Page 1

Manual

Digital Locking Cylinder 3061

08.2017

Page 2

SimonsVoss

Contents

Manual

Digital Locking Cylinder 3061

Contents

1 Intended use ....................................................................................................................................4

2 Safety instructions..........................................................................................................................5

3 General information on System 3060............................................................................................7

3.1 Product description................................................................................................................. 7

3.2 Locking cylinder design .......................................................................................................... 8

3.3 Half cylinder design ................................................................................................................ 9

3.4 Opening and locking from the outside....................................................................................9

3.5 Opening and locking from the inner side .............................................................................10

4 System 3060 designs....................................................................................................................11

4.1 FD version (Standard) .......................................................................................................... 12

4.2 HZ version (Standard) .......................................................................................................... 12

4.3 ............................................................................................................................................. 12

4.4 ZK version ............................................................................................................................ 12

4.5 version for steel and fire retardant doors.............................................................................. 12

4.6 TS version ............................................................................................................................ 13

4.7 MR option ............................................................................................................................. 13

4.8 MS version ...........................................................................................................................13

4.9 SKG or VdS versions (SZ) ...................................................................................................13

4.10 AP version ............................................................................................................................ 14

4.11 AP2 Version .........................................................................................................................15

4.12 CO version ...........................................................................................................................15

4.13 WP Version (FD) .................................................................................................................. 15

4.14 WP version (HZ/CO/AP)....................................................................................................... 16

4.15 SW version (CO) .................................................................................................................. 16

4.16 VR version (HZ).................................................................................................................... 16

4.17 DK version (HZ).................................................................................................................... 16

4.18 WN version (HZ)................................................................................................................... 16

4.19 DM version ........................................................................................................................... 16

4.20 Hybrid-Version...................................................................................................................... 17

4.21 Extra lengths ........................................................................................................................17

4.22 Examples of locking cylinder use ......................................................................................... 17

2 / 44

5 Installation instructions................................................................................................................18

5.1 General instructions .............................................................................................................18

5.2 Programming the locking cylinder ........................................................................................ 18

Page 3

SimonsVoss

Contents

Manual

Digital Locking Cylinder 3061

5.3 Installation variants............................................................................................................... 19

5.3.1 Installation of double thumb-turn cylinders (except types .AP/.SKG/.VdS) ..............19

5.3.2 Fitting an anti-panic cylinder......................................................................................21

5.3.3 Installation of SKG/VdS cylinders..............................................................................24

5.3.4 Half Cylinder DK/MR ................................................................................................. 25

5.3.5 Installing Swiss Round .............................................................................................. 27

6 System 3060 audible signals .......................................................................................................28

6.1 Battery warnings................................................................................................................... 28

6.2 Battery warning for transponders ......................................................................................... 30

7 System 3060 battery replacement ...............................................................................................31

7.1 General instructions .............................................................................................................31

7.2 Battery life ............................................................................................................................31

7.3 Emergency battery procedure .............................................................................................. 31

7.3.1 Storage mode (G1)....................................................................................................32

7.3.2 Freeze mode (G2) .....................................................................................................32

7.4 Procedure.............................................................................................................................33

7.5 Procedure for outer thumb turn (MH cylinder)......................................................................34

3 / 44

8 Maintenance, cleaning and disinfection .....................................................................................36

9 Areas of use...................................................................................................................................37

9.1 General................................................................................................................................. 37

9.2 Fire doors ............................................................................................................................. 37

9.3 Doors along rescue routes ................................................................................................... 37

9.4 Installation outdoors ............................................................................................................. 37

10 Accessories ...................................................................................................................................38

10.1 Thumb-turns ......................................................................................................................... 38

10.2 Core extraction protection adapter (Z4.KA.SET).................................................................. 38

10.3 Core extraction protection extension for SKG/VdS cylinders (Z4.KA.SET2)........................ 38

10.4 Core extraction protection extension for SKG/VdS cylinders (Z4.KA.SET2.IT) ................... 38

10.5 Tool ......................................................................................................................................38

10.6 Battery set ............................................................................................................................ 39

11 Data sheets ....................................................................................................................................40

11.1 Locking cylinder.................................................................................................................... 40

11.2 Half cylinder.......................................................................................................................... 41

12 Declaration of conformity.............................................................................................................43

13 Help & Contact ..............................................................................................................................44

Page 4

SimonsVoss

Manual

Digital Locking Cylinder 3061

1 Intended use

Digital SimonsVoss Locking Cylinder are installed in designated door locks,

such as DIN mortise locks, to integrate them into a digital locking system.

Digital half cylinders can also be operated in optionally available

SimonsVoss padlocks.

The digital Locking Cylinder may only be used for its intended purpose in a

designated door locking device. No other use is permitted.

Digital Locking Cylinders are available in various lengths. The selection of

the proper size is of significance. The length of the locking cylinder is

printed on the packaging and can be measured at any time. If the cylinder

is too short, the handles cannot be fitted. If the cylinder is too long, it may

be ripped out of the locking device. The may not protrude more than 3 mm

on each side of the door to ensure proper operation.

The product may not be changed in any way, other than in compliance with

the changes described in the instructions.

1 | Intended use

4 / 44

Page 5

SimonsVoss

Manual

Digital Locking Cylinder 3061

2 Safety instructions

2 | Safety instructions

5 / 44

Warning:

Important:

– Access through a door may be blocked due to an incorrectly

installed or incorrectly programmed Locking Cylinder.

SimonsVoss Technologies GmbH is not liable for consequences

of incorrect installation, such as denied access to injured persons,

physical damage or any other losses.

– The batteries used in the digital Locking Cylinder may pose a fire

or burn hazard if handled incorrectly. Do not recharge, open, heat

or burn these batteries. Do not short-circuit batteries.

– When used in combination with panic locks, after installation, you

must ensure that all parts of the locking system are fully functional

and the mortise lock panic function is guaranteed to work.

– The anti-panic cylinder may only be fitted into locks in which it is

expressly approved for use. Please also refer to the lock

manufacturer's information/documentation.

– If the anti-panic lock is used in non-approved locks, the escape

door function may malfunction and no longer be triggered. Contact

SimonsVoss Technologies GmbH for more information on use in

anti-panic locks.

– Do not activate the anti-panic lock before it is fitted as there is a

risk of injury from the cam springing back.

– As per European standard EN 179, Appendix C, all components in

the anti-panic cylinder locking mechanism must be checked at

intervals no greater than one month to ensure that all parts in the

locking mechanism are in satisfactory working order as part of

locking device maintenance.

– SimonsVoss Technologies GmbH accepts no liability for damage

caused to doors or components due to incorrect fitting or

installation.

– The SimonsVoss Locking Cylinder may only be used for its

intended purpose: opening and locking doors. No other use is

permitted.

– Only trained specialists may install the cylinder.

– Do not allow the cylinder to come into contact with oil, paint or

acids.

– Use the .WP version when installing outdoors.

– The inside Locking Cylinder thumb-turn features a protection

rating of IP40. This is why it is important to ensure that the inside

thumb-turn does not come into contact with water.

– Both knobs are freely rotating in anti-panic cylinders and can only

be engaged using an authorised ID medium.

Page 6

SimonsVoss

Manual

Digital Locking Cylinder 3061

– When used outdoors, the anti-panic cylinder is no longer

guaranteed to function at temperatures under - 20°C or over +

50°C.

– A functional test must be performed without fail after installing the

anti-panic cylinder or replacing its batteries.

– The WP variant must be installed when an anti-panic cylinder is

used outdoors.

– We reserve the right to make modifications or further technical

developments.

– This documentation has been compiled based on the best

knowledge available to us. However, errors cannot be ruled out.

No liability is accepted in such cases.

– Should there be differences in the content of other language

versions of this documentation, the German version applies in

cases of doubt.

– All instructions must be followed precisely during installation. The

person installing the system should hand these instructions as

well as any maintenance instructions over to the user.

– For security reasons, the locking system password must consist of

at least 8 characters. The code length for digital locking cylinders

in both System 3060/3061 and MobileKey) is 2

Instructions on battery

replacement

– Only trained specialists may replace the battery.

– Damage may be caused to the Locking Cylinder if you reverse the

polarity.

– Only use batteries which have been approved by SimonsVoss.

