Page 1

Manual

SmartRelais 3 Advanced

08.2018

Page 2

Contents

1 Intended use ....................................................................................................................................5

2 Safety instructions..........................................................................................................................6

3 System description .........................................................................................................................8

3.1 Controller................................................................................................................................8

3.2 Reader.................................................................................................................................... 9

3.3 SmartOutput module ............................................................................................................ 10

3.4 Versions ...............................................................................................................................10

3.5 Accessories .......................................................................................................................... 11

4 System requirements....................................................................................................................13

5 Connections ..................................................................................................................................14

5.1 Controller..............................................................................................................................14

5.2 Reader.................................................................................................................................. 15

5.3 SmartOutput module ............................................................................................................ 16

6 Setting up.......................................................................................................................................19

6.1 Unpacking and system test .................................................................................................. 19

6.2 Configuration ........................................................................................................................ 19

6.2.1 Establishing IP settings .............................................................................................23

6.2.2 Creating a communication node................................................................................ 23

6.3 Programming........................................................................................................................24

6.3.1 Adding SmartOutput modules ...................................................................................26

6.3.2 Resetting the controller .............................................................................................28

6.4 Application examples ...........................................................................................................33

6.4.1 Basic principle ...........................................................................................................33

6.4.2 Gateway function....................................................................................................... 34

6.4.3 General overview ......................................................................................................34

6.4.4 Solutions for scenarios .............................................................................................. 36

6.4.5 wiring ......................................................................................................................... 55

7 Installation .....................................................................................................................................78

8 SREL3 ADV in LSM .......................................................................................................................79

8.1 Changing over from SREL2 to SREL3.ADV......................................................................... 79

8.2 Access list ............................................................................................................................79

8.2.1 Import access list....................................................................................................... 79

8.2.2 Resetting the access list............................................................................................ 83

8.2.3 Event logging of unauthorised accesses...................................................................84

8.3 Flip-flop................................................................................................................................. 84

8.4 Time budgets........................................................................................................................ 85

Manual

SmartRelais 3 Advanced

2 / 135

SimonsVoss

Contents

Page 3

8.4.1 Time budget template for new locking system identification media ..........................85

8.4.2 Ignoring activation/expiry date................................................................................... 86

8.5 Consequences in the event of a network failure ..................................................................86

8.6 Signal settings ...................................................................................................................... 87

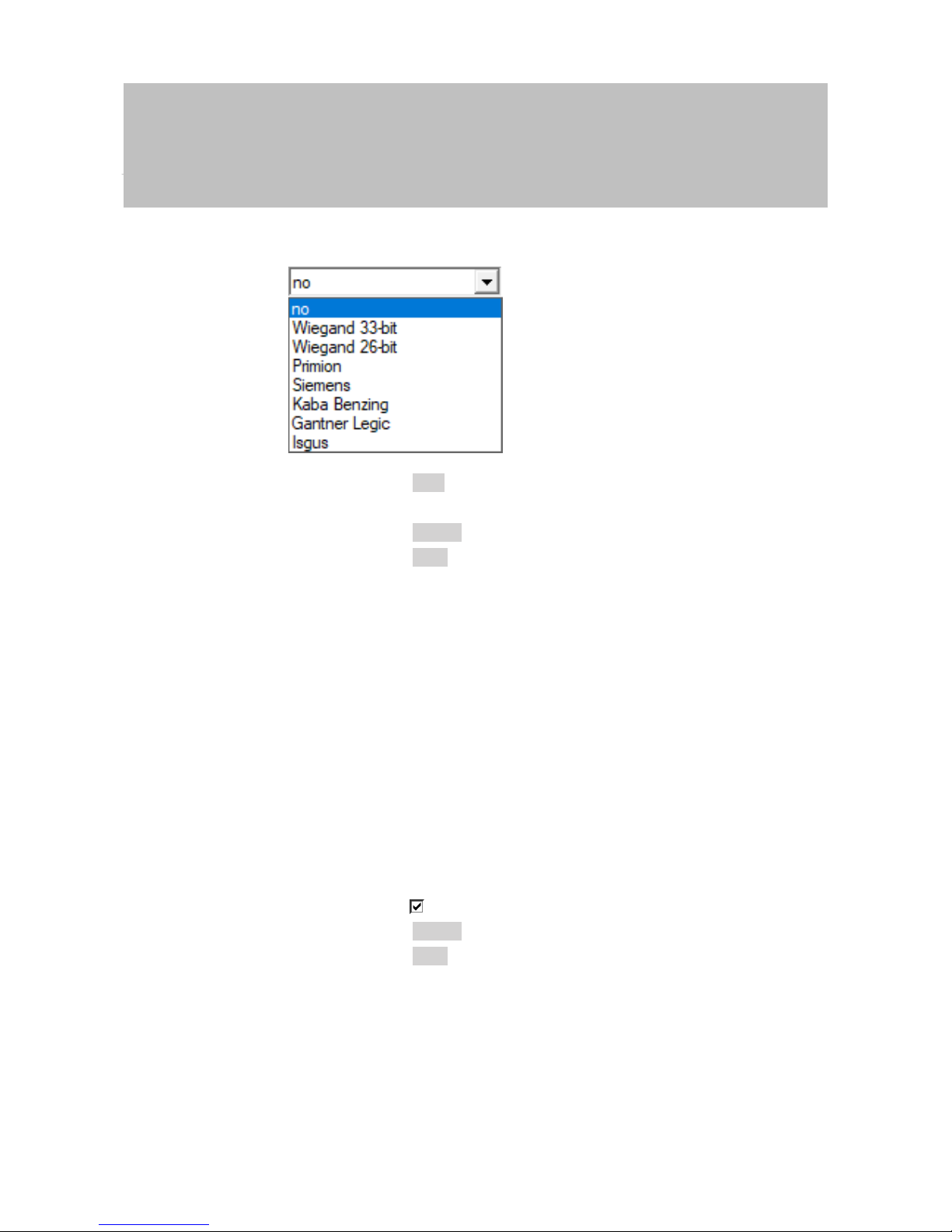

8.7 Operation as interface .......................................................................................................... 88

8.8 Near-field option ................................................................................................................... 89

8.9 Switching interval .................................................................................................................89

8.10 Software reset ...................................................................................................................... 90

8.11 Time switch-over function..................................................................................................... 91

8.11.1 Extended configuration without SmartOutput module ............................................... 93

8.11.2 Extended configuration with SmartOutput modules ..................................................94

8.12 Remote opening ................................................................................................................... 95

8.13 Firmware update ..................................................................................................................98

8.14 Events ..................................................................................................................................98

8.14.1 Evaluating controller inputs .......................................................................................98

8.14.2 SmartSurveil............................................................................................................101

8.15 Things to do........................................................................................................................ 103

8.15.1 Initial programming via TCP/IP................................................................................ 103

8.15.2 Different authorisations on transponders ................................................................104

8.15.3 Signalling for flip-flop ............................................................................................... 107

9 Signal ...........................................................................................................................................110

10 Maintenance ................................................................................................................................111

10.1 Battery warning ..................................................................................................................111

10.1.1 Reading the battery level with USB cable ...............................................................111

10.1.2 Reading the battery level over network ................................................................... 113

10.2 Battery replacement ........................................................................................................... 115

11 Fault rectification ........................................................................................................................117

11.1 Resetting components........................................................................................................ 117

11.2 Broadcast error................................................................................................................... 117

11.3 Permanent relay switching in the SmartOutput module ..................................................... 119

11.4 Problems with inputs or network readout/programming..................................................... 119

11.5 Time change-over does not respond to change................................................................. 120

12 Technical specifications.............................................................................................................121

12.1 Order numbers ................................................................................................................... 121

12.2 Properties ........................................................................................................................... 121

12.2.1 Controller.................................................................................................................121

12.2.2 Reader..................................................................................................................... 124

12.2.3 SmartOutput module ...............................................................................................125

12.2.4 Recommended cable types.....................................................................................127

Manual

SmartRelais 3 Advanced

3 / 135

SimonsVoss

Contents

Page 4

12.3 Power input in practice ....................................................................................................... 128

12.4 Dimensions......................................................................................................................... 130

12.4.1 Controller.................................................................................................................130

12.4.2 Reader..................................................................................................................... 131

12.4.3 SmartOutput module ...............................................................................................132

12.5 Drilling templates................................................................................................................132

12.5.1 Controller.................................................................................................................133

12.5.2 Reader..................................................................................................................... 134

13 Help & Contact ............................................................................................................................135

Manual

SmartRelais 3 Advanced

4 / 135

SimonsVoss

Contents

Page 5

Manual

SmartRelais 3 Advanced

5 / 135

SimonsVoss

1 | Intended use

1 Intended use

In its third generation, the SimonsVoss SmartRelay system (SREL 3 ADV)

is a system consisting of several networked components which provide

intelligent control of locking devices and third-party systems. The system

consists of a controller, at least one external reader and an optional

SmartOutput module.

The controller is the main component. A service communicates with the

LSM database and provides the controller with the latest information from

the database when it is used as a gateway. No manual updates or timeconsuming reprogramming are required.

The controller can use information retrieved from the LSM database and

identification data transmitted by the reader to verify identification data with

the database. Different actions are possible, depending on the settings

programmed in the controller, including:

– Assigning authorisations

– Withdrawing authorisations

– Loading time budgets

– Updating identification media configurations

– Switching relay outputs

– Reading lists

Identification media are read by up to three external readers, which may be

physically separate from one another and the controller. In the thirdgeneration SmartRelay system, the reader can read active and passive

identification media and transmit the information to the controller for

evaluation.

The controller features a built-in relay output which can be freely

programmed. The system can be extended with SmartOutput modules in a

daisy chain featuring up to 116 relay outputs, which are also freely

programmable.

Page 6

Manual

SmartRelais 3 Advanced

6 / 135

SimonsVoss

2 | Safety instructions

2 Safety instructions

DANGER

Risk of injury due to incorrect programming

The SREL3 ADV system is not suitable to replace existing security installations.

1. Ensure that the SREL3 ADV system is used as an additional securing

measure only.

2. Do not replace existing security installations with the SREL3 ADV

system.

WARNING

Blocked access

Access through a door may be blocked due to incorrectly fitted or incorrectly programmed components. SimonsVoss Technologies GmbH is not liable for the consequences of incorrect installation, such as physical damage or any other losses, or blocked access to injured persons or those at

risk.

CAUTION

Fire hazard posed by batteries

The batteries used may pose a fire or burn hazard if handled incorrectly.

1. Do not try to charge, open, heat or burn the batteries.

2. Do not short-circuit the batteries.

CAUTION

Risk of burns due to hot circuit board

The circuit board can become very hot if PoE is used (power supply over

Ethernet).

1. Let the controller cool down before you open the housing.

ATTENTION

Misuse

SmartRelay may only be used for its intended purpose. No other use is permitted.

IMPORTANT

SimonsVoss Technologies GmbH accepts no liability for damage caused to

doors or components due to incorrect fitting or installation.

IMPORTANT

Specialist knowledge in door mechanics, door approvals, electronic system

installation and the use of SimonsVoss software is required to install the

system and put it into operation. Only trained specialists may install the

system.

Page 7

Manual

SmartRelais 3 Advanced

7 / 135

SimonsVoss

2 | Safety instructions

IMPORTANT

This documentation has been compiled based on the best knowledge available to us. Nevertheless, errors cannot be ruled out. SimonsVoss Technologies GmbH is not liable in such cases.

IMPORTANT

Should there be differences in the content of other language versions of

this documentation, the German version applies in cases of doubt.

IMPORTANT

You must follow all instructions precisely when connecting and installing the

product. The person installing the system should hand these instructions as

well as any maintenance instructions over to the user.

IMPORTANT

Modifications or further technical developments cannot be excluded and

may be implemented without notice.

Page 8

Manual

SmartRelais 3 Advanced

8 / 135

SimonsVoss

3 | System description

3 System description

3.1 Controller

The SREL3 ADV system is connected to the network via Ethernet. The

Ethernet connection is PoE-capable, so an external power supply unit is not

essential. It is possible to use the system as a gateway in the virtual

network. The controller established a connection to the VN host server to

do so. The VN host server transmits modified authorisations (programming

requirement) and data from the LSM database to the controller. This means

there is no longer a need for the database to be fully loaded, which saves

time. Instead, the controller fetches the provided data when an identification

medium is detected (pull principle). The entire system is programmed via a

single interface – the controller.

The SREL3 ADV is also available in a ZK variant, which extends the

system's functions to include time zone control and event logging (access

lists).

Three available screw terminal inputs ensure that the controller is flexible in

its use.

– Forwarding to LSM (Inputs 1 and 2)

– Push-to-open contact (Input 3)

The built-in screw terminal relay output can activate any system and open

an electric door, for example.

An IP address needs to be issued using USB when the controller is

programmed for the first time. Once the IP address is issued, a USB

connection is no longer needed. The controller's configuration can be

modified over the network instead.

The built-in backup battery ensures that the programmed settings are

maintained after a power failure and guarantees that the controller

continues to function without any limitations once power is restored.

Page 9

Manual

SmartRelais 3 Advanced

9 / 135

SimonsVoss

3 | System description

IMPORTANT

Follow the switch-on sequence

After a power-on reset (power outage followed by restoration of power supply), the controller automatically searches for connected system components one time on restarting. System components which are not supplied

power until the controller restarts are thus unable to respond to the controller's query and are not recognised.

The controller must therefore be supplied power with the other system components at the same time or must be the last system component to receive

power.

3.2 Reader

At least one external reader is required to use the SREL3 ADV system.

SmartRelay 3 readers are ordered separately from the controller.

The controller is unable to read identification media. Up to three readers

can be connected via an RS-485 interface for this purpose. They can read

both active and passive identification media. After reading media, the

readers transmit the data to the controller, which checks the identification

medium's authorisation and triggers relevant actions as programmed. The

reader itself is unable to trigger actions and can thus be installed in less

protected areas. In the WP variant, the housing is sealed and protected

against splashing water.

Readers can either be powered through the controller or equipped with

their own power supply unit.

IMPORTANT

Too low operating voltage

When selecting the power supply, please allow for a voltage drop occurring

in conductors. A voltage drop can cause the operating voltage in the reader

to fall below the required level and malfunctions may occur. In such a case,

either the operating voltage on the controller needs to be increased or the

reader equipped with its own power supply unit.

A multi-coloured LED signals the different operating modes.

Page 10

Manual

SmartRelais 3 Advanced

10 / 135

SimonsVoss

3 | System description

3.3 SmartOutput module

SmartOutput modules are ideal complements to controllers if more than

one relay output is required. Every SmartOutput module is equipped with

eight relays, which each feature a change-over contact. SmartOutput

modules can be connected in parallel to one another and fitted on a DIN rail

(35 mm x 7.5 mm).

A multi-coloured LED signals the different operating modes.

IMPORTANT

Follow the switch-on sequence

After a power-on reset (power outage followed by restoration of power supply), the controller automatically searches for connected system components one time on restarting. System components which are not supplied

power until the controller restarts are thus unable to respond to the controller's query and are not recognised.

The controller must therefore be supplied power with the other system components at the same time or must be the last system component to receive

power.

3.4 Versions

Several improvements have been made for the newly launched SREL 3

ADV compared to its predecessor:

Comparison between SmartRelay 2 and SmartRelay 3

SmartRelay 2 SmartRelay 3 Advanced

Duration of data transmission to the gateway

– Depending on the

data volume (push

principle)

– Immediate (pull

principle)

Page 11

Manual

SmartRelais 3 Advanced

11 / 135

SimonsVoss

3 | System description

Comparison between SmartRelay 2 and SmartRelay 3

Interfaces

– Wiegand, 33 bit

– Wiegand, 26 bit

– Primion

– Siemens Cerpass

– Kaba Benzing

– Gantner Legic

– Isgus

– Wiegand, 33 bit

– Wiegand, 26 bit

– Primion

– Siemens Cerpass

– Kaba Benzing

– Gantner Legic

– Isgus

Components required

for networking

– Controller

– Reader

– LockNode

– Router

– Controller

– Reader

Networking – LockNode – Ethernet (integrated)

Power supply – 9–24 VDC

– 9-32 VDC

– PoE

Number of relay contacts

– 1

– Up to 116+1 (with

SmartOutput

modules)

Number of external

readers

– Max. 2 – Max. 3

Programming – SmartCD

– Ethernet

– USB (with power

adapter)

3.5 Accessories

You can adapt the SREL3 ADV system to different purposes with optional

accessories. The following accessories can be ordered:

Order code Name Purpose

MOD.SOM8 SmartOutput module

The SmartOutput module increases the number of switchable relay

outputs to up to 116+1

outputs.

POWER.SUPPLY.2

Power supply unit

(12VDC, 500mA)

This power supply unit

can be used to power

the controller.

Page 12

Manual

SmartRelais 3 Advanced

12 / 135

SimonsVoss

3 | System description

Order code Name Purpose

SREL2.COVER1 Anti-vandalism housing

Fastened with special

screws, this housing is

also suitable for the

SREL3 ADV system. It

protects the SREL3

ADV system reader

against the weather and

vandalism.

Page 13

Manual

SmartRelais 3 Advanced

13 / 135

SimonsVoss

4 | System requirements

4 System requirements

LSM 3.3 SP2 or higher (Basic Online, Business or Professional) is required

to programme SmartRelay 3.

The VN host must be installed and running, so that the controller can

retrieve data and programming requirements from the database via the VN

host in gateway mode.

