Page 1

Addressable Manual Stations

2099-9135, -9761, -9795, -9796, & -9797

Installation Instructions

2000 Simplex Time Recorder Co., Westminster, MA 01441-0001 USA

All specifications and other information shown were current as of publication, and are subject to change without notice.

574-155

Rev. A

These instructions describe installing and setting the address for a manual

station (single action, double action, or local). Installing a manual station

consists of the following tasks:

• Setting the Address. The address, which uniquely identifies the manual

station on the MAPNET II

channel, must be set in two places the dip

switch on the rear of the manual station and through the programmer. The

address must match in both places.

• Wiring. Addressable manual stations connect to either a 2120 Multiplex

Communicating Device Transponder (CDT), 4020, 4100+, or 4120 system

by a twisted, shielded (recommended) wire pair (MAPNET), and receive

both power and data over this wire pair.

• Installing. Manual stations mount to a variety of standard switch and back

boxes.

• Maintaining. Depending on the model of manual station, you may also

need to replace a small pane of glass or a glass rod following activation.

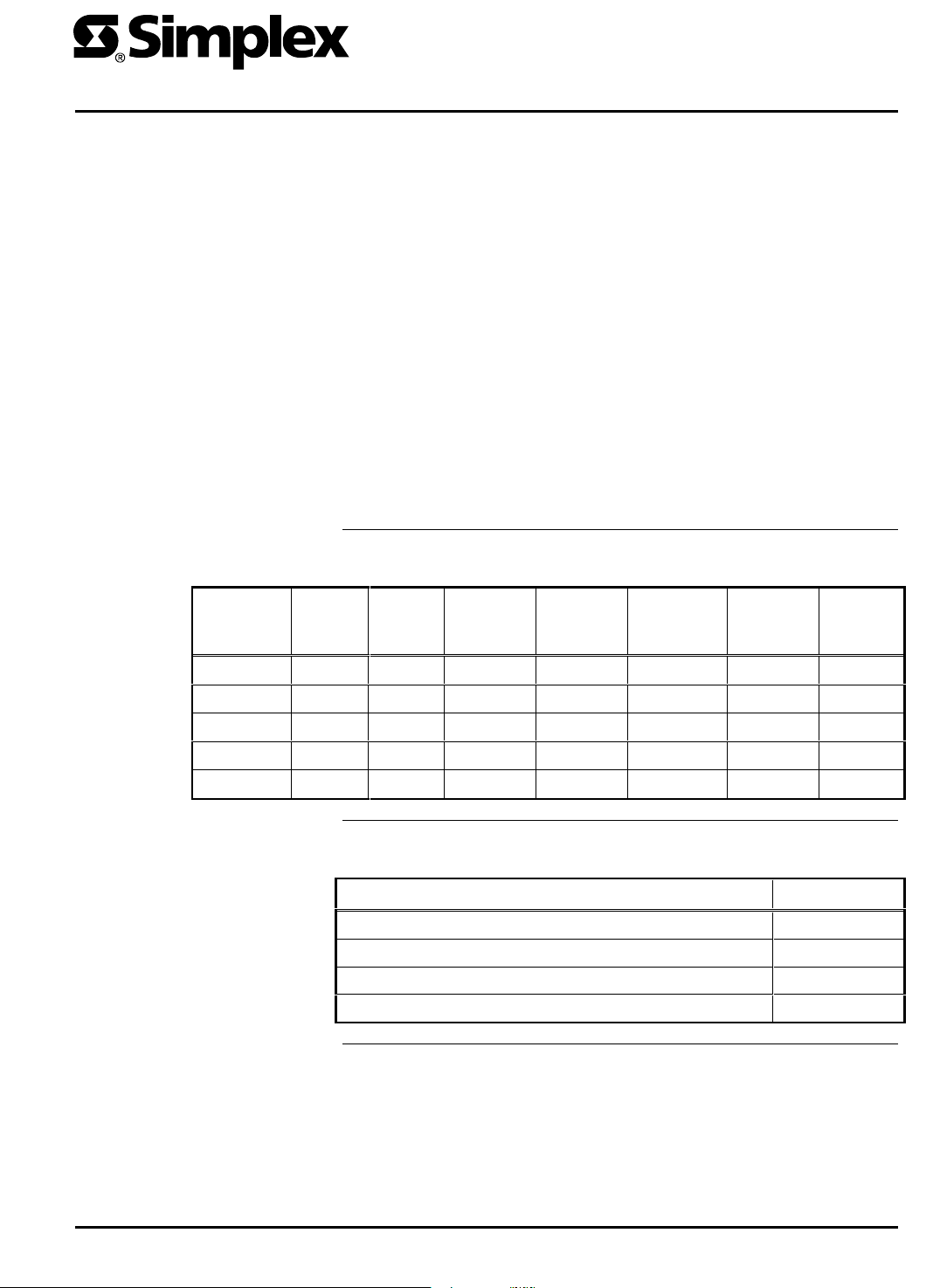

Table 1 summarizes the features of each manual station model.