– The cylinder must always be operated with two batteries.

– Dispose of old and used batteries in the proper manner and store

them out of children's reach.

– Always replace both batteries when changing batteries.

– Do not touch the contacts on the new batteries with your hands

when replacing the old ones. Use clean gloves free of fat or

grease to handle the battery.

– When replacing the batteries, make sure that the electronics are

not subject to mechanical load and are not damaged in any other

way.

– Only use the SimonsVoss installation/battery key

(Z4.SCHLUESSEL) to replace the battery.

2 | Safety instructions

168

bit.

6 / 44

Page 7

SimonsVoss

Manual

Digital Locking Cylinder 3061

3 General information on System 3060

3.1 Product description

The SimonsVoss Digital Locking System 3060 is an electronic version of a

mechanical locking system with the functions of a typical access control

system.

Digital Locking Cylinder 3061 and the digital half cylinder are a main

component in the locking and access control system, where radio

communication replaces the mechanical authentication of a conventional

key.

This product description details both the locking cylinder and the half

cylinder. The design and operating mode of the two products are

comparable in many respects. Any differences between the two products

and different versions are pointed out in the corresponding sections.

'Locking cylinder' is taken to mean both 'locking cylinder' and 'half cylinder'

in this document unless explicitly stated otherwise or taken out of context.

Data are transmitted for authentication using a transponder (25kHz

inductive) or a smart card featuring the RFID standard MIFARE© Classic or

MIFARE© DESFire.

Refer to the respective manuals for details about smart card products (SC).

This description mentions the smart card cylinder, but does not describe it

in any detail.

The locking cylinder is supplied in different versions and meets different

profile standards, such as DIN 18252/EN1303, so that almost any lock

anywhere in the world can be retrofitted with this cylinder. Digital Locking

Cylinder 3061 has much to offer – greater security, greater flexibility, lower

costs, network-ready without any wiring on the door or frame and less time

and effort required for installation.

Digital Locking Cylinder 3061 is powered by two batteries in a redundant

system. Cylinders operate as stand-alone components thanks to this

integrated power supply, which also means there is no need to wire doors.

An intelligent battery warning system also increases reliability.

The SimonsVoss system elements are not configured before delivery from

the factory. They are first assigned to a locking system during initial

programming. This makes it easier for stock keeping and makes product

management simpler.

Thanks to modularity, all locking cylinders are seamlessly integrated into

the SimonsVoss System 3060 and, like all SimonsVoss components, they

can be programmed using the locking plan software. Other authentication

components, such as Pin Code Keypad 3068, Biometric Reader Q3008 or

Compact Reader 3078, can be connected as a wireless element. If the

system is extended at a later stage, cylinders can be networked without

wiring and managed in an online interconnected system.

3 | General information on System 3060

7 / 44

Page 8

SimonsVoss

Manual

Digital Locking Cylinder 3061

The locking cylinders are provided with two different firmware generations –

G1 and G2. G2 features a more efficient communication protocol than G1.

It will allow you to create larger, more efficient locking systems.

Authorisations are written both on the locking cylinder and the transponder,

thus delivering greater flexibility for programming. A G2 system can also

form a virtual network, i.e. authorisations and blocking lists are written on

the transponder and transmitted into the locking system. Refer to the G2

manual for more details.

