Page 1

Manual 3060 System

State of: July 2007

SimonsVoss Technologies AG • Feringastraße 4 • 85774 Unterföhring • Germany

Hotline 01805-SV3060 • FAQs www.simons-voss.de

Telefon +49-89-99 228-0 • Fax +49-89-99 228-222

If the contents of the foreign language version of the documentation differ from the contents of the original German version,

the original German version shall apply in case of doubt. We reserve the right to make technical changes.

Page 2

Table of Contents

Version: March 2008

Page 3

Table of Contents

Seite 2

P

PEOPLE TO CONTACT

Sales

Technical

Address in Munich

D

DIGITAL LOCKING SYSTEM 3060

General method of operation

The components

Access control, time zone administration

T

TRANSPONDER 3064

Method of operation

Loss of a transponder

Password-protected transponder

Q

BIOMETRIC TRANSPONDER Q3007

Method of operation

Learn-mode

Recognize-mode

Deleate-mode

BIOMETRIC READER Q3008

Method of operation

Learn-mode

Recognize-mode

Deleate-mode

PINCODE-KEYPAD 3068

Method of operation

Initiation

Programming

Battery warning

V

DIGITAL LOCKING CYLINDER 3061

VDS (TN3)

Method of operation

Installation instructions

Battery warning, battery replacement

Page 4

Table of Contents

Seite 3

DIGITAL LOCKING CYLINDER 3061

(TN4)

Method of operation

Installation instructions

Battery warning, battery replacement

H

DIGITAL HALF CYLINDER 3061

(TN3)

Method of operation

Installation instructions

Battery warning, battery replacement

DIGITAL HALF CYLINDER 3061

(TN4)

Method of operation

Installation instructions

Battery warning, battery replacement

R

DIGITAL SMART RELAY 3063

Installation

Connections

Programming

SMART OUTPUT MODULE

Installation

Connections

Programming

SHUNT LOCK FUNCTION 3066

Activation unit

Deactivation unit

Installation and connecting plan

E

SHUNT LOCK FUNCTION 3066 VDS

Master activation unit

Slave activation unit

Deactivation unit

VdS-compliant installation

Page 5

Table of Contents

Seite 4

WAVENET RADIO NETWORK

Components

Structure

Installation

N

LON NETWORK 3065

Network configuration

Components

Installation

M

PROGRAMMING TRANSPONDER 3067

Backup card

Error messages

Programming

P

PALM CD2

Initiation

Export and import

Programming

SMART CD

Initiation

Export and import

Programming +65

K

KEY

Explanation of technical terms

Special Symbols

Page 6

People to contact

Version: September 2006

Page 7

People to contact

Page 2

SALES

If you have any questions please contact our specialist dealers, or the sales

representative responsible for your region. You can obtain information concerning the

responsible contact at the following telephone number.

+49 89-9 92 28-180

United Kingdom

SimonsVoss Technologies Ltd.

Mr. Oliver Quaisser

44 Newton Court, Old Windsor

Berkshire SL4 2SN

Great Britain

Tel. +44 / (0)1753 / 85 98 44

Fax +44 / (0)1753 / 83 17 03

Email: oliver.quaisser@simons-voss.co.uk

Singapore and Asia

SimonsVoss Security Technologies (Asia) Pte. Ltd.

Mr. Jason P. Kurek

72 B Pagoda Street

Republic of Singapore 059231

Tel. (65) 6227 7318

Fax (65) 6227 7018

Email: jpk@simonsvossasia.com

Middle East

SimonsVoss Technologies (Middle East) FZ-LCC

Dubai Internet City

P.O. Box 500188

Dubai, UAE

Tel. +9714 3629761

E-Mail: uae@simons-voss.com

Headquaters Munich

SimonsVoss Technologies AG

Feringastraße 4

85774 Unterföhring

Germany

Tel: +49 89-9 92 28-180

Fax +49 89-9 92 28-222

www.simons-voss.com

Page 8

Digital Locking System 3060

State of: June 2006

Page 9

Digital Locking System 3060

Register

1.0 General Method of Operation ___________________________3

2.0 The Components of the Digital Locking and ________________

Organization System 3060______________________________3

2.1 Software LDB ___________________________________________ 3

2.2 Programming ___________________________________________ 4

2.3 Digital Locking Cylinder 3061 ______________________________ 4

2.4 Digital Smart Relay 3063 __________________________________ 4

2.5 Transponder 3064________________________________________ 4

2.6 Network 3065____________________________________________ 5

2.7 Block Lock Function 3066 _________________________________ 5

3.0 Digital Components With Access Logging and _____________

Time Zone Control ____________________________________5

3.1 Access Logging _________________________________________ 5

3.2 Time Zone Control _______________________________________ 6

Page 10

Digital Locking System 3060

Page 3

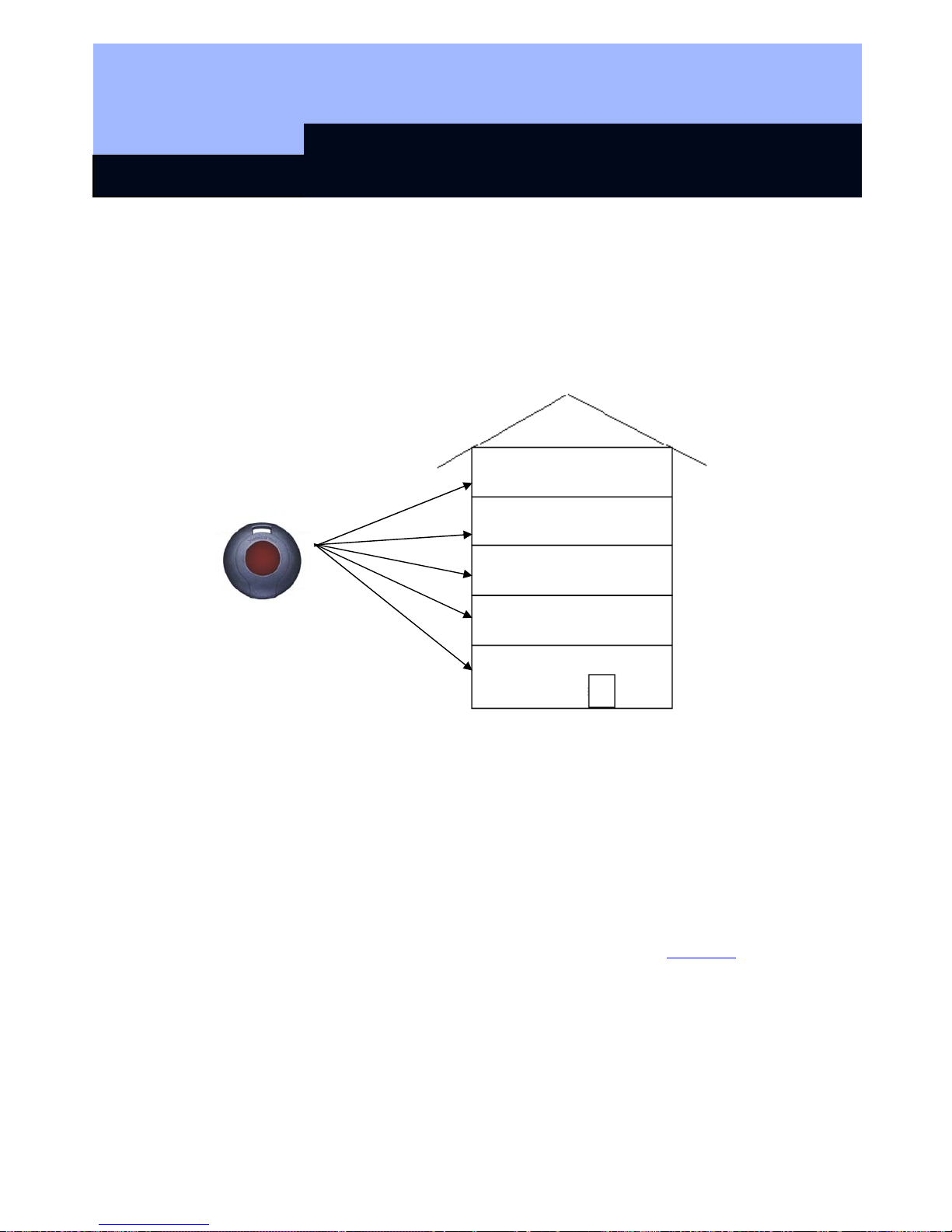

1.0 General Method of Operation

The Digital Locking and Organization System 3060 is modularly constructed and is

suitable for uses ranging from a simple locking system for individual doors all the way

to a complex PC-controlled access control system. Conventional mechanical keys are

replaced by the programmable transponder, which controls doors, gates, barriers,

furniture and elevators, for example, over radio transmission. Each transponder is

programmed individually for the locking system. The access authorisations are

assigned by means of the locking plan. This makes it possible to provide each

employee with an individual locking plan with access control and time zone control.

The identification in the system and the radio transmission are done by sending and

receiving constantly changing crypto codes, thus making the misuse of the system

technically practically impossible. Modifications or expansions of the system at a later

date are always possible.

