Page 1

Technical Manuals Online! - http://www.tech-man.com

Page 2

Copyright and Trademarks

© 2005 Tyco Safety Products Westminster, Westminster MA 01441-0001 USA

Printed in the United States of America.

Information in this document is subject to change without notice. No part of this document may be reproduced or transmitted

in any form or by any means, electronic or mechanical, for any purpose, without the express written consent of Tyco Safety

Products.

Tyco, Simplex, the Simplex logo, IDNet, SmartSync and WALKTEST are registered trademarks of Tyco International Services AG or its affiliates in the US and/or other countries.

TrueAlarm analog smoke detection is protected by one or more of the following U.S. Patents: 5,155,468; 5,173,683;

5,543,777. IDNet addressable communications are protected by U.S. Patent No. 4,796,025. IDNet duplicate device detection

is protected under U.S. Patent No. 6,034,601. WALKTEST system test is protected under US Patent No. 4,725,818. SmartSync horn/strobe operation is protected under U.S. Patent No. 6,281,789. Two wire synchronization circuit operation is protected by U.S. patent No. 5,559,492.

Technical Manuals Online! - http://www.tech-man.com

Page 3

FCC Information

This equipment complies with Part 68 of the FCC rules and the requirements adopted by the ACTA. On the door of this equipment is a label that contains, among other information, the following product identifier: US:5QWAL01B4008. If requested,

the number must be provided to the telephone company.

In the event of equipment malfunction, all repairs should be performed by an authorized agent. It is the responsibility of users

requiring service to report the need for service to our company or to one of our authorized agents. Service can be arranged

through our office at:

Tyco Safety Products

91 Technology Drive

Westminster, MA 01473

978-731-2500

The Ringer Equivalence Number (REN), which is 01 for the DACT installed in this panel, is used to determine the number of

devices that may be connected to a telephone line. Excessive RENs on a telephone line may result in the devices not ringing in

response to an incoming call. In most, but not all areas, the sum of RENs should not exceed five (5.0). To be certain of the

number of devices that may be connected to a line, as determined by the total number of RENs, contact the local telephone

company. For products approved after July 23, 2001, the REN is part of the product identifier, which uses the format

US:AAAEQ##TXXXX. The digits represented by ## are the REN without a decimal point (e.g. 01 is a REN of 0.1).

If the DACT causes harm to the telephone network, the telephone company will notify you in advance that temporary discontinuance of service may be required. But if advance notice isn’t practical, the telephone company will notify you as soon as

possible. If your service is discontinued, you will be advised of your right to file a complaint with the FCC.

The telephone company may make changes to its facilities, equipment, operations, or procedures that could affect the operation of the equipment. If this happens the telephone company will provide advance notice in order for you to make the necessary modifications to maintain uninterrupted service.

If trouble is experienced with the DACT, please contact Tyco Safety Products at the location identified above. If the equipment

is causing harm to the telephone network, the telephone company may request that you disconnect the equipment until the

problem is resolved.

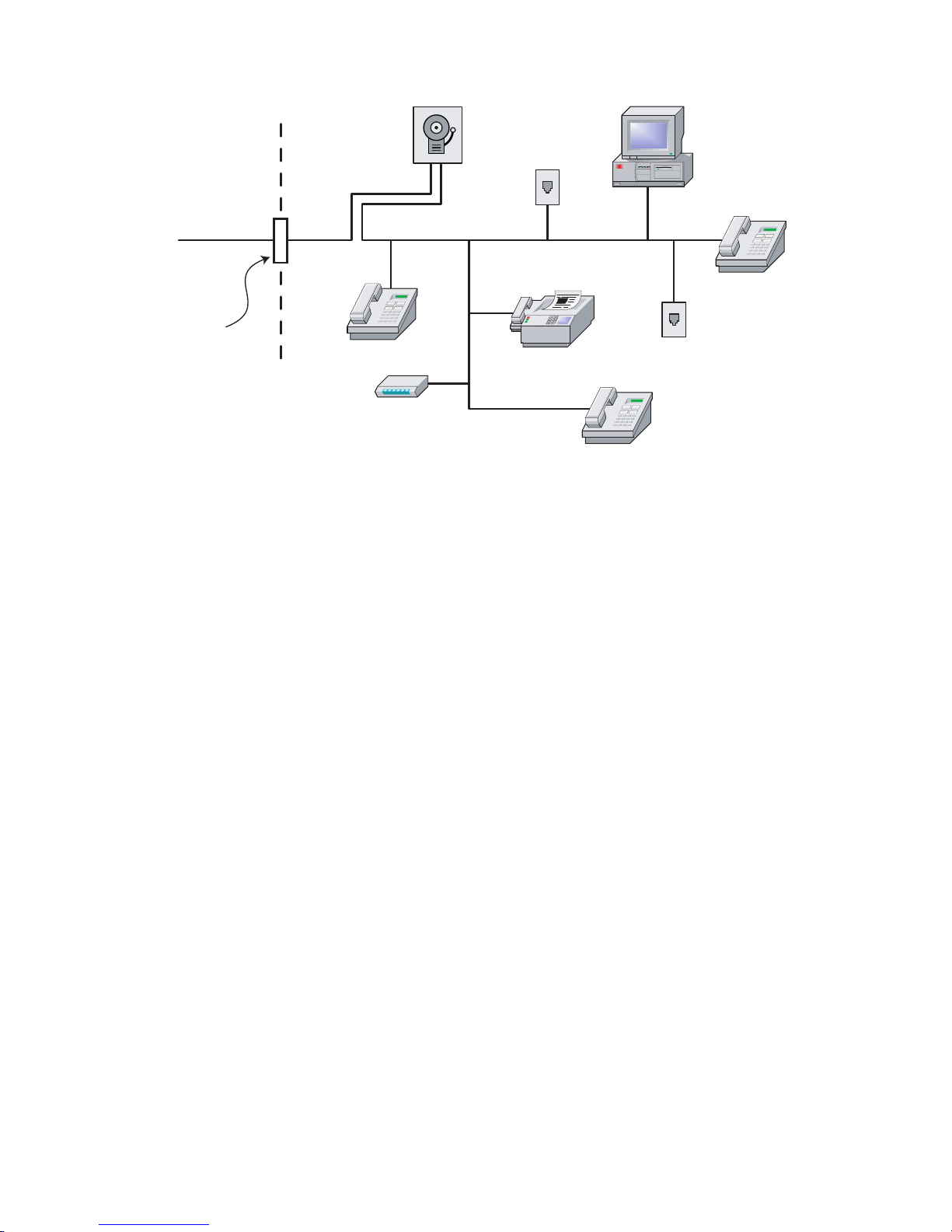

Alarm Dialing Equipment

This equipment must be able to seize the telephone line and place a call in an emergency situation. It must be able to do this

even if other equipment (telephone, answering system, computer modem, etc.) already has the telephone line in use. To do so,

the DACT must be electrically in series with and ahead of all other equipment attached to the same telephone line. Proper

installation is depicted in the figure below. If you have any questions concerning these instructions you should consult your

telephone company or a qualified installer about connecting the alarm dialing equipment for you.

Technical Manuals Online! - http://www.tech-man.com

Page 4

Connectors for the DACT are terminal blocks on the DACT module. Refer to DACT Wiring in Chapter 2 of this manual for

Telephone

Line

Network

Demarcation

Point

Unused

RJ-11 Jack

Network

Service

Provider's

Facilities

DACT

Computer

Unused

RJ-11 Jack

Fax

Telephone

Telephone

Telephone

Answering

System

specific DACT wiring instructions.

Technical Manuals Online! - http://www.tech-man.com

Page 5

Cautions and Warnings

READ AND SAVE THESE INSTRUCTIONS. Follow the instructions in this installation manual. These instructions must be

followed to avoid damage to this product and associated equipment. Product operation and reliability depends upon proper

installation.

DO NOT INSTALL ANY PRODUCT THAT APPEARS DAMAGED. Upon unpacking your product, inspect the contents of

the carton for shipping damage. If damage is apparent, immediately file a claim with the carrier and notify Simplex.

ELECTRICAL HAZARD - Disconnect electrical field power when making any internal adjustments or repairs. Servicing

should be performed by qualified Technical Representatives.

STATIC HAZARD - Static electricity can damage components. Therefore, handle as follows:

• Ground yourself before opening or installing components.

• Prior to installation, keep components wrapped in anti-static material at all times.

RADIO FREQUENCY ENERGY - This equipment generates, uses, and can radiate radio frequency energy and if not installed

and used in accordance with the instruction manual, can cause interference to radio communications. It has been tested and

found to comply with the limits for a Class A computing device pursuant to Subpart J of Part 15 of FCC Rules, which are

designed to provide reasonable protection against such interference when operated in a commercial environment. Operation of

this equipment in a residential area may cause interference in which case the user at his own expense will be required to take

whatever measures may be required to correct the interference.

SYSTEM REACCEPTANCE TEST AFTER SOFTWARE CHANGES - To ensure proper system operation, this product must

be tested in accordance with NFPA72 after any programming operation or change in site-specific software. Reacceptance testing is required after any change, addition or deletion of system components, or after any modification, repair or adjustment to

system hardware or wiring.

All components, circuits, system operations, or software functions known to be affected by a change must be 100% tested. In

addition, to ensure that other operations are not inadvertently affected, at least 10% of initiating devices that are not directly

affected by the change, up to a maximum of 50 devices, must also be tested and proper system operation verified.

Technical Manuals Online! - http://www.tech-man.com

Page 6

Technical Manuals Online! - http://www.tech-man.com

Page 7

Table of Contents

Overview ................................................................................................. 1-1

Main System Board.......................................................................................................................... 1-1

Power supply ................................................................................................................................... 1-2

Environmental Specifications .................................................................................................................. 1-2

Option Modules ....................................................................................................................................... 1-2

4006-9801 Expansion Power Supply (EPS) .................................................................................... 1-2

4006-9802 Expansion IDC Module (XIM) ....................................................................................... 1-2

4006-9805 and 4006-9806 City Circuit Cards.................................................................................. 1-2

4006-9803 Expansion Relay Module ............................................................................................... 1-2

Annunciator Modules ....................................................................................................................... 1-2

4009-9201/4009-9202CA NAC Extender ................................................................................................ 1-2

Initiating Devices ..................................................................................................................................... 1-3

Photoelectric Smoke Detector ......................................................................................................... 1-3

Heat Detector ................................................................................................................................... 1-3

Combination Photo/Heat Detector ................................................................................................... 1-3

Detector Bases ................................................................................................................................ 1-3

User Interface .......................................................................................................................................... 1-3

Logging In and Out .................................................................................................................................. 1-5

Login/Logout Procedure................................................................................................................... 1-5

Overview - Programming a Job ............................................................................................................... 1-5

Alarm Groups ................................................................................................................................... 1-6

Installation and System

Checkout ................................................................................................. 2-1

Back Box Mounting.................................................................................................................................. 2-1

Removing Electronics Assembly...................................................................................................... 2-1

Conduit Entrances ........................................................................................................................... 2-1

Guidelines for Locating Backbox ..................................................................................................... 2-2

Surface Mounting ............................................................................................................................. 2-2

Semi-Flush Mounting ....................................................................................................................... 2-2