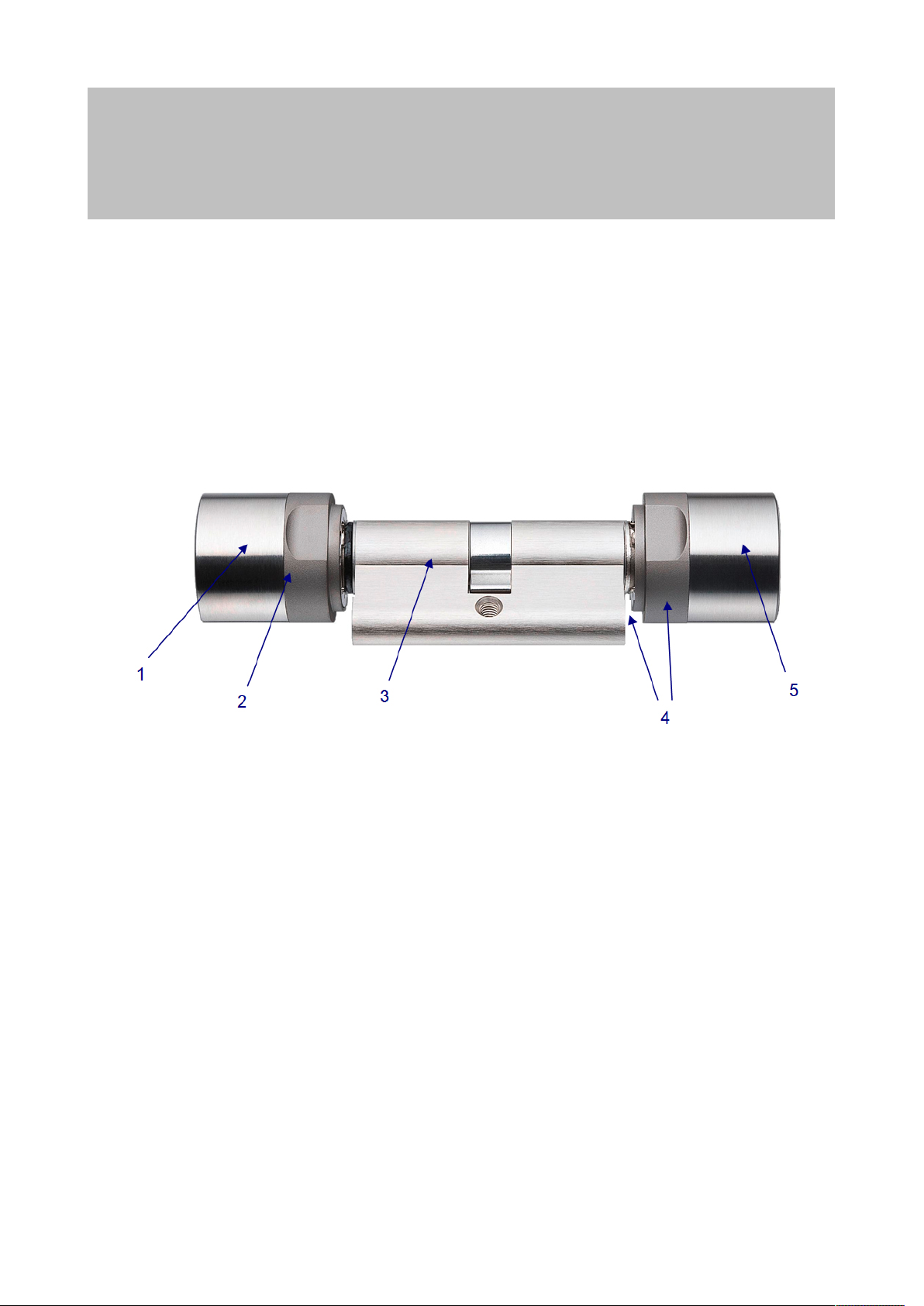

3.2 Locking cylinder design

3 | General information on System 3060

8 / 44

1. Inside thumb-turn

2. Batteries/electronics

3. Actuator

4. Drilling protection

5. Outer thumb-turn

Page 9

SimonsVoss

Manual

Digital Locking Cylinder 3061

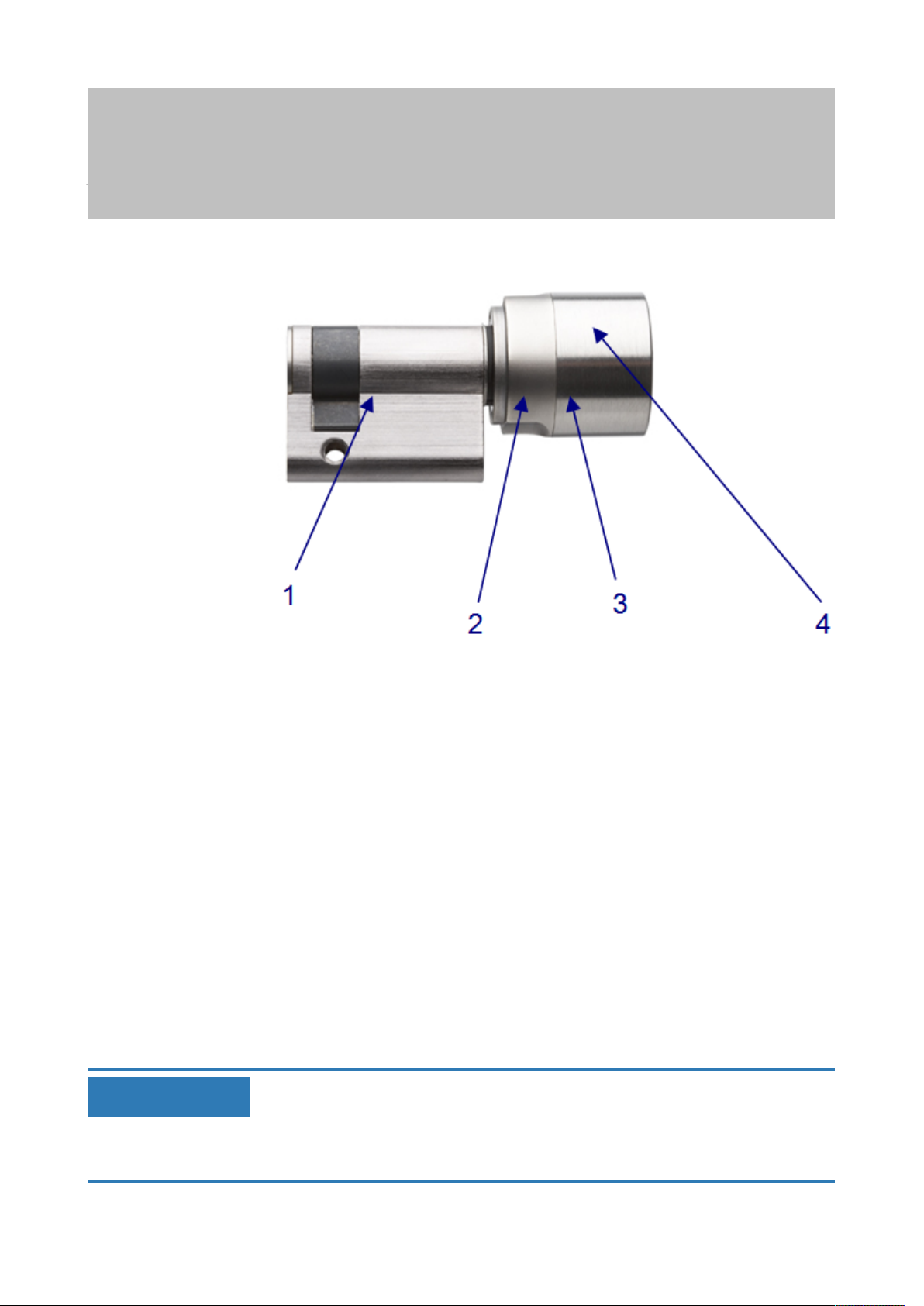

3.3 Half cylinder design

3 | General information on System 3060

9 / 44

1. Actuator

2. Electronics

3. Batteries

4. Thumb-turn

3.4 Opening and locking from the outside

With freely rotating

locking cylinders (FD)

NOTICE

If the user has an ID medium which is not authorised for use at that particular moment due to the time zone plan, a single audible signal will sound.

The cylinder will not engage, so the outer or inside thumb-turn continues to

rotate freely and the user cannot open the door. You need to configure this

response separately in third-party systems.

The outer and inside thumb-turn rotate freely when not activated in

the freely rotating Locking Cylinder, meaning it is not possible to open

or lock the door without a valid ID medium. Identify yourself with your

valid ID medium on the outer thumb-turn to activate the cylinder. If the

ID medium is authorised, an audible signal will sound twice, the blue

LED will flash twice and the locking cylinder will engage ready to

open. Turn the outer thumb-turn in the direction of locking or opening.

You have about five seconds to do so. The engage time can be

configured. A single audible signal will then sound and the outer or

inside thumb-turn will rotate freely again. Ensure that the outside or

inside locking cylinder thumb-turn rotates freely again after the

thumb-turn has been engaged ready for use.

Page 10

SimonsVoss

Manual

Digital Locking Cylinder 3061

3.5 Opening and locking from the inner side

3 | General information on System 3060

10 / 44

With freely rotating

locking cylinders (FD)

With non-freely

rotating locking

cylinders (FD)

The outer and inside thumb-turn rotate freely when not activated in

the freely rotating Locking Cylinder, Doors can also only be opened or

locked on the outside using an ID medium on the inside thumb-turn.

Locking Cylinders which are permanently engaged for use can be

operated from the inside without a ID medium. In this case, the door

can be opened and closed using the inside thumb-turn without an

authorised ID medium.

Page 11

SimonsVoss

Manual

Digital Locking Cylinder 3061

4 System 3060 designs

Different versions of the digital Locking Cylinder are offered to cover the

different needs of the market. The different versions are indicated by a

code. The different versions can be combined:

4 | System 3060 designs

11 / 44

ABBREVIATION DESIGNATION

FD

HZ Half cylinder X

Access control Access Control X X

FH

TS Button control X

MR Multi-point X X

MS Brass version X X

SKG

VDS

AP

CO Comfort cylinder X

WP Waterproof - WP X X

SW Seawater-proof X

WN

SC

VR Shortened range X

DK Detachable knob X

DM Door Monitoring X

Standard (freely

rotating)

Fire-retardant

version

Class AZ VdS

cylinder (basic

protection against

picking)

Class BZ VdS

cylinder (medium

protection against

picking)

Anti-panic

function

Network

integrated

SmartCard

version

LOCKING

CYLINDER

X

X

X

X

X

X X

X

HALF CYLINDER

Refer to the current product catalogue to see which particular versions can

be combined with one another. Locking cylinders are also supplied in

different profiles to satisfy differences in different regions:

PROFILE LOCKING CYLINDER HALF CYLINDER

Page 12

SimonsVoss

Manual

Digital Locking Cylinder 3061

Standard Euro profile

cylinder as per DIN

18252/EN1303

Scandinavian Oval X

British oval X

Swiss Round X X

Locking Cylinders are also offered in mortise and rim cylinder models for

American door profiles.

4.1 FD version (Standard)

Locking Cylinder freely rotating on both sides.

The .FD double thumb-turn cylinder is available from a length of 30-30 mm.

4 | System 3060 designs

X X

12 / 44

4.2 HZ version (Standard)

The standard version of the half cylinder.

4.3

4.4 ZK version

Design is similar to standard version but with access logging and time zone

control.

– Access event logging

The locking cylinder logs up to 3,072 of the most recent access events

with the date, time and transponder ID (TID). The data can be read via

the network using the programming device.

– Time zone control

TLocking Cylinder can be programmed in such a way that authorized

transponders are only authorized for access at specific times. For G1,

there are 5 (+1) time zone groups available per area (e.g. outer

perimeter) within the different time zone schedules while G2 has 100

(+1) such groups.

4.5 version for steel and fire retardant doors

Design is similar to standard version but for doors with sturdy metal

sections, such as fire doors, or doors with highly protective shielding. This

version is recommended in areas with high interference fields, such as

server rooms, and for all metal doors. The FH version cannot be retrofitted.

If wired networks are used, we recommend using this cylinder version due

to its reduced projection.

Before a locking cylinder is installed into a fire/smoke retardant door, the

fire certification has to be checked first to ensure that conformity is in place.

Page 13

SimonsVoss

Manual

Digital Locking Cylinder 3061

It must be ensured that any locking devices or sealing strips do not impede

the orderly operation of the MC.

4.6 TS version

Design as for standard version, but with the additional option of allowing the

cylinder to engage without an identification medium. This cylinder version

can be engaged mechanically with the aid of two buttons on the inside

thumb-turn. This means that no transponder is needed when the user is on

the internal. The cylinder will then engage for five seconds (configurable)

and the door can be opened or locked. Once this time interval expires, the

cylinder rotates freely again on both sides.

The .TS version cannot be retrofit.

4 | System 3060 designs

13 / 44

NOTICE

4.7 MR option

Design is similar to standard version but the locking cam features fixed

points where it positions itself when disengaged. This version is particularly

suitable for very smooth-running locks with multi-point locking systems.

