Page 1

4190-9007 Remote Printer

Installation Instructions

Cautions and Warnings

DO NOT INSTALL ANY SIMPLEX PRODUCT THAT APPEARS

DAMAGED. Upon unpacking your Simplex product, inspect the contents of the

carton for shipping damage. If damage is apparent, immediately file a claim

with the carrier and notify Simplex.

ELECTRICAL HAZARD - Disconnect electrical power when making any

internal adjustments or repairs. Servicing should be performed by qualified

Simplex Representatives.

STATIC HAZARD - Static electricity can damage components. Therefore,

handle as follows:

1. Ground yourself before opening or installing components (use the 553-484

Static Control Kit).

2. Keep uninstalled component wrapped in anti-static material at all times.

RADIO FREQUENCY ENERGY - This equipment has been tested and found

to comply with the limits for a Class B digital device, pursuant to Part 15 of the

FCC rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of this

equipment in a residential area may cause interference in which case the user

will be required to correct the interference at his own expense.

Overview

In This Publication

This document describes the installation procedure for the 4190-9007 Remote

Printer. Consult the User’s Guide supplied with your printer for a detailed

description of mechanical setup, features and operating principles.

The 4190-9007 Remote Printer interfaces with Simplex Fire Alarm and Nurse

Call systems. The printer provides hard copy of status reports for these systems:

• Fire Alarm

- 2120 Multiplex - 4120 Network

- 4010 - 4120 GCC

- 4020 - 4120 NPU

- 4100+

• 5001 Nurse Call

The following topics are covered in this publication.

Topic

Control Panel DIP Switches 2

Serial Interface DIP Switches 3

Printer Connections 6

Connecting to Fire Alarm Systems 7

4010 Front Panel Programming for an RS-232 Port 9

Connecting to 5001 Nurse Call 12

Control Panel 13

Page Number

2000 Simplex Time Recorder Co., Westminster, MA 01441-0001 USA

All specifications and other information shown were current as of publication, and are subject to change without notice.

