Page 1

4010ES

Fire Alarm System

Installation

Guide

579-989

Rev. M

Page 2

Page 3

Copyrights, Trademarks, Cautions, Warnings and Regulatory Info

Copyrights and Trademarks

Cautions, Warnings and Regulatory Information

©2011 - 2016 Tyco Fire Protection Products. All rights reserved.

Specifications and other information shown were current as of publication and are subject to

change without notice. TYCO, SIMPLEX, and the product names listed in this material are

marks and/or registered marks. Unauthorized use is strictly prohibited.

READ AND SAVE THESE INSTRUCTIONS- Follow the instructions in this installation

manual. These instructions must be followed to avoid damage to this product and asso ciated

equipment. Product operation and reliability depend upon proper installation.

DO NOT INST ALL ANY SIMPLEX® PRODUCT THAT APPEARS DAMAGED- Upon

unpacking your Simplex product, inspect the contents of the carton for shipping damage. If

damage is apparent, immediately file a claim with the carrier and notify an authorized Simplex

product supplier.

ELECTRICAL HAZARD - Disconnect electrical field power when making any internal adjust-

ments or repairs. All repairs should be performed by a representative or authorized agent of

your local Simplex product supplier.

ST ATIC HAZARD - Static electricity can damage components. Handle as follows:

• Ground yourself before opening or installing components.

• Prior to installation, keep components wrapped in anti-static material at all times.

EYE SAFETY HAZARD - Under certain fiber optic application conditions, the optical output of

this device may exceed eye safety limits. Do not use magnification (such as a microscope or

other focusing equipment) when viewing the output of this device.

FCC RULES AND REGULATIONS – PART 15 - This equipment has been tested and found to

comply with the limits for a Class A digital device pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

SYSTEM REACCEPT ANCE TEST AFTER SOFTWARE CHANGES - T o ensure proper system

operation, this product must be tested in accordance with NFPA 72® after any programming

operation or change in site-specific software. Re-acceptance testing is required after any

change, addition or deletion of system components, or after any modification, repair or

adjustment to system hardware or wiring.

All components, circuits, system operations, or software functions, known to be affected by a

change must be 100% tested. In addition, to ensure that other operations are not inadvertently

affected, at least 10% of initiating devices that are not directly affected by the change, up to a

maximum of 50 devices, must also be tested and proper system operation verified.

NFPA 72® is a registered trademark of the National Fire Protection Association.

iii

Page 4

Page 5

Table of Contents

Copyrights, Trademarks, Cautions, Warnings and Regulatory Info............................. iii

Copyrights and Trademarks ................................................................................................... iii

Cautions, Warnings and Regulatory Information ...................................................................iii

Chapter 1 Overview ...........................................................................................1-1

Introduction ..........................................................................................................................1-1

In this chapter ............... .. ............................................. ... ............................................. ........1-1

Standalone configuration ...............................................................................................1-2

Overview ..............................................................................................................................1-2

Standalone system layout ....................................................................................................1-2

Network configuration .....................................................................................................1-3

Overview ..............................................................................................................................1-3

Connecting network loops ....................................................................................................1-4

Network communication .......................................................................................................1-4

Chapter 2 Basic Hardware ................................................................................ 2-1

Introduction ..........................................................................................................................2-1

In this chapter ................................................... ... ............................................. .. .................2-1

CPU ...................................................................................................................................2-2

Overview ..............................................................................................................................2-2

CPU LEDs ............................................................................................................................2-3

CPU jumper settings ............................................................................................................2-5

CPU switches .......................................................................................................................2-6

CPU connectors/ports/terminal block ...................................................................................2-6

CPU card specifications .......................................................................................................2-7

Operator interface ...........................................................................................................2-8

Overview ..............................................................................................................................2-8

Main system supply (MSS) .............................................................................................2-9

Overview ..............................................................................................................................2-9

MSS LEDs and jumpers .....................................................................................................2-11

MSS specifications .............................................................................................................2-12

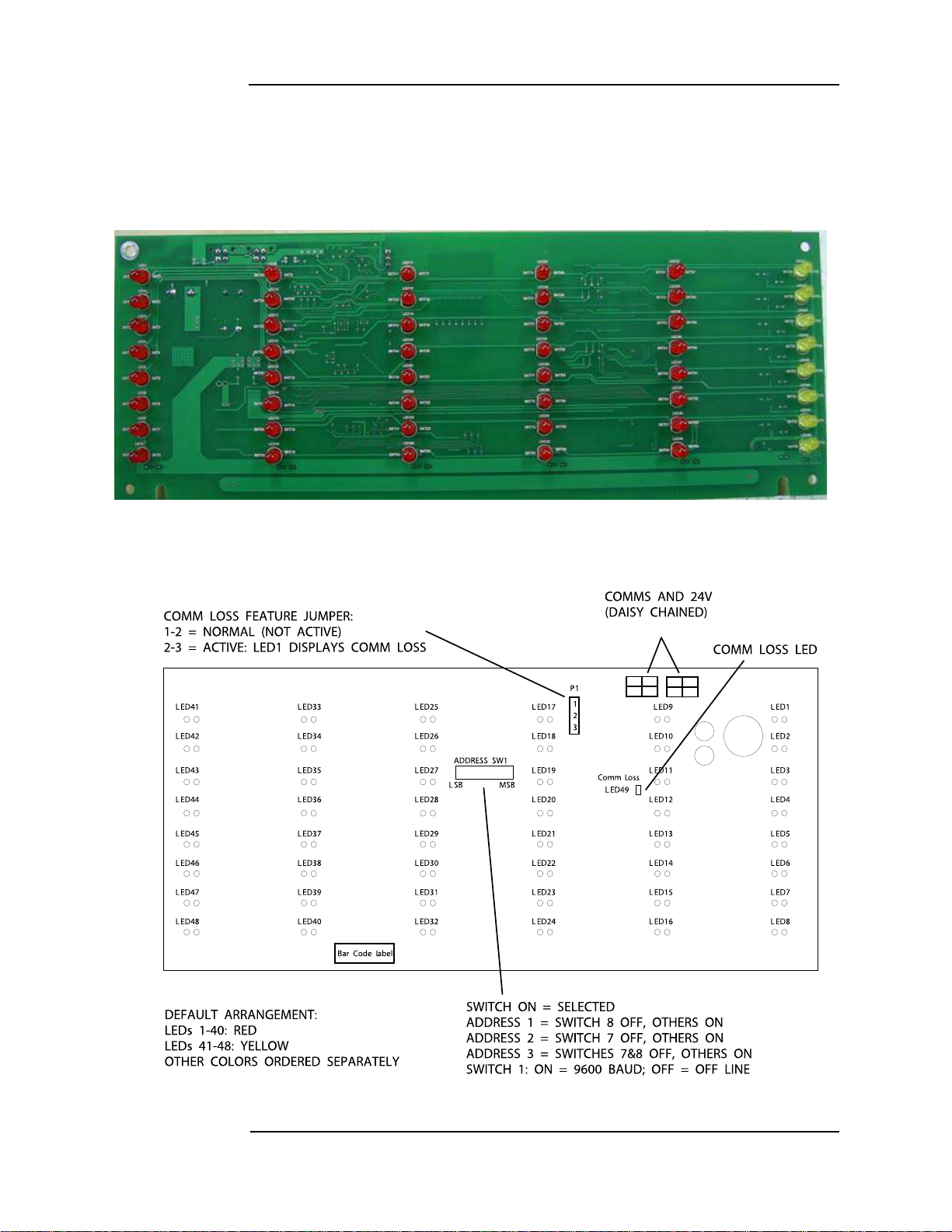

48-LED Module ...............................................................................................................2-14

Overview ............................................................................................................................2-14

48-LED Module specifications ...........................................................................................2-15

System power ...................................... ... ... .... ... ... ... .... ... ... ... .... ... ... ................................2-16

Main system power ............................................................................................................2-16

Backup batteries ................................................................................................................2-16

Chapter 3 Panel configurations ........................................................................3-1

Introduction ..........................................................................................................................3-1

In this chapter ................................................... ... ............................................. .. .................3-1

One-bay 4010ES Panels ..................................................................................................3-2

Overview ..............................................................................................................................3-2

Optional modules .............................................. ... ................................................................3-4

Back box mechanical specifications ....................................................................................3-5

Two-bay 4010ES Panels ............ .... ... ... ... ... .......................................... .... ... ... ..................3-6

Overview ..............................................................................................................................3-6

Optional modules .............................................. ... ................................................................3-9

Back box mechanical specifications ....................................................................................3-9

v

Page 6

Table of Contents

Chapter 4 Orderable panels and devices ........................................................ 4-1

Introduction ..........................................................................................................................4-1

In this chapter ................................................... ... ............................................. .. .................4-1

Panels ...............................................................................................................................4-2

One-bay 4010ES Panels .....................................................................................................4-2

Two-bay 4010ES Panels .....................................................................................................4-2

Optional modules ... ... ... .... ... ... ... .... ... ... ............................................................................4-3

Local optional modules ..................................... ... ............................................... ... ..............4-3

Remote devices ...................................................................................................................4-4

Adjunct features ...................................................................................................................4-5

End user programming tools ................................................................................................4-5

LED kits for the 48-LED Module ..........................................................................................4-5

Chapter 5 Installing 4010ES systems ..............................................................5-1

Introduction ..........................................................................................................................5-1

In this chapter ................................................... ... ............................................. .. .................5-1

Mounting the panel ..........................................................................................................5-2

Installing the back box .........................................................................................................5-2

Attaching the dead front .......................................................................................................5-3

Attaching doors ....................................................................................................................5-4

General field wiring guidelines ......................................................................................5-5

Power-limited guidelines ......................................................................................................5-5

Connecting 4010ES basic components .........................................................................5-7

Connecting the CPU and the operator interface ..................................................................5-7

Connecting the MSS ............................................................................................................5-9

Connecting the 48-LED Module .........................................................................................5-10

RUI wiring .......................................................................................................................5-11

Overview ............................................................................................................................5-11

Installing the optional modules .............................................. ................................ ......5-13

Overview ............................................................................................................................5-13

Installing one-block and two-block cards ...........................................................................5-13

Address configuration DIP switch ...............................................................................5-14

Overview ............................................................................................................................5-14

Connecting main system power ...................................................................................5-16

Overview ............................................................................................................................5-16

Panel power-up sequence .................................................................................................5-16

Chapter 6 MSS field wiring ...............................................................................6-1

Introduction ..........................................................................................................................6-1

In this chapter ................................................... ... ............................................. .. .................6-1

Power supply wiring distances ......................................................................................6-2

Overview ..............................................................................................................................6-2

Class A NAC wiring table ..................................... ... .. ................................................ ... ... .....6-2

Class B NAC wiring table ..................................... ... .. ................................................ ... ... .....6-3

MSS NAC field wiring guidelines ...................................................................................6-4

Guidelines ............................................................................................................................6-4

MSS NAC wiring ..............................................................................................................6-5

Class A NAC Wiring ................................................................... ..........................................6-5

Class B NAC wiring ........................................................................................... .. .................6-6

vi

Page 7

Table of Contents

MSS IDNet wiring .............................................................................................................6-7

Overview ..............................................................................................................................6-7

Wiring parameters ................................................................................................................6-7

Class A wiring ......................................................................................................................6-8

Class B wiring ......................................................................................................................6-9

MSS auxiliary power wiring ..........................................................................................6-10

Guidelines ..........................................................................................................................6-10

Wiring .................................................................................................................................6-11

MSS auxiliary relay wiring ............................................................................................6-12

Guidelines ..........................................................................................................................6-12

Wiring .................................................................................................................................6-12

Chapter 7 PC software connections ................................................................7-1

Introduction ..........................................................................................................................7-1

In this chapter ................................................... ... ............................................. .. .................7-1

Software modes ................ ... ... ... .... ... ... ....................................... ... ... ... .... ... ... ... .... ...........7-2

Software modes ...................................................................................................................7-2

Ethernet service port ........... ... ... .... ... ... ... ... ......................................................................7-4

Ethernet service port overview .............................................................................................7-4

Chapter 8 System wiring checkout and earth fault diagnostics ...................8-1

Introduction ..........................................................................................................................8-1

In this chapter ................................................... ... ............................................. .. .................8-1

Checking system wiring .................................................................................................8-2

Overview ..............................................................................................................................8-2

Using the multimeter ............................................................................................................8-2

Meter readings .................................................. ............................................. ... .. .................8-3

Earth fault diagnostics ....................................................................................................8-4

Overview ..............................................................................................................................8-4

General guidelines .................................................. .. ...........................................................8-4

Earth fault searching from the front panel ....................................................................8-6

Overview ..............................................................................................................................8-6

Access level selection ..........................................................................................................8-6

Starting the Earth Fault Search ............................................................................................8-6

Search Option A: Select Location ........................................................................................8-7

Search Option B: Select Location ........................................................................................8-7

Search Option C: Last Search Result ..................................................................................8-8

Completing the search .........................................................................................................8-8

Earth fault search results ...............................................................................................8-9

Overview ..............................................................................................................................8-9

Non-point faults ....................................................................................................................8-9

Point Faults ..........................................................................................................................8-9

Fault Not Found ............................................................................ ... ... ...............................8-10

No Fault .............................................................................................................................8-10

Result Not Available ...........................................................................................................8-10

Chapter A ULC programming requirements ...................................................A-1

Introduction .........................................................................................................................A-1

In this chapter ................................................... ... ............................................. .. ................A-1

vii

Page 8

Table of Contents

Common earth fault ground indicator .......................................................................... A-2

Overview .............................................................................................................................A-2

Step 1. Open CPU card properties dialog ...........................................................................A-2

Step 2. Program the LED .................................................................................................... A-3

Simultaneous alarm display .......................................................................................... A-4

Overview .............................................................................................................................A-4

Creating annunciation zone lists .............................................................. ... ........................A-4

Programming the address and mode for each LED ............................................................A-5

Setting alarm verification timer to Canadian operation .............................................. A-7

Introduction .........................................................................................................................A-7

Procedure ...........................................................................................................................A-7

Setting Alarm Reset/Inhibit Timer ................................................................................. A-8

Overview .............................................................................................................................A-8

Enabling Alarm Reset/Inhibit Timer .................................................................................... A-8