Please observe the lock manufacturer's declaration of conformity when

combining multi-point locks with a panic function.

4.8 MS version

The Locking Cylinder can be supplied with stainless steel or brass colour

finish (highly glossy thumb-turn covers).

4.9 SKG or VdS versions (SZ)

The Locking Cylinder is also available in a VdS cylinder version as an

option. The additional mechanical security features ensure that VdS

Classes AZ and BZ or Class SKG*** are achieved. These versions cannot

be combined with the brass, WP and anti-panic models. The VdS cylinder

can only be supplied in combination with access control (ZK) functions.

The profile cylinder must be protected with a VdS-approved burglar-resistant door plate of class B or C. Such door plates conform to DIN 18257,

Class ES 2 or ES 3. The cylinder may not protrude more than 3 mm above

the door plate. The scope of burglary-resistant measures is based on the

respective national provisions.

This version is available as .MS, .FH and WN versions.

Page 14

SimonsVoss

Manual

Digital Locking Cylinder 3061

4.10 AP version

A cylinder with an anti-panic function must be fitted to all doors where the

lock's panic function may be adversely affected by the position of the cam.

This version contains an integrated spring mechanism which places the

locking cam in a non-critical position, meaning a panic lock's panic function

cannot be blocked.

In contrast to all other cylinders, the .AP type cylinder is fitted the other way

round with the thumb-turn containing the battery and the electronics module

installed on the outside (see diagram).

Unlike the standard anti-panic cylinder (AP), the inside thumb-turn of which

is permanently engaged, the inside thumb-turn for the freely-rotating AP

version (AP.FD) is disengaged mechanically and cannot be engaged with

an identification medium.

4 | System 3060 designs

14 / 44

1. Inside thumb-turn

2. Recessed grip ring

3. Battery replacement key

4. Outside thumb-turn

Page 15

SimonsVoss

Manual

Digital Locking Cylinder 3061

The following aspects should be taken into consideration for doors along

rescue routes which have been installed after April 1, 2003 (exit devices as

per DIN EN 179 or DIN EN 1125): All Locking Cylinder models may be

used for all exit devices where their approval states that the Locking

Cylinder has no impact on the lock's function. The Locking Cylinder

type .AP (anti-panic cylinder) must be used for all exit devices where the

Locking Cylinder cam position affects the lock's function. This must be

stated in the lock manufacturer's approval.

4 | System 3060 designs

15 / 44

DANGER

4.11 AP2 Version

DANGER

Due to the structural design of panic locks, it is not permitted to turn the

Locking Cylinder thumb-turn to the stop position when the door is locked

since this may affect the lock's panic function.

A cylinder with an anti-panic function must be fitted to all doors where the

locking device's panic function may be adversely affected by the position of

the cam. This version contains an integrated spring mechanism which

places the locking cam in a non-critical position, meaning a panic locking

device's panic function cannot be blocked.

You install this version in the same way as a normal Locking Cylinder.

The following aspects should be taken into consideration for doors along

rescue routes which have been installed after April 1, 2003 (exit devices as

per DIN EN 179 or DIN EN 1125): All Locking Cylinder models may be

used for all exit devices where their approval states that the Locking

Cylinder has no impact on the locking device's function. The Locking

Cylinder type .AP2 (anti-panic cylinder) must be used for all exit devices

where the Locking Cylinder cam position affects the locking device's

function. This must be stated in the lock manufacturer's approval.

Due to the structural design of panic locks, it is not permitted to turn the

Locking Cylinder thumb-turn to the stop position when the door is locked

since this may affect the locking device's panic function.

4.12 CO version

In the comfort cylinder (CO), the inside knob is permanently interconnected

with the locking cam, so that doors can be opened and locked from the

inside without needing to use a transponder.

4.13 WP Version (FD)

The protection rating is increased from IP54 to IP66 in the WP version

(weatherproof) of the Locking Cylinder. This version is thus suitable for use

outdoors or on external doors even if the cylinder is not exposed to direct

splash water.

Page 16

SimonsVoss

Manual

Digital Locking Cylinder 3061

Anti-panic cylinder: The WP version is specifically designed for outdoor

areas and should be fitted if the outer thumb-turn comes into contact with

water (e.g. rainwater). The WP version features greater resistance to water,

meaning the cam should not come into contact with water.

This version is available from a length of 30-35 mm and as .FD, .ZK, .MS

and .FH models.

4.14 WP version (HZ/CO/AP)

The electronic thumb-turn is sealed in the WP version of the half, comfort

and anti-panic cylinders, thus providing an increased protection rating of

IP66. This version is thus suitable when the electronics side is outdoors, i.e.

the electronic thumb-turn is exposed to rain, for example. Water must not

enter through the door.

4 | System 3060 designs

16 / 44

4.15 SW version (CO)

The SW (seawater) version of the comfort cylinder has been specially

developed for use on ships or for direct use on the sea. A special, polished

V4A knob and a coated handle component are used on the outside.

4.16 VR version (HZ)

This version features a shortened operating range. It is suitable for use in

items such as locker doors and mail box systems when the distance to the

next door is less than 40 cm.

4.17 DK version (HZ)

The knob can be detached and is ideal for installation behind cover plates

on key switches, for example.

4.18 WN version (HZ)

The WN version is fitted with a network flap (LockNode Inside). This

network cap enables the lock to be networked directly (networked

connection between lock and the LSM).

This version is available for all models.

The network cover can be fitted to locking cylinder types manufactured

after May 2008. This allows such cylinders to be retrofit with a network

connection without a great deal of installation work.

4.19 DM version

The Door Monitoring Cylinder allows the Locking Cylinder to transmit door

events to LSM in real time.

Page 17

SimonsVoss

Manual

Digital Locking Cylinder 3061

4.20 Hybrid-Version

With the hybrid version of the digital locking cylinder, active identification

media (e.g., transponders) and passive identification media (e.g., MIFARE

or DESFire cards) can be used.

4.21 Extra lengths

All double knob cylinders are available with an overall length of up to 140

mm or a maximum of 90 mm on one side. Longer lengths can be supplied

on request. All half cylinders are available with an overall length of up to

100 mm or a maximum of 90 mm on the outside. Longer lengths can be

supplied on request.

4 | System 3060 designs

17 / 44

4.22 Examples of locking cylinder use

FD (ZK) FH (ZK) TS (ZK) AP (ZK)

Entrance doors Fire doors

Apartment

entrance doors

Office doors

Connecting doors

Self-locking doors

*Comply with EN 179 and EN 1125 requirements and the lock

manufacturer's data sheets.

The different versions can be combined as you wish. Exceptions are

indicated in the individual model descriptions.

Aluminium doors Office doors Emergency exits*

Apartment

entrance doors

Anti-panic doors*

Page 18

SimonsVoss

Manual

Digital Locking Cylinder 3061

5 Installation instructions

5.1 General instructions

When installing the digital Locking Cylinder, ensure that there are no

sources of low-frequency radio interference in the surrounding area.

The profile cylinder housing should be fitted flush in outside areas; it should

project a maximum of 3 mm and a profile cylinder escutcheon or security

fitting should be installed if necessary. It is also important to ensure that no

water is able to penetrate the cylinder via the cam section.

You must not strike the thumb-turns when installing the cylinder.

All thumb-turns are locked into place with a bayonet mount (exception: antipanic inside knob and SKG/VdS outside knob).

The inner side of the Locking Cylinder is laser-engraved with (the letters IL

for inside length) on the profile cylinder housing; the electronics side is

identifiable by the black plastic ring between the thumb-turn and the profile

cylinder housing.

Batteries are already installed before delivery.

All the tasks listed in this section can also be carried out using the

installation/battery key.

5 | Installation instructions

18 / 44

5.2 Programming the locking cylinder

Both the digital Locking Cylinder and the associated transponder must be

programmed before installation. You can find more detailed information in

the software operation instructions.