PID

Single

Action

Glass

Double

Action

Push

Double

Action

MAPNET

I

MAPNET

II

Local

Cover

No

Simplex

Logo

2099-9135

X

X

X

2099-9761

X

X

2099-9795

X

X

2099-9796

X

X

2099-9797

X

X X

This publication discusses the following topics:

Topic See Page #

Setting the Manual Station’s Address 2

Wiring 4

Installing the Manual Station 5

Replacing Glass Pane/Glass Rod 6

Overview

Features

In this Publication

Technical Manuals Online! - http://www.tech-man.com

Page 2

2

Each manual station has a unique address, which is set using a series of dip

switches located inside the manual station. The manual station’s address must

match the address listed in the specification sheets of the 2120 Job

Configuration Report or the Programmer’s Report for the 4020, 4100+, or 4120

system.

1. Set the manual station’s address using Table 2. See Figure 1 for the

location of the switches. Use a small screwdriver or pen to set the switches.

When positioning each dip switch, note that 0 equals ON and 1 equals OFF.

Note: The address you set must match the address entered in the 2120 Job

Configuration Report.

2. Mark an address label with the appropriate address for the manual station.

Shade a box for each dip switch in the ON position. Leave the OFF

positions blank. Apply the label to the manual station near the dip switches.

3. Double-check the address before wiring the manual station.

1. Set the manual station’s address using Table 2. See Figure 1 for the

location of the switches. Use a small screwdriver or pen to set the switches.

When positioning each dip switch, note that 0 equals ON and 1 equals OFF.

Note: The address you set must match the address entered in the

Programmer’s Report for the 4020, 4100+, or 4120 system.

2. Mark an address label with the appropriate address for the manual station.

Shade a box for each dip switch in the ON position. Leave the OFF

positions blank. Apply the label to the manual station near the dip switches.

3. Double-check the address before wiring the manual station.

Figure 1. Location of Dip Switches

Continued on next page

Setting the Manual Station’s Address

Introduction

Address Setting for the 2120

CDT System (MAPNET)

Address Setting for the 4020,

4100+, or 4120 System

(MAPNET Only)

Technical Manuals Online! - http://www.tech-man.com

Page 3

3

Use Table 2 to convert a decimal address, such as address 7, to its binary

equivalent. This binary number can then be set on the manual station as shown

in the figure at the top of the table.

Table 2. Address Settings

0000 1000 0100 1100 0010 1010 0110 1110

0000

0 163248648096112

1000

1 173349658197113

0100

2 183450668298114

1100

3 193551678399115

0010

4 2036526884100116

1010

5 2137536985101117

0110

6 2238547086102118

1110

7 2339557187103119

0001

8 2440567288104120

1001

9 2541577389105121

0101

10 26 42 58 74 90 106 122

1101

11 27 43 59 75 91 107 123

0011

12 28 44 60 76 92 108 124

1011

13 29 45 61 77 93 109 125

0111

14 30 46 62 78 94 110 126

15 31 47 63 79 95 111 127

LSB

MSB

1 2345678

1111

DIP SWITCHES 5 THRU 8

RESERVED FOR

FUTURE USE

DIP

SWITCHES

1 THRU 4

ON

OFF

1 = ON 0 = OFF

DIPSWITCH IS SHOWN SET AT ADDRESS 7.