Alarm Cutout Timer ........................................................................................................ A-9

Overview .............................................................................................................................A-9

Enabling Alarm Cutout Timer .............................................................................................. A-9

Chapter B UL programming requirements ......................................................B-1

Introduction .........................................................................................................................B-1

In this chapter ................................................... ... ............................................. .. ................B-1

Setting Alarm Verification to US operation .................................................................. B-2

Overview .............................................................................................................................B-2

Procedure ...........................................................................................................................B-2

Alarm Cutout Timer ........................................................................................................ B-3

Overview .............................................................................................................................B-3

Enabling Alarm Cutout Timer .............................................................................................. B-3

Non Steady Visual Evacuation system option ............................................................. B-4

Overview .............................................................................................................................B-4

Chapter C Simplex special application NAC-compatible notification appliances and

accessories ........................................................................................................C-1

Chapter D Cooper Wheelock appliances compatible with 4010ES Wheelock protocol

for special applications .....................................................................................D-1

Overview .............................................................................................................................D-1

Synchronizing horn strobes ................................................................................................ D-1

Synchronizing strobes .........................................................................................................D-2

Appliances with synchronizing strobes ...............................................................................D-3

Synchronizing horns ...........................................................................................................D-4

Coded audible appliances ...................................................................................................D-5

Non-synchronizing appliances ............................................................................................D-5

viii

Page 9

Chapter 1

Overview

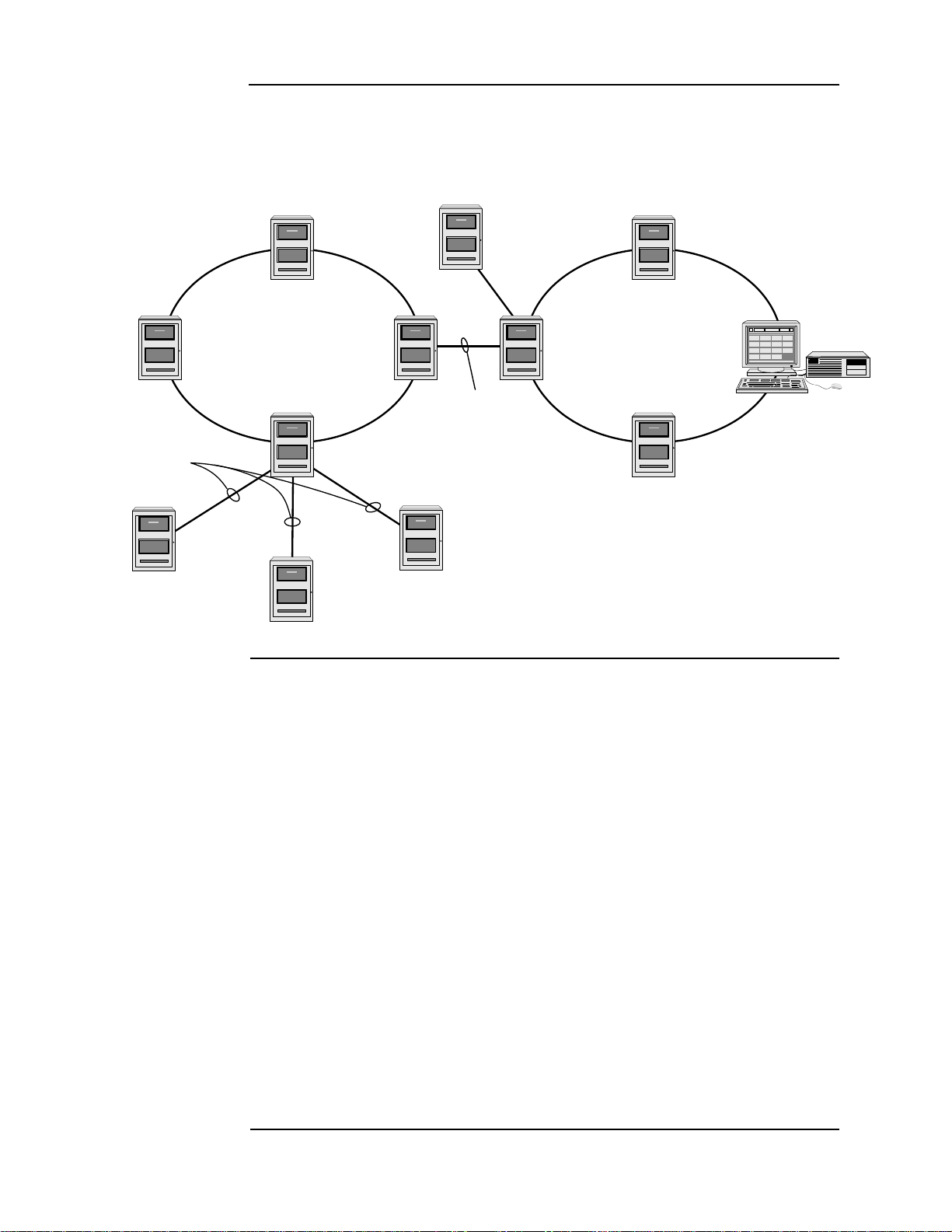

Introduction The 4100ES FACP panel is an expandable fire alarm panel, which can be used as a standalone

system, or can be networked with the following panels to create a larger network:

• 4002

• 4010

• 4020

• 4100

• 4100U

• 4100ES

• 4010ES

• 4007ES

• 4190 TrueSite Workstation

• 4190 TrueSite Incident Commander

• 4190 Network System Integrator

The 4100ES comes with basic system components pre-installed. This chapter provides an

overview of standalone and network 4010ES panel concepts:

Standalone. Comprised of on e 4010ES FACP and its assorted notification appliances,

initiating devices, and signaling line circuit devices.

Network. Multi-FACP systems connected by 4120 network cards. Each panel maintains the

status and control of its own circuit points, while monitoring and controlling activity at other

locations. Network nodes may perform similar tasks, or may be dedicated to specific

functions.

In this chapter This chapter covers the following topics:

Topic Page

Standalone configuration 1-2

Network configuration 1-3

1-1

Page 10

Standalone configuration

4010ES Panel

Remote Annunciation

(Graphical or LCD)

TrueAlert Non-Addressable

Devices

TrueAlarm Thermal

Sensor with Base

Monitor and

Control ZAMs

Addressable Station

Remote Line Powered

Isolator

Supervised

IAM

TrueAlarm Smoke

Sensor with Base

To additional IDNet devices

4009A Series

Devices

TrueAlert Non-Addressable

Devices

to Device(s)

to Device(s)

RUI

TrueAlert Non-Addressable

Devices

TrueAlert Non-Addressable

Devices

4010ES NAC

IDnet

Note: Some 4009-series

devices are controlled

through RUI and not

IDNet

4009T or

4009TPS

TrueAlert Addressable

Devices

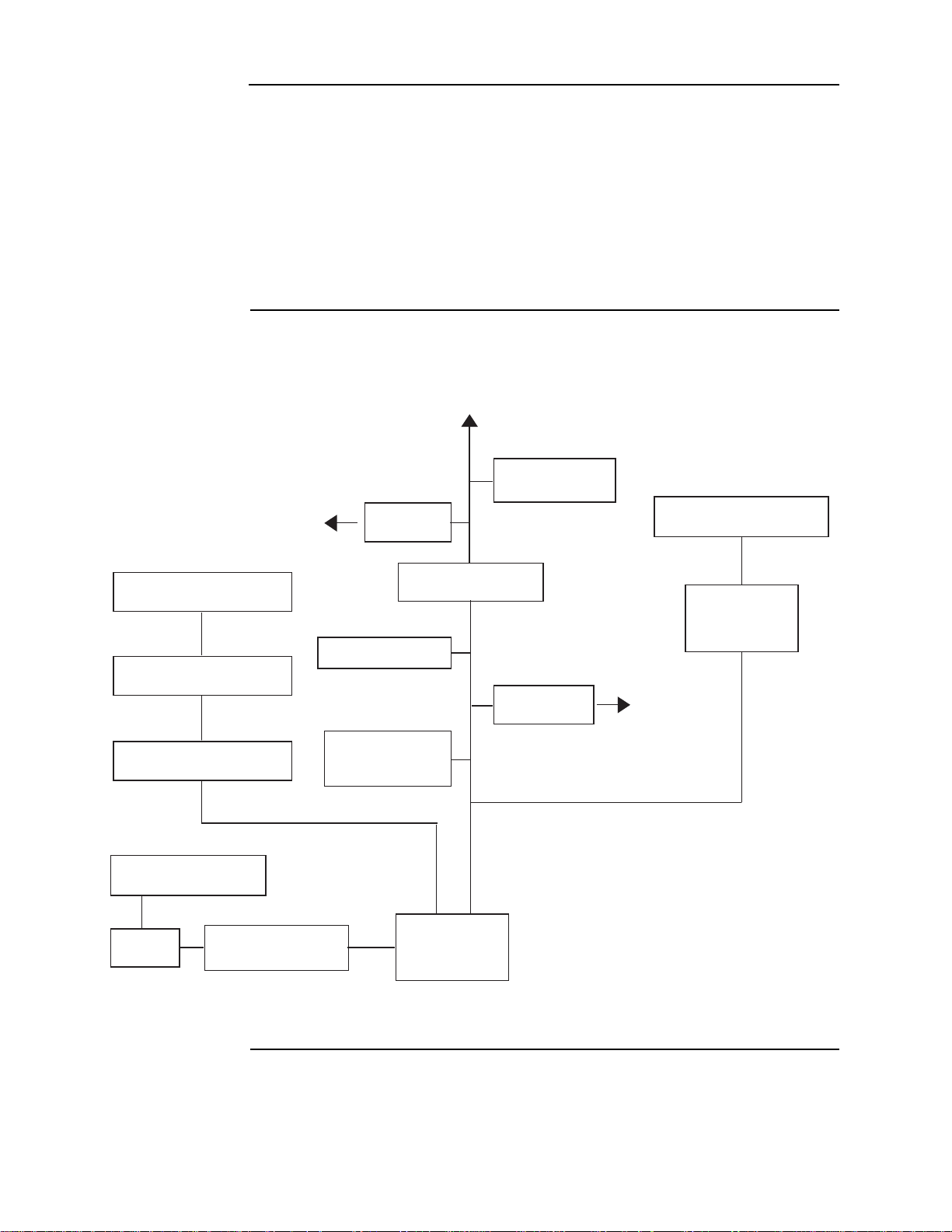

Overview The standalone version of the 4010ES is used for smaller, or single-building applications. A

standalone system is ideally placed into a small building that requires a limited number of

notification appliances and initiating devices.

If a small building is being expanded, or if other buildings are being constructed in the same

general area, as in a campus application, the standalone 4010ES can be upgraded to a network

system and linked with other 4010, 4100, 4100U, 4100ES and 4010ES panels to create a larger

network.

Note: You must order and install the 4010-9902 and the 4010-9922 network cards into the standalone

system to enable network functionality.

Standalone system layout

Figure 1-1 below shows the layout of the 4010ES standalone configuration.

Figure 1-1. Standalone 4010ES system

1-2

Page 11

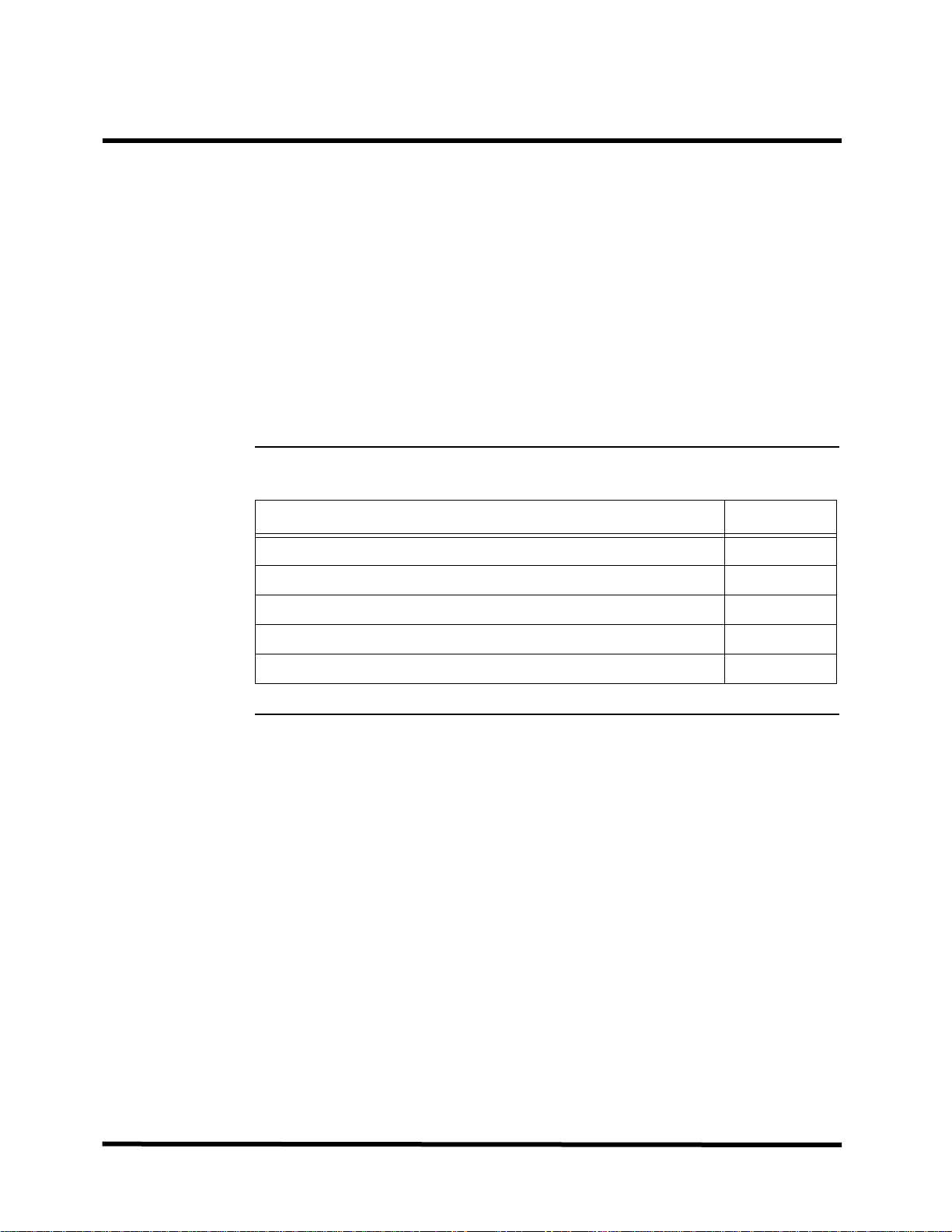

Network configuration

Ring Topology

Physical Bridge Links

(Star Topology)