General Wiring Guidelines....................................................................................................................... 2-2

IDC Wiring ............................................................................................................................................... 2-3

Wiring 4098-9682 Four-Wire Base .................................................................................................. 2-4

NAC Wiring.............................................................................................................................................. 2-5

Technical Manuals Online! - http://www.tech-man.com

Page 8

General Wiring Notes ....................................................................................................................... 2-5

Location of Expansion Power Supply NACs (If Used) ...................................................................... 2-5

NAC ratings ...................................................................................................................................... 2-7

Auxiliary Relay Wiring ..............................................................................................................................2-8

DACT........................................................................................................................................................2-9

Remote Annunciator Wiring ...................................................................................................................2-11

City Connect Module Wiring ...................................................................................................................2-12

Auxiliary 24 V Wiring ..............................................................................................................................2-13

Connecting to AC Power ........................................................................................................................2-14

Wiring Battery Power..............................................................................................................................2-15

Depleted Battery Cutout .........................................................................................................................2-16

Safety Ground/Ferrite Bead ...................................................................................................................2-16

System Powerup and Checkout .............................................................................................................2-16

Acceptance Testing ........................................................................................................................ 2-16

Testing Circuit Supervision ............................................................................................................. 2-16

Replacing Lithium Battery ......................................................................................................................2-17

Periodic Testing and Maintenance .........................................................................................................2-17

Smoke Detector Tests .................................................................................................................... 2-17

Battery Tests................................................................................................................................... 2-17

Programming IDCs, NACs, and AUX Relays ....................................... 3-1

Default General Alarm Programming .......................................................................................................3-2

Accessing Menus .....................................................................................................................................3-2

Editing IDCs .............................................................................................................................................3-2

Setting IDC Function Type................................................................................................................ 3-2

Entering Labels ................................................................................................................................. 3-4

Editing Alarm Groups........................................................................................................................ 3-5

Programming NACs .................................................................................................................................3-5

Setting NAC Function Type .............................................................................................................. 3-5

Editing Point Label ............................................................................................................................ 3-7

Editing Alarm Groups........................................................................................................................ 3-7

Programming AUX Relays .......................................................................................................................3-8

Editing Point Label ............................................................................................................................ 3-9

Clear Point Label .............................................................................................................................. 3-9

Saving Changes .......................................................................................................................................3-9

Programming the DACT ........................................................................ 4-1

Accessing DACT Menu ............................................................................................................................4-1

Programming DACT Options....................................................................................................................4-2

Enabling/Disabling DACT ................................................................................................................. 4-2

Setting Primary Phone Number ........................................................................................................ 4-2

Setting Primary Account Number...................................................................................................... 4-3

Setting Secondary Phone Number ................................................................................................... 4-3

Setting Secondary Account Number................................................................................................. 4-3

Setting Dialing Mode......................................................................................................................... 4-3

Technical Manuals Online! - http://www.tech-man.com

Page 9

Setting Pulse Rate ............................................................................................................................ 4-3

Setting Pulse Frequency................................................................................................................... 4-4

Reporting Format .............................................................................................................................. 4-4

AC Fail Delay .................................................................................................................................... 4-4

Test Report Time .............................................................................................................................. 4-5

Programming Contact ID (CID) Points .....................................................................................................4-5

Programming Event Codes ......................................................................................................................4-6

Saving Changes .......................................................................................................................................4-6

Programming Annunciator LEDs ......................................................... 5-1

Adding an Annunciator .............................................................................................................................5-2

Automatically Adding Annunciator Cards.......................................................................................... 5-2

Manually Adding an Annunciator Module ......................................................................................... 5-2

Accessing Annunciator Menus .................................................................................................................5-2

Programming LEDs Located on Zone Annunciator and Remote LED/Switch Modules ...........................5-3

Mapping LEDs to Software Points .................................................................................................... 5-3

Programming Overview .................................................................................................................... 5-3

Default Programming ........................................................................................................................ 5-3

Programming the LED’s Mode and Reference Point ........................................................................ 5-4

Programming Panel LEDs........................................................................................................................5-6

Setting LED Color ............................................................................................................................. 5-6

Setting LED Mode and Reference Point ........................................................................................... 5-6

Common LED Applications ......................................................................................................................5-7

Saving Changes .......................................................................................................................................5-7

Programming System Options ............................................................. 6-1

Accessing System Options Menu.............................................................................................................6-1

Programming Options ..............................................................................................................................6-1

Saving Changes .......................................................................................................................................6-4

Operating ................................................................................................ 7-1

Normal Operation .....................................................................................................................................7-1

Lamp Test ................................................................................................................................................7-1

Abnormal Conditions ................................................................................................................................7-1

Silencing Alarms.......................................................................................................................................7-2

System Reset ...........................................................................................................................................7-2

Viewing/Clearing Historical Logs ..............................................................................................................7-2

Viewing Logs .................................................................................................................................... 7-2

Clearing Logs.................................................................................................................................... 7-3

Viewing and Controlling Points.................................................................................................................7-3

Viewing Point Information ................................................................................................................. 7-3

Manually Activating a NAC/Relay.............................................................................................................7-4

Enabling or Disabling Points ....................................................................................................................7-4

Technical Manuals Online! - http://www.tech-man.com

Page 10

Control Functions .....................................................................................................................................7-4

Setting the Time and Date........................................................................................................................7-5

Reports.....................................................................................................................................................7-5

Diagnostics...............................................................................................................................................7-5

WalkTest ..................................................................................................................................................7-6

Setting WalkTest Options ................................................................................................................. 7-6

Advanced Operations...............................................................................................................................7-7

Upload/Download ............................................................................................................................. 7-7

Restarting the CPU ........................................................................................................................... 7-7

Viewing Software Revision Number and Job Info............................................................................. 7-7

Appendix A. Battery Standby Calculations

Current Draw for System Components ................................................................................................... A-1

Appendix B. Contact ID Default Values

Technical Manuals Online! - http://www.tech-man.com

Page 11

Technical Manuals Online! - http://www.tech-man.com

Page 12

Technical Manuals Online! - http://www.tech-man.com

Page 13

Chapter 1. Overview

This publication describes how to install, configure, operate, program,

and test an 4006-9101 and 4006-9121 (includes door-mounted annunciator) Fire Alarm Control Panel (FACP). In cases where the installation,

wiring, or programming procedure is identical for both panels, the term

4006 is used. If the procedure applies only to a specific panel, the complete product name (i.e., 4006-9121 is used).

The 4006 is a conventional fire alarm control panel. The base system

includes five Class B Initiating Device Circuits (IDCs), which may be

wired as Class A circuits with the addition of an optional Class A module. The base system also includes two Notification Appliance Circuits

(NACs), which may be wired class A or class B. A built-in DACT provides a means for remote station or central station monitoring.

The 4006 provides audible and visible indications during alarm, supervisory, or trouble conditions. Should any of these conditions occur, the

system activates the applicable notification appliances, LEDs, and the

panel tone-alert. The indications continue until an operator acknowledges the condition.

Main System Board

The 4006 base system includes the Main System Board (MSB) mounted

in a steel enclosure with locking door.

In This Chapter

Environmental Specifications . . . . . . . . . . . . . .1-2

Option Modules . . . . . . . . . . . . . . . . . . . . . . . . 1-2

4009-9201/4009-9202CA NAC Extender. . . . . 1-2

Initiating Devices . . . . . . . . . . . . . . . . . . . . . . . 1-3

User Interface. . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Logging In and Out. . . . . . . . . . . . . . . . . . . . . .1-5

Overview - Programming a Job . . . . . . . . . . . .1-5

The MSB contains everything needed for a UL-listed fire alarm system

on one board. It consists of:

• System power supply (3A); 24V filtered

• Five IDCs (Class B)

• Two, 2A Notification Appliance Circuits (Class A or B)

• DACT

• Two auxiliary relay circuits

• One auxiliary power tap

• 2x20 backlit LCD, LEDs and keypad

• Service Port

• Expansion power supply connection

• Expansion IDC connection

• Expansion port for Class A IDC adapter connection

• Connection for interface to optional city card

• Communication channel for remote annunciators

• Battery-backed, non-volatile memory preserves logs, time/date

information, and disabled points on AC loss.

Technical Manuals Online! - http://www.tech-man.com

1-1

Page 14

Chapter 1. Overview

Power supply

• 120 VAC, 60 Hz, 4A; 240V, 50 Hz, 3A

• 24 VDC (filtered) 3A alarm power

• 24 VDC, ½A auxiliary power

• Battery charger up to 25 Ah batteries per UL864; temperature compensated. Recharge 12.7Ah batteries per

ULC-S527.

Note: The 4006 back box can accommodate up to

12.7 Ah batteries.

Environmental Specifications

The panel operates normally with ambient temperatures

from 32° F to 120° F (0° C to 49° C), inclusive.

The panel operates normally under non-condensing humidity conditions up to 93% relative humidity at 90° F (32° C).

Option Modules

The following lists all of the option modules for the 4006.

Refer to the individual instructions that accompany each

module for more information. Refer to the label inside the

door of the 4006 for the placement of optional modules.

4006-9801 Expansion Power Supply (EPS)

When additional notification appliance circuits are required,

an expansion power supply may be added. The expansion

power supply provides two additional 2A NACs, and filtered/regulated 24 VDC, 3A power. The expansion power

supply is mounted to the right of the MSB at the bottom of

the chassis. It connects to the MSB with a ribbon harness.

The 3A alarm power of the EPS may be split between the 2

NACs and the 1/2A Aux. 24V power tap. One EPS per system is allowed.

4006-9802 Expansion IDC Module (XIM)

This module mounts to the right of the MSB. It includes five

Class B Initiating Device Circuits, and a mounting point for

the optional IDC Class A adapter module.

4006-9805 and 4006-9806 City Circuit Cards

The city circuit card connects to the MSB with a ribbon harness to provide connections to either Remote Station

(reverse polarity), or Municipal Master (local energy)

receiving units (selectable). The card has two circuits - circuit 1 reports alarm or alarm/trouble events (Remote Station

only) and circuit 2 can be configured to report trouble events

or supervisory events. In the event of a CPU failure, a city

card configured for a trouble output sends a trouble to the

city circuit. The card is mounted to the right of the MSB at

the top of the chassis. The 4006-9805 and 4006-9806 city

cards are identical except that the 4006-9805 provides hardware disconnect switches for each circuit. One City Circuit

Card per system is allowed.

4006-9803 Expansion Relay Module

The Expansion Relay Module (ERM) includes 10 relays.

The relays may be programmed for per-zone operation, one

relay per IDC, or as desired. For example, it is possible to

program any relay for general alarm, trouble or supervisory

conditions. Normally Open or Normally Closed contact

operation is selected by shunt jumper placement. Contacts

are rated for 2A, 30VDC, 0.35 power factor.

Annunciator Modules

The 4006 supports the following annunciator modules. A

total of four annunciators may be added to the system, one of

which can be located in the panel (the Local Zone LED

module).

• Local Zone LED Module. The local Zone LED

Modules provides 24 LEDs for visible zone alarm and

trouble indication. (The Local Zone LED module,

which mounts on the front of the panel, is standard for

ULC-S527 compliant systems.) There are 10 Red and

14 Yellow LEDs. This provides a red alarm and yellow

trouble LED for each of 10 initiating device circuits.