The controller requires a TCP/IP connection to the server for operation:

– 10/100 MB/s

– Latency typ. < 10 ms

Connection to faster networks is possible provided they are backwardscompatible.

.NET-Framework Version 4.0 or higher must be installed to use the

CommNode or VN host server.

If LSM Basic Online is used with a virtual network, then LSM Basic Online

must be run in administrator mode.

Page 14

Manual

SmartRelais 3 Advanced

14 / 135

SimonsVoss

5 | Connections

5 Connections

5.1 Controller

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

No.

Circuit

board

Explanation

1 -

GND. Optional connection to an external power supply

(earth).

2 +

VIN. Connection to an external power supply (positive

terminal).

3

Relay 1: NO (normally open). This contact is connected

to C when the relay switches.

4

Relay 1: C (common). Shared connection to changeover contacts.

5

Relay 1: NC (normally closed). This contact is disconnected from C when the relay switches.

6

Relay 2: NO (normally open). This contact is connected

to C when the relay switches. Availability for actuation

depends on the firmware.

7

Relay 2: C (common). Shared connection to changeover contacts. Availability for actuation depends on the

firmware.

8

Relay 2: NC (normally closed). This contact is disconnected from C when the relay switches. Availability for

actuation depends on the firmware.

9 +1

Reader 1: Power supply. Voltage is VIN-1V or 12V1V (PoE).

Page 15

Manual

SmartRelais 3 Advanced

15 / 135

SimonsVoss

5 | Connections

No.

Circuit

board

Explanation

10 - Reader 1: GND.

11 B1 Reader 1: Data Line B.

12 A1 Reader 1: Data Line A.

13 +2

Reader 2: Power supply. Voltage is VIN-1V or 12V-

1V (PoE).

14 - Reader 2: GND.

15 B2 Reader 2: Data Line B.

16 A2 Reader 2: Data Line A.

17 +3

Reader 3: Power supply. Voltage is VIN-1V or 12V-

1V (PoE).

18 - Reader 3: GND.

19 B3 Reader 3/SmartOutput module: Data Line B.

20 A3 Reader 3/SmartOutput module: Data Line A.

21 04 Serial interface: Open-drain, Data Line 4.

22 03 Serial interface: Open-drain, Data Line 3.

23 02 Serial interface: Open-drain, Data Line 2.

24 01 Serial interface: Open-drain, Data Line 1.

25 0+

Serial interface: Power supply. Voltage is VIN-1V or

12V-1V (PoE).

26 I3

Input 3: Push to open The relay switches as soon as

this contact is connected with I+ (Contact 30), a com-

parable potential or VIN (Contact 2).

27 I2 Input 2: Connection to external components:

28 I1 Input 1: Connection to external components:

29 - Output: GND.

30 I+

Output: Power supply. Voltage is VIN-1V or 12V-1V

(PoE).

5.2 Reader

1 2 3 4 5

No.

Circuit

board

Explanation

1 A RS-485: Data Line A.

2 B RS-485: Data Line B.

3 - GND. Connection for RS-485 bus.

Page 16

Manual

SmartRelais 3 Advanced

16 / 135

SimonsVoss

5 | Connections

No.

Circuit

board

Explanation

4 + VIN. Connection for external power supply.

5 -

GND. Connection for external power supply. Connected

electrically to 3.

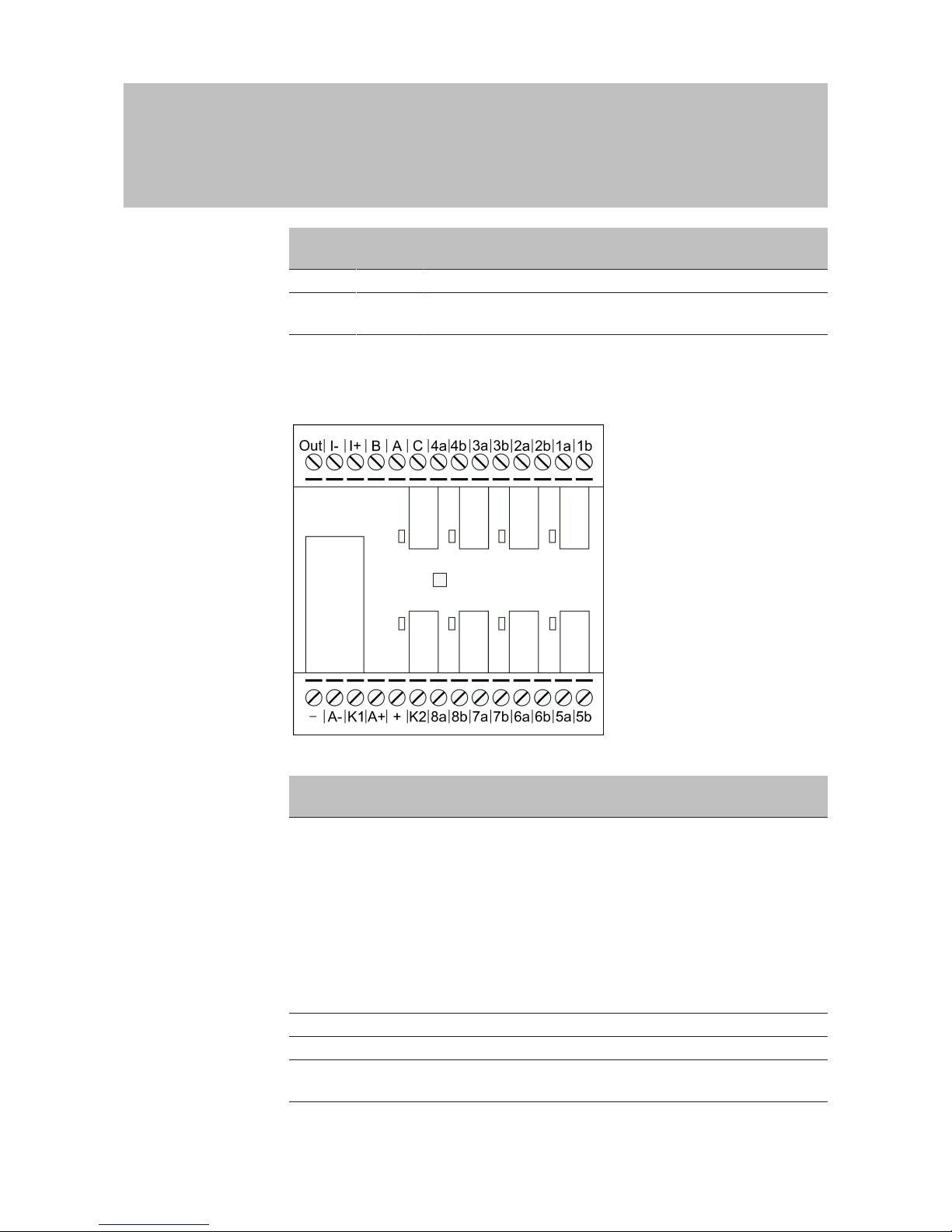

5.3 SmartOutput module

1 5432 9876 10 11 12 13 14

28 222324252627 18192021 151617

No.

Circuit

board

Explanation

1 Out

Brownout detection: Open collector, connected to GND

if supply voltage is sufficient.

This output activates if the supply voltage at VIN falls be-

low 10.0VDC (±0.5VDC). The earth connection is usually

connected to the AUX relay's coil. If the supply voltage

falls at VIN, the AUX relay activates before the other re-

lay contacts activate unchecked due to the decreasing

voltage. When the supply voltage is applied, the output

does not activate until the module has fully initialised

and relay contacts can no longer switch unchecked.

2 I- Isolated digital input. Currently not in use.

3 I+ Isolated digital input. Currently not in use.

4 B

Controller connection: Data Line B; connected to con-

tact for Reader 3.

Page 17

Manual

SmartRelais 3 Advanced

17 / 135

SimonsVoss

5 | Connections

No.

Circuit

board

Explanation

5 A

Controller connection: Data Line A; connected to con-

tact for Reader 3.

6 C

Controller connection: Earth; connected to contact for

Reader 3.

7 4a

Relay 4: Potential-free contact (NC treated as NO in

software); activated depending on authorisations.

8 4b

Relay 4: Potential-free contact (NC treated as NO in

software); activated depending on authorisations.

9 3a

Relay 3: Potential-free contact (NC treated as NO in

software); activated depending on authorisations.

10 3b

Relay 3: Potential-free contact (NC treated as NO in

software); activated depending on authorisations.

11 2a

Relay 2: Potential-free contact (NC treated as NO in

software); activated depending on authorisations.

12 2b

Relay 2: Potential-free contact (NC treated as NO in

software); activated depending on authorisations.

13 1a

Relay 1: Potential-free contact (NC treated as NO in

software); activated depending on authorisations.

14 1b

Relay 1: Potential-free contact (NC treated as NO in

software); activated depending on authorisations.

15 5b

Relay 5: Potential-free contact (NC treated as NO in

software); activated depending on authorisations.

16 5a

Relay 5: Potential-free contact (NC treated as NO in

software); activated depending on authorisations.

17 6b

Relay 6: Potential-free contact (NC treated as NO in

software); activated depending on authorisations.

18 6a

Relay 6: Potential-free contact (NC treated as NO in

software); activated depending on authorisations.

19 7b

Relay 7: Potential-free contact (NC treated as NO in

software); activated depending on authorisations.

20 7a

Relay 7: Potential-free contact (NC treated as NO in

software); activated depending on authorisations.

21 8b

Relay 8: Potential-free contact (NC treated as NO in

software); activated depending on authorisations.

22 8a

Relay 8: Potential-free contact (NC treated as NO in

software); activated depending on authorisations.

23 K2

AUX relay: Potential-free contact (NO). Contact is con-

nected with K1 (number 26) if coil is connected to

power.

Equipped with a detachable bridge to + (number 24) ex

works.

Page 18

Manual

SmartRelais 3 Advanced

18 / 135

SimonsVoss

5 | Connections

No.

Circuit

board

Explanation

24 +

VIN. Connection for power supply.

Equipped with a detachable bridge to K2 (number 23)

ex works.

25 A+

AUX relay: Coil's plus connection. AUX relay activates if

coil is connected to power.

Equipped with a detachable bridge to K1 (number 26)

ex works.

26 K1

AUX relay: Potential-free contact (normally open con-

tact). Contact is connected with K2 (number 23) if coil is

connected to power.

Equipped with a detachable bridge to A+ (number 25)

ex works.

27 A-

AUX relay: Coil's minus connection. AUX relay activates

if coil is connected to power.

28 - GND. Connection for power supply.

Page 19

Manual

SmartRelais 3 Advanced

19 / 135

SimonsVoss

6 | Setting up

6 Setting up

6.1 Unpacking and system test

Scope of delivery

Check to ensure the supply package is complete after receiving it.

Unless agreed otherwise, the supply package contains the following

components:

Controller

Controller 1x

Instruction leaflet 1x

Reader

Reader 1x

Instruction leaflet 1x

SmartOutput module

SmartOutput module 1x

Jumpers (pre-assembled) 2x

Instruction leaflet 1x

System test

You can check the supplied components to ensure they function

correctly before installation and programming. Proceed as follows:

1. Wire the components (see wiring [}55]).

2. Connect the components to the power supply (connect the

controller last).

3. Wait a few seconds until all components are ready for operation.

ð Controller flashes all colours first and then green.

ð Reader flashes all colours first, beeps and then no longer

flashes.

ð Optional SmartOutput module: Relay contacts are open

(indicated by LEDs and a tick-tack sound), then flashes green.

4. Use an identification medium on the reader (empty transponders

or empty DESFIRE card).

ð Reader flashes green twice and beeps.

ð The relay built into controller actuates (Contacts 3, 4 and 5).

Also see

2 Solutions for scenarios [}36]

2 Connecting one or more SmartOutput modules [}63]

6.2 Configuration

You can use the LSM software to programme and configure the controller

and the SREL3 ADV system. Other components do not need to be

programmed.

Page 20

Manual

SmartRelais 3 Advanced

20 / 135

SimonsVoss

6 | Setting up

IMPORTANT

Initial programming via USB

The controller can be addressed via TCP/IP. No IP is featured in storage

mode. That is why initial programming, during which an IP address is issued, must be carried out with a USB connection.

ü Components connected to power.

ü Controller connected to computer with USB cable.

ü Reader connected to the controller (see wiring [}55]).

ü LSM installed and launched as administrator.

ü System requirements met.

1. Create a new G2 locking system.

2. Create a new G2 Smart Relay 3 locking device.

3. Double-click on the SmartRelay 3 entry in the matrix to open the

settings.

4. Select the [IP settings] tab (see Establishing IP settings [}23] for help

on IP settings).

5. Enter an IPv4 address.

6. Enter an IPv4 subnet mask.

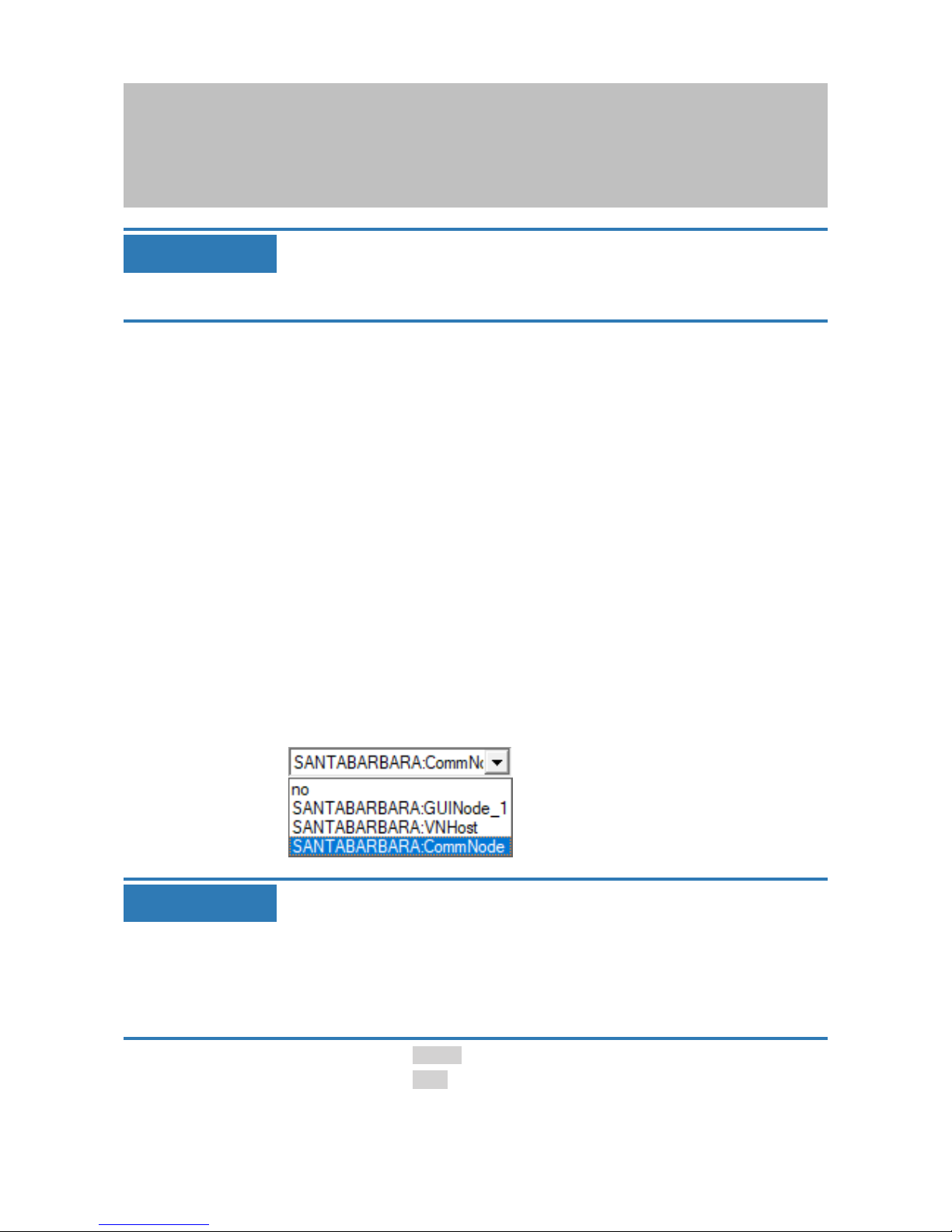

7. Open the Communication nodes drop-down menu.

8. Select a suitable communication node. If you haven't yet created a

communication node for the service, you need to add one first. See

Creating a communication node [}23].

IMPORTANT

Selecting the communication node

If you are using a CommNode server and a VN host server (use of tasks or

events in addition to the virtual network), then choose the CommNode

server entry here.

If you want to use a VN host server (use of the virtual network), then select

the VN host item here.

If you do not wish to use either, then select the GUI node item here.