TSW

Network Display Unit

(NDU)

Hub Node

Distributed Remote

Node Locations

Note: Physical Bridge

links in a 4010ES

requires a two-bay box

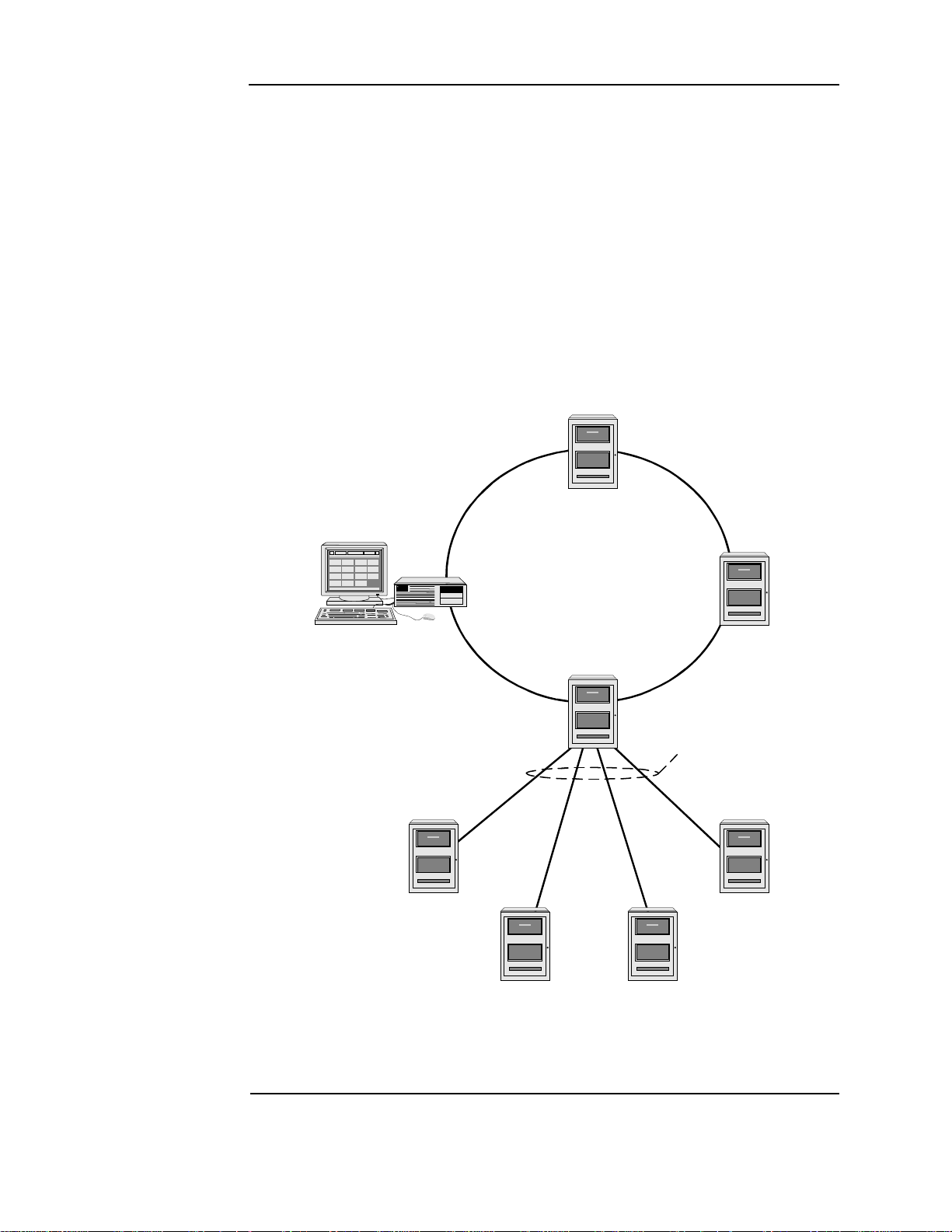

Overview The 4010ES can be expanded to a network system by using the 4010-9902 and the 4010-9922

network interface cards (NICs). When a NIC is installed into a 4010ES host panel, it is used to

connect to up to 98 other network nodes. Nodes may consist of other host 4010ES panels, or

they may be completely different: 4010ES FACPs and TrueSite Workstation (TSW) are

examples of what could be used as nodes. A node is a self-sufficient FACP that controls

appliances and devices, which also has the capability of controlling and communicating with

other nodes.

The network configuration supports two prevalent architectures or wiring configurations: hub

(or ring), or star. A networked system can also use a combination of the two.

The hub configuration consists of a main loop with nodes connected in a radial manner. The

star configuration consists of several nodes connected directly to one common node. Physical

bridge cards are used for the star configuration. Physical bridges reduce the amount of wire that

would otherwise be needed to connect all nodes in a loop. A combination of the two styles is

illustrated in Figure 1-2.

Figure 1-2. Hub/ring configuration

1-3

Page 12

Network configuration, continued

Remote Loop

Physical Bridge Link

Local Loop

Physical Bridging

(Star Configuration - 3 max)

TSW

Physical

Bridge

Link

Physical Bridge Links

Hub Node

Hub

Node

Remote

Node

Connecting network loops

Network loops can be joined by using physical bridge cards. There may be no more than two

Style 7 network loops, two hub configurations, connected in tandem. For every two loops that

are interconnected using one physical bridge, there can be a maximum of three physical

bridges used in a star configuration. See Figure 1-3.

Network communication

Network communication is achieved using the 4010-9902 and the 4010-9922 NICs. Each

network node requires a NIC. Once the FACP is a network node, it may be programmed to be

fully in control of other nodes, to be fully passive, or anywhere in between.

The 4010-9902 and the 4010-9922 NICs are option cards that use a PDI connector to

communicate with the CPU. The NICs allow for communication between each panel using a

fiber or twisted shielded pair wire in a Style 4 or Style 7 wiring configuration.

The NICs are designed to be connected in a point-to-point arrangement, so that one wire fault

does not cause the entire system to fail. The point-to-point arrangement provides the most

secure and fault-tolerant wiring possible.

Two types of media cards can be used with the NICs:

• The Fiber-Optic Media (4010-9819) card can be used for electrically noisy environments,

• The Wired Media Card (4010-9818) is used in all other types of applications.

Up to two media cards can be plugged into each NIC. The same NIC can use a combination of

different types of media boards; for example, a NIC may have a Wired Media card connected

to the left port, a Fiber-Optic Media card connected to the right port.

For setup and installation of a physical bridge card, refer to document 579-184: 4100/4120/

4010-Series Physical Bridges and Media Modules.

Figure 1-3. Interconnected loop configuration

or for connecting externally to other buildings.

For setup and installation of network interface cards, refer to document 579-956: 4010ES

Network Interface and Media Card Installation Instructions.

1-4

Page 13

Chapter 2

Basic Hardware

Introduction The 4010ES FACPs are one-bay or two-bay back boxes with a dead front and glass door,

containing a set of pre-installed basic system components:

• Dead front-mounted CPU (2x40 character LCD or InfoAlarm)

• Operator interface

• Main system supply (MSS) (notification appliance circuits and system power)

• 48-LED Module (for some 4010ES configurations)

• IDNet+ or MX Loop circuit (for initiating and other devices)

• PDI Blocks for optional modules

In addition to the basic modules, optional modules can be installed inside the one-bay or two-

bay 4010ES panels. The types of modules available depend on the panel configuration, as well

as the accessibility, and availability, of the power distribution interface (PDI) blocks. The

number of available PDI blocks depends on the system ordered. See Chapter 3, “Panel

Configurations.”

In this chapter This chapter covers the following topics:

Topic Page

CPU 2-2

Operator interface 2-8

Main system supply (MSS) 2-9

48-LED Module 2-14

System power 2-16

2-1

Page 14

CPU

SUPERVISORY LED (LED17)

2x40 LCD

USER-DEFINABLE LEDs TROUBLE LED (LED16)

(LED11-LED14, LED21, LED22)

CONTROL KEY LEDs PRIORITY 2 ALARM LED AC POWER LED (LED20)

(LED23-LED25)

(LED18)

FIRE ALARM LED (LED19) ALARM SILENCED LED (LED15)

Note: All LEDs on the front side of the board are used for standard fire

alarm functions and are visible through the dead front membrane.

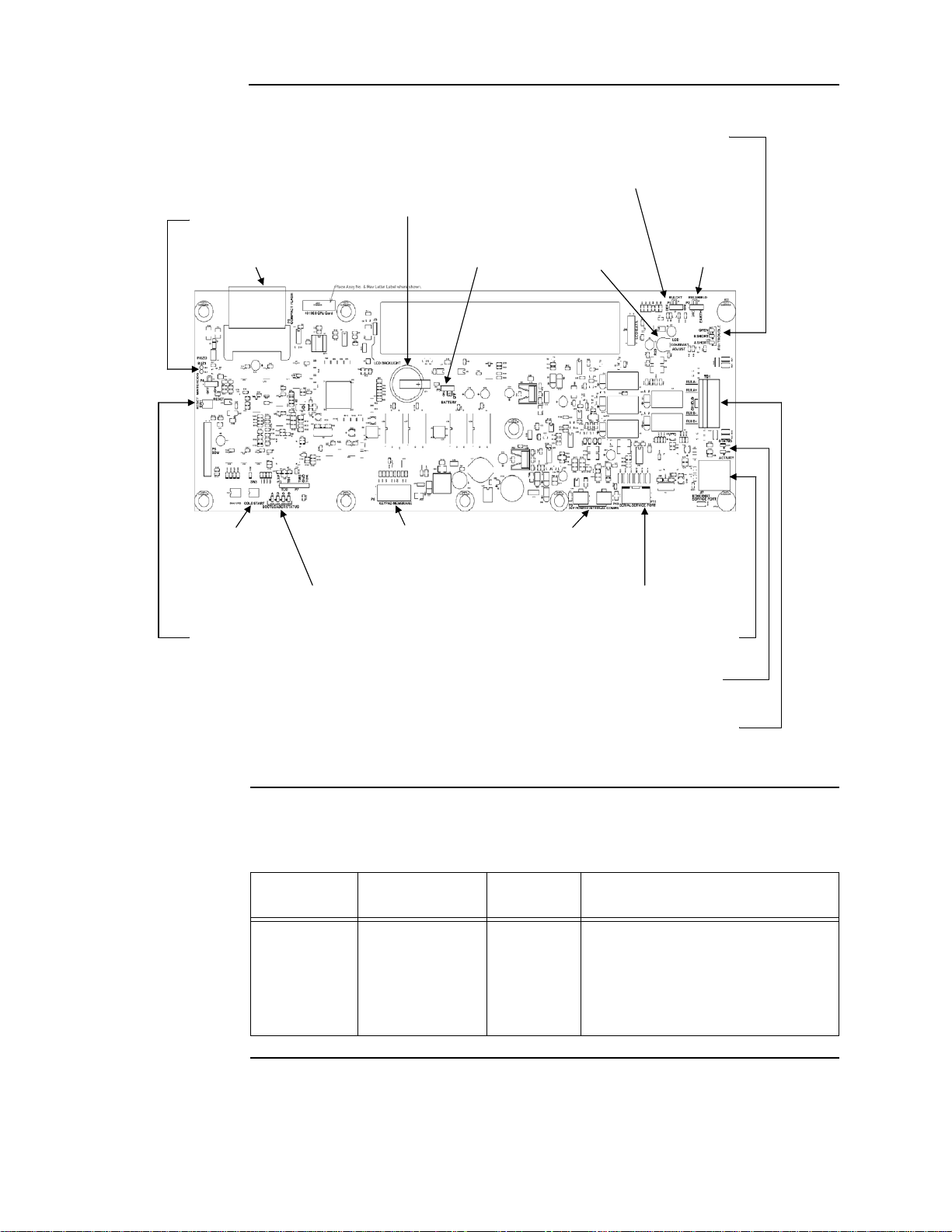

Overview The CPU card (Figure 2-1 and Figure 2-2) is the main decision maker in the 4010ES FACP. It

holds all job information, current system status, and communicates to all slaves connected to

the 4010ES panel. A 4010ES CPU contains the following features:

• 2 x 40 LCD display and piezo (non-InfoAlarm systems only) - Annunciation for

supervisory , trouble, priority 2 and fire alarm signals.

• Compact flash socket (card pre-installed) - Alternate exec and job storage.

• Ethernet service port - PC connection used by Simplex service personnel.

• Serial service port - Interface for service equipment or Simplex service personnel.

• Style 4/7 Remote Unit Interface - Remote connection to system components not located

within 4010ES box.