This module also provides 4 Yellow LEDs, one for each

of 4 NACs. The LEDs are programmable, and can be

used for other functions as appropriate per application.

• 4610-9111 Remote LED/Switch Annunciator.

This annunciator provides the following:

- 10 programmable red LEDs (default programming

tracks alarm state of IDC1-IDC10)

- 6 programmable yellow LEDs (no default operation)

- Green “power on” LED

- Yellow “Alarm Silenced” LED

- Yellow “Trouble”

- Yellow “Comm Loss” LED

- Tone-Alert

- Switches for ACK, Alarm Silence, System Reset,

and Lamp Test

- Key switch to enable switch functions

4009-9201/4009-9202CA NAC

Extender

The 4009-9201/4009-9202CA (Canadian) Notification

Appliance Circuit (NAC) Extenders are self-contained

Technical Manuals Online! - http://www.tech-man.com

1-2

Page 15

Chapter 1. Overview

adjunct panels for use with 4006 Fire Alarm Control Panels

(FACPs).

The base version of the NAC Extender is a single-board system consisting of four NACs, a power supply and charger,

and two conventional NAC inputs that connect to the host

panel for hardwired control of the NAC extender.

Option cards are available to provide the following additional capabilities:

• 4009-9808 Class A Adapter Option Card -- allows fault

tolerance in the case of open circuit wiring faults on the

NACs.

• 4009-9807 NAC Option Card -- adds four conventional

Notification Appliance Circuits.

Initiating Devices

The 4006 is compatible with the following conventional initiating devices.

Photoelectric Smoke Detector

Photoelectric smoke detectors detect smoke by means of

optical sensing technology.

• 4098-9601/4098-9601C: Standard Sensitivity (2.8%/

foot) Photoelectric Smoke Detector

• 4098-9605: Special Sensitivity (3.5%/foot) Photoelectric Smoke Detector

Heat Detector

Four models of conventional electronic heat detector are

available:

• 4098-9612/4098-9612C: 135°F Fixed Temperature

Heat Detector

• 4098-9613/4098-9613C: 135°F Fixed Temperature

Heat Detector w/ rate of rise detection

• 4098-9614/4098-9614C: 200°F Fixed Temperature

Heat Detector

• 4098-9615/4098-9615C : 200°F Fixed Temperature

Heat Detector w/ rate of rise detection

• Fixed temperature trip point: 135°F

Rate of Rise trigger: 15°F-25°F per minute only at temperatures of 90°F or greater

Detector Bases

The detectors described above may be installed in the following detector bases:

• 4098-9788/4098-9788C: Two-wire detector base with

remote LED connection.

• 4098-9683/4098-9683C: Two wire detector base with

auxiliary relay (limit 1 per IDC).

• 4098-9684/4098-9684C: Two wire detector base with

alarm LED output. For use with 4098-961x series heat

detectors only.

• 4098-9682/4098-9682C: Four wire detector base with

auxiliary alarm relay .

Each of the smoke detectors includes an output for a remote

alarm LED. Base 4098-9684 is required for remote LED

control with 4098-9612 through 4098-9615 electronic heat

detectors.

Maximum of 30 total bases per IDC, except for 4098-9683

(limit one per IDC).

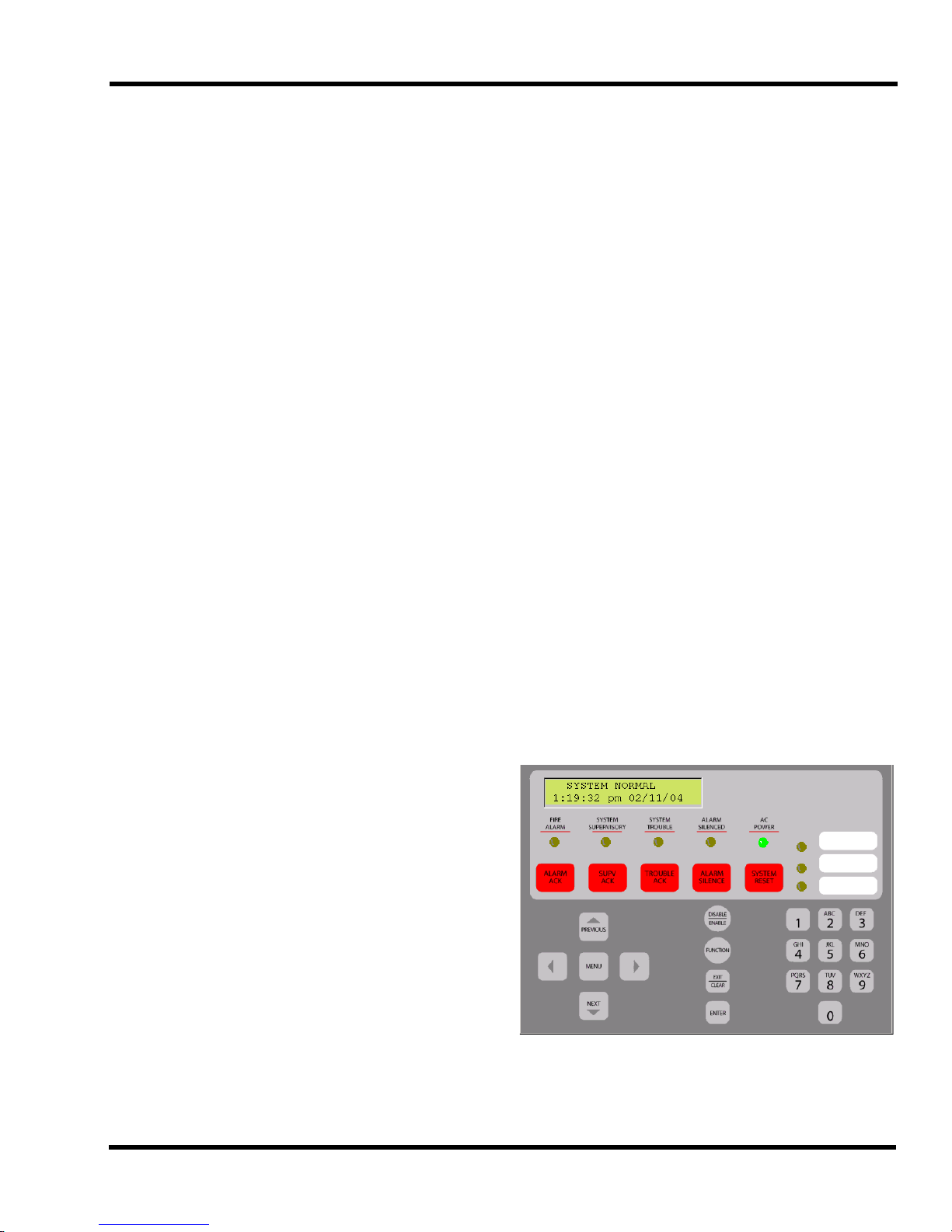

User Interface

The user interface consists of control keys, LEDs, a 2-line

by 20-character backlit LCD, and a sounder mounted in the

control panel. The purpose of the Operator and Menu keys is

listed below.

The rate of rise trigger is 15°F-25°F per minute.

Combination Photo/Heat Detector

The combination photo/heat detector ( 4098-9602/40989602C) is a combination photoelectric detector and thermal

detector in one head. This detector correlates smoke and

thermal activity to provide earliest alarm initiation.

• Smoke detector sensitivity: 2.8% /ft. obscuration

Technical Manuals Online! - http://www.tech-man.com

Figure 1-1 User Interface

1-3

Page 16

Chapter 1. Overview

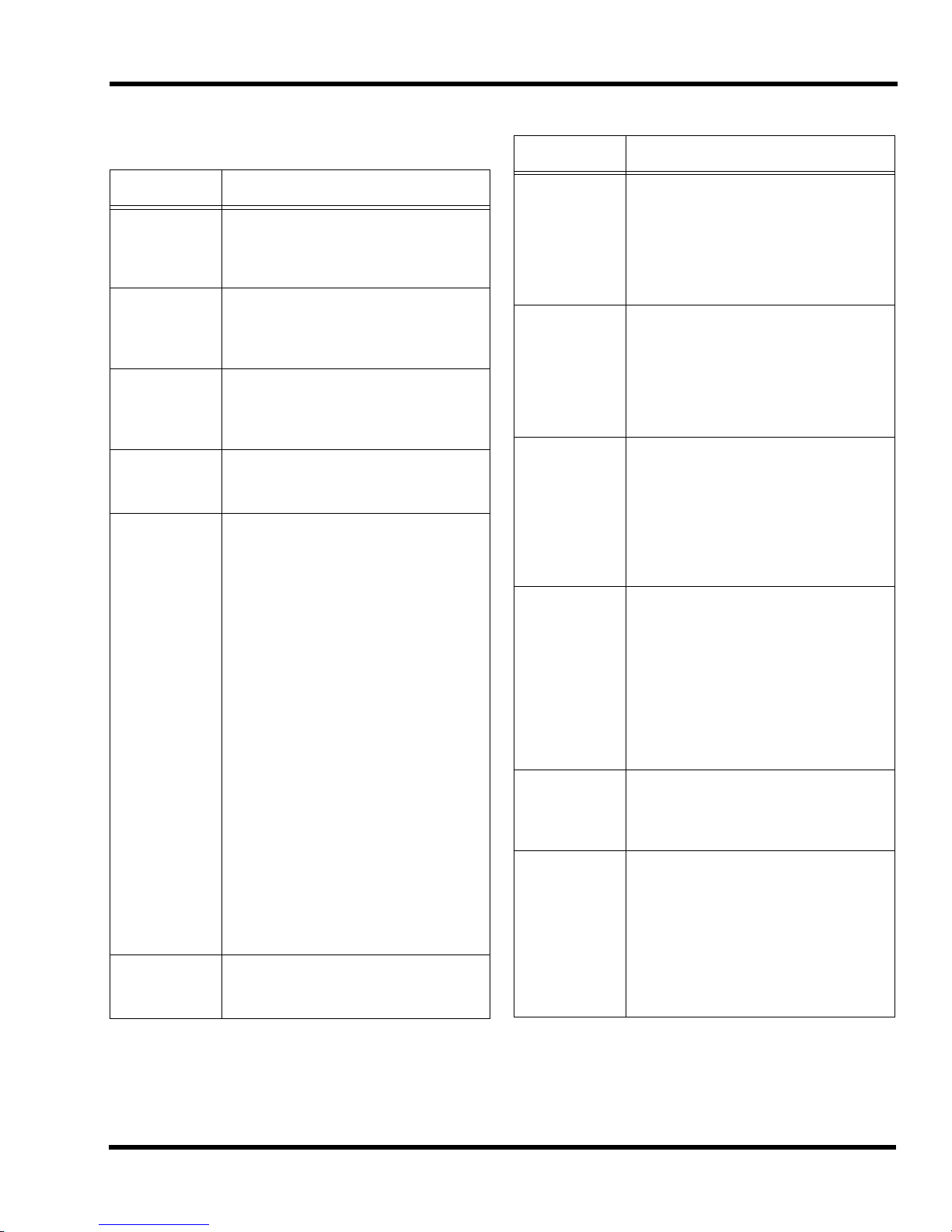

Table 1-1 Operator Keys (Continued)

Table 1-1 Operator Keys

Key Function

Acknowledges any unacknowledged fire

ALARM

ACK

SUPV

ACK

TROUBLE

ACK

ALARM

SILENCE

SYSTEM

RESET

MENU

alarms in the system, and scrolls

through the alarms in the active Alarm

List.