9. Click on the Apply button.

10. Click on the Exit button.

Page 21

Manual

SmartRelais 3 Advanced

21 / 135

SimonsVoss

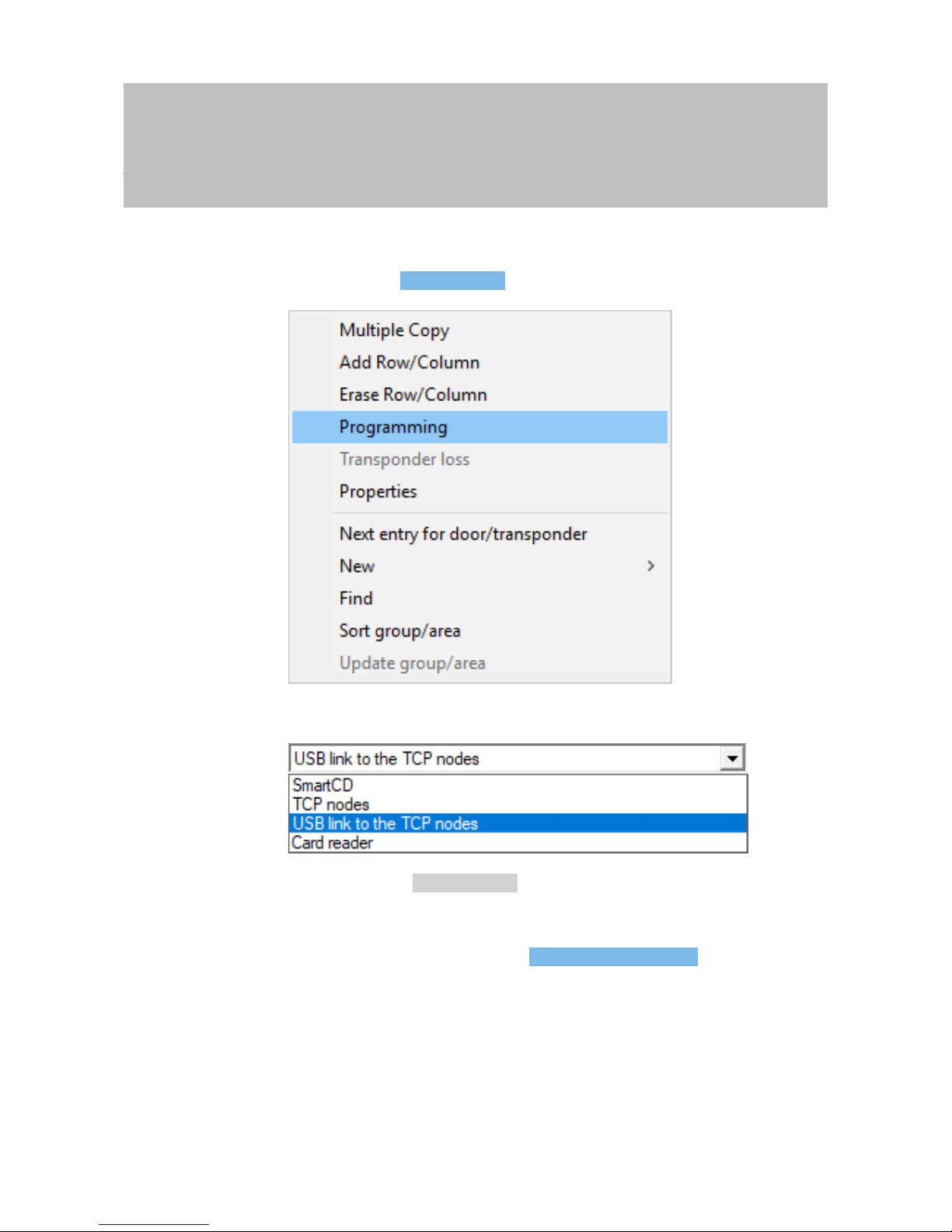

6 | Setting up

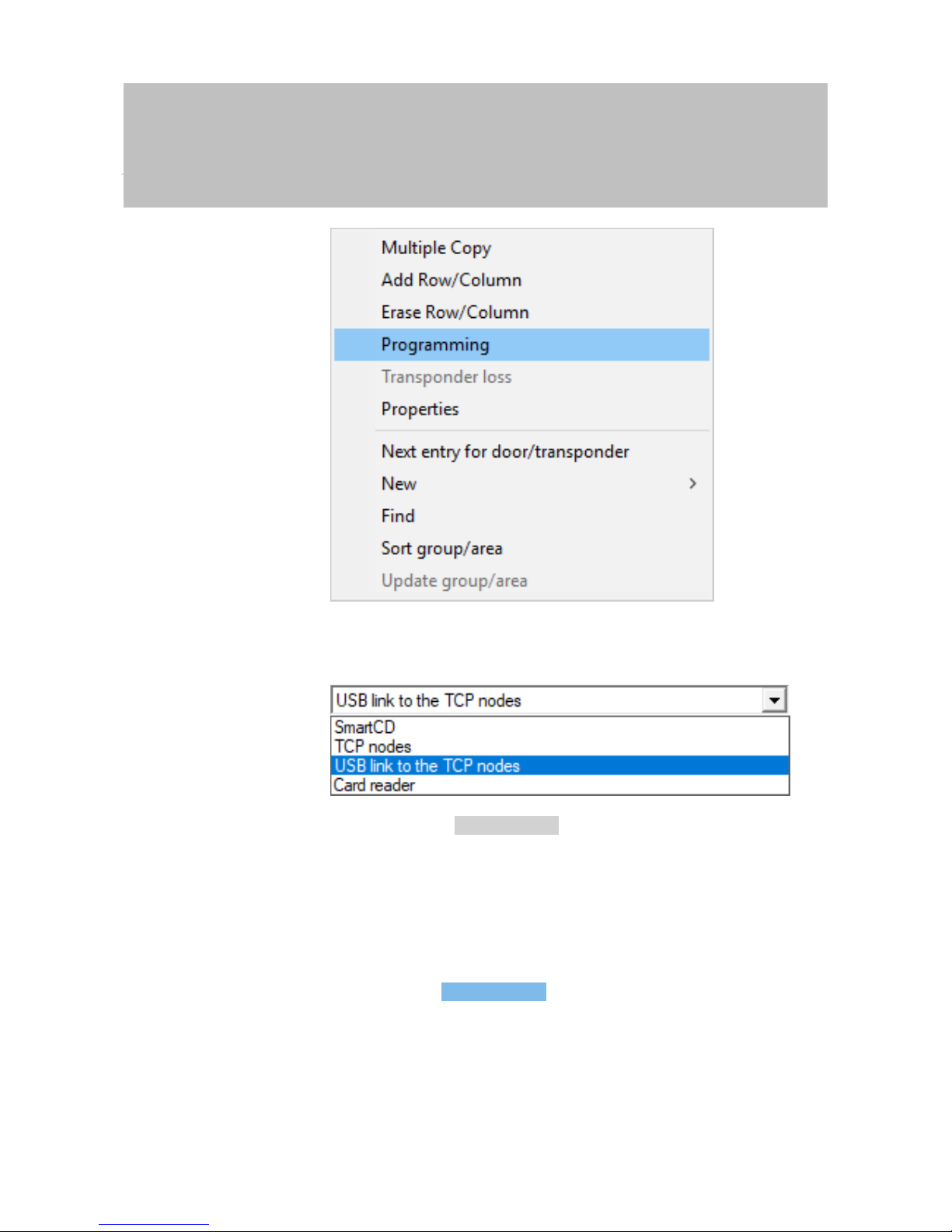

11. Right-click on the SmartRelay 3 entry in the matrix to open the context

menu.

12. Select the Programming item.

13. Select "USB link to the TCP nodes" in the programming window.

14. Click on the Programming button.

ð Programming launches.

15. Wait for programming.

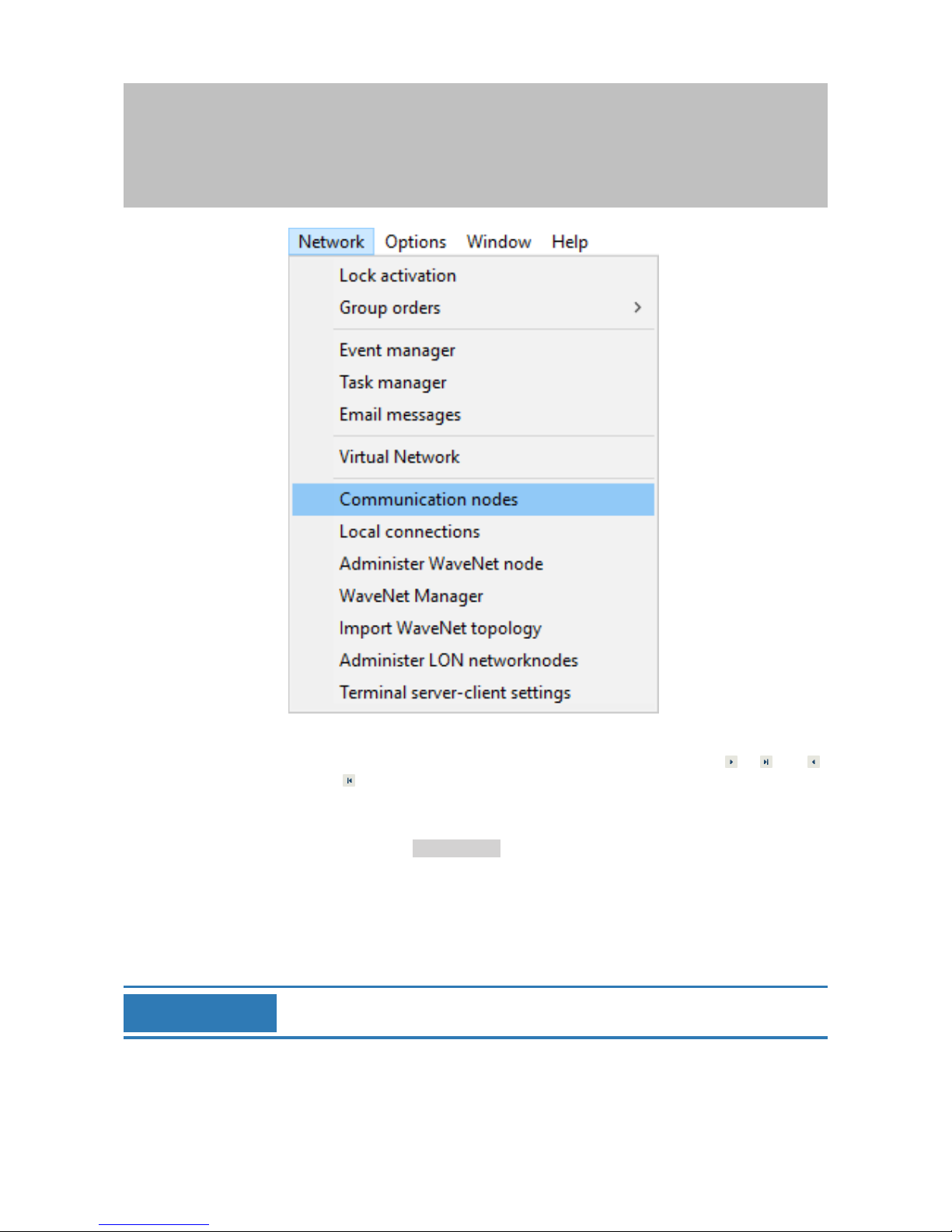

16. Use |Network| to select the Communication nodes item.

Page 22

Manual

SmartRelais 3 Advanced

22 / 135

SimonsVoss

6 | Setting up

17. If you have created more than one communication node, change to

the communication node you have just created. Use the or and

or buttons.

18. Terminate the SimonsVoss VNHost Server or SimonsVoss

CommNode Server service.

19. Click on the Config files button.

20. Open Windows services.

21. Save the service's configuration files locally on your computer.

22. Copy the configuration files saved locally and add them to the

service's installation folder (default: C:\Programme (x86)\SimonsVoss

\VNHost or C:\Program Files (x86)\SimonsVoss\CommNodeSvr_3_4).

IMPORTANT

All three XML files must be copied directly to the installation folder, not to a

sub-folder.

23. Launch the SimonsVoss VNHost Server or SimonsVoss CommNode

Server service again.

Page 23

Manual

SmartRelais 3 Advanced

23 / 135

SimonsVoss

6 | Setting up

IMPORTANT

Click on the Ping button to check whether the service is running and responding. If the service responds, you can continue. If it does not, try to

launch the service again.

24. Click on the Transmit button in LSM.

ð Controller can be reached via network.

25. Terminate the SimonsVoss VNHost Server und SimonsVoss

CommNode Server services.

26. Set up your backup again (see LSM manual).

27. Launch the SimonsVoss VNHost Server and SimonsVoss CommNode

Server services again.

ð Controller can be reached via network and flashes blue.

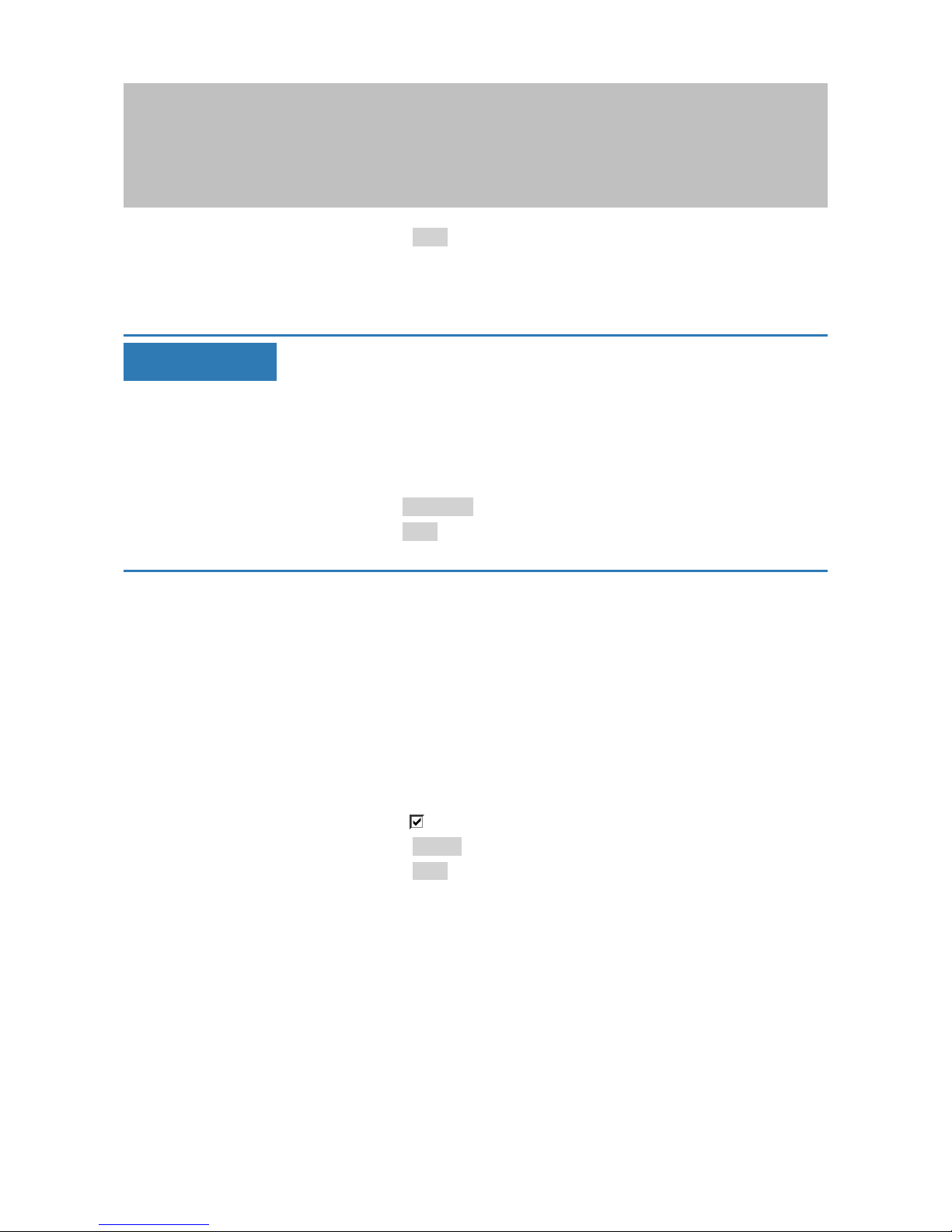

6.2.1 Establishing IP settings

The SREL3 ADV system controller needs a static IPv4 address to operate

in the network. Ask your IT Department or your network administrator to

assign you a free static IPv4 address and provide you with the following

information:

– IPv4 address

– Associated subnet mask

– Default gateway (only if not all LSM or System 3060 devices are in the

same network)

Alternatively, you can also use DHCP with LSM Version 3.4 SP1 and

above. To do so you need to open the [IP settings] tab and enable the

DHCP activated checkbox.

6.2.2 Creating a communication node

ü LSM launched.

1. Use |Network| to select the Communication nodes item.

2. Enter the communication node name (freely selectable;

recommended: VN host or CommNode).

3. Enter the host name of the computer on which SimonsVoss VNHost

Server has been installed.

IMPORTANT

You can verify the host name as follows:

1. Press the Windows key.

2. Enter cmd.

3. Press the Enter key to confirm.

ð The "[offen]" window will open.

Page 24

Manual

SmartRelais 3 Advanced

24 / 135

SimonsVoss

6 | Setting up

4. Enter hostname.

5. Press the Enter key to confirm.

ð The computer's host name is displayed.

4. Enter the full computer name (fully qualified domain name).

IMPORTANT

It only needs to be entered if the system is working with LSM clients or

database servers in different domains. The FQDN comprises the local computer name and the domain, e.g. COMPUTER.NETWORK.LOCAL. You

can verify the domain yourself:

1. Press the Windows key.

2. Enter cmd.

3. Press the Enter key to confirm.

ð The "[offen]" window will open.