Setting the Manual Station’s Address, Continued

Address and Dip Switch

Conversion Chart

Technical Manuals Online! - http://www.tech-man.com

Page 4

4

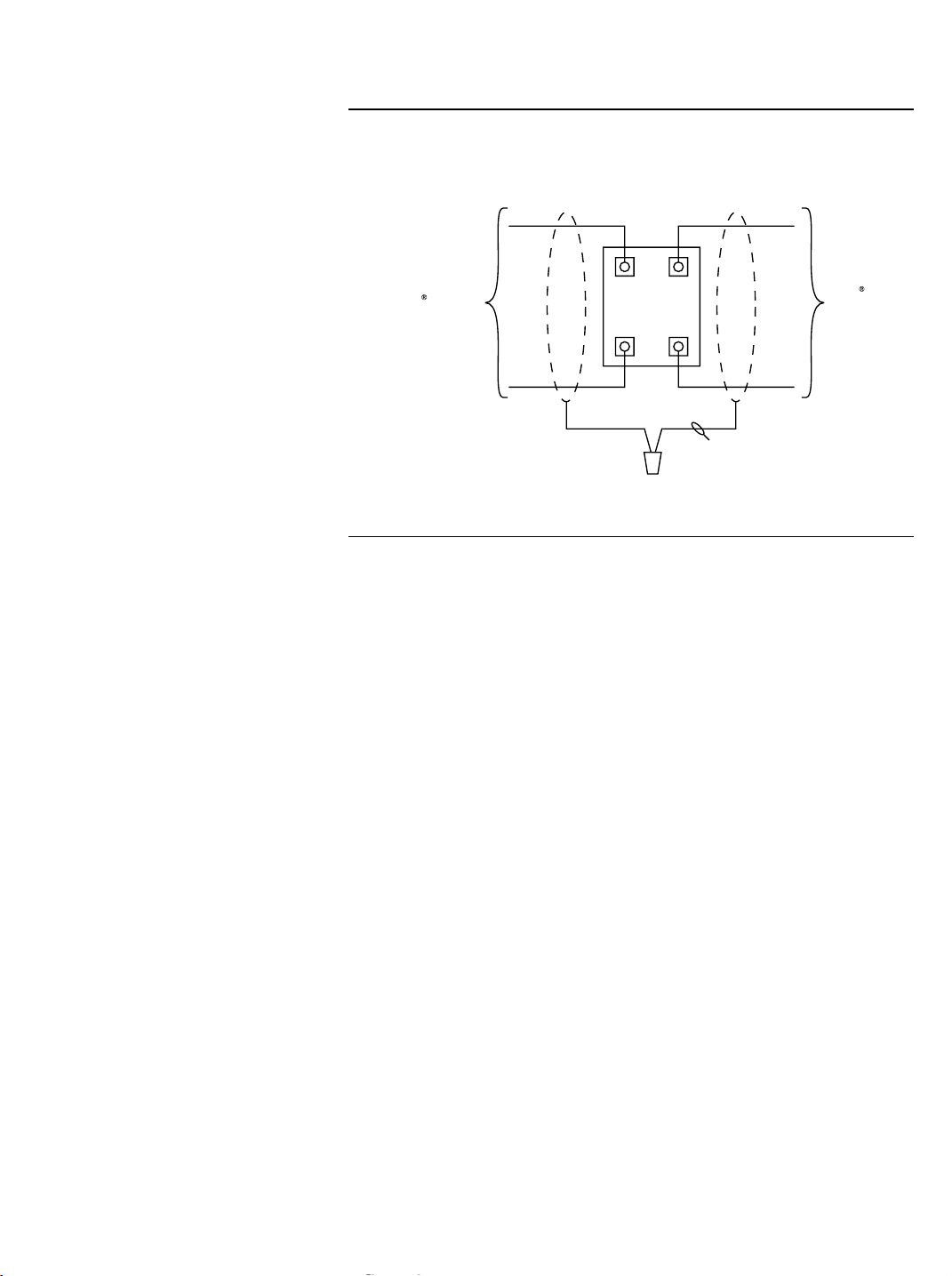

Connect the manual station to the MAPNET wire pair using Figure 2 as a

reference. (Refer to the appropriate 2120 CDT, 4020, 4100+, or 4120 panel

cabinet drawing for MAPNET to panel connections.)

(Recommended)

MAPNET

fi

FROM

4020, 4100+, 4120, OR CDT PANEL

MAPNETfi TO OTHER

ADDRESSABLE

DEVICES

A (+)

A (-)

A (+)

12

34

A (-)