Acknowledges any unacknowledged

supervisories in the system, and scrolls

through the supervisory conditions in the

active Supervisory List.

Acknowledges any unacknowledged

troubles in the system, and scrolls

through the trouble conditions in the

active Trouble List.

Silences any silenceable output types

(generally all audible notification appliances).

Allows the operator to reset all alarm

notification appliances and controls,

remove alarms from the Alarm List,

silence all silenceable outputs, reset

detectors, and return the system to a

normal state (provided that no alarm,

supervisory or trouble conditions are

present). The display indicates that a

reset is in progress and whether or not a

reset completes successfully.

Pressing the <SYSTEM RESET> key

will only attempt to return the system to

a normal, non-alarm state. All outputs

that were activated by the alarm will

remain active until all alarm inputs have

been restored and the reset was able to

successfully complete.

An open circuit fault on a Class A NAC

does not require a System Reset to

restore to normal.

Open circuit faults on the optional City

Connect module are cleared with a system reset after the circuit has been

repaired.

The Menu key always brings you to the

top of the main menu structure unless

you are in the Programming menu.

Key Function

The Function Menu is displayed when

the <Function> key is pressed at the

high-level status screen. Use the <Previ-

FUNCTION

DISABLE/

ENABLE

EXIT/

CLEAR

ENTER

RIGHT/LEFT

ARROWS

PREVIOUS/

NEXT

ous> and <Next> keys to scroll through

the list of functions. The function key

provides access to commonly used control and display functions.

The <Disable/Enable> key allows the

operator to quickly disable or enable any

point that is currently displayed. This key

is passcode protected. A confirmation

screen is displayed requesting <Enter>

be pressed before the actual enable or

disable is performed.

The <Exit/Clear> key is used to back out

of menus or displays and return to the

top-level menu structure. Where possible, the <Exit/Clear> key backs out one

level at a time. There are cases, however, that the Exit/Clear key will return

the operator directly to the top-level

menu.

The <Enter> key is used to confirm

selections. When pressed, this key provides additional information about the

point shown on the display. In a programming screen, pressing <Enter>

indicates that the information on the display is correct and can be accepted. The

<Enter> key is used in various other

places within the menu structure, always

for this same type of operation.

The right and left arrows are used in

screens with multiple choices. The keys

advance the focus (square brackets [ ])

from field to field.

The Previous & Next keys are used to

scroll through the system lists, historical

log, point database, etc. The <Next> key

selects the next display screen in

sequence, and the <Previous> key

selects the previous screen. These keys

are also used to view additional information about abnormal points or in viewing

historical logs.

Technical Manuals Online! - http://www.tech-man.com

1-4

Page 17

Chapter 1. Overview

Logging In and Out

Certain operator functions are passcode-protected at different levels. This section describes the operator functions,

their default access level, and the login/logout procedure.

Table 1-2 Access Levels and Features

Access

Level

Acknowledge, Silence, System Reset,

1

2

Passcode =

2000

3

Passcode =

3000

4

Passcode =

4000

View Historical Logs,

View Point Information, Lamp Test

All Level 1 operations, plus:

Set Time/Date, Point Control,

Enable/Disable points

All Level 1 & 2 operations, plus:

Clear Historical Logs,

Clear Verification Tallies

Custom Label editing

WALKTEST

All Level 1, 2, & 3 operations, plus:

Programming,

Upload/Download

Login/Logout Procedure

To perform any of the functions protected at Level 2 or

above, you must login to the panel using a passcode. After

completing a task at a certain access level, you should then

logout to return the access level to Level 1 to prevent unauthorized operation. When logged in at Level 2 or above and

no panel keys are pressed for more than 10 minutes, the

panel automatically returns the system to Level 1.

All passcodes consist of a 4-digit number. Logging in at

Level 4 causes a Service Mode trouble that may only be

cleared by restarting the panel.

To login, perform the following steps:

1. Obtain the passcode information for the desired level.

2. Press <MENU>

3. Press <NEXT> until [Login/Logout] is displayed, then

press <ENTER>. A prompt similar to the following

appears.

Access: Level 1

<ENTER>=[Login]

Operation

Access: Level 1

Passcode: [0]

5. Use the Keypad to enter the appropriate passcode.

6. When the passcode is correct, press the <ENTER> key

to login.

A “Login Accepted” message, which indicates your current

access level, is displayed briefly upon a successful login

attempt. If you did not enter the appropriate Login passcode,

a “Login Invalid” screen appears.

To logout, perform steps 1-4 above, but select Logout

instead of Login.

Overview - Programming a Job

A job refers to the file containing all of the panel’s programming information. This manual describes the process

required to create a job from the front panel of the system.

Creating a job involves:

• Setting the attributes of each IDC, NAC, and AUX

relay, including:

- Function Type. Determines the way in which the

IDC, NAC, or relay operates (i.e., fire point, trouble

point, on til silence, etc.)

- Custom Label. This is a 20-character label that

describes each zone, NAC, or relay.

- Alarm Group. Allows inputs and outputs to be

associated into groups to implement selective signaling applications. See “Alarm Groups” below.

• Defining the attributes (phone numbers, account numbers, reporting format, etc.) of the panel’s Digital Alarm

Communicator Transmitter (DACT). If the DACT will

not be used, programming consists of disabling the

DACT.

• Programming the operation of the LEDs contained on

the panel and connected annunciators. Programming an

annunciator consists of identifying the point being monitored by the LED and the mode (i.e., fire alarm, trouble, etc.) that will trigger the LED to illuminate.

• Setting values for the panel’s system options, which are

pre-defined modes of operation with a range of settings

from which to choose. System Options define global

operations such as the time and date format, door drop

timers, and whether the city circuit is enabled, etc.

4. Press <NEXT> until [Login] is displayed, then press

<ENTER>. A prompt similar to the following appears.

Technical Manuals Online! - http://www.tech-man.com

1-5

Page 18

Chapter 1. Overview

Alarm Groups

Alarm groups allow you to implement basic selective signalling applications. As you program input (zone of smoke

detectors) and output points (NAC or relay), you are given

the opportunity to associate the point with an alarm group

number. The number can range from 1-100 and each point

can be in up to three alarm groups. When programming is

complete, an initiating device can only trigger the output

devices (relays, NACs) that share its alarm group(s).

Technical Manuals Online! - http://www.tech-man.com

1-6

Page 19

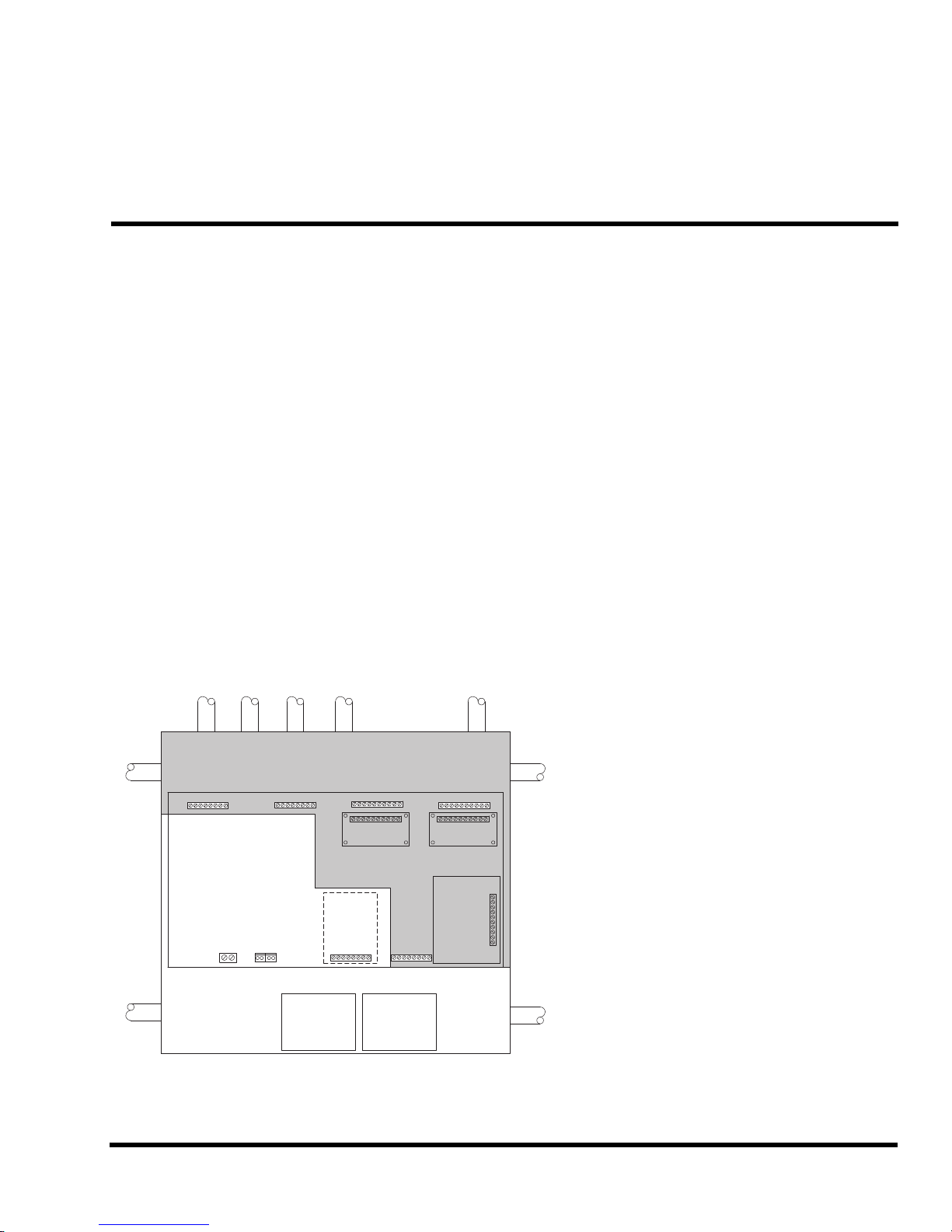

TB1 TB2 TB3

Battery

AC Voltage

Connection

Battery

Connection

Battery

City Connect

Module

Expansion

Power Supply

DACT

Chapter 2. Installation and System

Checkout

Back Box Mounting

The back box can be surface-mounted or semi-flush mounted to the

wall. Use separate conduit entrances for power-limited and non-power

limited wiring.

AC supply, battery supply, and City Connect wiring are all non-power

limited wiring.

Removing Electronics Assembly

Use either a #6 Torx or a slot-head screwdriver to remove the four

screws that secure the electronics assembly to the back box.

Conduit Entrances

• Nine knockouts are provided for conduit connection. Refer to Figure 2-1 for knockout locations.

• Power limited wiring must be located only in the shaded area of

the cabinet.

• AC power (non-power limited) wiring must be run in separate conduit from all other wiring, as shown in the figure below. Non-

power limited wiring must be separated from power limited

wiring by a minimum of 1/4”.