4. Enter echo %userDNSdomain%.

5. Press the Enter key to confirm.

ð The computer's domain is displayed.

5. Click on the Apply button.

ð The communication node is created.

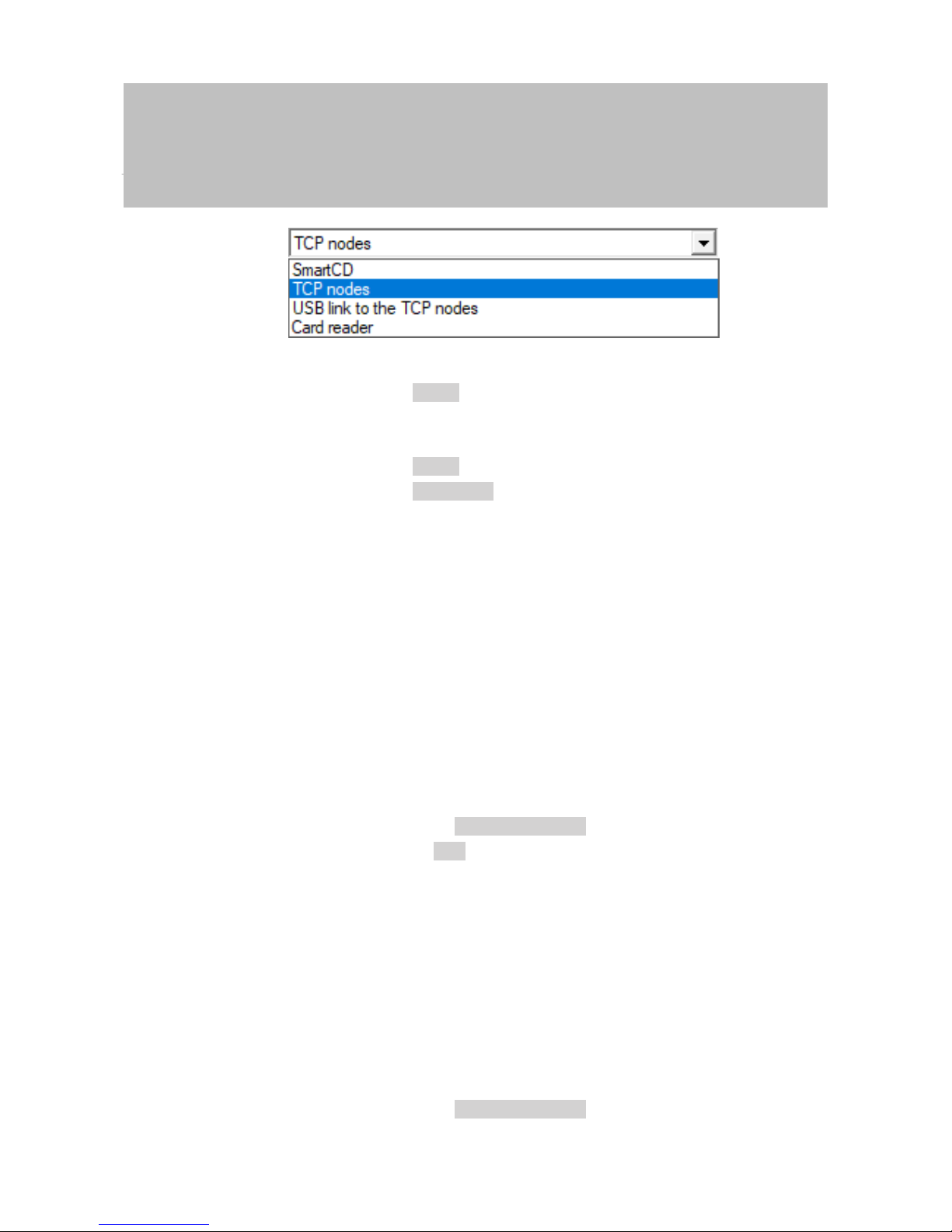

6.3 Programming

Programming does not differ from programming for other locking devices.

The SREL3 ADV system can be programmed using either a USB cable or a

network connection (except initial programming).

USB programming

ü Controller connected to computer with USB cable.

ü Components connected to power.

1. Right-click on the SmartRelay 3 entry in the matrix to open the

context menu.

2. Select the Programming item.

Page 25

Manual

SmartRelais 3 Advanced

25 / 135

SimonsVoss

6 | Setting up

3. Open the Type drop-down menu.

4. Select the "USB link to the TCP nodes" item.

5. Click on the Programming button.

ð Programming launches.

Network programming

ü Controller has already been programmed.

ü Controller connected to computer via network.

ü Components connected to power.

1. Right-click on the SmartRelay 3 entry in the matrix to open the

context menu.

2. Select the Programming item.

Page 26

Manual

SmartRelais 3 Advanced

26 / 135

SimonsVoss

6 | Setting up

3. Open the Type drop-down menu.

4. Select the "TCP nodes" item.

5. Click on the Programming button.

ð Programming launches.

6.3.1 Adding SmartOutput modules

The SREL3 ADV system controller searches for SmartOutput modules after

a power supply has been connected. The controller detects connected

SmartOutput modules when they are supplied electricity.

Programming requires that the number of SmartOutput modules detected

match the number indicated in LSM. You can add SmartOutput modules as

follows.

ü Components wired correctly (see wiring [}55]).

ü Components connected to power.

ü Controller reset (see Resetting the controller [}28]).

Page 27

Manual

SmartRelais 3 Advanced

27 / 135

SimonsVoss

6 | Setting up

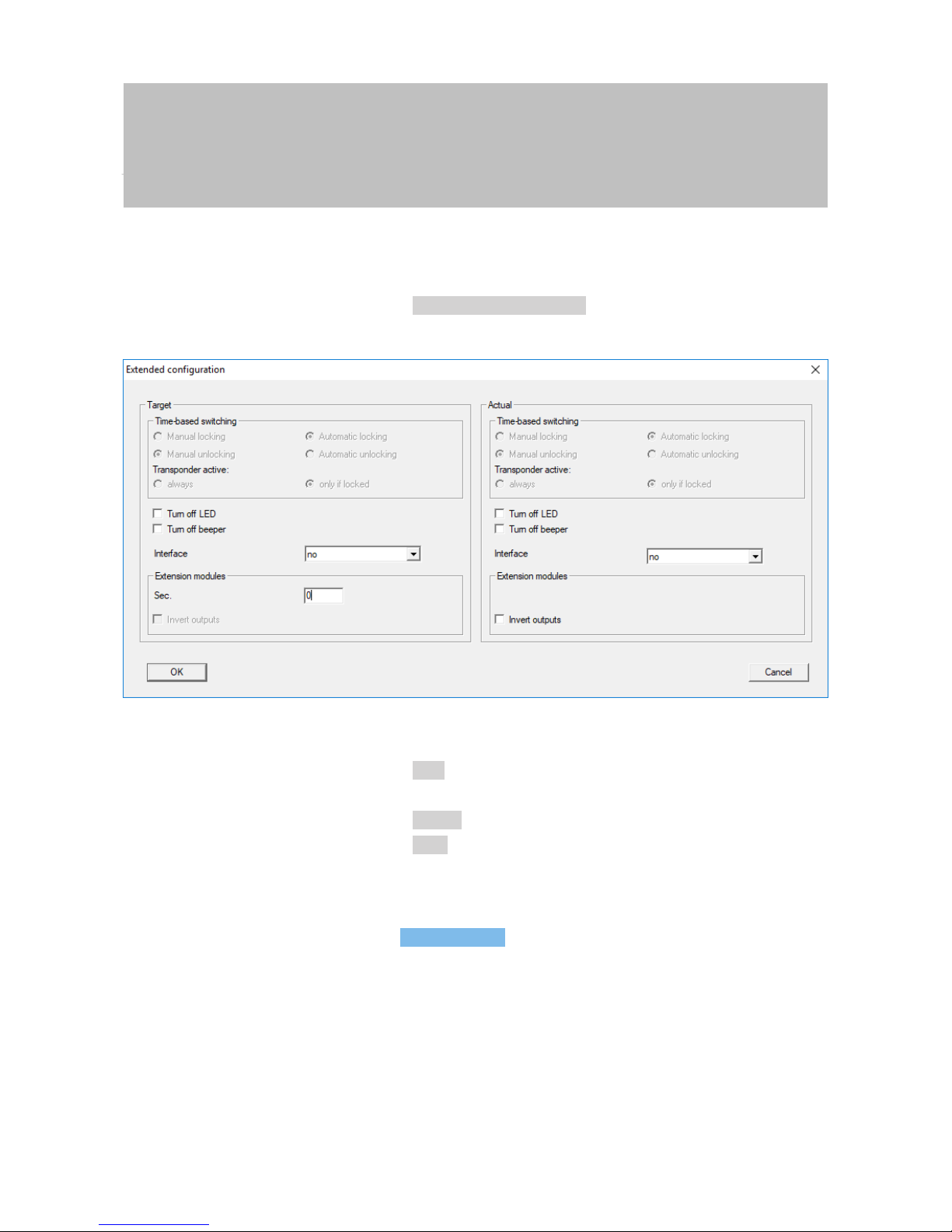

1. Double-click on the SmartRelay 3 entry in the matrix to open the

settings.

2. Change to the [Configuration/Data] tab.

3. Click on the Extended configuration button.

ð "Extended configuration" window will open.

4. Enter the number of connected SmartOutput modules in the

"Extension modules" area.

5. Click on the OK button.

ð Window closes.

6. Click on the Apply button.

7. Click on the Exit button.

ð LSM returns to the matrix.

8. Right-click on the SmartRelay 3 entry in the matrix to open the context

menu.

9. Select the Programming item.

Page 28

Manual

SmartRelais 3 Advanced

28 / 135

SimonsVoss

6 | Setting up

10. Open the Type drop-down menu.

11. Select the "USB link to the TCP nodes" item.

12. Click on the Programming button.

ð Programming launches.

Also see

2 Resetting the controller [}28]

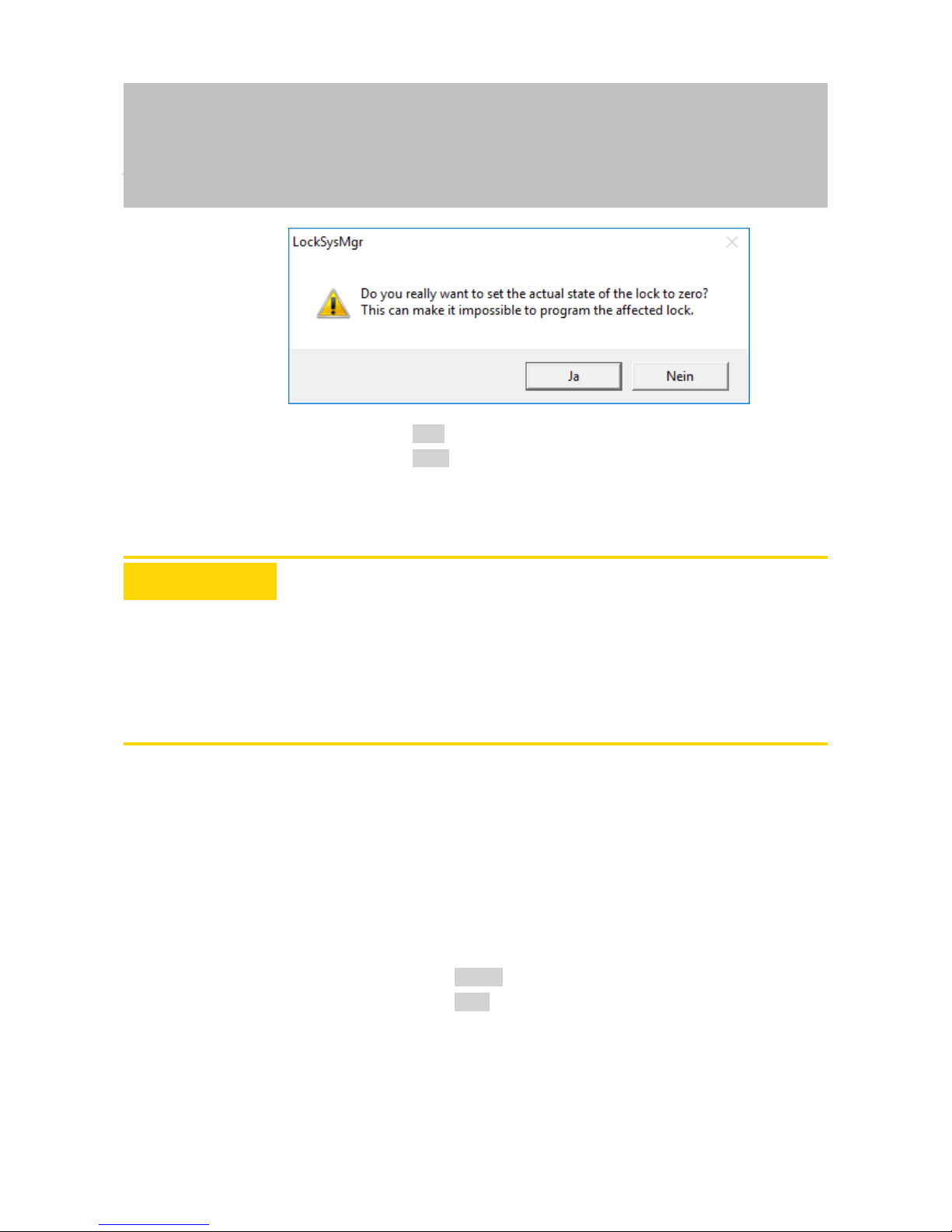

6.3.2 Resetting the controller

You need to reset the controller when changes are made to the connected

components. These include:

– SmartOutput modules added

– SmartOutput modules removed

– Readers added

– Readers removed

Page 29

Manual

SmartRelais 3 Advanced

29 / 135

SimonsVoss

6 | Setting up

A reset deletes the programmed settings.

IMPORTANT

Only the hardware settings and access lists on the controller are reset. The

IP setting remains unchanged

except for the IP settings made during initial programming. The controller

can still be reached using the saved IP address. This means you do not

necessarily need to establish a connection with a USB cable.

6.3.2.1 Resetting controller with a USB cable

The controller can be reset with a USB cable. This option is ideal if the

controller has not yet been installed and can simply be reached physically.

ü Components wired correctly (see wiring [}55]).

ü Components connected to power.

ü Controller connected to computer with USB cable.

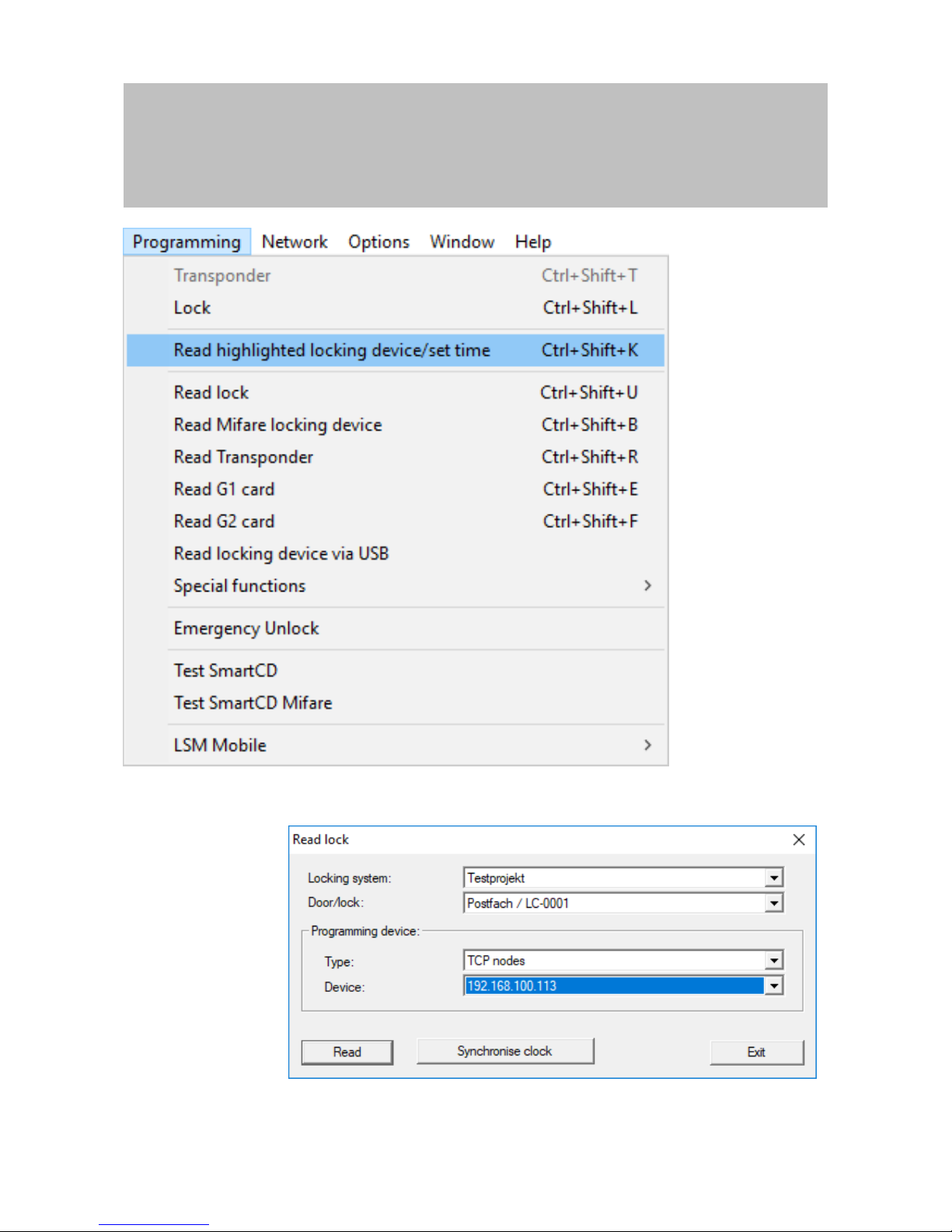

1. Mark the entry on the SmartRelay 3 controller in the matrix.

2. Use |Programming| to select the Read highlighted locking device/set

time item.

