rpm

- 82-20371 Spur Gear

- 4060123 Set Screw, 6-32 x 1/8

- 21-37055 Molex Plug, (2) Pin

- 41-98055 Grommet, Rubber

43 51-37009 Groove Pin, 1/4" x 1/8" Diameter

44 4060250 Screw, 6-32 x 1/2" Pan Head (4 req’d.)

45 81-37011 Spring, Aperture Catch

46 4030181 Screw , 3-48 x 3/16" Socket Head (2 req’d.)

47 51-70037 Washer , #3 (2 req’d. with Item 46)

48 4040620 Screw, 4-40 x 5/8" Pan Head (2 req’d.)

49 82-20448 Bushing

50 81-98121 Latching Stud, Wing Head

51 81-37022 Dowel Pin, 1.125" x .125" Diameter

52 51-58007 Expansion Spring, Strap Tension

53 52-00375 Aperture Motor Cover

- 52-00452 Sticker, “Threading Diagram” (not shown)

54 31-98209 Fastener, Quarter-Turn

DETAIL, Item 42

4060123

82-20371

81-33017

32

Page 38

TRAP BLOWER

Assembly No. 52-00387

Item Part No. Description

1 52-00338 Trap Heat Sink

2 52-00339 Heat Shield

3 52-00343 Air Channel

4 4060250 Screw, 6-32 x 1/4"

Pan Head (4 req’d.)

Blower Power Supply 51-98422 (OMROM T ype S85K, not shown) not included with 52-00387; order separately

Item Part No. Description

5 52-00379 Plug, Air Channel

6 51-02002 Blower, 12 V.DC

7 51-02003 Blower Grille

8 4081250 Screw, 8-32 x 1-1/4" Button

Head, (8 req.d.)