574-124

Rev. B

Page 2

Control Panel DIP Switches

Overview

Setting DIP Switch 1

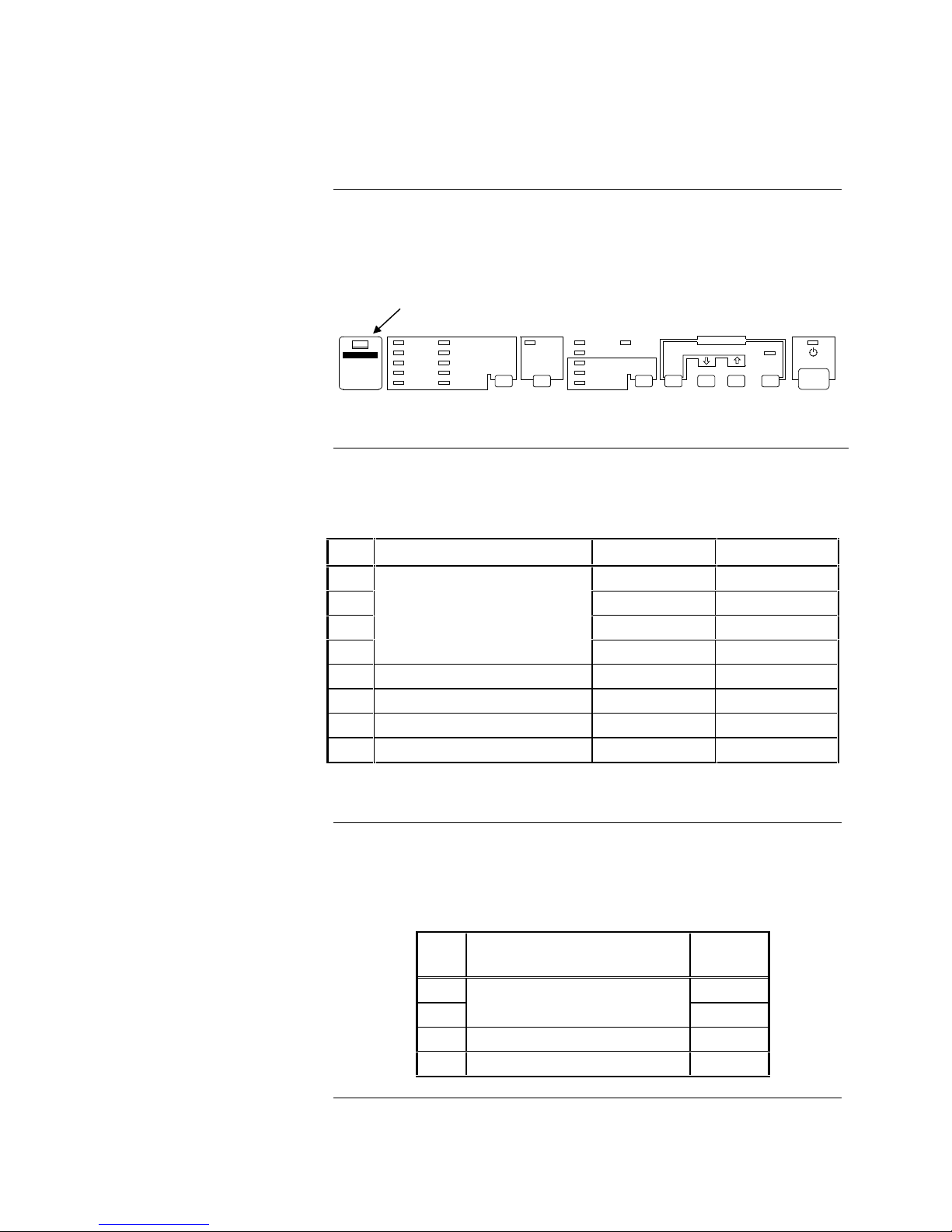

The 4190-9007 printer is equipped with two DIP switches that control the

printer’s features. The DIP switches are located behind the switch cover on the

control panel (see Figure 1). Tables 1 and 2 define the settings for DIP Switch 1

and 2.

DIP switch cover

DRAFT

COURIER

ROMAN

SANS SERIF

PRESTIGE

SCRIPT

SCRIPT C

OPERATOR

OPERATOR-S

OCR-B

FONT CONDENSED

MULTI-PART

PAPER-OUT

BIN 1

BIN 2

TEAR OFF

DATA

FONT FONT

BUFFER CLEAR

MICRO FEED

LOAD/EJECTLF/LL PAUSE

OPERATE

Figure 1. Location of DIP Switch Cover

DIP Switch 1 has eight switches. Table 1 describes the settings for DIP Switch 1.