Figure 2-1. Dead front-mounted CPU with a 2 x 40 display (front view)

Continued on next page

2-2

Page 15

CPU, continued

RUI TROUBLE LEDs (LED1-LED3)

RUI ENABLE JUMPER (P1)

BATTERY (BT1)

PIEZO CONNECTION (BUZ1)

BATTERY ENABLE LCD CONTRAST RUI SHIELD

COMPACT FLASH (P3) JUMPER (P5) ADJUST (R23) JUMPER (P2)

COLD START KEYPAD MEMBRANE 24V POWER/COMMS

SWITCH (SW3) CONNECTOR (P8) CONNECTORS (P9 & P10)

BOOTLOADER STATUS LEDs (LED7-LED10) SERIAL SERVICE PORT (P11)

RESET SWITCH (SW1) ETHERNET SERVICE PORT (J7)

ETHERNET STATUS LED (LED5) & ACTIVITY LED (LED6)

RUI PLUGGABLE TERMINAL BLOCK (TB1)

Overview

Figure 2-2. Dead front-mounted CPU with a 2 x 40 display (back view)

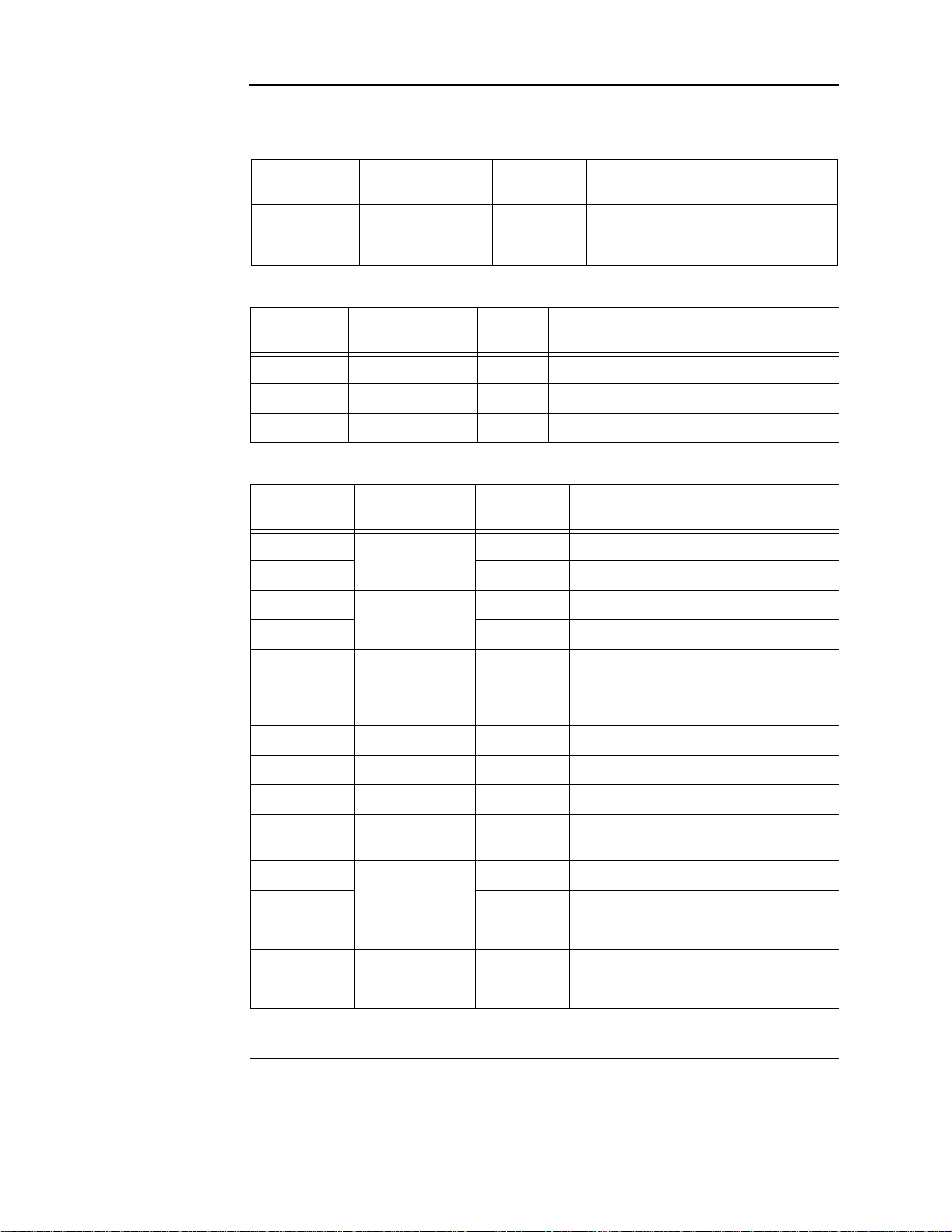

CPU LEDs The tables below outline the functions of the LEDs on the CPU card.

Table 2-1. Reset LED

Reference

designator

LED4 RESET Yellow

Silkscreen name Color Status

ON = CPU is in reset

FLASHING = Board is unable to come

out of reset. Possibly corrupt CFIG, or

board needs to be replaced.

OFF = CPU is running normally

2-3

Continued on next page

Page 16

CPU, continued

CPU LEDs

T able 2-2. Ethernet LEDs

Reference

designator

LED5 STATUS Green ON = Cable connected

LED6 ACTIVITY Red FLASHING = Ethernet activity

Reference

designator

LED1 OPEN Yellow ON = Class A fault (open-circuit) or a short

LED2 B SHORT Yellow ON = Short-circuit on the primary side

LED3 A SHORT Yellow ON = Short-circuit on the secondary side

Reference

designator

LED11

LED12 Yellow ON = User-definable key A active (Note)

LED13

LED14 Red ON = User-definable key B active (Note)

Silkscreen name Color Status

Table 2-3. RUI trouble LEDs

Silkscreen name Color Status

Table 2-4. Front panel LEDs

Silkscreen name Color Status

Red ON = User-definable key A active (Note)

USER-DEF A

Yellow ON = User-definable key B active (Note)

USER-DEF B

LED15

LED16 TRBL Y ellow ON = Trouble

LED17 SUPV Yellow ON = Supervisory

LED18 PRI2 Red ON = Priority 2 alarm

LED19 FIRE Red ON = Alarm

LED20 AC POWER Green

LED21

LED22 Green ON = User-definable key C active (Note )

LED23 CTRL 1 Yellow ON = Control key 1 active

LED24 CTRL 2 Yellow ON = Control key 2 active

LED25 CTRL 3 Yellow ON = Control key 3 active

Note: Only one LED in each user-definable pair will be on at a time, never both.

ALARM

SILENCED

USER-DEF C

Yellow ON = Alarm silenced

ON = System power is functioning

properly

Yellow ON = User-definable key C active (Note)

Continued on next page

2-4

Page 17

CPU, Continued

CPU LEDs

Table 2-5. Bootloader status LEDs

Status

Reference

designator

Silkscreen

Name

LED7 LED8 LED9 LED10

AB C D

Color Green Green Green Green

Bootloader

Initialization

Bad Master

CRC or No

Master

Present

Diagnostic

Fail - RAM

Diagnostic

Fail -

Bootloader

CRC

Downloading

Master

Downloading

CFIG

Downloading

MsgLib

On (0.25 s)

Off (0.25 s)

Off Off Off On

On Off Off On

Off On Off On

On On Off On

Off Off On On

On Off On On

On (0.25 s)

Off (0.25 s)

On (0.25 s)

Off (0.25 s)

On (0.25 s)

Off (0.25 s)

CPU jumper settings

Downloading

Bootloader

Download

Successful

Off On On On

On On On On

T able 2-6. CPU settings

Reference designator Silkscreen name Position Function

1-2 Enable RAM battery backup

P5 BATTERY

2-3 (default) Disable RAM battery backup

1-2 (default) Disable RUI

P1 RUI CKT

2-3 Enable RUI

1-2 (default) RUI shield tied to 24C (Note)

P2 RUI SHIELD

2-3 RUI shield tied to earth

Note: Some devices that connect to RUI have inherently grounded shield terminals, in which case, 24C

cannot be used. If 24C is used, a negative earth fault will occur.

2-5

Page 18

CPU, continued

CPU switches

Table 2-7. Switches

CPU connectors/ ports/terminal block

Reference

designator

SW1 RESET

SW3 COLD START

Reference

designator

P3 COMPACT FLASH

Silkscreen name Function

Silkscreen name Function

Short press (< 3 seconds) to activate a software-controlled

reset (warm start).

Press and hold (> 3 seconds) to force a hardware reset

(also a warm start).

Generally, unless the CPU card appears to be locked up,

you should always use the software-controlled reset.

A warm start preserves the logs and the disabled status of

any points that are in the disabled state.

During startup, press and hold this button to clear all history

logs and enable any points that were previously disabled.

Table 2-8. Connectors/po rts/terminal bl ock

Used for alternative job/exec storage. Card does not

“run” out of compact flash.

P8

P9 & P10

P11

J7

TB1

KEYPAD

MEMBRANE

24 V POWER/

INTERNAL COMMS

SERIAL SERVICE

PORT

Ethernet SERVICE

PORT

RUI A-, RUI A+,

SHIELD, RUI B-, RUI

B+

Used to communicate user inputs from the keypad

membrane to the CPU card.

Used to provide the necessary connections to daisy

chain 4100 comms and 24 VDC card power in an in-out

fashion. 24 VDC card power originates from the MSS.

4100 comms originates from the CPU card.

Used to connect the CPU card to the remote service

gateway. It may also be used as a service port if the

Ethernet service port is not available.

Used to connect the panel to a local PC through the front

panel Ethernet connection board, or 4010-9914 BNIC.

Remote user interface (RUI) used for communication

between the CPU and remote slaves.

2-6

Page 19

CPU, continued

CPU card specifications

Table 2-9 shows the battery current draw for the CPU card.

Table 2-9. Battery standby (24 V)

Configuration Supervisory current draw Alarm current draw

RUI disabled 124 mA 173 mA

RUI enabled - no load 149 mA 198 mA

RUI enabled - full load 176 mA 225 mA

T able 2-10 shows the maximum draw over the voltage range.

Table 2-10. Maximum draw over voltage range

Configuration Supervisory current draw Alarm current draw

RUI disabled 144 mA 208 mA

RUI enabled - no load 167 mA 226 mA

RUI enabled - full load 186 mA 248 mA

Note: CPU InfoAlarm supervisory and alarm current draws are both the same as the supervisory current

draw.

2-7

Page 20

Operator interface

A B C D E F G H I

J K L M N O P Q R

'S P' ( ) , # :

S T U V W X Y Z /

ZONE

1

SIG2AUX

3

FB4IO5IDNet

6

P7A8L

9

NET ADDR

0

C/Exit

Menu Enter

Prev ious

Next

Page Dn

Page Up

AC

Power

ALARMS

Fire

Alarm

Prior ity 2

Alarm

WARNINGS

System

Supervi sory

System

Trouble

Alarm

Silenced

Fir e A l ar m

Ack

Prior ity 2

Ack

Supv

Ack

Trouble

Ack

Alarm

Silence

System

Reset

Ground Fault

Water flow-We st

Waterflow-East

Cit y Disconnect

Manual E vac

Door Hold er

Bypass

Drill

Language

Toggle

Smoke Sensor

Almost Dirty Ch eck

Lamp Test

Overview The two operator interfaces which are available with the 4010ES are shown below.

The operator interface is used to obtain fire alarm, priority 2, supervisory, trouble, and other

statuses through the display and LEDs. Control functions are accessed using dedicated and

user-programmable keys.

Figure 2-3 is the standard 2 x 40 LCD operator interface. This model includes a 2 line by 40

character liquid crystal display. The membrane is available in both English and French.

Figure 2-3. Stan da rd op era t or interfa ce

Figure 2-4 is the InfoAlarm operator interface. This model includes a larger graphical display,

which can display more information simultaneously.

Note: The InfoAlarm operator interface can only be installed on two-bay 4010ES panels. See Chapter 3,

“Panel Configurations,” for details on two-bay panels.

Figure 2-4. InfoAlarm operator interface

2-8

Page 21

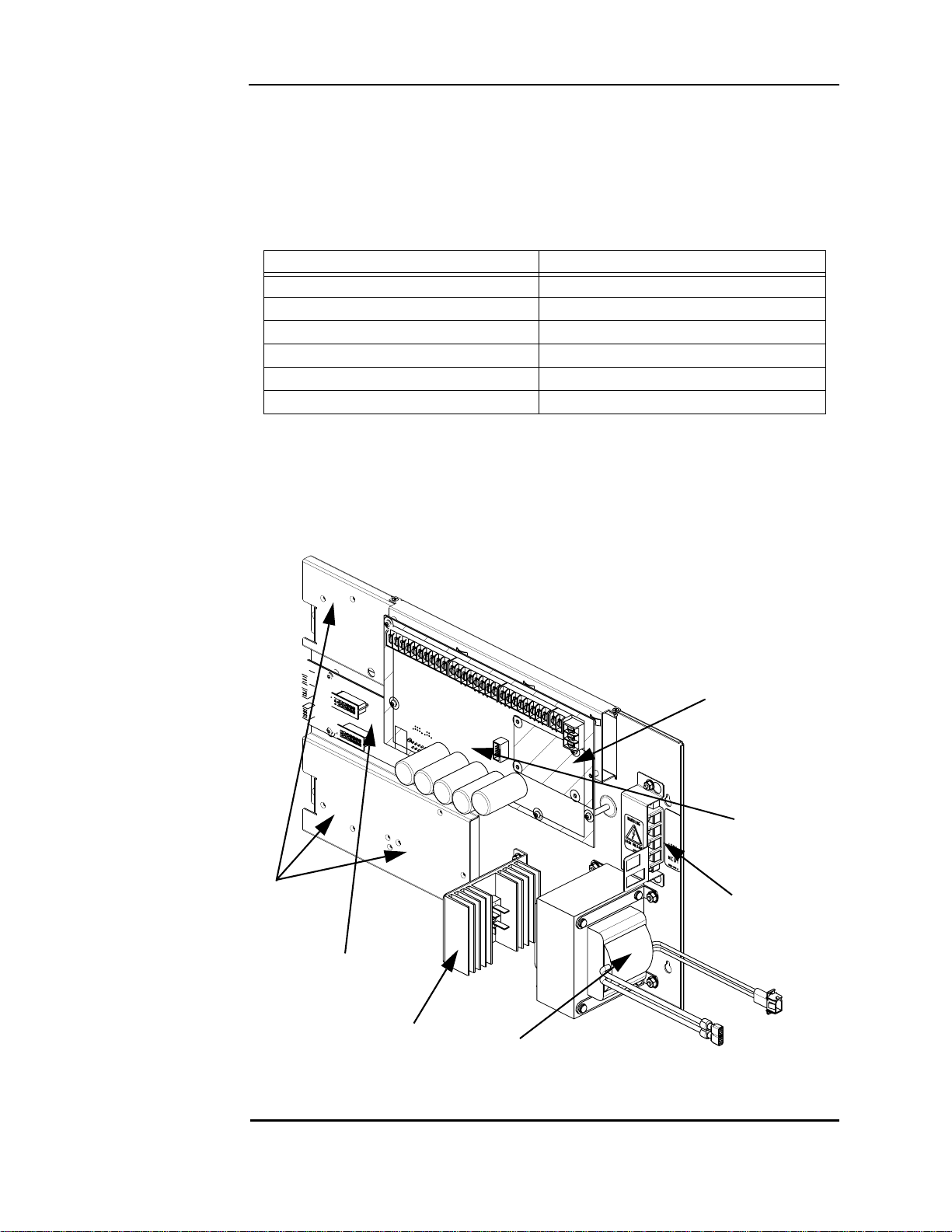

Main system supply (MSS)