33

Page 39

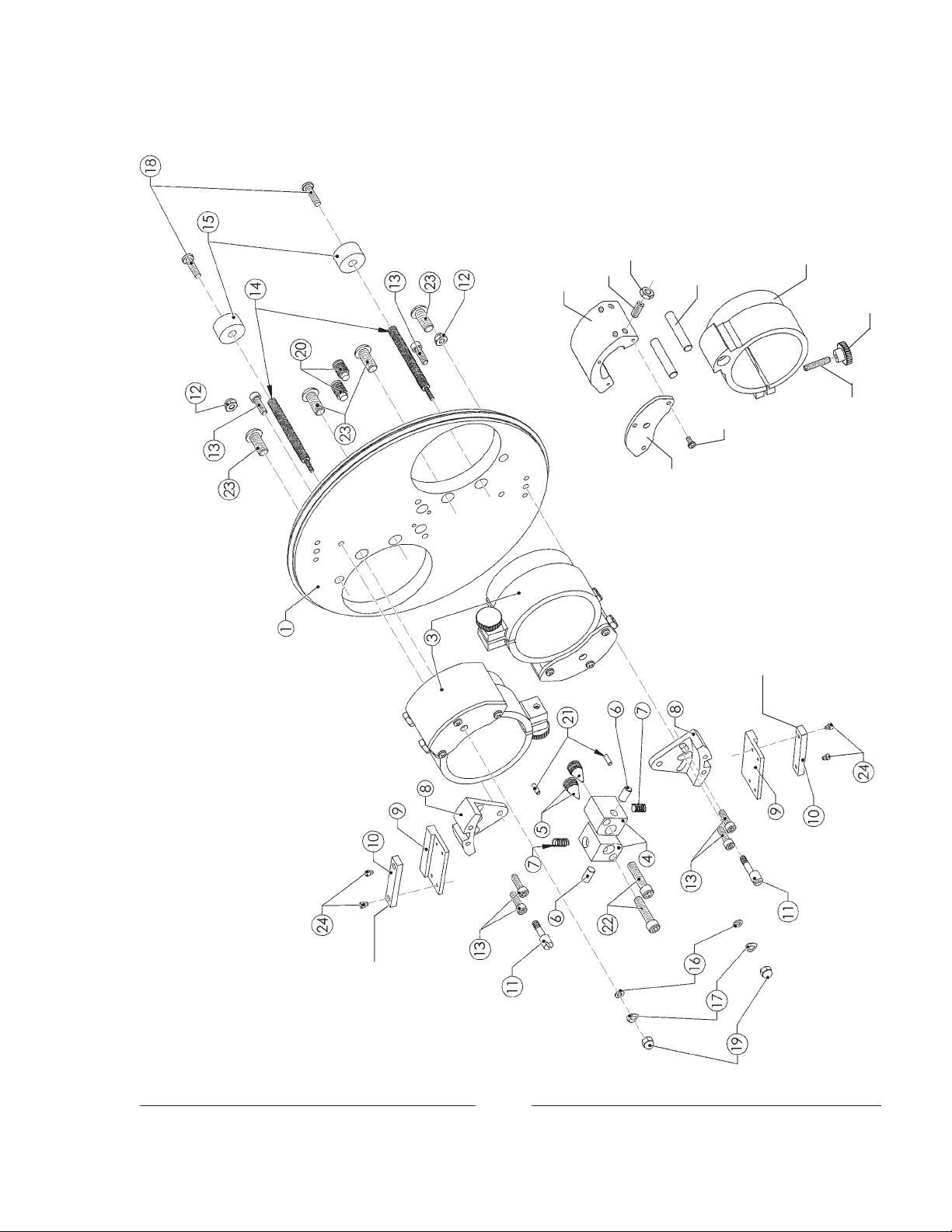

APOGEE LENS TURRET

Assembly No. 52-00279

34

Page 40

APOGEE LENS TURRET

Parts List

Item Part No. Description

1 52-00272 Turret Ring Casting

2 51-07012 Straight Bushing (2 req’d.)

3 51-49010 V -Groove Bearing (3 req’d.)

4 4257102 Washer, 1/4" I.D. 5/8" O.D. (3 req’d.)

5 4251250 Screw , 1/4-20 x 1-1/4" Socket Head (3 req’d.)

6 52-00263 Turret Lens Plate Assembly, Two-Lens

- Turret Lens Plate Assembly Three-Lens (not shown)

7 51-07013 Eccentric Bushing (Top Position only)

8 52-00268 Motor Bracket

9 52-00267 Motor Spacer Bracket

10 4060310 Screw, 6-32 x 5/16" Pan Head (3 req’d.)

11 52-00355 T urret Drive Gear Assembly

- 51-23005 Driven Gear

- 52-00265 Shaft, Drive Gear

- 51-37011 Roll Pin, 3/32" x 9/16"

12 4257108 Shim W asher, .021" Thick (2 req’d.)

13 52-00269 Motor Bracket Spacer

14 52-00270 Drive Wheel Positioning Block

15 4060372 Screw, 6-32 x 3/8" Socket Head (4 req’d.)

16 52-20613 T urret Plate Drive Wheel

17 4100252 Set Screw, 10-32 x 1/4"

18 21-48001 Drive Tire (2 req’d.)

19 52-00271 T urret Drive Motor Assembly

- 51-33004 Motor, 12 V.DC

- 21-40019 Molex Plug, (2) Pin

- 31-62007 Molex Pin (2 req’d.)

- 51-23011 Worm Gear

- 21-37026 Roll Pin, 3/32" x 3/8"

20 4040250 Screw, 4-40 x 1/4" Pan Head (3 req’d.)

21 52-20641 Spring Retaining Rod (P-7843)

22 21-51032 Shoulder Screw, 1/4" x 1/4" Dia. 10-24 Thrd. (2 req’d.)

23 52-00480 Motor Stabilizing Bracket

24 51-58018 Motor Tensioning Spring (P-2807)

25 52-00337 Motor Housing Assembly

26 52-00363 Turret Switch & L.E.D. Assembly

27 41-98049 S tandoff, 4-40 x 1/2" Nylon (2 req’d.)

28 4048001 Hexnut, 4-40 (2 req’d.)

29 4040251 Screw, 4-40 x 1/4" Button Head (2 req’d.)

30 52-00340 Cover, Motor Housing

35

Page 41

LENS TURRET, Parts List, continued

Item Part No. Description

31 4060250 Screw, 6-32 x 1/4" Pan Head

32 52-00322 Turret Latch

33 51-51011 Shoulder Screw (2 req’d.)

34 21-58060 Compression Spring

35 4370500 Set Screw, 3/8-16 x 1/2"

36 4372005 Deadstop Set Screw, 3/8-16 x 2-1/4"

37 4378001 Deadstop Lock Nut, 3/8-16 Hex

38 52-00277 Sensor Board Mounting Bracket

39 52-00278 Aperture Logic Sensor Board

40 51-56002 Spacer, Nylon (3 req’d.)

