Page 1

Expansion Power Supply (EPS)

Installation Instructions

Introduction

The 4008/4006-9801 Expansion Power Supply (EPS) is an option module

that installs into the main fire alarm control panel. The EPS provides two

additional NACs, and filtered/regulated 24 VDC, alarm power.

The 3 A alarm power may be split between the two NACs and the

0.5 A auxiliary 24 VDC power tap. Refer to the NAC ratings section of these

instructions for circuit loading restrictions. The expansion power supply is

mounted to the right of the main system board (MSB) at the bottom of the

chassis, and is connected by the installer via three separate harnesses.

One EPS per system is allowed.

Figure 1, below, is an illustration of the EPS assembly.

System

Compatibility

Operating

Temperature

Operating

Humidity

Dimensions

Current

Rating

AC Input

Voltage

Specifications

General

4006/4008 Fire Alarm System

0 to 49 degrees C

32 to 120 degrees F

Up to 93% relative humidity

(non condensing)

Mounting

Width = 4.38 in ( 1 1.2 cm)

Height = 7 in (17.8 cm)

Depth = 4 in (10.2 cm)

Power

2 A per NAC; 3 A.alarm power

@ 24 VDC

120 V, 60Hz, 2 A max

240 V, 50 Hz, 1.5 A max

Figure 1 The Expansion Power Supply

The EPS assembly is shipped with the following:

• EPS assembly (bracket with two PCBs)

• Screws/washers (441-002; qty: 2)

• AC harness (734-179): black/white leads

• Battery harness (734-180): red/black leads

• Data flex harness (166-438): flat cable

Note: This document contains instructions on installing the EPS into the fire

alarm control panel. For programming instructions, refer to the Front Panel

Installing, Operating, and Programming Instructions (579-704 for 4006, or

579-716 for 4008).

In this Document

Mounting.........................................2

Panel interconnections ...................3

NAC wiring......................................5

Auxiliary 24 V wiring .......................6

NAC ratings ....................................7

© 2004 Tyco Safety Products, Westminster, MA 01441 USA All specifications were current and are subject to change wit hout notice. PN: 579-707