Page 19

SimonsVoss

Manual

Digital Locking Cylinder 3061

5.3 Installation variants

5.3.1 Installation of double thumb-turn cylinders (except types .AP/.SKG/.VdS)

5 | Installation instructions

19 / 44

NOTICE

1. Installation key

2. Side marking

3. Recessed grip ring

4. Inside thumb-turn

5. Battery replacement key

6. Locking disc with opening (identical on outside)

7. Outer thumb-turn

5.3.1.1 Removing the outer thumb-turn

Place the installation key on the outer thumb-turn in such a way that its two

teeth engage into the outer thumb-turn; if necessary, turn the thumb-turn

until both teeth lock into the locking disc.

The installation tool must be placed flat on the internal front surface of the

thumb-turn to ensure that the tool can lock into the locking disc.

Hold the outer thumb-turn firmly and carefully turn the installation tool about

30° in a clockwise direction (until you hear a click). Remove the thumb-turn.

Page 20

SimonsVoss

Manual

Digital Locking Cylinder 3061

5.3.1.2 Fastening the digital cylinder into the locking device

Turn the cam until it is vertical and pointing downwards. Insert the digital

locking cylinder through the locking device in such a way that the inside

thumb-turn (see diagram above) is facing the inner side of the door. Fasten

the cylinder into the mortise lock with the fastening screw.

5 | Installation instructions

20 / 44

NOTICE

NOTICE

You must not strike the thumb-turns when installing the cylinder. Do not allow the cylinder to come into contact with oil, grease, paint or acids.

5.3.1.3 Fastening the outer thumb-turn

Replace the thumb-turn and turn in an anti-clockwise direction while

applying slight pressure until the outer thumb-turn grips into the indents in

the flange. Possibly place the thumb-turn in this position by pressing it

towards the profile cylinder housing.

Turning the bayonet disc when not installed may prevent the thumb-turn

from being fastened into position. In such a case, push the disc back into

the original 'bayonet disc open' position using the installation tool. (see diagrams)

1. Bayonet disc

2. Thumb-turn

3. Bayonet disc closed

4. Bayonet disc open

Page 21

SimonsVoss

Manual

Digital Locking Cylinder 3061

Place the installation key on the outer thumb-turn in such a way that its two

teeth engage into the outer thumb-turn (if necessary, turn the thumb-turn

until both teeth lock into the locking disc). Lock the thumb-turn into position

again by rotating it 30° in a clockwise direction.

5.3.1.4 Carry out a functional test

1. Engage cylinder using a valid ID medium and turn the thumb-turn in

both the locking and opening direction with the door open. The thumbturn must be able to rotate easily when you do so.

2. Close the door and repeat the process. If the locking cylinder should be

stiff, you need to align the door or modify the strike plate.

5.3.2 Fitting an anti-panic cylinder

5 | Installation instructions

21 / 44

1. Inside thumb-turn

2. Recessed grip ring

3. Battery replacement key

4. Outside thumb-turn

Page 22

SimonsVoss

Manual

Digital Locking Cylinder 3061

The locking cam is always in a pre-defined position in the AP cylinder when

disengaged. This prevents accidental blocking. Unlike other cylinder

versions, the AP cylinder is installed the other way round (inserted into the

lock from the inside to the outside).

5.3.2.1 Removing the inside thumb-turn

Loosen the inside thumb-turn's threaded pin (see diagram above) using an

Allen key. Do not unscrew completely. Hold the cam firmly and then turn

the inside thumb-turn anti-clockwise or, in the case of a freely rotating AP

cylinder, remove the thumb-turn after loosening the threaded pin.

5.3.2.2 Fastening the digital cylinder into the locking device

Turn the cam until it is vertical and pointing downwards. Insert the digital

locking cylinder through the locking device from the outside in such a way

that the outer thumb-turn is facing the outer side of the door. Fasten the

cylinder into the mortise lock with the fastening screw.

5 | Installation instructions

22 / 44

NOTICE

You must not strike the thumb-turns when installing the cylinder. Do not allow the cylinder to come into contact with oil, paint or acids.

5.3.2.3 Fastening the inside thumb-turn

Screw the inside thumb-turn onto the thread until it locks into place as it

comes up against the cam. Pull on the inside thumb-turn, or push on the

inside thumb-turn of a freely rotating AP cylinder, until it locks into position.

Fasten the threaded pin tightly using the Allen key.

5.3.2.4 Functional test

– To verify that the AP2 cylinder functions correctly in an anti-panic lock,

you must check that the cam moves easily and that the door opens

correctly using the procedure described below.

– Carry out the functional test in the direction of escape.

– You must carry out a functional test whenever the cylinder or the

fastening screw is repositioned.

– You will need an authorised identification medium to carry out the

functional test.

– Withdraw the dead bolt before the functional test.

Page 23

SimonsVoss

Manual

Digital Locking Cylinder 3061

5 | Installation instructions

23 / 44

U section: No restore force on the cam

R section: Restore force section towards U section

O section:

OG: Top threshold section

UG: Lower threshold section

1: Thumb-turn

2: Cam position (concealed)

1. With the cylinder engaged, first turn the thumb-turn in the direction of

locking as far as the deadbolt throw in the 'R' section.

ð You will feel the restore force. When you release the thumb-turn in

this position, it must turn back to the 'U' section of its own accord.

2. Lock the locking device and check the restore force. To do so, turn the

engaged thumb-turn in the direction of locking through the 'R' section

and into the 'O' section.

ð The dead bolt extends. There is no restore force in the 'O' section.

3. Move the thumb-turn slightly over the threshold between the 'O' and

'R' section in the same direction of rotation.

ð The dead bolt will extend. The restore force must turn the thumb-

turn automatically from this point as far as the 'U' section if it is

released.

ð If the thumb-turn does not automatically rotate as far as the 'U'

section, either the fastening screw has been tightened too firmly or

the locking device has been aligned incorrectly. The test is to be

repeated after the fault has been eliminated. A fastening screw

which has been tightened too firmly acts as a brake on the restoring

force mechanism.

Top dead point in deadbolt throw - no restore force on

the cam

Page 24

SimonsVoss

Manual

Digital Locking Cylinder 3061

4. Lock the door and check that the locking device functions correctly by

pressing the door fitting or panic bar in the direction of escape.

ð The dead bolt must spring back and it must be possible to open the

door easily.

ð If the dead bolt does not draw back when the handle is turned or the

door fitting catches, either the locking cylinder or the locking device

is incorrectly aligned or defective. The test is to be repeated after the

fault has been eliminated as described above.

If you cannot ensure that the locking device will function correctly after the

functional test, please contact the SimonsVoss hotline.

5.3.3 Installation of SKG/VdS cylinders

Loosen the outside knob's threaded pin using an Allen key. Do not unscrew

completely. Hold the inside knob firmly and then turn the outside knob anticlockwise.

Turn the cam until it is vertical and pointing downwards. Insert the digital

locking cylinder through the lock from the inner side. Fasten the cylinder

into the mortise lock with the fastening screw. Then screw the outside knob

back into position on the cylinder and tighten the threaded pin.

5 | Installation instructions

24 / 44

NOTICE

5.3.3.1 Installation of core extraction protection adapters (Z4.KA.SET)

The core extraction protection adapter (Z4.KA.SET) is compatible with all

SKG/VdS cylinders manufactured up to 2010 and all .FD cylinders.

Instructions:

1. Disassemble the non-electronic knob.

2. Remove the rubber seal on the tip of the outside tube.

3. Place the core extraction protection adapter on the outside tube and

turn while applying a little pressure, so that it grips into the indents on

the flange (in a similar way to the knob when installed). The openings

in the adapter and the outside tube web must align.

4. Insert the supplied screw through the lock and tighten carefully.

5. Replace the knob and turn in an anti-clockwise direction while applying

slight pressure until the outer knob grips into the indents in the flange.

Possibly place the knob in this position by pressing it gently towards

the profile cylinder housing.

Turning the bayonet disc when not installed may prevent the thumb-turn

from being fastened into position. In such a case, push the disc back into

the original 'bayonet disc open' position using the installation tool.

Page 25

SimonsVoss

Manual

Digital Locking Cylinder 3061

6. Place the installation key on the outside thumb-turn in such a way that

its two teeth engage into the outside thumb-turn (if necessary, turn the

thumb-turn until both teeth lock into the locking disc). Lock the thumbturn into position again by rotating it 30° in a clockwise direction.