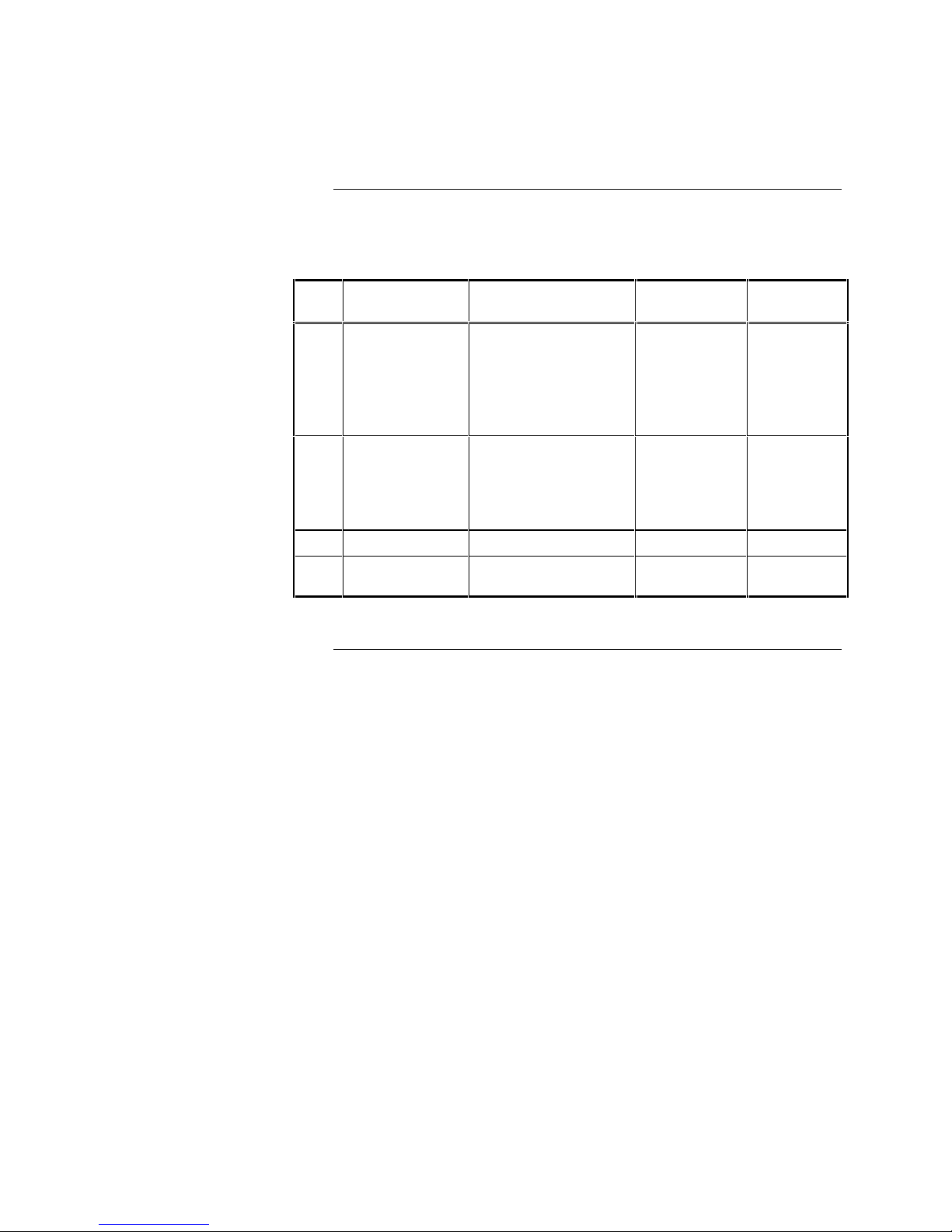

Table 1. DIP Switch 1

SW Description ON OFF

1-1 ON*

1-2 ON*

1-3 ON*

1-4

USA

OFF*

1-5 Print Direction Unidirectional Bidirectional*

1-6 Printer Mode** IBM emulation ESC/P 2*

1-7 Input buffer None 8KB*

1-8 1-inch skip-over-perforation ON OFF*

Setting DIP Switch 2

Notes: * Indicates S implex settings.

** SW 1-6 functions only on the European version of this printer.

DIP Switch 2 has four switches. Set these switches to the ON position.

Table 2 describes the settings for DIP Switch 2.

Table 2. DIP Switch 2

SW Description

2-1 ON

2-2

Page length

(for continuous paper)