Technical Manuals Online! - http://www.tech-man.com

Rev. A

Page 2

Expansion Power Supply (EPS) Installation Instructions

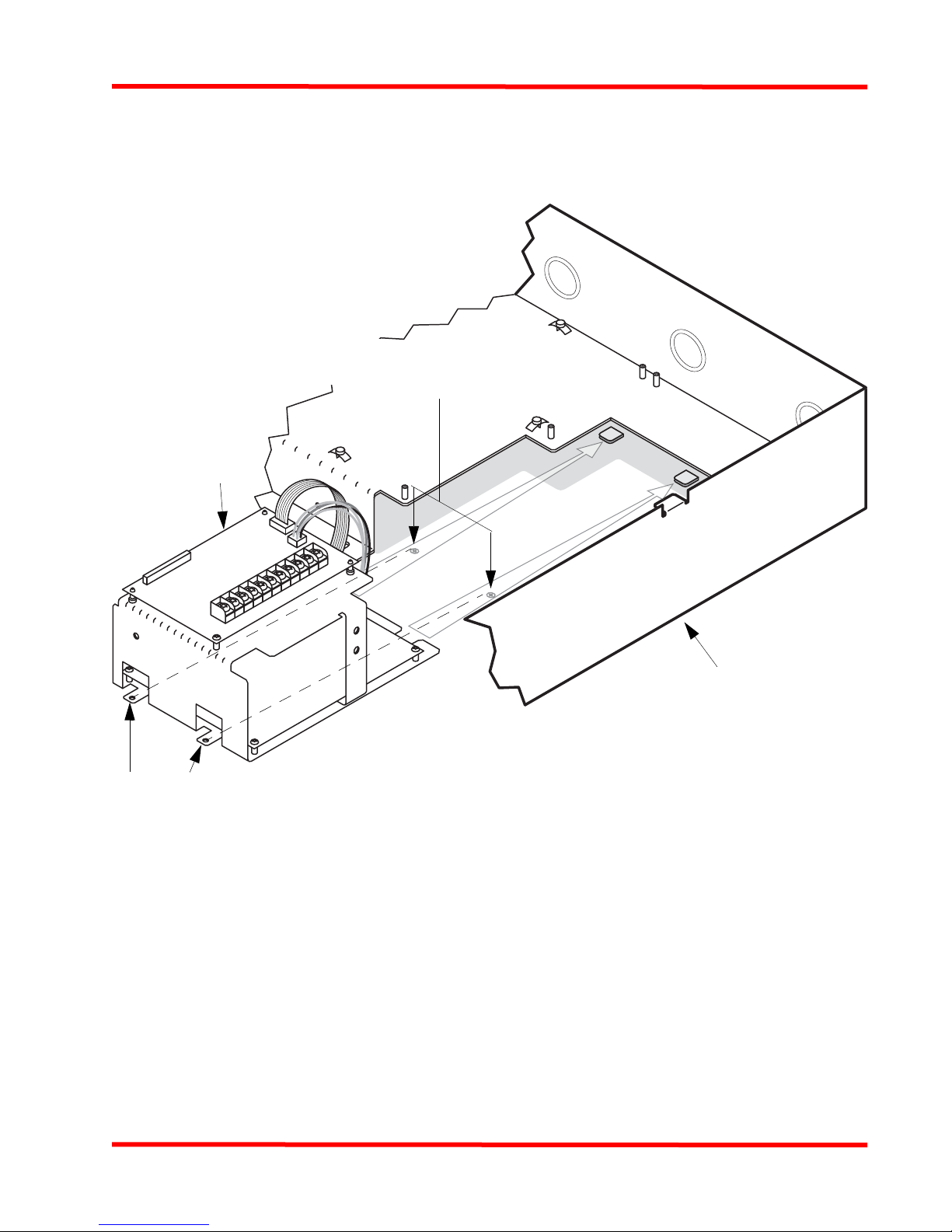

Mounting

Mount the EPS to the main annunciation cabinet as shown

in the figure below

Fasten the EPS to the cabinet with

two slotted torx screws (441-002).

EPS

Screwholes

MAIN

CABINET

Figure 2 Mounting the EPS

Technical Manuals Online! - http://www.tech-man.com

2

Page 3

Expansion Power Supply (EPS) Installation Instructions

Panel interconnections

Use the following steps and the figure on the next page to

connect the EPS to the Main System Board (MSB).

1. Remove AC and battery power from the panel. You

will be wiring to the AC line. Be sure the circuit

breaker is OFF and tagged.

2. You have the option of removing the Depleted Battery

Cutout jumper (R76) on the EPS. Removing the

jumper has the following effects:

- The system will NOT initiate an alarm if the first

alarm occurs after the depleted battery state has

been detected.

- The system will shut down 60 seconds after the

depleted battery condition is detected.

Remove the jumper if required. Note that there is a

corresponding option in the programmer that must be

set; see the Front Panel Installing, Operating, and

Programming Instructions (579-704 for 4006,

579-716 for 4008).

3. Connect the data flex harness (166-438) from J1 on

the EPS to

- J8 on the 4006-9801

- J3 on the 4008-9801

4. The AC harness (734-179) is used to connect AC

power from the MSB to the EPS.

- AC source is 120 VAC, 60 Hz (single phase) or

240 VAC (nominal), 50 Hz (single phase).

- Strip 3/8" insulation from the black and white

wires.

- Connect the black wire lead to the LEFT MSB

AC power terminal (TB4) marked “LINE.”

- Connect the white wire lead to the RIGHT MSB

AC power terminal (TB4) marked “NEUTRAL.”

- Connect the snap-on AC harness connector to P6

on the EPS.

5. Connect the battery harness (734-180) from P3 on the

EPS to the battery connector on the MSB (P13 on the

4006; P14 on the 4008). Do not connect the harness to

the batteries until you are ready to power up the

system. Connectors should be aligned such that:

- On P13 or P14 on the MSB, the red wire is on the

left and the black wire is on the right.

- On P3 on the EPS, the red wire is on the bottom

and the black wire is on top (closer to R76; see

the figure on the next page).

Technical Manuals Online! - http://www.tech-man.com

3

Page 4

Expansion Power Supply (EPS) Installation Instructions

MAIN SYSTEM BOARD

DEPLETED BATTERY

CUTOUT JUMPER

REMOVE POWER

FROM AC AND BATTERY

TERMINALS AND FROM

CIRCUIT BREAKER

BEFORE WIRING THE

EXPANSION POWER

SUPPLY.

R407 on 4008

R313 on 4006

TB4

EPS

+-

166-438 DATA FLEX

HARNESS

P14 on 4008

P13 on 4006

EPS

TOP BOARD

J1

734-180

BATTERY HARNESS

RED: LEFT ON P13/P14; BOTTOM

734-179

AC HARNESS

BLACK: LEFT ON TB4; RIGHT ON P6

WHITE: RIGHT ON TB4; LEFT ON P6

Figure 3 Interconnections between the MSB and EPS

J3 on 4008

J8 on 4006

ON P3

BLACK: RIGHT ON P13/P14;

TOP ON P3

DEPLETED BATTERY

CUTOUT JUMPER

R76

EPS

BOTTOM BOARD

(TINTED AREA = PORTION OF

BOTTOM BOARD OBSCURED

BY TOP OF ASSEMBLY)

P3

P6

Technical Manuals Online! - http://www.tech-man.com

4

Page 5

Expansion Power Supply (EPS) Installation Instructions

NAC wiring

MAIN CABINET

CLASS B WIRING:

route NAC

wiring upwards

MAIN

733-894

EOLR

SYSTEM

BOARD

• NAC wiring from the EPS is ro uted within th e

cabinet as shown above.