2.0 The Components of the Digital Locking and

Organization System 3060

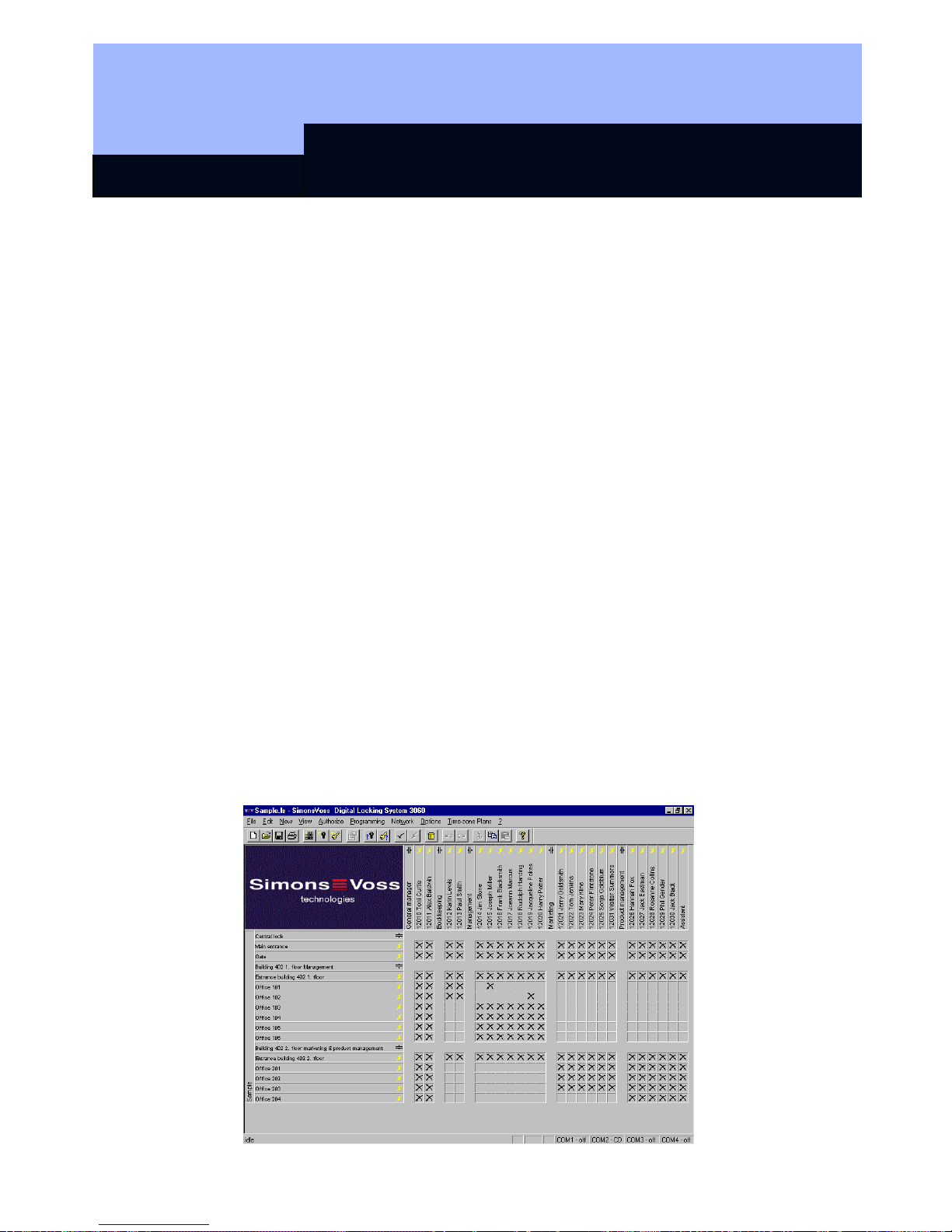

2.1 Software LDB

The locking plan software runs under Windows 98, Windows ME, Windows NT/2000

and Windows XP. All components can be programmed as required using the locking

plan software. One locking plan can contain a maximum of 16,386 lockings and 8000

transponders. For even larger locking systems, the lockings and transponders are

distributed among several locking plans. The locking authorisations are assigned by

simply clicking with the mouse. As a result, later modifications are possible with no

trouble.

☺ A detailed description is to be found in our Software Operating Instructions!

Page 11

Digital Locking System 3060

Page 4

2.2 Programming

You will need the SmartCD and a PDA for programming the digital

components. The data is encoded and then transmitted to the digital

components via radio signal.

Another possibility for programming a Digital Locking Cylinder 3061 and

Transponder 3064 is with the Programming Transponder 3067. For

example, you can issue or change access authorizations in small

systems by simply pressing a button when you lose a key or change the

locking plan. No PC or special system software is needed.

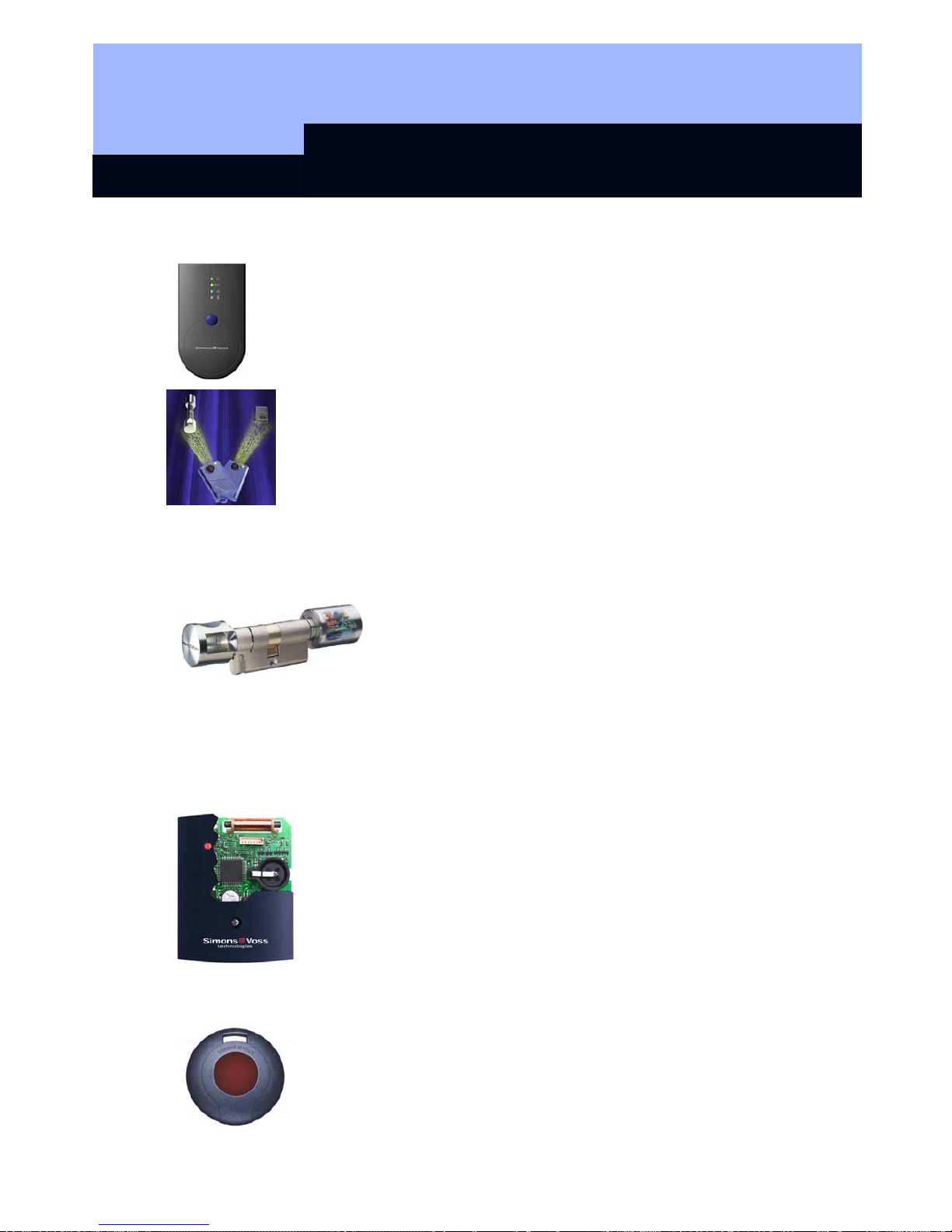

2.3 Digital Locking Cylinder 3061

The Digital Locking Cylinder 3061 is a compact, powerful

access control system that can be installed in any door in

only minutes. Its dimensions correspond to those of an

ordinary mechanical cylinder that meets the norms.

Because the Digital Locking Cylinder 3061 has batteries

(master and backup batteries), it can be installed without

wires in all Euro Profile doors and can replace already

existing

mechanical cylinders. A drop in the battery voltage is indicated by a multilevel

warning system (service life approximately 60,000 operations).

2.4 Digital Smart Relay 3063

The SimonsVoss Smart Relay is an electronic switch that can be

switched with a SimonsVoss transponder. You can use the

SimonsVoss software to configure the authorisation for transponders

that are permitted to operate the Smart Relay. In this way, the Smart

Relay offers the full function of an access control reader.

2.5 Transponder 3064

The Transponder 3064 is a digital key that can be programmed

using SimonsVoss software and that works by radio transmission,

without contact. It not only replaces mechanical keys, but also takes

over the function of identity cards. Simply pressing a button triggers

the encoded communication between the transponder and locking

Page 12

Digital Locking System 3060

Page 5

cylinder, Smart Relay or activation unit.

2.6 Network 3065

The cable-free Network 3065 is an online access control system that administers,

visualises and archives all System 3060 information in one central location, and all

without manipulations at the door, door frame or the door hardware.

It is especially recommended for medium-sized and large locking systems in order to

be able to configure and administer the locking system from a central PC. The LON

standard data transmission is done from the PC over the network wiring (twisted pair)

and out to the network nodes (LockNodes), which are installed near a digital

component. From the LockNode, the data is directed without wires over radio

transmission to the digital unit.

☺ While it is true that access to the network software is no longer possible if

there is a power failure (unless the network has been protected by a no-break

power supply), however, all of the locking system’s components that are

equipped with a battery still function.

2.7 Block Lock Function 3066

SimonsVoss has the Block Lock Function 3066 in its product line as an option of the

Digital Locking and Organization System. This function offers the possibility of

activating your alarm system from a central point while at the same time preventing

the monitored doors from being accidentally opened during this time. This rules out

annoying and expensive false alarms right from the start.

The Block Lock Function 3066 is also available as a VdS version

.

3.0 Digital Components With Access Logging and

Time Zone Control

3.1 Access Logging

The Plus versions of the digital locking cylinder, SmartRelay and activation unit record

the access attempts of authorised transponders. The read-out of the access list from

the lockings is done using the SmartCD or, in the case of a networked locking

system, over the LockNodes.

A total till 128 accesses (with Smart Relay 1.024), with date, time of day and

transponder designation can be stored in the access lists of the separate

components. After that, the complete file isn’t deleted, but instead the oldest access is

always overwritten with the new one.

Page 13

Digital Locking System 3060

Page 6

After the access list has been read out with the programming device or network

nodes, it is imported into the PC and administered there by the locking plan software.

A total of 10,000 accesses can be stored in the PC file. When the data is accepted

from the programming device, a comparison is done so that it is always only the

current, new accesses that are accepted into the PC file.