Simplex

Setting

ON

2-3 Tear Off ON

2-4 Auto line feed ON

2

Page 3

DIP

Serial Interface DIP Switches

Introduction

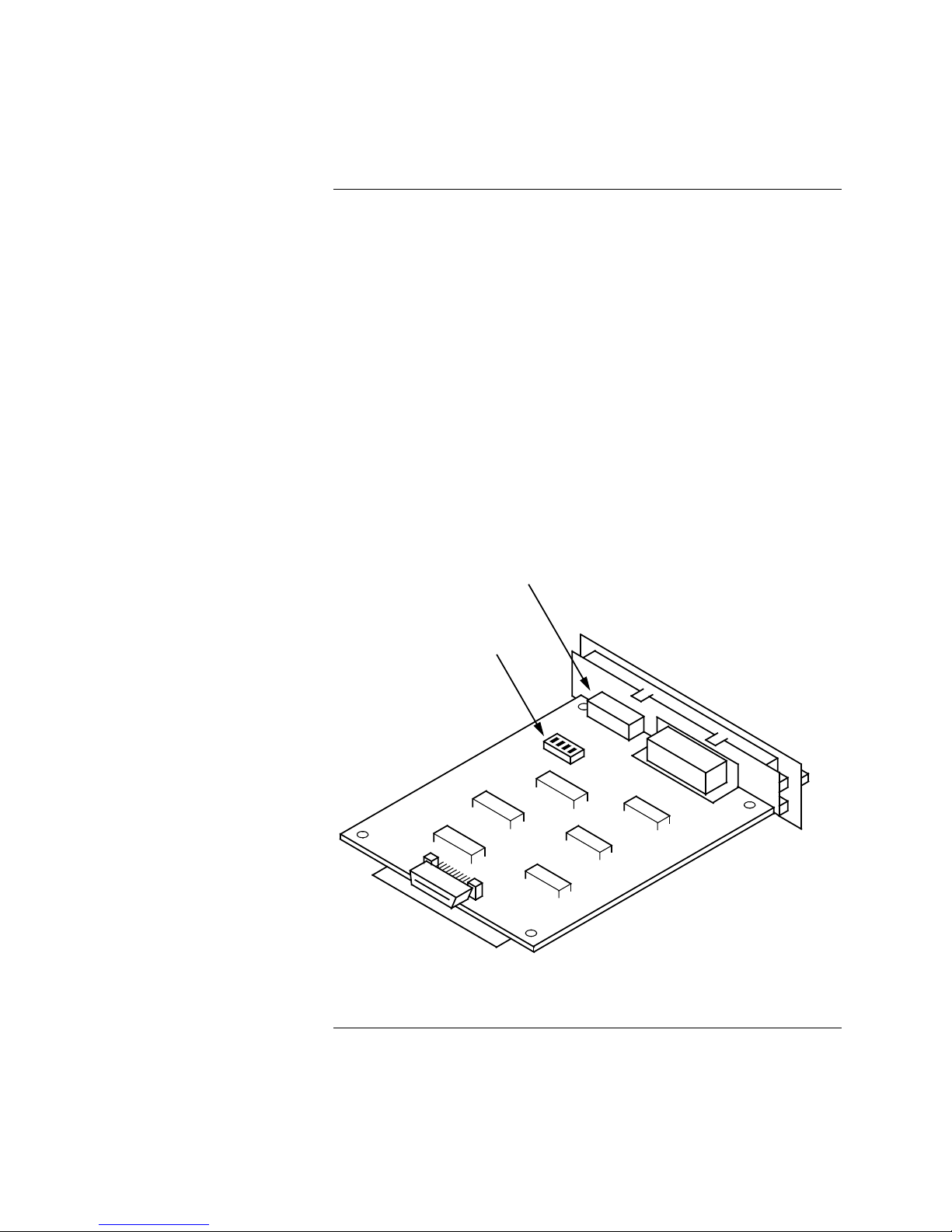

The serial interface card enables communication between the 4190-9007 Remote

Printer and a host computer (see Figure 3 for the location of the serial interface

compartment).

The serial interface card has two sets of DIP switches (see Figure 2). You

control interface operations by adjusting the switch settings.

Notes:

• You can access DIP Switch 1 and adjust settings as needed even after

installing the interface card.

• DIP Switch 2 is not readily accessible after installation. Therefore, make

any necessary adjustments to DIP Switch 2 before installing the serial

interface card.

This section describes the DIP switch settings for operation with compatible Fire

Alarm systems. Refer to the Serial Interfac e Card manual (provided with the

serial interface card) for detailed information on serial interface card installation.

SWITCH

1

DIP

SWITCH

2

Figure 2. Serial Interface Card DIP Switches

Continued on next page

3

Page 4

Serial Interface DIP Switches, Continued

Serial Interface

DIP Switch 1

Table 3 defines the serial interface settings for DIP Switch 1.

Table 3. DIP Switch 1 Settings

SW Function ON OFF

1-1

1-2 Word Length 8-bit 7-bit

1-3 Parity Check 1

1-4 Parity Check 2

1-5 Baud Rate 1

1-6 Baud Rate 2 N/A

Interface Card

Enable/Disable

Enable Disable

ON

For both even

parity (4020,

4100+, 4120), and

for odd parity

(4120 GCC,

4120 NPU)

ON

For even parity

(4020, 4100+,

4120)

ON

for both 1200 baud

(2120, 4020,

4100+, 4120), and

9600 baud (4010,

4120 GCC,

4120 NPU)

OFF

No parity

(2120, 4010)

OFF

For odd or no

parity (2120, 4010

4120 GCC,

4120 NPU)

N/A

OFF

for both 1200 baud

(2120, 4020,

4100+, 4120), and

for 9600 baud

(4010, 4120 GCC,

4120 NPU)

Simplex

Setting

ON

ON

ON

ON

ON

OFF

Note: Units must be set for NO parity at 1200 baud.

Continued on next page

4

Page 5

Serial Interface DIP Switches, Continued

Serial Interface Card

DIP Switch 2

Table 4 defines the settings for DIP Switch 2.

Table 4. DIP Switch 2 Settings

SW Function ON OFF

ON

for both 1200 baud

2-1 Baud Rate 3

2-2 Baud Rate 4

2-3 Handshake DTR X-on/X-off

2-4

RS-232D/

Current Loop

Note: Unit to be set for 1200 baud.