In This Chapter

Back Box Mounting . . . . . . . . . . . . . . . . . . . . 2-1

General Wiring Guidelines . . . . . . . . . . . . . . . 2-2

IDC Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

NAC Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Auxiliary Relay Wiring . . . . . . . . . . . . . . . . . . 2-8

DACT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Remote Annunciator Wiring . . . . . . . . . . . . . 2-11

City Connect Module Wiring. . . . . . . . . . . . . 2-12

Auxiliary 24 V Wiring . . . . . . . . . . . . . . . . . . 2-13

Connecting to AC Power . . . . . . . . . . . . . . . 2-14

Wiring Battery Power . . . . . . . . . . . . . . . . . . 2-15

Depleted Battery Cutout. . . . . . . . . . . . . . . . 2-16

Safety Ground/Ferrite Bead . . . . . . . . . . . . . 2-16

System Powerup and Checkout. . . . . . . . . . 2-16

Replacing Lithium Battery . . . . . . . . . . . . . . 2-17

Periodic Testing and Maintenance . . . . . . . . 2-17

Figure 2-1 Power-Limited (Shaded) and

Non-Power Limited Wiring Areas

Technical Manuals Online! - http://www.tech-man.com

2-1

Page 20

Chapter 2. Installation and System Checkout

1.000 11.250

13.500

13.250

15.632

16.000

1.5”

• All Aux Relay loads must be powered from the AUX

power circuit or from a regulated, 24 VDC, power-limited power supply that is UL-listed for fire protective

signaling service.

Guidelines for Locating Backbox

Always refer to engineering drawings/site installation plans

before beginning installation. The system is designed to

operate in a typical commercial environment. Choose a site

for each backbox that is:

• Well-ventilated, clean, and dust-free.

• Located near a dedicated AC individual branch circuit

with Earth ground (to maintain a consistent supply voltage).

• Away from sources of heat, including direct sunlight.

• Away from sources of vibration or physical shock.

• Away from sources of Radio Frequency Interference

(RFI), such as a radio transceiver base station or hand

held unit.

• Isolated from sources of strong electromagnetic fields,

such as air conditioners, large fans, and large electric

motors.

Be sure to mount the backbox to the wall so that the top of

the enclosure is no more than six feet above the floor.

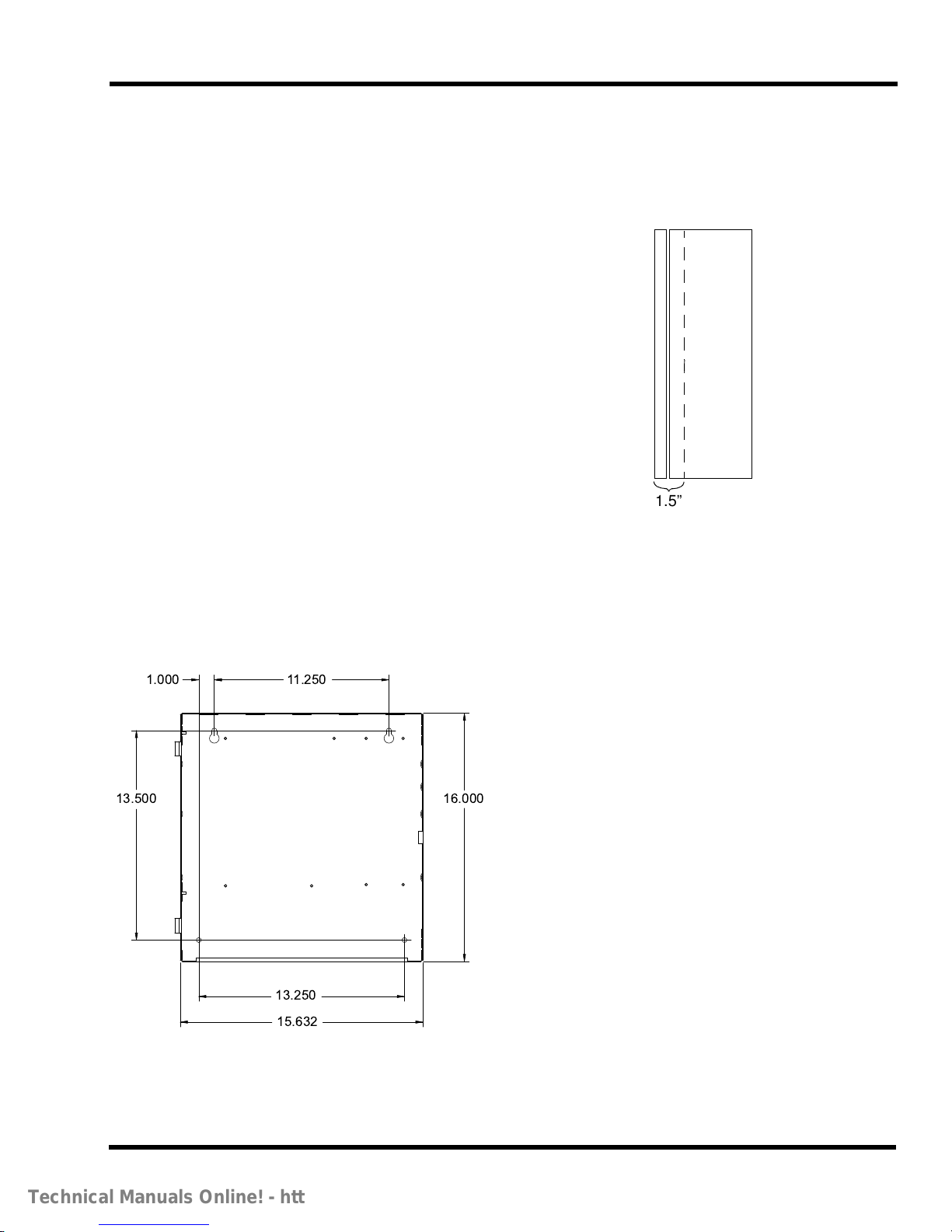

Semi-Flush Mounting

Semi-flush mounting involves recessing the backbox into a

wall and attaching it directly to the wall's studs. At a minimum, 1.5 inches of the backbox must protrude from the wall

to allow for clearance of the panel door.

Figure 2-3 Semi-Flush Mounting

General Wiring Guidelines

Surface Mounting

Refer to the figure below for hole dimensions.

Figure 2-2 Surface Mounting Hole Dimensions

All wiring to the 4006 and its peripherals must be performed

in accordance with NFPA 70, NFPA 72, all local codes, and

per the technical requirements listed in each section below.

Before connecting any wires to the system, including option

modules, wires must be tested as follows:

1. Use a voltmeter (VOM) to verify no stray voltages are

applied to the field wiring. Test for AC and DC voltages

across each pair of wires and from each wire to earth.

2. Use a VOM to verify that all wiring tests free of

grounds. Each conductor should test “open” against

earth (chassis).

Technical Manuals Online! - http://www.tech-man.com

2-2

Page 21

Chapter 2. Installation and System Checkout

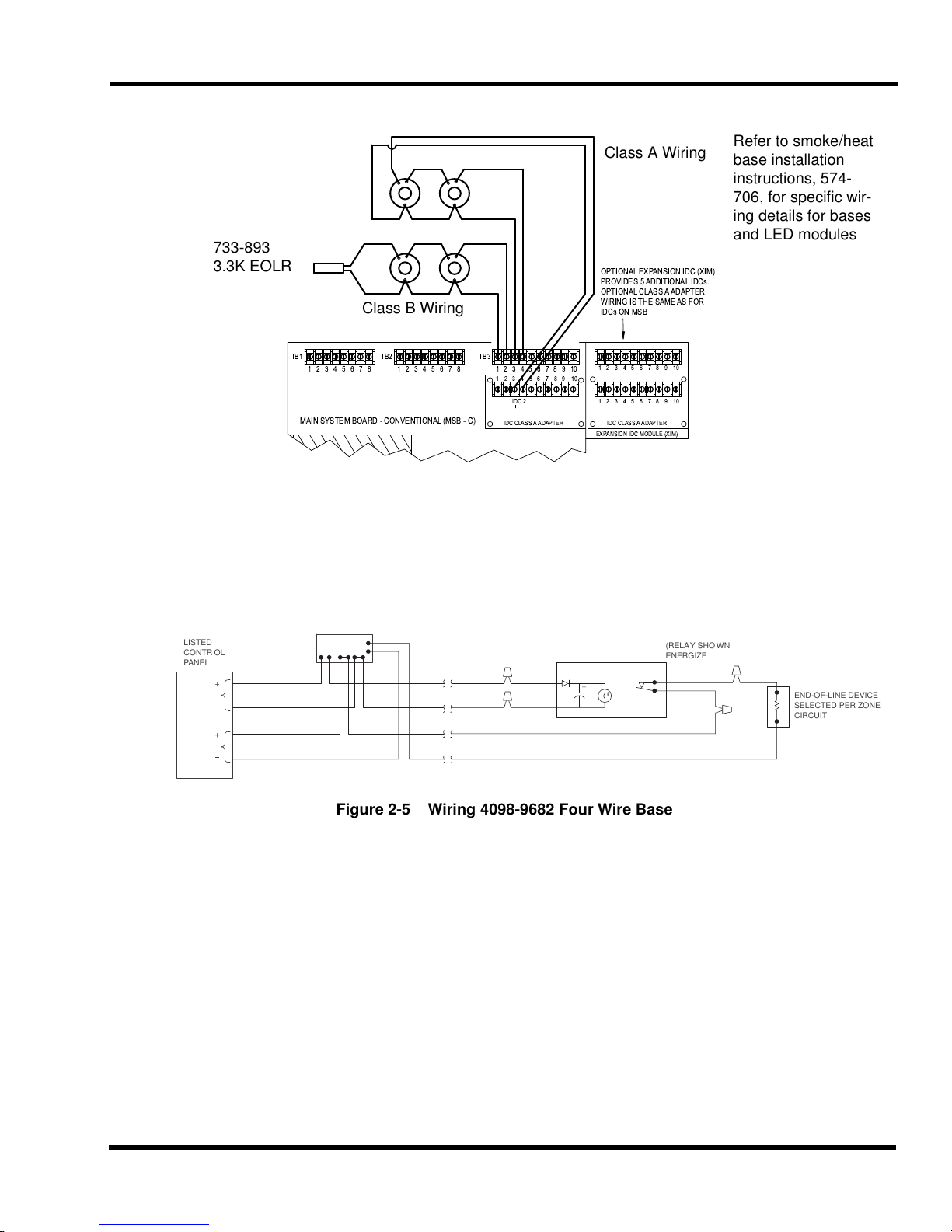

IDC Wiring

• All wiring must be 18 AWG min. to 12 AWG max.

• Conductors must test free of all grounds and stray voltages before connection to appliances and panel.

• All wiring is supervised and power-limited. IDCs

should be segregated from AC supply wiring. If wired

power-limited, segregate IDC wiring from non-power

limited wiring.

• Leave a 3.3K, 1/2 W resistor (supplied) across all

unused IDC terminals.

• Terminate Class B circuits with listed 3.3K, 1W end-ofline resistor, part number 733-893. For Canadian applications, mount end-of-line resistor to TEPG-US Model

431537 EOL plate in accordance with ULC-S527.

• Class A Circuits. Wire as follows:

- Wire from B+/B- from of TB3 to each initiating

device. Wire in a daisy-chain style, in and out from

each device to the next device.