Page 30

Manual

SmartRelais 3 Advanced

30 / 135

SimonsVoss

6 | Setting up

ð The "Read lock" window will open.

3. Open the Type drop-down menu.

Page 31

Manual

SmartRelais 3 Advanced

31 / 135

SimonsVoss

6 | Setting up

4. Select the "USB link to the TCP nodes" item.

5. Click on the Read button.

ð Locking device is read.

ð The "G2 Smart Relay 3" window will open.

6. Click on the Reset button.

ð The "Reset lock" window will open.

7. Enter the locking system password or apply it from the database.

8. Click on the Reset button.

ð Locking device is reset.

ð Locking device reset.

6.3.2.2 Resetting controller over the network

Alternatively, the controller can also be reset over the network after initial

programming. This option is ideal if the controller has already been installed

and cannot be reached physically.

ü Components wired correctly (see wiring [}55]).

ü Components connected to power.

ü Controller has already been programmed.

ü Controller connected to computer via network.

1. Mark the entry on the SmartRelay 3 controller in the matrix.

2. Use |Programming| to select the Read highlighted locking device/set

time item.

Page 32

Manual

SmartRelais 3 Advanced

32 / 135

SimonsVoss

6 | Setting up

ð The "Read lock" window will open.

3. Open the Type drop-down menu.

Page 33

Manual

SmartRelais 3 Advanced

33 / 135

SimonsVoss

6 | Setting up

4. Select the "TCP nodes" item.

5. Click on the Read button.

ð Locking device is read.

ð The "G2 Smart Relay 3" window will open.

6. Click on the Reset button.

ð The "Reset lock" window will open.

7. Enter the locking system password or apply it from the database.

8. Click on the Reset button.

ð Locking device is reset.

ð Locking device reset.

6.4 Application examples

This section explains the interplay between components in the SREL3 ADV

system and shows a few use cases as an example.

ATTENTION

Overload in a fitted relay

The permitted current and permitted voltage must not be exceeded.

1. Observe the specifications (see Properties [}121]).

2. Ensure that the load on the relay is not plugged into a different element

or has been increased in some other way.

6.4.1 Basic principle

The SmartRelay 3 system always comprises of a controller, at least one

reader and optional SmartOutput modules.

The reader is not able to evaluate detected identification media for security

reasons. The communication between the reader and controller is secured.

The reader can thus also be installed in unsecured areas without any

problems.

Page 34

Manual

SmartRelais 3 Advanced

34 / 135

SimonsVoss

6 | Setting up

6.4.2 Gateway function

The SREL3 ADV system can also be used as a gateway for the virtual

network, no matter whether a relay contact is used or not. Any identification

medium which is logged onto one of up to three readers is updated. In

doing so, a difference must be made between network-dependent and

network-independent functions.

Network-independent

– Loading time budgets: Users are able to re-upload their time

budgets at any time without the network.

– Automatic blacklist distribution: IDs which have already been

flagged for blocking in the controller are also distributed in the

virtual network without a network connection.

Partially network-independent

When the network connection is re-established, the controller

transmits information which was collected during the outage:

– Feedback signals from blacklist broadcasts: Locking devices

which have received authorisation changes for transponders emit

a feedback signal. This feedback signal is transmitted to the

controller via the virtual network.

– Battery warnings: Locking devices which have low batteries

transmit a battery warning to the controller via the identification

media in the virtual network.

– Physical access lists: The smart card physical access list are read

and saved by the controller independently of the network.

Network-dependent

If there is a network connection, other virtual network functions are

available on the gateway:

– Issuing of individual authorisations: When an identification

medium has logged on, the controller retrieves the latest

authorisation information for the transponder concerned from the

VN host server via the network. The authorisation changes are

updated on the transponder via the reader if necessary.

– Configuration changes: The controller retrieves configuration

changes to identification media, such as a time group change,

from the VN host server.

– Issuing of individual blacklist IDs: Up to two IDs to be blocked can

also be added to selected identification media in the virtual

network. To do so, the controller retrieves the IDs to be blocked

from the VN host server when such an identification medium logs

on.

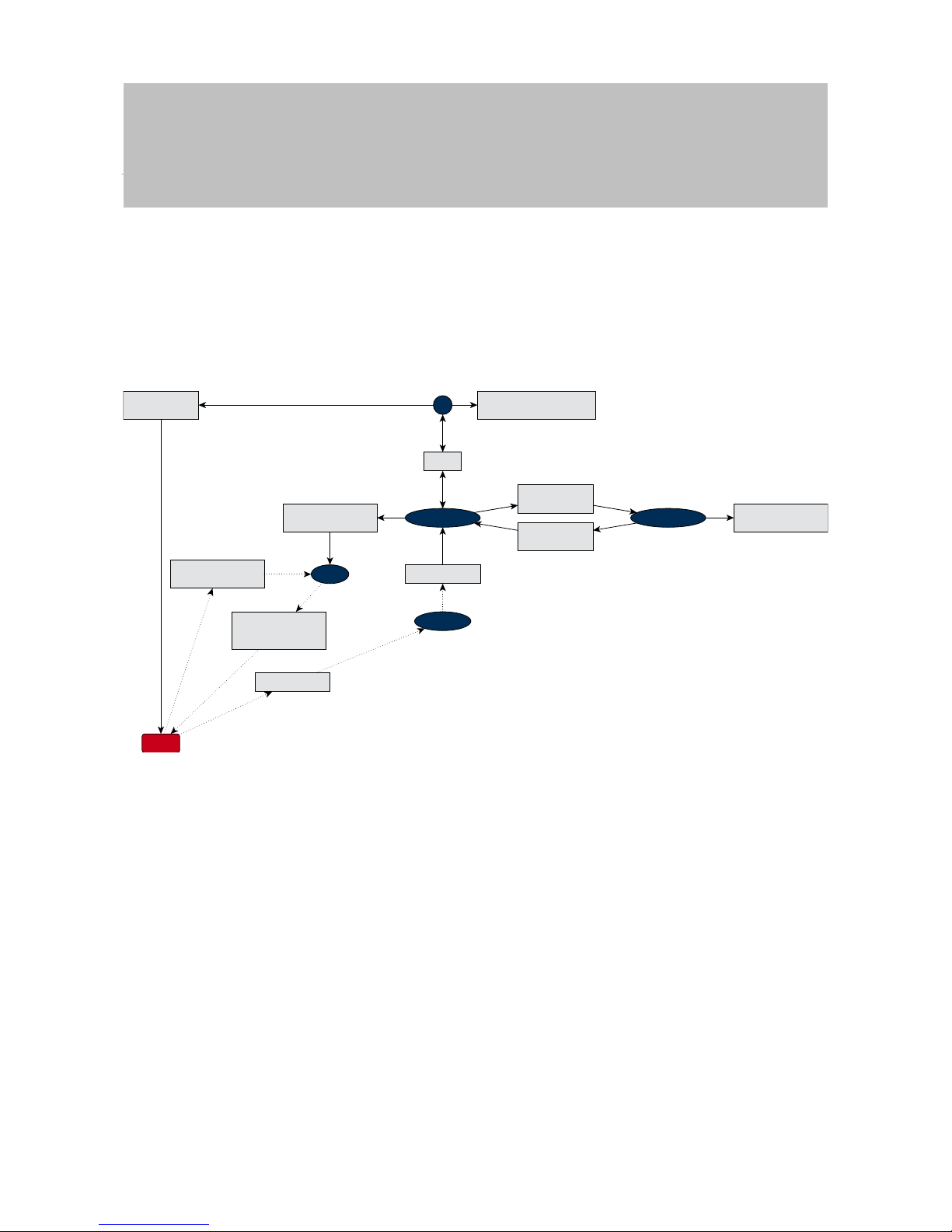

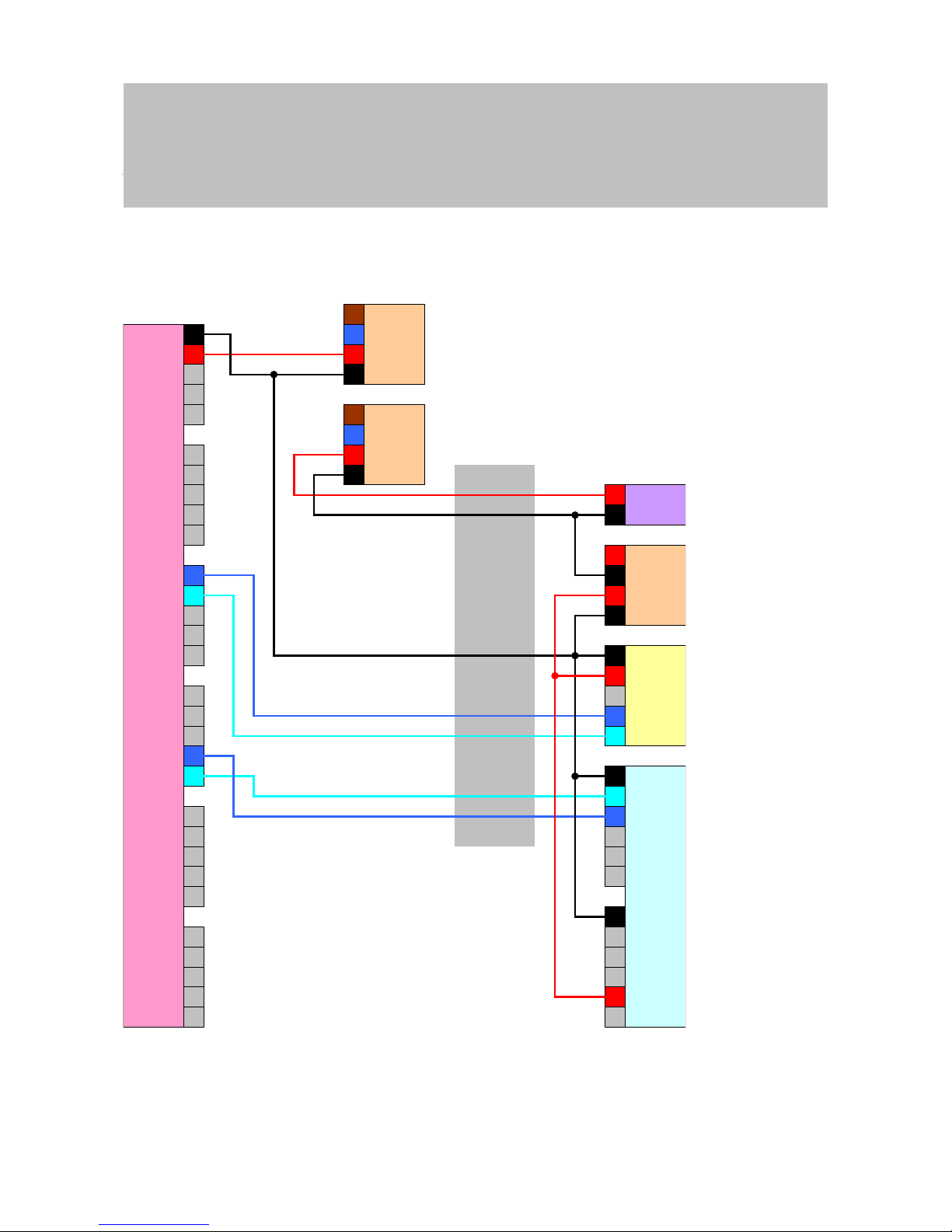

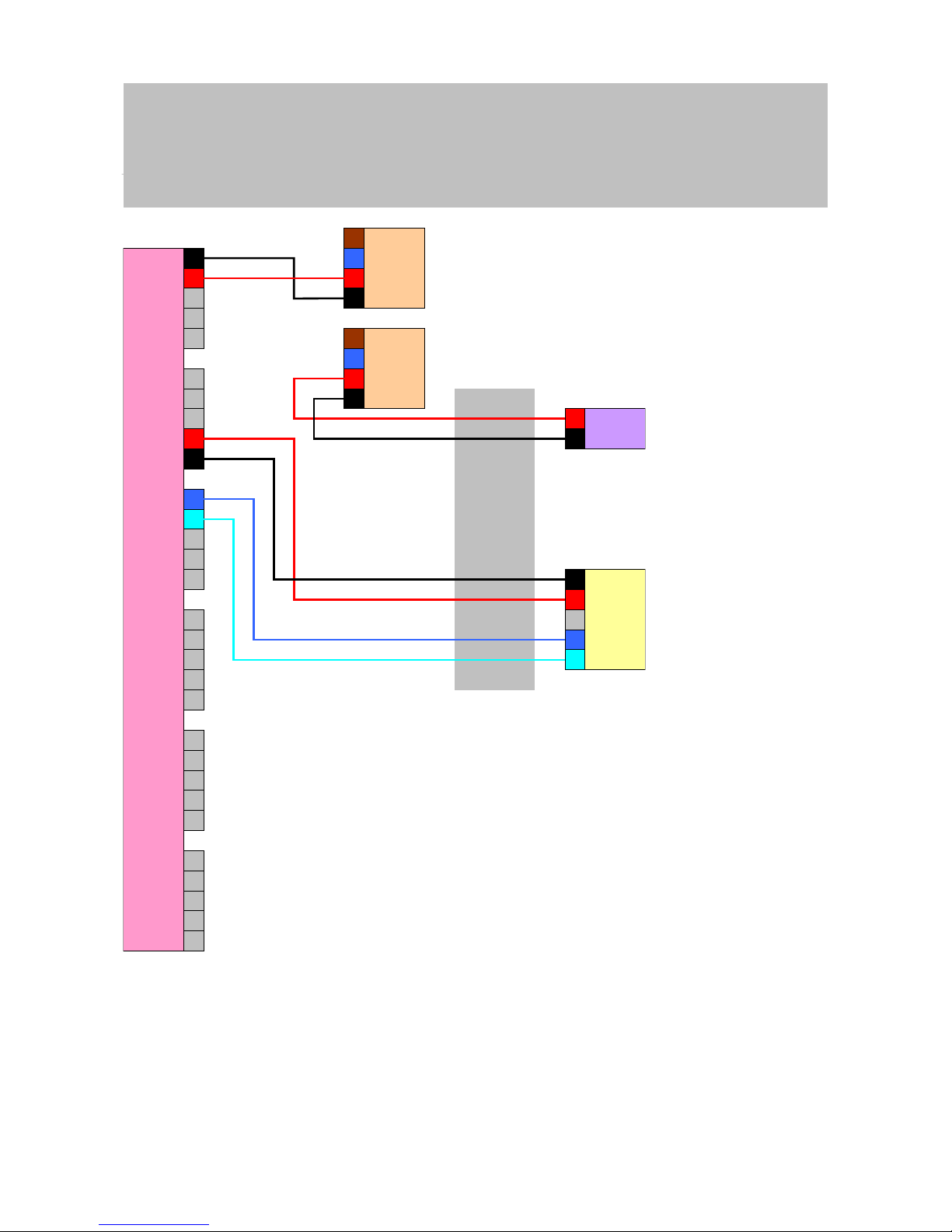

6.4.3 General overview

Controller communication with LSM

The controller does not communicate directly with the database. A

distinction must be made with communication between the controller

and the database:

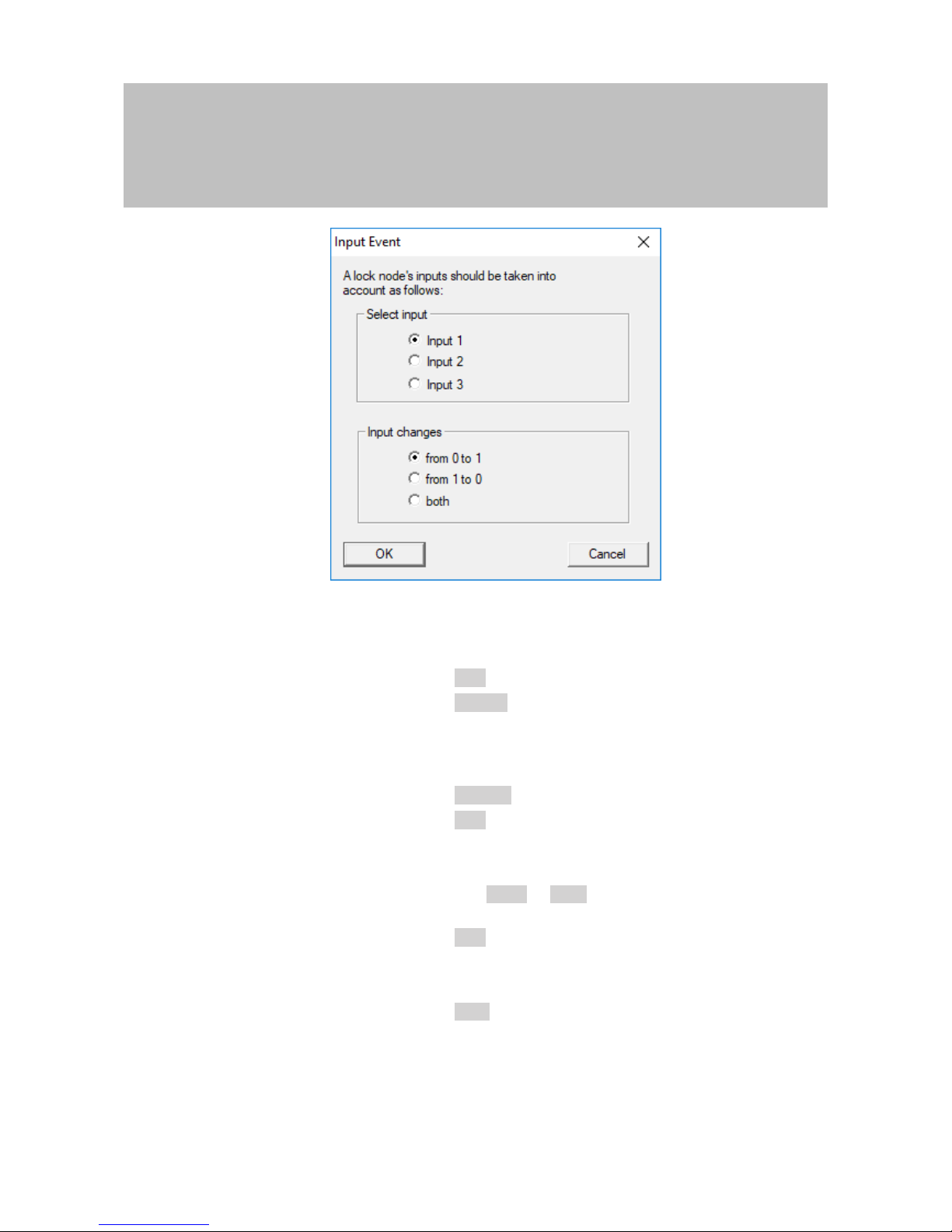

Page 35

Manual

SmartRelais 3 Advanced

35 / 135

SimonsVoss

6 | Setting up

– Use in the virtual network: The controller is programmed by LSM

and also requests information itself from the VN host using the

detected ID medium.