Top Bay

PDI card

Rectifier

Option Card

Blocks

Optional City Card

or Relay Card

Mounting Space

Transformer

AC Block

MSS

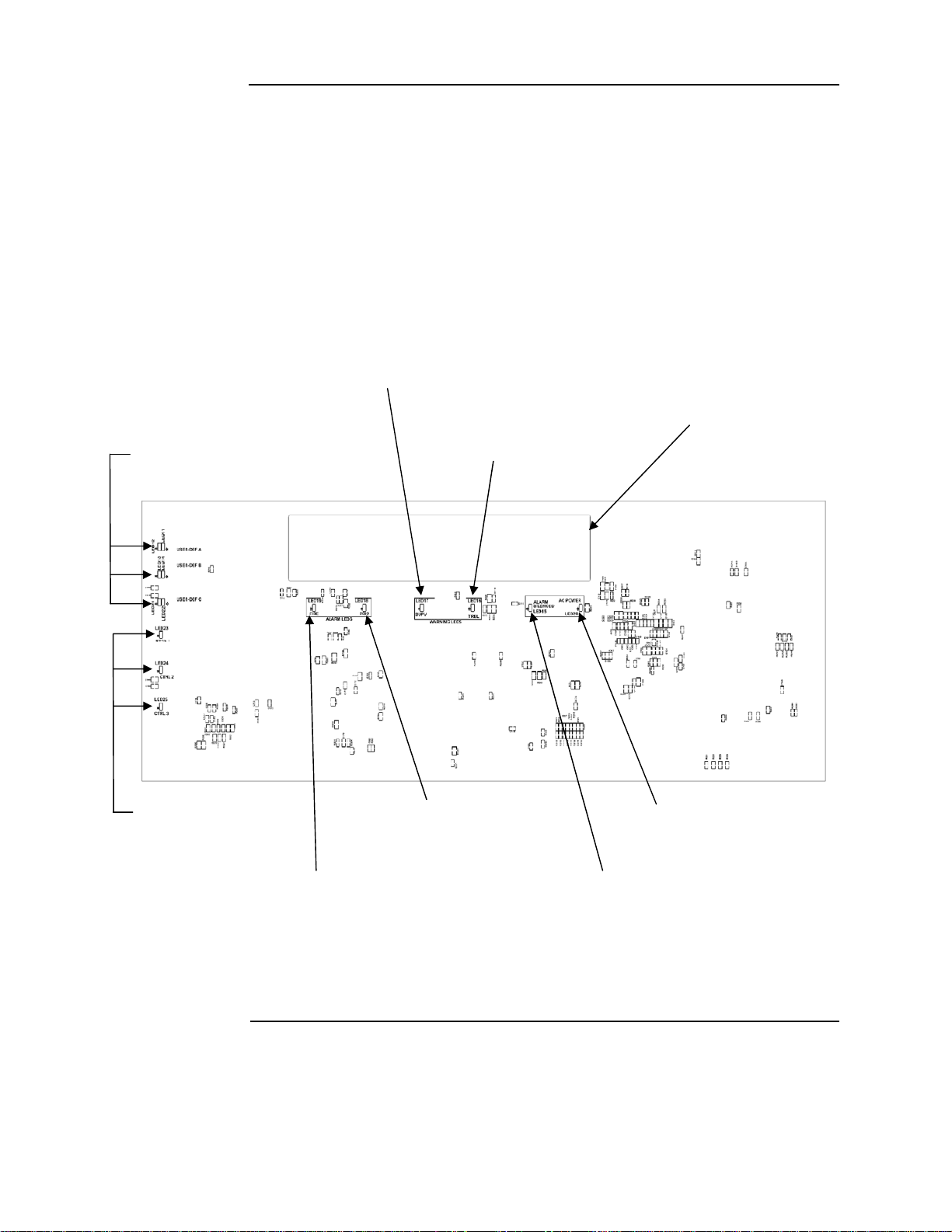

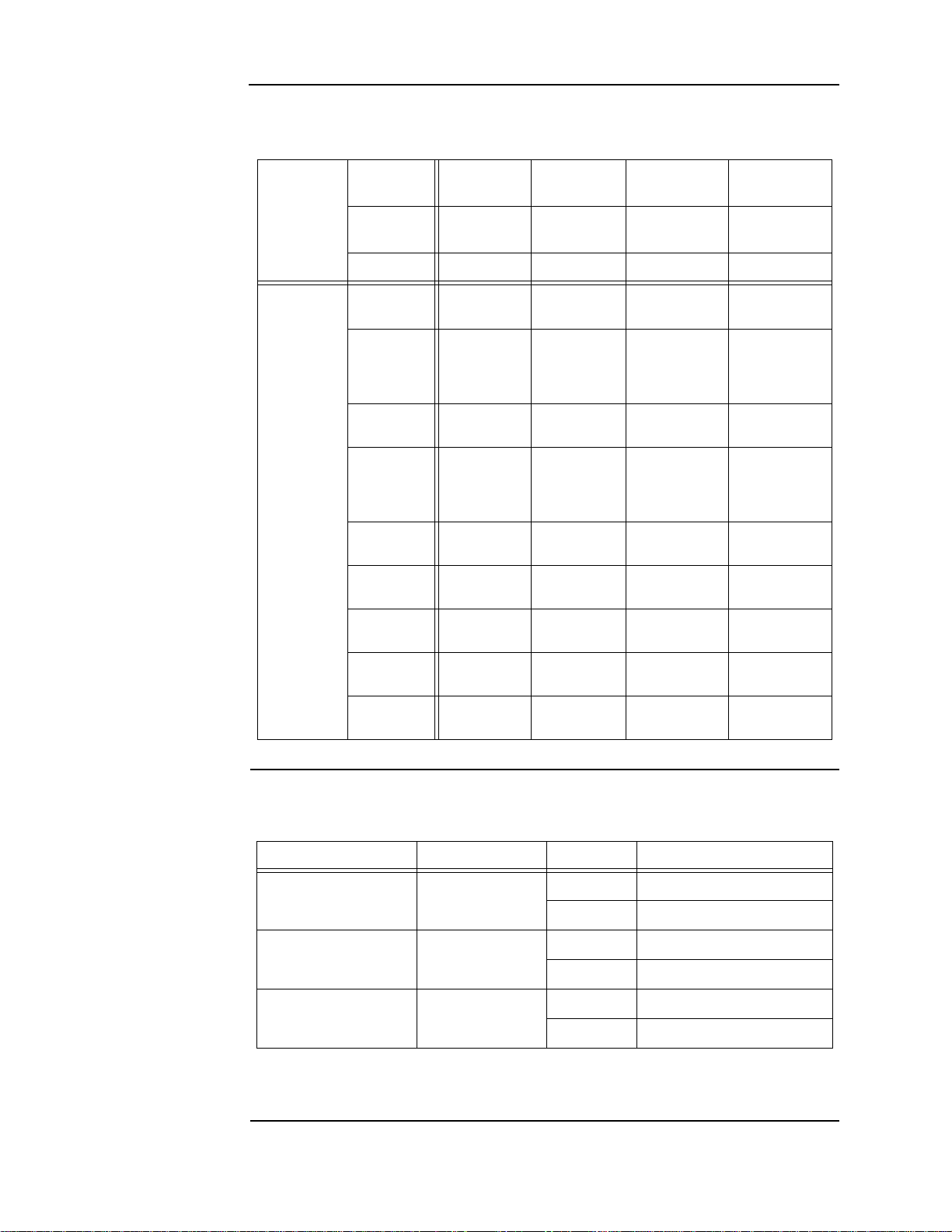

Overview The MSS is the power source for the FACP. It provides 24 VDC card power to the 4010ES.

T able 2-11 lists the MSS capabilities.

The MSS also performs standard fire alarm functions, such as brownout detect, battery transfer,

battery recharge, earth fault detection, and power limiting per UL 864. It is shipped, installed,

and connected in the 4010ES panel. Figures 2-5 and 2-6 illustrate a 4010ES MSS.

Table 2-11. MSS capabilities

MSS with IDNet MSS without IDNet

8 A of available power 8 A of available power

4 Class A NACs 4 Class A NACs

Battery charger (Note) Battery charger (Note)

1 AUX relay (2 A, 32 V) 1 AUX relay (2 A, 32 V)

1 AUX power tap (2 A) 1 AUX power tap (2 A)

Single channel, Dual Isolated Loop IDNet+

Note: The 4010ES can hold a maximum of 33 Ah batteries in the one-bay box and 50 Ah in the two-

bay box. The MSS charger is listed for 110 Ah UL and 50Ah ULC.

Note: The type of MSS you get depends on the base panel selected. See Chapter 3, “Panel

Configurations.”

Figure 2-5. MSS shown with IDNet

Continued on next page

2-9

Page 22

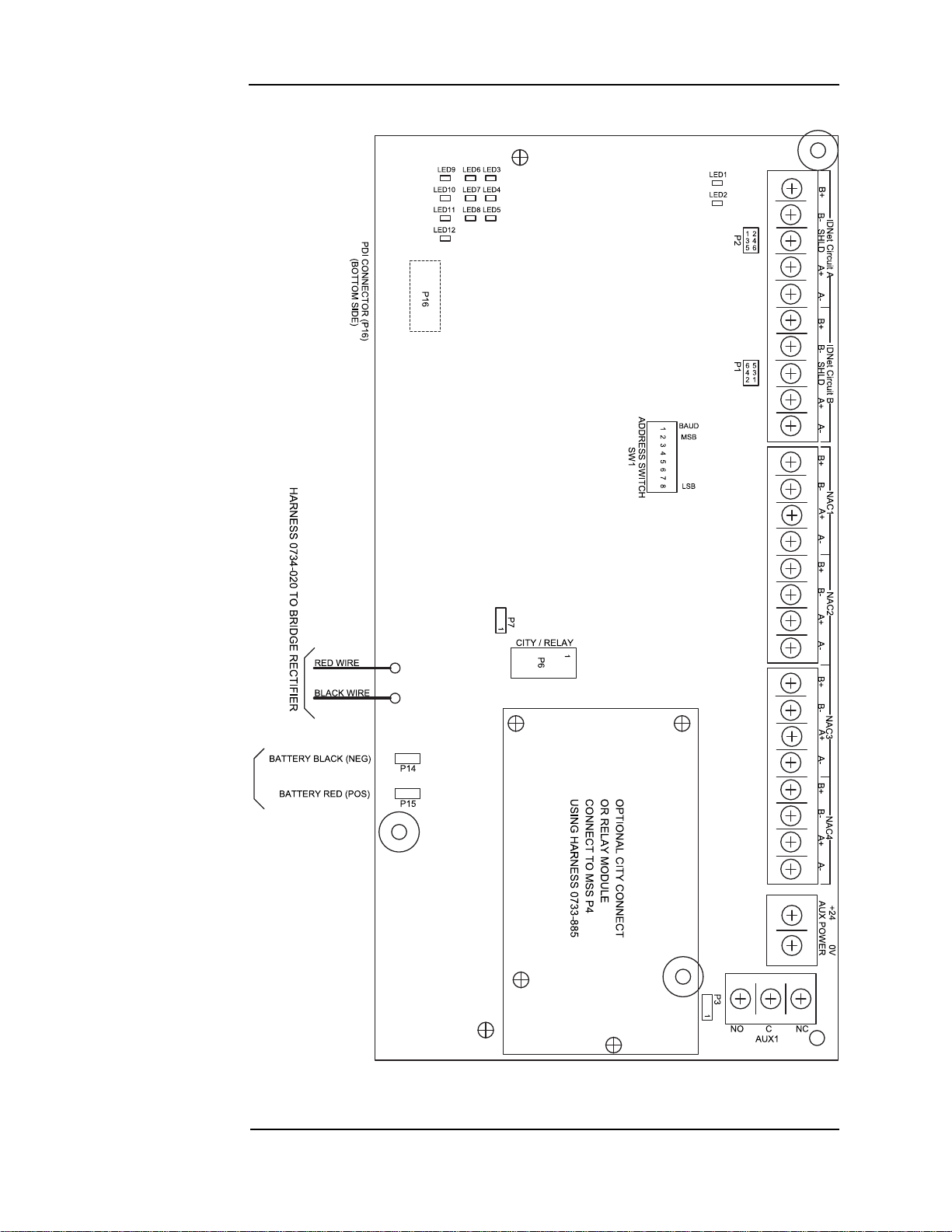

Main system supply (MSS), continued

Overview

Figure 2-6. MSS LEDS and switches

2-10

Page 23

Main system supply (MSS), Continued

MSS LEDs and jumpers

Tables 2-12 and 2-13 list the details associated with the LEDs and jumpers on the MSS.

Table 2-12. MSS LED Functions and Indications

LED number Silkscreen name Status

LED1 IDNet POS. EARTH ON = IDNet POS. EARTH (Note)

LED2 IDNet NEG. EARTH ON = IDNet NEG. EARTH (Note)

LED3 IDNet

LED4 IDNet CIRCUIT A ON = CLASS A / OPEN TRBL

LED5 IDNet CIRCUIT B ON = CLASS A / OPEN TRBL

LED6 4100 COMMS ON = COMM LOSS

LED7 GENERAL POWER TRBL

LED8 AC POWER ON = MSS POWER FROM AC MAIN

LED9 NAC1 NAC1 TRBL or NAC1 “ON”

LED10 NAC2 NAC2 TRBL or NAC2 “ON”

LED11 NAC3 NAC3 TRBL or NAC3 “ON”

STEADY = NO DEVICE DETECTED

BLINK = SHORT CIRCUIT TRBL

STEADY = OVERCURRENT

SINGLE BLINK = POS. EARTH

DOUBLE BLINK = NEG. EARTH

TRIPLE BLINK = BATTERY TRBL

QUAD BLINK = CHARGER TRBL

LED12 NAC4 NAC4 TRBL or NAC4 “ON”

Note: The IDNet circuit on the MSS is electrically isolated and has its own earth fault detection circuit.