• NAC terminals accept 18 AWG to 12 AWG

wire. Larger wire reduces line loss and

allows longer wiring distance from the FACP

to the notification applia nces.

• Use a VOM to test conductors for grou nds

and stray voltages before connecti on to

appliances and panel.

• All wiring is supervised and Power Limited.

• Circuits must not be “T”-tapped.

• Terminate each Class B circuit with a

10 k, 0.5 W resistor (733-894). For Canadian

applications, mount the end-of-line resistor

to TEPG-US Model 431537 EOL Plate per

Standard

ULC-5524.

• Wire Class A (Style Z) NACs from “B+” and

“B-” to each appliance. No end-of-line is

needed for Class A. Connect wires fro m “+”

and “-” on the last appliance to “A+” and A-”

on the EPS.

• The 10 k, 0.5 W (brown/black/ orange)

resistor (factory installed) should remain

installed across “B+” and “B-” on unused

NACs to keep them in the "normal" state.

• Current rating: Each NAC supplies 2 A

(special application). EPS provides 3 A,

which is split between AUX 24 V and NAC

loads. Refer to the NAC ratings section of

these instructions for circuit loading

restrictions.

• Terminal designations are for the alarm state (+/-).

• If wiring is routed outside the bui lding, use of a listed secondary

protector is required. Use 2 081-9028 or 2081-9044. A protector

must be installed at each bu ildin g exi t/ent ra nce. Each20 81- 9028

adds 0.2 Ohms wiring resistance. 2081-9044 adds 6 Ohms

resistance.

• The wiring chart to the right gives the maximum distance for 0.25

A to 2 A loads.

For Class B, distance = panel terminals to the last appliance.

For Class A, distance = EPS terminals to the las t appliance and

back to the EPS terminals.

• When using non-addressable Series 4901, 4903, and 4904 twowire audible/visible applianc es , max i mum wi rin g capacitance is

0.22 uF. Determine wiring capacitance by adding wire-to-wire

capacitance plus wire-to-shield capacitance (if shield is used).

Multiply the result by the wire length in feet. Example: A 12 AWG

FPLR is rated at 100 pF/foot, with no shield. The 0.22 uF limit

allows a maximum length of 2,200 ft. Also check th e wiring

distance chart, right, to determine that the voltage drop will not

be excessive.

• Max. number of Smart Sync appliances = 2 A divided by the

current draw amperage of the appliances used.

EPS

CLASS A WIRING:

NAC +

NAC-

NAC +

NAC-

NAC +

B+ B-

TYPICAL AUDIBLE/VISIBLE APPLIANCES

B+ B- A+ A- A+ A-

TB1 ON

EXPANSION POWER SUPPLY

NAC3 NAC4

NAC-

NAC +

NAC-

NAC +

NAC-

NAC +

B+ B- A+ A-

TYPICAL AUDIBLE/VISIBLE APPLIANCES

B+ B- A+ A-

TB1 ON

EXPANSION POWER SUPPLY

NAC3 NAC4

Alarm

Current

(Amps)

Max. Distance from Panel to Last Device (Feet) Line

Resistance

18 AWG 16 AWG 14 AWG 12 AWG

(Ohms)

0.25 840 1335 2126 3382 12

0.50 420 667 1063 1691 6

0.75 280 445 709 1127 4

1.00 210 334 532 845 3

1.25 168 267 425 676 2.4

1.50 140 222 354 564 2

1.75 120 191 304 483 1.71

2.00 105 167 266 423 1.5

Chart allows for a drop of 3.4 V due to wire resistance. Wire resistance given is for

copper wire at 50° C (122° F).

Figure 4 NAC Wiring (Class A and B)

Technical Manuals Online! - http://www.tech-man.com

5

Page 6

Expansion Power Supply (EPS) Installation Instructions

Auxiliary 24 V wiring

4008

MAIN SYSTEM BOARD

4006

MAIN SYSTEM

BOARD

AUX 24 V 0.5 A MAX

FROM MSB

- +

AUX 24 V

0.5 A MAX.

- +

AUX 24 V 0.5 A MAX

FROM MSB

+ -

EXPANSION

POWER

SUPPLY

• Aux terminals accept 18 AWG to 12 AWG wire.