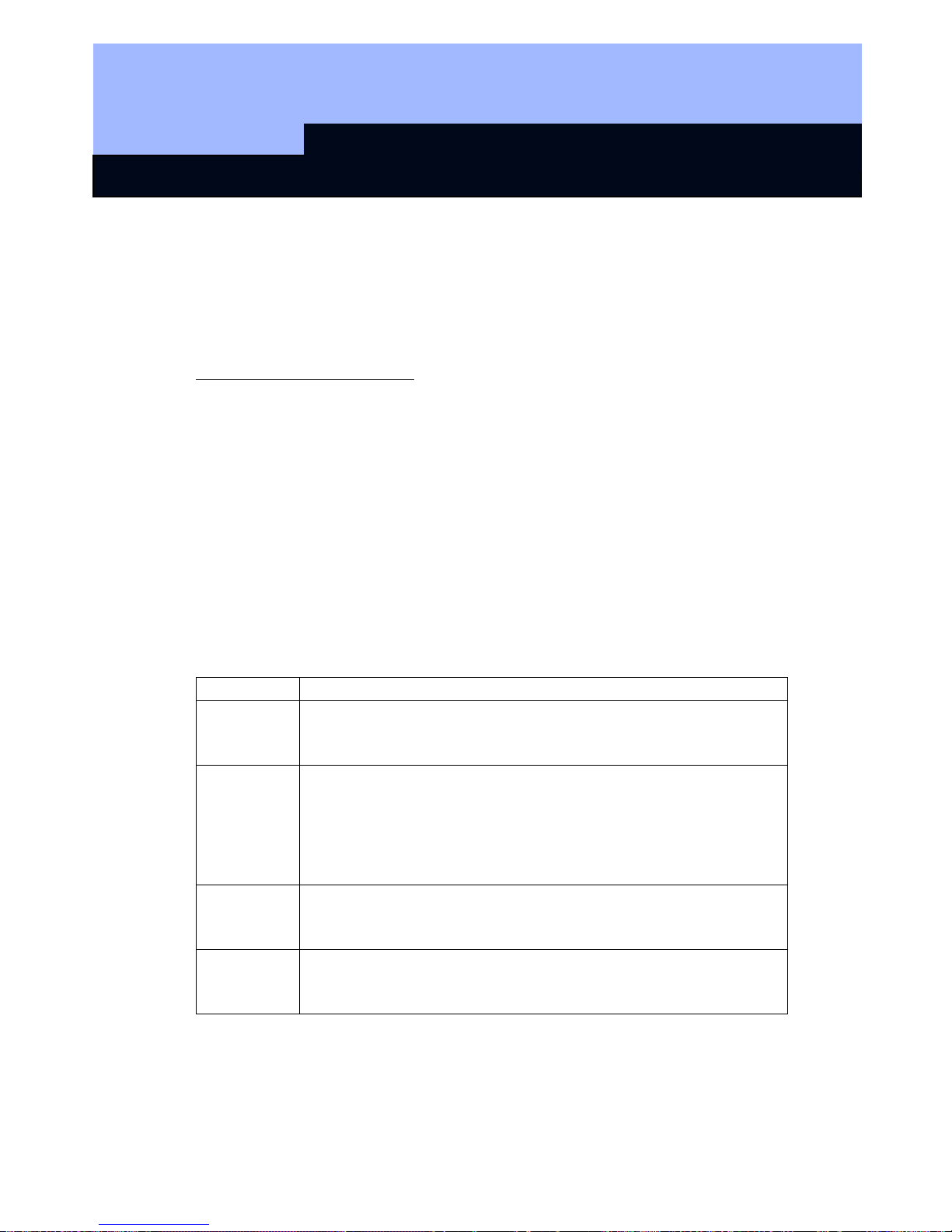

3.2 Time Zone Control

You can program lockings in such a way that authorised transponders are authorised

for access only at certain times.

Transponders normally have no time restrictions, i.e., that are always authorised for

locking 7 days a week, 24 hours a day. However, you can assign transponders to

time groups so that they can open or lock at times that can be freely defined. There

are five different time groups available (for a more precise description, see the

Software Operating Instructions).

Example:

No time restrictions

Mo-Su, 24 hours

Mr. Lewis, Mr. Ludwig, Ms.

Gorges

Group 1 Mo – Fr, 7 am – 5

pm

Mrs. Schulz, Mr. Fichtel

Group 2 Mo – Fr, 9 am – 8 pm

Mrs. Miller, Mr. Karlsen, Mr. Waas

You can draw up an individual time zone plan for each locking.

It is not

possible to equip a standard version with the access logging and time

zone control functions of the TZC-version at some later time.

Page 14

Transponder 3064

State of: September 2006

Page 15

Transponder 3064

Content

1.0 Method of Operation __________________________________3

1.1 General ________________________________________________ 3

1.2 Higher Priority Locking Level ______________________________ 4

2.0 Special Models _______________________________________5

2.1 Password Transponder ___________________________________ 5

2.2 Switching Transponder ___________________________________ 5

2.3 Explosion Protection Transponder__________________________ 5

3.0 Explosion Protection Transponder ______________________6

3.1 General Information ______________________________________ 6

3.2 Standards ______________________________________________ 6

3.3 Grouping _______________________________________________ 6

4.0 Additional Functions __________________________________7

4.1 Time Zone Control _______________________________________ 7

4.2 Validity Date ____________________________________________ 7

4.3 Activation Transponder ___________________________________ 7

5.0 Battery Replacement __________________________________8

5.1 Battery Replacement 3064 _________________________________ 8

5.2 Battery Replacement for the Explosion Protection Transponder _ 8

6.0 Loss of the Transponder _______________________________ 8

6.1 Emergency Opening______________________________________ 8

6.2 Replacement Transponder ________________________________ 8

7.0 Data Sheet___________________________________________ 9

Page 16

Transponder 3064

Page 3

1.0 Method of Operation

1.1 General

The Transponder 3064 is a digital “key” that is programmed with the locking plan

software and that works over radio transmission with no physical contact. All

functions, for example, opening and closing doors, gates, barriers, furniture locks,

etc., are carried out by pressing a button. Communication with the digital components

(cylinder, Smart Relay and activation unit) takes place by sending and receiving

constantly changing crypto codes, which makes misuse practically impossible.

Since the System 3060 works with active transponder technology, the transponder

has its own voltage source (battery) available. The advantage in comparison to

passive technologies lies in the smaller energy requirements of the cylinder and the

larger range.

In order to trigger an action, hold the transponder near the digital locking (refer to the

separate chapters for information on maximum transponder ranges) and then press

the transponder button. Provided that the transponder is authorised for this digital

locking, the desired action, for example, opening or locking the door, can be carried

out.

The housing of the transponder is protected against splash water. However it is not

waterproof!

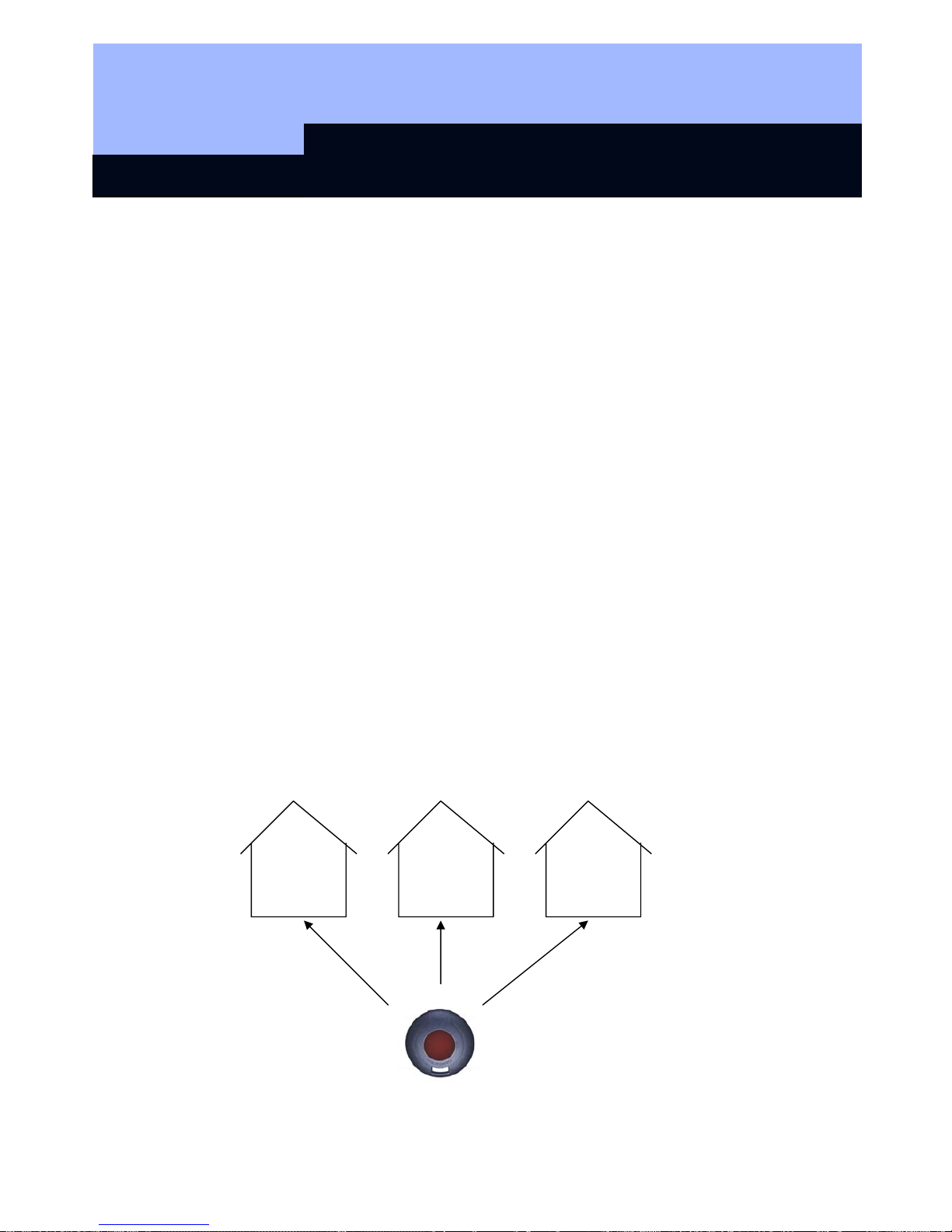

Each transponder can be used in three different, mutually independent locking

systems (assuming that no validity areas were programmed). Each locking system

has its own password and is administered separately.

Example:

Company Branch Private home

900 lockings 85 lockings 3 lockings

Page 17

Transponder 3064

Page 4

1.2 Higher Priority Locking Level

If it is necessary to have transponders that are authorised for more than 3 mutually

independent locking systems, “higher priority locking levels” must be set up in these

locking systems. There are a maximum of 3 higher priority locking levels available for

this. All transponders of a higher priority locking level have the same authorisation.