41 4040372 Screw, 4-40 x 5/8" Button Head (3 req’d.)

42 4060370 Screw, 6-32 x 3/8" Pan Head (for Item 38)

43 51-04015 Oilite Bushing, Index Stop Pin

44 52-00275 Solenoid Mounting Bracket

45 4080250 Screw, 8-32 x 1/4" Pan Head

46 52-00273 Index Stop Pin

47 52-00274 Index Stop Pin Pivot Plate

48 51-98254 Clevis Pin, 1/8" (P-7966), 2 req’d.

49 01704000 Spring Pin (2 req’d.)

50 52-00397 Solenoid, 12 V.DC

51 51-58059 Compression Spring

52 52-00346 Solenoid Cover Assembly

53 51-37032 Hinge Pin, 2-1/4" x .5" Dia. (2 req’d.)

54 52-00282 Hinge Bracket (2 req’d.)

- 4250755 Mounting Screw , 1/4-20 x 3/4" Socket Head

55 21-70016 Fiber Washer, .505" I.D. x 3/4" O.D.

56 425050A Set Screw, 1/4-20 x 1/2" (2 req’d.)

NOT SHOWN

52-00451 Wire Harness, Motor & Solenoid to Controller

52-00453 Wire Harness, Selector Switch to Controller

36

Page 42

TURRET LENS PLATE

Assembly No. 52-00263

3a

3b

3c

3i

3d

3h

for FLAT cue

Magnet INBOARD

3e

3f

3g

Magnet OUTBOARD

for SCOPE cue

37

Page 43

TURRET LENS PLATE ASSEMBLY

Parts List

Item Part No. Description

1 52-00258 Indexing Plate, Two-Lens

- 52-00259 Indexing Plate, Three-Lens (not shown)

2 52-00320 Labels (not shown) FLAT - SCOPE

3 52-00257 Lens Barrel Assembly (includes Items 14,16,17,19)

3a 52-00255 Slide Mount

3b 4100626 Set Screw, 10-32 x 5/8" (4 req’d.)

3c 4108001 Lock Nut, 10-32 (4 req’d.)

3d 52-20596 Slide Rod (2 req’d.)

3e 52-00254 Lens Barrel Casting

3f 21-28022 Knob, Black Plastic

3g 4101005 Set Screw, 10-32 x 1"

3h 4060310 Screw, 6-32 x 5/16" Pan Head (3 req’d.)

3i 52-00256 Lens Mount, Rear Cover Plate

4 52-00260 Spring Housing Block

5 52-00261 Horizontal Adjust Screw

6 52-00262 Push Rod

7 21-58040 Compression Spring

8 52-20769 Catch Bracket, Index Stop

9 52-00281 Magnet Mounting Bracket

10 51-61017 Bar Magnet

11 52-20618 Eccentric Screw , Index Stop Adjust

12 4108002 Hexnut, 10-32 NyLock

13 4100620 Screw , 10-32 x 5/8" Socket Head

14 52-20604 Focus Shaft

15 21-28010 Focus Knob

16 4067101 Flatwasher, #6

17 21-70028 Wave Spring Washer, #6

18 4100751 Screw, 10-32 x 3/4" Pan Head

19 4068002 NyLock Nut, 6-32

- 4068004 Hexnut, 6-32 (not shown)

20 4370620 Set Screw, 3/8-16 x 5/8" Dog Point

21 01513210 Roll Pin, 1/16 x 5/8"