(2120, 4020, 4100+,

4120), and 9600

baud (4010, 4120

GCC, 4120 NPU)

ON

for 9600 baud rate

(4010, 4120 GCC,

4120 NPU)

RS-232D Current Loop

N/A

OFF

for 1200

baud rate

(2120, 4020,

4100+, 4120)

Simplex

Setting

ON

OFF

ON

ON

5

Page 6

Printer Connections

Overview

Connector Ports

The following sections illustrate the connections between the 4190-9007 Remote

Printer and the various host systems (Fire Alarm or Nurse Call) with which it is

compatible.

Use the port on the serial interface card for connections between the printer and

host systems. The serial interface compartment is located directly above the

parallel interface port on the rear panel of the printer (see Figure 3).

Note: When connecting to a 4120 GCC system you have the option of using

the parallel port. If using this option, refer to the section “Parallel

Interface Option with the 4120 GCC.”

SERIAL INTERFACE

COMPARTMENT

RS-232 CONNECTOR

WITH INTERNAL SUPPRESSION

PARALLEL

733-937 HARNESS

(SUPPLIED)

INTERFACE

Figure 3. Connecting to the Printer

6

Page 7

TO 4190-9007 PRINTER

(

)

→

(

)

Connecting to Fire Alarm Systems

y

g

Connecting to 4020, 4100+,

4120 Network, 4120 GCC or

4120 NPU Systems

3 or 8 4 or 9 5 or 10 TB1

BLACK

(RECEIVE)

WHITE

(HAND

RED

(NOT USED)

TO 4190-9007 PRINTER

SHAKE)

32

Use the 733-937 harness provided with the Simplex shipment (see Figure 3).

The harness is equipped with an RS-232 connector with internal suppression.

Follow Steps 1 through 3 when using the serial interface port to connect to the

host system.

1. Connect the harness to the serial interface port of the printer.

2. 4020 FACP Refer to Figure 4 to complete the connection to the RS-232

card.

3. 4100+ System, 4120 Network, 4120 GCC, and 4120 NPU system Refer to

Figure 5 to complete the connection to a COM port.

GREEN

(COMMON)

720

4020, 4100+, OR 4120 NETWORK → RS-232 CARD

RED

NOT USED

4120 GCC OR 4120 NPU

275

BLK GRN WHT

RECEIVE

BLK GRN WHT

37202

COM PORT

COMMON

HANDSHAKE

733-937

HARNESS

FURNISHED

ure 4. Connecting to the 4020 FACP

Fi

Parallel Interface Option with

the 4120 GCC

Figure 5. Connecting to 4100+, 4120 Network,

4120 GCC, or 4120 NPU S

stems

Use the standard parallel cable supplied with the printer (the 733-937 harness is

not used with the parallel interface). Follow these steps.

1. Disable the serial interface as follows:

a. Loosen the two screws that hold the serial interface card in place.

b. Pull the card out of the unit.

2. Connect the cable from the parallel port of the printer to the parallel port of

the host system.

Note: The parallel cable provides a maximum distance of 6 feet from the

printer to host.

Continued on next page

7

Page 8

Connecting to Fire Alarm Systems, Continued

Connecting to 2120 Multiplex

System and 4010 FACP

Use the 733-937 harness provided with the Simplex shipment (see Figure 3).

The harness is equipped with an RS-232 connector with internal suppression.

Follow these steps to connect the printer to the 2120 Multiplex or 4010 FACP.

• Connect the harness to the serial interface port of the printer.

• Refer to Figure 6 to complete the connection to the 2120 BMUX.

• Refer to Figure 7 to complete the connection to the 4010 FACP.

2120 BMUX (RS-232 CONNECTOR)

3720

COMMON

RED

(NOT USED)

RECEIVE

BLK GRN WHT

37202

HANDSHAKE

733-937

HARNESS

(FURNISHED)

Note Refer to the “4010 Front Panel

Programming for an RS-232

Printer Port” section of this

document if you are wiring the

printer to a 4010 FACP.

(NOT USED)

TO 4190-9007 PRINTER

Figure 6. Connecting to 2120 Multiplex System

123456

RED

BLK

31

TO 4190-9007 PRINTER

720

GRN

WHTBLU

733-937

HARNESS

(FUNISHED)

Figure 7. Connecting to a 4010 FACP

8

Page 9

4010 Front Panel Programming for an RS-232 Port

Introduction

Adding an RS-232 Card

This section describes programming a printer port on a 4010 RS-232 card from

the front panel of the 4010 FACP.