The IDNet earth fault detection circuit detects a 10K Ohms (or less) stray impedance to earth

ground.

Table 2-13. MSS Jumper Functions

Jumper

number

P1 IDNet CIRCUIT B

P2 IDNet CIRCUIT A

P3 EARTH DETECT (Note 2)

P7

Note 1. When jumpers are set for Class B (Style 4) on IDNet, you may use both the B-side and the A-side

to wire devices. Thus, for Circuit B, you can have two pairs of wires per side or four branches per

circuit.

2. Only one power module should be set for earth fault monitoring for each location within a system.

Normally, the MSS is set to monitor for earth faults. The earth fault detection circuit will detect a

10K Ohms (or less) stray impedance to earth ground. The expansion battery charger (XBC,

4081-9306, -9308) may also be set to monitor for earth faults. When an XBC is used to provide

battery backup for a 4010ES panel, disable the earth fault detection on the XBC.

Silkscreen name Position Function

LOW BATTERY

DISCONNECT

CLASS B (STYLE 4) (Note 1)

CLASS A (STYLE 7)

CLASS B (STYLE 4) (Note 1)

CLASS A (STYLE 7)

ENABLE

DISABLE

DISABLE (DOMESTIC)

ENABLE (CANADA)

1-3, 2-4

3-5, 4-6 (DEFAULT)

1-3, 2-4

3-5, 4-6 (DEFAULT)

1-2 (DEFAULT)

2-3

1-2 (DEFAULT)

2-3

2-11

Page 24

Main system supply (MSS), continued

MSS specifications

Table 2-14 lists the specifications for the MSS.

Table 2-14. Input and output specifications

AC input specifications

MSS in 120V FACP 4 A maximum

120 VAC @ 60 Hz, nomi nal (Note 1)

MSS in 220/240V FACP 2 A maximum

220/230/240 VAC @ 50 or 60 Hz (Note 1)

DC output specifications

All MSSs Minimum: 19.9 VDC (special applications)

Maximum: 31.1 VDC

Ripple: 2 VDC p-p @ full load (8 A)

MSS with IDNet output (see

note)

Battery charger specification s (Note 3)

Input voltage range 21-33VDC

Output float voltage

High voltage output 29.1 V @ 3.3 A

Output current limit 1.4 A for 6.2 - 18 Ah battery

30V or 35V (Note 2)

o

27.4 VDC ±500 mV @ 20

24 mV to -36 mV/×C (32

C, temperature compensated at -

o

F to 120oF or 0oC to 49oC)

3.3 A (default; for 18-50 Ah battery- Canadian; for 18-110 Ah

battery - U.S.)

Note: 1. The MSS detects a low or missing AC input and switches to batteries automatically. The system

returns to AC when it detects the presence of acceptable AC levels for a minimum of 30 seconds. AC

wiring must run from a dedicated AC branch circuit, and the breaker/wiring must be sized according

to local codes.

2. When it is necessary to activate large numbers of output devices on IDNet peripherals, such as

piezo sounders, the output voltage increases to 35V to provide sufficient voltage at the end of line to

activate the piezo. The higher voltage state is an alarm condition for the purpose of standby battery

calculation. The 30V output is the normal condition, and is used to prolong battery standby. The CPU

will activate the boost feature when 10 LED, Piezo or other outputs are activated.

3. The battery circuit is supervised for overcurrent, low battery and missing or depleted battery.

Continued on next page

2-12

Page 25

Main system supply (MSS), continued

MSS

specifications

Tables 2-15 and 2-16 list the battery current draw for the MSS. The assumed voltage is

24 VDC, which is rated battery voltage for lead-acid type batteries.

Table 2-15. MSS with IDNet current specifications

Standby conditions (Note 1)

No alarms (NACs normal); TBL relay activated; IDNet LED ON, No IDNet devices connected 140 mA 190 mA

Add to above for each additional set of 50 IDNet devices in standby 40 mA

Total current for fully loaded IDNet channel (248 devices) in standby 339 mA 450mA

Alarm conditions (Note 2)

4 NACs ON (Note 3); TBL Relay Activated; IDNet LED ON, No IDNet devices connected 165 mA 220 mA

Add to above for each set of 50 IDNet devices in alarm 50 mA

Add to above for 20 LEDs ON 40 mA

Total current for a fully loaded IDNet channel (248 devices) in alarm (20 LEDs ON) 453 mA 600 mA

Current

(battery standby 24V)

Current

(battery standby 24V)

Current

(max)

Current

(max)

Table 2-16. MSS without IDNet current specifications

Standby conditions (Note 1)

No Alarms (NACs normal); TBL Relay activated 70 mA 110mA

Alarm Conditions (Note 2)

4 NACs ON (Note 3); TBL Relay activated 100 mA 150 mA

Current

(battery standby 24V)

Current

(battery standby 24V)

Current

(max)

Current

(max)

Note: 1. Additional standby conditions: Auxillary relay activated, power trouble LED on, battery charger off,

auxiliary power load = 0 mA.

2. Additional alarm conditions: Auxillary relay activated, power trouble LED on, battery charger off,

auxiliary power load = 0 mA, NAC alarm load = 0 mA, IDNet = 35 V.

3. Notification power must also be taken into account for alarm current. Consult the notification

appliances, used installation manuals to determined the current draw for each appliance used.

The notification appliance circuits on the MSS are rated for special application and for

regulated 24 VDC operation per UL864, 9th Edition.

When used with the notification appliances listed in Table C-1 (Appendix C) or Table D-1

(Appendix D), each NAC is rated for 3 A, and total MSS capacity is rated at 8 A. This rating is

the UL864 special application rating. Appliances listed in Tables C-1 or D-1 are synchronized

per UL864 between all NACs on the MSS, and any NACs on a MSS or 4009As within the

same 4010ES system.

When using notification appliances not listed in Tables C-1 or D-1, each circuit is rated for 2 A

maximum, with a total notification appliance load of 4 A per MSS. This rating is the UL864

regulated 24 VDC rating. Synchronization of strobes and other appliances requires use of the

associated, listed, compatible synchronization module. Consult the supplier of notification

appliances for synchronization limits and details.

Simplex appliances (Table C-1) may not be mixed with Wheelock appliances (Table D-1) on a

single power supply. A 4010ES system with mix of appliances from Tables C-1 and D-1 will

not meet the UL864 9th Edition requirement for visual synchronization (10 milliseconds)

between power supplies. Appliances listed in Table C-1 will be consistently out of visual sync

with appliances in Table D-1 by about 30 milliseconds. Appliances listed Ta ble C-1 will be

notably out of audible sync with appliances in Table D-1 by a consistent time, Wheelock

leading by 1/2 second. In order to meet the requirements for visual and audible sync system

wide, all appliances in the system must be exclusively from either Table C-1 or D-1. Nonpulsing, linear-type notification appliances, such as horns or bells may be used up to the full

rating (3 A/NAC, 8 A total for the MSS).

2-13

Page 26

48-LED Module

Overview The 48-LED Module (Figure 2-7) comes pre-installed inside some base configurations of the

4010ES panel. Each LED can be associated with a point, or group of points. By default, the

module is supplied with red LEDs, except for the last column which has yellow LEDs. All of

the LEDs can be replaced by different color LEDs. Refer to Chapter 4, “LED Kits for the 48LED Module,” for a list of LED kits. Refer to Chapter 5, “Installing 4010ES Systems,” for

instructions on replacing LEDs.

Figure 2-7. 48-LED Module (front view)

Figure 2-8 outlines what the different LEDs, jumpers and switches represent.

Figure 2-8. 48-LED Module LEDs, jumper s an d switches (rear view)

2-14

Page 27

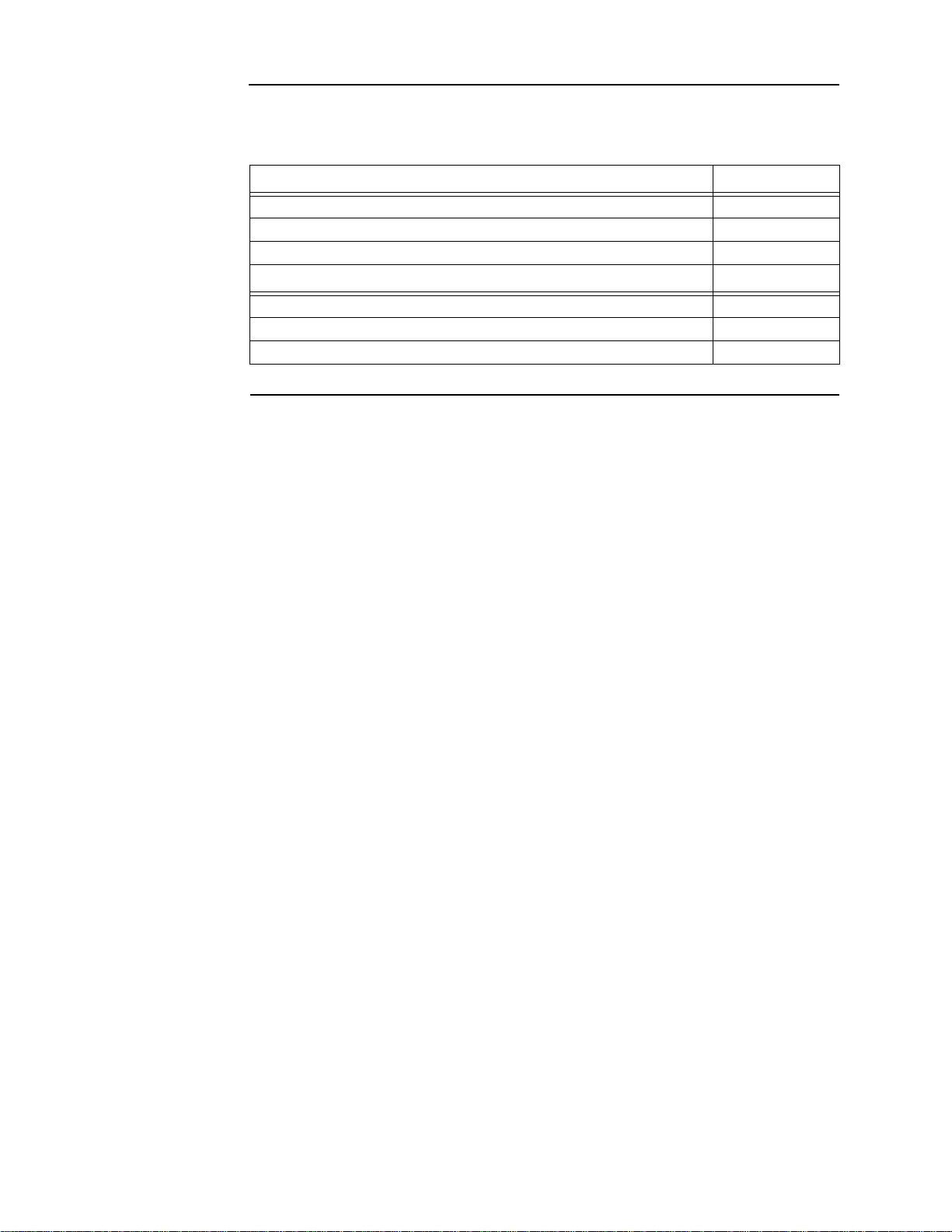

48-LED Module, continued

48-LED Module specifications

Standby current Current

LED controller circuit 20 mA

Add to above for each additional LED that is on 1.89 mA

Total current for fully loaded 48-LED Module 111 mA

Maximum alarm current

LED controller circuit 20 mA

Add to above for each additional LED that is on 2.39 mA

Total current for fully loaded 48-LED Module 135 mA

Table 2-17. 48-LED Module current specifications

Current

2-15

Page 28

System power

Main system power

Backup batteries A pair of 12V sealed lead acid batteries are used as a backup power source in the event of AC

The 4010ES FACP is powered primarily by the MSS. The MSS draws power from the main

power line, via an AC block, a transformer and a rectifier (Figure 2-5). In the case of main

power failure, backup power is provided by backup batteries.

failure. The backup batteries are ordered and shipped separately from the 4010ES system. They

are installed at the bottom of the 4010ES back box.

Batteries larger than 33 Ah for a one-bay 4010ES and 50 Ah for a two-bay 4010ES can be

used. However, they must be accepted and installed per UL and local authority requirements

using 4100-5128 Battery Distribution Terminal Block. The connection from the battery box to

the 4010ES panel must be within 20 feet and in conduit.

For 50 Ah external batteries with a one-bay box, use box 2081-9282 Remote Battery Cabinet

(Red). For 110 Ah external batteries with a one or two-bay box, use box 2081-9280 Remote

Battery Cabinet (Red).

2-16

Page 29

Chapter 3

Panel configurations

Introduction The 4010ES comes in either in a one-bay or a two-bay configuration. Each of these can be

ordered in a variety of base systems to satisfy various market needs.