22 4251250 Screw , 1/4-20 x 1-1/4" Socket Head

23 4320750 Screw , 10-32 x 5/8" Button Head

24 4040121 Screw , 4-40 x 1/8" Socket Head

38

Page 44

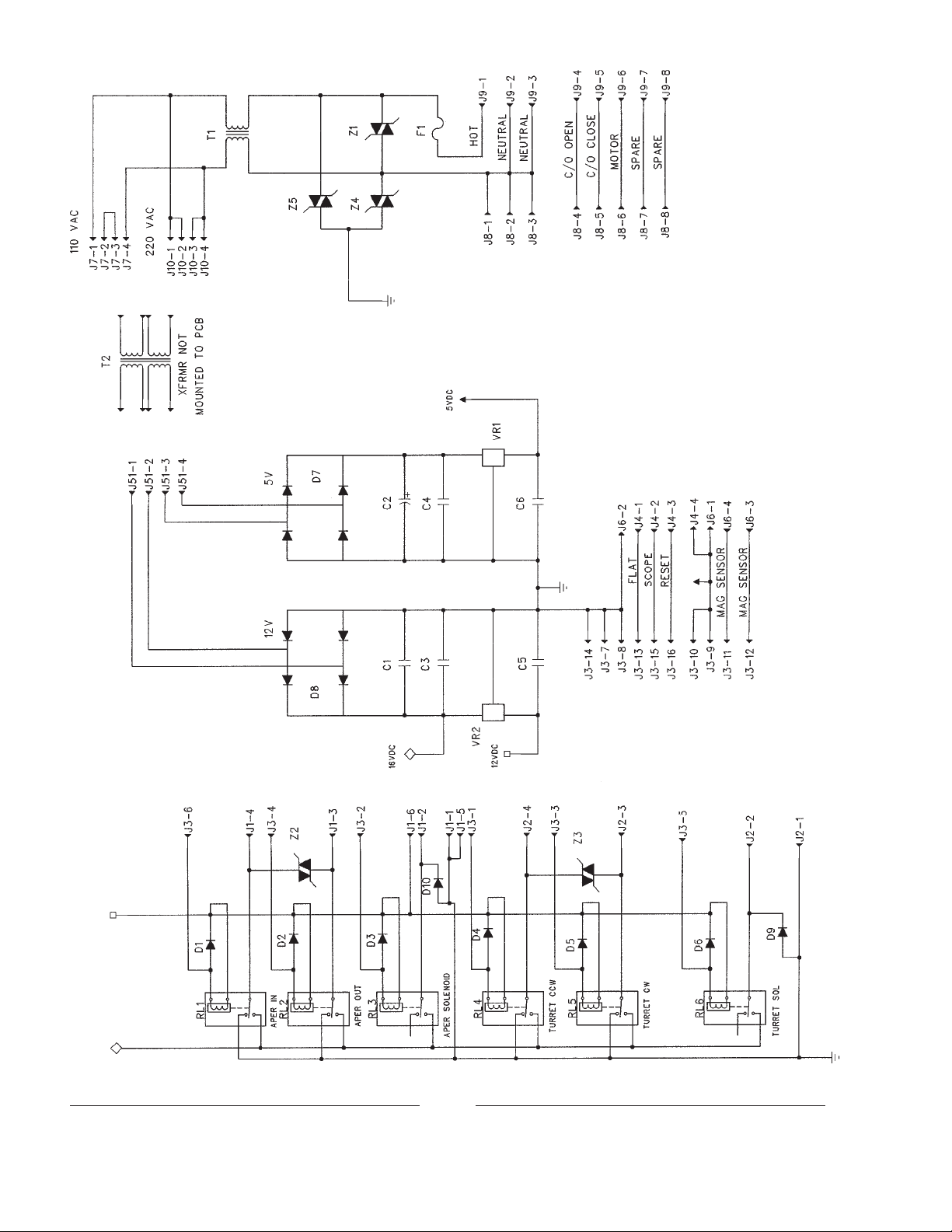

TURRET CONTROL BOX

Assembly No. 52-00385

10 4060310 Screw, 6-32 x 5/16" Pan Head (2 req’d.)

11 4067100 Flatwasher, #6 (2 req’d.)

12 4068001 Hexnut, 6-32 (2 req’d.)

13 31-98209 Fastener, Quarter-Turn

14 31-98200 Receptacle, Quarter-Turn Fastener

15 4060250 Screw, 6-32 x 1/4" Pan Head (20 req’d.)

16 41-98090 Standoff (5 req’d.)

17 408025D Screw, 8-32 x 1/4" Pan Head (5 req’d.)

Item Part No. Description

1 52-00383 Box, Welded Assembly

2 52-00386 Transformer

Item Part No. Description

3 41-98097 Standoff, 1/4" x 3/4" 6-32 Thrd. (4 req’d.)

4 4061500 Screw, 6-32 x 1-1/2" Pan Head (4 req’d.)

5 52-70077 PC Board Assembly, “Power”

6 61-98022 Standoff (4 req’d.)