Note: Login to the system at access level 4 before attempting to

program the port.

This section describes adding the RS-232 card to the 4010 job.

1. Press <MENU>.

2. Press <NEXT> or <PREVIOUS> until [PROGRAMMING] is displayed

and then press <ENTER>. The following warning appears, indicating that

the 4010 is no longer in the Fire Alarm Operation mode.

Please Wait . . .

Fire Alarm Operation Suspended

3. Press <ENTER> to co ntinue.

4. Press <NEXT> or <PREVIOUS> until <CONFIGURE CARDS> is

displayed and then press <ENTER>.

5. Press <NEXT> or <PREVIOUS> until <ADD A 4010 CARD> is

displayed and then press <ENTER>.

6. Press <NEXT> or <PREVIOUS> until <RS232> is displayed and then

press <ENTER>. P ress <ENTER> again to confirm that you want to add

an RS-232 card. A message appears indicating that the system is

configuring the card.

Configuring RS-232 Port

Settings

Press the <EXIT> key once to move back one menu level and then continue

below with Step 5 in the next section.

Use the following steps to configure the printer settings (baud rate, etc) for the

RS-232 port to which the printer is attached. Before beginning, ensure you

know the hardware settings enabled on the printer (i.e., baud rate set on printer

itself).

1. Press <MENU>.

2. Press <NEXT> or <PREVIOUS> until [PROGRAMMING] is displayed

and then press <ENTER>. A warning appears, indicating that the 4010 is

no longer in the Fire Alarm Operation mode.

Please Wait . . .

Fire Alarm Operation Suspended

3. Press <ENTER> to continue.

Continued on next page

9

Page 10

4010 Front Panel Programming for an RS-232 Port, Continued

Configuring RS-232 Port

Settings (continued)

4. Press <NEXT> or <PREVIOUS> until <CONFIGURE CARDS> is

displayed and then press <ENTER>.

5. Press <NEXT> or <PREVIOUS> until <MODIFY 4010 CARD> is

displayed and then press <ENTER>.

6. Press <NEXT> or <PREVIOUS> until the display reads

<CARD TYPE=RS232 CARD> and then press <ENTER>.

7. Press <NEXT> or <PREVIOUS> to select either <PORT A> or

<PORT B> and then press <ENTER>.

A display similar to the following appears, allowing you to set the

communication settings for the port.

<ENTER> to ACCEPT <ARROW KEYS> to Change

Port[PRT80U] BAUD 9600 Parity None

8. Use the arrow keys to move the bracket to the [PORT] Parameter. Use the

<NEXT> and <PREVIOUS> keys to select a choice for this parameter.

Note that you must have an 80-column printer to print 4010 reports.

Choices are as follows:

• PRT80U. Unsupervised, 80-column printer

• Unused.

• PRT40S. Supervised, 40-column printer

• PRT40U. Unsupervised, 40-column printer

• PRT80S. Supervised, 80-column printer

9. Use the arrow keys to move the bracket to the [BAUD] Parameter. Use the

<NEXT> and <PREVIOUS> keys to select a choice for this parameter.

Choices are as follows:

• 1200

• 2400

• 4800

• 9600

• 19200

• 38400

10. Use the arrow keys to move the bracket to the [PARITY] parameter. Use

the <NEXT> and <PREVIOUS> keys to select a choice for this parameter.

Choices are as follows:

• None

• Even

• Odd

11. Press <ENTER>. A display similar to the following appears, allowing you

to select which events are routed to the printer

Press <ENTER> to Send ALL Events to Port

Press <NEXT> to Select Events

Continued on next page

10

Page 11

4010 Front Panel Programming for an RS-232 Port, Continued

Configuring RS-232 Port

Settings (continued)

12. Choose which events are sent to the printer when they occur, as follows:

Send All Events to Printer. Press <ENTER> to send all of the events

listed in Table 5 (below) to the printer. After you press <ENTER>, the

display indicates that the option is updated and exits to the <MODIFY 4010

CARD> selection in the Programming menu. Press the <EXIT> key twice.

A message appears, i ndicating that the c onfiguration has changed. Move to

the <SAVE CFIG> choice and press <ENTER>. Another message

appears, as ki ng you t o confirm the Save op eration. Press <ENTER> to

save the new CFIG.