SHIELD

Figure 2. Wiring Manual Stations

Wiring

Procedure

Technical Manuals Online! - http://www.tech-man.com

Page 5

5

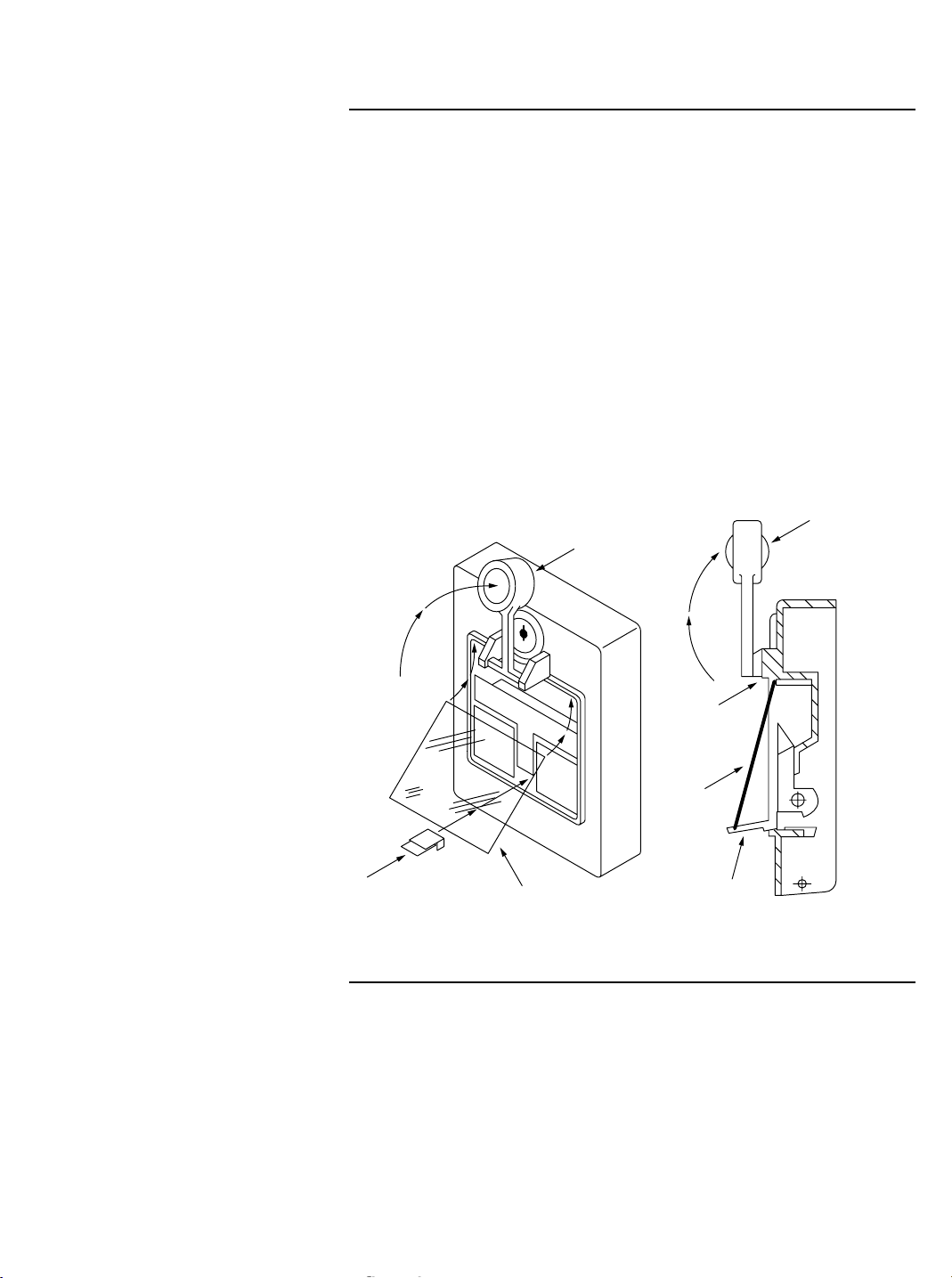

The type of box used depends on whether the manual station is to be installed

flush with the wall or surface-mounted.

• Surface Installation. Mount the station on a Simplex Back Box, No.

2975-9178 (no trim required), or a receptacle box such as a Wiremold No.

57441S DEEP, or equivalent, with surface trim.

• Flush Installation. Use two 3” x 2” x2 ¾ gangable switch boxes ganged

together with flush trim.

Install the manual station, using Figure 3 as a reference.

Figure 3. Installing a Manual Station

Installing the Manual Station

Electrical Boxes

Installation

Technical Manuals Online! - http://www.tech-man.com

Page 6

6

Model 2099-9796 uses a glass pane to cover the T-handle used to activate an

alarm. Follow these steps to replace this pane. Refer to Figure 4 for an

illustration of this procedure.

1. Lift the hammer (B) to an upright position.

2. Position the top edge of the glass pane (C) under the tab on the manual

station, This tab is located at the top of the opening in which the glass pane

fits. Callout (D) in Figure 4 identifies the location of this tab.

3. Fit the bottom of the glass pane into the notch located in the glass retainer.

See (E) in Figure 4.

4. Push the glass retainer (A) into place. The tab at the end of the glass

retainer fits into a slot on the back of the manual station to hold the retainer

in place.