One digital locking distinguishes between a maximum of three higher priority levels.

Example:

Higher priority transponder

Four companies are accommodated in an office building with a central locking that is

used by all the companies. Each company administers its own locking system with its

own password. Every employee receives a transponder that is authorised for 2

locking systems, namely the central locking und his or her own company.

However, the fire brigade, for example, needs a transponder that is authorised for all

five of the building’s locking systems. To accomplish this, a higher priority locking

level with the same separate password must be set up in all five locking systems and

the authorisations must be set up for the higher priority transponders. The

transponders set up in this level all have the same authorisation. If higher priority

transponders with other authorisations are required, an additional higher priority

locking level must be set up (max. 3 higher priority locking levels per locking!). The

higher priority transponder must then be programmed into all shutdown

s of all 5

locking systems.

Company D

Company C

Company B

Company A

Central

locking

system

Page 18

Transponder 3064

Page 5

2.0 Special Models

2.1 Password Transponder

Instead of manually entering the locking system password, you can transmit it over

radio frequency with the help of a special transponder. Standard transponders cannot

be used as password transponders.

2.2 Switching Transponder

With this transponder, a two-wire cable (approx. 1m or 37 inches) is connected to the

switch contacts of the button and guided outside the device. When both wires are

connected, the transponder switches through.

Application examples:

• Connecting external systems

• Remote triggering of a Digital Locking Cylinder or Smart Relay

• Block Lock Function 3066: System activation from more than one location

2.3 Explosion Protection Transponder

This is a transponder with the same functions as the Transponder 3064. In addition,

this transponder is released for use in explosion protection zone 1.

(Note Chapter 3 in this regard).

2.4 SmartClip

The special design of this transponder means that the SmartClip is suitable for

holding an ISO 7816 format card.

2.5 Transponder, bonded

The standard transponder as described above, but with a glued-shut casing. This

prevents end-users from opening the case and using the transponder electronics

improperly.

2.6 Transponder, numbered

Sequentially numbered transponders can also be ordered if required.

Page 19

Transponder 3064

Page 6

Explosion Protection Transponder

2.7 General Information

This special product is a transponder that is permitted to be carried into and used in

areas subject to explosion hazards, called Zone 1. An area is denoted as Zone

1 when atmospheres capable of exploding occur occasionally. It is crucial that you

keep in mind the following issues:

• You are not permitted to open the housing.

• Unlike with the Transponder 3064, only SimonsVoss Technologies AG is

permitted to change the battery.

• Normally, you must comply with the general operating instructions of the

BGR132 (German rules for occupational safety and health) when using the

device in Zone 1.

3.2 Standards

The transponder has been tested according to the applicable explosion protection

standards. Refer to:

• Directive 94/9/EC

• DIN EN 50014 (Electrical apparatus for potentially explosive atmospheres)

• DIN EN 50020 (Intrinsic safety "i")

3.3 Grouping

The transponder is grouped in the following way:

• Explosion protection: zone 1

• Intrinsic safety: ib

• Explosion group: IIC

• Temperature class: T3

• Device group: II2 G

This applies to areas in which a potentially explosive atmosphere can arise due to

gases, vapours or mists. The information quoted relates to an ambient temperature of

from -20°C to +40° C (-4° F to +104° F) in the place of use.

Page 20

Transponder 3064

Page 7

3.0 Additional Functions

The following functions can be activated in the locking plan software:

3.1 Time Zone Control

For TZC version digital lockings, you can program transponders that have locking

authorisation for specific times only. These time zones are deposited in the locking

plan software, and the transponders are then assigned to an appropriate time zone

group.

Example: Mr. Miller receives the following authorisation:

Monday to Friday from 9:00 am, until 6:30 p.m.

Saturday from 9:00 am, until 12:45 p.m.

Sunday no authorisation

3.2 Validity Date

It is possible to program transponders whose authorisation is tied to a validity date

(this also applies to non-TZC-versions):

¾ Transponders that are valid from a specific point in time

(e.g., from 8:00 a.m. on July 12, 2003

¾ Transponders that are valid up to a specific point in time

(e.g., until 5:00 p.m. on July 12, 2003

¾ Transponders that are valid for a specific time interval

(e.g., from July 1, 2003 until July 31, 2003)

& One data record is assigned for each activation or expiry date!

3.3 Activation Transponder

Within the scope of the block lock function, all authorised transponders for a digital

locking in the security area are blocked when the alarm system has been activated in

order to avoid false alarms. For emergency situations, transponders can be

programmed (for example, for the fire brigade) that release this block. Afterwards, the

door can be opened with an authorised transponder.

Page 21

Transponder 3064

Page 8

4.0 Battery Replacement

4.1 Battery Replacement 3064

If a battery warning occurs, then the transponder battery can be changed at any time

(see the Manual on the 3061 Locking Cylinder – Battery warning). Open the casing

carefully so that you can see the battery. Open the battery clip and remove the

battery, insert a new one, and close the clip. Press the casing back together again.

When you change the battery it is important to ensure that the procedure does not

take more than two minutes, that the transponder button is not pressed during that

period, and that you do not short the battery – otherwise you may lose data.

Alternatively:

Send the transponder that needs its battery changing to:

SimonsVoss Technologies AG, Eichenweg 6, 07616 Petersberg.

4.2 Battery Replacement for the Explosion Protection Transponder

Attention:

Only SimonsVoss Technologies AG is permitted to change the transponder battery!

5.0 Loss of the Transponder

5.1 Emergency Opening

An emergency opening can be carried out using the SmartCD + PDA (only use

devices approved by SimonsVoss) and with the input of the locking system password.

5.2 Replacement Transponder

If a transponder is lost, it can be deleted from the locking plan and a replacement

transponder can be set up. When operating the locking system in overlay mode, the

lost transponder is automatically blocked as soon as the replacement transponder is

activated at the digital locking. (See the Software Operating Instructions Page H3 for

programming and procedure information.)

Page 22

Transponder 3064

Page 9

6.0 Data Sheet

Housing

• Made of weather-resistant plastic

• Colour: Black

• Degree of protection: IP 65

• Diameter: 42 mm

• Integrated lithium battery

• Max. 1,000,000 operations, or 10 years standby

• Access authorisations for up to 48.149 doors

• Can be used in 3 mutually independent

locking systems

Page 23

Q3007 Biometric Transponder

State of: September 2006

Page 24

Q3007 Biometric Transponder

Content

1.0 General Instructions __________________________________3

1.1 Safety instructions _______________________________________ 3

1.2 Product description ______________________________________ 3

2.0 Overview of function __________________________________ 4

2.1 Basic information on operation_____________________________ 4

2.2 Operating states _________________________________________ 4

2.3 How the transponder works _______________________________ 5

2.4 "Learn" mode: start-up, scanning in fingerprints ______________ 5

2.5 Querying the number of fingerprints scanned in ______________ 8

2.6 "Recognise" mode: one-off triggering of transponder __________ 9

3.0 "Delete" mode: deleting fingerprints ____________________ 10

4.0 Transparent mode ___________________________________ 10

5.0 Programming the Transponder_________________________11

with the SimonsVoss software _________________________11

6.0 Changing the Batteries _______________________________ 11

7.0 Technical Data ______________________________________ 12

8.0 Table of Diode Signals________________________________13

Page 25

Q3007 Biometric Transponder

Page 3

1.0 General Instructions

Please take 15 minutes to familiarise yourself with how your Biometric Transponder

Q3007 works with the help of these operating instructions.

1.1 Safety instructions

Caution! – The batteries used in this product could burn or cause a fire if they are not

handled properly. Do not charge, open or burn these batteries or heat to over 100°C.

Make sure that the sensor surface is not dirty or scratched. Do not drop the Q3007 or

expose it to any other strong impacts.

In addition, please make sure that the initial scanning in of fingerprints is not carried

out by unauthorised persons!

We advise you to protect the Q3007 against unauthorised access if possible.

Handling a Q3007 assumes knowledge of how to use SimonsVoss software.

Programming should therefore only be carried out by trained specialist staff.

SimonsVoss Technologies AG is not liable for any damage caused by incorrect

programming.

An incorrectly programmed or faulty Q3007 can block access via a door. SimonsVoss

AG is not liable for the consequences of such an occurrence, such as blocked access

to persons who are injured or in danger, material damage or any other damage.

1.2 Product description

The Q3007 differs from normal transponders by the fact that

it is also equipped with a highly sensitive Atmel Fingerprint

Sensor. In just a few seconds, a high-powered processor in

the transponder compares the saved fingerprint with the

fingerprint read in by the sensor. In this way, only people

whose fingerprints have been scanned in already can use

the transponder. This guarantees maximum security against

unauthorised use by third parties, e.g. if the transponder is

unsupervised, or is lost or stolen. The Q3007 is therefore

particularly suitable for applications where a transponder is

provided with very many or very specific authorisations, e.g. if one person has a

general transponder for all doors or access to high-security areas.

Page 26

Q3007 Biometric Transponder

Page 4

2.0 Overview of function

2.1 Basic information on operation

The Biometric Transponder Q3007 scans fingerprints using a fingerprint sensor. The

finger is dragged across the sensor, rather than being pressed against it.

The following should be noted:

The fingerprint to be scanned/ memorised should always be dragged over the sensor

in the same way.

To do this, place the tip of the finger that is to be stored or to be recognised at the

upper edge of the Biometric Transponder and draw it across the sensor from top to

bottom (towards the button) at a constant speed whilst applying slight pressure. The

design of the housing means that the finger is guided properly through the slightly

raised side walls. This more or less excludes the possibility of using the transponder

incorrectly.

The fingerprint sensor can thus pick up the fingerprint line by line and reassemble it

into a complete image in the integrated processor. If the reassembled image matches

the saved image, the Transponder is released.