Route Specific Events to Printer. Press <NEXT> to individually select

which events are sent to the printer when they occur. A series of prompts,

each of which is listed in Table 5, appears. For each prompt, press the

<NEXT> and <PREVIOUS> keys to toggle between the YES and NO

selections. When the setting is correct, press <ENTER>. After the last

prompt appears, the system prompts you to <PRESS ENTER TO SAVE

OR EXIT TO CANCEL>. After you press <ENTER>, the display

indicates that the option is updated and exits to the <MODIFY 4010

CARD> selection in the Programming menu. Press the <EXIT> key twice.

A message appears, i ndicating that the c onfiguration has changed. Move to

the <SAVE CFIG> choice and press <ENTER>. Another message

appears, as ki ng you t o confirm the Save op eration. Press <ENTER> to

save the new CFIG.

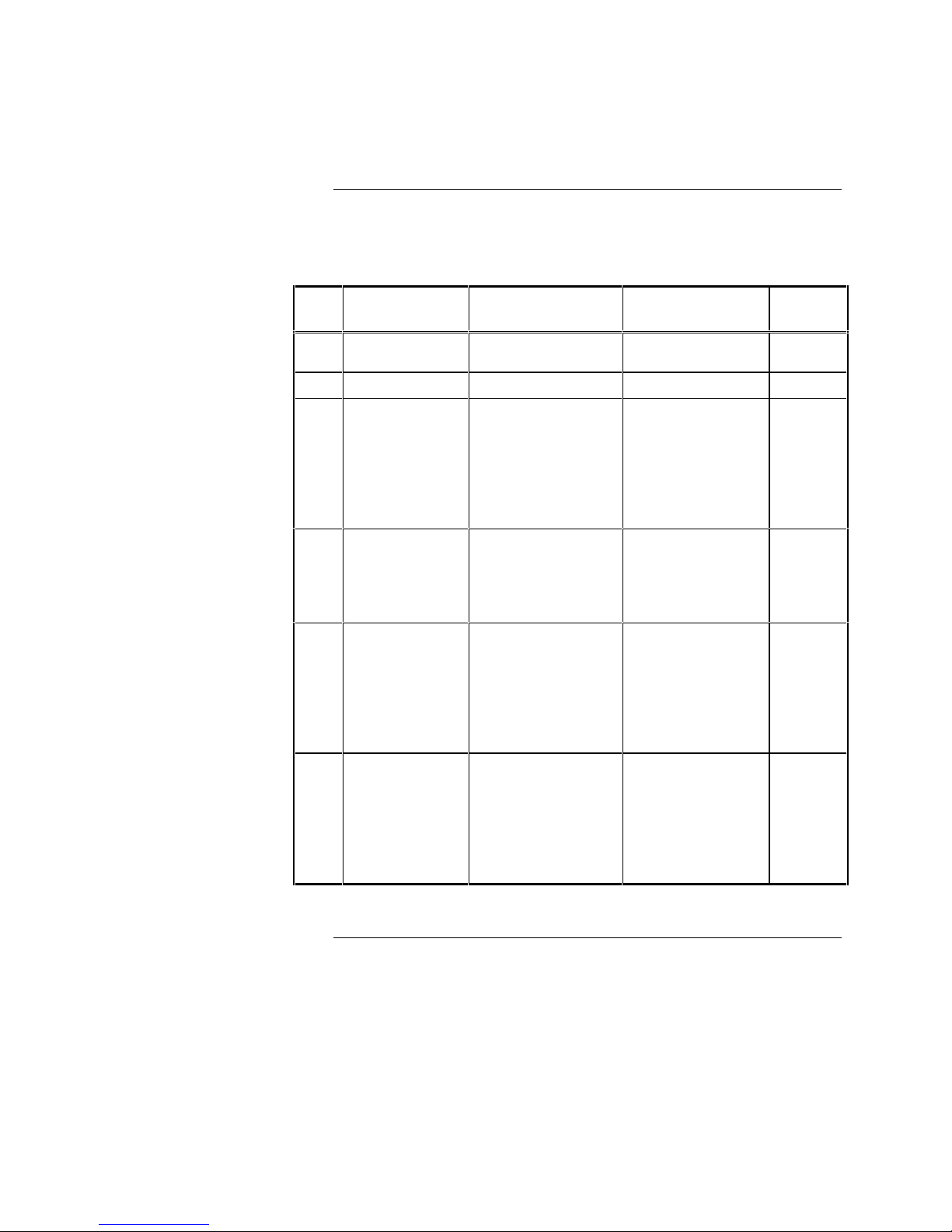

Table 5. Routing Specific Events

Prompt

Send Fire Events to Port? Yes Routes information on all fire alarms to the printer.