5.3.3.2 Installation of core extraction protection adapters (Z4.KA.SET2)

The core extraction protection adapter (Z4.KA.SET2) is compatible with all

SKG/VdS cylinders manufactured from 2011 onwards.

Instructions:

1. Disassemble the non-electronic knob.

2. Then screw the core extraction protection adapter into position on the

cylinder and lock into place using the threaded pins.

3. Install the non-electronic knob on the core extraction protection

adapter.

An elongated version of the adapter is available for the Italian market.

(Z4.KA.SET2.IT).

5 | Installation instructions

25 / 44

5.3.4 Half Cylinder DK/MR

The thumb-turn, including the inside tube, can be removed from the

cylinder housing to install the DK and MR versions. The procedure is

described below. It is only necessary for key switches, for example, if the

half cylinder cannot be installed using the fastening screw.

5.3.4.1 Disassembly

Page 26

SimonsVoss

Manual

Digital Locking Cylinder 3061

If you need to disassemble the half cylinder, please proceed as follows:

1. Using a tool such as a screwdriver, grip into the two slots in the plastic

disc between the thumb-turn and the profile cylinder housing and turn

the tool while applying a little pressure. This breaks the disc.

2. Remove the remains of the plastic disc.

3. Engage the half cylinder using an authorised ID medium.

4. While the thumb-turn is engaged, turn it anti-clockwise until it will turn

no more (e.g. towards the lock when installed or holding the cam with

your hand when not installed; see Step A in the diagram).

5. Press thumb-turn towards profile cylinder housing until it stops (you

will hear it click. If necessary, move thumb-turn backwards and

forwards several times until you hear a click; see Step B and D in the

diagram).

6. If needed, engage the half cylinder once more using an authorised ID

medium.

7. While the thumb-turn is engaged, turn it anti-clockwise and apply

pressure against the stop position (see Step B and D in the diagram).

8. While applying pressure, pull the thumb-turn (including inside tube)

from the profile cylinder (see Step D in the diagram).

5 | Installation instructions

26 / 44

NOTICE

NOTICE

NOTICE

You must not strike the thumb-turn during installation. Do not allow the cylinder to come into contact with oil, paint or acids.

5.3.4.2 Installation

1. Remove the metal discs on the inside tube and push a plastic disc

onto it instead. You will find the plastic disc in the supplied package.

2. Push the removed metal discs onto the inside tube, so that a plastic

disc and a varying number of metal discs, depending on the half

cylinder type, are on the inner tube.

3. Push the inner tube thumb-turn into the profile cylinder housing until it

stops.

4. Engage cylinder using an authorised ID medium.

5. While the thumb-turn is engaged, press it gently against the profile

cylinder housing while turning clockwise at the same time until the

inside tube clicks into place in the profile cylinder housing.

Check that it has locked into position correctly by pulling the thumb-turn

gently while turning it backwards and forwards.

You will find the required plastic discs in the supplied package.

Page 27

SimonsVoss

Manual

Digital Locking Cylinder 3061

When installing, ensure that only one plastic disc and the same number of

metal discs are on the inner tube as when you took it apart. The plastic disc

must be placed directly on the thumb-turn.

5.3.4.3 Functions test

1. Engage half cylinder using a valid ID medium and turn the thumb-turn

in the locking and opening direction with the door open. The thumbturn must be able to rotate easily when you do so.

2. Close the door and repeat the process. If the half cylinder should be

stiff, you need to align the door or modify the strike plate.

This generally also applies when installing the cylinder in a key switch, for

example.

5 | Installation instructions

27 / 44

5.3.5 Installing Swiss Round

Both cylinders and a fitting need to be removed from doors when installing

a Swiss round cylinder.

The inside thumb-turn is removed and re-fitted in the same way as Half

Cylinder DK / MR.

The outside knob is removed and re-fitted in the same way as the outside

knob on a VdS cylinder.

1. Disassemble inside thumb-turn and outside thumb-turn. Remove a

fitting from the door.

2. Push cylinder into the profile and fasten with the fastening screw.

3. Fit inside thumb-turn and outside thumb-turn. Mount fitting again.

Page 28

SimonsVoss

Manual

Digital Locking Cylinder 3061

6 System 3060 audible signals

The Locking Cylinder emits an audible signal to indicate its status and an

authorisation. The table below lists what the audible signals mean.

2 short audible signals

before engaging and a

short tone after

disengaging.

1 short audible signal:

cylinder does not

engage.

Battery Warning Level

1: 8 short audible

signals before engaging.

Battery Warning Level

2: 8 short audible

signals 30 seconds long

with one second pause

each time before

engaging.

Freeze mode (G2 only):

6 audible signals (long –

pause – short).

8 short audible signals

after disengaging.

6 | System 3060 audible signals

Normal activation None

Attempted entry with a

transponder listed in the

locking system, but:

– used outside time

zone.

– Activated alarm

system while using

the SimonsVoss

Block Lock.

Batteries are low.

Batteries are almost

completely empty.

Battery empty. Cylinder

can no longer be

opened using an

authorised transponder.

Cylinder can only be

engaged using a battery

replacement

transponder.

Transponder battery is

low.

None

Replace batteries in the

cylinder.

Replace batteries in the

cylinder immediately.

Replace batteries and

reset with a battery

replacement

transponder.

Have transponder

battery replaced.

28 / 44

6.1 Battery warnings

A battery management system has been implemented in locking cylinders

and transponders which warns the user in good time that the battery

capacity is diminished. This prevents the batteries from becoming fully

discharged. The individual battery warning levels are described below.

The locking cylinder batteries feature a redundant system. If one of the

batteries fails or its capacity falls below a certain level, the system emits a

battery warning.

Page 29

SimonsVoss

Manual

Digital Locking Cylinder 3061

The battery warning levels between G1 and G2 differ after Battery Warning

Level 2 if the battery capacity falls under the emergency battery warning

threshold values.

– Warning Level 1: Low batteries

If the charged capacity falls below 25% in one of the batteries, Battery

Warning Level 1 is activated. After you activate the transponder, you will

hear eight brief audible signals in rapid succession before the cylinder

engages. You must replace the batteries.

– Warning Level 2: Extremely low batteries

If the locking cylinder batteries discharge even further, short audible

signals are heard in rapid succession for about 30 seconds before the

cylinder engages after the transponder is activated. The cylinder does

not engage until the audible signals have finished. The batteries should

be replaced as quickly as possible.

If this warning level is ignored, the locking cylinder switches to what is

known as storage or freeze mode.

– Emergency battery – Storage mode (G1 cylinders):

In storage mode, the cylinder can only be opened with the aid of a

programming device (Smart CD).

– Emergency battery – Freeze mode (G2 cylinders):

In freeze mode, an audible signal will sound if an attempt is made to

open using an authorised transponder (Section ), but the cylinder will

not engage.

The G2 cylinder can now only be opened using a battery replacement

transponder or programming device.

– Active locking devices: The system administrator can use a G2

battery replacement transponder (freeze mode transponder) for

about 30 seconds to eliminate freeze mode and open the door with

a user transponder to replace the batteries.

– SmartCard locking devices: The system administrator can use a G2

battery replacement transponder (freeze mode transponder) to

permanently eliminate freeze mode (including warning levels) and

open the door with a user transponder to replace the batteries.

6 | System 3060 audible signals

29 / 44

NOTICE

After using the "2 battery replacement transponder"on SC locks, you must

change the batteries immediately; if not, the batteries may discharge completely without any further warnings.

Active cylinder:

WARNING

LEVEL 1

8 short audible

signals before

engaging

WARNING

LEVEL 2

30 seconds long

with one second

pause each time

before engaging

FREEZE MODE

6 audible signals

(long – pause –

short)

Page 30

SimonsVoss

Manual

Digital Locking Cylinder 3061

6 | System 3060 audible signals

30 / 44

Battery change:

activate with

battery

replacement

transponder

6 audible signals

(long – pause –

short)

LED flashes red

once and blue

once

Battery change:

activate with

battery

replacement

transponder

Cylinder SC

(transponder

use):

Cylinder SC

(SmartCard use):

Up to 15,000

access events or

up to 9 months on

standby

8 short audible

signals before

engaging

LED flashes red

briefly 8 times

before engaging

Up to 300 access

events or up to 30

days

Up to 50 access

events or up to 30

days

30 seconds long

with one second

pause each time

before engaging

LED flashes red

briefly twice for 30

seconds before

engaging

Up to 200 access

events or up to 20

days

6.2 Battery warning for transponders

When the transponder battery is low, short audible signals are heard in

rapid succession on the locking cylinder (not the transponder) after the

locking cylinder disengages each time the transponder is used.