– Use without virtual network: The controller does not request

information itself on its own. Changes need to be programmed.

Events on the controller such as a pressed button are transmitted to

the LSM database via the CommNode.

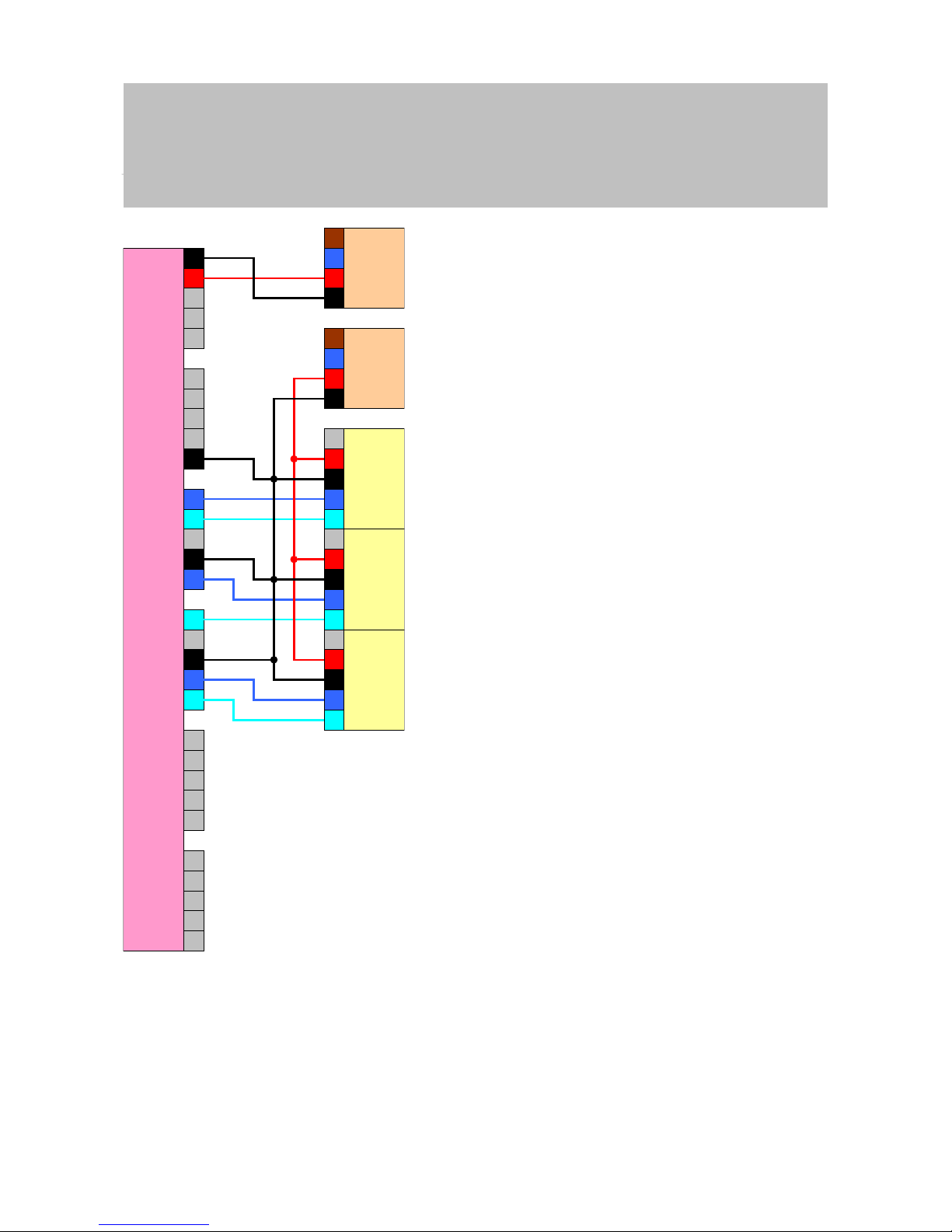

Shows interface to

control and edit

Programmes and

updates

Requests updates for

detected ID medium

Supplies information

on detected ID medium

on request

Transmits events

Adds changes to

identification media

GUI

Edits

LSM database

Saves events

in LSM database

CommNode

Receives information

about locking system

Checks statuses

in the database

SmartSurveil

Shows status

changes on the monitor

Controller

VN host

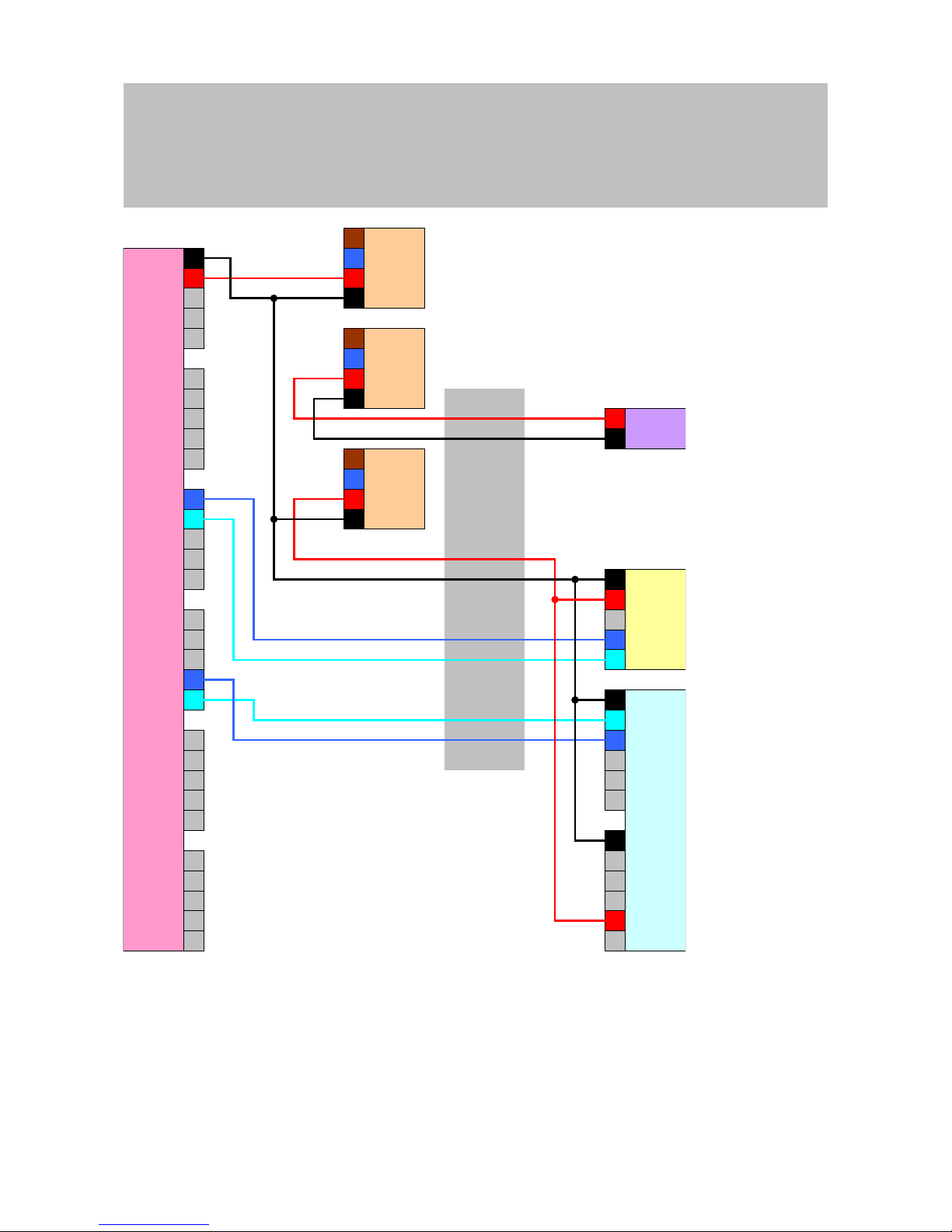

Controller communication with the components

A user can log onto up to three readers with an ID medium. The

reader forwards encrypted information to the controller, which is

located within a protected area. The controller evaluates the

information:

– Use in the virtual network: The controller verifies the information

with the VN host.

– Use without virtual network: The controller draws on information

stored locally when it was last programmed.

If the authorisation was checked successfully, the controller can:

– Actuate an internal relay, which can then be used to activate

external devices.

– Transmit a recognised identification medium to an external device

via the serial interface.

– Switch one or several outputs via an optional SmartOutput module

chain.

Page 36

Manual

SmartRelais 3 Advanced

36 / 135

SimonsVoss

6 | Setting up

The controller can also respond to a digital entry and, consequently, a

connected button or similar as an alternative to successful

identification.

Reader 1

(obligatory)

Reader 2

(optional)

Reader 3

(optional)

As Reader 1

As Reader 1

Forwards identification

media

Supplies electricity where required

Reads access lists

Updates time budgets

Writes authorisation changes

Emits signals (opt., aud.)

Controller

Transmits commands to actuate

SmartOutput module

(optional)

Parallel

circuit

Connection to external

devices, e.g. electric strikes

Connection to external

devices, e.g. electric strikes

Internal relay

Digital outputs

Digital inputs

Connection to external

devices, e.g. buttons

Push-to-open on 3

Transmits commands to external

devices. Available protocols

see specifications

Connection to external

devices, e.g. electric strikes

SmartOutput module

(optional)

6.4.4 Solutions for scenarios

The SREL3 ADV system is the time-tested solution for a large number of

use cases. This section presents a few of them and shows how the SREL3

ADV system is used. The wiring is basically always as described in terms of

electrics (see wiring [}55]). However, line lengths, cable types and wiring

installation options vary, depending on the use case.

IMPORTANT

Protected areas are areas which can only be accessed with an authorised

identification media or are secured against unauthorised access in some

other way.

DANGER

Risk of injury due to incorrect programming

The SREL3 ADV system is not suitable to replace existing security installations.

1. Ensure that the SREL3 ADV system is used as an additional securing

measure only.

2. Do not replace existing security installations with the SREL3 ADV

system.

Page 37

Manual

SmartRelais 3 Advanced

37 / 135

SimonsVoss

6 | Setting up

In the following section, the term unprotected area refers to an area or

place which anyone can access. The protected area refers to an area or

place which only persons who have previously identified themselves at

least once as access-authorised with an authorised identification media

may access.

6.4.4.1 Doors

The SREL3 ADV system can be used to secure doors.

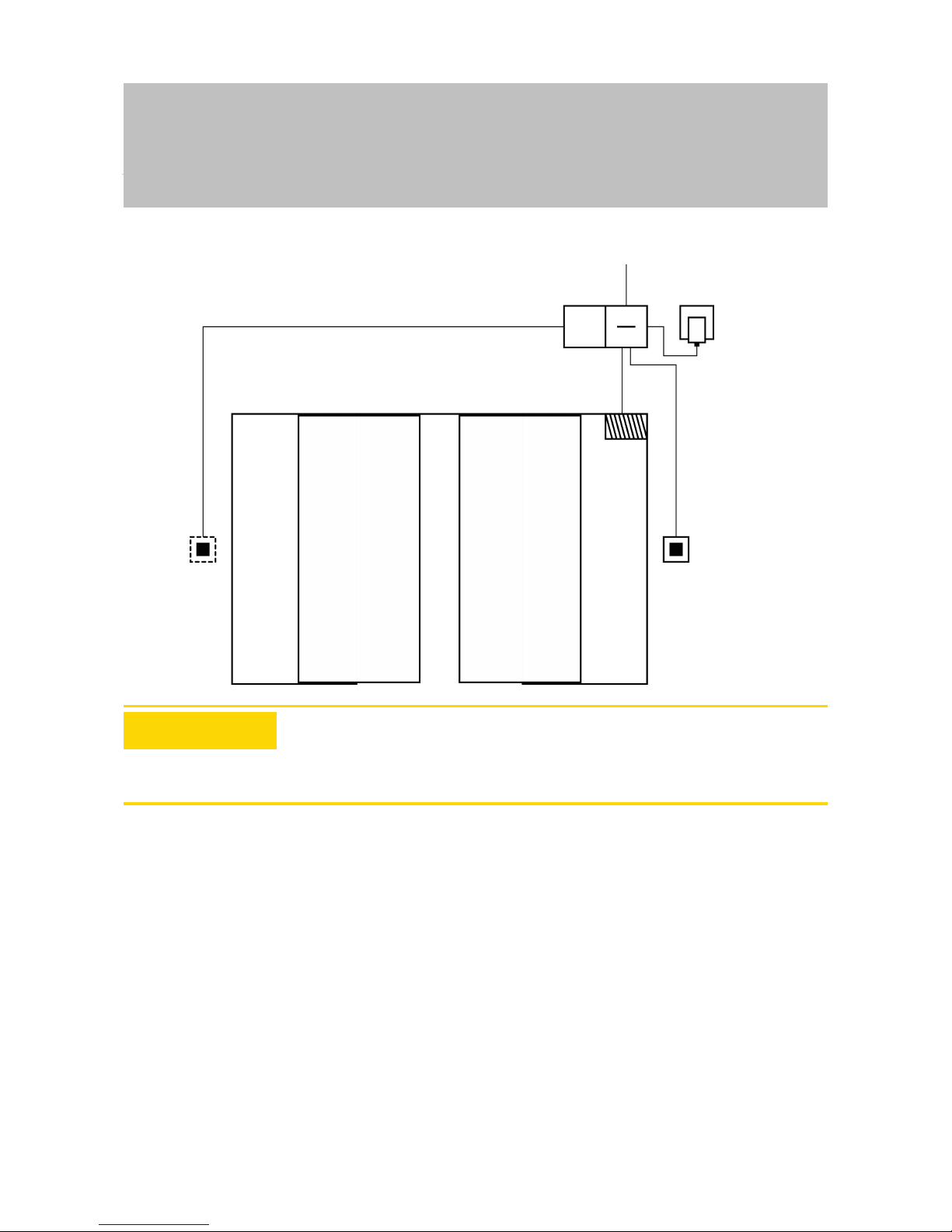

Door with a reader and

a button

Button in the

protected

area

Elec. connection

to the button

Elec. connection to electric

strike on sliding door, for example

Encrypted

connection

to the reader

Reader in

the unprotected

area

External

power supply unit

Ethernet connection to LSM

Optional PoE instead of PSU

Controller with relay output

in the protected area

Serial connection

to third-party systems

In this use case, the controller is installed in a protected area, such as

the building interior. An external reader is mounted on the

unprotected side of the door and can read identification media.

No-one can manipulate the data since communication is secured

from the reader to the controller and to LSM. When the data reach the

controller, the controller evaluates them. If there is a virtual network

and connection to LSM (Ethernet), the latest information is retrieved

using the identification medium; if not, the system used the last status

saved internally. Depending on the result of the evaluation, the

controller triggers the required action, such as actuate a relay.