18 51-13006 Ribbon Cable Connector

7 52-70080 Relay PC Board Assembly

8 52-70081 PC Board Assembly, “Control”

9 --- Capacitor, 7.5 µf, 370 V.AC (with Motor)

39

Page 45

CONTROL CABINET, Wiring Diagram

40

Page 46

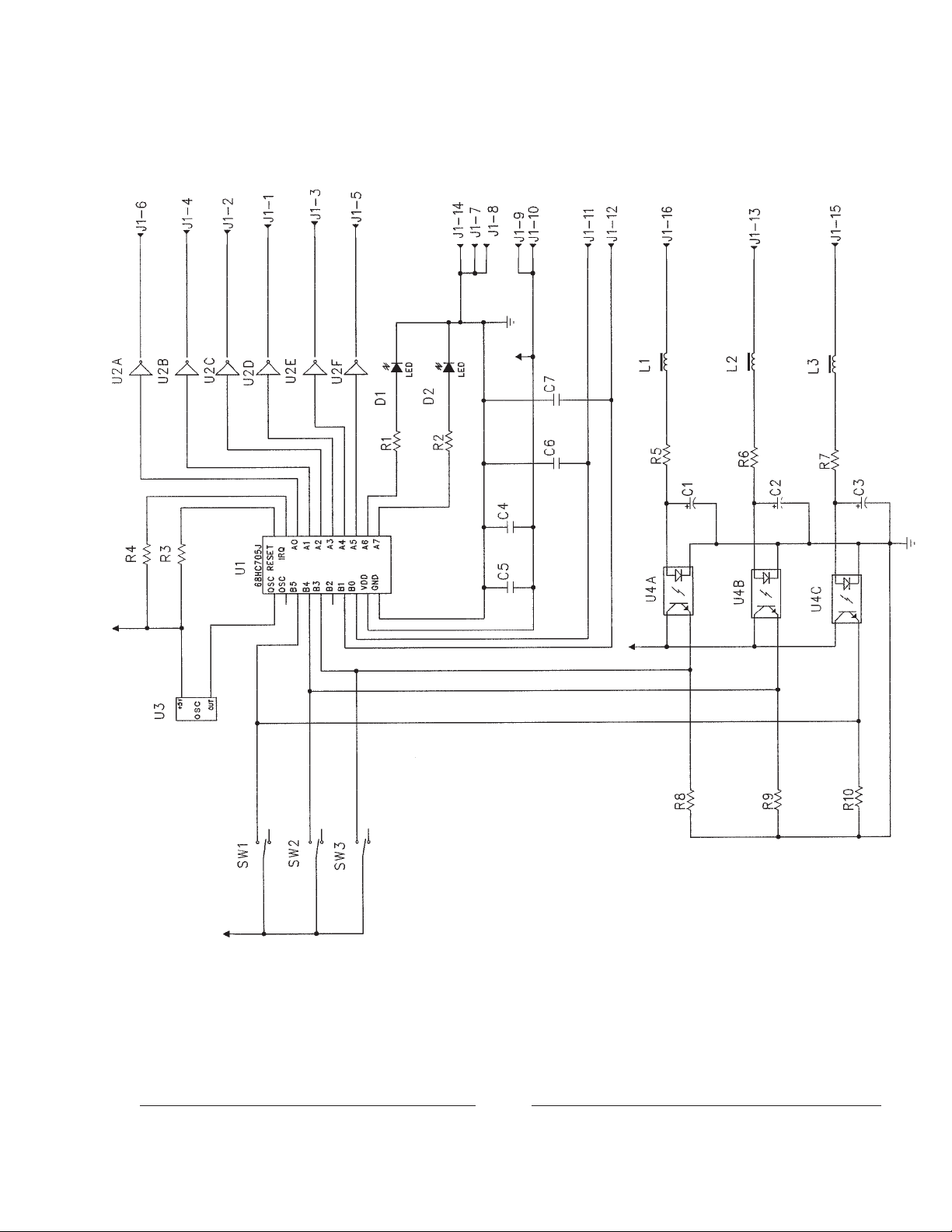

REPLACEMENT CHIP (U1),

Programmed

52-00391: Two-Lens

52-00392: Three-Lens

TURRET CONTROL PRINTED CIRCUIT BOARD

41

Wiring Diagram

Page 47

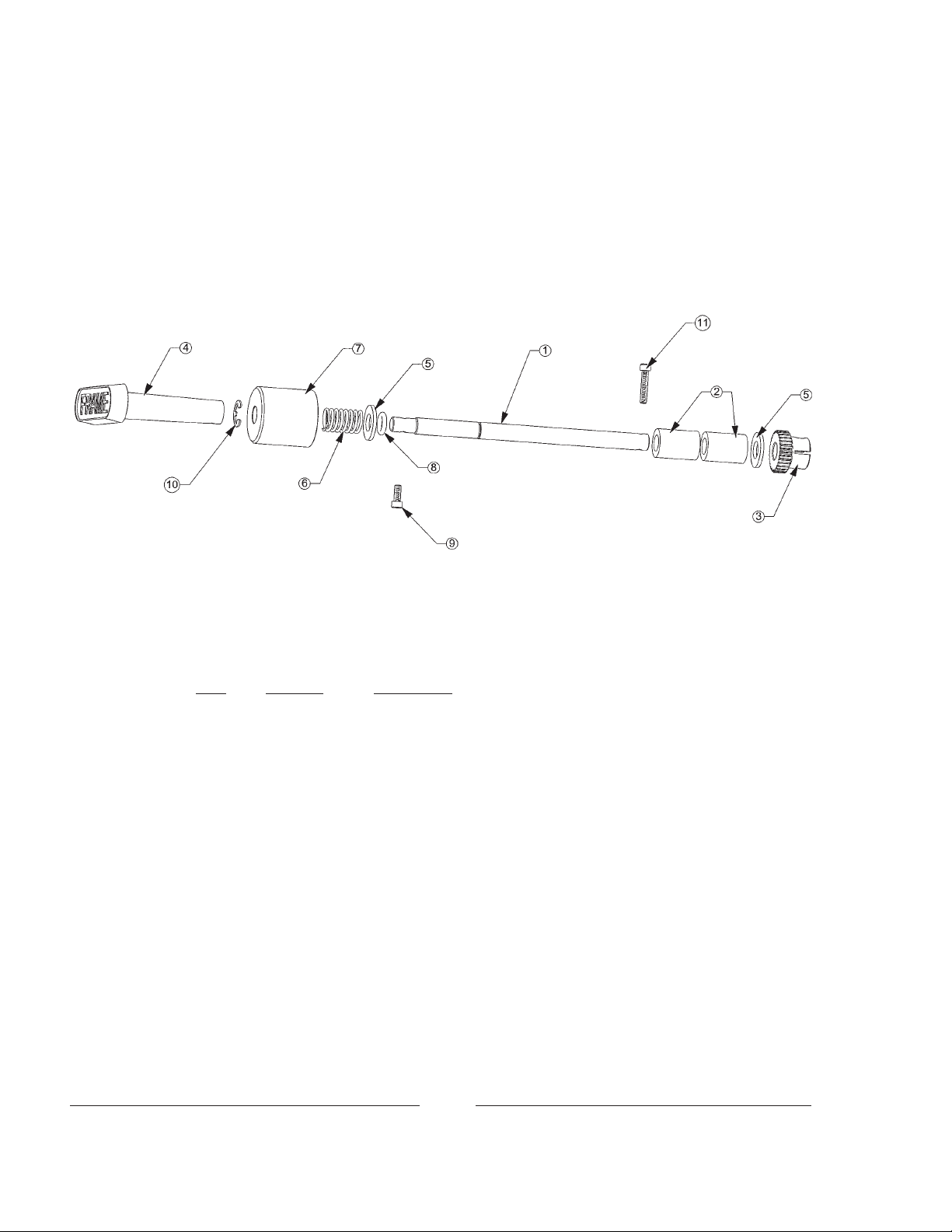

FRAMING SHAFT

Assembly No. 52-00205

Item Part No. Description

1 52-00207 Framing Shaft

2 51-04004 Linear Bearing (2 req’d.)

3 52-00206 Framing Gear

4 51-28028 Framing Handle

5 4507100 Flatwasher, 1/2" (2 req’d.)

6 51-58036 Compression Spring

7 52-00336 Framing Cover

8 21-48024 O-Ring

9 4100500 Screw, 10-32 x 1/2" Socket Head

10 51-48010 Snap Ring, Truarc

11 4101000 Screw, 10-32 x 1" Socket Head

42

Page 48

HORIZONTAL DRIVE SHAFT

Assembly No. 52-00235

Item Part No. Description

1 52-00234 Horizontal Drive Shaft

2 21-48027 Snap Ring, Truac 5100-50 (3 req’d.)

3 51-27004 Woodruff Key (P-1537)

4 52-00166 Main Drive Gear

5 51-04007 Ball Bearing (2 req’d.)