• Conductors must test free of all grounds and stray voltages before connection to appliances, devices, and panel.

• All wiring is supervised and Power Limited.

• Voltage rating (24 VDC special application): 1 V p-p ripple (maximum)

0.5 A maximum available aux 24 V from EPS

Additional 0.5 A maximum available from Main System Board (MSB) aux 24 V

3 A total available from MSB NACs and MSB aux 24 V.

3 A total available from EPS NACs and EPS aux 24 V.

• Compatible with Simplex 4098 Series Peripherals; 2098 Series Relay Modules; all Simplex 4090 Series IDNet

Peripherals; and 4610-9111 / 4606-9101 Annunciators.

• If wiring is routed outside the building, use of a listed secondary protector is required. Use 2081-9044or 2081-9028. A

protector must be installed at each building exit/entrance. Each 2081-9044 adds 6 Ohms resistance at 200 mA. Each

2081-9028 adds 0.2 Ohms wiring resistance, and is rated for more than the 0.5 A aux 24 V capacity.

• If the circuit is used to power the Model 4098-9682 Four-Wire Base, the auxiliary 24 V power must be routed through the

2098-9735 End-Of-Line Relay, as shown in Figure 6 (below).

Figure 5 Aux 24 V Wiring

24VDC

Power

IDC

LISTED

CONTROL

PAN E L

24VDC

TYPICAL 4-WIRE

DETECTOR

TYPICAL 4-WIRE ZONE 24VDC DEVICES

2098-9735

E.O.L. RELAY

RED

BLACK

(RELAY SHOWN

ENERGIZED)

YELLOW

YELLOW

END-OF-LINE DEVICE

SELECTED PER ZONE

CIRCUIT

Figure 6 2098-9735 End-Of-Line Relay

Technical Manuals Online! - http://www.tech-man.com

6

Page 7

Expansion Power Supply (EPS) Installation Instructions

NAC ratings

The panel is rated Special Application for 2 A maximum

per NAC with Simplex 4901 and 4906 TrueAlert MultiCandela Notification Appliances.

For all other UL Listed Notification Appliances, NACs are

rated Regulated 24 VDC at 1.5 A maximum each.

Maximum allowed strobe load on either the main or

Table 1 NAC Ratings

15Cd 30Cd 75Cd 110Cd

4906-

9101 0.060 33 0.094 21 0.186 10 0.252 7

9102 0.075 26 0.125 16 0.233 8 0.316 6

9103 0.060 33 0.094 21 0.186 10 0.252 7

9104 0.075 26 0.125 16 0.233 8 0.316 6

9127 0.075 26 0.116 17 0.221 9 0.285 7

9128 0.086 23 0.132 15 0.250 8 0.320 6

9129 0.075 26 0.116 17 0.221 9 0.285 7

Rated

Current

Max. # per

NAC

Rated

Current

Max. #

per NAC

expansion power supply is 1.35 A. The balance of the 3 A

capacity can be auxiliary loads or audible notification

appliances.

Synchronization of strobes across all NACs in a system is

UL Listed for the Simplex models noted in the table

below. See the table below for maximum number allowed

of each model appliance per NAC.

Rated

Current

Max. # per

NAC

Rated

Current

Max. # per

NAC

9130 0.086 23 0.132 15 0.250 8 0.320 6

9151 0.060 33 0.094 21 0.186 10 0.252 7

9154 0.075 26 0.125 16 0.233 8 0.316 6

9153 0.060 33 0.094 21 0.186 10 0.252 7

All other regulated 24 VDC synchronized notification

appliances require the use of their associated Listed

external synchronization module. Notification Circuit

rating is 1.5 A maximum, 1.35 A maximum strobe load

per power supply.

Technical Manuals Online! - http://www.tech-man.com

7

Page 8

Expansion Power Supply (EPS) Installation Instructions

DO NOT INSTALL ANY PRODUCT THAT APPEARS DAMAGED. Upon unpacking your product, inspect the contents of the carton for

shipping damage. If damage is apparent, immediately file a claim with the carrier and notify the manufacturer.

ELECTRICAL HAZARD - Disconnect electrical power when making any internal adjustments or repairs. Servicing should be performed

by qualified personnel.

STATIC HAZARD - Static electricity can damage components. Therefore, handle as follows:

1. Ground yourself before opening or installing components.

2. Keep uninstalled components wrapped in anti-static material at all times.

Warning: Changes or modifications to this unit not expressly approved by the party responsible for compliance could void

the user's authority to operate equipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required

to correct the interference at his own expense.

Technical Manuals Online! - http://www.tech-man.com

8

Loading...

Loading...