- Do not “T-Tap” wiring.

- Wire from last device back to the A+/A- terminals

on the Class A adapter for that circuit. EOLR is

built onto Class A board.

• For Class A, set CLA Adapter 1 (IDCs 1-5) or CLA

Adapter 2 (IDCs 1-10) System Option to ON. If using

expansion IDC module, set EXP IDC system option to

ON. See Chapter 6.

• Class B Circuits. Wire the circuit to the B+ / B- terminals. The circuit must be wired with IN/OUT wiring

from detector to detector and terminate with 733-893

EOLR.

• Maximum allowed wiring resistance is 50 ohms per circuit. Suggested wire is 18 AWG, allowing up to 3500’

distance from panel to EOLR (Class B) or Class A

Board (Class A). For Simplex Model 4098-9683 relay

base, limit is one device per circuit. For all other detectors and bases, up to 30 devices per circuit are allowed.

• Maximum detector standby current is 3 mA per IDC.

Maximum detector alarm current is 60 mA per IDC.

16-32 VDC, 1/2 V peak-to-peak maximum ripple. Maximum circuit capcitance is 100 uf per IDC.

• Compatible detectors:

- 4098-9601, photoelectric smoke (2.8%) detector

- 4098-9602, combination photo/heat detector

- 4098-9605, photoelectric smoke (special

sensitivity) detector

- 4098-9612, 135° F, Fixed temp heat detector

- 4098-9613, 135° F, Fixed temp/rate of rise heat

- 4098-9614, 200° F Fixed temp heat detector

- 4098-9615, 200° F Fixed temp/rate of rise heat

The compatibility identifier is the model number associated with the board or module.

• Compatiblebases:

- 4098-9788, two-wire base (max. 30 per loop).

- 4098-9683, two-wire base with auxiliary relay

(limit of one per IDC).

- 4098-9684, two-wire base with LED for use with

heat detectors 4098-9612

- through 9615 (max. 30 per loop).

- 4098-9682, 4-wire base with aux. alarm relay (max.

30 per loop). See “Wiring 4098-9682 Four-Wire

Base” below.

Technical Manuals Online! - http://www.tech-man.com

2-3

Page 22

Chapter 2. Installation and System Checkout

TB1

1 2 3 4 5 6 7 8

TB2

1 2 3 4 5 6 7 8

TB3

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7

IDC 2

IDC CLASS A ADAPTER IDC CLASS A ADAPTER

EXPANSION IDC MODULE (XIM)

8 9 10

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8 9 10

MAIN SYSTEM BOARD - CONVENTIONAL (MSB - C)

OPTIONAL EXPANSION IDC (XIM)

PROVIDES 5 ADDITIONAL IDCs.

OPTIONAL CLASS A ADAPTER

WIRING IS THE SAME AS FOR

IDCs ON MSB

733-893

3.3K EOLR

Class A Wiring

Class B Wiring

Refer to smoke/heat

base installation

instructions, 574706, for specific wiring details for bases

and LED modules

LISTED

CONTROL

PANEL

END-OF-LINE DEVICE

SELECTED PER ZONE

CIRCUIT

(RELAY SHOWN

ENERGIZED)

YELLOW

YELLOW

TYPICAL 4-WIRE ZONE

24VDC DEVICES

TYPICAL 4-WIRE

DETECTOR

24VDC

RED

BLACK

E.O.L. RELAY

24 VDC

Power

IDC

R

2098-9735

Figure 2-4 IDC Wiring

Wiring 4098-9682 Four-Wire Base

When the 4098-9682 base is used, the auxiliary 24V power

must be routed through 2098-9735 end-of-line relay, as

shown in Figure 2-5.

Figure 2-5 Wiring 4098-9682 Four Wire Base

Technical Manuals Online! - http://www.tech-man.com

2-4

Page 23

Chapter 2. Installation and System Checkout

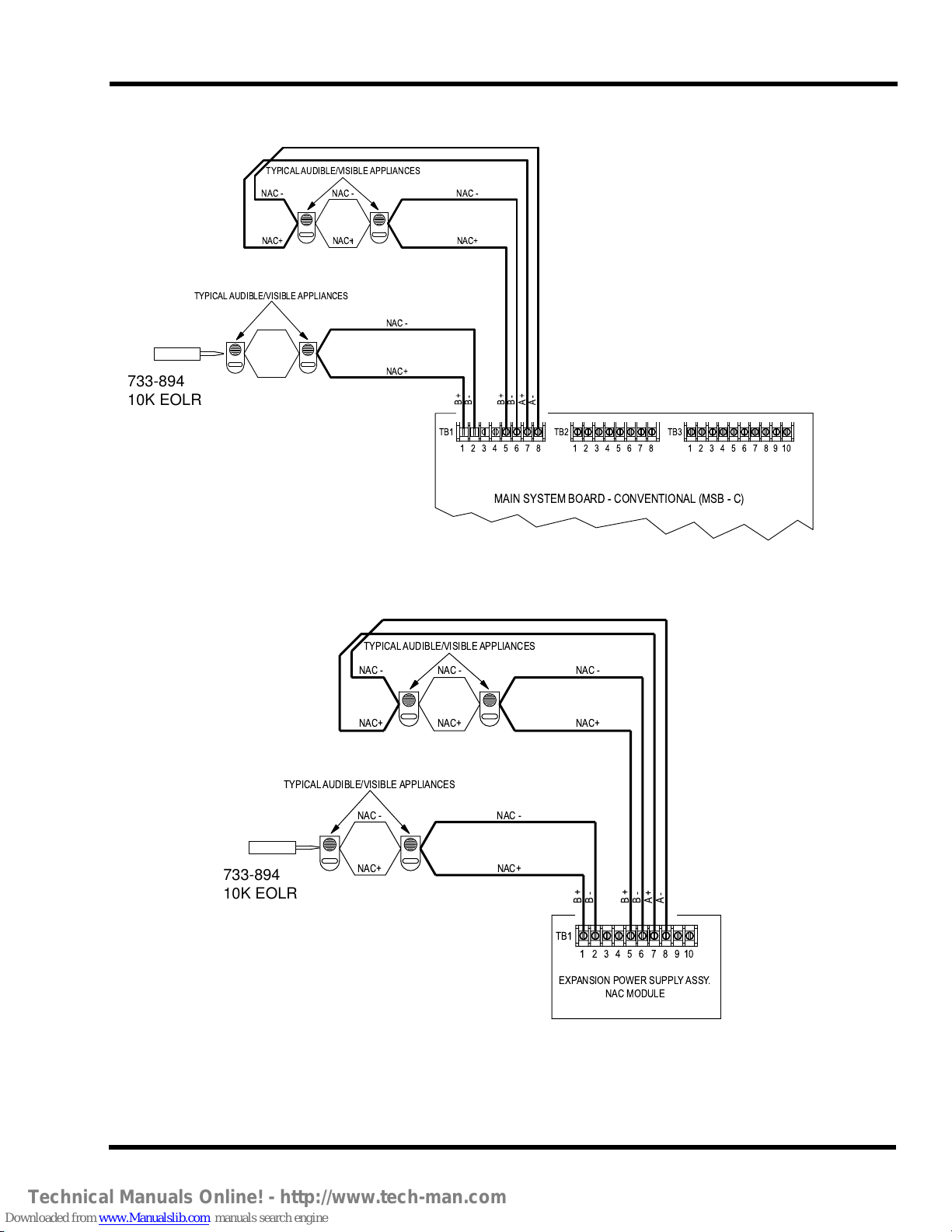

Main

System

Board

EPS

NACs

NAC Wiring

General Wiring Notes -- Apply to NACs on Main

System Board (MSB) and Expansion Power Supply

Refer to Figure 2-6 and Figure 2-7.

• All wiring must be 18 AWG (min.) to 12 AWG (max.).

• Conductors must test free of all grounds and stray voltages before connection to appliances and panel.

• All wiring is supervised and power limited.

• Terminate Class B (Style Y) NACs as shown using 733-

894. For Canadian applications, mount end-of-line

resistor to TEPG-US Model 431537 EOL plate in accordance with ULC-S527.

• Wire Class A (Style Z) NACs from B+/B- to each appliance as shown. No EOL device is required. Connect

wires from +/- terminals of last appliance to the A+/Aterminals as shown.

• System is shipped with 10K, 1/2 W resistors connected

across NAC B+/B- of each circuit. Remove this resistor

from any circuits in use. Leave resistor installed if circuits are unused.

• Voltage rating: Refer to “NAC Ratings” on Page 2-7 for

specific voltage specifications. Maximum ripple: 1/2V

peak-to-peak.

• Current rating: 2A maximum for either circuit. 3A total

between both circuits and Aux. 24 V load.

• Terminal designations (+/-) are for the alarm state.

• When using two-wire audible/visible appliances, maximum wiring capacitance must be considered. For

TrueAlert Non-Addressable notification appliances,

.22uF maximum is allowed.

• If wiring is routed outside the building, use of a listed

secondary protector is required. Use Simplex 20819028 or 2081-9044. A protector must be installed at

each building exit/entrance. Each 2081-9028 adds .2

ohms wiring resistance. 2081-9044 adds 6 ohms wiring

resistance. Use of 2081-9044 will greatly reduce wiring

distance.

• Wiring chart gives max. distance for 1/4 -2A loads. For

Class B circuits wiring distance is from panel terminals

to last appliance. For Class A circuits, wiring distance is

from panel terminals to last appliance and back to panel

terminals. Use of 2081-9044 reduces wiring distance.