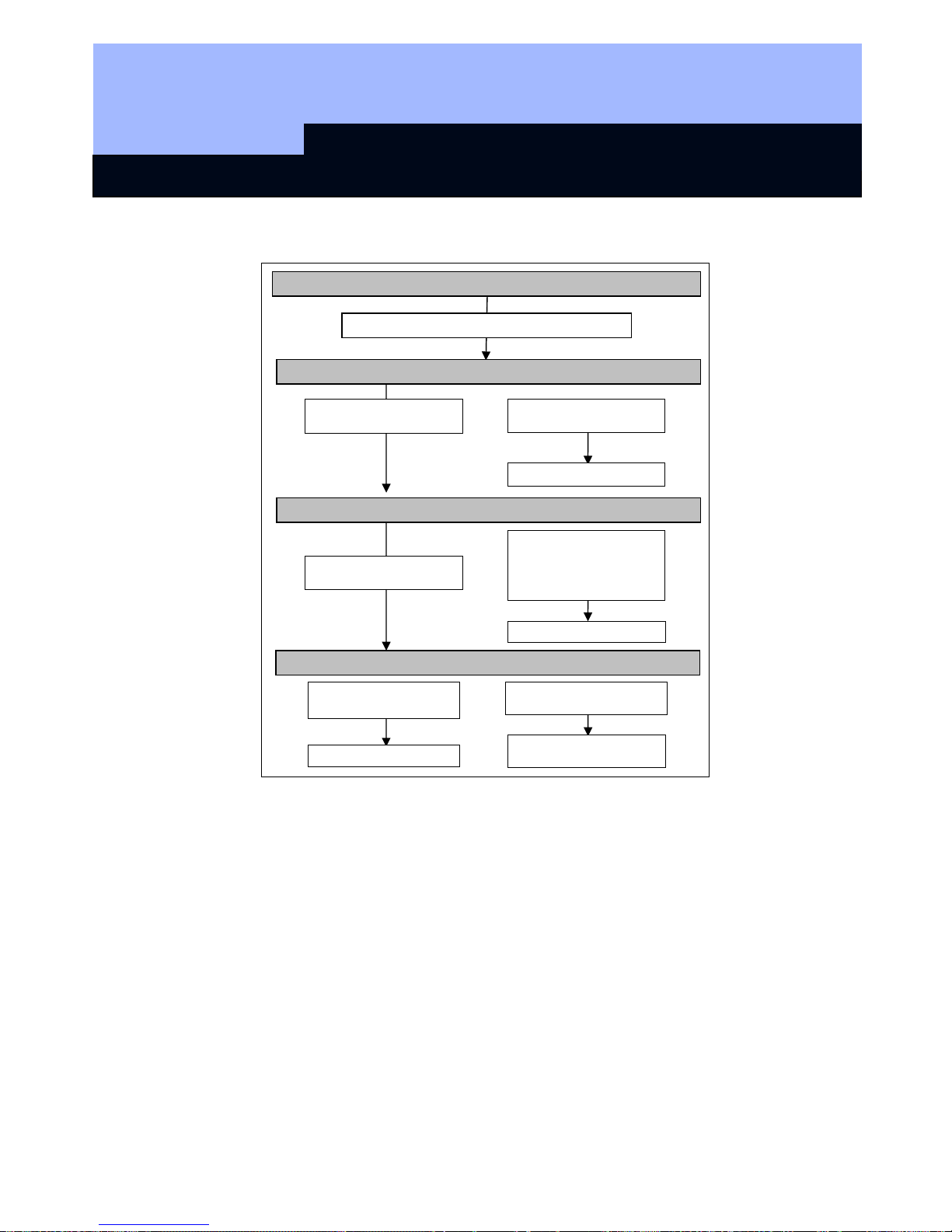

2.2 Operating states

The Q3007 has four different operating modes:

Mode Function

Standby

The Q3007 is normally on "Standby" in order to save the battery

capacity. After it has completed a function (e.g. scanning), it

always returns to the standby mode.

Learn

In the "Learn" mode, new fingerprints can be memorised. Up to 6

different fingerprints can be saved, two of which are what we call

"administrator" fingerprints. New fingerprints (user fingerprints)

can only be scanned in with the help of an administrator. The

only exception is the scanning of the first two fingerprints

(Administrator fingerprints), see below

Delete

In the "Delete" mode, fingerprints that have been memorised can

be deleted. Individual prints can be deleted, or all fingerprints can

be deleted at once.

Recognise

The "Recognise" mode is the mode before a door is opened. In

this mode, the Transponder is released if a fingerprint is correctly

recognised.

Page 27

Q3007 Biometric Transponder

Page 5

2.3 How the transponder works

You can interrupt the action in each mode by pressing the button briefly to change to

Standby.

2.4 "Learn" state: start-up, scanning in fingerprints

Initial start-up - scanning in the first 2 fingerprints (Administrator fingerprints)

To start the Q3007, two "Administrator fingerprints" need to be scanned in first of all.

We recommend that a fingerprint from the left and right hand of one person, the

administrator (e.g. safety officer) is used for this. However, you can also use one

finger from two different people.

Stand-by mode: LED not illuminated

Briefly press button once, then release

Recognise mode: LED flashes green

Learn mode: LED flashes yello

w

Delete state: LED flashes red

Drag finger across sensor

Transponder triggered

Press button and hold

down for 3 sec.

New finger is memorised

Press button and hold

down for 3 sec.

Drag Administrator finger

once over sensor and new

finger (User finger) 3 times

over sensor.

Draw user finger once

across sensor

Draw Administrator finger

once across sensor

All fingerprints are deleted

Only user fingerprint is

deleted

Page 28

Q3007 Biometric Transponder

Page 6

Please note:

The first two fingerprints to be scanned in are automatically (!) the Administrator

fingerprints. Without them, no further fingerprints can be scanned in or deleted later!

To scan in and store the first Administrator fingerprint (e.g. left thumb), please do the

following:

1. Briefly press the transponder button; the LED will flash green.

2. Then press the button again and hold it pressed for at least 3 seconds (until the

LED flashes yellow).

3. Release the button. The system is now ready to scan for 30 seconds, and this is

indicated by rapid yellow flashing.

4. As a high quality of the fingerprint to be teached in is important for good

recognition during every day use, please make sure, that your finger to be

scanned in is not too dry (e.g. breath on them before having them scanned

in).

5. Drag finger across the sensor; the LED goes off; after about 1 second, the LED

flashes green once to indicate that the fingerprint has been accepted.

6. When the LED flashes yellow rapidly again, drag the finger to be scanned in

across the sensor again.

7. Now repeat steps 4 and 5 twice again (so that you have drawn your finger three

times across the fingerprint sensor altogether). If an attempt has been

unsuccessful (LED is illuminated red), drag your finger across the sensor again.

Using for the first time – ‘learning’ the first two fingers (Administrator Fingers)

Once the fingerprint has successfully been scanned, the data are saved. This step

takes about 2-5 seconds and is indicated by a yellow light flashing at 2 second

intervals. The diode is then briefly illuminated green, and the Q3007 returns to

Standby.

The Q3007 can now be used by the Administrator, or other fingerprints can be

scanned in. Please note that the second fingerprint that is scanned in also has

Administrator rights!

Scanning in more fingerprints (User fingerprints)

Page 29

Q3007 Biometric Transponder

Page 7

Further fingerprints (maximum 4) can be scanned in as the Administrator fingerprints

have been, except that the Q3007 must first be cleared for this by an Administrator

fingerprint. This prevents unauthorised persons from scanning in their own

fingerprints and thus gaining access rights that are not allowed.

We recommend that every person who is to use the Q3007 should also be scanned in

with two fingerprints, one per hand. This means that three people can be scanned in,

with two fingerprints for each one. To scan in more fingerprints, please proceed as

follows:

1. Briefly press the transponder button and wait until the LED flashes green.

2. Then press the button again and hold it pressed for at least 3 seconds until the

LED flashes yellow, then release the button.

3. Draw the Administrator finger across the sensor; the LED goes off and then

flashes green once after about 2 seconds. The system is now ready to scan for 30

seconds, and this is indicated by rapid yellow flashing light. Drag the User finger

across the sensor; the LED goes off; after about 1 second, the LED flashes green

once to indicate that the fingerprint has been accepted.

4. When the LED flashes yellow rapidly again, draw the finger to be scanned in

across the sensor again.

5. Now repeat step 4 twice again (so that you have drawn your finger three times

across the fingerprint sensor altogether). If an attempt has been unsuccessful

(LED is illuminated red), drag your finger across the sensor again.

Once the fingerprint has successfully been scanned, the data are saved. This step

takes about 2-5 seconds and is indicated by a yellow flashing light at 2 second

intervals. The diode is then briefly illuminated green, and the Q3007 returns to

Standby.

Fingerprints that are already known can always be scanned in, even if 6 fingerprints

have already been saved. Unknown fingerprints are then rejected by the LED flashing

red twice.

Tips:

• Care in scanning in is rewarded by reliable recognition in use.

• Scanning in the same fingerprint several times improves the quality of the

scanned features and thus makes the recognition of the fingerprint more

reliable.

• Use a firm base when scanning in fingerprints. We recommend operation with

one hand when scanning in thumb prints.

• When scanning in fingerprints, drag the finger across the sensor in a straight

line, not too quickly, at an even speed and pressure.

• Make sure that the sensor is clean and that your fingers are not too dry

(e.g. by breathing on them before having them scanned).

Page 30

Q3007 Biometric Transponder

Page 8

6. Now repeat step 4 twice again (so that you have drawn your finger three times

across the fingerprint sensor altogether). If an attempt has been unsuccessful

(LED is illuminated red), drag your finger across the sensor again.

Once the fingerprint has successfully been scanned, the data are saved. This step

takes about 2-5 seconds and is indicated by a yellow flashing light at 2 second

intervals. The diode is then briefly illuminated green, and the Q3007 returns to

Standby.

Fingerprints that are already known can always be scanned in, even if 6 fingerprints

have already been saved. Unknown fingerprints are then rejected by the LED flashing

red twice.

Tips:

• Care in scanning in is rewarded by reliable recognition in use.

• Scanning in the same fingerprint several times improves the quality of the

scanned features and thus makes the recognition of the fingerprint more

reliable.

• Use a firm base when scanning in fingerprints. We recommend operation with

one hand when scanning in thumb prints.

• When scanning in fingerprints, drag the finger across the sensor in a straight

line, not too quickly, at an even speed and pressure.

• Make sure that the sensor is clean and that your fingers are not too dry

(e.g. by breathing on them before having them scanned).

2.5 Querying the number of fingerprints scanned in

You can query the number of fingerprints already scanned in as follows:

1. Press the button once briefly (the LED flashes green)

2. Press the button again and hold it down for 1.5 - 2 seconds (not as long as 3

seconds, which will take you into "learn" mode).

3. The LED flashes red.

4. Then the LED will flash green as many times as the number of fingerprints

scanned in (max. 6).

5. The LED flashes red (for a long time if the maximum possible number of

fingerprints has been reached, or briefly if it has not).