In this chapter This chapter covers the following topics:

Topic Page

One-bay 4010ES Panels 3-2

Two-bay 4010ES Panels 3-6

3-1

Page 30

One-bay 4010ES Panels

With 48 LED Module

Without 48 LED Module

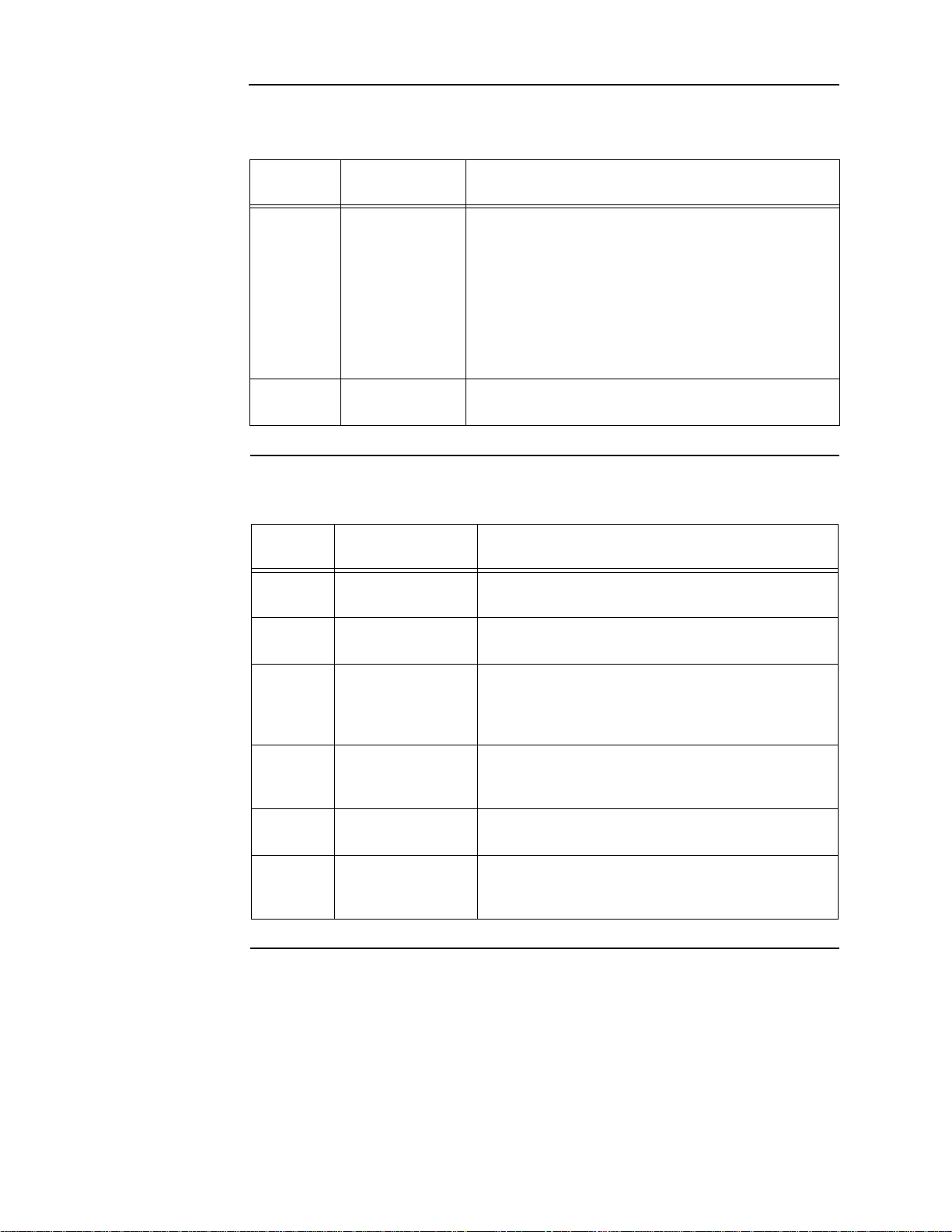

Overview The basic components are shipped pre-assembled inside the 4010ES panel. The optional

components need to be ordered and installed separately.

The one-bay 4010ES panel comes in three configurations. Table 4-1 of Chapter 4, “Orderable

Panels and Devices,” lists the basic components that are shipped with each of the three

configurations.

Note: The dead front on a one-bay 4010ES panel is different for 48-LED Module configurations, as seen in

Figure 3-1. See Figure 3-2 for detailed diagrams of one-bay 4010ES panels.

Figure 3-1. One-bay dead front with and without 48-LED Module

3-2

Continued on next page

Page 31

One-bay 4010ES Panels, continued

Without 48-LED Module

With 48-LED Module

Glass Door

Glass Door

Dead

Front

Dead

Front

CPU

CPU

Back

Box

Back

Box

Option Card

Mounting Space

Option Card

Mounting Space

48-LED

Module

Overview

Figure 3-2. One-Bay 4010ES Panel

3-3

Page 32

One-bay 4010ES Panels, continued

Optional modules In addition to the basic modules, optional modules can be installed inside the one-bay 4010ES

panels. The types of modules available depend on the panel configuration as well as the

accessibility and availability of the power distribution interface (PDI) blocks.

Note: Out of four PDI blocks in the top bay PDI card, three are available since the MSS card utilizes one

(Figure 2-5).

Table 3-1 lists the optional modules that can be installed insid e the different configurations of

the 4010ES panels. Refer to the user manual associated with each card for specifications and

installation instructions. The list of these manuals is available in Table 4-3 in Chapter 4,

“Orderable Panels and Devices.”

Table 3-1. Optional modules

Optional modules Description Blocks

4010-9818 Network Media Card Wired (Mounts on 4010-9902 and 4010-9922) none

4010-9819 Network Media Card Fiber Optic (Mounts on 4010-9902 and 4010-9922) none

4010-9901 VESDA Interface Card 1

4010-9902 and 4010-9922 4120 Network Interface Card 2

4010-9903 and 4010-9924

(Note 2)

4010-9904 and 4010-9925

(Note 2)

4010-9905 and 4010-9926

(Note 2)

4010-9906 and 4010-9927

(Note 2)

4010-9908 4-Point Flat AUX Relay (2 A) 1

4010-9909 City Connect Card with Disconnect Switches (MSS mounted) none

4010-9910 City Connect Card without Disconnect Switches (MSS mounted) none

4010-9911 Alarm Relay Card (MSS mounted) none

4010-9912

4010-9913 SafeLinc Internet Interface (FPII) Card 2

4010-9914 Building Network Interface Card (BNIC) 2

4010-9916 25 VDC Voltage Regulator Card 1

4010-9917 MX Digital Loop Card (international models only) 2

4010-9918 Dual RS232 Card 1

4010-9919

4010-9920 8 Zone Initiating Device Circuit, Class B 2

4010-9921 8 Zone Initiating Device Circuit, Class A 2

4010-9929 IDNet 2+2 Card 1

4120 Network Interface w/ Modem physical Bridge Style 4 2

4120 Network Interface w/ Modem physical Bridge Style 7 2

4120 Network Interface TCP/IP physical Bridge Style 4 3

4120 Network Interface TCP/IP physical Bridge Style 7 3

SDACT Card

(Mounts in top bay Block D only)

TrueInsight Remote Service Gateway (Perle)

(mounts on dead front)

none

1

Note: 1. Consult your local sales office to determine which modules are available in your area.

2. Physical bridge cards must also be installed with a network interface card. Therefore, the 4010ES

one-bay systems do not have enough option card space left to install a physical bridge after a NIC is

added.

3-4

Page 33

One-bay 4010ES Panels, continued

Back box mechanical specifications

Back boxes ship with the panel and can only be ordered separately as a service part. Table 3-2

lists the specifications for the one-bay back boxes.

Table 3-2. Back box specifications

PID number Height Width Depth

699-467 (Platinum)

22 in. (559 mm) 24 in. (610 mm)

699-466 (Red)

6-29/32 in.

(175 mm)

Depth with

door

11-11/16 in.

(297 mm)

3-5

Page 34

Two-bay 4010ES Panels

#05#ARD

/PERATOR)NTERFACE

'ROUNDING3TRAP

$EAD&RONT,ATCH

0IEZO

%THERNET3ERVICE0ORT

'ROUNDING3TRAP

'ROUNDING3TRAP

#05#ARD

)NFO!LARM5SER

)NTERFACE

)NFO!LARM!PPLIQUE

3TANDARD5SER)NTERFACE

)NFO!LARM5SER)NTERFACE

$EAD&RONT,ATCH

Overview A two-bay system is used when more option card space is required than is given in a one-bay

system, or when InfoAlarm is the primary display. Refer to Figure 2-4 for an illustration of the

InfoAlarm interface.

The basic components of the two-bay panels are the same as for the one-bay panels and are preinstalled in the top bay. The expansion bay contains another PDI card with eight available

blocks. Those can be used to connect optional modules to the 4010ES panels. The Expansion

Bay PDI card comes pre-installed inside the two-bay panel.

See Figures 3-3 through 3-5 for two-bay 4010ES diagrams.

Figure 3-3. Two-bay, standard and InfoAlarm dead fronts

Continued on next page

3-6

Page 35

Two-bay 4010ES Panels, continued

CPU

Dead Front

Expansion PDI

MSS

Back Box

Glass Door

Top Bay

Overview

Figure 3-4. Two-bay 4010ES Panel with standard user interface

Continued on next page

3-7

Page 36

Two-bay 4010ES Panels, continued

MSS

Expansion PDI

InfoAlarm

Interface

Dead Front

CPU

Glass Door

Back Box

Top Bay

Overview

Figure 3-5. Two-bay 4010ES Panel with InfoAlarm interface

3-8

Page 37

Two-bay 4010ES Panels, continued

Optional modules The same optional modules can be used with the two-bay panels as with the one-bay panels.

For a complete list of optional components, see Chapter 4, “Orderable Panels and Devices.”

Back box mechanical specifications

Table 3-3 lists the specifications for the two-bay back boxes.

Table 3-3. Back box specifications

PID number Height Width Depth

699-465 (Platinum)

40.0 in. (1016 mm) 24 in. (610 mm)

699-464 (Red)

6-29/32 in.

(175 mm)

Depth with

door

11-11/16 in.

(297 mm)

3-9

Page 38

Page 39

Chapter 4

Orderable panels and devices

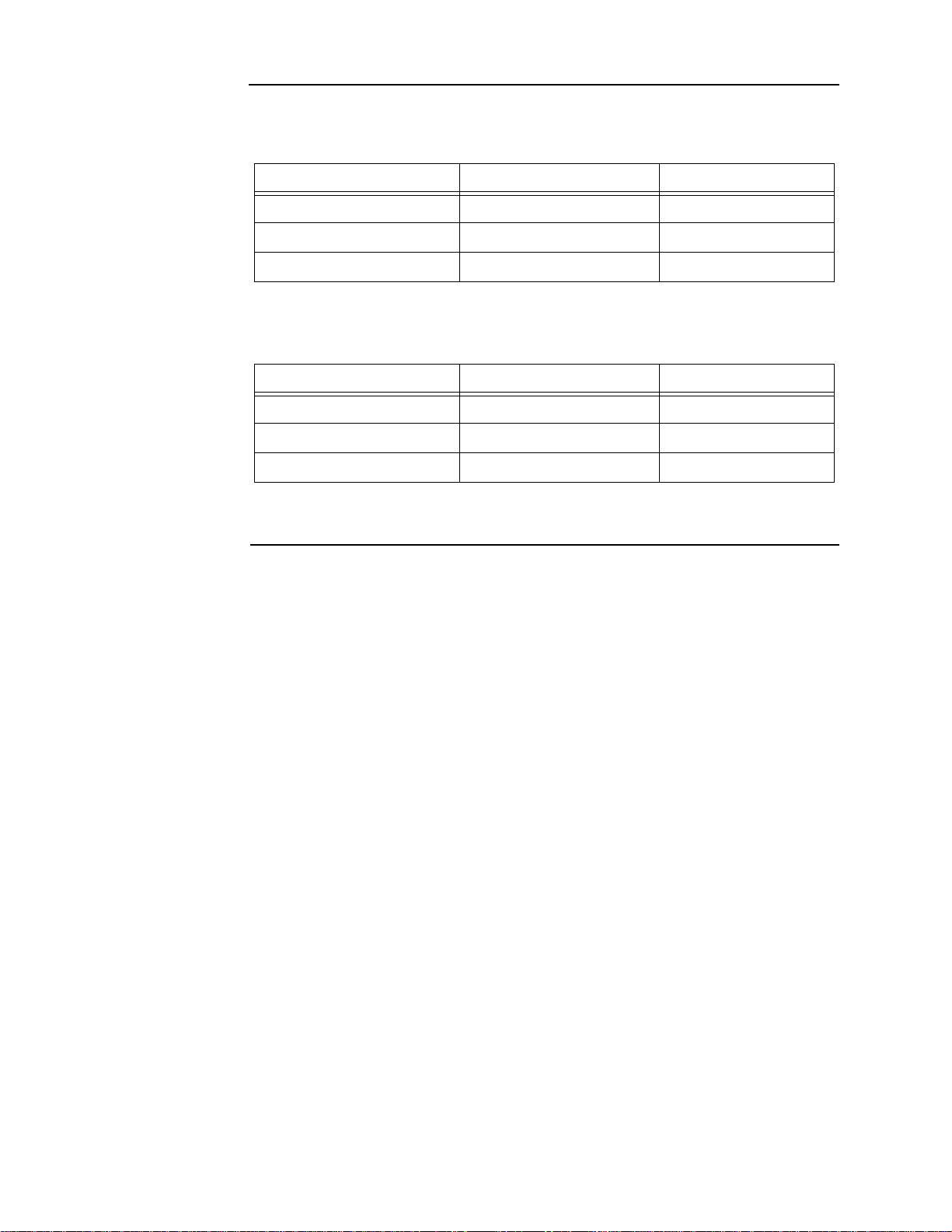

Introduction The following chapter lists the 4010ES panels and optional modules that can be ordered. It

also lists the installation manuals that are associated with each optional device.