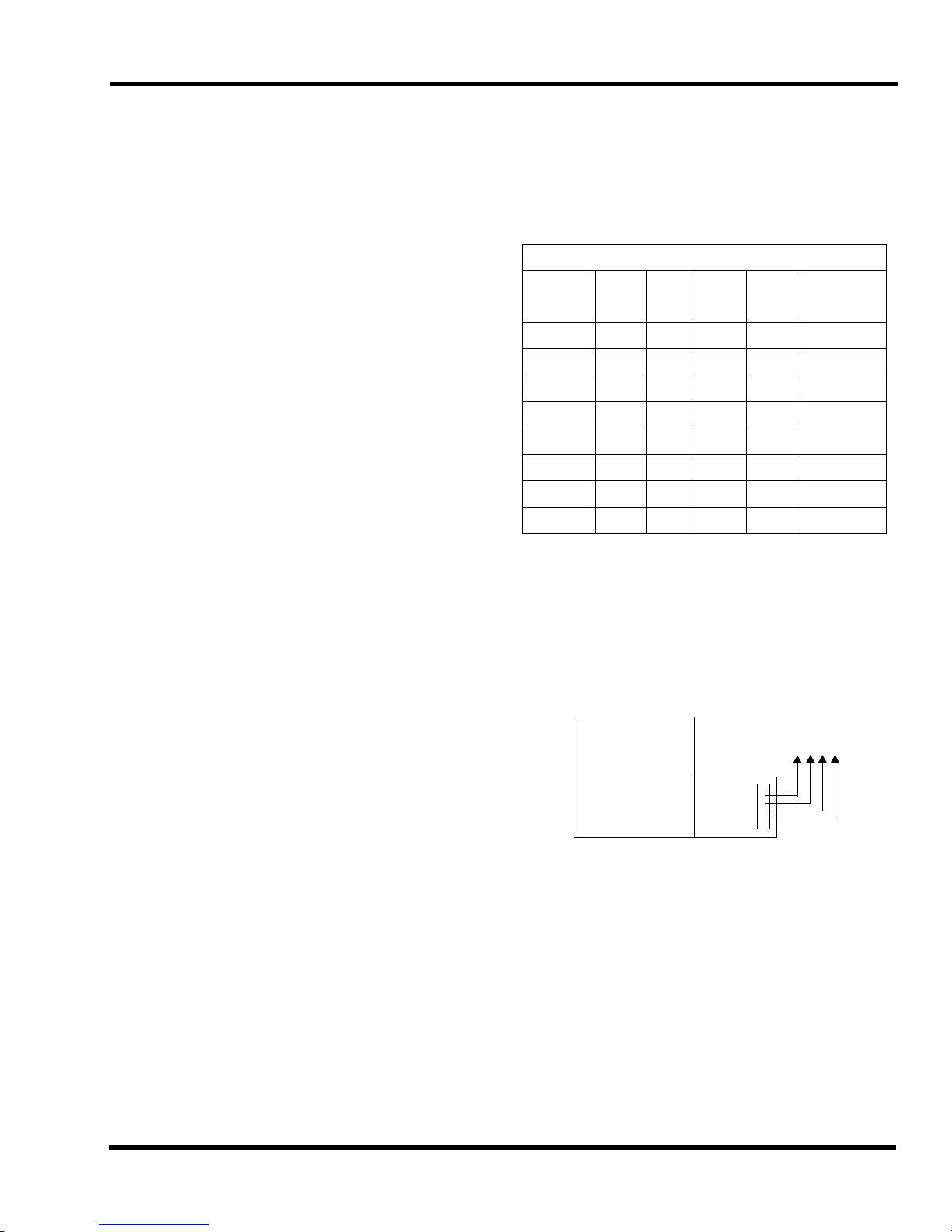

Table 2-1 Wiring Distances

Maximum Wiring Distance in Feet

Alarm

Current

(Amps)

.25 840 1335 2126 3382 12

.50 420 667 1063 1691 6

.75 280 445 709 1127 4

1.0 210 334 532 845 3

1.25 168 267 425 676 2.4

1.50 140 222 354 564 2

1.75 120 191 304 483 1.71

2.0 105 167 266 423 1.5

18

AWG

16

AWG

14

AWG

12

AWG

Line

Resistance

(Ohms)

Location of Expansion Power Supply NACs (If

Used)

The Expansion Power Supply (EPS) is located to the bottom

right of the main system board (MSB), as shown below. Wiring guidelines for these NACs are identical to the guidelines

for the MSB NACs.

Technical Manuals Online! - http://www.tech-man.com

2-5

Page 24

Chapter 2. Installation and System Checkout

TB1

NAC -

TYPICAL AUDIBLE/VISIBLE APPLIANCES

NAC+

NAC -

NAC+

TYPICAL AUDIBLE/VISIBLE APPLIANCES

NAC -

NAC+

NAC -

NAC+

TB2

1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 9 10

TB3

MAIN SYSTEM BOARD - CONVENTIONAL (MSB - C)

B +

B -

B +

B -

A +

A -

733-894

10K EOLR

NAC -

TYPICAL AUDIBLE/VISIBLE APPLIANCES

NAC+

NAC -

NAC+

NAC -

NAC+

TYPICAL AUDIBLE/VISIBLE APPLIANCES

NAC -

NAC+

TB1

EXPANSION POWER SUPPLY ASSY.

NAC MODULE

1 2 3 4 5 6 7 8 9 10

NAC -

NAC+

B +

B -

B +

B -

A +

A -

733-894

10K EOLR

Figure 2-6 Main System Board NACs

Technical Manuals Online! - http://www.tech-man.com

Figure 2-7 Expansion Power Supply NACs

2-6

Page 25

Chapter 2. Installation and System Checkout

NAC ratings

The panel is rated Special Application for 2A maximum per

NAC with Simplex 4901 and 4906 TrueAlert & TrueAlert

Multi-Candela Notification Appliances.

For all other UL Listed Notification Appliances, NACs are

rated regulated 24 VDC at 1.5 A maximum each. Maximum

allowed strobe load on either the main or expansion power

Table 2-2 NAC Ratings

15Cd 30Cd 75Cd 110Cd

4906-

9101 0.060 33 0.094 21 0.186 10 0.252 7

9102 0.075 26 0.125 16 0.233 8 0.316 6

9103 0.060 33 0.094 21 0.186 10 0.252 7

9104 0.075 26 0.125 16 0.233 8 0.316 6

9127 0.075 26 0.116 17 0.221 9 0.285 7

9128 0.086 23 0.132 15 0.250 8 0.320 6

9129 0.075 26 0.116 17 0.221 9 0.285 7

9130 0.086 23 0.132 15 0.250 8 0.320 6

Rated

Current

Max. # per

NAC

Rated

Current

Max. #

per NAC

supply is 1.35 A. The balance of the 3 A capacity can be

auxiliary loads or audible notification appliances.

Synchronization of strobes across all NACs in a system is

UL Listed for the Simplex models noted in the table below.

See the table below for maximum number allowed of each

appliance per NAC.

Rated

Current

Max. # per

NAC

Rated

Current

Max. # per

NAC

9151 0.060 33 0.094 21 0.186 10 0.252 7

9154 0.075 26 0.125 16 0.233 8 0.316 6

9153 0.060 33 0.094 21 0.186 10 0.252 7

All other regulated 24 VDC synchronized notification

appliances require the use of their associated, listed external

synchronization module. Notification Circuit rating is 1.5 A

maximum, 1.35 A maximum strobe load per power supply.

Use the UL-rated operating current to determine maximum

number of appliances allowed per NAC.

Technical Manuals Online! - http://www.tech-man.com

2-7

Page 26

Chapter 2. Installation and System Checkout

Auxiliary Relay Wiring

• All wiring must be 18 AWG (minimum) to 12 AWG

(maximum). Conductors must test free of all grounds

and stray voltages before connection to appliances,

devices, and panel.

• Contact rating: 30VDC @ 2A, 0.35 power factor

• If using expansion relay module, set EXP RELAY system option to ON.

• Each relay is selected for normally closed or normally

open operation. Shunt jumper setting (see figure) selects

desired contact.

• Relay 1 is programmable. Its default operation is Common Alarm - On Until Reset. Jumper is P1.

• Relay 2 is a normally energized, common trouble relay.

The jumper settings noted in the figure account for the

relay being normally energized. Jumper is P2.

• When the panel is completely powered off, the trouble

relay will be in the “Off Normal” state.

• All wiring is unsupervised.

Figure 2-8 Relays on Main System Board

Technical Manuals Online! - http://www.tech-man.com

2-8

Page 27

Chapter 2. Installation and System Checkout

DANGER

HIGH VOLTAGE

IN THIS AREA

DACT TELEPHONE

CONNECTIONS

LINE 2 TELCO SERVICE IN

LINE 1 TELCO SERVICE IN

WIRE TO MODULAR JACK

TO USE LINE 1 FOR

OTHER TELCO EQUIP.

WIRE TO MODULAR JACK

TO USE LINE 1 FOR

OTHER TELCO EQUIP.

1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 9 10

TB1 TB2 TB3

MAIN SYSTEM BOARD - CONVENTIONAL (MSB - C)

TB5

1 2 3 4 5 6 7 8

R

I

N

G

R

I

N

G

R

I

N

G

R

I

N

G

T

I

P

T

I

P

T

I

P

T

I

P

DACT

The DACT connection is made from the Main System Board

to the public telephone system via terminals TB5-1/TB5-2

and TB5-5/TB5-6. Wiring information is shown in

Figure 2-9.

• The DACT requires two telephone line connections to

meet NFPA72 requirements. Wire from TB5-3/TB5-4

and TB5-7/TB5-8 to an RJ-11 or other Telcom wiring

block for connection to other telephone equipment. The

DACT will seize control of the telephone line (if necessary) to transmit emergency messages. When wired as

shown, the DACT will properly control access to lines

in an emergency.

• Wire from Telcom equipment to TB5 using 18 AWG to

24 AWG.

• All DACT wiring is supervised.

• Digital Alarm Communicator Receiver (DACR) compatibility is shown in Table 2-3.

• If wiring is routed outside the building, use of a listed

secondary protector is required. Use Simplex 20819028 or 2081-9044. A protector must be installed at

each building exit/entrance. Each 2081-9028 adds .2

ohms wiring resistance. 2081-9044 adds 6 ohms wiring

resistance. Use of 2081-9044 will greatly reduce wiring

distance.

Figure 2-9 DACT Wiring

Technical Manuals Online! - http://www.tech-man.com

2-9

Page 28

Chapter 2. Installation and System Checkout

Table 2-3 Compatible DACRs

Digital Alarm Communicator Receiver (DACR)

Communication

Format

Contact ID

(Preferred)

3/1 Standard

1800/2300 Hz

(10 and 20PPS)

3/1 Standard

1900/1400 Hz

(10 and 20PPS)

4/2 Standard

1800/2300 Hz

(10 and 20PPS)

4/2 Standard

1900/1400 Hz

(10 and 20PPS)

Radionics

BFSK

1800/2300 Hz

Simplex

Central

Station

Services

2, 3

FBII

CP220FB

Osborne/

Hoffman

QuickAlert

II

ADEMCO

1, 3

685

SUR-

GARD

MLR2-DG

Radionics

D6600

Silent

Knight

9000

Silent

Knight

9500

With 9032

Line Card

With 9032

Line Card

With 9032

Line Card

With 9032

Line Card

With 9032

Line Card

SUR-

GARD

MLR

2000

TBD

TBD

TBD

TBD

TBD

Radionics

BFSK

1900/1400 Hz

SIA

Notes:

1. With 685-8 Line Card

2. With Rec-11 Line Card

3. These receivers are also Factory Mutual (FM) approved.

With 9032

Line Card

TBD

TBD

Technical Manuals Online! - http://www.tech-man.com

2-10

Page 29

Chapter 2. Installation and System Checkout

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

TB2

TB1

N2

Comms

-

+

0V Shield

(If Used)

MSB

MSB

RAMRAM

RAM

RAM

RAM

RAM

RAM

T-Tap Style Wiring

Bus Style Wiring

A A

A

RAM = Remote Annunciator Module

MSB = Main System Board

Remote Annunciator Wiring

• All wiring must be 18 AWG (min.) to 12 AWG (max.),

twisted pair or shielded twisted pair.

• Conductors must test free of all grounds and stray voltages before connection to appliances, devices, or panel.

• All wiring is supervised and power-limited.

• Refer to instructions packed with remote annunciator

modules for connection details to each module.

• Remote annunciators require power and communications wiring.

• For “bus-style” wiring (see figure), maximum wiring

limit is 4, 000 feet.

- Maximum wiring capacitance is 0.58µF total,

wire-to-wire plus wire-to-shield.

- Attach 733-974 (100 ohm, 1/2W) resistor as shown

for line matching. See Note A in figure below. Wire

remote devices “daisy-chain” style, using in/out

terminals on each device.