If no fingerprints have been scanned in, the LED flashes red twice and then returns to

Standby mode.

Page 31

Q3007 Biometric Transponder

Page 9

2.6 "Recognise" mode: one-off triggering of transponder

The mode known as the Recognise mode is the normal operating state for the

Q3007, i.e. a person whose fingerprint has been scanned in would like to trigger a

Transponder signal, e.g. to open a door with a digital locking cylinder or to

programme the Transponder within a locking plan.

To do this, proceed as follows:

1. Press the button of the Q3007 briefly (for around 0.5 sec.), and the LED will then

flash green.

2. Now drag your scanned finger over the sensor. Make sure that it is in the same

position as it was when you scanned it in.

3. If the recognition attempt was successful, the LED shows green and the

Transponder is triggered.

If the LED shows red, the recognition attempt was not successful. You can now try

three more times. If these are not successful, the Q3007 automatically returns to

Standby mode.

Please note

:

• It may occasionally happen that the Q3007 does not recognise your finger

even though it has been properly scanned in.

• If the fingerprint is rejected with a single red flash, the quality of the fingerprint

trace was not adequate. This may be due to the fact, for example, that you did

not drag your finger properly across the sensor (too quickly, not straight or not

even) or that the surface of the sensor is dirty. If a finger is too dry, it may

happen that it "judders" across the sensor. If this happens, please repeat the

attempt, or moisten your finger slightly before you do so by breathing on it, for

example. With a little practice, however, you'll soon get the knack.

• If the features of your fingerprint cannot be assigned to any of the scanned

fingerprints, the diode will flash red twice. You may have accidentally

presented a fingerprint that has not been scanned in, or you may have drawn

this finger across the sensor quite differently initially from the way you are

doing it now (e.g. at an angle, or with more or less of your fingertip in contact

with the sensor).

Tip:

Not every fingerprint from a person is recognised equally reliably. If you are often not

recognised with one finger, you should perhaps scan in another finger.

Make sure that the sensor is clean and that your fingers are not too dry dry (e.g.

by breathing on them before having them scanned)..

Page 32

Q3007 Biometric Transponder

Page 10

3.0 "Delete" mode: deleting fingerprints

Both individually scanned fingerprints and all the fingerprints can be deleted from the

memory.

If normal fingerprints (not Administrator fingerprints) are deleted, the other fingers that

have been scanned in are not deleted. No Administrator fingerprint is needed to do

this (any normal user can delete his own fingerprint).

If one of the two Administrator fingerprints is deleted, all the fingerprints are

automatically deleted. The first two fingerprints that are then scanned in are

automatically the Administrator fingerprints again.

Fingerprints are deleted as follows:

1. Briefly press the transponder button and wait until the LED flashes green.

2. Then press the button again and hold it pressed for at least 3 seconds until the

LED flashes yellow. Release the button.

3. Press the button again and hold it pressed for at least 3 seconds until the LED

flashes red. Release the button. You are now in the "Delete" state.

4. Drag finger across sensor.

5. If the first recognition attempt was successful, the LED flashes green. If the

fingerprint is a normal one (user fingerprint), only this fingerprint is deleted; if it

was one of the two Administrator fingerprints, then all the fingerprints are deleted.

Deleting all the fingerprints can take up to 15 seconds. During this time, the diode

flashes red every 2 seconds.

6. If the LED flashes yellow, the recognition attempt was not successful. You can

now try three more times. If these all fail, the Q3007 automatically returns to

Standby mode.

4.0 Transparent mode

It is possible to switch the Biometric Transponder to what is called Transparent mode.

In this state, the biometric inquiry is interrupted for 5 minutes and the Biometric

Transponder can be used as a normal transponder (doors can be opened simply by

pressing a button). At the end of 5 minutes or so, the Biometric Transponder returns

to Standby mode.

Transparent mode is required, for example, for setting/cancelling alarms (if an SV

Shuntlock VdS is installed) or if several doors need to be passed through in a short

time.

Page 33

Q3007 Biometric Transponder

Page 11

To enter Transparent mode, please proceed as follows:

1. Press and hold the transponder button (longer than 1.5 seconds, < 3 sec.). The

LED will flash green rapidly. The Transponder will now react to the button as if it

were in Recognise mode.

2. Drag finger across sensor (LED shows green if the fingerprint is recognised).

3. The Biometric Transponder is triggered and switches to Transparent mode. The

LED flashes red.

4. Pressing the button triggers the system and the LED shows green, followed by

red flashing.

After 5 minutes, the Transponder switches off Transparent mode and returns to

Standby.

Transparent mode can also be switched off manually by pressing the Transponder

button before automatic switch-off until the green LED goes out (approx. 1.5 sec).

5.0 Programming the Transponder with the SimonsVoss software

The "Set validity" function and the "Quasi-proximity mode" are not

available for the

Q3007.

6.0 Changing the Batteries

To replace the batteries, push the battery cover downwards and remove. Take out all

the batteries and replace with new ones. Make sure that the polarity is correct

(stamped into the base of the battery compartment).

Page 34

Q3007 Biometric Transponder

Page 12

7.0 Technical Data

Dimensions: H x W x D

65 x 32 x18 mm

Weight

22 g

Colour

Grey, with blue button

Operating distance,

locking cylinders

approx. 40 cm (if the transponder

(lengthways) is held parallel with the

cylinder antenna)

Operating distance,

Smart Relay

approx. 120 cm (if the transponder is

parallel with the antenna of the Smart

Relay)

Protection category

IP 54

Operating temperature

range

0°C to 40°C without condensation

Battery type

3 V DC lithium battery type CR-1/3N

Page 35

Q3007 Biometric Transponder

Page 13

8.0 Table of Diode Signals

LED Mode

off Standby

off

moving finger on sensor followed by comparison

with scanned fingerprint, please wait (max. 4

seconds)

Slow green flashing light Recognise mode, wait for finger

(max. 30 seconds)

Fast green flashing light Release for transparent mode, wait for finger

(max. 30 seconds)

One green flash Successful action (recognise, learn, save, delete,

trigger)

Slow yellow flashing light Release for Learn mode, wait for Administrator

finger (max. 30 seconds)

Fast yellow flashing light Learn mode, wait for finger (max. 30 seconds)

Yellow flashing light Save scanned finger, please wait (max. 5

seconds)

One or two yellow flashes Error message in Delete state (cf. 1x or 2x red

flashing)

Slow red flashing light Delete state, wait for finger (max. 30 seconds)

Red flashing light Delete scanned fingerprint, please wait (max. 15

seconds)

Red flashing light Transparent state (max. 5 minutes)

Flash red 1x Action unsuccessful

Flash red 2x Fingerprint not recognised

Red, 0 to 6 times green, red Query number of scanned-in fingerprints

Page 36

BIOMETRIC READER Q3008

State of: August 2007

Page 37

MANUAL - BIOMETRIC READER Q3008

Page 2

2

1.0 General information ___________________________________ 4

1.1 Safety information ________________________________________ 4

1.2 Description of product _____________________________________ 5

2.0 Overview of function___________________________________6

2.1 Functional overview _______________________________________ 6

2.2 Basic operation ___________________________________________ 6

2.3 Operating statuses ________________________________________ 8

2.4 Operation ________________________________________________ 8

3.0 Programming_________________________________________9

3.1 Commissioning ___________________________________________ 9

3.2 Programming additional fingerprints (users) _________________ 10

4.0 ‘Recognize’ process __________________________________11

5.0 Assigning fingerprints to transponder IDs ________________12

6.0 Replacing fingerprints ________________________________ 13

7.0 Querying the number of learned fingerprints______________14

8.0 Deleting an individual fingerprint _______________________ 14

9.0 Deleting all fingerprints _______________________________ 15

10.0 Reading the biometric reader __________________________ 15

11.0 Master finger mode __________________________________ 16

11.1 Commissioning – Programming master fingers ______________ 16

11.2 Programming user fingers________________________________ 17

11.3 ‘Recognize’ process _____________________________________ 18

11.4 Deleting individual fingerprints____________________________ 18

11.5 Deleting all fingerprints __________________________________ 18

11.6 Resetting the biometric reader ____________________________ 19

12.0 Manipulation alarm___________________________________19

13.0 Meaning of LED signals_______________________________20

14.0 Battery warning _____________________________________20

15.0 Replacing the battery_________________________________21

Page 38

MANUAL - BIOMETRIC READER Q3008

Page 3

3

16.0 Assembly __________________________________________21

17.0 Special functions ____________________________________22

17.1 Wireless circuit for SimonsVoss VdS shunt lock 3066_________ 22

17.2 Miscellaneous __________________________________________ 22

18.0 Technical data ______________________________________ 23

Page 39

MANUAL - BIOMETRIC READER Q3008

Page 4

4

1.0 General information

Please take 15 minutes to read this manual and

familiarise yourself with the function of your Q3008

biometric reader.

To assemble the housing you will need a Torx key of

size TX6.

1.1 Safety information

Caution! – The battery used in this product may present a risk of fire or burns if

misused. Do not charge or open the battery. Do not heat it to over 100°C or burn it.

Do not short-circuit.

Only use batteries which have been approved by SimonsVoss.

Dispose of old and used batteries in the correct way. Keep out of the reach of

children.

Reversing the polarities may cause damage to the Q3008 biometric reader.

Do not allow the Q3008 biometric reader to become dirty or scratched. Do not drop it

or subject it to any other sudden impact.

It is essential to ensure that the device does not come into direct contact with

moisture and is not exposed to temperatures below +5°C.

The biometric reader is for indoor use only.

Master finger mode should only be used when the device is installed in a secure

indoor location and with a very small number of doors.

Program the reader as soon as it is commissioned to prevent any risk of misuse.

If the reader fails to recognise a finger, or does not recognise it correctly, this does

not necessarily mean there is a defect. SimonsVoss Technologies AG accepts no

liability for poor recognition caused by skin dryness or the physical structure of the

finger.

In order to configure a SimonsVoss biometric reader Q3008 you must be familiar with

the product and SimonsVoss software. The Q3008 biometric reader should therefore

only be programmed by trained specialists.

SimonsVoss Technologies AG shall assume no liability for damage caused by

incorrect programming.

Access through a door may be denied if a Q3008 biometric reader is incorrectly

programmed or is defective. SimonsVoss AG shall assume no liability for

consequences such as denied access to injured persons or persons at risk, damage

to property or any other form of damage.