5. Gently lower the hammer back into place.

A

C

B

B

D

C

E

Figure 4. Replacing the Glass Pane

Continued on next page

Replacing the Glass Pane/Glass Rod

Replacing a Glass Pane

Technical Manuals Online! - http://www.tech-man.com

Page 7

7

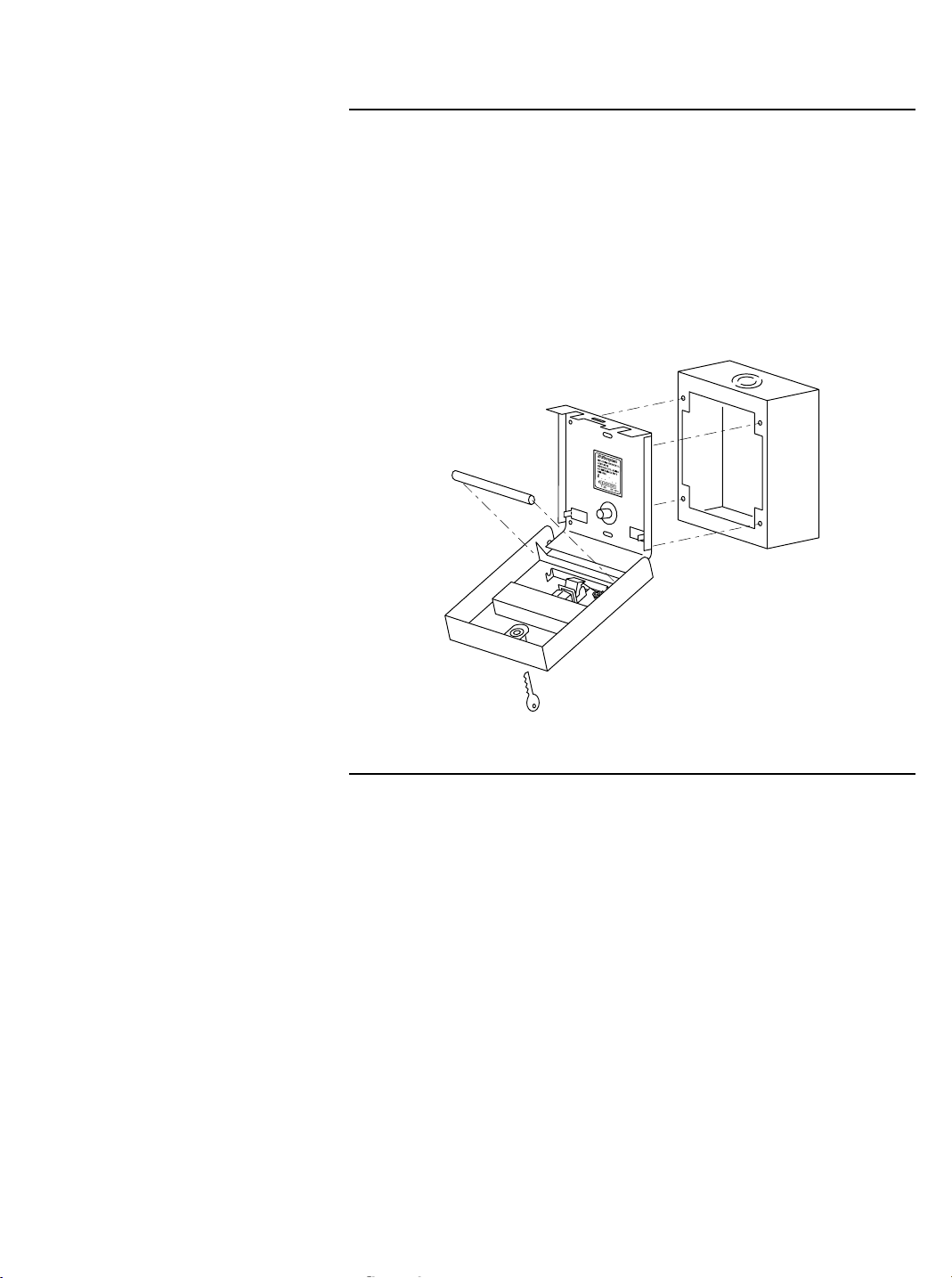

With this type of station, pulling the T-handle down breaks the glass rod, located

just below the handle, and activates the alarm. Replace the glass rod as

described below.

1. Use a key to open the station.

2. Carefully clean any pieces of broken glass from the unit.

3. Position the rod in the slot located near the bottom of the station. See

Figure 5 for the location of the slot. Close the station and lock.

Figure 5. Replacing the Glass Rod

Replacing the Glass Pane/Glass Rod, Continued

Replacing a Glass Rod

Technical Manuals Online! - http://www.tech-man.com

Page 8

574-155

Rev. A

Technical Manuals Online! - http://www.tech-man.com

Loading...

Loading...