• For “T-Tap” style wiring, total cable limit is 10,000 feet,

2,500 feet to the furthest device.

- Maximum wiring capacitance is .58uF total, wire-

to-wire plus wire-to-shield.

- Attach 733-974 (100 ohm, 1/2W) resistor (see Note

A in figure) for line matching.

• Shielded wire is not required for most installations. If

communications wiring is not in conduit with strobes or

voice speaker circuits, shielded wiring is not required.

Use shielded wiring if remote annunciator wiring shares

a conduit with these signals. Terminate shield to 0V

(Aux 24V Neg.) or to chassis.

• If wiring is routed outside the building, use of a listed

secondary protector is required. Use Simplex 20819028 or 2081-9044. A protector must be installed at

each building exit/entrance. Each 2081-9028 adds .2

ohms wiring resistance. 2081-9044 adds 6 ohms wiring

resistance. Use of 2081-9044 will greatly reduce wiring

distance.

• Wiring must pass through a ferrite bead. Wrap the wiring twice through the ferrite bead, as shown in

Figure 2-12.

Figure 2-10 Annunciator Wiring Connections

Figure 2-11 Bus Style and T-Tap Wiring

Technical Manuals Online! - http://www.tech-man.com

Figure 2-12 Ferrite Bead

2-11

Page 30

Chapter 2. Installation and System Checkout

EMPLOY A 14.5 OHM TRIP COIL.

P5

LE

RP

LE

RP

P4

10 9

8 7

6 5

4 3

2 1

P3

LE

RP

LE

RP

P2

10 9

8 7

6 5

4 3

2 1

P6

1

2

3

4

City Connect Module Wiring

• City connect module mounts to the main system as

shown. Refer to City Module Installation Instructions

for details.

• City module consists of two circuits that are jumperconfigured. Circuits may be configured for reversepolarity or local energy operation. See jumper setting

table for details. Modules must also be added to the system configuration. See “System Options” later in this

manual.

• All wiring to be per NPFP-72, NEC, and local codes.

Minimum 20 AWG for reverse polarity; minimum 18

AWG for local energy circuits.

• Conductors must test free of all grounds.

• Wiring is supervised for opens and grounds, but not

power-limited.

• For specific information about reverse polarity and local

energy circuits, see Figure 2-13.

• If wiring is routed outside the building, use of a listed

secondary protector is required. Use Simplex 20819028 or 2081-9044. A protector must be installed at

each building exit/entrance. Each 2081-9028 adds .2

ohms wiring resistance. 2081-9044 adds 6 ohms wiring

resistance. Use of 2081-9044 will greatly reduce wiring

distance.

• Circuits are shipped with 3.3K, 1/2W resistor installed.

Remove resistor before wiring circuit. Leave installed

on unused circuits.

Figure 2-13 City Connect Module Wiring

Technical Manuals Online! - http://www.tech-man.com

2-12

Page 31

Chapter 2. Installation and System Checkout

Auxiliary 24 V Wiring

• All wiring must be 18 AWG (minimum) to 12 AWG

(maximum).

• Conductors must test free of all grounds and stray voltages before connection to appliances, devices, and

panel.

• All wiring is supervised and power-limited.

• Voltage rating (24 VDC special application): 1 V p-p

ripple (maximum)

- 0.5 A maximum available aux 24 V from EPS

- Additional 0.5 A maximum available from Main

System Board (MSB) AUX 24 V

- 3 A total available from MSB NACs and MSB

AUX 24 V.

- 3 A total available from EPS NACs and EPS AUX

24 V.

• Compatible with Simplex 4098 Series Peripherals; 2098

Series Relay Modules; all Simplex 4090 Series IDNet

Peripherals; and 4610-9111 / 4606-9101 Annunciators.

• If wiring is routed outside the building, use of a listed

secondary protector is required. Use Simplex Model

2081-9028 or 2081-9044. A protector must be installed

at each building exit/entrance. Each 2081-9044 adds 6

ohms wiring resistance, and is rated for 200mA. Each

2081-9028 adds .2 ohms wiring resistance, and is rated

for more than 1/2A Aux. 24V capacity.

• Compatible devices must operate from a range of 19.5

to 28 VDC or greater, and have a total current draw of 1/

2 A or less.

Figure 2-14 Aux 24V Wiring

Technical Manuals Online! - http://www.tech-man.com

2-13

Page 32

Chapter 2. Installation and System Checkout

TB1

DANGER

HIGH VOLTAGE

IN THIS AREA

DACT TELEPHONE

CONNECTIONS

EXPANSION POWER SUPPLY ASSY.

NAC MODULE

THE POWER SUPPLY MODULE, PART OF THE EPS

ASSEMBLY, IS MOUNTED BENEATH THE NAC MODULE

PORTION OF THE EPS ASSEMBLY.

734 - 179

WIRE AC LINE AND NEUTRAL AS SHOWN.

HOT TO LEFT TERMINAL, NEUTRAL TO RIGHT TERMINAL.

WHITE

LINE

NEUTRAL

BLACK

WHITE / BLACK HARNESS 734 - 179

FROM EPS (LOWER MODULES)

TO MAIN SYSTEM BOARD.

EPS

POWER SUPPLY MODULE

TB5

1 2 3 4 5 6 7 8

TB2

1 2 3 4 5 6 7 8

TB3

1 2 3 4 5 6 7 8 9 10

TB1

B+ B- B+B- A+ A-

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8

MAIN SYSTEM BOARD - CONVENTIONAL (MSB - C)

Connecting to AC Power

• Before handling AC feed, use a voltmeter to verify the

feed is not live. Make sure the circuit is de-energized

and tagged to prevent injury.

• AC feed must be routed in the wiring area below the

main system board, in the area designated “not power

limited.”

• AC power must be wired from a dedicated circuit

breaker or fuse, rated 20 A, per NFPA-72, NEC, and

local codes.

• AC supply wiring must be 14 AWG minimum to 12

AWG maximum.

• Connect a 12 AWG copper ground wire from safety

ground in the electrical distribution panel to the panel

safety ground stud.

• Input voltage range:

- 120 VAC, 60 Hz

- 240 VAC, 50Hz

- No configuration settings required to select

• The Expansion Power Supply (EPS) is an option, and

requires AC power when used. Connect the Black/

White AC harness from the EPS to the TB4 AC input

terminals on the main system board. Wire Black to the

left terminal of TB4. Wire White to the right terminal of

TB4.

• AC wiring is supervised. Safety ground wire is not

supervised.

• Supply Power Requirements

- 120 VAC 60 Hz, 2A maximum

- 240 VAC 50 Hz, 1.5A maximum

1. Remove insulating cover marked with the high voltage

warning.

2. Connect AC feed wires to terminal block located at bottom left of board. Terminals are labeled LINE (120V)

and NEUTRAL. Wire the AC feed through the ferrite

bead (provided). Refer to Figure 2-18.

3. Before applying AC power to the system, connect the

batteries per the instructions on the following page, and

replace the protective cover removed in step 1.

4. Connect Safety Ground from electrical service to

mounting stud (see Figure 2-18) marked with Earth

symbol. Use a terminal lug that is suitable for the

ground wire and nut used.

5. Replace protective cover.

Technical Manuals Online! - http://www.tech-man.com

Figure 2-15 AC Wiring

2-14

Page 33

Chapter 2. Installation and System Checkout

TB1

DANGER

HIGH VOLTAGE

IN THIS AREA

DACT TELEPHONE

CONNECTIONS

EXPANSION POWER SUPPLY ASSY.

NAC MODULE

THE POWER SUPPLY MODULE, PART OF THE EPS

ASSEMBLY, IS MOUNTED BENEATH THE NAC MODULE

PORTION OF THE EPS ASSEMBLY.

734 - 180

ATTACH TO BATTERY CONNECTOR

RIGHT - JUSTIFIED, BLACK WIRE TO THE RIGHT

CONNECT TO

BATTERY TERMINALS

(FUSED ON PCB)

BLACK

RED

HARNESS 734 - 180

FROM EPS (LOWER MODULES)

TO MAIN SYSTEM BOARD

BATTERY CONNECTOR

EPS

POWER SUPPLY MODULE

TB5

1 2 3 4 5 6 7 8

TB2

1 2 3 4 5 6 7 8

TB2

1 2 3 4 5 6 7 8 9 10

TB1

3B+

3B-

3A+

3A-

4B+

4B-

4A-

4A-

24V

0V

1 2 3 4 5 6 7 8 9 10

1 2 3 4 5 6 7 8

MAIN SYSTEM BOARD - CONVENTIONAL (MSB - C)

R

E

D

R

E

D

B

L

K

B

L

K

Wiring Battery Power

• The main battery harness connects the main system

board to the battery set in the same cabinet.

• The system requires 24V battery backup. Use two 12V

batteries, connected in series. The main battery harness

connects to the .250” fast-on battery terminals, as follows:

1. Connect black wire to the negative battery terminal

of Battery 1

2. Connect white wire from the positive battery termi-

nal of Battery 1 to the negative battery terminal of

Battery 2.

3. Connect the red wire to the positive battery termi-

nal of Battery 2.

• Connect the main battery harness to the four-position

header, located approximately in the center of the bot-

tom edge on the main system board. Insert the connector left-justified, with the red wire to the left.

• The EPS connects to the battery header next to the battery harness described in the previous bullet. Install the

EPS red/black harness right-justified to the battery

header, with the black wire to the right.

• Battery circuit is supervised, but not power-limited.

• For depleted battery cutout operation, remove jumper

per installation instructions. Separate jumper removal

required for main system board and EPS. System programming option “Depleted Battery Cutout” must also

be selected. ULC-S527 depleted battery operation

requires jumper removal.

• For 18 Ah or larger batteries, the 4009-9801 external

battery cabinet must be used. Mount the battery box

within 20 feet of the control panel, in accordance with

the mounting instruction label in the box. All interconnecting wiring must be enclosed in conduit.

Figure 2-16 Battery Connections

Technical Manuals Online! - http://www.tech-man.com

2-15

Page 34

Chapter 2. Installation and System Checkout

LINE NEUTRAL

BATT EPS

+ - + -

Remove this

Jumper

Depleted Battery Cutout

For depleted battery cutout, remove the jumper shown in

Figure 2-17 from the main system board. If you are using an

Expansion Power Supply (EPS), you must also remove

Jumper R76 from the EPS. (When programming the panel,

make sure to enable the Depleted Battery Cutout system

option.)

Figure 2-17 Location of Depleted Battery Jumper

Safety Ground/Ferrite Bead

System Powerup and Checkout

Use the following procedure to apply AC and battery power

to the 4006.

On power up, the panel performs the following:

• Displays revision of boot-loader software

• CPU self test

• Link Scan - checks for a programming unit connection

• Memory Test - Verifying system and job-specific software

• Startup - 4006 Exec startup

If the panel successfully completes its start up self-test, it

will indicate a warm or cold start trouble, which clears when

acknowledged. If there are no other troubles in the system,

the following is displayed:

SYSTEM NORMAL

12:00 am 21-FEB-03

If other troubles exist in the system, the following is displayed:

FIRE | SUPV | TRBL

00 | 00 | 02

Proper operation and protection against transient energy per