SimonsVoss Technologies AG reserves the right to make enhancements and

modifications to the product without notice. Consequently, descriptions and

Page 40

MANUAL - BIOMETRIC READER Q3008

Page 5

5

representations in this documentation may vary from the most recent product and

software versions.

Should there be any variations in the content of other language versions of the

documentation, the German original shall apply in the event of any doubt.

This documentation has been produced to the best of our knowledge, but we cannot

guarantee that it is free of errors. We therefore offer no guarantee and accept no legal

responsibility for the consequences of any errors in this manual.

1.2 Description of product

The Q3008 biometric reader is a digital ‘key’ (transponder), designed to be mounted

on a wall, which opens SimonsVoss locks by radio when it recognises an authorised

fingerprint. The difference between this reader and, for instance, a PIN code keypad,

is that it features a highly sensitive Atmel fingerprint strip sensor. A high-performance

processor integrated in the reader compares learned fingerprints with the fingerprints

read by the sensor. If the fingerprint is recognised, the reader addresses the lock,

which can then be opened. This system offers maximum security against

unauthorised use by third parties. This makes the Q3008 biometric reader particularly

suitable for applications where only a few doors need to be accessed by just a few

members of staff, or for additional security for doors or access to high-security areas.

For the system to be configured, the biometric reader must be programmed with the

SimonsVoss programming software and it must learn a finger. Then, when the

authorised finger is recognised, the appropriate lock is released.

The Q3008 biometric reader may only be used in indoor areas (IP41). The product

has its own power supply and can therefore operate self-sufficiently. Assembly is very

simple as there is no need for wiring.

Because of its modular nature, this component can be easily integrated into the

SimonsVoss System 3060 and like all SimonsVoss components can be programmed

with the locking plan software.

Page 41

MANUAL - BIOMETRIC READER Q3008

Page 6

6

2.0 Overview of function

2.1 Functional overview

The Q3008 biometric reader consists of the following components:

• Biometric analysis unit

• Integrated digital transponder which opens the appropriate lock when

triggered by a successful biometric analysis.

The Q3008 biometric reader enables you to address all SimonsVoss locks (e.g.

cylinders, smart relays or even arming units, etc.) using biometry.

The reader can learn up to 50 different fingerprints. Each finger is assigned its own

transponder ID (TID). In SimonsVoss locks (with time control function, i.e. access

control and time zone control) it is also possible to grant an individual time-limited

access to a building and to keep a log of who accessed an area and when they did

so.

2.2 Basic operation

The Q3008 biometric reader scans fingerprints using a strip sensor. The finger is not

placed on the sensor (the small grey rectangle inside the black finger guide) but

drawn across it.

Please note:

The learned finger image must be of good quality in order for the reader to recognise

your fingerprint quickly and easily later on.

So whether you want the reader to learn or recognise your fingerprint, you must

always draw your finger across the sensor in the same way.

Place your finger (the finger to be learned or which has already been learned) in the

finger guide, above the sensor. At a constant speed and with gentle pressure, draw

your finger down the strip sensor from top to bottom as shown in the pictures (moving

towards the LED). Because of the design of the housing, you will find that your finger

is guided clearly by the higher side walls. This makes it very difficult to operate the

reader wrongly.

The strip sensor reads the fingerprint line by line and reassembles these lines in the

integrated processor to form a complete image. If the assembled image corresponds

to a stored image, the transponder is triggered.

Page 42

MANUAL - BIOMETRIC READER Q3008

Page 7

7

Activate the biometric reader by placing your

finger on the finger guide (see chapter 2.4),

and then place your finger at the top of the

sensor.

Figure 1

Draw your finger across the sensor at an even

speed and applying gentle pressure.

Figure 2

Keep your finger straight and extended, i.e. do

not bend or curl it.

Figure 3

When scanning your finger please ensure that your finger remains in contact with the

sensor at all times. In other words, you should maintain gentle pressure on the sensor

during the scanning process.

Page 43

MANUAL - BIOMETRIC READER Q3008

Page 8

8

2.3 Operating statuses

The Q3008 biometric reader distinguishes between 5 different operating statuses:

Status:

Explanation:

Standby The biometric reader is in idle mode and consumes very little power.

Recognize Recognize mode is the status used before an attempt is made to open

a door.

Once an authorised fingerprint is recognised, the lock is

addressed by radio and can then be opened.

Learn

In this mode, the relevant integrated transponders (up to 50) can be

programmed or reset with the SimonsVoss software.

The reader can store up to 50 different fingerprints.

Delete In delete mode, learned fingerprints can be deleted. You can delete

individual fingerprints or all fingerprints.

Battery warning A battery warning system gives you adequate warning when a battery

needs replacing.

2.4 Operation

Once the Q3008 biometric reader has been commissioned and configured, it forms a

‘wireless circuit’ with a SimonsVoss lock within the System 3060. The following

chapters describe in detail how to program individual fingerprints and the relevant

transponder data records and how to use the Q3008 biometric reader.

Finger guide

Sensor

LED

Page 44

MANUAL - BIOMETRIC READER Q3008

Page 9

9

3.0 Programming

The following chapters describe the programming process in detail. If you are using

the biometric reader in a small-scale locking system, please refer to chapter 11.0

Master finger mode.

Do not undertake any programming after a battery warning. Replace the battery

before proceeding. Refer to chapter 15.0 Replacing the battery.

3.1 Commissioning

Please note:

The 3008 biometric reader must be created in the locking plan as a lock

(biometric reader) and users as transponder type biometric reader users. Users

(transponder IDs) and fingerprints can only be learned in situ with the SmartLSM and

the SmartCD.

Please proceed as follows:

1. Create a locking plan in the SimonsVoss software.

2. Create ‘biometric reader’ as a lock

Æ

biometric reader.

3. Create lock (e.g. locking cylinder).

4. Create transponder using the option Biometric reader user.

5. Issue authorisation for the ‘biometric reader’ and the corresponding lock.

6. Connect the SmartCD to the PC and bring within communication range of the

‘biometric reader’.

7. Highlight the biometric reader and launch ‘Programming Æ Lock’ in the

programming software. This is where you undertake basic configuration of the

biometric reader.

8. Once the reader has been successfully programmed, this is indicated by a pop-

up window. This time, the yellow programming lightning symbol remains

displayed in the locking plan.

9. Bring the SmartCD into the communication range of the lock to be addressed.

10. Highlight the lock to be addressed by the biometric reader and launch

‘Programming Æ Lock‘ in the programming software. This is where you

undertake basic configuration of the lock.

11. Once the lock has been successfully programmed, this is indicated by a pop-up

window.

The following programming steps are performed in situ with a PDA and

SmartLSM:

12. Export the complete locking plan (pocket PC).

13. Bring the SmartCD into the communication range of the biometric reader.

Page 45

MANUAL - BIOMETRIC READER Q3008

Page 10

10

14. In SmartLSM, launch the ‘Read’ locks function. The biometric reader is

recognised and read.

15. Select ‘Modify transponder‘ and start the function by selecting ‘Execute’.

16. Select the appropriate transponder (biometric reader user) and launch the

‘Programming’ function.

17. While the transponder is being programmed, the biometric reader automatically

switches to Learn mode (LED flashes yellow), and you will be asked to draw

your finger over the finger guide.

18. Draw the finger you want the reader to learn over the sensor.

19. If the fingerprint is recognised, the LED on the biometric reader gives two long

flashes in green.

20. If programming was successful, the message “Programming successful“

appears in the SmartLSM. The fingerprint has been successfully stored.

21. After you re-import the locking plan the programming lightning symbols

disappear, both from the transponder and the biometric reader (if all

transponders have been programmed).

3.2 Programming additional fingerprints (users)

To learn additional users, proceed as follows:

1. Create transponder using the option Biometric reader user.

2. Issue authorisation for the ‘biometric reader’ and the corresponding lock (e.g.

locking cylinder).

3. Fully export the locking plan (pocket PC).

4. Bring the SmartCD into the communication range of the biometric reader in situ.

5. In SmartLSM, launch the ‘Read’ locks function.

6. Select ‘Modify transponder‘ and start the function by selecting ‘Execute’.

7. Select the appropriate transponder (biometric reader user) and launch the

‘Programming’ function.

8. While the transponder is being programmed, the biometric reader automatically

switches to Learn mode (LED flashes yellow), and you will be asked to draw

your finger over the finger guide.

9. Draw your finger over the sensor.

10. If the fingerprint is recognised, the LED on the biometric reader gives two long

flashes in green.

11. If programming was successful, the message “Programming successful“

appears in the SmartLSM. The fingerprint has been successfully stored in the

biometric reader.

Page 46

MANUAL - BIOMETRIC READER Q3008

Page 11

11

12. If you want the reader to learn other fingerprints, repeat from step 4. You must

first create additional transponders in the software using the biometric reader

user option (see step 1) and assign authorisations to them.

13. Bring the SmartCD into the communication range of the lock to be addressed in

situ.

14. In SmartLSM, launch the ‘Execute’ function.

15. If programming was successful, the message “Programming successful“

appears in the SmartLSM. The new biometric reader users have been

successfully stored in the lock.

16. After you import the locking plan the programming lightning symbols disappear,

both from the biometric reader user and the biometric reader (if all transponders

(biometric reader users) and the corresponding lock have been programmed).

4.0 ‘Recognize’ process

‘Recognize’ mode is the normal operation for the Q3008 biometric reader, where a

person whose fingerprint has been learned wants to open a door using a digital

locking cylinder.

Please proceed as follows:

1. When the finger is placed on the finger guide, an integrated proximity sensor

activates the biometric reader. After about 0.5 seconds, the LED flashes green.

2. You can now draw your finger (the one learned by the reader) across the sensor,

with gentle pressure, making sure that the whole of the top finger joint passes

over the sensor (refer to photos in chapter 2.2). Make sure that your finger is in

roughly the same position as when the fingerprint was learned.

3. If the fingerprint is recognised and the integrated transponder has been

successfully programmed, the LED flashes green twice and the biometric reader

is triggered.

If the LED lights up red, fingerprint recognition was not successful. If this happens,

you must start again from step 1.

If you moved your finger too quickly over the sensor, the LED gives one rapid flash in

red and then turns green again. Draw your finger across the sensor again, this time

slightly slower.

If the fingerprint is recognised, the LED will light up green. However, if the lock could

not be contacted the LED will light up red again. If this happens, start again from step

1.

Please note

:

• The Q3008 may occasionally fail to recognise a fingerprint even though it was

correctly learned.