Page 38

Manual

SmartRelais 3 Advanced

38 / 135

SimonsVoss

6 | Setting up

The controller also features a pre-configured, non-reprogrammable

push-to-open function. The relay actuates if the relevant contacts

(see Controller [}14]) are interconnected with one another. The relay

integrated into the controller can be operated with an authorised

identification medium or by connecting the relevant contacts. One or

more buttons can be installed on the contacts. Users can press these

buttons instead of using an identification medium in a secured area.

This improves user convenience without losing control over the door

status.

If the reader needs to be protected against vandalism, sabotage or

the effects of the weather, a protective housing can be fitted to the

reader (SREL2.COVER1).

Building entrance doors are a special case:

– All users need to pass through one of the building entrance doors

on a daily basis.

– Building entrance doors are exposed to the weather on one side.

– Building entrance doors are in an unsecured area on one side.

– It must also be possible to open building entrance doors without

an identification medium in an emergency at times.

If a virtual network is used, building entrance doors are ideal for use

as a gateway. The building entrance is a door which many users pass

through on a daily basis. This means that each identification medium

used here is verified on the reader and, consequently, in the LSM

database via the controller. Authorisation changes, IDs to be blocked

and time budgets are thus efficiently managed.

Access events can be forwarded to a third-party system via the serial

interface.

The controller can be powered either via an external power supply

unit or via the network line. The controller, in turn, can power the

reader. If the voltage drop is too great, the reader can also be

supplied by an external power supply unit (see External power supply

[}57]).

See Connecting one or more readers [}55] and Connecting one or

more buttons [}61] on wiring.

Use with two buttons

Page 39

Manual

SmartRelais 3 Advanced

39 / 135

SimonsVoss

6 | Setting up

Button in the

protected

area

Button in the

protected area

Elec. connection

to the button

Controller with relay output

in the protected area

Elec. connection to electric

strike (e.g. sliding door)

External

power supply unit

Ethernet connection to LSM

Optional PoE instead of PSU

Elec. connection

to the button

ATTENTION

No check on authorisation

Any person who has physical access can operate the relay by using the

two buttons.

1. Ensure that no unauthorised persons can access this locking device.

There is no longer a need to use an identification medium. Users only need

to press a button to operate the relay (and open the sliding door in this

example). Compared to a purely electrical connection, this approach brings

the advantage of providing an overview when the relay was actuated and

what its current status is (see SmartSurveil [}101]).

The relay is not protected against unauthorised operation. This type of

connection is thus only suitable for installing in areas which are already

secured.

See Connecting one or more buttons [}61] on wiring.

Page 40

Manual

SmartRelais 3 Advanced

40 / 135

SimonsVoss

6 | Setting up

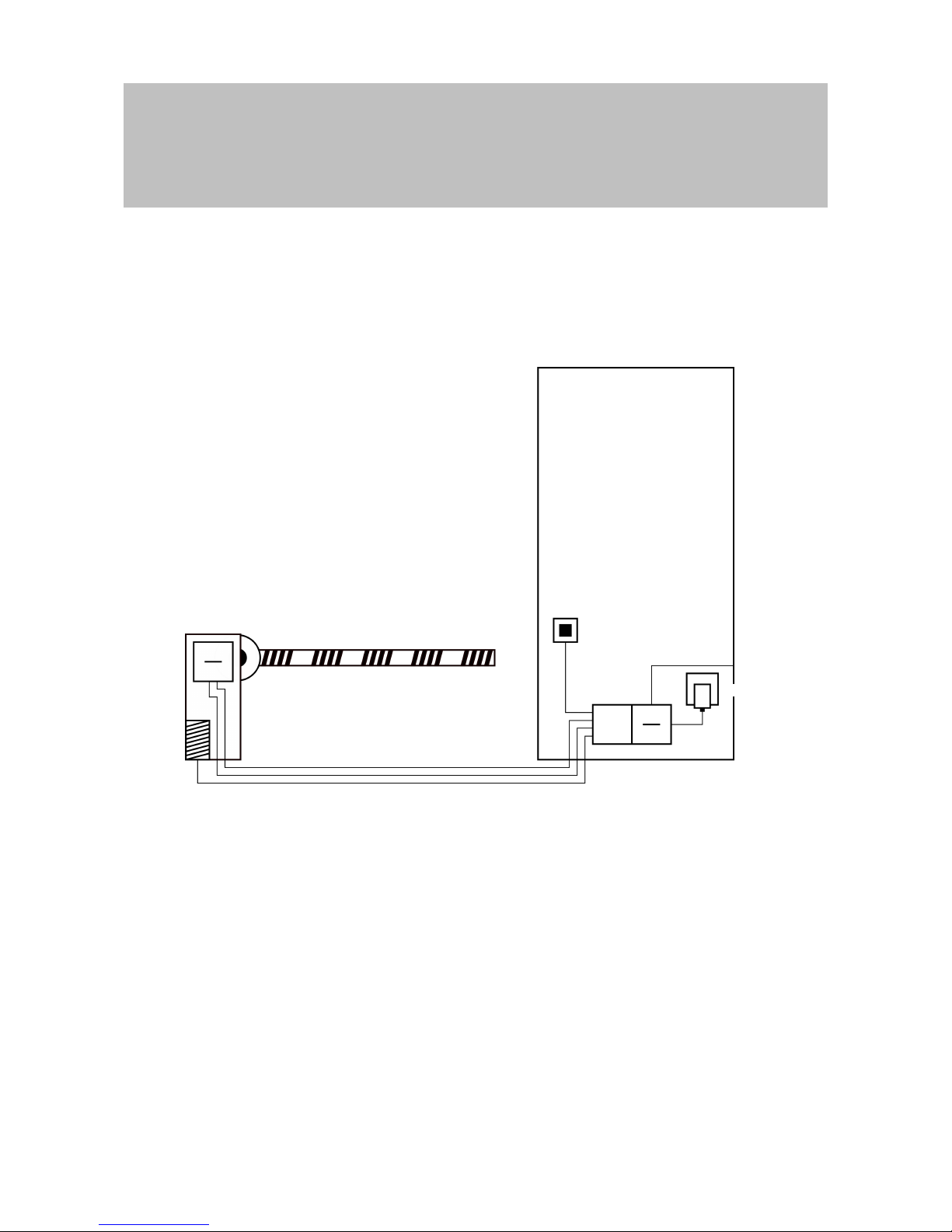

6.4.4.2 Entrance barrier

People who want to drive into a segregated area, such as a company car

park, need to pass through an entrance barrier. Not everyone can have an

authorised identification medium as this would involve considerable

organisation. An entrance barrier is also normally installed outdoors and is

thus exposed to the weather, vandalism and sabotage.

Button in the

protected

area

Ethernet connection to LSM

Optional PoE instead of PSU

Elec. connection

to the controller

Reader in the

unprotected area

Encrypted connection

to the controller

Elec. connection

to the barrier drive

Barrier

drive

External PSU

The SREL3 ADV system offers an intelligent solution for such situations.

The controller is installed in a protected area, such as the engineering

room. A reader needs to be installed close to the barrier. There are two

solutions:

– The reader is fitted into the barrier housing. This variant discreetly

blends in. It provides excellent protection against the weather,

vandalism and sabotage.

– The reader is fitted on the barrier housing. This variant is visible on the

outside and makes it easier for users to place their identification

medium onto the reader. The read range is better compared to a reader

fitted inside the barrier housing. The protective housing

(SREL2.COVER1) ensures protection against the weather, vandalism

and sabotage.

Page 41

Manual

SmartRelais 3 Advanced

41 / 135

SimonsVoss

6 | Setting up

The user can use their identification media to check authorisation while in

the car. If the user does not have an identification medium, but is expected,

they can still announce their arrival, using an intercom, for example.

Another person who is in the protected area can then let the user in by

pressing the connected button. The button can be installed in a gatehouse,

for example, which only allows external customers to enter during business

hours while users with identification media can come in at any time.

No-one can manipulate the data since communication is secured from the

reader to the controller and to LSM. When the data reach the controller, the

controller evaluates them. If there is a virtual network and connection to

LSM (Ethernet), the latest information is retrieved using the identification

medium; if not, the system used the last status saved internally. Depending

on the result of the evaluation, the controller triggers the required action,

such as actuate a relay.

If a virtual network is used, the system is ideal for use as a gateway. The

barrier is a locking device which is very heavily used. This means that

many identification media are already synchronised with the LSM database

before they reach the building entrance. As a result, there is less load on

the gateway on the building door. In this case, the reader should be

installed where it is visible for users to ensure that they can hear or see the

reader feedback signals.

The controller can be powered either via an external power supply unit or

via the network line. The controller, in turn, can power the reader. If the

voltage drop is too great, the reader can also be supplied by an external

power supply unit (see External power supply [}57]).

Since a feed line needs to be installed for the barrier motor, the power

supply for the reader can be easily connected to this line. Power is reliably

supplied to the reader with a power supply unit, so the reader is not

affected by any voltage drops due to line length.

See Connecting one or more readers [}55] and Connecting one or more

buttons [}61] on wiring.

6.4.4.3 Lift

A lift is a special case. Lift cabs are usually connected to their environment

through a trailing cable. However, the number of lines within the trailing

cable is limited. The SREL3 ADV system requires a varying large number

of lines, depending on the configuration.

It is highly recommended to use one or several SmartOutput modules in a

lift to provide sufficient relay contacts. We also need to consider that the

controller should be mounted on top of the lift cab or a network connection

must be laid through the trailing cable.

If one or several SmartOutput modules are used, effective access

management can be implemented in the lift itself with authorisation required

for buttons for specific floors.

Page 42

Manual

SmartRelais 3 Advanced

42 / 135

SimonsVoss

6 | Setting up

The reader and the SmartOutput module are installed in the lift. Users

identify themselves with their identification medium in the lift.

No-one can manipulate the data since communication is secured from the

reader to the controller and to LSM. When the data reach the controller, the

controller evaluates them. If there is a virtual network and connection to

LSM (Ethernet), the latest information is retrieved using the identification

medium; if not, the system used the last status saved internally. Depending

on the result of the evaluation, the controller triggers the required action,

such as actuate a relay.

ATTENTION

Interferences in the trailing cable

Lines in the trailing cable through which data is to be transmitted must be

shielded (also see Recommended cable types [}127]).

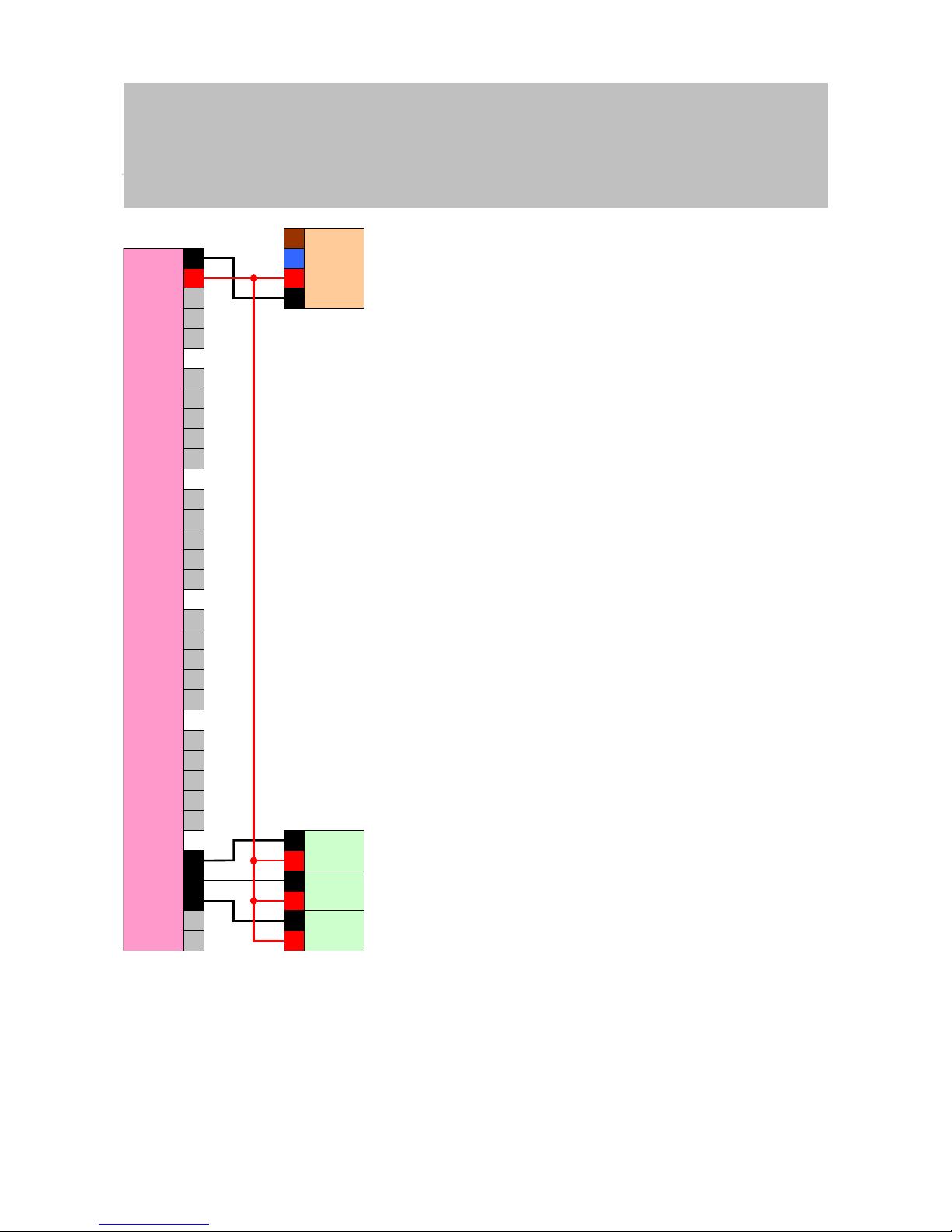

Power supply from cab

This connection option requires the fewest free lines in the trailing cable

and avoids voltage drops due to excessively long lines. The controller can

be installed outside the lift where it is protected in a place, such as the

engineering room.

The reader is not powered via the controller. Instead, it is connected to the

existing power supply in the lift cab, which provides electricity for lighting,

doors and other elements. The voltage may need to be converted with a

power supply unit, so that it is within the specified voltage range for the

SmartOutput module and reader (see Properties [}121]). The voltages

supplied to the individual components do not need to be identical. It is thus

possible to operate the controller with 12V while the reader in the lift is

operated with 24V.

Common earth connection

In this specific case, four lines are also needed to supply power to the

cab.

Line Use

1 Controller – reader: Data line A

2 Controller – reader: Data line B

3 Controller – SmartOutput module: Data line A

4 Controller – SmartOutput module: Data line B

DANGER

Electric shock due to mains voltage

An electric shock may be caused when connecting the non-hazardous

earth (low voltage) to a conductor which carries the mains voltage.

1. Only use conductors with a low-voltage potential (<42V) as a common

earth cable!

2. Protect live cables, so people do not touch them accidentally!

Page 43

Manual

SmartRelais 3 Advanced

43 / 135

SimonsVoss

6 | Setting up

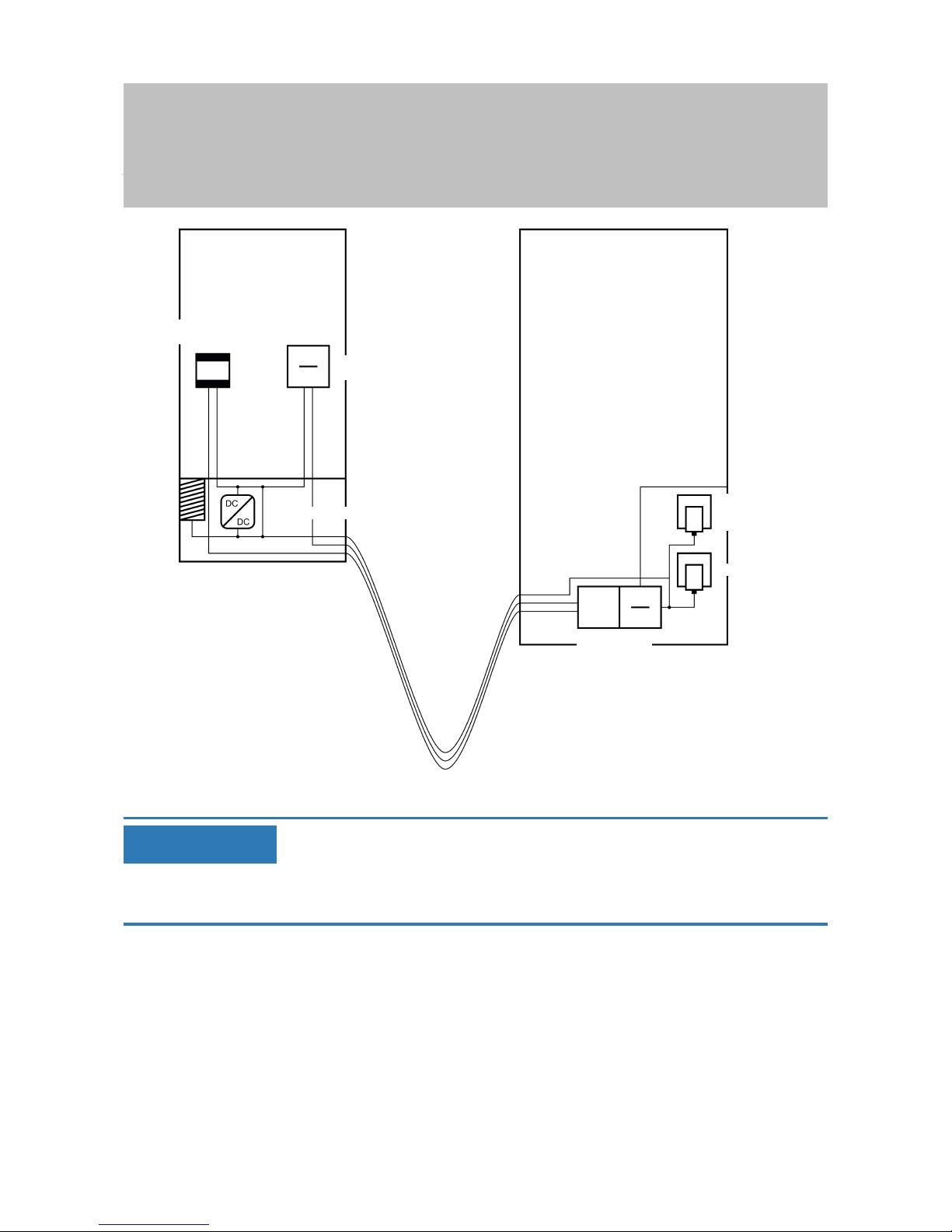

SmartOutput module

in cab

Reader in

the unprotected area

Lift

electronics

Voltage converter

Ethernet connection to LSM

External PSU

Controller in the

protected area

Power

supply for

lift cab

Trailing cable

IMPORTANT

A common earth connection is required between the controller, reader and

SmartOutput modules. The cab power supply earth connection can be used

to save on lines in the trailing cable. The controller's earth connection

needs to be connected to the cab power supply earth connection in this

case.