6 52-00335* Seal Plate Assembly

- 4080375 Mounting Screw, 8-32 x 3/8" Pan Head

6a 52-00233 Seal Plate

6b 51-36011 Oil Seal

6c 51-48007 O-Ring (2 req’d.)

* Item 6 not included with 52-00235; order separately

43

Page 49

VERTICAL SHAFT

Assembly No. 52-00253

Item Part No. Description

1 52-00248 Vertical Shaft

2 51-23018 Intermittent Movement Drive Gear (P-1418)

3 52-00186 Sprocket Shaft Drive Gear (2 req’d.)

4 51-23009 Shutter Shaft Drive Gear (G-1803)

5 52-00167 Vertical Shaft Main Driven Gear

6 52-00249 Bearing Block, Upper

7 51-04007 Ball Bearing (3 req’d.)

8 52-00250 Oil Pump Drive Gear

9 52-00251 Bearing Block, Lower

10 4507106 Flatwasher, 1/2" Brass (2 req’d.)

11 52-40181 Oil Slinger (P-7815)

12 408025D Screw, 8-32 x 1/4" Pan Head (9 req’d.)

13 51-58036 Compression Spring

14 4080870 Screw , 8-32 x 7/8" Socket Head (6 req’d.)

15 4060250 Screw, 6-32 x 1/4" Pan Head (2 req’d.)

16 52-00384 Spacer, 1.56" x .75" Diameter

44

Page 50

Mounting Screws for Item 5

(1) 4250620 1/4-20 x 5/8" (upper)

(2) 4250755 1/4-20 x 3/4" (lower)