Page 31

SimonsVoss

Manual

Digital Locking Cylinder 3061

7 System 3060 battery replacement

7.1 General instructions

Only trained personnel may replace the batteries.

You must wear clean gloves made of cloth and free of fat or grease when

replacing the batteries to prevent the batteries being contaminated by

fingerprints. Fingerprints on batteries may reduce battery life considerably.

Only use batteries which have been approved by SimonsVoss.

7 | System 3060 battery replacement

31 / 44

NOTICE

NOTICE

You may cause damage to the Locking Cylinder if you reverse the polarity.

The batteries used in this device may pose a fire or burn hazard if handled

incorrectly. Do not recharge, open or burn batteries, or heat them to over

100° C.

Dispose of lithium batteries properly immediately after they have discharged. Store them out of children's reach; do not open and do not throw

into a fire. Always replace both batteries when changing batteries. Please

note safety instructions.

The locking cylinder retains its status, programming and saved protocols

even without power supply.

7.2 Battery life

Battery life is different for each locking cylinder version as power

consumption varies when the cylinder is activated or a data connection is

established.

VERSION BATTERY LIFE

Standard cylinder

and versions

WN (LNI /

LockNode)

Up to 10 years Up to 300,000 2

Up to 5 years Up to 150,000 2

NUMBER OF

ACTIVATIONS

NUMBER OF

BATTERIES

The specified battery life is for guidance only. A battery warning is not

emitted when the aforementioned battery life expires, but is based on the

measured battery status instead.

7.3 Emergency battery procedure

As stated above, a locking cylinder changes to storage mode (G1) or freeze

mode (G2) if Battery Warning Level 2 is ignored. A different procedure is

used each for G1 and G2 to eliminate this mode.

Page 32

SimonsVoss

Manual

Digital Locking Cylinder 3061

7.3.1 Storage mode (G1)

If the locking cylinder is in emergency battery storage mode, proceed as

follows to open the door to change the battery and reset the cylinder.

1. Take notebook or PDA (import locking plan beforehand) and

programming device to the door in question.

2. Select the corresponding lock from the locking plan.

3. Re-programme locking cylinder without making any modifications. This

eliminates the battery warning and storage mode.

4. Engage the locking cylinder using an authorised transponder and open

the door. The cylinder will immediately revert to storage mode, as both

batteries are almost empty.

5. Renew batteries (see below).

6. Re-programme locking cylinder without making any modifications. This

eliminates the battery warning check marks and storage mode.

7. Engage the locking cylinder using an authorised transponder.

After battery replacement, the locking cylinder signals Warning Level 2

again. The locking cylinder's electronics then detect that the batteries are

fully charged or have been replaced and the cylinder is available for normal

use again.

7 | System 3060 battery replacement

32 / 44

NOTICE

7.3.2 Freeze mode (G2)

Emergency opening of the door and elimination of emergency retention

mode in G2 is easier than G1 generation systems.

1. Programme the G2 battery replacement transponder if necessary.

2. Deactivate freeze mode using the G2 battery replacement

transponder.

3. Use an authorised transponder to engage the locking cylinder and

open the door.

4. Replace the battery.

5. Deactivate freeze mode using the G2 battery replacement

transponder.

6. Perform an opening transaction on the locking cylinder with an

authorised transponder to test that it is functioning and eliminate

freeze mode.

Only use the G2 battery replacement transponder to deactivate freeze

mode and then immediately replace the cylinder batteries. Misuse may lead

to complete battery discharge and, consequently, a complete failure of the

cylinder.

Page 33

SimonsVoss

Manual

Digital Locking Cylinder 3061

7.4 Procedure

1. Place the installation/battery key on the inside thumb-turn in such a

way that the two teeth lock into the openings in the locking disc; if

necessary, turn the thumb-turn until both teeth engage into the locking

disc.

7 | System 3060 battery replacement

33 / 44

NOTICE

The tool must be placed flat on the inside front surface of the recessed grip

ring to ensure that the installation/battery key can engage into the locking

disc.

2. Hold the inside thumb-turn firmly and carefully turn the installation/

battery key about 30° in a clockwise direction (until you hear a click).

3. Remove installation/battery key from the thumb-turn.

4. Push recessed grip ring backwards towards the door, so that it comes

away from the thumb-turn.

5. Hold recessed grip ring firmly and turn thumb-turn about 10° in an anticlockwise direction and remove.

6. For MH cylinders only: Carefully fold antenna upwards.

7. Carefully remove both batteries from the holder.

8. Insert the new batteries into the holder at the same time with the

positive poles next to each other; change the batteries as quickly as

possible. Use clean gloves free of fat or grease to handle new

batteries.

Page 34

SimonsVoss

Manual

Digital Locking Cylinder 3061

7 | System 3060 battery replacement

34 / 44

9. For MH cylinders only: Lock antenna back into place.

10. Replace the thumb-turn (align the triangle mark as in the diagram),

hold the recessed grip ring firmly and fasten the inside thumb-turn by

turning in a clockwise direction (about 10°). (Diagram may differ

slightly from the purchased product)

11. Push recessed grip ring back onto the thumb-turn, so that the thumbturn and ring close together in a flush fit.

12. Place the installation/battery key on the inside thumb-turn in such a

way that the two teeth lock into the openings in the locking disc; if

necessary, turn the thumb-turn until both teeth engage into the locking

disc.

13. Close the thumb-turn again by turning it about 30° in a clockwise

direction (until you hear a click).

Then activate an authorised ID medium and check that it functions.

7.5 Procedure for outer thumb turn (MH cylinder)

4 batteries are built into the MH cylinder: 2 in the inside thumb-turn, 2 in the

outer thumb-turn.

Proceed as follows to replace the two batteries:

Page 35

SimonsVoss

Manual

Digital Locking Cylinder 3061

1. Use the battery replacement key to detach the outer thumb-turn. To do

so, face the outer thumb-turn and place the battery replacement key

on the bayonet mount and turn in a clockwise direction until you can

remove the thumb-turn easily.

ð The outer thumb-turn is now fully detached.

2. Place the battery replacement key on the detached thumb-turn again

and open the bayonet mount completely ( turn in an anti-clockwise

direction as you face the mount). You may be able to skip this step.

ð The lid springs open by itself as the bayonet mount is unscrewed.

3. Carefully lift off the lid.

ð The lid is attached to the thumb-turn with a small securing strap and

a ribbon cable; the batteries are now exposed.

4. Insert new batteries in such a way that the two plus poles lie flat on

one another and then position in the thumb-turn.

7 | System 3060 battery replacement

35 / 44

NOTICE

NOTICE

You should always replace both batteries with new ones when changing

the batteries.

You must place the ribbon cable loop crossways directly under the thumbturn lid.

5. Reattach lid to the outer thumb-turn and press gently.

ð The lid is now flush against the outer thumb-turn.

6. Use the battery replacement key to lock the bayonet mount to a

minimum extent until the lid locks into the outer lid of its own accord.

(about 1° in a clockwise direction)

7. Re-attach outer thumb-turn onto the locking cylinder.

ð The outer thumb-turn is now flush against the locking cylinder.

8. Now use the battery replacement key to lock the bayonet mount

completely. To do so, face the outer thumb-turn and place the battery

replacement key on the bayonet mount and turn in an anti-clockwise

direction until the thumb-turn is firmly in position.

9. Check that the outer thumb-turn is firmly attached again and test the

locking cylinder function to ensure that it works.

Page 36

SimonsVoss

Manual

Digital Locking Cylinder 3061

8 Maintenance, cleaning and disinfection

8 | Maintenance, cleaning and disinfection

36 / 44

NOTICE

NOTICE

NOTICE

Digital locking cylinders MUST not come into contact with oil, grease, paint

or acids.

The use of unsuitable or aggressive disinfectants can damage the locking

cylinder.

Clean the locking cylinder if necessary with a soft, moist cloth.