See Common earth with power supply [}69] on wiring.

Separate earth connection

If a common earth cable cannot be used for the cab power supply

and the components, an additional line needs to be assigned in the

trailing cable. In this specific case, five lines are also needed to

supply power to the cab.

Page 44

Manual

SmartRelais 3 Advanced

44 / 135

SimonsVoss

6 | Setting up

Line Use

1

Earth connection between controller, reader

and SmartOutput modules

2 Controller – reader: Data line A

3 Controller – reader: Data line B

4 Controller – SmartOutput module: Data line A

5 Controller – SmartOutput module: Data line B

Reader in

the unprotected area

Lift

electronics

Voltage converter

Trailing cable

SmartOutput module

in cab

Controller in the

protected area

Power

supply for

lift cab

External PSU

Ethernet connection to LSM

Optional PoE instead of PSU

The earth cables in the power supplies are separated from the

common earth cable in this case.

See Common earth with SREL3 components [}70] and Connecting

one or more readers [}55] on wiring.

Page 45

Manual

SmartRelais 3 Advanced

45 / 135

SimonsVoss

6 | Setting up

Power supply via trailing cable

This connection option does not access existing lift electronics. This

means the lift electronics remain intact and a new inspection may be

avoided.

The components are powered via the trailing cable only. The required

power supply unit is at the other end of the trailing cable. Depending

on the length of the trailing cable, a possible voltage drop must be

taken into account to meet specifications (see Properties [}121]).

ATTENTION

Malfunctions due to voltage drop

The physically induced voltage drop in the trailing cable may cause low

voltages in power supplies which come from outside the cab.

1. Take the cable length into account.

2. Switch to a version with power supply in the cab if necessary (see

Common earth with power supply [}69] and Common earth with

SREL3 components [}70]).

3. Make the cable gauge larger by merging lines in the trailing cable.

Insert: Reader with

SmartOutput module

and common supply

The SmartOutput module requires its own power supply. The reader

can also be connected to this power supply. Six free lines are

required in addition to the existing lines.

Line Use

1

Earth connection between controller, reader

and SmartOutput modules

2 Positive terminal on the power supply

3 Controller – reader Data line A

4 Controller – reader Data line B

5 Controller – SmartOutput module: Data line A

6 Controller – SmartOutput module: Data line B

Page 46

Manual

SmartRelais 3 Advanced

46 / 135

SimonsVoss

6 | Setting up

SmartOutput module

in cab

Lift electronics

Reader in

the unprotected area

Ethernet connection to LSM

Optional PoE instead of PSU

Power supply for

lift cab

External power supply

unit

Controller in the

protected area

Trailing cable

External power supply

unit for SOM and reader

IMPORTANT

The power supply unit for the reader and the SmartOutput modules can be

omitted if the controller power supply unit can deliver sufficient electricity

and supply a voltage of 12VDC.

See Power supply through trailing cable [}72] and Connecting one or

more readers [}55] on wiring.

Insert: Reader without

SmartOutput module

The controller powers the reader. An additional power supply unit is

not required. Four free lines are required in addition to the existing

lines.

Page 47

Manual

SmartRelais 3 Advanced

47 / 135

SimonsVoss

6 | Setting up

Line Use

1

Earth connection between controller and

reader

2 Positive terminal on the power supply

3 Controller – reader: Data line A

4 Controller – reader Data line B

Reader in

the unprotected area

Lift

electronics

Trailing cable

Controller in the

protected area

External PSU

Power

supply for

lift cab

Ethernet connection to LSM

Optional PoE instead of PSU

See Power supply through the controller [}74] on wiring.

Insert: Controller-fed

reader with SmartOutput module

The controller powers the reader. Connected SmartOutput modules

are powered via an additional power supply unit at the other end of

the trailing cable. Nine free lines are required in the trailing cable in

addition to the existing lines.

The reader and its connection to the controller do not need to be

removed. This means it is possible to retrofit SmartOutput modules to

an existing connection.

Page 48

Manual

SmartRelais 3 Advanced

48 / 135

SimonsVoss

6 | Setting up

Line Use

1

Earth connection between SmartOutput mod-

ule and power supply unit

2

Positive terminal for power supply between

SmartOutput module and power supply unit

3

Earth connection between controller and

reader

4

Positive terminal for power supply between

controller and reader

5 Controller – SmartOutput module: Data line A

6 Controller – SmartOutput module: Data line B

7

Controller – SmartOutput module: Data line

earth connection

8 Controller – reader Data line A

9 Controller – reader Data line B

Page 49

Manual

SmartRelais 3 Advanced

49 / 135

SimonsVoss

6 | Setting up

SmartOutput module

in cab

Reader in

the unprotected area

Lift

electronics

Trailing cable

Ethernet connection to LSM

Optional PoE instead of PSU

External power supply

unit for SOM

Power

supply for

lift cab

Controller in the

protected area

External PSU

See Controller-fed reader with SmartOutput modules [}75] and

Connecting one or more readers [}55] on wiring.

Also see

2 Power supply from cab [}42]

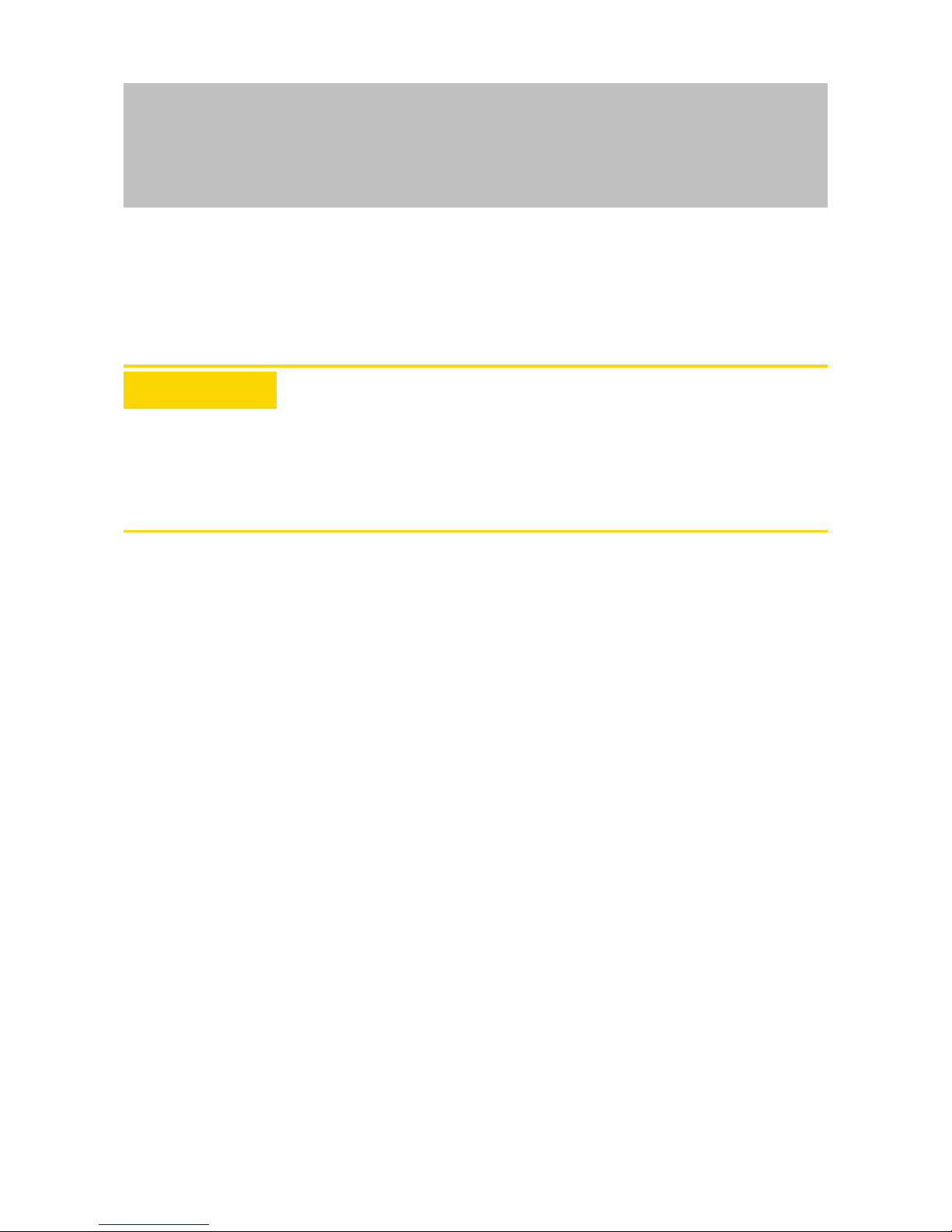

6.4.4.4 Safe deposit boxes

Safe deposit box systems are used by a variety of users. Only authorised

persons should be able to open their designated deposit boxes. Deposit

box systems are not always installed in areas protected from the weather.

Suppliers, deliverers and a selected group of people should be able to

access all deposit boxes. Some people may need to be able to open

several deposit boxes.

Page 50

Manual

SmartRelais 3 Advanced

50 / 135

SimonsVoss

6 | Setting up

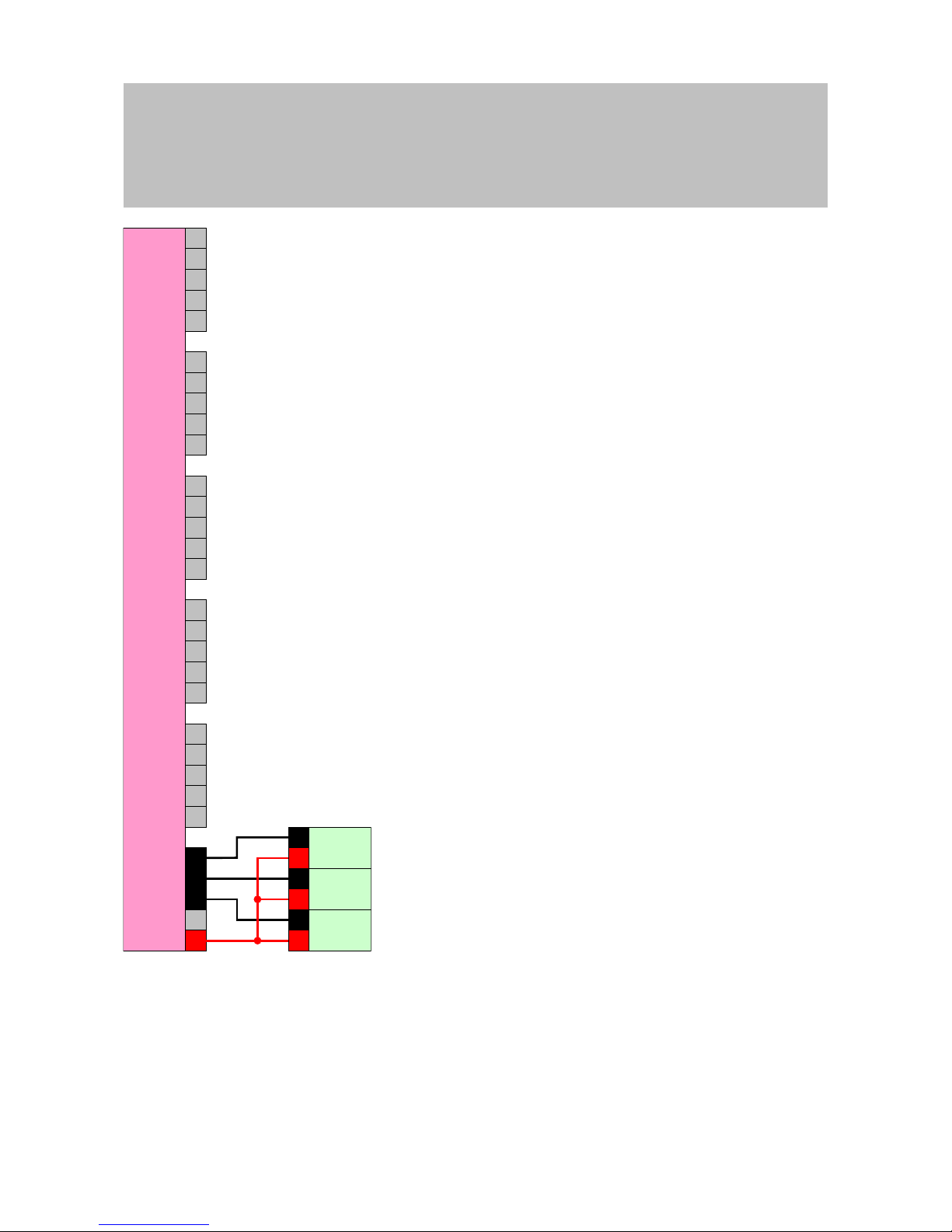

SOM in

deposit box

system

Reader in

the unprotected area

Parallel connection

Controller in the

protected area

External PSU

PSU for

SmartOutput module

Ethernet connection to LSM

Optional PoE instead of PSU

SOM in

deposit box

system

Parallel connection

Encrypted

connection

to the controller

The existing connections to open the locking system can be actuated with

the SmartOutput modules, no matter whether a direct or alternating current

is used. The SmartOutput modules are connected in parallel for this

purpose. The address can be configured individually on each SmartOutput

module. This allows up to fifteen SmartOutput modules with eight outputs

each to be connected to the system (except the last module, which

supports only four relays). The deposit box is opened as soon as the

controller receives an opening command to the corresponding relay.

Identification media can be authorised for individual relays and,

consequently, individual deposit boxes in LSM. However, it is also possible

to group identification media together, for a department, for example, and

authorise this group to use a single relay, in a departmental deposit box.

Identification medium verification means you can trace which of the group's

identification media has operated the relay (and taken documents, for

example). If individual persons are supposed to be able to open a number

of deposit boxes, relays can be grouped – in different trust levels, for

example. The group of authorised persons becomes smaller as the trust

level increases.

There are two options for installing the reader:

– The reader is installed in an existing housing – in an intercom housing,

for example. This variant is hidden from view and offers effective

protection against the weather, vandalism and sabotage.

Page 51

Manual

SmartRelais 3 Advanced

51 / 135

SimonsVoss

6 | Setting up

– The reader is fitted on the wall. This variant is visible on the outside and

makes it easier for users to place their identification medium onto the

reader. The read range is better compared to a reader fitted inside the

housing. If the reader is installed outdoors, protection against the

weather, vandalism and sabotage can be assured with the protective

housing (SREL2.COVER1).

A master identification medium can be created for emergencies. This can

be used to open several or all boxes at the same time.

The controller can be powered either via an external power supply unit or

via the network line. The controller, in turn, can power the reader. If the

voltage drop is too great, the reader can also be supplied by an external

power supply unit (see External power supply [}57]).

See Connecting one or more readers [}55] and Connecting one or more

SmartOutput modules [}63] on wiring.

Also see

2 Connecting one or more buttons [}61]

6.4.4.5 Machine safety

Machines can pose significant hazards:

– Cuts

– Burns

– Electric shocks

– Laser radiation

– Crushing

For safety reasons, only qualified people should therefore be allowed to

operate hazardous machines. Unauthorised persons must not be able to

put hazardous machines into operation.

An option to switch off the machine without authorised identification media

further increases operational safety.

DANGER

Risk of injury due to incorrect programming

The SREL3 ADV system is not suitable as a sole disconnecting device. A

contactor activated via the controller must never be the only means to

switch off a machine.

1. Use the SREL3 ADV system as an additional disconnecting device only,

not as the sole one.

2. Use the actuated contactor in a series circuit with the machine's

emergency stop switch only.

Page 52

Manual

SmartRelais 3 Advanced

52 / 135

SimonsVoss

6 | Setting up

Safety switch

(zero voltage switch)

Reader in

the unprotected

area

External PSU

Ethernet connection to LSM

Optional PoE instead of PSU