Send Supervisory Events to Port? Yes

Send Trouble Events to Port? Yes Routes information on all trouble events to the printer.

Send Reset/Silence to Port? Yes

Send Test Events to Port? Yes Routes all Walktest events to the printer.

Send Control Events to Port? No

Send Utility Events to Port? No

Send Pseudo Events to Port? No

Send CCE Print Events to Port? Yes Routes Custom Control Print statements to the printer.

Send Reports to Port? Yes Sends reports to the printer.

Default

Setting

Explanation

Routes information on all supervisory events to the

printer.

Routes information to the printer each time a system

reset or signal silence occurs.

Routes information to the printer each time a control

circuit (signals/aux relays) turns ON or OFF.

Routes information to the printer each time the

ON/OFF state of a utility point changes.

Routes information to the printer each time the

ON/OFF state of a pseudo point changes.

11

Page 12

)

Connecting to 5001 Nurse Call

Connecting to 5001 Nurse Call

Male and female DB25 connectors (with pigtails) are provided with the printer

port.

Follow Steps 1 and 2 to make the connection between the printer and the

5001 Nurse Call system:

1. Connect the male DB25 connector to the printer.

2. Connect the female DB25 connector to the serial port

of the 5001 CPU.

Note: The 733-937 harness is not used when connecting to the 5001 Nurse

Call system. Figure 8 illustrates the connection between the 4190-9007

printer and the 5001 CPU.

5001 CPU (DB25 SERIAL PRINTER PORT

267

15

SHIELD

5-CONDUCTOR

CABLE W/SHIELD

(#18 AWG)*

RED

WHT GRN BLK

SHIELD

RECEIVE

Figure 8. Connecting to 5001 Nurse Call

HANDSHAKE

SEND

DATA

3671

* MAXIMUM DISTANCE BEWEEN

PRINTER AND 5001 CPU IS 100 FEET

11 20

TO 4190-9007 PRINTER

12

COMMON

Page 13

Control Panel

Control Panel Illustration

DRAFT

COURIER

ROMAN

SANS SERIF

PRESTIGE

Control Panel Buttons

SCRIPT

SCRIPT C

OPERATOR

OPERATOR-S

OCR-B

Figure 9 illustrates the front panel of the printer. Refer to the indicator lights on

the control panel for current status of the printer. Use the buttons to control

printer settings.

BUFFER CLEAR

MICRO FEED

LOAD/EJECTLF/LL PAUSE

OPERATE

FONT CONDENSED

MULTI-PART

PAPER-OUT

BIN 1

BIN 2

TEAR OFF

DATA

ALT

Figure 9. Control Panel Buttons and Lights

The following sections detail the functions of the buttons and lights that are

useful when setting up the printer for operation.

Table 6 identifies the functions of panel buttons.

Table 6. Using the Control Panel Buttons

If you want to… Then:

Temporarily stop printing Press the PAUSE button

Resume printing Press PAUSE again

Load paper manually—single sheet

or continuous (Printer normally

loads paper automatically)

Eject single-sheet paper already in

the loading position

Press the LOAD/EJECT

button

Feed continuous paper backward

from the loading or tear-off position

to the standby position

Feed paper forward one line

Load a single sheet of paper from

the cut-sheet feeder

Feed continuos paper from standby

position to loading position

Eject a single sheet of paper

Advance continuous paper to top of

next page

13

Press the LF/FF

(line feed/form feed) button

Hold down the LF/FF button

Continued on next page

Page 14

Control Panel, Continued

Control Panel Lights

Additional Information

Table 7 describes the messages indicated when panel lights are ON.

Table 7. Control Panel Light Messages

Light Color Message

Operate Green Operate switch is on and power is supplied.

Printer is not ready to print data.

Pause Orange

Paper Out Red Printer is out of paper.

Consult printer manual for details on printer set-up, control logic, and paper

loading.

Operator has pressed PAUSE button to

prevent printing.

574-124

Rev. B

Loading...

Loading...