Page 47

MANUAL - BIOMETRIC READER Q3008

Page 12

12

• If a fingerprint is rejected and the LED lights up red, the quality of the scan was

not sufficient. This may be because the finger was not moved correctly across

the sensor (not straight or not evenly, for example), or because the surface of the

sensor is dirty. If the finger is too dry, it may ‘judder’ across the sensor. Please try

again. You may wish to dampen your finger slightly first, for example by breathing

on it.

• If the features of your finger could not be assigned to any learned fingerprint, the

diode will light up red. You may have inadvertently used the wrong finger.

Alternatively, you may have moved your finger differently over the sensor when

the reader was learning your fingerprint (for example by turning the finger or with

more or less fingertip).

Tip:

A person’s fingerprint will not be recognised first time, every time. If you find that a

fingerprint is frequently not being recognised, please have the reader learn a different

finger.

Dry fingers can make fingerprint recognition more difficult. This can be

remedied by moistening your finger or breathing on it, for example.

5.0 Assigning fingerprints to transponder IDs

The maximum of 50 different fingerprints are assigned 50 different transponder IDs.

In order to use and differentiate between these 50 different fingerprints, they must be

individually programmed.

Each fingerprint is assigned a unique transponder ID (TID). If the locks in a system

feature a time control function (i.e. access control), the TIDs are stored in the locks

whenever access takes place. This allows you to track which user was given access

when.

It is therefore essential to ensure that you keep the same allocations during

programming. Otherwise access to the lock may not be guaranteed.

Page 48

MANUAL - BIOMETRIC READER Q3008

Page 13

13

6.0 Replacing fingerprints

You can replace existing fingerprints with new ones at any point, for example if an

employee has left the company or no longer requires access through a certain door.

Do not undertake any programming after a battery warning. Replace the battery

before proceeding. Refer to chapter 15.0 Replacing the battery.

Please proceed as follows:

1. Open the locking plan with the SimonsVoss software.

2. Export the locking plan (pocket PC).

3. Bring the SmartCD into the communication range of the biometric reader.

4. In SmartLSM, launch the ‘Read’ locks function.

5. Select ‘Modify transponder‘ and start the function by selecting ‘Execute’.

6. Select the appropriate transponder (biometric reader user) and launch the

‘Programming’ function.

7. While the transponder is being programmed, the biometric reader automatically

switches to Learn mode (LED flashes yellow), and you will be asked to draw

your finger over the finger guide.

8. Draw the new finger over the sensor.

9. If the fingerprint is recognised, the LED gives two long flashes in green.

10. If programming was successful, the message “Programming successful“

appears in the SmartLSM. The fingerprint has been successfully stored.

11. After you import the locking plan the programming lightning symbols disappear,

both from the programmed transponder (biometric reader user) and the

biometric reader (if all transponders (biometric reader users) have been

programmed).

To replace additional fingerprints, repeat from step 3.

Page 49

MANUAL - BIOMETRIC READER Q3008

Page 14

14

7.0 Querying the number of learned fingerprints

You can query the number of learned fingerprints / transponder IDs at any time.

Please proceed as follows:

1. Open the locking plan with the SimonsVoss software.

2. Export the locking plan (pocket PC).

3. Bring the SmartCD into the communication range of the biometric reader.

4. Select the ‘Read‘ function.

5. Select the ‘Modify trans.‘ function.

6. Select the ‘Execute‘ function.

7. You will see a list of all users. Approved biometric reader users are indicated by

a thick black cross.

8.0 Deleting an individual fingerprint

Do not undertake any programming after a battery warning. Replace the battery

before proceeding. Refer to chapter 15.0 Replacing the battery.

To delete an individual fingerprint, proceed as follows:

1. Open the locking plan with the SimonsVoss software.

2. Remove the cross indicating authorisation from the locking plan by clicking on it.

3. Export the locking plan (pocket PC).

4. Bring the SmartCD into the communication range of the biometric reader.

5. Select the ‘Read‘ function.

6. Select the ‘Modify trans.‘ task.

7. Select the ‘Execute‘ function.

8. Select the relevant transponder.

9. Select the ‘Program.‘ function.

10. Following successful programming, the SmartLSM will display the message

“Programming successful“ and a green dot.

11. Re-import the locking plan.

The fingerprint and transponder ID have now been deleted from the biometric reader.

Page 50

MANUAL - BIOMETRIC READER Q3008

Page 15

15

9.0 Deleting all fingerprints

Do not undertake any programming after a battery warning. Replace the battery

before proceeding. Refer to chapter 15.0 Replacing the battery.

To delete all stored fingerprints from the Q3008 biometric reader at the same time,

you need to completely reset the device. Please proceed as follows:

1. Open the locking plan with the SimonsVoss software.

2. Export the locking plan (pocket PC).

3. Bring the SmartCD into the communication range of the biometric reader.

4. Click on the ‘Select‘ function.

5. Select ‘Biometric reader’.

6. Select the ‘Read‘ function.

7. Select ‘Reset‘ and confirm by selecting ‘Execute’.

8. Enter the password for the locking system or take ‘From the database’ and click

on ‘Start’.

9. Re-import the locking plan.

10.0 Reading the biometric reader

It is possible at any time to read the biometric reader and identify programmed

transponders using the SimonsVoss locking plan software.

Please proceed as follows:

1. Open the locking plan with the SimonsVoss software.

2. Export the locking plan (pocket PC).

3. Bring the SmartCD into the communication range of the biometric reader.

4. Click on the ‘Select‘ box.

5. Select the biometric reader.

6. Start the ‘Read lock’ function in the SimonsVoss SmartLSM.

Page 51

MANUAL - BIOMETRIC READER Q3008

Page 16

16

11.0 Master finger mode

Master finger mode was developed specially for small locking systems. The biometric

reader is programmed once and fingerprints can then be learned simply on the

biometric reader itself. No distinctions can be made using different transponder IDs

(TIDs), because no TIDs are learned in master finger mode.

Generally, we recommend using SimonsVoss programming software for

programming purposes.

You can exit master finger mode at any time. To do this, all learned fingerprints

(including the master fingers) must be deleted.

Do not undertake any programming after a battery warning. Replace the battery

before proceeding. Refer to chapter 15.0 Replacing the batteryFehler! Es wurde

kein Textmarkenname vergeben.Fehler! Es wurde kein Textmarkenname

vergeben..

11.1 Commissioning – Programming master fingers

The following chapters describe in detail the programming process for master finger

mode.

Please note:

The first two fingerprints learned are automatically stored as the master

fingers. A master finger cannot also be programmed as a user finger (it will be

rejected during the learning process, indicated by 4 red flashes). Unlike normal mode,

individual fingerprints cannot be allocated a transponder ID (TID), i.e. the lock does

not make a distinction between individual users. In master finger mode it is possible

to use the biometric reader to produce an access log for all locks in the same system.

Please proceed as follows:

1. Create a locking plan in the SimonsVoss software.

2. Create ‘biometric reader’ as a lock

Æ

biometric reader.

3. Create lock (e.g. locking cylinder).

4. Connect the SmartCD to the PC and bring within communication range of the

‘biometric reader’.

5. Highlight the biometric reader and launch ‘Programming Æ Lock’ in the

programming software. This is where you undertake basic configuration of the

biometric reader.

6. If programming was successful, the programming lightning symbol disappears

from the locking plan for the relevant biometric reader.

7. Bring the SmartCD into the communication range of the lock.

Page 52

MANUAL - BIOMETRIC READER Q3008

Page 17

17

8. Highlight the lock to be addressed by the biometric reader and launch

‘Programming Æ Lock‘ in the programming software. This is where you

undertake basic configuration of the lock.

Please perform the next steps on the biometric reader itself. The first two

fingerprints are automatically stored as the master fingers!

9. Place your finger on the sensor to activate the biometric reader.

10. The biometric reader automatically switches to Learn mode (LED flashes slowly

in yellow).

11. Draw the finger to be learned as the master finger across the sensor, for as long

as the LED keeps flashing slowly in yellow. (If the LED starts flashing quickly in

yellow (indicating time-out), wait until the LED goes out and start again.)

12. If the fingerprint is recognised, the LED gives one long flash in green (fingerprint

recognised). The LED gives one more long flash in green. The first master

finger has now been stored.

13. To learn the second master finger (which must be different from the first one),

please repeat from step 7.

Only once both master fingers have been successfully stored can the reader start

learning user fingers. The persons chosen as the master fingers should be the locking

system administrator or other persons with direct access to the locking system. As a

general principle, ensure that only one finger of each hand is used to program in the

master fingers.

11.2 Programming user fingers

Please perform the next steps on the biometric reader itself. The first two fingerprints

learned are automatically stored as the master fingers!

1. Place your finger on the sensor to activate the biometric reader. The LED

flashes slowly in green.

2. Draw a master finger across the sensor.

3. The biometric reader automatically switches to Learn mode (LED flashes slowly

in yellow).

4. Draw the finger to be learned across the sensor, for as long as the LED keeps

flashing slowly in yellow. (If the LED starts flashing quickly in yellow (indicating

time-out), wait until the LED goes out and start again.)

5.

If the fingerprint is recognised, the LED gives one long flash in green (fingerprint

recognised). The LED gives one more long flash in green. The user finger has

now been stored.

6. To program additional user fingers, repeat from step 1.

Page 53

MANUAL - BIOMETRIC READER Q3008

Page 18

18

11.3 ‘Recognize’ process

Please refer to chapter 4.0 Recognize process.

11.4 Deleting individual fingerprints

To delete an individual fingerprint, proceed as follows:

1. Place your finger on the sensor to activate the biometric reader. The LED

flashes slowly in green.

2. Draw a master finger across the sensor.

3. The biometric reader automatically switches to Learn mode (LED flashes slowly

in yellow).

4. Wait until the LED flashes quickly in yellow.

5. Touch the finger guide briefly three times with your finger.

6. The biometric reader automatically switches to Delete mode (LED flashes

slowly in red).

7. Draw the user finger over the sensor.

8. The LED gives two slow flashes in green. The user finger has been deleted.

11.5 Deleting all fingerprints

To delete all stored fingerprints from the Q3008 biometric reader, you need to delete

the complete fingerprint database. Please proceed as follows:

1. Place your finger on the sensor to activate the biometric reader. The LED

flashes slowly in green.

2. Draw a master finger across the sensor.

3. The biometric reader automatically switches to Learn mode (LED flashes slowly

in yellow).

4. Wait until the LED flashes quickly in yellow.

5. Touch the finger guide briefly three times with your finger.