In this chapter This chapter covers the following topics:

Topic Page

Panels 4-2

Optional modules 4-3

4-1

Page 40

Panels

One-bay 4010ES Panels

Table 4-1. One-bay 4010ES systems

Panel PIDs

4010-9401 Red

4010-9402 Platinum

4010-9501 Red

4010-9502 Platinum

4010-9403 Red

4010-9404 Platinum

4010-9405 Red

4010-9406 Platinum

4010-9503 Red

4010-9504 Platinum

Panel

color

Panel language

and AC voltage

English

120V

English

220V-240V

English

120V

French

120V

English

220V-240V

CPU with a 2 x 40

display and a piezo

Standard

operator

interface

Panel components

MSS with an IDNet

channel

MSS (No IDNet)

Three free

option blocks

One free

option block

48-LED Module

(door-mounted)

One MX Loop

Option Card pre-

installed (4010-

Two-bay 4010ES Panels

T able 4-2. Two-bay 4010ES systems

Panel PIDs

4010-9421 Red

4010-9422 Platinum

4010-9521 Red

4010-9522 Platinum 10 free

4010-9425 Red

4010-9426 Platinum

4010-9525 Red

4010-9526 Platinum -4010-9523 Red

4010-9524 Platinum

4010-9527 Red

4010-9528 Platinum

4010-9529 Red

4010-9530 Platinum

4010-9423 Red

4010-9428 Platinum

4010-9430 Platinum French 120V

Panel

color

Panel

language and

AC voltage

English 120V

English

220V-240V

English 120V

English

220V-240V

English 120V

CPU with a 2 x 40

display and a piezo

CPU

CPU with a 2 x 40

display and a piezo

CPU

CPU with a 2 x 40

display and a piezo

Panel components

Standard operator

interface

InfoAlarm interface

(display and piezo)

Standard operator

interface

InfoAlarm interface

(display and piezo)

Standard operator

interface

MSS with an

IDNet channel

MSS

(No IDNet)

MSS with an

IDNet channel

option

card blocks

11 free

option card

blocks

7 free option

card blocks

9 free option

card blocks

7 free option

card blocks

10 free

option card

blocks

One IDNet 2+2 Card

pre-installed

(4010-9929)

One IDNet 2+2 Card

pre-installed (4010-

One IDNet 2+2 Card

pre-installed (4010-

Two MX Loop Option

Cards pre-installed

(4010-9917)

One MX Loop Option

Card pre-installed

(4010-9917)

Two MX Loop Option

Cards pre-installed

(4010-9917)

One IDNet 2+2 Card

pre-installed (4010-

48 LED Module (door

mounted)

---

9917)

9929)

9929)

--

9929)

4-2

Page 41

Optional modules

Local optional modules

T able 4-3. Local optional modules installation instructions

PID Description

4010-9818 Wired Network Media Card 579-956

4010-9819 Fiber Optic Network Media Card 579-956

4010-9901 4010ES/4100/4120-Series VESDA Card 579-963

4010-9902

and

4010-9922

4010-9903

and

4010-9924

4010-9904

and

4010-9925

4010-9905

and

4010-9926

4010-9906

and

4010-9927

Network Interface Card

Style 4 Network Modular Physical Bridge

Style 7 Network Modular Physical Bridge

Style 4 Network TCP/IP Physical Bridge

Style 7 Network TCP/IP Physical Bridge

Installation

instructions

579-956

574-041

579-818

579-184

574-041

579-818

579-184

574-041

579-818

579-184

574-041

579-818

579-184

574-041

4010-9908 4-Point Flat AUX Relay Card 5 79-220

4010-9909 City Connect Module with Disconnect Switches (MSS mounted) 579-955

4010-9910 City Connect Module without Disconnect Switches (MSS mounted) 579-955

4010-9911 Alarm Relay Modul e (MSS mounted) 579-955

4010-9912 SDACT 579-954

4010-9913 SafeLinc Internet Interface (FPII) 579-349

4010-9914 B uilding Network Interface Card (BNIC) 579-949

4010-9916 25 VDC Voltage Regulator Module (international only) 579-812

4010-9917 M X Digital Loop (international only) 579-833

4010-9918 Dual RS232 Module 574-910

4010-9919 TrueInsight Remote Service Gateway 579-953

4010-9920 8 Zone Initiating Device Circuit, Class B 579-205

4010-9921 8 Zone Initiating Device Circuit, Class A 579-991

4010-9929 IDNet 2+2 Module 579-1170

4-3

Page 42

Optional modules, continued

Remote devices

Table 4-4. Remote power and notification devices installation instructions

PID Description

4010-9818 Wired Network Media Card 579-956

4010-9819 Fiber Optic Network Media Card 579-956

4009-9401 4009T TrueAlert Controller 574-762

4081-9306

4009-9201 4009A 120V 574-181

4009-9202CA 4009A 120V ULC-listed model 574-181

4009-9301 4009A 240V 574-181

4009-9813 Transponder Interface Card (TIC) 579-875

4100-5120 120 V Domestic TPS 579-875

4100-5121 120 V Canadian TPS 579-875

4100-5122 220-240 V International TPS 579-875

4100U External Battery Charger 120V (with cabinet,

holds 11 Ah batteries)

4009 Remote TrueAlert Power Supply (TPS)

Installation

instructions

579-268

Table 4-5. Remote display and annunciation devices installation instructions

PID Description

4100-9401 Remote InfoAlarm - Red 579-687

4100-9402 Remote InfoAlarm - Beige 579-687

4100-9421 Remote InfoAlarm (French) - Red 579-687

4100-9422 4100-9422 Remote InfoAlarm (French) - Beige 579-687

4100-9441 Remote InfoAlarm (international) - Red 579-687

4100-9442 Remote InfoAlarm (international) - Beige 579-687

4100-7401 24-Point I/O Graphic Module (requires mounting cabinet) 574-348

4606-9102 4010ES RUI LCD Annunciator 579-977

Installation

instructions

4-4

Page 43

Optional modules, continued

Adjunct features

Table 4-6. Adjunct features

End user programming tools

PID Description

4081-9308

4190-9021

4190-9022

4190-9023 Right Port Modem for Exp Cabinet – Single Mode 579-831

4190-9024

4190-9025

4190-9026 Right Port Modem for Expansion Cabinet – Single Mode 579-831

4100U External Battery Charger 220/230/240 V (with

cabinet. Holds 110Ah batteries)

Red Fiber Modem Expansion Cabinet with Left Port

Modem – Single Mode

Beige Fiber Modem Exp Cabinet with Left Port Modem Single Mode

Red Fiber Modem Exp Cabinet with Left Port Modem –

Multimode

Beige Fiber Modem Exp Cabinet with Left Port Modem Multimode

T able 4-7. End user programming tools

PID Description

Installation

instructions

579-268

579-831

579-831

579-831

579-831

LED kits for the 48-LED Module

4100-0292 Custom Label Editing (USB Dongle)

4100-0295 Port Vectoring Setup and Control (USB Dongle)

4100-0296 User Group/Passcode Editing (USB Dongle)

4100-0298 Walktest Configuration Setup and Control (USB Dongle)

4100-8802 Programming Unit Software

T able 4-8. LED kits for the 48-LED Module

PID Description

4100-9843 8 Yellow LEDs

4100-9844 8 Green LEDs

4100-9845 8 Red LEDs

4100-9855 8 Blue LEDs

4-5

Page 44

4-6

Page 45

Chapter 5

Installing 4010ES systems

Introduction This chapter describes how to mount the 4010ES back boxes to a wall, and install basic

system components into the boxes.

Before beginning the installation, review this chapter to get a sense of the types of bays and

modules that make up the FACP.

IMPORTANT: Verify ES Panel Programmer, Executive, and Slave Software compatibility

when installing or replacing system components. Refer to the technical

support website for up-to-date compatibility information.

In this chapter This chapter covers the following topics:

Topic Page

Mounting the panel 5-2

General field wiring guidelines 5-5

Connecting 4010ES basic components 5-7

RUI wiring 5-11

Installing the optional modules 5-13

Address configuration DIP switch 5-14

Connecting main system power 5-16

5-1

Page 46

Mounting the panel

POTPOT

RESERVED

FOR

BATTERIES

(SEE NOTE 6)

ADDITIONAL

BACK BOX

USE 4 HOLES TO

SECURE BACKBOX

TO THE WALL

USE 4 HOLES TO

SECURE BACKBOX

TO THE WALL

24”

(610 mm)

3 17/32”

(90 mm)

5 17/32”

(140 mm)

16”

(406 mm)

See Notes 3 and 5

6 29/32”

(175 mm)

22”

(559 mm)

(ONE

BAY)

ALIGNMENT MARKERS

FOR WALL STUDS:

6” (152 mm)

4” (102 mm)

WAL L

WAL L

PANEL

FRONT

Installing the back box

Store the system electronics containers in a safe, clean, and dry location until the back box

installation is completed and you are ready to install additional modules. Make certain that you

have the necessary hardware before you begin the installation procedure.

Install the back box as shown in Figure 5-1. Use the holes in the back box to secure it to the

wall.

Note: • Conductor entrance and routing restrictions apply to power-limited systems only.

• While the pre-installed system components may be left in the backbox during installation, due to

the danger of metal fragments falling into electronics, it is recommended to remove the dead front

and any bay pans in the system.

• For surface or flush mounting to a wooden wall structure, the back box must be attached with four

3/8-inch-diameter x 1-½-inch-long (9.5 mm x 38 mm) fasteners and four 3/8-inch-diameter (9.5

mm) washers.

• For surface mounting, secure the box to the wall using the tear-drop mounting holes on the back

surface. For flush and semi-flush mounting, secure the box to the wall studs using the indicated

areas (dents in the metal) on the sides of the box. Note that the front surface of the back box must

protrude at least three inches from the wall surface for semi-flush installations.

• Power-limited systems have entrance and routing restrictions for field wiring. See section

“General Field Wiring Guidelines” on page 5-5 for more details.

Figure 5-1. Back box installation

Notes:

1. Dimensions shown are typical for all surface and semi-flush installations.

2. Use suitable punch when conduit is required. Knockouts are not provided. Locate and create on-site

as required during installation.

3. A minimum clearance of 5 inches (127 mm) from the hinge side is required to provide a maximum

door opening of 90 degrees.

4. Do not install any power-limited wiring in the shaded area of the back box as shown in Figure 5-1.

This area is reserved for non power-limited devices and circuits. for example, AC power, batteries,

and city circuits. The non power-limited area is determined by the internal barriers, but is always

below and to the right of these barriers.

5. Minimum distance between boxes is 3 1/4 inches (83 mm). Maximum distance between boxes is 10

inches (254 mm).

5-2

Page 47

Mounting the panel, continued

,%$

-ODULE

'ROUNDING3TRAP

/PERATOR)NTERFACE

#05

#ARD

$EAD&RONT,ATCH

0IEZO

,%$-ODULE/VERLAY

%THERNET3ERVICE0ORT

$EAD&RONT,ATCH

#05

#ARD

0IEZO

%THERNET3ERVICE0ORT

'ROUNDING3TRAP

/PERATOR)NTERFACE

One-Bay

Two-Bay

Top

Bottom

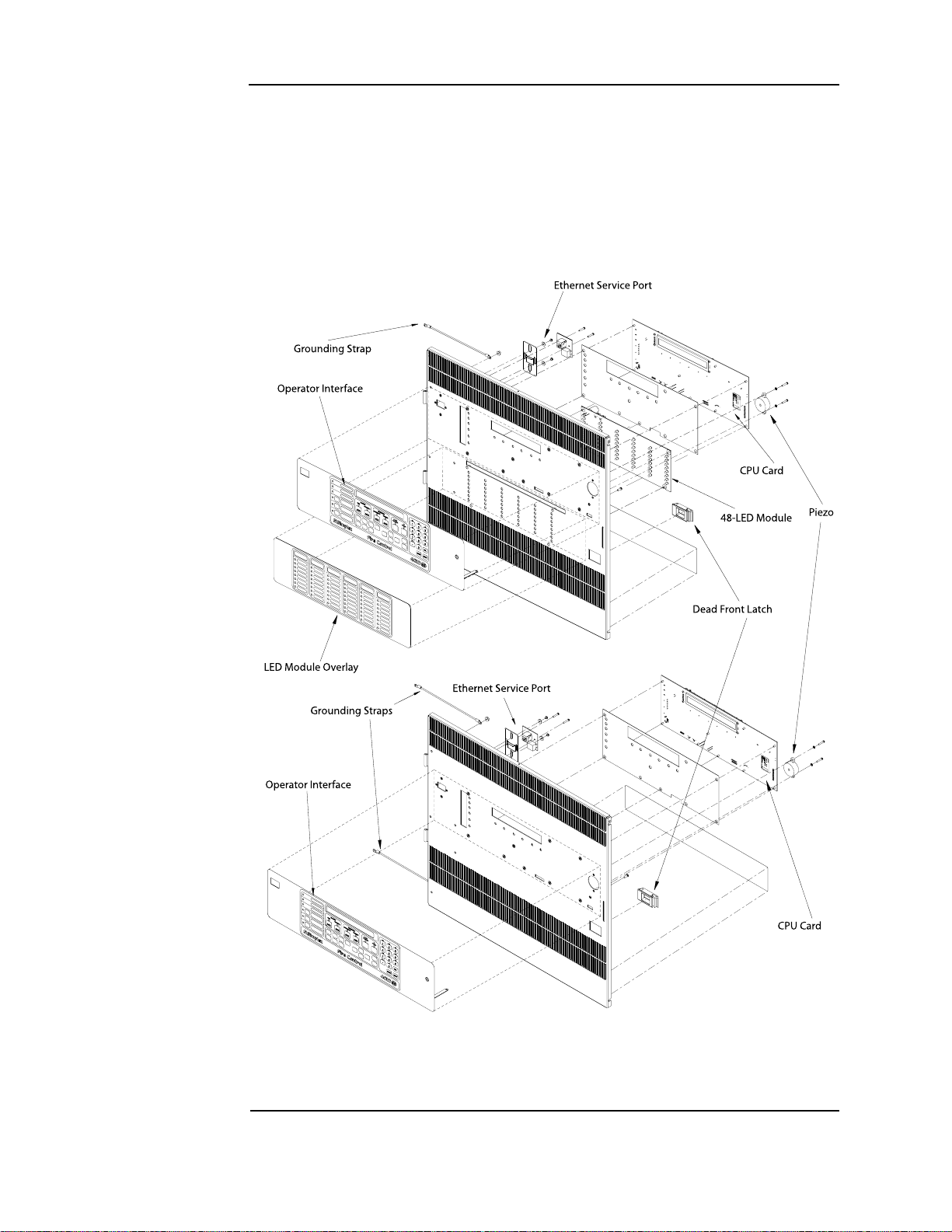

Attaching the dead front

To attach the 4010ES panel dead fronts containing the operator interface and the 48-LED

Module (where applicable), perform the following steps:

1. Align the dead front hinges with the hinge pins on the back box, and slide the door down

onto the hinge pins.

2. Attach the two grounding straps to the back box with the # 6 hex flange nuts. See Figure 5-3.

The grounding straps should already be attached to the dead front.

Figure 5-2. 4010ES dead fronts

Figure 5-3. Dead front grounding straps

5-3

Page 48

Mounting the panel, continued

One-bay

Two-bay

Attaching doors To attach the glass doors (Figure 5-4) to the cabinet, follow the steps below:

1. Align the door hinges with the hinge pins on the back box, and slide the door down onto the

hinge pins.

2. Attach the two grounding straps to the back box with the # 6 hex flange nuts. The grounding

straps should already be attached to the door.