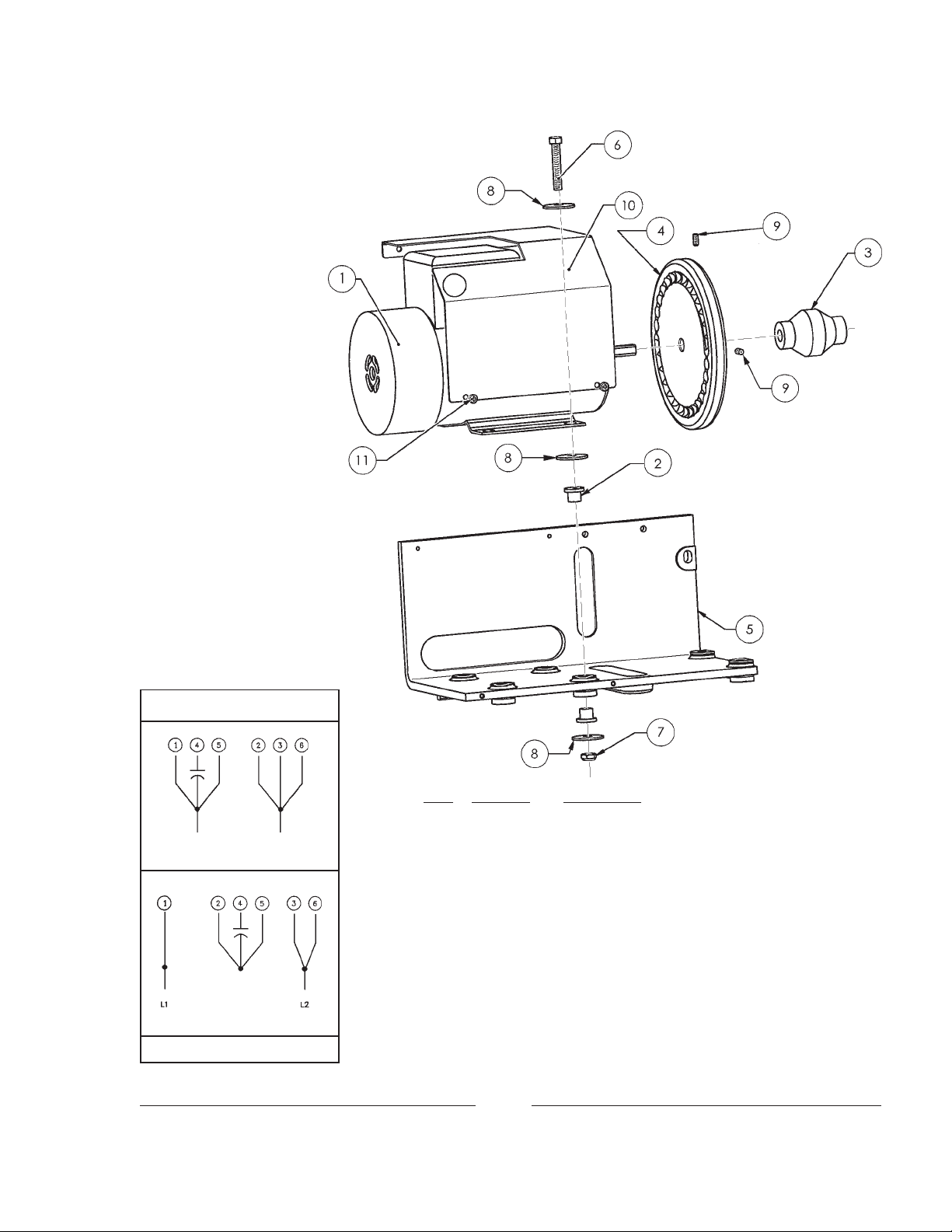

DRIVE MOTOR

Assembly No. 52-00204

MOTOR HOOK-UP

115 Volt

230 Volt

Fuse AC Input at 4 A.

Item Part No. Description

1 51-33003 Motor, 115/230 V.AC, 50/60 Hz.

2 51-07011 Grommet, Shock Mount (8 req’d.)

3 51-16003 Coupler

4 52-00344 Inching Wheel

5 52-00203 Motor Bracket

6 4251500 Screw, 1/4-20 x 1-1/2" (4 req’d.)

7 4258001 Nut, 1/4-20 FlexLock (4 req’d.)

8 4257102 Flatwasher, 1/4" SAE (12 req’d.)

9 408037C Set Screw, 8-32 x 3/8" (2 req’d.)

10 52-00464 Motor Guard

- 41-13004 Wire Clamp Bushing (not shown)

11 4060180 Screw, 6-32 x 3/16" Pan Head (4 req’d.)

Capacitor (7.5µf, 370 V.AC) included with Item 1 Motor

45

Page 51

G-4312 INTERMITTENT MOVEMENT

Assembly No. 52-60038

G-1830

P-2524

P-2524

NOTE: 52-00477 Stripper replaces P-1593

4060371 Screw replaces 4060250

on Apogee only

4060371

4060250

4060502

4060123

P-1938

52-00477

P-9711

P-4924

P-1593

4080374

G-2144

4050501

4058002

G-2330

P-1592

4080374

P-9118

P-4325

(Mounting Screws 4020253

not shown)

P-4384

P-9710

G-2178

51-48027

4040252

4040252

P-1599

G-1836

P-4398

4080623

G-1828

G-1828 Main Drive Gear (51-23014) P-9118 O-Ring (51-48020)

G-1830 Intermittent Flywheel & Gear (52-00061) P-9710 Starwheel Shaft (51-98197)

G-1836 Main Drive Shaft & Gear (51-52005) P-9711 Camshaft (51-98198)

G-2144 Outboard Bearing Arm (52-20078) 4020235 Screw, 2-56 x 1/2" (3 req’d.)

G-2178 Intermittent Case & Bearings (52-20094) 4040252 Oil Trap Screw (4 req’d.)

®

G-2330 Intermittent Sprocket, VKF

(21-59004) 4050501 Sprocket Retaining Screw

P-1592 Cover Gasket (51-22005) 4058002 Hex Nut, NyLock

P-1593 Intermittent Film Stripper (52-40027) 4060123 Collar Set Screw (2 req’d.)

P-1599 Oil Trap (52-20075) 4060250 Stripper Mounting Screw

P-1938 Starwheel Shaft Collar (51-11002) 4060371 Stripper Mounting Screw

P-2524 Flywheel Screw (51-51047; 2 req’d.) 4060502 Mounting Screw (2 req’d.)

P-4325 Cap (51-98176) 4080374 Fastening Screw (4 req’d.)

P-4384 Camshaft Spacer (51-70030) 4080623 Gear Retaining Screw

P-4398 Drive Gear Spacer (52-20169) 51-48027 O-Ring

P-4924 Intermittent Cover (52-00128) 52-00477 Film Stripper (Apogee only)

ORDER P-9710 & P-9711 IN MATCHED PAIRS

Rebuilt Simplex Intermittent Movements are available from the factory under a Repair/Exchange program.

Contact an authorized Strong International Dealer for details.

46

Page 52

INTERMITTENT PAD ARM

Assembly No. 52-00243

Item Part No. Description

1 52-00236 Base, Upper Guide