Only use disinfectants explicitly suitable for the disinfection of sensitive

metal surfaces and plastic.

HZ.SL:it is recommended to grease the latching edge on the electrical enclosure lever handle.

Empty batteries always must be replaced by new ones approved for use by

SimonsVoss. Dispose of old batteries in the proper manner.

Carry out a new functional test after changing the batteries in anti-panic

cylinders.

Page 37

SimonsVoss

Manual

Digital Locking Cylinder 3061

9 Areas of use

9.1 General

The digital locking cylinder is compatible with locks for Euro profile cylinder

as per DIN 18252 and EN1303.

9.2 Fire doors

As a general rule, this cylinder can be fitted into fire doors. However, you

must check that it is actually approved for use in fire doors.

9.3 Doors along rescue routes

9 | Areas of use

37 / 44

Type .AP should be installed for use in doors with an anti-panic function in

which the position of the cam may have an effect on the lock's functioning.

This must be specified in the lock manufacturer's approval. Also see

industrial standards EN 179 and EN 1125 and the individual lock

manufacturers' data sheets.

9.4 Installation outdoors

If you are unable to ensure that no water will come through the door, we

recommend using the respective .WP versions. The outer thumb-turn is

completely sealed in the anti-panic cylinder model and the whole cylinder is

sealed in the double thumb-turn cylinder variant.

Page 38

SimonsVoss

Manual

Digital Locking Cylinder 3061

10 Accessories

10.1 Thumb-turns

The following special thumb-turns are available as accessories:

– Outer thumb-turn in a TN4 design

– Outer thumb-turn, 42 mm in diameter with recessed grips

– Inside thumb-turn, 36 mm in diameter for a .TS cylinder

– Outer thumb-turn, shortened

– Brass thumb-turn, matt (inside and outer thumb-turn)

These thumb-turns can replace the original locking cylinder thumb-turns at

any time. See Installation instructions or Battery replacement for thumb-turn

installation.

10 | Accessories

38 / 44

10.2 Core extraction protection adapter (Z4.KA.SET)

This adapter is compatible with all SKG/VdS cylinders manufactured up to

2010 and all .FD cylinders.

There is a mechanical extension for core extraction protection fittings as the

profile cylinder profile is not cut out of these fittings. The extension is 8 mm

long and can be retrofitted at any time.

10.3 Core extraction protection extension for SKG/VdS cylinders (Z4.KA.SET2)

This adapter is compatible with all SKG/VdS cylinders manufactured in

2011 and onwards.

There is a mechanical extension for core extraction protection fittings as the

profile cylinder profile is not cut out of these fittings. The extension is 8 mm

long and can be retrofitted at any time.

10.4 Core extraction protection extension for SKG/VdS cylinders (Z4.KA.SET2.IT)

This adapter is compatible with all SKG/VdS cylinders manufactured in

2011 and onwards.

There is a mechanical extension for core extraction protection fittings as the

profile cylinder profile is not cut out of these fittings. The extension length is

16 mm for special Italian escutcheons and can be retrofitted at any time.

10.5 Tool

In addition to the installation tool, a battery replacement key is also included

in the supply package. You can use this tool to install or remove outer

thumb-turns and replace batteries.

Page 39

SimonsVoss

Manual

Digital Locking Cylinder 3061

10.6 Battery set

A new set of batteries can be ordered, which contains ten CR2450

batteries. Only ever use batteries approved by SimonsVoss.

10 | Accessories

39 / 44

Page 40

SimonsVoss

Manual

Digital Locking Cylinder 3061

11 Data sheets

11.1 Locking cylinder

11 | Data sheets

40 / 44

Profile cylinder

Batteries

Ambient conditions

Features

Basic length:

Installation lengths in 5mm increments, overall length up to 140 mm

(max. 90mm on one side); special lengths on request.

Type: CR, 2450, 3V

Manufacturer: Sony, Panasonic, Varta

Quantity: 2 units

Battery life:

Operating temperature: -25°C to +65°C

Storage temperature: -35°C to +65°C

Protection class:

Air humidity: <95%: non-condensing

– 3,000 access events can be logged (ZK)

– Network-ready with integrated LockNode (WN)

– LockNode can be retrofitted

– Time zone groups: G1: 5 / G2: 100

– Max. number of transponders per G1 Cylinder: 8000 / G2: 64,000

– Different permanent/open modes

Outside 30 mm, internal 30 mm

(AP/WP 35mm)

up to 300,000 lock operations or

up to 10 years on standby

Standard protection rating IP54

(when installed); .WP variant:

IP66

Thumb-turns

FH cylinder thumbturns

Material: Stainless steel

Colours: Stainless steel, brushed

Diameter: 30 mm

Length:

Material:

Colours:

Diameter: 30 mm

37 mm (from front surface of

profile)

Inside thumb-turn: stainless steel

cover; recessed grip: plastic;

outer thumb-turn: identical to

standard cylinders

Cover: brushed stainless steel;

recessed grip: black; outside

thumb-turn identical to standard

cylinders

Page 41

SimonsVoss

Manual

Digital Locking Cylinder 3061

11 | Data sheets

41 / 44

AP cylinder thumbturns

MS cylinder thumbturns

Length:

Material:

Colours:

Diameter: 30 mm

Length:

Material:

Colours:

Diameter: 30 mm

Length:

37 mm (from front surface of

profile)

Outside thumb-turn: identical to

standard cylinders: Aluminium

Outside thumb-turn: Brushed

stainless steel; internal thumbturn: Nickel-coated aluminium

Outside: 37 mm (from front

surface of profile); internal: about

36 mm (from front surface of

profile)

Outside thumb-turn: identical to

standard cylinders; internal

thumb-turn: identical to standard

cylinders

Outside thumb-turn: Cover made

of high-gloss brass; recessed

grip: matt brass: internal thumbturn: Cover made of high-gloss

brass; recessed grip: Matt brass

Outside: 37 mm (from front

surface of profile)

Thumb-turns

Profile cylinder

Batteries

11.2 Half cylinder

Material: Stainless steel

Colours: Stainless steel, brushed

Diameter: 30 mm

Length:

Basic length: outside 30 mm, internal 10 mm

Installation lengths in 5mm increments (no installation kit) an overall

length of up to 100 mm with a maximum length of 90 mm on the outer

side of the cylinder. Greater lengths on request.

Type: CR, 2450, 3V

Manufacturer: Sony, Panasonic, Varta

Quantity: 2 units

Battery life:

37 mm (from front surface of

profile)

up to 300,000 lock operations or

up to 10 years on standby

Page 42

SimonsVoss

Manual

Digital Locking Cylinder 3061

11 | Data sheets

42 / 44

Features

Ambient conditions

Cam HZ.SL

– 3,000 access events can be logged (ZK)

– Network-ready with integrated LockNode (WN)

– LockNode can be retrofitted

– Time zone groups: G1: 5 / G2: 100

– Max. number of transponders per G1 Cylinder: 8000 / G2: 64,000

– Different permanent/open modes

Operating temperature: -25°C to +65°C

Storage temperature: -35°C to +65°C

Standard protection rating IP54

Protection class:

Air humidity: <95%: non-condensing

Cam position handle: 37°

Cam width from neutral position: 11 mm

(when installed); .WP variant:

IP66 thumb-turn

Page 43

SimonsVoss

Manual

Digital Locking Cylinder 3061

12 Declaration of conformity

You can access documents such as declarations of conformity and other

certificates online at www.simons-voss.com.

12 | Declaration of conformity

43 / 44

Page 44

SimonsVoss

Manual

Digital Locking Cylinder 3061

13 Help & Contact

13 | Help & Contact

44 / 44

Instruction manuals

Hotline

Email

FAQs

You will find detailed information on operation and configuration

online under INFOCENTER > DOWNLOADS on our homepage at

www.simons-voss.de

If you have any questions, the SimonsVoss Service Hotline will be

happy to help you on +49 (0)89 99 228 333 (German fixed network;

call charges vary, depending on the operator)

You may prefer to send us an email.

hotline@simons-voss.com

You will find information and help for SimonsVoss products in the

FAQs section under INFO CENTRE > FAQ SECTION at

www.simons-voss.de

SimonsVoss Technologies GmbH, Feringastrasse 4, 85774

Unterföhring, Germany

Loading...

Loading...